40 SERIES GAS BURNER

MODEL 400 NATURAL GAS/PROPANE

INSTALLATION INSTRUCTIONS AND OWNER’S HANDBOOK

CAUTION: All gas burners MUST be installed by trained and licensed technicians.

WARNING: Installation of this burner must conform with local codes or, in the absence of local codes, with

the Standard for the Installation of Domestic Gas Conversion Burners, ANSI Z21.8-1984, and Addendum,

Z21.8a-1989, and the National Fuel Gas code, ANSI Z223.1-1984, and CAN/CGA B149.1 &.2. If an external

electrical source is utilized, the conversion burner, when installed, must be electrically grounded in

accordance with local codes or, in the absence of local codes, with the national Electrical Code, ANSI/NFPA

No. 70-1990 and CSA Electrical Code.

Owner is required to retain this manual for future reference.

TECHNICAL SPECIFICATIONS

FIRING RATE 170,000 TO 400,000 Btu/hr

NATURAL PROPANE

GAS SUPPLY PRESSURES

MANIFOLD PRESSURES

POWER 120 VOLTS 60 Hz 1 PHASE

MOTOR 232T 2.2 AMPS 3250 RPM

CONTROL MODULE 525 SE/A ELECTRONIC

MIN. 4" w.c.

MAX. 10" w.c.

MIN. 0.90" w.c.

MAX. 1.80" w.c.

MIN. 8" w.c.

MAX. 13" w.c.

MIN. 1.04" w.c.

MAX. 3.04" w.c.

WARNING: If the information in these instructions is not followed exactly, a fire or

explosion may result causing property damage, personal injury or death.

Do not store or use gasoline or any other flammable vapours or liquid in the

vicinity of this or any other appliance.

WHAT TO DO IF YOU SMELL GAS:

1) Do not try to light any appliance.

2) Do not touch electrical switches; Do not use any phone in your building.

3) Immediately call your gas supplier from a neighbour's phone. Follow the gas

supplier's instructions.

4) If you cannot reach your gas supplier, call the fire department.

Installation and service must be performed by a qualified installer, service agency

or the gas supplier.

C6505020 STD G400 Manual Rev.5 -06/10/2002 1

TABLE OF CONTENT

PRINCIPAL BURNER COMPONENTS .................................................................................................4

DIMENSIONS..........................................................................................................................................4

ELECTRODE & FLAME PROBE ADJUSTMENTS ..............................................................................5

TYPICAL GAS TRAIN LAYOUT...........................................................................................................6

INSTALLING THE BURNER .................................................................................................................7

INSTALLATION OF SEDIMENT TRAP & BURNER SUPPLY ...........................................................9

FIELD WIRING DIAGRAM..................................................................................................................10

FACTORY WIRING DIAGRAM...........................................................................................................10

SETTING UP THE BURNER ...........................................................................................................11-12

OPERATING FAULTS ..........................................................................................................................12

AIR GATE ADJUSTMENT ...................................................................................................................12

COMBUSTION HEAD SETTING ........................................................................................................13

MANIFOLD PRESSURES ................................................................................................................13-14

PRESSURE WORKING CHART...........................................................................................................14

COMBUSTION CHECKS .....................................................................................................................15

STARTING CYCLE ..............................................................................................................................16

PROBLEM SOLVING GUIDE .........................................................................................................16-17

OWNER INFORMATION & ROUTINE MAINTENANCE............................................................17-18

INSTALLATION DATA........................................................................................................................18

SPARE PARTS LIST..............................................................................................................................19

SPARE PARTS DIAGRAM ..................................................................................................................20

Burner Start-up Form………………………………………………………………………………...21

C6505020 STD G400 Manual Rev.5 -06/10/2002 2

The following pages contain information, descriptions and diagrams for the proper

Year of

BI-week of

Burner produc

t

installation and wiring of the burner. Please read carefully before attempting final

installation.

The responsibility for ensuring that this manual is complete rests with the holder of these

instructions.

SERIAL NUMBER IDENTIFICATION

The Riello 15 character serial number, example, 99 A 8511111 00025, is identified as follows:

99 = last two digits of the year of manufacture; A = BI-week of manufacture; 8511111 = burner product code;

00025 = increment of 1 for each burner produced – specific to product code – reset to zero each January 1st.

manufacture

(99) (A) (8511111) (00025)

manufacture

code

Increment

C6505020 STD G400 Manual Rev.5 -06/10/2002 3

PRINCIPAL BURNER COMPONENTS

1. Air Damper (Optional Delete)

2. Air Gate Lock-screws

3. Wiring Terminal Block

4. Air Pressure Switch

5. Motor

6. Lockout Lamps and Reset Button

7. Cover Screw

8. Rubber Grommet

9. Capacitor

BURNER DIMENSIONS

Model 400

inches 10 5/16 12 1 3/8 13 11/16 3 3/4 10 4 1/8

mm 2262 305 35 347 95 255 61

A B C F G *G1 H

*G1 is for LBT version

Gasket thickness is 4 millimeters

C6505020 STD G400 Manual Rev.5 -06/10/2002 4

UNIVERSAL MOUNTING FLANGE

UNIVERSAL MOUNTING FLANGE DIMENSIONS

inches 1 1/4 1/4 7/16 2 3/16

millimeters 32 6 11 56

A B C D

ELECTRODE AND FLAME PROBE ADJUSTMENTS

IMPORTANT: Do not turn the ignition electrode. Leave it as shown in the drawing. If the ignition

electrode is put near the ionization probe, the amplifier of the control box may be damaged.

C6505020 STD G400 Manual Rev.5 -06/10/2002 5

TYPICAL GAS TRAIN LAYOUT

FIELD SUPPLIED

RIELLO SUPPLIED

1 2 3 5 6

4

7

8

SEE GAS

SUPPLY

Ø

RANGE

NOTE: ITEMS 5,6 & 7 COMBINATION GAS VALVE(S) ASSEMBLIES MAY BE UTILIZED WHERE APPROVED.

GAS TRAIN LEGEND

1) GAS SUPPLY & FLOW DIRECTION OF GAS

2) GAS SUPPLY MAIN SHUTOFF MANUAL VALVE (FIELD

SUPPLIED)

3) GAS SUPPLY PRESSURE TEST POINT (FIELD SUPPLIED)

4) GAS TRAIN PIPE DIAMETER SIZE(S):

BURNER G120 1/2" NPT (REDUCED AT COMBUSTION HEAD

TO 3/8")

BURNER(S) G200 & G400 3/4" NPT

GAS SUPPLY PRESSURE RANGES:

NATURAL GAS PRESSURE:

MIN. = 4.0" WC

MAX. 10.5" WC

L.P. PROPANE GAS PRESSURE:

MIN. = 8.0" WC

MAX. 13.0" WC

5) GAS APPLIANCE PRESSURE REGULATOR

6) SAFETY SHUTOFF GAS VALVE (VS) 24V OR 120V

OPERATED

7) MAIN GAS VALVE (V1) 24V OR 120V OPERATED

SINGLE STAGE

8) GAS BURNER MANIFOLD TEST POINT

C6505020 STD G400 Manual Rev.5 -06/10/2002 6

INSTALING THE BURNER

Wet Base Illustration

A) Burner Chassis

B) Combustion Head Assembly

1. Locking Nut

2. Appliance Mounting Plate Insulation

3. Insulation Gasket

Use this checklist prior to installation:

1) Check the input/output requirements

of the appliance. We suggest that the

appliance output should be

approximately 85% of input (85%

efficiency).

2) Check the dimensions of the combustion chamber for correct sizing against the input requirements

of the application.

3) Check that there is sufficient air for proper combustion and adequate ventilation. Local codes

should be followed. In the absence of local codes, refer to the NFPA Manual No. 31, CAN/CGA B149.1

&.2, ANSI Z223.1-1984 and Addendum 221.8A 1989.

4) Check that you have adequate space for servicing the equipment. The Riello burner requires a

minimum of 13 inches clear space behind the red cover. This is required to allow easy removal of the

cover for servicing and periodic maintenance.

5) Check that the chimney is of sufficient area to handle the exhaust gases. Make sure the chimney is

clear and there are no obstructions.

6) Barometric draft regulators must be of the double acting type, and must be installed in accordance

with the draft regulator manufacturer's instructions. Single acting barometric dampers are not

permitted. For further clarification, refer to ANSI Z21.8-1984 and Z21.17A-1993.

NOTE: A vent shutoff system shall be applied to a barometric damper installed in the venting

system at the time of conversion of the appliance. This will electrically disconnect the burner

should there be a blockage in the vent (chimney).

IMPORTANT:

The installer must identify the main electrical power switch and manual gas shut off valve, for emergency

conditions. The burner cover must be in place and secured before the burner is placed in operation.

GENERAL INFORMATION

Your Riello gas burner comes to you completely assembled and factory wired, ready for installation.

Models equipped with the short combustion head have a fixed flange, which bolts directly to the front of the

appliance. When equipped with the long combustion head, the burner comes with a universal flange, which

when bolted to the appliance, allows the burner to be adjusted for exact positioning in the combustion zone.

C6505020 STD G400 Manual Rev.5 -06/10/2002 7

STEP -BY-STEP PROCEDURE

1) Remove the burner from the carton, taking care not to lose any of the supplied accessories. Check for

signs of physical damage.

2) Bolt the combustion head and burner to the appliance. Be sure to install the supplied mounting

gasket. Ensure that the burner is level (we suggest using a spirit level) and that the combustion head is

centred in the appliance port. Refer to Page 7 for positioning of combustion head relative to the chamber.

3) Check that all gas train connections are tight and make your connections to the incoming gas supply.

a) A sediment trap must be provided. See pg. 9.

b) If not already installed, a manual shutoff valve must be supplied. This valve must be upstream of

the burner gas train supply connection.

c) A 1/8" NPT plugged tapping must be installed immediately upstream of the burner gas train

supply connection and must be accessible for a test gauge.

d) If required by local codes, provide gas vent lines at the gas regulators and valve.

e) Perform required gas pressure test on incoming gas supply lines.

NOTE: Details of sediment trap, manual gas valve, pressure test point, and line pressure test point can

be found on Page 9.

4) To make electrical connections, refer to field wiring diagram on p age 10. A manual disconnect switch

must be installed in the incoming lines. Wiring to the low voltage -switching relay, if used, (Honeywell

R8038A) must be rigid conduit or flexible approved cable.

CAUTION: Label all wires prior to disconnection when servicing controls. Wiring errors can

cause improper and dangerous operation. Verify proper operation after servicing (Step 5 (e) below).

CAUTION: The phase (HOT) wire must be connected to the black lead of the 24v relay if used; neutral

to the white lead. Do not reverse the polarity. The burner will not operate with the Phase/Neutral reversed,

and the control box may be damaged.

5) Check the burner functions as follows:

a) Make a final check on both the gas and electrical connections.

b) Loosen the screw in the manifold gas test point and install an appropriate manometer.

c) Set the thermostat at its highest setting.

d) Switch on power.

e) With the manual gas valve turned off, press the burner reset button (see page 4), and allow the burner to

run through a complete cycle to ensure that the sequence of operations is correct, (see page 16). A full

starting cycle should take approximately 70 seconds from a no power condition until burner lockout,

when equipped with motorized air damper, otherwise refer to the start-up cycle chart found on page 16.

f) Once the burner is operational (up and running) a final gas leak check must be completed on the gas

train.

6) If the burner is installed on a central warm air furnace, affix the mandatory warning labe ls to the

furnace fan cover door (inside and outside).

C6505020 STD G400 Manual Rev.5 -06/10/2002 8

INSTALLATION OF SEDIMENT TRAP AND BURNER SUPPLY

Gas piping to the burner must be 1/2 inch minimum. Install only a full ported shutoff valve. The valve must

be located outside the appliance jacket, and the pressure gauge port must be accessible.

PRESSURE TEST -OVER 1/2 PSIG.

The appliance and its individual shutoff valve must be disconnected from the gas supply piping system during

any pressure testing of the system at a test pressure in excess of 1/2 PSIG.

PRESSURE TEST -1/2 PSIG OR LESS

The appliance must be isolated from the gas supply piping system by closing its individual manual shutoff

valve during any testing of the gas supply piping system at test pressures equal to or less than 1/2 PSIG.

C6505020 STD G400 Manual Rev.5 -06/10/2002 9

FIELD WIRING DIAGRAM

120 V controlled 24 V controlled

V1 V2 L N L N

24 Volts

operating

control

Gnd.

Green

red

operating

control

white

black

Optional 24 V

controlled

24 Volt Relay *

Green

Gnd.

T T

F

service

switch

L

N

120 Volts 60 Hz.

F

service

switch

L N

FACTORY WIRING DIAGRAM

RIELLO POWER GAS BURNER

MODELS G120, G200 & G400

INTERNAL FACTORY WIRING DIAGRAM:

A) Standard burner come with 120/24 volt transformer for 24v

operated gas valves, for 120V operated gas valves delete

transformer.

B) Optional AIR DAMPER MOTOR

C) Remote sensing of 525 SE/A control box lock out. Installer

supplied and wired.

525 SE/A

9

CONTROL

BOX

3

681

NL

2

7

4

125

NO

NC

PA

C

Air damper motor

B

C

Optional wiring

Remote lock out

sensing wiring

Capacitor

A

MM

White

Brown

Blue

White

Black

Black

Black

Black

V2V1

NOTE:

1) This burner is approved for use without the motorized air damper. In these instances optional wiring is used

2) The SAFETY SWITCH on the 525 SE CONTROL BOX is equipped with a contact allowing remote sensing of

burner lockout. The electrical connection is located on the CONTROL BOX terminal 4 as indicated. Should

C6505020 STD G400 Manual Rev.5 -06/10/2002 10

burner lockout occur, the 525 SE CONTROL BOX will supply a power source of 120 Vac to the connection

terminal. The maximum allowable current draw on this terminal is 1 A.

IMPORTANT

Terminal 4 is to be used only for the connection of a remote sensing device. If a neutral or ground lead is

attached to terminal 4 the control box will be damaged should lockout occur

SETTING UP THE BURNER

After burner output has been determined, use TABLE 1 below AS AN INITIAL GUIDE for burner settings.

Table 1

Approximate Btu/hr

burner output

Natural Gas

Head Air gate Manifold

setting setting pressure

170, 000 0.0 1.6 0.90”w.c.

216, 000 1.0 1.8 0.90”w.c.

262,000 2.0 2.2 1.00”w.c.

308,000 3.0 2.5 1.20”w.c.

354,000 4.0 2.8 1.42”w.c.

400,000 5.0 3.4 1.80 w.c.

Propane

170, 000 0.0 1.6 1.04”w.c.

216, 000 1.0 1.8 1.16”w.c.

262,000 2.0 2.2 1.48”w.c.

308,000 3.0 2.5 1.80”w.c.

354,000 4.0 3.0 2.42”w.c.

400,000 5.0 3.6 3.04”w.c.

STEP BY STEP PROCEDURE

1) Set air gate. See AIR GATE ADJUSTMENT on pg. 13/14.

2) Set combustion head. See COMBUSTION HEAD SETTING on pg. 13.

3) Set the manifold pressure using the following method.

a) In order to determine existing manifold pressure, start the burner. At the end of the prepurge cycle

(approx. 30s), the gas valve is energized. During the 5 sec. trial for ignition, note the manifold pressure.

If the burner lights and continues to run, go to step (d).

b) Compare the observed manifold pressure from step (a) to the required value from TABLE 1.

c) Repeat step (a), making adjustments to the gas valve, until flame is established.

d) Once flame has been established, set your manifold pressure to the desired value from TABLE 1.

4) Check combustion gases using proper combustion analysis equipment to ensure safe levels of CO2 and CO

during appli ance heat up. The gas valve should be used to make any necessary adjustments to ensure safe

combustion. At this point do not adjust the air or head settings unless absolutely necessary.

5) Allow burner to run until normal operating temperatures and conditions have been achieved.

6) a) Clock the gas meter to determine actual burner output.

b) Set the manifold pressure, by adjusting the gas valve, to achieve desired output.

c) Check combustion gases once again to ensure safe operation. Make sure the burner cover is in

place and air gate locking screws are secure for all combustion analysis. Adjust air gate if

necessary (refer to page12). This test must be done by a qualified technician. The maximum

recommended CO2 level for natural gas is 10%; the maximum recommended level for propane gas is

12%. The recommended flue gas temperature is from 350?F to 550?F.

7) After completing the adjustments, remove the manometer and tighten the screw inside the manifold test

point. Replace the regulator cap on the gas valve.

8) Complete the adjustment data tag, described on page18. Explain the burners essential functions (starting

and stopping) to the owner. Do not forget to give the dealer or service company's name and address. Please

see page17 and 18 for information on burner maintenance procedures.

All settings in this table were

obtained under the following

conditions.

?? 0 (zero) draft in the combustion

zone.

?? Small DIN test boiler.

?? 7” supply pressure for natural

gas.

?? 11” supply pressure for

propane.

?? steady state (HOT) operating

conditions

NOTE: Do not assume the heating system is operating at optimum performance.

C6505020 STD G400 Manual Rev.5 -06/10/2002 11

THERE IS NO SUBSTITUTE FOR PROPER COMBUSTION TESTING

OPERATING FAULTS

The integrated control system is self checking. The cycle from start up to flame establishment, takes

approximately 70 seconds.

The burner will go into lockout under the following circumstances:

a) Burner fails to ignite.

b) The ionization probe is grounded.

c) Opening of the air pressure switch or the normally open contacts of the air pressure switch not

Should overheating of the appliance occur, shut off the manual gas valve to the burner. Do NOT

shut off the switch to the circulating pump or blower fan.

SHUT DOWN PROCEDURE

Switch off electrical power to the unit. Close the manual supply gas valve.

START UP PROCEDURE

See page 8, Item 5

NOTE: If an external electrical source is utilized, the conversion burner, when installed, must be electrically

grounded in accordance with local codes. In the absen ce of local codes, refer to the National Electrical Code,

ANSI/NFPA 70-1990.

In Canada follow the Canadian Electrical Code Part 1 CSA C22.1.

making.

AIR GATE ADJUSTMENT

The mobile air damper (1), operated by the air damper motor (2), assures the complete opening of the air

intake. To regulate the combustion air, adjust the

manual air gate (3), by loosening the locking screws (4).

Once the optimal adjustment is reached, tighten the

locking screws(4), to assure free movement of the mobile

air damper.

EXAMPLE SETTING

(for natural gas)

To set the air intake for a desired burner

output of 308,000 Btu/hr, use TABLE 2 to

determine the correct air gate setting. In this

case, the setting would be 2.5 for natural gas.

Turn the manual air gate (3) until the arrow

points to 2.5 on the scale. Tighten locking

screws (4).

C6505020 STD G400 Manual Rev.5 -06/10/2002 12

All settings in table 2 are obtained with

Table 2

Table 3

zero (0) pressure in the combustion

zone and at normal operating

temperatures. i.e., steady state hot

conditions.

Please Note: Burner must be fired ONLY with

fuel that is listed on the burner serial label.

Burner Output Air Gate Setting

Btu/hr x 1000 Natural Propane

Riello 40 Model 400 N/P

Air Gate Settings

170.0 1.6 1.6

216.0 1.8 1.8

262.0 2.2 2.2

308.0 2.5 2.5

354.0 2.8 3.0

400.0 3.4 3.6

COMBUSTION HEAD SETTING( Stop Gate)

Loosen the Allen screw (A). Slide the elbow (B) so

that the number on the indicator scale (D) aligns

with the back edge of the air tube (C). See

TABLE 3 for set points. Tighten the Allen screw (A).

NOTE: To disassemble remove the combustion head,

use the procedure below.

1) Remove the Allen screw completely.

2) Withdraw the head.

3) Pull the head straight out.

Example (for natural gas):

For a desired burner output of 308,000 Btu/hr,

the combustion head setting would be 3.0

NOTE:

This table is designed to ensure a good

working pressure for the air proving switch.

If a problem is encountered with the air

switch proving combustion air flow, we

suggest moving the head closer to the

zero (0) set point.

For a boiler or furnace with positive

pressure in the combustion zone, we

suggest moving the head closer to the zero

(0) set point.

All settings in table 3 are obtained with zero

(0) pressure in the combustion zone and at

(1) normal

operating temperatures. i.e.; steady state hot conditions.

Please Note: Burner must be fired ONLY with fuel that is listed on the burner serial label.

Combustion Head Settings (STOP GATE)

Burner Output

Btu/hr x 1000 Natural Propane

Riello 40 Model 400 N/P

Head Setting

170.0 0.0 0.0

216.0 1.0 1.0

262.0 2.0 2.0

308.0 3.0 3.0

354.0 4.0 4.0

400.0 5.0 5.0

C6505020 STD G400 Manual Rev.5 -06/10/2002 13

MANIFOLD PRESSURES

Table

4

Manifold gas pressure for various firing rates must be set by adjusting the gas regulator of the gas valve. To

check manifold gas pressure, attach a manometer to the manifold test point, shown on typical gas train layout

on page 6. Approximate manifold pressure settings are indicated in TABLE 4.

Example (for natural gas):

For a burner to be fired at 308,000 Btu/hr, the manifold pressure would be approximately 1.20" w.c. (inches

of water column).

Riello 40 Model 400 N/P

Manifold Pressure Inches of w.c.

Burner Output Inches of w.c.

Btu/hr x 1000 Natural Propane

170.0 0.90 1.04

216.0 0.90 1.16

262.0 1.00 1.48

308.0 1.20 1.80

354.0 1.42 2.42

400.0 1.80 3.04

HIGH ALTITUDE SETTINGS

It should be noted that for higher altitudes more air for combustion is required. All settings in this manual

have been obtained at approximately sea level. Special attention should be paid to air for combustion at

elevations above sea level . If an increase in combustion air is insufficient, the burner must then be derated by

approximately 4% for every 1000 feet above sea level.

Manifold pressure will have to be

adjusted to compensate for varying

application conditions.

All settings in table 4 are obtained with

zero (0) pressure in the combustion

zone and at normal operating

temperatures. i.e.; steady state hot

conditions.

Please Note: Burner must be fired ONLY

with fuel that is listed on the burner serial

label.

PRESSURE WORKING CHART

The chart below shows effects of pressure in the combustion zone on the minimum/maximu m burner outputs.

In this example, with a maximum operating pressure of 0.6 inches water column in the combustion zone, you

will be able to obtain a maximum of 370,000 Btu/hr burner output.

In/wc

3.5

3.0

2.5

2.0

1.5

PRESSURE

1.0

0.5

0.0

170 210 250 290 330 370 410

PRESSURE WORKING CHART

Natural and LPG gas

INPUT (000's) BTUH

C6505020 STD G400 Manual Rev.5 -06/10/2002 14

Any change from zero (0) pressure in the combustion zone will affect the Btu output of the burner. To supply

the required input to the appliance, manifold pressure will have to be adjusted to compensate for this

condition.

COMBUSTION CHAMBER SIZE

28

26

24

22

Recommended Minimum Sizes

20

Inches

18

16

14

12

10

150 200 250 300 350 400

INPUT (000's) BTUH

LENGTH

DIAMETER

NOTES:

1) Sizes shown above are for cylindric al or wet base boilers, or air cooled heat exchangers.

2) To size the chamber in applications other than wet base boilers, you must calculate area in square inches

of the combustion zone required to give you a grate area or floor area to match the BTU inputs according to

the local authority. Refer to CAN/CGA B149.1 & .2 ANSI Z21.8-1984, and ANSI Z223.1-1984.

3) Fire brick or cerafelt chamber materials should have a continuous run temperature rating of 2400 degrees

Fahrenheit and a melting point of 3000 degrees Fahrenheit.

COMBUSTION CHECKS

CO

2

It is advisable not to exceed a measured reading of 10% CO2 for Natural Gas or 12% CO2 for Propane Gas.

CO

For safety reasons, the value of .02% (200ppm) free air sample must not be exceeded.

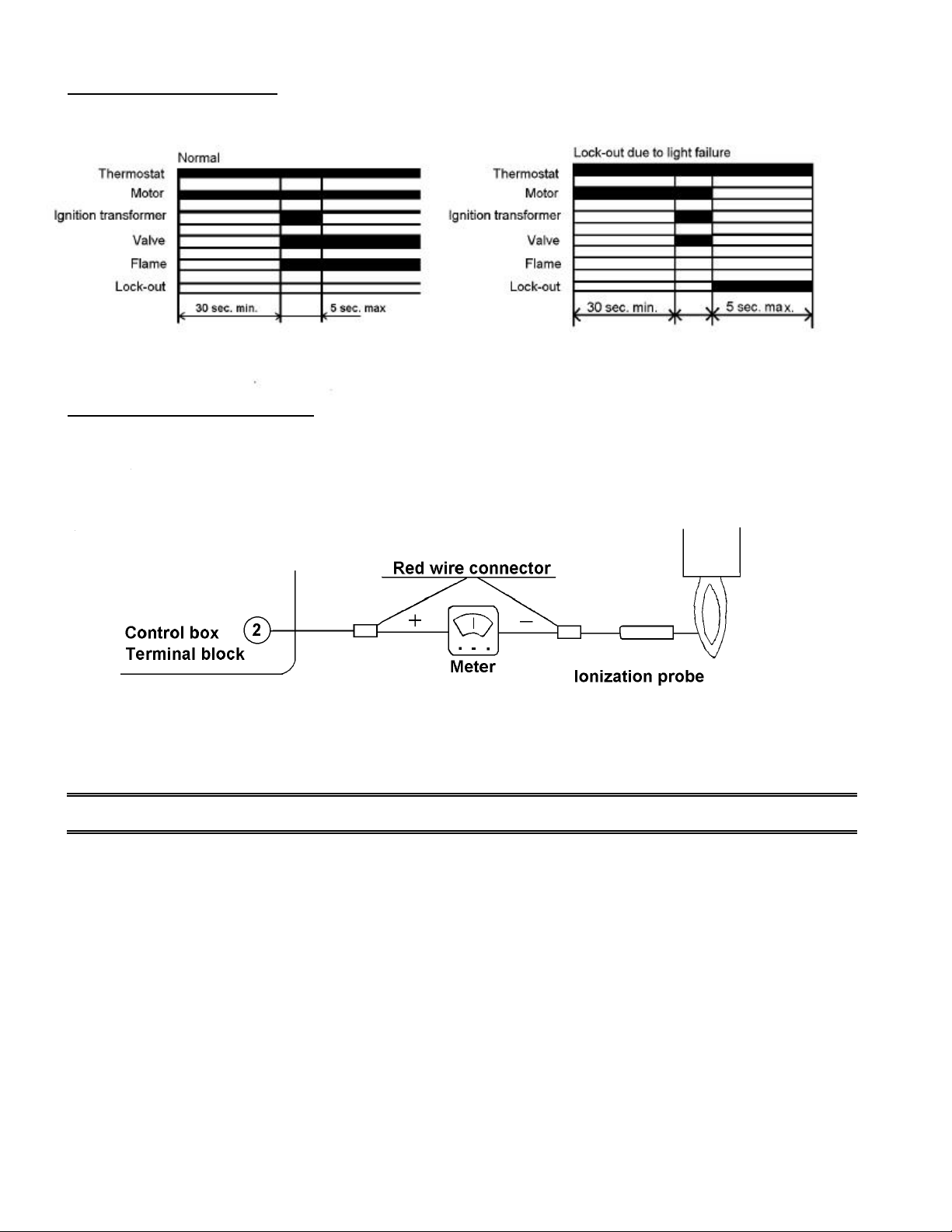

IONIZATION CURRENT

The minimum amount of current necessary for the control box to operate properly is 5 microamps DC.

To measure the ionization current, disconnect the red wire connector and insert a DC micro ampmeter in

series with control box terminal 2 and the ionization probe which senses the flame. Refer to the diagram

below.

C6505020 STD G400 Manual Rev.5 -06/10/2002 15

Burner Start-up Cycle

Ionization Current Check

PROBLEM SOLVING GUIDE

Burner starting difficulties and their causes:

1) The burner goes through the prepurge period normally. The flame ignites, but the burner goes to lockout

within five seconds.

a) The phase/neutral lines are reversed.

b) The wiring to ground is absent or ineffective.

c) The ionization probe is grounded, or not in contact with the flame, or the circuit to the control box is

broken.

d) The spark interferes with the flame signal due to incorrect setting of the electrode.

2) The burner goes to lockout after the prepurge period because the flame does not ignite.

a) Air has not been fully bled from the gas lines.

b) The gas valve is passing too little gas.

c) The spark is irregular or not present.

C6505020 STD G400 Manual Rev.5 -06/10/2002 16

3) The burner does not start when the thermostat calls for heat.

a) The gas pressure switch (if supplied) does not close contact due to low gas pressure.

b)

The 24 vo lt switching relay is defective.

c) The line switch is off.

d) There is a blown fuse in the panel.

e) Terminals on the control module are bent or loose

f) The motor is defective.

g) The capacitor is defective.

h) The end switch on the air damper is d efective.

i) The control box is defective.

j) The air pressure switch is not in the normally closed position

4) The burner continues to repeat the starting cycle without going into lockout.

This is a very specific situation caused when gas pressure in the gas main lines is very close to the

value at which the gas pressure switch has been set. This can be corrected by resetting the gas

pressure switch to a lower level. The gas pressure switch, if required, may be supplied, or may have to

be field in stalled.

5) The burner does not go through prepurge, and the control module goes to lockout. The air pressure switch

does not change over from normally closed to normally open contacts.

This condition exists because there is insufficient air pressure in the combustion head.

OWNER INFORMATION AND ROUTINE MAINTENANCE

SAFETY LOCKOUT

This burner is equipped with multiple interlocking safety devices. In the event of a failure in the flame, or any

blockage of the combustion air supply, the burner will "lock out" in a safety condition. In such an event, an

illuminated red button will show on the centre front of the red cover. To restart the burner, press the button

once only. Should the burner return to the lock out condition, call a qualified service technician or your gas

company for assistance.

NOTE: Keep the area around the burner free and clear of all combustible materials, gasoline and other

flammable vapours and liquids. Do not allow any obstructions which may prevent the free flow of air to the

burner.

MAINTENANCE

Like all precision equipment, your burner will require periodic maintenance. At an interval of 2 months, you

should:

1) Visually check the flame if your heating appliance has an observation port.

2) Check and clean the air intake louver to remove any build up of fluff, dust, pet hair etc.

3) The motor is permanently lubricated and does not need oiling.

For any maintenance or repairs over and above those listed, contact your service technician or gas company.

THERE ARE NO OWNER SERVICEABLE PARTS INSIDE THE BURNER COVER.

Once a year, you should have the burner serviced as indicated below. This service should be

performed by your local authorized dealer.

1) Check burner distributor head and mixing plates. Clean if necessary.

2) Check ignition electrode. Clean, adjust, or replace as necessary.

C6505020 STD G400 Manual Rev.5 -06/10/2002 17

3) Check the flame sensor rod (ionization rod) for dirt or carbon build up. Clean, adjust, or replace as

necessary.

4) Check manifold gas pressure.

5) Check all burner adjustments.

6) Generally clean all exposed parts and components.

7) Do a complete combustion test with the burner cover in place and the air gate locking screws secure.

Your Riello 40 gas burner is only part of your heating system. Once every year you sho uld have your heating

appliance serviced by a qualified service technician. You should also have the chimney checked, and cleaned

if necessary.

INSTALLATION DATA

Note: This label is supplied in the package with the burner

and should be filled out and affixed to the appliance when the

conversion burner is installed.

C6505020 STD G400 Manual Rev.5 -06/10/2002 18

SPARE PARTS

GAS BURNER SYSTEM

RIELLO 40 N400

REVISED: 10/01

No.

1 3007238

2 C7020008

3 3001162

4 3002307

5 C7020006

6 3007288

7 3007310

8 3007293

9 3006688

10 3007223

11 3007279

12 3006930

13 3007205

SPARE

PARTS

CODE

DESCRIPTION

Burner back cover

Air switch

Primary control box 525 SE/A

Primary control sub -base

120/24 volt transformer

Air switch tube and connector

Ionization lead

Air tube cover plate

Chassis mounting collar

Chassis front plate

Air damper motor

Motorized air damper

Manual air shutter(air gate)

No.

21 3950371 Short combustion head (279T1)

22 3006696

23 3007275

24 3007265

25 3006708

26 3006702

27 3006699

28 3007299

29 3006693

30 3005447

31 3000870

33 3950372 Long combustion head (279T2)

SPARE

PARTS

CODE

DESCRIPTION

Drawer assembly elbow

Electrode assembly

Electrode and ionization clamp

Ionization assembly

Natural gas orifice

Distributor head and mixing plate

Manifold

End cone

Gas test point

Hinge assembly

14 3007209

15 3005788

16 3005834 Capacitor 10? F 36 3007265

17 3005843

18 3005856

19 3006356

20 3007448

49 C7010003

ACCESSORIES 45 3007303

C7020004

Air intake housing

Fan

Burner motor

Mounting gasket

Universal mounting flange

Ground lead and connector

Mounting bracket -Transformer

Honeywell R8038A 24 v

switching relay

34 3006696

35 3007276

37 3007277

38 3007300

39 3007290

40 3005854

41 3006693

42 3007282

43 3006702

44 3006699

46 3007285

47 3005447

48 3000870

Drawer assembly elbow

Electrode assembly

Electrode & ionization clamp

Ionization assembly

Manifold

Natural gas tube

Semi flange 2 required

E nd cone

E nd cone adapter

Natural gas orifice

Distributor head and mixing plate

Electrode support

Air tube -long

Gas test point

Hinge assembly

C6505020 STD G400 Manual Rev.5 -06/10/2002 19

C6505020 STD G400 Manual Rev.5 -06/10/2002 20

Hingham, MA 02043

8292

7637

Mississauga,On L5H 3R2

0303

3898

Two

35 Pond Park Rd.

Phone: 781-749-

Toll Free: 800-992-

Fax: 781-740-2069

2165 Meadowpine Blvd.

Phone: 905-542-

Toll Free: 800-387-

Fax: 905-542-1525

BURNER START- UP FORM *

Burner S/N. or

Model:

Installer name:

Appliance:

Company: Installation date:

Address:

Phone: Fax:

Owner Name:

Address:

Phone: E-mail:

Burner Start-up Info (OIL)

Burner Start-up Info (GAS)

Nozzle Info: Gas Supply Pressure:

Pump Pressure: Pump pressure:

Turbulator

Air Setting:

setting:

Air Setting: Head Setting:

Draft

Draft Overfire:

breech:

Draft Overfire: Draft breech:

CO2:

CO:

O2:

CO2: CO: O2:

Smoke density: (Bacharach)

Manifold pressure:

Single Line:

Lines:

Ionization Reading µAdc:

Input BTU/Hr:

* This form was designed and provided in the installation manual for reference and also for providing technical

information which can be faxed or mailed to our technical hot -line coordinator when technical assistance is required.

Please complete this form, fax it or mail it at the address/fax above, or send an e-mail with the information listed below

to: techservices@riellocanada.com

C6505020 STD G400 Manual Rev.5 -06/10/2002 21

35 Pond Park Road

Hingham, MA 02043

Phone 781-749-8292

Toll Free 800-992-7637

Fax 781-740-2069

www.riellousa.com

2165 Meadowpine Blvd

Mississauga, ON L5N 6H6

Phone 905-542-0303

Toll Free 800-387-3898

Fax 905-542-1525

www.riellocanada.com

Technical Support Hotline

1-800-4-RIELLO

1-800-474-3556

C6505020 STD G400 Manual Rev.5 -06/10/2002 22

Loading...

Loading...