Page 1

1

SRL – SR D Instruction Manual

SELF-RETRACTING LIFELINES - INSTRUCTION MANUAL

MaltaDynamics

8

405 Watertown Road, Waterford, OH 45786

THESE INSTUCTIONS APPLY TO THE FOLLOWING MODEL(S):

C7000 C7001 C7002 C7003 C7004

C7005 C7020 C7021 C7100 C7201

C7202 C8000 C8001

00-494-1840

.com

0120

EN 360:2002

Th

is manual must be read and understood in its entirety and used as part of your fall protection training program

as required by OSHA 1926 and State and local regulatory agencies. This instruction manual is intended to meet

industry standards required by and ANSI Z359.2007 and should be used as part of an Employee Fall Safety

training program as required by OSHA. User must read and fully understand the limitations and proper use of the

equipment, and be properly trained by employer prior to use per OSHA 29 CFR 1910.66, 29 CFR 1926.503, and

applicable local standards. NOTE: This User Instruction Manual is not to be removed except by the user of this

equipment. Current User Instruction Manuals must always be available to the user. Read and understand these

instructions before using equipment. Do not discard these instructions.

Mis

ail w w ing , in ion imit ion h

his ip m in io p i h.

i i b p , p rvi

Malta Dynamics.

Page 2

SRL – SR D Instruction Manual

Materials and Construction

SRL – SR D Instruction Manual

Webbing Materials

• Constructed with high tenacity polyester; breaking strength >5000 lbs tensile strength

C

able Materials

• 7X19 Galvanized Steel (3/16” diameter)

C

onnector Materials

• Galvanized Steel

H

ousing Materials

• Aluminum

• High-Impact Resistant Polymer

Purpose

Malta Dynamics Self-Retracting Lifelines are devices used to safely expand the working area

where a harness with a six-foot lanyard is not adequate. A Self-Retracting Device (SRD) such as a

self-retracting lifeline, is designed to reduce the shock load to the body of a worker by limiting the

distance of a fall. The SRD allows complete freedom of movement. An SRD is one component of a

Personal Fall Arrest System (PFAS). PFAS normally include a full body harness, anchorage

connector (such as a carabiner and an SRD.)

The Self-Retracting Lifeline (SRL) may be used in a stationary or mobile manner. As a stationary

device, the SRL should be mounted to an approved, fixed anchorage connector overhead. The

SRL extends as the user moves away from the anchor point, and retracts as the user moves back

toward the anchorage point. An SRL used in a mobile manner should travel on a steel cable, rope

or fixed rail, travelling from one anchorage connector to another.

Self-Retracting Lifelines may include a swivel eye anchorage, self-locking swivel snap hook with

impact indicator, and 3/16” wire cable or webbing, carabiner and tag line.

Instructions for Use

• WARNING: Do not alter or intentionally misuse this equipment.

• Personal Fall Arrest System (PFAS) MUST limit the average arrest force to 900 lbs. (4kN) or

less.

• Employees shall be trained in accordance with the requirements of OSHA 29 CFR 1910.66 in

the safe use of the system and its components before using a PFAS.

• Inspect all Personal Fall Arrest System equipment for wear, damage, and other deterioration

prior to each use. Remove defective equipment from service immediately.

• Thoroughly evaluate and plan all elements of Fall Protection System(s) before using this

equipment. Make sure that your Personal Fall Arrest System is appropriate for your needs

and facility. Calculate fall clearance and swing fall clearance. The amount of clearance

required is dependent on the type of connecting subsystem, the anchorage location, and

other factors. When calculating distance, be sure to consider:

• Deceleration Distance

• Movement of harness attachment (D-ring)

• Free Fall Distance

• Height of the worker (how tall is the worker?)

• Elevation of Anchorage Connector

2 15

Page 3

SRL – SR D Instruction Manual

• Connecting Subsystems length

Illustration

1: Examples

of

Swing

Fall

Hazards

• D-ring connector length

• Length of Full Body Harness stretch

• Swing falls occur when the anchorage point is not directly above the point where a fall occurs.

The force of striking an object in a swing fall may cause serious injury or death. Minimize

potential for swing falls by working as close to the anchorage point as possible. Do not permit a

swing fall if injury could occur. Swing falls significantly increase the amount of clearance

required.

• Users must have a rescue plan and the means to implement it. This plan must provide prompt

employee rescue or assure that employees have the ability to rescue themselves in the event

of a fall.

• Store this equipment in a cool, dry, and clean environment that is out of direct light when not in

use to prevent UV degradation.

• This equipment must be removed from service immediately if a fall is incurred.

S

ee Illustration 1.

Limitations for Use

• WARNING: Do not use this equipment if you are unable to tolerate the impact of a fall

arrest. Age and fitness can seriously affect your ability to withstand a fall. Consult with a

physician if in doubt. Minors, pregnant women, and anyone with a history of back and/or neck

problems must not use this equipment.

• WARNING: Use caution when employing this equipment around machines, electrical

hazards, chemical hazards and sharp edges or abrasive surfaces, as contact may cause

equipment failure, personal injury, or death.

• Use only with compatible components of subsystems. Substitutions or replacements made with

non-approved components or subsystems may jeopardize compatibility of equipment and may

affect the safety and reliability of the complete system.

• Self-Retracting Lifelines are designed for a single user with combined weight - including

clothing, tools, etc. - within weight capacity range 130 lbs. to 310 lbs.

• Use only with structures capable of supporting static loads required for Personal Fall Arrest

Systems (PFAS). Anchorages used for PFAS must be capable of sustaining static loads in the

direction permitted by the PFAS of at least: 3,600 lbs. with certification of a qualified person; or

5,000 lbs. without certification. When more than one PFAS is attached to an anchorage, the

strengths stated above must be met independently at and for each anchorage location.

• Do not expose this equipment to chemicals or harsh solutions that may have a harmful effect.

• User must not use or install equipment before receiving proper training from a Competent

Person, as defined by OSHA 29 CFR 1926.32(f).

• Only Malta Dynamics shall make repairs or alterations to the equipment.

3

Page 4

SRL – SR D Instruction Manual

• All synthetic material must be protected from slag, hot sparks, open flames, or other heat

SRL – SR D Instruction Manual

Materials:- Impact-Resistant-Polymer-Housing,

Steel-Cable,-Steel-Hardware

40omax

Materials:- Impact-Resistant-Polymer-Housing,

Steel-Cable,-Steel-Hardware

40omax

40omax

sources. The use of heat resistant materials is recommended in these applications.

Connector Compatibility Limitations

Malta Dynamics equipment must be coupled only to compatible connectors that are suitable to

your application. Ensure all connections are compatible in size, shape and strength. Ensure all

connectors are fully closed and locked. OSHA 29 CFR 1926.502 prohibits the use of snap

hooks to engage to objects unless the following requirements are met:

• Snap hook must be a locking type snap h

• Snap hook must be explicitly designed for such a connection. “Designed for” means that the

manufacturer of the snap hook specifically created the snap hook to be used to connect to

the equipment in question.

Use of a non-lo

cking snap hook can result in rollout (a process by which a snap hook or

carabiner unintentionally disengages from another connector or object to which it is coupled.

ANSI Z359.0- 2007). Malta Dynamics connectors (snap hooks and carabiners) are designed to

be used only as specified in each product’s user’s instructions.

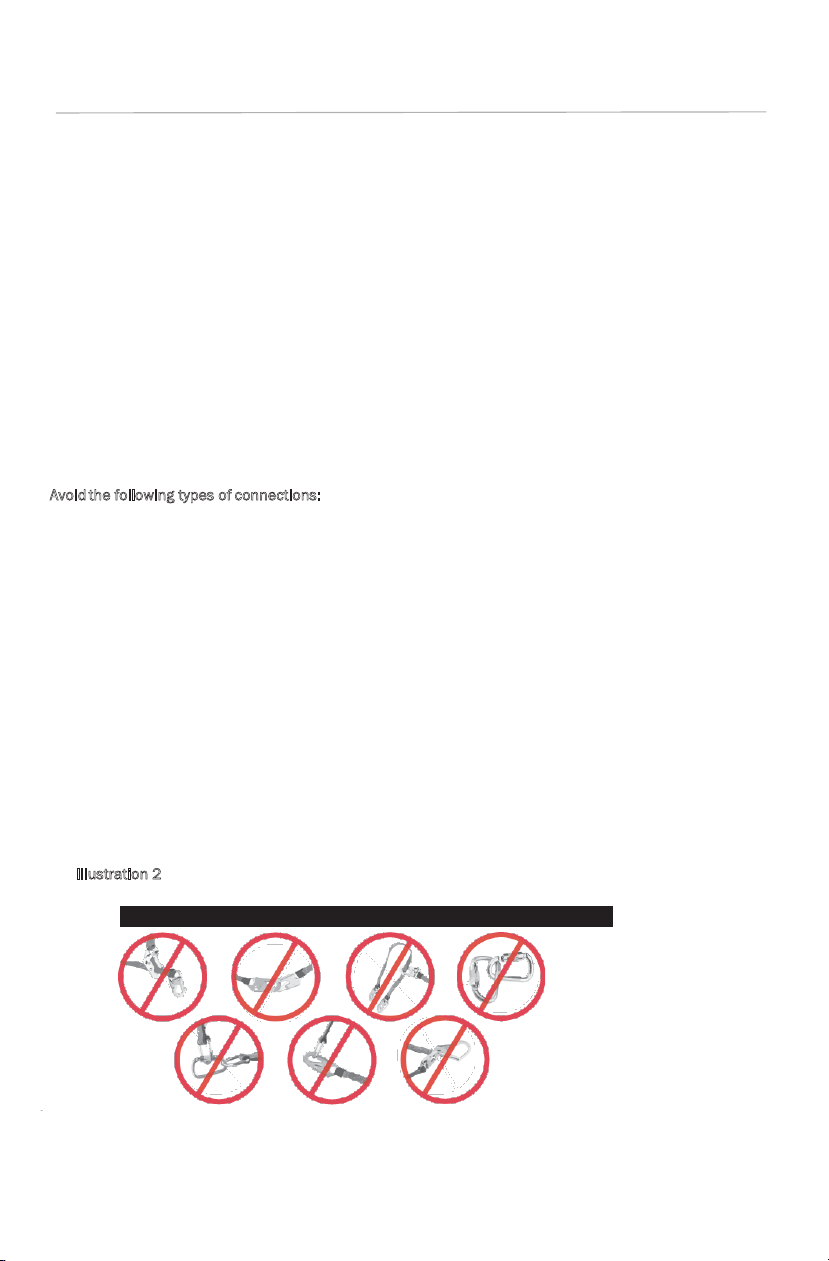

void the following types of connections:

A

• Connection of two (or more) snap hooks or carabiners to one D-ring.

• Connection of a snap hook back to its integral lanyard.

• Direct connection of a snap hook to horizontal lifeline.

• Connection in a manner that results in a load on the gate. NOTE: Large throat opening snap

hooks should not be connected to standard size D-rings or similar objects, as such use will

result in a load on the gate if the hook or D-ring twists or rotates. Large throat snap hooks

are designed for use on structural elements such as rebar or cross members that are not

shaped in such a way that they may capture the gate of the hook.

• False engagement connections, where protruding features of the snap hook or carabiner

may catch on the anchor and seem to be fully engaged to the anchor point. Always confirm

engagement.

• Connection to snap hooks or carabiners.

• Direct connection to webbing lanyard, webbing loop, rope lanyard or tie-back (unless the

manufacturer’s instructions for both the lanyard and connector specifically allow such a

connection).

• Connection of a snap hook to a D-ring, rebar, or other connection point of improper

dimensions in relation to the snap hook dimensions or configurations that could cause the

snap hook keeper to be depressed by a turning motion of the snap hook, or such that snap

hook or carabiner will not fully close and lock, or that roll-out could occur.

• I

llustration 2 depicts examples of inappropriate connections:

ook.

4 13

Illustration 2: Inappropriate Connections

Page 5

SRL – SR D Instruction Manual

Connecting Component Limitations

• A Competent Person must ensure the compatibility of all connections and that of the

system.

• Do not use the system if any connector does not lock or if any other component in the

system does not operate properly.

• Allow sufficient safe clearance in the event of a Free Fall.

• System must be rigged to limit the total Free Fall Distance according to the type of system,

and in compliance with ANSI and OSHA directives.

• Do not use if any part of the system appears to be damaged.

• Do not use a body belt for fall arrest applications.

Performance

Each Self-Retracting Lifelines have an average arresting force of 900 lbs (4kN) when statically

tested in accordance with the requirements of the ANSI Z359.14:2014 standard.

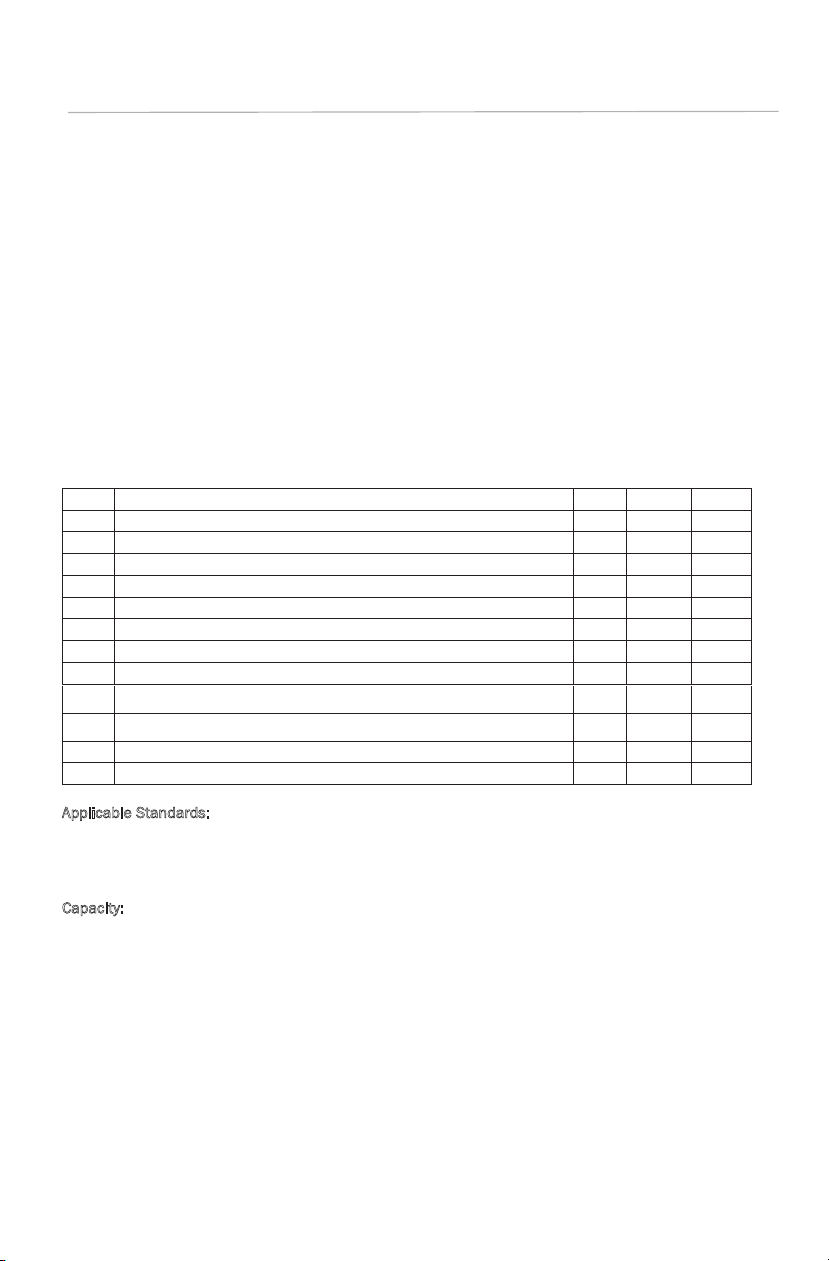

Max

Model/

Part # Description (Materials & Size)

C7000

C7001 Impac t Resist ant Pol ymer H ousing , Steel Cabl e, Steel Ca rabin er 30 ft. 54 in. B

C7002

C7003 Im pact Resi stant Polym er Housi ng, Steel Cabl e, Steel C arabin er, Sn out & Tagline 100 ft. 54 in. B

C7004

C7005 Im pact Resista nt Polym er Hous ing, Pol yester W ebbing, Steel S nap Hoo k & Swiv el 11 ft. 54 in. B

C7020

C7021

C7100

C7201

C7202

C8000 Impac t Resist ant Pol ymer H ousing , Steel Ca ble, Steel Car abiner , Steel Snap Ho ok & Tagl ine 20 ft. 54 in. B

C8001 Impact Res istant Polym er Housi ng, Steel Cabl e, Steel Carabi ner, St eel Sna p Hook & T agline 30 ft. 54 in. B

A

pplicable Standards:

Impac t Resist ant Pol ymer Housing, Steel Cable, Steel Carabiner, Snout & Tagline

Impac t Resist ant Pol ymer H ousing , Steel Ca ble, Steel Car abiner

Impac t Resist ant Pol ymer H ousing , Steel Ca ble, Steel Car abiner , Snout & Tagline

Alumi num Hou sing, Polyester Webbing, Steel Snap Hook Twin SRL

Aluminum Housing, Polyester Webbing, Steel Universal Rebar Hook Twin SRL

Impac t Resist ant Pol ymer H ousing , Polyes ter W ebbing, Steel Sn ap Hook, & Steel Carabiner

Impact Resistant Polymer Housing, Polyester Webbing, Swivel Top with

Impact Resistant Polymer Housing, Polyester Webbing, Swivel Top with

Steel Carabiner; Steel Snap Hook on Bottom

Steel Carabiner; Steel Universal Rebar Hook on Bottom

Lifeline

Length

Arrest

Distance

20 ft. 54 in. B

50 ft. 54 in. B

10 ft. 54 in. B

6 ft. 54 in. B

6 ft. 54 in. B

6 ft. 54 in. B

11 ft. 54 in. B

11 ft. 54 in. B

Z359.14

Refer to national standards, including ANSI Z359.1, and local, state and federal (OSHA 1910.66,

appendix C, 1926.500) requirements for more information on personal fall arrest systems and

associated components.

C

apacity:

Malta Dynamics Self-Retracting Lifelines are designed for use by an individual person with a

combined weight (worker, clothing, tools, etc.) of 130 lbs. minimum to no more than 310 lbs.

maximum. No more than one person may be connected at one time.

ANSI

Class

512

Page 6

SRL – SR D Instruction Manual

Anchorage Strength:

30°

Always attach to an

SRL – SR D Instruction Manual

40omax

40omax

Min. 5000lbs

Min. 5000lbs

In accordance with ANSI Z359.1, any anchorage selected for P

m

eet all anchorage strength requirements. Anchorages used for PFAS must be capable of

ersonal Fall Arrest Systems must

sustaining static loads in the direction permitted by the PFAS of at least: 3,600 lbs. with

certification of a qualified person; or 5,000 lbs. without certification. When more than one PFAS

is attached to an anchorage, the strengths stated above must be met independently at and for

each anchorage location. Avoid potential swing fall hazards and obstructions.

ree Fall:

F

Maximum free fall distance allowed for use in a Personal Fall Arrest System is 6 ft. Do not work

above the anchorage level to avoid increased Free Fall Distance. Avoid slack in the line and do not

lengthen the Self-Retracting Lifeline by connecting a lanyard or other snap hook directly to the

retractable. Do not use this device at or below the level of your feet. Using it thus will increase your

free fall distance beyond the allowable limits set by OSHA and exceed the capabilities of this

device to safely arrest a fall.

F

all Arrest Forces:

The Personal Fall Arrest System must limit fall arrest forces to 900 lbs. (4kN). Deceleration

distance shall not be allowed to exceed 42 in.

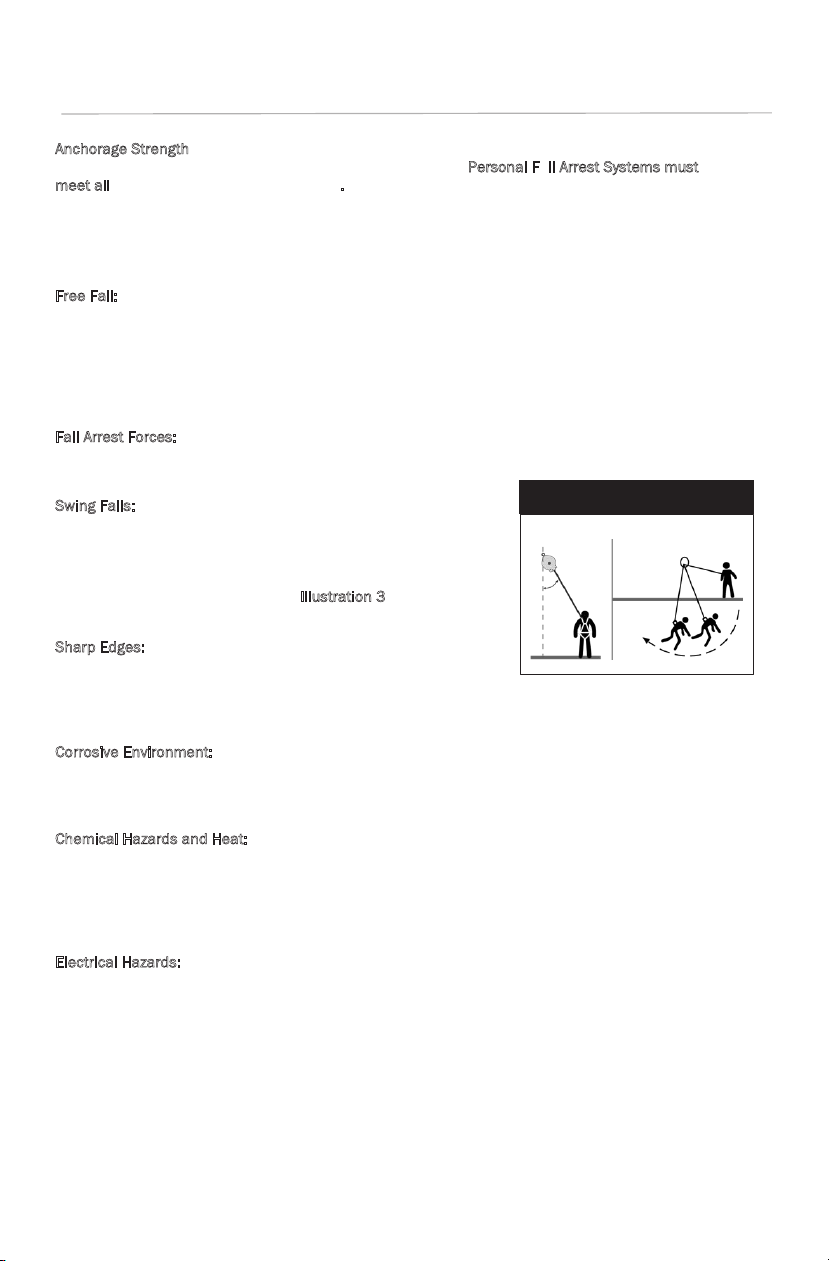

S

wing Falls:

Self-Retracting Lifelines should be used in a vertical position only.

Minimize swing fall by working as directly below the anchorage

point as possible. Worker movement should remain within 30

degrees maximum deflection of the lifeline from the vertical line

directly below the anchorage point. (

I

llustration 3). Do not permit a

Illustration 3: Minimize Swing Fall

overhead anchor. Swing

falls significantly increase

fall arrest

distance.

swing fall if injury could occur.

S

harp Edges:

working where sharp edges may contact lifeline. Provide

Avoid

sufficient protective

possible. Malta Dynamics

padding where avoiding sharp edges is not

energy absorbing device may be required to reduce impact force on the

entire system.

C

orrosive Environment:

Extensive exposure to environments where corrosion may occur will damage metal parts in the

Self-Retracting Lifeline. Use caution when working around corrosive compounds such as

ammonia, sewage, fertilizers, sea water or other corrosives.

C

hemical Hazards and Heat:

Use extreme caution

temperatures, as chemical damage that can impair the

in environments containing acid or caustic chemicals, particularly at elevated

functionality of the Self-Retracting Lifeline

(SRL) is difficult to detect. Periodic replacement of the SRL is recommended to ensure safety. Do not

use SRL in high temperature environments. Protect SRL if used near welding, metal cutting, or similar

activities. Hot sparks and slag can damage

E

lectrical Hazards:

Use extreme

caution to avoid contact with high voltage power lines. Both web and wire cable model

SRL and impair functionality.

Self-Retracting Lifelines may conduct electricity. Moisture absorbed by the lifeline can provide a

path for electrical current

to flow, resulting in potential electrical shock.

General Adverse Environment Conditions:

User must be aware of working conditions and environment during all aspects of use. Adverse

working conditions and environment require additional attention and extreme caution. Adverse

working conditions and environments include but are not limited to areas involving mortar/cement/

concrete, dust/demolition, caustic/corrosive materials, falling objects, gypsum, slurry, petroleum

based liquids, extreme wet conditions, mud, or metal/plastic shavings. User is to use extreme

caution of materials that may adhere to or strike the SRL line constituent. Material that adheres to

line constituent may damage parts within the Self-Retracting Lifeline and may lead to

6

serious injury or death. Falling objects that strike the SRL line constituent may cause a fall

to occur in addition to weakening or breaking the SRL and anchorage which will may result

in serious injury or death.

Page 7

SRL – SR D Instruction Manual

Locking Speed:

A. Connecting Su bsystems (Energy

Illustration 4:

Considerations

6 ft. Free Fall

ANCHORAGE

Total Min.

Anchorage

6 ft. Energy

12 ft. Free Fall

6 ft. Energy

Total Min.

Anchorage

Illustration 5: Calculating Total Fall Distance

ANCHORAGE

Use extreme caution when working on low-pitched roofs where a worker may slide, rather than fall. A

clear path is require to ensure positive locking of the Self-Retracting Lifeline.

F

all Clearance:

Consider the following when calculating fall clearance. Clearance required is dependent on the following

factors:

• Elevation of Anchorage

• Connecting Subsystem Length

• Deceleration Distance

Fall Clearance

• Free Fall Distance

• Worker Height

• D-ring / connector length

• Movement of Harness Attachment Element

• Length of Full Body Harness (FBH) Stretch

• Working Level

See I

llustration 4.

If there is a risk of a fall or if the only anchorage

point is below the attachment points on the

harness, it is essential to use a lanyard

provided with an energy absorber. Before using

a shock absorbing lanyard, ensure that there is

sufficient fall clearance below the user to

Absorbing Lanya rd shown) Length

+ Movement of H arness Attachment

+ Length of FBH Stretch

B. Working Level (thickness)

C. Worker Height + Connector Length

D. Free Fall – 6 ft. Max. (per ANSI Z359.1)

E. Decelerati on Distance

F. Total Fall Distance: Sum of A through E

G. Lower Level or Obstruction

prevent any collision with the structure or the

ground.

C

alculating Total Fall Distances:

Total Fall Clearance below worker is calculated from Anchorage Connection. Free Fall Distance +

Working Level + Energy Absorber + Deceleration Distance + Worker Height + Connector Length +

Safety Factor. Ensure that the total fall distance is clear of obstructions and equipment. Avoid

potential contact with a lower level. See

I

llustration 5.

19 ft. from

Absorbing

Lanyard

Length

4 ft.

Decel

eration

Distance

6 ft. Worker

Height

3 ft. Safety

Factor

20 ft. from

ENERG Y

ABSORBING

LANYARD MUST BE

CERTIFIED FOR 12

FT. FREE FALL

Absorbing

Lanyard

Length

5 ft.

Decel

eration

Distance

6 ft. Worker

Height

3 ft. Safety

Factor

7

Page 8

SRL – SR D Instruction Manual

Horizontal Systems and Tripods:

Illustration 6: Inspection

SRL – SR D Instruction Manual

MIN. 5000 lbs

22kN

40omax

310lbs

Max

follow

for

instructions

proper

SRL

attachment

GREEN

RED

directlyto

horizontal

54oC

-40

o

C

130oF

-40

o

F

SUITABLE FOR

HORIZONTAL

LIFELINE

800-494-1840

405 Watertown Road

Waterford, OH 45786

40omax

Ensure the support structure and/or horizontal system components are compatible if using SelfRetracting Lifeline in conjunction with a horizontal system, tripod or davit arm. Horizontal systems

must be designed and installed under the supervision of a qualified engineer.

Training

Employers are responsible for providing training to any employee who may be exposed to fall hazards

in order to enable the employee to recognize and reduce fall hazards. Training must be conducted by

a Competent or Qualified Person. Trainer and trainees must not be exposed to fall hazards during

the training course.

Inspection

Record all observations and results of each inspection in your Hog Tracker account or inspection

log. I

f inspection reveals any defect, inadequate maintenance, or unsafe condition, remove Full

B

ody Harness from service immediately.

A

fter a Fall:

Remove Self-Retracting Lifeline (SRL) from service immediately after a fall has occurred. Inspect the

impact indicator on the snap hook of the SRL; look for an exposed red color band. Do not reset the

impact indicator. SRL with a webbed lifeline requires additional inspection of the shock pack, looking

for deformation, elongation or other signs of the shock pack being torn or deployed.

lf-Retracting Lifeline (SRL) must be inspected by a Competent Person a minimum of twice per year

Se

(every six months). If the SRL is exposed to extreme or severe conditions, more frequent formal

inspections may be required. Record the results of each formal inspection in your Hog Tracker

account or inspection log.

U

ser Inspection

Self-Retracting Lifeline (SRL) should be inspected by the user before each use, using the inspection

procedures below (I

and inspected to ensure:

• Markings are legible

• Components are free from corrosion, bending, cracks, dents or deformity

• SRL is clean and free of dirt, oil, mold, mildew and contaminants

llustration 6). In addition, unit should be fully examined

nspection Procedure

I

S

tep 1: Inspect for loose screws and bent or damaged parts.

S

tep 2: Inspect housing for distortion, cracks or other damage. Ensure

swivel eye is not damaged or distorted. Swivel eye must turn

freely.

S

tep 3: Ensure lifeline extends and retracts fully without hesitation or

creation of slack in the line.

tep 4: Ensure device engages (locks up) when lifeline is jerked

S

(tugged) sharply.

tep 5: Inspect wire cable lifelines for cuts, kinks, broken wires, bird-

S

caging corrosion, welding splatter, chemical damage or severe

abrasion. Check all thimbles and other areas for excessive wear,

including cracks or separation of metal components.

S

tep 6: Inspect webbed lifelines for frayed strands, broken webbing,

burns, cuts and abrasions. Look for heat damage, paint build-up,

corrosion and chemical damage indicated by discoloration.

8 9

Page 9

SRL – SR D Instruction Manual

Step 7: Inspect all snap hooks and connectors for damage; ensure secure, locking engagement

MIN. 5000 lbs

22kN

40omax

310lbs

Max

follow

for

instructions

proper

SRL

attachment

GREEN

RED

directlyto

horizontal

54oC

-40

o

C

130oF

-40

o

F

SUITABLE FOR

HORIZONTAL

LIFELINE

800-494-1840

405 Watertown Road

Waterford, OH 45786

40omax

able Inspection Considerations:

C

User must be aware of the potential for damage or deterioration that may occur while in use.

C

rushing: Cable may get crushed or bent while in general use, resulting in unsafe condition for use.

C

utting: Movement over sharp edges or other objects while cable in under tension can damage or

break strands, resulting in an unsafe condition for use.

brasion: Normal wear can result in abrasion. Pay particular attention to outer strands, which are most

A

susceptible to abrasion. Extreme abrasion results in an unsafe condition for use.

inking: Deformation in the cable causes the lifeline to appear bent or kinked, and results in an unsafe

K

condition for use.

orrosion Damage: Use extreme caution to avoid potential damage when using a Self-Retracting

C

Lifeline in an environment where corrosive compounds, welding or high heat may exist. Corrosion

damage can cause cable to crack. Working in a corrosive environment requires increased inspection

frequency to ensure corrosive damage does not impact the performance of the SRL.

A

rc or Heat Damage: Welding or high heat may fuse cable wires and change the strength

characteristics of the wire and cable as a whole. Periodically examine the SRL if it must be used in

these types of environments.

Cleaning and Maintenance

C

leaning

Wipe off all surface dirt. Store in clean, dry area, away from heat and areas where chemical vapors may

exist. Avoid storing in direct light to prevent UV degradation.

M

aintenance

Do not attempt to disassemble or repair. O

D

ynamics shall make repairs, authorized maintenance or alterations to the equipment.

uct Labels

Prod

nly Malta Dynamics or entities authorized in writing by Malta

The following labelling is affixed to product and must not be removed:

CLASS B SRD

SRL -Weight: -8.5 -lbs.

Max -Arresting-Distance:-54-in..

Material:

steel,

aluminum housing

2

with Carabiner, Steel Snap Hook,

Snout and Tag Line

Average -Arresting -Force: 900 -lbs.

Capacity: -1 -Person

Working -Load: -130-310 -lbs.

®

MIN. 5000 lbs

22kN

follow

54oC

130oF

instructions

GREEN

RED

800-494-1840

405 Watertown Road

Waterford, OH 45786

-40

310lbs

Max

SUITABLE FOR

proper

for

HORIZONTAL

o

o

-40

F

C

LIFELINE

SRL

attachment

directlyto

horizontal

C7000

Page 10

40omax

SRL – SR D Instruction Manual

A. Connecting Su bsystems (Energy

Illustration 4:

Considerations

6 ft. Free Fall

ANCHORAGE

Total Min.

Anchorage

6 ft. Energy

12 ft. Free Fall

6 ft. Energy

Total Min.

Anchorage

Illustration 5: Calculating Total Fall Distance

ANCHORAGE

SRL – SR D Instruction Manual

40omax

310lbs

50oC

-30

o

C

122oF

-22

o

F

40omax

Max

MIN. 5000 lbs

22kN

GREEN

with Carabiner, Steel Snap Hook,

54oC

RED

follow

130oF

SUITABLE FOR

instructions

HORIZONTAL

proper

for

o

o

F

-40

-40

C

attachment

LIFELINE

SRL

Materials:- Impact -Resistant-Polymer-Housing,

Steel-Cable,-Steel-Hardware

Average -Arresting-Force: 900-lbs.

Snout and Tag Line

SRL -Weight:-8.7-lbs.

Capacity:-1-person

Working -Load:-130-310-lbs.

Max -Arresting-Distance:-54-in.

C7001

310lbs

Max

CLASS B SRD

Materials:- Impact -Resistant-Polymer-Housing,

---------- ----- Polyester-Webbing,-Steel-Hardware

800-494-1840

405 Watertown Road, Waterford, OH 45786

MIN. 5000 lbs

22kN

GREEN

RED

800-494-1840

405 Watertown Road, Waterford, OH 45786

1

Materials:- Impact -Resistant-Polymer -Housing,

Average-Arresting-Force:-900-lbs.

Max-Arresting-Distance:-54-in.

----------- ---- ---- --- -- --- Steel - Cable,-Steel-Hardware

130oF

o

o

-40

F

C

Working-Load: -130-310-lbs.

follow

SUITABLE FOR

instructions

HORIZONTAL

proper

for

LIFELINE

SRL

attachment

Snout and Tag Line

Capacity:-1-Person

54oC

-40

with Carabiner, Steel Snap Hook,

C7002

™

C7003

Average -Arresting-Force: 900-lbs.

MIN. 5000 lbs

22kN

GREEN

310lbs

Max

Class -B -SRD

with Carabiner, Steel Snap Hook,

Materials:- Impact -Resistant-Polymer-Housing,

Steel-Cable,-Steel-Hardware

Class -B -SRD

54oC

RED

130oF

o

o

F

-40

-40

C

Snout and Tag Line

SRL -Weight:-8.7-lbs.

Capacity:-1-person

Working -Load:-130-310-lbs.

Max -Arresting-Distance:-54-in.

follow

instructions

SUITABLE FOR

proper

for

HORIZONTAL

SRL

LIFELINE

attachment

3

10

Page 11

SRL – SR D Instruction Manual

40omax

CLASS B SRD

40omax

Min. 5000lbs

Min. 5000lbs

SRL -Weight: -8 -lbs.

Max -Arresting-Distance: 54-in.

CLASS B SRD

SRL -Weight: -5.2 -lbs.

Max -Arresting-Distance: 54-in.

1

with Carabiner, Steel Snap Hook,

Materials:- Impact - Resistant-Polymer-Housing,

---------- ----- Polyester -Webbing,-Steel-Hardware

Average -Arresting-Force: 900-lbs.

®

1

1

11

’ Webbing with Swivel & Snap Hook

Materials:- Impact -Resistant-Polymer-Housing,

---------- ----- Polyester-Webbing,-Steel-Hardware

Average -Arresting-Force: 900-lbs.

Working-Load: -90-130-lbs.

®

CLASSBSRD

C7020

PART#

Weight: -5.2 - lbs.

SERIAL#

BATCH#

MFG

DATE:

54oC 130oF

310lbs

-40oC -40oF

Max

™

Snout and Tag Line

Capacity:-1-Person

Working-Load: -130-310-lbs.

™

Capacity:-1-Person

6'

follow

instructions

for

_

proper

SRL

attachment

22kN

SUITABLE FOR

HORIZONTAL

LIFELINE

310lbs

Max

Twin

Self-Retracting

GREEN

RED

MIN. 5000 lbs

22kN

GREEN

with

MIN. 5000 lbs

22kN

GREEN

RED

310lbs

Max

54oC

130oF

RED

o

C

-40

800-494-1840

405 Watertown Road

Waterford, OH 45786

Steel- Snap

Average -Arresting -Force: 900lbs.

Working- Load: 130-310lbs.

Max Distance:

800-494-1840

405 Watertown Road

Waterford, OH 45786

800-494-1840

405 Watertown Road

Waterford, OH 45788

follow

instructions

proper

for

o

-40

F

SRL

attachment

™

Lifeline

Capacity: 1 person

Arrest

54oC

o

C

-40

SUITABLE FOR

HORIZONTAL

LIFELINE

Hook

4

C7004

follow

130oF

instructions

SUITABLE FOR

proper

HORIZONTAL

for

o

-40

F

LIFELINE

SRL

attachment

SUITABLE FOR

HORIZONTAL

LIFELINE

C7005

54"

C7020

CLASSBSRD

C7021

PART#

310lbs

Max

SERIAL#

BATCH#

MFG

Weight: -5.2 - lbs.

DATE:

54oC 130oF

-40oC -40oF

instructions

for

attachment

6'

follow

_

proper

SRL

22kN

SUITABLE FOR

HORIZONTAL

LIFELINE

Twin

Self-Retracting

GREEN

RED

™

with- Universal- Rebar- Hook

Lifeline

Average -Arresting -Force: 900lbs.

Capacity: 1 person

Working- Load: 130-310lbs.

Max Distance:

Arrest

800-494-1840

405 Watertown Road

Waterford, OH 45786

54"

C7021

Page 12

SRL – SR D Instruction Manual

SRL – SR D Instruction Manual

PART# C7201

™

SRL -Weight:-5-lbs.

11’ Polyester Webbing, Swivel Top with

Carabiner ; Snap Hook on Bottom

Capacity:-1-person

Working -Load:-130-310-lbs.

Max -Arresting-Distance:-54-in.

Average -Arresting-Force:

Materials:- Impact -Resistant -Polymer-Housing,-

------------ Polyester-Webbing,-Steel-Hardware

Class -B -SRD

Materials:- Impact -Resistant-Polymer-

-Housing, -Polyester-Web,-

--Steel-Hardware

Capacity:-1-person

SRL -Weight:-5-lbs.

Class -B -SRD

CLASSBSRD

C7021

PART#

900-lbs.

with Universal Rebar Hook

Average -Arresting-Force:

900-lbs.

Working -Load:-130-310-lbs.

Max -Arresting-Distance:-54-in.

Weight: -5.2 - lbs.

SERIAL#

BATCH#

MFG

DATE:

310lbs

™

6'

Max

Twin

MIN. 5000 lbs

22kN

GREEN

RED

800-494-1840

Watertown Road, Waterford, OH 45786

MIN. 5000 lbs

22kN

310lbs

Max

Self-Retracting

with- Universal- Rebar- Hook

™

40omax

54oC

130oF

instructions

for

o

o

-40

F

-40

C

attachment

800-494-1840

405 Watertown Road, Waterford, OH 45786

™

40omax

54oC

130oF

GREEN

RED

o

o

-40

C

-40

SUITABLE FOR

HORIZONTAL

LIFELINE

™

Lifeline

Average -Arresting -Force: 900lbs.

Capacity: 1 person

Working- Load: 130-310lbs.

Max Arrest Distance:

follow

SUITABLE FOR

proper

HORIZONTAL

LIFELINE

SRL

follow

instructions

proper

for

F

SRL

attachment

C7201

C7103

54"

C7021

310lbs

54oC 130oF

follow

instructions

for

_

proper

-40oC -40oF

SRL

Max

attachment

SUIT

HORIZONT

LIFELINE

GREEN

RED

Min. 5000lbs

22kN

ABLE FOR

AL

800-494-1840

405 Watertown Road

Waterford, OH 45786

Page 13

SRL – SR D Instruction Manual

Materials:- Impact-Resistant-Polymer-Housing,

Steel-Cable,-Steel-Hardware

40omax

Materials:- Impact-Resistant-Polymer-Housing,

Steel-Cable,-Steel-Hardware

40omax

40omax

PART# C7202

SRL -Weight:-5-lbs.

CLASS B SRD

Max-Arresting-Distance:-54-in.

Working-Load: -130-310-lbs.

Capacity:-1-Person

Average-Arresting-Force:-900-lbs.

Materials: -Impact -Resistant-Polymer

Housing,-Steel-Cable,-Steel-Hardware

11’ Polyester Webbing, Swivel Top with

Carabiner; Universal Rebar Hook on Bottom

Max -Arresting-Distance:-54-in.

Average -Arresting-Force:

Materials:- Impact -Resistant -Polymer-Housing,-

------------ Polyester-Webbing,-Steel-Hardware

Class -B -SRD

Materials: -Impact -Resistant-Polymer

Housing,-Steel-Cable,-Steel-Hardware

™

Capacity:-1-person

Working -Load:-130-310-lbs.

900-lbs.

310lbs

Max

MIN. 5000 lbs

22kN

310lbs

Max

MIN. 5000 lbs

22kN

GREEN

RED

405 Watertown Road, Waterford, OH 45786

GREEN

RED

800-494-1840

405 Watertown Road, Waterford, OH 45786

54oC

o

-40

C

800-494-1840

54oC

130oF

instructions

for

o

o

F

-40

-40

C

attachment

C7202

™

follow

130oF

instructions

SUITABLE FOR

proper

HORIZONTAL

for

o

-40

F

LIFELINE

SRL

attachment

C8000

SUITABLE FOR

HORIZONTAL

LIFELINE

follow

proper

SRL

CLASS B SRD

Max-Arresting-Distance:-54-in.

Working-Load: -130-310-lbs.

Capacity:-1-Person

Average-Arresting-Force:-900-lbs.

3/16” diameter

Galvanized Steel Cable

with Carabiner, Swivel Top

Steel Snap Hook & Tag Line

MIN. 5000 lbs

22kN

310lbs

Max

GREEN

RED

800-494-1840

405 Watertown Road, Waterford, OH 45786

C8001

SUITABLE FOR

HORIZONTAL

LIFELINE

follow

54oC

130oF

instructions

proper

for

o

o

F

-40

C

-40

SRL

attachment

Page 14

SRL – SR D Instruction Manual

Illustration

1: Examples

of

Swing

Fall Hazards

SRL – SR D Instruction Manual

Inspection Log

Date of Manufacture: Model Name/#:

Serial #: Date of First Use:

INSPECTION DATE ITEMS NOTED CORRECTIVE ACTION APPROVED BY

14

8

00-494-1840

405 Watertown Road, Waterford, OH 45786

Page 15

SRL – SR D Instruction Manual

Warranty

THE FOLLOWING IS MADE IN LIEU OF ALL WARRANTIES OR CONDITIONS, EXPRESS OR IMPLIED,

INCLUDING THE IMPLIED WARRANTIES OR CONDITIONS OF MERCHANTABILITY OR FITNESS FOR A

PARTICULAR PURPOSE. Equipment offered by Malta Dynamics is warranted against factory defects

in workmanship and materials for a period of one year from date of installation or first use by the

original owner. LIMITED REMEDY: Upon notice in writing, Malta Dynamics will repair or replace all

defective items at Malta Dynamics’s sole discretion. Malta Dynamics reserves the right to require

that the defective item be returned to its plant for inspection before determining the appropriate

course of action. Warranty does not cover equipment damage resulting from wear, abuse, damage

in transit, failure to maintain the product or other damage beyond the control of Malta Dynamics.

Malta Dynamics shall be the sole judge of product condition and warranty options. This warranty

applies only to original purchaser and is the only warranty applicable to this product. Please contact

Malta Dynamics customer service department at 800-494-1840 for assistance. LIMITATION OF

LIABILITY: IN NO EVENT WILL MALTA DYNAMICS BE LIABLE FOR ANY INDIRECT, INCIDENTAL,

SPECIAL OR CONSEQUENTIAL DAMAGES INCLUDING, BUT NOT LIMITED TO LOSS OF PROFITS, IN

ANY WAY RELATED TO THE PRODUCTS REGARDLESS OF THE LEGAL THEORY ASSERTED.

Page 16

SRL – SRD Instruction Manual

te of First Use:

INSPECTION DATE ITEMS NOTED CORRECTIVE ACTION APPROVED BY

1

SRL – SR D Instruction Manual

MaltaDynamics

8

405 Watertown Road, Waterford, OH 45786

8

00-494-1840

405 Watertown Road, Waterford, OH 45786

Loading...

Loading...