RIGOL

User’s Guide

DSA800E Series

Spectrum Analyzer

May 2016

RIGOL TECHNOLOGIES, INC.

Find Quality Products Online at: sales@GlobalTestSupply.com

www.GlobalTestSupply.com

RIGOL

I

Guaranty and Declaration

Copyright

© 2016 RIGOL TECHNOLOGIES, INC. All Rights Reserved.

Trademark Information

RIGOL is a registered trademark of RIGOL TECHNOLOGIES, INC.

Publication Number

UGD17100-1110

Software Version

DSA832E: 00.01.02

Software upgrade might change or add product features. Please acquire the latest

version of the manual from RIGOL website or contact RIGOL to upgrade the

software.

Notices

RIGOL products are covered by P.R.C. and foreign patents, issued and

pending.

RIGOL reserves the right to modify or change parts of or all the

specifications and pricing policies at the company’s sole decision.

Information in this publication replaces all previously released materials.

Information in this publication is subject to change without notice.

RIGOL shall not be liable for either incidental or consequential losses in

connection with the furnishing, use, or performance of this manual, as well as

any information contained.

Any part of this document is forbidden to be copied, photocopied, or

rearranged without prior written approval of RIGOL.

Product Certification

RIGOL guarantees that this product conforms to the national and industrial

standards in China as well as the ISO9001:2008 standard and the ISO14001:2004

standard. Other international standard conformance certifications are in progress.

User’s Guide for DSA800E Series

Find Quality Products Online at: sales@GlobalTestSupply.com

www.GlobalTestSupply.com

RIGOL

II

Safety Requirement

General Safety Summary

Please review the following safety precautions carefully before putting the

instrument into operation so as to avoid any personal injury or damage to the

instrument and any product connected to it. To prevent potential hazards, please

follow the instructions specified in this manual to use the instrument properly.

Use Proper Power Cord.

Only the exclusive power cord designed for the instrument and authorized for use

within the local country could be used.

Ground the Instrument.

The instrument is grounded through the Protective Earth lead of the power cord.

To avoid electric shock, connect the earth terminal of the power cord to the

Protective Earth terminal before connecting any input or output terminals.

Connect the Probe Correctly.

If a probe is used, the probe ground lead must be connected to earth ground. Do

not connect the ground lead to high voltage. Improper way of connection could

result in dangerous voltages being present on the connectors, controls or other

surfaces of the oscilloscope and probes, which will cause potential hazards for

operators.

Observe All Terminal Ratings.

To avoid fire or shock hazard, observe all ratings and markers on the instrument

and check your manual for more information about ratings before connecting the

instrument.

Use Proper Overvoltage Protection.

Ensure that no overvoltage (such as that caused by a bolt of lightning) can reach

the product. Otherwise, the operator might be exposed to the danger of an electric

shock.

User’s Guide for DSA800E Series

Find Quality Products Online at: sales@GlobalTestSupply.com

www.GlobalTestSupply.com

RIGOL

III

Do Not Operate Without Covers.

Do not operate the instrument with covers or panels removed.

Do Not Insert Objects Into the Air Outlet.

Do not insert objects into the air outlet, as doing so may cause damage to the

instrument.

Use Proper Fuse.

Please use the specified fuses.

Avoid Circuit or Wire Exposure.

Do not touch exposed junctions and components when the unit is powered on.

Do Not Operate With Suspected Failures.

If you suspect that any damage may occur to the instrument, have it inspected by

RIGOL authorized personnel before further operations. Any maintenance,

adjustment or replacement especially to circuits or accessories must be performed by

RIGOL authorized personnel.

Provide Adequate Ventilation.

Inadequate ventilation may cause an increase of temperature in the instrument,

which would cause damage to the instrument. So please keep the instrument well

ventilated and inspect the air outlet and the fan regularly.

Do Not Operate in Wet Conditions.

To avoid short circuit inside the instrument or electric shock, never operate the

instrument in a humid environment.

Do Not Operate in an Explosive Atmosphere.

To avoid personal injuries or damage to the instrument, never operate the

instrument in an explosive atmosphere.

Keep Instrument Surfaces Clean and Dry.

To avoid dust or moisture from affecting the performance of the instrument, keep

the surfaces of the instrument clean and dry.

User’s Guide for DSA800E Series

Find Quality Products Online at: sales@GlobalTestSupply.com

www.GlobalTestSupply.com

RIGOL

IV

Prevent Electrostatic Impact.

Operate the instrument in an electrostatic discharge protective environment to

avoid damage induced by static discharges. Always ground both the internal and

external conductors of cables to release static before making connections.

Use the Battery Properly.

Do not expose the battery (if available) to high temperature or fire.

Keep it out of the reach of children. Improper change of a battery (lithium battery)

may cause an explosion. Use the RIGOL specified battery only.

Handle with Caution.

Please handle with care during transportation to avoid damage to keys, knobs,

interfaces, and other parts on the panels.

User’s Guide for DSA800E Series

Find Quality Products Online at: sales@GlobalTestSupply.com

www.GlobalTestSupply.com

RIGOL

V

CAUTION

DANGER

Hazardous

Safety

Protective

Terminal

Chassis

Test

Safety Notices and Symbols

Safety Notices in this Manual:

WARNING

Indicates a potentially hazardous situation or practice which, if not

avoided, will result in serious injury or death.

Indicates a potentially hazardous situation or practice which, if not

avoided, could result in damage to the product or loss of important data.

Safety Terms on the Product:

It calls attention to an operation, if not correctly performed, could

result in injury or hazard immediately.

WARNING It calls attention to an operation, if not correctly performed, could

result in

potential injury or hazard.

CAUTION It calls attention to an operation, if not correctly performed, could

result in

damage to the product or other devices connected to the

product.

Safety Symbols on the Product:

Voltage

Warning

Earth

Ground

Ground

User’s Guide for DSA800E Series

Find Quality Products Online at: sales@GlobalTestSupply.com

www.GlobalTestSupply.com

RIGOL

VI

Allgemeine Sicherheits Informationen

Überprüfen Sie diefolgenden Sicherheitshinweise

sorgfältigumPersonenschädenoderSchäden am Gerätundan damit verbundenen

weiteren Gerätenzu vermeiden. Zur Vermeidung vonGefahren, nutzen Sie bitte das

Gerät nur so, wiein diesem Handbuchangegeben.

Um Feuer oder Verletzungen zu vermeiden, verwenden Sie ein

ordnungsgemäßes Netzkabel.

Verwenden Sie für dieses Gerät nur das für ihr Land zugelassene und genehmigte

Netzkabel.

Erden des Gerätes.

Das Gerät ist durch den Schutzleiter im Netzkabel geerdet. Um Gefahren durch

elektrischen Schlag zu vermeiden, ist es unerlässlich, die Erdung durchzuführen.

Erst dann dürfen weitere Ein- oder Ausgänge verbunden werden.

Anschluss einesTastkopfes.

Die Erdungsklemmen der Sonden sindauf dem gleichen Spannungspegel des

Instruments geerdet. SchließenSie die Erdungsklemmen an keine hohe Spannung

an.

Beachten Sie alle Anschlüsse.

Zur Vermeidung von Feuer oder Stromschlag, beachten Sie alle Bemerkungen und

Markierungen auf dem Instrument. Befolgen Sie die Bedienungsanleitung für

weitere Informationen, bevor Sie weitere Anschlüsse an das Instrument legen.

Verwenden Sie einen geeigneten Überspannungsschutz.

Stellen Sie sicher, daß keinerlei Überspannung (wie z.B. durch Gewitter verursacht)

das Gerät erreichen kann. Andernfallsbestehtfür den Anwender die

GefahreinesStromschlages.

Nicht ohne Abdeckung einschalten.

Betreiben Sie das Gerät nicht mit entfernten Gehäuse-Abdeckungen.

User’s Guide for DSA800E Series

Find Quality Products Online at: sales@GlobalTestSupply.com

www.GlobalTestSupply.com

RIGOL

VII

Betreiben Sie das Gerät nicht geöffnet.

Der Betrieb mit offenen oder entfernten Gehäuseteilen ist nicht zulässig. Nichts in

entsprechende Öffnungen stecken (Lüfter z.B.)

Passende Sicherung verwenden.

Setzen Sie nur die spezifikationsgemäßen Sicherungen ein.

Vermeiden Sie ungeschützte Verbindungen.

Berühren Sie keine unisolierten Verbindungen oder Baugruppen, während das

Gerät in Betrieb ist.

Betreiben Sie das Gerät nicht im Fehlerfall.

Wenn Sie am Gerät einen Defekt vermuten, sorgen Sie dafür, bevor Sie das Gerät

wieder betreiben, dass eine Untersuchung durch RIGOL autorisiertem Personal

durchgeführt wird. Jedwede Wartung, Einstellarbeiten oder Austausch von Teilen

am Gerät, sowie am Zubehör dürfen nur von RIGOL autorisiertem Personal

durchgeführt werden.

Belüftung sicherstellen.

Unzureichende Belüftung kann zu Temperaturanstiegen und somit zu thermischen

Schäden am Gerät führen. Stellen Sie deswegen die Belüftung sicher und

kontrollieren regelmäßig Lüfter und Belüftungsöffnungen.

Nicht in feuchter Umgebung betreiben.

Zur Vermeidung von Kurzschluß im Geräteinneren und Stromschlag betreiben Sie

das Gerät bitte niemals in feuchter Umgebung.

Nicht in explosiver Atmosphäre betreiben.

Zur Vermeidung von Personen- und Sachschäden ist es unumgänglich, das Gerät

ausschließlich fernab jedweder explosiven Atmosphäre zu betreiben.

Geräteoberflächen sauber und trocken halten.

Um den Einfluß von Staub und Feuchtigkeit aus der Luft auszuschließen, halten Sie

bitte die Geräteoberflächen sauber und trocken.

Schutz gegen elektrostatische Entladung (ESD).

Sorgen Sie für eine elektrostatisch geschützte Umgebung, um somit Schäden und

User’s Guide for DSA800E Series

Find Quality Products Online at: sales@GlobalTestSupply.com

www.GlobalTestSupply.com

RIGOL

VIII

Funktionsstörungen durch ESD zu vermeiden. Erden Sie vor dem Anschluß immer

Innen- und Außenleiter der Verbindungsleitung, um statische Aufladung zu

entladen.

Die richtige Verwendung desAkku.

Wenneine Batterieverwendet wird, vermeiden Sie hohe Temperaturen bzw. Feuer

ausgesetzt werden. Bewahren Sie es außerhalbder Reichweitevon Kindern auf.

UnsachgemäßeÄnderung derBatterie (Anmerkung: Lithium-Batterie) kann zu einer

Explosion führen. VerwendenSie nur von RIGOL angegebenenAkkus.

Sicherer Transport.

Transportieren Sie das Gerät sorgfältig (Verpackung!), um Schäden an

Bedienelementen, Anschlüssen und anderen Teilen zu vermeiden.

User’s Guide for DSA800E Series

Find Quality Products Online at: sales@GlobalTestSupply.com

www.GlobalTestSupply.com

RIGOL

IX

CAUTION

DANGER

Sicherheits Begriffe und Symbole

Begriffe in diesem Guide:

WARNING

Die Kennzeichnung WARNING beschreibt Gefahrenquellen die leibliche

Schäden oder den Tod von Personen zur Folge haben können.

Die Kennzeichnung Caution (Vorsicht) beschreibt Gefahrenquellen die

Schäden am Gerät hervorrufen können.

Begriffe auf dem Produkt:

weist auf eine Verletzung oder Gefährdung hin, die sofort

geschehen kann.

WARNING weist auf eine Verletzung oder Gefährdung hin, die möglicherweise

nicht sofort geschehen.

CAUTION weist auf eine Verletzung oder Gefährdung hin und bedeutet, dass

eine mögliche Beschädigung des Instruments oder anderer

Gegenstände auftreten kann.

Symbole auf dem Produkt:

Gefährliche

Spannung

SicherheitsHinweis

Schutz-erde Gehäusemasse Erde

User’s Guide for DSA800E Series

Find Quality Products Online at: sales@GlobalTestSupply.com

www.GlobalTestSupply.com

RIGOL

X

WARNING

Care and Cleaning

Care

Do not store or leave the instrument where it may be exposed to direct sunlight for

long periods of time.

Cleaning

Clean the instrument regularly according to its operating conditions.

1. Disconnect the instrument from all power sources.

2. Clean the external surfaces of the instrument with a soft cloth dampened with

mild detergent or wa te r. W hen cleaning the LCD, take care to avoid scarifying

it.

CAUTION

To avoid damage to the instrument, do not expose it to caustic liquids.

To avoid short-circuit resulting from moisture or personal injuries, ensure

that the instrument is completely dry before connecting it to the power

supply.

User’s Guide for DSA800E Series

Find Quality Products Online at: sales@GlobalTestSupply.com

www.GlobalTestSupply.com

RIGOL

XI

Environmental Considerations

The following symbol indicates that this product complies with the WEEE Directive

2002/96/EC.

Product End-of-Life Handling

The equipment may contain substances that could be harmful to the environment or

human health. To avoid the release of such substances into the environment and

avoid harm to human health, we recommend you to recycle this product

appropriately to ensure that most materials are reused or recycled properly. Please

contact your local authorities for disposal or recycling information.

User’s Guide for DSA800E Series

Find Quality Products Online at: sales@GlobalTestSupply.com

www.GlobalTestSupply.com

RIGOL

XIII

DSA800E Series Overview

DSA800E series spectrum analyzers which are small, light and cost-effective, are

portable spectrum analyzers designed for starters. Configured with

easy-to-operate numeric keyboard, high-resolution color LCD display and various

remote communication interfaces, they can be widely used in various fields, such

as education, company research and development as well as industrial

manufacture.

Main features:

The highest frequency: 3.2 GHz

Displayed Average Noise Level (DANL): <-148 dBm (Typical)

Phase Noise: <-90 dBc/Hz @ 10 kHz offset ( Typic al )

Level Measurement Uncertainty: <1.0 dB

Minimum Resolution Bandwidth (RBW): 10 Hz

EMI Filter and Quasi-Peak Detector Kit (Option)

VSWR Measurement Kit (Option)

AM/FM Demodulation Function

Various measurement functions (option)

3.2 GHz Tracking Generator (DSA832E-TG)

8 inche (800×480 pixels) high-definition display with clear, vivid, and

easy-to-use graphical interface

Various interfaces such as LAN, USB Host, USB Device and GPIB (option)

User’s Guide for DSA800E Series

Find Quality Products Online at: sales@GlobalTestSupply.com

www.GlobalTestSupply.com

RIGOL

XIV

Document Overview

Topics in this manual:

Chapter 1 Quick Start

This chapter introduces the front/rear panel and user interface as well as

announcements during first use of the analyzer.

Chapter 2 Front Panel Operation

This chapter gives detailed function descriptions of the front panel keys with their

associated menu keys.

Chapter 3 Remote Control

This chapter shows how to control the analyzer in remote mode.

Chapter 4 Troubleshooting&Message

This chapter lists the troubleshooting information and messages that may appear

during the use of the analyzer.

Chapter 5 Specifications

This chapter lists the specifications and general specifications of the analyzer.

Chapter 6 Appendix

This chapter lists the options and accessories that can be ordered along with your

analyzer as well as the service and support information.

User’s Guide for DSA800E Series

Find Quality Products Online at: sales@GlobalTestSupply.com

www.GlobalTestSupply.com

XV

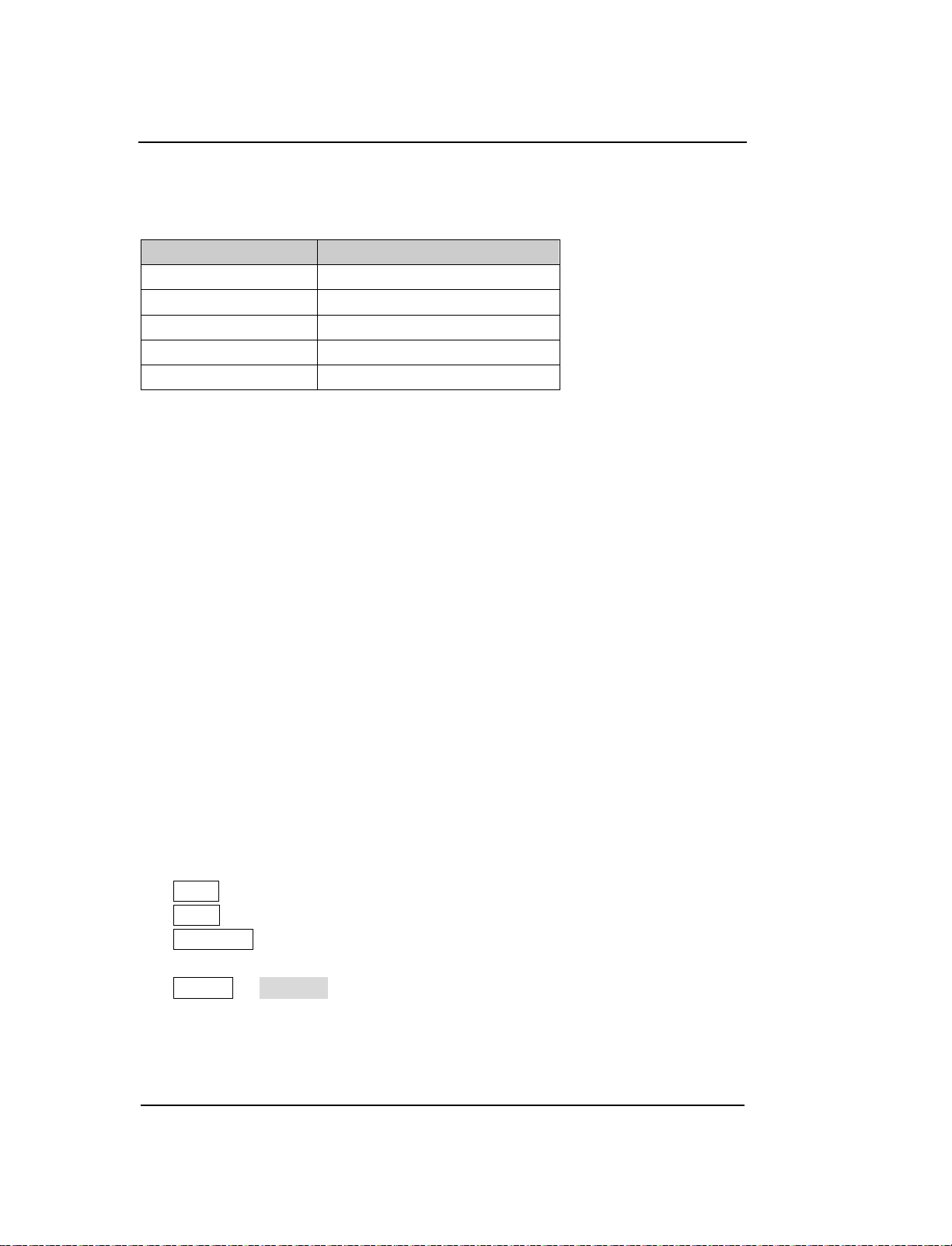

Format conventions in this manual:

Model

Frequency Range

Tracking Generator

1. Keys:

The keys at the front panel are usually denoted by the format of "Key name

(Bold) +textbox". For example, FREQ denotes the FREQ k ey.

2. Menu keys:

The menu softkeys are usually denoted by the format of "Menu word (Bold)

+character shading". For example, Center Freq denotes the center

frequency menu item under the FREQ function key.

3. Connectors:

The connectors at the front or rear panel are usually denoted by the format of

"Connector name (Bold) +square brackets (Bold)", such as [GEN OUTPUT

50Ω].

4. Operation steps:

"" represents the next step of operation. For example, FREQ Center

Freq indicates pressing FREQ at the front panel and then pressing the menu

softkey Center Freq.

Content conventions in this manual:

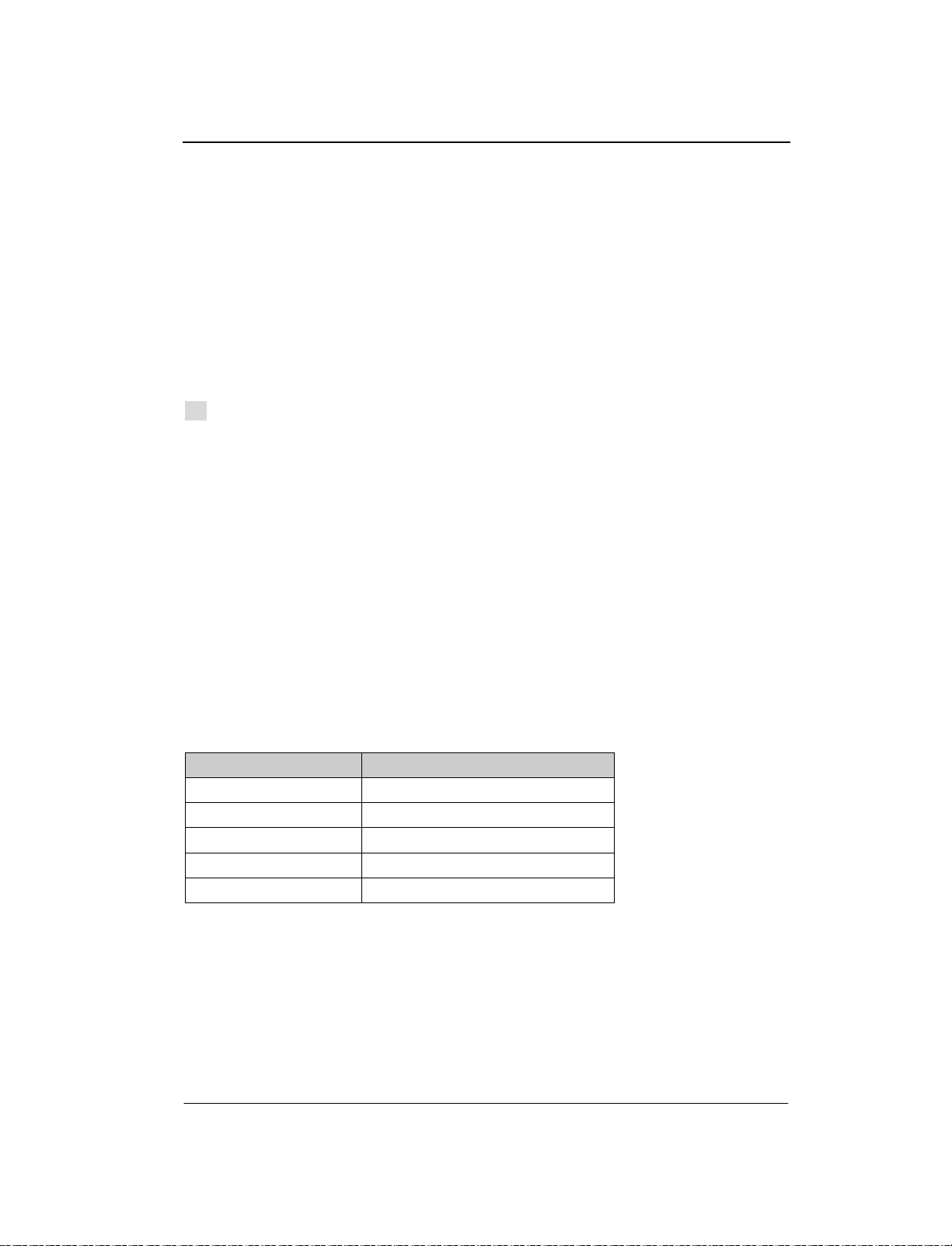

The DSA800E series spectrum analyzer includes the following two models.

RIGOL

DSA832E 9 kHz to 3.2 GHz None

DSA832E-TG 9 kHz to 3.2 GHz 3.2 GHz

User manuals provided with this product:

User’s Guide, Quick Guide, Programming Guide, Data sheet etc. For the desired

manual, please download it from www.rigol.com.

User’s Guide for DSA800E Series

Find Quality Products Online at: sales@GlobalTestSupply.com

www.GlobalTestSupply.com

RIGOL Contents

XVI

Contents

Guaranty and Declaration ......................................................................... I

Safety Requirement ................................................................................. II

General Safety Summary........................................................................... II

Safety Notices and Symbols ...................................................................... V

Allgemeine Sicherheits Informationen ....................................................... VI

Sicherheits Begriffe und Symbole .............................................................. IX

Care and Cleaning .................................................................................... X

Environmental Considerations ................................................................... XI

DSA800E Series Overview ................................................................... XIII

Document Overview ............................................................................. XIV

Chapter 1 Quick Start ........................................................................ 1-1

General Inspection ................................................................................. 1-2

Appearance and Dimensions ................................................................... 1-3

To Prepare for Use ................................................................................. 1-4

To Adjust the Supporting Legs .......................................................... 1-4

To Connect to Power ........................................................................ 1-5

Power-on Inspection ........................................................................ 1-6

Self-calibration ................................................................................ 1-6

To Set the System Language ............................................................. 1-6

Front Panel ............................................................................................ 1-7

Front Panel Function Keys ................................................................ 1-8

Front Panel Key Backlight ............................................................... 1-10

Front Panel Connectors .................................................................. 1-11

To Use the Numeric Keyboard ......................................................... 1-13

Rear Panel ........................................................................................... 1-15

User Interface ...................................................................................... 1-17

Menu Operation ................................................................................... 1-20

Parameter Setting ................................................................................ 1-22

To Input Filename ................................................................................ 1-24

To Lock the Keyboard ........................................................................... 1-27

Use the Built-in Help ........................................................................ 1-28

To

To Use the Security Lock ....................................................................... 1-30

User’s Guide for DSA800E Series

Find Quality Products Online at: sales@GlobalTestSupply.com

www.GlobalTestSupply.com

Contents RIGOL

XVII

To Replace the Fuse ............................................................................. 1-31

Chapter 2 Front Panel Operation ........................................................ 2-1

Basic Settings ....................................................................................... 2-2

FREQ ............................................................................................. 2-2

SPAN ............................................................................................. 2-9

AMPT ............................................................................................ 2-12

Sweep and Function Settings ................................................................. 2-23

BW/Det ......................................................................................... 2-23

Sweep/Trig .................................................................................... 2-28

Trace/P/F ...................................................................................... 2-34

TG ................................................................................................ 2-41

Measurement Settings .......................................................................... 2-45

Meas ............................................................................................ 2-45

Meas Setup ................................................................................... 2-49

Demod ......................................................................................... 2-75

Marker Measurements........................................................................... 2-77

Marker .......................................................................................... 2-77

Marker-> ...................................................................................... 2-84

Marker Fctn ................................................................................... 2-86

Peak ............................................................................................. 2-89

Shortcut Key ........................................................................................ 2-93

Auto ............................................................................................. 2-93

User Key ....................................................................................... 2-95

Preset ........................................................................................... 2-96

Print ........................................................................................... 2-102

System Settings ................................................................................. 2-103

System ....................................................................................... 2-103

Print Setup .................................................................................. 2-116

Storage ....................................................................................... 2-119

Ch

apter 3 Remote Control .................................................................. 3-1

Remote Control Overview ....................................................................... 3-2

Remote Control Method ......................................................................... 3-3

User-defined Programming .............................................................. 3-3

To Use PC software ......................................................................... 3-6

Chapter 4 Troubleshooting&Message ................................................. 4-1

Troubleshooting .................................................................................... 4-2

User’s Guide for DSA800E Series

Find Quality Products Online at: sales@GlobalTestSupply.com

www.GlobalTestSupply.com

RIGOL Contents

XVIII

Messages .............................................................................................. 4-4

Information Message ....................................................................... 4-6

Error Message ................................................................................. 4-9

Status Message ............................................................................. 4-22

Chapter 5 Specifications .................................................................... 5-1

Technical Specifications*......................................................................... 5-2

Frequency ....................................................................................... 5-2

Amplitude ....................................................................................... 5-3

Distortion ........................................................................................ 5-6

Sweep ............................................................................................ 5-7

Tracking Generator (Option) ............................................................. 5-7

Trigg e r ........................................................................................... 5-7

Input /Output .................................................................................. 5-8

General Specifications ............................................................................ 5-9

Chapter 6 Appendix ........................................................................... 6-1

Appendix A: Ordering Infomation ............................................................. 6-1

Appendix B: Warranty ............................................................................. 6-2

Index ........................................................................................................ 1

User’s Guide for DSA800E Series

Find Quality Products Online at: sales@GlobalTestSupply.com

www.GlobalTestSupply.com

Chapter 1 Quick Start RIGOL

1-1

Chapter 1 Quick Start

This chapter guides users to quickly get familiar with the appearance, dimensions,

front/ rear panel and the user interface, as well as announcements during first use

of DSA800E series spectrum analyzer.

Subjects in this chapter:

General Inspection

Appearance and Dimensions

To Prepare for Use

Front Panel

Rear Panel

User Interface

Menu Operation

Parameter Setting

To Input Filename

To Lock the Keyboard

To Use the Built-in Help

To Use the Security Lock

To Rep lace the Fuse

User’s Guide for DSA800E Series

Find Quality Products Online at: sales@GlobalTestSupply.com

www.GlobalTestSupply.com

RIGOL Chapter 1 Quick Start

1-2

General Inspection

1. Inspect the packaging

If the packaging has been damaged, do not dispose the damaged packaging

or cushioning materials until the shipment has been checked for completeness

and has passed both electrical and mechanical tests.

The consigner or carrier shall be liable for the damage to the instrument

resulting from shipment. RIGOL would not be responsible for free

maintenance/rework or replacement of the instrument.

2. Inspect the instrument

In case of any mechanical damage, missing parts, or failure in passing the

electrical and mechanical tests, contact your RIGOL sales representative.

3. Check the accessories

Please check the accessories according to the packing lists. If the accessories

are damaged or incomplete, please contact your RIGOL sales

representative.

User’s Guide for DSA800E Series

Find Quality Products Online at: sales@GlobalTestSupply.com

www.GlobalTestSupply.com

Chapter 1 Quick Start RIGOL

1-3

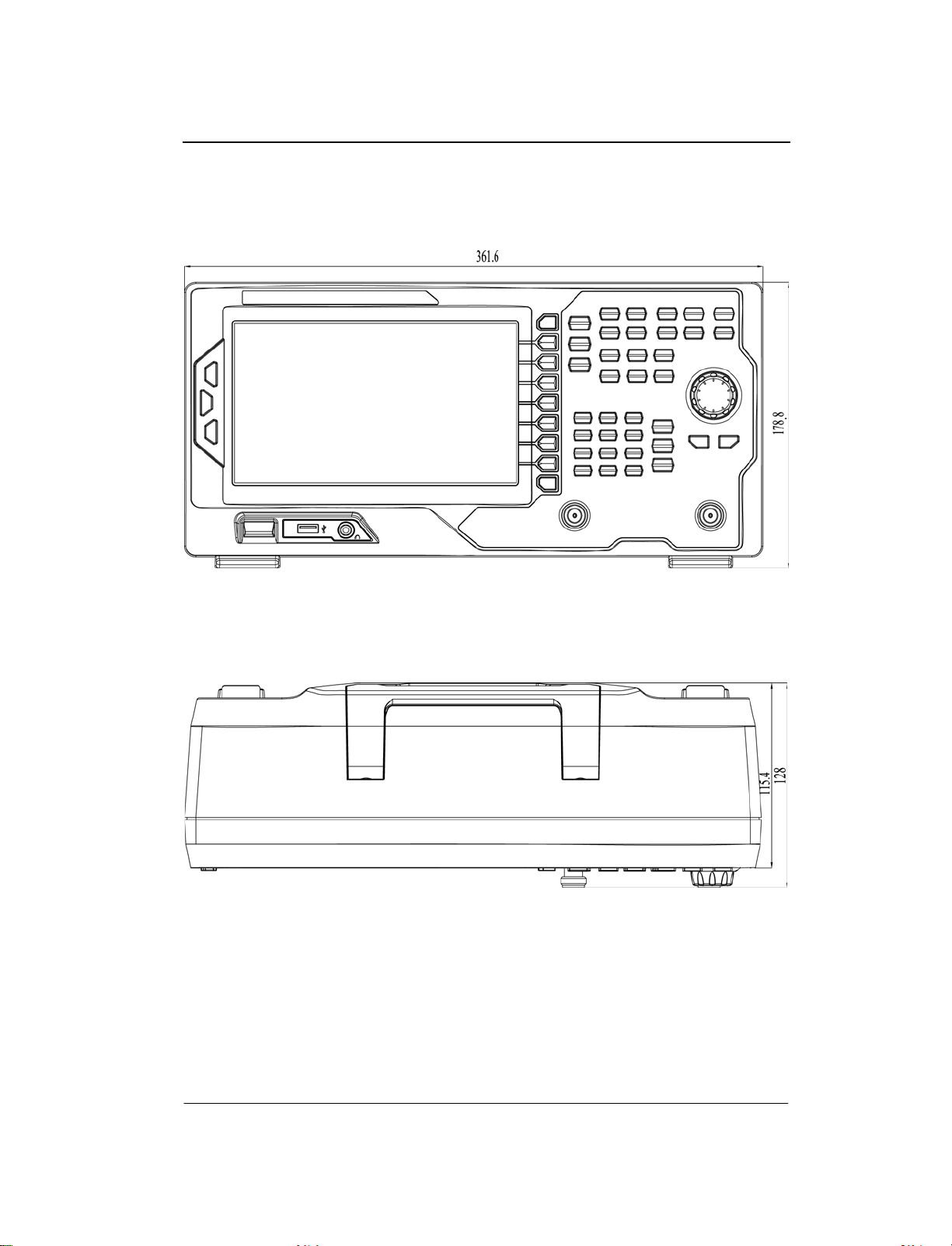

Appearance and Dimensions

Figure 1-1 Front View Unit: mm

Figure 1-2 Side View Unit: mm

User’s Guide for DSA800E Series

Find Quality Products Online at: sales@GlobalTestSupply.com

www.GlobalTestSupply.com

RIGOL Chapter 1 Quick Start

1-4

To Prepare for Use

To Adjust the Supporting Legs

Users can unfold the supporting legs to use them as stands to tilt the instrument

upwards for easier operation and observation. Users can also fold the supporting

legs when the instrument is not in use for easier storage or shipment.

To unfold the supporting legs

Figure 1-3 To Adjust the Supporting Legs

To fold the supporting legs

User’s Guide for DSA800E Series

Find Quality Products Online at: sales@GlobalTestSupply.com

www.GlobalTestSupply.com

Chapter 1 Quick Start RIGOL

1-5

CAUTION

To Connect to Power

Please use the power cord provided with the accessories to connect the spectrum

analyzer to AC power source as shown in the figure below. The AC power supply

specification of this spectrum analyzer is 100-240 V, 45-440 Hz. The power

consumption of the instrument cannot exceed 50 W. When the spectrum analyzer

is connected to AC power supply via the power cord, the instrument select the

correct voltage range automatically and users do not need to select the voltage

range manually.

Figure 1-4 Power Cord Connection

Make sure that the instrument is properly grounded to avoid electric

shock.

User’s Guide for DSA800E Series

Find Quality Products Online at: sales@GlobalTestSupply.com

www.GlobalTestSupply.com

RIGOL Chapter 1 Quick Start

1-6

Power-on Inspection

After connecting the instrument to power source correctly, press

panel to start the spectrum analyzer. Following the start-up screen which shows

the start-up initialization process information, the sweep curve is displayed.

at the front

Self-calibration

After the instrument starts, execute self-calibration.

Press System Calibrate Cal Now and the instrument will perform

self-calibration using the internal calibration source.

To Set the System Language

DSA800E series spectrum analyzer supports multiple system languages. You can

press System Language to switch the system language.

User’s Guide for DSA800E Series

Find Quality Products Online at: sales@GlobalTestSupply.com

www.GlobalTestSupply.com

Chapter 1 Quick Start RIGOL

1-7

1 2 3

14

13

12

11 10 9 8 7

Front Panel

The front panel of DSA800E is as shown in the figure below.

Figure 1-5 Front Panel

Tab le 1-1 Front Panel Description

NO. Description NO. Description

1 LCD 8 Tracking generator output*

2 Menu softkeys/menu control keys 9 Earphone jack

3 Function key area 10 USB Host

4 Knob 11 Power switch

5 Arrow keys 12 Help

6 Numeric Keyboard 13 Print

7 RF input 14

Note: *This function is only available for DSA832E-TG.

Preset

4

5

6

User’s Guide for DSA800E Series

Find Quality Products Online at: sales@GlobalTestSupply.com

www.GlobalTestSupply.com

RIGOL Chapter 1 Quick Start

1-8

Front Panel Function Keys

Figure 1-6 Function Key Area

Tab le 1-2 Function keys description

Key Description

FREQ

SPAN Set the frequency span of the sweep.

AMPT

BW/Det

Sweep/Trig Set the sweep and trigger parameters.

Trace/P/F

TG Set the tracking generator*.

Meas Select and control the measurement function**.

Meas Setup Set the parameters for the selected measurement function**.

Set the center, start and stop frequency, etc; enable the

signal tracking function.

Set the reference level, RF attenuator, scale and the unit of

Y-axis, etc.

Set the reference level offset, maximum mixing level and

input impedence.

Execute auto scale and auto range as well as turn on the RF

preamplifier.

Set the resolution bandwidth (RBW), video bandwidth (VBW)

and V/R ratio.

Set the detector and filter types.

Set the parameters related to trace.

Configure the Pass/Fail test.

User’s Guide for DSA800E Series

Find Quality Products Online at: sales@GlobalTestSupply.com

www.GlobalTestSupply.com

Chapter 1 Quick Start RIGOL

1-9

User Key

Preset

Demod Set the demodulation function.

Marker

Marker—>

Marker Fctn

Peak

Read the amplitude, frequency and sweep time of a certain

point on the trace via marker.

Set other system parameters on the basis of the current

marker value.

Special functions of the marker such as noise marker, N dB

bandwidth measurement and frequency counter.

Open the peak search menu and search for peaks

immediately.

System Set the system parameters.

Print Setup Set the print parameters.

Storage Provide file storage and recall functions.

Auto Search for signals automatically within full frequency range.

User-defined shortcut key.

Restore the system to factory settings or user-defined state.

Print or save the current screen.

Help Turn on the built-in help.

Note:

*This function is only available for DSA832E-TG.

**This function is only available for DSA800E with the corresponding option.

User’s Guide for DSA800E Series

Find Quality Products Online at: sales@GlobalTestSupply.com

www.GlobalTestSupply.com

RIGOL Chapter 1 Quick Start

1-10

Front Panel Key Backlight

The on/off state and the color of the backlights of some keys at the front panel

indicate the working state of the spectrum analyzer. The states are as listed below.

1. Power Switch

Flash on and off alternatively, in breathing state: indicate the unit is in

stand-by state.

Constant on: indicate the instrument is in normal operating state.

2. TG*

When the TG function is enabled, the backlight of TG turns on and turns off

when the function is disabled.

3. Auto

When Auto is pressed, the backlight turns on. The instrument starts sweeping

within the full frequency range, searches for the signal with the maximum

amplitude and moves it to the center of the screen. Then the backlight turns off.

4. Meas**

The backlight of Meas turns on when VSWR or any of the advanced

measurements is enabled and stays on until all measurement functions are

disabled.

Note:

*This function is only available for DSA832E-TG.

**This function is only applicable to DSA800E installed with the corresponding option.

User’s Guide for DSA800E Series

Find Quality Products Online at: sales@GlobalTestSupply.com

www.GlobalTestSupply.com

Chapter 1 Quick Start RIGOL

1-11

and gradually turn the volume up after putting on the earphone.

USB Host

RF input

Front Panel Connectors

Earphone jack

Tracking

generator

output

Figure 1-7 Front Panel Connectors

1. USB Host

The analyzer can serve as a "host" device to connect external USB devices.

This interface is available for USB storage devices and USB-GPIB interface

converter.

USB Storage Device

Read the trace or state file stored in the USB storage device, store the

current instrument state or trace in the USB storage device or store the

contents currently displayed on the screen in the USB storage device in

".bmp", ".jpg" or ".png" format.

USB-GPIB Interface Converter

Extend a GPIB interface for the analyze r.

2. Earphone Jack

The analyzer provides AM and FM demodulations. Insert the earphone to the

jack to aquire the audio output of the demodulated signal. You can turn on or

off the earphone output and adjust the volume via Demod Demod

Setup.

CAUTION

For fear of damaging your hearing, please turn the volume down to zero

User’s Guide for DSA800E Series

Find Quality Products Online at: sales@GlobalTestSupply.com

www.GlobalTestSupply.com

RIGOL Chapter 1 Quick Start

1-12

MHz. The reverse DC voltage cannot exceed 50 V.

dBm respectively.

3. GEN OUTPUT 50Ω

The output of the tracking generator can be connected to a receiver through a

cable with an N male connector. The tracking generator is only available for

DSA832E-TG.

CAUTION

To avoid damage to the tracking generator, the reverse power cannot

exceed +10 dBm when the frequency is lower than 10 MHz; the reverse

power cannot exceed +20 dBm when the frequency is greater than 10

4. RF INPUT 50Ω

The input terminal of the signal under measurement. [RF INPUT 50Ω] can

be connected to the device under measurement via a cable with an N male

connector.

CAUTION

To avoid damage to the instrument, for the signal input from the RF

input terminal, the DC voltage component and the maximum continuous

power of the AC (RF) signal component can not exceed 50 V and +20

User’s Guide for DSA800E Series

Find Quality Products Online at: sales@GlobalTestSupply.com

www.GlobalTestSupply.com

Chapter 1 Quick Start RIGOL

1-13

To Use the Numeric Keyboard

DSA800E provides a numeric keyboard at the front panel (as shown in the figure

below). The numeric keyboard which supports the Chinese characters, English

uppercase/lowercase characters, numbers and common symbols (including

decimal point, #, space and +/-) are mainly used to edit file or folder name (refer

to "To Input Filename") and set parameters (refer to "Parameter Setting").

Figure 1-8 Numeric Keyboard

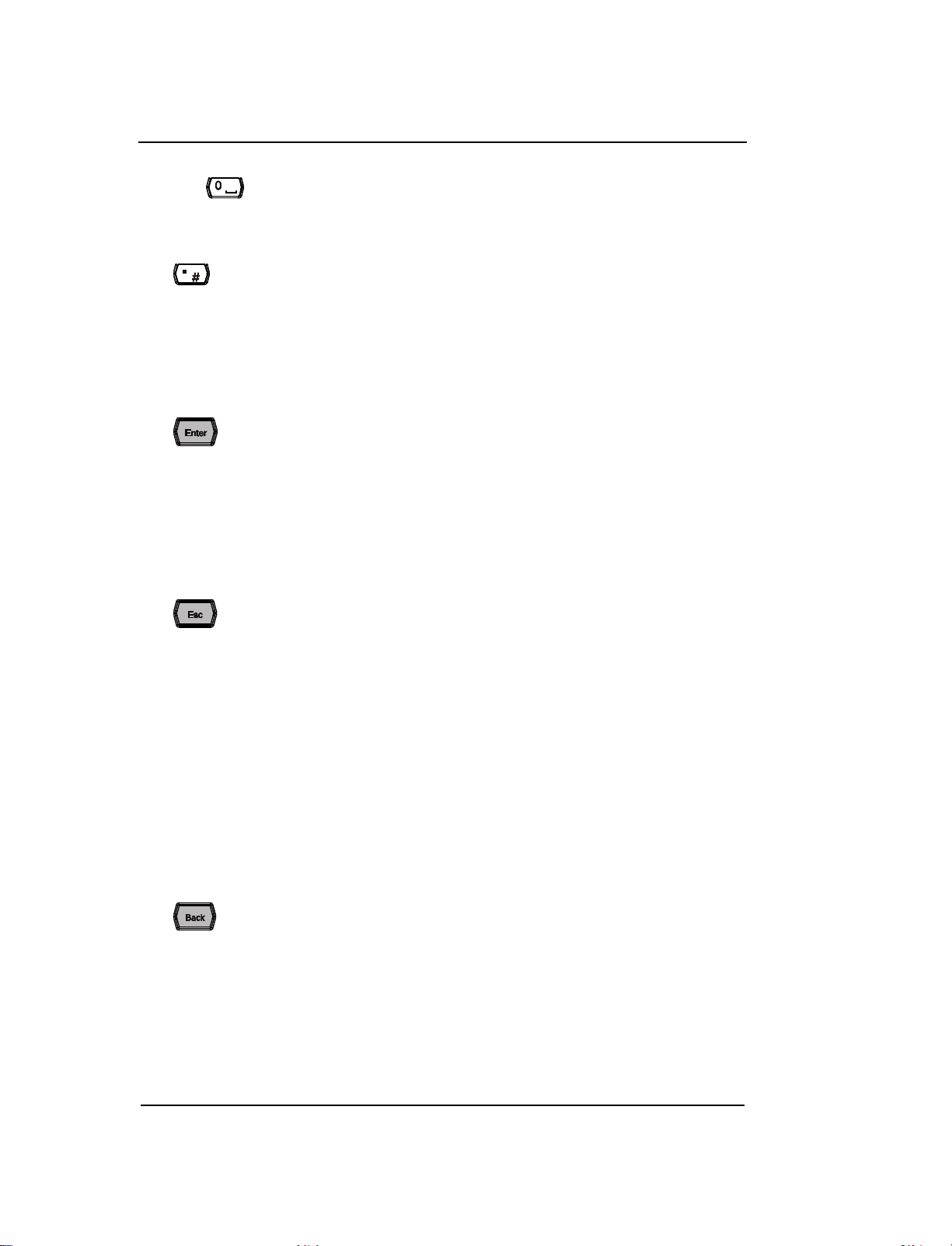

The numeric keyboard consists of the following parts:

1.

2. Number/Letter

User’s Guide for DSA800E Series

The input mode is fixed at number input during parameter setting. During

parameter setting, press this key to input the symbol ("+" or "-") of the

figure. When the key is pressed for the first time, the parameter symbol

is "-" and "+" when the key is pressed again.

Press

file or folder name editing.

Multiplexing keys for numbers and letters. They are used to directly input

the desired number or letter.

uppercase and lowercase letter in English input. This key is invalid in

Chinese input.

to switch among Chinese, English and number input during

: press this key to input 1 in number input and switch between

Find Quality Products Online at: sales@GlobalTestSupply.com

www.GlobalTestSupply.com

RIGOL Chapter 1 Quick Start

1-14

is the multiplexing key for 0 and space. Press this key to input 0 in

number input and space in Chinese or English input.

3.

Press this key to input a decimal point at the current cursor position in

number input.

Press this key to input "#" in English input.

This key is invalid in Chinese input.

4.

When pressed during parameter editing process, the system will

complete the input and insert a default unit for the parameter

automatically.

While in the process of file name editing, this key is used to input the

character currently selected by the cu rs or.

5.

During parameter editing process, press this key to clear the inputs in the

active function area and exit parameter input.

While in the process of file name editing, press this key to delete

characters that have been entered.

Press this key to turn off the display of the active function area when the

main measurement screen is displayed.

Press this key to exit the current test mode in keyboard test.

Press this key to unlock the screen when it is locked.

When the instrument is in remote mode, use this key to return to local

mode.

6.

During the process of parameter editing, press this key to delete the

character on the left of the c ur so r.

While in the process of file name editing, press this key to delete the

character on the left of the c urs or.

User’s Guide for DSA800E Series

Find Quality Products Online at: sales@GlobalTestSupply.com

www.GlobalTestSupply.com

Chapter 1 Quick Start RIGOL

1-15

1 2 3

Rear Panel

The rear panel of DSA800E is as shown in the figure below.

1. AC Power Connector

The AC power supply specification of this spectrum analyzer is 100-240 V,

45-440 Hz.

2. Fuse Seat

You can replace the fuse. DSA800 supports 250V AC, T2A fuse.

3. Security Lock Hole

If needed, you can use a security lock (buy it yourself) to lock the analyzer to

a desired location.

4. Handle

Users can adjust the handle to the vertical position for easier carry of the

analyzer.

5. 10MHz IN

DSA800E can use internal or external reference source.

When a 10 MHz external clock signal is received through the [10MHz IN]

Figure 1-9 Rear Panel

9

8

7

6

5

4

User’s Guide for DSA800E Series

Find Quality Products Online at: sales@GlobalTestSupply.com

www.GlobalTestSupply.com

RIGOL Chapter 1 Quick Start

1-16

connector, this signal is used as the external reference source and "Ext

Ref" is displayed in the status bar of the user interface. When the

external reference is lost, transfinite or not connected, the instrument

swithes to its internal reference source automatically and "Ext Ref" on the

screen disappears.

The [10MHz IN] and [10MHz OUT] connectors are usually used to

build synchronization among multiple instruments.

6. 10MHz OUT

DSA800E can use internal or external reference source.

When internal reference source is used, the [10MHz OUT] connector

can output a 10 MHz clock signal generated by the analyzer. This signal

can be used to synchronize other instruments.

The [10MHz OUT] and [10MHz IN] connectors are usually used to

build synchronization among multiple instruments.

7. TRIGGER IN

In external trigger mode, the connector receives an external trigger signal

through a BNC cable.

8. LAN Interface

Through this interface, the analyzer can be connected to your local network

for remote control. An integrated testing system can be built quickly, as the

analyzer conforms to LXI Core 2011 Device instrument standards.

9. USB Device Interface

The analyzer can serve as a "slave" device to connect external USB devices.

Through this interface, a PictBridge printer can be connected to print screen

image or a PC can be connected to control DSA800E remotely through

programming or PC software.

User’s Guide for DSA800E Series

Find Quality Products Online at: sales@GlobalTestSupply.com

www.GlobalTestSupply.com

Chapter 1 Quick Start RIGOL

1-17

NO.

Name

Description

RIGOL

RIGOL

User Interface

Figure 1-10 User Interface

Tab le 1-3 User interface labels

1

2 System status

( "UNCAL" and

"Identification…"

are displayed in

different place as

others; refer to the

figure above)

3 External reference Ext Ref

4 Time System time

5 Input impedance Show "75Ω" if the current input impedance is 75Ω.

6 Printer status

User’s Guide for DSA800E Series

Logo of

Auto Tune

Auto Range

Wait for Trigger

Calibrating

UNCAL (Measurement is not calibrated)

Identification… (LXI instrument is identified)

: displayed alternatively, denote the printer

Find Quality Products Online at: sales@GlobalTestSupply.com

www.GlobalTestSupply.com

RIGOL Chapter 1 Quick Start

1-18

ursor. Note that Y indicates

connection is in process.

: denote the connection succeeds, the print

finishes or the printer is idle.

: displayed alternatively, denote the print is

in process.

: denote the print has been paused.

7 Print process Show the current print copy and total print copies.

8 USB storage device

status

is displayed when USB storage device is

installed.

9 Operation status Display "Local" (in local mode) or "Rmt" (in remote

mode).

10 Menu title Function of the current menu.

11 Menu items Menu items of the current function.

12 Reference level Reference level.

13 Active function area Current parameter and its value.

14 Attenuator settings Attenuator settings.

15 Trigger level Set the trigger level in video trigge r.

16 Display line Reading reference and threshold condition for

peak value display.

17 Average times Average times of trace.

18 Cursor X Current X value of the cursor. Note that X indicates

different physical quantities in different functions.

19 Cursor Y Current Y value of the c

different physical quantities in different functions.

20 Invalid data Current measured data is invalid as a full sweep

dosen’t complete after the system parameters

have been modified.

21 Menu page number Show the current page number and total number

of pages.

22 Sweep position Current sweep position.

23 Sweep time Sweep time.

24 Span or stop

frequency

The frequency range of the current sweep channel

can be expressed by the combination of center

frequency and span or the combination of start

frequency and stop frequency.

25 Manual setting The corresponding parameter is in manual setting

User’s Guide for DSA800E Series

Find Quality Products Online at: sales@GlobalTestSupply.com

www.GlobalTestSupply.com

Chapter 1 Quick Start RIGOL

1-19

User Key

User Key

symbol mode.

26 VBW Video bandwidth.

27 Spectrum line

Display the spectrum line.

display area

28 RBW Resolution bandwidth.

29 Center or start

frequency

The frequency range of the current sweep channel

can be expressed by the combination of center

frequency and span or the combination of start

frequency and stop frequency.

30 Y scale Label of Y scale.

31 Parameter status Icons on the left side of the screen indicate the

status of system parameters.

32 Detector type Pos peak, Neg peak, Sample, Normal, RMS Avg,

Voltage Avg and Quasi-Peak.

33 Trigger type Free, video and external.

34 Sweep mode Continuous or Single sweep (with the current

number of sweeps)

35 Correction switch Turn amplitude correction on or off.

36 Signal tracking Enable or disable the signal tracking function.

37 Preamplifier status Enable or disable the preamplifier.

38 Trace 1 type and

status

Trace types: Clear Write, Max Hold, Min Hold,

Video Avg, Power Avg and Freeze.

Trace status: yellow denotes On and gray denotes

Off.

39 Trace 2 type and

status

Trace types: Clear Write, Max Hold, Min Hold,

Video Avg, Power Avg and Freeze.

Trace status: purple denotes On and gray denotes

Off.

40 Trace 3 type and

status

Trace types: Clear Write, Max Hold, Min Hold,

Video Avg, Power Avg and Freeze.

Trace status: light blue denotes On and gray

denotes Off.

41 MATH trace type and

status

Trace types: A-B, A+Const, A-Const.

Trace status: green denotes On and gray denotes

Off.

42

User’s Guide for DSA800E Series

Find Quality Products Online at: sales@GlobalTestSupply.com

definition Display the definition of

www.GlobalTestSupply.com

.

RIGOL Chapter 1 Quick Start

1-20

of Y-axis changes to dBm.

Menu Operation

There are 7 types of menus according to their operation modes. Each type of menu

and its operation method are introduced below.

1. Parameter Input

When selected, use the numeric keys to modify the

parameters directly.

For example, select Center Freq, input the desired figure

2. State Switching

3. Enter Lower Menu (with parameter)

and press Enter to change the center frequency.

Press the corresponding menu key to switch between

the sub-options.

For example, press Signal Track to enable or disable

the signal tracking function.

Press the corresponding menu key to enter the lower

menu and change the option currently selected. The

parameter in the upper menu will change when you

4. Enter Lower Menu (without parameter)

return to the upper menu.

For example, press Units to enter the lower menu.

Select dBm and return to the previous menu. The unit

Press the corresponding menu key to enter the lower

menu.

For example, press Corrections to enter the lower

menu directly.

User’s Guide for DSA800E Series

Find Quality Products Online at: sales@GlobalTestSupply.com

www.GlobalTestSupply.com

Chapter 1 Quick Start RIGOL

1-21

5. Direct Execution

Press the key to execute the corresponding function.

For example, press Peak->CF to execute a peak search

and set the center frequency of the analyzer to the

frequency of the current peak signal.

6. Function Switch + Parameter Input

Press the corresponding menu key to switch between

functions; change the parameter directly using the

numeric keys.

For example, press CF Step to switch between Auto

and Manual; if Manual is selected, you can directly

input the desired number to change the CF Step.

7. State Selection

Press the corresponding menu key to modify the

parameter and return to the menu one level up.

For example, press Trig Type Free Run to select

free trigger and the analyzer is in Free Run state at

present.

User’s Guide for DSA800E Series

Find Quality Products Online at: sales@GlobalTestSupply.com

www.GlobalTestSupply.com

RIGOL Chapter 1 Quick Start

1-22

Parameter Setting

You can use the numeric keys, the knob, or the arrow keys to enter the desired

parameter values.

through an example (to set the center frequency to 800 MHz).

1. Use the numeric keyboard

1) Press FREQ

2) Input 800 using the numeric keys;

3) Select the desired unit (MHz) from the popup menu.

2. Use the knob

When the parameter is editable (namely when the parameter is selected),

turn the knob clockwise to increase or counterclockwise to decrease the

parameter value at the specified step.

1) Press FREQ

2) Rotate the knob until the parameter is set to the desired value (800 MHz).

This section describes the three methods of parameter setting

Center Freq;

Center Freq;

Figure 1-11 The Knob

Note: In the storage function, the knod can also be used to select the

currentpath or file.

3. Use the arrow keys

When the parameter is editable (namely when the parameter is selected), you

can use the arrow keys to increase or decrease the parameter value at the

specific step.

1) Press FREQ

2) Press the up/down arrow key until the parameter is set to the desired

value (800 MHz).

Center Freq;

User’s Guide for DSA800E Series

Find Quality Products Online at: sales@GlobalTestSupply.com

www.GlobalTestSupply.com

Chapter 1 Quick Start RIGOL

1-23

Figure 1-12 Arrow Keys

Note: In the storage function, the arrow keys can also be used to select the

current path or file.

User’s Guide for DSA800E Series

Find Quality Products Online at: sales@GlobalTestSupply.com

www.GlobalTestSupply.com

RIGOL Chapter 1 Quick Start

1-24

To Input Filename

DSA800E supports filenames consisting of Chinese characters, English letters,

numbers and #.

1. Enter the filename input interface

Press Storage and select the desired file type and storage location. Then

press Save to enter the filename input interface. You can press to

switch among English, Chinese and number input modes.

Pinyin Selecting Area Chinese Character Selecting Arear

Chinese Characters Entered Chinese Input Mode

(a) Chinese Input Mode

Letter Selecting Area Uppercase/Lowercase

Letters Entered English Input Mode

(b) English Input Mode

User’s Guide for DSA800E Series

Find Quality Products Online at: sales@GlobalTestSupply.com

www.GlobalTestSupply.com

Chapter 1 Quick Start RIGOL

1-25

Number Input Mode

Numbers Entered

(c) Number Input Mode

Figure 1-13 Filename Input Interface

Tip:

If a USB storage device is currently connected, the instrument will also enter

the filename input interface when

is pressed.

2. Input Chinese Filename

1) Press

to switch to Chinese input mode. At this point, the

corresponding label is displayed at the lower right corner of the filename

input interface.

2) Press the key of the first letter of the pinyin of the Chinese character. At

this point, the pinyins available are displayed in the pinyin selecting

area and the corresponding Chinese characters of the pinyin currently

selected are displayed in the Chinese character selecting area. If the

desired pinyin is displayed, refer to 3). Otherwise, please continue to

input the other letters in the pinyin and then refer to 3).

3) Rotate the knob until the background color of the desired pinyin becomes

brown. Then, press Enter to select the pinyin. At this point, the

corresponding Chinese characters are numbered and displayed in the

Chinese character selecting area. Use the numeric keys to select the

desired Chinese character. You can also use the the arrow keys to open

the previous or next page in the Chinese character selecting area.

4) Use the same method to input the other Chinese characters.

3. Input English Filename

1) Press

User’s Guide for DSA800E Series

Find Quality Products Online at: sales@GlobalTestSupply.com

to switch to English input mode. You can also press to

www.GlobalTestSupply.com

RIGOL Chapter 1 Quick Start

1-26

switch between upper and lower cases. At this point, the corresponding

label is displayed at the lower right corner of the filename input interface.

2) Press the key of the desired letter. At this point, the letters available are

displayed in the letter selecting area. Press this key repeatedly or

retate the knob until the desired letter is selected (the background color

of the letter becomes brown). Then press Enter to input the desired

letter.

3) Use the above method to input the other letters.

Tip:

If you need to use numbers as the filename (or part of the filename), press

to switch to number input mode and use the numeric keys to input the desired

number.

User’s Guide for DSA800E Series

Find Quality Products Online at: sales@GlobalTestSupply.com

www.GlobalTestSupply.com

Chapter 1 Quick Start RIGOL

1-27

To Lock the Keyboard

You can lock one or more function keys or all keys (except the power switch) and

knob at the front panel using keyboard lock commands.

1. The intrudction of keyboard lock commands

:SYSTem:KLOCk ON|OFF|1|0,<key> /* Lock or unlock the specified key*/

:SYSTem:KLOCk? <key> /* Query whether the specified key is

locked*/

Wherein, the parameter <key> is used to specify the keys. The range of this

parameter is as follows.

FREQ|SPAN|AMP| /*FREQ, SPAN, AMPT keys*/

BW|SWEEP|TRACE|TG| /*BW/Det, Sweep/Trig, Trace/P/F, TG

keys*/

MARK|MARKFUNC|MARKTO|PEAK| /*Marker, Marker Fctn, Marker->, Peak

keys*/

TUNE| /*Auto key*/

MEAS|MEASSET|DEMOD| /*Meas, Meas Setup, Demod keys*/

SYSTEM|PRINTSETUP|STORAGE| /*System, Print Setup, Storage keys*/

PRESET|PRINT /* Preset, Print keys*/

The parameter ON|OFF|1|0 is used to lock or unlock the key. Select ON|1

to lock the specified key; select OFF|0 to unlock the specified key. When

more than one key is locked or unlocked at the same time, please use "," to

separate the keys.

:SYSTem:KLOCk ON|1,ALL /*Lock all keys (except the power

switch) and knob at the front panel*/

:SYSTem:KLOCk OFF|0,ALL /*Unlock all keys and knob at the front

panel*/

2. Send the commands to lock or unlock the keyboard via Ultra Sigma

Build the communication between spectrum analyzer and the PC.

Start up the Ultra Sigma and search for the instrument resources.

Open the remote command control panel and send the above commands.

User’s Guide for DSA800E Series

Find Quality Products Online at: sales@GlobalTestSupply.com

www.GlobalTestSupply.com

RIGOL Chapter 1 Quick Start

1-28

To Use the Built-in Help

The built-in help system provides information about every function key at the front

panel and every menu softkey.

1. How to acquire built-in help

Press Help and a prompt about how to obtain help information will be shown

at the center of the screen. Then, press the key that you want to get help of

and the relevant help information will be shown at the center of the screen.

2. Page up and down

If there is more than one page of information, you can read the help

information on the previous or next page using the arrow keys or the knob.

3. Close the current help information

Press any key at the front panel to close the help information currently

displayed at the center of the screen.

4. Acquire the menu help

Press Help and the help information display window is displayed at the center

of the screen. Then, press the menu key and the help information of the

corresponding menu item is displayed.

5. Acquire the help information of any function key

Press Help and the help information display window is displayed at the center

of the screen. Then, press any function key and the corresponding function

help information is displayed.

User’s Guide for DSA800E Series

Find Quality Products Online at: sales@GlobalTestSupply.com

www.GlobalTestSupply.com

Chapter 1 Quick Start RIGOL

1-29

Figure 1-14 The Built-in Help Interface

User’s Guide for DSA800E Series

Find Quality Products Online at: sales@GlobalTestSupply.com

www.GlobalTestSupply.com

RIGOL Chapter 1 Quick Start

1-30

To Use the Security Lock

If necessary, use a security lock to lock the analyzer in a desired location. As shown

in the figure below, align the lock with the lock hole and plug it into the lock hole

vertically, turn the key clockwise to lock the instrument and then pull the key out.

Key

Security Lock

Security Lock Hole

Figure 1-15 To Use the Security Lock

Note: Please do not insert other articles into the security lock hole to avoid

damaging the instrument.

User’s Guide for DSA800E Series

Find Quality Products Online at: sales@GlobalTestSupply.com

www.GlobalTestSupply.com

Chapter 1 Quick Start RIGOL

1-31

To Replace the Fuse

Please replace the old fuse with specified fuse according to the following steps

when needed:

1. Turn off the instrument, cut off the power and remove the power cord.

2. Use a small straight screw driver to prize out the fuse seat.

3. Take out the fuse seat.

4. Replace the old fuse with a specified fuse.

5. Install the fuse seat.

Fuse

Fuse Seat

Figure 1-16 To Replace the Fuse

WARNING

Please ensure that the instrument has been turned off, the power source

has been cut off and the fuse to be used is a specified one before

replacing the fuse in order to avoid electric shock.

User’s Guide for DSA800E Series

Find Quality Products Online at: sales@GlobalTestSupply.com

www.GlobalTestSupply.com

Chapter 2 Front Panel Operation RIGOL

2-1

Chapter 2 Front Panel Operation

This chapter describes in detail the function keys at the front panel and the

associated functions.

Subjects in this chapter:

Basic Settings

Sweep and Function Settings

Measurement Settings

Marker Measurements

Shortcut Key

System Settings

User’s Guide for DSA800E Series

Find Quality Products Online at: sales@GlobalTestSupply.com

www.GlobalTestSupply.com

RIGOL Chapter 2 Front Panel Operation

2-2

start

f

stop

f

center

f

span

f

2)(

startstopcenter

fff +=

startstopspan

fff −=

Basic Settings

FREQ

Set the frequency parameters of the analyzer. The analyzer sweeps within a

specified frequency range and restarts sweeping every time the frequency

parameters are modified.

The frequency range of a channel can be expressed by either of two groups of

parameters: Start Frequency and Stop Frequency (

/

Frequency and Span (

). If any of the parameters is changed, the

/

); or Center

others would be adjusted automatically in order to ensure the coupling relationship

among them:

(2-1)

(2-2)

User’s Guide for DSA800E Series

Find Quality Products Online at: sales@GlobalTestSupply.com

www.GlobalTestSupply.com

Chapter 2 Front Panel Operation RIGOL

2-3

Default

Range*

Unit

Center Freq

Set the center frequency of the current channel. Press this key to switch to center

frequency/span input mode. The center frequency and span values are displayed

at the lower left and right sides of the grid respectively.

Key Points:

The start and stop frequencies vary with the center frequency when the span

is constant.

Changing the center frequency horizontally shifts the current channel and the

adjustment is limited by the specified frequency range.

In Zero Span mode, the start frequency, stop frequency and center frequency

are always the same. If one is changed, the others are updated to match.

You can use the numeric keys, the knob, or the arrow keys to modify the

parameter. Refer to "Parameter Setting" for more details.

Tab le 2-1 Center Frequency

Parameter Explanation

1.6 GHz

0 Hz to 3.2 GHz

GHz, MHz, kHz, Hz

Knob Step Span > 0, step = Span/200

Span = 0, step = RBW/100

Min = 1 Hz

Arrow Key Step CF step

Note: *The range is from 50 Hz to (3.2 GHz-50 Hz) in non-zero span.

Start Freq

Set the start frequency of the current channel. Press this key to switch to

start/stop frequency input mode. The start and stop frequencies are displayed at

the lower left and right sides of the grid respectively.

Key Points:

The span and center frequency vary with the start frequency. The change of

User’s Guide for DSA800E Series

Find Quality Products Online at: sales@GlobalTestSupply.com

www.GlobalTestSupply.com

RIGOL Chapter 2 Front Panel Operation

2-4

Knob Step

span would affect other system parameters. For more details, please refer to

"Span".

In Zero Span mode, the start frequency, stop frequency and center frequency

are always the same. If one is changed, the others are updated to match.

You can use the numeric keys, the knob, or the arrow keys to modify the

parameter. Refer to "Parameter Setting" for more details.

Tab le 2-2 Start Frequency

Parameter Explanation

Default 0 GHz

Range* 0 Hz to 3.2 GHz

Unit GHz, MHz, kHz, Hz

Span > 0, step = Span/200

Span = 0, step = RBW/100

Min = 1 Hz

Arrow Key Step CF step

Note: *The range is from 0 Hz to (3.2 GHz-100 Hz) in non-zero span.

Stop Freq

Set the stop frequency of the current channel. Press this key to switch to start/stop

frequency input mode. The start and stop frequencies are displayed at the lower

left and right sides of the grid respectively.

Key Points:

The span and center frequency vary with the stop frequency. The change of

span would affect other system parameters. For more details, please refer to

"Span".

In Zero Span mode, the start frequency, stop frequency and center frequency

are always the same. If one is changed, the others are updated to match.

You can use the numeric keys, the knob, or the arrow keys to modify the

parameter. For more details, please refer to "Parameter Setting".

User’s Guide for DSA800E Series

Find Quality Products Online at: sales@GlobalTestSupply.com

www.GlobalTestSupply.com

Chapter 2 Front Panel Operation RIGOL

2-5

Arrow Key Step

Tab le 2-3 Stop Frequency

Parameter Explanation

Default 3.2 GHz

Range* 0 Hz to 3.2 GHz

Unit GHz, MHz, kHz, Hz

Knob Step Span > 0, step = Span/200

Span = 0, step = VBW/100

Min = 1 Hz

CF step

Note: *The range is from 100 Hz to 3.2 GHz in non-zero span.

Freq Offset

You can set a frequency offset value to account for frequency conversions between

the device under test and the input terminal of the spectrum analyzer.

Key Points:

The change of this parameter only changes the display values of the center

frequency, start frequency and stop frequency; but does not impact any

hardware settings of the spectrum analyzer.

You can use the numeric keys, the knob, or the arrow keys to modify the

parameter. For more details, please refer to "Parameter Setting".

To eliminate an offset, you can perform Preset operation or set the frequency

offset to 0Hz.

Tab le 2-4 Frequency Offset

Parameter Explanation

Default 0 Hz

Range -100 GHz ~ 100 GHz

Unit GHz, MHz, kHz, Hz

Knob Step 16 MHz

Arrow Key Step CF Step

User’s Guide for DSA800E Series

Find Quality Products Online at: sales@GlobalTestSupply.com

www.GlobalTestSupply.com

RIGOL Chapter 2 Front Panel Operation

2-6

Parameter

Explanation

CF Step

Set the step of center frequency. Changing the center frequency in a fixed step

continuously switches the channel to be measured.

Key Points:

The CF step can be set in "Manual" or "Auto" mode. In Auto mode, the CF step

is 1/10 of the span in Non-zero span mode or equals the RBW while in Zero

span mode; in Manual mode, you can set the step using the numeric keys.

After you set an appropriate CF step and select Center Freq, use the up and

down arrow keys to switch between measurement channels in a specified

step in order to sweep the adjacent channel manually.

You can use the numeric keys, the knob, or the arrow keys to modify the

parameter. For more details, please refer to "Parameter Setting".

Tab le 2-5 CF Step

Default 320 MHz

Range 1 Hz to 3.2 GHz

Unit GHz, MHz, kHz, Hz

Knob Step Span > 0, step = Span/200

Span = 0, step = 100 Hz

Min = 1 Hz

Arrow Key Step in 1, 2, 5 sequence

Signal Track

Turn on or off signal track. This function is used to track and measure signal with

unstable frequency and less than 3 dB transient variation in amplitude. Place

Marker1 (see "Marker Measurements") onto the signal under measurement to

track and measure the variation of the signal continuously.

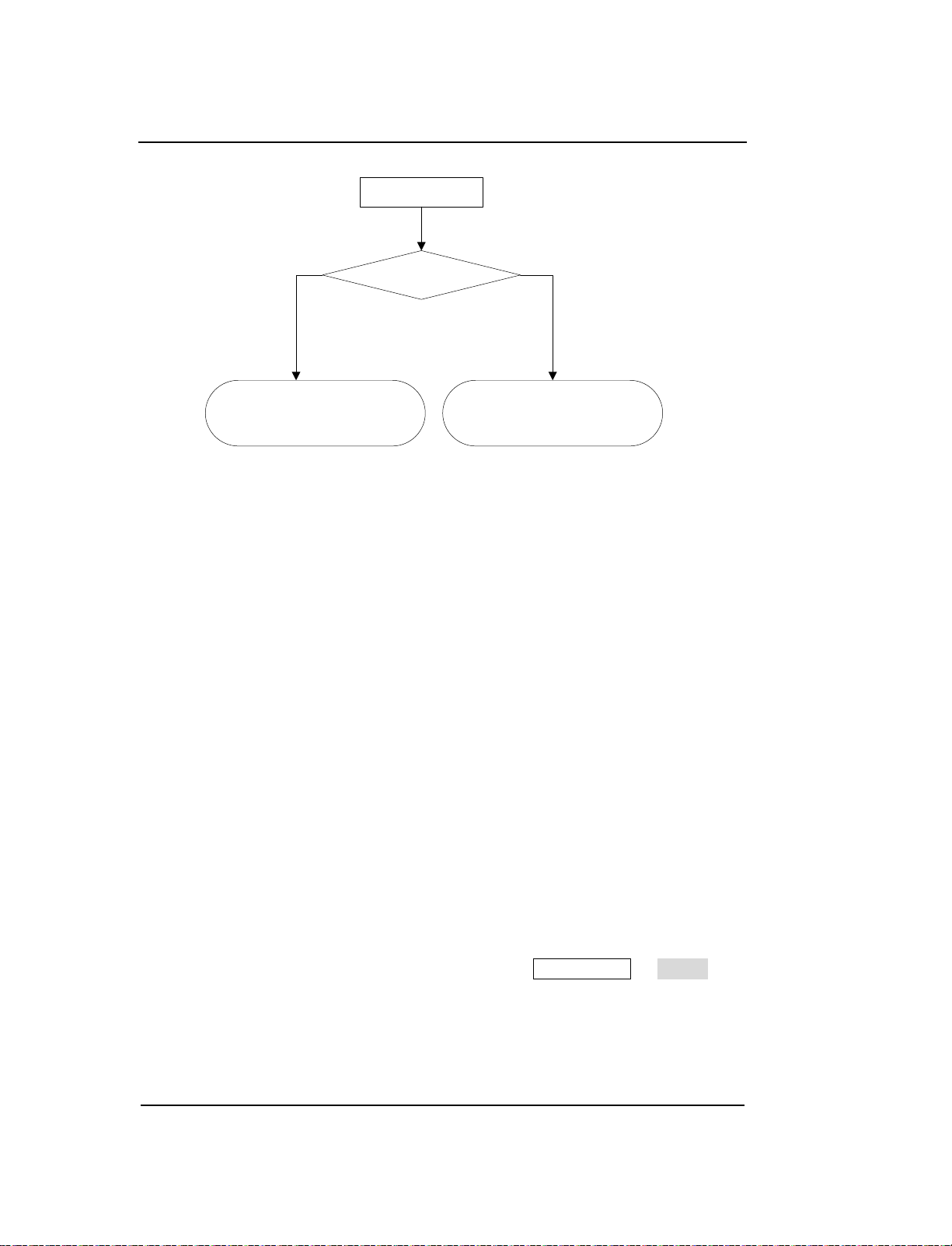

The signal track process is as shown in the figure below:

User’s Guide for DSA800E Series

Find Quality Products Online at: sales@GlobalTestSupply.com

www.GlobalTestSupply.com

Chapter 2 Front Panel Operation RIGOL

2-7

Start

Execute a

sweep

Search for

peak and

mark it as

Marker

Active Marker

exists?

N

Set marker

frequency to

center freq

Y

Execute the

next sweep

Search for and mark the

frequency point (variation

< 3dB) near the Marker

Figure 2-1 Process of Signal Track

Key Points:

When Signal Track is turned on, the ST (Signal Track) icon

is highlighted

in the status bar at the left of the screen.

If an active marker currently exists, when Signal Track is enabled, the

instrument will search for and mark the point (with no more than 3 dB

variation in amplitude) near the marker as well as set the frequency of this

point as the center frequency to hold the signal at the center of the screen.

If no marker is currently active, when Signal Track is enabled, the instrument

will activate Marker 1, execute a peak search automatically and set the

frequency of the current peak as the center frequency to hold the signal at the

center of the screen.

In continuous sweep, the system tracks the signal continuously; in single

sweep, the instrument only performs a single signal track; in Zero Span,

Signal Track is invalid.

User’s Guide for DSA800E Series

Find Quality Products Online at: sales@GlobalTestSupply.com

www.GlobalTestSupply.com

RIGOL Chapter 2 Front Panel Operation

2-8

Peak -> CF

Execute a peak search and use the frequency of the current peak as the center

frequency (CF) of the analyzer. The function is invalid in Zero Span mode.

Peak

Center Freq

Figure 2-2 Before Peak->CF

Peak

Center Freq

Figure 2-3 After Peak->CF

User’s Guide for DSA800E Series

Find Quality Products Online at: sales@GlobalTestSupply.com

www.GlobalTestSupply.com

Chapter 2 Front Panel Operation RIGOL

2-9

CF -> Step

Set the current center frequency as the CF step. At this point,

the CF step will switch to "Manual" mode automatically. This function is usually

used with channel switching. Take harmonic waveform measurement for example:

locate a signal at the center frequency of a channel, execute CF-> Step and then

press the down arrow key continuously to measure each order of harmonic in

sequence.

SPAN

Set the span of the analyzer. The change of this parameter will affect the frequency

parameters and restart the sweep.

Span

Set the frequency range of the current channel. Press this key to switch to center

frequency/span input mode. The center frequency and span are displayed at the

lower left and right sides of the grid respectively.

Key Points:

The start and stop frequencies vary with the span when the center frequency

is constant.

In manual span mode, the span can be set down to 100 Hz (the only way into

the zero-span mode is pressing the Zero Span menu option) and up to the

full span described in "

maximum, the analyzer enters full span mode.

Modifying the span in non-zero span mode may cause an automatic change in

both CF step and RBW if they are in Auto mode. Besides, the change of RBW

may influence VBW (in Auto VBW mode).

Variation in the span, RBW or VBW would cause a change in the sweep time.

In non-zero span mode, neither "Video" trigger nor "1/Δtime" readout

function is valid.

You can use the numeric keys, the knob, or the arrow keys to modify the

Specifications". When the span is set to the

User’s Guide for DSA800E Series

Find Quality Products Online at: sales@GlobalTestSupply.com

www.GlobalTestSupply.com

RIGOL Chapter 2 Front Panel Operation

2-10

Arrow Key Step

parameter. For more details, please refer to "Parameter Setting".

Tab le 2-6 Span

Parameter Explanation

Default 3.2 GHz

Range* 0 Hz to 3.2 GHz

Unit GHz, MHz, kHz, Hz

Knob Step Span/200, Min = 1 Hz

in 1, 2, 5 sequence

Note: *0 Hz is available only in zero span.

Full Span

Set the span of the analyzer to the maximum.

Zero Span

Set the span of the analyzer to 0 Hz. Both the start and stop frequencies will equal

the center frequency and the horizontal axis will denote time. The analyzer

measures the time domain characteristics of the amplitude of the corresponding

frequency point on the input signal.

Key Points:

As opposed to Non-zero span, the screen shows the time domain characteristics of

the fixed frequency component of the signal in zero span mode.

The following functions are invalid in Zero span mode:

FREQ: Peak->CF and Signal Track;

SPAN: Zoom In and Zoom Out;

Marker->: Mkr->CF, Mkr->Step, Mkr->Start, Mkr->Stop, MkrΔ->CF and

MkrΔ->Span;

Marker Readout: Frequency, Period and 1/ΔTime (valid in Delta marker

type).

User’s Guide for DSA800E Series

Find Quality Products Online at: sales@GlobalTestSupply.com

www.GlobalTestSupply.com

Chapter 2 Front Panel Operation RIGOL

2-11

Zoom In

Set the span to half of its current value. At this point, the signal on the screen is

zoomed in to observe signal details.

Zoom Out

Set the span to twice the current value. At this point, the signal on the screen is

zoomed out to gain more information about the signal.

Last Span

Set the span to the previous span setting.

X Scale

Select the scale type of X-axis to Lin or Log. The default is Lin.

Key Points:

In Log scale type, the frequency scale of X-axis is displayed in the logarithmic

form.

When the scale type of X-axis is set to Log and any advanced measurement

function (including T-P ow er, ACP (Adjacent Channel Power), Chan Pwr

(Channel Power), OBW (Occupied Bandwidth), EBW (Emission Bandwidth),

C/N Ratio, Harmo Dist (Harmonic Distortion) and TOI (Third Order

Intermodulation)) is selected, the instrument switches the scale type of X-axis

to Lin automatically.

User’s Guide for DSA800E Series

Find Quality Products Online at: sales@GlobalTestSupply.com

www.GlobalTestSupply.com

RIGOL Chapter 2 Front Panel Operation

2-12

AMPT

Set the amplitude parameters of the analyzer. Through modifying these

parameters, signals under measurement can be displayed in a proper mode for

easier obsercation and minimum error.

Auto Scale

This function enables the readout resolution of the Y-axis to be the maximum

possible while at the same time ensures the completeness of the signal. When

enabled, the system sets the reference level automatically in order to place the

peak of the signal within the topmost grid for easier observation of the trace.

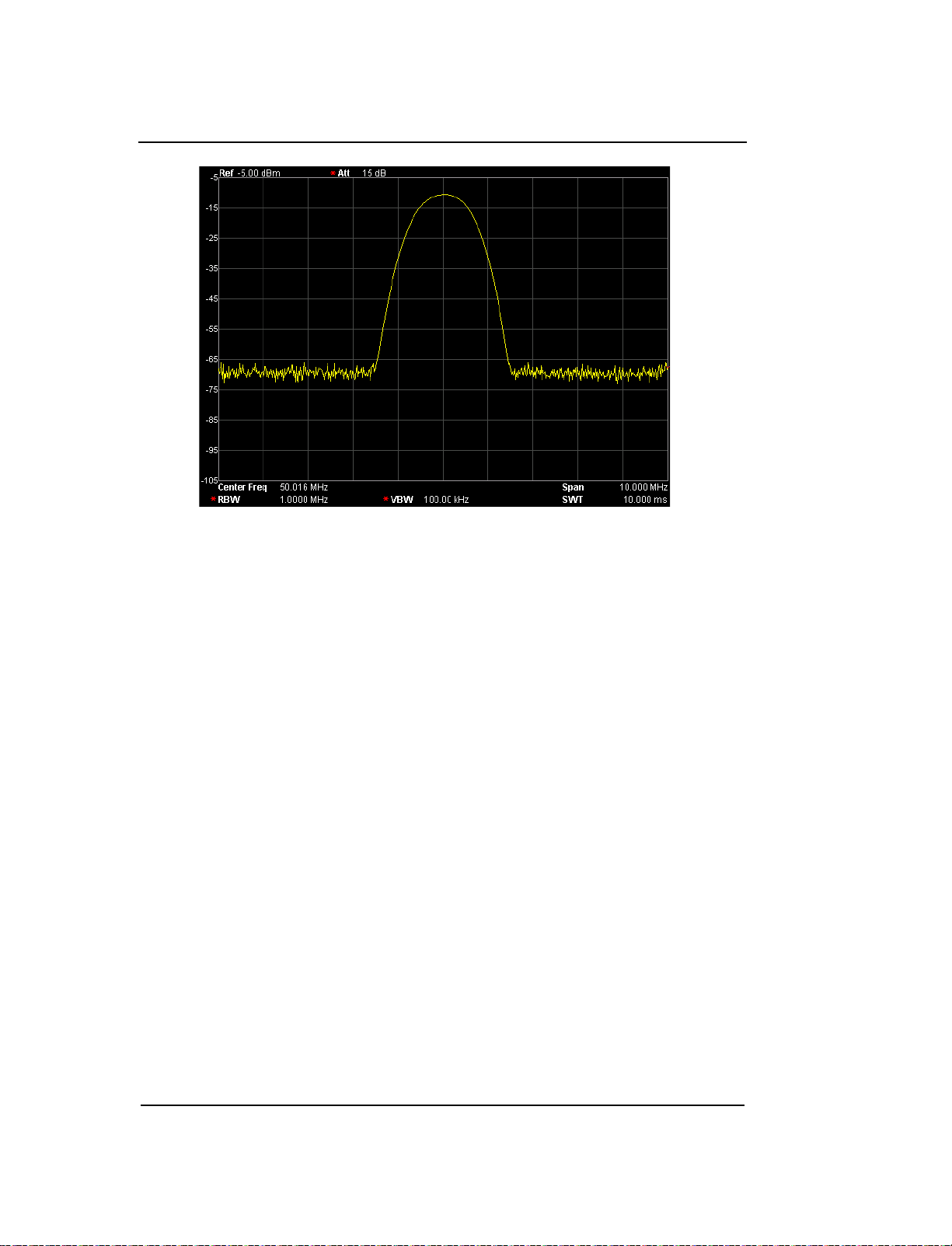

Figure 2-4 Before Auto Scale

User’s Guide for DSA800E Series

Find Quality Products Online at: sales@GlobalTestSupply.com

www.GlobalTestSupply.com

Chapter 2 Front Panel Operation RIGOL

2-13

mixPARFRef

LaaL ≤+−

Ref

L

RF

a

PA

a

mix

L

Figure 2-5 After Auto Scale

Ref Level

Set the maximum power or voltage can be currently displayed in the window. The

value is displayed at the upper left corner of the screen grid.

Key Points:

The maximum reference level available is affected by the maximum mixing

level, input attenuation and preamplifier. When you adjust it, the input

attenuation is adjusted under a constant maximum mixing level in order to

fulfill the following inequality:

(2-3)

Wherein,

attenuation, preamplifier and maximum mixing level respectively.

You can use the numeric keys, the knob, or the arrow keys to modify the

parameter. For more details, please refer to "Parameter Setting".

,

,

and