R41Z-EVAL User Guide

R41Z-EVAL User Guide Rev 2.0

1

Contents

Table of Contents

Contents ............................................................................................................................................... 1

Introduction ......................................................................................................................................... 2

2.1 Key Features ................................................................................................................................. 2

Hardware Kit ......................................................................................................................................... 2

Development Tools .............................................................................................................................. 1

Application Firmware Development ................................................................................................... 2

5.1 Set Up Toolchain .......................................................................................................................... 2

5.2 Try an Example ............................................................................................................................. 3

Hardware Description .......................................................................................................................... 9

6.1 Power .......................................................................................................................................... 10

6.1.1 R41Z Power Modes ............................................................................................................... 11

6.1.2 Power Configuration Switch ................................................................................................ 12

6.1.3 DC-DC Mode Selection .......................................................................................................... 13

6.1.4 Measuring Power Consumption ........................................................................................... 14

6.2 Debug Interface .......................................................................................................................... 15

6.2.1 OpenSDA Interface ............................................................................................................... 15

6.2.2 Reset Button ......................................................................................................................... 15

6.2.3 External Debug Header ........................................................................................................ 15

6.3 Peripherals ................................................................................................................................. 17

6.3.1 Expansion Headers ............................................................................................................... 17

6.3.2 IR LED Provision .................................................................................................................... 18

6.3.3 User LEDs .............................................................................................................................. 18

6.3.4 Thermistor ............................................................................................................................ 19

6.3.5 User Buttons ......................................................................................................................... 19

6.3.6 SPI Flash ................................................................................................................................ 20

6.3.7 I2C Acceleration/Magnetometer Sensor .............................................................................. 21

6.4 R41Z Module ............................................................................................................................... 22

6.4.1 32.768kHz Oscillator ............................................................................................................. 22

Related Documents ............................................................................................................................ 23

Life Support and other High-Risk Use Warning ................................................................................. 23

Environmental .................................................................................................................................... 23

9.1 RoHS ........................................................................................................................................... 23

9.2 REACH ......................................................................................................................................... 23

9.3 California Proposition 65 (P65) .................................................................................................. 23

Contact Information ........................................................................................................................... 24

List of Tables ....................................................................................................................................... 25

List of Figures ..................................................................................................................................... 25

Document History .............................................................................................................................. 26

R41Z-EVAL User Guide Rev 2.0

2

Introduction

The R41Z Evaluation Kit from Rigado allows for stand-alone use of the R41Z Module featuring the NXP

MKW41Z RF System on Chip (SoC).

This guide provides setup instructions for starting development and describes the hardware

functionality of the R41Z Evaluation Kit that can facilitate development of your project.

The R41Z Evaluation Kit provides a great starting point for almost any Bluetooth Smart (4.2 Low

Energy) or Thread project. All the features of the R41Z module are easily accessed from the evaluation

board. A simple USB connection provides power and OpenSDA V2.1 based debugging. Four user

buttons (two conventional and two capacitive) are available, as well as an RGB LED, reset button,

combination acceleration/magnetometer sensor, and an external 4Mbit flash module. Arduino form

factor headers provide access to 16 GPIO and 6 analog inputs. This allows for easy use of the Rigado

R41Z Shields, as well as many existing Arduino shields. Current sense resistors allow for measuring

current into the R41Z module and into the shield.

2.1 Key Features

• R41Z Thread + Bluetooth Module

• On-board programming and debug (OpenSDA

v2.1)

• Virtual COM port over USB

• Pin-for-pin compatible with projects created

for the NXP FRDM-KW41Z board

• Buttons and LEDs for user interaction

• 3-axis combination accelerometer and

magnetometer, I2C interface

• 4Mbit Flash, SPI interface

• Provision for IR LED

• 32.768kHz crystal

• CR2032 battery holder

• Supports all DC-DC modes of the R41Z

module

• Adjustable output regulator simplifies

development

Hardware Kit

Figure 1 – R41Z Evaluation Board (Top View)

R41Z-EVAL:

• R41Z Evaluation Board

• Micro-USB Cable

• Quick start guide

R41Z-EVAL User Guide Rev 2.0

1

Development Tools

The tools listed below will aid in development with the R41Z modules. Not all tools will be required

depending on which software suite is used.

Tool

Description

MCUXpresso IDE

An easy-to-use integrated development environment (IDE) for

creating, building, debugging, and optimizing your application.

MCUXpresso SDK

An open source software development kit (SDK) built specifically

for your processor and evaluation board selections.

MCUXpresso Config Tools

A comprehensive suite of system configuration tools, including

pins, clocks, Peripherals, and more.

NXP IoT Toolbox

IoT Toolbox is an all-in-one application capable of demonstrating

NXP’s Bluetooth® LE, Zigbee and Thread capabilities through the

implementation of Bluetooth® LE and custom proprietary

profiles, allowing the interaction with different smartphones.

Table 1 – Useful Tools

R41Z-EVAL User Guide Rev 2.0

2

Application Firmware Development

This section walks through how to set up and program the R41Z Evaluation Kit with an example

application.

NOTE: This process will erase any preloaded firmware provided by Rigado including bootloader and

demonstration firmware, if provided. To access any firmware or demo applications that may be

preloaded on the R41Z evaluation kit, please contact Rigado (modules@rigado.com)

5.1 Set Up Toolchain

The MCUXpresso tools are used for application development for the R41Z. All examples within the SDK

for the NXP FRDM-KW41Z will function, unchanged, on the R41Z-EVAL.

1. Establish an account and login to the NXP website:

a. https://www.nxp.com/webapp-signup/register for a new account

b. https://www.nxp.com/security/login to login to an existing account

2. Download and install the NXP Semiconductors “IoT Toolbox” app on an available iOS or

Android device. The app is available from the respective app stores. This app will be used to

connect to the R41Z-EVAL board loaded with the SDK examples.

3. Download and install the MCUXpresso IDE on a PC. Windows, macOS and Linux are supported.

4. Download and install the MCUXpresso Config Tools on a PC. Windows, macOS and Linux are

supported.

5. Download the MCUXpresso SDK. Select the FRDM-KW41Z Development Board. This download

will be a zip file.

a. The SDK documentation is available in the “docs” directory within the zip file.

6. Open the MCUXpresso IDE.

7. Install the MCUXpresso SDK into the IDE by dragging the downloaded zip file to the lower right

pane:

8. Connect your R41Z Evaluation Board to your host computer using the supplied USB cable. The

board should show up as a mass storage device and a new virtual COM port will also appear.

Figure 2 – SDK installation

R41Z-EVAL User Guide Rev 2.0

3

5.2 Try an Example

Import and run an example from the SDK.

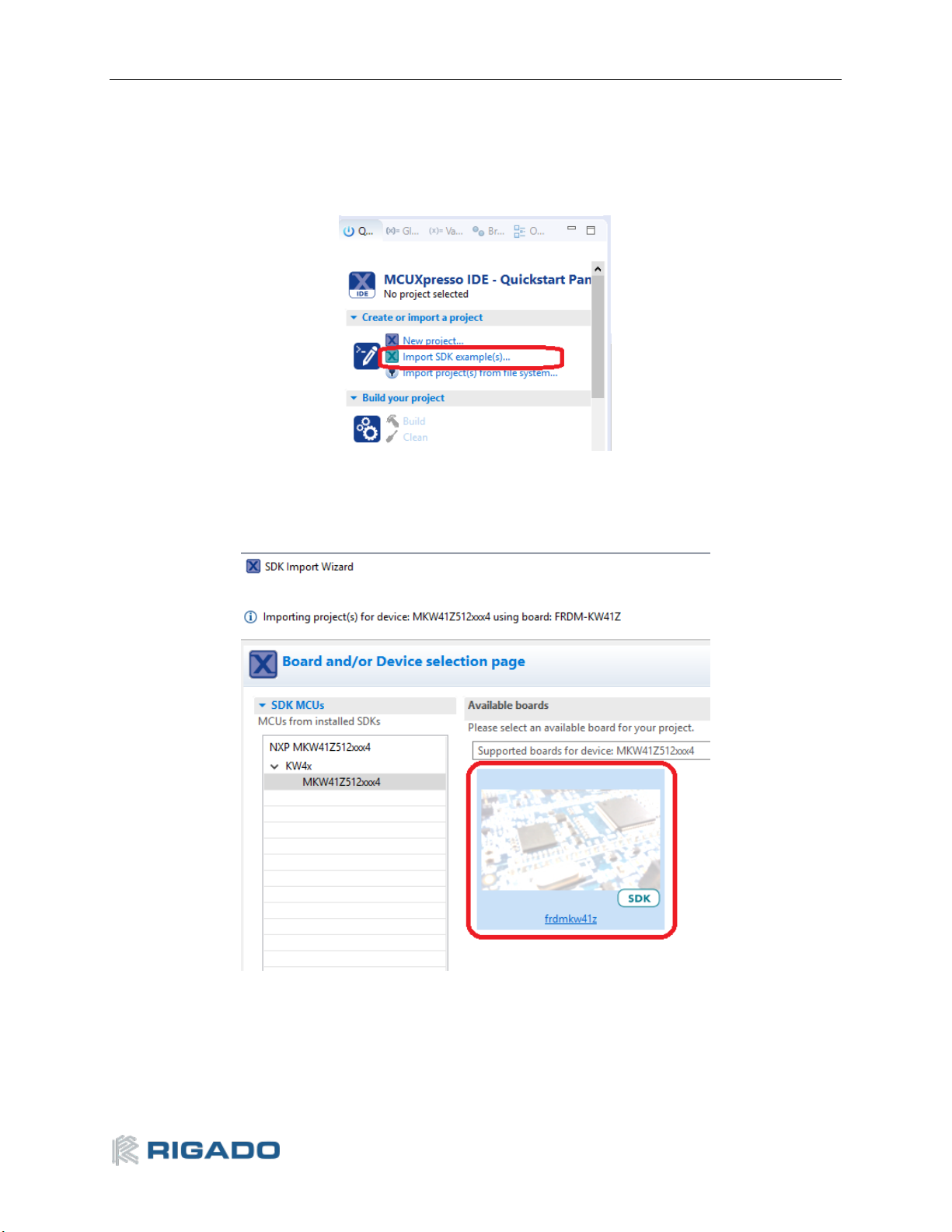

1. In the lower left pane, click on “Import SDK example(s)…”

2. Click on the “frdmkw41z” under “Available boards”, then click “Next”

Figure 3 – Import example

Figure 4 – Select board

R41Z-EVAL User Guide Rev 2.0

4

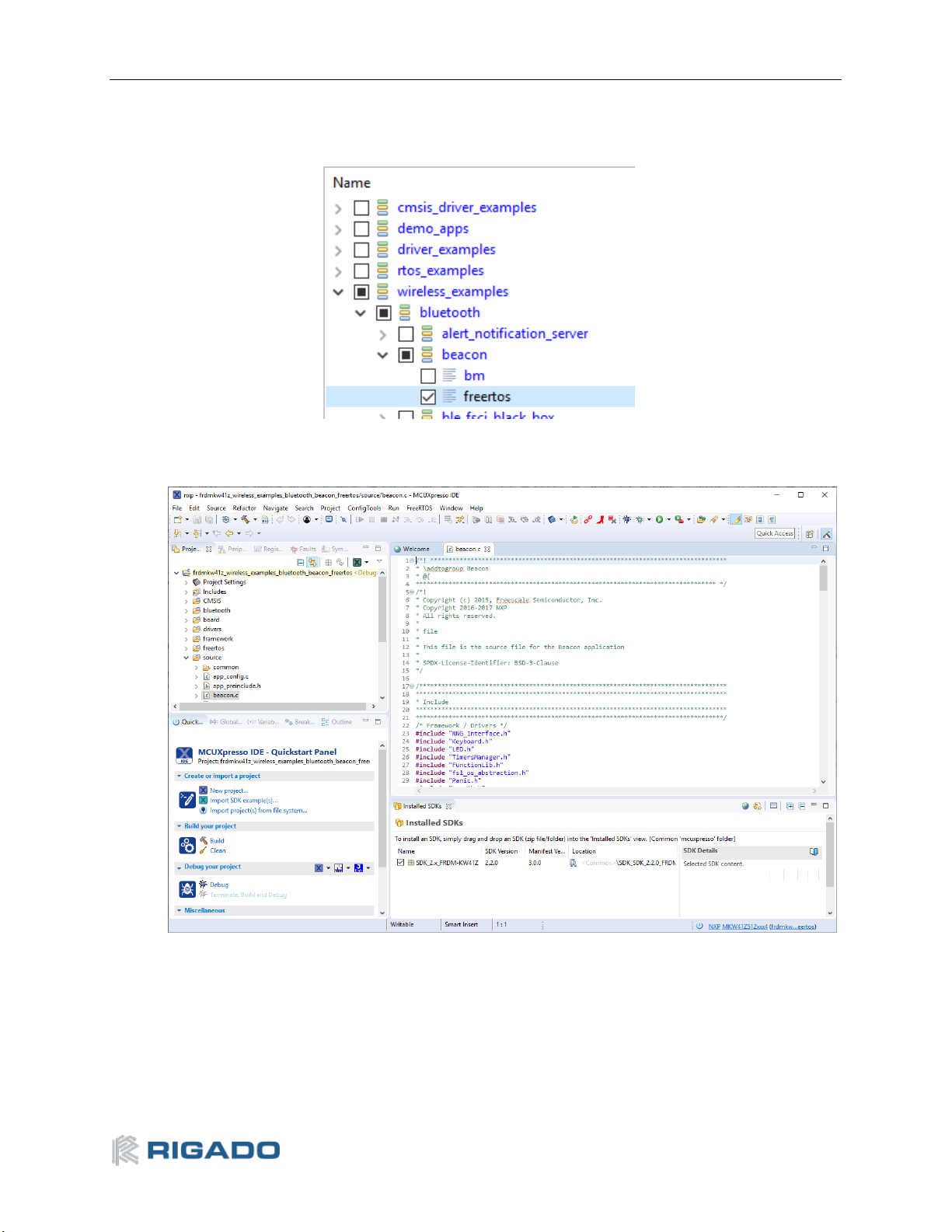

3. On the next screen, select the example, then click Finish. In this case, we’ll use the “Bluetooth

Beacon”.

4. Application source code is in the project tree under the “source” directory:

Figure 6 – Example source code

Figure 5 – Select Bluetooth Beacon example

R41Z-EVAL User Guide Rev 2.0

5

5. Click the “hammer” icon to build the project:

6. Click the “bug” icon to start debugging:

7. Select the “J-Link OpenSDA” debug probe and click OK:

Figure 9 – Debug probe selection

Figure 7 – Build the example

Figure 8 – Start debugging

R41Z-EVAL User Guide Rev 2.0

6

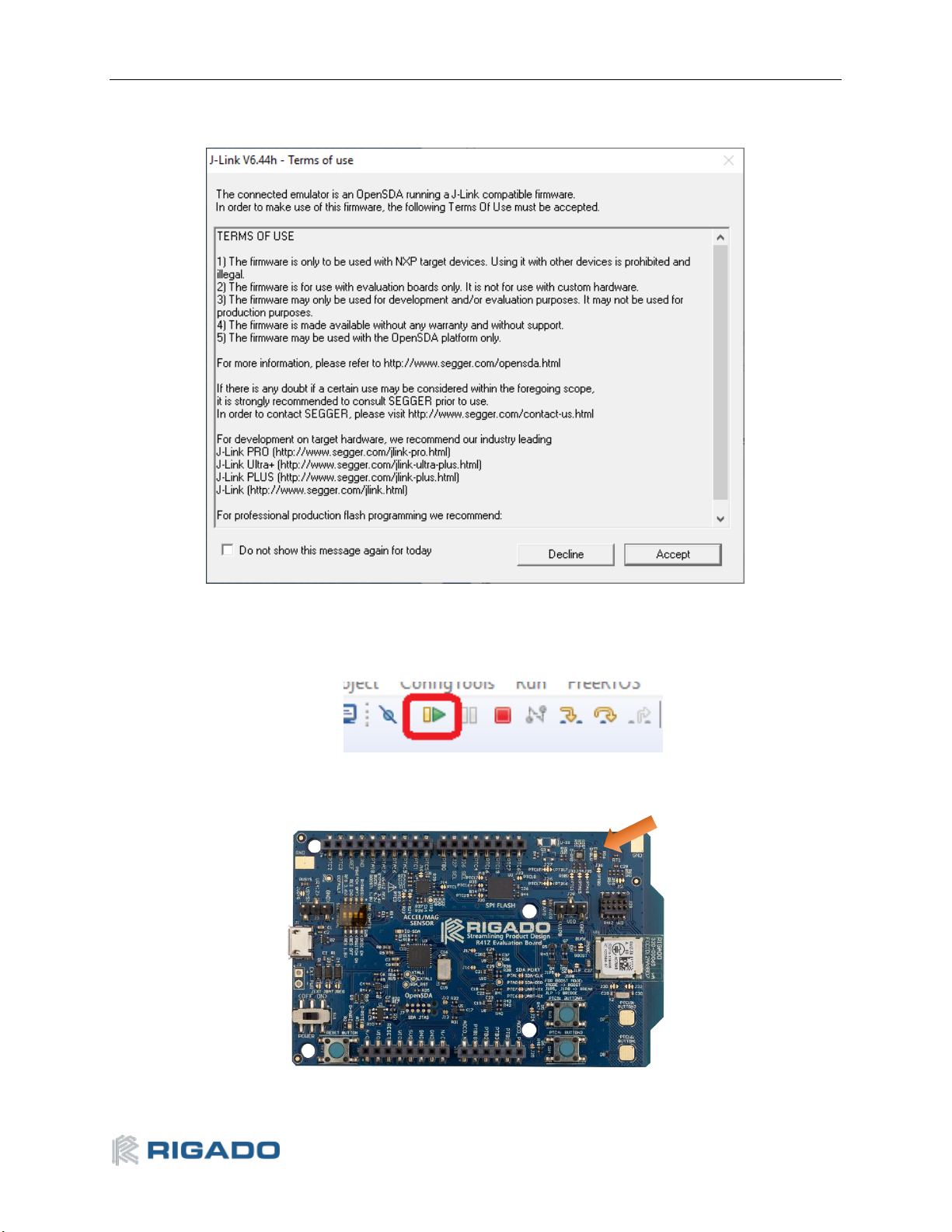

8. Accept the OpenSDA terms of use:

Figure 10 – OpenSDA Terms of Use

9. Click the “Play” icon to run the application:

Figure 11 – Run the example

10. Observe the blue LED flashing on the R41Z-EVAL board:

Figure 12 – Flashing LED

R41Z-EVAL User Guide Rev 2.0

7

11. Open the NXP IoT Toolbox mobile app on your mobile device, and tap the “Beacons” icon:

Figure 13 – NXP IoT Toolbox mobile app

12. Observe the beacon RSSI increase as you move the mobile device closer to the R41Z-EVAL.

Figure 14 – Advertising Beacon

R41Z-EVAL User Guide Rev 2.0

8

13. The advertising data for A, B, and C values may be changed in the file “app_config.c”:

/* Advertising Data */

static const uint8_t adData0[1] = {

(gapAdTypeFlags_t)(gLeGeneralDiscoverableMode_c | gBrEdrNotSupported_c) };

static uint8_t adData1[26] = {

/* Company Identifier*/

mAdvCompanyId,

/* Beacon Identifier */

mBeaconId,

/* UUID */

mUuid,

/* A */

0x00, 0x00,

/* B */

0x00, 0x00,

/* C */

0x00, 0x00,

/* RSSI at 1m */

0x1E};

R41Z-EVAL User Guide Rev 2.0

9

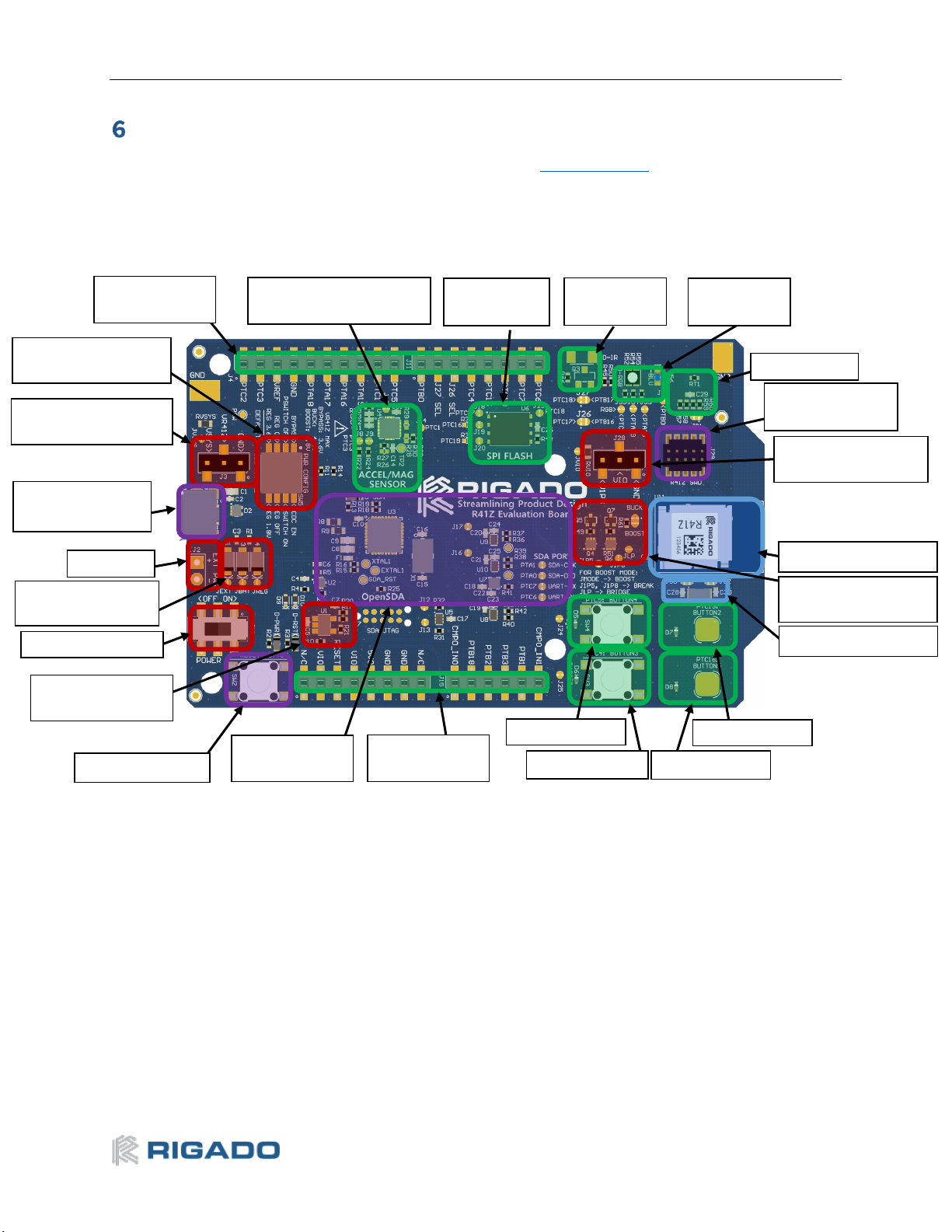

Hardware Description

Design files for the R41Z Evaluation Kit may be found on the Rigado website.

Figure 15 – Evaluation Board Layout

Accelerometer /

Magnetometer Sensor

SPI Flash

Module

IR-LED

Provision

RGB and

Blue User

Thermistor

External Debugger

Header

Peripheral Current

Measurement Header

R41Z Module

Power Configuration

Jumpers

User Button2

User Button5

User Button3

User Button4

Breakout

Headers

OpenSDA Debug

Interface

Reset Button

USB Power

Regulator

Power Switch

Power Protection

Diodes

Ext. Power

Micro-USB for

Power and Debug

Board Current

Measurement Header

Power Configuration

Switch

Breakout

Headers

32.768kHz Oscillator

R41Z-EVAL User Guide Rev 2.0

10

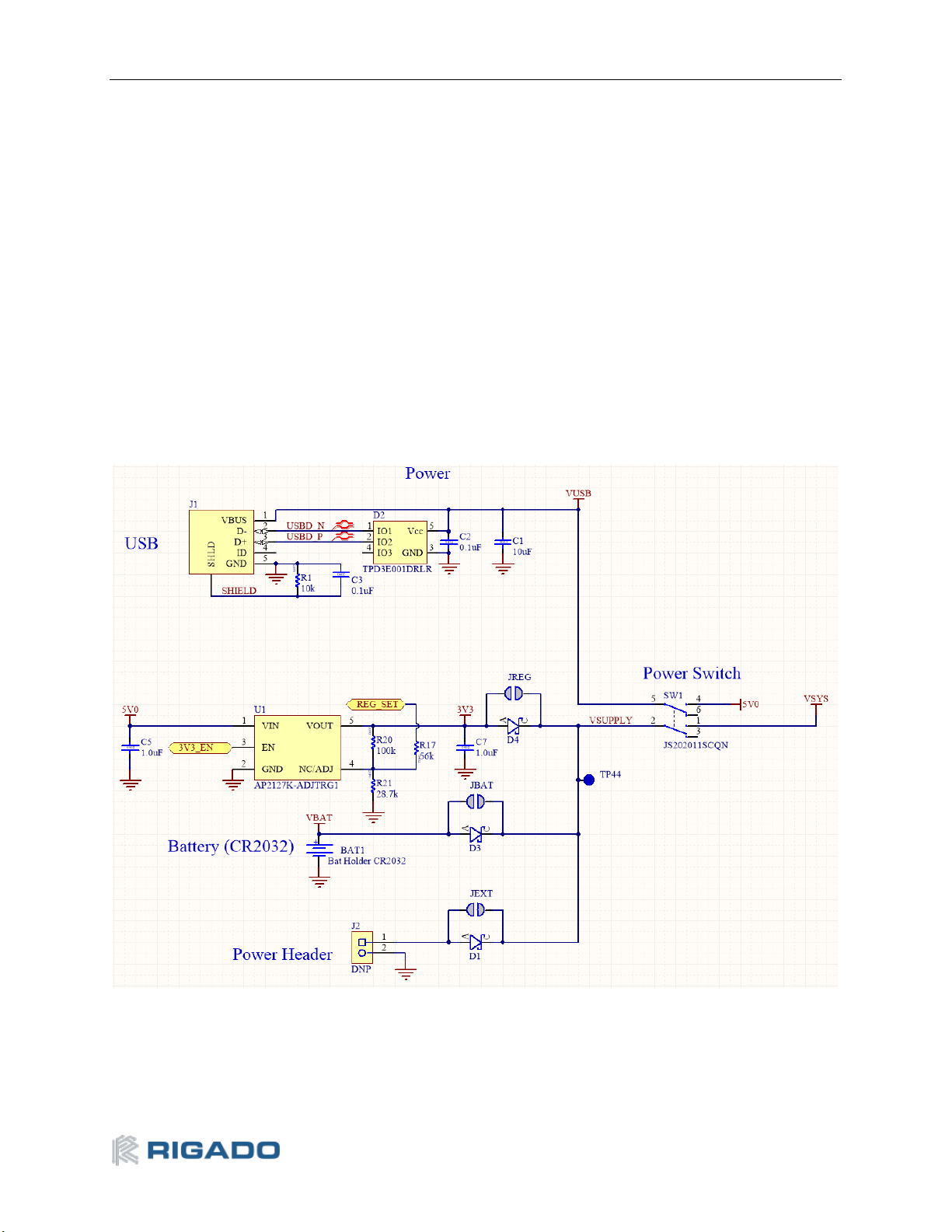

6.1 Power

The R41Z Evaluation Board has three possible power sources: USB, a CR2032 coil cell, and a 0.1”

through-hole connector. These sources are OR’d together with protection diodes to prevent reverse

voltage to any supply. These allows for more than one source to be connected at a time. For example,

a coil cell battery may remain connected to the board while the board is being debugged with the USB

source connected. However, since the diodes do cause approximately a 0.3V drop in source voltage,

there is the option to bypass the diodes via solder jumpers. Care should be taken to not damage the

supplies or Evaluation board when the protection is by-passed.

If necessary, the LDO regulator can be disabled in order to allow for USB based debugging while

powering the R41Z from either an external source or a coil cell. Since the R41Z can accept a wide

range of power options, the LDO regulator can be adjusted to simulate some sources. For details on

these options, see Power Configuration Switch section later in this document.

Figure 16 – Schematic: Power Supply

R41Z-EVAL User Guide Rev 2.0

11

6.1.1 R41Z Power Modes

The Rigado R41Z module contains a DC-DC converter that allows it to operate in a variety of power

environments. The R41Z Evaluation board supports all these operating modes, which are summarized

below:

R41Z DC-DC Converter Modes

Mode

Input

Voltage

Output

Voltage

Usage Notes

Bypass

1.71V – 3.6V

N/A

DC-DC Converter is bypassed: Input voltage directly

supplies all internal module power rails. Suitable for

larger or non-battery powered applications that have

steady, regulated 3.3V or 1.8V power rails that power

multiple devices. Since the DC-DC converter is bypassed

in this mode, the R41Z cannot provide regulated power

to other devices.

Buck

1.8V – 4.2V

1.8V – 3.0V

1

DC-DC Converter operates in buck mode. Internal power

rails are sourced and regulated by the R41Z module. An

externally available power rail (V1P8) allows the R41Z to

supply regulated power to other peripheral devices.

Suitable for small applications powered directly from a

lithium ion battery 2. If total power consumption is low,

the R41Z module can provide a regulated power rail to

supply other devices.

Boost

0.9V – 1.8V

1.8V – 3.0V

1

DC-DC Converter operates if boost mode. Internal power

rails are sourced and regulated by the R41Z module. An

externally available power rail (V1P8) allows the R41Z to

supply regulated power to other peripheral devices.

Suitable for small applications powered directly from a

low voltage battery 2 (For example, alkaline or NiMH). If

total power consumption is low, the R41Z module can

provide a regulated power rail to supply other devices.

Note 1: Output voltage is user adjustable in Buck and Boost mode. Defaults to 1.8V at Power On

Reset. In Buck mode, output voltage cannot be greater than input voltage.

Note 2: The R41Z does not include automatic battery management. Applications powered from

batteries must include battery management and protection features implemented with additional

hardware and/or software.

Table 2 – R41Z Power Modes

R41Z-EVAL User Guide Rev 2.0

12

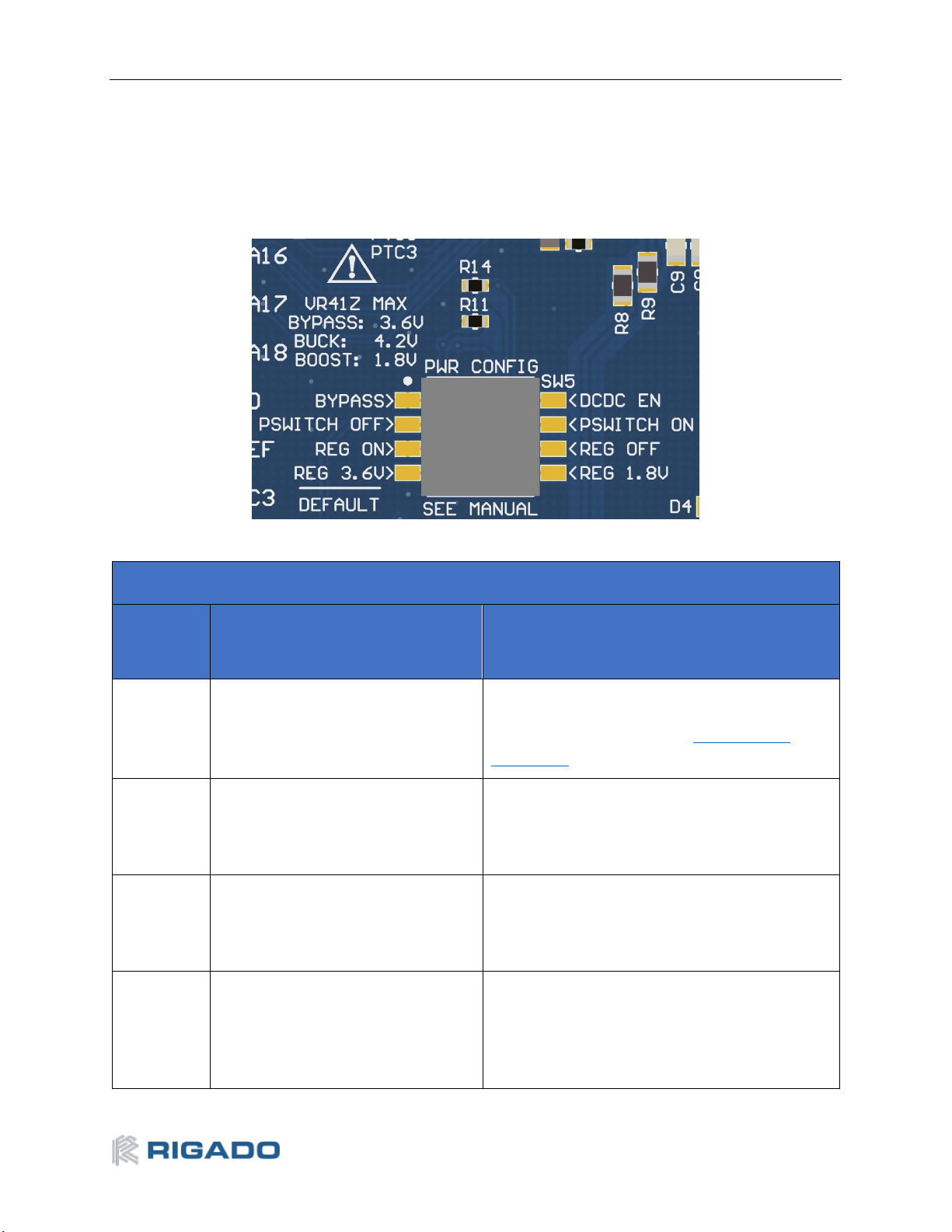

6.1.2 Power Configuration Switch

The power configuration switch allows easy and quick adjustment of most power settings on the R41Z

Evaluation Board.

Figure 17 – Power Configuration Switch

Power Configuration Switch

SW

Position

Default

Option

1

Bypass Power Mode

DC-DC Power Mode. Buck Mode by default;

Boost mode selectable with Power

Configuration Jumpers. See DC-DC Mode

Selection.

2

PSWITCH OFF. When in Buck Mode,

the DC-DC converter will not start

when power is applied. Use this

option when using Bypass Mode.

PSWITCH ON. When in Buck mode, the DC-DC

Converter will automatically start when power

is applied. Use this option when using Boost

Mode.

3

Regulator On. When USB is

connected, the LDO regulator will

supply power to the Evaluation

Board.

Regulator Off. When USB is connected, the LDO

regulator will not supply power.

4

Regulator 3.6V. When USB is

connected, the LDO regulator will

output 3.6V. With the reverse

protection diode, 3.3V is applied to

the R41Z.

Regulator 1.8V. When USB is connected, the

LDO regulator will output 1.8V. With the reverse

protection diode, 1.5V is applied to the R41Z.

Useful for using Boost mode.

Table 3 – Power Configuration Switch Options

R41Z-EVAL User Guide Rev 2.0

13

6.1.3 DC-DC Mode Selection

For details regarding the electrical connections required to implement each power mode, please

reference the R41Z Evaluation Board Schematic and R41Z Module Data Sheet. These documents are

available online at the Rigado website.

Switching between Bypass Mode and Buck mode can easily be accomplished using the Power

Configuration Switch. To use Boost Mode there are other changes that must be made via the Power

Configuration Jumpers, summarized below.

Figure 18 – Power Configuration Jumpers (Default)

The 4 jumpers used to switch between Buck and Boost DC-DC modes are labeled JMODE, JLP, J1P5,

and J1P8. See the figures below for how to set these jumpers along with the correct Power

Configuration Switch positions.

DC-DC Mode Selection

Mode

PWR Config SW

JMODE

JLP

J1P5

J1P8

Bypass

Pos. 1: Bypass

(Default)

Pos. 2: OFF (Default)

Pos. 4: REG 3.6V

Buck

(Default)

Open

(Default)

Closed

(Default)

Closed

(Default)

Buck

Pos. 1: DC-DC EN

Pos. 2: Off or On*

Pos. 4: REG 3.6V

Buck

(Default)

Open

(Default)

Closed

(Default)

Closed

(Default)

Boost

Pos. 1: DC-DC EN

Pos. 2: On

Pos. 4: REG 1.8V

Boost

Closed

Open

Open

*Note: See Error! Reference source not found. for using PSWITCH in Buck mode

Table 4 – DC-DC Mode Selection

R41Z-EVAL User Guide Rev 2.0

14

Figure 19 below shows the Power Configuration Jumpers in Boost mode with solder jumpers across

JMODE and JLP. JMODE features a white dot, highlighted by a red circle below, to indicate the default

bridged connection. Do not bridge all three pads of jumper JMODE.

Figure 19 – Power Configuration Jumpers (Boost Mode)

6.1.4 Measuring Power Consumption

When operating the R41Z Evaluation Board in DC-DC power mode, the board power source (LDO

regulator, coin cell, or external power) directly powers both the R41Z module but also all onboard

peripheral devices and provides expansion shield power. However, when operating in either Buck or

Boost DC-DC Mode, the R41Z module supplies regulated power to the peripheral devices and shield.

This makes it difficult to directly measure the power consumption of just the R41Z module. The

Evaluation Board features two current measurement headers that allow direct measurement of total

current and peripheral current. The current consumption of only the R41Z Module can be indirectly

measured by subtracting the peripheral current from the system current reading.

Figure 20 – Schematic: Current Measurement Headers

R41Z-EVAL User Guide Rev 2.0

15

6.2 Debug Interface

The R41Z Evaluation Board features an OpenSDA 2.1 interface which includes a SWD connection and

virtual COM port for easy programming and debugging of the R41Z module.

6.2.1 OpenSDA Interface

The OpenSDA hardware is separated from the R41Z target by a set of level shifters to ensure that

debugging can be done regardless of the DC-DC mode used. The interface will operate in a similar

manner to other evaluation boards that use OpenSDA. When connected to a host computer, the

Evaluation board will appear as a mass storage device named “FRDM-KW41Z”. Binary files can be

directly copied to this drive to load them to the R41Z target.

The R41Z Evaluation Board ships with a Segger debug application loaded but other OpenSDA 2.1

applications may be used. To load a new OpenSDA application, apply power to the board while

holding the reset button. The Evaluation Board will appear as mass storage device named

“Maintenance” onto which the OpenSDA application binary can be copied.

6.2.2 Reset Button

The reset button is primarily meant to be used to reset the R41Z module. It is also used to put the

OpenSDA interface into “Maintenance” mode to allow for different Debug Applications to be loaded.

The reset pin on the R41Z module and the OpenSDA I/O are both connected to the reset button and

isolated from each other by diodes. Unlike the standard OpenSDA implementation, a header is not

needed to select which device the reset button is connected to.

When power is initially applied, the OpenSDA interface momentarily ignores any reset signal asserted

by the R41Z in order to sample the state of the reset button. This is done by setting the reset line level

shifter between the OpenSDA interface and the R41Z to a high impedance state.

Figure 21 – Schematic: Reset Button

6.2.3 External Debug Header

R41Z-EVAL User Guide Rev 2.0

16

In addition to the onboard OpenSDA interface, the R41Z Evaluation Board supports the use of external

debuggers. A standard 10-pin SWD/JTAG header is provided with the following pinout to the target

R41Z module:

0

Pin

Usage

1

V1P8 (R41Z I/O

voltage)

2

SWDIO

3

GND

4

SWCLK

5

GND

6

N/C 7 N/C 8 N/C

9

GND

10

RESET_n

Table 5 – External Debugger Header Pinout

R41Z-EVAL User Guide Rev 2.0

17

6.3 Peripherals

The R41Z Evaluation Board includes a set of onboard peripherals and a set of Arduino style headers

that allow for additional peripherals of the user’s choice to be added in the form of expansion shields.

These headers share I/O connections to the R41Z module with the existing onboard peripherals. If an

on-board peripheral will interfere with the operation of a shield, jumpers can be used to disconnect

the on-board device.

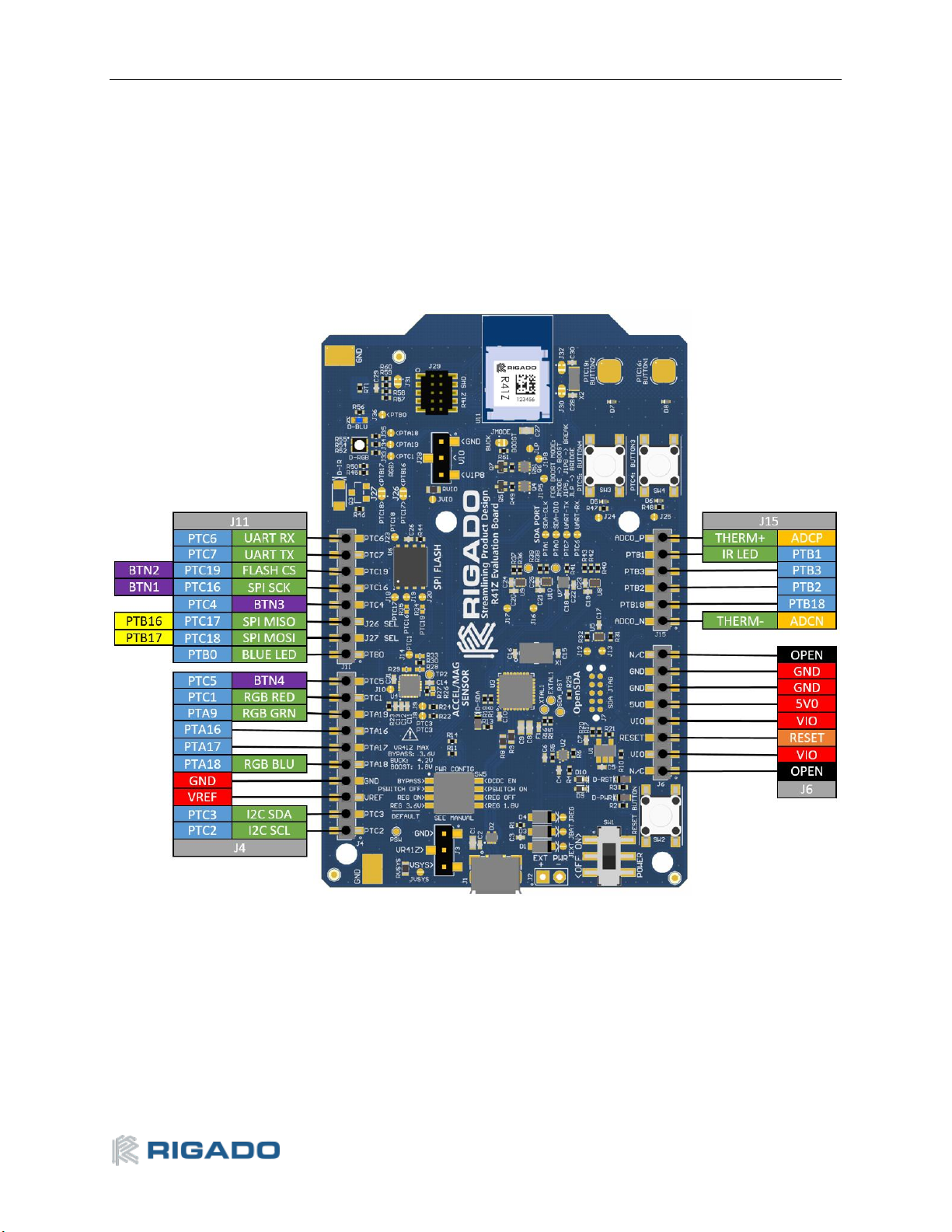

6.3.1 Expansion Headers

Figure 22 – Expansion Header Pinout

R41Z-EVAL User Guide Rev 2.0

18

6.3.2 IR LED Provision

An unpopulated position for an IR LED and driver transistor are provided on the Evaluation board. If IR

is part the application under development, these parts can be populated by the end user. The IR LED

footprint is intended for a right angle, SMT 3317 package. The drive transistor footprint is intended for

an SOT-23 NPN BJT. Resistor R45 is not provided on the board to avoid pulling down PTB1.

Figure 23 – Schematic: IR LED

6.3.3 User LEDs

The R41Z Evaluation Board features an RGB LED and a separate blue LED. Since the GPIO used are

shared with the expansion header, solder jumpers are provided to disconnect the LEDs if required.

Since the LEDs are powered from the peripheral power bus “VIO”, they will be powered directly by the

R41Z module when it is operating in either Buck or Boost DC-DC mode. This may affect LED visibility at

low output voltages.

Figure 24 – Schematic: User LEDs

R41Z-EVAL User Guide Rev 2.0

19

6.3.4 Thermistor

A thermistor circuit is provided to demonstrate the analog capabilities of the R41Z module and to aid

development of applications requiring temperature measurement.

Figure 25 – Schematic: Thermistor and ADC Mode Selection

6.3.5 User Buttons

Two mechanical buttons (SW3, SW4) and two capacitive touch buttons (SW2, SW5) are provided on

the Evaluation Board. The Capacitive touch buttons enable easy development of applications that

make use of the R41Z’s Touch Sense Input (TSI) module.

Figure 26 – Schematic: User Buttons

R41Z-EVAL User Guide Rev 2.0

20

6.3.6 SPI Flash

To assist development of applications requiring external storage, a 4Mbit flash module is provided

(Adesto Tech. AT45DB041E-MHN2B-T). The flash uses an SPI interface with signals shared with the

expansion headers. When using multiple Chip Select (CS) signals, this allows the same SPI bus to be

used with both the Flash module and one or more SPI devices on an expansion shield. However, some

signals are also shared with the TSI user buttons.

SPI Flash

Signal

R41Z I/O

SPI CLK

PTC16

SPI MOSI

PTC17

SPI MISO

PTC18

Flash

CS_n

PTC19

Table 6 – SPI Port Signals

Figure 27 – Schematic: SPI Flash

R41Z-EVAL User Guide Rev 2.0

21

6.3.7 I

2

C Acceleration/Magnetometer Sensor

For development of applications that require orientation and movement tracking, a combined

accelerometer and magnetometer is provided (NXP FXOS8700CQR1). The sensor can support either

SPI or I2C interfaces but is used exclusively with the I2C interface on the R41Z Evaluation Board. When

in I2C mode, the address of the sensor can be set using external pull-up and pull-down resistors. The

signals used for the I2C bus are shared with the expansion headers. Because of the addressed nature of

I2C it is possible to use this same bus to connect to additional devices on a shield.

Combo Sensor Address

Address

SA1

SA0

0x1C

1

0

0x1D

0

1

0x1E

0

0

0x1F

(Default)

1

1

Table 7 – Combo Sensor Addresses

I2C Sensor

Signal

R41Z I/O

Interrupt

PTC1

SCLK

PTC2

SDA

PTC3

Table 8 – I2C Sensor Signals

Figure 28 – Schematic: I2C Combo Sensor

R41Z-EVAL User Guide Rev 2.0

22

6.4 R41Z Module

For details on the R41Z module, see the Rigado R41Z Data Sheet (rigado.com/r41z). The R41Z

module is an industry leading Bluetooth and Thread pre-certified (pending) module with a wide range

of potential applications.

6.4.1 32.768kHz Oscillator

For RTC and to maintain high accuracy Bluetooth time keeping in low power modes, an external

32.768kHz crystal oscillator is provided. Some applications may not require this external oscillator in

which case a set of jumpers can be used to connect these I/O to the expansion headers. The R41Z

module features programmable capacitors which can be used in place of external capacitors.

However, external capacitors are provided on the R41Z Evaluation Board to simplify firmware

development.

Figure 29 – Schematic: 32kHz Oscillator

R41Z-EVAL User Guide Rev 2.0

23

Related Documents

Rigado Documents:

• R41Z Module Product Brief

• R41Z Module Data Sheet

• Evaluation Kit Regulator Information

NXP Documents:

• KW41Z Fact Sheet

• NXP BLE Mobile Toolbox

• KW41Z Data Sheet

• KW41Z Reference Manual

• KW41Z Errata

Life Support and other High-Risk Use Warning

This product is not designed nor intended for use in a life support device or system, nor for use in

other fault-intolerant, hazardous or other environments requiring fail-safe performance, such as any

application in which the failure or malfunction of the product could lead directly or indirectly to

death, bodily injury, or physical or property damage (collectively, “High-Risk Environments”). RIGADO

EXPRESSLY DISCLAIMS ANY EXPRESS OR IMPLIED WARRANTY OF FITNESS FOR USE IN HIGH-RISK

ENVIRONMENTS. The customer using this product in a High-Risk Environment agrees to indemnify and

defend Rigado from and against any claims and damages arising out of such use.

Environmental

9.1 RoHS

Rigado’s modules are in compliance with Directive 2011/65/EU, 2015/863/EU of the European

Parliament and the Council on the restriction of the use of certain hazardous substances in electrical

and electronic equipment. The declaration may be found here: https://go.rigado.com/RoHS-Modules

9.2 REACH

Rigado’s modules listed below do not contain the 191 SVHC (Substance of Very High Concern), as

defined by Directive EC/1907/2006 Article according to REACH Annex XVII. The compliance statement

may be found here: https://go.rigado.com/REACH-Modules

9.3 California Proposition 65 (P65)

This product can expose you to Nickel (metallic), which is known to the State of California to cause

cancer. For more information go to www.P65Warnings.ca.gov.

R41Z-EVAL User Guide Rev 2.0

24

Contact Information

Headquarters

Rigado Inc.

3950 Fairview Industrial Drive SE, Suite 100

Salem, Oregon 97302

Portland

Rigado Inc.

101 SW Main Street, Suite 2000

Portland, Oregon 97204

Tel: +1 971 208 9870

Fax: +1 971 208 9869

Sales: https://www.rigado.com/contact/

modules@rigado.com

Support: https://rigado.zendesk.com/hc

support@rigado.com

R41Z-EVAL User Guide Rev 2.0

25

List of Tables

Table 1 – Useful Tools .................................................................................................................................. 1

Table 2 – R41Z Power Modes ..................................................................................................................... 11

Table 3 – Power Configuration Switch Options ........................................................................................ 12

Table 4 – DC-DC Mode Selection ................................................................................................................ 13

Table 5 – External Debugger Header Pinout ............................................................................................. 16

Table 6 – SPI Port Signals ........................................................................................................................... 20

Table 7 – Combo Sensor Addresses ........................................................................................................... 21

Table 8 – I2C Sensor Signals ...................................................................................................................... 21

Table 9 – Document History ....................................................................................................................... 26

List of Figures

Figure 1 – R41Z Evaluation Board (Top View) ............................................................................................. 2

Figure 2 – SDK installation ........................................................................................................................... 2

Figure 3 – Import example ........................................................................................................................... 3

Figure 4 – Select board ................................................................................................................................. 3

Figure 5 – Select Bluetooth Beacon example .............................................................................................. 4

Figure 6 – Example source code .................................................................................................................. 4

Figure 7 – Build the example ........................................................................................................................ 5

Figure 8 – Start debugging ........................................................................................................................... 5

Figure 9 – Debug probe selection ................................................................................................................ 5

Figure 10 – OpenSDA Terms of Use ............................................................................................................. 6

Figure 11 – Run the example ........................................................................................................................ 6

Figure 12 – Flashing LED .............................................................................................................................. 6

Figure 13 – NXP IoT Toolbox mobile app ..................................................................................................... 7

Figure 14 – Advertising Beacon .................................................................................................................... 7

Figure 15 – Evaluation Board Layout ........................................................................................................... 9

Figure 16 – Schematic: Power Supply ....................................................................................................... 10

Figure 17 – Power Configuration Switch ................................................................................................... 12

Figure 18 – Power Configuration Jumpers (Default) ................................................................................ 13

Figure 19 – Power Configuration Jumpers (Boost Mode) ......................................................................... 14

Figure 20 – Schematic: Current Measurement Headers ........................................................................... 14

Figure 21 – Schematic: Reset Button ......................................................................................................... 15

Figure 22 – Expansion Header Pinout ........................................................................................................ 17

Figure 23 – Schematic: IR LED .................................................................................................................... 18

Figure 24 – Schematic: User LEDs .............................................................................................................. 18

Figure 25 – Schematic: Thermistor and ADC Mode Selection .................................................................. 19

Figure 26 – Schematic: User Buttons ......................................................................................................... 19

Figure 27 – Schematic: SPI Flash ............................................................................................................... 20

Figure 28 – Schematic: I2C Combo Sensor ................................................................................................ 21

Figure 29 – Schematic: 32kHz Oscillator ................................................................................................... 22

R41Z-EVAL User Guide Rev 2.0

26

Document History

Revision

Date

Changes / Notes

0.9

2016-11-09

Initial release

2.0

2019-05-09

Updated to new document format

Changed tools to MCUXpresso

Table 9 – Document History

Loading...

Loading...