Page 1

RIGOL

Quick Guide

M300 Series

Data Acquisition/Switch System

Dec. 2014

RIGOL Technologies, Inc.

Page 2

Page 3

RIGOL

I

Guaranty and Declaration

Copyright

© 2013 RIGOL Technologies, Inc. All Rights Reserved.

Trademark Information

RIGOL is a registered trademark of RIGOL Technologies, Inc.

Publication Number

QGC07107-1110

Notices

RIGOL products are covered by P.R.C. and foreign patents, issued and pending.

RIGOL reserves the right to modify or change parts of or all the specifications and

pricing policies at company’s sole decision.

Information in this publication replaces all previously corre sp onding material.

Information in this publication is subject to change without notice.

RIGOL shall not be liable for either incidental or consequential losses in connection

with the furnishing, use or performance of this manual as well as any information

contained.

Any part of thi s document is forbidden to b e copied, photocopied or rearranged

without prior written approval of RIGOL.

Product Certification

RIGOL guarantees this product conforms to the national and industrial standards in

China as well as the ISO9001:2008 standard and the ISO14001:2004 standard. Other

international standard conformance certification is in progress.

Contact Us

If you have any problem or requirement when using our products or this manual, please

contact RIGOL.

E-mail: service@rigol.com

Website: www.rigol.com

M300 Quick Guide

Page 4

RIGOL

II

Safety Requirement

General Safety Summary

Please review the following safety precautions carefully before putting the instrument

into operation so as to avoid any personal injur y or damage to the instr ument and any

product connected to it. To prevent potential haz ards, please use the instrument only

specified by this manual.

Use Proper Power Cord.

Only the power cord designed for the instrument and authorized for use within the local

country could be used.

Ground the Instrument.

The instrument is grounded through the Protective Earth lead of the power cord. T o avoid

electric shock, it is essential to connect the earth termi na l of the power cord to the

Protective Earth terminal before connecting any inputs or outputs.

Connect the Probe Correctly.

If a probe is used, do not connect the ground lead to high volta ge since it has isobaric

electric potential as the ground.

Observe All Terminal Ratings.

To avoid fire or shock hazard, observe all ratings and markers on the instrument and

check your manual for more information about ratings before connecting the instrument.

Use Proper Overvoltage Protection.

Make sure that no overvoltage (such as that caused by a thunderstorm) can reach the

product, or else the operator might be exposed to the danger of electrical shock.

Do Not Operate Without Covers.

Do not operate the instrument with covers or panels removed.

Do Not Insert Anything Into the Holes of Fan.

Do not insert anything into the holes of the fan to avoid damaging the instrument.

Use Proper Fuse.

Please use the specif ied fuses.

Avoid Circuit or Wire Exposure.

Do not touch exposed junctions and components when the unit is po wered.

Do Not Operate With Suspected Failures.

If you suspect damage occurs to th e instrument, ha ve it inspected by RIGOL authorized

personnel before further operations. Any maintenance, adjustment or replacement

especially to circuits or accessories must be performed by RIGOL authorized personnel.

M300 Quick Guide

Page 5

RIGOL

III

Keep Well Ventilation.

Inadequate ventilation may cause an increase of instrument temperature which would

cause damage to the instrument. So please keep the instrument well ventilated and

inspect the intake and fan regularly.

Do Not Operate in Wet Conditions.

In order to avoid short circuiting to the interior of the device or electric shock, please do

not operate the instrument in a humid environment.

Do Not Operate in an Explosive Atmosphere.

In order to avoid damage to the device or per sonal injuries, i t is important to operate the

device away from an explosive atmosphere.

Keep Product Surfaces Clean and Dry.

To avoid the influence of dust and/or moisture in the air, please keep the surface of the

device clean a nd dry.

Electrostatic Prevention.

Operate the instrument in an electrostatic disc ha r g e protective environment to avoid

damage induced by static discharges. Always ground both the internal and external

conductors of cables to release static before making connections.

Proper Use of Battery.

If a battery is supplied, it must not be exposed to high temperature or in contact with fire.

Keep it out of the reach of children. Improper change of battery (note: lithium battery)

may cause explosion. Use RIGOL specified battery only.

Handling Sa fety.

Please handle with care during transportation to avoid damage to buttons, knob

interfaces and other parts on the panels.

M300 Quick Guide

Page 6

RIGOL

IV

WARNING

or loss of life.

CAUTION

damage to this product or other property.

DANGER

It calls attention to an operation, if not correctly performed, could result in

injury or hazard immediately.

WARNING

It calls attention to an operation, if not correctly performed, could result in

potential injury or hazard.

CAUTION

It calls attention to an operation, if not correctly performed, could result in

damage to the product or other devices connected to the product.

Hazardous

Safety

Protective

Terminal

Chassis

Test

Safety Terms and Symbols

Terms Used in this Manual. These terms may appear in this manual:

Warning statements indicate conditions or practices that could result in injury

Caution statements indicate conditions or practices that could result in

Terms Used on the Product. These terms may appear on the Product:

Symbols Used on the Product. These symbols may appear on the product:

Voltage

Warning

Earth

Ground

Ground

M300 Quick Guide

Page 7

RIGOL

V

Allgemeine Sicherheits Informationen

Überprüfen Sie diefolgenden Sicherheitshinweise

sorgfältigumP ersonenschädenoderSc häden am Gerätundan damit verb undenen weiteren

Gerätenzu vermeiden. Zur Vermeidung vonGefahren, nutzen Sie bitte das Gerät nur so,

wiein diesem Handbuchangegeben.

Um Feuer oder Verletzungen zu vermeiden, verwenden Sie ein

ordnungsgemäßes Netzkabel.

Verwenden Sie für dieses Gerät nur das für ihr Land zugelassene und genehmigte

Netzkabel.

Erden des Gerätes.

Das Gerät ist durch den Schutzleiter im Netzkabel geerdet. Um Gefahren durch

elektrischen Schlag zu vermeiden, ist es unerlässlich, die Erdung durchzuführen. Erst

dann dürfen weitere Ein- oder Ausgänge verbunden werden.

Anschluss einesTastkopfes.

Die Erdungsklemmen der Sonden sindauf dem gleichen Spannungspegel des

Instruments geerdet. SchließenSie die Erdungsklemmen a n keine hohe Spannung an.

Beachten Sie alle Anschlüsse.

Zur Vermeidung von Feuer oder Stromschlag, beachten Sie alle Bemerkungen und

Markierungen auf d em Instrument. Befolgen Sie die Bedienungsanleitung für we itere

Informationen, bevor Sie weitere Anschlüsse an das Instrument legen.

Verwenden Sie einen geeigneten Überspannungsschutz.

Stellen Sie sicher, daß keinerlei Überspannung (wie z.B. durch Gewitter verursacht) das

Gerät erreichen kann. Andernfallsbestehtfür den Anwender die

GefahreinesStromschlages.

Nicht ohne Abdeckung einschalten.

Betreiben Sie das Gerät nicht mit entfernten Gehäuse-Abdeckungen.

Betreiben Sie das Gerät nicht geöffnet.

Der Betrieb mit offenen oder entfernten Gehäuseteilen ist nicht zulässig. Nichts in

entsprechende Öffnungen stecken (Lüfter z.B.)

Passende Sicherung verwenden.

Setzen Sie nur die spezifikationsgemäßen Sicherungen ein.

Vermeiden Sie ungesc hützte Verbindungen .

Berühren Sie keine unisolierten Verbindungen oder Baugruppen, während das Gerät in

Betrieb ist.

Betreiben Sie das Gerät nicht im Fehlerfall.

Wenn Si e am Gerät einen Def ekt ver muten, so rgen Sie dafü r, bevor Sie das Gerät wieder

M300 Quick Guide

Page 8

RIGOL

VI

betreiben, dass eine Untersuchung durch RIGOL autori siertem Personal durchgeführt

wird. Jedwede Wartung, Einstellarbeiten oder Austausch von Teilen am Gerät, sowie am

Zubehör dürfen nur von RIGOL autorisiert em Personal durchgeführt werden.

Belüftung sicherstellen.

Unzureichende Belüftung kann zu Temperaturanstiegen und somit zu thermischen

Schäden am Gerät führen. Stellen Sie deswegen die Belüftung sicher und kontrollieren

regelmäßig Lüfter und Belüftungsöffnungen.

Nicht in feuchter Umgebung betreiben.

Zur Vermeidung von Kurzschluß im Geräteinneren und Stromschlag betreiben Sie das

Gerät bitte niemals in feuchter Umgebung.

Nicht in explosiver Atmosphäre betreiben.

Zur Vermeidung von Personen- und Sachschäden ist es unumgänglich, das Gerät

ausschließlich fernab jedweder explosiven Atmosphäre zu betreiben.

Geräteoberflächen sauber und trocken halten.

Um den Einfluß von Staub und Feuchtigkeit aus der Luft auszuschließen, halten Sie bitte

die Geräteoberflächen sauber und trocken.

Schutz gegen elektrostatische Entladung (ESD).

Sorgen Sie für eine elektrostatisch geschützte Umgebung, um somit Schäden und

Funktionsstörungen durch ESD zu vermeiden. Erden Sie vor dem Anschluß immer Innenund Außenleiter der Verbindungsleitung, um statische Aufladung zu entladen.

Die richtige Verwendung desAkku.

Wenneine Batterieverwendet wird, vermeiden Sie hohe Temperaturen bzw. Feuer

ausgesetzt werden. Bewahren Sie es außerhalbder Reichweitevon Kindern auf.

UnsachgemäßeÄnderung derBatterie (Anmerkung: Lithium-Batterie) kann zu einer

Explosion führen. VerwendenSie nur von RIGOL angegebenenAkkus.

Sicherer Transport.

Transportieren Sie das Gerät sorgfältig (Verpackung!), um Schäden an Bedienelementen,

Anschlüssen und and eren Teilen zu vermeiden.

M300 Quick Guide

Page 9

RIGOL

VII

WARNING

Schäden oder den Tod von Personen zur Folge haben können.

CAUTION

Schäden am Gerät hervorrufen können.

DANGER

weist auf eine Verletzung oder Gefährdung hin, die sofort geschehen

kann.

WARNING

weist auf eine Verletzung oder Gefährdung hin, die möglicherweise

nicht sofort geschehen.

CAUTION

weist auf eine Verletzung oder Gefährdung hin und bedeutet, dass

Gegenstände auftreten kann.

Sicherheits Begriffe und Symbole

Begriffe in diesem Guide. Diese Begriffe können in diesem Handbuch auftauchen:

Die Kennzeichnung WARNING beschreibt Gefahrenquellen die leibliche

Die Kennzeichnung Cautio n (Vorsicht) beschreibt Gefahrenquell en die

Begriffe auf dem Produkt. Diese Bedingungen können auf dem Produkt erscheinen:

eine mögliche Beschädigung des Instruments oder anderer

Symbole auf dem Produkt. Diese Symbole können auf dem Produkt erscheinen:

GefährlicheS

pannung

SicherheitsHinweis

Schutz-erde Gehäusemasse Erde

M300 Quick Guide

Page 10

RIGOL

VIII

CAUTION

WARNING

completely dry before reconnecting to a power source.

General Care and Cleaning

General Care

Do not store or leave the instrumen t wh ere it may be exposed to direct sunlight for long

periods of time.

Cleaning

Clean the instrument regularly according to its operating conditions. To clean the exterior

surface, perform the following steps:

1. Disconnect the instrument from all power sources .

2. Clean the loose dust on the outside of the instrument with a lint-free cloth (with a

mild detergent or water). When cleaning the LCD, take care to avoid scarifying it.

To avoid damage to the instrument, do not expose it to caustic liquids.

To avoid injury resulting from short circuit, make sure the instrument is

Environmental Consideratio ns

The following symbol indicates that this product complies with the applicable WEEE

Directive 2002/ 96/E C.

Product End-of-Life Handling

The equipment may contain substances that could be harmful to the environment or

human health. In order to avoid release of such substances into the environment and

harm to human health, we encourage you to recycle this product in an appropriate

system that will ensure that most of the materials are reused or recycled appropriately.

Please contact your local authorities for disp osal or recycling information.

M300 Quick Guide

Page 11

RIGOL

IX

Contents

Guaranty and Declaration ......................................................................... I

Safety Requirement ................................................................................ II

General Safety Summary ........................................................................... II

Safety Terms and Symbols ....................................................................... IV

Allgemeine Sicherheits Informationen ......................................................... V

Sicherheits Begriffe und Symbole ............................................................. VII

General Care and Cleaning ..................................................................... VIII

Environmental Considerations ................................................................. VIII

Document Overview ................................................................................. 1

Quick Start ............................................................................................... 1

General Inspection ................................................................................... 1

Appearance and Dime nsions ...................................................................... 2

Front Panel .............................................................................................. 3

Rear Panel ............................................................................................... 7

Power On and Inspection ......................................................................... 11

User Interface ......................................................................................... 12

Plug-in Module Overview .......................................................................... 13

Outside View drawing of the module ................................................... 13

Insert the Module into the Mainframe ................................................. 14

Module Overview .............................................................................. 15

To Use the Built-in Help System ................................................................ 17

Menu Quick Navigation ............................................................................ 17

Config ............................................................................................. 18

Monitor ............................................................................................ 19

View Switch Key ............................................................................... 19

Control ............................................................................................ 20

Alarm Channel Setting Ke ys ............................................................... 20

Basic Operations .................................................................................... 21

Measurement Connections ....................................................................... 21

To Configure Sc an List ............................................................................. 25

Configuration Copy .................................................................................. 27

Channel Monitor ...................................................................................... 28

Remote Control ....................................................................................... 29

Troubleshooting ..................................................................................... 31

M300 Quick Guide

Page 12

Page 13

RIGOL

1

Document Overview

This manual briefly introduces the front and rear panels, the user interface and the

basic measurement method of M300 Series Data Acquisition/Switch System. It

guides users to quickly get familiar with the instrument. For more de t a i l e d

information, please refer to the User’s Guide.

Quick Start

This section provides the basic inf ormati on about the front and rear panels, the user

interface and the plug-in modules.

General Inspection

1. Inspect the shipping container for damage

Keep the damaged shipping container or cushioning material until the contents

of the shipment have been checked for completeness and the instrument has

passed both electrical and mechanical tests.

The consigner or carrier shall be liable for the damage to instrument resulting

from shipment. RIGOL would not be re sponsible fo r free maintenan ce/rework

or replacement of the unit.

2. Inspect the instrument

In case of any damage, or defect, or failure, notify your RIGOL sales

representative.

3. Check the accessories

Please check the accessories according to the packing lists. If the accessories

are incomplete or damaged, please contact your RIGOL sales representative.

M300 Quick Guide

Page 14

RIGOL

2

Appearance and Dimensions

Figure 1 Front View Unit: mm

Figure 2 Side View Unit: mm

M300 Quick Guide

Page 15

3

Front Panel

Configure the scan list and the measurement parameters of each

Enable or disable the channel monitor function.

channels in the scan list.

1 2

6 7 8 9 10

3

RIGOL

4

5

Figure 3 M300 Front Panel

1. LCD

4.3 inch high-res ol u t i on color LCD. It displays the menu, configuration guide,

measurement parameters, system status, prompt messages and etc.

2. Function Keys

channel.

Create, edit, read and save the scan list.

Set the number of scans, trigger mode and scan interval.

Provide the channel configuration guide which can be used to

configure the measurement parameters, scaling parameters,

alarm parameters and advanced measurement parameters of

the channel.

Support single-channel, multi-channel and all-channel monitor

functions.

In single-channel monitor function, you can swit ch t he chan ne l

monitored at any time.

In multi-channel monitor function, you can monitor up to 7

M300 Quick Guide

Page 16

RIGOL

4

In all-cha nne l mo nitor function , you can monitor all the

Control the modules currently inserted.

Auto Trigger/Stop

Single-channel Switch

monitor interface.

Numeric Keyboard

Open the previous or next page of the current interface.

keys (Page U p and Page Dn).

If a USB sto r age device is currently connected to the

When the instrument is in local mode, pressing this key

channels in the scan list.

Control the status of each channel of the modules.

Initialize the modules.

Configure the channels of the multifunction module.

Cannot cont rol the DMM mo dule.

Press this key, the instrument triggers or enters the wait-for-trigger

state and the backlight of the key goes on. At this point, press and

hold this key; the instrument stops triggering or exits the

wait-for-trigger state and the backlig ht of th e key goes off.

Note: This key is invalid when the scan list is empty.

When the instrument is in the single-channel monitor interfa ce,

pressing this key can switch the channel monitored to the next

channel in the scan list; when the instrument is in other interfaces,

pressing this key can switch the instrument to the single-channel

3. Control Keys

Include numbers (0-9), decimal point (.) as well as

positive/negative sign (+/-).

Used to input parameter value, date and time.

Note: These keys are different from the menu page up/down

Direction keys and confirmation key.

4. System Keys

instrument, pressing this k ey will store the current cont ent on

the screen in the USB storage device in *.bmp format.

can lock the front panel. At this point, all the keys at the

front panel except this key become invalid. Pressing and

holding this key can unlock the front panel.

M300 Quick Guide

Page 17

5

When the instrument is in remote mode, pressing this

Store and recall the system configuration, measurement

Configure the system-related parameters.

Enable the built-in help system. Provide Chinese/English help

information for the front p anel f uncti on keys a nd menu ite ms.

Press this key to turn on or off the instrument.

Via this interface, M300 can be connected with an USB storage

key can switch to loc al mode.

RIGOL

configuration, measurement data and etc.

Store the file in the internal non-volatile memory or

external USB storage device.

Read the f ile stored.

Set various parameters such as the time, date, system

language and display brightness.

Conf igure the remote interface (RS232, LAN, GPIB and

USB) parameters.

Query the system information (such as the model and

serial number).

Execute self-test and view the information of each

module (such as the name and model of th e module).

System update.

5. Alarm Channel Setting

M300 provides 4 alarm channels. When an alarm is generated, the

corresponding pin of the Alarms/Ext Trig interface (converted from the

[RS-232/Alarms/Ext Trig] interface) at the rear panel outputs a pulse. You

can press the corresponding key to set the output mode of the corresponding

pin.

6. Power Key

7. USB Host

8. Menu Softkeys

device as host device to store or recall instrument status,

measurement configuration, measurement data and etc.

Correspond to t h e menus above t h em . Pressing any softkey can enable the

corresponding menu.

M300 Quick Guide

Page 18

RIGOL

6

View the scan history information, channel status table,

to 20).

9. View Switch

measurement curve and channel information.

Scan history information: view the start time, scan sweep,

count, channel number as well as the corresponding

function, maximum, minimum, average and standard

deviation measured as well as the scan rea dings of each

channel of the latest scan.

Channel status table: display the current status of each

channel.

Measurement curve: display the measurement curve of the

specified channel.

Channel information: view the cycle count of each relay of

the module, the alarm messages of the current scan (the

first 100 on each alarm channel, including the reading and

time when the alarm is generated) and error messages (up

Note: Up to 100 alarm messages on each alarm channel can be logged in t he

alarm queue and the subsequent alarm messages would be lost. Up to 20 error

messages can be logged in the error queue and the other error message s wi l l

also be lost.

10. Module Indicators

Correspond to the 5 module slots at the rear panel respectively. The

corresponding module indicator goes on when the module is inserted into the

slot at the rear panel.

M300 Quick Guide

Page 19

7

Rear Panel

CAUTION

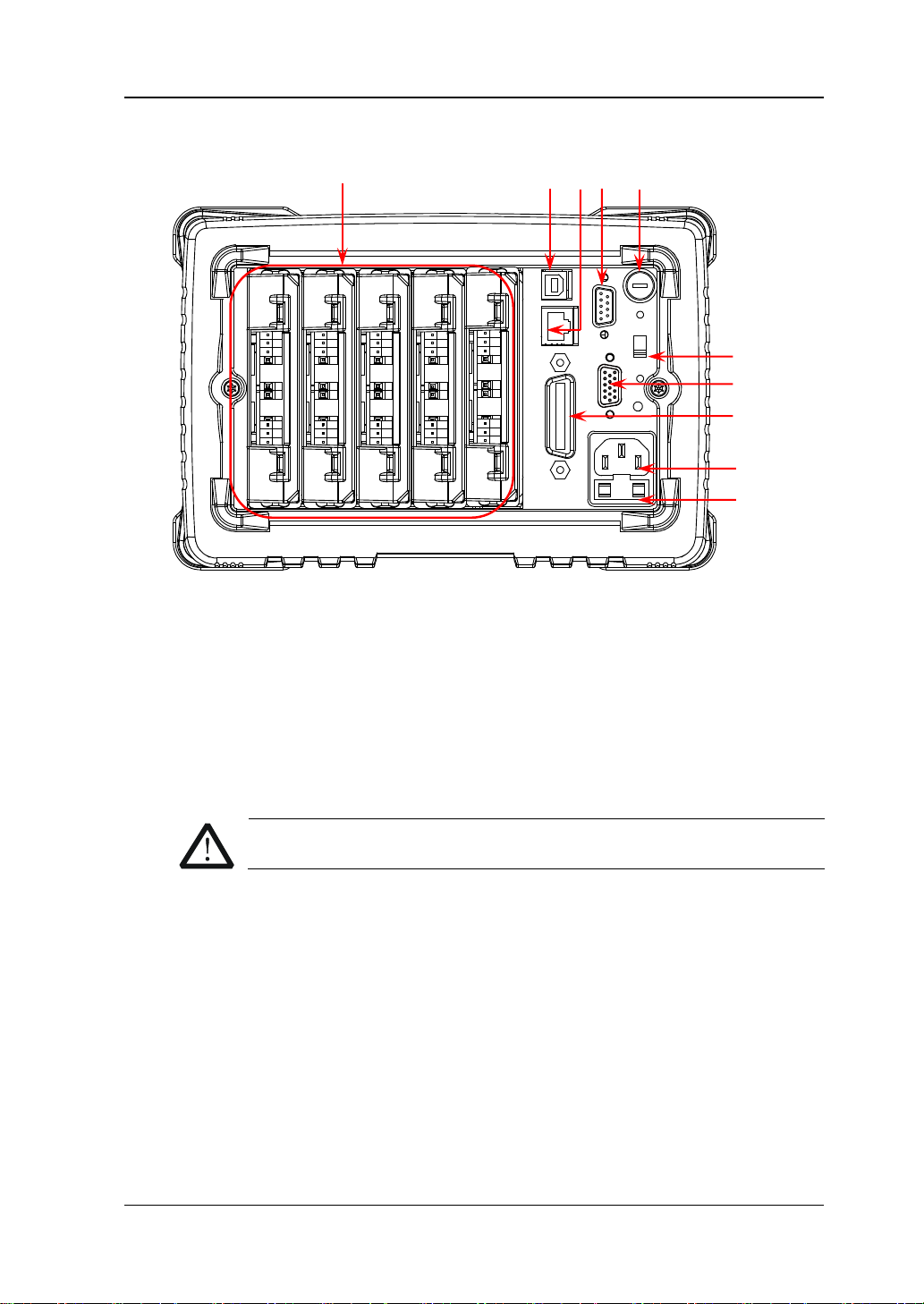

1 2 3 4 5

9

10

6

7

8

Figure 4 M300 Rear Panel

1. Slots

M300 provides 5 slots for 5 modules. The 5 slots from left to right in the figure

above correspond to the 5 module indicators at the front panel respectively.

When a module is inse rted in the slot, the correspond ing module indi cator at the

front panel goes on. Figure 4 is the schematic diagra m of the rear panel withou t

any module inserted. For the information of each module, refer to “Plug-in

Module Overview”.

RIGOL

Only a single DMM module is permitted for one mainframe.

2. USB Device Interface

Via this interface, M300 can communi cate with the PC as a sla ve devi ce and yo u

can control it remotely via the PC.

3. LAN

M300 conforms to the LXI Core 2011 Device standard. The instrument can be

connected to the network via this interface and you can control the instrument

remotely via a PC in the same network.

4. Analog Bus Interface (Female)

M300 provides two internal 2-wire analog buses for signal routing as well as an

external analog bus interface (namely analog bus interface). The analog bus

M300 Quick Guide

Page 20

RIGOL

8

CAUTION

6 7 4 5 2 3 1

8

9

Pin

Definition

1

Current Input

2

Lo

3

LoSense

4

--

5

--

6

Hi 7 HiSense

8

Float GND

9

--

interface is a 9-pin female interface.

Analog Bus Interface

5. DMM Module Power Fuse

The AC power supply input from the power socket is divided into two paths with

one for the DMM module and the other for the other circuits. M300 is equipped

with the DMM module power fuse ( AC 250V T250 mA). To replace the fuse, refer

to the method below.

1) Turn off the instrument and remove the power cord.

2) Press down the fuse cover using a st ra ight screw driver an d rotate the

straight screw driver clockwise.

3) Select a proper voltage through the voltage selector.

4) Disassemble the fuse cap and fuse.

5) Replace a specified fuse and install the fuse cap.

Please use the specified fuse to avoid electric shock or fire.

6. Voltage Selector

M300 supports two kinds of AC voltages (115 V and 230 V). Please select the

proper voltage scale according to the AC power used.

7. RS-232/Alarms/Ext Trig Mix Interface (Male)

This is a 25-pin male interface. You can convert this interface into two 9-pin

interfaces using the Mix Interface Convert Cable (accessory); wherein, one is a

9-pin male interface use d as a st andar d RS232 int erface a nd the other is a 9-pin

female interface used for alarm output, external trigger signal input and etc.

M300 Quick Guide

Page 21

RIGOL

9

Pin

Definition

1

Alarm 1 Output

2

Alarm 2 Output

3

Alarm 3 Output

4

Alarm 4 Output

5

Channel Closed Output

6

Ext Trig Input/Channel Advance Input

7

GND

8

Not Used

9

Not Used

6 7 4 5 2 3 1 6 7 4 5 2 3

1

8

9

Pin

Name

Definition

1

--

--

2

RXD

Received Data

3

TXD

T ransmitted Data

4

DTR

Data T erminal Ready

5

SGND

Signal Ground

6

DSR

Data Set Ready

7

RTS

Request To Send

8

CTS

Clear To Send

9

--

--

8

9

RS232: via this interface, M300 can communicate with the PC and you can

control the instrument remotely via the PC.

RS232 Interface

Alarms/Ext Trig: as shown in the figure below, pin 1 to pin 4 are used to

output TTL pulse when an alarm is generated in the corresponding alarm

channel. Pin 6 is used to receive external trigger signal. When an external

digital multimeter is connected for measurement, pin 5 and pin 6 are used

together to control the measurement.

Alarms/Ext Trig Interface

Note:

Pin 5 outputs a TTL negative pulse with about 7μs pulse width at each

measurement completion. The output rate is dependent upon the actual

measurement rate and cannot exceed 1000 times per second.

In external trigger mode, when Pin 6 accepts an external trigger signal with a

pulse width equal to or greater than 2μs and specified edge (press Config,

select “External” trigge r m ode an d se lect “Rising” or “Falling” in the Edge item),

the instrument triggers. If the external trigger signal is a continuous pulse,

please make sure the pulse period is greater than 100μs.

8. GPIB Interface

M300 conforms to the IEEE-488.2 standard. Via this interface, M300 can

communicate with the PC and you can control the instrument remotely via the

PC.

M300 Quick Guide

Page 22

RIGOL

10

CAUTION

scale using the voltage selector.

CAUTION

seat is not short-circuited to avoid electric shock or fire.

9. Power Socket

M300 can accept two kinds of AC power supplies. Use the power cord provided

in the accessories to connect the AC power supply to the instrument via this

socket.

Before connecting the AC power supply, select the correct voltage

10. Power Fuse

The specification of the fuse of M300 is AC 250V T3.15 A. If a new fuse is

required, please refer to the following steps.

1) Turn off the instrument and remove the power cord.

2) Insert a small straight screwdriver into the slot at the power socket and

prize out the fuse seat.

3) Replace a specified fuse.

4) Insert the fuse seat into the slot.

Please use the specified power fuse and make sure that the fuse

M300 Quick Guide

Page 23

11

Power On and Inspection

AC Power Input Terminal

1. Connect the power

1) Adjust the power voltage selector at the rear panel according to the power

supply volta ge. M300 suppo rt s two types of AC pow e r inputs:

If your supply voltage is between 115*(1-10%) V and115*(1+1 0%) V,

please select 115.

If it is between 230*(1-10%) V and 230*(1+10%) V, please select 230.

2) Connect the instrument to AC power using the power cord provided in the

accessories.

RIGOL

2. Start the ins t rument

Press the power key at the front panel and the instrument starts.

After the instrument starts, it checks the modules. This process would take

several to dozens of seconds according to the number of modules inserted.

During this process, user operation is forbidden.

3. Check the instrument following the steps below if the instrument

does not start normally

Check whether the powe r is corre ctly connected.

Check whether the power key at the front panel is really on.

Remove the power cord and check whether the voltage selector is at the

correct scale and whether the power fuse is burned out. If the fuse is

burned out, replace it with a specified one.

Restart the instrument after finishing the above inspections.

If it still does not work correctly, please contact RIGOL.

M300 Quick Guide

Page 24

RIGOL

12

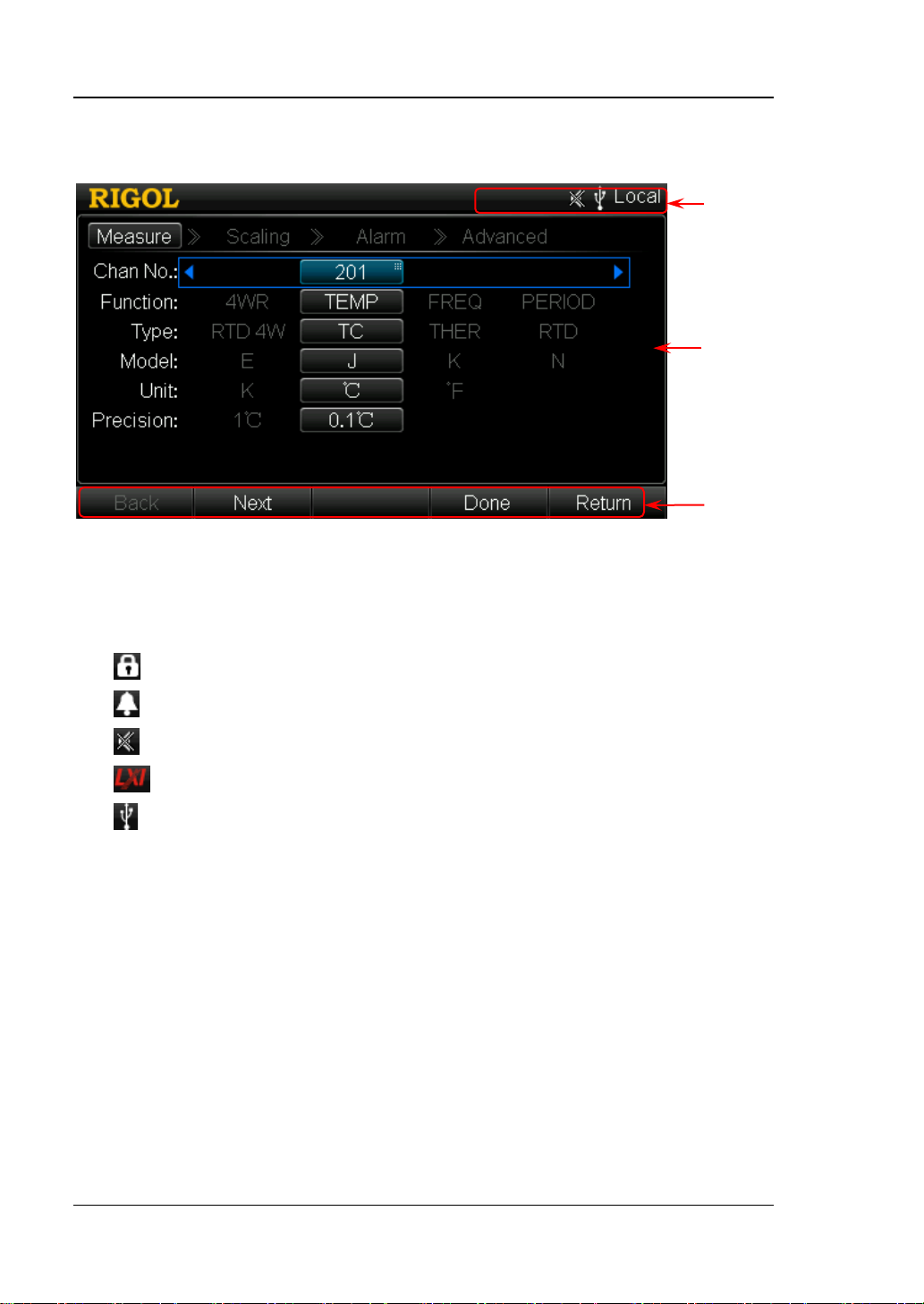

Help

Displayed when the built-in help is enabled.

Error

Displayed when an error occurs.

Displayed when the keyboard is locked.

Displayed when an alarm is generated.

Displayed when the system sound is disabled.

Displayed when the instrument is connected to network correctly.

Displayed when an U SB storage device is detect ed.

Local

Displayed when the instrument is in local mode.

Rmt

Displayed when the instrument is in remote mode.

Status

User Interface

Figure 5 User Interface

1. Status Bar

Bar

Content

Bar

Menu

Bar

2. Content Bar

Display the measurement conf iguration guide, measurement parameters

settings and etc. For more detailed information, please refer to the User’s Guide.

3. Menu Bar

Display the menus of the current function. The menus correspond to the menu

softkeys below respectively . Pressing the softkey can activate the corresponding

menu.

M300 Quick Guide

Page 25

RIGOL

13

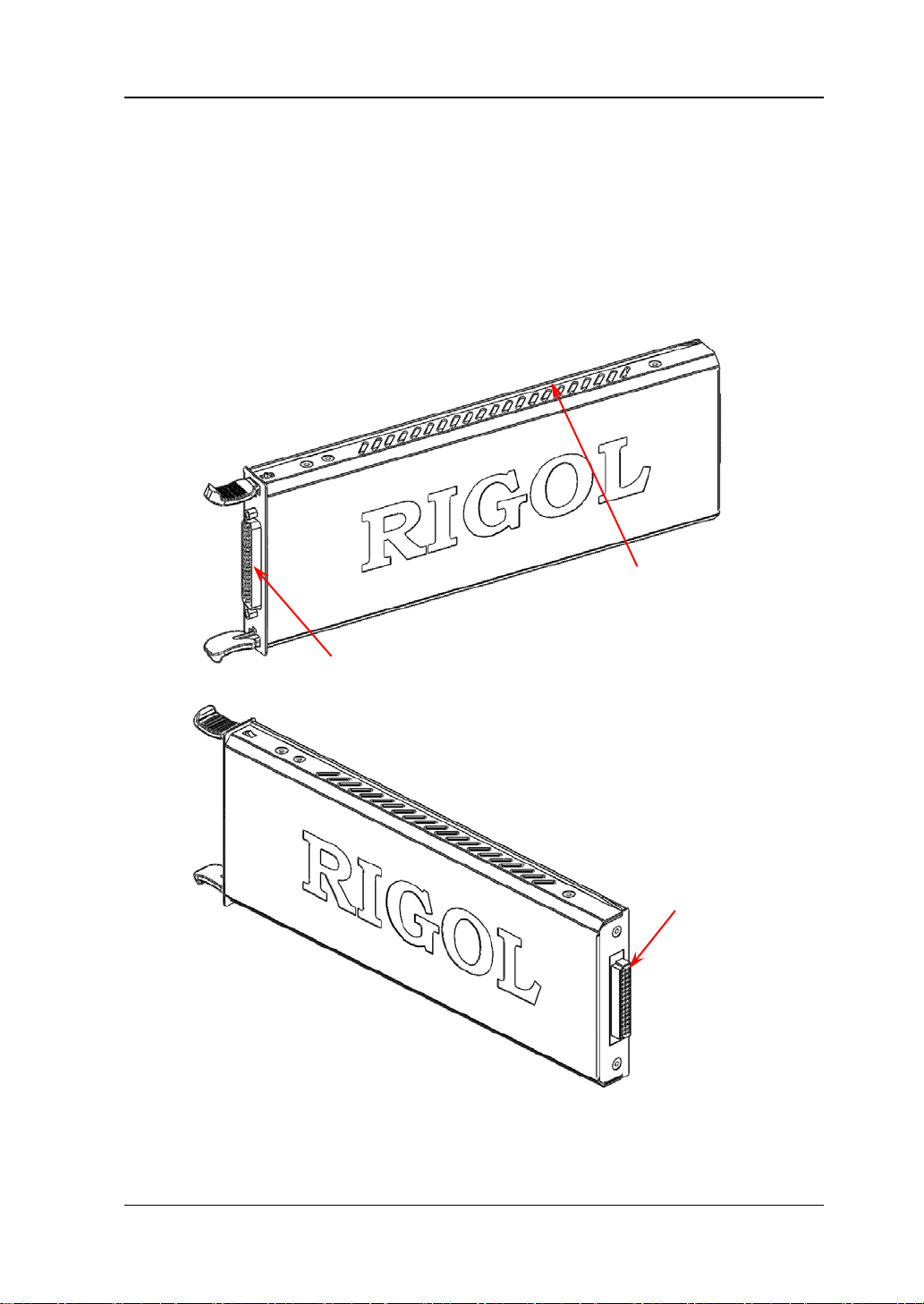

Golden Circuit board Edge: each on the

Interface 1: connect the signal under test via the

Interface 2: connect

Plug-in Module Overview

M300 provides 8 kinds of modules including the DMM module , 20-channel multiplexer,

32-channel multiplexer, 64-channel multiplexer, multi-function module and etc. This

section introduces the functions and characteristics of each module.

Outside View Drawing

top and bottom for sliding into the slot

terminal block (the DMM module does not have this

interface)

with the main frame

Figure 6 Outside View Drawing of the Plug-in Module

M300 Quick Guide

Page 26

RIGOL

14

Note:

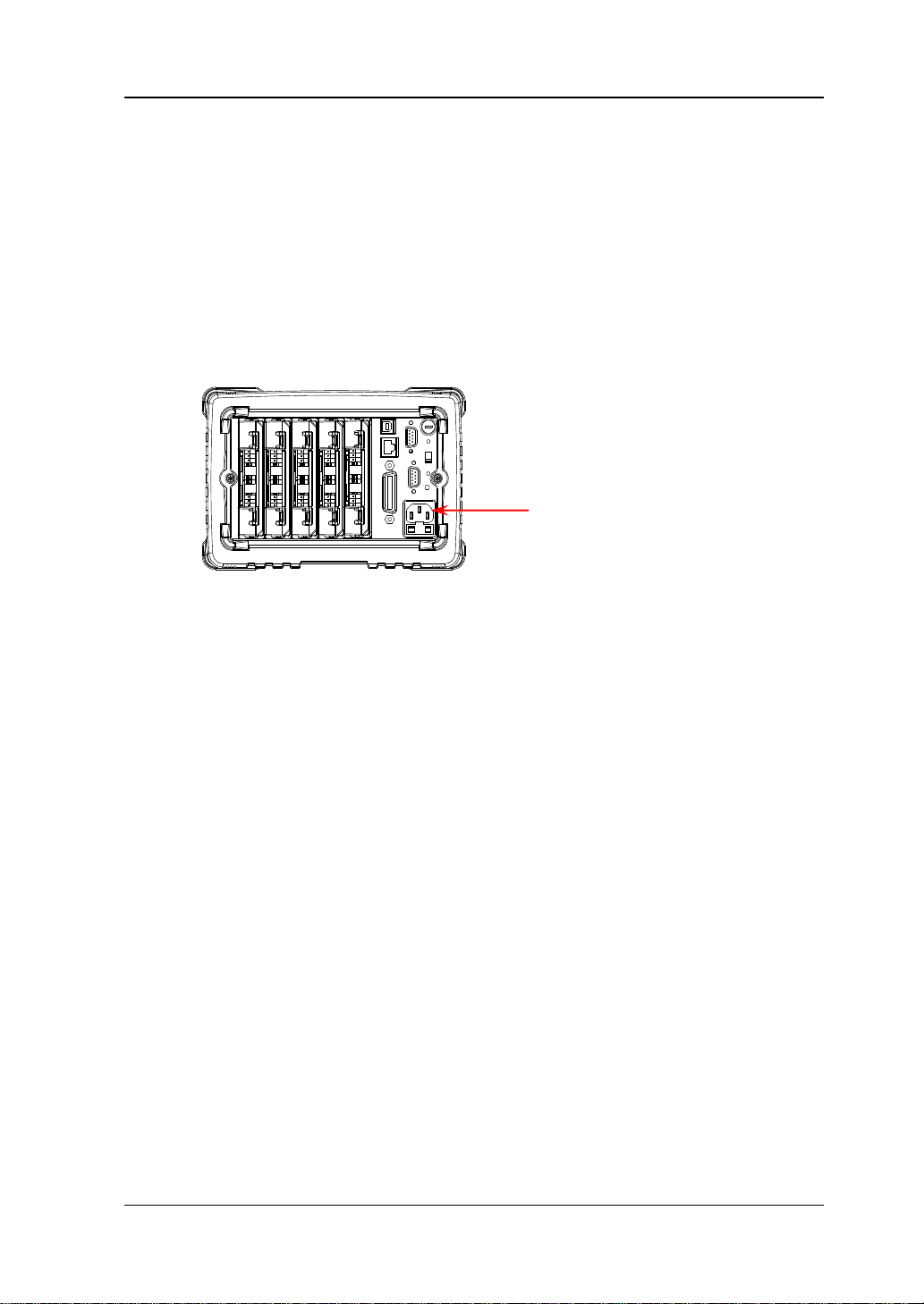

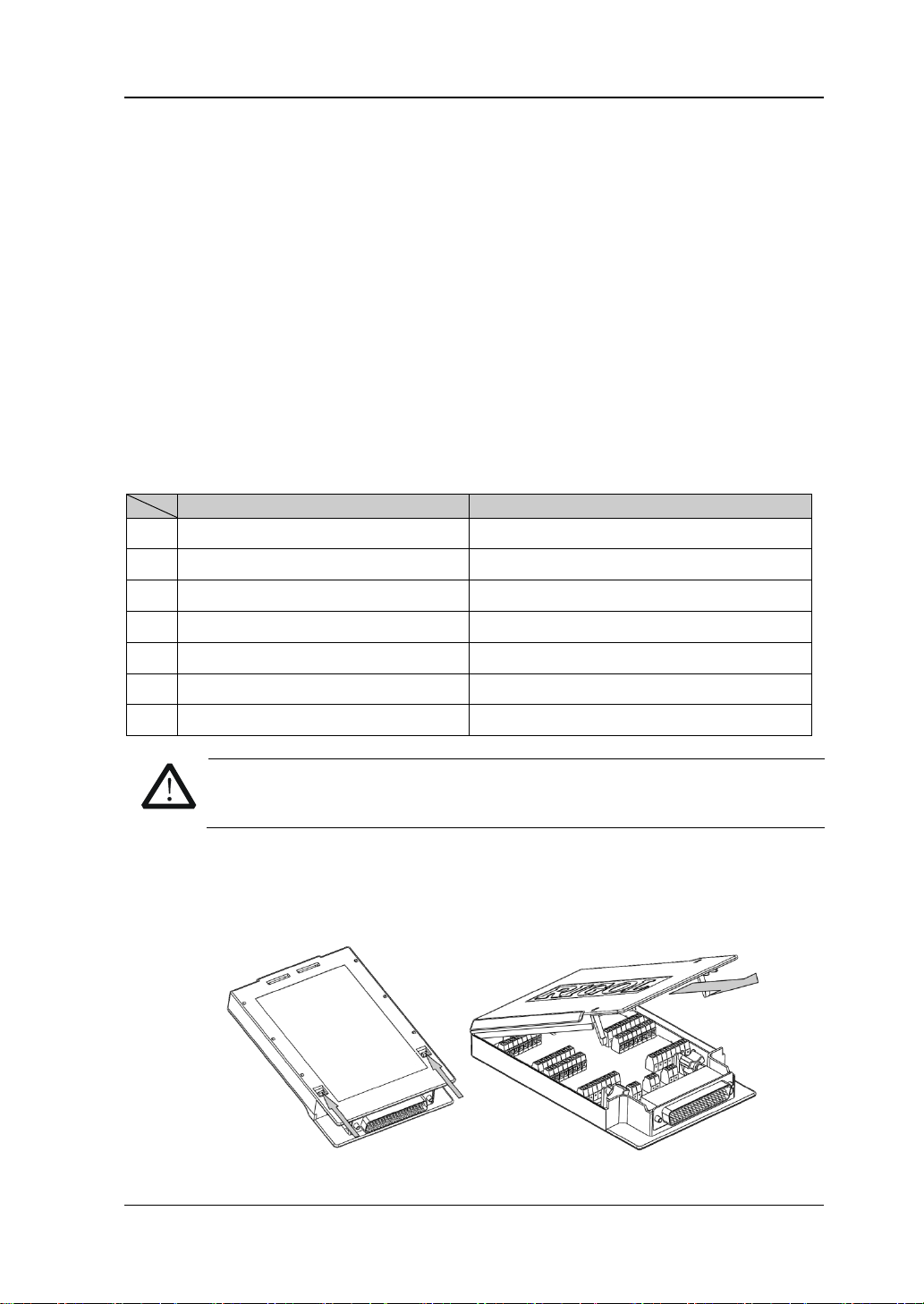

Insert the Module into the Main Frame

Turn the main frame off; and then, insert the modules following the instructions

below.

As shown in Figure 6, there is a golden circuit board edge on the top and bottom of

the module. Aim the two edges with the sli ding chutes (as pointed out by the arrows

in the figure below) in the main frame slot and push the module in until you hear a

sound. At this point, interface 2 is connected to the main frame.

Note: For module that needs to be connected to the signal under measurement,

please refer to “Measurement Connections” to connect the external terminal

block and the signals under measurement before inserting it into the mainframe.

Figure 7 Insert the Module into the Main Frame

All the modules of M300 do not support hot-plugging. Please turn the m ai n frame

off before inserting the modules into the main frame.

M300 Quick Guide

Page 27

15

Module Overview

1. MC3065 (DMM Module):

The DMM module is used to measure the signals under test and provides 6½

digit reading resolution. Its measurement functions include DCV, ACV, DCI, ACI,

2-wire resistance, 4-wire resistance, frequency, period, temperature and any

sensor.

Note: After connecting the DMM module, make sure that the signal under test

connected to the analog bus is no greater than 300 Vdc or 300 Vrms.

2. MC3120 (20-Channel Multiplexer):

All the 20 channels switch both HI and LO inputs, thus providing fully isolated

signals for the DMM module. MC31 20 is divided into two banks (calle d A a nd B)

with 10 two-wire channels in each bank. When making 4-wire resistance

measurement, the instrument automatically pairs channels of A bank and B

bank. All channels in the scan list are b reak -before-make. You can close multiple

channels on this module only if y ou have not configured any channel to be part

of the scan list.

This module can be connected with MC3065 (DMM Module, if MC3065 is

currently inserted).

For the specifications of this module, please refer to the User’s Guide or Data

Sheet of this product.

3. MC3132 (32-Channel Multiplexer):

All the 32 channels switch both HI and LO inputs, thus providing fully isolated

signals for the DMM module. MC31 32 is divided into two banks (calle d A a nd B)

with 16 two-wire channels in each bank. When making 4-wire resistance

measurement, the instrument automatically pairs channels of A bank and B

bank. All channels in the scan list are b reak -before-make. You can close multiple

channels on this module only if y ou have not configured any channel to be part

of the scan list.

This module can be connected with MC3065 (DMM Module, if MC3065 is

currently inserted).

For the specifications of this module, please refer to the User’s Guide or Data

Sheet of this product.

4. MC3164 (64-Channel Single-Ended Multiplexer):

All the 64 channels can only switch HI input. MC3164 is divided into two banks

(A and B) with 32 single-ended channels in each bank. All channels in the scan

list are break-before-make. In any case, you cannot close multi ple channels on

this module.

This module can be connected with MC3065 (DMM Module, if MC3065 is

currently inserted) but cannot be used for 4-wire resistance measurement.

For the specifications of this module, please refer to the User’s Guide or Data

Sheet of this product.

RIGOL

M300 Quick Guide

Page 28

RIGOL

16

5. MC3324 (24-Channel Multiplexer):

All the 20 voltage channels switch both HI and LO inputs, thus providing fully

isolated inputs for the DMM module. The 20 voltage channels are divided into

two banks (called A and B) with 10 two-wire channels in each bank. When

making 4-wire resistance measurement, the instru ment aut omatic all y pairs

channels of A bank and B bank. All channels in the scan list are

break-before-make. You can close multiple channels on this module only if you

have not configured any channel to be part of the scan list.

The 4 current channels are used in combination with the DMM module to

perform DC current or AC current measurement. All channels in the scan list are

break-before-make. In any case, you cannot close multiple channels on this

module.

This module can be connected with MC3065 (DMM Module, if MC3065 is

currently inserted).

For the specifications of this module, please refer to the User’s Guide or Data

Sheet of this product.

6. MC3416 (16-Channel Actuator):

MC3416 can connect signal to the device under test or enable external device.

Any of the 16 channels can switch to Normally-Open (NO) and Normally-Closed

(NC) states.

For the specifications of this module, please refer to the User’s Guide or Data

Sheet of this product.

7. MC3534 (Multifunction Module):

It provides 3 kinds of functions with 4 channels for each function. This module

can be used to check status or control external device (such as the solenoid,

power relay and microwave switch). Y ou can also read the digital inputs and the

totalizer count during a scan.

Four 8–bit digital input/output (DIO) ports

4 totalizer (TOT) input terminals (the first two channels are 10 MHz TOT

and the other two channels are 100 kHz TOT) with 1 Vpp sensitivity

4 analog output terminals, ±12 V calibrated voltage

For the specifications of this module, please refer to the User’s Guide or Data

Sheet of this product.

8. MC3648 (4×8 Matrix Switch):

MC3648 is used to connect multiple devices to multiple points on the device

under test. Y ou can conne ct the rows and columns of multiple mat rix switches to

form relatively larger matrix (such as 8×8 and 4×16, the number of crosspoints

cannot exceed 160).

32 two-wire crosspoints which can connect any combination of inputs and

outputs at the same time. For the specifications of this module, please refer to

the User’s Guide or Data Sheet of this product.

M300 Quick Guide

Page 29

RIGOL

17

To Use the Built-in Help System

The built-in help syst em of M300 p rovides the hel p informat ion about an y front panel

key and menu. T o acquire the help i nformation of a ny front panel key or menu, press

Help (the backlight goes on and “Help” is displayed in the status bar in the user

interface) and then press the desired key or menu. The built-in help interface is as

shown in the figure below. Pressing OK can exit the built-in help system.

Figure 8 Built-in Help Syste m

Menu Quick Navigation

This section provides the structure diagrams of the main menus for M300 to guide

users to quickly get familiar with the operation methods of M300. Fo r more detailed

information, please refer to the User’s Guide.

M300 Quick Guide

Page 30

RIGOL

18

Config

M300 Quick Guide

Page 31

19

Monitor

RIGOL

View Switch Key

M300 Quick Guide

Page 32

RIGOL

20

Control

Alarm Channel Setting Keys

M300 Quick Guide

Page 33

RIGOL

21

Terminal Block

Module

3.

WARNING

removing the terminal block from the module.

Basic Operations

This section introduces the basic operations of M300, including how to connect the

signals to be measured, how to configure the scan list as well as how to control the

instrument remotely.

Measurement Connections

Multiple signals to be measured are connected to the plug-in modules through the

external terminal blocks and then are switched to the DMM module or external DMM.

M300 provides 7 kinds of terminal blocks. The models of the terminal blocks and

their corresponding modules are listed in the table below. This section introduces

how to connect the signals to be measured through the external blocks.

Table 1 External Terminal Blocks

M3TB20 MC3120

1.

M3TB32 MC3132

2.

M3TB64 MC3164

M3TB24 MC3324

4.

M3TB48 MC3648

5.

M3TB16 MC3416

6.

M3TB34 MC3534

7.

Cut off all the power supplies before opening the terminal block or

1. Place the terminal block with the front (with the RIGOL caption) facing

downward; pull the two latches in the arrow direction in the f igure below and

press them down. Place the termi nal block wit h the front f acing upwar d and pull

the upper cover of the terminal block upward and remove it.

M300 Quick Guide

Page 34

RIGOL

22

01

H

L

H

L

...

H

L

H

L

...

H

L

16

17

32

Channel

Switches

Terminal

Box: TB32

H

L

01

H

L

32

.

.

.

78-Pin

Interface

M300

Mainframe

DMM Module

MC3065

+

V

measured

V

measured

Fuse

Fuse

2. Connect the cables for connecting the signal under test according to the labels

on the circuit board of the terminal block (for the connecting method, refer to

Table 2). Pass the binding wire s through th e two gro ups of holes as pointed out

by the arrows in the figure below to fix the cable connected. Pay attention to the

channel or terminal connected to the cable to ensure that the signal connected

is correct.

Note:

For the connection method of each module and the corresponding terminal

block as well as the specif ic ation requirements of the connecting cable,

please log in RIGOL official website (www.rigol.com) get more related

materials.

When usin g the mutliple x er module for measu rement, make su re that both

the amplitude of the signal under measurement and the commom mode

voltage are no greater than the maximum input voltage of the module.

When the multiplexer mod ule is used to measure an object with high-power

output ability (such as battery and power supply), to avoid damagi ng the

relay, you are recommended to connect a fuse in serial when making

connections (as shown in the figure below).

M300 Quick Guide

Page 35

23

Table 2 Measurement Connections

DCV/ACV/FREQ/PERIOD/Sensor

DCI/ACI/Sensor (DCI)

MC3324.

2WR/RTD/Thermistor/

4WR/RTD 4W/Sensor (4WR)

Thermocouple

WARNING

sure that all the input signals are within the rated input range.

Resistance to be

+

+ - -

RIGOL

(DCV, FREQ)

+ -

Signal to be

measured

CH1

Sensor (2WR)

+ -

Resistance to be

measured

CH1

H L

H L

+ -

Signal to be

measured

CH21

H L

Note: Only available for CH21 to CH24 of

H L Source

CH1

measured

+ -

Thermocouple

to be measured

CH1

To avoid elec t ric shock, the measurement cables should meet the

H L

Note: Only available for all the channels of

MC3120 and MC3132 as well as CH1 to CH20

of MC3324.

maximum voltage requirement. To avoid damaging the module, make

M300 Quick Guide

H L Sense

CH17

Page 36

RIGOL

24

3. Connect the terminal block to i nt erf ace 1 (the interface definition is in Figure 6)

on the module and sc rew down the two screw rods to fix them onto the nuts on

the module.

4. Close the upper cover of the terminal block.

5. Insert the module connected with the terminal block into the slot of the main

frame.

M300 Quick Guide

Page 37

RIGOL

25

To Configure Scan List

Create a scan list and add any channels of the multiplexer or the DIO or TOT

channels of the multifunction module to the scan list; then, configure the basic

measurement, scaling, alarm and advanced measurement parameters for each

channel. The edited scan list can be stored in internal or external memory and be

recalled when required.

1. Create a new list

Press Config New, input the desired list name and press OK.

Note: The existing scan li st will be o verwritten by th e scan list currently created.

2. Set the sc an parameters

(1) Select Sweep and use the left/right direction key to select “Infinite” or “1”

(you need to set a value and the range is from 1 to 50000).

(2) Select Trigger M ode and use the left/right direction key to select “Auto”,

“Manual”, “External”, “AbsTime” or “Alarm”.

(3) If “Auto” is selected, please select Interval and use the numeric keyboard

to set a de sired interval. The range i s from 00:00:00.000 to 99:59:59.999

(the time format is Hour:Minute:Second.Millisecond) and the default is 0.

If “External” is selected, please select Edge and use the left/right direction

key to select “Rising” or “Falling”.

If “AbsTime” is selected, please select AbsTime and use the numeric

keyboar d t o s et a desired time. The time format is “Month-Date

Hour:Minute:Second”.

If “Alarm” is selected, please select Channel and use the left/right direction

key to select “Alarm1”, “Alarm2”, “Alarm3” or “Alarm4”.

3. Configure a channel to the scan list (taking the DCV measurement

function as an example

Press ConfigEditNew to enter the channel configuration guide.

(1) Step 1: Measuremen t Conf i guration

Select Chan No. and use the left/right direction key to select the desired

channel number (for example, 101);

Select Function and use the left/right direction key to select the desired

function (for example, DCV);

Select Range and use the left/right direction key to select the desired

range (for example, 2 V).

Note: The parameters need to be set in this step depend on the

measurement function selected.

(2) Step 2: Scaling Configuration

Select Scaling and use the left/right direction key to enable the scaling

)

M300 Quick Guide

Page 38

RIGOL

26

configuration;

Select A, B and C and use the numeric keyboard to input the desired

scaling coefficients;

Select x1 and press Curr Value to ac quire x1.

Select Unit and input the desired unit.

Note: For multiplexer channel using the “SENSOR” function and the DIO

and TOT channels of the multi f unctio n mo dule, the configuration guide

does not contain scaling conf iguration. Besides, for multiplexer channel, if

the DMM m odule is not currently inserted or it is inserted but is not enabled,

the configuration guide also does not contain “Scaling Configuration” when

an external DMM is connected to execute scan and measurement.

(3) Step 3: Alarm Configuration

Select Mode and use the left/right direction key to select the desired alarm

mode (for example, HI);

Select Channel and use the left/right direction key to select the desired

alarm channel (for example, Alarm1);

Select HI or LO and use the numeric keyboard to input the desired alarm

limit (for example, 12).

Note: For multiplex er channel, if the DMM module is not currentl y i nserted

or it is inserted but is not enabled, the configuration guide d oes not contain

“Alarm Configuration” when an external DMM is connected to execute scan

and measurement.

(4) Step 4: Advanced Configuration

Select Integ and use the left/right direction key to select the desired

integration time (for example 1PLC);

Select IMP and use the left/right direction key to select 10MΩ or >10GΩ;

Select AZ and use the left/right direction key to select “ON” or “OFF”;

Select Delay and use the left/right direction key to “Auto” or set the de lay

time manually.

Note: The parameters need to be set in this step depend on the

measurement function selected.

Press Done to finish the channel configuration guide and return to the s can

list editing interface.

4. Configure other channels to the scan list

Press New and configure other channels to the scan list according to step 3.

5. Save the scan list

After the scan list configuration is completed, you can press Save to save the

conf igured scan list in the internal or external memory of the instrument.

M300 Quick Guide

Page 39

RIGOL

27

Configuration Copy

M300 provides the configuration copy function (include module copy, channel copy

and extended copy) which can be used to quickly configure multi-channels with the

same configuration to the scan list.

Press Config Edit Copy to ente r the configuration copy interfac e.

1. Module Copy:

Copy the configuration of a module (source module) to another module (target

module) of the same mode l. After that, t he configura tion of each channe l of t he

source module is copied to the target module automatically.

Press Module in the configuration copy interface to open the module copy

interface.

(1) The “Source Module” area is selected by default. Use the up/down directio n

key to select the desired source module.

(2) Press Switch to move the cursor to the “Target Module” area and use the

up/down direction key to select the desired target module.

(3) Press OK to execute module copy.

Note: The source module and target module selected must be of the same

model. The configuration of a module to itself is not supported.

2. Channel Copy:

Copy the configuration of a channel (source channel) to another channel or

multiple channels (target channel) of the same type.

Press Channel in the configuration copy in terface to open the channel copy

interface. B y default, the channel selected is fixed as the source channel and the

upper area is selected. At this p oint, use the left/right direction key to select th e

desired target channel and press OK (pressing OK again will give up the

selection); press Done to execute channel copy.

After opening the channel copy interface, you also can press Switch to fix the

channel selected as the target channel. At this point, the lower area is selected.

Use the left/right direction key to select the desired source channel and press

Done to execute channel copy.

Tips:

(1) When the channel selected is fixed as the source channel, multiple target

channels can be selected and will be displayed in the lower area.

(2) When the channel selected is fixed as the target channel, only a single

source channel can be selected.

(3) Switch is graye d o u t and disabled if the current scan list only has a single

M300 Quick Guide

Page 40

RIGOL

28

channel.

Note: For channel copy, only copies between channels of the same type

(namely, channels of the same type of modules) are allowed.

3. Extended Copy:

Copy the configuration of a channel (source channel ) of a module to all the

channels (of which the type i s the same t o that of the source channel) of the

target module.

Press Extended in the configuration copy interface to open the extended copy

interface.

(1) The “Source Channel” area is selected by default. Use the direction keys to

select the desired source channel.

(2) Press Switch to move the cursor to the “Target Module” area and use the

up/down direction key to select the desired target module.

(3) Press OK to execute extended copy.

Note: For extended copy, on ly copies among the same type of modules are

allowed. This function makes it easy to configure several channels with the

same configurations.

Channel Monitor

The channel monitor function of M300 allows users to monitor a single channel,

multiple channels or all of the channels in the sca n list. The instrument monito rs the

channel and takes readings from the channel monitored contin uously even during a

scan. This function is helpful for troubleshooting your system before a test or for

observing important signals.

The channel monitor function can monitor the following channels: multiplexer

channels (configured to the scan list and the DMM module is ena bled), DIO and T O T

channels of the multifuncti on module (no mat ter wh ether the y are configured to the

scan list and the DMM module is not required). Press Monitor at the front panel to

configure the channel monitor functi on.

1. Single-chan n el Monitor

Press Monitor Single to enter the single-channel monitor interface. By

default, the first channel in the scan list is monitored. If no scan list is currently

configured, the first channel of the multifunction module (DIO channel) is

monitored. Only a single channel can be monitored at a time; but you can

change the channel being monitored at any time. Readings acquired during the

monitor process are displayed on the screen but will not be stored in memory.

When the alarm function is applied to the channel being monitored, all the alarm

M300 Quick Guide

Page 41

RIGOL

29

data will be stored in the alarm queue (the data will be cleare d at power-off). To

monitor a multiplexer channel, the DMM module must be installed and enabled

(Utility DMM “ON”); the channel to be m onit ore d must be configured to

the scan list. You can monitor a DIO or TOT channel even if the channel is not

configured to the scan list.

2. Multi-channel Mon ito r

Press Monitor Multiple to enter the multi-channel monitor interface. At

most 7 channels can be monitored. You can add or delete the channels being

monitored.

3. All Channel Monitor

Press Monitor All Moni to enter the all channel monitor interface. All the

channels in the scan list can be monitored.

Remote Control

M300 can communicate wit h PC through USB , LAN, G PIB and RS232 (con verted fr om

the [RS-232/Alarms/Ext Trig] interface at the rear panel of M300) to realize

remote contr ol ba s e d o n the SCPI (Stand ar d Commands for Programmable

Instruments) commands. This section introduces how to use the PC software Ultra

Sigma of RIGOL to control the instru ment remotely t hro ugh the USB interface. For

the detailed inf ormation about the SCPI commands, please refer t o the Prog rammi ng

Guide.

1. Install Ultra Sigma

Download Ultra Sigma from RIGOL website (

according to the instructions.

2. Control the in s tr ument via USB

(1) Connect the devices

Connect the USB Device i nterf ace of M300 to th e USB H ost interface of your

computer using a USB cable.

(2) Install the USB driver

As this instrument is a USB-TMC device, after you connect it to the PC and

turn both on f or th e first time, Found New Hardware Wizard is display ed on

the PC. Please install the “USB Test an d Measurement Device (IVI)” driver

following the directions in the wizard.

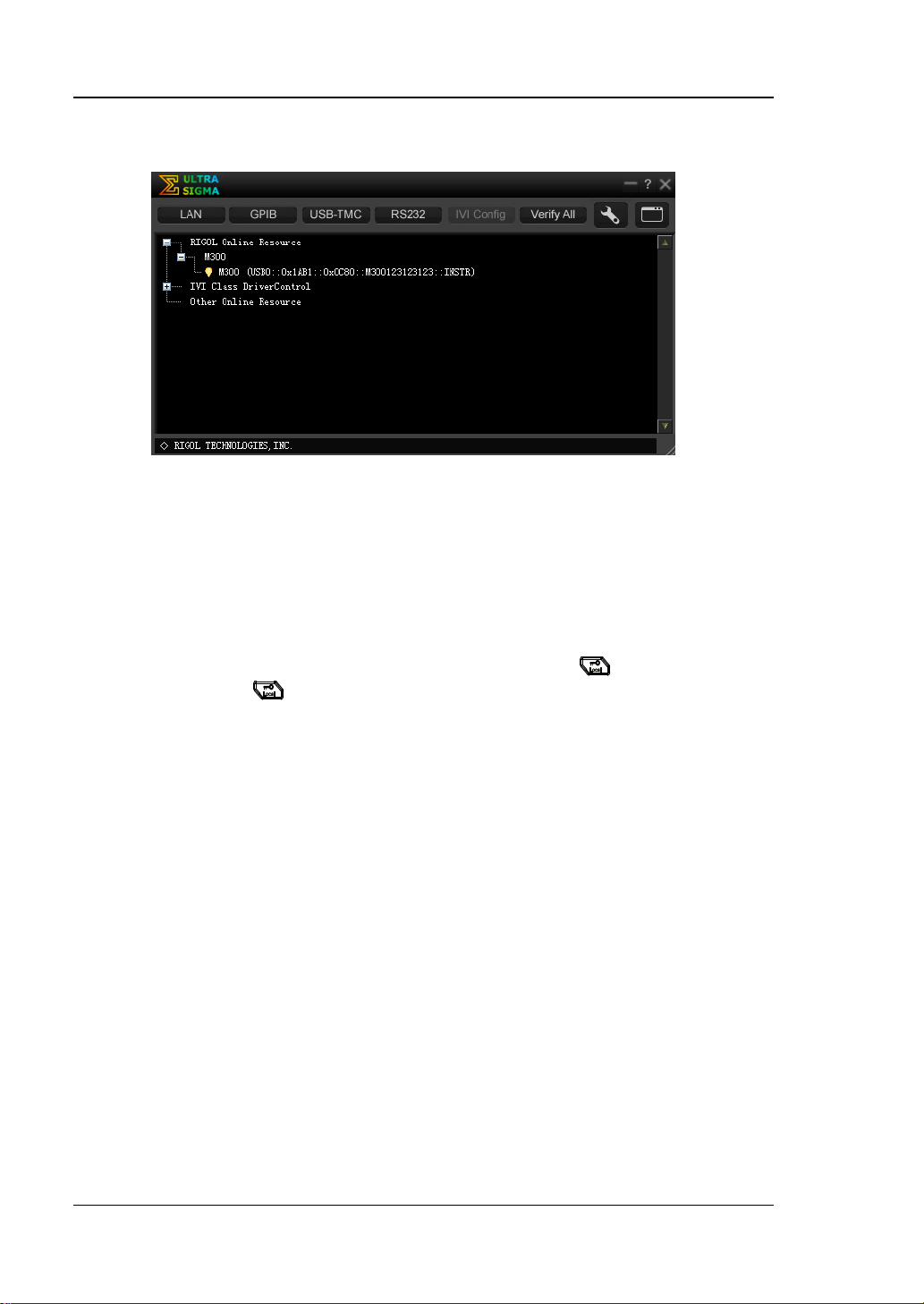

(3) Search for device resources

Start up Ultra Sigma and the software will automatically search for the

instrument resources currently connected to the PC. Yo u can also click

to search for the resources.

(4) View the device resource

The resources found will appear under the “RIGOL Online Resource”

www.rigol.com) and install it

M300 Quick Guide

Page 42

RIGOL

30

directory and the model number and USB interface information of the

instrument will also be displayed as shown in the f igure below.

Figure 9 View USB Instrument Reso urce

(5) Send Command/Read Data

Right click the resource name “M300

(USB0::0x1AB1::0x0C80::M300123123123::INSTR))” and select “SCPI

Panel Control” to turn on the remote command contr ol panel th rough which

you can send commands and read data.

Note: When the instrument is in remote m ode, Rmt is displaye d in the st atus bar in

the user interface and all the k eys at the front panel (except

point, you can press

to exit the r emote mode.

) are locked. At this

M300 Quick Guide

Page 43

RIGOL

31

Troubleshooting

When the failures listed below occur, please solve them according to the following

steps. If the problem remains, please contact RIGOL and provide the system

information of your instrument (Utility Info).

1. The instrument does not start.

1) Check whether the power cord is correctly connected.

2) Check whether the power switch at the front panel is really on.

3) Remove the power cord; check whether the volta ge sele ctor is at the proper

scale and whether the pow er in put fuse is burned out. If the fuse is burned

out, replace it with a specified one.

4) Restart the instrument after executing the above inspections.

5) If the problem remains, please contact RIGOL.

2. The USB storage device cannot be recognized.

1) Check whether the USB storage device can work norm a l l y.

2) Make sure the USB storage device used is Flash type, as this instrument

does not support hardware type USB storage device.

3) Restart the instrument and insert th e USB stor age devic e to check it.

4) If the USB storage device still cannot work normally, please contact

RIGOL.

3. How to recover the configurations from the last power failure or

unexpected shutdown and continue the work before the shutdown

automatically?

Restart the instrument. Press Utility System, select Power-off using the

up/down direction key and select “ON” using the left/right direction key.

4. The screen is too dark.

Press Utility System, select Brightness using the up/down direction key

and set a proper brightne s s using the left/right direction key.

5. The instrument is locked.

1) Check whether the instrument is in remote mode (namely check whether

“Rmt” is displayed in the status bar in the user interface). If yes, you can

press

2) Check whether the front panel of the instrument is locked (namely check

whether

can press and hold

3) Check whether a progress bar is displayed in the interface. If yes, please

wait and try again until the progress bar disappears.

4) If the problem remains, please restart the instrument.

to exit the remote mode and unlock the front panel.

is displayed in the status bar in the user interface). If yes, you

to unlock the front panel.

M300 Quick Guide

Page 44

RIGOL

32

6. How to change the system language?

Press Utility System, select Language using the up/down direction key

and select the desired language using the left/right direction key.

7. How to view the information and model number of the plug-in

modules?

Press Utility Test; select the desired module using the left/right direction

key and press View to view the information and model number of th e module

currently selected.

8. The corresponding indicator at the front panel does not go on when

the module has been inserted?

1) Press Utility Test; select the desired module using the left/right

direction key and press Re-test.

2) If the problem remains, press View. If the information of the module

cannot be viewed, please refer to the failure 9.

3) If the information of the module can be viewed, the module indicator is

possibly damaged. Please contact RIGOL for maintenance information.

9. Unable to view the information of the module or unable to use the

module when the module has been inserted?

1) Turn the main frame off and remove the module from the main frame;

insert the module into the mainframe again f irmly.

2) Restart the main frame, wait f or about 1 minut e and try t o view the module

information again.

3) If the problem remains, please contact RIGOL.

10. Unable to make configurations or operations related to the DMM

module when it has been inserted?

1) Make sure that Utility System DMM is set “ON”.

2) Press Utility Test; select the DMM mo dule using the left/right direction

key and press View to view whether the information of the DMM module is

normal. If the information is not displayed or is not displayed correctly, it is

possibly that the DMM module is working abnormally due to high current or

power load failure. At this point , please t ur n t he main frame off and restart

it a few minutes later.

3) If the problem remains, please contact RIGOL.

11. The GPIB interface cannot work normally?

1) Check whether the cable works normally and the connection is correct and

reliable.

2) Make sure that the GPIB addresses of M300 and the PC are ide ntical.

3) If the problem remains, please contact RIGOL.

M300 Quick Guide

Page 45

33

12. The USB Device interface cannot work normally?

1) Check whether the cable works normally and the connection is correct and

reliable.

2) Check whether the “USB Test and Measurement Device (IVI)” drive

program has been correctly installed on your PC.

3) If the problem remains, please contact RIGOL.

13. The RS232 interface cannot work normally?

1) Make sure that the RS232 interface parameters (such as the baud rate)

settings of M300 and the PC are identical.

2) Check whether the RS232 cable is a cross cable.

3) If the problem remains, please contact RIGOL.

14. The LAN interface cannot work normally?

1) Check whether the cable works normally and the connection is correct and

reliable.

2) Check the IP configuration mode:

If DHCP is enabled, please make sure that the current network

supports DHCP configuration mode and can distribute network

parameters (such as the IP address) to M300 automatically.

If DH CP is disabled and Auto IP is enabled, please check whether the

IP addresses automatically acquired by M300 and the ne t w ork

paramet e rs of the PC are in the same network segment.

If only Manual IP is enabled, please make sure that the network

parameter settings of M300 and the PC are in the same network

segment.

3) If the problem remains, please contact RIGOL.

RIGOL

M300 Quick Guide

Loading...

Loading...