Rievtech PR-6AC-R, PR-6DC-DA-R, PR-12AC-R-HMI, PR-12AC-R-E-CAP, PR-12DC-DA-R-HMI User Manual

...

Applied to ELC&PR series Ver: 3.0

Programmable Relay User's Manual

Rievtech Electronic Co.,Ltd

2

Contents

Introduction

Getting started

Installation and wiring

Programming xLogic

Configuring &software

Applications

Technical data

3

Introduction

Congratulations with your xLogic Micro PLC provided by Rievtech Electronic Co., Ltd.

The xLogic Micro PLC is a compact and expandable CPU replacing mini PLCs, multiple timers, relays and

counters.

The xLogic Micro PLC perfectly fits in the space between timing relays and low-end PLCs. Each CPU

incorporates not only a real-time clock and calendar, but also provides support for optional expansion I/O

modules to enhance control and monitoring applications. Data adjustments can easily be performed via

the keypad, the LCD display, or through the Rievtech-to-use xLogic soft. DIN-rail and panel-mounted

options are both available, offering full flexibility to the various installation needs of your application.

The xLogic Micro PLC is available in 120V/240V AC or 12V and 24V DC versions, making it the ideal

solution for relay replacement, or simple control applications as building and parking lot lighting,

managing automatic lighting, access control, watering systems, pump control, ventilation systems,

home automation and a wide field of other applications demanding low cost to be a primary design issue.

We strongly recommended taking the time to read this manual, before putting the xLogic Micro PLC to

work. Installation, programming and use of the unit are detailed in this manual. The feature-rich xLogic

Micro PLC provides a for off-line operation mode, allowing full configuration and testing prior to in-field

service commissioning. In reviewing this manual you will discover many additional advantageous product

properties, it will greatly simplify and optimize the use of your xLogic Micro PLC.

Valid range of this manual

The manual applies to devices of ELC series and PR series modules . For more information about EXM

series module(GSM and WIFI module) ,please refer to the x-Messenger user's manual.

Safety Guideline

This manual contains notices you have to observe in order to ensure your personal safety, as well as to

4

prevent damage to property. The notices referring to your personal safety are highlighted in the manual

by a safety alert symbol; notices referring to property damage only have no safety alert symbol. The

notices shown below are graded according to the degree of danger.

Caution

Indicates that death or severe personal injury may result if proper precautions are

not taken

Caution

With a safety alert symbol indicates that minor personal injury can result if proper

precautions are not taken.

Caution

Without a safety alert symbol indicates that property damage can result if proper

precautions are not taken.

Attention

Indicate that an unintended result or situation can occur if the corresponding

notice is not taken into account.

If more than one degree of danger is present, the warning notice representing the highest degree of

danger will be used. A notice warning of injury to persons with a safety alert symbol may also include a

warning relating to property damage.

Qualified Personnel

The device/system may only be set up and used in conjunction with this documentation. Commissioning

and operation of a device/system may only be performed by qualified personnel. Within the context of

the safety notices in this documentation qualified persons are defined as persons who are authorized to

commission, ground and label devices, systems and circuits in accordance with established safety

practices and standards. Please read the complete operating instructions before installation and

commissioning.

Rievtech does not accept any liability for possible damage to persons, buildings or machines, which occur

due to incorrect use or from not following the details.

5

Prescribed Usage

Note the following:

Warning

This device and its components may only be used for the applications described in the catalog or the

technical description, and only in connection with devices or components from other manufacturers

which have been approved or recommended by Rievtech. Correct, reliable operation of the product

requires proper transport, storage, positioning and assembly as well as careful operation and

maintenance.

Trademarks

All names identified by xLogic are registered trademarks of the Rievtech. The remaining trademarks in

this publication may be trademarks whose use by third parties for their own purposes could violate the

rights of the owner.

Copyright Rievtech 2015 all rights reserved

The distribution and duplication of this document or the utilization and transmission of its contents are

not permitted without express written permission. Offenders will be liable for damages. All rights,

including rights created by patent grant or registration of a utility model or design, are reserved.

Disclaim of Liability

We have reviewed the contents of this publication to ensure consistency with the hardware and software

described. Since variance cannot be precluded entirely, we cannot guarantee full consistency. However,

the information in this publication is reviewed regularly and any necessary corrections are included in

subsequent editions.

Additional support

We take pride in answering your question as soon as we can:

Please consult our website at www.rievtech.com for your closest point of contact or email us at

sales@rievtech.com

6

Contents

Contents

Chapter 1 General Introduction to xLogic

1.1 Overview

1.2 Highlight feature

Chapter 2 Hardware models and resources

2.1 Naming Rules of ELC&PR Series

2.2 Hardware model selection

2.3 Structure & dimension

Chapter 3 Installing/removing xLogic

3.1 DIN rail mounting

3.2 Wall-mounting

3.3 wiring xLogic

Chapter 4 Parameters modification HMI operation

4.1 Overview of xLogic menu

4.2 LCD panel instruction

4.3 Select function page

Chapter 5 Configuring & Programming software

5.1 xLogic Functions

5.2 General Input & Output functions

5.3 Basic functions list – GF

...........................................................................................................................................................................................

........................................................................................................................

...............................................................................................................................................................................

................................................................................................................................................................

....................................................................................................................

..................................................................................................................................

..............................................................................................................................................

.....................................................................................................................................................

...............................................................................................................................

..............................................................................................................................................................

.....................................................................................................................................................................

........................................................................................................................................................................

3.4.1 Connecting the power supply

3.4.2 Connecting xLogic inputs

3.4.3 Connecting xLogic Outputs

3.4.4 Communication port instructions:

...............................................................................................................................................

.......................................................................................................................................................

.........................................................................................................................................................

4.3.1 How to switch Run/Stop

4.3.2 Set parameter

4.3.3 Set password

4.3.4 How to set address of CPU and expansion module

4.3.5 Set LCD (backlight and Contrast)

4.3.6 Set communication parameters

4.3.7 Modification of System Time

5.2.1 Inputs

5.2.2 Cursor keys

5.2.3 Outputs

5.2.4 Permanent logical levels HI and LO

5.2.5 Panel Key

5.2.6 Shift register bits

5.2.7 Analog inputs

5.2.8 F (digital flag)

5.2.9 AF (Analog flag)

5.3.1 AND

5.3.2 AND with edge evaluation

.........................................................................................................................................................................

.............................................................................................................................................................................

.........................................................................................................................................................

...........................................................................................................................................................

.................................................................................................................................................................

..............................................................................................................................................................

......................................................................................................................................................................

..................................................................................................................................................................

...................................................................................................................................................

...........................................................................................................................................................

..........................................................................................................................................................

......................................................................................................................................................

..................................................................................................................................................

............................................................................................................................

....................................................................................................................................

................................................................................................................................

...................................................................................................................

......................................................................................................................................

....................................................................................................................

.......................................................................................................................

.............................................................................................................................

..........................................................................................................

...............................................................................................................................

................................................................................................................

..................................................................................................................................

..................................................................................................

..................................................................................

6

11

11

11

16

16

17

19

23

24

25

28

28

29

33

35

38

38

39

42

44

44

47

51

54

56

58

60

61

61

61

62

62

63

63

64

64

65

66

66

67

68

7

5.3.3 NAND

5.3.4 NAND with edge evaluation

5.3.5 OR

5.3.6 NOR

5.3.7 XOR

5.3.8 NOT

5.3.9 Boolean Function

5.4 Basics on special functions

5.4.1 Designation of the inputs

5.4.2 Time response

5.4.3 Backup of the real-time clock

6.4.4 Retentivity

5.4.5 Parameter protection

5.4.6 Calculating the gain and offset of analog values

5.5 Special functions list – SF

5.5.1 On-delay

5.5.2 Off-delay

5.5.3 On-/Off-delay

5.5.4 Retentive on-delay

5.5.5 Wiping relay (pulse output)

5.5.6 Edge triggered wiping relay

5.5.7 Asynchronous pulse generator

5.5.8 Random generator

5.5.9 Stairway lighting switch

5.5.10 Multiple function switch

5.5.11 Weekly timer

5.5.12 Yearly timer

5.5.13 Up/Down counter

5.5.14 Hours counter

5.5.15 Threshold trigger

5.5.16 Latching relay

5.5.17 Pulse relay

5.5.18 Message text

5.5.18.1 How to change parameters of blocks in displayed message ?

5.5.19 Softkey

5.5.20 Shift register

5.5.21 Analog comparator

5.5.22 Analog threshold trigger

5.5.23 Analog amplifier

5.5.24 Analog value monitoring

5.5.25 Analog differential trigger

5.5.26 Analog multiplexer

5.5.27 System cover

5.5.28 Pulse Width Modulator (PWM)

..........................................................................................................................................................................

...............................................................................................................................

................................................................................................................................................................................

.............................................................................................................................................................................

.............................................................................................................................................................................

..............................................................................................................................................................................

....................................................................................................................................................

.............................................................................................................................................

....................................................................................................................................

.........................................................................................................................................................

...........................................................................................................................

.................................................................................................................................................................

............................................................................................................................................

...............................................................................................................................................

....................................................................................................................................................................

....................................................................................................................................................................

..........................................................................................................................................................

................................................................................................................................................

...............................................................................................................................

...............................................................................................................................

.........................................................................................................................

.................................................................................................................................................

......................................................................................................................................

....................................................................................................................................

.........................................................................................................................................................

.........................................................................................................................................................

..............................................................................................................................................

.....................................................................................................................................................

..............................................................................................................................................

.....................................................................................................................................................

...........................................................................................................................................................

.......................................................................................................................................................

..................................................................................................................................................................

.......................................................................................................................................................

...........................................................................................................................................

................................................................................................................................

................................................................................................................................................

................................................................................................................................

..............................................................................................................................

...........................................................................................................................................

......................................................................................................................................................

.....................................................................................................................

......................................................................................

............................................

69

70

71

72

72

73

74

75

75

76

76

77

77

77

79

83

85

86

87

89

90

91

92

94

96

97

102

107

109

111

113

114

115

124

125

127

129

132

134

135

137

139

141

142

8

5.5.29 Analog Ramp

5.5.30 Analog Math

5.5.31 Analog math error detection

5.5.32 Modbus Read

5.5.33 Modbus Write

5.5.34 Modbus read write

5.5.35 Data latching relay

5.5.36 PI controller

5.5.37 Memory write

5.5.38 Memory Read

5.5.39 Word to Bit

5.5.40 Bit to Word

5.5.41 Stopwatch

5.5.42 Analog filter

5.5.43 Max/Min

5.5.44 Average value

5.5.45 Device Reset

5.5.46 Comport Status

5.5.47 Astronomical clock

5.5.48 Cam Control

5.5.49 Angular Cam Timer

5.5.50 Pumps Management

5.5.51 Defrost

5.5.52 Comparison of 2 values

5.5.53 Multicompare

5.5.54 Compare in zone

5.5.55 Conversion Word bits

5.5.56 Conversion bits Word

5.5.57 Demultiplexer

5.5.58 Multiplexing

5.5.59 Multiplexer

5.5.60 Square Boot

5.5.61 Sin Cos

5.5.62 Absolute Humidity

5.6 xLogicsoft

5.7 Main Functions

5.8 Operation Instructions

5.8.1 Menu Bar

...........................................................................................................................................................................

5.8.1.1 File

5.8.1.2 Edit

5.8.1.3 Tools

5.8.1.4 SMS

5.8.1.5 View

5.8.1.6 Help

......................................................................................................................................................

........................................................................................................................................................

......................................................................................................................................................

......................................................................................................................................................

.........................................................................................................................................................

.....................................................................................................................................................

......................................................................................................................................................

..........................................................................................................................................................

..........................................................................................................................................................

............................................................................................................................................................

.........................................................................................................................................................

................................................................................................................................................................

.....................................................................................................................................................

.......................................................................................................................................................

.................................................................................................................................................

........................................................................................................................................................

..................................................................................................................................................................

......................................................................................................................................................

...............................................................................................................................................

.....................................................................................................................................................

.........................................................................................................................................................

...........................................................................................................................................................

........................................................................................................................................................

..................................................................................................................................................................

..................................................................................................................................................................

...................................................................................................................................................

.................................................................................................................................................................

.................................................................................................................................................................

................................................................................................................................................................

..............................................................................................................................................................

...............................................................................................................................................................

..............................................................................................................................................................

...............................................................................................................................................................

........................................................................................................................

............................................................................................................................................

...........................................................................................................................................

............................................................................................................................................

..........................................................................................................................................

........................................................................................................................................

..................................................................................................................................

......................................................................................................................................

......................................................................................................................................

............................................................................................................................................

145

147

149

151

157

161

167

169

180

184

187

189

190

192

193

196

197

199

202

204

205

206

208

209

210

211

212

213

213

214

215

216

216

217

218

224

224

225

225

226

226

227

228

228

9

5.8.2 Toolbar

5.8.3 Programming Toolbar

5.8.4 Simulation Tool and status window

5.9 Basic Operation

5.9.1 Open File

5.9.1.1 Open New File

5.9.1.2 Open Existed Document

5.9.2 Edit Function Diagram Program

5.9.2.1 Place Function Block

5.9.2.2 Edit Property of Function Block

5.9.2.3 Setup link

5.9.2.4 Delete Function Block or Delete Link

5.9.2.5 Change block index

5.10 Simulation Running

5.11 Save and Print

5.12 Modify Password and transfer the Program

5.13 On-line monitoring/test circuit program

Chapter 6 How to configure the Ethernet CPU ?

6.1 How to separate the new version and old version?

6.2 How to Configure the Network parameters through program software?

6.3 How to view and configure the Ethernet parameters through LCD panel?

6.4 How to create the communication between the CPU and PC through Ethernet?

6.4.1 CPU works as TCP server

6.4.2 CPU works as TCP Client

6.4.2 CPU works as UDP Server

6.5 How to log on the built-in Web server

6.5.1 How to enable the webserver?

6.5.2 How to log on the webserver?

6.6 How to establish the communication between new Ethernet CPUs?

6.6.1 Example1: One master CPU(TCP server) connect with 3 slave CPUs(TCP Clients)

6.6.2 Example2: One master CPU(TCP Client) connect with 3 slave CPUs(TCP Servers)

6.6.3 Example3: One master CPU(UDP Server) connect with 3 slave CPUs(UDP clients)

6.6.4 Example4: One master CPU(UDP Client) connect with 3 slave CPUs(UDP Servers)

6.7 Configuration with DeviceManager

6.8 Establish communication between CPU and xLogicSoft/SCADA via Ethernet.

6.9 How to establish the communication among CPUs via Ethernet ?

Chapter 7 Applications

7.1 Dual-function switch

7.1.1 Standard solution

7.1.2 The scheme of xLogic

7.2 Automatic gate

7.2.1 Standard solution

7.2.2 The scheme of xLogic

7.3 Ventilation system

.....................................................................................................................................................................

.........................................................................................................................................

..............................................................................................................

................................................................................................................................................................

.................................................................................................................................................................

...........................................................................................................................................

.......................................................................................................................

....................................................................................................................

...............................................................................................................................

..........................................................................................................

...................................................................................................................................................

...............................................................................................

................................................................................................................................

......................................................................................................................................................

................................................................................................................................................................

.......................................................................................................

..............................................................................................................

........................................................................................................

...................................................................................

.........................................................................................................................

..........................................................................................................................

........................................................................................................................

............................................................................................................

...............................................................................................................

...............................................................................................................

..................................................

...................................................................................................................

......................................................

..........................................................................................................................................................

......................................................................................................................................................

...............................................................................................................................................

........................................................................................................................................

.................................................................................................................................................................

................................................................................................................................................

........................................................................................................................................

...........................................................................................................................................................

..........................................

......................................

..........................

.......

.......

......

.....

.............................

228

229

230

233

233

233

235

236

236

236

237

239

240

240

242

243

245

251

251

252

257

261

261

265

270

271

272

273

281

282

289

297

303

311

321

323

335

335

335

337

338

339

340

342

10

7.3.1 Standard solution

7.3.2 The scheme of xLogic

7.4 Factory door

7.4.1 Standard solution

7.4.2 The scheme of xLogic

7.5 Daylight lamp system

7.5.1 Standard solution

7.5.2 The scheme of xLogic

7.6 Rainwater pump

7.6.1 Standard solution

7.6.2 The scheme of xLogic

Chapter 8 Modbus function code and Register addresses

8.1 xLogic modbus function code

8.2 Register addresses of xLogic

Appendix

A Technical data

A.3 Switching capacity and service life of the relay outputs

......................................................................................................................................................................

.....................................................................................................................................................................................

.......................................................................................................................................................................

................................................................................................................................................

........................................................................................................................................

................................................................................................................................................

........................................................................................................................................

....................................................................................................................................................

................................................................................................................................................

........................................................................................................................................

...............................................................................................................................................................

................................................................................................................................................

........................................................................................................................................

......................................................................................

....................................................................................................................................

......................................................................................................................................

.................................................................................

342

343

345

345

346

348

349

349

351

352

353

354

354

355

364

364

390

11

Chapter 1 General Introduction to xLogic

4-lines, 16-characters per line, backlight display.

Multiple value display and input via keypad and LCD display.

70 kinds of function Blocks can be used in a circuit program in maximum

1.1 Overview

xLogic is a universal logic module made by Rievtech.

xLogic , a compact, expandable CPU that can replace mini PLC, multiple timers, relays and counters,

Splitting the difference between a timing relay and a low-end PLC, Each CPU has a real-time clock and

calendar, and supports optional expansion I/O modules to enhance your control and monitoring

applications . Data adjustments can be done via the on-board keypad and LCD display, or with xLogicsoft.

It can be either DIN-rail or panel mounted, depending upon the needs of your application, and it is

available in 120V/240V ac as well as 12V and 24V dc versions, and it is the ideal solution for relay

replacement applications, simple control applications such as building and parking lot lighting, managing

automatic lighting, access control, watering systems, pump control, or ventilation systems in factory, and

home automation and applications in which cost is a primary design issue.

1.2 Highlight feature

12

Standard Modbus RTU/ASCII/TCP communication protocol supported.

It’s optional for xLogic to act as slave or master in certain Modbus communication network.

(easy connect to other factory touch screen by RS232 cable, RS485 module)

CAN BUS protocol based expansion modules(PR-18/PR-24 series CPU)

Expandable up to 16 linked IO expansion modules reaching 282 I/O points in maximum

Optional RS232, RS485 and Ethernet connectivity

Multiple channels analog inputs available with DC 0-10V signal ,PT100 signal& 0/4….20mA.

Default Real Time Clock (RTC) and summer/winter timer is available

Backup at Real Time Clock (RTC) at 25 °C:20 days

4 channels high-speed counting

Pre-configured standard functions, e.g. on/ off-delays, pulse relay and softkey

2 PWM channels(10KHz in maximum)

Retentive memory capability (Not applied to PR-6&PR-12-E series CPU)

RS232 and USB communication download cable with photo-electricity isolation

Programmable capability up to 1024 function blocks(PR-18/PR-24);512 function

Mounting via modular 35mm DIN rail or screw fixed mounting plate

On-line monitor capability(Free charge SCADA for all series xlogic)

Datalogging

Kinds of analog signals process capacity (DC 0..10V ,0/4...20mA and PT100 probe inputs and DC

Low cost

blocks(PR-12&ELC-12-N) and 64 function blocks for PR-6&PR-12-E

0..10V and 0/4...20mA outputs)

Some of the things xLogic can do for you?

The xLogic Micro PLC provides solutions for commercial, industrial, building and

domestic applications such as lighting, pumping, ventilation, shutter operations or

in switching cabinets. The application field is widespread and these are just a few to mention.

Using the RS485 bus and Ethernet connectivity allows the user to realize various extensive (real-time)

monitoring and control applications.

Special versions without operator panel and display unit are available for series production applications

in small machine, installation and cabinet building environments to further slash cost.

xLogic devices:

xLogic Basic is available in two voltage classes:

*Classes 1:DC12-24V: i.e.: PR-6DC Series, PR-12DC series, PR-18 series, PR-24DC series.

13

*Classes2: AC110-240V: i.e.: PR-6AC Series, PR-12AC series, PR-18AC series , PR-24AC series.

xLogic:RS232 communication cable (Model:ELC-RS232)

xLogic: USB communication cable (Model: ELC-USB).

xLogic: PRO-RS485 cable (Model: PRO-RS485).

xLogic: RS485 module(Model:PR-RS485)

In the versions:

* With Display: with “-HMI” model, such as PR-12DC-DA-R-HMI

* Without Display: PR-6 series and with “-CAP” model, such as PR-12DC-DA-R-CAP. Only PR-12 has -CAP

version. PR-18,PR-24 all have display in default.

.

Expansion modules:

PR-E (applied to PR-18/PR-24 CPU)

* xLogic digital modules are available for operation with 12…24V DC, and 110.. .240 V AC, and are

equipped with eight inputs and eight outputs.

* xLogic analog modules are available for operation with 12…24 V DC and are equipped with six digital

and 4 analog inputs.

Communication cable and module:

It is kind of universal cable with photoelectricity isolation which can be directly connected to standard

9-pin port of PC, also kind of interface module which can enable user’s program to be downloaded into

xLogic CPU through xLogicsoft for running. It also is the connection cable between CPU and third party

device with the RS232 port(just like HMI) in modbus communication system.

It is kind of communication cable with photoelectricity isolation through which PC with USB port only can

be connected to xLogic main module, moreover, it has same features as ELC-RS232 module, so it is

quite convenient for user whose computer has no standard serial port.

It is kind of converter cable with photoelectricity isolation to make the program port serves as RS485

port.

isolated 485 converter,used to bring out the terminals of RS485 port built-in PR-18,PR-24 series CPU for

connection with third party devices.

Communication / Network

14

xLogic offers different ways to communicate within the system.

RS485 port

The RS485 port is used for communication between the CPU and various devices or equipments which

have the standard RS485 port. Communicate using Modbus RTU/ASCII protocol.

Note:PR-RS485 module is required to connect the CPU to RS485 BUS.

RS232 or USB port (ELC-ES232/ ELC-USB needed)

If there is no network required and only one main module with some expansion modules is needed for the

application, the down- and upload of the project to and from the main module happens over the standard

RS232 or USB port. It allows system maintenance like monitoring too.

Note:PR-E-RS485 module is required to connect the CPU to RS485 BUS.

Ethernet network

If the application requires a system where more than one main module is needed and these main

modules have to communicate, each Ethernet CPU will be connected directly to the Ethernet by the

built-in LAN port. The project down- and upload to and from the main modules and the communication

between the CPU happens over the Ethernet network. Furthermore the our free of charge SCADA can be

also established connection with Ethernet CPU

15

Note

Digital inputs I1 to I4(PR-6), I1 to I8(PR-12), I1 to IC(ELC-18),I1 to IE(PR-24). I11-I18(Expansion

Analog inputs I1 to I6(PR-18/PR-24), I1 to I4(PR-12), I11 to I14(PR-E expansion with address

Digital outputs Q1 to Q6(PR-18), Q1 to Q4(PR-12),Q1 to QA(PR-24);Q11 to Q18((PR-E expansion

Digital flag blocks F1-F32(PR-6,PR-12-E), F1-F256(PR-12/PR-18/PR-24) ;

-F8 : Startup flag

-F64: Backlight control bit(to control the backlight of LCD and backlight of ELC-43TS)

-F63: Buzzer of ELC-43TS control bit

Analog flag blocks AF1 to AF256(PR-12/PR-18/PR-24);AF1-AF32(PR-6/PR-12-E)

Shift register bits S1 to S8

xLogic CPU may be equipped with expansion modules of the different voltage class, but expansion

module must be supplied the correct power corresponding to its type.

Each xLogic CPU provides the following connections for the creation of the circuit program, regardless of

the number of connected blocks:

with address 1)...I161--I168(Expansion with address 16)

1),....AI161 to AI164(PR-E expansion with address 16)

with address 1), Q161 to Q168(PR-E expansion with address 16)

16

Chapter 2 Hardware models and resources

2.1 Naming Rules of ELC&PR Series

1.Series name: ELC series; PR series.

2.Points of input and output

3.Supply power AC or DC

4.Digital/Analog D: digital DA: digital/analog

5.Output type R: relay T: transistor TN = “PNP” transistor; TP= “NPN” transistor

6. E: economic mode

7. N: Ethernet port built-in

Note:

The model end with “-HMI” means the CPU has LCD and panel keys on it;

The model end with “-CAP” means the CPU has no LCD on it.

Model name (expansion module ,plus with PR-18/PR-24 CPU together to use):

1.Series name

2.E: expansion module

3.Points of input and output

4.Supply power AC or DC

17

5.Digital/Analog D: digital DA: digital/analog

PR-6 Series CPU Units (None expandable)

Model

Expansion

Supply voltage

Inputs

Outputs

High-speed

count

PWM

HMI

RTC

PR-6AC-R

no

AC110~AC240V/

DC110-DC240V

4 digital

2 relays (10A)

nonono

yes

PR-6DC-DA-R

no

DC12-24V

4 digital/4(0...10V)

2 relays (10A)

nonono

yes

PR-12 Series CPU Units(None expandable)

Model

Expansio

n

Supply voltage

Inputs

Outputs

High-speed c ount

PWM

HMI

RTC

PR-12AC-R-HMI

no

AC110~AC240V

8 digital

4 relays (10A)

nonoyes

yes

PR-12AC-R-E-CAP

no

AC110~AC240V

8 digital

4 relays (10A)

nonono

yes

PR-12DC-DA-R-HMI

no

DC12-24V

4(0...10V)+4 digital

4 relays (10A)

4(I5-I8)(60KHZ)

no

yes

yes

PR-12DC-DA-R-E-CAP

no

DC12-24V

4(0...10V)+4 digital

4 relays (10A)

nonono

yes

PR-12DC-DA-TN-HMI

no

DC12-24V

4(0...10V)+4 digital

4Transistor(0.3A/

PNP)

4 (I5-I8)(60KHZ)

Yes(10KHZ)

yes

yes

PR-14 Series CPU Units(Expandable)-built-in RS485 port

Model

Expansion

Supply voltage

Inputs

Outputs

High-speed c ount

PWM

HMI

RTC

PR-14AC-R-HMI

yes

AC110~AC240V

/DC110-DC240V

10 digital

4 relays (10A)

nonoyes

yes

PR-14DC-DA-R-HMI

yes

DC12-24V

6(0...10V)/6digit

al+4 digital

4 relays (10A)

4(I7-IA)(60KHZ)

no

yes

yes

PR-18 Series CPU Units(Expandable)

Model

Expansion

Supply voltage

Inputs

Outputs

High-speed c ount

PWM

HMI

RTC

PR-18AC-R-HMI

yes

AC110~AC240V

/DC110-DC240V

12 digital

6 relays (10A)

nonoyes

yes

PR-18DC-DA-R-HMI

yes

DC12-24V

6(0...10V)/6digit

al+6 digital

6 relays (10A)

4(I9-IC)(60KHZ)

no

yes

yes

PR-18DC-DA-RT-HMI

yes

DC12-24V

6(0...10V)/6digit

al+6 digital

4 relays (10A)+

2 transistor(0.3A)

4(I9-IC)(60KHZ)

yes(10khz)

yes

yes

PR-24 Series CPU Units(Expandable)-built-in RS485 port

Model

Expansion

Supply voltage

Inputs

Outputs

High-speed

count

PWM

HMI

RTC

6.Output type R: relay TP: “NPN” transistor;TN :“PNP” transistor

2.2 Hardware model selection

18

PR-24AC-R-HMI

yes

AC110~AC240V

16 digital

10 relays (10A)

nonoyes

yes

PR-24DC-DA-R-HMI

yes

DC12-24V

6(0...10V)/6digital

+8 digital

10 relays (10A)

4(I9-IC)(60KHZ)

no

yes

yes

PR-24DC-DAI-RTA

yes

DC12-24V

2(0/4...20mA)+

4(0...10V)/4digital

+8 digital

6

relays(10A)+2Transistor(0.3

A/PNP)+1(0...10V)/(0...20m

A)

4(I9-IC)(60KHZ)

YES(10khz)

yes

yes

Expansion Modules(For PR-18,PR-24 series)

Model

Supply voltage

Inputs

Outputs

PR-E-16AC-R

AC110~

AC240V

8 digital

4 relays(10A)+4 relays(3A)

PR-E-16DC-DA-R

DC12-24V

4digital+4analog(0..10V)/digital

4 relays(10A)+4 relays(3A)

PR-E-16DC-DA-TN

DC12-24V

4digital+4analog(0..10V)/digital

8 transistors(PNP)(0.3A)

PR-E-PT100

DC12-24V

3 Channels PT100, resolution: 0.5°), temperature range : -50℃- 200℃

none

PR-E-AQ-VI

DC12-24V

none

2 Channels (DC 0…10V/0...20mA)

PR-E-AI-I

DC12-24V

4 Channels (0/4…..20 mA), Current Signal

none

PR-RS485

DC12-24V

isolated 485 converter,used to bring out the terminals of RS485 port built-in PR-18&PR-24 series CPU for connection with third

party devices.

Accessories

ELC-RS232

RS232 communication module /download cable between PC and xLogic CPU u nits

ELC-USB

USB communication module /download cable between PC and xLogic CPU units

ELC-COPIER

ELC-COPIER can be used to save user program and download program into xLogics.(including all the ELC series and EXM series PLC)

ELC-MEMORY

Real time data-logging device with a mini-SD card slot for ELC&EXM series CPUs. The history data( IO status , analog value, current value of registers)

of ELC&EXM CPU can be recorded, retrieved an d viewed via it.

PRO-RS485

Converter cable from program port to RS485 port.

ELC-BATTERY

RTC BATTERY, t he RTC c an be backup f or 20days in default, but with this battery, the RTC shall be backup for 1 year(only can be applied with PR-18

CPU).

19

2.3 Structure & dimension

1.Power supply 2. Input 3. Program port for applied to ELC-6 CPU 4.Output

1.Power supply&Input terminals 2. Program Port(can be used as RS232 port with ELC-RS232 or RS485

1. PR-6 Series CPU&EXM-E Series Extension

2. Standard PR-12 series with LCD model:

port with PRO-RS485) 3.HMI/LCD panel 4.keypad 5.Output terminals

3. Economic PR-12 series without LCD model:

20

1.Power supply&Input terminals 2. Program Port(can be used as RS232 port with ELC-RS232 or RS485

1.Power supply&Input terminals 2.HMI/LCD panel 3.keypad 4.Output terminals 5. Program

port with PRO-RS485) 3.RUN/STOP Indicator 4.Output terminals

4. PR-14 and PR-18 series model:

Port(can be used as RS232 port with ELC-RS232 or RS485 port with PRO-RS485) 6.Extension port

Dimensions of PR-14 and PR-18:

21

5. PR-24 series CPU

1. Power supply 2.Input 3. Program/RS232 port 4.HMI/LCD panel 5.keypad 6.Extension/RS485

port 7.Output

6. ELC-22 Ethernet CPU

22

1.Power supply 2.Input 3. Program/RS232 port 4.HMI/LCD panel 5.keypad 6.Extension/RS485

11. PR-E extension module:

port 7.Output 8.LAN port

1. Power supply&Input terminals 2. Connection cable between CPU and extension(Detached)

3.Extension port(left) 4. RUN/STOP indicator 5. Extension port( Right) 6. Output terminals

Dimensions of PR-E:

23

Dimensions of ELC-12-N Ethernet CPU:

EXM-E expansion module and PR-6 series CPU have a width of 48mm

PR-14,PR-18&ELC-12-N Series CPU has a width of 95mm.

PR-E expansion modules have a width of 72mm.

PR-24 Series CPU has a width of 133mm.

PR-12 Series CPU has a width of 72mm

Chapter 3 Installing/removing xLogic

Dimen si ons

The xLogic installation dimensions are compliant with DIN 43880.

xLogic can be snap-mounted to 35 mm DIN rails to EN 50022 or on the wall.

xLogic width:

24

Note

The figure below shows you an example of the installation and removal of an PR-18 CPU and one

expansion module of PR-18 CPU.

W a r n i n g

Always switch off power before you “remove” and “insert” an expansion module.

3.1 DIN rail mounting

Mounting

How to mount a xLogic module and an expansion module onto a DIN rail:

1. Hook the xLogic Basic module onto the rail.

2. Push down the lower end to snap it on. The mounting interlock at the rear must engage.

3. Hook the xLogic expansion module onto the rail

4. Slide the module towards the left until it touches the xLogic CPU.

5. Push down the lower end to snap it on. The mounting interlock at the rear must engage.

6. Remove the plastic cover in the expansion port of CPU and expansion module.

7. Plus the connector on the flat cable to CPU

Repeat the expansion module steps to mount further expansion modules.

25

Note:If you need install the expansion and CPU on different rows, you need order the longer

flat connection which is used to connected with CPU, the longest distance can

be 200meters between the CPU and the end expansion module.

Removal

To remove xLogic:

....... if you have installed only one xLogic Basic:

1. Insert a screwdriver into the eyelet at the bottom of the slide interlock and move the

latch downward.

2. Swing the xLogic Basic off the DIN rail.

....... if you have connected at least one expansion module to xLogic Basic:

1. Remove the connector on the flat cable

2. Slide the expansion module off towards the right.

3. Insert a screwdriver into the eyelet at the bottom of the slide interlock and lever it

downward.

4. Swing the expansion module off the profile rail.

Repeat steps 1 to 4 for all other expansion modules.

3.2 Wall-mounting

For wall-mounting, first slide the mounting slides on the rear side of the devices towards the outside. You

can now wall-mount xLogic by means of two mounting slides and two ØM4 screws (tightening torque 0.8

to 1.2 Nm).

26

Drilling template for wall-mounting

Before you can wall-mount xLogic, you need to drill holes using the template shown below.

All dimensions in mm

Bore hole for Ø M4 screw, tightening torque 0.8 to 1.2 Nm

1. xLogic CPU

PR-6 series:

PR-12 Series CPU

27

PR-14 and PR-18 series:

1.PR-18 CPU;2. PR-E extension

PR-24 series

28

ELC-12-N series(applied to CPU and extensions):

1 x 2.5 mm

2

2 x 1.5 mm2for each second terminal chamber

Tightening torque: 0.4.. .0.5 N/m or 3. ..4 lbs/in

3.3 wiring xLogic

Wire the xLogic using a screwdriver with a 3-mm blade.

You do not need wire ferrules for the terminals. You can use conductors with

cross-sections of up to the following thicknesses:

Note

Always cover the terminals after you have completed the i ns t al l at i on . To pr o te ct

xL o gi c a d e q u at e ly fr o m impermissible contact to live parts, local standards must

be complied with.

3.4.1 Connecting the power supply

The PR-6AC, PR-12AC,PR-18AC, PR-24AC versions of xLogic are suitable for

operation with rated voltages of 110 V AC and 240 V AC. The PR-6DC,

PR-12DC,PR-18DC, PR-24DC versions can be operated with a 12 or 24 VDC power

supply.

29

Note

1. Requirements

A power failure may cause an additional edge triggering signal.

Data of the last uninterrupted cycle are stored in xLogic

To connect xLogic to the power supply:

3.4.2 Connecting xLogic inputs

the inputs you connect sensor elements such as: momentary switches, switches, light barriers,

daylight control switches etc.

30

2.

AC Type

DC Type

Signal status 0

<40VAC

<0.03mA

<5VDC

Signal status 1

>79 VAC

Typical 0.06

>10VDC

Typical 0.3mA

Analogue input

NO

AI1-AI4(0-10V DC)(PR-6,PR-12)

Note:

1. For PR-6DC-DA-R, PR-12DC-DA ,PR-14DC-DA,

PR-18DC-DA ,PR-24DC-DA Series and versions. That can receive analog

input. They can be set to analog input or digital input as either may be

used in the program. They will be recognized as analog inputs when the

input terminal is connected with an analog function block, and they will be

recognized as switching inputs when the input terminal is not connected

with an analog function block.

2. The analog inputs require DC 0V ~ +10V voltage signals. These are

divided equally in 0.01V increments. In programming, all the block

parameters related to the analog inputs are based on the minimum

increment of 0.01V.

3. They can be recognized as switching input when the input voltage is more

than 10.0V and cannot be recognized as an analog input.

4. For the switching input off, when the switch status changes from 0 to 1,

the time of Status 1 must be greater than 50ms, and when the switch status

changes from 1 to 0, the time of Status 0 also must be greater than 50ms.

Connecting xLogic is shown as in the following figures:

* DC type digital inputs

31

* AC type digital inputs

* Analog Inputs (DC 0…10V)

*Analog inputs current Inputs (0…20mA)

32

The above figure shows how to make a four-wire current measurement.

PR-E-PT100

It can be connected with one two-wire or three-wire resistance-type thermocouple.

When two-wire technology applied, the terminals “M1+ and IC1” (this rule also shall be applied to” M2+

and IC2”, “M3+ and IC3” ) would be short connected. Such connection can not compensate

error/tolerance caused by the resistance in measurement loop. The measurement error of 1 Ω impedance

of power cord is proportional to +2.5 °C

The three-wire technology can inhibit the influence of measurement results caused by cable length

(ohmic resistance).

2-wire (short circuit M+ and Ic) 3 wire

33

3.4.3 Connecting xLogic Outputs

1. Requirement for the relay output

Various loads such as lamp, fluorescent tube, motor, contact, etc., can be connected to the outputs of

xLogic. The maximum ON output current that can be supplied by xLogic is 10A for the resistance load and

3A for the inductive load. The connection is in accordance with the following figure:

2. Requirement for the electronic transistor output:

The load connected to xLogic must have the following characteristics:

* The maximum switch current cannot exceed 0.3A.

* When the switch is ON (Q=1), the maximum current is 0.3A.

Notes (PNP):

* The load connecting voltage must be ≤60VDC and it must be DC.

* The “+” terminal of the output wiring must be connected with the DC positive

voltage, and it must be connected with the “L+” terminal of the xLogic power ,a

load must be connected with the “-” terminal of the DC negative voltage.

34

PR-E-AQ-VI(DC0..10V analog output).

EXM-E-AQ-I /PR-E-AQ-VI

PR-RS485

Actually, PR-RS485 is just a converter with photo isolation bringing out 3 wiring terminals(short circuited

inner of such 3 terminals, so only one channel RS485 bus is available) from RS485 port (2x8pin) of

CPU(PR-18/ELC-22/PR-24) for your easy connection with other devices.

35

If “RT1”, RT2” terminal are short connected, one 120R resistor will be connected between A/+ and B/-

3.4.4 Communication port instructions:

PR-6 CPUs

PR-14,PR-18 ,ELC-22 and PR-24 CPUs

36

1. Programming port/RS232 port

2. Expansion port/RS485 ( pin definition)

PIN

function

2

RXD

3

TXD

5

GND

others

NULL

(ELC-RS232 ,ELC-USB,ELC-Copier,ELC-MEMORY,ELC-BATTERY,PRO-RS485) should be inserted in this

port)

When the programming port should be used as the standard RS232 port (D-shape 9 pin header) ,the

ELC-RS232 cable needed.Blow is show you the pin definition of the header:

37

3------RS485 A

5------RS485 B

4------GND

6------GND

7------CANL

9------CANH

15------+5V

16------+5V

Communication between CPU and expansion module will use 4.7,9,15 pin.

PR-RS485 module is required when PR-18/ELC-22/PR-24 CPU communicate with the third party devices

via RS485 bus

PR-12 CPUs

With HMI model Without HMI model

1. Programming port/RS232

port(ELC-RS232 ,ELC-USB,ELC-Copier,ELC-MEMORY,ELC-BATTERY,PRO-RS485 should be inserted in this

port) Named COM0.

When the programming port should be used as the standard RS232 port (D-shape 9 pin header) ,the

ELC-RS232 cable is required.

38

Chapter 4 Parameters modification HMI operation

4.1 Overview of xLogic menu

PR-12 ,PR-14,PR-18,ELC-22,ELC-26 series CPU has same menu on the LCD, so here we show the PR-18

for example.

Parameter assignment mode

Parameter assignment menu:

39

4.2 LCD panel instruction

1. Display area: 4x16 characters can be displayed

2. 4 X Function key: operate the program by pressing down these key (Only for ELC-22-N and PR-24

3. 6x Panel key: you can modify the parameters, programming, view alarming message.

1. Display the RUN/STOP status of the CPU

2. Display or modify the Clock.

3. Display the IO status of CPU& extensions

4. Display all kinds registers value(AI/AO, Parameters of blocks etc)

5. Display multiple alarming messages

6. Modify the parameters of blocks

7. Backlight can be controlled via programming(Light on Alarm)

8. System cover message can be customized

9. Up to 64 different alarming messages is allowed.

10. The CPU address can be modified

11. Set password protection

12. Change communication parameters for COM port

PR-12 Series CPU PR-18 Series CPU ELC-22 and ELC-26 series CPU

series CPU, invalid for PR-12 and PR-18 series CPU;F1--F4 are all available on ELC-43TS)

What this operate panel can do for you?

……..

Menu shows:

40

41

After being powered on, xLogic shall self-check program stored in the CPU.

If the program is accurate, then the CPU will be running, meanwhile the system cover will show as

follows:

In xLogicsoft, this interface is defaulted as its initialization screen.

If there are several parameter pages, users can press or key to go to the page you would like.

The last page is the cursor mode:

42

Cursor keys can be controlled in this page by press arrow keys and ESC key at the same time.

If xLogic has several alarm interfaces in the same period and it only displays the message with highest

priority in the function block, also you may go through all alarm messages by pressing or key.

Note:

The message text block would be treated as parameter page only when it has no input, otherwise, it may

be regarded as alarm page. When input has high pulse, LCD shall display alarm message.

4.3 Select function page

Press ESC key to change from running mode to function page.

After pressing ESC key, xLogic would be switched to function page and meanwhile open function menu as

figure below shows.

43

Brief introduction on 5 options of function page:

Run/stop

Set Param

Set…

1. ”Press ”UP” or “DOWN” key to move the cursor to “Set….”

2. Then press OK key ,xLogic will display as follows:

Clock

Menu Language

Network(This only for Ethernet CPU)

Select this menu to switch over xLogic status between RUN and Stop. Refer to

chapter4.3.1 for details.

To set function block parameter. Refer to chapter 4.3.2 for details.

Used to set /modify password ,set address of CPU&extension , LCD settings and

communication parameters settings refer to chapter 4.3.3 and 4.3.4 for details

please.

To set and modify date and time .Refer to chapter 4.3.5 for details.

To change the language of the Menu. Refer to chapter 4.3.6 for detail

Recovery ET: when you press ok when the cursor stay on this menu, the Ethernet modem

built-in Ethernet CPU will be reset to default settings.

44

4.3.1 How to switch Run/Stop

1. Under the FUNCTION PAGE, select

You should first select FUNCTION PAGE. (Read 4.3)

1. Move the cursor to “Run/stop”: Press “UP” or “DOWN” key.

2. Move the cursor to "Yes": Press OK key.

After pressing ESC key, you’ll find out your circuit program has changed to “stop” status as figure below

shows:

4.3.2 Set parameter

If you want to select a parameter, you need do as the following procedures:

“Set parameter”: Press or key

45

2. Confirm by pressing OK key.

1. Move the cursor to the parameter to be modified: press or key.

2. Modify value: press or key.

Then xLogic displays the first parameter, so you can modify as you like. If there is no parameter to

set/modify, you can press ESC key to return.

3. Select parameter you intend to modify.

4. Select certain specific value of that parameter which you want to edit, then press OK key.

How to modify parameter?

A. First select certain parameter which you need to edit by following the below procedures:

1. Under the FUNCTION PAGE, select

“Set parameter”: Press or key

2. Confirm by pressing OK key.

B. then you can perform the below actions to modify parameter:

46

3. Confirm the value after modification: press OK key.

Note:

When xLogic is running, not only time value but also time unit(S,M,H) can be

altered , but Besides alter time parameter at RUN time ,you can alter time

base(s=second, m=minute ,h=hour).

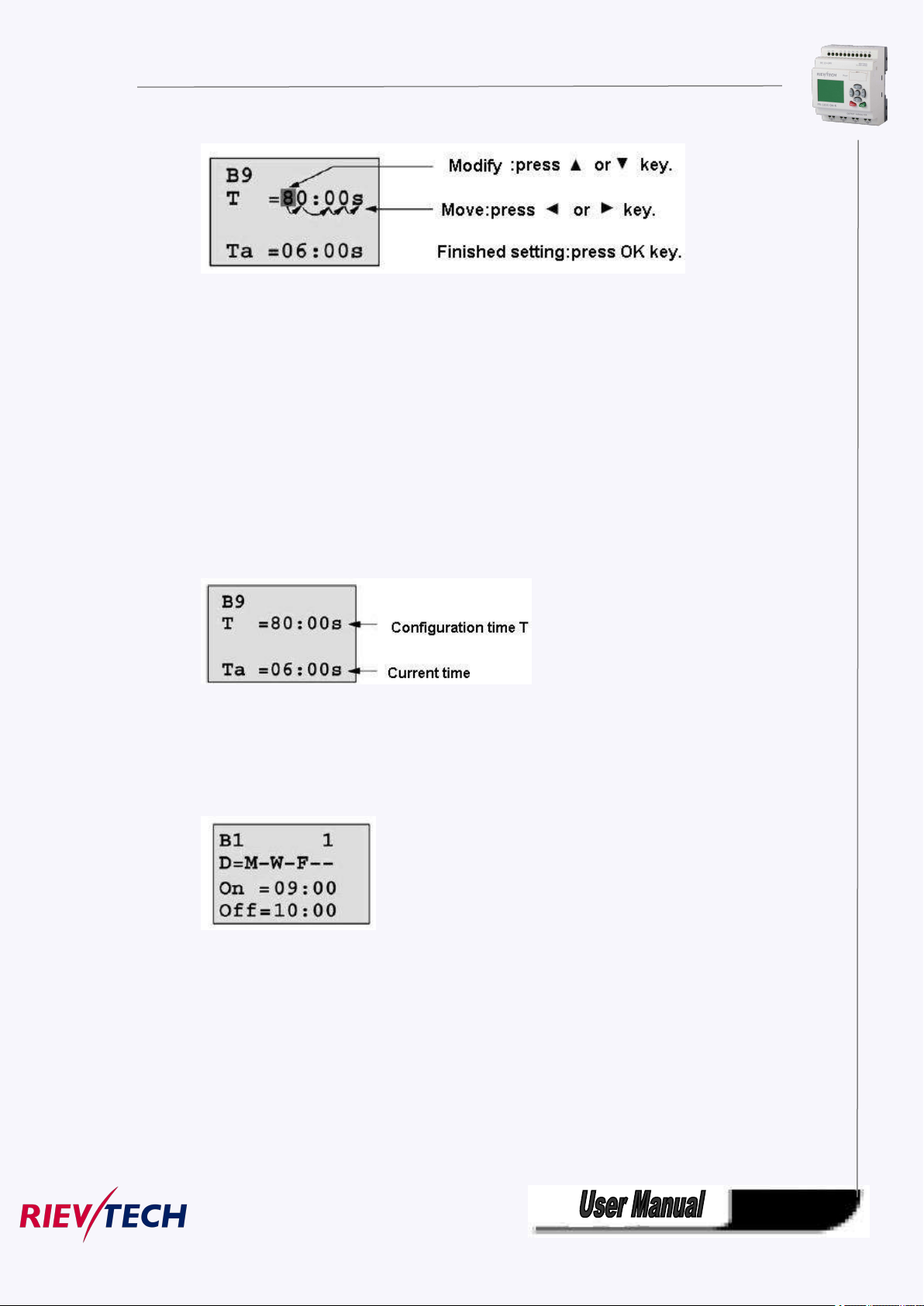

Current value of time T

View time T in parameter mode:

You are allowed to modify configuration time. Switch on/off time for a time segment.

In parameter mode, time segment figure of a timer:

You can alter the time and date of switch on/off.

Current value of counter

In parameter mode, the parameter view of a counter:

47

Current value of hour counter

In parameter mode, the view of hour counters:

You can edit configured time interval (MI).

Current value of threshold trigger

In parameter mode, the view of threshold trigger:

You can alter the threshold value of switching on /off.

4.3.3 Set password

xLogic supply password protection function for your program. You can choose according to your need.

See the following instruction; you’ll understand the method of setting password.

Set one password

48

A password contains less than or equal to 4 characters and each character is Arabian number from 0 to

9 .It is easy to specify, edit or remove the password directly on the xLogic in the “Password” menu of the

function page:

You should first select the FUNCTION PAGE. (Read 5.2)

1. Move the cursor to “Password”: Press “UP” or “DOWN” key.

2. Confirm “Password”: Press OK key.

Example: let us set “1234” as password for a program. Now the LCD displays the following interface:

Select “New” option, and then edit it.

3. Select “1”: press “UP” key once.

4. Move the cursor to the next character: press “Right” key.

5. Select “2”: press “UP” key twice.

6. Move the cursor to the next character: press “Right” key.

7. Select”3”: press “UP” key three times.

8. Move the cursor to the next character: press “Right” key.

9. Select “4”: press “UP” key four times.

Now display:

10. Confirm password: press OK key.

Now, the program is protected by the password of “1234”, and then you can return to the main menu.

Note:

You can cancel a password newly-set via ESC key. In this instance, xLogic will return to main menu and

not reserve that password. Such password is for the parameter, that means only when you operate the

menu of LCD, the password is required. The program password need be set in xlogicosoft by the menu

File->Property-> Parameter

49

Modify password:

In order to modify password, you are required to present current password.

In the menu of the FUNCTION PAGE:

1. Move the cursor to “Password”: Press “UP” or “DOWN” key.

2. Confirm “Password”: Press OK key.

Select “Old” and input primary password (in our instance is “1234”), the process is the same as the step

3 to step 10 mentioned above.

LCD displays:

Thus, you could select “New” to input new password such as “8888”:

3. Select “8”: press “UP” key.

4. Move the cursor to next character: press “Right” key.

Repeat the step 3 and 4 to realize the third and fourth character.

LCD displays:

4.Confirm new password: press OK key.

So you have set the new password and then return to main menu.

50

How to remove the password:

In case you need to remove password .e.g. allow the other users to edit your program, then you must

know the current password. The process of removing password is the same as that of modifying

password.

In the menu of the FUNCTION PAGE. :

1. Move the cursor to “Password”: Press “UP” or “DOWN” key.

2. Confirm “Password”: Press OK key.

Select “Old” and input primary password (in our instance is “8888”), the process is the same as the step

3 to step 10 mentioned above.

LCD displays as follows:

Input nothing under the “New”, and let it keep blank to clear password.

4.Confirm “blank” password: press OK key. Now you have cleared password and return to main menu. If

you want to set password next time, the LCD will display:

Password settings in xlogicsoft.

51

The menu File->Properties (Parameter)

1.The password which set in the LCD menu is the parameter password.

2.The program password cannot be set in the LCD menu, it only can be set in xlogicsoft.

A. Set CPU address

There are 2 password settings can be applied to the program, one is the program password,

one is parameter password.

Program password:

If you set the program password, then the password is required when you want to upload the

program into PC.

Parameter password:

If you set the parameter password, then the password is required when you want to upload the

program into PC.

Note:

4.3.4 How to set address of CPU and expansion module

If there are more than one CPU in a certain communication network,well then the address of CPU must

be set differently each other. You can change the address of CPU via xLogicsoft, or via the panel key if the

CPU with LCD panel. The address range is from 1 to 247 for ELC and PR series CPU

52

Confirm with "OK"

Change the address with arrow keys, and confirm with "Ok".

The CPU address also can be set by xlogicsoft, if the CPU without HMI, you only can set the expansion

address with such method.

You can set the CPU address by the menu Tools-> transfer-> set PLC’s address in xlogicsoft.

Part 2 :Set address of PR-E extensions.(PR-E-16DC-DA-R etc..)

53

1. Plastic slice

Step 1: Using a screwdriver , take the plastic slice down and we’ll find a dial switch.

2: Dial the switch as the below instructions to set the address what you need.

Up to 8 extensions (includes IO ,AQ,AI,PT100 modules) can be connected with the CPU .

The default address of PR-E extensions is 1 and the dial switch as below:

Address 1:

means the switch position

Address 2:

Address 3:

Address 4:

Address 5:

Address 6:

Address 7:

54

Address 8:

Notes:

1.The address setup of the extension module must be before powering on. Modification when powering

on will be ineffective.

2.Freely connection with CPU and expansion , do not care the power supply type of CPU and

extensions ,that means the AC type module also can be connected with the DC type module or AC type

expansion module also can be connected with DC type CPU.

3.If the communication is established between CPU and extensions , the indicator on the top of the

extensions’ house will turn to RUN(green color)(If the LED is red, that means the CPU cannot get

communication with it).

4.If more than one expansion module connect to CPU at the same time ,the address of expansion module

must be different each other, otherwise the system(CPU+expansions) would run abnormal, but if the

expansion already has each own separately address, then the installation sequence of the expansion is

not important anymore, for example you can let the expansion with address 8 as the first one with CPU.

4.3.5 Set LCD (backlight and Contrast)

The backlight of CPU can be set “ON” time as 10 sec or “ON” all the time. The setting way as follows:

1. Select “Set...” menu and click OK.

2. Select “Set LCD” menu and click “OK”

55

3.Select "Backlight"menu and click "OK"

4. Default is 10 seconds, and another option is "Always On". Confirm with "OK"

Modify the contrast

Confirm with "OK"

56

Modify the contrast with Left or right key, and confirm with "Ok".

4.3.6 Set communication parameters

Select "Set Com" menu from the menu "Set..".