Page 1

RIGOL

Service Guide

DS1000E, DS1000D Series

Digital Oscilloscopes

DS1102E, DS1052E, DS1102D, DS1052D

May 2009

RIGOL Technologies, Inc.

Page 2

Page 3

RIGOL

I

Copyright

© 2009 RIGOL Technologies, Inc. All Rights Reserved.

Trademark Information

RIGOL is registered trademark of RIGOL Technologies, Inc.

Notices

RIGOL products are protected by patent law in and outside of P.R.C..

RIGOL Technologies, Inc. reserves the right to modify or change parts of or all the

specifications and pricing policies at company’s sole decision.

Information in this publication replaces all previously corresponding material.

RIGOL shall not be liable for losses caused by either incidental or consequential in

connection with the furnishing, use or performance of this manual as well as any

information contained.

Any part of this document is forbidden to copy or photocopy or rearrange without prior

written approval of RIGOL.

Service Guide for DS1000E, DS1000D Series

Page 4

RIGOL

II

Safety Notices

Review the following safety precautions carefully before operating the instrument to

avoid any personal injuries or damages to the instrument and any product connected

to it. To prevent potential hazards, do use the instrument specified by this user’s guide

only.

The instrument should be serviced by qualified personnel only.

To avoid instrument damage or personnel injury caused by misoperation, the

instrument should be serviced by qualified personnel only.

Use Proper Power Cord.

Use the power cord designed for the instrument and authorized in your country only.

Connect and Disconnect Accessories.

Do not connect or disconnect probes or test leads while they are connected to a

voltage source.

Ground The Instrument.

The oscilloscope is grounded through the grounding conductor of the power cord. To

avoid electric shock the instrument grounding conductor(s) must be grounded

properly. Before making connections to the input or output terminals of the

instrument.

Connect The Probe.

The probes’ ground terminals are at the same voltage level of the instrument ground.

Do not connect the ground terminals to a high voltage.

Observe All Terminal Ratings.

To avoid fire or shock hazard, observe all ratings and marks on the instrument. Follow

the user’s guide for further ratings information before making connections to the

instrument.

Do Not Operate Without Covers.

Do not operate the instrument with covers or panels removed.

Use Proper Fuse.

Use the fuse of the type, voltage and current ratings as specified for the instrument.

Avoid Circuit or Wire Exposure.

Do not touch exposed connections and components when power is on.

Do Not Operate With Suspected Failures.

If suspected damage occurs with the instrument, have it inspected by qualified service

personnel before further operations.

Service Guide for DS1000E, DS1000D Series

Page 5

RIGOL

III

Keep Well Ventilation.

Inadequately ventilated will cause the temperature rises or damages to the device.

Please keep well ventilation and inspect the intake and fan regularly.

Do not Operate in Wet/Damp Conditions.

In order to avoid short circuit to the interior of the device or electric shock, please do

not operate in a humid environment.

Do not Operate in an Explosive atmosphere.

In order to avoid damages to the device or personal injury, please operate far away

from an explosive atmosphere.

Keep Product Surfaces Clean and Dry.

In order to prevent the performance of the device from influencing by dust or water in

air, please keep the surface of device clean and dry.

The disturbance test of all the models meet the limit values of A in the

standard of EN 61326: 1997+A1+A2+A3, but can’t meet the limit values of

B.

Measurement Category

The DS1000E, DS1000D series Digital Oscilloscope is intended to be used for

measurements in Measurement Category I.

Measurement Category Definitions

Measurement Category I is for measurements performed on circuits not directly

connected to MAINS. Examples are measurements on circuits not derived from MAINS,

and specially protected (internal) MAINS derived circuits. In the latter case, transient

stresses are variable; for that reason, the transient withstand capability of the

equipment is made known to the user.

WARNING

IEC Measurement Category I, The input terminals may be connected to circuit

terminal in IEC Category I installations for voltages up to 300 VAC. To avoid the

danger of electric shock, do not connect the inputs to circuit’s voltages above 300 VAC.

Transient overvoltage is also present on circuits that are isolated from mains. The

DS1000E, DS1000D series Digital Oscilloscopes is designed to safely withstand

occasional transient overvoltage up to 1000Vpk. Do not use this equipment to

measure circuits where transient overvoltage could exceed this level.

Service Guide for DS1000E, DS1000D Series

Page 6

RIGOL

IV

!

!

Protective

Earth

Terminal

Hazardous

Voltage

Refer to

Instructions

Test

Ground

Chassis

Ground

!

Safety Terms and Symbols

Terms in this Guide. These terms may appear in this manual:

WARNING

Warning statements indicate the conditions or practices that could result in

injury or loss of life.

CAUTION

Caution statements indicate the conditions or practices that could result in

damage to this product or other property.

Terms on the Product. These terms may appear on the product:

DANGER indicates an injury or hazard that may immediately happen.

WARNING indicates a potential injury or hazard that may happen.

CAUTION indicates that a potential damage to the instrument or other property

might occur.

Symbols on the Product. These symbols may appear on the product:

Service Guide for DS1000E, DS1000D Series

Page 7

RIGOL

V

Document Overview

Chapter 1 Specifications

List the specifications and general specifications of DS1000E, DS1000D series.

Chapter 2 Prepare for Use

Introduce the preparatory work should be done before using the oscilloscope.

Chapter 3 Performance Test

Introduce how to execute the performance test to understand current performance

status of the oscilloscope.

Chapter 4 Calibration

Introduce how to calibrate the oscilloscope.

Chapter 5 Disassembly and Assembly

Introduce how to disassemble and assemble the oscilloscope to understand its

structure.

Chapter 6 Troubleshooting

List the troubles may appear during measuring and the corresponding solutions.

Chapter 7 Replaceable Parts

List the replaceable parts for user’s repair or exchange.

Chapter 8 Service & Support

Provide the service and support information.

Service Guide for DS1000E, DS1000D Series

Page 8

RIGOL

VI

Contents

Safety Notices ............................................................................................. II

Safety Terms and Symbols ........................................................................... IV

Document Overview ..................................................................................... V

Contents .................................................................................................... VI

Figures .................................................................................................... VIII

Tables ........................................................................................................ IX

Chapter 1 Specifications ........................................................................ 1-1

Specifications ........................................................................................... 1-2

General Specifications ............................................................................... 1-5

Chapter 2 Prepare for Use ..................................................................... 2-1

General Inspection .................................................................................... 2-2

Power-On Inspection ................................................................................. 2-3

Connect the Probe .................................................................................... 2-4

Probe Compensation ................................................................................. 2-5

Digital Probe (Only for DS1000D Series) ..................................................... 2-7

Display a Waveform Automatically .............................................................. 2-9

Chapter 3 Performance Test .................................................................. 3-1

Interfaces Test .......................................................................................... 3-2

USB Host Interface Test ...................................................................... 3-2

USB Device Interface Test ................................................................... 3-4

RS-232 Interface Test ......................................................................... 3-6

P/F Interface Test ............................................................................... 3-8

Logic Analyzer Interface Test (Only for DS1000D Series) ....................... 3-9

Specifications Test .................................................................................. 3-11

Chapter 4 Calibration ............................................................................. 4-1

Chapter 5 Disassembly and Assembly ................................................... 5-1

Notices .................................................................................................... 5-2

Structure Chart ......................................................................................... 5-3

Disassemble and Assemble the Cover ......................................................... 5-4

Disassemble and Assemble the Upper and Rear Covers ............................... 5-5

Disassemble and Assemble the Power Board and the Fan ............................ 5-6

Disassemble and Assemble the Panel ......................................................... 5-8

Disassemble and Assemble LCD and the Keyboard ...................................... 5-9

Disassemble and Assemble the Mainboard ................................................ 5-10

Chapter 6 Troubleshooting .................................................................... 6-1

Chapter 7 Replaceable Parts .................................................................. 7-1

Chapter 8 Service & Support.................................................................. 8-1

Service Guide for DS1000E, DS1000D Series

Page 9

RIGOL

VII

Warranty .................................................................................................. 8-2

Care and Cleaning ..................................................................................... 8-3

Contact Us ................................................................................................ 8-4

Index ........................................................................................................... 1

Service Guide for DS1000E, DS1000D Series

Page 10

RIGOL

VIII

Figures

Figure 2-1 Connect the power cord ................................................................... 2-3

Figure 2-2 Power-on inspection ........................................................................ 2-3

Figure 2-3 Connect probe to oscilloscope .......................................................... 2-4

Figure 2-4 Connect probe to circuit ................................................................... 2-4

Figure 2-5 Set the probe attenuation quotient and switch ................................... 2-5

Figure 2-6 Connect the probe compensator ....................................................... 2-5

Figure 2-7 Waveform compensation .................................................................. 2-6

Figure 2-8 Connect the digital probes to oscilloscope ......................................... 2-7

Figure 2-9 Test clip of digital probe ................................................................... 2-7

Figure 2-10 Attach the clip to testing point ........................................................ 2-8

Figure 2-11 Connecting to the ground ............................................................... 2-8

Figure 3-1 Connect the U disk .......................................................................... 3-2

Figure 3-2 Successful prompt of USB interface connection .................................. 3-2

Figure 3-3 USB Device interface connection ....................................................... 3-4

Figure 3-4 Select USB interface ........................................................................ 3-4

Figure 3-5 Fail prompt of USB interface connection ............................................ 3-5

Figure 3-6 RS-232 interface connection ............................................................. 3-6

Figure 3-7 Select RS-232 interface .................................................................... 3-6

Figure 3-8 RS-232 interface setting ................................................................... 3-7

Figure 3-9 Fail prompt of RS-232 interface connection ........................................ 3-7

Figure 3-10 P/F interface connection ................................................................. 3-8

Figure 3-11 DS1000D LA interface connection ................................................... 3-9

Figure 3-12 Setting interface .......................................................................... 3-10

Figure 3-13 Edge trigger of digital channel ...................................................... 3-10

Figure 3-14 Connect the testing device ........................................................... 3-11

Figure 4-1 Self-Calibration interface .................................................................. 4-1

Figure 4-2 Finish Self-Calibration ...................................................................... 4-1

Figure 5-1 Stucture chart ................................................................................. 5-3

Figure 5-2 Disassemble and assemble the cover ................................................ 5-4

Figure 5-3 Disassemble and assemble the upper and rear covers ........................ 5-5

Figure 5-4 Disassemble and assemble the power board and the fan .................... 5-6

Figure 5-5 Disassemble and assemble the panel ................................................ 5-8

Figure 5-6 Disassemble and assemble LCD and the keyboard ............................. 5-9

Figure 5-7 Disassemble and assemble the mainboard ....................................... 5-10

Figure 7-1 DS1000E, DS1000D Exploded View ................................................... 7-1

Service Guide for DS1000E, DS1000D Series

Page 11

RIGOL

IX

Tables

Table 2-1 The auto items .................................................................................. 2-9

Table 3-1 Pass/Fail setting items........................................................................ 3-8

Table 3-2 Testing specifications and the ranges ................................................ 3-11

Table 7-1 Replaceable parts list ......................................................................... 7-1

Service Guide for DS1000E, DS1000D Series

Page 12

Page 13

Chapter 1 Specifications RIGOL

1-1

Chapter 1 Specifications

All specifications apply to DS1000E, DS1000D series Oscilloscopes unless noted

otherwise. To meet these specifications, two conditions must first be met:

The instrument must have been operating continuously for thirty minutes within

the specified operating temperature.

Do perform the “Self Cal” operation, accessible through the Utility menu, if the

operating temperature changes by more than 5°C.

NOTE: All specifications are guaranteed unless noted “typical”.

Service Guide for DS1000E, DS1000D Series

Page 14

RIGOL Chapter 1 Specifications

1-2

Acquisition

Sampling Modes

Real-Time

Equivalent

Sampling Rate

1GSa/s, 200MSa/s

[1]

DS1102X

DS1052X

25GSa/s

10GSa/s

Averages

N time acquisitions, all channels simultaneously, N is

selectable from 2, 4, 8, 16, 32, 64, 128 and 256.

Inputs

Input Coupling

DC, AC, GND

Input Impedance

1MΩ±2%

18pF± 3pF

Probe Attenuation Factors

1X, 5X, 10X, 50X, 100X, 500X,1000X

Maximum Input Voltage

400V (DC+AC Peak, 1MΩ input impedance)

40V (DC+AC Peak)

[1]

Time delay between channel

(typical)

500ps

Horizontal

Sample Rate

Range

Real-Time: 13.65Sa/s-1GSa/s

Equivalent: 13.65Sa/s-25GSa/s

Waveform

interpolation

Sin(x)/x

Record Length

Channel Mode

Sample rate

Record

Length

(normal)

Record

Length

(long record)

Single channel

1GSa/s

16kpts

N.A.

Single channel

500MSa/s

Or lower

16kpts

1Mpts

Double channel

500MSa/s

Or lower

8kpts

N.A.

Double channel

250MSa/s

Or lower

8kpts

512kpts

Scan speed Range

(Sec/div)

2ns/div~50s/div, DS1102X

5ns/div~50s/div, DS1052X

1-2-5 Sequence

Sample Rate and

Delay Time

Accuracy

± 50ppm (over any 1ms time interval)

Delta Time

Measurement

Accuracy

(Full Bandwidth)

Single-shot: ± (1 sample interval + 50ppm × reading + 0.6 ns)

>16 averages: ± (1sample interval + 50ppm × reading + 0.4

ns)

Vertical

Specifications

Service Guide for DS1000E, DS1000D Series

Page 15

Chapter 1 Specifications RIGOL

1-3

A/D converter

8-bit resolution, each channel samples simultaneously

[2]

Volts/div Range

2mV/div~10V/div at input BNC

Maximum Input

Analog channel maximum input voltage

CAT I 300Vrms, 1000Vpk; instantaneous voltage 1000Vpk

CAT II 100Vrms, 1000Vpk

RP2200 10:1: CAT II 300Vrms

RP3200 10:1: CAT II 300Vrms

RP3300 10:1: CAT II 300Vrms

Offset Range

± 40V(250mV/div~10V/div),± 2V(2mV/div~245mV/div)

Analog Bandwidth

100MHz (DS1102D,DS1102E)

50MHz (DS1052D, DS1052E)

Single-shot

Bandwidth

100MHz (DS1102D, DS1102E)

50MHz (DS1052D, DS1052E)

Selectable Analog

Bandwidth Limit

(typical)

20MHz

Lower Frequency

Limit (AC –3dB)

≤5Hz (at input BNC)

Rise Time at BNC,

typical

<3.5ns, <7ns,

On (100MHz, 50MHz) respectively

Dynamic range

± 5div

DC Gain Accuracy

2mV/div-5mV/div:

± 4% (Normal or Average acquisition mode)

10mV/div-10V/div:

± 3% (Normal or Average acquisition mode)

DC Measurement

Accuracy, Average

Acquisition Mode

Average of ≥16 Waveforms with vertical position at zero:

±(DC Gain Accuracy× reading+0.1div+1mV)

Average of ≥16 Waveforms with vertical position not at zero:

±[DC Gain Accuracy× (reading+vertical position)+(1% of

vertical position) + 0.2div]

Add 2mV for settings from 2mV/div to 245 mV/div

Add 50mV for settings from >250mV/div to 10V/div

Delta Volts

Measurement

Accuracy (Average

Acquisition Mode)

Delta Volts between any two averages of 16 waveforms

acquired under same setup and ambient

conditions: ± (DC Gain Accuracy× reading + 0.05 div)

Trigger

Trigger Sensitivity

0.1div~1.0div (adjustable)

Trigger Level Range

Internal

± 6 divisions from center of screen

EXT

± 1.2V

Trigger Level Accuracy

(typical) applicable for

the signal of rising and

falling time ≥20ns

Internal

± (0.3div × V/div)(± 4 divisions from center of

screen)

EXT

± (6% of setting + 200 mV)

Service Guide for DS1000E, DS1000D Series

Page 16

RIGOL Chapter 1 Specifications

1-4

Trigger Offset

Normal mode: pre-trigger (storage depth/ 2*sampling

rate), delayed trigger 1s

Slow Scan mode: pre-trigger 6div, delayed trigger 6div

Trigger Holdoff range

500ns~1.5s

Set Level to 50%

(Typical)

Input signal frequency ≥50Hz

Edge Trigger

Edge trigger slope

Rising, Falling, Rising + Falling

Pulse Trigger

Trigger condition

(>, <, =) Positive pulse, (>, <, =) negative pulse

Pulse Width range

20ns ~10s

Video Trigger

Video standard &

line frequency

Support standard NTSC, PAL and SECAM broadcast systems.

Line number range: 1~525 (NTSC) and 1~625 (PAL/SECAM)

Slope Trigger

Trigger condition

(>, <, =) Positive slope, (>, <, =) negative slope

Time setting

20ns~10s

Alternate Trigger

Trigger on CH1

Edge, Pulse, Video, Slope

Trigger on CH2

Edge, Pulse, Video, Slope

Pattern Trigger

[1]

Trigger mode

D0~D15 select H, L, X, ,

Duration Trigger

[1]

Trigger Type

D0~D15 select H, L, X

Qualifier

>, <, =

Time setup

20ns~10s

Measurements

Cursor

Manual

Voltage difference between cursors (∆V)

Time difference between cursors (∆T)

Reciprocal of ∆T in Hertz (1/∆T)

Track

Voltage value for Y-axis waveform

Time value for X-axis waveform

Auto

Cursors are visible for Automatic Measurement

Auto Measure

Vpp, Vamp, Vmax, Vmin, Vtop, Vbase, Vavg, Vrms, Overshoot,

Preshoot, Freq, Period, Rise Time, Fall Time, +Width, -Width,

+Duty, -Duty, Delay1→2 , Delay1→2

Remarks:

[1] For DS1000D series;

[2] When sampling is 1GSa/s, only single channel can be used.

Service Guide for DS1000E, DS1000D Series

Page 17

Chapter 1 Specifications RIGOL

1-5

Display

Display Type

5.7 in. (145 mm) diagonal TFT Liquid Crystal Display

Display Resolution

320 horizontal × RGB× 234 vertical pixels

Display Color

64k color

Display Contrast (typical)

150:1

Backlight

Brightness(typical)

300 nit

Probe Compensator Output

Output Voltage(typical)

Approximately 3Vpp (peak to peak value)

Frequency(typical)

1kHz

Power

Supply Voltage

100 ~ 240 VAC

RMS

, 45~440Hz, CAT II

Power Consumption

Less than 50W

Fuse

2A, T rating, 250 V

Environmental

Ambient Temperature

Operating 10℃~ 40℃

Non-operating -20℃~ +60℃

Cooling Method

Fan force air flow

Humidity

+35℃ or below: ≤90% relative humidity

+35℃~ +40℃: ≤60% relative humidity

Altitude

Operating 3,000 m or below

Non-operating 15,000 m or below

Mechanical

Size

Width

303mm

Height

154mm

Depth

133 mm

Heavy

Without package

2.3 kg

Packaged

3.5 kg

IP Protection

IP2X

Calibration Interval

The recommended calibration interval is one year

General Specifications

Service Guide for DS1000E, DS1000D Series

Page 18

Page 19

Chapter 2 Prepare for Use RIGOL

2-1

Chapter 2 Prepare for Use

This chapter contains the following topics:

General Inspection

Power-On Inspection

Connect the Probe

Probe Compensation

Digital Probe (Only for DS1000D Series)

Display a Waveform Automatically

Service Guide for DS1000E, DS1000D Series

Page 20

RIGOL Chapter 2 Prepare for Use

2-2

General Inspection

When you get a new DS1000E, DS1000D series oscilloscope, please inspect the

instrument according to the following steps:

1. Inspect the shipping container for damage.

Keep a damaged shipping container and cushioning material until the contents of

the shipment have been checked for completeness and the instrument has been

checked mechanically and electrically.

2. Inspect the instrument.

In case there is any mechanical damage or defect, or the instrument does not

operate properly or fails performance tests, please notify the RIGOL Sales

Representative.

If the shipping container is damaged, or the cushioning materials show signs of

stress, please notify the carrier as well as the RIGOL sales office. Keep the

shipping materials for the carrier’s inspection. RIGOL offices will arrange for

repair or replacement at RIGOL’s option without waiting for claim settlement.

3. Check the accessories.

Accessories supplied with the instrument are listed below. If the contents are

incomplete or damaged, please notify the RIGOL Sales Representative.

Standard Accessories:

Probe× 2 (1.5m), (1:1 or 10:1 adjustable) Passive Probes

The passive probes have a 6MHz bandwidth with a rating of 150V CAT II

when the switch is in the 1X position, and a Full oscilloscope bandwidth with

a rating of 300 V CAT II when the switch is in the 10X position.

A Power Cord that fits the standard of destination country

An USB Cable

A Logic Cable (only for DS1000D series)

An active logic head (only for DS1000D series)

20 Logic Testing Nips (only for DS1000D series)

20 Logic Testing Leads (only for DS1000D series)

A CD-ROM (including “User’s Guide” and Application Software)

A Quick Guide

Service Guide for DS1000E, DS1000D Series

Page 21

Chapter 2 Prepare for Use RIGOL

2-3

!

Storage button

Power button

Power-On Inspection

Generally, normal operating voltage and frequency for DS1000E, DS1000D series

digital oscilloscope are 100-240V

terminal of the power cord to the socket in left side of the oscilloscope and the other

to the AC power source.

and 45-440Hz respectively. Please connect one

RMS

Figure 2-1 Connect the power cord

Press the power button on top of the oscilloscope, some keys on the front panel will

light for about 2 seconds until the normal display appears. And then you can operate

the oscilloscope.

WARNING

To avoid the electric shock, make sure the oscilloscope is under good

grounding before connecting AC power.

After power-on, the oscilloscope performs all the self-testing automatically. Then,

press Storage and select Storage to recall the Factory settings after passing test (the

screen will appear).

Figure 2-2 Power-on inspection

Service Guide for DS1000E, DS1000D Series

Page 22

RIGOL Chapter 2 Prepare for Use

2-4

!

Connect the Probe

DS1000E series is a type of digital oscilloscope with dual channel inputs and one

external trigger input. While, DS1000D series is a type with dual channel input, one

external trigger input and sixteen channel digital inputs.

Please take the following steps to connect the probe:

1. Attach BNC connector of the probe to the channel input or external trigger

interfaces, insert it vertically until it latches into places. Then circumvolve the BNC

connector clockwise to get a firm connection.

Figure 2-3 Connect probe to oscilloscope

2. Connect the other end of probe to circuit under test.

Figure 2-4 Connect probe to circuit

3. Disconnect the circuit after testing, and then circumvolve the BNC connector of

probe anticlockwise, and pull it out of the interface vertically.

WARNING

When use 10:1 attenuation probe, don’t input a signal with higher than

maximum input voltage.

Service Guide for DS1000E, DS1000D Series

Page 23

Chapter 2 Prepare for Use RIGOL

2-5

Probe Attenuation Quotient

Probe Compensation

You are suggested to compensate probe before first using so as to match its

characteristics with oscilloscope. Measurement error may be generated without

compensation or because of deviation compensation. To compensate the probe,

follow the steps below.

1. Set both the attenuation switch of the probe and the probe scale in the menu to

10X.

Figure 2-5 Set the probe attenuation quotient and switch

2. Connect the probe to CH1. And attach both the probe tip and ground lead to the

connector of probe compensator.

Figure 2-6 Connect the probe compensator

3. Open CH1 and press AUTO button after a few seconds, a square wave will be

displayed (1 kHz, approximately 3 V peak- to- peak). Check if the compensation is

Service Guide for DS1000E, DS1000D Series

Page 24

RIGOL Chapter 2 Prepare for Use

2-6

!

correct in accordance with the shape of waveform.

Over compensation Correct Compensation Under Compensation

Figure 2-7 Waveform compensation

4. If necessary, use a non-metallic screwdriver to adjust the variable capacitor of the

probe until a “Correct Compensation” wave displayed on the screen.

5. Continue in the same way to check CH2.

WARNING

To avoid electric shock while using the probe, be sure the perfection of the

insulated cable, and do not touch the metallic portions of the probe head

while it is connected with a high-voltage power supply.

Service Guide for DS1000E, DS1000D Series

Page 25

Chapter 2 Prepare for Use RIGOL

2-7

Test clip

!

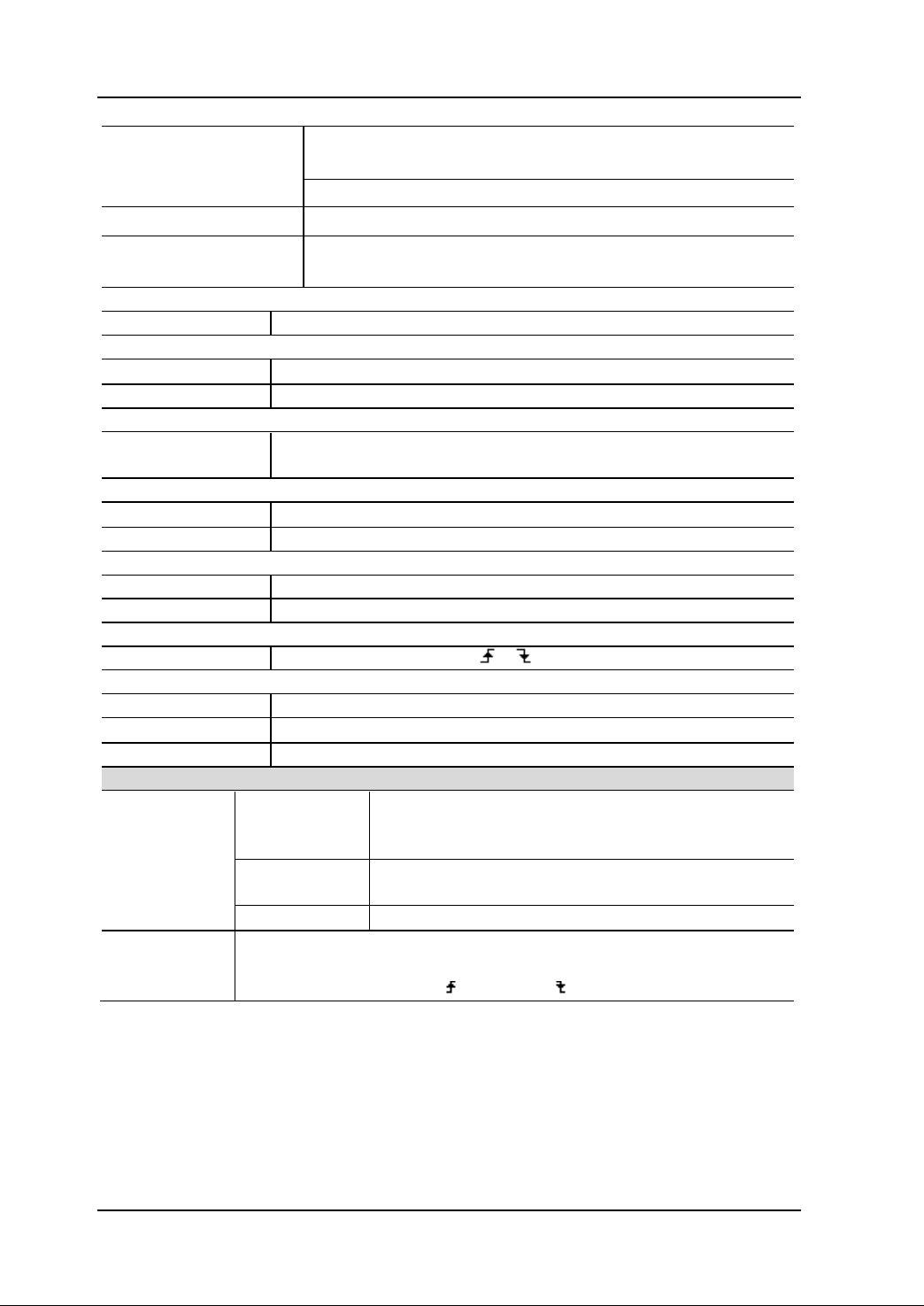

Digital Probe (Only for DS1000D Series)

DS1000D series provide sixteen digital channels. Take the steps below to connect

instrument and test points by digital probes:

1. Switch off power supply of the device under test if necessary to avoid short circuit.

Since no voltage is applied to the leads at this step, you may keep the

oscilloscope on.

2. Connect one terminal of the flat cable FC1868 to the Logic Analyzer Input;

connect the other end to Logic Head LH1116. An identifier is located on each end

of the flat cable; it can only be connected in one way. It is unnecessary to switch

off power supply of your oscilloscope when connecting the cable.

Figure 2-8 Connect the digital probes to oscilloscope

CAUTION

Use only FC1868, LH1116, TC1100 and LC1150 made by RIGOL for

specified DS1000D series.

3. Connect a test clip to one lead wire; make sure it’s connection good.

Figure 2-9 Test clip of digital probe

4. Test your device with the clip.

Service Guide for DS1000E, DS1000D Series

Page 26

RIGOL Chapter 2 Prepare for Use

2-8

Ground

Figure 2-10 Attach the clip to testing point

5. Connect the test clip to the ground.

Figure 2-11 Connect to the ground

Service Guide for DS1000E, DS1000D Series

Page 27

Chapter 2 Prepare for Use RIGOL

2-9

Functions

Settings

Display format

Y-T

Acquire mode

Normal

Vertical coupling

Adjust to AC or DC according to the

signal.

Vertical “V/div”

Adjust to right position

Volts/Div

Coarse

Bandwidth limit

Full

Signal Invert

OFF

Horizontal position

Center

Horizontal “S/div”

Adjust to right position

Trigger type

Edge

Trigger source

Find the channel with input signal

automatically.

Trigger coupling

DC

Trigger voltage

Midpoint setting

Trigger mode

Auto

knob

Trigger offset

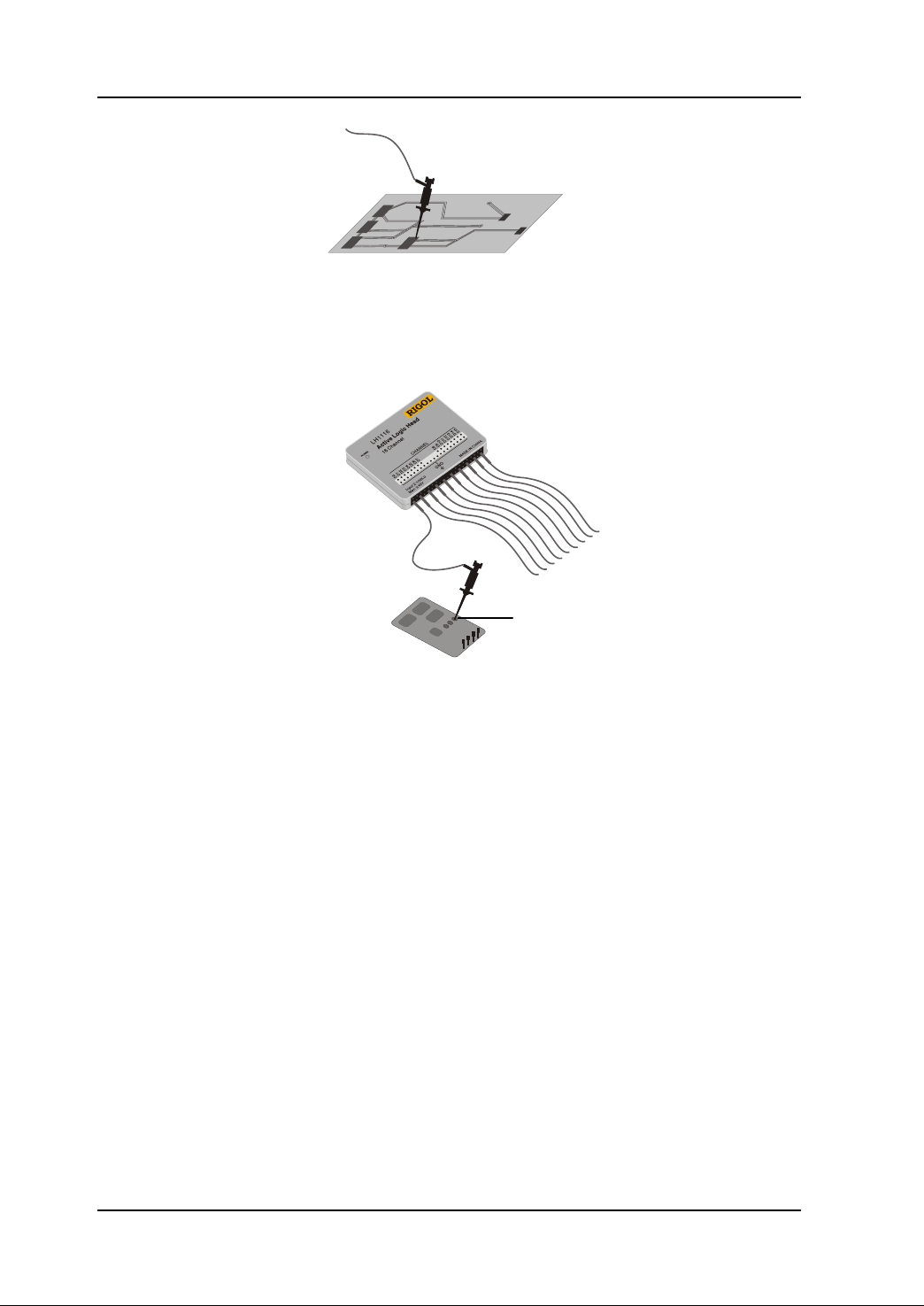

Display a Waveform Automatically

DS1000E, DS1000D series digital oscilloscopes have an automatic feature to display

the input signal best-fit. The oscilloscope enables to automatically set up VERTICAL,

HORIZONTAL and TRIGGER parameters for the input signal under display. The input

signal should be 50Hz or higher of frequency and the duty cycle of which should

greater than 1%.

1. Operation steps

Connect a signal to input channel.

Press AUTO and adjust parameters manually to get the best display if necessary.

2. Auto settings

Table 2-1 The auto items

Service Guide for DS1000E, DS1000D Series

Page 28

Page 29

Chapter 3 Performance Test RIGOL

3-1

Chapter 3 Performance Test

This chapter contains the following topics:

Interfaces Test

USB Host Interface Test

USB Device Interface Test

RS-232 Interface Test

P/F Interface Test

Logic Analyzer Interface Test (Only for DS1000D Series)

Specifications Test

Service Guide for DS1000E, DS1000D Series

Page 30

RIGOL Chapter 3 Performance Test

3-2

Interfaces Test

USB Host Interface Test

Purpose:

Test if the USB Host interface works normally through U disc.

Tools:

A set of DS1000E, DS1000D series digital oscilloscope

An U disk

Steps:

1. Insert the U disk into the USB Host interface on the front panel of the

oscilloscope.

Figure 3-1 Connect the U disk

2. Wait until a prompt “USB device install success” appeared on the screen, which

indicates the USB Host interface works normally, otherwise, you need to check or

repair this interface.

Figure 3-2 Successful prompt of USB interface connection

Service Guide for DS1000E, DS1000D Series

Page 31

Chapter 3 Performance Test RIGOL

3-3

3. If an update program about the oscilloscope available in the U disc is detected, a

prompt will appeared to ask you whether to update or not; if select OK, the

corresponding update process will be shown on the screen.

4. Press Storage→External to copy or delete the information in U disc.

5. Remove the U disc and a corresponding prompt “USB device removed” will

appear.

Service Guide for DS1000E, DS1000D Series

Page 32

RIGOL Chapter 3 Performance Test

3-4

USB Device Interface Test

Purpose:

Test if the USB Device interface works normally through Ultrascope for DS1000E,

DS1000D series.

Tools:

A set of DS1000E, DS1000D series digital oscilloscope

A PC with USB interface

A standard USB cable (Type AB)

Ultrascope for DS1000E, DS1000D series

Steps:

1. Install the Ultrascope for DS1000E, DS1000D series software on the PC.

2. Connect the oscilloscope with PC using an USB cable, and install the driver

program step by step following the prompt.

Figure 3-3 USB Device interface connection

3. Run Ultrascope for DS1000E, DS1000D series, then click Tools→Options and

select USB as the current IO.

Figure 3-4 Select USB interface

Service Guide for DS1000E, DS1000D Series

Page 33

Chapter 3 Performance Test RIGOL

3-5

Hint

For the newest version of this software please go to www.rigolna.com download.

4. Click Tools → Connect to Oscilloscope; If successful, the corresponding

indicator at the upper right corner of the software will be changed from red to

blue; if failed, a prompting message will be appeared as below.

Figure 3-5 Fail to connection

Service Guide for DS1000E, DS1000D Series

Page 34

RIGOL Chapter 3 Performance Test

3-6

RS-232 Interface Test

Purpose:

Test if RS-232 interface works normally through Ultrascope for DS1000E, DS1000D

series.

Tools:

A set of DS1000E, DS1000D series digital oscilloscope

A PC with RS-232 interface

A standard RS-232 cable

Ultrascope for DS1000E, DS1000D series

Steps:

1. Install the Ultrascope for DS1000E, DS1000D series software on the PC.

2. Connect the oscilloscope with PC using an RS-232 cable.

Figure 3-6 RS-232 interface connection

3. Run Ultrascope for DS1000E, DS1000D Series, then click Tools→Options and

select RS-232 as the current IO.

Figure 3-7 Select RS-232 interface

Service Guide for DS1000E, DS1000D Series

Page 35

Chapter 3 Performance Test RIGOL

3-7

4. Click Communication Setting and setup the communication interface under

using and the baud rate.

Figure 3-8 RS-232 interface setting

5. Press Utility→I/O Setting and set the baud rate as the same value in Ultrascope.

6. Click Tools → Connect to Oscilloscope; If successful, the corresponding

reminder light at the upper right corner of the software will be changed from red

to blue; otherwise, a prompting message will be appeared as below.

Figure 3-9 Fail prompt of RS-232 interface connection

Service Guide for DS1000E, DS1000D Series

Page 36

RIGOL Chapter 3 Performance Test

3-8

Items

Setting

Enable Test

ON

Source

CH1

Msg display

ON

Output

Fail

Stop on Output

OFF

P/F Interface Test

Purpose:

Test if P/F interface work normally through RS5101 module.

Tools:

A set of DS1000E, DS1000D series digital oscilloscope

A BNC cable

A RD5101 module

Steps:

1. Power on the oscilloscope and RD5101 respectively.

2. Connect P/F interface on DS1000E, DS1000D with [Pass/Fail out] interface on

RD5101 by BNC cable.

Figure 3-10 P/F interface connection

3. Turn on the oscilloscope, press Storage → Storage → Factory to recall the

factory settings.

4. Press Utility→Pass/fail to enter the setting interface of Pass/Fail, see the table

below

Table 3-1 Pass/Fail setting items

5. After setting, press Operate to start Pass/Fail test.

6. Observe the reminder light of PASS/FAIL INDICATO of RRD5101; if the reminder

light twinkles at a frequency, which indicates that the interface works normally, if

no response to the lighter, errors might happened to the interface.

Service Guide for DS1000E, DS1000D Series

Page 37

Chapter 3 Performance Test RIGOL

3-9

DIGITAL OUTPUT

Interface

DG3000

DS1000D

17 Logic Testing Leads

Logic Cable

Logic Cable

LA Interface

Logic Analyzer Interface Test (Only for DS1000D Series)

Purpose:

Test if the Logic Analyzer (hereinafter referred to as LA) interface works normally

through the logic signal output module (DG-POD-A) of DG3000.

Tools:

A set of DS1000D series digital oscilloscope

A set of DG3000 Function/ Arbitrary waveform Generator

An active logic head

Two logic cables

17 logic testing leads

A DG-POD-A module

Steps:

1. Connect LA interface on DS1000D with the active logic head by logic cable.

2. Connect “DIGITAL OUTPUT” interface on the rear panel of DG3000 with

DG-POD-A module by logic cable.

3. Connect the active logic head with DG-POD-A module by logic testing leads, so as

to realize DS1000D and DG3000 connection.

Figure 3-11 DS1000D LA interface connection

4. Power on DS1000D and DG3000 respectively.

5. Turn on DG3000 and press Utility→Output Setup→Digit-Modu→Power on to

enable the digital module power on.

6. Press Arb→Edit Digital W, select Protocol→PO, Code Pat→ 32PRBS and adjust

Output Length as 16 Byte as follows, then press Arb button to output digital

signal.

Service Guide for DS1000E, DS1000D Series

Page 38

RIGOL Chapter 3 Performance Test

3-10

Figure 3-12 Setting interface

7. Press LA button on the oscilloscope, select D7-D0 and D15-D8 to open all the

logic channels.

8. Select EDGE mode under the trigger menu and select any one source among Do

to D15, if obtain the stable interface as follows, the LA module will be proved

works normally.

Figure 3-13 Edge trigger of digital channel

Service Guide for DS1000E, DS1000D Series

Page 39

Chapter 3 Performance Test RIGOL

3-11

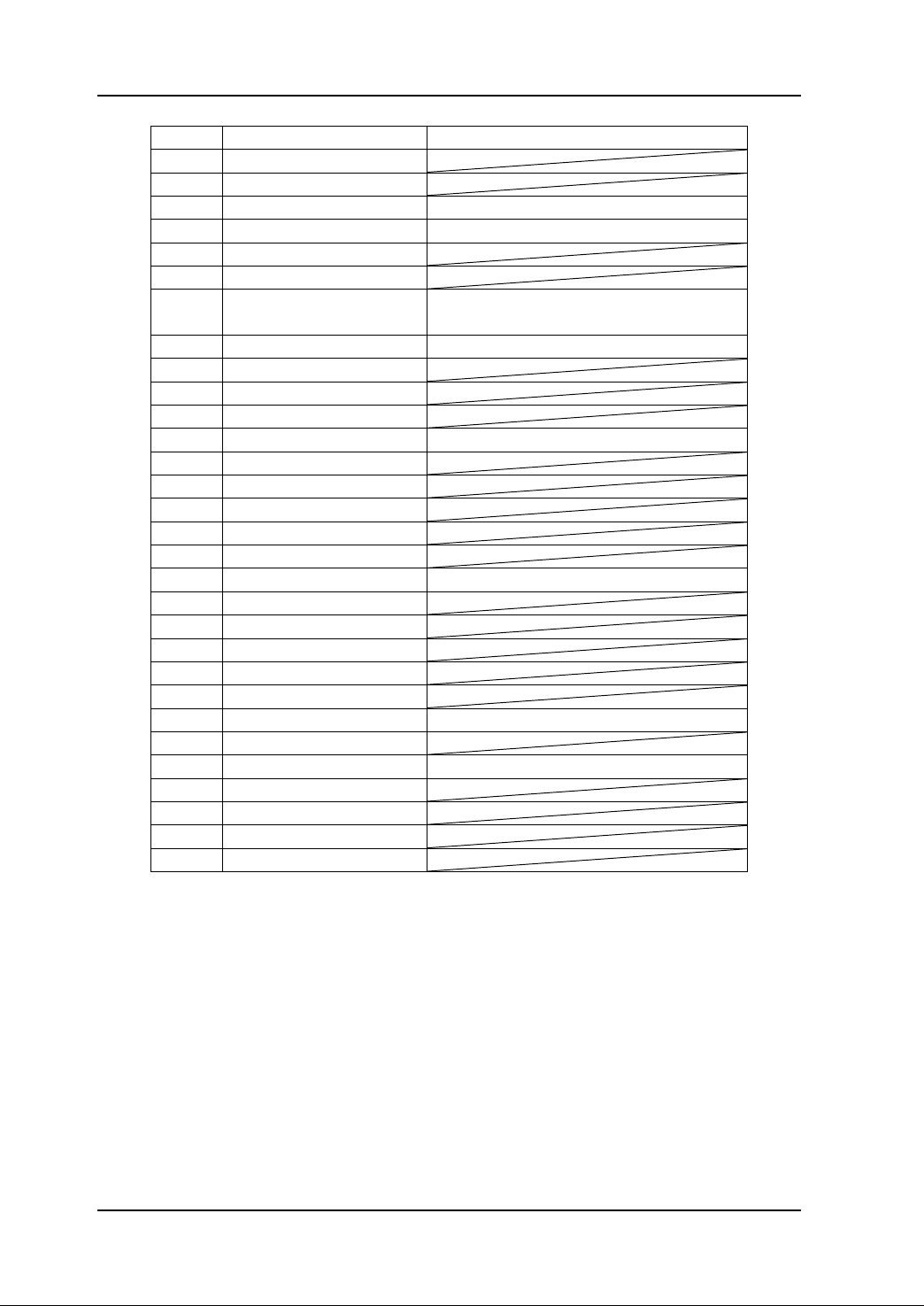

Testing item

Returned value

Errors

Noise

Vpp:

CH1, CH2

0.0~0.65div

Input impedance

Input impedance:

CH1:100mV

500mV

CH2:100mV

500mV

1MΩ±2%, in parallel with

15pF± 3pF

1MΩ±2%, in parallel with

15pF± 3pF

PROBE (9500B accessories)

Fluke

9500B

GPIB

USB

Specifications Test

Purpose:

Test if all the specifications are in the specified range.

Requirement:

Verify whether the oscilloscope is qualified through FLUKE calibration instrument and

relative softwares.

Tools:

A set of DS1000E, DS1000D series oscilloscope

A set of FLUKE 9500B calibration instrument for oscilloscope and accessories to it

Auxiliary testing softwares

A computer with GPIB and USB interfaces

A GPIB cable

A standard USB cable (Type AB)

Three BNC terminals with 50Ω of resistance

Steps:

1. Connect the FLUKE oscilloscope with PC using a GPIB cable.

Figure 3-14 Connect the testing device

2. Connect the oscilloscope with PC using an USB cable.

3. Use the testing software to test the specifications listed in the table below. Check

if all the specifications are in the specified range.

Table 3-2 Testing specifications and the ranges

Service Guide for DS1000E, DS1000D Series

Page 40

RIGOL Chapter 3 Performance Test

3-12

1MΩ±2%, in parallel with

15pF± 3pF

1MΩ±2%, in parallel with

15pF± 3pF

Voltage accuracy

Relative error between the

average and the actual:

CH1, CH2

2mV, 5mV scale

>5mV scale

± 4%

± 3%

DC linearity

DC voltage error array:

CH1, CH2

200mV scale

5V scale

-2.60~2.60(mV)

-2.60~2.60(mV)

DC offset

Relative error of the voltage:

CH1, CH2, 5V scale

0~6%

Horizontal time

Accuracy

delta-t error

-5.00e-9~5.00e-9(s)

Trigger sensitivity

Trigger sensitivity error:

10MHz

Full bandwidth

0.1~1.0div

0.1~1.5div

Timebase linearity

Period error

0.0~5.0e-10(s)

Channel delay

Delay:

CH1, CH2

500ps

Trigger delay

Delay:

CH1, CH2

500ps

Service Guide for DS1000E, DS1000D Series

Page 41

Chapter 4 Calibration RIGOL

4-1

Chapter 4 Calibration

The oscilloscope can achieve the optimum state fleetly by performing the calibration

program and get accurate measurement. You can execute the calibration at any time.

But when the operating temperature changes up to or more than 5℃, you must

perform this programme.

NOTE:

The oscilloscope must have been working or warm-up at least 30-minutes before

running self-calibration to get best accuracy.

Steps:

1. Disconnect any probes or cables from all channel inputs, otherwise failure or

damage to the oscilloscope may occur.

2. Press Utility→Self-Cal, enter the Self-Calibration interface.

Figure 4-1 Self-Calibration interface

3. Press RUN/STOP to start the Self-Calibration, the oscilloscope will calibrate the

vertical system (CH1, CH2 and Ext), horizontal system and the trigger system

automatically to guarantee the specifications in different environment.

4. The screen will give a message of “Calibration finished” after finish the calibration

and you can press RUN/STOP to exit.

Figure 4-2 Finish Self-Calibration

Service Guide for DS1000E, DS1000D Series

Page 42

RIGOL Chapter 4 Calibration

4-2

Generally speaking, the Self-Calibration will take about 5-6 minutes, if the calibration

does not pass after this time, or the progress bar stop at one of the calibration item,

there may be a trouble to the instrument. To resolve the trouble, restart the

instrument and perform the Self-Calibration again, if the problem still remains, contact

RIGOL for help.

Service Guide for DS1000E, DS1000D Series

Page 43

Chapter 5 Disassembly and Assembly RIGOL

5-1

Chapter 5 Disassembly and Assembly

This chapter includes the following topics:

Notices

Structure Chart

Disassemble and Assemble the Cover

Disassemble and Assemble the Upper and Rear Cover

Disassemble and Assemble the Power Board and the Fan

Disassemble and Assemble the Panel

Disassemble and Assemble LCD and the Keyboard

Disassemble and Assemble the Mainboard

Service Guide for DS1000E, DS1000D Series

Page 44

RIGOL Chapter 5 Disassembly and Assembly

5-2

!

Notices

Notices:

Don’t disassemble the product except the work needed.

Disassemble only can be done by qualified person.

Cut the power before disassembling.

Take ESD glove under disassembling.

Use proper tools and follow the disassembly sequence.

Prevent metallic parts from transfiguration and avoid being scratched when

disassembling.

Required tools:

TORX drivers (T6, T10, T20)

BNC sleeve

WARNING

Before disassembling, please make sure the power has been cut off. The

operator should be trained or had related qualification.

Service Guide for DS1000E, DS1000D Series

Page 45

Chapter 5 Disassembly and Assembly RIGOL

5-3

Function

Buttons

Power Button

Multi-function Knob

Run Control

Vertical Control

Horizontal Control

Trigger Control

USB Host

Interface

Digital

Signal Input

Analog

Signal Input

External

Trigger Input

Handle

Structure Chart

Figure 5-1 Structure chart

Service Guide for DS1000E, DS1000D Series

Page 46

RIGOL Chapter 5 Disassembly and Assembly

5-4

①

Handle

Power Button

Foot Mat

Cover

①

②

②

Disassemble and Assemble the Cover

Figure 5-2 Disassemble and assemble the cover

Parts Explanations:

① Bolts on the bottom of the cover (M3*8 Pan head Torx recess Drilling tapping

screws): 2

② Bolts at the groove of the handle (M3*8 Pan head Torx recess machine screws): 2

Disassemble steps:

1. Backout both the two bolts ① and ② using a TORX driver (T10);

2. Jiggle the power button and pull the cap out from it;

3. Remove the cover at the power socket forcibly.

Assemble steps:

About assembly, please operate as reverse orders, the same below.

Service Guide for DS1000E, DS1000D Series

Page 47

Chapter 5 Disassembly and Assembly RIGOL

5-5

④

③

③

④

Panel

Tank Body

Upper Cover

Rear Cover

Disassemble and Assemble the Upper and Rear

Covers

Figure 5-3 Disassemble and assemble the upper and rear covers

Parts Explanations:

③ Bolts at the interface of RS-232 (DB9 interface bolts): 2

④ Bolts at the upper cover (M3*6 Pan head Torx recess composite machine screws):

2

Disassemble steps:

1. Backout the two bolts ③ and remove the rear cover;

2. Backout the two bolts ④ using a TORX driver (T10); Then, remove the upper

cover.

Service Guide for DS1000E, DS1000D Series

Page 48

RIGOL Chapter 5 Disassembly and Assembly

5-6

⑧

⑦

⑦

⑧

⑤ ⑥ ⑤

⑤

⑧

⑧

Power Board

Fan

Mainboard

Panel

Disassemble and Assemble the Power Board and

the Fan

Figure 5-4 Disassemble and assemble the power board and the fan

Parts Explanations:

⑤ Small bolts for fixing the power board (M3*6 Pan head Torx recess composite

machine screws): 3

⑥ Big bolts for fixing the power board (M4*8 Pan head Torx recess machine screws):

1

⑦ Bolts (M3*8 Pan head Torx recess Drilling tapping screws) and nuts (M3 hexagon

nut with locking plate) for linking up the power board and shell: 2 pairs

⑧ Bolts for fixing the fan (M5*8 Pan head Torx recess machine screws): 4

Disassemble steps:

1. Pull out the power line 12pin from the J2 interface of mainboard and the power

Service Guide for DS1000E, DS1000D Series

Page 49

Chapter 5 Disassembly and Assembly RIGOL

5-7

line 2pin for the screen as well as the power ground wire;

2. Back out both the three bolts ⑤ and the bolt ⑥ on the power board separately

using TORX driver T10 and T20;

3. Backout the two bolts and nuts ⑦ for linking up the power board and shell using

a TORX driver (T10) and remove the power board;

4. Pull out the line 12pin power to fan from the J5 interface of mainboard (locates

under the fan), and then backout the four bolts ⑧ using a TORX driver (T10) to

remove the fan.

Service Guide for DS1000E, DS1000D Series

Page 50

RIGOL Chapter 5 Disassembly and Assembly

5-8

⑨

⑨

⑨

⑩

⑩

⑨

⑪

⑪ ⑪ ⑪

⑪

Button, Knob

Panel

Tank Body

Disassemble and Assemble the Panel

Figure 5-5 Disassemble and assemble the panel

Parts Explanations:

⑨ Small knobs: 4

⑩ Big knobs: 2

⑪ Bolts for fixing board on the tank body (M3*8 Pan head Torx recess Drilling tapping

screws): 5

Disassemble steps:

1. Pull out the four small knobs ⑨ and two big knobs ⑩ (note do not damage the

board by something hard)

2. Backout the five bolts from the tank body using a TORX driver (T10) to remove

the board.

Service Guide for DS1000E, DS1000D Series

Page 51

Chapter 5 Disassembly and Assembly RIGOL

5-9

⑫

⑬

⑬ ⑬ ⑬

Keyboard

Rubber Button

Tank Body

LCD

Disassemble and Assemble LCD and the

Keyboard

Figure 5-6 Disassemble and assemble LCD and the keyboard

Parts Explanations:

⑫ Bolts for the screen ground wire (M2*4 Pan head Torx recess machine screws): 1

⑬ Bolts fixed on the keypad board (M3*6 Flush head Torx recess machine screws): 4

Disassemble steps:

1. Pull out the LCD wire from the J603 interface of the mainboard;

2. Backout the one bolt of the screen ground wire using a TORX driver (T6);

3. Take out the LCD screen gently (Be careful the screen cable and ground wire);

4. Backout the keypad board cable from the J604 interface of the mainboard;

5. Backout the four bolts ⑬ from the keypad board using a TORX driver (T10); the

moment of force is 6 NM;

6. Take out the keypad board gently (pay attention to the wire).

Service Guide for DS1000E, DS1000D Series

Page 52

RIGOL Chapter 5 Disassembly and Assembly

5-10

⑱ ⑲ ⑱

⑱ ⑲ ⑲ ⑳ ⑳

Cooling Plate

LA Board

Mainboard

BNC Nut

Tank Body

⑭

⑭

⑯ ⑯ ⑮

⑮

⑮

⑰

Disassemble and Assemble the Mainboard

Figure 5-7 Disassemble and assemble the mainboard

Parts Explanations:

⑭ Bolts on the LA board ((M3*6 Pan head Torx recess composite machine screws): 2

⑮ Bolts on the cooling plate (M3*6 Pan head Torx recess composite machine screws):

3

⑯ Bolts for fixing the mainboard (M3*6 Pan head Torx recess composite machine

screws): 2

⑰ Stud on the mainboard (M3*6 Copper pillar): 3

⑱ Nuts at BNC terminal (BNC nuts): 3

⑲ Spacer at BNC fracture (BNC lock spacer): 3

Service Guide for DS1000E, DS1000D Series

Page 53

Chapter 5 Disassembly and Assembly RIGOL

5-11

⑳ Bolts at LA terminal (0.1*0.3inch Hexagon Bolt in British system): 2

Disassemble steps:

1. Backout the two bolts ⑭ from LA board using a TORX driver (T10);

2. Backout the three bolts ⑮ from the cooling plate using a TORX driver (T10);

3. Backout the two mainboard bolts ⑯ using a TORX driver (T10), and backout the

three mainboard studs ⑰ using sleeve (D89); (Pay attention that one M3 spacer

is existed between LA board and stud whose position is next to the L808.)

4. Backout the three bolts ⑱ using sleeve, and remove the three spacers ⑲;

5. Backout the two bolts ⑳ at LA terminal using a TORX (T10);

6. Disconnect the earth card on the metal shell from the shore at the USB

interface of the mainboard using an electric iron. (Note: please set the

temperature of iron as 310℃)

7. Take out the mainboard gently after check.

Service Guide for DS1000E, DS1000D Series

Page 54

Page 55

Chapter 6 Troubleshooting RIGOL

6-1

Chapter 6 Troubleshooting

1. After the oscilloscopes is powered on, the screen remains dark (no

display):

(1) Check the power cable connection.

(2) Ensure the power switch has been turned on.

(3) After above inspection, restart the oscilloscope.

(4) If the problem still remains, please ask RIGOL for help.

2. After the signal acquisition the waveform does not appear:

(1) Check if the probe is connecting with the signals.

(2) Check if the probe is connecting to the channels firmly.

(3) Check if the probe is connecting with the object being tested.

(4) Check if any signal generated from testing point.

(5) Repeat the acquisition.

3. The measurement result is 10 times higher or lower than the value

expected.

Check if the probe attenuation corresponds with the channel attenuation.

4. If the oscilloscope does not get a stable waveform display:

(1) Check the Source and notice if it is set to the channel in use.

(2) Check the Mode. Use Edge for normal signals, and use Video for VIDEO

signals.

(3) Switch the Coupling into HF Rejection or LF Rejection in order to filter

the noise which disturbs trigger.

(4) Adjust the trigger Sensitivity and the Holdoff time.

5. After pressing RUN/STOP, the oscilloscope does not display any

waveform on screen.

Check whether the Sweep is set to Normal or Single and see whether the

trigger level is out of the signal range. If it is, set the trigger level in proper range

by turning the knob or pressing the 50% button. Or set the Mode as

AUTO. Moreover, push AUTO button to display the waveform on screen.

6. After the Acquisition was set to “Averages” or Display Persistence is set

ON, the waveform refreshes slowly.

Normal phenomenon.

7. The waveform is displayed on the appearance of ladder.

(1) Normal phenomenon. Maybe the time base setting maybe is too slow. Please

Service Guide for DS1000E, DS1000D Series

Page 56

RIGOL Chapter 6 Troubleshooting

6-2

rotate the horizontal knob to increase horizontal resolution to

improve the display.

(2) Maybe the display Type is set to Vectors set it to Dots mode to improve the

display.

Service Guide for DS1000E, DS1000D Series

Page 57

Chapter 7 Replaceable Parts RIGOL

7-1

No.

Name

Specification

1

Big Knob

2 Small Knob

3

Panel

Chapter 7 Replaceable Parts

RIGOL provides some replaceable parts in order to maintain or update for users.

Please see as the following figure and table. Note that the numbers in the figure and

the table are associated with each other.

Figure 7-1 DS1000E, DS1000D Exploded View

Table 7-1 Replaceable parts list

Service Guide for DS1000E, DS1000D Series

Page 58

RIGOL Chapter 7 Replaceable Parts

7-2

4

LCD

Color Screen: FG050600ANNNA-01

5

Metallic Tank Body

6 Rubber Button

7 BNC Nut

BNC Nut

8

BNC Lock Spacer

BNC Lock Spacer

9

Encoder

10

Keyboard

11

Bolt

0.1*0.3inch Hexagon Bolt, British

system

12

Fan

AFB0612LC-714

13

Large Terminal

14

Small Terminal

15

BNC

16

Cooling Plate

Aluminum

17

LA Board

18

LA Interface

19

RS-232 Interface

20

Power Jacket

21

USB Host Interface

22

Mainboard

RDSB1003

23

USB Device Interface

24

Power Switch Cap

25

Upper Metallic Cover

26

Power Interface

27

Power Supply

28

Power Board

RDSB1001

29

Rear Metallic Cover

30

Female ScrewLock

M3*7/ DB9 bolt, British system

31

Front Trestle

32

Rear Trestle

33

Handle

34

Cover

Service Guide for DS1000E, DS1000D Series

Page 59

Chapter 8 Service & Support RIGOL

8-1

Chapter 8 Service & Support

This chapter contains the following topics:

Warranty

Care and Cleaning

Contact Us

Service Guide for DS1000E, DS1000D Series

Page 60

RIGOL Chapter 8 Service & Support

8-2

Warranty

RIGOL warrants that its products mainframe and accessories will be free from

defects in materials and workmanship within the warranty period. If a product proves

defective within the respective period, RIGOL guarantees the free replacement or

repair of products which are approved defective.

To get repair service or obtain a copy of the whole warranty statement, please contact

with your nearest RIGOL sales and service office.

RIGOL does not provide any other warranty items except the one being provided by

this summary and the warranty statement. The warranty items include but not being

subjected to the hint guarantee items related to tradable characteristic and any

particular purpose.

RIGOL will not take any responsibility in cases regarding to indirect, particular and

ensuing damage.

Service Guide for DS1000E, DS1000D Series

Page 61

Chapter 8 Service & Support RIGOL

8-3

!

Care and Cleaning

General Maintenance

Do not store or leave the instrument in where the instrument will be exposed to direct

sunlight for long periods of time.

Caution

To avoid damages to the instrument or probes, do not expose them to liquids which

have causticity.

Cleaning

Clean the instrument and probes often based on its operating conditions require. To

clean the exterior surface, perform the following steps:

1. Disconnect the instrument from all power sources.

2. Clean the loose dust on the outside of the instrument and probes with a lint- free

cloth (with a mild detergent and water). When clean the LCD, take care to avoid

scarifying it.

WARNING

To avoid injury resulting from short circuit, make sure the instrument is

completely dry before reconnecting into a power source.

Service Guide for DS1000E, DS1000D Series

Page 62

RIGOL Chapter 8 Service & Support

8-4

Contact Us

If you have any problem or requirement during using our products, please contact

RIGOL Technologies, Inc. or the local distributors.

Domestic: Please call

Tel: (86-10) 8070 6688

Fax: (86-10) 8070 5070

Service & Support Hotline: 800 810 0002

9:00 am –5: 00 pm from Monday to Friday

Or by e-mail:

service@rigol.com

Or mail to:

RIGOL Technologies, Inc.

156# CaiHe Village, ShaHe Town, ChangPing District, Beijing, China

Post Code: 102206

Overseas: Contact the local RIGOL distributors or sales office.

For the latest product information and service, visit our website: www.rigolna.com

Service Guide for DS1000E, DS1000D Series

Page 63

Index RIGOL

1

Index

Acquisition ................................... 1-2

Big Knob ..................................... 7-1

BNC ............................................ 7-2

BNC Lock Spacer .......................... 7-2

BNC Nut ...................................... 7-2

Bolt ............................................. 7-2

Calibration ................................... 4-1

Calibration Interval ....................... 1-5

Care and Cleaning ........................ 8-3

Cleaning ...................................... 8-3

Connect the Probes ...................... 2-4

Contact Us .................................. 8-4

Cooling Plate ............................... 7-2

Cover ................................... 5-4, 7-2

Digital Probes ....................... 2-1, 2-7

Disassembly and Assembly ........... 5-1

Display ........................................ 1-5

Display a Waveform Automatically . 2-9

Encoder ...................................... 7-2

Environmental ............................. 1-5

Exploded View ............................. 7-1

Fan ............................................. 7-2

Front trestle ................................ 7-2

General Inspection ....................... 2-2

General Specifications .................. 1-5

Handle ........................................ 7-2

Horizontal .................................... 1-2

Inputs ......................................... 1-2

IP Degree .................................... 1-5

Keyboard..................................... 7-2

LA board ..................................... 7-2

LA interface ................................. 7-2

Large Terminal ............................ 7-2

LCD ............................................ 7-2

LCD and the Keyboard .................. 5-9

Logic Analyzer Interface ........ 3-1, 3-9

Mainboard .......................... 5-10, 7-2

Measurements ............................. 1-4

Mechanical ................................... 1-5

Metallic Case ................................ 7-2

Metallic Rear Cover ....................... 7-2

P/F Interface ......................... 3-1, 3-8

Panel .................................... 5-8, 7-1

Performance Test ......................... 3-1

Power .......................................... 1-5

Power Board ................................ 7-2

Power Board and the Fan .............. 5-6

Power interface ............................ 7-2

Power Jacket ............................... 7-2

Power Supply ............................... 7-2

Power-On Inspection .................... 2-3

Prepare for Use ............................ 2-1

Probe Compensator ...................... 1-5

Probes Compensation ................... 2-5

Rear trestle .................................. 7-2

Replaceable Parts ......................... 7-1

RS-232 Interface ................... 3-1, 3-6

Rubber Button ............................. 7-2

Small Knob .................................. 7-1

Small Terminal ............................. 7-2

Specifications ............................... 1-1

Specifications Test ...................... 3-11

Structure Chart ............................ 5-3

Trigger ........................................ 1-3

Troubleshooting ........................... 6-1

Upper and Rear Covers ................. 5-5

Upper Metallic Cover ..................... 7-2

USB Device Interface ............. 3-1, 3-4

USB Host Interface ................ 3-1, 3-2

Vertical ........................................ 1-2

Warranty ..................................... 8-2

Service Guide for DS1000E, DS1000D Series

Loading...

Loading...