RIKON Power Tools 10-370 User Manual

18” Wood/Metal Bandsaw

Model: 10-370

Part #10-370M1

Owner’s Manual

Record the serial number and date of purchase

in your manual for future reference.

Serial number:

Date of purchase:

For more information:

www.rikontools.com or info@rikontools.com

For Parts or Questions:

techsupport@rikontools.com or 877-884-5167

Operator Safety: Required Reading

IMPORTANT! Safety is the single most important consideration in the operation of this equipment. The following

instructions must be followed at all times.

There are certain applications for which this tool was designed. We strongly recommend that this tool not be modied and/

or used for any other application other than that for which it was designed. If you have any questions about its application,

do not use the tool until you have contacted us and we have advised you.

General Safety Warnings

KNOW YOUR POWER TOOL. Read the owner’s manual carefully. Learn the tool’s applications, work

capabilities, and its specic potential hazards.

ALWAYS GROUND ALL TOOLS.

If your tool is equipped with a three-pronged plug, you must plug it into a three-hole electric receptacle.

If you use an adapter to accommodate a two-pronged receptacle, you must attach the adapter plug to a

known ground. Never remove the third prong of the plug.

ALWAYS AVOID DANGEROUS ENVIRONMENTS.

Never use power tools in damp or wet locations. Keep your work area well lighted and clear of clutter.

ALWAYS REMOVE THE ADJUSTING KEYS AND WRENCHES FROM TOOLS AFTER USE.

Form the habit of checking to see that keys and adjusting wrenches are removed from the tool before

turning it on.

ALWAYS KEEP YOUR WORK AREA CLEAN. Cluttered areas and benches invite accidents.

ALWAYS KEEP VISITORS AWAY FROM RUNNING MACHINES.

All visitors should be kept a safe distance from the work area.

ALWAYS MAKE THE WORKSHOP CHILDPROOF.

Childproof with padlocks, master switches, or by removing starter keys.

NEVER OPERATE A TOOL WHILE UNDER THE INFLUENCE OF DRUGS,

MEDICATION, OR ALCOHOL.

ALWAYS WEAR PROPER APPAREL.

Never wear loose clothing or jewelry that might get caught in moving parts. Rubber-soled footwear is

recommended for the best footing.

ALWAYS USE SAFETY GLASSES AND WEAR HEARING PROTECTION.

Also use a face or dust mask if the cutting operation is dusty.

NEVER OVERREACH.

Keep your proper footing and balance at all times.

NEVER STAND ON TOOLS.

Serious injury could occur if the tool is tipped or if the cutting tool is accidentally contacted.

2

ALWAYS DISCONNECT TOOLS.

Disconnect tools before servicing and when changing accessories such as blades, bits, and cutters.

ALWAYS AVOID ACCIDENTAL STARTING.

Make sure switch is in “OFF” position before plugging in cord.

NEVER LEAVE TOOLS RUNNING UNATTENDED.

ALWAYS CHECK FOR DAMAGED PARTS.

Before initial or continual use of the tool, a guard or other part that is damaged should be checked to

assure that it will operate properly and perform its intended function. Check for alignment of moving

parts, binding of moving parts, breakage of parts, mounting, and any other conditions that may affect its

operation. A guard or other damaged parts should immediately be properly repaired or replaced.

Special Safety Rules For Bandsaws

1. Always allow the Bandaw blade to stop before removing scrap pieces from table.

2. Always keep hands and ngers away from the blade.

3. Never attempt to saw stock that does not have a at surface, unless a suitable support is used.

4. Always hold material rmly and feed it into the blade at a moderate speed.

5. Always turn off the machine if the material is to be backed out of an uncompleted cut.

6. Adjust the upper guide about 1/8” above the material being cut.

7. Check for proper blade size and type for thickness and type of material being cut.

8. Make sure that the blade tension and blade tracking are properly adjusted.

9. Make “relief” cuts before cutting long curves.

10. Release blade tension when the saw will not be used for a long period of time.

Note: This owner’s manual is not a teaching aid. Use of this owner’s manual is intended to

show assembly, adjustments, and general use.

California Proposition 65 Warning

WARNING: Some dust created by power sanding, sawing, grinding, drilling, and other construction activities contains

chemicals known to the State of California to cause cancer and birth defects or other reproductive harm.Your risk from

exposure to these chemicals varies, depending on how often you do this type of work. To reduce your exposure, work in

a well-ventilated area and with approved safety equipment, such as dust masks that are specially designed to lter out

microscopic particles.

For more detailed information about California Propostion 65 log onto rikontools.com.

SAVE THESE INSTRUCTIONS.

Refer to them often.

3

Table of Contents

Safety Warnings..................................................................................................................................................2 -3

Bandsaw Safety Rules ..........................................................................................................................3

Specications ........................................................................................................................................4

Contents of Package ............................................................................................................................5

Loose Parts List...........................................................................................................................................6

Getting To Know Your Bandsaw ............................................................................................................7

Switch Assembly...................................................................................................................................8-9

Work Table Assembly .....................................................................................................................................9-10

Rip Fence Assembly .............................................................................................................................10

Hand-Wheel Assembly .........................................................................................................................10

Setting 90o Table Stop ...........................................................................................................................11

Tilting the Table .....................................................................................................................................11

Tracking the Saw Blade ......................................................................................................................................12

Adjusting the Blade Tension .......................................................................................................................12

Blade Tension Indicator Adjustment.....................................................................................................12

Changing the Bandsaw Blade...........................................................................................13

Upper Blade Guide Adjustment ..........................................................................................................14

Lower Blade Guide Adjustment ..........................................................................................................14

Cutting Height Adjustment ..................................................................................................................14

Changing Blade Speed .......................................................................................................................15

Drift Adjustment ................................................................................................................................16

Resawing .............................................................................................................................16

Basic Operation ............................................................................................................................................16

Metal Cutting..................................................................................................................17

Cutting Plastic/Composite Material..............................................................................................17

Electrical Requirements ..................................................................................................................................18

Maintenance .......................................................................................................................................... ..... 19

Wiring Diagram ...................................................................................................................................19

Troubleshooting .........................................................................................................................20-21

Changing Bandsaw Tire ..................................................................................................................................21

Adjusting Fence 90 Degrees to the Table..................................................................................................................21

Parts Diagra m .................. ............. .................. ............................... .................. .22-31

Blade How-To’s ..............................................................................................................................................32

Warranty ..............................................................................................................................................33

Throat width

Max. cutting depth

Blade length

Blade width

Table size

Table tilt

Blade speeds

Motor

Amps

Volts

Net weight

Specications

18-3/8” (467 mm)

12” (305 mm)

142” (3607 mm)

1/4” – 1-1/4”(6-32 mm)

21”x 19” (534 mm x 483 mm)

Left-10o Right-45

VS 82-1312 / 328-3280 ft/min

2.5 HP

12.5

220

400 lbs

4

o

Contents of Package

18” Wood/Metal Bandsaw

Model: 10-370

Owner’s Manual

For more information:

www.rikontools.com

or

info@rikontools.com

For Parts or Questions:

techsupport@rikontools.com or 877-884-5167

Record the serial number and date of purchase

in your manual for future reference.

Serial number:

Date of purchase:

Part #10-370M1

Model 10-370 18” Wood/Metal Bandsaw is shipped complete in one box.

Unpacking and Checking Contents

a. Separate all “loose parts” from packaging materials and check each item with “Table of Loose

Parts” to make sure all items are accounted for, before discarding any packaging material.

b. Thread hoist ring into threading hole on top of Bandsaw frame. This allows the user to connect

a properly secured hoist mechanism to lift the Bandsaw.

c. With the help of another person or by installing hoist ring, unbolt the Bandsaw from the packing

pallet. Properly lift the Bandsaw off the packing pallet and place on level oor.

d. Remove protective oil that is applied to the table. Use any ordinary house hold type grease or

spot remover.

e. Apply a coat of paste wax to the table to prevent rust. Wipe all parts thoroughly with a clean

dry cloth.

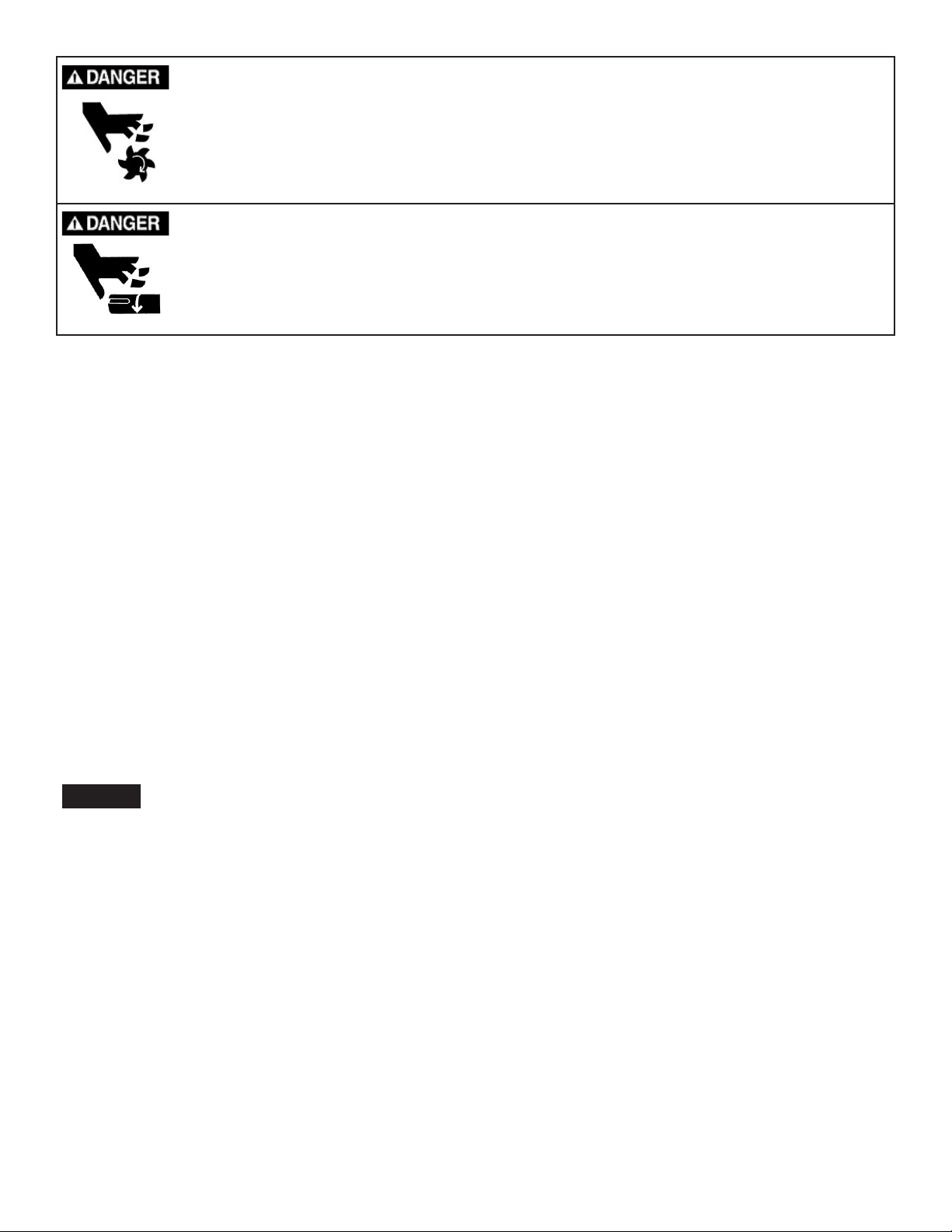

TABLE OF LOOSE PARTS

A

Item Part Name Qty

A Bandsaw Assembly 1

B Table w/insert 1

C Owner’s manual 1

D Parts Package 1 1

E Parts Package 2 1

D

B

C

E

5

LIST OF LOOSE PARTS

Table assembly:

A. Table

B. Table leveling bar and hardware

C. 90° table stop bolt

D. Table mounting bolts and washers

Rip fence assembly:

A. Fence bar

B. Fence

C. Resaw bar

D. Fence carrier

Loose Parts List

D

C

A B

Tool holder assembly:

A. L wrench 3MM

B. L wrench 4MM

C. L wrench 5MM

D. L wrench 6MM

A

A

B

B

C

C

D

D

6

A

B

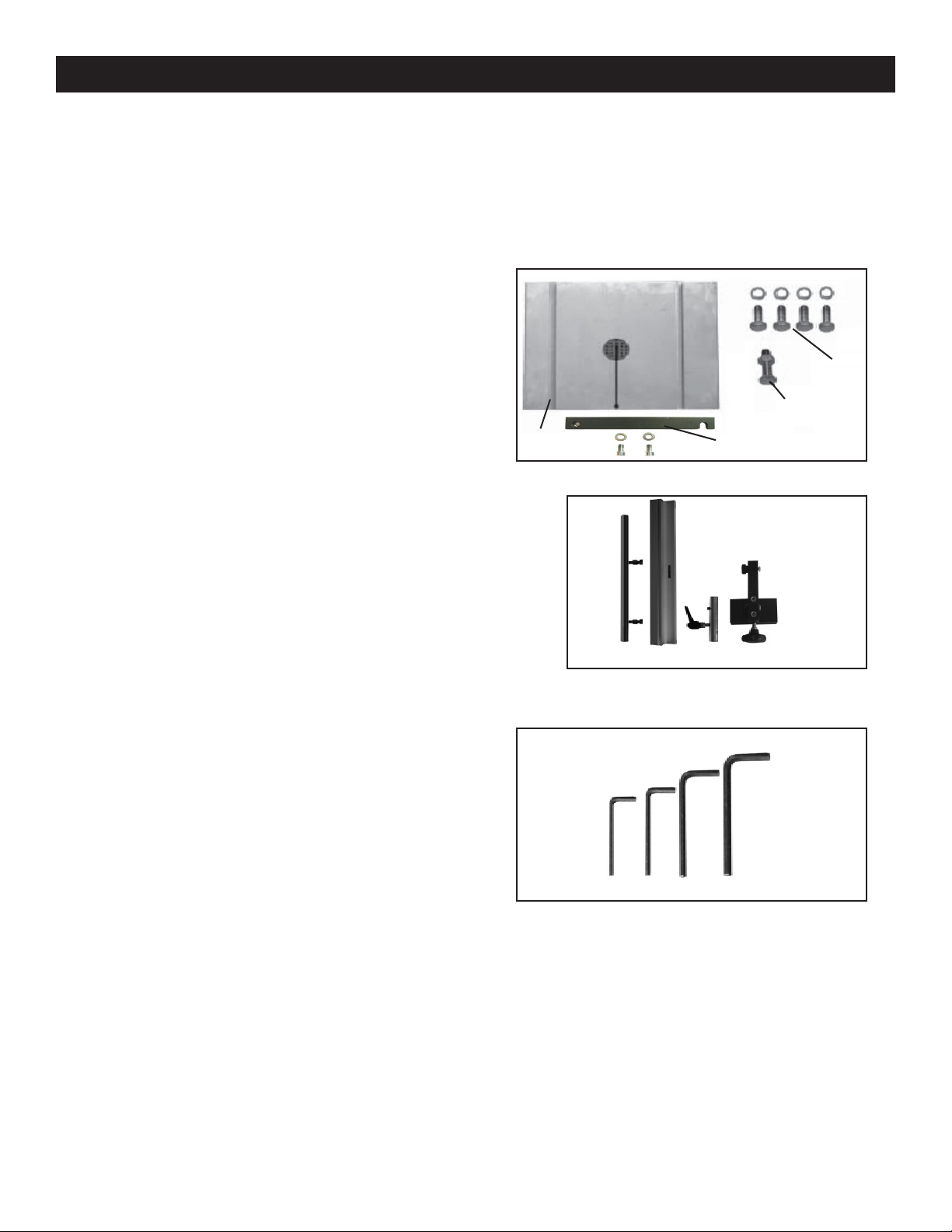

Getting to Know Your Bandsaw

F

L

G

M

C

D

E

H

K

I

J

N

O

P

Q

R

A. Hoist Ring

B. Tension Indicator Window

C. Blade Tension Hand-Wheel

D. Switch

E. Rip Fence

F. Blade Tracking Window

G. Guide Post Hand-Wheel

H. Guide Post Lock Knob

I. Hinged Blade Guard

J. Drive Belt Tension Wheel

K. 4” Dust Ports

L. Blade Tracking Knob

M. Quick Release Lever

N. Tool Holder

O. Table Tilt & Lock Knobs

P. Speed Sensor Cable

Q. VFD Control Housing

R. Motor

7

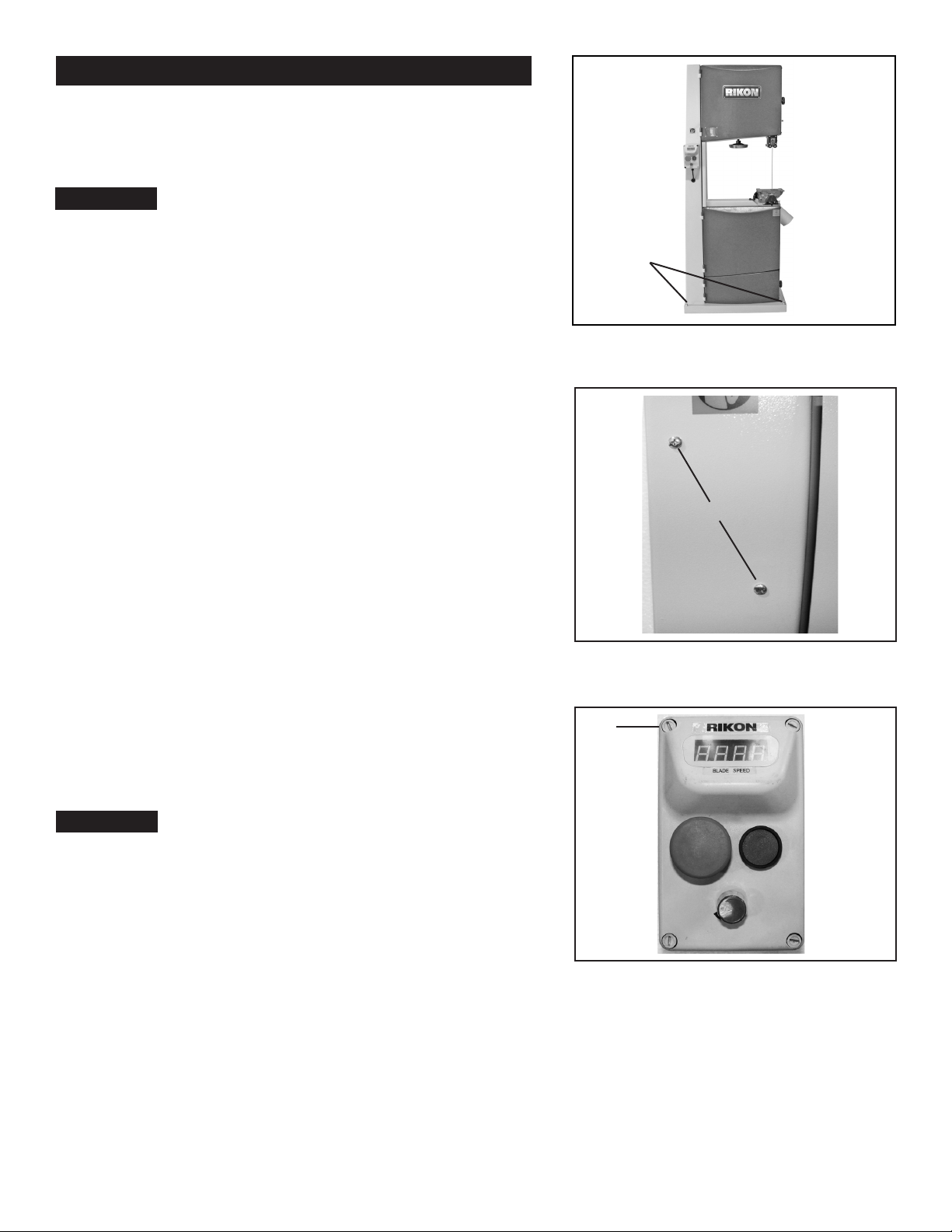

Assembly

The 10-370 Bandsaw is supplied partly assembled.

Prior to use, the following items have to be assembled:

switch, working table, rip fence and hand-wheels.

Warning!

To ensure sufcient upright stability and safety of this

bandsaw, you need to bolt the bandsaw to the oor with

M10 screws.(Fig 1) (not supplied).

Installing the Switch Box

Remove the two screws that were pre-installed on the

bandsaw column (A-Fig.2). These screws will be used

to mount the switch box to the column.

Mounting Holes

Figure 1

A

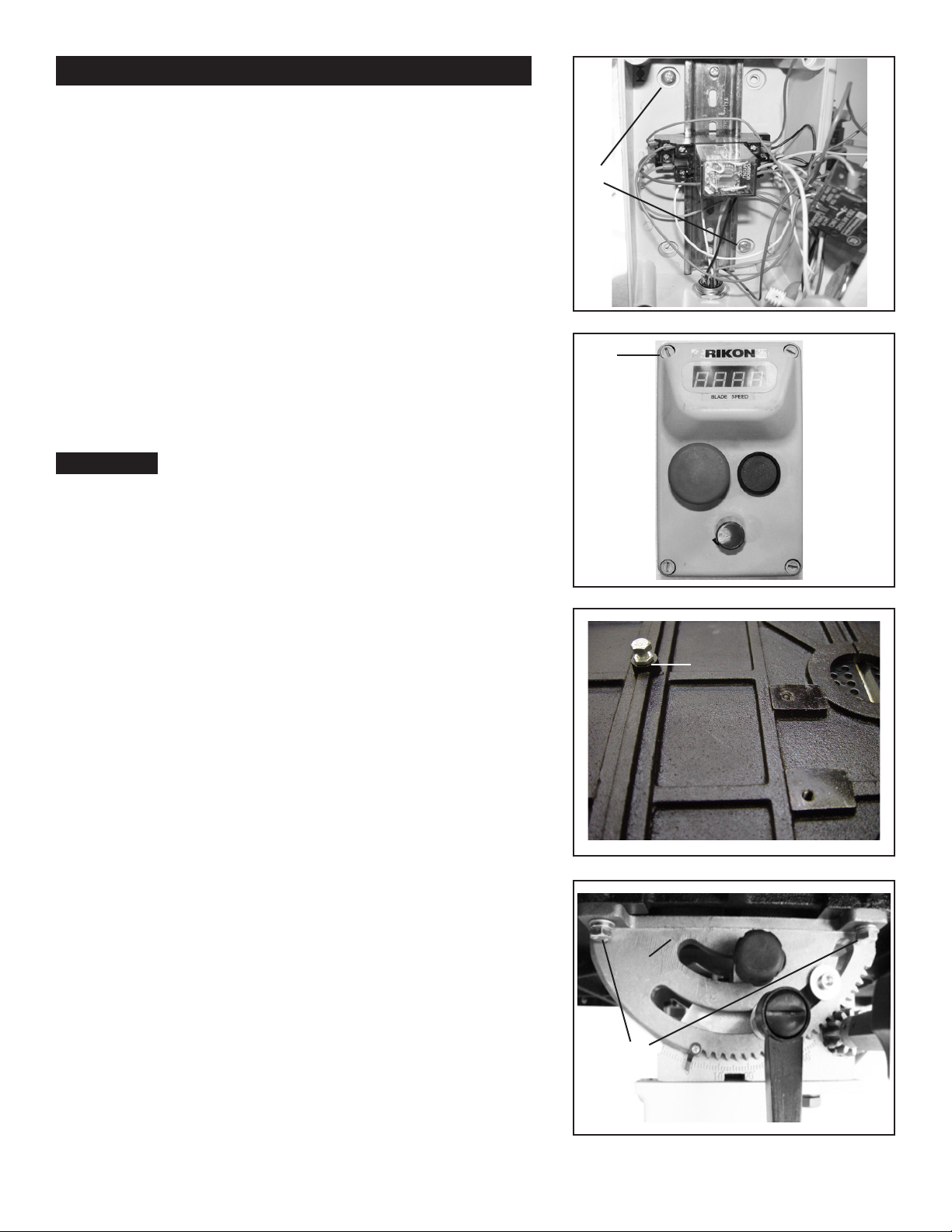

Loosen the four screws (A-Fig.3) on the front of the

switch box with a at-head screw driver. Carefully

separate the control panel from the switch box.

Caution!

Take extra care when handling the control panel as

wires are attached to the switch box. Do not allow the

control panel to be supported or hang by the wiring as

damage can occur to the electronics.

Figure 2

A

Figure 3

8

Assembly

Installing the Switch Box Cont.

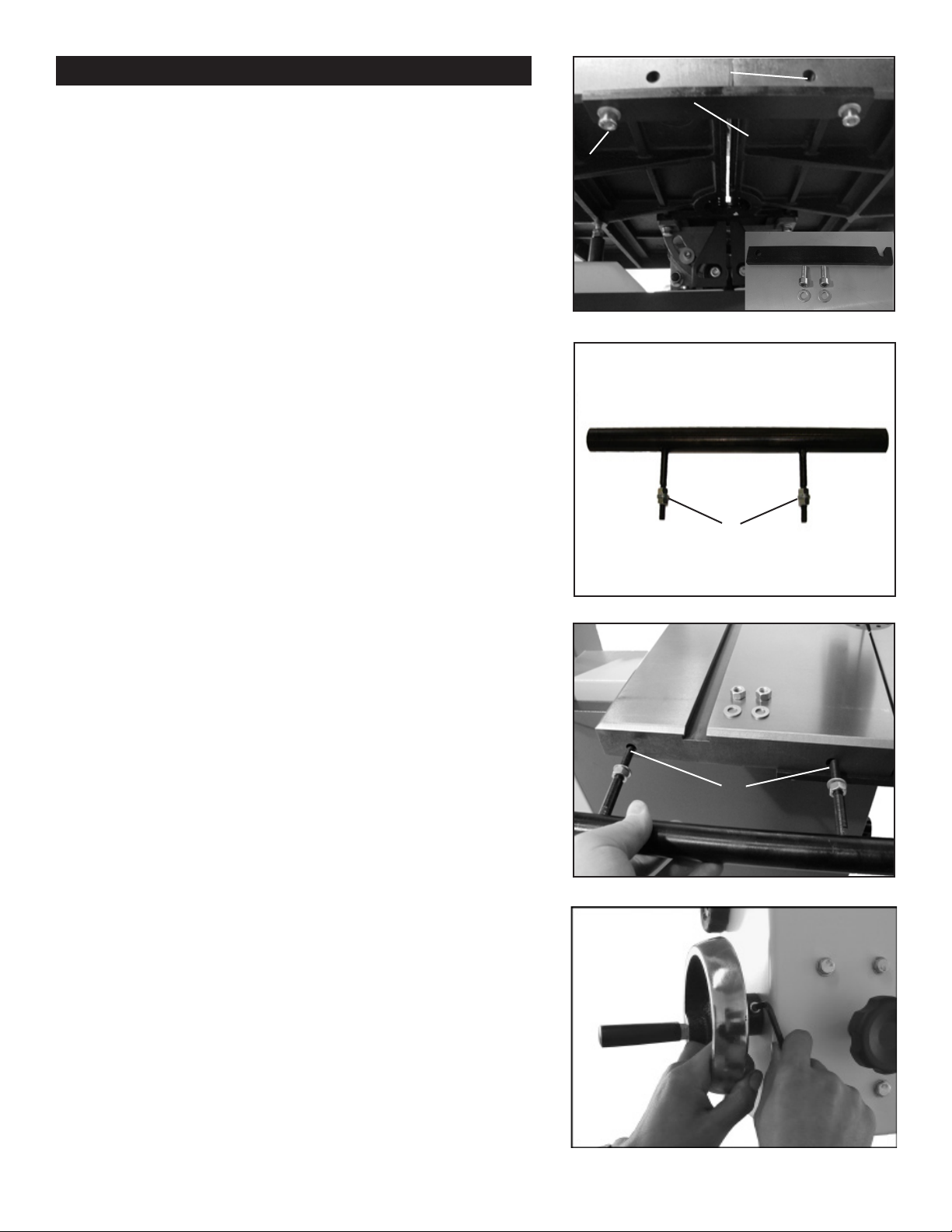

Mount the switch by using the corresponding holes

(A-Fig.5) in the back of the switch box. Use screws that

were removed from the frame shown in Fig.3. to mount

switch box to the column.

Next, install the control panel to the switch box. Make

sure that wires in the switch box do not become cut or

pinched while intalling the control panel. Tighten the four

control panels screws (A-Fig.6) with a at-head screw

driver.

Caution!

Take extra care when handling the control panel as

wires are attached to the switch box. Do not allow the

control panel to be supported or hang by the wiring as

damage can occur to the electronics.

A

Figure 5

A

Work Table Assembly

Installing 90° table stop:

Thread screw (M8x25) and nut (M8-1.25) to the bottom

of the table. (Shown Fig.7A)

With the help of another person, lift the work table onto

the trunnion (A-Fig.8).

Mount the work table to the trunnion using the supplied

(4) hex bolts, (4) lock washers and (4) washers

(B-Fig.8).

Figure 6

A

Underside of Table

Figure 7

A

B

Figure 8

9

Assembly

Work Table Assembly

Installing Table Leveling Bar:

Locate the table leveling bar, two hex socket screws

and two washers (A-Fig.9 Inset).

Insert a hex socket screw and washer through the left

hole of the table leveling bar and into the threaded hole

on the left side of the blade slot (B-Fig.9). Make sure

that the opening of the slot on the right side of the table

leveling bar faces toward the table trunnion. This will

allow the table leveling bar to open outward from the

bandsaw.

Rip Fence Assembly

With a 13mm wrench, remove one 13mm hex nut and

one washer from each stud on the fence bar (A-Fig.10).

Leave one each of 13mm hex nut and washer on each

stud on the fence bar. The remaining nut and washer

will be used for drift adjustments that will be described

later in this manual.

Blade Slot

Table Leveling Bar

B

Underside of Table

A

Figure 9

A

Figure 10

Next, install the fence bar studs into the table as shown

(Fig.11). Locate the 13mm hex nuts and washers

removed in Fig.10 and install on the opposite ends of

each fence bar stud. NOTE: It may be necessary to

open the table leveling bar to gain access to the right

side fence bar stud.

Hand Wheel Installation

There are two hand wheels used on the 10-370 Wood/

Metal bandsaw. The rst controls the height of the upper

guide post, the second adds/removes tension on the

drive belt.

Attach the rst hand wheel (Fig.12) to the rack and

pinion shaft on the upper part of the bandsaw, using the

5mm “L” wrench provided.

Attach the second crank handle to the belt and speed

control rod located below the 4” dust port, using the

5mm “L” wrench provided.

A

Figure 11

10

Figure 12

Assembly

Storage for the “L” wrenches is provided for quick

access when adjustments are needed.

Place the (4) “L” wrenches (3mm, 4mm, 5mm and 6mm)

in the tool holder on the rear column support (Fig.13).

Adjustments

Setting the Table Square to Saw Blade

The table may be set at 90° to the saw blade sides

by adjusting the table stop screw under the table. The

table stop screw rests on the top of the quick release

adjustment stop. By rst loosening the locking nut

(A-Fig.14) and then adjusting the screw (B-Fig.14), the

table can be set correctly. Retighten the locking nut

(A-Fig.14) making sure that the setting is maintained.

Tool Holder

Figure 13

A

B

The table may also be set at 90° to the back of the saw

blade by adjusting the four trunnion micro adjustment

screws (A-Fig.15). First, slightly loosen part #98 (refer to

parts explosion on page 18 of this manual). Using the

3mm “L” wrench, turn the rear trunnion micro adjusting

screws part #125. Turning the screws clockwise will

raise the trunnion; counterclockwise will lower. Check

table for 90° and tighten part #98.

(Trunnion has been removed from bandsaw for clarity. Micro

adjusting screws are raised to exaggerate location. Only two of the

four micro adjusting screws shown.)

Tilting the Table

Loosen the lock handle (A-Fig.16) on the table trunnion.

Turn the table tilting knob (B-Fig.16) to adjust the table

to the desired angle. Use the angle indicator scale on

the trunnion bracket to nd the desired angle. Retighten

the lock handle to secure the table.

Figure 14

A

Figure 15

11

A

B

Figure 16

Loading...

Loading...