RIKON Power Tools 10-201 User Manual

10” Left Tilt Contractor Saw

30” Rip Fence

Model: 10-201

Part # 10-201M1

Record the serial number and date of purchase

in your manual for future reference.

Serial number:

Date of purchase:

For more information:

233282

www.rikontools.com or info@rikontools.com

For Parts or Questions:

techsupport@rikontools.com or 877-884-5167

Owner’s Manual

Safety Warning

IMPORTANT! Safety is the single most important consideration in the operation of this equipment. The following

instructions must be followed at all times.

There are certain applications for which this tool was designed. We strongly recommend that this tool not be modified and/

or used for any other application other than that for which it was designed. If you have any questions about its application,

do not use the tool until you have contacted us and we have advised you.

General Safety Warnings

KNOW YOUR POWER TOOL. Read the owner’s manual carefully. Learn the tool’s applications, work

capabilities, and its specific potential hazards.

ALWAYS GROUND ALL TOOLS.

If your tool is equipped with a three-pronged plug, you must plug it into a three-hole electric receptacle.

If you use an adapter to accommodate a two-pronged receptacle, you must attach the adapter plug to a

known ground. Never remove the third prong of the plug.

ALWAYS AVOID DANGEROUS ENVIRONMENTS.

Never use power tools in damp or wet locations. Keep your work area well lighted and clear of clutter.

ALWAYS REMOVE THE ADJUSTING KEYS AND WRENCHES FROM TOOLS AFTER USE.

Form the habit of checking to see that keys and adjusting wrenches are removed from the tool before

turning it on.

ALWAYS KEEP YOUR WORK AREA CLEAN. Cluttered areas and benches invite accidents.

ALWAYS KEEP VISITORS AWAY FROM RUNNING MACHINES.

All visitors should be kept a safe distance from the work area.

ALWAYS MAKE THE WORKSHOP CHILDPROOF.

Childproof with padlocks, master switches, or by removing starter keys.

NEVER OPERATE A TOOL WHILE UNDER THE INFLUENCE OF DRUGS,

MEDICATION, OR ALCOHOL.

ALWAYS WEAR PROPER APPAREL.

Never wear loose clothing or jewelry that might get caught in moving parts. Rubber-soled footwear is

recommended for the best footing.

ALWAYS USE SAFETY GLASSES AND WEAR HEARING PROTECTION.

Also use a face or dust mask if the cutting operation is dusty.

NEVER OVERREACH.

Keep your proper footing and balance at all times.

NEVER STAND ON TOOLS.

Serious injury could occur if the tool is tipped or if the cutting tool is accidentally

2

ALWAYS DISCONNECT TOOLS.

Disconnect tools before servicing and when changing accessories such as blades, bits, and cutters.

ALWAYS AVOID ACCIDENTAL STARTING.

Make sure switch is in “OFF” position before plugging in cord.

NEVER LEAVE TOOLS RUNNING UNATTENDED.

ALWAYS CHECK FOR DAMAGED PARTS.

Before initial or continual use of the tool, a guard or other part that is damaged should be checked to

assure that it will operate properly and perform its intended function. Check for alignment of moving

parts, binding of moving parts, breakage of parts, mounting, and any other conditions that may affect its

operation. A guard or other damaged parts should immediately be properly repaired or replaced.

Special Safety Rules For Table Saws

1. Always wear eye protection.

2. Keep hands away from the saw blade while machine is running.

3. Always use blade guard during normal cutting operations.

4. Always use splitter during normal cutting operations.

5. Use push sticks when ripping narrow stock.

6. Always use fence while ripping and miter gauge while cross-cutting.

7. Never reach over or behind saw blade while machine is running.

8. Do not remove cut-off or jammed pieces until blade has come to a full stop.

9. Disconnect machine from power source before making repairs or adjustments.

10. Do not expose saw or power cord to water or use in damp locations.

California Proposition 65 Warning

WARNING: Some dust created by power sanding, sawing, grinding, drilling, and other construction activities contains

chemicals known to the State of California to cause cancer and birth defects or other reproductive harm.Your risk from

exposure to these chemicals varies, depending on how often you do this type of work. To reduce your exposure, work in

a well-ventilated area and with approved safety equipment, such as dust masks that are specially designed to fi lter out

microscopic particles.

For more detailed information about California Propostion 65 log onto rikontools.com.

SAVE THESE INSTRUCTIONS.

Refer to them often.

3

Table of Contents

Safety Warnings......................................................................................................................................2-3

Table Saw Safety Rules....................................................................................................................... 3

Specifi cations.........................................................................................................................................................4

Unpacking and Contents..................................................................................................................................... .5

Getting to Know Your Table Saw..............................................................................................................6

Assembly..............................................................................................................................................................7

Adjustments ..................................................................................................................................................15

Operations ..............................................................................................................................................19

Maintenance ......................................................................................................................................................24

Electrical Requirements .......................................................................................................................25

Grounding Instructions .........................................................................................................................26

Parts Explosion & List .................................................................................................................................. 27

Warranty .............................................................................................................................................. 37

Model Number

Motor Induction

Amps

Volts/Hertz

Motor/Blade Speed

Blade Tilt

Blade Diameter

Blade Arbor

Table Size w/o Wings

Table Size with Wings

Left Wing Dimension

Right Wing Dimension

Table Front of Blade

Rip Capacity (Right)

Rip Capacity (Left)

Max Depth of Cut @

90°

Specifi cations

10-201

1.5HP

13/6.5

120/240 60Hz

3450RPM

Left

10”

5/8”

11-39/64”(W)x27”(D)

40”(W)x27”(D)

13-45/64”(W)x27”(D)

14-29/32”(W)x27”(D)

12/1/2”

30”

20”

3-3/8”

4

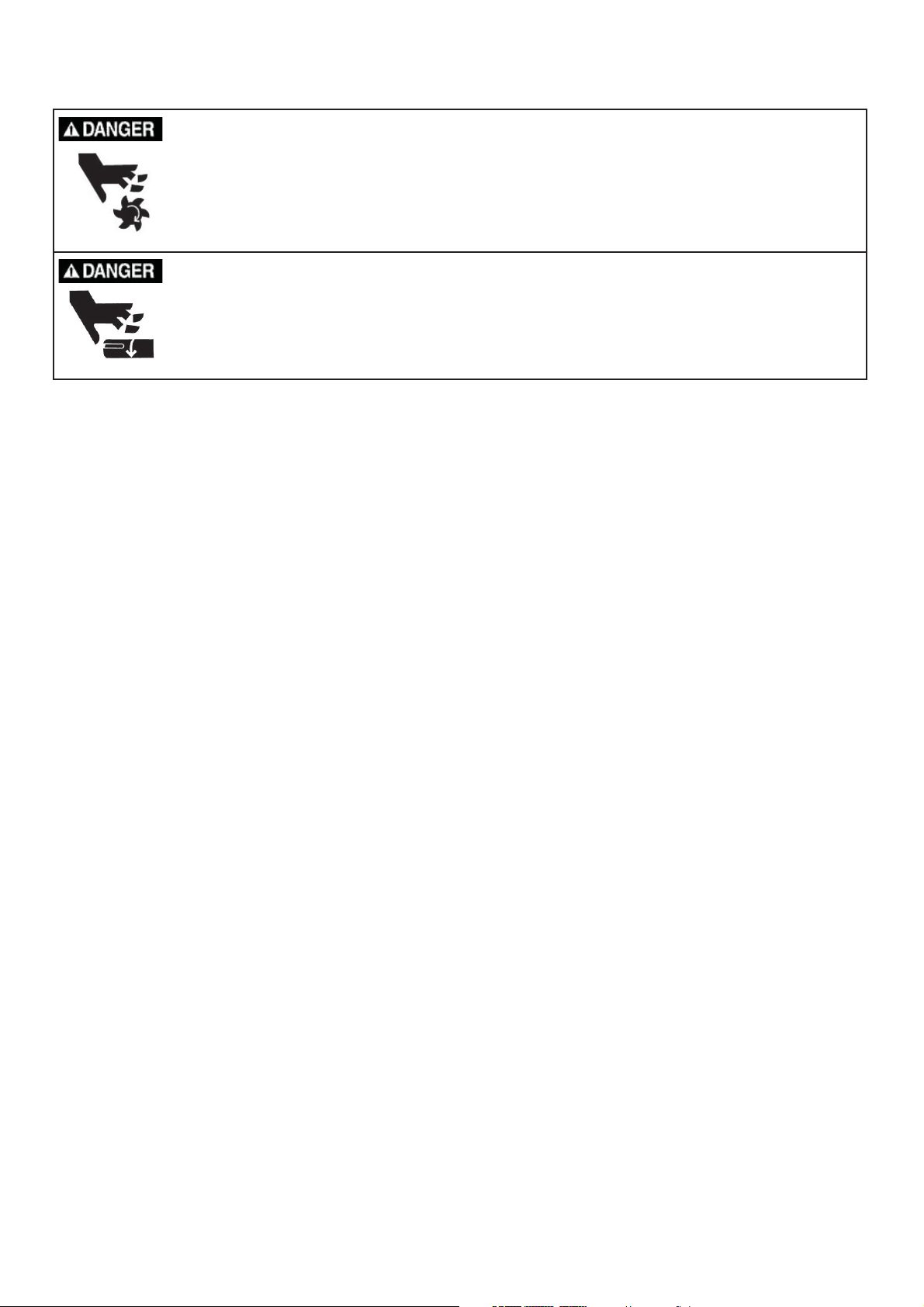

Contents of Package

Unpacking and Checking Contents

Unpack your 10-201 Contractor Saw from its carton and check to see that you have all of the

following items. Do not turn your saw ON if any of these items are missing. You may cause injury to

yourself or damage to your machine. If any parts are missing contact RIKON Technical Support at

1-877-884-5167 or techsupport@rikontools.com.

A) Blade Guard and Splitter Assembly

B) On/Off Switch

C) Miter Gauge

D) Blade Wrench

E) Blade Wrench

F) Handwheel Assembly(2)

G) Handwheel Lock Knob(2)

AA) M4x8mm ROUND HD TAP SCREW (2)

AB) WRENCH HOOK

AC) M8 HEX NUT (2)

AD) M8 SPRING WASHER (2)

AE) M8 FLAT WASHER (2)

AF) M8X16mm CARRIAGE SCREW (2)

AG) FENCE BRACKET (2)

5

Getting to Know Your Table Saw

B

A

H

C

I

D

E

F

G

A) Miter Gauge

B) Blade Guard Assembly with riving knife

C) Motor Cover

D) Bevel Scale

E) Height Adjustment Handwheel

F) Bevel Adjust ment Handwheel

G) Fence Hooks(2)

H) On/Off Switch

I) Mobile Base Caster Assembly

6

• The table saw is a heavy machine; two people may be

required for certain assembly operations.

• DO NOT assemble the table saw until you are sure the

tool is unplugged.

• DO NOT assemble the table saw until you are sure the

power switch is in the "OFF" position.

• For your own safety, DO NOT connect the machine to

the power source until the machine is completely

assembled and you read and understand this entire

User Manual.

INSTALLATION AND LEVELING

Final location for the saw must be level, dry, well lighted,

and have enough room to allow movement around the

saw with long pieces of wood stock.

Level the saw front to back and side to side. If necessary,

but make sure the saw is stable before being placed in to

service.

CABINET LEG ASSEMBLY

1. Attach leg assemblies (A) to the right (J) and left (k)

of the table saw cabinet by placing (B) eight

M8X16mm carriage screws through the mounting

holes and place an M8 flat washer, M8 lock washer

and M8 hex nut onto each of the eight screws

attaching leg assembly to cabinet. Do not completely

tighten hardware at this time.

2. Attach two tie bars(C) and (H) between right and left

legs inside and tighten them with D) eight

carriage screws M8 flat washer M8 lock washer

and s.

M8 hex nut

3. Attach middle bar (E) between tie bar (H) and (C)

inside, using four

washers M8 lock washers and M8 hex nuts to tighten

SEE FIG.1

it.

4. To tighten the legs (A) and tie bar (C) by two (L)

M8x45mm hex soc head screws, M8 flat washers, M8

lock washers;

5. Attach Mobile base caster assembly (I) to the tie bar

(H) and using two M8X16mm carriage screws and M8

flange hex nuts to tighten it.

6. Place two leveling screws (G) to the lags (A) and

place an M8 flat washer, M8 lock washer and M8 hex

nut onto each of the two screws and tighten them.

7. Attach two caster wheels(F) to the tie bar(C) and

place two M8x55mm hex soc head screws through the

mounting holes of the bar and wheels, and using M8

lock nut to ighten them.

M8X16mm carriage screws M8 flat

t SEE FIG.1

( M8X16mm

ss

1. Turn the table saw side lay. The table saw

is heavy; two people are required for this operation. Be

sure to lay cardboard on the floor to protect the table

and cabinet.

CAUTION:

Fig. 1

I

G

H

K

E

D

A

B

J

L

C

F

L

Fig.2

7. To align the hole of cabinet with the hole of cabinet

leg, and using eight M8x20mm hex head screws, M8

flat washers M8 lock washers and M8 hex nuts to

tighten them.

SEE FIG.2 & FIG.3

7

Fig.3

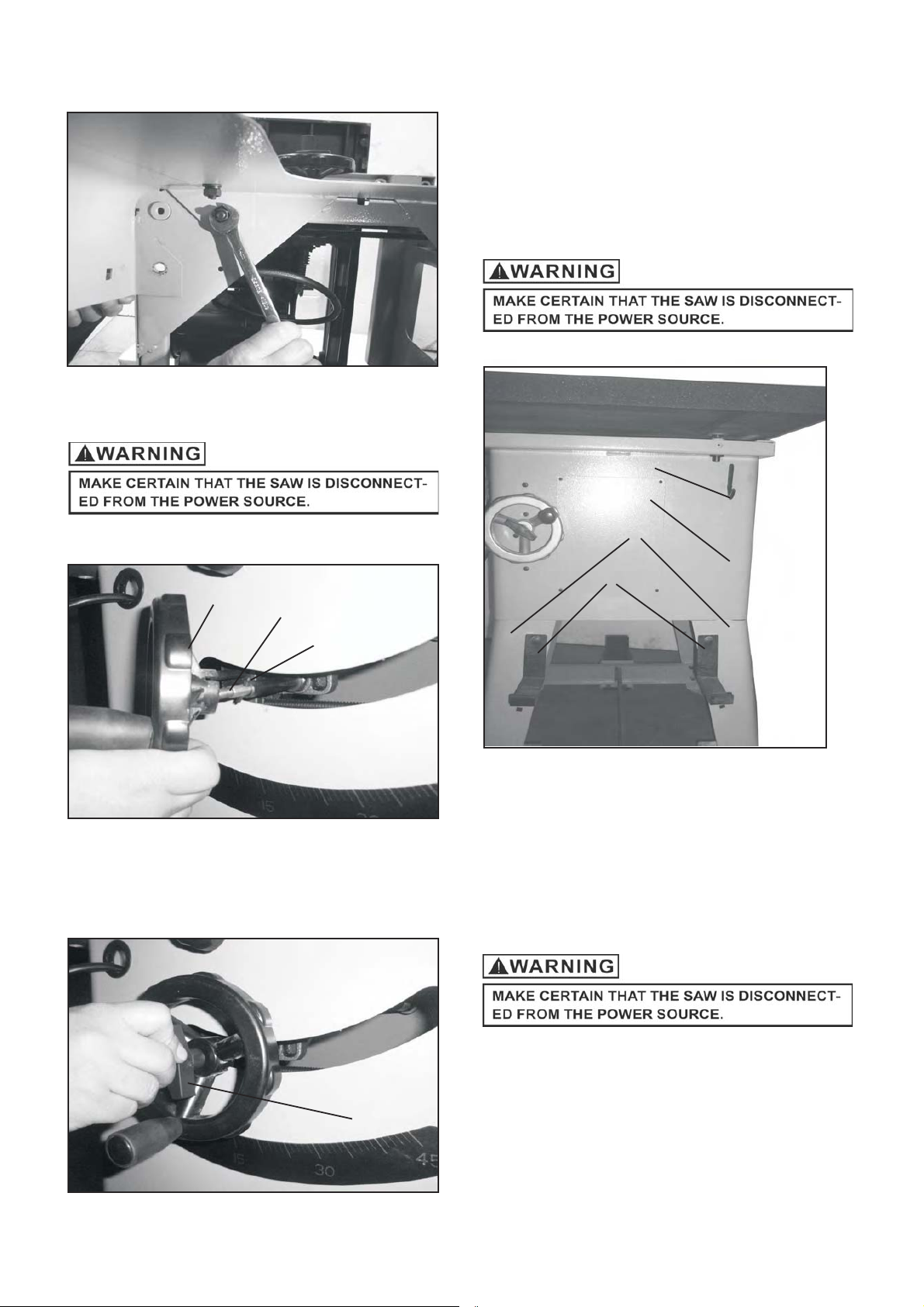

HANDWHEEL ASSEMBLY

2. Thread the locking knob (D) onto the threaded end of

the shaft.

3. Repeat the steps above to assemble the remaining

handwheel and locking knob onto the bevel shaft

located on the side of the cabinet.

SEE FIG 5.

WRENCH AND FENCE HOOK

ASSEMBLY

Fig.6

A

D

Fig.4

A

B

C

1. Place one of the handwheels (A) onto the blade

raise/lower shaft (B) located on the front of the

cabinet. Align the groove in the back of the

handwheel with the pin (C). SEE FIG 4.

Fig.5

B

C

1. Assemble both of the fence hooks (C) to the left

right cabinet leg (B) using four M8x16mm

carriage screws, M8 flat washer, M8 lock washer and

M8 hex nut to tighten them.

2. Assemble wrench hook (A) to the right side of cabinet

(D) using two M4X8mm round head tap screws.

SEE FIG 6

and

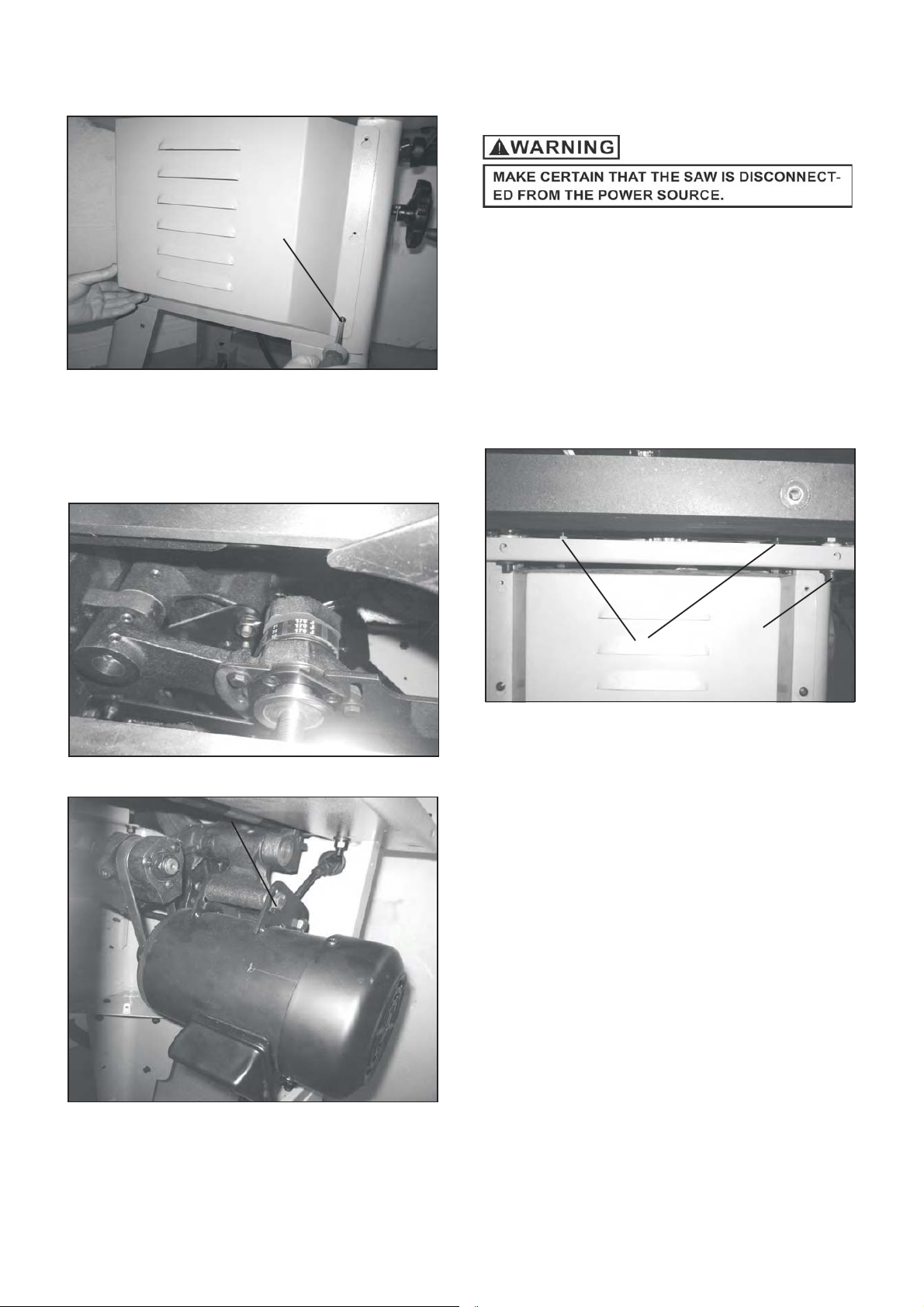

POLY-V BELT REPLACEMENT

1. 6 5 10 cross ALoosen of M x mm pan head tap screws ( )

and remove the cabinet access door. SEE FIG. 7.

D

8

Fig.7

1.One person put right/left extension wing on the top of

cabinet. Alignment pin into bottom of wing (A).

SEE FIG.10

2.

Another

person

locks 4

bolts(B(B)

with

flatanand

spring

washeranand

fromththe

bottom of

cabinetanand

tighten

it.

SEE

FIG.1010

Neednonot

adjustththe

flatness

for

extension

wings

after

assembling.

Because we

have

doneththe

pre-

adjustmentanand

pre-setting of

the

extension

wingsfoforththe

flatnessinin

factory.

EXTENSION WING ASSEMBLY

A

2. Install the belt on the Arbor Pulley and raise motor

by loosing 1 of the motor mounting screws (B) to

reach the belt distance for assembling the belt on

the motor Pulley. SEE FIG.8 & FIG.9

Fig.8

CAUTION: The extension wing is heavy; two people are

required for assemble. The installation method for

granite and cast iron wing is the same.

1.One person put right/left extension wing on the top of

cabinet. Alignment pin into bottom of wing (A).

SEE FIG.10

Fig.10

A

B

Fig.9

B

3. Replace the cabinet access door.

Anothe

2. Another person locks 4 bolts (B) with flat and spring

washe

washer and from the bottom of cabinet and tighten it.

SE

SEE FIG. 10

NOTE: Step1 and step2 can complete

perso

FIG

lock

fro

bolt

botto

wit

fla

cabine

spring

tighte

it.

the assembly for extension wings easily.

Need not adjust the flatness for

Nee

extension wings after assembling.

extensio

Because we have done the pre-

Becaus

adjustment and pre-setting of the

adjustmen

extension wings for the flatness in

extensio

factory.

factor

adjus

wing

hav

wing

flatnes

afte

don

pre-settin

for

assembling.

pre-

the

flatnes

9

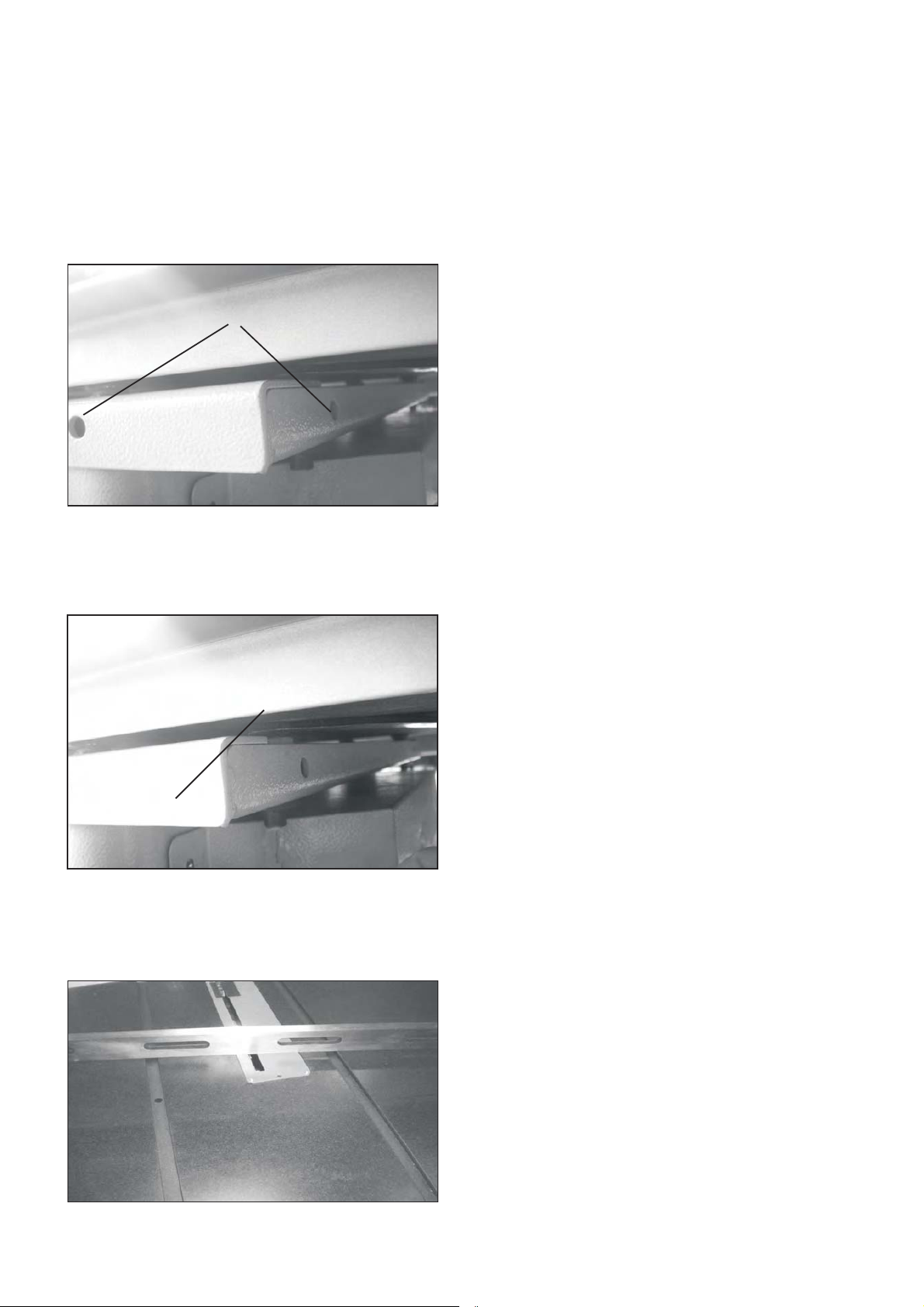

3. The user can adjust the flatness for the extension

3. The user can adjust the flatness for the extension

Wings to obtain more flatness. We suggest that user

need not do this adjustment again, the process are as

following if user want to do the adjustment again.

Wings to obtain more flatness. We suggest that user

need not do this adjustment again, the process are as

following if user want to do the adjustment again.

4.To loose 4 screws (B) by 6.0mm Allen Wrench;

5.To loose 4 setting screws (C) by 2.5mm Allen wrench.

SEE FIG.12

Fig.12

C

6.EUsing an open wrench to adjust the 4 elevation

screws ( ) to raise or lower the extension wing to the

table. SEE FIG.13

8. Make sure both wings are aligned, if not, refer to step

(6) until completely adjusted.

9.

Using a 6.0mm Allen wrench to secure 4 screws (B).

Fig.13

E

7.Use a straight edge across to the main table and

extension wings, checking the flatness of both main and

extension wings. SEE FIG.14

Fig.14

10

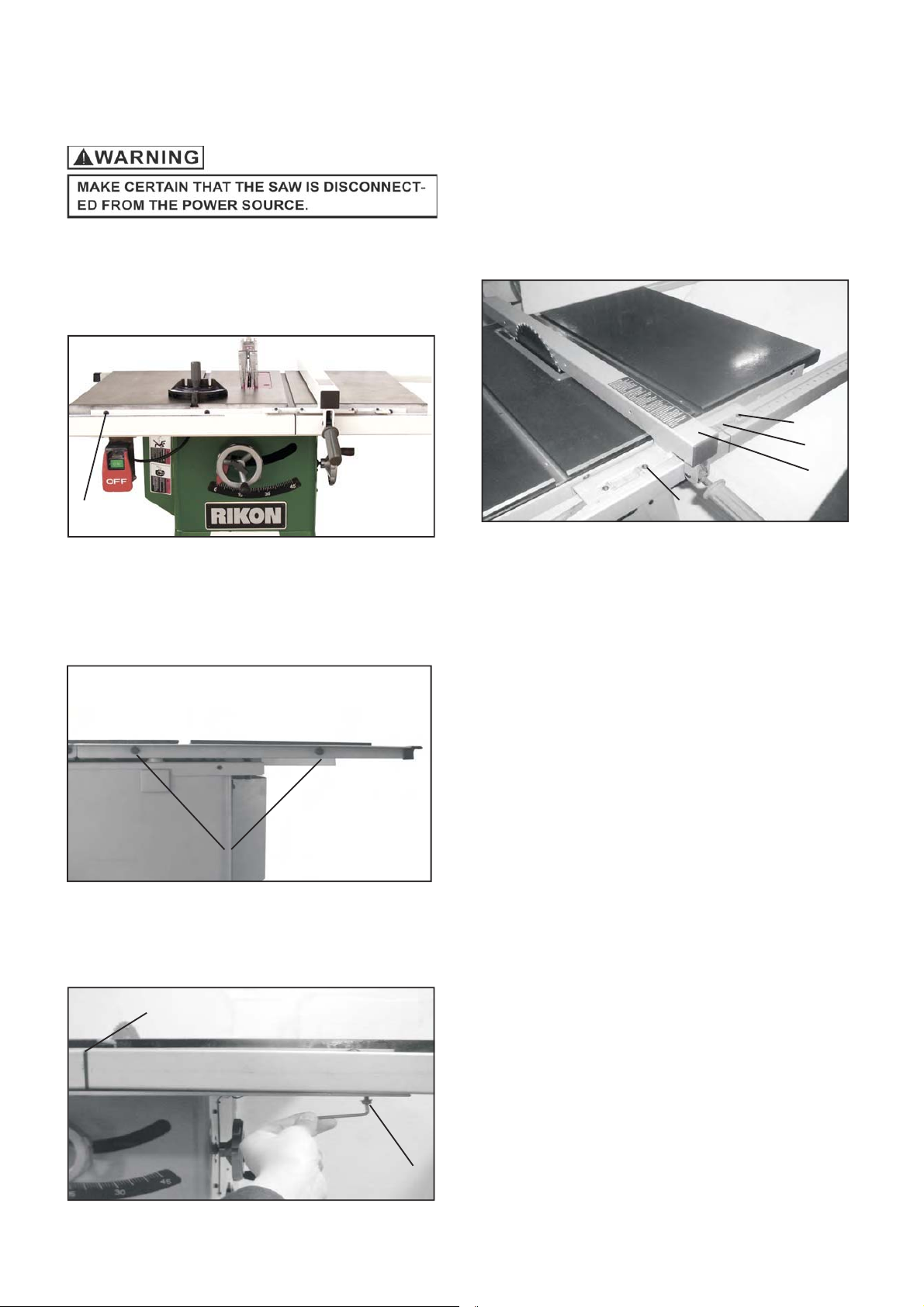

FENCE ASSEMBLY

1. Fasten the front rail to the table top using four

5/16-18x5/8mm cup hex soc head screws (A)

SEE FIG.17

Fig.17

4. Connecting the right guide tube(long)and left guide

tube(short)with cap (D), and place them on the front

rail.

5. The guide tube must be fasten by eight M6X16mm

hex soc round head screws(C) with M6 flat washer

and M6 lock washer. SEE FIG.19

Fig.20

G

F

E

A

2. Fasten the left rear rail to the table using two

5/16-18x5/8mm hex head screws(B) with M8 flat

Washer and M8 lock washer. SEE FIG.18

Fig.18

B

3. The installation method for right rear rail is the same

As the left one.

G

7. Place the Fence Body (E) on the table top and

against the blade to make sure that if the "zero"

scale on the cursor (F) is align with the "zero" scale of

the right/left scale label stuck on the guide tube.

8. Loosen the pan head screw (G) and move the cursor

(F) till the zero scale aligns with the zero scale on the

right/left scale. SEE FIG.20

Fig.19

D

C

11

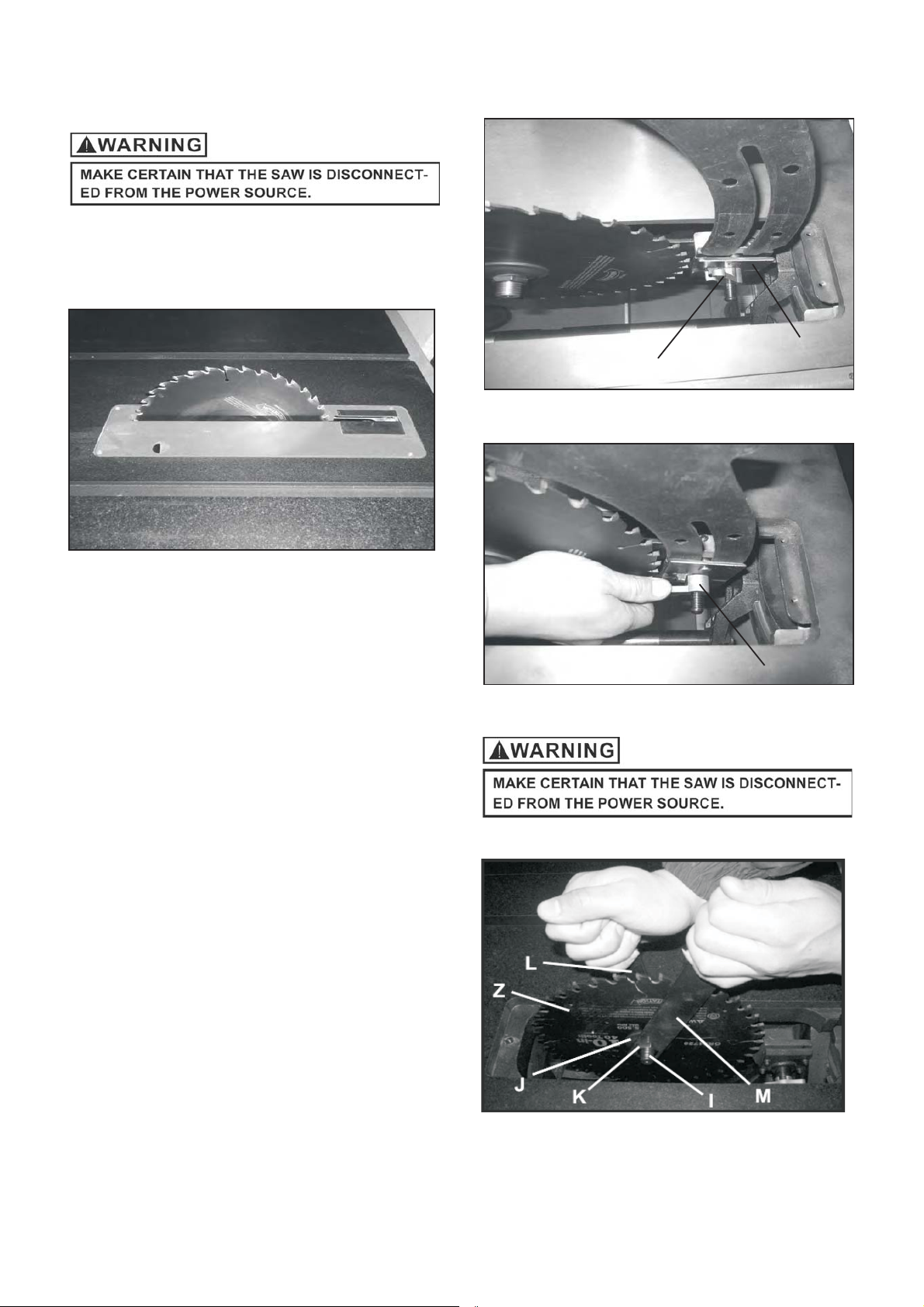

RIVING KNIFE/SPLITTER COMPONENTS

ASSEMBLY

Note: Remove the table insert ( Table insert are gripped

by four magnets on the table).

Fig.21

Fig.22

B

C

Fig.23

INSTALLING AND REMOVING

THE RIVING KNIFE/SPLITTER

1. Loosen the knob (C),Line up the riving knife/splitter in

the proper direction to the mounting bracket (B).

SEE FIG22.

2. Push the Riving Knife/ all the way down into the

mounting bracket, make sure the location pin is

properly locked in the hole of the Riving Knife/ .

(The location hole is on the button side of the Riving

Knife/ ).

splitter

3. Tighten the fasting knob(C).

splitter

splitter

SEE FIG.23

•Remove

1. Loosen the fasten knob (C).

2. Remove the Riving Knife/ out of mounting

bracket.

NOTE:

Make sure blade or arbor is at the highest

position before adding or removing the riving

splitter

Knife/ .

splitter

C

BLADE ASSEMBLY

Fig. 24

12

Loading...

Loading...