RIGOL

Performance Verification Guide

DSG800 Series

RF Signal Generator

Aug. 2015

RIGOL Technologies, Inc.

RIGOL

Guaranty and Declaration

Copyright

© 2015 RIGOL Technologies, Inc. All Rights Reserved.

Trademark Information

RIGOL is a registered trademark of RIGOL Technologies, Inc.

Publication Number

PVG02100-1110

Notices

RIGOL products are covered by P.R.C. and foreign patents, issued and pending.

RIGOL reserves the right to modify or change parts of or all the specifications and pricin g

policies at company’s sole decision.

Information in this publication replaces all previously corresponding material.

Information in this publication is subject to change without notice.

RIGOL shall not be liable for either incidental or consequential losses in connection with the

furnishing, use or performance of this manual as well as any information contained.

Any part of this document is forbidden to be copied, ph ot ocopied or rearranged without prior

written approval of RIGOL.

Product Certification

RIGOL guar antees this pr oduct confo rms t o the nati onal an d indust rial stan dar ds in China as well

as the ISO9001:2008 standard and the ISO14001:2004 standard. Other international standard

conformance certification is in progress.

Contact Us

If yo u have any problem or requirement when using o ur prod uct s or this manual, please contact

RIGOL.

E-mail: service@rigol.com

Website: www.rigol.com

DSG800 Performance V e rification Guide I

RIGOL

General Safety Summary

Please review the following safety precautions carefully before putting the instrument into

operation so as to avoid any personal injury or damage to the instrument and any product

connected to it. To prevent potential hazards, please use the instrument only specified by this

manual.

Use Proper Power Cord.

Only the power cord designed for the instrument and authorized for use within the local country

could be used.

Ground the Instrument.

The instrument is grounded through the Protective Earth lead of the power cord. To avoid electric

shock, it is essential to connect the earth terminal of the power cord to the Protective Earth

terminal before connecting any inputs or outputs.

Connect the Probe Correctly.

If a probe is used, do not connect the ground lead to high vol t age since it has isobaric electric

potential as the ground.

Observe All Terminal Ratings.

To avoid fi re or shock hazard, observe all ratings and markers on the instrument and check your

manual for more information about ratings before connecting the instrument.

Use Proper Overvoltage Protection.

Make sure that no overvoltage (such as that caused by a thunderstorm) can reach the product, or

else the operator might be exposed to the danger of electrical shock.

Do Not Operate Without Covers.

Do not operate the instrument with covers or panels rem o v ed.

Do Not Insert Anything Into the Holes of Fan.

Do not insert anything into the holes of the fan to avoid damaging the instrument.

Use Proper Fuse.

Please use the specified fuses.

Avoid Circuit or Wire Exposure.

Do not touch exposed junctions and components when the unit is powered.

Do Not Operate With Suspected Failures.

If you suspect damage occurs to the instrument, have it inspected by RIGOL authorized pe rson ne l

before furth er operations. Any maintenance, adjustment or replacement especially to circuits or

II DSG800 Performance Verification Guide

RIGOL

III

accessories must be performed by RIGOL authorized personnel.

Keep Well Ventilation.

Inadequate ventilation may cause an increase of instrument temperature which would cause

damag e to the instrument. So please keep the instrument well ventilated and inspect the intake

and fan regularly.

Do Not Operate in Wet Conditions.

In order to avoid short circuiting to the interior of the device or electric shock, please do not

operate the instrument in a humid environment.

Do Not Operate in an Explosive Atmosphere.

In order to avoid damage to the device or personal injuries, it is important to operate the device

away fro m an explosive atmosphere.

Keep Product Surfaces Clean and Dry.

To avoid the influence of dust and/or moisture in the air, please keep the surface of the device

clean and dry.

Electrostatic Prevention.

Operate the instrument in an electrostatic discharge protective environment to avoid damage

induced by static dischar ges. Alw ays ground both th e internal an d external condu ctors of cabl es to

release static before making connections.

Proper Use of Battery.

If a battery is suppli ed, it mus t not be ex pos ed to high temperature or in contact with fire. Keep it

out of the reach of children. Improper change of battery (note: lithium battery) may cause

explosion. Use RIGOL specified ba tte ry only.

Handling Safety.

Please handle with care during transportation to avoid da ma ge to keys, knob interfaces and other

parts on the panels.

DSG800 Performance V e rification Guide

RIGOL

Warning state ments indica te con ditions or p r acti ces that coul d result in i njury or l oss of

DANGER

WARNING

Hazardous

Safety

Protective

Terminal

Chassis

Test

Safety Terms and Symbols

Terms Used in this Manual. These terms may appear in this manual:

WARNING

life.

CAUTION

Caution statements indicate conditions or practices that could result in damage to this

product or other pro perty.

Terms Used on the Product. These terms may appear on the product:

It calls attention to an operation, if not correctly performe d, could result in injury or

hazard immediately.

It calls attention to an operation, if not correctly perf ormed, could result in potential

injury or hazard.

CAUTION It calls attention to an o per ation, if not corre ctly pe rformed, could result in

to the product or other devices connected to the product.

Symbols Used on the Product. These symbols may appear on the product:

damage

Voltage

Warning

Earth

Ground

Ground

IV DSG800 Performance Verification Guide

RIGOL

V

Allgemeine Sicherheits Informationen

Überprüfen Sie diefolgenden Sicherheitshinweise sorgfältigumPersonenschädenoderSchäden am

Gerätundan damit verbundenen weiteren Gerätenzu vermeiden. Zur Vermeidung vonGefahren,

nutzen Sie bitte das Gerät nur so, wiein diesem Handbuchangegeben.

Um Feuer oder Verletzungen zu vermeiden, verwenden Sie ein ordnungsgemäßes

Netzkabel.

Verwenden Sie für dieses Gerät nur das für ihr Land zugelass ene u nd genehm igte Net zkabel .

Erden des Gerätes.

Das Gerät ist durch den Schutzleiter im Netzkabel geerdet. Um Gefahren durch ele ktrischen Schlag

zu vermeiden, ist es unerlässlich, die Erdung durchzuführen. Erst dann dürfen weitere Ein- oder

Ausgänge verbunden werden.

Anschluss einesTastkopfes.

Die Erdungsklemmen der Sonden sindauf dem gleichen Spannungspegel des Instruments gee rdet.

SchließenSie die Erdungsklemmen an keine hohe Spannung an.

Beachten Sie alle Anschlüsse.

Zur Vermeidung von Feuer oder Stromschlag, beachten Sie alle Bemerkungen und Markierungen

auf dem Instrument. Befolgen Sie die Bedienungsanleitung für weitere Informationen, bevor Sie

weitere Anschlüsse an das Instrument legen.

Verwenden Sie einen geeigneten Überspannungsschutz.

Stellen Sie sicher, daß keinerlei Überspannung (wie z.B. durch Gewitter verurs a cht) das Gerät

erreichen kann. Andernfallsbestehtfür den Anwender die GefahreinesStromschlages.

Nicht ohne Abdeckung einschalten.

Betreiben Sie das Gerät nicht mit entfernten Gehäuse-Abdeckungen.

Betreiben Sie das Gerät nicht geöffnet.

Der Betrieb mit offenen oder entfernten Gehäuseteilen ist nicht zulässig. Nichts in entsprechende

Öffnungen stecken (Lüfter z.B.)

Passende Sicherung verwenden.

Setzen Sie nur die spezifikationsgemäßen Sicherungen ein.

Vermeiden Sie ungeschützte Verbindungen.

Berühren Sie keine unisolierten Verbindun gen oder Baugruppen, während das Gerät in Betrieb ist.

Betreiben Sie das Gerät nicht im Fehlerfall.

Wenn Sie am Gerät einen Defekt vermuten, sorgen Sie dafür, bevor Sie das Gerät wieder betreiben,

DSG800 Performance V e rification Guide

RIGOL

dass eine Untersuchung durch RIGOL autorisiertem Personal durchgeführt wird. Jedwede

Wartung, Einstellarbeiten oder Austausch von Teilen am Gerät, sowie am Zubehör dürfen nur von

RIGOL autorisiertem Personal durchgeführt werden.

Belüftung sicherstellen.

Unzureichende Belüftung kann zu Temp eraturanstiegen und somit zu thermischen Schäden am

Gerät führen. Stellen Sie deswegen die Belüftung sicher und kontrollieren regelmäßig Lüfter und

Belüftungsöffnungen.

Nicht in feuc h te r Um g ebung betreiben.

Zur Vermeidung von Kurzschluß im Geräteinneren und Stromschlag betreiben Sie das Gerät bitte

niemals in feuchter Umgebung.

Nicht in explosiver Atmosphäre betreiben.

Zur Ve rm e idung von Pe rs onen- und Sachschäden ist es unumgänglich, das Gerät ausschließlich

fernab jedweder explosiven Atmosphäre zu betreiben.

Geräteoberflächen sauber und trocken halten.

Um den Einfluß von Staub und Feuchtigkeit aus der Luft auszuschließen, halten Sie bitte die

Geräteoberflächen sauber und trocken.

Schutz gegen elektrostatische Entladung (ESD).

Sorgen Sie für eine elektrostatisch geschützte Umgebung, um somit Schäden und

Funktionsstörungen durch ESD zu vermeiden. Erden Sie vor dem Anschluß immer Innen- und

Außenleiter der Verbindungsleitung, um statische Aufladung zu entladen.

Die richtige Verwendung desAkku.

Wenneine Batterieverwendet wird, vermeiden Sie hohe Temperaturen bzw. Feuer ausgesetzt

werden. Bewahren Sie es außerhalbder Reichweit ev on Kin dern auf. UnsachgemäßeÄnderung

derBatterie (Anmerkung: Lithium-Batterie) kann zu einer Explosion führen. VerwendenSie nur von

RIGOL angegebenenAkkus.

Sicherer Transport.

Transportieren Sie das Gerät sorgfälti g (Verpackung!), um Schäden an Bedienelementen,

Anschlüssen und anderen Teilen zu vermeiden.

VI DSG800 Performance Verification Guide

RIGOL

VII

DANGER

Sicherheits Begriffe und Symbole

Begriffe in diesem Guide. Diese Begriffe können in diesem Handbuch auftauchen:

WARNING

Die Kennzeichnung WARNING beschreibt Gefahrenquellen die leibliche Schäden oder

den Tod von Personen zur Folge haben können.

CAUTION

Die Kennzeichnung Caution (Vorsicht) beschreibt Gefahrenquellen die Schäden am

Gerät hervorru fen können.

Begriffe auf dem Produkt. Diese Bedingungen können auf dem Produkt erscheinen:

weist auf eine Verletzung oder Gefährdung hin, die sofort geschehen kann.

WARNING weist auf eine Verletzung ode r Gefäh r dun g hin, die mögliche rweise nicht sofort

geschehen.

CAUTION weist auf eine Verletzung oder Gefährdung hin und bedeutet, dass eine mögliche

Beschädigung des Instruments oder anderer Gegenstände auftreten kann.

Symbole auf dem Produkt. Diese Symbole können auf dem Produkt erscheinen:

Gefährliche

Spannung

SicherheitsHinweis

Schutz-erde Gehäusemasse Erde

DSG800 Performance V e rification Guide

RIGOL

Document Overview

This manual guides users to correctly test the performance specifications of RIGOL DSG800

series RF signal generator. For the operation methods of the instrument mentioned in this manual ,

please refer to

DSG800 User’s Guide

Main Contents in this Manual:

Chapter 1 Overview

This chapter introduces the preparations and precautions of the performance verific ation test.

Chapter 2 Performance Verification Test

This chapter introduces the limit, test devices, test method and test procedures o f ea ch

performance specification.

Appendix Test Record Form

In the appendix, a test record form is provided for recording the test results so as to determine

whether each performance specification fulfills the requirement.

Format Conventions in this Manual:

Front panel key: denoted by the format of "Text Box + Key Name (Bold)". For example, Syst.

Menu softkey: denoted by the format of "Character Shading + Menu Word (Bold)". For example,

Information.

Operation step: denoted by an arrow "". For example, Syst Information.

Connector: denoted by t he format of " Square Brackets + Connector Name (Bold)". For example,

[RF OUTPUT 50Ω].

.

VIII DSG800 Performance Verification Guide

Contents RIGOL

IX

Contents

Guaranty and Declaration .............................................................................................. I

General Safe ty Summary ............................................................................................. II

Safety Terms and Symbols .......................................................................................... IV

Allgemeine Sicherheits Informationen ...............................................................................V

Sicherheits Begriffe und Symbole................................................................................... VII

Document Overview ................................................................................................. VIII

Chapter 1 Overview ................................................................................................ 1-1

Test Prep ar a tions ......................................................................................................... 1-1

Test Res ult Record ....................................................................................................... 1-2

Specifications .............................................................................................................. 1-2

Chapter 2 Performance Verification Test ................................................................. 2-1

Amplitude Accuracy Test ............................................................................................... 2-2

Specifications ........................................................................................................ 2-2

Test Devices ......................................................................................................... 2-2

Test Connection Diagram ....................................................................................... 2-2

Test Procedures..................................................................................................... 2-2

Test Record Form .................................................................................................. 2-5

Single-sideband Phase Noise Test .................................................................................. 2-7

Specifications ........................................................................................................ 2-7

Test Devices ......................................................................................................... 2-7

Test Connection Diagram ....................................................................................... 2-7

Test Procedures..................................................................................................... 2-7

Test Record Form .................................................................................................. 2-8

Second Harmonic Distortion Test ................................................................................... 2-9

Specification ......................................................................................................... 2-9

Test Devices ......................................................................................................... 2-9

Test Connection Diagram ....................................................................................... 2-9

Test Procedures..................................................................................................... 2-9

Test Record Form ................................................................................................ 2-10

AM Test .................................................................................................................... 2-12

Specifications ...................................................................................................... 2-12

Test Devices ....................................................................................................... 2-12

Test Connection Diagram ..................................................................................... 2-12

Test Procedures................................................................................................... 2-12

Test Record Form ................................................................................................ 2-13

FM Test ..................................................................................................................... 2-14

Specifications ...................................................................................................... 2-14

Test Devices ....................................................................................................... 2-14

Test Connection Diagram ..................................................................................... 2-14

DSG800 Performance V e rification Guide

RIGOL Contents

Test Procedures .................................................................................................. 2-14

Test Record Form ................................................................................................ 2-15

ØM Test .................................................................................................................... 2-16

Specifications ..................................................................................................... 2-16

Test Devices ....................................................................................................... 2-16

Test Connection Diagram ..................................................................................... 2-16

Test Procedures .................................................................................................. 2-16

Test Record Form ................................................................................................ 2-17

Pulse Modulation Test ................................................................................................ 2-18

Specification ....................................................................................................... 2-18

Test Devices ....................................................................................................... 2-18

Test Connection Diagram ..................................................................................... 2-18

Test Procedures .................................................................................................. 2-18

Test Record Form ................................................................................................ 2-19

10 MHz Reference Input A mplitude R ange Test ............................................................. 2-20

Specification ....................................................................................................... 2-20

Test Devices ....................................................................................................... 2-20

Test Connection Diagram ..................................................................................... 2-20

Test Procedures .................................................................................................. 2-20

Test Record Form ................................................................................................ 2-21

Appendix Test Record Form .......................................................................................... 1

X DSG800 Performance Verification Guide

Chapter 1 Overview RIGOL

1-1

Chapter 1 Overview

Test Preparations

Before perfo rm ing the test, make the following preparatio ns .

1. The RF signal generator is stored for at least two hours under a temperat u re of 0℃ to 50℃

and is warmed up for 40 minutes.

2. Make sure that the instrument is within the calibration period (1 year).

3. The test devices required should fulfill the requirements of the "Specification" column in Table

1-1. You can also use the recommended models in the following table for the test.

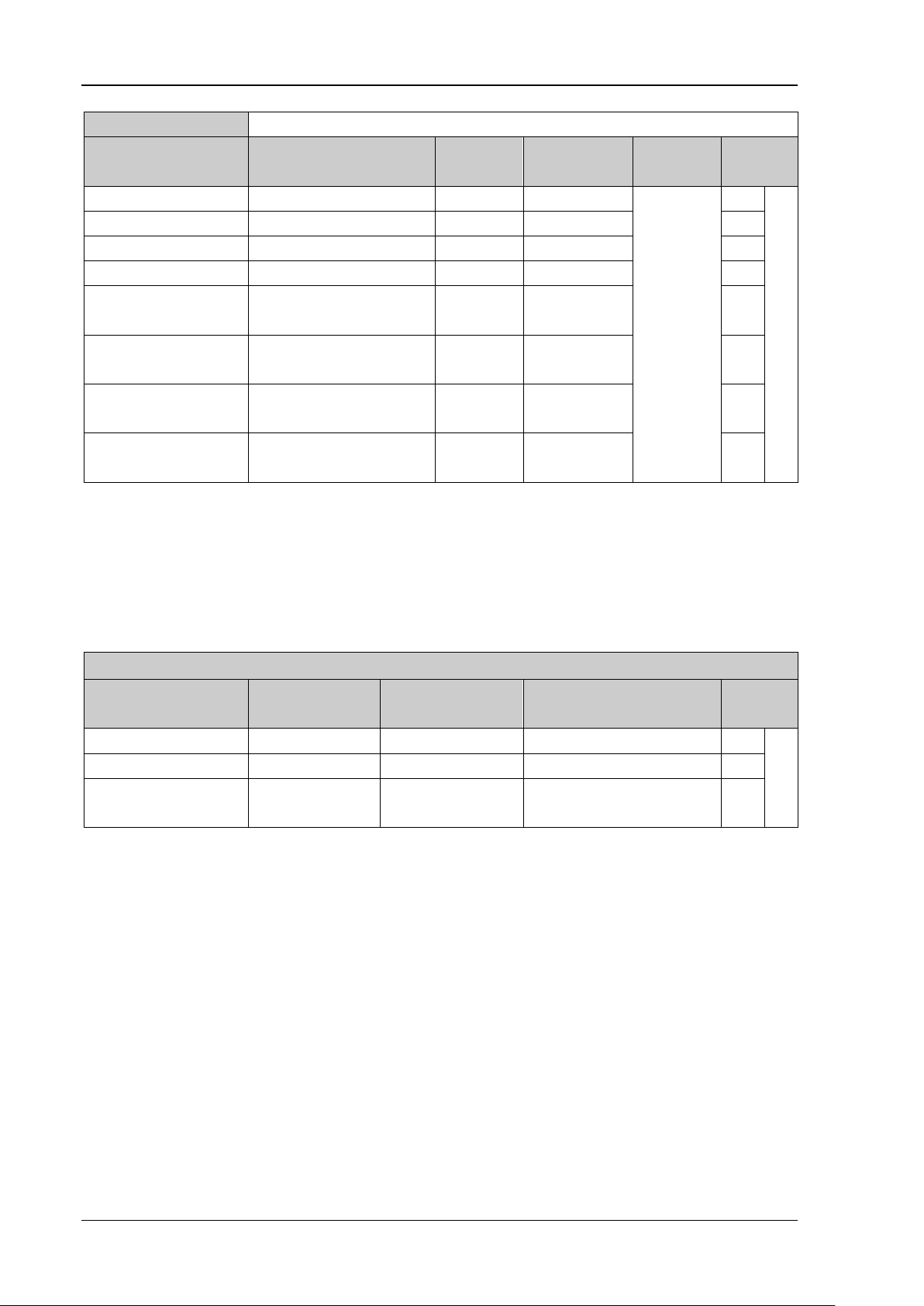

Table 1-1 Test Devices Required

Device Specification Qty. Recommended

Total amplitude uncertainty: ±0.19 dB

Signal Analyzer

Spectrum Analyzer

(Optional)

Signal Analyzer

(Optional)

Power Meter and

Power Sensor

Function/Arbitrary

Waveform Generator

Dual-N Cable

Dual-BNC Cable BNC (male)-BNC (male) cable 2

N-BNC Cable N (male)-BNC (male) cable 1

Note: [1] This signal analyzer can be used in place of the Agilent E4440A spectrum analyzer plus the N9000A

signal analyzer.

[1]

Option: analog modulation and demodulation, phase noise

test

Total amplitude uncertainty: ±0.24 dB 1 Agilent E4440A

Frequency range: 9 kHz to 7.5 GHz

Option: analog modulation and demodulation

Resolution: 0.001 dB

Reference accuracy: ±1.2%

Frequency range: 9 kHz to 18 GHz

Max. SWR:

1.13 (9 kHz to 2 GHz)

1.19 (2 GHz to 14 GHz)

1.22 (14 GHz to 16 GHz)

1.26 (16 GHz to 18 GHz)

Amplitude range: 1 nW to 100 mW (-60 dBm to +20 dBm)

Max. output frequency: > 1 MHz

Flatness (< 1 MHz): ±0.3 dB

Amplitude accuracy (the amplitude is 2 Vpp): < ±30 mV

N (male)-N (male) cable

Frequency range: DC to 6 GHz

SWR: < 1.1

Insertion loss: < 1 dB

1 Agilent N9030A

1 Agilent N9000A

Agilent N1913A

1

1

1

and Agilent

E9304A

RIGOL DG4162 or

DG4062

--

--

--

DSG800 Performance V e rification Guide

RIGOL Chapter 1 Overview

Tip:

Test Result Record

Record and keep the test result of each test. In the Appendix of this manual, a test result record

form which lists all the test items and their corresponding performance specification limits as well

as spaces for users to record the test results, is provided.

Tip:

It is recommended that users photocopy the test record form before each test and record the test

results in the copy so that the form can be used repeatedly.

Specifications

The specification of each test item is provided in chapter 2. For other specif ications, refer to

DSG800 User’s Guide

or

DSG800 Data Sheet

(can be downloaded from www.rigol.com).

All the specifications are only valid when the instrument has been warmed up for more than 40

minutes.

1-2 DSG800 Performance Verification Guide

Chapter 2 Performance Verification T est RIGOL

Chapter 2 Performance Verification Test

This chapter introduces the performance verification test methods and procedure s of DSG800

series RF signal generator.

Note:

1) Make sure that the instrument has been warmed up for at least 40 minutes before executing

any of the following test items.

2) Reset the instrument to the factory setting before or after executing any of the following test

items.

3) The definitions of "Typical Value", "Nominal Value" and "Measured value" for this product.

Typical (typ .): the typical performance that 80 percent of the measurement results can

meet at roo m temperature (approximately 25℃). This data is not warranted and does not

include the measurement uncertainty.

Nominal (nom.): the expected ave r age performan ce or the designed per formance

attribute (fo r examp le, the 50 Ω connector). This data is not warranted and is measured

at room temperature (approximately 25℃).

Measured (meas.): the performance attribute measured during the design phase and

used to be compared with the expected performance (for example, the variation of the

amplitude drift with time). This data is not warranted and is measured at room

temperature (approximately 25℃).

DSG800 Performance V e rification Guide 2-1

RIGOL Chapter 2 Performance Verification Test

(a)

(b)

N9030A

Dual-N Cable

Dual-BNC Cable

RF IN

RF OUT

RF OUT

N1913A

E9304A

10MHz OUT

EXT REF IN

DSG800

DSG800

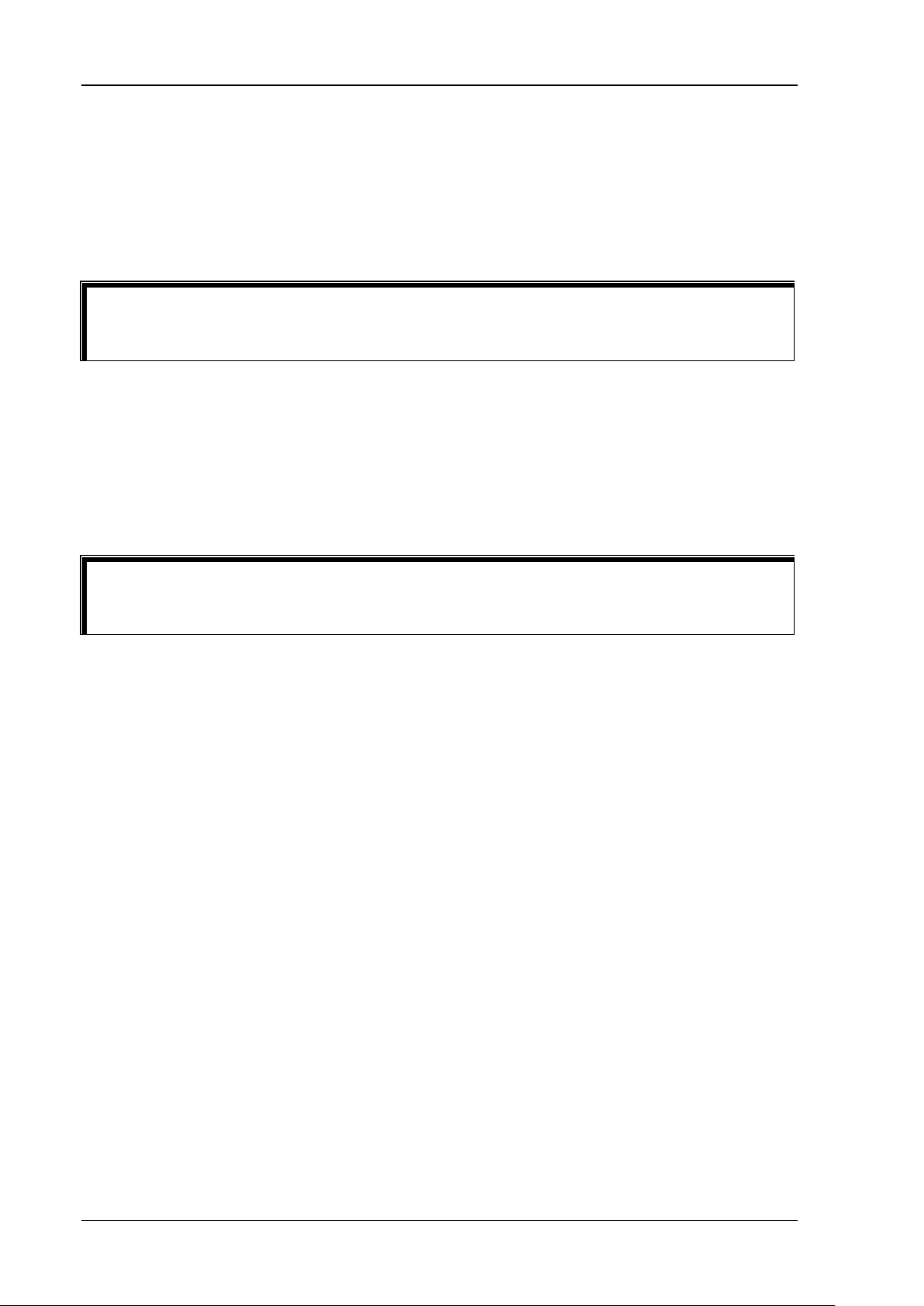

Amplitude Accuracy Test

Specifications

Absolute Level Uncertainty

Temperature range: 20℃ to 30℃

100 kHz ≤ f ≤ 3 GHz

+13 dBm to -60 dBm

≤ 0.9 dB,

≤ 0.5 (typ.)

Test Devices

1. Power Meter and Power Sensor × 1

2. Dual-N Cable × 1

3. Dual-BNC Cable × 1

4. Signal Analyzer × 1

Test Connection Di ag ram

-60 dBm to -110 dBm

≤ 1.1 dB,

≤ 0.7 (typ.)

Figure 2-1 Amplitude Accuracy Test Connection Diagram

Test Procedures

1. Calibrate the power meter:

a) Connect the power sensor with the [REF] terminal and channel A of the pow er meter.

Press Channel and set the frequency of channel A to 50 MHz.

b) Press Cal and enable Power Ref in the Zero/Cal menu. Press Zero+Cal and wait for

2-2 DSG800 Performance Verification Guide

Chapter 2 Performance Verification T est RIGOL

2-3

the calibration to finish; then, observe whether the measurement value of the power

meter i s a 0 dB m , 50 MHz signa l.

c) Disable Power Ref.

2. Connect th e output terminal of DSG800 with the power sensor, as shown in Figure 2-1 (a).

3. Set DSG800 to output a sine waveform with -10 dBm amplitude. Then, modify the output

frequency of DSG800 accordin g to Table 2-1

and turn on the RF output switch RF/on.

Table 2-1 Output Frequency of DS G800

Model Output Frequency

DSG830 103 kHz 1.03 MHz 50.03 MHz 503 MHz 1.903 GHz 2.493 GHz 2.903 GHz

DSG815 103 kHz 1.03 MHz 50.03 MHz 503 MHz 1.403 GHz

Note: When the frequency of the signal measured is less than 10 MHz, you need to switch t he

signal analyzer to DC coupling mode to ensure the measurement accuracy.

4. Modify the frequency of the power meter accordingly each time the output frequency of

DSG800 is modif ie d. Read the amplitude measurement value A1 and record it to the Test

Record Form.

5. Disconnect DSG800 and the power meter. Connect the [10MHz OUT] terminal of DSG800

with the [EXT REF IN] terminal at the rear panel of the signal analyzer using a dual-BNC

cable to synchronize the two instruments.

6. Connect the output terminal of DSG800 with the input terminal of the signal analyzer using a

dual-N cable as shown in Figure 2-1 (b)

.

7. Configure the signal analyzer:

a) Set the frequency reference inp ut to exter na l.

b) Set the span to 1 MHz.

c) Set the reference level to 0 dBm.

d) Set the input attenuation to 10 dB.

e) Set the resolution bandwidth to 10 kHz.

f) Set the sweep time to auto and the sweep time method to accurate.

g) Set the self-calibratio n t o normal and perform all of the calibration items.

8. Set the output frequency of DSG800 and the center frequency of the si gnal analyzer accordin g

to Table 2-1 (the center frequency of the signal analyzer corresponds to output frequency of

DSG800).

9. Each time the center frequency is changed, press Single, wait for the instrument to finish a

sweep and press Peak Search to find the maximum peak. Then, record the result A2 to the

Test Record Form.

DSG800 Performance V e rification Guide

RIGOL Chapter 2 Performance Verification Test

10. Calculate the System Error (the input at tenuation of the s ignal a nalyzer is 10 dB) = A2 - A1

and record the result.

11. Keep the connections shown in Figure 2-1

(b) unchanged, press Mode Preset to restore the

signal analyzer to its factory setting and set the output amplitude of DSG800 according to

Table 2-2.

Table 2-2 Output Amplitude of DSG800

Output Amplitude

-10 dBm

-80 dBm

Note: Here, the output amplitude of DSG800 is used a s the amplitude Reference Value.

Different output amplitudes correspond to different reference values.

12. Each time the output amplitude o f DSG800 is cha nged, modify the configurations of the signal

analyzer accordingly.

a) Set the frequency reference input to external.

b) Set the span to 100 Hz.

c) Set the reference level to -20 dBm.

d) Set the input attenuation to 10 dB.

e) Set the resolution bandwidth to 1 Hz.

f) Set the sweep time method to accurate.

g) Set the self-calibration to normal and perform all of the calibration items.

13. Set the output frequency of DSG800 and the cent er frequency of the signal anal yzer accordin g

to Table 2-1 (the center frequency of the signal analyzer corresponds to output frequency of

DSG800).

14. Each time the center frequency is changed, press Single and wait for the inst rument to finish

a sweep; then, press Peak Search to find the maximum peak and record the measurement

result A3 to the Test Record Form.

15. Calculate the Global Error = A3 - Reference Value and recor d the result .

16. Calculate the Amplitude Accuracy = |Global Error - System Error| and compare the

measurement result with the specification.

2-4 DSG800 Performance Verification Guide

Chapter 2 Performance Verification T est RIGOL

2-5

Test Record Form

DSG800 Output

Frequency

103 kHz

1.03 MHz

50.03 MHz

503 MHz

1.403 GHz (Only for

DSG815)

1.903 GHz (Only for

DSG830)

2.493 GHz (Only for

DSG830)

2.903 GHz (Only for

DSG830)

Power Meter

Measurement Value A1

Signal Analyzer

Measurement Value A2

System Error

Reference Value -10 dBm

DSG800 Output

Frequency

103 kHz

1.03 MHz

50.03 MHz

503 MHz

1.403 GHz (Only for

DSG815)

1.903 GHz (Only for

DSG830)

2.493 GHz (Only for

DSG830)

2.903 GHz (Only for

DSG830)

Signal Analyzer

Measurement Value A3

Global

[2]

Error

Amplitude

Accuracy

[3]

Limit

≤ 0.9 dB,

≤ 0.5 (typ.)

[1]

Pass/

Fail

DSG800 Performance V e rification Guide

RIGOL Chapter 2 Performance Verification Test

Reference Value -80 dBm

DSG800 Output

Frequency

103 kHz

Signal Analyzer

Measurement Value A3

Global

[2]

Error

Amplitude

Accuracy

[3]

Limit

Pass/

Fail

1.03 MHz

50.03 MHz

503 MHz

1.403 GHz (Only for

DSG815)

1.903 GHz (Only for

DSG830)

2.493 GHz (Only for

DSG830)

2.903 GHz (Only for

DSG830)

≤ 1.1 dB,

≤ 0.7 (typ.)

Note:

[1] System Error = A2 - A1

[2] Global Error = A3 - Reference Value

[3] Amplitude Accuracy = |Global Error - System Error|

2-6 DSG800 Performance Verification Guide

Chapter 2 Performance Verification T est RIGOL

2-7

Dual

-N Cable

Dual-BNC Cable

RF IN

RF OUT

10MHz OUT

EXT REF IN

DSG800

N9030A

Single-sideband Phase Noise Test

Specifications

Single-sideband Phase No i se

Carrier Offset

20 kHz 100 MHz < -100 dBc/Hz < -100 dBc/Hz

Frequency DSG815 DSG830

1 GHz < -100 dBc/Hz < -100 dBc/Hz

3 GHz -- < -94 dBc/Hz

Test Devices

1. Signal Analyzer × 1

2. Dual-N Cable × 1

3. Dual-BNC Cable × 1

Test Connection Di ag ram

Figure 2-2 Single-sideband Ph a s e Noise Test Connection Diagram

Test Procedures

1. Connect the [10MHz OUT] terminal of DSG800 with the [EXT REF IN] terminal at the rear

panel of the signal analyzer using a dual-BNC cable to synchronize the two instruments, as

shown in Figure 2-2.

2. Connect the RF output terminal of DSG800 with the RF input terminal of the signal analyzer.

3. Set DSG800 to output a sine waveform with 1 GHz frequency and 0 dBm amplitude. Then,

turn on the RF output switch RF/on.

4. Configure the signal analyzer:

a) S et the freque ncy reference input to external.

DSG800 Performance V e rification Guide

RIGOL Chapter 2 Performance Verification Test

b) Set the center frequency to 1 GHz.

c) Set the span to 50 kHz.

d) Set the resolution bandwidth to 1 kHz.

e) Set the video bandwidth to 3 Hz.

f) Set the reference level to 0 dBm.

g) Set the input attenuation to 10 dB.

h) Set the trace type to clear write.

i) Set the detector type to RMS average.

j) Set the sweep time to auto and the sweep time method to accurate.

5. Press Single, wait for the instrument to finish a sweep and press Peak Search to find the

maximum peak.

6. Press Marker Delta input 20 kHz. Press Single and wait for the i nstrument to finish a

sweep. Press Marker Function Marker Noise, read the current measurement result and

record it to the Test Record Form.

7. Press Mode Preset to reset the signal analyzer to the factory setting. Set the output

frequency of DSG800 according to Table 2-3, repeat steps 4 to 6 (note that modify the center

frequency of the signal analyzer accordingly in step 4 each t ime the output frequency of

DSG800 is modified) and record the result.

Table 2-3 Output Frequency of DSG800

Output Frequency

100 MHz 3 GHz (Only for DSG830)

8. Compare the measurement result with the specific ation.

Test Record Form

Single-sideband Phase No i se

DSG800 Output

Frequency

100 MHz Offset 20 kHz < -100 dBc/Hz

1 GHz Offset 20 kHz < -100 dBc/Hz

3 GHz (Only for

DSG830)

2-8 DSG800 Performance Verification Guide

Offset Measurement Value Limit Pass/Fail

Offset 20 kHz < -94 dBc/Hz

Chapter 2 Performance Verification T est RIGOL

2-9

Dual-N Cable

Dual-BNC Cable

RF IN

RF OUT

10MHz OUT

EXT REF IN

DSG800

N9030A

Second Harmonic Distortion Test

Specification

Second Harmonic Distortion

Model DSG815/DSG830

Specification < -30 dBc

Test Devices

1. Signal Analyzer × 1

2. Dual-BNC Cable

3. Dual-N Cable × 1

Test Connection Di ag ram

× 1

Figure 2-3 Second Harmonic Distortion Test Connection Diagram

Test Procedures

1. Synchronize DSG800 and the si gnal analyzer. Connect the RF output terminal of DSG800 with

the RF input terminal of the signal analyzer as shown in Figure 2-3.

2. Set the output frequency of DSG800 to F0 according to Table 2-4

Turn on the RF output swi t ch RF/on.

Table 2-4 Output Frequency of DS G800

Output Frequency (F0)

10 MHz 100 MHz 500 MHz 1.5 GHz 2 GHz (Only for DSG830)

3. Configure the signal analyzer:

a) Set the center frequency to the output frequency of DSG800.

b) Set the span to 10 kHz.

and the amplitude to 0 dBm.

DSG800 Performance V e rification Guide

RIGOL Chapter 2 Performance Verification Test

c) Set the reference level to 10 dBm.

d) Set the input attenuation to 20 dB.

e) Set the resolution bandwidth to 30 Hz.

f) Set the video bandwidth to 10 Hz.

g) Set the sweep time method to accurate.

Note: Modify the center frequency of the signal analyzer accordingly each time the output

frequency of DSG800 is changed (the center frequency of the signal analyzer corresponds to

output frequency of DSG800).

4. Press Single and wait for the instrument to finish a sweep; press Peak Search to f ind the

maximum peak. Then, press Marker Delta to set the cursor type to Delta. Set the center

frequency to 2 × F0, press Single and wait for the i nstrument to finish a sweep; press Peak

Search and record the delta result A1.

5. Calculate the Second Harmonic Distortion = Delta A1 and compare the calculation result

with the specification.

6. Press Mode Preset to reset the signal analyzer to the factory setting. Set the output

amplit ude of DSG800 in step 2 to 10 dBm.

7. Configure the signal analyzer: set the input at tenuation to 30 dB, set the refe rence level to 20

dBm and the settings of the other parameters are the same with those in step 3.

8. Repeat steps 2 to 5 to measure the second harmo nic distortion when the out put amplitude o f

DSG800 is 10 dBm and record the result.

Test Record Form

DSG800 Output

Amplitude

DSG800 Output

Frequency

10 MHz

100 MHz

500 MHz

1.5 GHz

2 GHz (Only for

DSG830)

2-10 DSG800 Performance Verification Guide

0 dBm

Delta A1

Calculation

[1]

Result

Limit Pass/Fail

< -30 dBc

Chapter 2 Performance Verification T est RIGOL

2-11

DSG800 Output

Amplitude

DSG800 Output

Frequency

10 MHz

100 MHz

500 MHz

1.5 GHz

2 GHz (Only for

DSG830)

Note: [1] Calculation Result = Delta A1

10 dBm

Delta A1

Calculation

[1]

Result

Limit Pass/Fail

< -30 dBc

DSG800 Performance V e rification Guide

RIGOL Chapter 2 Performance Verification Test

Dual-N Cable

Dual-BNC Cable

RF IN

RF OUT

10MHz OUT

EXT REF IN

DSG800

N9030A

AM Test

Specifications

AM

Model DSG815/DSG830

Item Condition Specification

Modulation

Accuracy

Distortion f

Note: [1] m represents the AM depth.

Test Devices

1. Signal Analyzer × 1

2. Dual-BNC Cable

3. Dual-N Cable × 1

f

= 1 kHz < Modulation depth setting × 4% + 1%

mod

= 1 kHz, m

mod

× 1

[1]

< 30%, level = 0 dBm < 3% (typ.)

Test Connection Diagram

Figure 2-4 AM Test Connection Diagram

Test Procedures

1. Synchronize DSG800 and the si gnal analyzer. Connect the RF output terminal of DSG800 with

the RF input terminal of the signal analyzer as shown in Figure 2-4.

2. Configure DSG800:

a) S e t the fr eque ncy to 1 GHz.

b) Set the amplitude to -10 dBm.

c) Turn on the RF output switch RF/on.

d) Turn on the AM switch.

e) Set the modulation source to internal.

2-12 DSG800 Performance Verification Guide

Chapter 2 Performance Verification T est RIGOL

2-13

f) Set the modulation depth to 30%.

g) Set the modulation frequency to 1 kHz.

h) Set the modulation waveform to Sine.

i) Turn on the modulation output switch Mod/on.

3. Configure the signal analyzer:

a) Set the center frequency to 1 GHz.

b) Set the span to 10 kHz.

c) Set the reference level to 0 dBm.

d) Set the input attenuation to 10 dB.

e) Set the resolution bandwidth to 100 Hz.

f) Set the video bandwidth to 100 Hz.

g) Set the sweep time method to accurate.

h) Select AM analog demodulation.

4. Press Meas Setup Auto Scale on the signal analyzer and then read the results of the

demodulated signal in the AM analog demodulation test interface of the signal analyzer.

Record the measurement results of (Pk - Pk) / 2 and Distortion.

Note: (Pk - Pk) / 2 represents the peak of the l ow fre quency signal after AM demodulation.

5. Calculate the Modulation Accuracy = |(Pk - Pk) / 2 - 30%|, Distortion = Distortion

Value. Then, compare the calculation results with the specifications.

Test Record Form

DSG800 Output

Frequency

1 GHz

Note:

[1] Modulation Accuracy = |(Pk - Pk) / 2 - 30%|

[2] Distortion = Distortion Value in the AM Analog Demodulation Test Interface

Item

Modulation

Accuracy

Distortion

Measurement

Value

[1]

[2]

< 3% (typ.)

Calculation

Result

Limit

< Modulation Depth Setting

× 4% + 1%

Pass/

Fail

DSG800 Performance V e rification Guide

RIGOL Chapter 2 Performance Verification Test

Dual-N Cable

Dual-BNC Cable

RF IN

RF OUT

10MHz OUT

EXT REF IN

DSG800

N9030A

FM Test

Specifications

FM

Model DSG815/DSG830

Item Condition Specification

Modulation

Accuracy

Distortion f

Note: [1] The corresponding relations between the values of N and the frequency ranges are as shown in the table

below.

Frequency Range N

f < 227.5 MHz 0.25

227.5 MHz ≤ f < 455 MHz 0.125

455 MHz ≤ f < 910 MHz 0.25

910 MHz ≤ f < 1820 MHz 0.5

1820 MHz ≤ f ≤ 3000 MHz 1

f

= 1 kHz, internal modulation

mod

= 1 kHz, deviation = N

mod

[1]

× 50 kHz < 2% (typ.)

< Modulation frequency deviation setting ×

2% + 20 Hz

Test Devices

1. Signal Analyzer × 1

2. Dual-BNC Cable × 1

3. Dual-N Cable × 1

Test Connection Di ag ram

Figure 2-5 FM Test Connection Diagram

Test Procedures

1. Synchronize DSG800 and the si gnal analyzer. Connect the RF output terminal of DSG800 with

the RF input terminal of the signal analyzer as shown in Figure 2-5.

2-14 DSG800 Performance Verification Guide

Chapter 2 Performance Verification T est RIGOL

2-15

2. Configure DSG800:

a) S e t the fr eque ncy to 1 GHz.

b) Set the amplitude to -10 dBm.

c) Turn on the RF output switch RF/on.

d) Select FM modulation.

e) Turn on the FM switch.

f) Set the modulation source to internal.

g) Set the modulation frequency deviation to 50 kHz.

h) Set the modulation rate to 1 kHz.

i) Set the modulation waveform to Sine.

j) Turn on the modulation output switch Mod/on.

3. Configure the signal analyzer:

a) Set the center frequency to 1 GHz.

b) Set the span to 200 kHz.

c) Set the reference level to 0 dBm.

d) Set the input attenuation to 10 dB.

e) Set the resolution bandwidth to 1 kHz.

f) Set the video bandwidth to 1 kHz.

g) Set the sweep time method to accurate.

h) Select FM analog demodulation.

4. Press Meas Setup Auto Scale on the signal analyzer and read the results of the

demodulated signal in the FM analog demodulation test interface of the signal analyzer.

Record the measurement results of (Pk - Pk) / 2 and Distortion.

Note: (Pk - Pk) / 2 represents the peak of the low f requency si gnal a fter FM demo dulation.

5. Calculate the modulation accuracy and the distortion using the formulas: Modulation

Accuracy = |(Pk - Pk) / 2 - 50 kHz|, Distortion = Distortion Value. Then, comp ar e

the calculation results with the specifications.

Test Record Form

DSG800 Output

Frequency

1 GHz

Note:

[1] Modulation Accuracy = |(Pk - Pk) / 2 - 50 kHz|

[2] Distortion = Distortion Value in the FM Analog Demodulation Test Interface

DSG800 Performance V e rification Guide

Item

Modulation

Accuracy

Distortion

Measurement

Value

[1]

[2]

< 2% (typ.)

Calculation

Result

Limit

< Modulation Frequency

Deviation Setting × 2% + 20 Hz

Pass/

Fail

RIGOL Chapter 2 Performance Verification Test

Dual-N Cable

Dual-BNC Cable

RF IN

RF OUT

10MHz OUT

EXT REF IN

DSG800

N9030A

ØM Test

Specifications

ØM

Model DSG815/DSG830

Item Condition Specification

Modulation

Accuracy

Distortion f

Note: [1] For the values of N, please refer to the note of "Specifications" in "FM Test".

f

= 1 kHz, internal modulation

mod

= 1 kHz, deviation = N

mod

[1]

× 5 rad < 1% (typ.)

Test Devices

1. Signal Analyzer × 1

2. Dual-BNC Cable × 1

3. Dual-N Cable × 1

< Modulation phase deviation setting × 1% + 0.1

rad

Test Connection Di ag ram

Figure 2-6 ØM Test Connection Diagram

Test Procedures

1. Synchronize DSG800 and the si gnal analyzer. Connect the RF output terminal of DSG800 with

the RF input terminal of the signal analyzer as shown in Figure 2-6.

2. Configure DSG800:

a) S e t the fr eque ncy to 1 GHz.

b) Set the amplitude to -10 dBm.

c) Turn on the RF output switch RF/on.

d) Select ØM modulation.

e) Turn on the ØM switch.

2-16 DSG800 Performance Verification Guide

Chapter 2 Performance Verification T est RIGOL

2-17

f) Set the modulation source to internal.

g) Set the modulation phase deviation to 5 rad.

h) Set the modulation rate to 1 kHz.

i) Set the modulation waveform to Sine.

j) Turn on the modulation output switch Mod/on.

3. Configure the signal analyzer:

a) Set the center frequency to 1 GHz.

b) Set the span to 200 kHz.

c) Set the reference level to 0 dBm.

d) Set the input attenuation to 10 dB.

e) Set the resolution bandwidth to 1 kHz.

f) Set the video bandwidth to 1 kHz.

g) Set the sweep time method to accurate.

h) Select ØM analog demodulation.

4. Press Meas Setup Auto Scale on the signal analyzer and read the results of the

demodulated signal in the ØM analog demodulation test interface of the signal analyzer.

Record the measurement results of (Pk - Pk) / 2 and Distortion.

Note: (Pk - Pk) / 2 represents the peak of the low frequency signal after ØM demodulation.

5. Calculate the Modulation Accuracy = |(Pk - Pk) / 2 - 5 rad|, Distortion = Distortion

Value. Then, compare the calculation results with the specifications.

Test Record Form

DSG800 Output

Frequency

1 GHz

Note:

[1] Modulation Accuracy = |(Pk - Pk) / 2 - 5 rad|

[2] Distortion = Distortion Value in the ØM Analog Demodulation Test Interface

Item

Modulation

Accuracy

Distortion

Measurement

Value

[1]

[2]

< 1% (typ.)

Calculation

Result

Limit

< Modulation Phase Deviation

Setting × 1% + 0.1 rad

Pass/

Fail

DSG800 Performance V e rification Guide

RIGOL Chapter 2 Performance Verification Test

Dual-N Cable

Dual-BNC Cable

RF IN

RF OUT

10MHz OUT

EXT REF IN

DSG800

N9030A

Pulse Modulation Test

Specification

Pulse Modulation

Model DSG815/DSG830

Item

On/Off Ratio 100 kHz ≤ f < 3 GHz > 70 dB

Test Devices

1. Signal Analyzer × 1

2. Dual-BNC Cable × 1

3. Dual-N Cable × 1

Condition

Specification

Test Connection Di ag ram

Figure 2-7 Pulse Modulation Test Connection Diagram

Test Procedures

1. Synchronize DSG800 and the si gnal analyzer. Connect the RF output terminal of DSG800 with

the RF input terminal of the signal analyzer as shown in Figure 2-7.

2. Configure DSG800:

a) S e t the fr eque ncy to 1 GHz.

b) Set the amplitude to -10 dBm.

c) Turn on the RF output switch RF/on.

d) Turn on the pulse modulation switch.

e) Set the modulation source to internal.

f) Set the pulse mode to single.

g) Set the pulse period to 1 s.

h) Set the pulse width to 0.5 s.

2-18 DSG800 Performance Verification Guide

Chapter 2 Performance Verification T est RIGOL

2-19

i) Set the trigger mode to auto.

j) Turn on the modulation output switch Mod/on.

3. Configure the signal analyzer:

a) Set the center frequency to 1 GHz.

b) Set the span to 0 Hz.

c) Set the reference level to 0 dBm.

d) Set the input attenuation to 10 dB.

e) Set the resolution bandwidth to 100 Hz.

f) Set the video bandwidth to 100 kHz.

g) Set the sweep time to 2 s.

h) Set the sweep time method to accurate.

i) Set the trigger mode to video trigger.

4. Press Single and wait for the instrument to finish a sweep; press Peak Search to f ind the

maximum peak.

5. Press Marker Delta i nput 0.5 s; pr e ss Single and wait for the instrument to f i nish a

sweep. Read the current measurement result; calculate the On/Off Ra t io = -Delta and

compare the calculation result with the specification.

6. If the model of DSG800 under test is DSG830, press Mode Preset to reset the signal analyzer

to the factory setting. Set the frequency of DSG800 to 2 GHz (other parameters keep

unchanged); then, repeat steps 2 to 5. Record the measurement result and compare the

result with the specification.

Test Record Form

DSG800 Output

Frequency

1 GHz On/Off Ratio > 70 dB

2 GHz (Only for

DSG830)

Note: [1] Calculation Result = -Delta

Item

On/Off Ratio > 70 dB

Measurement

Value

Calculation

[1]

Result

Limit

Pass/

Fail

DSG800 Performance V e rification Guide

RIGOL Chapter 2 Performance Verification Test

10MHz OUT

DSG800

DG

4000

N9030A

CH1 CH2

10MHz IN

10MHz IN

RF IN

Dual-

BNC Cable

Dual-BNC Cable

N-BNC Cable

10 MHz Reference Input Amplitude Range Test

Specification

10 MHz Reference Input Amplitude Range

Specification 0 dBm to +10 dBm

Test Devices

1. Function/Arbitrary Waveform Generator × 1

2. Signal Analyzer × 1

3. Dual-BNC Cable × 2

4. N-BNC Cable × 1

Test Connection Di ag ram

Figure 2-8 10 MHz Reference Input Amplitude Range Test Connection Diagram

Test Procedures

1. Connect the [CH1] output terminal of the function/arbitrary waveform generator with the

[10MHz IN] input terminal of the signal analyzer. Set the signal analyzer to external

reference; set the frequency and amplitude of CH1 of the function/arbitrary waveform

generator to 10 MHz and +5 dBm respectively and turn on the output to synchronize the

function/arbitrary waveform generator and signal analyzer, as shown in Figure 2-8.

Note: The 10 MHz signal output from the function/arbitrary waveform generator must have

relatively higher accuracy (with lower than ±5 ppm deviation); otherwise, this specification

cannot be measured.

2-20 DSG800 Performance Verification Guide

Chapter 2 Performance Verification T est RIGOL

2-21

2. Connect the [CH2] output terminal of the function/arbitrary waveform generator with the

[10MHz IN] input terminal at the rear panel of D SG800. C onnect the [10MHz OUT] output

terminal of DSG800 with the [RF IN] terminal of the signal analyzer.

3. Set the frequency and amplitude of CH2 of the function/arbitrary waveform generator to 10

MHz and 0 dBm respectively and turn on the output.

4. Set the center frequency and span of the signal analyzer to 10 MHz and 1 kHz respectively.

Press Peak Search to read the frequency of the signal.

5. Set the amplitude of CH2 of the function/arbitrary waveform generator to gradually decrease

from 0 dBm and mo nitor the signal frequency measured by the signal analyzer; stop the

measurement when the frequency measured is not 10 MHz and record the current amplitude

A1 of CH2 of the function/arbitrary waveform generator.

6. Set the amplitude of CH2 of the function/arbitrary waveform generator to gradually increase

from 0 dBm and monitor the signal frequency measured by the signal analyzer; stop the

measurement when the frequency measured is not 10 MHz (note th at you also need to stop

the measurement if the frequency measured is still 10 MHz when the amplitude of CH2

increases to +15 dBm) and record the current amplitude A2 of CH2 of the function/arbitrary

waveform generator.

7. Record the result of (A1 to A2), namely the 10 MHz reference input amplitude range.

Compare the result with th e specification. If the amplitude range measure d includes the ra nge

required by the specification, the instrument passes the test.

Test Record Form

Amplitude Measurement

Value A1

0 dBm to +10 dBm

Amplitude Measurement

Value A2

A1 to A2 Specification Pass/Fail

DSG800 Performance V e rification Guide

Appendix RIGOL

Appendix Test Record Form

RIGOL DSG800 Series RF Signal Generator

Perform a nce Verification Test Record Form

Model:

Tested By:

Test Date:

Amplitude Accuracy Test:

DSG800 Output

Frequency

103 kHz

1.03 MHz

50.03 MHz

503 MHz

1.403 GHz (Only for

DSG815)

1.903 GHz (Only for

DSG830)

2.493 GHz (Only for

DSG830)

2.903 GHz (Only for

DSG830)

Power Meter

Measurement Value A1

Signal Analyzer

Measurement Value A2

System Error

Reference Value -10 dBm

DSG800 Output

Frequency

103 kHz

1.03 MHz

50.03 MHz

503 MHz

1.403 GHz (Only for

DSG815)

1.903 GHz (Only for

DSG830)

2.493 GHz (Only for

DSG830)

2.903 GHz (Only for

DSG830)

Signal Analyzer

Measurement Value A3

Global

[2]

Error

Amplitude

Accuracy

[3]

Limit

≤ 0.9 dB,

≤ 0.5 (typ.)

[1]

Pass/

Fail

DSG800 Performance V e rification Guide 1

RIGOL Appendix

Reference Value -80 dBm

DSG800 Output

Frequency

103 kHz

Signal Analyzer

Measurement Value A3

Global

[2]

Error

Amplitude

Accuracy

[3]

Limit

Pass/

Fail

1.03 MHz

50.03 MHz

503 MHz

1.403 GHz (Only for

DSG815)

1.903 GHz (Only for

DSG830)

2.493 GHz (Only for

DSG830)

2.903 GHz (Only for

DSG830)

≤ 1.1 dB,

≤ 0.7 (typ.)

Note:

[1] System Error = A2 - A1

[2] Global Error = A3 - Reference Value

[3] Amplitude Accuracy = |Global Error - System Error|

Single Sideband Phase Noise Test:

Single-sideband Phase Noise

DSG800 Output

Frequency

Offset

Measurement

Result

Limit

100 MHz Offset 20 kHz < -100 dBc/Hz

1 GHz Offset 20 kHz < -100 dBc/Hz

3 GHz (Only for

DSG830)

Offset 20 kHz < -94 dBc/Hz

Pass/

Fail

2 DSG800 Performance Verification Guide

Appendix RIGOL

3

Second Harmonic Distortion Test:

DSG800 Output

Amplitude

DSG800 Output

Frequency

10 MHz

100 MHz

0 dBm

Delta A1 Calculation Result

[1]

Limit Pass/Fail

500 MHz

1.5 GHz

2 GHz (Only for

DSG830)

< -30 dBc

DSG800 Output

Amplitude

DSG800 Output

Frequency

10 MHz

100 MHz

500 MHz

1.5 GHz

2 GHz (Only for

DSG830)

Note: [1] Calculation Result = Delta A1

10 dBm

Delta A1 Calculation Result

[1]

Limit Pass/Fail

< -30 dBc

AM Test:

DSG800 Output

Frequency

1 GHz

Note:

[1] Modulation Accuracy = |(Pk - Pk) / 2 - 30%|

[2] Distortion = Distortion Va lue i n the AM Ana log Demodulation Test Interface

Item

Modulation

Accuracy

Distortion

Measurement

Value

[1]

[2]

< 3% (typ.)

Calculation

Result

Limit Pass/Fail

< Modulation Depth

Setting × 4% + 1%

DSG800 Performance V e rification Guide

RIGOL Appendix

FM Test:

DSG800 Output

Frequency

Item

Modulation

1 GHz

Accuracy

Distortion

Note:

[1] Modulation Accuracy = |(Pk - Pk) / 2 - 50 kHz|

[2] Distortion = Distortion Value in the FM Analog Demodulation Test Interface

Measurement

Value

[1]

[2]

< 2% (typ.)

Calculation

Result

Limit

< Modulation Frequency

Deviation Setting × 2% + 20 Hz

Pass/

Fail

ØM Test:

DSG800 Output

Frequency

Item

Modulation

1 GHz

Accuracy

Distortion

Note:

[1] Modulation Accuracy = |(Pk - Pk) / 2 - 5 rad|

[2] Distortion = Distortion Value in the ØM Analog Demodulation Test Interface

Measurement

Value

[1]

[2]

< 1% (typ.)

Calculation

Result

Limit

< Modulation Phase Deviation

Setting × 1% + 0.1 rad

Pass/

Fail

Pulse Modulation Test:

DSG800 Output

Frequency

1 GHz

2 GHz (Only for

DSG830)

Item

On/Off

Ratio

On/Off

Ratio

Note: [1] Calculation Result = -Delta

Measurement

Value

Calculation

Result

Limit

> 70 dB

> 70 dB

Pass/

Fail

10MHz Reference Input Amplitude Range Test:

Amplitude Measurement

Value A1

0 dBm to +10 dBm

Amplitude Measurement

Value A2

A1 to A2 Specification

Pass/

Fail

4 DSG800 Performance Verification Guide

Loading...

Loading...