Page 1

RIGOL

User’s Guide

DP800 Series Programmable

Linear DC Power Supply

May 2015

RIGOL Technologies, Inc.

Page 2

Page 3

RIGOL

Guaranty and Declaration

Copyright

© 2012 RIGOL Technologies, Inc. All Rights Reserved.

Trademark Information

RIGOL is a registered trademark of RIGOL Technologies, Inc.

Publication Number

UGH04107-1110

Software Version

00.01.14

Software upgrade might change or add product features. Please acquire the latest

version of the manual from RIGOL website or contact RIGOL to upgrade the

software.

Notices

RIGOL products are cove red by P.R.C. and f oreign pa tents, issue d and pendin g.

RIGOL reserves the right to modify or change parts of or all the specifications

and pricing policies at company’s sole decision.

Information in this publica tion re places all previ ously corresponding material.

Information in this publication is subject to change without notice.

RIGOL shall not be liable for either incidental or consequential losses in

connection with the furnishing, use or performance of this manual as well as an y

information contained.

Any part of this document is forbidden to be copi e d, ph otoc o pie d or rearranged

without prior written approval of RIGOL.

Product Certification

RIGOL guar antees this pr oduct confo rms to the national and industrial standards in

China as well as the ISO9001:2008 standard and the ISO14001:2004 standard.

Other international standard conformance certif ication is in progress.

Contact Us

If you have any problem or requirement when using our products or this manual,

please contact RIGOL.

E-mail: service@rigol.com

Website: www.rigol.com

DP800 User’s Guide I

Page 4

RIGOL

Safety Requirement

General Safety Summary

Please review the following safety precautions carefully before putting the

instrument into operation so as to avoid any personal injury or damage to the

instrument and any product connecte d to it. To prevent potential haza rds, please us e

the instrument only specified by this manual.

Use Proper Power Cord.

Only the power cord designed for the instrument and authorized for use within the

local country could be used.

Ground the Instrument.

The instrument is grounded through the Protective Earth lead of the power cord. To

avoid electric shock, it is e ssential t o connect the ea rth terminal of the power cord to

the Protective Earth terminal before connecting any inputs or outputs.

Connect the Probe Correctly.

If a probe is used, do not connect the ground lead to high vol tage since it has

isobaric electric potential as the ground.

Observe All Terminal Ratings.

To avoid fire or shock hazard, observe all ratings an d markers on the instrume nt and

check your manual for more information about ratings before connecting the

instrument.

Use Proper Overvoltage Protection.

Make sure that no overvoltage (such as that caused by a thunderstorm) can reach

the product, or else the operator might be exposed to the danger of electrical shock .

Do Not Operate Without Covers.

Do not operate the instrument with covers or panels removed.

Do Not Insert Anything Into the Holes of Fan.

Do not insert anything into the holes of the fan to avoid damaging the instrument.

Use Proper Fuse.

Please use the specified fuses.

Avoid Circuit or Wire Exposure.

Do not touch exposed junctions and components when the unit is powered.

II DP800 User’s Guide

Page 5

RIGOL

Do Not Operate With Suspected Failures.

If you suspect damage occurs to the instrument, have it inspected by RIGOL

authorized personnel before further oper at io ns. Any maintenance, adjustment or

replacement especially to circuits or accessories must be performed by RIGOL

authorized personnel.

Keep Well Ventilation.

Inadequate ventilation may cause an increase of instrument temperature which

would cause damage to the instrument. So please keep the instrument well

ventilated and inspect the intake and fan regularly.

Do Not Operate in Wet Conditions.

In order to av oid short circuiting t o the interi or of the device or electric shock, please

do not operate the instrument in a humid environment.

Do Not Operate in an Explosive Atmosphere.

In order to avoid damage to the device or personal injuries, it is important to o perate

the device away fr om an expl osive atmosphere.

Keep Product Surfaces Clean and Dry.

To avoid the influence of dust and/or moisture in the air, please keep the surface of

the device clean and dry.

Electrostatic Prevention.

Operate the instrument i n an ele ctrostatic discha rge protectiv e envi ronment to avoid

damage induced by static discharges. Always ground both the internal and external

conductors of cables to release static before making connections.

Proper Use of Battery.

If a battery is supplied, it must not be exposed to high temperature or in contact with

fire. Keep it out of the reach of children. Improper change of battery (note: lithium

battery) may cause explosion. Use RIGOL specified battery on l y.

Handling Safety.

Please handle with care during transportation to avoid damage to keys, knob

interfaces and other parts on the panels.

Do Not Provide Power for the Active Load.

In order to avoid the anti-irrigation current which leads to the power control loop out

of control and damages the powered device, this power supply can only provide

power for the pure load without the current output function.

DP800 User’s Guide III

Page 6

RIGOL

WARNING

injury or loss of life.

CAUTION

damage to this product or other property.

DANGER

It calls attention to an operation, if not correctly pe rformed, could

result in injury or hazard immediately.

WARNING

It calls attention to an operation, if not correctly pe rformed, could

result in potential injury or hazard.

CAUTION

It calls attention to an operation, if not correctly pe rformed, could

product.

Hazardous

Safety

Protective

Terminal

Chassis

Test

Safety Terms and Symbols

Terms Used in this Manual. These terms may appear in this manual:

Warning statements indicate conditions or practices that could result in

Caution statements indicate conditions or practices that could result in

Terms Used on the Product. These terms may appear on the product:

result in damage to the product or other devices connected to the

Symbols Used on the Product. These symbols may appear on the product:

Voltage

Warning

Earth

Ground

Ground

IV DP800 User’s Guide

Page 7

RIGOL

Allgemeine Sicherheits Informationen

Überprüfen Sie diefolgenden Sicherheitshinweise

sorgfältigumPersonenschädenoderSchäden am Gerätundan damit verbundenen

weiteren Gerätenzu vermeiden. Zur Vermeidung vonGefa hren, nutze n S ie bitte das

Gerät nur so, wiein diesem Handbuchangegeben.

Um Feuer oder Verletzungen zu vermeiden, verwenden Sie ein

ordnungsgemäßes Netzkabel.

Verwenden Sie für dieses Gerät nur das für ihr Land zugelassene und genehmigte

Netzkabel.

Erden des Gerätes.

Das Gerät ist durch den Schutzleiter im Netzkabel geerdet. Um Gefahren durch

elektrischen Schlag zu vermeiden , ist es unerlässlich, die Er dung durchzufüh ren. Erst

dann dürfen weitere Ein- oder Aus gä nge verbunden werden.

Anschluss einesTastkopfes.

Die Erdungsklemmen der Sonden sindauf dem gleichen Spannungspegel des

Instruments geerdet. SchließenSie die Erdungsklemmen an keine hohe Spannung

an.

Beachten Sie alle Anschlüsse.

Zur Ve rm e idung von Feuer oder Stromschlag, beachten Sie alle Bemerkungen und

Markierungen auf dem Instrument. Bef olgen Sie die Bedienun gsanleitung für weitere

Informationen, bevor Sie weitere Anschlüsse an das Instrument legen.

Verwenden Sie einen geeigneten Überspannungsschutz.

Stellen Sie sicher, daß keinerlei Überspannung (wie z.B. durch Gewitter verursa cht)

das Gerät erreichen kann. Andernfallsbestehtfür den Anwender die

GefahreinesStromschlages.

Nicht ohne Abdeckung einschalten.

Betreiben Sie das Gerät nicht mit entfernten Gehäuse-Abdeckungen.

Betreiben Sie das Gerät nicht geöffnet.

Der Betrieb mit offenen oder entfernten Gehäuseteilen ist nicht zulässig. Nichts in

entsprechende Öffnungen stecken (Lüfter z.B.)

Passende Sicherung verwenden.

Setzen Sie nur die spezifikationsgemäßen Sicherungen ein.

Vermeiden Sie ungeschützte Verbindungen.

Berühren Sie keine unisolierten Verbindungen oder Baugruppen, während das Gerät

in Betrieb ist.

DP800 User’s Guide V

Page 8

RIGOL

Betreiben Sie das Gerät nic h t i m Fehlerfall.

Wenn Sie am Gerät einen Defekt vermuten, sorgen Sie dafür, bevor Sie das Gerät

wieder betreiben, dass eine Untersuchung durch RIGOL autorisiertem Personal

durchgeführt wird. Jedwede W artun g, Einstellarbeit en oder Austausch v on Teilen am

Gerät, sowie am Zubehör dürfen nur von RIGOL autorisiertem Personal

durchgeführt werden.

Belüftung sicherstellen.

Unzureichende Belüftung kann zu Temperaturanstiegen und somit zu thermischen

Schäden am Gerät führen. Stellen Sie deswegen die Belüftung sicher und

kontrollieren regelmäßig Lüfter und Belüftungsöffnungen.

Nicht in feuc h te r Um g ebung betrei be n .

Zur Vermeidun g von Kurzschluß im Geräteinne ren und Stromschlag betreiben Sie das

Gerät bitte niemals in feuchter Umgebung.

Nicht in explosiver Atmosphäre betreiben.

Zur Ve rm e idung von Pers onen- und Sachschäden ist es unumgängli ch, das Ger ät

ausschließlich fernab jedweder explosiven At mosphäre zu betreiben.

Geräteoberflächen sauber und trocken halten.

Um den Einfluß von Staub und Feuchtigkeit aus der Luft auszuschließen, halten Sie

bitte die Geräteoberflächen sauber und trocken.

Schutz gegen elektrostatische Entladung (ESD).

Sorgen Sie für eine elektrostatisch geschützte Umgebung, um somit Schäden und

Funktionsstörungen durch ESD zu vermeiden. Erden Sie vor dem Anschluß immer

Innen- und Außenleiter der V erbindungsleitung, um st atische Aufladung zu entladen.

Die richtige Verwendung desAkku.

Wenneine Batterieverwendet wird, vermeiden Sie hohe Temperaturen bzw. Feuer

ausgesetzt werden. Bewahren Sie es außerhalbder Reichweitevon Kindern auf.

UnsachgemäßeÄnderung derBatterie (Anmerkung: Lithium-Batterie) kann zu einer

Explosion führen. VerwendenSie nur von RIGOL angegebenenAkkus.

Sicherer Transport.

Transportieren Sie das Gerät sorgfältig (Verpackung!), um Schäden an

Bedienelementen, Anschlüssen und anderen Teilen zu vermeiden.

Vermeiden Sie das einprägen von Strom und Spannung an den

Testklemmen.

Das DP800 Power Supply kann hierdurch zerstört werden , k eine akive Last. Das

DP800 kann nur Strom und Spannungen leifern.

VI DP800 User’s Guide

Page 9

RIGOL

WARNING

Schäden oder den Tod von Personen zur Folge haben können.

CAUTION

Schäden am Gerät hervorrufen können.

DANGER

weist auf eine Verletzung ode r Gefäh r dun g hin, die sof ort

geschehen kann.

WARNING

weist auf eine V erletzung oder Gefäh rdung hin, die möglicherweise

nicht sofort geschehen.

CAUTION

weist auf eine Verletzun g ode r Gefährdung hin und bedeutet, dass

Gegenstände auftreten kann.

Sicherheits Begriffe und Symbole

Begriffe in diesem Guide. Diese Begriff e können in diese m Handbuch aufta uchen:

Die Kennzeichnung WARNING beschreibt Gefahrenquellen die leibliche

Die Kennzeichnung Caution (Vorsicht) beschreibt Gefahrenquellen die

Begriffe auf dem Produkt. Diese Bedingungen können auf dem Produkt

erscheinen:

eine mögliche Beschädigung des Instruments oder anderer

Symbole auf dem Produkt. Diese Symbole können auf dem Produkt erscheinen:

Gefährliche

Spannung

SicherheitsHinweis

Schutz-erde Gehäusemasse Erde

DP800 User’s Guide VII

Page 10

RIGOL

CAUTION

WARNING

supply.

General Care and Cleaning

General Care

Do not store or leave the instrument where it may be exposed to direct sunlight for

long periods of time.

Cleaning

Clean the instrument regularly according to its operating conditions. To clean the

exterior surface, perform the following steps:

1. Disconnect the instrument from all power sources.

2. Clean the loose dust on th e outside of the i nstrumen t with a lint -f ree clot h (with

a mild detergent or water). When cleaning the LCD, take care to av oid sca rifying

it.

To avoid damage to the instrument, do not expose it to caustic liquids.

To avoid short-circuit and personal injury resulting from moisture, make

sure the instrument is completely dry before reconnecting it to power

VIII DP800 User’s Guide

Page 11

RIGOL

Environmental Consideratio ns

The following symbol indicates that this product complies with the requirements in

WEEE Directive 2002/96/EC.

Product End-of-Life Handling

The equipment may contain substances that could b e harmf ul t o the envi ronm ent or

human health. In order to avoid release of such substances into the environment and

harm to human health, we encourage you to recycle this product in an appropriate

system that will ensure that most of the materials are reused or recycled

appropriately. Please contact your local authorities for disposal or recycling

information.

DP800 User’s Guide IX

Page 12

RIGOL

DP800 Series Overview

DP800 series is high-performance programmable line a r DC power supply. DP800

series which provides clear user interface, superb performance specifications,

various analysis functions as well as various communication interfaces can fulfill

versatile test requirements.

Main Features:

User-friendly Design:

3.5 inch TFT display, can display multiple parameters and states at the same

time

Support Chinese/English interface and input method

Novel and exquisite industrial design and easy operation

Provide waveform display function to provide real-time and dynamic d isplay of

the output voltage/current waveform, clearly showing the output state and

tendency of the instrument in together with the digital display of the voltage,

current and power values

Provide dial display function, indicating the current output state using the dial

pointer by simulating the traditional power display mode

Provide on-line help system for easy acquisition of help information

Multiple Safety Protection:

Provide overvoltage/overcurrent protection function; users can set the

overvoltage and overcurrent parameters to realize effective protection of the

load

Provide seco nd ary over-temperature protection function to realize double

over-temperatu re protection of the s of t ware and hardware

Provide intelligent fan speed control function; judge and control the fan speed

automatically according to the working condition to effectively reduce the fan

noise

Provide fan failure check and alar m fu nction

Provide keyboard lo ck function to avoid misop erat i on

Various Functions and Superb Performance:

Multi-channel output; up to 200W total output power; the output of each

channel can be controlled independently

Superb load regulation rate and linear regulatio n r ate

Provide ultra-low output ripples an d noise

Provide timing output function and support infinite and specified number of

cycles of output

Provide track function to track the channel voltage setting value and output

on/off status

Provide Sense fun ction to automaticall y compensate for the voltage drop caused

by the load lead in high current output.

Provide delay on/off out put f unction and sup port infinite or specified number of

X DP800 User’s Guide

Page 13

RIGOL

cycles of channel on/off toggle

Support digital trigger (option) to realize digital trigger input and trigger output

functions

Support on-line analyzer (option) to perform on-line analysis of various statistic

parameters

Support monitor (option) to monitor the output according to the user-defined

monitor condition

Provide built-in recorder to perfor m background recording of the output state

after power-on according to certain record period

Provide de di cat ed p res et key to perf o rm one -key reset and one-key recall of the

commonly used output voltage and current configurations

Support serial and parallel output functions

Support on-line self-test and manual calibration functions

Provide store and recall function

Support voltage and current linear programmable functions

Complete In te rface Configu rations and Fle xible Control Method:

Standard configuration interfaces: USB HOST, USB DEVICE, LAN (option),

RS232 (option), Digital I/O (option), rear panel output interface (D P81 1)

Support to extend a GPIB interface via the USB-GPIB int e rface conve rter

(option)

Support USB st orage device storage

Support SCPI remote command control

Conform to LXI Core 2 011 Devi ce instrument standard

Provide standard 9 pin RS232 interface with flow control function

Provide 4-wire digital I/O interface which supports the trigger input/output

function

DP800 User’s Guide XI

Page 14

RIGOL

Tip

Document Overview

Chapter 1 Quick Start

Introduce the appearance and dimensi ons, front panel, rear panel as well as user

interface of DP800. In addition, it provides the detail ed p roced ures of power

connection, power-on inspection and fuse replacement as well as the method of rack

mount installation of DP800.

Chapter 2 Front Panel Oper a tio n s

Introduce the functi on and operation method of each key at the front panel of DP800

in detail.

Chapter 3 Remote Control

Introduce how to realize the remote control of the instrument.

Chapter 4 Troubleshooting

Introduce the possible failures and their solutions when using DP800.

Chapter 5 Specifications

List the specifications of DP800.

Chapter 6 Appendix

Provide the accessory and option list as well as the warranty information of DP800.

Index

Provide keyword se a rch to quickly loca t e the desired informa tion.

For the newest version of this manual, download it from RIGOL officia l website

www.rigol.com).

(

XII DP800 User’s Guide

Page 15

RIGOL

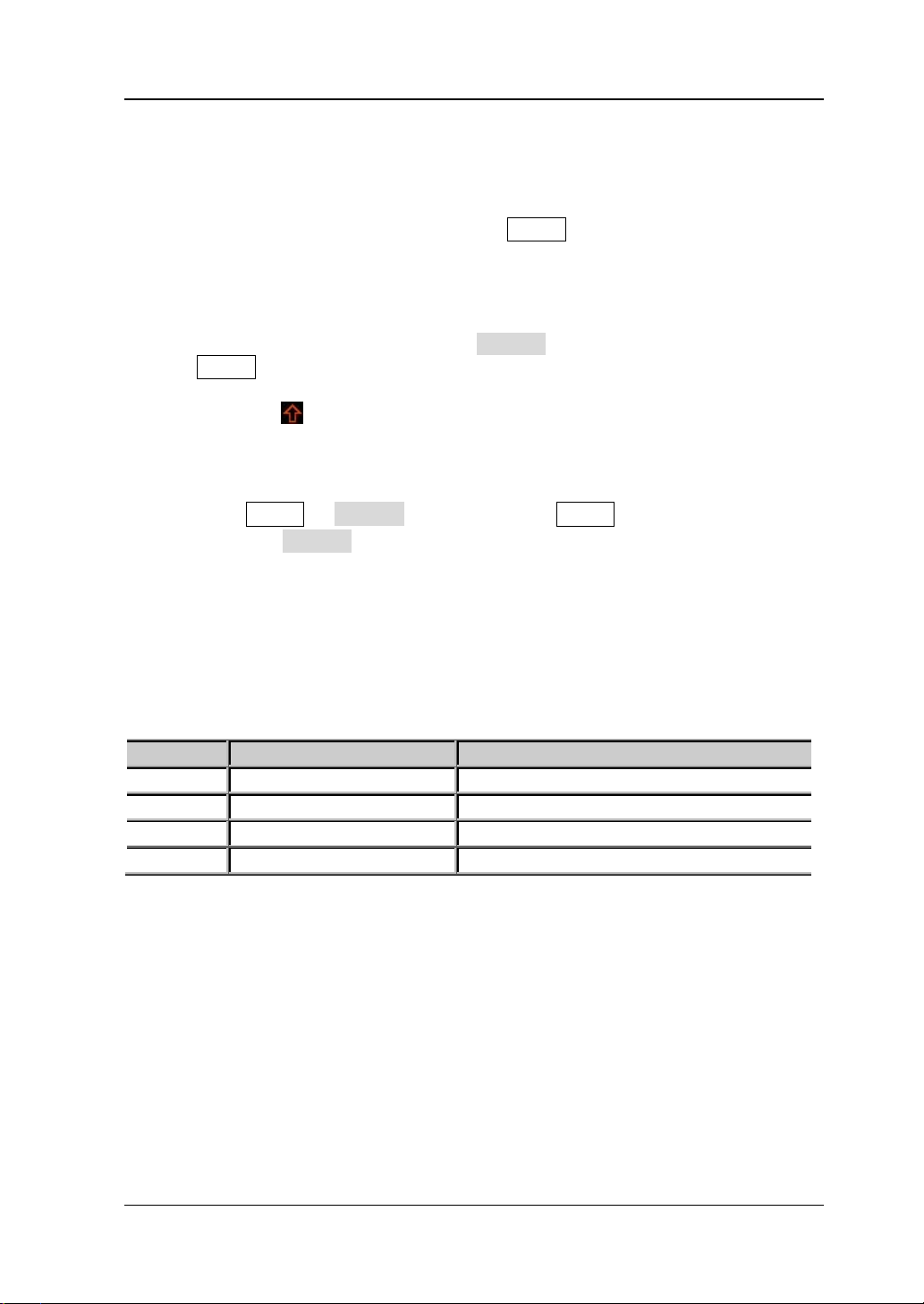

Model

Number of Channels

Channel Output Voltage/Current

DP832

3

30V/3A, 30V/3A, 5V/3A

DP831

3

8V/5A, 30V/2A, -30V/2A

DP821

2

60V/1A, 8V/10A

DP811

1

Range1: 20V/10A; Range2: 40V/5A

Format Conventions in this Manual

1. Key

The function key at the front panel is denoted by the format of "Key Name (Bold)

+ Text Box" in the manual. For example, Utility denotes the "Utility" key.

2. Menu

The menu item is denoted in the following two modes in this manual.

(1) The menu item can be denoted by the format of "Menu Word (Bold) +

Character Shading". F or example, System denotes the "System" item under

Utility.

(2) The menu item can be denoted by the screenshot of the menu key. For

example,

.

3. Operation Step

The next step of the operation is denoted by an arrow "" in the manual. For

example, Utility System denotes pressing Utility at the front panel and

then pressing System.

Content Conventions in this Manual

DP800 series programmable linear DC power supply includes the following models.

Unless otherwise noted, this man ual ill ustrates the functions and ope r a tion methods

of DP800 series by taking DP832 as an example.

DP800 User’s Guide XIII

Page 16

RIGOL Contents

Contents

Guaranty and Declaration ......................................................................... I

Safety Requirement ................................................................................. II

General Safety Summary........................................................................... II

Safety Terms and Symbols ....................................................................... IV

Allgemeine Sicherheits Informationen ........................................................ V

Sicherheits Begriffe und Symbole ............................................................. VII

General Care and Cleaning ..................................................................... VIII

Environmental Considerations ................................................................... IX

DP800 Series Overview ........................................................................... X

Document Overview ............................................................................. XII

Chapter 1 Quick Start ........................................................................ 1-1

General Inspection ................................................................................. 1-2

Appearance and Dim e nsions ................................................................... 1-3

Front Panel ............................................................................................ 1-4

Rear Panel ........................................................................................... 1-11

To Connect to Power ............................................................................ 1-13

Power-on Inspection ............................................................................. 1-14

To Replace the Fuse ............................................................................. 1-14

User Interface ...................................................................................... 1-16

To Use the Built-in Help System ............................................................. 1-18

To Rack Mount the Instrument .............................................................. 1-19

To Install a Single Instrument ......................................................... 1-19

To Install Two Instruments ............................................................. 1-26

Chapter 2 Front Panel Operations ...................................................... 2-1

Constant Voltage Output ......................................................................... 2-2

Constant Current Output ......................................................................... 2-6

Power Supply Series and Parallel Connections ........................................... 2-8

Power Supply Series Connect i on ........................................................ 2-8

Power Supply Parallel Connection ...................................................... 2-9

Track Function ..................................................................................... 2-10

To Enable the Track Function .......................................................... 2-10

To Track the On/Off Status of the Channel Output............................. 2-12

Sense Working Mode ............................................................................ 2-13

Timer and Delayer ................................................................................ 2-15

To Set the Timer Parameters........................................................... 2-16

To Enable the Timer ....................................................................... 2-25

To Set the Delay Parameters ........................................................... 2-26

To Enable the Delayer .................................................................... 2-30

Advanced Functions ............................................................................. 2-31

Recorder ....................................................................................... 2-32

XIV DP800 User’s Guide

Page 17

Contents RIGOL

Analyzer (option) ........................................................................... 2-33

Monitor (option) ............................................................................ 2-36

Trigger (option) ............................................................................. 2-37

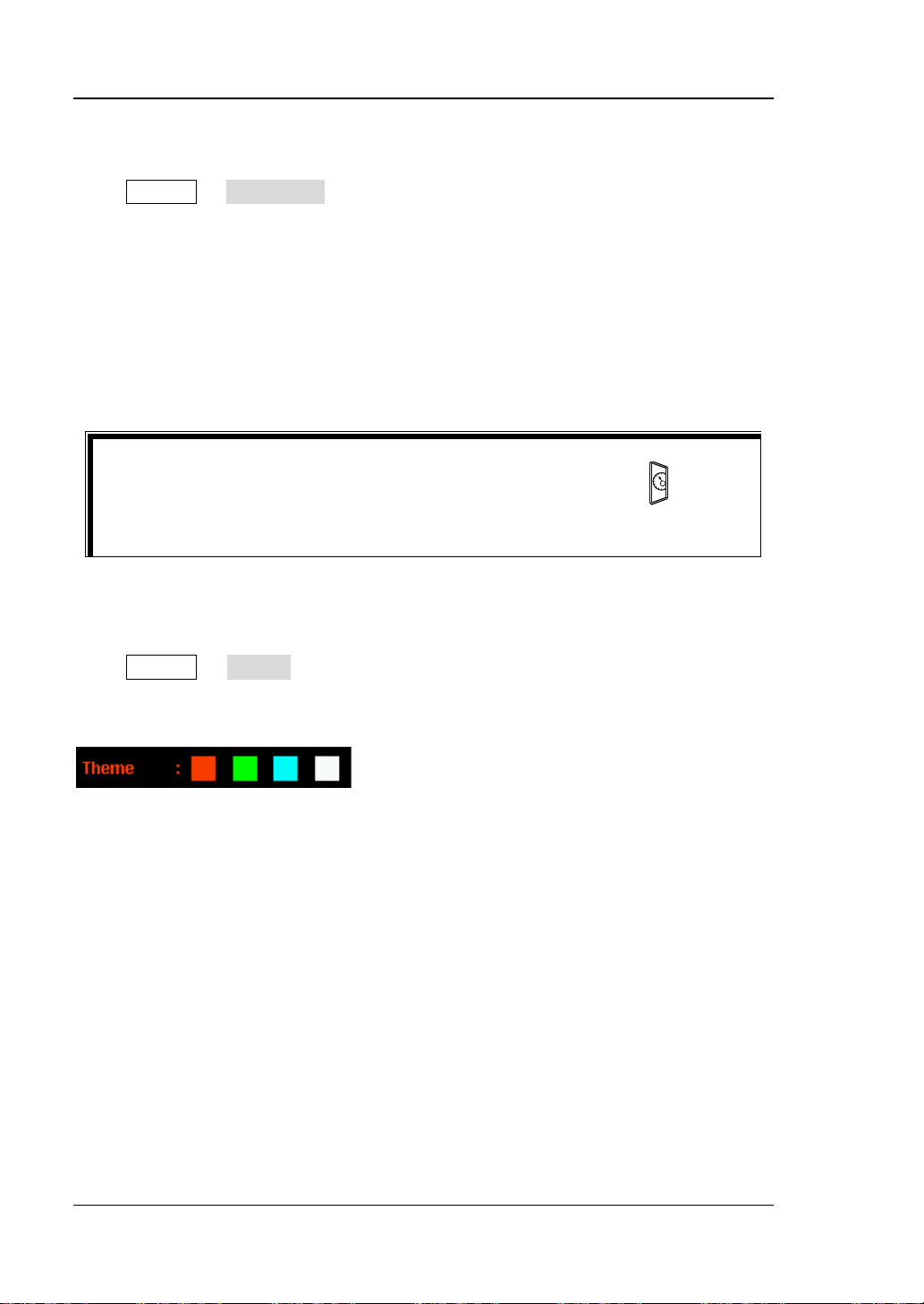

Display Setting ..................................................................................... 2-41

Brightness ..................................................................................... 2-41

Contrast ........................................................................................ 2-41

RGB Luminance ............................................................................. 2-41

Display Mo de ................................................................................. 2-42

Display Theme ............................................................................... 2-42

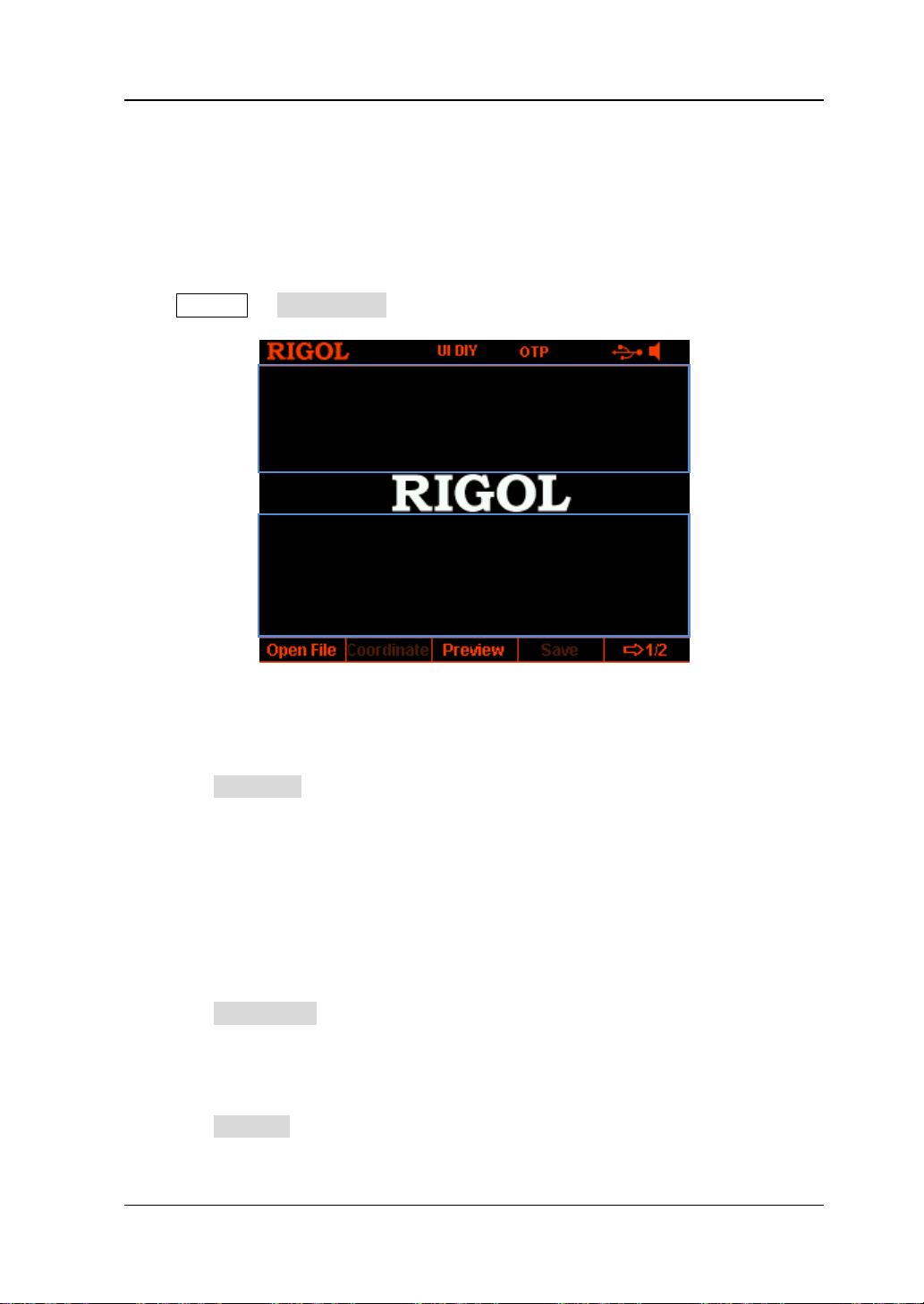

User-defined Start-up Interface ....................................................... 2-43

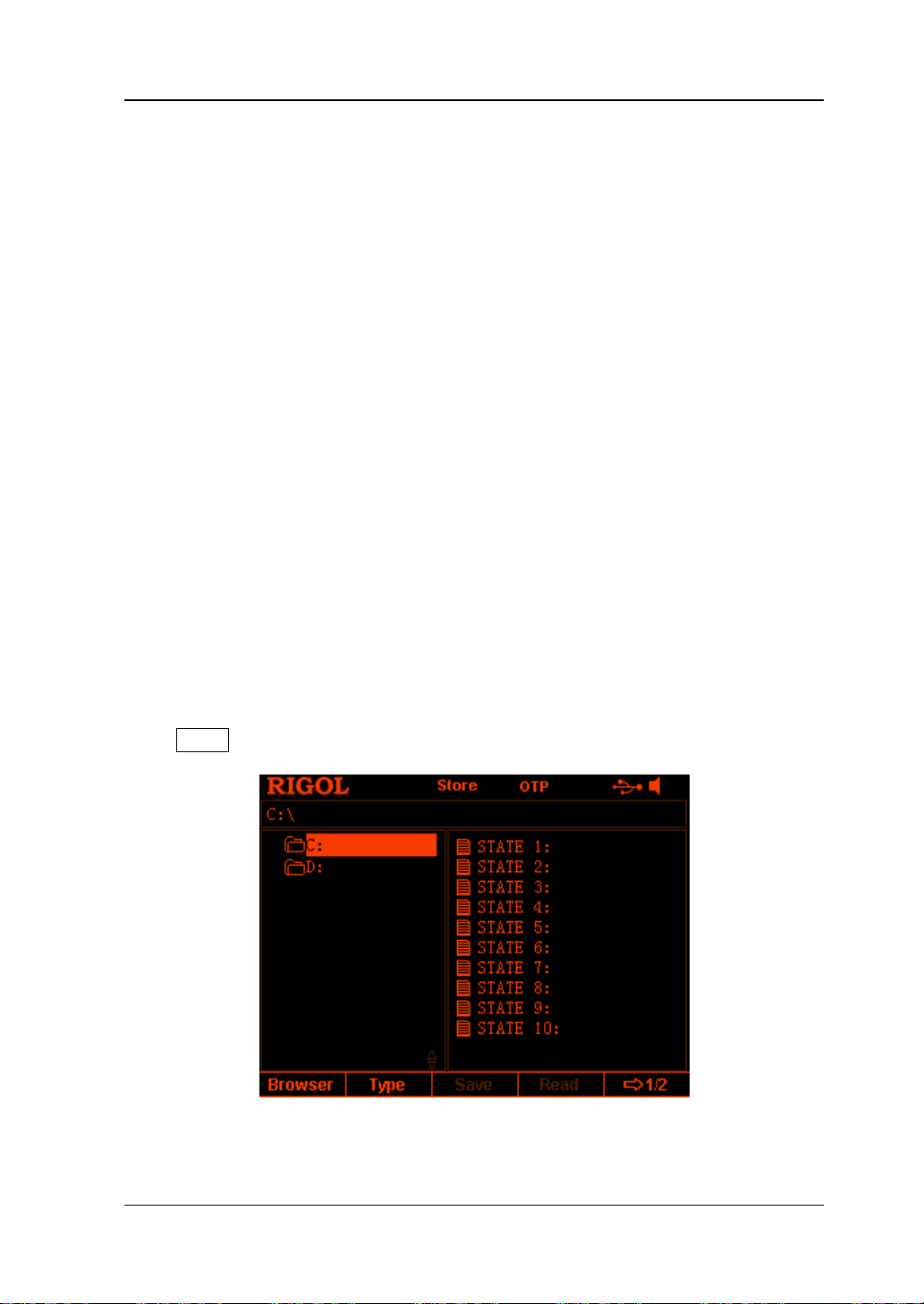

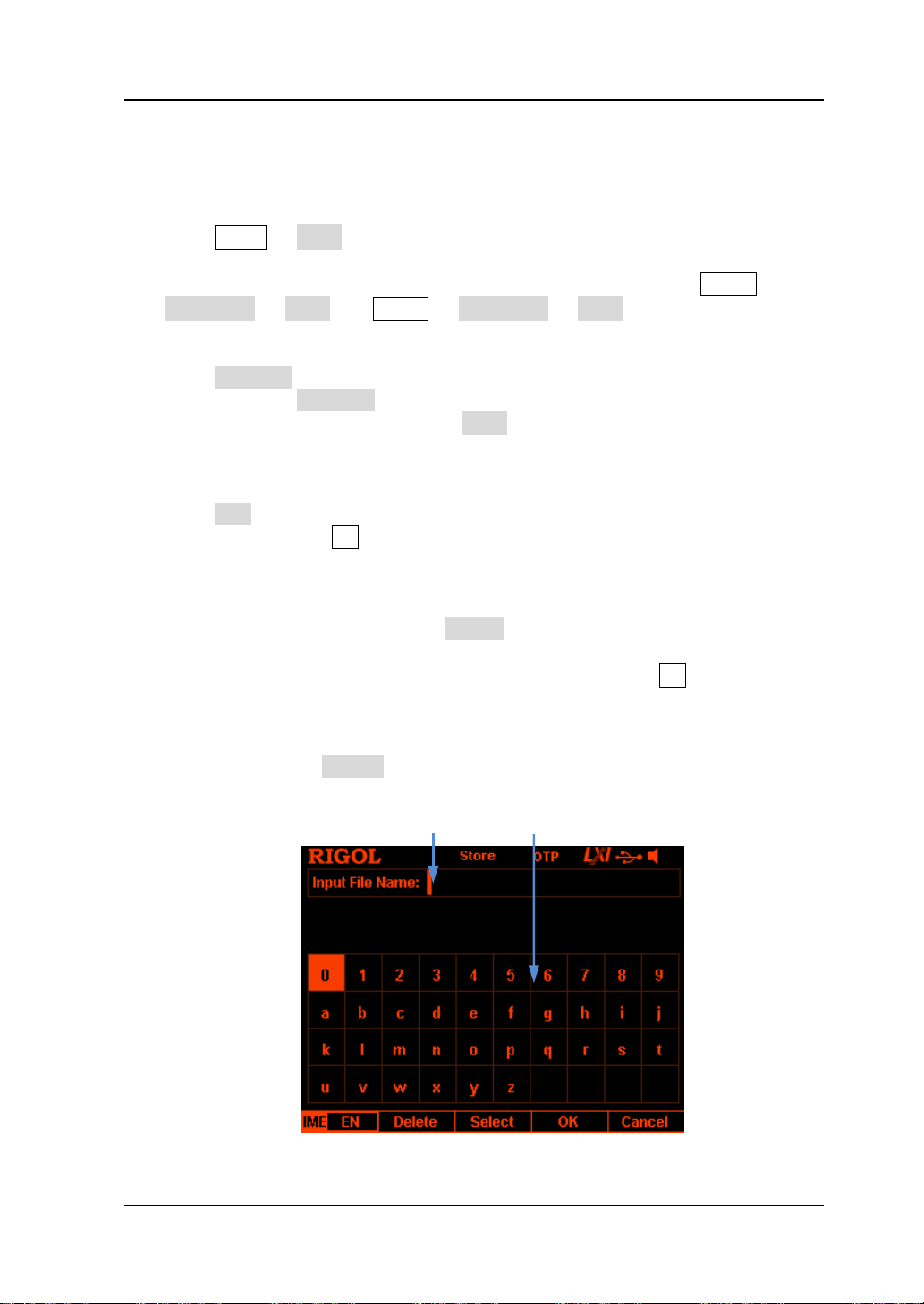

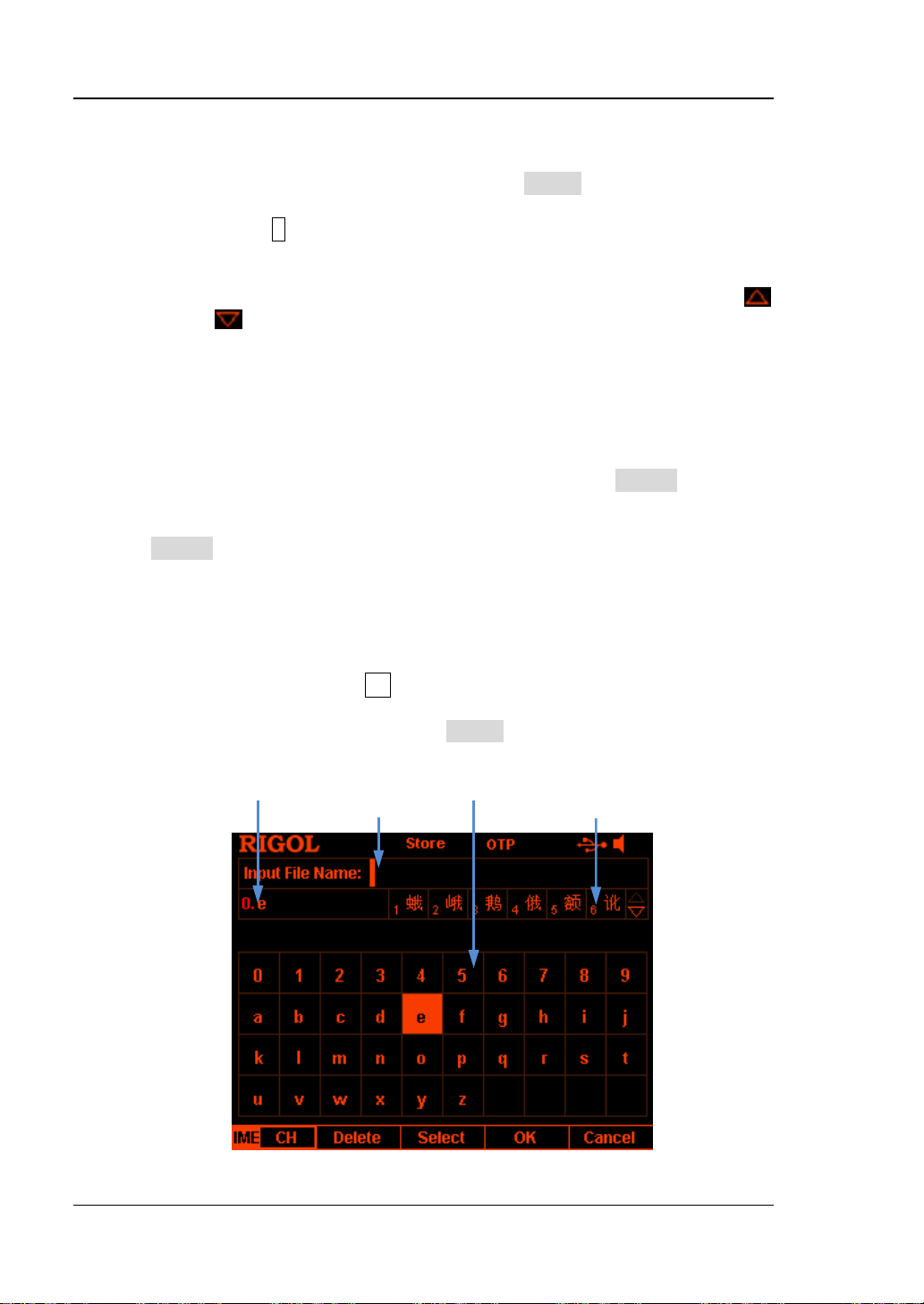

Store and Recall ................................................................................... 2-45

Browser ........................................................................................ 2-46

File Type ....................................................................................... 2-46

Save ............................................................................................. 2-47

Read............................................................................................. 2-49

Delete........................................................................................... 2-49

Copy and Paste .............................................................................. 2-50

Utility .................................................................................................. 2-51

I/O Configuration ........................................................................... 2-52

System Setting .............................................................................. 2-58

System Informat i on ........................................................................ 2-60

System La nguage .......................................................................... 2-60

Test/Calibration.............................................................................. 2-60

Print ............................................................................................. 2-61

Preset Setting ................................................................................ 2-62

Options ......................................................................................... 2-69

Key Locking ......................................................................................... 2-71

Chapter 3 Remote Control .................................................................. 3-1

Remote Control via USB ......................................................................... 3-2

Remote Control via LAN (option) ............................................................. 3-5

Remote Control via GPIB (option) ........................................................... 3-8

Remote Control via RS232 (option) ........................................................ 3-10

Chapter 4 Troubleshooting ................................................................. 4-1

Chapter 5 Specifications ..................................................................... 5-1

Chapter 6 Appendix ............................................................................ 6-1

Appendix A: Access ories and Options ...................................................... 6-1

Append i x B: Warranty ............................................................................ 6-2

Index ....................................................................................................... 1

DP800 User’s Guide XV

Page 18

Page 19

Chapter 1 Quick Start RIGOL

Chapter 1 Quick Start

The contents of this chapter are as follows:

General Inspection

Appearance and Dim e nsions

Front Panel

Rear Panel

To Connect to Power

Power-on Inspection

To Replace the Fuse

User Interface

To Use the Built-in Help System

To Rack Mount the Instrument

DP800 User’s Guide 1-1

Page 20

RIGOL Chapter 1 Quick Start

General Inspection

1. Inspect the shipping container for damage

Keep the damaged shipping container or cushioning material until the contents

of the shipment have been checked for completeness and the instrument has

passed both ele ctrica l a nd mechanical tests.

The consigner or carrier shall be liable for the damage to instrument resulting

from shipment. RIGOL woul d n ot be responsible for free maintenance/rework

or replacement of the unit.

2. Inspect the instrument

In case of any damage, or defect, or failure, notify your RIGOL sales

representative.

3. Check the accessories

Please check the accessories according to th e pack i ng li s ts . If the acce ssories

are incomplete or damaged, please contact your RIGOL sales representative.

1-2 DP800 User’s Guide

Page 21

Chapter 1 Quick Start RIGOL

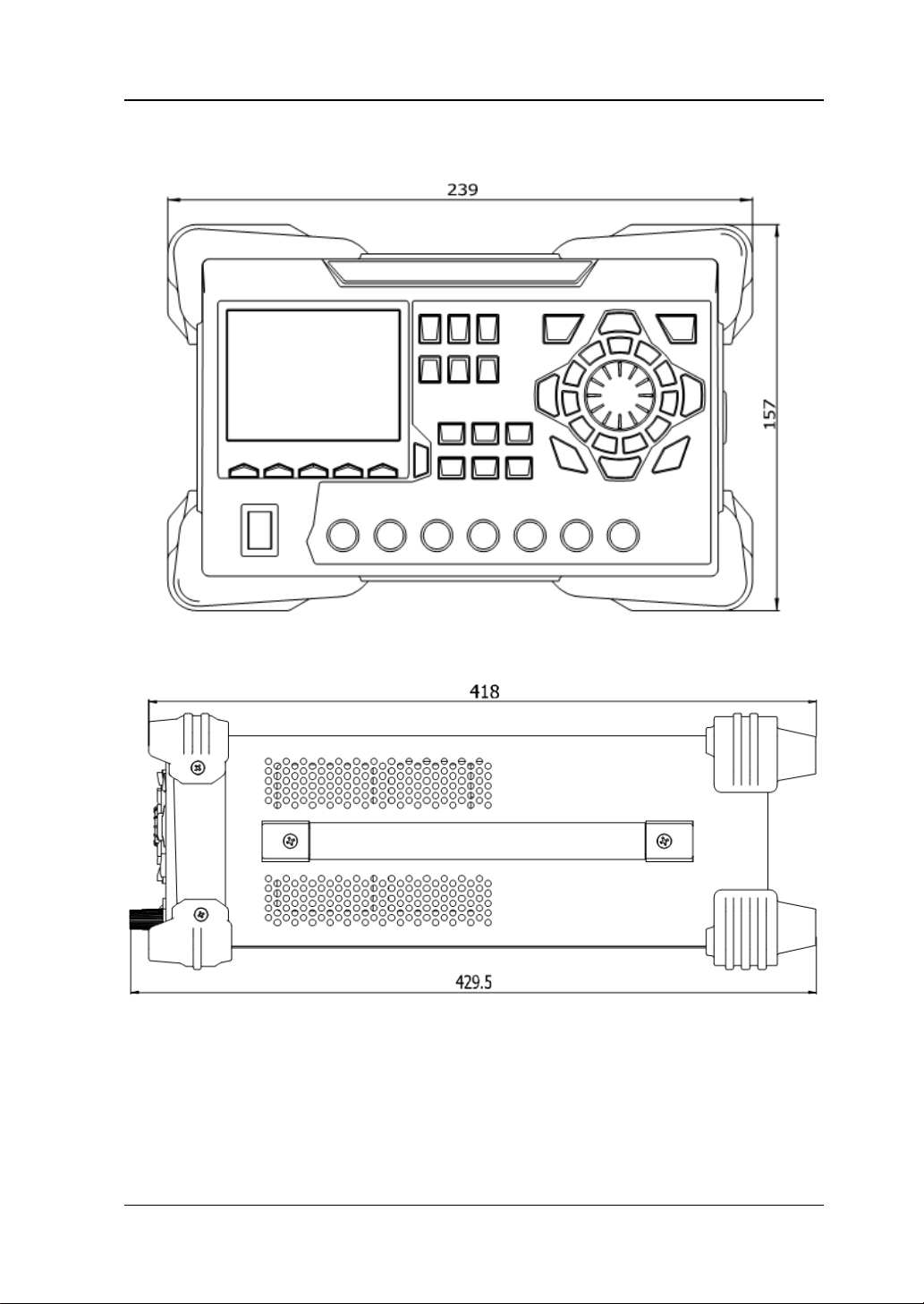

Appearance and Dimensions

Figure 1-1 Front View Unit: mm

Figure 1-2 Side View Unit: mm

DP800 User’s Guide 1-3

Page 22

RIGOL Chapter 1 Quick Start

1 2 3 4

11 10 9 8 7 6 5

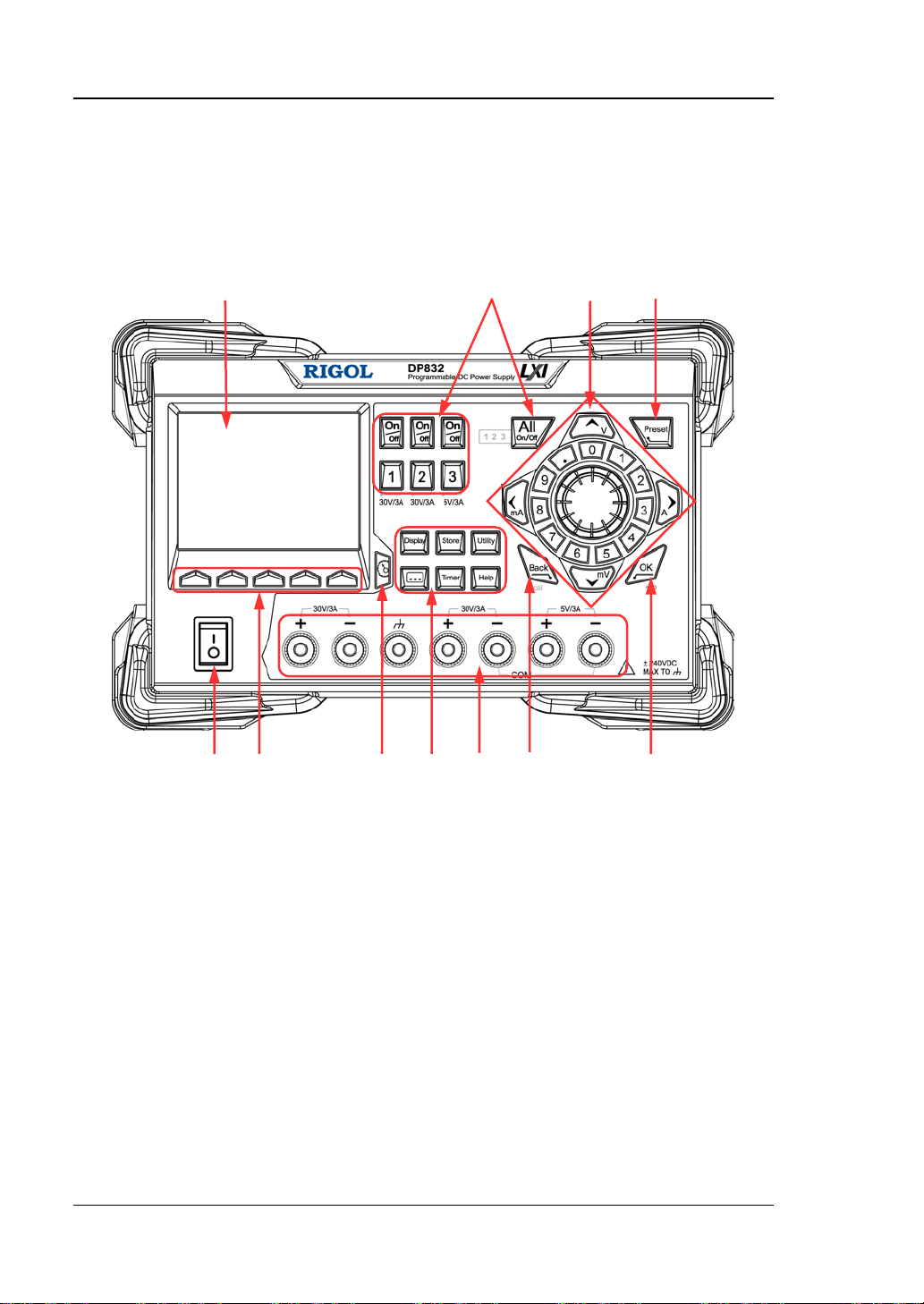

Front Panel

This section introduces the front panel of DP800 serie s by takin g DP832 (as sh own in

the figure below) as an example. The differences of different models are introduced

separately.

Figure 1-3 DP832 Front Panel

1-4 DP800 User’s Guide

Page 23

Chapter 1 Quick Start RIGOL

Press this key to select CH1 as the current channel and you can set

Press this key to select CH2 as the current channel and you can set

Press this key to select CH3 as the current channel and you can set

Press this key to enable or disable the output of the corresponding

Press this key and t h e prompt message asking whether to enable

the outputs of all the channels.

1. LCD

3.5 inches TFT display. It is used to display the system parameter setting,

system output state, menu items, prompt messages, etc.

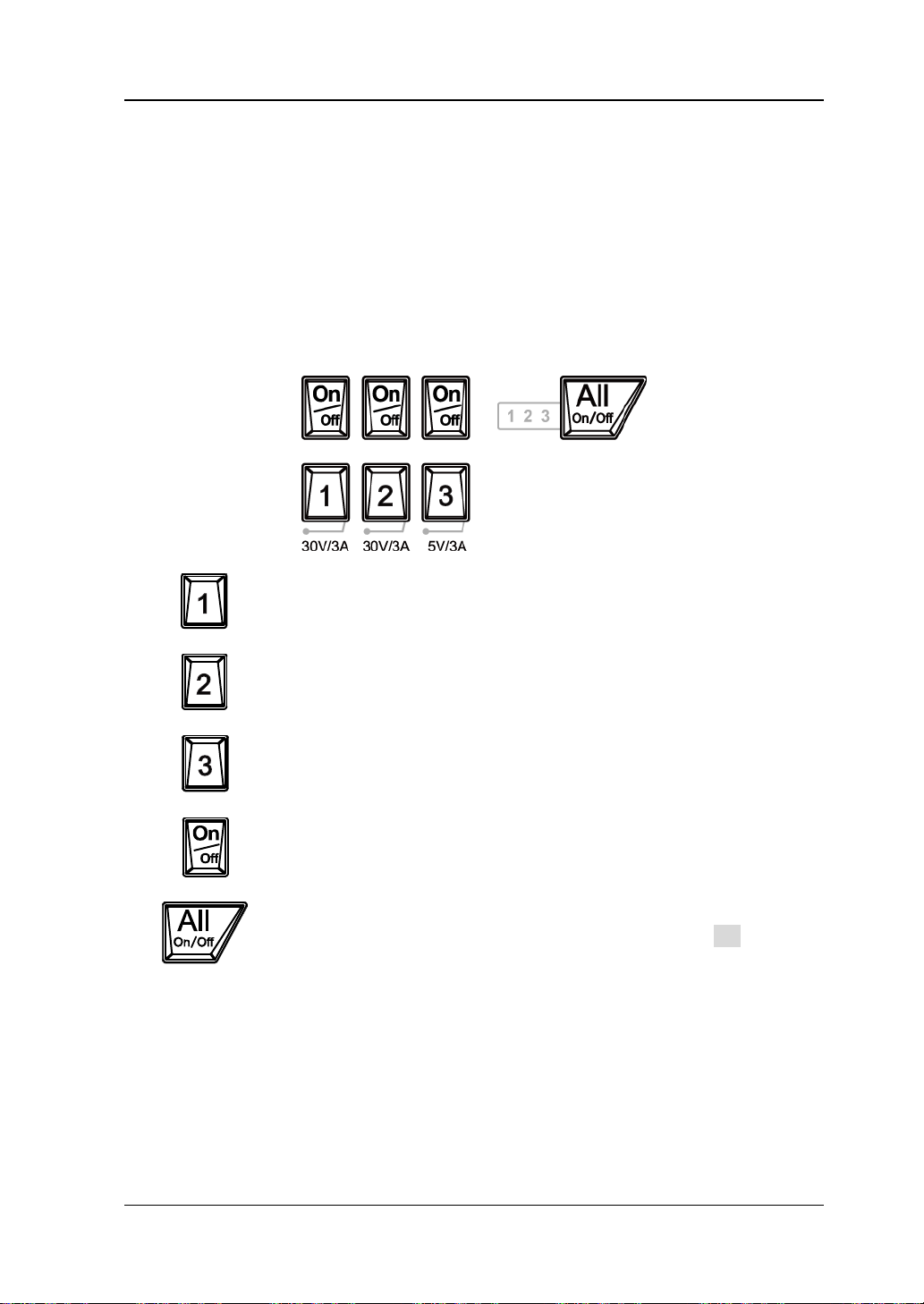

2. Channel (Range) Selection and Output Switch

For the multi-channel model, the function of this part is channel selection and

output switch. For the single-channel model, the function of this part is range

selection and output switch.

Multi-channel models (take DP832 as an example):

the parameters of this channel, such as voltage, current and

overvoltage/overcurren t protection.

the parameters of this channel, such as voltage, current and

overvoltage/overcurren t protection.

the parameters of this channel, such as voltage, current and

overvoltage/overcurren t protection.

channel.

the outputs of all the channels will be dis played. Pres s OK to enable

the outputs of all the channels. Pressing this key again will disable

DP800 User’s Guide 1-5

Page 24

RIGOL Chapter 1 Quick Start

20V

10A

40V

5A

Press this key to select 20V/10A range as the current r an ge and

Press this key to select 40V/5A range as the current range and you

Press this key to enable or disable the output of the channel.

Single-channel model (DP811):

you can set the parameters of the channel, such as voltage,

current and overvoltage/overcurrent protection.

can set the parameters of the channel, such as voltage, current

and overvoltage/overcurrent protection.

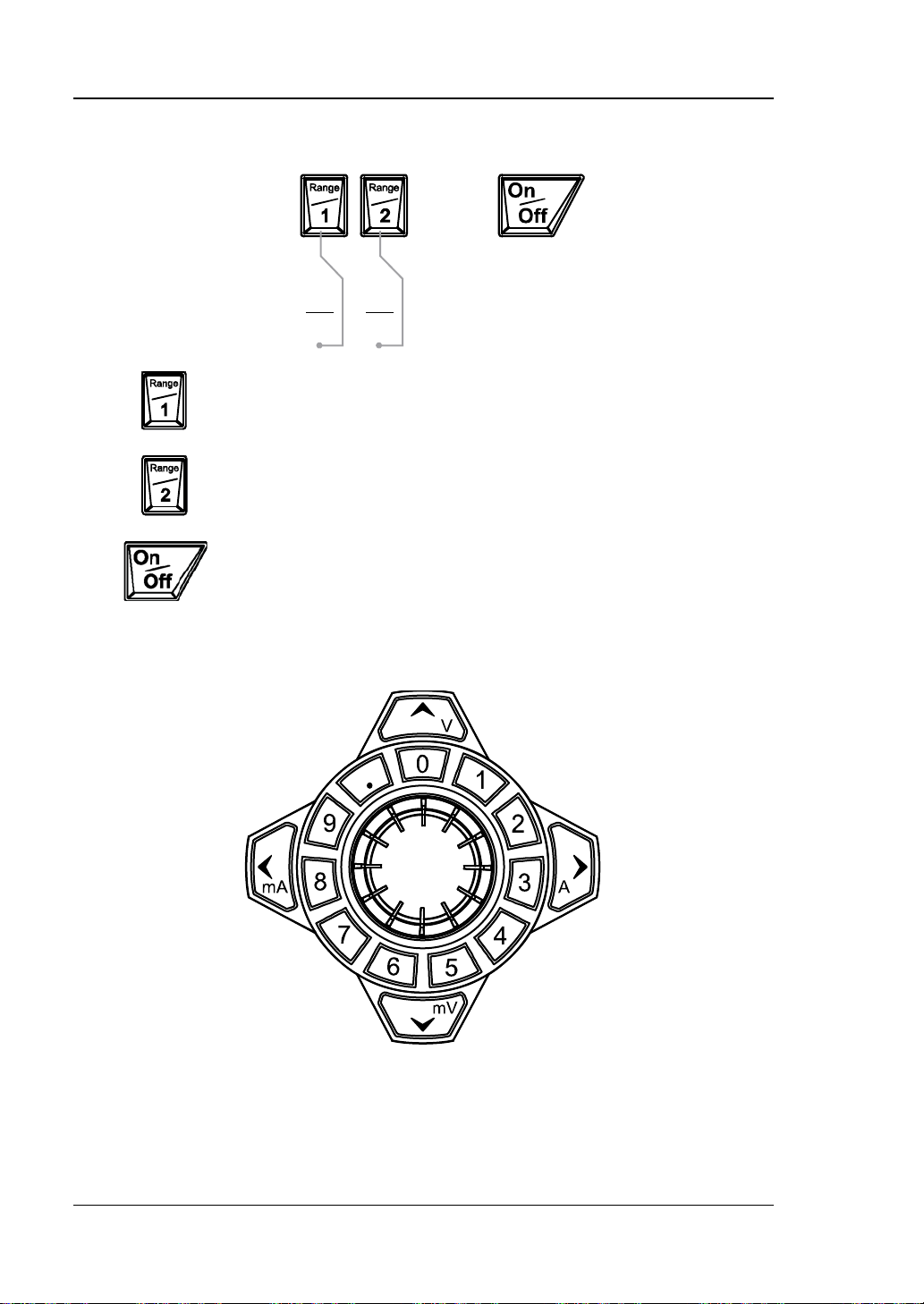

3. Parameter In p ut Area

The parameter input area is as shown in the figure below. This area includes the

direction keys (unit selection keys), numeric keyboard and knob.

(1) Direction keys and unit selection keys

Direction keys: move the cursor. When setting parameters, use the

up/down direction key to increase or reduce the value at the cursor.

Unit selection keys: whe n usi ng the nume ric ke yboa rd t o i nput par ameter s,

1-6 DP800 User’s Guide

Page 25

Chapter 1 Quick Start RIGOL

Restore all the settings of the instrument to default values or

Confirm the parameter setting.

Press and hold this key to lock the front pane l keys; at this point,

(2012) to unlock the front panel keys.

the keys are use d to enter the v oltage units (V and mV) or the current units

(A and mA).

(2) Numeric Keyboard

Ring-type numeric keyboard: include numbers 0-9 and the decimal point.

Press the corresponding key to directly input the number or decimal point.

(3) Knob

When setting parameters, rotate the knob to increase or reduce the value

at the cursor.

When browsing the setting objects (timer parameters, delay parameters,

filename input, etc.), rotate the knob to quickly move the cursor.

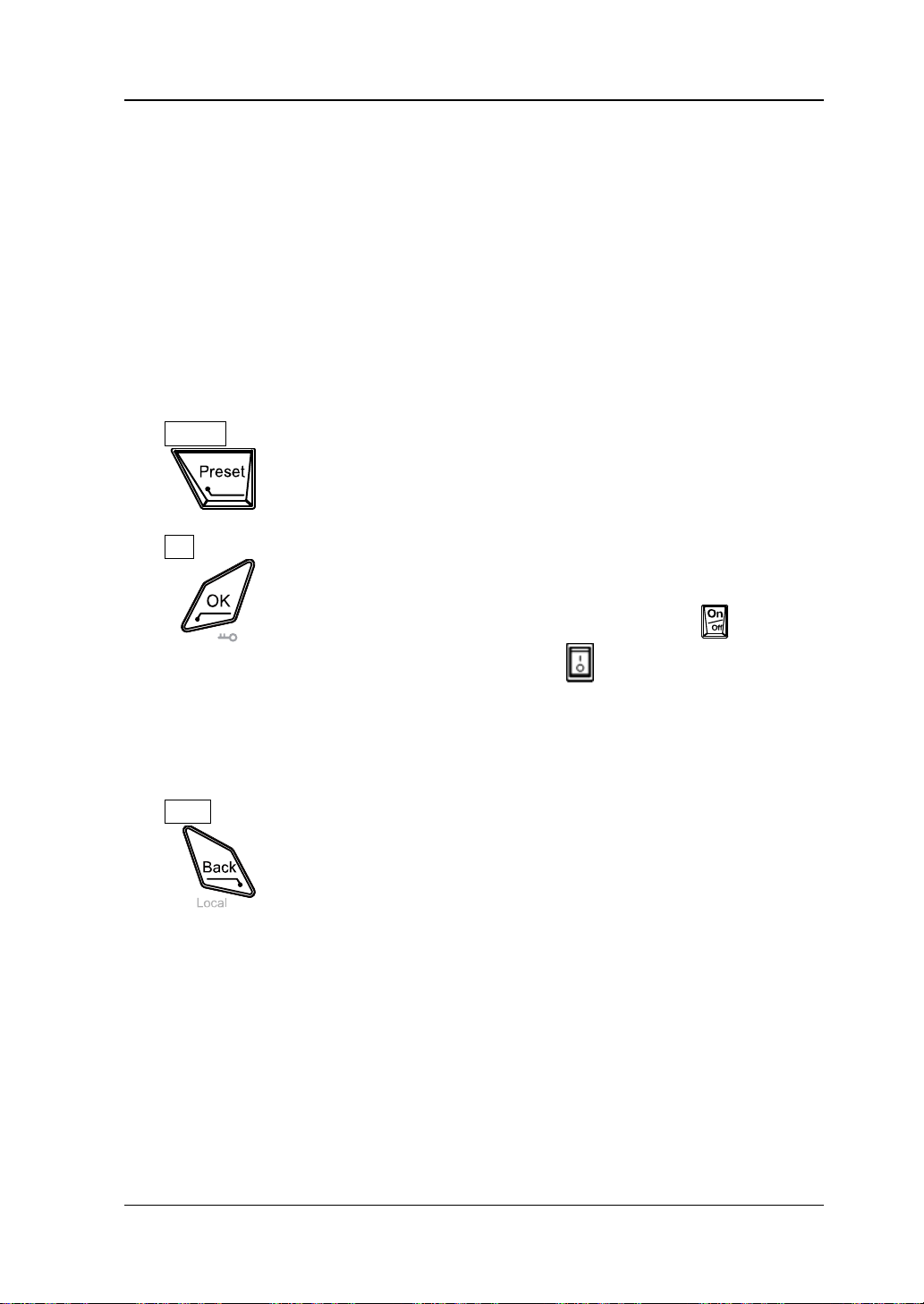

4. Preset

recall the user-defined channel voltage/current configuration.

5. OK

the front panel keys (except the output on/off key o f each

channel and the power switch key ) are not available. When

the keyboard lock password is disabled, press and hold this key

again to unlock the front panel keys. When the keyboard lock

password is enabled, you need to input the correct password

6. Back

Delete the character currently before the cursor.

When the instrument is in rem ote mode, press t his key to return

to local mode.

DP800 User’s Guide 1-7

Page 26

RIGOL Chapter 1 Quick Start

8V/10A60V/1A

S S

Output

(1)

(3)

(1) (2)

7. Output Terminals

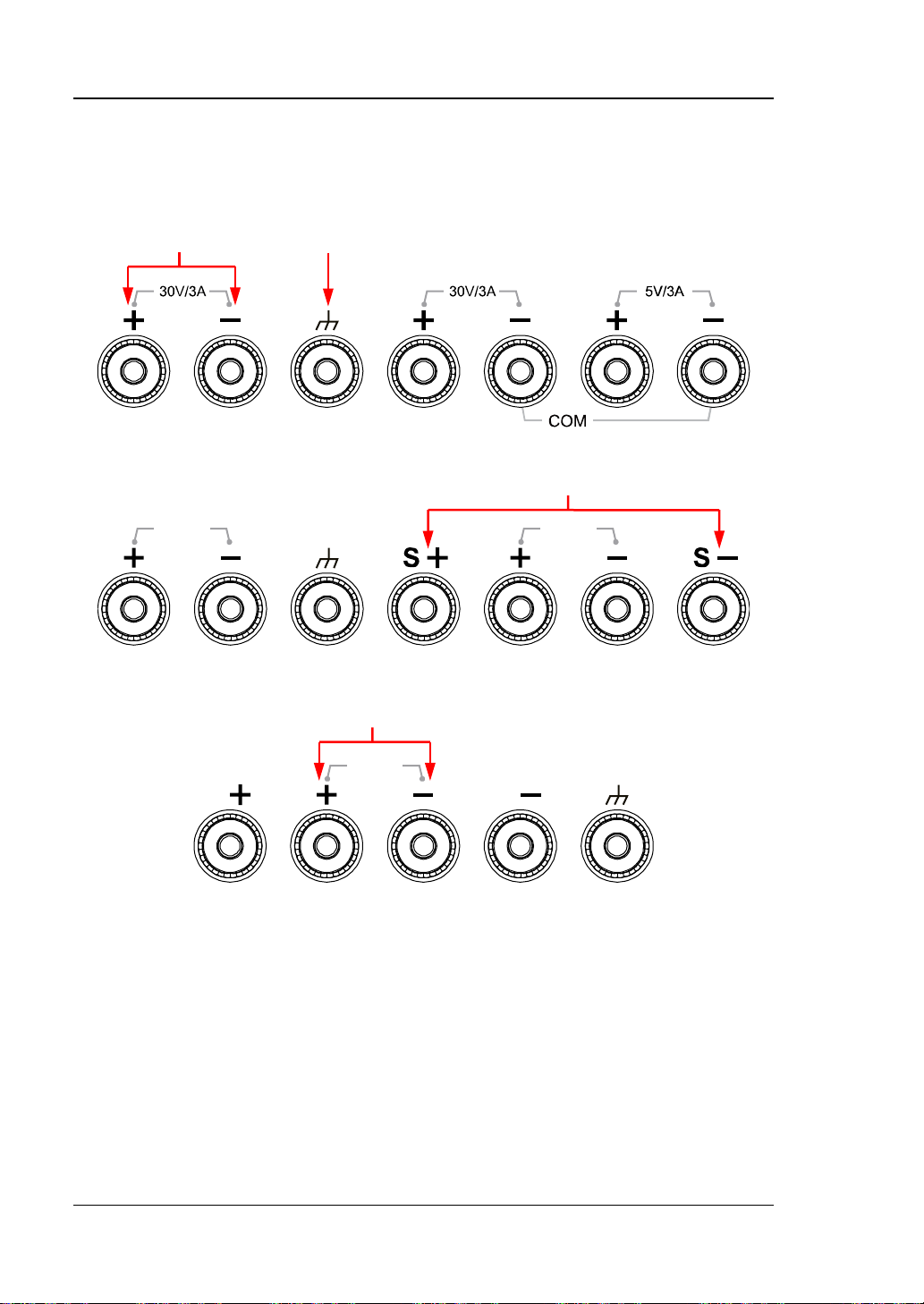

The output terminals of different models of DP800 series are different.

DP832:

DP821:

DP811:

(1) Channel output terminals: used to output the voltage and current of the

channel.

(2) Ground terminal: this terminal is connected to the instrument chassis and

ground wire (the ground terminal of the power cord) and is in grounded

state.

(3) Sense terminals: used to detect the actual voltage at the load terminal so as

to compensate for the voltage drop c a u s ed by the load l e ad.

1-8 DP800 User’s Guide

Page 27

Chapter 1 Quick Start RIGOL

Press this key to enter the display parameter setting interface.

interface.

Press this key to enter the file store and recall interface. You can

and recall.

A

B

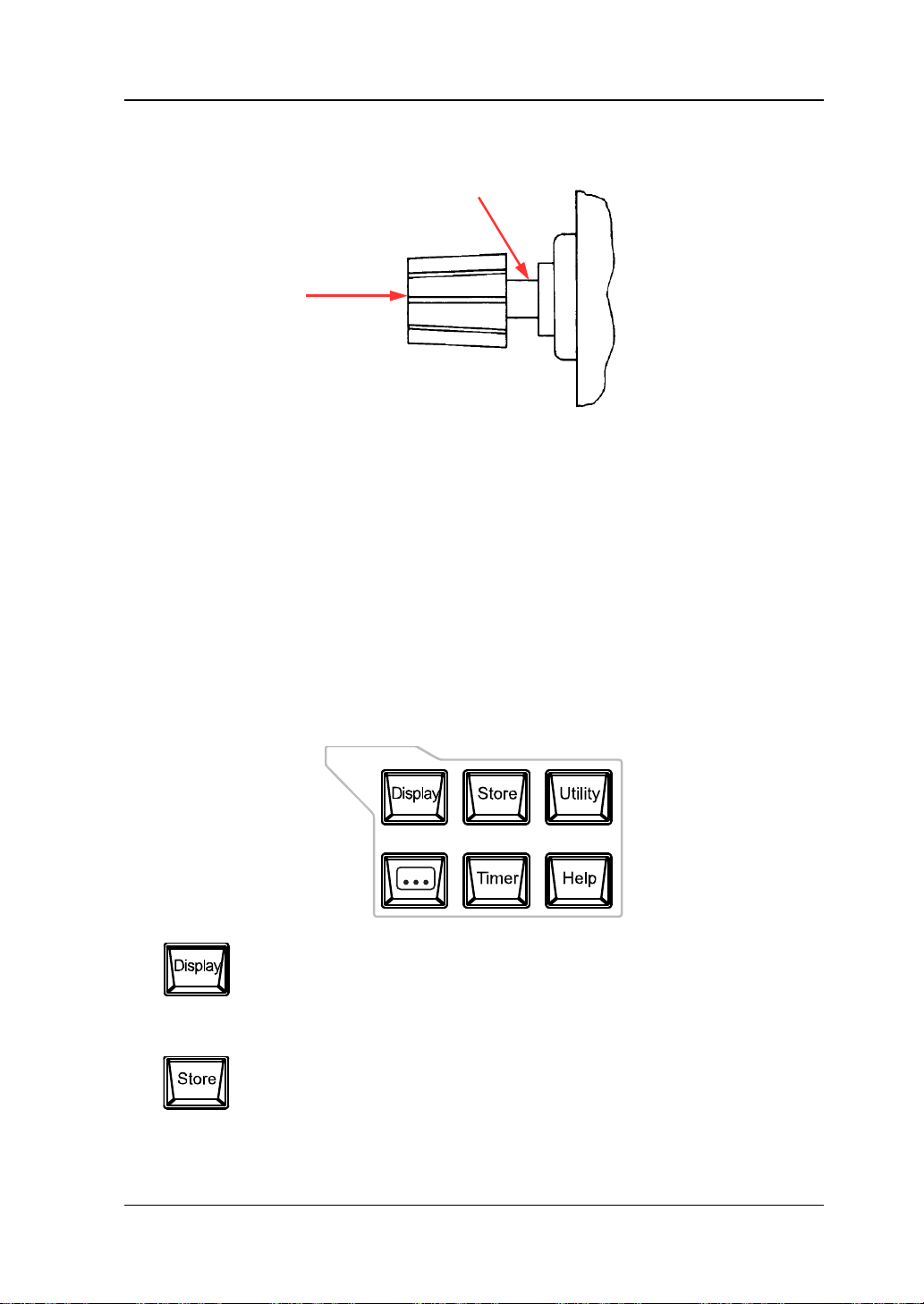

Connection methods of the output terminal:

Method 1:

Connect the test lead to A of the output terminal.

Method 2:

Rotate the outer nut of the output terminal counterclockwise and connect the

test lead to B of the output terminal; then, rotate the outer nut of the output

terminal clockwise. This connection method can eliminate the error caused by

the resistance of the output terminal.

Note: Connect the posit ive terminal of the test lea d w ith the (+) terminal of the

channel output and connect the negative terminal of the test lead with the (-)

terminal of the channel output.

8. Function Menu Area

Users can set the brightness, contrast, RGB luminan ce, display

mode and display theme. Besides, you can a lso define the start-up

save, read, delete, copy and paste files. The file types available for

storage include state file, record file, timer f ile, delay file and

bitmap file. The instrument supports internal and external storage

DP800 User’s Guide 1-9

Page 28

RIGOL Chapter 1 Quick Start

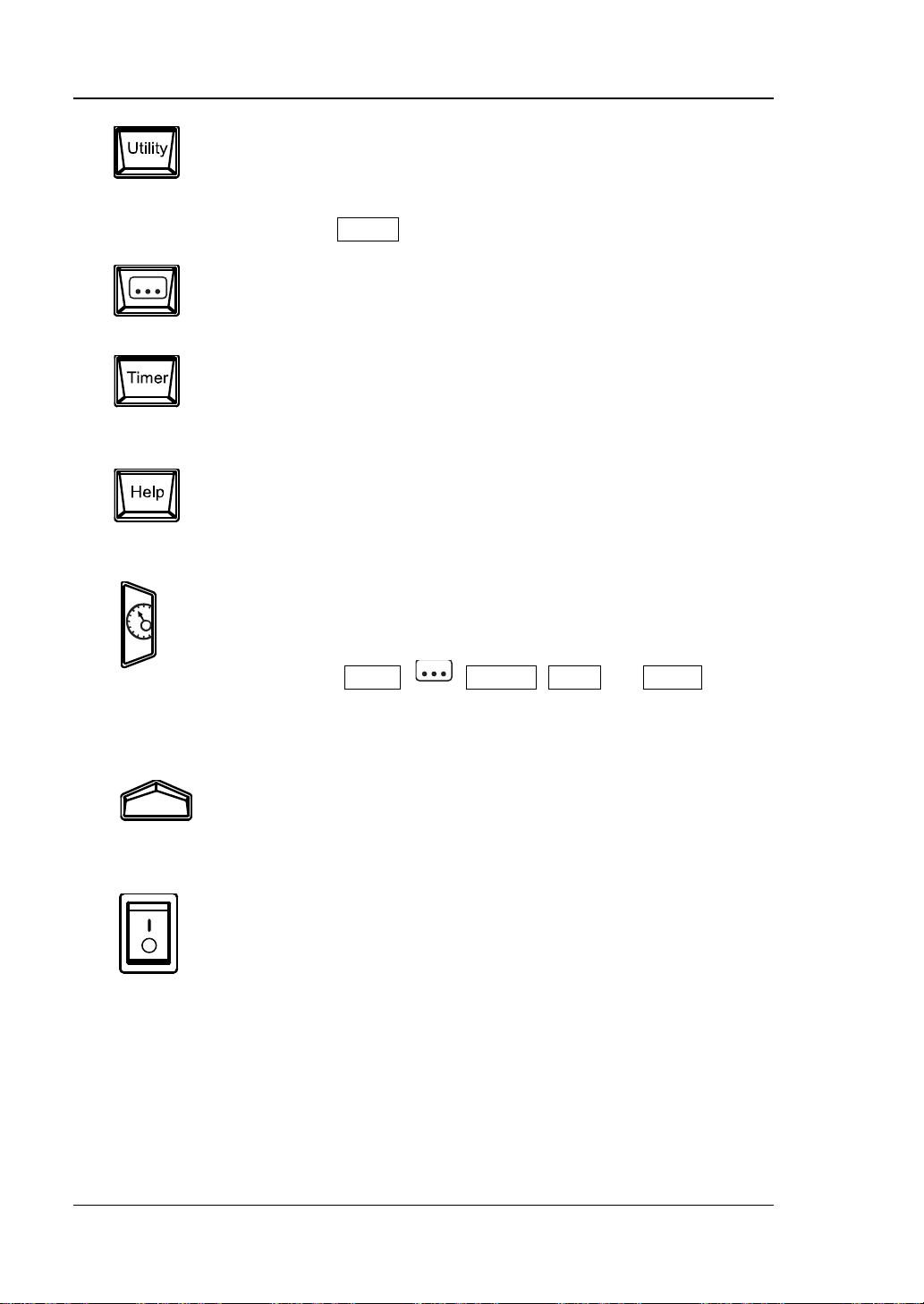

Press this key to enter the system utility function setting interface.

configuration of Preset and install options.

Press this key to enter the advanced function setting interface.

trigger (option) parameters.

Press this key to enter the timer and delayer setting interface.

Press this key to open the built-in help system and press the

introductions, refer to "To Use the Built-in Help System".

interface.

The menu keys correspond to the menus above them

menu.

Users can set the remote interface parameters, system parameters

and print parameters. Besides, users can also calibrate the

instrument, view system information, define the recall

Users can set the recorder, analyzer (option), monitor (option) and

Users can set the timer and delayer parameters as well as enable

and disable the timer and delayer functions.

desired key to get the corresponding help information. F or detailed

9. Display Mode Switch/Return to the Main Interface

Switch between the current display mode and dial display mode.

Besides, when the instrument is in a function interface (any

interface under Timer,

press this key to exit the f unction interf ace and return to the main

10. Me nu Keys

respectively. Press any menu key to select the corresponding

11. Power Switch Key

Turn on or off the instrument.

, Display, Store and Utility),

1-10 DP800 User’s Guide

Page 29

Chapter 1 Quick Start RIGOL

T6

.3A

T

3.

1

5A

AC 1

00V

A

C 1

1

5V

AC

23

0V

500V

A

O

pt

. O

p

t.

Op

t

.

T6.

3A

T3.15A

AC 100V

AC 115V

AC 230V

500VA

Opt. Opt.

Opt.

S

S+

1 2 3 4 5 6

10 9 8 7

11

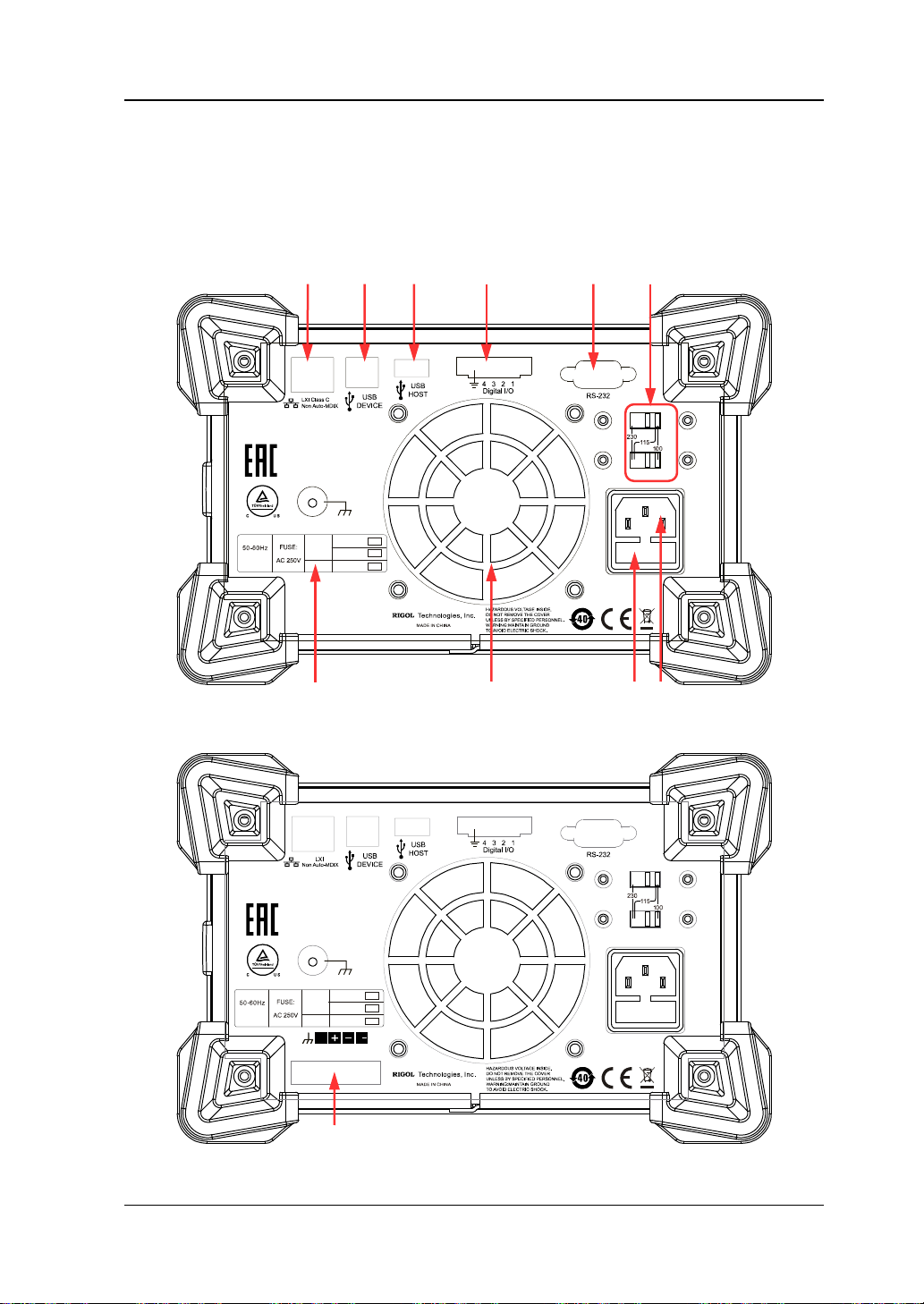

Rear Panel

This section introduces the rear panel of DP800 series by taking DP832 and DP811

(as shown in the figures below) as examples. The introduction of each part is as

shown in Table 1-1.

Figure 1-4 DP832 Rear Panel

Figure 1-5 DP811 Rear Panel

DP800 User’s Guide 1-11

Page 30

RIGOL Chapter 1 Quick Start

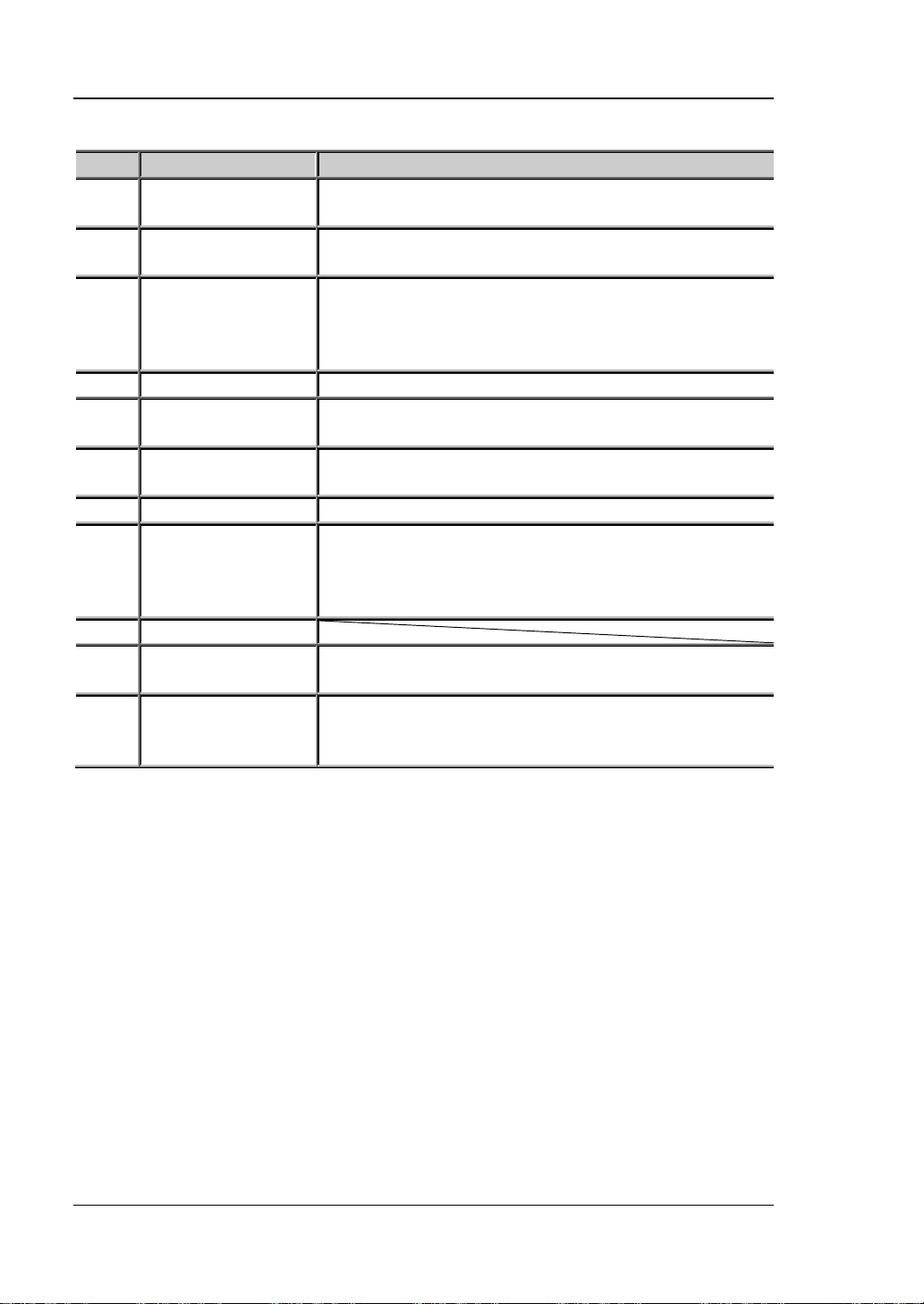

No.

Name

Explanation

LAN Interface

(option)

The instrument is connected to the local network via

RJ45 interface

Connect the instrument (as "slave" device) to

Connect the instrument (as "host" device) to external

USB-GPIB interface converter (option)

4

Digital I/O (option)

Digital I/O interface

RS232 Interface

(option)

Select the specification of the input voltage (100, 115

or 230; please refer to Table 1-2)

7

Power Socket

AC power input interface.

The specification of the fuse is related to the

panel of the instrument or refer to Table 1-3).

9

Fan

Input Power

Requirement

Corresponding relations of the AC input power

frequency, voltage and the specification of the fuse.

DP811 provides this interface. The function of this

Terminals" at the front panel.

Table 1-1 DP800 rear panel explanation

1

2 USB DEVICE

3 USB HOST

5

6 Voltage Selector

8 Fuse

10

11 Output Interface

external USB device (such as PC)

USB device (such as USB storage device);

extend a GPIB interface for the power supply using

Serial communication interface

instrument model and actual input voltage (please

refer to the "Input Power Requirements" at the rear

interface is the same as that of the "Output

Note: The "Output Terminals" at the front panel and "Output Interface" at the rear

panel cannot be used for output at the same time. You can only select one of them

for output at each time (wherein, the output terminals at the front panel provide

higher output accuracy).

1-12 DP800 User’s Guide

Page 31

Chapter 1 Quick Start RIGOL

AC Input Power

Voltage Sele ctor Settin g

100Vac±10%, 50Hz to 60Hz

100

115Vac±10%, 50Hz to 60Hz

115

230Vac±10% (250Vac maximum ), 50Hz to 60Hz

230

WARNING

grounded.

To Connect to Power

DP800 series power supply supports various AC power supply inputs. The voltage

selector setting at the rear panel differs when the input power connected is different,

as shown in the table below.

Table 1-2 AC input power specifications (including voltage selector settings)

Please connect the power following the steps below.

1. Check the input power

Make sure that the AC power to be connected to the instrument fulfills the

requirements in Table 1-2.

2. Check the voltage selector at the rear panel

Make sure that the v oltage selector set ting (110, 115 or 230) at the rear panel of

the instrument matches the actual input voltage (for the matching relations refe r

to Table 1-2).

3. Check the fuse

When the instrument leav es f actory, the specified fuse is installed. Please che ck

whether the fuse matches the actual input voltage according to the "Input

Power R e quirements" at the rear panel of the instrument or Table 1-3.

4. Connect the AC power

Connect the instrument to AC power supply using the power cord provided in

the accessories.

To avoid electric shock, make sure that the instrument is correctly

DP800 User’s Guide 1-13

Page 32

RIGOL Chapter 1 Quick Start

Tip

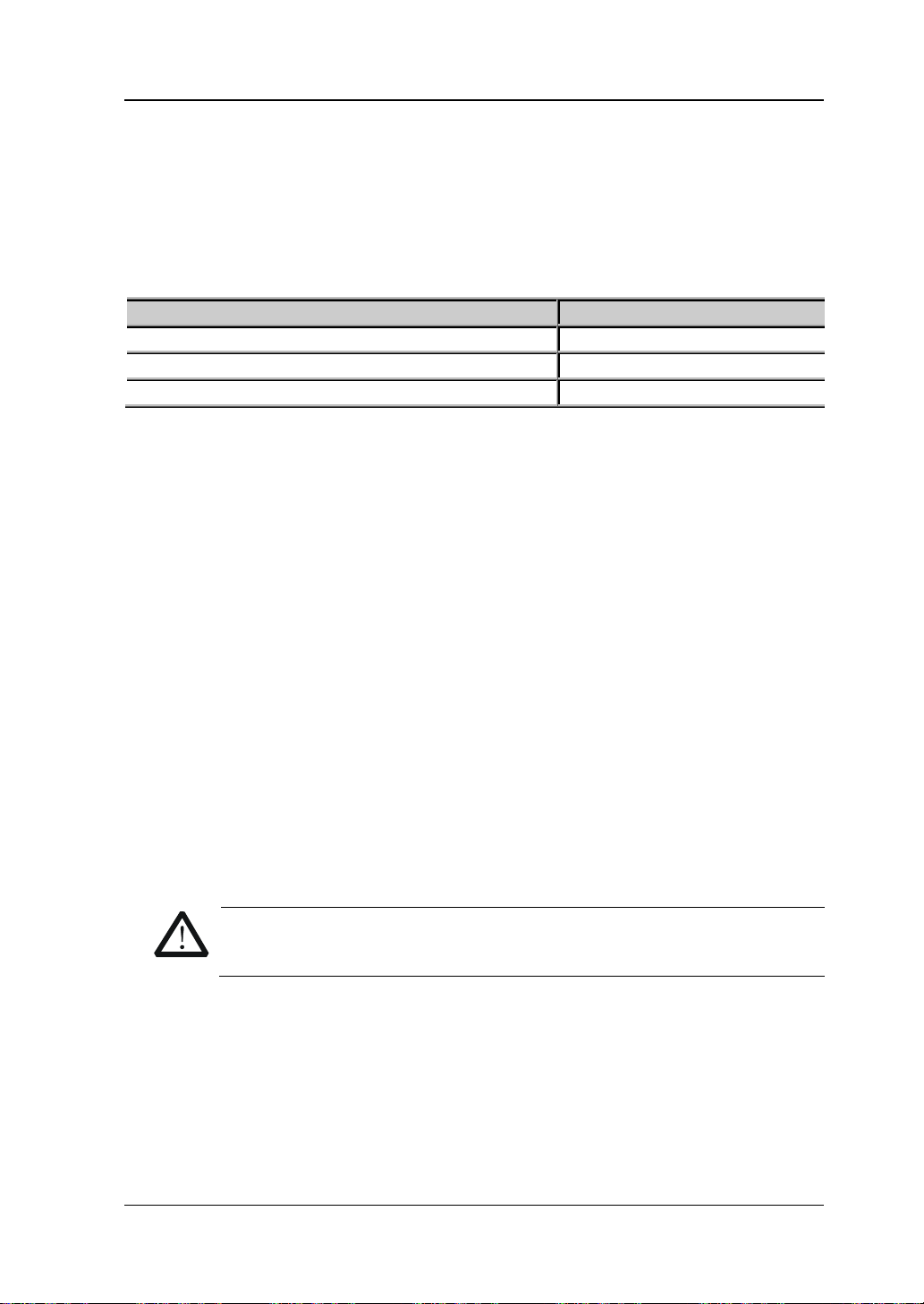

Input Voltage

Fuse Specification

DP832/DP811

100Vac/115Vac

T6.3A

230Vac

T3.15A

DP831/DP821

100Vac/115Vac

T5A

230Vac

T2.5A

Fuse Seat

Fuse

Power-on Inspection

Press the power switch at the front panel, the instrument starts and executes

self-test. If the instrument passes the self-test, the welcome interface will be

displayed; otherwise, the corresponding self-test failure information (including the

top board, bottom boa rd, fan and tem pe rature) will be di s pl ayed.

When powering on the instrument after powering off it, make sure that the time

interval between the two operations is greater than 5s.

To Replace the Fuse

The fuse specification is related t o the inst rument model and actual input voltage, a s

shown in the table below. You can also refer to the "Input Power Requirements" at

the rear panel of the instrument.

Table 1-3 Fuse specifications

To replace the fuse, follow the steps below.

1. Turn off the instrument and remove the power cord.

2. Insert a small straight sc rewdrive r into th e slot at the pow er socke t and pri ze out

the fuse seat gently.

1-14 DP800 User’s Guide

Page 33

Chapter 1 Quick Start RIGOL

WARNING

to this specification before connecting to power.

3. If needed, adjust the power volta ge selector manually to select the voltage s cale

(please refer to Table 1-4) that matches the actual input voltage.

4. Take out the fuse and replace it with a specified one (please refer to the "Input

Power R e quirements" at the rear panel of the instrument or Table 1-3).

5. Re-insert the fuse seat into the power socket (pay attention to the direction).

To avoid personal injuries, cut off the power supply before replacing the

fuse; to avoid elect ric shock or fire, select the power supply specification

that matches the actual input voltage and replace a fuse corresponding

DP800 User’s Guide 1-15

Page 34

RIGOL Chapter 1 Quick Start

1 2 3 4 5

6

User Interface

DP800 series po wer su pply provide s th ree kin ds of displa y mo des (no rmal, wav ef orm

and dial). The default is normal. You can press Display Disp Mode to select

different display mode. This section introduces the user interface layout under the

normal display mode (as shown in the figure below and

7

8

9

10

Table 1-4 on the next page).

11

Figure 1-6 User Interface (Normal Di splay Mode)

1-16 DP800 User’s Guide

Page 35

Chapter 1 Quick Start RIGOL

No.

Explanation

1

Channel number

2

Channel output voltage/current

3

Channel output status

4

Channel output mode

5

Status bar. Display the system status labels.

: the instrument is in remote mode.

6

Actual output voltage

7

Actual output current

8

Actual output power

9

Voltage and current setting values

10

Overvoltag e and over current protecti on setting values

11

Menu bar

Tip

panel to quickly switch between the current display mode and dial displa y mo de.

Table 1-4 User Interface Explanation

: over-temperature protection is enabled

: the front panel is locked.

: the network is connected.

: USB device is recognized.

: the beeper is enabled.

: the beeper is disabled.

When the current display mode is "Normal" or "Waveform", press at the front

DP800 User’s Guide 1-17

Page 36

RIGOL Chapter 1 Quick Start

To Use the Built-in Help System

The built-in help s ystem provides help inf ormation f or any f ront panel k ey (except the

parameter input area) and menu keys for users to quickly obtain the function

prompts of the function keys or menus.

Obtain the help information of any key or menu key

Press Help to illuminate it and press the desired key or menu key to get the

corresponding help information; at the same time, the backlight of Help goes off.

Press to ex it the help system.

Built-in help interface

Press Help to illuminate it and press Help again to open the built-in help interface.

Use the up/d own direction key or knob to select the desired help topic and press

View to view the corresponding help information.

The help topics include:

1. View the last displayed message.

2. View error queue of the remote comm ands .

3. Get the help information of a key.

4. Storage manageme nt.

5. Abbreviations list.

6. Series-parallel Help.

7. Get technical support from RIGOL.

1-18 DP800 User’s Guide

Page 37

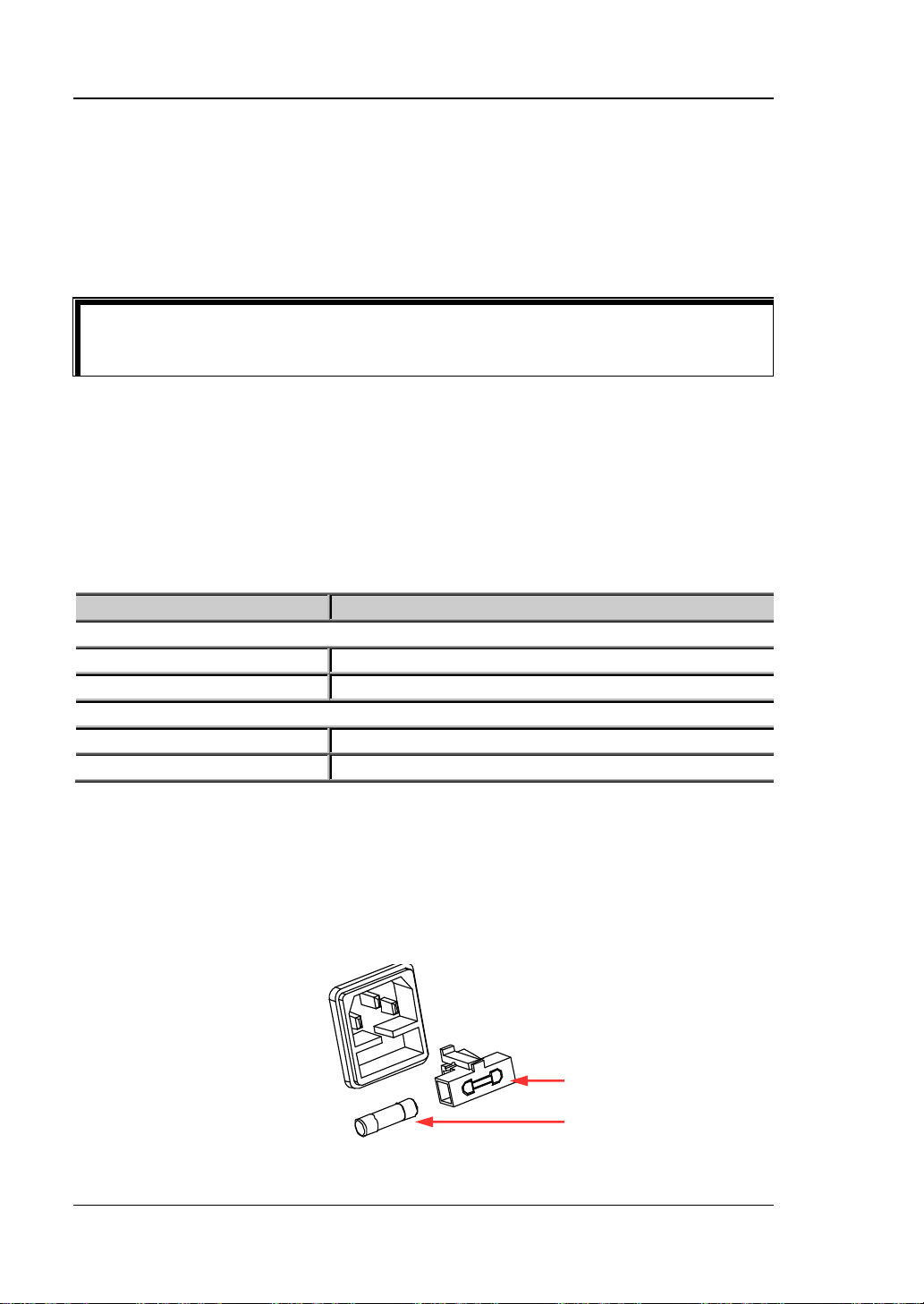

Chapter 1 Quick Start RIGOL

No.

Name

Qty.

Description

Rack Support Shelf

1

②

Front Filler Panel

1

Rack Left Fixing Part

1

Rack Right Fixing Part

1

⑤

Rack Rail

2

⑥

Side B e am Fixing Part

2

M4 Screw

26

M4×6 Phil-Slot Pan Head Screw

M6 Screw

8

M6×16 Phil-Slot Pan Head Screw

M6 Screw

8

M6×5 Lock Blade Square Nut

⑧ ③ ⑤ ② ① ④ ⑨ ⑦ ⑥

To Rack Mount the Instrument

If you want to i nstall the inst rument int o a standar d 19 in ch ma chine cabinet, please

order the rack mount kit (RM-1-DP800 or RM-2-DP8 00; the forme r is used to i nstall a

single instrument and the latter is used to install two instruments) and install the

instrument according to the instructions below.

To Install a Single Instrume nt

Part List

Table 1-5 Rack mount kit (RM-1-DP800) part list

①

③

④

⑦

⑧

⑨

(a)

DP800 User’s Guide 1-19

Page 38

RIGOL Chapter 1 Quick Start

⑦ ⑧ ⑨

(b)

Figure 1-7 Rack Mount Kit (RM-1-DP800) Parts

Installation Tool

PH2 Phillips screwdriver is recommended.

Installation Space

The machine cabinet should fulf ill the following requirements.

It should be a standard 19 inch machine cabinet;

At least 4U (177.8 mm) space should be provided by the machine cabinet ;

The depth inside the machine cabinet should not be less than 463.75mm.

The rack-mounted instrument is as shown in the figure below.

1-20 DP800 User’s Guide

Page 39

Chapter 1 Quick Start RIGOL

CAUTION

of the instrument onto the rack.

Installation Procedures

Only authorized personnel can perform the installation. Improper

operation might cause damage to the instrument or incorrect installation

1. Remo ve t he f our rubbe r bumpers on the front and rear panels of the inst rument

respectively.

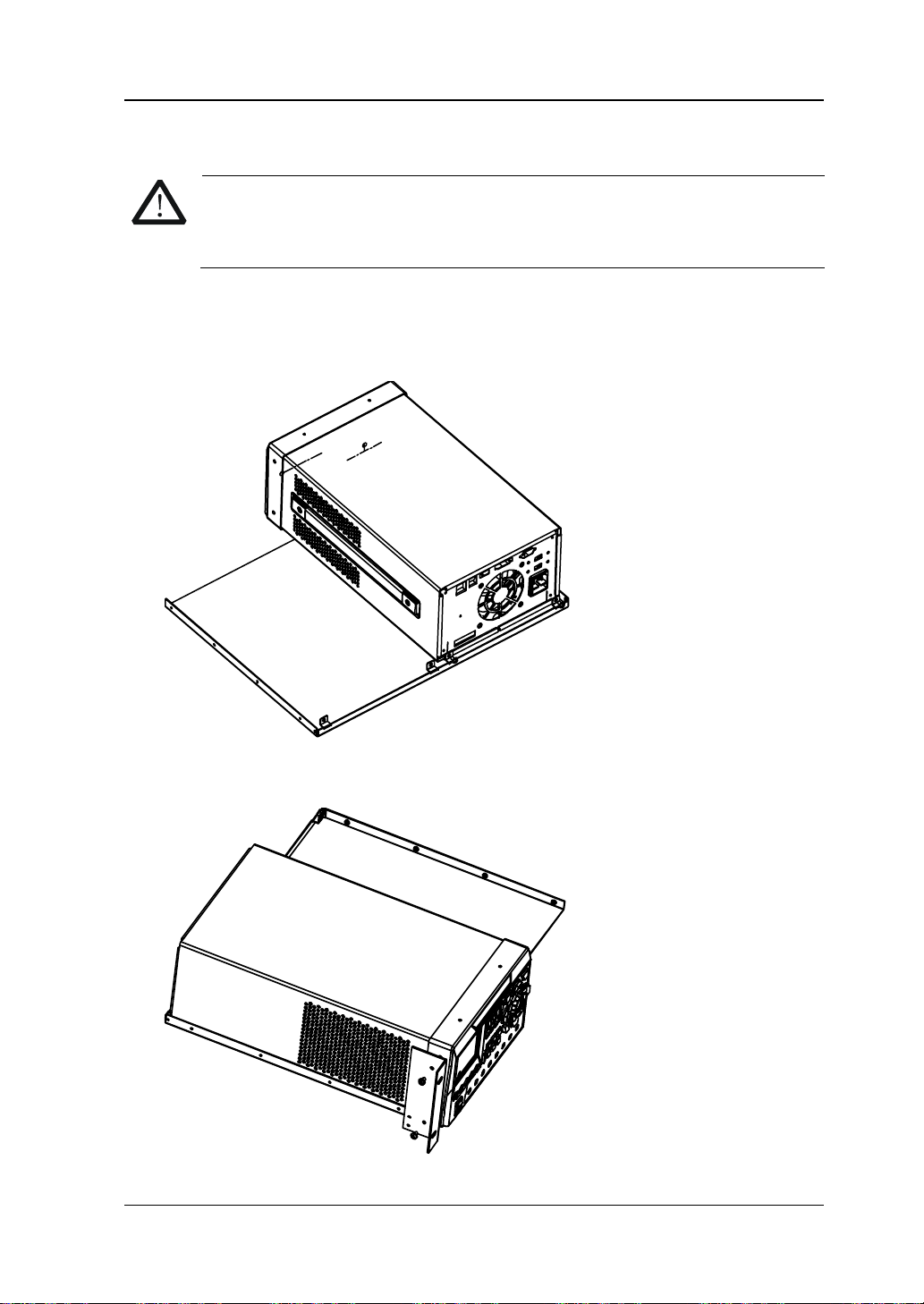

2. Fix the instrument onto the rack support shelf using two M4 screws.

3. Fix the left fixing part to the left side of the front panel of the instrument using

two M4 screws.

DP800 User’s Guide 1-21

Page 40

RIGOL Chapter 1 Quick Start

4. Fix the front f iller panel to the right side of the front panel of the instrument

using two M4 screws.

5. Fix the right fixing part to the right side of the front filler panel using two M4

screws.

1-22 DP800 User’s Guide

Page 41

Chapter 1 Quick Start RIGOL

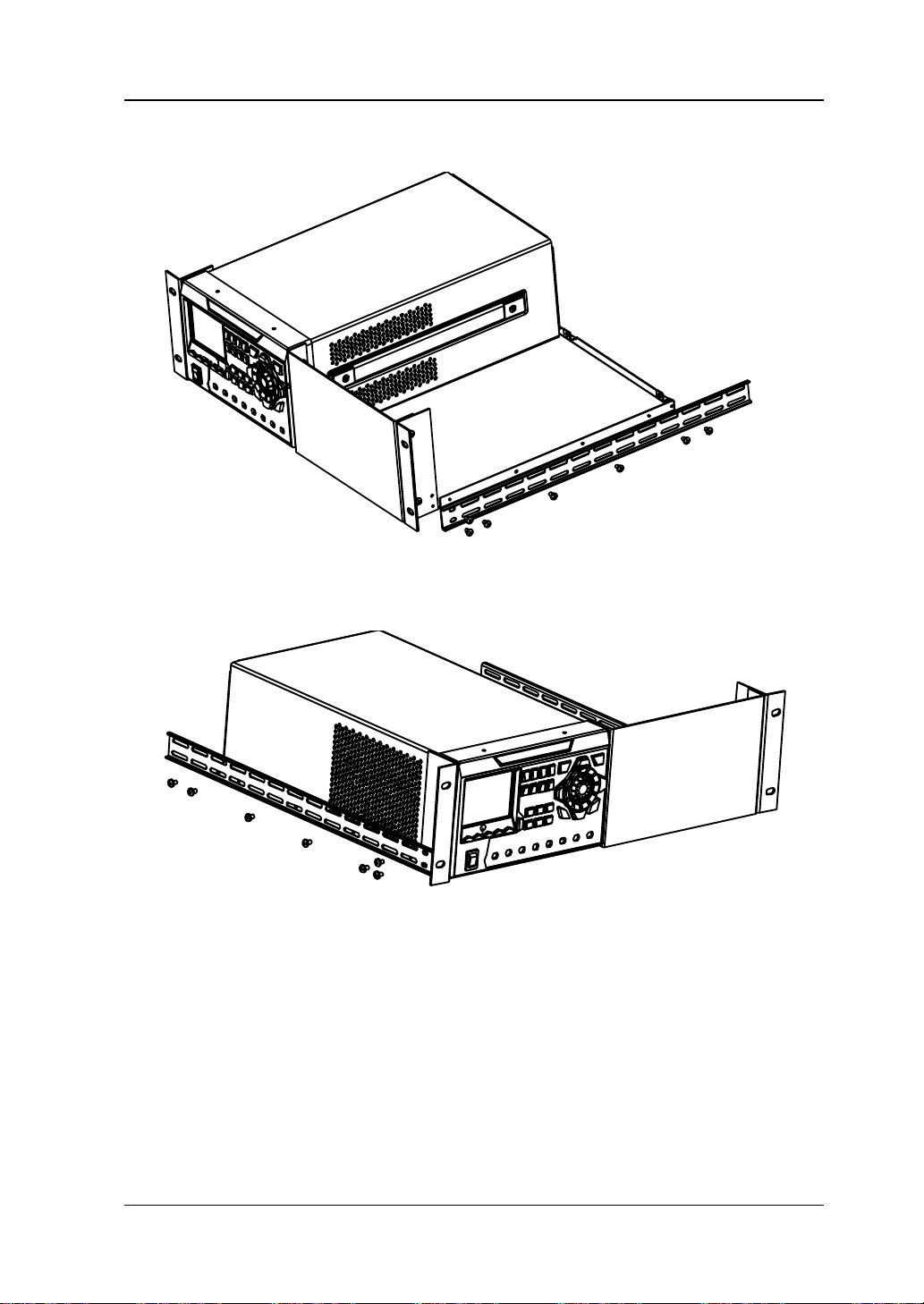

6. Fix a rack rail to the right side of the rack support shelf using seven M4 screws.

7. Fix the other rack rail to th e left side of the rack support shelf using seven M4

screws.

DP800 User’s Guide 1-23

Page 42

RIGOL Chapter 1 Quick Start

8. Fix the t wo side bea m fixing pa rts t o the en d pa rts of t he le ft a nd right r ack r ails

using four M4 screws respectively.

9. Install the rack mounted with the instrument into a standard 19 inch machine

cabinet using eight M6 screws and eight M6 nuts.

1-24 DP800 User’s Guide

Page 43

Chapter 1 Quick Start RIGOL

10. At this point, the diagram of the instrument is as shown in the figure below.

DP800 User’s Guide 1-25

Page 44

RIGOL Chapter 1 Quick Start

No.

Name

Qty.

Description

Rack Support Shelf

1

Left Fixing Part

1

③

Right Fixing Part

1

Rack Rail

2

Side B e am Fixing Part

2

M4 Screw

26

M4×6 Phil-Slot Pan Head Screw

⑦

M6 Screw

8

M6×16 Phil-Slot Pan Head Screw

⑧

M6 Nut

8

M6×5 Lock Blade Square Nut

⑦ ② ④ ① ③ ⑧ ⑥ ⑤

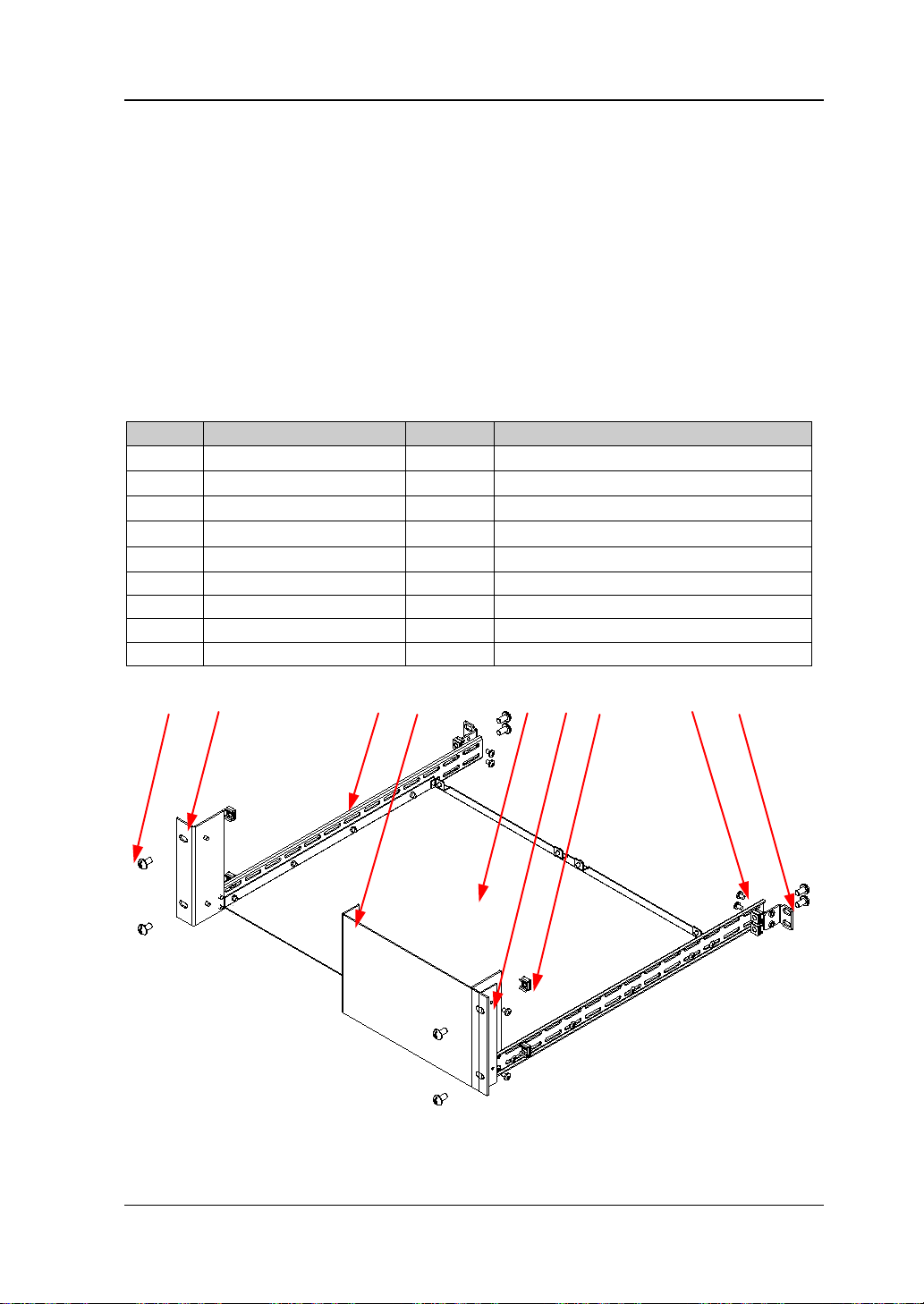

To Install Two Instruments

Part List

Table 1-6 Rack mount kit (RM-2-DP800) part list

①

②

④

⑤

⑥

(a)

1-26 DP800 User’s Guide

Page 45

Chapter 1 Quick Start RIGOL

⑥ ⑦ ⑧

(b)

Figure 1-8 Rack Mount Kit (RM-2-DP800) Parts

Installation Tool

PH2 Phillips screwdriver is recommended.

Installation Space

The machine cabinet should fulf ill the following requirements.

It should be a standard 19 inch machine cabinet;

At least 4U (177.8 mm) space should be provided by the machine cabinet ;

The depth inside the machine cabinet should not be less than 463.75mm.

The rack-mounted instruments are as shown in the f ig ure below.

DP800 User’s Guide 1-27

Page 46

RIGOL Chapter 1 Quick Start

CAUTION

of the instrument onto the rack.

Instrument A Instrument B

Installation Procedures

Only authorized personnel can perform the installation. Incorrect

operation might cause damage to the instrument or incorrect installation

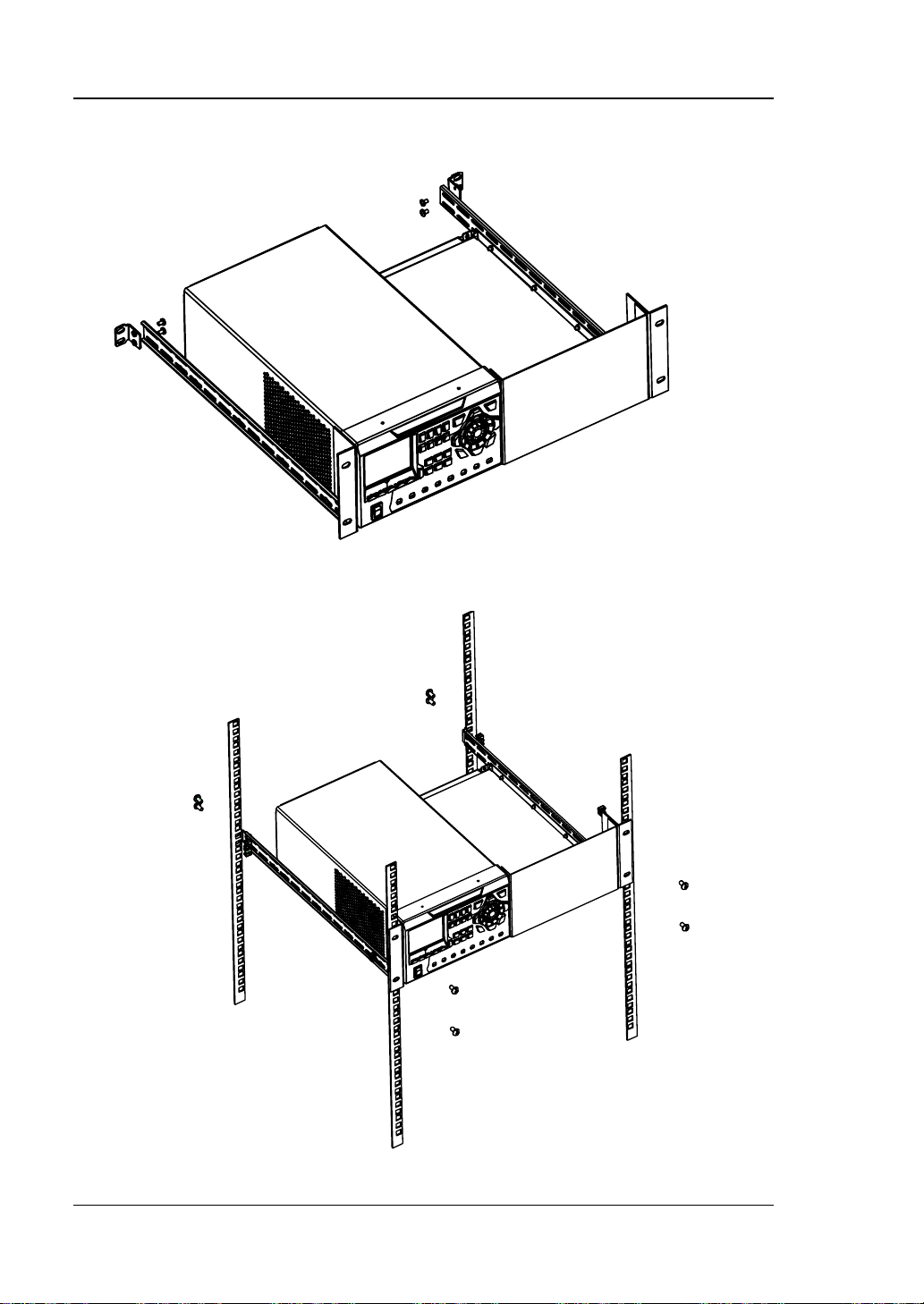

1. Remove the four rubber bumpers on the front and rear panels respectively.

2. Fix the two instruments onto the rack support shelf using two M4 screws

respectively.

3. Fix the left fixing part to the left side of the front panel of instrument A using tw o

M4 screws.

1-28 DP800 User’s Guide

Page 47

Chapter 1 Quick Start RIGOL

Instrument A Instrument B

4. Fix a rack rail to the left side of the rack support shelf using seven M4 screws.

5. Fix the right fixing part to the right side of the front panel of inst rument B using

two M4 scre ws.

DP800 User’s Guide 1-29

Page 48

RIGOL Chapter 1 Quick Start

6. Fix the other rack rail to th e right side of th e rack support shelf using seven M4

screws.

7. Fix the two side beam fixing parts to the end parts o f the left and right rack rails

using four M4 screws respectively.

1-30 DP800 User’s Guide

Page 49

Chapter 1 Quick Start RIGOL

8. Install the rack mounted with the instruments into a standard 19 inch machine

cabinet using eight M6 screws and eight M6 nuts.

DP800 User’s Guide 1-31

Page 50

RIGOL Chapter 1 Quick Start

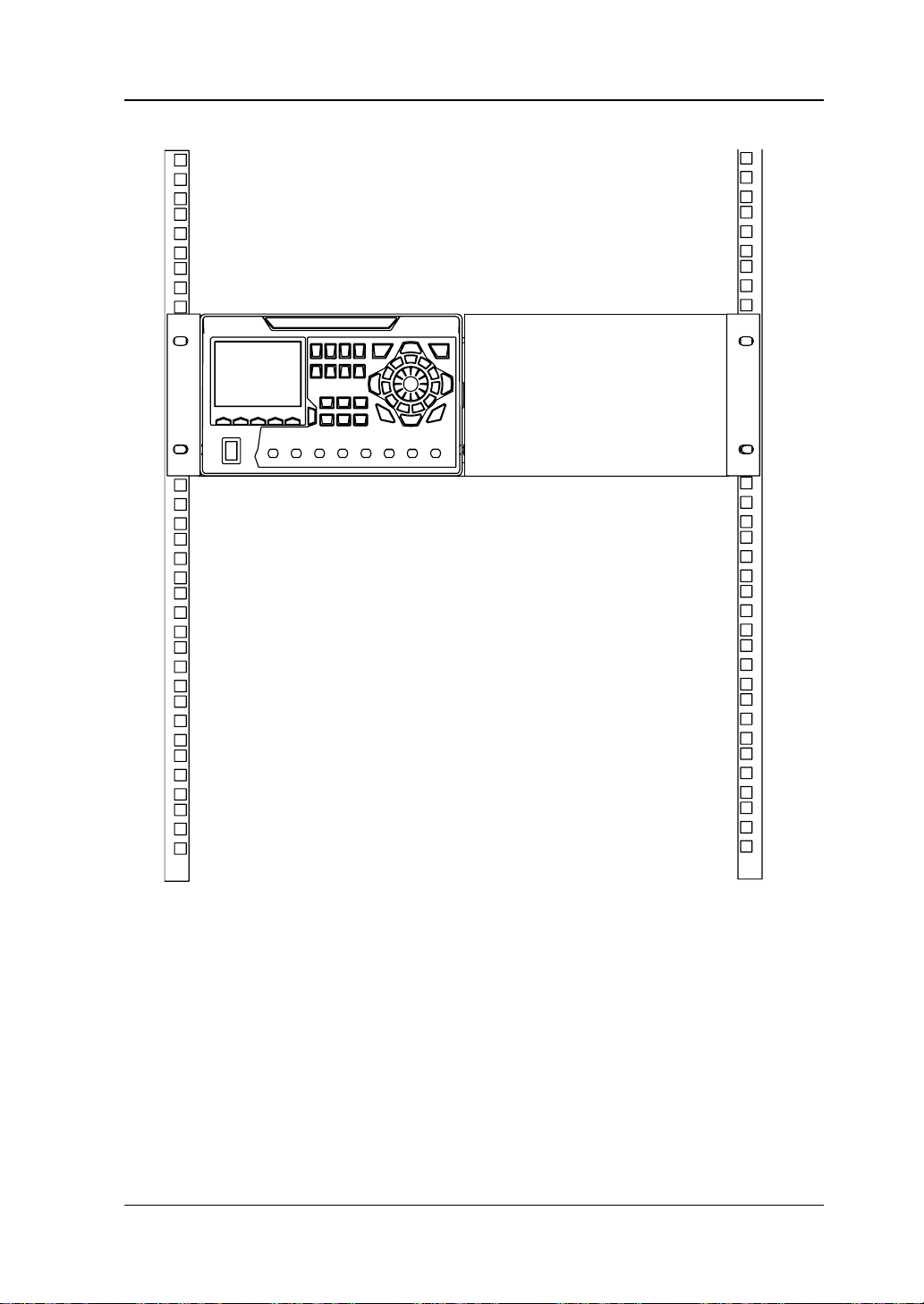

9. The rack -mounted instruments are as shown in the figure below.

1-32 DP800 User’s Guide

Page 51

Chapter 2 Front Panel Operations RIGOL

Chapter 2 Front Panel Operations

The contents of this chapter are as follows:

Constant Voltage Output

Constant Current Output

Power Supply Series and Parallel Connections

Track Function

Sense Working Mo de

Timer and Delayer

Advanced Functions

Display Setting

Store and Recall

Utility

Key Locking

DP800 User’s Guide 2-1

Page 52

RIGOL Chapter 2 Front Panel Operations

CAUTION

the instrument and the devices connected to the instrument.

Constant Voltage Output

DP800 series power supply provides three ou tput modes : consta nt voltag e output

(CV), constant current output (CC) and critical mode (UR). In CV mode, the output

voltage equals the volta ge set ting v alue a nd the output current is deter mined by th e

load; in CC mode, the output current equals the current se tting v alue an d the outpu t

voltage is determined by the load; UR is the critical mode between CV and CC. This

section introduces the operation method in constant v olt age output mo de.

Operation Method:

1. Connect the channel output terminals

As shown in the figure below, connect the load with the channel output

terminals of the corresponding channel at the front panel.

Pay attention to the polarity when connecting them to avoid damaging

2. Tu r n on the power switc h to start th e instrum en t.

3. Select the channel

Select the proper output channel according to the d e sired output voltage. Press

the correspon di ng channel selection key; at this point, this channel, its channel

number, output state and output mode are high-lighted on the screen.

4. Set the voltage

Method 1

Press Voltage and use the left/right direction key to move the cursor; then,

rotate the knob to quickly set the volta ge and the default unit is V. After selecting

the digit to be set, you can also use the up/down direction key to modify the

value of the corresponding digit. The default unit is V.

Method 2

Press Voltage, use the numeric keyboard to directly input the desired voltage

value and press V or mV or press the unit selection key ( or ) to

2-2 DP800 User’s Guide

Page 53

Chapter 2 Front Panel Operations RIGOL

select the desired unit. Besides, y ou can also press OK to select the default u nit

(V). During the input, you can press Back to delete the character currently

before the cursor or press Cancel to cancel the input.

Method 3

If Current is currently selected, you can also use the numeric keyboard to

directly input the desired voltage value; and then press the unit selection key

(

or ) to select the desired voltage unit. During the input, you can

press Back to delete the character currently before the cursor or press Cancel

to cancel the input.

5. Set the current

Method 1

Press Current and use the left/right direction key to move the cursor; then,

rotate the knob to quickly set the current and the default unit is A. After

selecting the digit to be set, you can also use the up/down direction key to

modify the value of the corresponding digit. The default unit is A.

Method 2

Press Current, use the numeric keyboard to directly input the desired current

value and press A or mA or press the unit selection k ey ( or ) to select the

desired unit. Besides, you can also press OK to select the default unit (A).

During the input, you can press Back to delete the character currently before

the cursor or press Cancel to cancel the input.

Method 3

If Voltage is currently selected, you can also use the numeric keyboard to

directly input the desired current value; and then press the unit selection key

or ) to select the desired current unit. During the input, you can

(

press Back to delete the character currently before the cursor or press Cancel

to cancel the input.

6. Set the overcurrent protection

Press OCP to set a proper overcurrent protection value (for the sett ing metho d,

refer to "

Set the current"). Then, enable the overcurrent protection function

(you can enable or disable the OCP function by pres s ing OCP) and the output

will be turned off automatically when the actual output current is greater than

the overcurrent protection value.

7. Turn on the output

Turn on the output of t he corresponding channel and the actual output voltag e,

output current, output power as well as the output mode (CV) are high-lighted

in the user interface.

DP800 User’s Guide 2-3

Page 54

RIGOL Chapter 2 Front Panel Operations

Warning

output terminals are correctly connected.

CAUTION

otherwise, "The fan stops, stop the output!" will be displayed.

Ouput Interface at

Connecting

To avoid electric shock, please turn on the output switch after the

When the fan stops, the channel switch can not be turned on;

8. Check the output mode

In constant voltage output mode, the output mode displayed should be "CV"; if

"CC" is displayed, you can increase the current setting value properly and the

power supply will switch to CV mode automatically.

In addition, DP811 provides an output interface at the rear panel for constant voltage

output. As shown i n t he figure below, connect the load and the output interface at

the rear panel via the connecting terminal.

the Rear Panel

Terminal

Connecting Procedures:

1. Connect the load to the corresponding positions on the connecting terminal

correctly. Pay attention to the polarity when making connections.

2. Insert the connecting terminal into the output interface at the rear panel of the

instrument. Pay attent ion to the corresp on ding relations of the connecting

terminal and the output interface.

Note: The output terminals at the front panel and the output interface at the rear

panel cannot be used for output at the same time. You can only select one of them

for output at each time (wherein, the output terminals at the front panel provide

2-4 DP800 User’s Guide

Page 55

Chapter 2 Front Panel Operations RIGOL

Tip

value, the power supply will swit ch to CC output mode aut omatically. At this point,

the output current equals the current sett ing value a nd the output v oltage reduces

proportionally.

higher output accuracy).

In CV output mode, when the load current is greater than the current setting

DP800 User’s Guide 2-5

Page 56

RIGOL Chapter 2 Front Panel Operations

Warning

terminals are correctly connected.

Constant Current Output

In constant current output mode, the output current equals the c urrent set ting v alue

and the output voltage is determined by the load. This section introduces the

operation method in constant current output mo de.

Operation Method:

1. Connect the channel output terminals

Connect the load with the channel output terminals of the corresponding

channel at the front panel by referring to "Connect the channel output

terminals" in "Constant Volta ge Out put".

2. Tu r n on the power switc h to start th e instrum en t.

3. Select the channel

Select the proper output channel a cco rding to the desired output current. Pres s

the corresponding channel selection key; at this point, this channel, its channel

number, output state and output mode are high-lighted on the screen.

4. Set the voltage

Press Voltage to set the desired voltage according to "Set the voltage" in

"Constant Voltage Out put".

5. Set the current

Press Current to set the desired current according to "Set the current" in

"Constant Voltage Out put".

6. Set the overvoltage protection

Press OVP to set a proper overvoltage prot ecti on v alu e (for the setting method,

refer to "

overvoltage protection fun ction (you can enable or disable the OVP function by

pressing OVP) and the output will be turned off automatically when the actual

output voltage is greater than the overvoltage protection value.

7. Turn on the output

Turn on the output of t he corresponding channel and the a ctual output volta ge,

output current, output power as well as the output mode (CC) are high-lighted

in the user interface.

Set the voltage" in "Constant Voltage Output"). Then, enable the

To avoid electric shock, please turn on the output switch after the output

2-6 DP800 User’s Guide

Page 57

Chapter 2 Front Panel Operations RIGOL

CAUTION

"The fan stops, stop the output!" will be displayed.

Tip

value, the power supply will swit ch to CV output mode automati cally. At this point,

e setting value and the output current reduces

proportionally.

When the fan stops, the c hannel switch cannot be t urned on; otherwise ,

8. Check the output mode

In constant current output mode, the output mode displayed should be "CC"; if

"CV" is displayed, you can increase the voltage setting value properly and the

power supply will switch to CC mode automatically.

In addition, DP811 p rovides an output int erface at th e rear panel f or constant current

output. For the connecting method, please refer to the related introduction in

"Constant Voltage Output".

Note: The output terminals at the front panel and the output interface at the rear

panel cannot be used for output at the same time. You can only select one of them

for output at each time (wherein, the output terminals at the front panel provide

higher output accuracy).

In CC output mode, when the load voltage is greater than the voltage setting

the output voltage equals the volta g

DP800 User’s Guide 2-7

Page 58

RIGOL Chapter 2 Front Panel Operations

Power Supply

Channel #1

-

+

Power Supply

Channel #2

-

+

V

1

V

2

V

L

R

Load

-

+

VL=V1+V

2

Power Supply Series and Parallel Connections

Higher voltages can be pro vided when t wo or more i nsulated channels (the ch annels

can be from a single power supply or multiple power supplies) are connected in

series. Higher currents can be provided when two or more insulated channels (the

channels can be from a single power supply or multiple power supplies) are

connected in parallel.

Note:

1. Only insulated channels can be connected in series or in parallel.

For a single power supply, CH1 and CH2/CH3 of DP832 can be connected in

series or in parallel, but CH2 and CH3 cannot be connected in series or

parallel; any two of the three channels of DP831 can be connected in series,

CH1 and CH2/CH3 can be connected in parallel, but CH2 and CH3 cannot be

connected in parallel; the two channels of DP821 can be conne cted in series

or in parallel.

Channels (insulate d channels) of different power supplies can be connecte d

in series or parallel.

2. In power series and parallel connections, the settings of the corresponding

parameters must comply with the safety requirements.

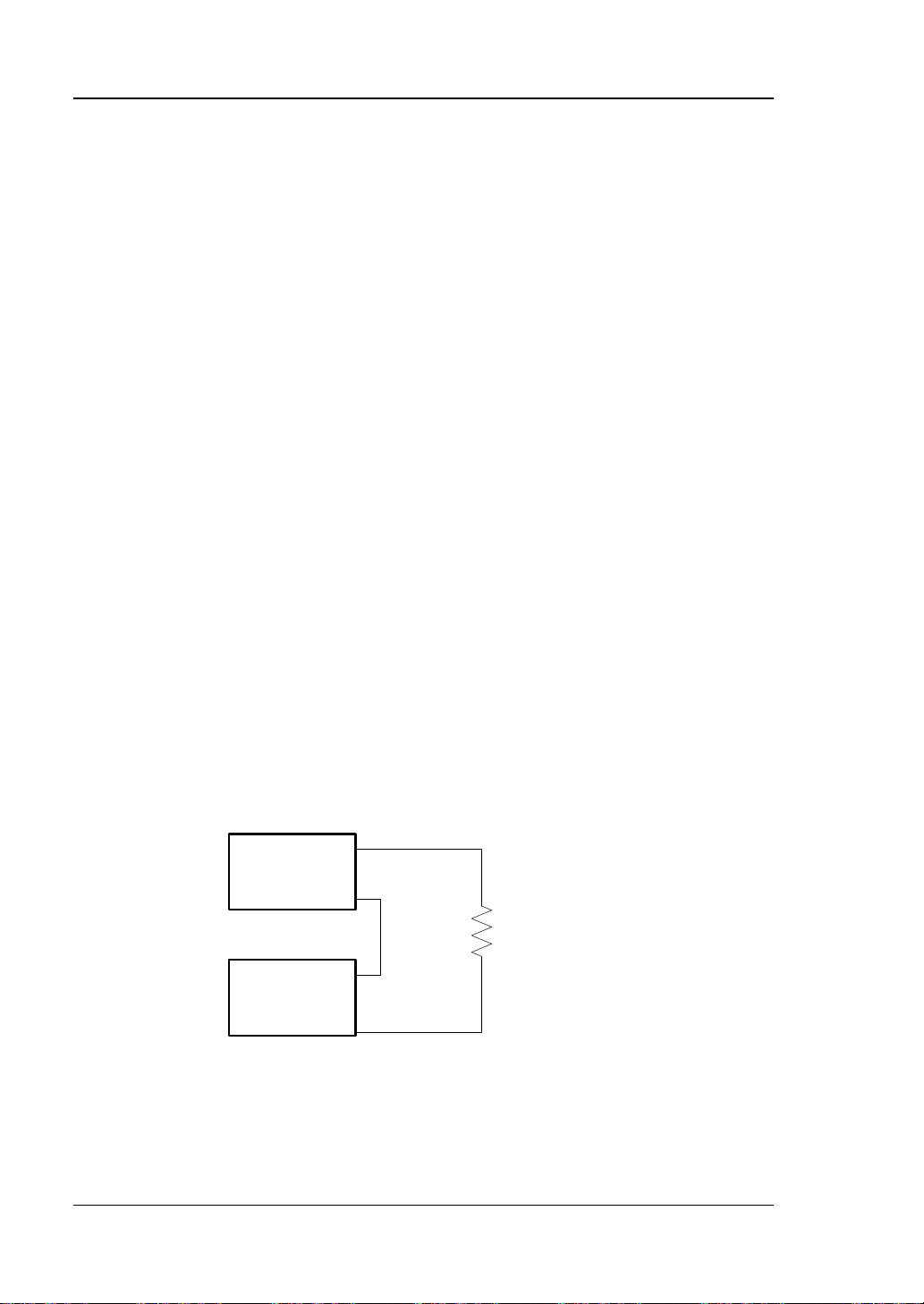

Power Supply Series Connection

Higher voltages can be provided by connecting power supplies in se ries. In this case,

the output voltage is the sum of the output voltages of all the channels. In power

supply series connection, you need to set the same current setting value and

overcurrent protection value for all the channels. Take the series connection of two

channels as an example; the connection method is as shown in the figure below.

Operation Procedures:

1. Connect the power supply and load as shown in t he figure above. Pay attention

2-8 DP800 User’s Guide

to the polarity when making connections.

Page 59

Chapter 2 Front Panel Operations RIGOL

Power Supply

Channel #

1

-

+

Power Supply

Channel #2

-

+

I

1

I

L

R

Load

I

2

IL=

I1+I

2

2. Set proper voltage, current and overcurrent protection value for each channel

(all the channels in series connection should be working in constant voltage

mode; you should set the same current setting v alue s and the same overcurrent

protection values for all the channels) by ref e rring to "Constant Voltage

Output". Turn on the output of each channel.

Note: Make sure that all the channels in series connection are working in constant

voltage mode. If one of the channels is workin g in constant current mode, the other

channels will enter critical state in which their outputs are unpredictable.

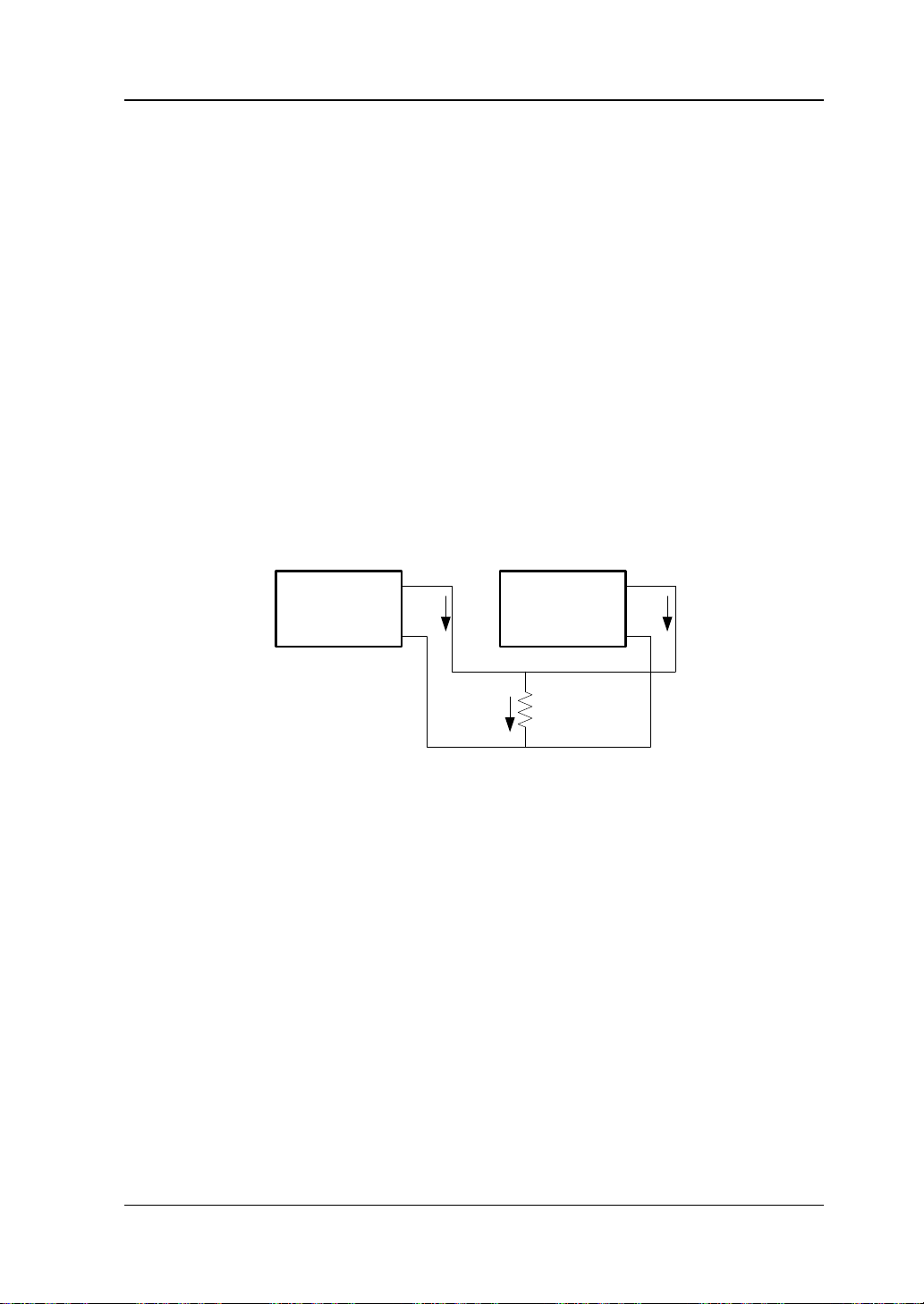

Power Supply Parallel Connection

High currents can be p rovided by connecting p ower supplies in parallel. I n this case,

the output current is the sum of the output currents of all the channels. In power

supply parallel connection, you can set the parameters of each power supply. Take

the parallel connection of two channels as an example; the connection method is as

shown in the figure below.

Operation Procedures:

1. Connect the power supply and load as shown in t he figure above. Pay attention

to the polarity when making connections.

2. Set proper parameters for each channel (all the channels can work in constan t

voltage or constant current mode) by ref errin g to "Constant Voltage Output"

and "Constant Current Output". Turn on the output of each channel .

Note: All the channels can work in constant voltage or constant current mode

according to the actual need of the load.

DP800 User’s Guide 2-9

Page 60

RIGOL Chapter 2 Front Panel Operations

Tip

is selected, users ca n quickly enable or disa ble the tra ck

functions of the two channels at the same time.

Track Function

The track function is usually used to provide symmetric voltage for the operation

amplifier or other circuit. For DP800 series power supply, the specified channels of

the following models support the track function.

DP832: CH1, CH2

DP831: CH2, CH3

For channels that support the track function, you can set the tracking states of the

voltage setting value and output on/off state respectively accord ing to you r ne e d.

To Enable the Track Functi on

Press Utility System Track Set Track to switch between "Synchronous"

and "Independent".

Independent: for two channels (the channels should be of the same

instrument) that support the track function, the status of the track function of

the other channel will not be affected when the track function of a channel is

enabled or disabled.

Synchronous: for two channels (the channels should be of the same

instrument) that support the track function, the track function of the other

channel will be enabled or disabled at the same t ime when the track f unction of

a channel is enabled or disabled.

When "Independent" is selected, users can enable or disable the track

function of a single channel freely.

When "Synchronous"

For channels (the channels should be of the same in strument) th at support th e tra ck

function, the tracking status of the channel voltage setting values is related to the

number of channels of which the track functions are enabled.

If only the track functi on of a single channel is en abled, the voltage set ting value

of the other channel will change accordingly when the voltage setting value of

this channel is modified. At this point, the voltage setting va lue of the channel of

which the track function is not enabled cannot be set and can only c h ange with

that of the channel of which the track function is enabled.

If the track functions of the two channels are both enabled, the voltage setting

value of the other channel will change accordingly when the voltage setting

value of a channe l is modified. At this point, the volta ge setting v alues of both of

the two channels can be set.

2-10 DP800 User’s Guide

Page 61

Chapter 2 Front Panel Operations RIGOL

Tip

voltage will not be affected.

The track function only tracks the voltage setting value and the actual output

You can perform the following operations according to your need.

1. Only enable the track function of a single channel and track the

voltage setting value

The operation pro cedures are as follows (in this exa mple, only the t rack fun ction

of CH1 of DP832 is enabled).

Select the "Independent" tracking mode

Press Utility System Track Set Track to select "Independent".

Enable the track function of CH1

Select CH1 and press Track to select "On". At this point, the track function

of CH1 is enabled and the tracking status icon

is displayed between

the CH1 and CH2 areas in the user interface.

Disable the track function of CH2 (ignore this step if the track function of

CH2 is currently disabled)

Select CH2 and press Track to select "Off". At this point, the track f unction

of CH2 is disabled.

Track the voltage setting value

Select CH1, press Voltage and set the desired voltage. At this point, the

voltage of CH2 changes acco rdingly. For example, se t the volt age of CH1 t o

+5V; the voltage of CH2 will change to +5V automatically.

Note: At this point, the v oltage se tt ing v alue of CH2 cannot be set and can

only change with that of CH1.

2. Enable the track functions of both of the two channels and track the

voltage setting value

First, you can enable the track functions of the two channels using any of the

following methods (take DP832 as an example).

Method 1

Select the "Synchronous" tracking mode

Press Utility System Track Set Track to select "Synchronous".

Enable the track functions of CH1 and CH2 at the same time

Select CH1 or CH2, press Track and select "On". At this point, the track

functions of CH1 and CH2 are both ena bled. The tr acking status icon

is

DP800 User’s Guide 2-11

Page 62

RIGOL Chapter 2 Front Panel Operations

displayed between the CH1 and CH2 areas in the user interface.

Method 2

Select the "Independent" tracking mode

Press Utility System Track Set Track to select "Independent".

Enable the track functions of CH1 and CH2

Select CH1 and press Track to select "On". At this point, the track function

of CH1 is enabled and the tracking status icon

the CH1 and CH2 areas in the user interface. Use the same method to

enable the track function of CH2.

Then, select CH1 or CH2 and press Voltage an d set the desired voltage. At this

point, the voltage setting value of the other channel changes accordingly. For

example, set the voltage of CH1 to +5V; the voltage of CH2 will change to +5V

automatically.

Note: At this point, both of the voltage setting values of CH1 and CH2 can be

set.

is displayed between

To Track the On/Off Status of the Channel Output

Press Utility System Track Set On/Off to selec t "Enable" or "Disable".

Disable: the output status of the other channel will not be affected when the

output of a channel is turned on or off.

Enable: for channels (the channels should be of the same instrument) that

support the track fun ction, the tracking st atus of the on/of f status of the channel

output is related to the number of channels of which the track functions are

enabled.

If only the track function o f a sin gle cha nnel is enable d (please re fer to "To

Enable the Track Function"), the output of the other channel will be

turned on or off a t t he same time when the o utput of this channel is turne d

on or off. At this point, the output status of the channel of which the track

function is not enabled cannot be set and can only change with that of the

channel of which the track function is enabled.

If the track functions of the two channels are both enabled (please refer to

"To Enable the Track Function"), the output of the other channel will be

turned on or off at the same time when the output of a channel is turned on

or off. At this point, the output status of both of the two channels can be

set.

2-12 DP800 User’s Guide

Page 63

Chapter 2 Front Panel Operations RIGOL

Tip:

Sense leads and load leads together.

Lead Equivalent

Load Lead

Sense Lead

Load Lead

Lead Equivalent

Resistance

Sense Working Mode

When the output current of the power supply is high, the voltage drop on the load

lead cannot be ignored. To ensure that the load can a cquire the cor rect voltage d rop,

CH2 of DP821 and DP811 (both provide 10A output current) provide the Sense

(remote sense) working mode. In this mode, the instrument detects the voltage at

the load terminal instead of the voltage at the output terminal of the power supply;

in this way, the instrument can automatically compensate for the voltage drop

caused by the load lead to ensu re that the power supply output v a lue set by users is

consistent with the voltage acquired by the load.

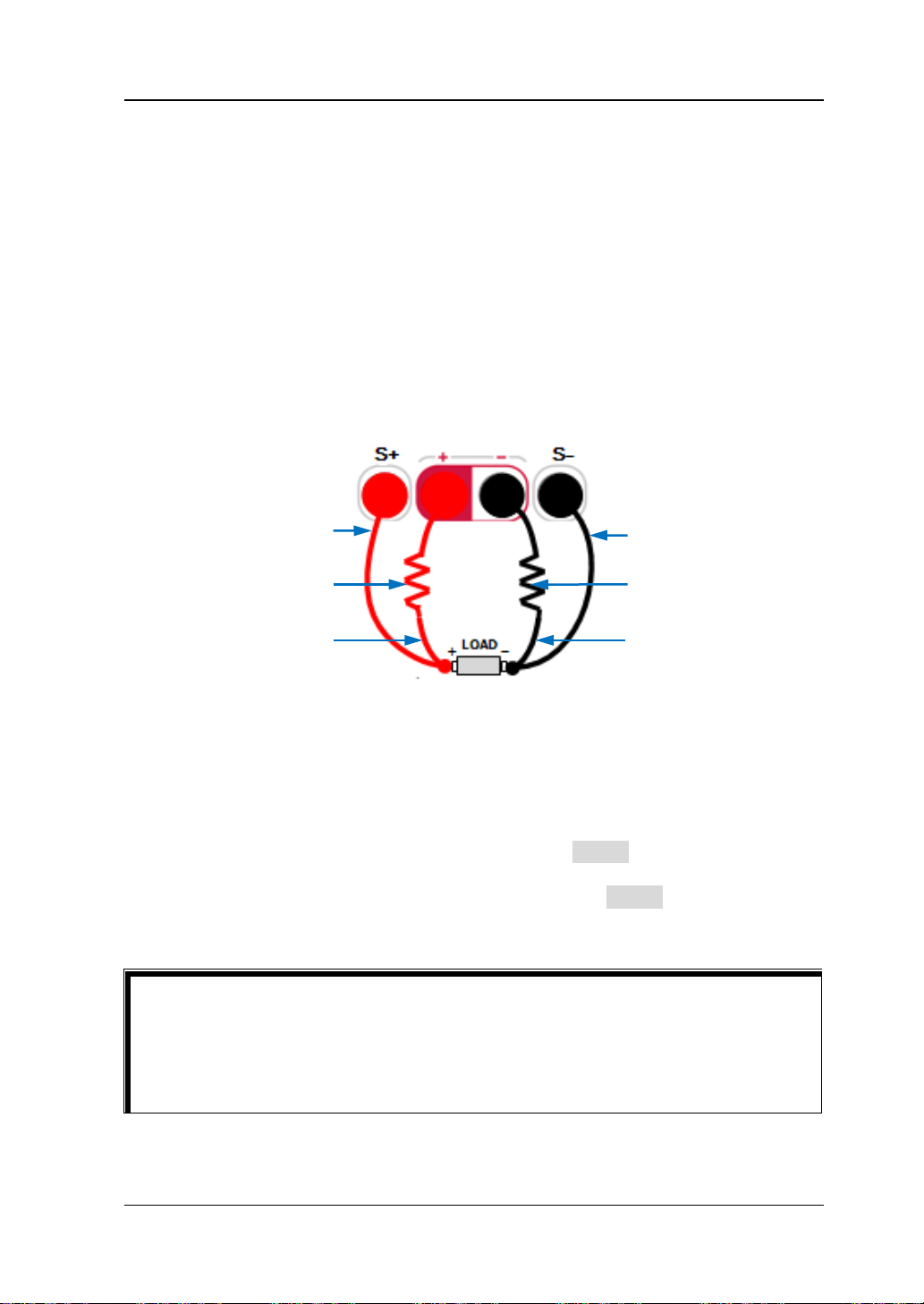

The Sense connecting method at the front panel is as shown in the figure below.

Sense Lead

Resistance

Operation Procedures:

1. Connect the channel output terminals and Sense terminals at the front panel of

the instrument to the two ends of the load respectively, as shown in the figure

above. Pay attention to the polarity when making connections.

2. For DP821: after you select C H2 (8V/10A), press Sense to turn on the Sense

function.

For DP811: after you select the desired range, press Sense turn on the Sense

function.

When the output current is high, to acquire the best output characteristics,

the load leads should be a s sho rt as p ossible an d it is recommended that you

twist the load leads together.

Twisted pairs are recommended for the Sense leads and do not twist the

In addition, the output interface a t the rear panel of DP811 can also be used for the

DP800 User’s Guide 2-13

Page 64

RIGOL Chapter 2 Front Panel Operations

Output Interface at

the Rear Panel

Connecting

Terminal

Sense working mode. The Sense connecting method at the rear panel is as shown in

the fi g ure below.

Operation Procedures:

1. Connect the load to the corresponding position on the connecting terminal

correctly as shown in the f ig ure above. Pay attention to the polarity when

making connections.

2. Insert the connecting terminal into the output interface at the rear panel of the

instrument correctly. Pay attention to the corresponding relations of the

connecting terminal and the output interface.

3. After selecting the desired range, press Sense to turn on the Sense function.

Note: The output terminals at the front panel and the output interface at the rear

panel cannot be used for the Sense mode at the same time. You can only sel ect one

of them for the Sense function at each time (wherein, the output terminals at the

front panel provide higher output accuracy).

2-14 DP800 User’s Guide

Page 65

Chapter 2 Front Panel Operations RIGOL

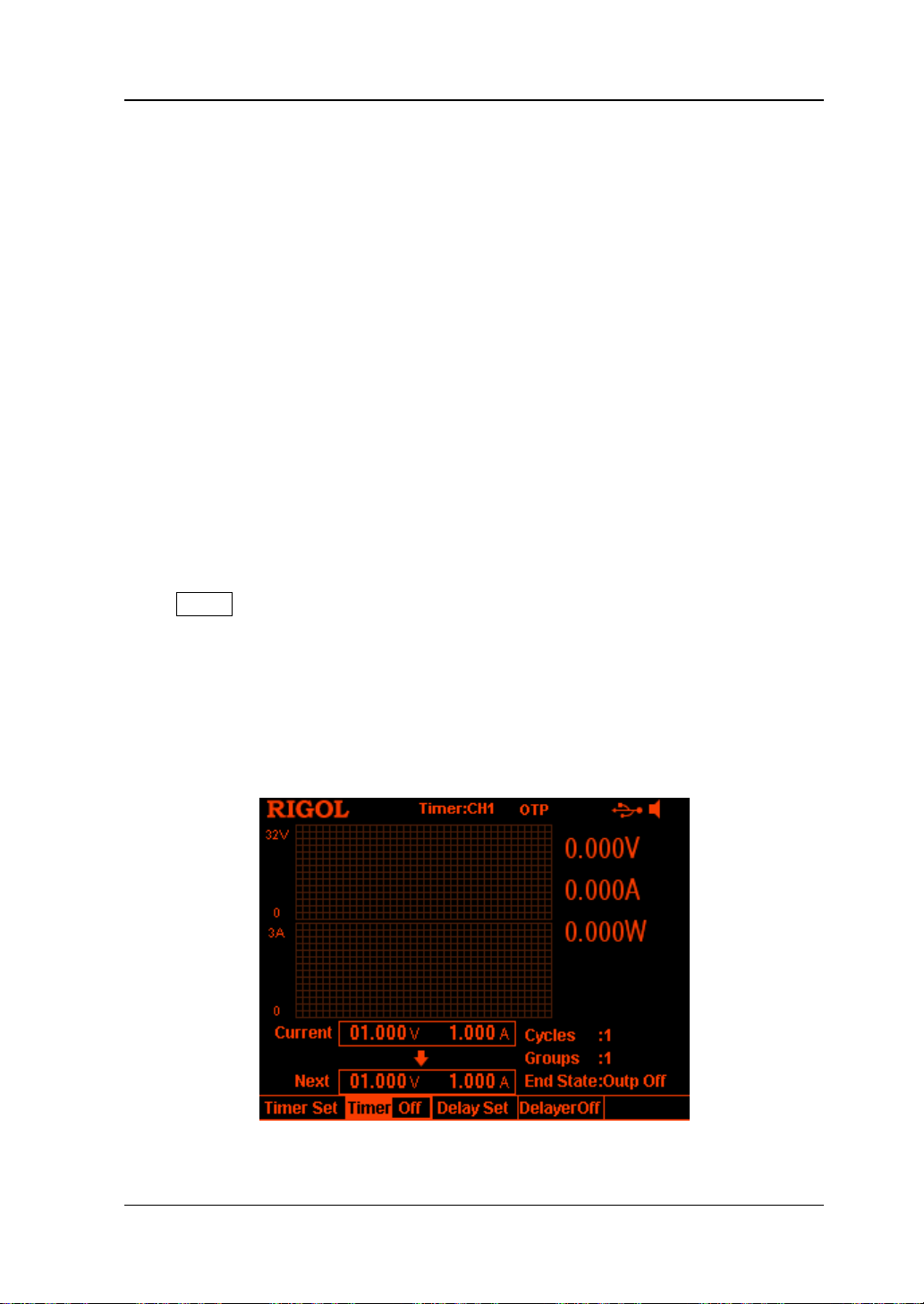

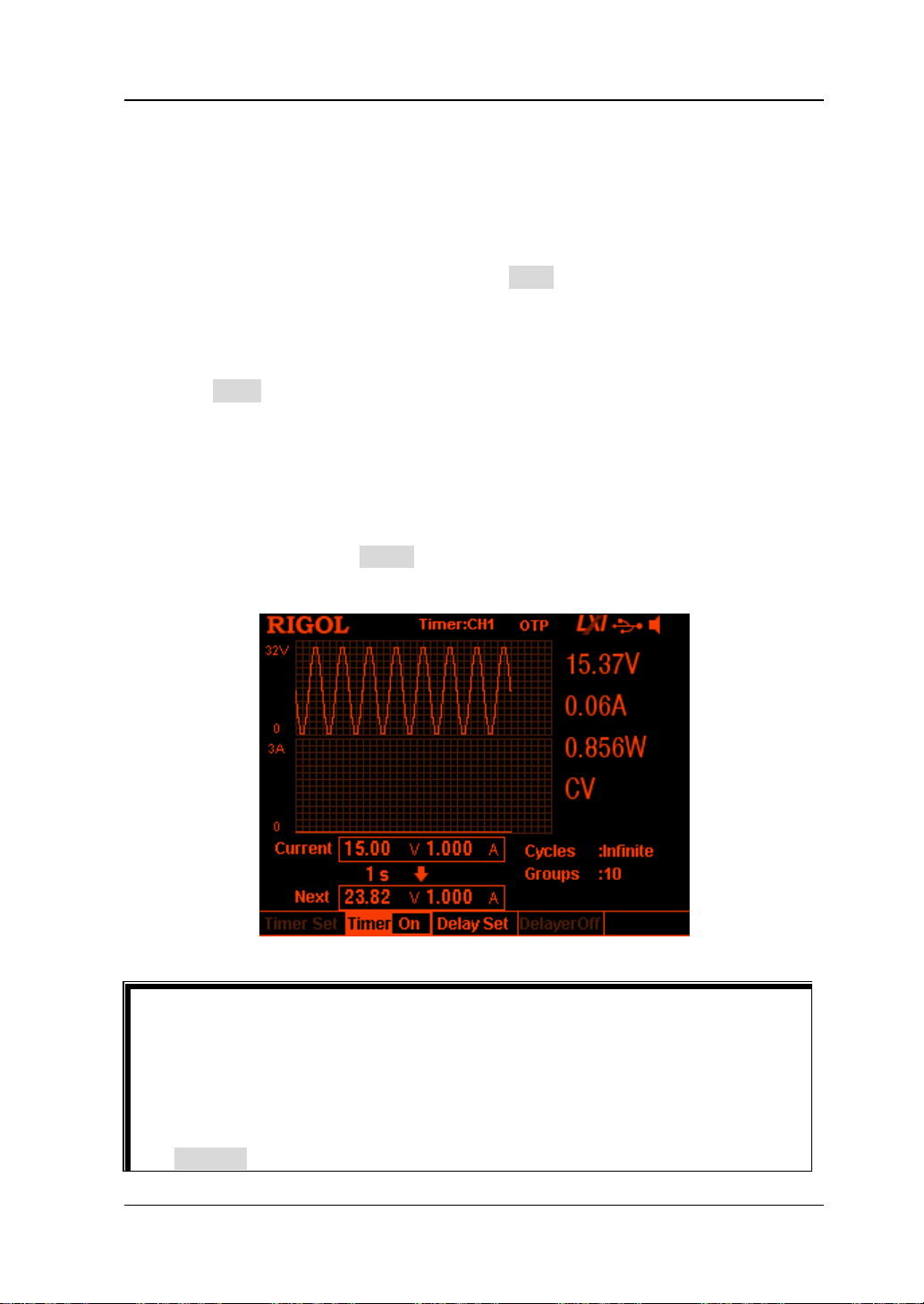

Timer and Delayer

DP800 provides the timer and delayer functions.

When the timer is enabled, the instrument outputs the preset voltage and current

values (at most 2048 groups). Users can set the number of output groups of the

timer as well as the voltage, current and timing time of each group. Besides, the

instrument provides various built-in output templets and users can select and edit

the templet as well as create timer parameters based on the templet. The instrument

will output according to the parameters currently created.

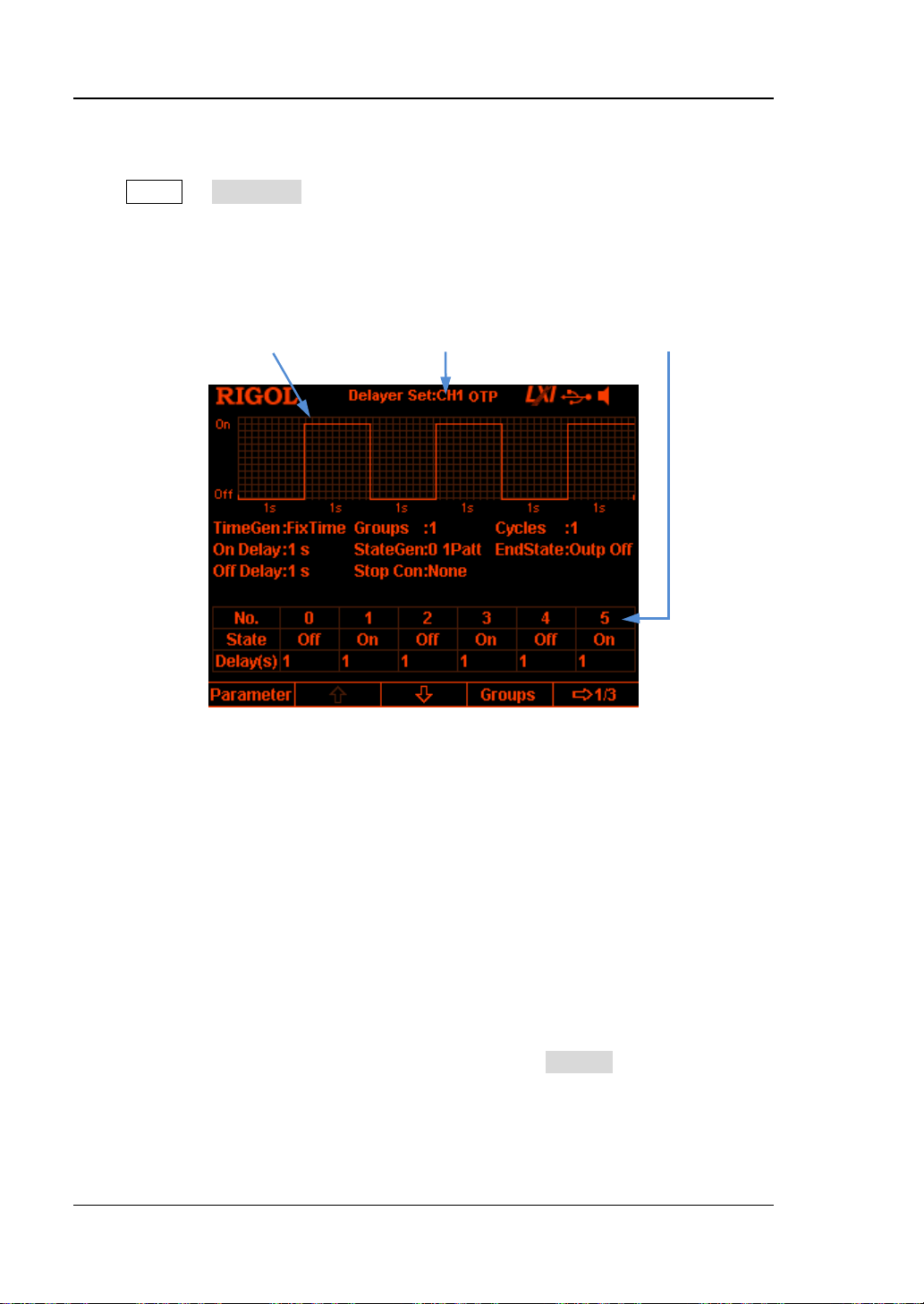

When the delayer is enabled, the instrument enables or disables the output