INSTRUCTION MANUAL EBIKES

RIESE & MÜLLER

AVENUE

CULTURE

DELITE

HOMAGE

KENDU

LOAD

BLUELABEL CHARGER

BLUELABEL CRUISER

BLUELABEL PONY

BLUELABEL SWING

BLUELABEL WAVE

BLUELABEL

TRANSLATION OF THE ORIGINAL GERMAN INSTRUCTION MANUAL

2

Dear customer,

congratulations on your new Riese & Müller E-bike. Thank you for

choosing us for your mobility needs. Riese & Müller builds lightweight

and practical E-bikes that are characterized by exceptional handling

and award winning design. During the design process, we constantly

think about your riding enjoyment and safety. Even though we cannot

anticipate every possible scenario, this manual answers many of the key

questions you may have and gives you many tips on using your bike.

Furthermore, a lot of interesting facts about bicycle technology, main

tenance and upkeep are summarized for you to ensure that you enjoy

your new Riese & Müller E-bike for many years for come. Since our

E-bikes are constantly being updated and improved, we may provide

additional supplementary pages to ensure you have the most up to

date information. Please be mindful that some updated information

may have already been included with your new E-bike.

Your dealer has performed the final assembly of the E-bike and possibly

implemented some requested changes for you. He has performed a

test ride to ensure an enjoyable riding experience from the very start.

If after reading this manual, you still have questions, please feel free to

contact your dealer or us directly.

The Riese & Müller Team

3

CONTENT

General information

Safety

Legal requirements

Intended use

Statutory provisions for fast E-bikes

Before the first ride

Before every ride (quick check)

Quick releases

Adjusting the riding position

Adjusting the rear suspension

Suspension seat post (blueLABEL)

Adjusting the suspension fork

Braking system

Shifting system

Chain

Belt drive

Wheels and tires

Repairing a puncture

Headset

Lighting system

Luggage and children transport

Integrated lock

Kickstand

Pedals

Load – separating the frame

Bosch drive

E-Bikes – range in cold weather

E-Bikes – HS models

Transporting the E-bike

General care / Inspections

Warranty / Guar antee

Weight rating

Recommended torque settings

Service and maintenance plan

Documents

Service record

4

6

8

9

10

12

14

16

18

26

31

32

33

39

44

46

47

51

58

59

60

61

62

62

63

64

66

67

68

70

74

77

78

80

82

83

4

Carrier, S. 60

Seat post, S 18, S. 31

Saddle, S. 20

Shifting

Derailleur, S. 41

Hub gear, S. 42

Wheel attachment, S. 16

Wheels and tires, S. 47

Kickstand, S. 62

Brake lever, S. 25

Shifter, S. 40

Stem, handlebar, S. 21

Headset, S. 58

Lighting, S. 59

Suspension

fork, S. 32

Brakes

Disc brakes,

S. 35

Rim brakes,

S. 36

Bosch drive, S. 64

Chain, S. 44

Belt drive, S. 46

Pedals, S. 62

Suspension, S. 26

5

Torque settings in this manual are

specied in Nm. Do not rely on

your feeling: “tight” is simply not

precise enough. ONLY a torque

wrench can ensure that the bolt

is properly tightened. You must

always use this tool to tighten

the components when a torque

setting is specied. A bolt that is

too tight or too loose can cause

malfunctions which could lead to

an accident with serious injuries

as a result.

DANGER!

6

GENERAL INFORMATION

DANGER!

Do not ride if the test wasn’t

passed with 100 % certainty.

Riese & Müller E-bikes are equipped with exceptionally innovative technology. Even if you are

a seasoned rider that has been riding for many years, we strongly recommend reading and

observing the following instructions.

First we would like to familiarize you with the components of your Riese & Müller E-Bike.

Please flip open the front cover of the manual. Here you will find an example of a

Riese & Müller E-bike upon which all of the mentioned components are identified.

TIP! KEEP THE FRONT COVER OPENED AS THIS MAKES ORIENTATION EASIER!

We have tried to vividly portray all of the relevant information to ensure your satisfaction

with your new Riese & Müller E-bike. Therefore we use the following symbols:

Attention! Here is a hint that will help you quickly become familiar with your bike

and its technology.

Danger! This symbol indicates that life-threatening risks are possible if the

corresponding instructions are not followed. Please read carefully.

Tip! This symbol indicates useful additional information.

This symbol indicates that you must use a torque wrench and comply with

the specified torque.

To ensure you always have a fun and safe ride, you should perform the quick check before

every ride. For instructions on this quick check please visit page 16.

7

This manual covers the installation and maintenance work that may be best

performed by your local dealer (page 80 – 81). Do not perform any task that

you are uncomfortable with. Many of these tasks require special knowledge

and tools and should only be performed by an expert. Never ride your bike

with incomplete or improper maintenance. You could endanger your life or

the lives of others.

DANGER!

In this manual, a number of maintenance and repair tasks are described in detail. If you

engage in this activity you must always consider that the instructions are exclusively for the

designated Riese & Müller E-Bikes and are not transferable to other bikes.

Through a variety of design and model changes it is possible that the included instructions are

not up to date. If necessary, review the separately attached instructions.

Note that the successful execution of the included instructions may require special tools or

technical expertise. If you are uncomfortable performing any of the listed tasks, please seek

the assistance of a professional.

If you reach a certain point where you are not sure how to proceed, please contact your local

dealer or us directly. We are happy to help!

WE HOPE YOU ENJOY YOUR NEW RIESE & MÜLLER EBIKE.

8

SAFETY

The following are a few things that we hold very dear:

• Always take care in trac as not to endanger yourself or others.

• Respect the rules of the road so you don’t draw the ire of other road users.

• If you tour through forests and meadows, please respect nature by cycling

only on marked or paved roadways. Observe the legal requirements for the

o-road use of bicycles. These are available from your local authorities.

• Never ride without a helmet.

• Make sure you always wear appropriate clothing.

• Make sure you always wear shoes with non-slip and rigid sole.

• Do not ride with hands o the handlebar.

• Do not ride with headphones and do not use your phone on the E-bike. do

not drive if you are impaired in your driving ability by medication, alcohol or

other drugs

• Check if the quick releases, thru axles or axle bolts are properly secured. Do

this before every ride and even if you only shortly parked your E-bike.

• Adapt your driving style to the weather conditions. Wet or slippery roads

increase the braking distance.

• Adjust your speed to the terrain and your riding ability.

Note to all parents and guardians

As guardians you are responsible for the technical condition of E-bike and the

safety of your child.

ATTENTION

Minors may only ride E-bikes, when they

have reached the required age and possess

the necessary license respectively.

9

DANGER!

Shut off the E-bike drive and remove the battery before you start to work at

your E-bike. Unintended activation of the E-bike drive can lead to injuries.

Note that the E-bike immediately moves when you put your foot on the pedal

and the E-bike drive is switched on. So rst pull the brake and then get on the

E-bike. Otherwise the unexpected move can lead to accidents and hazards.

DANGER!

10

LEGAL REQUIREMENTS

If you want to participate on public roads

with your E-bike, your E-bike must be

equipped in accordance with local regula

tions. In Germany this is governed by the

Road Trac Licensing Regulations (StVZO)

and the Road Trac Act (StVO).

STVZO

To legally use a bike on a public road in

Germany it must conform to the Road Trac

Regulations (StVZO). The requirements relate

to the brake and lighting system and bell.

Every rider is obliged to maintain his bike

at a roadworthy state. The general trac

rules that apply to automobiles also apply to

bicycles. Please familiarize yourself with the

trac regulations.

THE BRAKING SYSTEM

The braking system of an E-bike must have

at least two independently functioning

brakes (front and rear wheel). The mode of

operation is not strictly regulated.

DIE LICHTANLAGE

All lighting devices on the bike need to dis

play the ocial mark. This mark consists of a

wavy line, the letter “K” and a number. Only

lights (battery powered and dynamo) with

this mark can be used on public roads.

The §67StVZO states that the front and rear

light must be operated by the same fixed

power source (battery or dynamo). Front and

tail light can be switched on and o sepa

rately. The rated power and voltage must be

at least three watts or six volts. The rear light

must be mounted at a height of at least

25 cm above the road surface and the center

of the front light cone must touch the road

surface no further than 10 meters from the

front of the E-bike.

REFLECTORS

In addition to the light sources, each bicycle

must also have the following reflectors:

• as large as possible white reflector in

combination with the headlights.

• in the rear, at least two red reflectors with

a large area with the “Z” mark. The tail light

can be combined with the rear reflectors.

• two lateral yellow reflectors per wheel

must be attached. Alternatively white

reflective rings can be attached to the

spokes around the complete circumference

of the wheel or on the rim edge or on the

sidewalls of the tires.

• two yellow reflectors per pedal

(front and rear).

TIP!

Before using your bicycle in a country

other than Germany you can seek

advice at your local dealer regarding

any legal peculiarities in your country

11

INTENDED USE

Your Riese & Müller E-bike is designed for

use on roads and paved trails only. When

using the E-bike in public trac it must be

equipped conforming national legislation.

Your E-bike is not approved for extreme

loads. Riese & Müller is not liable for dam

ages resulting from improper use, incorrect

assembly, negligence, accidents, racing,

jumping, wheelies or similar activities.

Your E-bike is not approved for use in

competitions.

Terms of use and maintenance described in

this manual are part of the intended use.

The manufacturer or dealer accepts no

liability or warranty if the E-bike is out of

intended use, when safety instructions are

not observed, when overloaded or

improperly deficiencies are eliminated.

The warranty does not cover damage caused

by installation errors, intent, crashes and

poor care or poor maintenance.

DANGER!

Your E-bike is basically intended

for the transportation of a single

person only. One exception is

the transportation of a child in

a child seat or a child trailer.

Please note the terms of your

national legislation.

Pay attention to the use of high

quality child seats and trailers.

Pay attention to the maximum

gross weight (see page 77,

technical data).

TIP!

Gross weight =

Riders weight +

E-bike weight +

luggage weight

12

LEGAL FRAMEWORK

The following paragraph applies to the

Federal Republic of Germany. Please refer

to your local regulations in your country. If

you were born after April 1, 1965, you need a

license (regardless of class) to use a fast

E-bike on public roads. You also need insur

ance and a license plate. These can usually

be obtained at your local insurance oces.

You’ll need to bring the vehicle documents

you received from your dealer. We recom

mend comprehensive vehicle coverage.

Please mount the license plate on the

included holder (see picture).

BICYLE HELMET

A fast E-bike is capable of speeds over

40 km/h, a speed range previously reserved

for scooters and motorcycles. Although

you are not required to wear a motorcycle

helmet, we STRONGLY encourage the use of

a bicycle helmet.

USAGE OF CYCLE PATHS

Please familiarize yourself with the trac

regulations for fast E-bikes in your country.

REFLECTORS AND REARVIEW MIRROR

Please familiarize yourself with the trac

regulations for fast E-bikes in your country.

TRANSPORT OF CHILDREN

Please familiarize yourself with the trac

regulations for fast E-bikes in your country.

MODIFICATIONS AT FAST EBIKES

Your vehicle’s technical capabilities were set

and approved in our factory. Therefore any

adjustment to certain components of your

fast E-bike voids the approval.

STATUTORY PROVISIONS FOR FAST EBIKES

13

The following components may, subject to

certain conditions, be replaced/exchanged:

Tires ECE-R75 approved tires of the same

width and diameter (other tire sizes

possible, see details in the registra

-

tion document).

TIP!

All other components must be replaced

by identical parts or parts with ocial

type approval. Or the parts must be

presented to a technical service like

TÜV or DEKRA and listed in the regis

-

tration paper of the E-bike.

14

BEFORE THE FIRST RIDE

Make sure that your dealer has performed

the final assembly of the E-bike and adjusted

the E-bike to your preferred riding position.

This includes:

• adjustment of the brakes

• adjustment of the brake levers, so you can

reach them every time

• wheel attachment to frame and front fork

• adjustment and attachment of saddle,

handlebar and stem for a secure and

comfortable riding position

CARRIER, CHILD SEATS

Please note that carrier and child seat are

not allowed to be modified. The following

E-bikes can be directly fitted with a child seat

(eg Polisport Bilby): Avenue, Culture, Delite,

Homage, Cruiser, Swing, Wave

TRAILES/TRAILERBIKES

Riese & Müller E-bikes are only approved

for use with two wheeled trailers. The max.

towing capacity (including trailer weight)

is 50 kg. When mounting the trailer at the

carrier, please add the support load to the

carrier load.

Single-track trailers are approved for the use

on blueLABEL E-bikes only. The maximum

trailer load is 20 kg.

DANGER!

If your E-bike is tted with pedals with rubber or plastic cage,

please become familiar with

their grip. Pedals with rubber

or plastic cage may get slippery

when wet!

The authorized dealer must make

the E-bike ready to ride, so that safe

operation is guaranteed. The dealer

must do a nal check and a test ride

with your E-bike. The transfer of the

E-bike must be documented in the

e-Bike passport (see page 87).

Check the tight t of quick releases

and all important bolts and nuts.

Check the tires air pressure. You will

nd the required air pressure at the

sidewall of the tires. Do not exceed

the minimum and maximum air

pressure! Make sure that tires and

rims are free from damages, cracks

and deformations.

Check the tight t of the battery.

Check the battery charge condition.

Become familiar with the functions

of all controls.

ATTENTION!

Child trailers are not allowed

on fast E-bikes.

ATTENTION!

15

BRAKING SYSTEM

Are you familiar with the braking system?

Check to make sure that the front brake lever

is on the side of the handlebar that you are

used to. If it isn’t then you can either train

with the new arrangement or have your

dealer change the arrangement to fit your

needs. More details on brakes can be found

on pages 33.

SHIFTING

Conduct a test ride to familiarize yourself

with the shifting system in a low-trac area.

More details on the shifting on page 39.

SEATING POSITION

Is the saddle and handlebar in the right

position? Your dealer can assist you in

finding the best seating position. More

details on seating position on page 18 – 25.

SUSPENSION

Is the suspension adjusted to suit your

needs? More information regarding

suspension on page 28 –36.

DANGER!

Modern brakes are much more

powerful than simple rim or

drum brakes. Make sure to rst

test the braking power before

heading into trac. Unintended

braking can lead to an accident.

Slowly squeeze the brake to

generate more braking force.

When riding with a full load, the

handling is affected and it takes

longer to stop. Be sure to make

some handling and braking test

prior to heading into trac.

DANGER!

With activated E-bike drive, the

E-bike immediately moves, when

you put a foot on the pedal! So

pull the brakes before getting on

the E-bike. The unaccustomed

move may lead to hazards and

accidents.

16

DANGER!

BEFORE EVERY RIDE QUICK CHECK

Before each ride the following items must

be checked:

QUICK RELEASE/AXLE BOLTS/THRU AXLES

Are the quick releases or bolts of stem, sad

dle, front and rear wheel properly secured?

More details can be found on page 16 – 17.

SUSPENSION

Check to make sure the suspension is

functioning. Press down on the saddle to

check the rear saddle. While holding the

front brake, press down on the handlebars to

check the suspension fork. In both cases the

suspension should move up and down with

uniform resistance and without significant

noise. No components of the bicycle should

scrape or rub together.

TIRES

Sind die Reifen in gutem Zustand? Stimmt

der Are the tires in good condition? Is the air

pressure correct? More information regard

-

ing tires can be found on page 47–50.

LIGHTING

Do the lights stay on when standing still?

More information regarding lighting can be

found on page 59.

BRAKES

Vigorously pull the brake lever. The levers

should stop just before reaching the han

dlebar. The brake pads on rim brakes must

touch the entire rim area while not touching

the tire. More details on the brakes can be

found on page 33 – 38.

Quick releases and ttings that

are not properly closed can

result in severe accidents!

Check the tight t of quick

releases, thru axles and bolts

even if you parked your E-bike

only shortly at an unattended

place. Do not ride your E-bike

with untightened quick releases.

17

LOADING

Check the fixation of basket or child seat. The

luggage must be fixed securely and noth

ing should get caught by the wheels. Please

note that your E-bike may change under

loading.

WEIGHT LIMITS

Check to ensure the gross vehicle weight rat

-

ing is not exceeded. Please see page 77.

UNUSUAL NOISES

Be aware of any unusual noises or changes

to handling characteristics which may

indicate a problem. Check the bearings and

couplings.

DANGER!

Do not ride your E-bike if concerned about any of these points!

If in doubt please consult your

dealer. A faulty E-bike can result

in accidents!

ATTENTION!

After a crash or accident your

dealer must inspect the E-bike for

damages before you use it again.

18

QUICK RELEASES

Even though quick releases are very convenient, many accidents occur because of

their misuse. So please pay attention to this

article

DESIGN OF QUICK RELEASES

The quick release consists of two control

elements:

• A lever A on one side of the hub that pro

-

duces the clamping force.

• A locking nut B which is threaded on the

opposite side that sets the tension

HANDLING OF QUICK RELEASES

• Open the lever A You should now be able to

read the word “Open“.

• To close it, move the lever so that on the

outside it reads ”Close“. At the beginning

of the closing movement, about halfway

through its travel, the lever must be slightly

tight.

• During the second half of the lever’s travel,

the leverage increases significantly. Finally,

the lever is very tight and is dicult to

move. Use the palm of the hand to close

the lever. Once closed the lever must be

parallel to the wheel and not project out

laterally.

B

A

OPEN

CLOSED

19

• Check the fit by attempting to turn the

closed lever. When the lever rotates, it is

not safe to use the bike. You have to open

it again to retighten it. Do this by turning

the locking nut one-half turn (while holding

quick release).

• Repeat the closing process and check the fit

again. When the lever no longer rotates, it

is clamped properly.

• Check the tightness of the wheel: lift the

wheel several inches o of the ground and

give the top of the tire a little whack. A

securely fixed wheel should remain in the

frame.

• Check the tight fit of saddle and handlebar

by trying to twist them.

TIP!

Components secured with a quick

release are at risk of theft.

If possible place an additional

lock on the wheels when you park

the E-bike.

DANGER!

Never ride a bike without rst

checking that the wheels are

securely attached to the frame

with a quick release or bolt.

If not securely attached, the

wheel could fall out during the

ride and lead to a severe injury!

Check the tight t of quick

releases, thru axles and bolts

even if you parked your E-bike

only shortly at an unattended

place. Do not ride your E-bike

with untightened quick releases.

20

ADJUSTING THE RIDING POSITION

RIDING POSITION

The correct riding position is essential for

comfort and power delivery. Your E-bike is

designed so that he various components can

be adjusted to accommodate your body size.

This section describes adjusting the riding

position on your new Riese & Müller E-bike.

CORRECT SEAT HEIGHT ADJUSTMENT

The necessary height is based on body posi

tion while pedaling. While pedaling the balls

of the big toes should be over the pedal axle.

The leg must not be fully extended at the

lowest position of the pedaling circle. If the

seat is too high, it is dicult to pedal through

this low point and the pedaling is not smooth

and circular. If the seat is too low, knee pain

is possible.

Check the seat height using the following

method and be sure to wear shoes with a

flat sole:

• Sit on the saddle and place the heel on the

pedal in the lowest position. In this position

the leg should be fully stretched. Make sure

that your hips remain straight.

DANGER!

The successful execution of the

following operations requires

some experience, proper tools and

expertise. Make sure to conduct a

brief check (page 14) and test ride

in a trac free area. If you have

any doubts about the adjustments,

please discuss them with your

local dealer. This can be combined

with a normal workshop visit (i.e.

initial inspection).

TIP!

With full suspension bikes, the bottom

bracket height is inherently greater.

It may happen that you can only reach

the ground with an outstretched toe.

21

• To adjust the seat height, you must loosen

the clamping screw for the seat post.

• Now you can adjust the seat post height.

Make sure that the seat post is greased.

If the seat post feels tight, clean and re

grease both surfaces. Never force the seat

post and if you have further issues, please

contact your local dealer for further advice.

• Align the saddle in the direction of

travel and tighten the clamping

screw to a torque of 9–12 Nm.

• Check the tightness of the seat post. Try to

twist the saddle. If it doesn’t twist, the seat

post is tight.

• Double check to make sure the leg exten

sion is correct. Verify that you can easily

and safely reach the ground. If this is not

the case, position the saddle lower.

Never ride when the minimum

insertion mark on the seat post

is visible. This indicates that

the seat post is not inserted far

enough into the frame. It could

break or damage the frame. If

the seat post is ever shortened, a

minimum of 80 mm must remain

in the seat tube!

DANGER!

22

ADJUSTING THE RIDING POSITION

SADDLE ORIENTATION AND ANGLE

The distance between the handlebars and

saddle and the angle of the saddle have an

eect on riding comfort and riding dynam

ics. By moving the saddle horizontally, this

distance can be altered which has a pro

found eect on pedaling. Furthermore, the

seat should usually be oriented parallel to

the ground.

• Loosen the bolt A three to four turns only,

otherwise the entire mechanism may fall

apart.

• Move the seat forward or backward as

desired. Often this only requires a little

bump to the saddle.

• Adjust the angle.

• Tighten the bolt A

to 12–15 Nm.

• Check to see if the tightened saddle moves

by alternately loading the front and back of

the saddle.

DANGER!

When replacing the saddle, be

aware that only saddles with a

frame diameter of 7 – 8 mm can

be used. Using saddles with other

frame diameters can lead to failure and cause the rider to fall.

A

A

TIP!

The Riese & Müller ip op seat post

can be rotated with its head facing

forward to get a smaller distance to

the handlebar.

23

HANDLEBAR HEIGHT ADJUSTMENT

The stems at Riese & Müller E-bikes are

height and partially angle adjustable. This

allows for the adjustment of the seating

position.

Upright seating position

Advantages: less strain on the wrist, arms

and neck.

Disadvantages: higher load on the saddle.

Outstretched seating position

Advantages: less load in the saddle, more

ecient power transfer, more streamlined,

more weight on the front wheel.

Disadvantages: higher load on wrists, arms

and neck.

HANDLEBAR HEIGHT AT ERGOTECSTEMS

The height can be reduced by leaving o

spacers. But the steerer tube has to be

cutted in the same way.

ATTENTION!

Let your dealer change the handlebar height.

24

ADJUSTING THE RIDING POSITION

Height Adjustment:

• Open the quick release lever C.

• Press the pin D and adjust the stem to

one of five height positions until the pin D

engages.

• Attention: the stem should not be extend

ed beyond the “MIN. INSERTION“ mark!

Use the stem only in the five positions in

which the pin engages.

• Align the handlebar in the direction of

travel and close the quick release lever C.

C

D

ADJUSTABLE STEM AT KENDU/ LOAD/PONY

The stem of the Kendu, Load and Pony is

adjustable in both height and angle. Both

adjustments can be made without tools by

means of a locking pin and quick releases.

Angle adjustment:

• Open both quick release levers A on the

front hinge.

• Press the side button B and adjust the stem

in one of the three angle positions. Release

the button again moving the stem until it

clicks into place (possibly move the stem a

little back and forth).

• Attention: Only use the stem in the three

positions in which the pin engages!

• Close both quick release levers A.

• In engaged state both red marks are in one

line.

A

B

ATTENTION!

Before each ride, ensure that the pin

is rmly in place and quick-release

levers are completely closed. If the

bars or stem move while driving by

yourself, have your dealer inspect

it immediately as this could be very

dangerous.

25

DANGER!

The height adjustment of

A-Headset stems requires properly setting the steering bearings

and improper installation can

result in accidents. Therefore it

is recommended that this is only

performed by or at least checked

by your local dealer.

HANDLEBAR HEIGHT FOR AHEADSET STEMS

The height is adjusted by using spacer rings.

26

ADJUSTING THE RIDING POSITION

F

H H

H

H

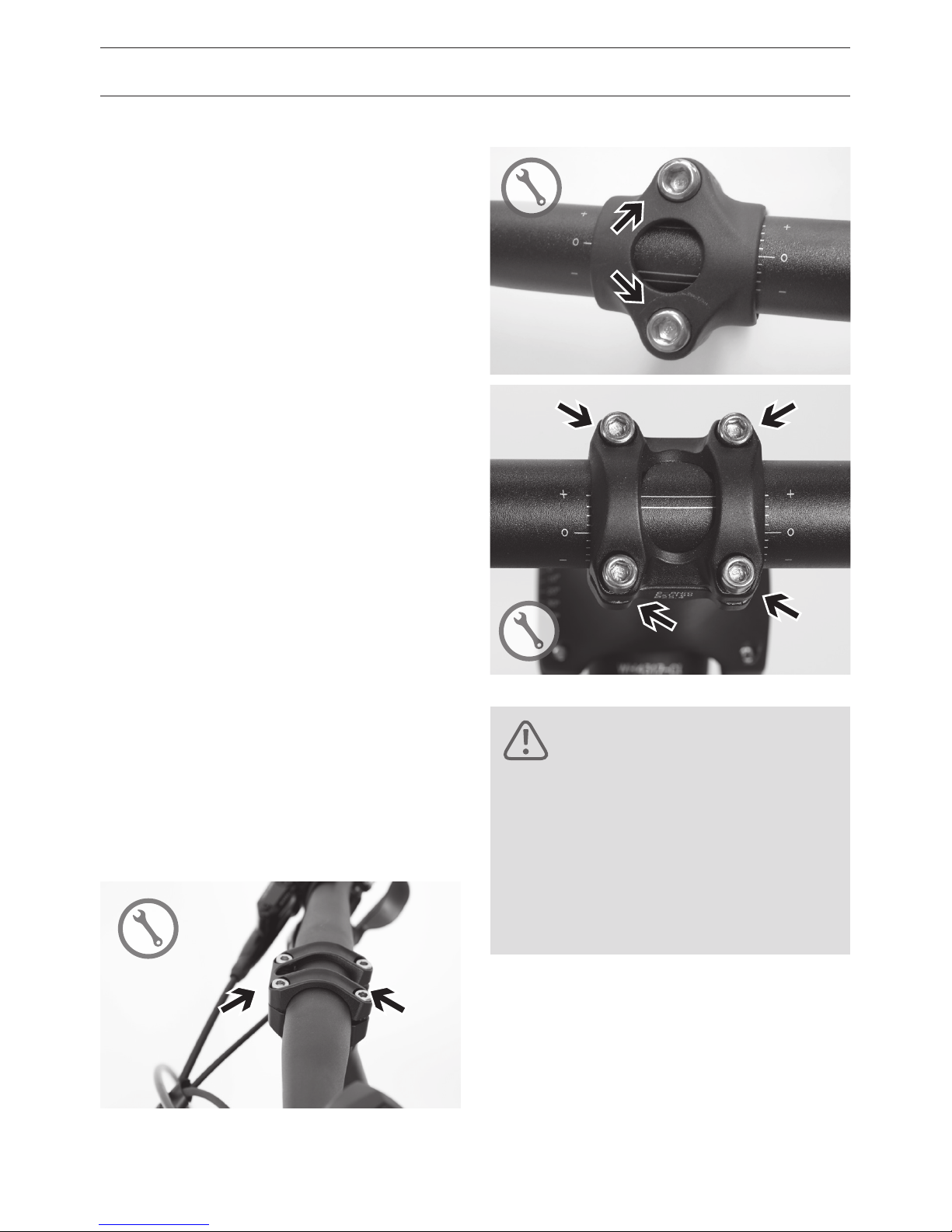

ADJUSTING THE ANGLE OF THE HANDLEBARS

Adjust the handlebars so that the wrists

are relaxed and not too strongly twisted.

Adjust the handlebar position by rotating the

handlebar.

• The Bosch display may cover the bolts of

the handlebar clamp. In this case you must

loosen the four display bracket bolts and

twist the display.

• Loosen the two bolts F or the four bolts H

on the handlebar clamp.

• Rotate the handlebar to the desired posi

-

tion.

• Make sure that the handlebar is clamped

exactly in the middle of the stem.

• Tighten the two bolts F to a torque setting

of 10 Nm or the bolts H to a setting of

5.5 Nm using an “X” pattern.

• Re-tighten the Bosch display bolts again.

The handlebar clamp at the stem of Load/

Kendu/Pony must be tightened first and

gapless at the inscripted side (see arrow A).

Observe the tightening torque (6–8 Nm).

Fix the handlebar by tightening the opposite

bolts.

After modications of stem and

handlebar position you must

check if all cables are still long

enough. It is necessary to have

the full steering range without

any limitations by the cables.

DANGER!

HANDLEBAR ADJUSTMENT

When adjusting grip position, adding bar

ends or changing handlebars, it may be

necessary to replace shifting and brake

cables with longer ones.

A B

27

ADJUSTMENT OF VBRAKE LEVER REACH

Riders with small hands can adjust the brake

lever closer to the handlebar:

• Where the brake cable enters the brake

lever there is a small screw. Tighten the

screw until the desired reach is achieved.

• Now check whether there is enough

free travel of the lever before the brake

engages. If this is not the case, the brake

cable can be adjusted (see page 20).

BRAKE LEVER ROTATION

Loosen the Allen bolts on the brake lever

handlebar clamp.

• Sit on the saddle and put your fingers on

the brake lever. Then twist the brake levers

until your hand and forearm form a

straight line.

• Tighten the bolts on the brake lever

handlebar clamp to a torque setting of

5 – 6 Nm.

BAR ENDS

These provide an additional grip position.

They are usually set so that the hands fit

comfortably on it when the rider is leaning

slightly forward. The bar ends are typically

set at approximately 25 degrees

to horizontal direction.

DANGER!

The brake lever should not touch

the handlebar before full braking

is achieved!

DANGER!

The bolts on the stem, handlebar, grips and bar ends must be

tightened to the specied torque

settings. The corresponding

values can be found on page 78.

If bolts are not tightened to the

correct specication it may

cause the parts to loosen or

break which may lead to serious

accidents.

28

DANGER!

ADJUSTING THE REAR SUSPENSION

Your Riese & Müller E-bike is equipped with

a low maintenance rear suspension system

(excluding blueLABEL). The shock contains

either an air chamber or a combination

of steel spring and oil hydraulic damping.

To tune the air suspension, please refer to

the separately included manual from the

suspension manufacturer.

REAR SUSPENSION ADJUSTMENT

With steel spring shocks, the correct spring

must be chosen for the desired ride char

acteristics. Furthermore you can adjust the

spring preload and damping.

The standard spring is designed for 90 % of

all applications. If the bike sinks dramatically

when you mount it or bounces when hitting

small bumps, you need a stier spring. If the

bike sinks only a little when you mount it

and hardly reacts to bumps, then you need

a softer spring. Riese & Müller oers softer

and stier springs in order to meet specific

customer requirements.

The adjustment ring of some E-bike models

is fitted with holes and can easily be ad

-

justed by a 3 mm Allen key.

If you do not have the special

knowledge or the special tools

for this work, you must contact

your dealer.

29

DANGER!

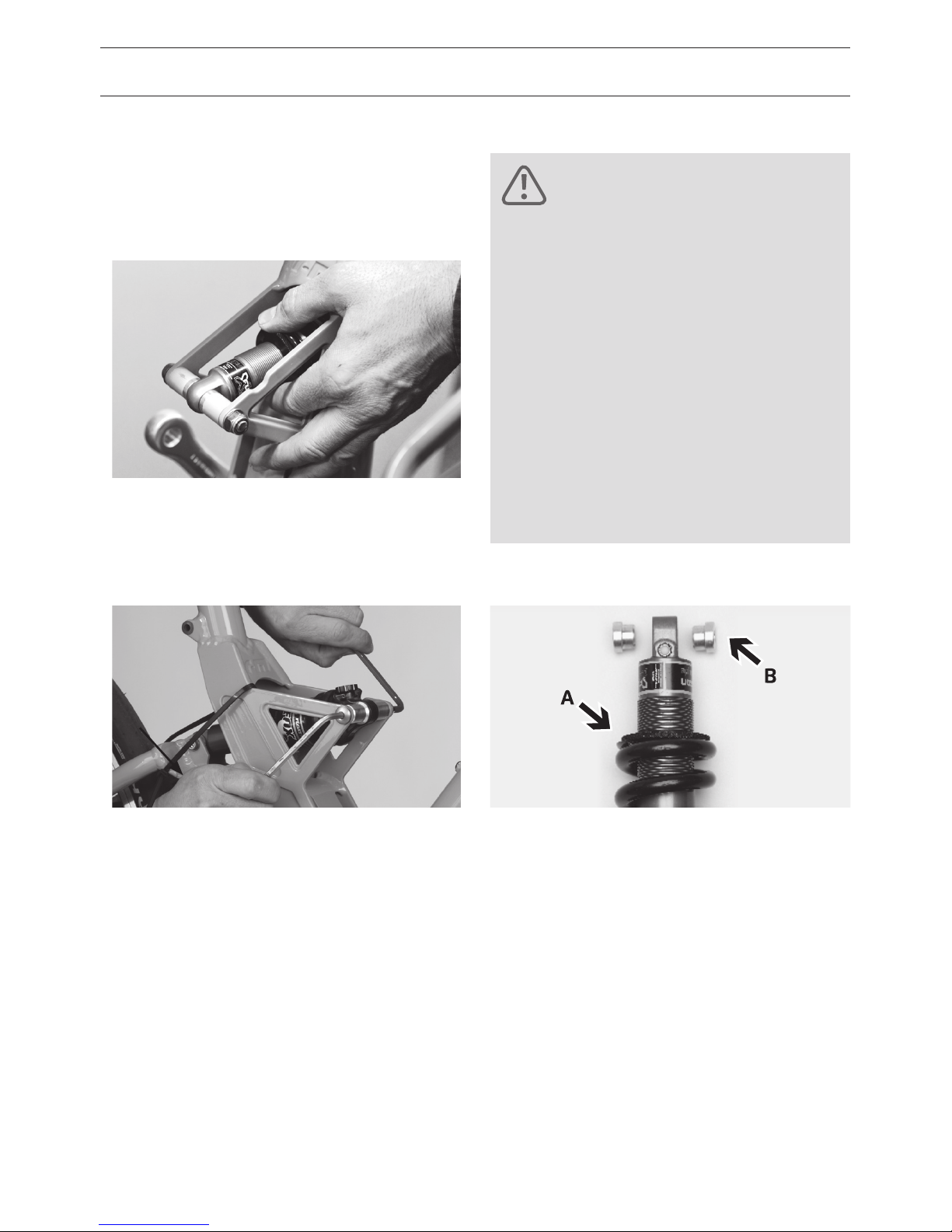

REPLACING THE SPRING

• Hang the bike in an assembly stand.

• Relax the shock fully. Rotate the adjust

-

ment ring counterclockwise.

• Prevent the swingarm from accidentally

folding down with the help of a stable

cord or cable ties between the frame and

swingarm.

• Loosen the bolts at both ends of the shock

with a 5 mm Allen wrench and a 10 mm

wrench. Carefully remove both bolts. Look

for the washers and remember their orien

-

tation for later reassembly.

• Remove the bushings B from the side of

the shock with the adjustment ring.

• Turn the adjustment ring A until it is

removed completely from the shock.

If the swingarm is not secured,

it could fall down injuring you

or damaging the bike.

If the bike is placed on the

ground while disassembling the

shock, the rear swingarm can

fold under suddenly. There is

a risk of pinching your hands

between the bike frame and

swingarm or damaging the bike

itself!

30

ADJUSTING THE REAR SUSPENSION

• Pull the spring plate D and remove the

spring.

• Clean the threads and apply some grease.

• To reinstall the shock, repeat the process in

reverse order.

• Put the shock back in the frame and tighten

the screw connections (torque 7 – 9 Nm).

ADJUSTING SPRING PRELOAD

With spring preload, you set how far the

suspension sags when you sit on the bike.

Ideally it should be between 20 and 25 % of

the total travel.

Sag to great

The shock requires more preload. Turn the

adjustment ring A (see fig. at 27) page-

clockwise.

Sag to little

The spring needs less preload. Turn the

adjustment ring A counterclockwise or use a

softer spring.

The adjustment ring should not be

tightened more than three rotations.

If after three rotations, the preload is

still not enough, you require a stiffer

spring. For optimal suspension

convenience, the spring should

require as little preload as possible.

ATTENTION!

Ensure the adjustment ring is not too

loose. The spring on the unloaded

E-bike should not t loosely.

ATTENTION!

31

DANGER!

ADJUSTING DAMPING

Rebound damping of the shock determines

how the rear swingarm returns to its original

position after being loaded. To test, ride o

of a curb. The suspension should bounce

back at once. If the suspension oscillates in

stead of coming directly back to the original

position, turn the knob clockwise to increase

damping. If the suspension rebounds too

slowly and over several closely spaced

bumps sinks continually lower, the damping

can be reduced by turning the knob counter

-

clockwise.

When working on a shock, never

load the shock by leaning on the

E-bike’s saddle, handlebars or

racks. One can simply pinch his/

her hands compressing the rear

suspension.

While riding under heavy compression, the fender struts come very

close to the frame or rack. From

time to time, check the adjustment

of the rear fender. The front struts of

the rear mudguard (Avenue, Culture

and Homage) contain a bend that

prevents the struts from grinding on

the frame or luggage rack. Grinding

struts can permanently damage the

frame!

ATTENTION!

32

MAINTENANCE OF THE SHOCK

The steel spring shocks used by

Riese & Müller oer very good suspension

characteristics and user-friendly service

intervals. Shocks used under normal

conditions only need to be serviced every

5000 km. When riding on rough roads /trails

or harsh snow conditions, it is advisable

to perform maintenance more frequently to

prevent premature damage.

During servicing, the shock should be re

-

moved and the following parts cleaned:

• Mounting bolts

• Bushings A

• Threads B

• Piston rod C

The following parts should be greased:

• Bushings A only for X-Fusion Shocks

• Threads B

For information regarding the maintenance

of air suspension shocks please see the

separately enclosed manufacturer’s instruc

-

tions.

ADJUSTING THE REAR SUSPENSION

A

A

A

A

B

C

ATTENTION

Let your dealer do the maintenance work at the suspension.

33

The stiness of the seat post can be adjusted (within certain limits) to the weight of

the rider.

• Open the seat post clamp on the frame and

remove the seat post from the frame.

• Adjust the spring preload with a 6 mm Allen

key. Turn clockwise to increase the tension.

Rotate counter-clockwise to decrease the

preload. The preload can only be reduced to

the extent that the adjustment screw

D doesn’t project out of the seat post.

• Install the seat post in the frame

(see page 21 ).

If the lateral play between shaft and outer

tube is too great you can rotate the nut E by

hand to make it a bit harder. Make sure that

the boot does not slip o of the nut. Do a

regular check if the nut E has a tight fit

SUSPENSION SEAT POST (ONLY FOR blueLABEL)

D

E

34

ADJUSTING THE SUSPENSION FORK

AIR SUSPENSION FORKS

With air suspension forks, the preload is set

using the standard (supplied) air pump.

For details regarding the adjustment of

these forks, please see the separately en

closed instructions from the shock manufacturer. Please also visit the manufacturers

homepages at the Internet:

• www.ridefox.com

• www.xfusionshox.com

• www.srsuntour-cycling.com

Maintenance of suspension forks

Please refer to the notes in the separately

enclosed instructions from the various

suspension fork manufacturers.

DANGER!

When rotating in the “-” direction and you receive some

resistance, you should not

continue turning to prevent over

loosening the tting. This could

cause an accident!

DANGER!

The suspension components at

your E-bike are safety-relevant.

Check and maintain the suspension components of your E-bike

on a regular base or let this be

done by your local dealer.

Suspension fork adjustment

The sag for the suspension fork should also

be approximately 20 %.

With RST and Suntour suspension forks, you

adjust the preload with one or two knobs

on the fork crown. Turning the knob towards

the “+” will increase the preload, turning it

towards the “-” reduces preload.

Should the amount of adjustment prove

insucient, please contact your dealer.

He can check if your front fork can be tuned

harder or softer.

35

DANGER!

DANGER!

BRAKING SYSTEM

USE BRAKES PROPERLY

The brakes on Riese & Müller E-bikes allow

you to achieve powerful braking with little

hand force. The stopping distance however

depends also on the rider’s skill. No worries

as this can be trained. When you brake, your

weight is shifted to the front wheel from the

rear wheel. The strength of the deceleration

is the primary factor in bicycle rollover with

the secondary factor being the traction of

the tires. This can be particularly problematic

when riding downhill. During an emergency

stop try to shift your weight as far back as

possible.

Press both brake levers at the same time

and note that the front brake transmits

much more braking force due to the shifting

weight. Avoid, however, locking the front

wheel as this can cause slipping or even a

rollover.

On slippery ground you must use the front

brake carfully to prevent an uncontrolled

slide away of the front wheel.

ORIENTATION OF THE BRAKE LEVERS

If your E-bike is equipped with a coaster

brake and only one hand brake, the brake

lever will be located on the right side and

will operate the front brake. If your bike is

equipped with two brake levers, the one on

the right operates the rear brake and the

one on the left operates the front brake.

Familiarize yourself with the orientation

or ask your dealer to change them to your

liking.

Make sure to familiarize yourself

with the brakes gradually.

Practice emergency braking in

a trac-free area until you are

able to safely control the E-bike.

This can prevent accidents while

on the road.

Some dealers change the orientation of the brake levers because

there are different opinions as

to which orientation is correct.

Therefore please check before

your rst ride, whether the

above orientation matches your

E-bike and your preferences.

36

OPERATION

By using a brake lever or reverse pedaling a

fixed pad is pressed onto a rotating brak

ing surface and causes friction. This friction

causes the rotating wheel to slow. In addi

tion to the force with which the pad presses

against the surface, the so called friction

coecient between the fixed pad and the

braking surface is crucial. If water, dirt or oil

gets onto the braking surface, the friction

coecient is worsened. This is the reason

why a rim or disc brake does not respond as

well in the rain.

WEAR AND TEAR AT VBRAKES

The friction between the brake pads and the

rim leads to the wearing of both the pad and

the rim! Riding often in the rain increases the

wear. If the rim sidewall is abraded to a criti

cal level, the tire pressure will cause the rim

to burst. The wheel can jam or the tube may

burst, both of which can lead to an accident.

By the time you have worn through your

second set of brake pads, it is time to have

your dealer check the thickness of your rims’

sidewalls. For rims with a wear indicator A,

the rim must be replaced when the indicator

is no longer visible.

Moisture decreases the braking

effectiveness. When riding in rainy

conditions expect longer braking

distances! When replacing brake

pads, you should only use pads that

have been specied for your system.

Your dealer can advise you in the

matter. The braking surface of rims

should be absolutely wax, grease

and oil free.

ATTENTION!

ATTENTION!

Have the rims checked at the latest

after the second set of brake pads.

Worn wheels can lead to material

failures and accidents.

DANGER!

Damaged brake cables in which

individual wires protrude must

be replaced immediately. Brake

failure and an accident can result. Ask your dealer for advice.

A

BRAKING SYSTEM

37

BRAKING SYSTEM

TIP!

New brake pads only reach their

optimum braking performance after

30 to 40 strong braking attempts.

• The braking effect of disc brakes can be greatly reduced when contaminated with

oil, maintenance, or cleaning uids! When cleaning your E-bike or lubricating

the chain make sure you don’t contaminate the rotors. Oily brake pads must be

replaced and brake discs must be cleaned with a brake cleaner.

• After the wheel is removed you should no longer operate the brake lever. The brake

pads will press together making it dicult to mount the wheel. After removing the

wheel, insert the transportation safety shims to ensure a sucient distance between

the brake pads.

• Before every ride, check the brake system for leaks or kinks in the lines. The loss of

brake uid can lead to the reduction and even failure of the brakes! Go immediately

to a dealer to have the leak corrected.

• Do not transport your E-bike with the wheels up as this can render the brakes

ineffective.

ATTENTION!

DISC BRAKES

Maintenance of Disc Brakes

Check the function of the brakes on a regular

base (braking performance, brake pad wear,

leakage). Brake pads must be replaced when

they are contaminated or thinner than one

millimeter. In no condition the brake pad

carrier plate must touch the brake disc.

For information regarding hydraulic disc

brakes please refer to the separate enclosed

instructions from the disc brake manufacturer.

DANGER!

Brake disc and calipers can

heat up during heavy braking.

This is especially true during

long descents. To avoid potential burns do not handle the

brakes right after heavy use.

ATTENTION!

Let the dealer replace worn out

brake pads.

38

BRAKING SYSTEM

VBRAKES

V-brakes consist of separately mounted

brake arms on the left and right side of the

wheel. When the brake arms are pulled to

gether with a cable the pads rub on the rim

generating friction.

Function check

• Check that the brake pads are properly

aligned with the rim and that they have

sucient thickness. This can be seen by

checking the transverse grooves in the

brake pad. When these grooves are worn

down, it’s time to change them.

• Additionally the front portion of the brake

pads should be the first to touch the rim.

Once touching the rear portion of the pad

should be one millimeter away from the

rim. This v-shaped orientation helps pre

-

vent the squealing of the brake pads.

• Both pads must simultaneously hit the rim

when the lever is pulled.

• The brake lever must exhibit a reserve in its

travel. It should not pull up to the handle

-

bars even during emergency braking.

DANGER!

Make sure that the pads touch

the sidewall with their entire

surface. Otherwise brake failure

or wheel lock could lead to an

accident. Make sure that the surfaces of the brake do not touch

the tires. Incorrectly set brake

pads can cause tire rub-through

leading to a tire failure.

Driving direction

39

V-brakes synchronization

The V-brakes have to be synchronized by ad

-

justing the spring preload using the respective adjustment screws A.

• Turn these screws until the pads are the

same distance from the rim.

Adjusting the brake cable

When the brake lever pulls all the way to

the handlebar, the brake cable must be

readjusted.

• Loosen the knurled lock ring B where the

brake cable enters the brake lever.

• Turn slotted barrel adjuster C a few turns.

The free travel of the brake lever is re

-

duced.

• Hold the barrel adjuster C while tightening

the lock ring B firmly against it so that the

barrel adjuster is locked in place.

• Take care that the slot of the adjustment

screw is not orientated to top or front. Oth

-

erwise water and dust could enter.

C

B

A A

TIP!

Be sure to try the brakes in a

trac free area to get a feel for

the newly adjusted brakes.

40

DANGER!

BRAKING SYSTEM

HYDRAULIC RIM BRAKES

For information regarding hydraulic rim

brakes please refer to the separate enclosed

instructions from Magura.

COASTER BRAKES

Some Riese & Müller and blueLABEL models

oer a coaster brake option. Coaster brakes

allow you to apply the brake to the rear

wheel at any time by pedaling backwards.

Riese & Müller only use coaster brakes

whose braking performance is not influ

-

enced by the current gear that one is using.

If your E-bike is equipped with a coaster

brake, you brake by pedaling backwards.

Then you have no freewheel and you can

not move the pedals backwards. The best

way to use a coaster brake is with a horizon

tal position of the pedals. With one pedal on

top you will have bad brake performance

due a a poor force application. On long

downhill passages the brake performance

can decrease due to heating up. So also use

the front brake on long downhill passages

and let the coaster brake cool down.

Before each trip and after any

maintenance work, ensure that

the coaster brake arm is securely

attached to the bracket on the

frame. This connection requires

a torque of 4 – 6 Nm.

41

SHIFTING SYSTEM

THEORETICAL FOUNDATIONS

The shifting system on the E-bike is used to

adapt one’s own performance to the terrain

and the desired speed. The physical work is

not reduced by the shifting system rather

the force required per crank revolution is

changed.

PROPER SHIFTING

Gradients can be powered up using low

gears and moderate force but you’ll have

to pedal faster. Downhill you can travel a

greater distance per turn of the crank. The

speed will be correspondingly high. Like

a car you must maintain your optimum

“engine” speed to perform well. What’s key

to your performance is keeping the number

of crank revolutions per minute (cadence)

above 60. Racing cyclists typically ride with a

cadence of 90 – 110. This rate naturally falls

o a bit during hill climbs but you should still

maintain smooth pedaling. The incremental

shifting steps and ease of use of modern

shifting systems oer the best conditions for

an ecient ride that is easy on your knees.

DERAILLEUR SYSTEM

The derailleur on the E-bike is currently the

most eective systems in terms of power

transfer. In a clean and well-oiled system

about 97 – 98 percent of the energy placed

in the pedals is transferred to the rear wheel.

Despite this near optimal performance, many

cyclists fear a bike without a coaster brake.

This fear is unfounded. The operation of the

derailleur system leaves nothing to be de

sired. With specially designed sprocket teeth,

flexible chains and precisely spaced shifting

steps, the system shifts very easily. Re

member to engage the shifter smoothly and

momentarily stop applying pressure to the

pedals until the chain is on the next sprocket.

Even though the special tooth forms of

today’s sprockets allows shifting under load,

it shortens the life of the chain and therefore

should be avoided.

ATTENTION!

Never pedal backwards while

changing the gears. The shifting

system could be damaged.

42

SHIFTERS

Riese & Müller models with derailleur system

use two dierent types of shifters:

Twist grip

Rotating the right grip towards the driver

leads to an easier gear and rotating the

left grip away from the driver leads to an

easier gear. The grip indicates which gear

you are currently using. The shifter transmits

the commands to the transmission via the

Bowden cable.

Rapid Fire shifter

The thumb on the right side shifts to easier

gears and the index finger on the right side

shifts to harder gears.

Practice shifting in a trac-free

area so that you can become

familiar with the rotation of the

shifters and pressing the levers.

The practice area should be free

of potential hazards. Practicing

in daily trac could affect your

attention to potential hazards.

DANGER!

SHIFTING SYSTEM

43

CHECKING AND ADJUSTING SHIFTING SYSTEM

Your derailleur system was carefully set by

your dealer before handing it over to you.

During the first few kilometers the shift

ing cables may lengthen thereby leading

to imprecise shifting. The chain then only

reluctantly moves to the next sprocket or

chainring.

Tensioning the rear derailleur

• Tension the cable using one of the screws

through which the cable passes (barrel

adjuster).

• After each tensioning check to see whether

the chain moves easily to the next larger

sprocket. To check this you must turn the

cranks by hand or ride the bike.

• If the chain moves easily to the next larger

sprocket, then you must also make sure

that it also changes easily to the next

smaller sprocket. For precise setting,

several attempts may be necessary.

TIP!

If you cannot properly adjust your

shifting system, it could be due to

worn or kinked shifting cables.

Visit your dealer for replacements.

DANGER!

The adjustment of the rear

derailleur is dicult and should

be left to an experienced mechanic. Incorrect settings can cause

serious mechanical damage.

If you have problems with the

system or after a crash or transport damage, please contact

your dealer.

TIP!

In case of derailleur replacement

take care of same cage length as

the original part. Otherwise a

different cage length could lead

to shifting problems because the

chain tension is to low.

44

SHIFTING SYSTEM

Function and operation

It uses a twist grip shifter to select the

desired gears. The chosen gear is indicated.

The IGH requires a momentary pause in the

application of pedal power.

Adjusting gears for internally geared hub

There are several methods used to adjust

gears for IGH and each hub is dierent. For

questions, see your dealer.

SHIMANO 8SPEED IGH

• Shift to the fourth gear.

• Now the two marks on the hub can be

brought into alignment. This is done by an

adjusting screw that the shifter cable runs

through. By turning the screw to the right

the markings move towards the front of

the bike while turning left moves the

markings towards the rear.

INTERNALLY GEARED HUB

One advantage of an internally geared hub

(IGH) is the encapsulated construction. The

technical mechanisms are almost completely

enclosed inside the hub. This prevents con

tamination from dirt and grime. The chain

on an IGH system lasts longer than on an

equivalent derailleur system. A disadvantage

is the slightly higher power losses within the

hub. IGH are sometimes used in combination

with a derailleur, freewheel and rim, roller or

integrated coaster brake.

Practice shifting in a trac free

area. Practice also using the

brakes. In road trac you may

be distracted from shifting and

braking by potential hazards.

DANGER!

45

DUALDRIVE IGH

• Shift the IGH to the middle gear.

• Now the yellow mark inside the clickbox

can be brought into alignment. This is done

by the adjusting screw where the shifter

cable goes into the clickbox.

ROHLOFF IGH

Please follow the instructions in the sepa

-

rately included Rohlo manual.

NUVINCI IGH

Please follow the instructions in the

separately included NuVinci manual.

46

CHAIN

CHAIN CARE

The old saying is still true: “Whoever oils well,

rides well”. The amount of lubrication is not

as important as the distribution and regular

-

ity of application.

• Clean your chain from time to time with a

dry cloth the removed built up dirt and oil.

• Lubricate the most clean chain possible

using chain oil, grease or wax. Wax is a very

clean lubricant which is recommended for

Riese & Müller E-bikes.

• Turning the crank and drizzle or spray

the rollers of the chain. Rotate the chain

several times. Let the bike stand for several

minutes to allow the lubricant to penetrate

the chain links.

• Finish up by wiping excess lubricant o

with a cloth to prevent it from slinging o

while riding.

CHAIN WEAR

Chains are one of the consumable parts on

a bicycle but the lifespan of the chain is

determined by how the rider maintains it.

Be sure the chain is lubricated regularly,

especially after riding in the rain. Chains of

derailleurs often last from 1,500 – 3,000 km

before needing replacement. Greatly elon

gated chains impair shifting and wear down

sprockets and chainrings more quickly.

Replacing these items cost much more than

a chain so we recommend changing the

chain regularly.

CHECKING THE CHAIN TENSION

On bikes with internally geared hubs and

without a chain tensioner sometimes the

chain is insuciently tensioned. It is very

important to maintain the correct chain ten

sion otherwise the chain will hit the inside of

the enclosure and cause noise or a too high

tension increases wear.

How to check the chain tension:

• When grabbed in the rear lower section

and pulled up, the chain should move a few

millimeters only.

TIP!

For the protection of the environment use only biodegradable

lubricants because a small amount

of lubricant always ends up on the

ground, especially during rain.

47

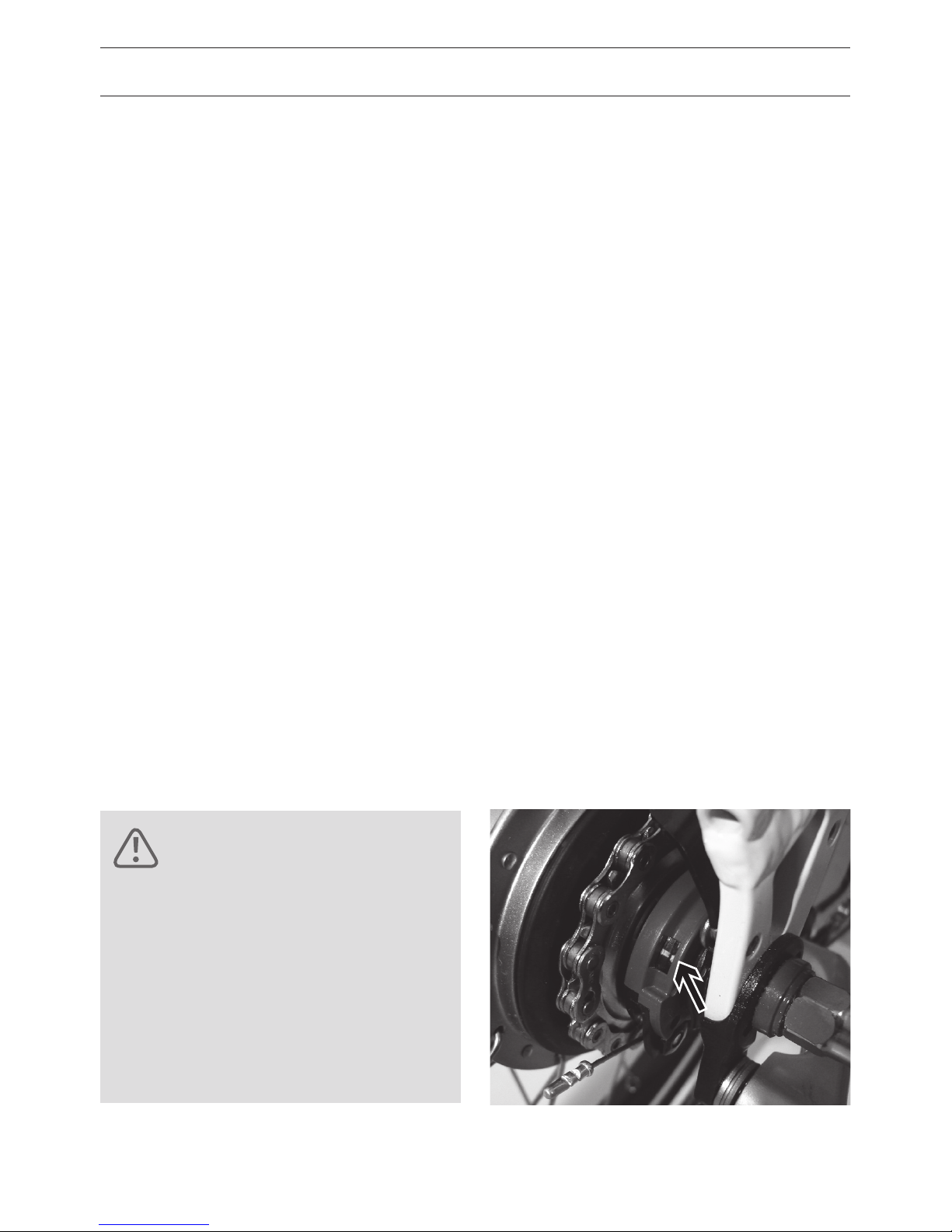

• Check the chain tension at dierent crank

positions.

• Check that the rear wheel is aligned cor

-

rectly in the direction of travel.

• Tighten the bolts A and possibly the brake

anchor with the correct tightening torque.

Checking rear brake and shifting system

The adjustment of the chain tension changes

the rear wheel position. Make sure the rear

brake pads are correctly oriented to the rim

(see page 40).

• If the chain moves more than a few millim

eters down, then it could slap the swingarm

and should be tensioned.

• Shut o the E-bike drive, lift the rear wheel

o the ground and turn the crank. When

the crank is sti and provides uneven

resistance when turning, the chain is too

tight.

ADJUSTING THE CHAIN TENSION

• At models with coaster brake loosen the

brake anchor attachment of the coaster

brake.

• At models without slider dropouts loosen

the axle nuts a few turns. At models with

slider dropouts loosen the four bolts A a

few turns.

• At models without slider dropouts pull the

rear wheel back and tighten the axle nuts

slightly. At models with slider dropouts

tighten the two adjustment bolts B on both

sides with the same number of revolutions.

Turning clockwise tightens the chain and

counterclockwise relaxes the chain.

A

B

The chain tension at the models

Avenue, Culture and Kendu

increases a little bit when the

suspension starts to work.

This is another reason to adjust

the chain tension not to tight.

ATTENTION!

Wrong assembly can cause

malfunction or failure at shifting

and braking system. Absolutely

check the function of shifting

and braking system after chain

tension adjustment.

DANGER!

48

A poorly riveted chain can break

and lead to a fall. It’s best to let

your dealer replace the chain.

DANGER!

REPLACING THE CHAIN

The replacement of a chain is best left to

your dealer who has special tools to accu

rately measure your chain and to cut your

chain to the appropriate length. Many mod

ern chains have no chain lock and a special

tool is required to link up the two halves of

the chain. Your dealer has all of the tools that

match your chain.

REPLACING THE SPROCKET

BELT DRIVE

If your E-Bike is fitted with a belt drive please

follow the instructions in the separately

included Gates manual.

ATTENTION!

At the models Avenue, Culture and

Kendu the front sprocket must

always be replaced by parts with the

same number of teeth. Using other

sprocket sizes affects the chain tension and the chain may snatch

or fall down!

BELT DRIVE

49

WHEELS AND TIRES

The wheels on the bike keep you in contact

with the road. They experience heavy loads

during riding over irregular surfaces and

when carrying cargo. Although the wheels

are carefully manufactured and trued, they

settle in after the first few kilometers. After

a short break-in period from 200 to 400

kilometers, your dealer should true the

wheels again. Regularly check the wheels

but additional tensioning is rarely necessary.

CONSTRUCTION OF A WHEEL

The wheel consists of a hub, rim and spokes.

The tire is mounted to the rim in which the

tube is inserted. Rim tape is applied to

protect the sensitive tube from the often

sharp-edged rim.

TIRES AND AIR PRESSURE

The tire provides grip and traction on the

road which is required during braking,

accelerating, and cornering. Furthermore, it

ensures smooth running. Tires can only work

well if it filled to the correct air pressure.

The correct inflation pressure also prevents

failures such as the crushing of the tube

especially when traveling over an edge, the

so called “snake bite”. Snake bites are caused

when going over an edge such as a curb

with a tire pressure that is too low. The man

ufacturer’s suggested pressure is indicated

on the sidewall of the tire in bar and PSI.

TUBE AND VALVE

The tire and rim alone are not airtight.

To maintain the pressure on the interior,

TIP!

Always ride with the prescribed air

pressure and check it regularly. Because Riese & Müller E-bikes are full

suspension (excluding blueLABEL)

you can always inate the tires to the

maximum recommended pressure.

This provides you the best and safest

riding position and low rolling resistance which saves energy. Comfort is

maintained because of the full suspension system.

TIP!

For the model blueLABEL Charger GT

we recommend an air pressure range

from 1.5 up to 2.5 bar.

Never pump the tires below the

minimum or over the maximum

recommended pressure rating!

The tire can spring from the rim

or burst leading to an accident!

DANGER!

50

WHEELS AND TIRES

the tube is inserted into the tire. It is filled

through a valve. Riese & Müller E-bikes use

presta valves exclusively. Before inflation,

the small knurled nut is unscrewed and

then pressed back down into the valve. It is

normal for a little air to escape during this

process.

If the presta valve is not suciently tight

ened, this leads to the gradual loss of air.

Check the tightness of the of the valve body

in the elongated shaft. Make sure the valve

diameter matches the hole in the rim and

that the valve stands up straight.

CHECKING THE TIRES

Regularly check the tires.

DANGER!

If the tread is worn or the edges

are brittle, you should replace

them. The inside of the tire may

be damaged if is contaminated

by moisture or dirt. Defective rim

tape must be replaced immediately. Damage to the tires can lead

to their sudden bursting which

could be dangerous.

51

RIM RUNOUT AND SPOKE TENSION

The spokes connect the rim with the hub in

the center of the wheel. The uniform spoke

tension is responsible for maintaining the

concentricity of the wheel. When a spoke

breaks when running over a severe bump,

the tension of the spokes is no longer in

equilibrium. Even before the rider notices the

malfunction it is aecting your bike. The side

walls of the rims no longer run parallel to

the braking surface so braking eectiveness

cannot be ensured.

Be sure to check the concentricity (runout)

from time to time. Lift the wheel from the

ground and spin it with your hand. Watch the

gap between the rim and brake pad. If this

gap changes by more than one millimeter it

needs to be trued by a professional.

TIP!

The truing of wheels is dicult

work and is best left to your dealer!

TIP!

Please read more on rim wear

indicators at page 34.

Do not ride with wheels that are

out of true. If the rim is severely

out of true then the brake pad

can miss the rim sidewall and

actually strike the spokes leading

to an accident.

DANGER!

Check the rims for wear and

defects on a regular base. Worn

out rims are more delicate for

defects. V-brakes cause more

wear. A deformed or broken rim

may lead to heavy accidents.

DANGER!

52

B

A

WHEEL ATTACHMENT

The wheels are attached to the frame via ei

ther an axle with a hex nut or a quick release

clamped in the dropouts. More information

on quick releases on page 18 –19.

AXLE NUTS

Note the respective torque settings of the

axle nuts.

THROUGH AXLES

Some Riese & Müller models use a front fork

with through axle. Please follow the instruc

tions in the separately included front fork

manual.

QUICK RELEASES

The quick release consists of two control

elements:

• A lever A on one side of the hub that pro

-

duces the clamping force.

• A locking nut B which is threaded on the

opposite side that sets the tension.

DANGER!

Never ride a bike without rst

checking that the wheels are

securely attached to the frame

with a quick release or bolt. If

not securely attached, the wheel

could fall out during the ride and

lead to a severe injury!

DANGER!

Check the tight t of quick releases, thru axles and bolts even

if you parked your E-bike only

shortly at an unattended place.

Do not ride your E-bike with

untightened quick releases.

WHEELS AND TIRES

53

REPAIRING A PUNCTURE

PREPARING TO REMOVE THE WHEEL

Each model has certain things that must be

done before the wheel can be removed.

These are described below.

Unhook V-brakes

With V-brakes the brake cable must first be

unhooked. Grasp it with one hand, moving

the cable hanger A and the guide tube B

with the other hand. If the brake cable is set

to tight, you can reduce the tension by turn

-

ing the barrel adjuster on the brake lever.

DISC BRAKES

Please note the tips regarding disassembly

of wheels on page 35.

TIP!

Depending on the E-bike model,

the removal and replacement

of the rear wheel may be more

dicult than you are used to.

Carefully read the notes on the

following pages. Should you

encounter any problems your

dealer or Riese & Müller are at

your disposal.

B

A

54

REPAIRING A PUNCTURE

MAGURA RIM BRAKES

Please note the tips in the separately in

-

cluded instruction manual from Magura.

ROHLOFF SYSTEM

Please observe the instructions of the sepa

-

rately included Rohlo manual.

DERAILLEUR GEAR

Before removing the rear wheel of derail

leur systems, be sure to shift to the smallest

sprocket. Thus the derailleur is all the way to

the outside and does not hinder the removal.

SHIMANO IGH

• Shift into first gear.

• Loosen the axle nuts.

• Take the rear wheel out.

• Rotate the fixing ring F counter-clockwise

and remove the shifting arm G from the

axle.

INTERNALLY GEARED HUB WITH

COASTER BRAKE

The brake arm A which attaches to the frame

and supports the hub while under brake

torque. Loosen the screws B.

SRAM DUAL DRIVE SYSTEM

Before removing the rear wheel, the clickbox

must be removed.

• Press the black button D on the clickbox

and remove it.

• A push rod is inserted in the axle. Be sure

not to lose it.

• Note the position of the washers and axle

nuts.

A

B

D

G

F

55

• Remove the left slider A diagonally to the

rear top. The tube can be replaced through

the now resulted gap.

• Alternatively you can remove the rear

wheel and remove the Harmony shifting

box (see NuVinci manual). Then it is pos

sible to lift the chain from the rear sprocket.

For assembly please note exactly the same

position of the shifting box.

NUVINCI AND NUVINCI HARMONY SYSTEM

Please observe the instructions of the sepa

-

rately included NuVinci manual.

CHANGING THE WHEEL ON BIKES WITH

QUICKRELEASE

Open the quick-release lever as described on

page 18.

• To facilitate the removal, draw the derail

leur or chain tensioner back with your hand.

Lift the bike slightly from the ground and

gently press down on the rear wheel.

WHEEL REMOVAL AT AVENUE HARMONY

Instead of removing the rear wheel it is also

possible to do the following:

• Open the quick-release of the left brake

body.

• Lift the left sidewall of the tire over the rim

and pull out the tube.

• Loosen the left axle nut.

• Loosen both bolts of the left slider dropout.

A

56

REPAIRING A PUNCTURE

REMOVING TIRES

• Unscrew the valve cover and mounting

nuts and let all of the air out.

• Press the tire from the sidewall towards the

center of the rim. Do this over the entire

circumference to make removing the tire

easier.

• Insert the brake levers on the right and left

side of the valve at the lower edge of the

tire. Keep one lever in this position and pry

the rim bead over the sidewall with the

other lever.

• Now you can remove the tube. Make sure

the valve doesn’t get caught in the rim and

that the tube isn’t damaged.

CHECK TIRE AND APPLY PATCH

• Patch hole according to the instructions

from the patch manufacturer.

• If you have removed the tire, you should

also check the rim tape. It should sit evenly

and must not be cracked or damaged and

should cover all spoke holes. If you have

questions about your rim tape, please ask

your dealer.

MOUNTING TIRE

• Make sure when installing the tire that no

foreign matter such as dirt or sand gets

inside as this could damage the tube.

• Place the rim with a horn in the tire. Press

the tire sidewall completely over the rim.

This should be possible with every tire

without using a tool.

• Insert the valve in the valve hole in the rim.

• Inflate the tube lightly so that it assumes a

round shape. Insert it completely in the tire

being careful not to crease it.

Make sure not to damage the

tube with the levers.

ATTENTION!

57

• Begin the installation on the side opposite

of the valve. Press the tire on the rim mak

ing sure not to pinch the tube between the

rim and the tire. Push the tube repeatedly

into the interior of the tire.

• Work both sides evenly around the circum

ference of the wheel. Towards the end you

will need to press the tire down firmly. Pull

the already mounted portion deep into the

rim as this facilitates mounting the last few

centimeters.

• Check again to make sure the tube is well

seated and press the tire with your palm

over the rim bead. If this fails, you must use

tire levers. Make sure that the dull side is

facing the tube so as not to damage it.

• Press the valve into the interior of the tire

so that the tube is not pinched between

the tire and rim.

• Is the valve facing straight up? If it is not

remove one side of the tire and readjust

the tube. If you want to make sure that the

tube is not crushed under the edge, you

should halfway inflate the tire and roll it

back and forth around the circumference of

the wheel.

• Pump up the tire to the desired pressure.

The maximum pressure is indicated on the

sidewall of the tire.

• Check the fit of the tire specifically the wire

(or Kevlar) bead against the sidewall of the

rim. The important thing is that the whole

tire has a uniform distance from the rim.

58

REPAIRING A PUNCTURE

FITTING CHAIN AND INSTALLING WHEEL

• On bikes with derailleur or chain tensioner,

pull it backwards and set the chain to the

smallest sprocket.

• Insert the rear wheel into the dropouts.

• At E-bikes with enclosed drive you must

place the rear wheel as shown and set the

chain onto the sprocket.

REINSTALLING THE WHEEL

The following section covers the reinstalla

tion of wheels in all Riese & Müller E-bikes.

Please read the entire section dealing with

your specific bike. Essentially the installation

process is the reverse of the removal.

CASSETTE JOINT FIXING RING

For bicycles with Shimano gear hubs, the

shift ring must in place before the rear wheel

can be reinstalled. The mounting ring must

be locked by rotating clockwise. Note the po

sition of the colored dots and that the shifter

is in the in the first gear.

Source: Shimano techdocs

For assembling align the

yellow marks •

Cassette joint fixing ring

Cassette joint

59

• Take care that the shifting arm point front

up. Insert the rear wheel into the dropouts.

Take care of correct position of the chain on

chainwheel and sprocket.

• Insert the rear wheel into the dropouts.

Take care of correct position of the chain on

chainwheel and sprocket.

POSITION OF THE WHEEL AND

CHAIN TENSION

• Check that the wheel is centered and if the

chain tension is sucient. More details on

the chain tension can be found on page

44 – 45 .

• Make sure that the chain is correctly placed