RIGOL

User’s Guide

M300 Series

Data Acquisition/Sw itch System

May 2015

RIGOL Technologies, Inc.

RIGOL

Guaranty and Declaration

Copyright

© 2013 RIGOL Technologies, Inc. All Rights Reserved.

Trademark Information

RIGOL is a registered trademark of RIGOL Technologies, Inc.

Publication Number

UGC07111-1110

Software Version

00.02.00.04.19

Software upgrade might c hange or add prod uct feat ures. Please a cqui re the la test

version of the manual from RIGOL website or contact RIGOL to upgrade the

software.

Notices

RIGOL products are covered by P.R.C. and foreign patents, issued and

pending.

RIGOL reserves the right to modify or change parts of or all the

specif ications and pricing policies at company’s sole decision.

Information in this publica tion re places all previ ously corresponding material.

Information in this publication is subject to change without notice.

RIGOL shall not be liable for either incidental or consequential losses in

connection with the furnishing, use or performance of this manual as well as

any information contained.

Any part of this document is forbidden to be copied, photocopied or

rearranged without prior written approval of RIGOL.

Product Certification

RIGOL guara nte es t his product conforms t o t he national and indus trial standards

in China as well as the ISO9001:2008 stan da rd and the ISO14001:20 04 standard.

Other international standard conforman ce certifications are in progress.

Contact Us

If you have any problem or requirement when using our products or this manual,

please contact RIGOL.

E-mail: service@rigol.com

Website: www.rigol.com

M300 User’s Guide I

RIGOL

Safety Requirement

General Safety Summary

Please review the following safety precautions carefully before putting the

instrument into operation so as to avoid any personal injury or damage t o t he

instrument and any product connected to it. To prevent potential hazards, please

use the instrument only specified by this manual.

Use Proper Power Cord.

Only the power cor d desig ned fo r the ins trument an d authorized for us e within the

local country could be used.

Ground the Instrument.

The instrument is grounded through the Protective Earth lead of the power cord.

To avoid electric shock, it is essential to connect the earth terminal of the power

cord to the Protective Earth terminal before connecting any inputs or outputs.

Connect the Probe Correctly.

If a probe is used, do not connect the ground lead to high voltage since it has

isobaric electric potential as the ground.

Observe All Terminal Ratings.

To avoid fir e or sh ock hazard, observe all ratings and markers on the instrument

and check your manual for more information about ratings before connecting the

instrument.

Use Proper Overvoltage Protection.

Make sure that no overvoltage (such as that caused by a thunderstorm) can re ach

the product, or else th e op erator might be exposed to the danger of electrical

shock.

Do Not Operate Without Covers.

Do not operate the instrument with covers or panels removed.

II M300 User’s Guide

RIGOL

Do Not Insert Anything Into the Holes of Fan.

Do not insert anything int o the holes of the fan to avoid damaging t he inst rument .

Use Proper Fuse.

Please use the specified fuses.

Avoid Circuit or Wire Exposure.

Do not touch exposed junctions and components when the unit is powered.

Do Not Operate With Suspected Failures.

If you suspect damage occurs to the instrument, have it inspected by RIGOL

authorized personnel before further oper at io ns. Any maintenance, adjustment or

replacement especially to circuits or accessories must be performed by RIGOL

authorized personnel.

Keep Well Ventilation.

Inadequate ventilation may cause an increase of instrument temperature which

would cause damage to the instrument. So please keep the instrument well

ventilated and inspect the intake and fan regularly.

Do Not Operate in Wet Conditions.

In order to avoid short circuiting to the interior of the device or electric shock,

please do not operate the instrument in a humid environment.

Do Not Operate in an Explosive Atmosphere.

In order to avoid damage to the device or personal injuries, it is important to

operat e the devi ce away from an explosive atmospher e.

Keep Product Surfaces Clean and Dry.

T o a void the influence of dus t and/or moisture in the air, please keep the surface of

the device clean and dry.

Electrostatic Prevention.

Operate the instrument in an electrostatic discharge protective environment to

avoid damage induced by static discharges. Always ground both the internal and

external conductors of cables to release static before making connections.

M300 User’s Guide III

RIGOL

Proper Use of Battery.

If a battery is supplied, it must not be exposed to high temperature or in contact

with fire. Keep it out of the reach of children. Improper change of battery (n ote:

lithium battery) may cause explosion. Use RIGOL specified battery only.

Handling Safety.

Please handle with care during transportation to avoid damage t o keys, knob

interfaces and other parts on the panels.

IV M300 User’s Guide

RIGOL

CAUTION

DANGER

Hazardous

Safety

Protective

Terminal

Chassis

Test

Safety Terms and Symbols

Terms Used in this Manual. These terms may appear in this manual:

WARNING

Warning statements indicate conditions or practices that could result in

injury or loss of life.

Caution statements indicate conditions or practices that could result in

damage to this product or other property.

Terms Used on the Product. These terms may appear on the Product:

It calls attention to an operation, if not correctly pe rformed, could

result in injury or hazard immediately.

WARNING It calls attention to an operation, if not correctly pe rformed, could

result in

CAUTION It calls attention to an operation, if not correctly pe rformed, could

result in

product.

Symbols Used on the Product. These symbols may appear on the product:

potential injury or hazard.

damage to the product or other devices connected to the

Voltage

Warning

Earth

Ground

Ground

M300 User’s Guide V

RIGOL

Allgemeine Sicherheits Informationen

Überprüfen Sie diefolgenden Sicherheitshinweise

sorgfältigumPersonenschädenoderSchäden am Gerätundan damit verbundenen

weiteren Gerätenzu vermeiden. Zur Vermeidung vonGefa hren, nutze n S ie bitte das

Gerät nur so, wiein diesem Handbuchangegeben.

Um Feuer oder Verletzungen zu vermeiden, verwenden Sie ein

ordnungsgemäßes Netzkabel.

Verwenden Sie für dieses Gerät nur das für ihr Land zugelassene und genehmigte

Netzkabel.

Erden des Gerätes.

Das Gerät ist durch den Schutzleiter im Netzkabel geerdet. Um Gefahren durch

elektrischen Schlag zu vermeiden , ist es unerlässlich, die Er dung durchzufüh ren. Erst

dann dürfen weitere Ein- oder Ausgä nge verbunden werden .

Anschluss einesTastkopfes.

Die Erdungsklemmen der Sonden sindauf dem gleichen Spannungspegel des

Instruments geerdet. SchließenSie die Erdungsklemmen an keine hohe Spannung

an.

Beachten Sie alle Anschlüsse.

Zur Vermeidung von Feuer oder Stromschlag, beachten Sie alle Bemerkungen und

Markierungen auf dem Instrument. Bef olgen Sie die Bedienun gsanleitung für weitere

Informationen, bevor Sie weitere Anschlüsse an das Instrument legen.

Verwenden Sie einen geeigneten Überspannungsschutz.

Stellen Sie sicher, daß keinerlei Überspannung (wie z.B. durch Gewitter verursacht)

das Gerät erreichen kann. Andernfallsbestehtfür den Anwender die

GefahreinesStromschlages.

Nicht ohne Abdeckung einschalten.

Betreiben Sie das Gerät nicht mit entfernten Gehäuse-Abdeckungen.

Betreiben Sie das Gerät nicht geöffnet.

Der Betrieb mit offenen oder entfernten Gehäuseteilen ist nicht zulässig. Nichts in

entsprechende Öffnungen stecken (Lüfter z.B.)

Passende Sicherung verwenden.

Setzen Sie nur die spezifikationsgemäßen Sicherungen ein.

Vermeiden Sie ungeschützte Verbindungen.

Berühren Sie keine unisolierten Verbindungen o der Baugrup pen, während das Gerät

VI M300 User’s Guide

RIGOL

in Betrieb ist.

Betreiben Sie das Gerä t n ic h t i m Fehlerfall .

Wenn Sie am Gerät einen Defekt vermuten, sorgen Sie dafür, bevor Sie das Gerät

wieder betreiben, dass eine Untersuchung durch RIGOL autorisiertem Personal

durchgeführt wird. Jedwede W artun g, Einstellarbeit en oder Austausch v on Teilen am

Gerät, sowie am Zubehör dürfen nur von RIGOL aut ori s i e rt e m Personal

durchgeführt werden.

Belüftung sicherstellen.

Unzureichende Belüftung kann zu Temperaturanstiegen und somit zu thermischen

Schäden am Gerät führen. Stellen Sie deswegen die Belüftung sicher und

kontrollieren regelmäßig Lüfter und Belüftungsöffnungen.

Nicht in feuc h te r Um g ebung betreiben.

Zur Vermeidun g von Kurzschluß im Geräteinne ren und Stromschlag betreiben Sie das

Gerät bitte niemals in feuchter Umgebung.

Nicht in explosiver Atmosphäre betreiben.

Zur Ve rm e idung von Personen- und Sachschäden ist es unumgänglich, das Gerät

ausschließlich fernab jedweder explosiven At mosphäre zu betreiben.

Geräteoberflächen sauber und trocken halten.

Um den Einfluß von Staub und Feuchtigkeit aus der Luft auszuschließen, halten Sie

bitte die Geräteoberflächen sauber und trocken.

Schutz gegen elektrostatische Entladung (ESD).

Sorgen Sie für eine elektrostatisch geschützte Umgebung, um somit Schäden und

Funktionsstörungen durch ESD zu vermeiden. Erden Sie vor dem Anschluß immer

Innen- und Außenleiter der V erbindungsleitung, um st atische Aufladung zu entladen.

Die richtige Verwendung desAkku.

Wenneine Batterieverwendet wird, vermeiden Sie hohe Temperaturen bzw. Feuer

ausgesetzt werden. Bewahren Sie es außerhalbder Reichweitevon Kindern auf.

Unsachgemäße Änderung derBatterie (Anmerkung: Lithium-Batterie) kann zu einer

Explosion führen. VerwendenSie nur von RIGOL angegebenenAkkus.

Sicherer Transport.

Transportieren Sie das Gerät sorgfältig (Verpackung!), um Schäden an

Bedienelementen, Anschlüssen und anderen Teilen zu vermeiden.

M300 User’s Guide VII

RIGOL

WARNING

Schäden oder den Tod von Personen zur Folge haben können.

CAUTION

Schäden am Gerät hervorrufen können.

DANGER

weist auf eine Verletzung ode r Gefäh r dun g hin, die sof ort

geschehen kann.

WARNING

weist auf eine Verletzung oder Gefäh rdung hin, die möglicherweise

nicht sofort geschehen.

CAUTION

weist auf eine Verletzun g ode r Gefährdung hin und bedeutet, dass

Gegenstände auftreten kann.

Sicherheits Begriffe und Symbole

Begriffe in diesem Guide. Diese Begrif fe können in diesem Handbuch aufta uchen:

Die Kennzeichnung WARNING beschreibt Gefahren quellen die leibliche

Die Kennzeichnung Caution (Vorsicht) beschreibt Gefahrenquellen die

Begriffe auf dem Produkt. Diese Bedingungen können auf dem Produkt

erscheinen:

eine mögliche Beschädigung des Instruments oder anderer

Symbole auf dem Produkt. Diese Symbole können auf dem Produkt erscheinen:

GefährlicheS

pannung

SicherheitsHinweis

Schutz-erde Gehäusemasse Erde

VIII M300 User’s Guide

RIGOL

IX

CAUTION

WARNING

supply.

General Care and Cleaning

General Care

Do not store or leave the instrument where it may be exposed to direct sunlight for

long periods of time.

Cleaning

Clean the instrument regularly according to its operating conditions. To clean the

exterior surface, perform the following steps:

1. Disconnect the instrument from all power sources.

2. Clean the loose dust on the outside of the i nstrument with a lint -f ree cloth (with

a mild detergent or water). When cleaning the LCD, take care to av oid sca rifying

it.

To avoid damag e t o t he instrument, do not expose it to caustic liquids.

To avoid short-circuit and personal injury resulting from moisture, make

sure the instrument is completely dry before reconnecting it to power

Environmental Consideratio ns

The following symbol indicates that this product complies with the applicable WEEE

Directive 2002/96/EC.

Product End-of-Life Handling

The equipment may c ontain s ubstan ces that could b e ha rmful t o the envi ronm ent o r

human health. In order to avoid release of such substances into the environment an d

harm to human health, we encourage you to recycle this product in an appropriate

system that will ensure that most of the materials are reused or recycled

appropriately. Please contact your local authorities for disposal or recycling

information.

M300 User’s Guide

RIGOL

M300 Overview

The M300 series data acquisition/switch system provides 5 slots to accept any

combina tion of 8 kinds of plug-in modules, including a DMM module, multiple

multiplexers, an actuator, a matrix switch module and a multifunction module . With

its modular structure, it combines precision measurement capability with flexible

signal connections and can provide versatile solutions for the applications that

require multiple points or signals t o be tested. This can be especially useful in

product performance testing during the R&D phase, and automatic test during

production process.

It com e s with a 4.3 inch high-re s olution color LCD, us e r -friendly interface design,

easy-to-use keyboard layout as well as clear key backlight and operation prompts.

The M300 is extremely flexible and easy to use. Fo r rem ote cont r ol ve rsat ility, it

comes with RS232, USB, LAN and GPIB interfaces standard.

Main Features:

Up to 320 switch channels per mainframe (with very low cost per channel)

Can run independently without PC

USB data logging

Interval scanning with storage of up to 100,000 time-stamped readings

8 modules supported

6½ digit DMM can be inserted into any slot. It als o supports multiple

measurement functions, including DCV, DCI, ACV, ACI, 2WR, 4WR, PERIOD,

FREQ, TEMP (Thermocouple, Thermistor and RTD) and any sensor.

Standard multiple communication interface: USB Device, USB Host, GPIB,

LAN(LXI Core 2011 Device) and RS232

Standard SCPI commands for remote programming capability

Math statistics function : AV G , MA X, MIN and SDEV

Friendly interface

Built-in help system

Multiple system language

4.3 inch c olor LCD

PC control and analysis software

X M300 User’s Guide

RIGOL

XI

Document Overview

Main topics in this manual:

Chapter 1 Quick Guide

This chapter introduces the front panel, rear panel, user interface and plug-in

modules of the M300 as well as the precautions when using it for the first time.

Chapter 2 Front Panel Operations

This chapter introduces in details t he fr ont pane l ope ration methods and f unctions o f

M300.

Chapter 3 To Use External DMM

This chapter illustrates the method of connecting external DMM and configuring scan

list to scan.

Chapter 4 Remote Control

This chapter introdu ces how to control the M300 remotely.

Chapter 5 Troubleshooting

This chapter introduces the commonly encountered failures and their solutions.

Chapter 6 Specifications

This chapter provides the performance specifications and general technical

parameters of the M300.

Chapter 7 Appendix

This chapter provides the accessory list of the M300 as well as service and support

information.

M300 User’s Guide

RIGOL

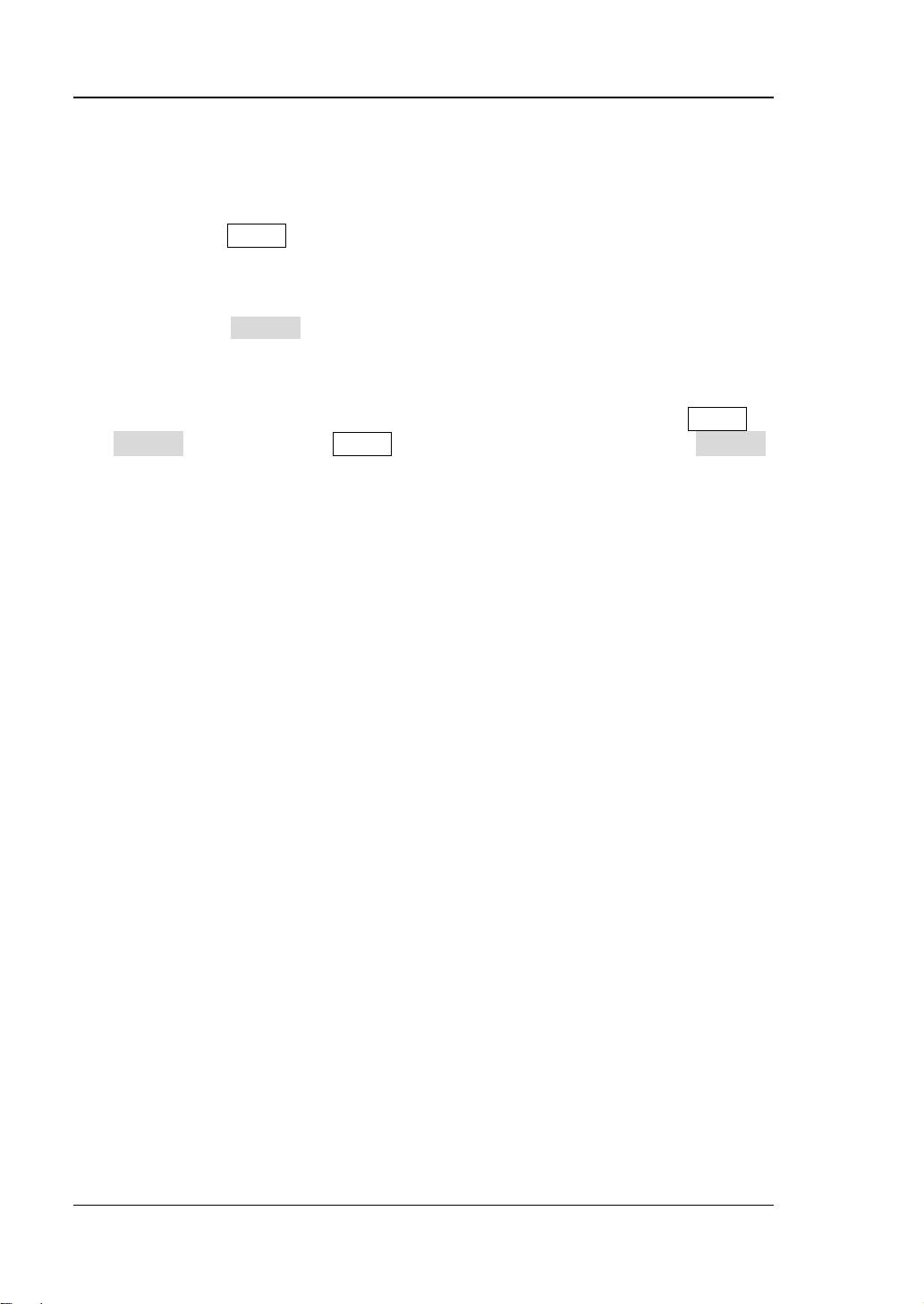

Format Conventions in this Manual:

1. Key:

The front panel key is denoted by the format of “Text Box + Key Name (Bold)”.

For example, Utility denotes the Utility key.

2. Menu:

The menu is denoted by th e format of “Chara cter Shading + Menu W ord (Bold)”.

For examp le, System denotes the system menu item of the Utility function

key.

3. Operation Step:

The next step of operation is de note d by a n arr ow “ ”. For exa mple , Utility

System denotes pressing Utility at the front panel and then pressing System.

User Manuals of This Product:

The main user manuals of this product include the Qui ck Guide , User’s Guide,

Programming Guide and Data sheet. Users can dow nload the desire d manual fr om

www.rigol.com.

XII M300 User’s Guide

Contents RIGOL

XIII

Contents

Guaranty and Declaration ......................................................................... I

Safety Requirement ................................................................................ II

General Safety Summary ........................................................................... II

Safety Terms and Symbols ........................................................................ V

Allgemeine Sicherheits Informationen ........................................................ VI

Sicherheits Begriffe und Symbole ............................................................ VIII

General Care and Cleaning ....................................................................... IX

Environmental Considerations ................................................................... IX

M300 Overview ........................................................................................ X

Document Overview ............................................................................... XI

Chapter 1 Quick Guide ........................................................................ 1-1

General Inspection ................................................................................ 1-2

Appearance and Dim e nsions ................................................................... 1-3

Front Panel ........................................................................................... 1-4

Rear Panel ............................................................................................ 1-8

Power On Inspection ............................................................................ 1-12

User Interface ...................................................................................... 1-13

To Input Filename ................................................................................ 1-14

Plug-in Module Overview ....................................................................... 1-16

Outside View Drawing of the Module................................................ 1-16

Insert the Module into the Mainframe .............................................. 1-17

Module Overview ........................................................................... 1-18

To Use the Built-in Help System ............................................................. 1-20

Measurement Connections .................................................................... 1-21

To Replace the Fuse ............................................................................. 1-25

Menu Quick Navigation ......................................................................... 1-26

Config .......................................................................................... 1-26

Monitor ......................................................................................... 1-27

View Switch Key ............................................................................ 1-27

Control ......................................................................................... 1-28

Alarm Channel Setting Ke ys ............................................................ 1-28

Chapter 2 Front Panel Operations ...................................................... 2-1

Scan Configuration ................................................................................ 2-2

Scan List ........................................................................................ 2-2

Trigger Mode .................................................................................. 2-8

Channel Configuration .................................................................... 2-12

Channel Configuration When Using External DMM ............................. 2-21

Measurement Parameter Configuration ............................................ 2-22

Digital Input .................................................................................. 2-35

Totalizer ........................................................................................ 2-37

M300 User’s Guide

RIGOL Contents

Configuration Copy ........................................................................ 2-39

Channel Monitor ................................................................................... 2-44

Single-channel Monitor ................................................................... 2-44

Multi-channel Monitor .................................................................... 2-46

All Channel Monitor ........................................................................ 2-46

Module Control .................................................................................... 2-47

To Control MC3120 ........................................................................ 2-48

To Control MC3132 ........................................................................ 2-51

To Control MC3164 ........................................................................ 2-54

To Control MC3324 ........................................................................ 2-56

To Control MC3416 ........................................................................ 2-59

To Control MC3534 ........................................................................ 2-61

To Control MC3648 ........................................................................ 2-64

Alarm Channel Setting .......................................................................... 2-66

View Switch ......................................................................................... 2-68

Scan History Information ................................................................ 2-68

Channel Status Table ..................................................................... 2-70

Measurement Curve ....................................................................... 2-70

Channel Information ...................................................................... 2-72

Store and Recall ................................................................................... 2-73

File Type ....................................................................................... 2-74

Internal Storage ............................................................................ 2-75

External Storage ............................................................................ 2-75

To Save a File ................................................................................ 2-76

Utility .................................................................................................. 2-77

System Setting .............................................................................. 2-78

I/O Configuration .......................................................................... 2-86

System Information ....................................................................... 2-92

Detect .......................................................................................... 2-92

System Update .............................................................................. 2-93

Chapter 3 To Use External DMM ......................................................... 3-1

To Connect Instruments .......................................................................... 3-2

To Configure the Instruments .................................................................. 3-4

Scan Control Method .............................................................................. 3-5

Chapter 4 Remote Control ................................................................. 4-1

User-defined Programming ..................................................................... 4-2

To Use PC Software ................................................................................ 4-6

To Control M300 through GPIB .......................................................... 4-6

To Control M300 through USB ........................................................... 4-8

To Control M300 through RS232 ........................................................ 4-9

To Control M300 through LAN ......................................................... 4-11

Chapter 5 Troubleshooting ................................................................ 5-1

Chapter 6 Specifications .................................................................... 6-1

DC Charac t eristic s .................................................................................. 6-1

XIV M300 User’s Guide

Contents RIGOL

XV

AC Characteristics .................................................................................. 6-3

Frequency and Period Characteristics ...................................................... 6-6

Temperature Characteristics ................................................................... 6-8

Module Specifications ........................................................................... 6-10

MC3120/MC3132/MC3164/MC3324/MC3416/MC3648 ........................ 6-10

MC3534 ........................................................................................ 6-12

General Specifications ........................................................................... 6-13

Chapter 7 Appendix ............................................................................ 7-1

Appendix A: Accessories and Options List ................................................ 7-1

Appendix B: Definitions of the Pins of the 78-pin Interface of the Plug-in

Modules ............................................................................................... 7-2

MC3120 ......................................................................................... 7-2

MC3132 ......................................................................................... 7-3

MC3164 ......................................................................................... 7-4

MC3324 ......................................................................................... 7-5

MC3416 ......................................................................................... 7-6

MC3534 ......................................................................................... 7-7

MC3648 ......................................................................................... 7-8

Appendix B: Warranty ............................................................................ 7-9

Index ....................................................................................................... 1

M300 User’s Guide

Chapter 1 Quick Guide RIGOL

1-1

Chapter 1 Quick Guide

This chapter guides users to quickly get familiar with the front/rear panels, user

interface as well as the m e asurement connections of the M300.

Topics in this chapter:

General Inspection

Appearance and Dim e nsions

Front Panel

Rear Panel

Power On Inspection

User Interface

To Input Filename

Plug-in Module Overview

To Use the Built-in Help System

Measurement Connections

To Replace the Fuse

Menu Quick Navigation

M300 User’s Guide

RIGOL Chapter 1 Quick Guide

General Inspection

1. Inspect the shipping container for damage.

Keep the damaged shipping container or cushioning material until the contents

of the shipment have been checked for completeness and the instrument has

passed both electrical and mechanical tests.

The consigner or carrier shall be liable for the damage to instrument resulting

from shipment. RIGOL would not be responsible for free mai ntenance/rework

or replacement of the unit.

2. Inspect the instrument.

In case of any damage, or defect, or failure, notify your RIGOL sales

representative.

3. Check the Accessories

Please check the accessories according to the packing lists. If the accessories

are incomplete or damaged, please contact your RIGOL sales representative.

1-2 M300 User’s Guide

Chapter 1 Quick Guide RIGOL

1-3

Appearance and Dimensions

Figure 1-1 Front View (Unit: mm)

Figure 1-2 Side View (Unit: mm)

M300 User’s Guide

RIGOL Chapter 1 Quick Guide

Configure the scan list and the measurement parameters of each

Enable or disable the channel monitor function.

channels in the scan list.

1 2

6 7 8 9 10

3

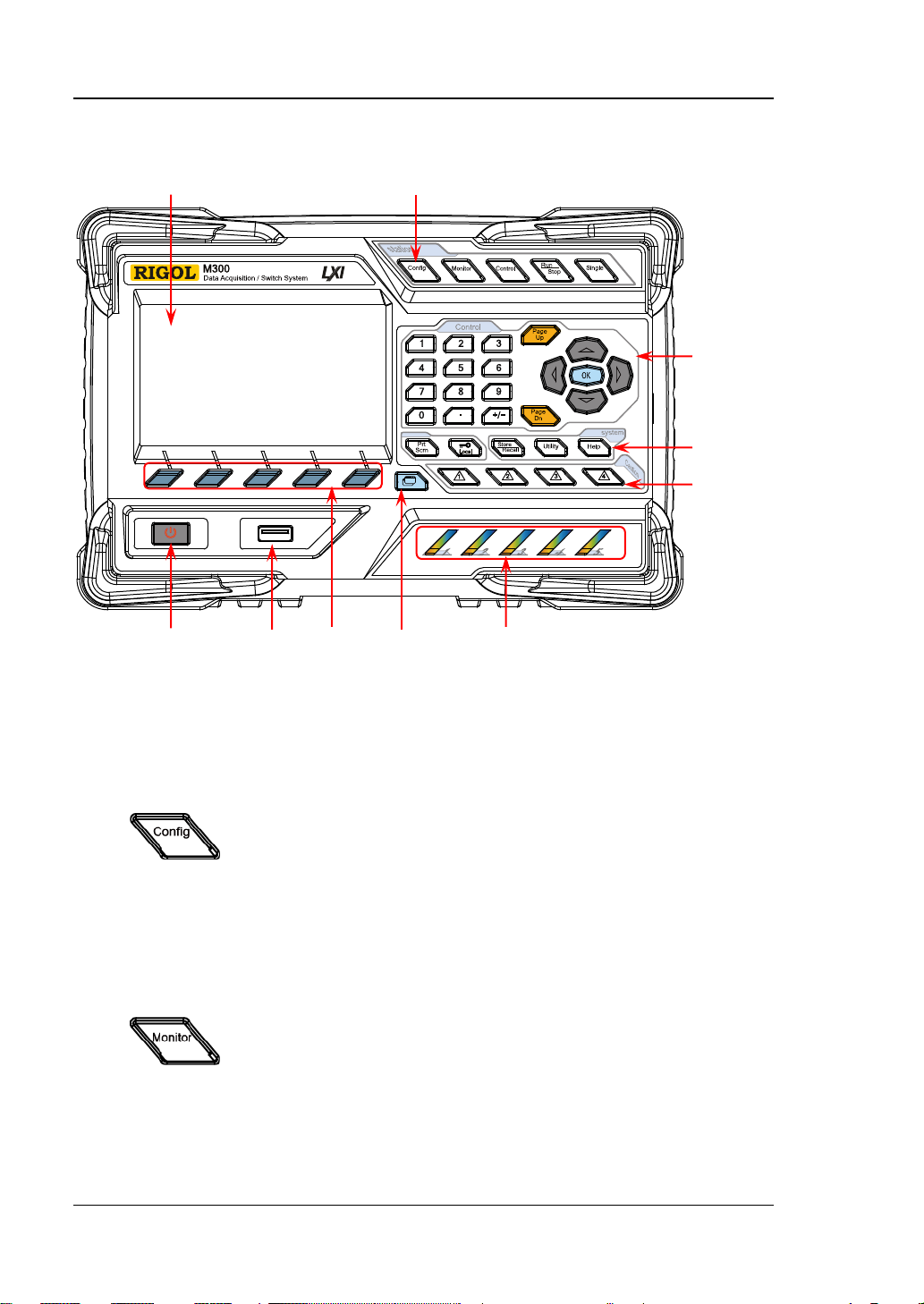

Front Panel

4

5

Figure 1-3 Front Panel of M300

1 LCD

4.3 inches high-resolution color LCD displaying the menu, configuration guide,

measurement parameters, system status and prompt messages.

2 Function Keys

channel.

Create, edit, read and save the scan list.

Set the number of scans, trigger mode and scan interval.

Provide the channel configuration guide used to configure

the measurement parameters, scaling parameters, alarm

parameters and advanced measurement parameters of the

channel.

Support single-channel, multi-channel and all-channel

monitor functions.

1-4 M300 User’s Guide

In single-channel monitor function, you can switch the

channel monitored at any time.

In multi-channel monitor function, you can monitor up to 7

Chapter 1 Quick Guide RIGOL

1-5

In all-channel monitor function, you can monitor all the

Control the modules currently inserted.

Auto Trigger/Stop

Single-channel Switch

single-channel monitor interface.

Numeric Keyboard

Use this key to open the previous or next page of the

and down ke ys (Page U p and Page Dn).

If a USB storage device is currently c onnected to t he ins trument,

storage device in *.bmp format.

channels in the scan list.

Control the status of each channel of the modules.

Reset the modules.

Configure the DIO and TOT channels of multifunction

module.

Can not control the DMM module.

Press this key, the instrument triggers or enters the

wait-for-trigger state and the backlight goes on. Press and hold

this key, the instrument stops triggering or exits the

wait-for-trigger state and the backlight goes off.

Note: This key is invalid when the scan list is empty.

When the instrument is in the single-channel monitor interface,

press this key to switch the channel monitored to the next

channel in the scan list. When the instrument is in other

interfaces, press this key to switch the instrument to the

3 Control Keys

Include numbers (0-9), decimal point (.) as well as

positive/negative signs (+/-).

Used to input parameter value, date and time.

current interface.

Note: These keys are different from the menu page up

Direction keys and conf irmation key.

4 System Keys

press this key to store the current content on the screen in USB

M300 User’s Guide

RIGOL Chapter 1 Quick Guide

When the instrument is in local mode, pressing this key can

Store and reca ll the system configuration, measurement

Configure the system-related parameters.

Enable the built-in help system. Provide Chinese/English help

information for the front panel function keys and menu items.

Press this key to turn on or off the instrument.

Via this interface, M300 can be as a host device and connected

measurement configuration, measurement data, etc.

lock the front panel. At this point, all the keys at the front

panel except this key become invalid. Press a nd hold this key

to unlock the front panel.

When the instrument is in remote mode, press this key to

switch to local mode.

conf iguration and measurement data, etc.

Store the file in the internal non-volatile memory or external

USB storage device.

Read the file stored.

Set various parameters such as the time, date, system

language and display brightness.

Configure the remote inte rface parame t e rs: RS232, LAN,

GPIB and USB.

Query the system information (su ch as t he model and serial

number).

Execute self-test and view the information of each module

(such as the name and model of the module).

System update.

5 Alarm Channel Setting

M300 provides 4 alarm channels. When an alarm is generated, the

corresponding pin of the Alarms/Ext Trig interface (converted from the

[RS-232/Alarms/ Ext Trig] interface) at the rear panel outputs a pulse. You

can press the corresponding key to set the output mode of the corresponding

pin.

6 Power Key

7 USB Host

with an USB storage device to store or recall instrument status,

1-6 M300 User’s Guide

Chapter 1 Quick Guide RIGOL

1-7

View the scan history information, channel status table, measurement

mum, average and st anda rd de viation meas ure d and the sc an

error messages (up to 20).

8 Menu Softkeys

Correspond to the menus on the screen. Pressing any softkey can enable the

corresponding menu.

9 View Switch

curve and channel information.

Scan history information: view the start time, scan sweep, count,

channel number as well as the corresp ondi ng function, maximum,

mini

readings of each channel of the latest scan.

Channel status table: display the current status of each channel.

Measurement curve: display the measurement curve of the

specified channel.

Channel information: view the cycle count of each relay of the

module, the alarm messages of the current scan (the first 100,

including the reading and time when the alarm is generated) and

Note: Up to 100 alarm messag es on each alarm channel can be logged in the

alarm queue and the other alarm messages would be lost and up to 20 error

messages can be logged in the error queue and the other error messages will

also be lost.

10 Module Indicators

Correspond to t h e 5 module slots at the rear panel respectively. The

corresponding module indicator goes on when the module is inserted into the

slot at the rear panel.

M300 User’s Guide

RIGOL Chapter 1 Quick Guide

CAUTION

10

6

7

8

9

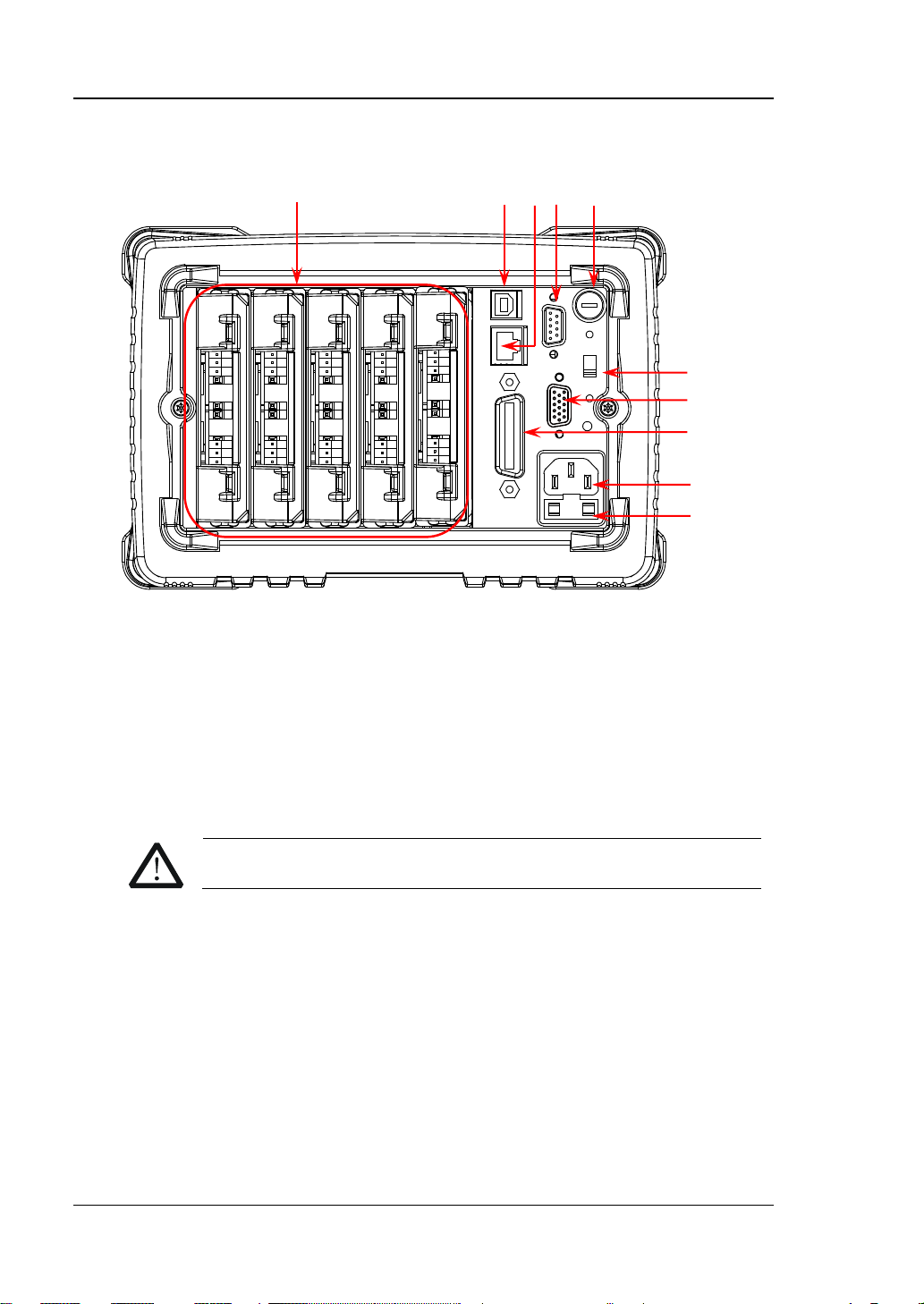

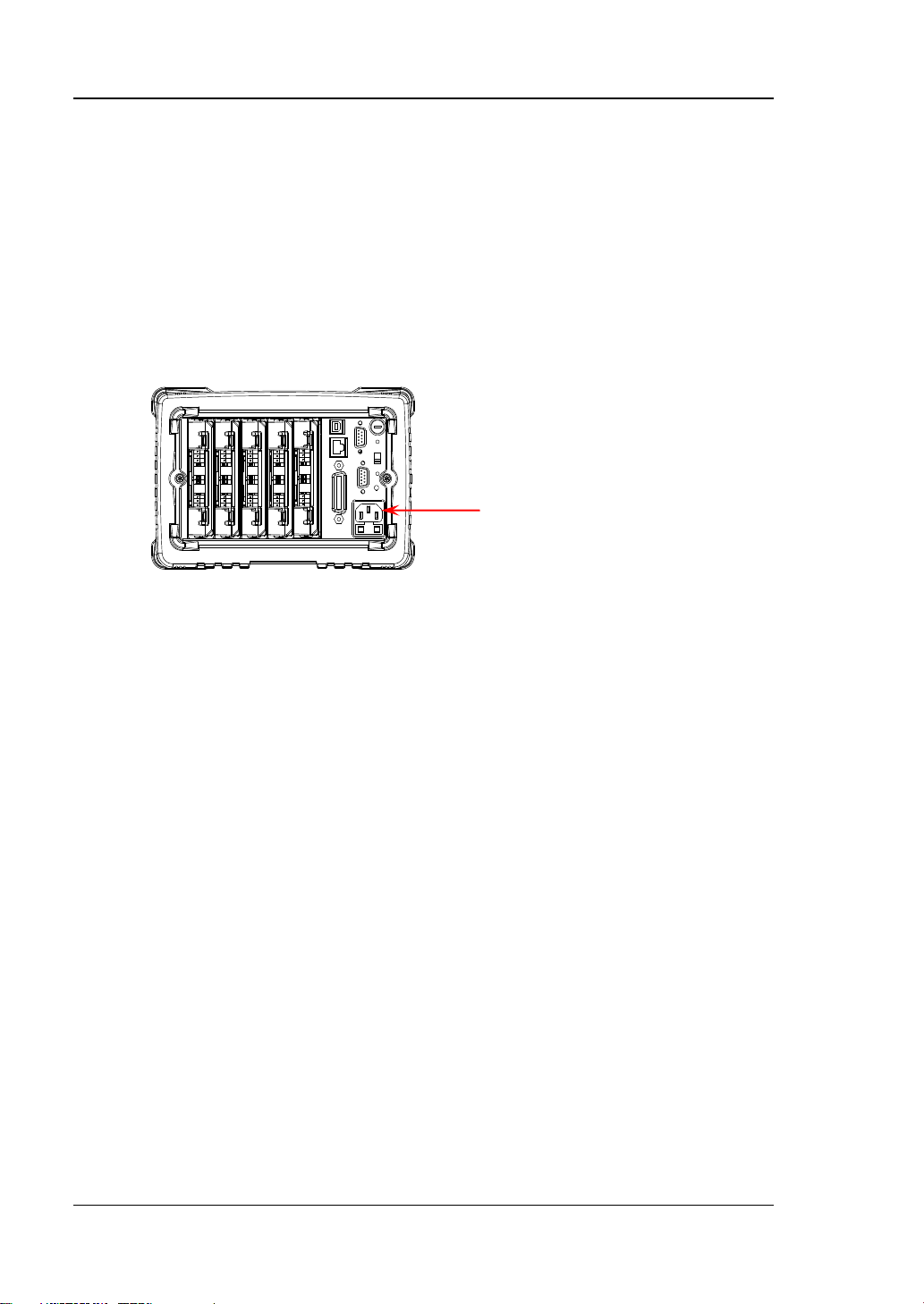

Rear Panel

1 Slots

The M300 provides 5 slots for 5 modules. The 5 slots from left to right in the

figure above correspond to the 5 module indicators at the front panel

respectively. When a module is inserted in the slot, the corresponding module

indicator at the front panel goes on. Figure 1-4 is the schematic diagram of the

rear panel without the modules inserted. For information of each module, refer

to “Plug-in Module Over vie w ”.

1 2 3 4 5

Figure 1-4 Rear Panel of M300

2 USB Device

3 LAN

4 Analog Bus Interface (Female)

1-8 M300 User’s Guide

Only one DMM module is permitted for one mainf r ame.

Via this interface, M300 can communi cate with the PC as a sla ve devi ce and yo u

can control it remotely via the PC.

M300 conforms to the LXI Core 2011 Device standard. The instrument can be

connected to the network via this interface and you can control the instrument

remotely via a PC in the same network.

M300 provides two internal 2-wire analog buses for signal routing as well as an

Chapter 1 Quick Guide RIGOL

1-9

CAUTION

6

7

4

5

2 3 1

8

9

Pin

Definition

1

Current Input

2

Lo

3

LoSense

4

--

5

--

6

Hi 7 HiSense

8

Float GND

9

--

external interface (namely Analog Bus Interface). The analog bus interface is a

9-pin female interface.

Analog Bus Interface

5 DMM Module Power Fuse

The AC power supply from the power socket is divided into two paths with one

for the DMM module and the other for other circuits except the DMM module.

M300 is equipped with the DMM module power fuse (AC 250V T250 mA). To

replace the fuse, refer to the method below.

1) Turn off the instrument and remove the power cord.

2) Press down the fuse cover using a straight screw driver and rotate

clockwise.

3) Select a proper voltage through the voltage selector.

4) Disassemble the fuse cap and fuse.

5) Replace a specified fuse and install the fuse cap.

Please use the specified fuse to avoid electric shock and fire.

6 Voltage Selector

M300 supports two kinds of AC voltages (115 V and 230 V). Please select the

proper voltage scale according t o the AC power used.

M300 User’s Guide

RIGOL Chapter 1 Quick Guide

Pin

Function

Pin

Function

1

Alarm1

Output

9

PC_RX

Output

2

Alarm2

Output

10

PC_DSR

Output

3

Alarm3

Output

11

GND

--

4

Alarm4

Output

12

PC_DTR

Input

5

CH Close

Output

13

PC_CTS

Output

6

Trig

Input

14

PC_RTS

Input

7

GND

--

15

NC

-- 8 PC_TX

Input

--

--

--

Pin

Definition

1

Alarm 1 Output

2

Alarm 2 Output

3

Alarm 3 Output

4

Alarm 4 Output

5

Channel Closed Output

6

Ext Trig Input/Channel Adv a nce Inp ut

7

GND

8

--

9

--

6 7 4 5 2 3 1 6 7 4 5 2 3 1 8

9

Pin

Name

Definition

1

--

--

2

RXD

Received Data

3

TXD

T ransmitted Data

4

DTR

Data T erminal Ready

5

SGND

Signal Ground

6

DSR

Data Set Ready

7

RTS

Request To Send

8

CTS

Clear To Send

9

--

--

8

9

7 RS-232/Alarms/Ext Trig Mixed Interface (Male)

This interface is a 15-pin male interf ace. The definitions of the pins are as sh own

in the table below.

You can convert this interface into two 9-pin interfac es using the Mixed Interface

Convert Cabl e (accessory). This break out cable consis ts of a 9-pin male interfa ce

used as a standard RS232 interface and a 9-pin female interface used for alarm

output, external trigger signal input and etc.

RS232: via this interface, M300 can communicate with the PC and you can

control the instrument remotely via the PC.

RS232 Interface

Alarms/Ext Trig: as shown i n t he figure bel ow, pin 1 to pin 4 are use d to

output TTL pulse when an alarm is generated in the corresponding alarm

channel. Pin 6 is used to receive external trigger signal. When an external

digital multimeter is connected for measurement, pin 5 and pin 6 are used

together to control the measurement.

Alarms/Ext Trig Interface

1-10 M300 User’s Guide

Chapter 1 Quick Guide RIGOL

1-11

CAUTION

scale using the voltage selector.

CAUTION

seat is not short-circuited to avoid electric shock and fire.

Note:

The Pin 5 outputs a TTL negative pulse with about 7μs pulse width each time the

measurement is completed. The output rate is dependent upon the actual

measurement rate. The maximum output rate is 1000 times per s econd.

In external trigger mode, Pin 6 accepts external trigger signal. The trigger can

have a pulse width equal to or greater than 2μs with specified edge. To

configure, press Config, select “External” trigger mode and select “Rising” or

“Falling” in Edge item. If the external trigger signal is continuous pulse, please

make sure the pulse period is larger than 100μs.

8 GPIB

The M3 00 confo rms to th e IEEE-488.2 standard. Via this interfa ce, the M300 can

be controlled remotely via a PC with a GPIB interface.

9 Power Socket

The M300 can accept two kinds of AC power supplies. Use the power cord

provided in the accessories to connect the AC power supply to the instrument

via this socket.

Before connecting the AC power supply, select the correct voltage

10 Power Fuse

The specification of the fuse of M300 is AC 250V T3.15 A. If a new fuse is

required, please refer to “To Replace the Fuse”.

Please use the specif ied power fuse and make sure that the fuse

M300 User’s Guide

RIGOL Chapter 1 Quick Guide

AC Power Socket

Power On Inspection

1 Connect the power

(1) Adjust the power voltage selector at the rear panel according to the power

supply volta ge. M300 supports two types of AC power. If your supply

voltage is in the range of 115*(100%-10%) V and115*(1 00%+10%) V,

please select 115 and if it is in the range of 230*(100%-10%) V and

230*(100%+10%) V, please select 230.

(2) Connect the instrument to AC power using the power cord provided i n the

accessories.

2 Start the instrument

Press the power key at the front panel and the instrument starts.

After the instrument starts, it checks the modules. This process would take

several to dozens of seconds according to t he number of modules inserted.

During this process, user operation is forbidden.

3 Check the instrument following the steps below if the instrument

does not start normally

1) Check whether the power is correctly connected.

2) Check whether the power key at the front panel is really on.

3) Check whether the power fuse is burned out. If the fuse needs to be

changed, use the specified fuse.

4) Check whether the correct power voltage is selected. Please select the

proper power voltage according to the power supply voltage.

5) Restart the instrument after finishing the above inspections. If it still does

not work correctly, please contact RIGOL.

1-12 M300 User’s Guide

Chapter 1 Quick Guide RIGOL

1-13

Help

Displayed when the built-in help is enabled.

Error

Displayed when an error occurs.

Displayed when the keyboard is locked.

Displayed when an alarm is generated.

Displayed when the system sound is disabled.

Displayed when the instrument is connected to a network correctly.

Displayed when an U SB storage device is detected.

Local

Displayed when the instrument is in local mode.

Rmt

Displayed when the instrument is in remote mode.

Status

User Interface

Bar

Content

Area

Menu

Figure 1-5 User Interface

1. Sta tus Bar

Bar

2. Cont ent Area

Display the measurement configuration guide, measurement parameters

settings, etc. For more detailed information, please refer to the User’s Guide.

3. Me nu Bar

Display the menus of the current function corresponding to the menu softkeys

below respectively. Pressing the softkey can activate the corresponding menu.

M300 User’s Guide

RIGOL Chapter 1 Quick Guide

To Input Filename

M300 supports filenames consisting of Chinese characters, English letters and

numbers. The length of the filename cannot exceed 12 bytes. The filename input

interface is as shown in the figure below.

Input Mode Icon/Chinese Character Selecting Area Letter Selecting Area

Filename Input Area

Figure 1-6 Filename Input Interface

1 Input Mode Icon/Chinese Character Selecting Area

Display the icon of the input mode currently selected.

Chinese input mode: display

English uppercase input mode: display

English lowercase input mode: display

In additional, in Chinese input mode, this area displays Chinese characters for

selection. Use the numeric keyboard to input the number corresponding to the

Chinese character to input the desired Chinese character.

2 Filename Input Area

Display the letter entered. You can use the left/right direction key to select the

desired letter to edit.

3 Letter Selecting Area

Use th e direction keys to select desired letter and press OK.

1-14 M300 User’s Guide

Chapter 1 Quick Guide RIGOL

1-15

4 Switch the Input Mode

Press Ch/A/a to switch the input mode to Chinese, English uppercase or

English lowercase.

Chinese: can input Chinese characters and number (from 0 to 9) and

is displayed in the “Input Mode Icon Area”.

English uppercase: can input English uppercase letters (from A to Z) and

number (from 0 t o 9 ) an d

is displayed in the “Input Mode Icon Area”.

English lowercase: can input English lowercase letters (from a to z) and

number (from 0 t o 9 ) and

is displayed in the “Input Mode Icon Area”.

5 Switch the Cursor

Press Cursor to switch the cursor to select “Filename Input Area”, “Letter

Selecting Area” or “Chinese Character Selecting Area” (only available in Chinese

input mode).

When “Filename Input Area” is selected, you can use left /right di rection ke y

to select desired letter to edit.

When “Letter Selecting Area” is selected, use the direction keys to select

desired letter and press OK. At this point, letters in “Filename Input Area”

or “Chinese Character Selecting Area” varies.

In Chinese input mode, when “Chinese Character Se lecting Area” is selected,

you can use the up/down direction key to open the previous or next page of

“Chinese Character Selecting Area” and use the numeric keyboard to input

the number corresponding to the Chinese character to input the desired

Chinese character.

6 Delete

Press this softkey to delete the letter selected by the cursor in “Filename Input

Area”.

7 OK

Press this softkey to use the letters displayed in “Filename I nput Are a” as the

filename.

8 Return

Press this softkey to cancel inputting filename and return to the pre vious men u .

M300 User’s Guide

RIGOL Chapter 1 Quick Guide

Golden Circuit board Edge: each on the

Interface 1: connect the signal under test via the

Interface 2: connect

Plug-in Module Overview

The M300 provides 8 kinds of modules. These include a DMM module, 20-channel

multiplexer, 32-channel multiplexer, 64-channel multiplexer, multi-function module,

etc. This section introduces the functions and characteristics of each module.

Outside View Drawing of the Module

top and bottom for sliding into the slot

terminal block (the DMM module does not have this

interface)

with the main frame

Figure 1-7 Outside view drawing of the module

1-16 M300 User’s Guide

Chapter 1 Quick Guide RIGOL

1-17

Note:

mainframe off before inserting the modules into the mainframe.

Insert the Module into the Mainframe

Please turn the mainframe off and insert the modules following the instructions

below.

As shown in Figure 1-7, there is a golden circuit board edge both on the top and

bottom of the module. Aim the two edges with the sliding chutes (as pointed out by

the arrows in the figure below) into the main f ra me sl ot and push the module in unti l

you hear a sound. At this point, interface 2 is connected to the main frame.

Note: Please refer to “Measurement Connections” to connect the external

terminal block and the sig nals to be measured and then insert it into the mainframe.

Figure 1-8 Insert the Module into the Mainframe

All the modules of the M300 do not support hot-plugging. Please turn the

M300 User’s Guide

RIGOL Chapter 1 Quick Guide

Module Overview

MC3065 (DMM Module):

The DMM module is used to measure the signals under test and has 6½ digit reading

resolution. The measurement functions include DCV, ACV, 2-wire resistance, 4-wire

resistance, frequency, period, temperature and any sensor.

After connecting the DMM module, make s ure that the signal under test connected to

the analog bus is no greater than 300 Vdc or 300 Vrms.

MC3120 (20-Channel Multiplexer):

All 20 channels switch both HI and LO inputs, thus providing fully isolated inputs to

the DMM module. MC3120 is divided into two banks (called A and B) of 10 two-wire

channels each. When making 4-wire resistance measureme nt , the instrument

automatically pairs channels of A bank and B bank. All channels in the scan list are

break-before-make. You can close multiple channels on this module only if you have

not configured any channel to be part of the scan list.

This module can be connected with MC3065 (DMM Module, if MC3065 is currently

inserted).

MC3132 (32-Channel Multiplexer):

All 32 channels switch both HI and LO inputs, thus providing fully isolated inputs to

the DMM module. MC3132 is divided into two banks (called A and B) of 16 two-wire

channels each. When making 4-wire resistance measureme nt , the instrument

automatically pairs channels of A bank and B bank. All channels in the scan list are

break-before-make. You can close multiple channe ls on this module only if you have

not configured any channel to be part of the scan list.

This module can be connected with MC3065 (DMM Module, if MC3065 is currently

inserted).

MC3164 (64-Channel Single-Ended Multiplexer):

All 64 channels can switch the HI input only. MC3164 is divided into two banks (A and

B) of 32 single-ended channels each. All channels in the scan list are

break-before-make. In any case, y ou cann ot close multiple channels on thi s module.

This module can be connected with MC3065 (DMM Module, if MC3065 is currently

inserted) but cannot be used for 4-wire resistance measurement.

MC3324 (24-Channel Multiplexer):

The MC3324 is a mixed multiplexer with 20 v oltage channels a nd 4 current channe ls.

All 20 voltage channels switch both HI and LO inputs, thus providing fully isolated

inputs to the DMM module, and is divided into two banks (called A and B) of 10

two-wire channels each. When making 4-wire resistance measurement, the

instrument automatically pairs channels of A bank and B bank. All channels in the

scan list are break-before-make. You can close multiple channels on this module only

if you have not configured any channel to be part of the scan list.

1-18 M300 User’s Guide

Chapter 1 Quick Guide RIGOL

1-19

4 current channels are used in combination with the DMM module to measure DC

current or AC current. All channels in the scan list are break-before-make. In any

case, you cannot close multiple channels on this module.

This module can be connected with MC3065 (DMM Module, if MC3065 is currently

inserted).

MC3416 (16-Channel Actuator):

The MC3416 can connect signals to the device under test or enable external devices.

Any of the 16 channels can switch to Normally-Ope n (NO ) a nd N ormal ly -Closed (NC)

states.

MC3534 (Multifunction Module):

This module provides 3 kinds of functions with 4 channels for each function. This

module can be used to check status or control external devices (such as solenoid,

power relays and microwave switches). You can also read digital inputs and the

totalizer count during a scan.

Four 8–bit digital input/output (DIO) ports

4 totalizer (TOT ) input terminals (the first two channels are 10 MHz TO T and the

other two channels are 100 kHz TOT) with 1 Vpp sensitivity

4 analog output terminals, ±12 V calibrated voltage

MC3648 (4×8 Matrix Switch):

The MC3648 is used to connect multiple devices to multiple points on the device

under test. You can connect the rows and columns of multiple matrix switches to

form relatively larger matrix (such as 8×8 and 4×16, the number of crosspoints

cannot exceed 160).

32 two-wire cross points which can connect any com bination of inputs an d outputs at

the same time.

M300 User’s Guide

RIGOL Chapter 1 Quick Guide

To Use the Built-in Help System

The built-in help syst em of M300 p rovide s the h elp i nform ation about any fro nt panel

key and menu. To acquire the help information of an y front panel k ey or menu , press

Help (the backlight goes on and “Help” is displayed in the status bar in the user

interface) and then press the desired key. The built-in help interface is as shown in

the fi g ure below. Press OK to exit.

Figure 1-9 Built-in Help System

1-20 M300 User’s Guide

Chapter 1 Quick Guide RIGOL

1-21

Terminal Block

Module

1.

M3TB20

MC3120

2.

M3TB32

MC3132

3.

M3TB64

MC3164

4.

M3TB24

MC3324

5.

M3TB48

MC3648

6.

M3TB16

MC3416

7.

M3TB34

MC3534

WARNING

removing the terminal block from the module.

Measurement Connections

Multiple signals to be measured are connected to the plug-in modules through the

external terminal blocks and then switched to the DMM module or external DMM.

M300 provides 7 kinds of terminal b locks. The models of the terminal blocks and

corresponding modules are listed in the table below. This section introduces how to

connec t the signals to be measured t hrough the external block.

Table 1-1 External T e r minal Blocks

Cut off all the power supplies before opening the terminal block or

1. Place the terminal block with the front (with the RIGOL caption) facing

downward and pull the two latches in the arrow direction in the figure below an d

press them down. Place the termi nal block wit h the front f acing upwar d and pull

the upper cover of the terminal block upward and remove it.

2. Connect the cables for connecting the signal under test according to the labels

on the circuit board of the terminal block (for the connecting method, refer to

M300 User’s Guide

RIGOL Chapter 1 Quick Guide

01

H

L

H

L

...

H

L

H

L

...

H

L

16

17

32

Channel

Switches

Terminal

Box: TB32

H

L

01

H

L

32

.

.

.

78-Pin

Interface

M300

Mainframe

DMM Module

MC3065

+

V

measured

V

measured

Fuse

Fuse

Table 1-2). Pass the binding wires through the two groups of holes as pointed

out by the a rrows in the figure below to fix the cable connected. Pay attention to

the channel or terminal connected to the cable to ensure that the signal

connected is correct.

Note:

For the connectio n method of each module and the corresponding terminal

block as well as the specification requirements of the connecting cable,

please log in RIGOL official websi t e (www.rigol.co m) to get more related

materials.

When using the mutliplexer module for measurement, make sure that both

the amplitude of the signal under measurement and the commom mode

voltage are no greater than the maximum input voltage of the module.

When the multiplexer module is use d to measure an object wi th high-power

output ability (such as battery and power supply), to avoid damaging the

relay, you are recommended to connect a fuse in serial when making

connections (as shown in the fi gure below ) .

1-22 M300 User’s Guide

Chapter 1 Quick Guide RIGOL

1-23

DCV/ACV/FREQ/PERIOD/Sensor

DCI/ACI/ Sensor (DCI)

channel 24 of MC3324.

2WR/RTD/Thermistor/

4WR/RTD 4W/ Sensor (4WR)

Thermocouple

WARNING

requirement. To avoid damaging the module, make sure that all

the input signals are within the rated input range.

Resistance to be

+

+ - -

Table 1-2 Measurement Connections

(DCV, FREQ)

+ -

Signal to be

measured

CH1

H L

Sensor (2WR)

+ -

Resistance to be

measured

CH1

H L

+ -

Signal to be

measured

CH21

H L

Note: Only available for the channel 21 to

H L Source

CH1

measured

+ -

Thermocouple

under test

CH1

To avoid electric shock, the connecting wire should meet the maximum

H L

current

M300 User’s Guide

H L Sense

CH17

Note: Only available for all the channels of

MC3120 and MC3132 as well as the channel 1

to channel 20 of MC3324.

RIGOL Chapter 1 Quick Guide

3. Connect the terminal block to t he module via interfac e 1 (the inte rface definition

is in Figure 1-7) on the module and screw down the two screw rods onto the

nuts on the module.

4. Close the upper cover of the terminal block.

5. Insert the module with the terminal block into the slot of the mainframe.

1-24 M300 User’s Guide

Chapter 1 Quick Guide RIGOL

1-25

CAUTION

seat is not short-circuited to avoid electric shock and fire.

To Replace the Fuse

If a new fuse is required, please refer to the following steps.

1 Turn off the instrument and remove the power cord.

2 Insert the small straight screw driver into the slot at the power socket and pry

out the fuse seat.

3 Replace a specified fuse.

4 Insert the fuse seat into the slot.

Please use the specified power fuse and make sure that the fuse

M300 User’s Guide

RIGOL Chapter 1 Quick Guide

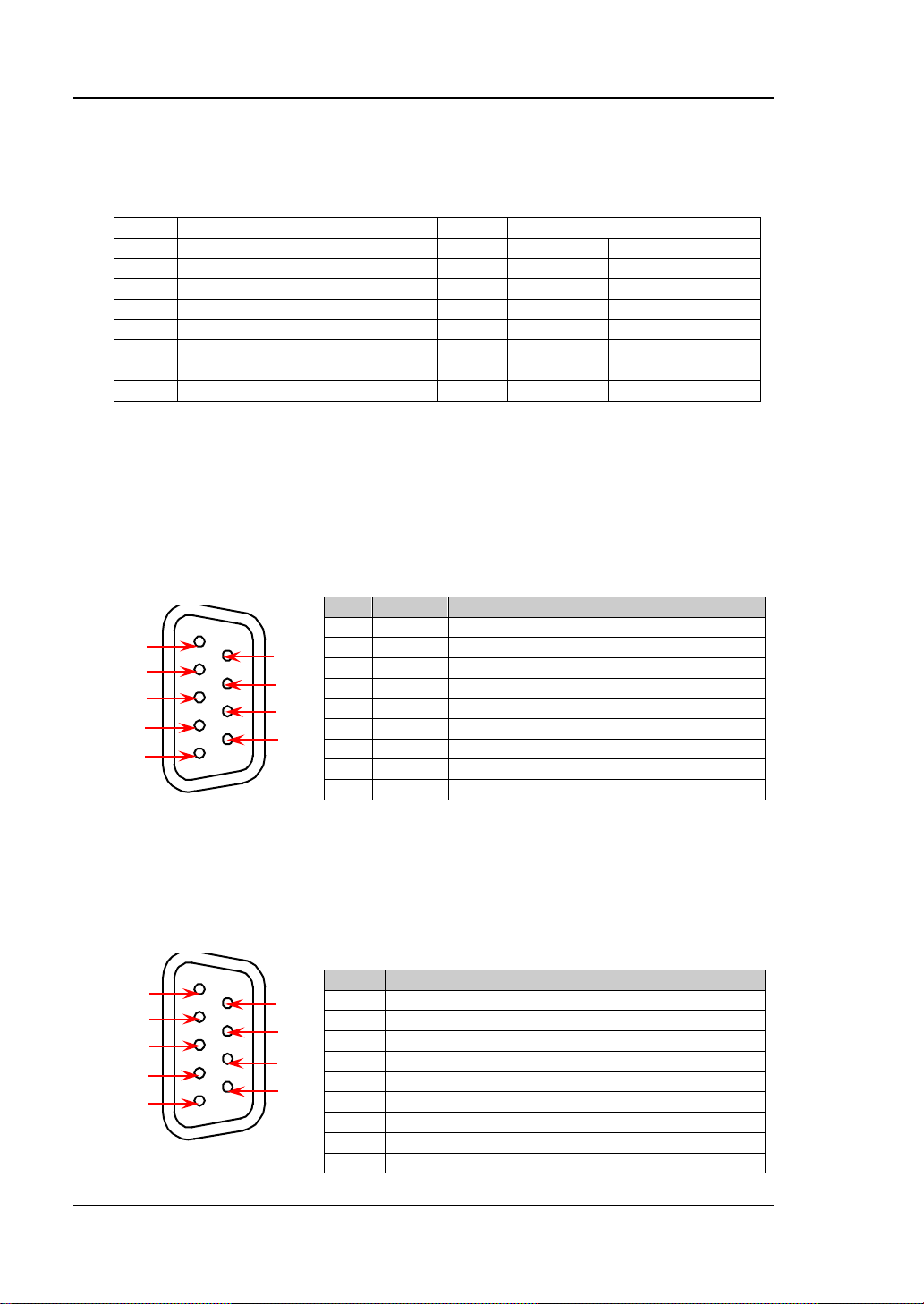

Menu Quick Navigation

This section provides the structures of the main menus for M300 to guide users to

quickly get familiar with the operations. For more detailed information, please refer

to “Front Pane l Operations”.

Config

1-26 M300 User’s Guide

Chapter 1 Quick Guide RIGOL

1-27

Monitor

View Switch Key

M300 User’s Guide

RIGOL Chapter 1 Quick Guide

Control

Alarm Channel Setting Keys

1-28 M300 User’s Guide

Chapter 2 Front Panel Operations RIGOL

2-1

Chapter 2 Front Panel Operations

This chapter introduces in details t he fr ont pane l ope ration methods and f unctions o f

M300.

Top ics in this chapter:

Scan Configuration

Channel Monitor

Module Control

Alarm Channel Setting

View Switch

Store and Recall

Utility

M300 User’s Guide

RIGOL Chapter 2 Front Panel Operations

Scan Configuration

Press Config at the front panel to configure M300 to create a scan (create and edit

the scan list and configure the parameters of each channel). During the scan, each

time the DMM module is connected to one channel in the scan list and executes a

measurement according to the channel configuration.

Scan List

Create a scan list, add any channels of the multiplexer or the DIO or T OT channels of

the multifunction module to the scan list and configure the basic measurement,

scaling, alarm and adv anced measurement parameters for ea ch c hanne l. The edited

scan list can be stored in i nternal or exte rnal memory and be recalled whe n require d.

To Create a New List

The instrument enters the scan list configuration interface when you start the M300

or press Config. You can set the scan parameters (such as sweep count, trigger

mode) as well as create, edit, recall and save the scan list.

Figure 2-1 Scan List Configuration Interface

1 To Create Scan List

Press New to create a new scan list and enter the filename input interface. At

this point, you can input the desired list name by referring to “

Filename” and press OK. The scan list na me can consist of Chinese char acters,

English uppercase/lowercase letters and numbers and cannot exceed 12 bytes

2-2 M300 User’s Guide

To Input

Chapter 2 Front Panel Operations RIGOL

2-3

Interval

A Scan

(each English letter or number occupies 1 byte and each Chinese character

occupies 2 byt e s).

To modify the name of the scan list created, please select Scan Li st firstly and

press OK to enter the filename input interface.

2 Sweep Count

Select Sweep using the up/down direction key and select “Infinite” or “1” (you

need to set a value) using the left/right direction key.

Infinite: execute continuous scan. You can press and hold Run/Stop to

stop the scan.

Number of Scans: you can use the numeric keyboard to set a value. The

range is from 1 to 50000 . After executing the specified number of scans, the

instrument stops scanning automatically.

3 Trigger Mode

Select TrigMode using the up/down direction key and select “Auto”, “Manual”,

“External”, “AbsTime” or “Alarm” using the left/right direction key.

Auto: the instrument executes infinite scan or the specified number of

scans at the specified interval automatically.

Manual: the instrument executes a scan when you press Run/Stop.

External: the instrument executes a scan when the external trigger signal

input interface receives a TTL trigger pulse.

AbsTime: the instrument executes a scan when the system t ime reaches the

specif ied time.

Alarm: the instrument executes a s can when an alarm is generated from the

specified alarm channel.

For details of the trigger mode, refer to “Trigger Mode”.

4 Interval

Interval is defined as the time interval between the start of a scan to the start of

the next scan in auto scan mode as show n in the figure below . When the t rigger

mode is “Auto”, selec t Interval using the up/down direction key and use the

numeric keyboard to set a desired interval. The range is from 00:00:00.000 to

99:59:59.999 (the time format is Hour:Minute:Second.Millisecond) and the

default is 00:00:00.000.

……

M300 User’s Guide

RIGOL Chapter 2 Front Panel Operations

Pin 6: Ext Trig Input/Channel Advance Inp ut

5 Advanced Source (Available only when the DMM module is not

installed or disabled)

This setting is only available when an external digital multimeter is used. The

advanced source provides the advanced channel signal. When receiving the

advanced channel signal, the instrument disc onnects the channel currently

selected and closes the next channel in the scan list.

When an external DMM is connected, use the up/down direction key to select

Adv Src and use the left/right direction key to select the desired advanced

source.

Auto:

After finishing measuring the current channel, the cur rent channel is

disconnected and the next channel in the list is closed automatically.

Single:

After finished measuring the current channel, the unit will wait for user

input before moving to the next channel in the list. Pressing Single to

disconnect the current channel and close the next channel.

Because both the “Single” advanced source and the manual trigger use the

same way, pressing Single, to generate signal, the manual trigger mode

does not support “Single” advanced source.

External:

The scan will advance after receiving a trigger on the external advanced

channel signal. This signal , typica lly the VMC signal from the external DMM,

is input from pin 6 of the Alarm/Ext Trig interface (converted from the

[RS-232/Alarms/Ext Trig] interface). After “External” is selected, you

need to select the ed ge type of the input signal (use the up/ down direction

key to select Input Edge and use the left/right direction key to select

“Rising” or “Falling”).

As the “External” advanced source input and the external trigger input use

the same pin, the external trigger mode does not support “External”

advanced source.

Alarms/Ext Trig Interface

6 Absolute Time

Absolute time is defined as the time when the instrument executes the scan in

2-4 M300 User’s Guide

Chapter 2 Front Panel Operations RIGOL

2-5

absolute time scan mo de. When the tri gger mo de is “AbsTime”, select AbsTime

using the up/down direction key and set the desired time using the numeric

keyboard. The time format i s “ Month-Date Hour:Minute:Second”. You need to

set a valid time. The ranges of the parameters are as follows.

Month: 01 to 12

Date: 01 to 31, 30, 29 or 28

Hour: 00 to 23

Minute: 00 to 59

Second: 00 to 59

The instrument can also ignore some time parameters and trigger when the

system time fulfills some of the parameters. Use “.” on the numeric keyboard to

set the parameters to be ignore d and the cor responding position will display “ **”.

For example, set the inst rument t o ignore the “ Month” and “Date” and trigger at

8:00 every day; use the numeric keyboard to set the absolute time to “**-**

08:00:00”.

7 Alarm Channel

When the trigger mode is set to “Alarm”, select Channel using the up/down

direction key and set the alarm channel to “Alarm1”, “Alarm2”, “Alarm3” or

“Alarm4” usin g the left/right directi on key. The instrument executes a scan when

an alarm is generated from the channel selected.

8 Trigger Edge Type

When the trigger mode is “External”, select Edge using the up/down direction

key and select “Rising” or “Falling” using the left/right direction key. The

instrument executes a scan when a TTL trigger pulse with specified edge is

received by the external trigger signal input terminal.

M300 User’s Guide

RIGOL Chapter 2 Front Panel Operations

To Edit the List

Press ConfigEdit to enter the scan list editing interface.

Figure 2-2 Scan List Editing Interface

1 New

Create a new channel configuration. Press this softkey to enter the channel

conf iguration guide. Finish all the configurations according to the introductions

in “Channel Configuration” and press Done to return to the scan list editing

interface.

2 Copy

Copy the channel c onfiguration created to other channel or module. For details,

refer to the introduction in “Configuration Copy”.

3 Modify

Modify the channel configuration created. Select the desired channel using the

direction keys and press Modify to open the configuration guide of the

corresponding channel. At this point, you can modify the configuration of this

channel and after the mod ification is finished, press Done to return to the scan

list editing interface.

Note: The channel in Chan No. can only be modified to the channels in the

scan list.

4 Delete

Delete a channel configuration created. Select the channel to be deleted using

the direction keys and press Delete to delete the corresponding channel.

2-6 M300 User’s Guide

Chapter 2 Front Panel Operations RIGOL

2-7

5 Search

When a great number of channels are added into the scan list, you can press

Page Dn Search, use the numeric keyboard to input the desired channel

number and then press OK to quickly locate this channel. You can copy, modify

or delete the channel configuration located.

To Save the List

The M300 allows users to save the configured scan list in internal or external

memory as measurement conf iguration file.

Press Config Save to enter the store and recall interface (the file type is

automatically set to “Measurement configuration”). Select the desired directory

according to the method introduced in “Store and Recall” and then press Save to

enter the filename input interface. Input the specified filename to save the current

scan list.

You can read the scan li st stored as well as modify its configuration and sav e it again.

To Read the List

The M300 allows users to read the scan list stored. Press Config Read to enter

the store and recall interface (the file type is set to “Measurement Configuration”

automatically). Select and read the desired file according to the method introduced

Store and Recall”.

in “

You can modify the configuration of the scan list read and save it again.

M300 User’s Guide

RIGOL Chapter 2 Front Panel Operations

Trigger Mode

The M300 provides 5 trigger modes including auto trigger, manual trigger, external

trigger, absolute time trigger and alarm trigger.

Auto Trigger

In auto trigger mode, the scan rate is determined by the specified interval. If the

time required for a complet e scan of the scan list is greater than the specified interval,

the instrument will execute a continuous scan at the fastest possible rate (no error

message will be generated).

The range of the interval is from 0 ms to 99:59:59.999 hours (the time format is

“Hour:Minute:Second.Millisecond”) and the resolutio n is 1 ms.

If the number of s cans is set to “Infinite” , press Run/Stop at the front panel and the

instrument executes a continuous scan automatically at the specified interval. You

can press and hold the key to stop the scan.

If the number of scans is a specific value (1 to 5000 0), p ress Run/Stop at the front

panel and the instrument executes the specified number of scans at the specified

interval and then stops automatically.

During the scan, the instrument stores the measurement data, scaling data and

alarm data in the non-volatile memo ry automatically. You can press

panel to view the history measurement data (including the maximum, minimum,

average and standard deviation).

Manual Trigger

In manual trigger mode, after you press Run/Stop at the front panel, the

instrument executes a sca n and then enters the w ait -for-trigger state. After that, the

instrument triggers each time you press Run/Stop at the front panel.

If the n u mber of scans is set to “Infinite”, after each trigger is finished, th e

instrument will always stay in wait-for-trigger state. You can press and hold the key

to stop the scan and the instrument will exit the wait-for-trigger state.

If the number of scans is set to a specific value (1 to 50000), after the trigger is

finished, the instrument enters the wait -for-trigger state. The instrument will exit the

wait-for-trigger state when the number of triggers reaches the preset value.

During the scan, the instrument stores the measurement data, scaling data and

at the front

2-8 M300 User’s Guide

Chapter 2 Front Panel Operations RIGOL

2-9

Pin 6: Ext Trig Input/Channel

alarm data in the non-volatile memo ry automatically. You can press at the front

panel to view the history measurement data (including the maximum, minimum,

average and standard deviation).

External Trigger

To use the externa l t rigger mode, first use the mixed-inter face separator line

(accessor y) to convert the [RS-232/Alarms/Ext Trig] interface at the rear panel

to two 9-pin interfaces. Wherein, the 9-pin male interface is a standard RS232

interface and the 9-pin female interface is used for alarm output, external trigger

signal input (pin 6, as shown in the figur e below) and so on. Secondly, you need to

select the edge type (rising or falling) for the external trigger signal. In external

trigger mode, the instrument initialize a trigger when a trigger signal met the

conditions is received by the Ext Trig Input terminal.

Advance Input

Alarms/Ext Trig

In external trigger mode, if the number of scans is set to “Infinite”, after you press

Run/Stop at th e front panel, the instrument enters the wait-for-trigger state and

then executes a scan each time an e xternal trig ger si gnal i s re ceived . Press and hold

Run/Stop and the instrument will exit the wait-for-trigger state.

If the number of scans is a specific value, after you press Run/Stop at the front

panel, the instrument enters the wait-for-trigger state and then the instrument

executes a scan each time an external trigger signal is received. After executing the

specified number of e xternal tri ggers, t he ins trumen t exits t he w ait-for-trigger state.

During the scan, the instrument stores the measurement data, scaling data and

alarm data in the non-volatile memory automatically.

M300 User’s Guide

RIGOL Chapter 2 Front Panel Operations

Absolute Time Trigger

To use the absolute time trigger mode, set an accurate system time for the

instrument by referring to “Date” and “Time”. Then select absolute time trigger

mode and set a time. The instrument e xecutes a scan w hen the system time re aches

the specified time. If the system time reaches the next specified time point when th e

instrument is in a scan , the instrument will ign ore the new trigger and c ontinue with

the current scan.

The absolute time format is “Month-Date Hour:Minute:Second”. You need to set a

valid time. The ranges of the parameters are as follows.

Month: 01 to 12

Date: 01 to 31, 30, 29 or 28

Hour: 00 to 23

Minute: 00 to 59

Second: 00 to 59

The instrument can also ignore some time parameters and trigger when the system

time fulfills some of the parameters. Use “.” on the numeric keyboard to set the

parameters to be ignored and the corresponding position will display “**”. For

example, to set the instrument to ignore the “Month” and “Date” and trigger at 8:00

every day, use the numeric keyboard to set the absolute time to “**-** 08:00:00”.

When parameters in “Month-Date Hour:Minute:Second” are all ignored, it is similar

to auto trigger mode.

In absolute time trigger mode, if the number of scans is set to “Infinite”, a fter you

press Run/Stop at the front panel, the instrument enters the wait-for-trigger state

and then executes a scan each time the system time reaches the specified time.

Press and hold Run/Stop and the instrument will exit the wait-for-trigger state.

If the number of scans is a specific value, after you press Run/Stop at the front

panel, the instrument enters the w ait-for-trigger state and then executes a scan each

time the system time reaches the specif ied time. After executing the specified

number of absolute time triggers, the instrument exits the wait-for-trigger state.

During the scan, the instrument stores the measurement data, scaling data and

alarm data in the non-volatile memory automatically.

2-10 M300 User’s Guide

Chapter 2 Front Panel Operations RIGOL

2-11

Explanation:

Alarm Trigger

To use the alarm trigger mode, configure the alarm by referring to “Alarm

Configuration” and select alarm trigger mode , then select an alarm channel. The

instrument executes a scan when an alarm is generated in the specified alarm

channel.

In alarm trigger mode, if the number of scans is set to “Infinite”, after you press

Run/Stop at the front panel, the inst ru ment enters the wait-for-trigger state. Then

the instrument executes a scan when an alarm is generated in the specified alarm

channel. Press and hold Run/Stop and the instrument will exit the wait-for-trigger

state.

If the number of scans is a specific value, after you press Run/Stop at the front

panel, the instru ment enters the wait -for-trigger state. Then the i nstrument executes

a scan when an alarm is generated in the specified alarm channel. After executing

the specified number of alarm triggers, the instrument exits the wait-for-trigger

state.

During the scan, the instrument stores the measurement data, scaling data and

alarm data in the non-volatile memory automatically.

The instrument triggers a scan when the trigger condition is met and scans the

channels in the scan list in ascending order (from slot 1 to slot 5) automatically.