RIKON Power Tools 10-050 User Manual

10” Cabinet Saw

Sliding Table Model: 10-110

Cast Table Wings Model: 10-050

Part #10-110M2

Owner’s Manual

Record the serial number and date of purchase

in your manual for future reference.

Serial number:

Date of purchase:

For more information:

www.rikontools.com or info@rikontools.com

For Parts or Questions:

techsupport@rikontools.com or 877-884-5167

Operator Safety: Required Reading

IMPORTANT! Safety is the single most important consideration in the operation of this equipment. The following in-

structions must be followed at all times.

There are certain applications for which this tool was designed. We strongly recommend that this tool not be modifi ed and/or

used for any other application other than that for which it was designed. If you have any questions about its application, do not

use the tool until you have contacted us and we have advised you.

General Safety Warnings

KNOW YOUR POWER TOOL. Read the owner’s manual carefully. Learn the tool’s applications, work capabilities, and its

specifi c potential hazards.

ALWAYS GROUND ALL TOOLS.

If your tool is equipped with a three-pronged plug, you must plug it into a three-hole electric receptacle.

If you use an adapter to accommodate a two-pronged receptacle, you must attach the adapter plug to a

known ground. Never remove the third prong of the plug.

ALWAYS AVOID DANGEROUS ENVIRONMENTS.

Never use power tools in damp or wet locations. Keep your work area well lighted and clear of clutter.

ALWAYS REMOVE THE ADJUSTING KEYS AND WRENCHES FROM TOOLS AFTER USE.

Form the habit of checking to see that keys and adjusting wrenches are removed from the tool before turning

it on.

ALWAYS KEEP YOUR WORK AREA CLEAN. Cluttered areas and benches invite accidents.

ALWAYS KEEP VISITORS AWAY FROM RUNNING MACHINES.

All visitors should be kept a safe distance from the work area.

ALWAYS MAKE THE WORKSHOP CHILDPROOF.

Childproof with padlocks, master switches, or by removing starter keys.

NEVER OPERATE A TOOL WHILE UNDER THE INFLUENCE OF DRUGS, MEDICATION, OR ALCOHOL.

ALWAYS WEAR PROPER APPAREL.

Never wear loose clothing or jewelry that might get caught in moving parts. Rubber-soled footwear is

recommended for the best footing.

ALWAYS USE SAFETY GLASSES AND WEAR HEARING PROTECTION.

NEVER OVERREACH.

Keep your proper footing and balance at all times.

NEVER STAND ON TOOLS.

Serious injury could occur if the tool is tipped or if the cutting tool is accidentally contacted.

2

ALWAYS DISCONNECT TOOLS.

Disconnect tools before servicing and when changing accessories such as blades, bits, and cutters.

ALWAYS AVOID ACCIDENTAL STARTING.

Make sure switch is in “OFF” position before plugging in cord.

NEVER LEAVE TOOLS RUNNING UNATTENDED.

ALWAYS CHECK FOR DAMAGED PARTS.

Before initial or continual use of the tool, a guard or other part that is damaged should be checked to assure

that it will operate properly and perform its intended function. Check for alignment of moving parts, binding of

moving parts, breakage of parts, mounting, and any other conditions that may affect its operation. A guard or

other damaged parts should immediately be properly repaired or replaced.

Table Saw Safety Rules

1. Always wear eye protection.

2. Keep hands away from the saw blade while machine is running.

3. Always use blade guard during normal cutting operations.

4. Always use splitter during normal cutting operations.

5. Use push sticks when ripping narrow stock.

6. Always use fence while ripping and miter gauge while cross-cutting.

7. Never reach over or behind saw blade while machine is running.

8. Do not remove cut-off or jammed pieces until blade has come to a full stop.

9. Disconnect machine from power source before making repairs or adjustments.

10. Do not expose saw or power cord to water or use in damp locations.

SAVE THESE INSTRUCTIONS.

Refer to them often.

3

Table of Contents

Safety Warnings........................................................................................................................................2 -3

Table Saw Safety Rules ..........................................................................................................................3

Specifi cations ........................................................................................................................................4

Contents of Package ............................................................................................................................5

Unpacking and Checking Contents ...........................................................................................................................5

Loose Parts ...........................................................................................................................................6

Getting To Know Your Table Saw ............................................................................................................7

Assembly ..............................................................................................................................................8

Installing the Right Table Wing...................................................................................................................................8

Installing the Optional Left Table Wing.......................................................................................................................8

Installing the Optional Sliding Table .........................................................................................................................9

Installing Front Fence Rail ...........................................................................................................................9

Rear Fence Rail Installation.....................................................................................................................................9-10

Mounting the Fence Guide Bar..................................................................................................................................10

Installing Fence to Guide Bar ....................................................................................................................10

Installing the Fence Scale..........................................................................................................11

Leveling Fence to Saw Table ..........................................................................................................11

Squaring Fence to Table ...............................................................................................................12

Fence Cursor Adjustment ..................................................................................................................12

Blade Guard and Splitter Installation .......................................................................................................................13

Blade Installation and Removal.........................................................................................................................14

Leveling the Blade Insert .............................................................................................................................14

Operation ............................................................................................................................................15

Raising and Tilting the Saw Blade.....................................................................................................................15

Switch Operation..............................................................................................................................15

Maintenance ............................................................................................................................................... 16

Wiring Diagram ..........................................................................................................................16

Troubleshooting ........................................................................................................................17

Electrical Requirements........................................................................................................18

Parts Diagram ................................................................................................................................19-21

Parts List .......................................................................................................................................22-23

Warranty .............................................................................................................................................26

Specifi cations

Blade Diameter

Maximum Depth of Cut

Maximum Depth of Cut at 45°

Table in Front of Blade

Maximum Width of Dado

Blade Speed 4300RPM

Motor Power 3HP

Volts 230V / 60Hz

Current 13A

Height 37-1/2”

Net Weight 615 lbs

10”

3-1/8”

2-1/8”

13-7/8”

29/32”

4

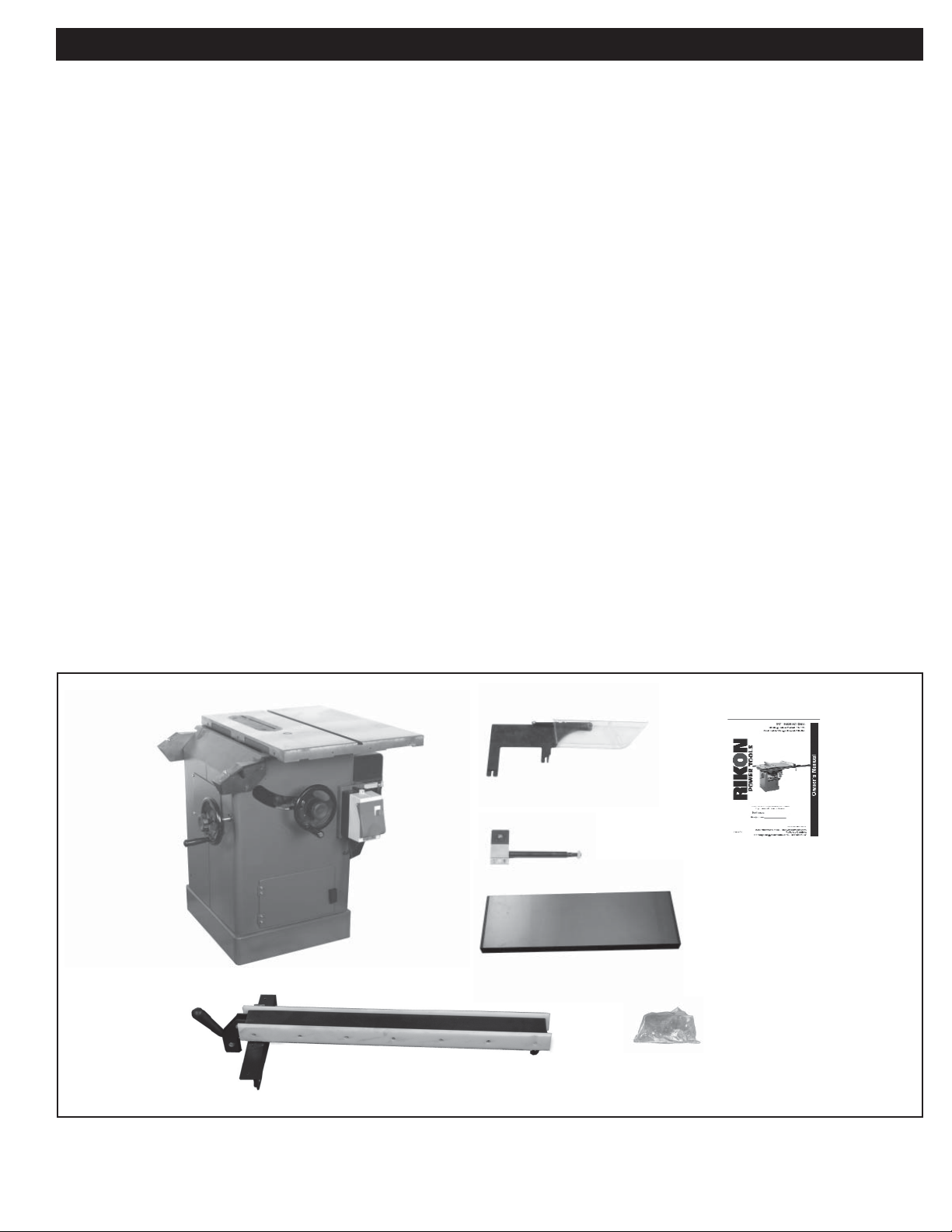

Content of Package

Model 10-050 10” Table Saw is shipped complete in three boxes.

1. Unpacking and Checking Contents

a. Separate all “loose parts” from packaging materials and check each item with “Table of Loose

Parts” to make sure all items are accounted for, before discarding any packaging material.

b. With the help of another person, unbolt the table saw from the packing pallet. Properly lift the

table saw off the packing pallet and place on level fl oor.

c. Remove protective oil that is applied to the table. Use any ordinary house hold type grease or

spot remover.

d. Apply a coat of paste wax to the table to prevent rust. Wipe all parts thoroughly with a clean dry

cloth.

2. Loose Parts

TABLE OF LOOSE PARTS

Item Part Name Qty

A Table Saw Assembly 1

B Fence Assembly 1

C Right Extension Wing 1

D Blade Guard Assembly 1

E Blade Guard Support 1

F Owner’s manual 1

G Bag of loose parts 1

Box #1

A

B

D

F

E

C

G

5

Loose Parts Continued

TABLE OF LOOSE PARTS

Item Part Name Qty

A Rear Guide Rail 1

B Front Guide Rail 1

Box #2

A

B

TABLE OF LOOSE PARTS

Item Part Name Qty

A Left Extension Wing 1

B Bag of loose parts 1

Box #3

A

B

6

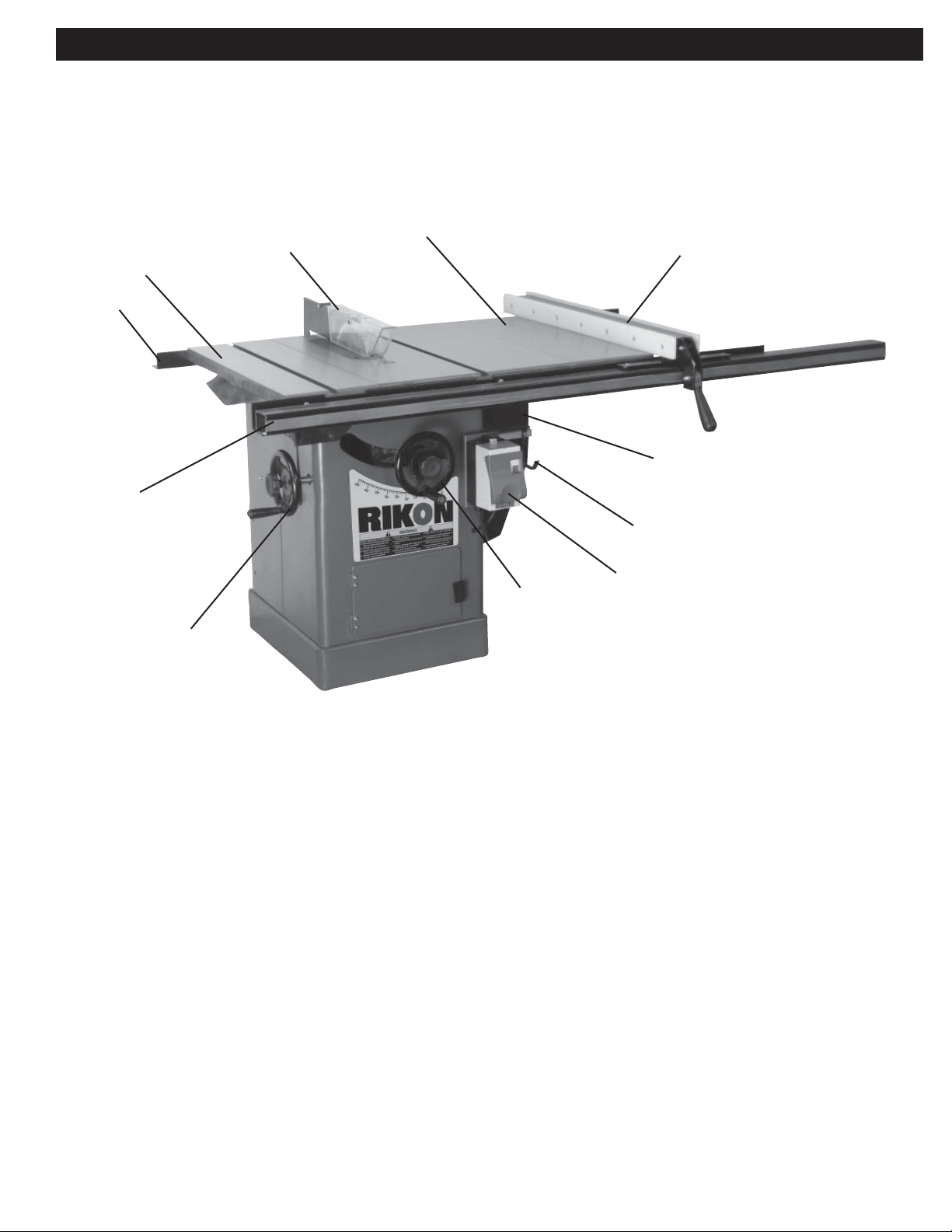

Getting To Know Your Table Saw

C

B

F

G

J

A

E

I

H

D

K

A. Right Extension Wing

B. Left Extension Wing

C. Blade Guard Assembly

D. Switch

E. Fence Assembly

F. Rear Rail

G. Front Rail

H. Tool Holder

I. Motor Cover

J. Blade Tilting Handwheel

K. Blade Raise/down Handwheel

7

Assembly

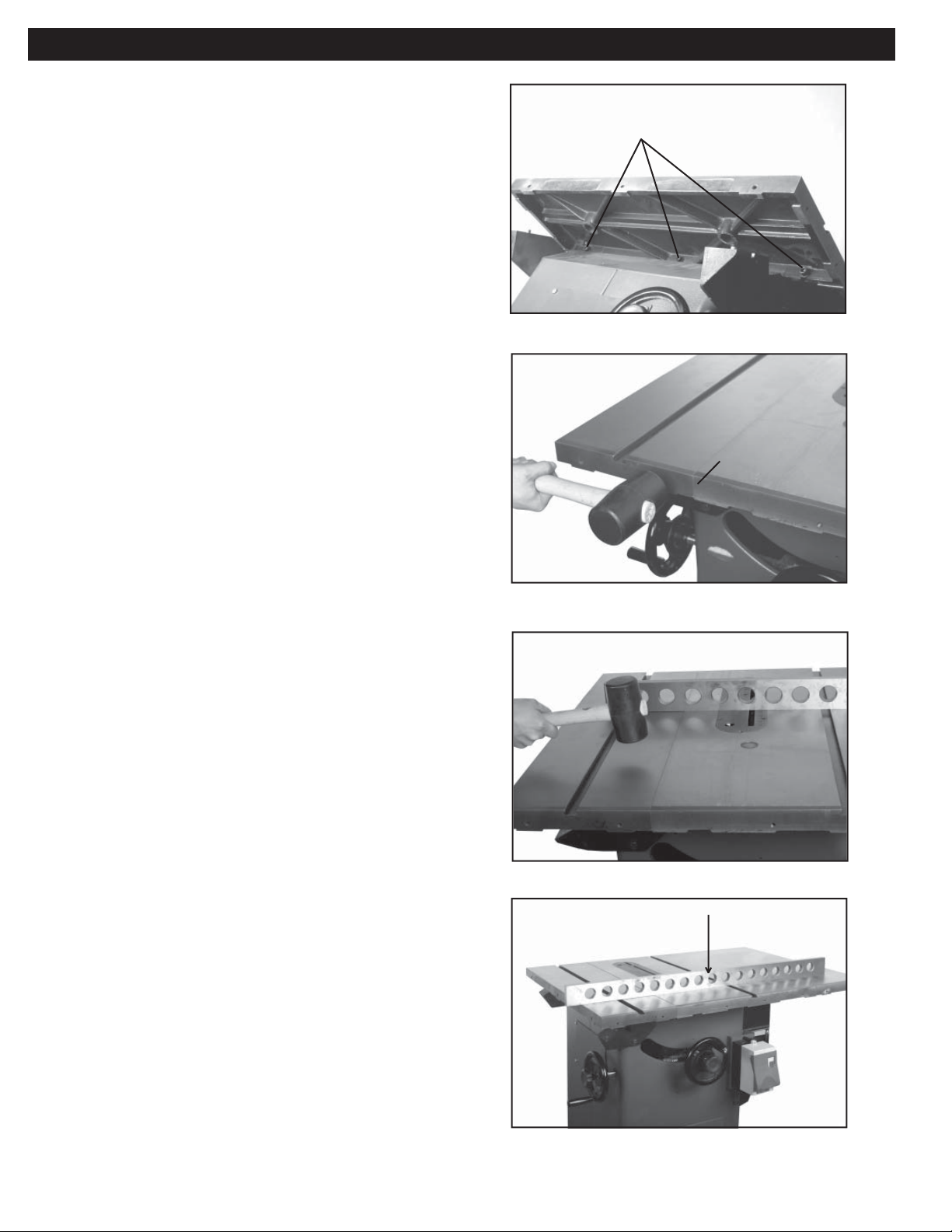

Installing the Right Table Wing

1. Mount the cast iron table wing using

three M10x30 hex head bolts and three M10

fl at washers. Figure 1.

With assistance hold the extension wing up to the

table, and insert the bolts and washers.

Finger tighten only.

Hex. socket screw

Spring washer

NOTE: If assistance is not available, hold the wing

in vertical position up to the saw table, insert the

middle screw and lock washer fi nger tight, then

pivot the wing to level position. Insert the other two

screws and washers fi nger tight.

2. Align table wing toward the front edge of the

saw table until the two faces are fl ush. Figure 2.

3. Level table wing with the saw table across its

entire width, using a straight edge and hammer

with rubber hammer (or block of wood ). Figure 3.

Figure 1

Front edge fl ush

Figure 2

As each section of the table wing becomes fl ush

with the table, tighten the screw under that area.

Continue until all three screws are fully tightened.

Check with straight edge and adjust as needed.

Figure 4.

Installing the Optional Left Wing

The optional left cast iron table wing with miter slot

is used in place of the optional slide table. Please

refer to the instructions above for proper installation.

Figure 3

Figure 4

8

Assembly

Assembling the Optional Sliding Table

Please refer to the Sliding Table Attachment

manual located in the separate shipping carton for

proper installation procedures.

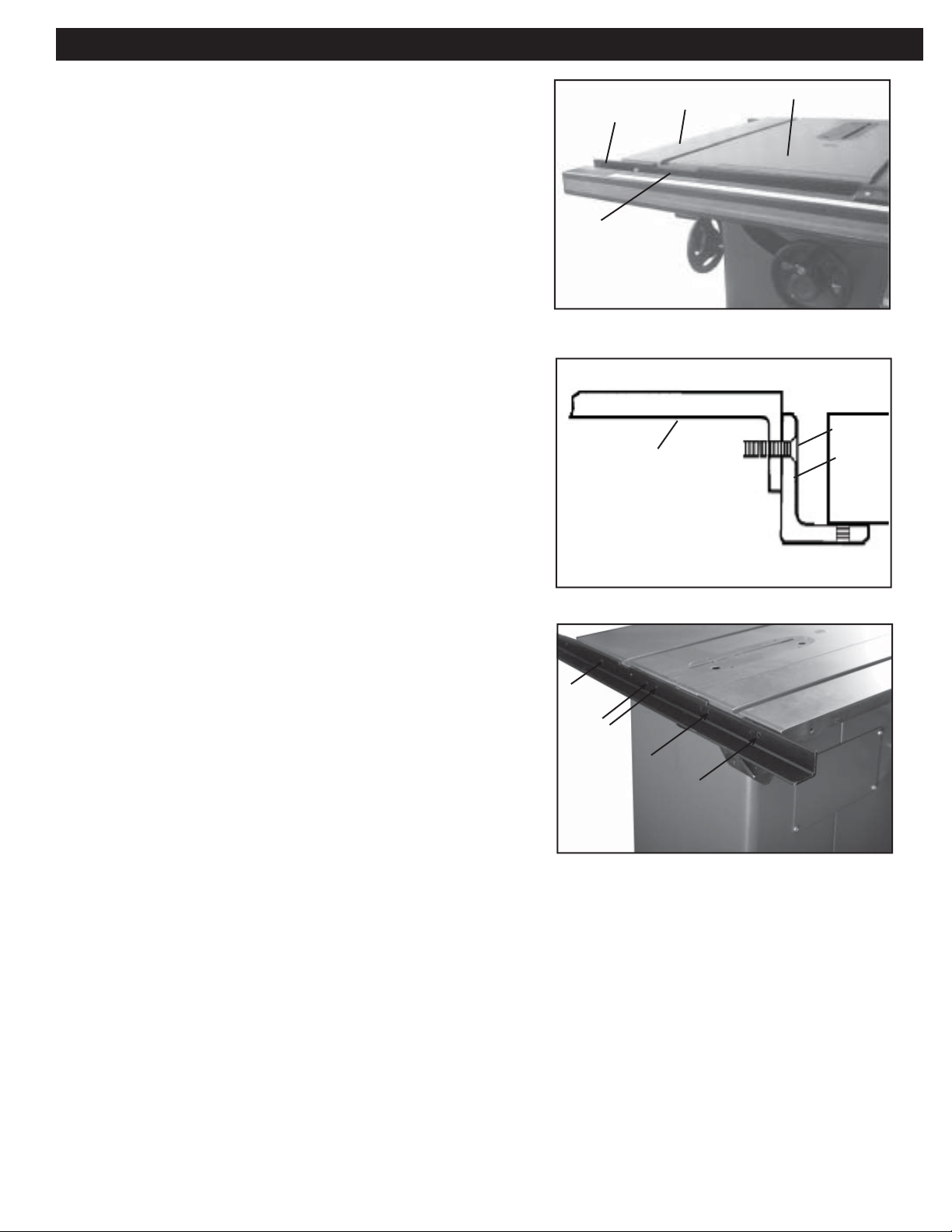

Installing Front Fence Rail

1. Identify the front rail (E), which is the larger “L”

shaped bar with the countersunk mounting holes

facing front.

NOTE: The front fence rail can be mounted

differently depending on the use of the cast

table wing or the sliding table attachment. When

using the table wing the front fence rail should

be installed as described below. Please refer to

the Sliding Table Attachment manual for proper

placement of the front fence rail. Figure 5.

H

E

G

F

Figure 5

G

A

E

2. Align the “L” shaped bar so the left notch (H)

matches the miter slot on the left extension wing.

3. Secure the front rail (E) to the table (G) and

table wings (F) with fi ve countersunk head screws

(A). Tighten just enough to hold the rail next to

the table but keep loose enough to allow height

adjustment. Figure 6.

4. When the Front Rail has been correctly

positioned, tighten all mounting screws securely

with the 5MM L wrench provided.

Rear Fence Rail Installation

1. Identify the rear fence rail, which is the smaller

“L” shaped bar. Place against the table and align

as shown. Figure 7.

E

D

Figure 6

C

B

A

Figure 7

9

Loading...

Loading...