LASER MIRROR SCANNER

LMS-Q280i

TECHNICAL DOCUMENTATION AND US E R’S INSTRUCTIONS

Version 07/2004 CE

Rev. 25-03-2004 (V5.63)

Rev. 01-07-2004 (V5.64)

(c) 2004 RIEGL Austria

All rights reserved.

This manual has been compiled with care. However, should you discover any

error, we would be grateful if you would let us know.

RIEGL Laser Measurement Systems GmbH

A-3580 Horn, Riedenburgstrasse 48, AUSTRIA

Tel.: +43-2982-4211, Fax.: +43-2982-4210

e-mail: office@riegl.co.at

www.riegl.com

I m p o r t a n t N o t e:

The LMS-Q280i makes use of a high power laser source and an extremely high

sensitive optical receiver. As a result of this powerful signal detection

electronics, the LMS-Q280i works with non-cooperative targets (natural

reflecting targets like trees, stones etc.) as well as with cooperative targets

(reflecting targets). The following reflecting target materials can be used:

o Reflecting paint

o Reflecting foil

Due to the high power level of the laser transmitter, high quality glass

retro-reflectors must not be used as a target !!! Using such retroreflectors can permanently damage the instrument.

C O N T E N S

1 GENERAL ................................................................................................ ... 1

1.1 System Configuration ................................................................ .............. 1

1.1.1 Rangefinder System................................................................ ............ 1

1.1.2 Scanner Mechanism................................................................ ............ 2

1.1.3 True Color Channel (optional)................................ ............................. 3

1.1.4 Interfaces................................................................ ............................. 4

2 DESIGN OF LASER SCANNER LMS-Q280I................................ .............. 5

2.1 Mechanical Design................................................................ ................... 5

2.2 Mechanical Drawings ................................................................ .............. 6

3 SAFETY INSTRUCTIONS................................................................ ........... 9

3.1 General Safety................................................................ .......................... 9

3.2 Electromagnetic Compatibility ............................................................. 11

3.3 Laser Safety ............................................................................................ 14

4 OPERATING INSTRUCTIONS .................................................................. 15

4.1 Preparing the Power Supply ................................................................. 15

4.1.1 Fuses ................................................................................................. 16

4.2 Connectors and Pin Assignments ........................................................ 17

4.2.1 Plug for Power Supply ....................................................................... 18

4.2.2 Plug for Serial Interface (RS232) ....................................................... 19

4.2.3 Plug for Parallel Interface .................................................................. 20

4.2.4 Plug for Ethernet Interface ................................................................. 21

4.3 Cables ..................................................................................................... 22

4.3.1 Power Supply Cable .......................................................................... 22

4.3.2 Parallel Data Cable ............................................................................ 23

4.3.3 Serial Data Cable .............................................................................. 24

4.3.4 LAN-TCP/IP Data Cable .................................................................... 25

4.4 Mounting the LMS-Q280i ....................................................................... 26

4.5 Instrument Cooling ................................................................................ 27

4.6 General System Set Up and Cabling .................................................... 27

4.7 Laser Setup and Test Procedure .......................................................... 29

5 SPECIFICATIONS ..................................................................................... 30

5.1 Technical data ........................................................................................ 30

5.2 Definition of axes ................................................................................... 32

5.3 LMS-Q280i Timing Characteristic ......................................................... 34

5.4 External Synchronization and Internal Reference Timer .................... 35

6 DATA COMMUNICATION AND I NTERFACES ........................................ 36

6.1 Programmin g Mode / M easur ement Mo de fo r Seria l Interf ace ................. 36

6.2 Data Format for Serial Interface ............................................................ 37

6.2.1 Data Format for Serial Interface in Programming Mode .................... 37

6.2.2 Data Format for Serial Interface in Measurement Mode .................... 38

6.3 Parameters and Controlling Commands ............................................. 41

6.3.1 Parameter Data Types in Programming Mode .................................. 41

6.3.2 Several Basic Commands ................................................................. 42

6.3.3 Basic Measurement Par am eter s ....................................................... 46

6.3.4 Adjusting Parameters for Serial Interface .......................................... 48

6.3.5 Definition of Scan Patter n .................................................................. 50

6.3.6 Several Additional Commands .......................................................... 54

6.3.7 Control Commands in Measurement Mode ....................................... 55

6.3.8 Additional Low Level Commands ...................................................... 56

6.4 ECP Data Output .................................................................................... 59

6.4.1 Reading Data via ECP ....................................................................... 59

6.4.2 Configuring the ECP Data Output ...................................................... 70

6.5 LAN interface .......................................................................................... 72

6.5.1 Overview ............................................................................................ 72

6.5.2 Activation ........................................................................................... 72

6.5.3 Configuring the LAN Interface ........................................................... 73

6.6 Errors and Error Handling ..................................................................... 75

6.7 Status and Error Messages ................................................................... 77

Page 1 of 79

Technical Documentation and

User Instructions

Laser Mirror Scanner LMS-Q280i

1 General

The Laser Mirror Scanner LMS-Q280i is a 2D laser scanner based upon

accurately measuring the distance by means of electro-optical pulsed time-offlight range measurement and upon f ast scanning the laser beam by m eans of

an opto-mechanical scan mechanism. The high range performance, the fast line

scanning, and the overall system design makes the LMS-Q280i well suited for

airborne laser scanning applications.

1.1 System Configuration

The laser scanner LMS-Q280i consists mainly of two subsystems, an accurate

laser rangefinder electronics and a line scanning mechanism, installed in a

rugged housing.

1.1.1 Rangefinder System

The rangefinder system is based upon the principle of time-of-flight

measurement of short infrared laser pulses.

A laser source emits infrared light pulses, which are collimated by a transmitter

lens system. Via the receiver lens, part of the echo signal reflected by the target

hits a photodiode which generates an electrical receiver signal. The time

interval between transmitted and received pulses is counted by means of a

quartz-stabilized clock frequency. The measured time value is passed to the

internal microcomputer which processes the measured data and prepares it for

data output.

Fig. 1 Measurement principle of the pulsed range finder

Page 2 of 79

Technical Documentation and

User Instructions

Laser Mirror Scanner LMS-Q280i

S

c

a

n

n

e

d

l

a

s

e

r

b

e

a

m

Rotating

polygonal

mirror

T

r

a

n

s

mi

t

t

e

r

R

e

c

e

i

v

e

r

1.1.2 Scanner Mechanism

The scanner mechanism deflects the laser beam for range measurement into a

precisely defined direction. Each scan line is composed of a number of pixels

(single laser measurements).

The angular deflection of the laser beam is realized by a rotating polygon mirror

wheel. The polygon-mirror is composed of flat reflective surfaces arranged

around the wheel perimeter. The wheel rotates continuously at a fixed speed to

provide repetitive unidirectional scans.

Fig. 2 Principle of beam deflection by a rotating mirror

Page 3 of 79

Technical Documentation and

User Instructions

Laser Mirror Scanner LMS-Q280i

Due to the finite aperture dimensions, only a fractional part of the polygon mirror

surfaces (excluding the edge areas) can be used for scanning (please refer to

chapter 5.3, LMS-Q280i Timing characteristic).

1.1.3 True Color Channel (optional)

Beside the laser transmitter and the laser receiver, the LMS-Q280i has

optionally an integrated true color channel which provides the color of the

target´s surface as an additional information to each laser measurement. Color

data are included in the binary data stream of the LMS-Q280i allowing

straightforward texturing of scanned surface model.

Page 4 of 79

Technical Documentation and

User Instructions

Laser Mirror Scanner LMS-Q280i

1.1.4 Interfaces

1.1.4.1 Electrical Interfaces

The laser sca nner LMS-Q280i requires a singl e power supply with no minall y 24V DC .

Supply voltage 24V DC

Permitted supply voltage range 18V DC to 32V DC

Current consumption

(scanning operation)

1.1.4.2 Data Interfaces

LAN Interface Ethernet Network interface, using the

RS232 serial interfac e Bi-directional interface for scanner

Parallel interface ECP compatible, Uni-directional interface,

typically 3A at 24V DC

TCP/IP protocol

configuration

provides the scan data

The pin assignment of the interface connectors can be found in chapter 4.2,

Connectors and Pin Assignments.

Page 5 of 79

Technical Documentation and

User Instructions

Laser Mirror Scanner LMS-Q280i

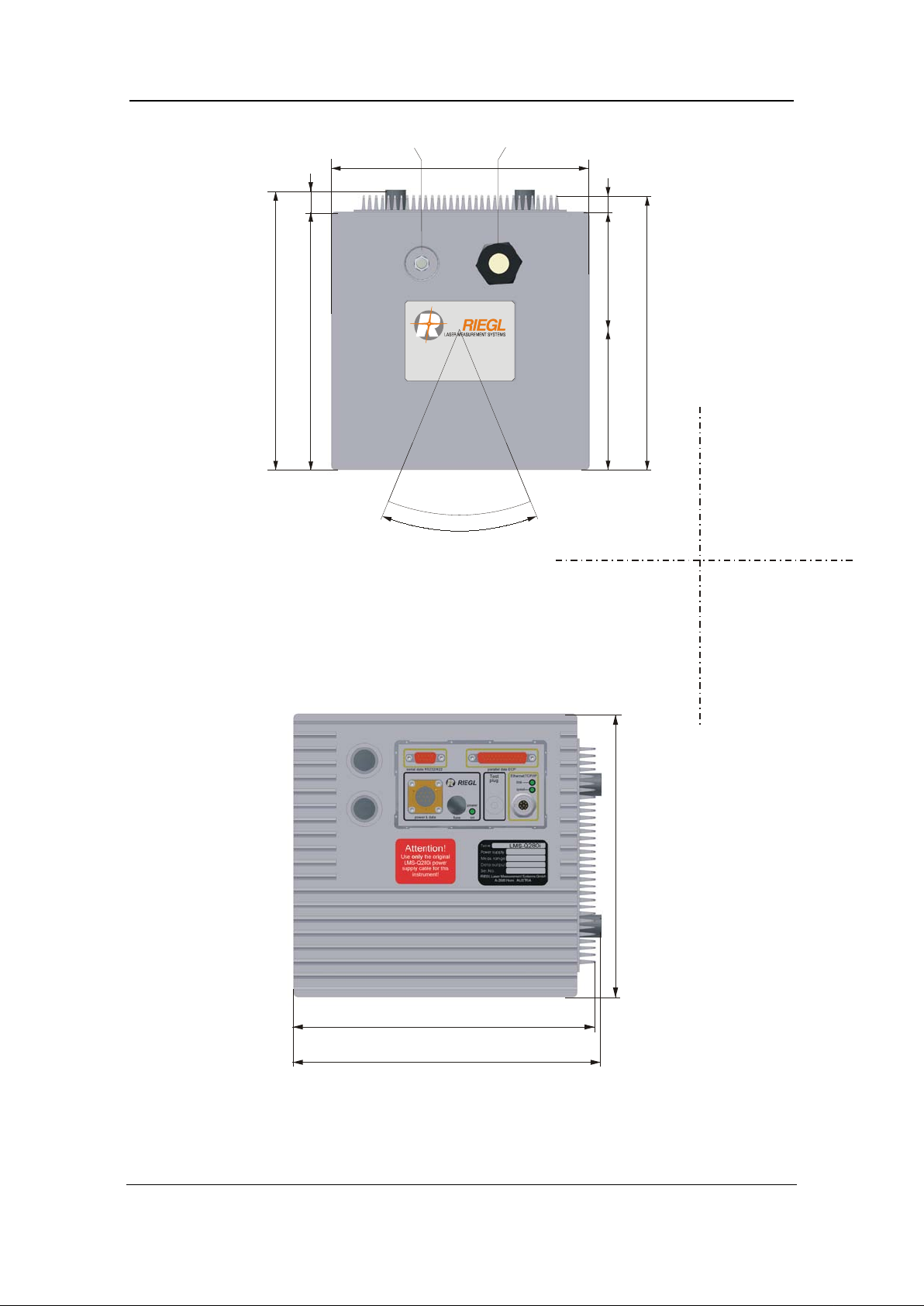

2 Design of Laser Scanner LMS-Q280i

2.1 Mechanical Design

The housing of the LMS-Q280i laser scanner is designed to meet the

requirements for an installation on board of an airplane or helicopter. The slim

design and the scan direction perpendicular to the longitudinal axis of the laser

scanner allows straightforward integration also under narrow space conditions.

The housing consists of a very stable base plate, which carries 6 pcs. M6

mounting threads and the beam output aperture window.

The top plate provides 6 pcs. M6 mounting threads for the installation of an

inertial measurement unit or other additional equipment. This mounting threads

are firmly connected to the internal frame structure. Additionally, the top plate is

equipped with a heat-sink profile.

For adequate heat dissipation, the rear plate

profile. On this side of the laser scanner, there are the connectors for power

supply and data interface as well as the fuse holders located.

For additional information about heat dissipation, please refer to chapter

Instrument Cooling

The front plate carries a desiccant cartridge and valve for nitrogen purging of

the instrument.

The side plates are made of aluminum pro file s hel ls .

All outer parts are colorless or black anodized.

The figures on the next pages show the mechanical dimensions of the LMS-

is equipped with a heat-sink

4.5,

Q280i laser scanner.

Technical Documentation and

User Instructions

Laser Mirror Scanner LMS-Q280i

2.2 Mec ha nical Drawings

24.5

262

505

75

156

95.5

560

132

200

135

6xM6

mounting

threads

depth 10 mm

scan

window

center of laser beam output

Page 6 of 79

Fig. 3 Bottom view of LMS-Q280i (base plate side)

Technical Documentation and

User Instructions

Laser Mirror Scanner LMS-Q280i

78

186

408

100

6xM6

mounting

threads

depth 10 mm

heat sink

profile

Page 7 of 79

Fig. 4 Top view of LMS-Q280i (top plate side)

Page 8 of 79

Technical Documentation and

User Instructions

Laser Mirror Scanner LMS-Q280i

www.riegl.com

108.8

213

200

217

-22.5°

+22.5°

scanned laser beam

(up to ±30°)

desiccant

cartridge

fitting for

purging

200

17

91.2

13

213

200

217

Fig. 5 Front view of LMS-Q280i (front plate side)

Fig. 6 Rear view of LMS-Q280i (rear plate side)

Page 9 of 79

Technical Documentation and

User Instructions

Laser Mirror Scanner LMS-Q280i

exceeds the requirements of the following European

Safety requirements for electrical

Temperature:

See chapter 5 Specifications for temperature limits for storage

Storage and operation at temperatures outside the specified

surement results or

technique to determine the distance to the object. For this

purpose it comprises sensitive optical, electrical and

appropriate handling:

Unnecessary exposure of the internal optical and electronic

should be

The unit is specified for an altitude up to 2000m (operation or

Relative

The unit is specif ied for a relative humidity of 80% at or below

Enclosure:

is water resistant on the outside

dripping water or

The optical glass panes should be treated with the care

customarily due to optical instruments and, only when

absolutely necessary, should they be gently cleaned using a

Never apply mechanical force or shock to the glass panes

should be

protected from being shaken or knocked.

3 Safety Instructions

3.1 General Safety

GENERAL SAFETY EN 61010-1

LMS-Q280i meets or

Standard: EN 61010-1 (April 1993)

equipment for measurement, control, and laboratory use Part 1: General

Requirements

Note the following explanations and important instructions:

and operation.

Sunlight: The LMS-Q280i makes use of the optical time-of-flight

Altitude:

Humidity:

temperature ranges may cause wrong mea

even damage of the instrument.

mechanical components. Thus the LMS-Q280i requires

parts to direct sunlight via the front window

avoided.

storage).

+31°C; linearly decreasing to 50% at +40°C.

The instrument LMS-Q280i

but must not however be subjected to rain or

submerged under water.

suitable lens cleaning fluid (e.g. pure ethylene alcohol).

or to the housing itself!

As with other optical instruments, the LMS-Q280i

Page 10 of 79

Technical Documentation and

User Instructions

Laser Mirror Scanner LMS-Q280i

Power supply:

Before operating the LMS-Q280i make sure that its case is

The power supply cable is to be connected with a suitable

power supply with a maximum voltage of 32 V DC

be connected to 110 or 230

unacceptable due to the danger

presented by the high voltages, and must therefore be

The negative pole of the external line voltage is directly

connected to the instrument’s housing. This should be

ANY USE OF THE LMS-Q280i IN CONTRADICTION TO THE

THEREFORE, STRICTLY FORBIDDE N!

properly grounded.

DC-

(nominal 24 V DC).

The instrument must never

VAC!

Opening the instrument is

avoided at all costs.

remembered when connecting it to other instruments.

INSTRUCTIONS AS GIVEN IN T HE MANUAL CAN BE DANGEROUS AND IS,

Page 11 of 79

Technical Documentation and

User Instructions

Laser Mirror Scanner LMS-Q280i

meets or exceeds the requirements of the following

WARNING:

, which is affixed on the front side of the housing

of the instrument, meets the requirements of the commission’s guideline

be used in residential, commercial

3.2 Electromagnetic Compatibility

ELECTROMAGNETIC COMPATIBILITY EN 61326

1

Laser scanner LMS-Q280i

European Standards:

EN 61326-1 (1997) Electrical equipment for measurement, control and

laboratory use; EMC requirements; P a rt 1: General requirements

(IEC 61326-1:1997)

EN 61326/A1 (1998) Electrical equipment for measurement, control and

laboratory use; EMC requirements (IEC 61326:1997/A1:1998)

The LMS-Q280i is a class A equipment intended for industrial

environment. Therefore, it must not

and light industry environment.

The labeli ng of the LMS-Q280i

89/336/EEC:

1)

The tests have been run using default scanner parameter settings. The tests

have been performed using original RIEGL data and power supply cables,

powered with 24 V DC provided by an PbGel-Powerpack.

To maintain emission requirements when connecting to the I/O interface of the

LMS-Q280i use only a high-quality shielded data interface cable. The cable

shield must have low impedance connections to both connector housings.

Any changes or modifications to the standard equipment not expressly

approved by RIEGL as well as any non-observance if the directions for

installation may cause harmful interference and void the authorization to

operate this equipment.

The following table lists the applied standards and the performance criteria (see

also definition below) for the evaluation of the immunity test results:

CISPR 16-1 Edition 2.1: 2002

Specification for radio disturbance and immunity measuring apparatus and

methods; Part 1: Radio disturbance and immunity measuring apparatus

CISPR 16-2 Edition 1.2: 2002

Specification for radio disturbance and immunity measuring apparatus and

methods; Part 2: Methods of measurement of disturbances and immunity

Page 12 of 79

Technical Documentation and

User Instructions

Laser Mirror Scanner LMS-Q280i

EN 61000-4-2 + A1 + A2 : 2002

Electromagnetic compatibility (EMC); Part 4-2: Testi ng and me asurement

techniques - Electrostatic discharge immunity test (IEC 61000-4-2:1995 +

A1:1998 + A2:2001)

Performance Criter ion B

EN 61000-4-3 + A1 + A2: 2002

Electromagnetic compatibility (EMC); Part 4-3: Testi ng and me asurement

techniques - Radiated, radio frequency, electromagnetic field immunity test

(IEC 61000-4-3:1995 + A1:1998 + A2:2000)

Performance Criter ion A

EN 61000-4-4 + A1 + A2: 2002

Electromagnetic compatibility (EMC); Part 4-4: Testi ng and me asurement

techniques - Electrical fast transient/burst immunity test (IEC 61000-44:1995 + A1:2000 + A2:2001)

Performance Criter ion B

EN 61000-4-5 + A1: 2002

Electromagnetic compatibility (EMC); Part 4-5: Testi ng and me asurement

techniques - Surge immunity test (IEC 61000-4-5:1995 + A1:2001)

Performance Criter ion C

EN 61000-4-6 + A1: 2002

Electromagnetic compatibility (EMC); Part 4-6: Testi ng and me asurement

techniques - Immunity to conducted disturbances, induced by radio

frequency fields (IEC 61000-4-6:1996 + A1:2000)

Performance Criter ion A

EN 61000-4-8 + A1: 2002

Electromagnetic Compatibility (EMC); Part 4-8: Testing and Measurement

Techniques - Power Frequency Magnetic Field Immunity Test (IEC 610004-8:1993 + A1: 2000)

Performance Criter ion A

Definition of the performance criteria and acceptable degradations:

Performance Criterion A: during testing, normal performance within defined

limits

• additional distance depending range error up to ±10 cm;

• additional statistical range error up to ±25 cm;

• loss of ran ge

• additional angle error up to ±1 °;

Performance Criterion B: during testing, temporary degradation or loss of

function or performance which is self-recovering

• loss or heavy degradation of functionalities during testing with selfrecovering after finishing the test;

Page 13 of 79

Technical Documentation and

User Instructions

Laser Mirror Scanner LMS-Q280i

Performance Criterion C: during testing, temporary degradation or loss of

function or performance which requires operator intervention or system

reset occurs

• loss or heavy degradation of functionalities during testing with selfrecovering after finishing the test; a system reset may occur;

• loss or heavy degradation of functionalities which require simple user

intervention, e.g. replacement of a fuse, switching the device Off and On,

restoration of settings;

Page 14 of 79

Technical Documentation and

User Instructions

Laser Mirror Scanner LMS-Q280i

the instrument may

! Do not operate evidently damaged

d incompetently, the

manufacturers absolve themselves from granting any guarantee or

3.3 Laser Safety

The laser scanner instrument LMS-Q280i is classified as Class 1 laser product

in compliance with the International Eye safety regulation IEC60825-

1:1993+A1:1997+A2:2001 and the European Eye safety regulation EN608251:1994+A1:2002+A2:2001 Safety of Laser Products, Equipment Classification,

Requirements and User´s Guide.

Class 1: Lasers which are safe under reasonably foreseeable conditions of

operation, including the use of optical instruments for intrabeam viewing

(IEC60825-1:2001, Sub-clause 8.2).

The labeling of the LMS-Q280i meets the requirements of the above standard

(IEC60825-1:2001, sub-clause 5.1 and 5.2). It is affixed two times near the front

pane on the LMS-Q280i.

CAUTION! The invisible laser radiation inside

exceed the accessible emission limits of laser class 1, thus never

open the instrument’s housing

instruments! If the instrument is handle

insurance whatsoever.

Aligning the infrared laser instrument with the lenses of CCD-cameras or

infrared night vision devices can result in damage to them and is therefore not

permitted.

Note: The laser beam exits the instrument via the front window as

indicated in the mechanical drawings.

IMPORTANT NOTE : This classification is based on the condition that the laser

beam is continuously scanned. The LMS-Q280i emits laser radiation only, when

in scanning operation. In case of any fault of the driving mechanism, the laser is

switched off immediately.

Page 15 of 79

Technical Documentation and

User Instructions

Laser Mirror Scanner LMS-Q280i

RS232: RxD & TxD

laser safety lock

RS232: GND

RS422: (optional)R & T

GND output

+UB input

GND input

laser mirror scanner

housing = ground = GND input =

= GND RS232 (RS422 optional) =

= GND ECP port = GND output

(connections inside the instrume nt)

LMS-Q280

RS422: (optional)GND

ECP port data lines

ECP port GND

4 Operating Instructions

4.1 Pre pa ring the Power Supply

• All ground terminals of data interfaces, control lines and power supply and

the housing are internally connected (common ground). Details are shown by

the following scheme:

• The connections between the ground terminals and the housing, which are

within the instrument, are not suitable to drain off potential differences.

Therefore, further ground connections have to be provided during installation.

• The DC-power supply has to fulfill the requirements for ‘Limited Circuit’

according to EN 61010-1 and the requirements for ‘SELV’ circuits according

to EN 60950.

• The power supply cable is to be connected to a suitable DC power supply

with a voltage specified in chapter 5 Specifications. The negative pole of the

supply voltage has to be grounded.

• The LMS-Q280i is protected by 3 fuses (located on the rear plate of the

instrument), one for the range finder part electronics, one for the scanning

mechanism and one for the laser transmitter (for fuse types and ratings see

chapter 4.1.1). The current drain capacity of the power supply must be at

least three times the sum of the rated currents of the three fuses, so the

fuses can be activated reliably if necessary (for example, in the case of false

polarity).

• When using a long power supply cable, the drop of voltage should be

considered when adjusting the supply voltage. The negative pole of the

supply voltage should be connected to ground near the instrument.

• The internal resistance of the power supply must be low enough for the

supply voltage not to fall short below the minimum voltage of the instrument.

• The control inputs, analog and digital outputs, and the serial interface of the

laser mirror scanner may be connected only to equipment fulfilling the

requirements for ‘SELV’ circuits according to EN 60950.

•

For e lectromagnetic compatibility, use only original RIEGL power supply

cables and low-noise power supply units, which meet the relevant CE

requirements.

Page 16 of 79

Technical Documentation and

User Instructions

Laser Mirror Scanner LMS-Q280i

fuse holder for scanning mechanism

fuse holder for laser module

fuse holder for rangefinder electronics

4.1.1 Fuses

The laser scanner LMS-Q280i is equipped with 3 glass tube fuses. The fuse

holders are located at the rear side of the instrument.

2.0 A quick-acting

(according to IEC60127 and EN60127)

1.25 A quick-acting

(according to IEC60127 and EN60127)

1.0 A quick-acting

(according to IEC60127 and EN60127)

Fig. 7 Fuse Holders LMS-Q280i

The fuse holders can be opened and closed by means of a coin used like a

screw driver.

Note: Replace a blown fuse only with specified type and rated fuse!

Page 17 of 79

Technical Documentation and

User Instructions

Laser Mirror Scanner LMS-Q280i

serial interface

parallel ECP interface

power & control lines

test plug

LAN interface

4.2 Connectors and Pin Assignments

The connectors for power supply and data interface are located at the rear side

of the LMS-Q280i.

(for service

Fig. 8 Connectors for power supply and data interfaces

purposes only)

Page 18 of 79

Technical Documentation and

User Instructions

Laser Mirror Scanner LMS-Q280i

4.2.1 Plug for Power Supply

Type of connector : Souriau 851 02E 12-10 P50, male

Pin Assignment Color Note

A Laser safety lock brown

B *) not used for LMS-Q280i

C GNDin yellow

green

D *) not used for LMS-Q280i

E Trigger yellow Input for external SYNC

F Marker green TTL output factory

G +UB 18-32 VDC black 2 Power Supply

H GNDout white

J GNDin black 3 Power Supply Ground

K +UB 18-32 VDC black 1

*) Any use of these pins for whatever connections can damage the data output

and is, therefore, strictly prohibited!

Power Supply Ground

signal

internal usage

Power Supply

Page 19 of 79

Technical Documentation and

User Instructions

Laser Mirror Scanner LMS-Q280i

4.2.2 Plug for Serial Interface (RS232)

Type of connector : Sub-D, 9-pin, male

Pin Assignment Color Note

1 must not be connected *)

2 RxD RS232 data input

3 TxD RS232 data output

4 must not be connected *)

5 GND Signal GND

6 must not be connected *)

7 must not be connected *)

8 must not be connected *)

9 must not be connected *)

*) Any use of these pins for whatever connections can damage the data output

and is, therefore, strictly prohibited!

The serial data interface is used for configuration of the scanner.

Page 20 of 79

Technical Documentation and

User Instructions

Laser Mirror Scanner LMS-Q280i

1

2

RD

Data 1 (LSB)

Data 1

7

RD

Data 6

Data 6

12

17

22 Signal GND

4.2.3 Plug for Parallel Interface

Type of plug: Sub-D, 25-pin, male

Pin Source Name Centronics Name

3 RD Dat a 2 Data 2

4 RD Dat a 3 Data 3

5 RD Dat a 4 Data 4

6 RD Dat a 5 Data 5

8 RD Dat a 7 Data 7

9 RD Data 8 (MSB) Data 8

10 RD PeriphClk nAck

11

13

14 PC HostAck nAutoFd

15

16 PC Direction nInit

18 Signal GND

19 Signal GND

20 Signal GND

21 Signal GND

23 Signal GND

24 Signal GND

25 Signal GND

PC...Personal Computer

RD...Riegl Device

Levels are TTL-levels

For detailed information about the parallel data interface, please refer to chapter

6.4, ECP Data output.

Page 21 of 79

Technical Documentation and

User Instructions

Laser Mirror Scanner LMS-Q280i

4.2.4 Plug for Ethernet Interface

Manufacturer: Lumberg Inc.

Type: Micro (M12) Female/S3426 Receptable

Number of Pins: 8

For detailed information about the Ethernet data interface, please refer to

chapter 6.5 LAN interface .

Page 22 of 79

Technical Documentation and

User Instructions

Laser Mirror Scanner LMS-Q280i

Attention!

Use this power supply

cable for scanner

type LMS-Q280i

only

A

t

te

n

tio

n

!

U

s

e

t

h

is

p

o

w

e

r

s

u

p

p

ly

c

a

b

le

f

o

r

s

c

a

n

n

e

r

ty

p

e

L

M

S

-

Q

2

8

0

i

o

n

l

y

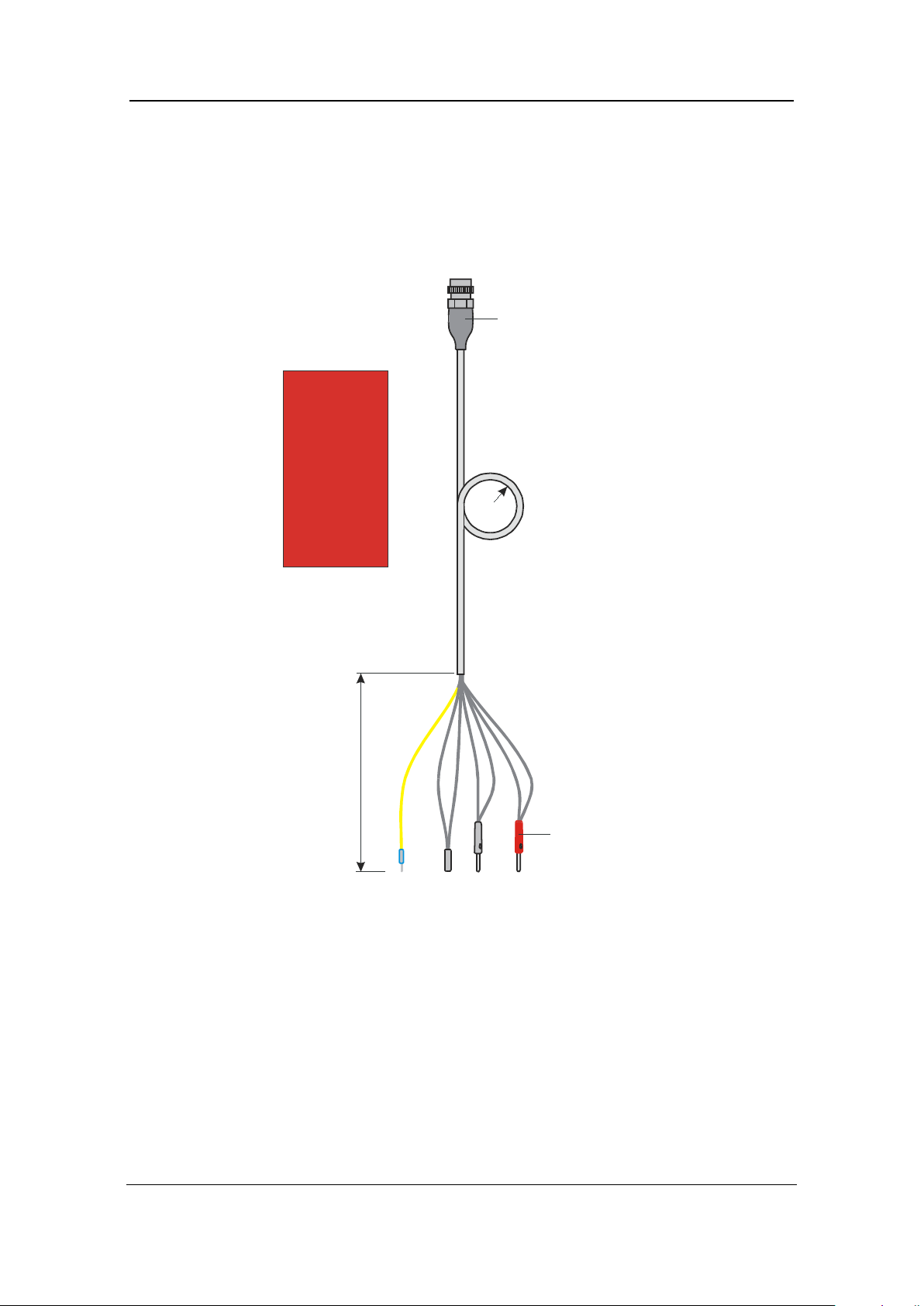

10-pole plug /female,

series 851

>200mm

shielded cable

20 cm

banana plugs

T

r

ig

g

e

r

/ y

e

llo

w

L

a

s

e

r

s

a

fe

ty

lo

c

k

&

G

N

D

o

u

t / b

r

o

w

n

&

w

h

ite

G

N

D

in

p

u

t /

b

la

c

k

3

&

y

e

llo

w

/g

r

e

e

n

+

U

b

/ b

la

c

k

1

&

2

4.3 Cables

The laser scanner LMS-Q280i is shipped with three cables.

4.3.1 Power Supply Cable

The length of the cable is approx. 6m.

Fig. 9 Power supply cable

Page 23 of 79

Technical Documentation and

User Instructions

Laser Mirror Scanner LMS-Q280i

25-pole Sub-D

25-pole Sub-D

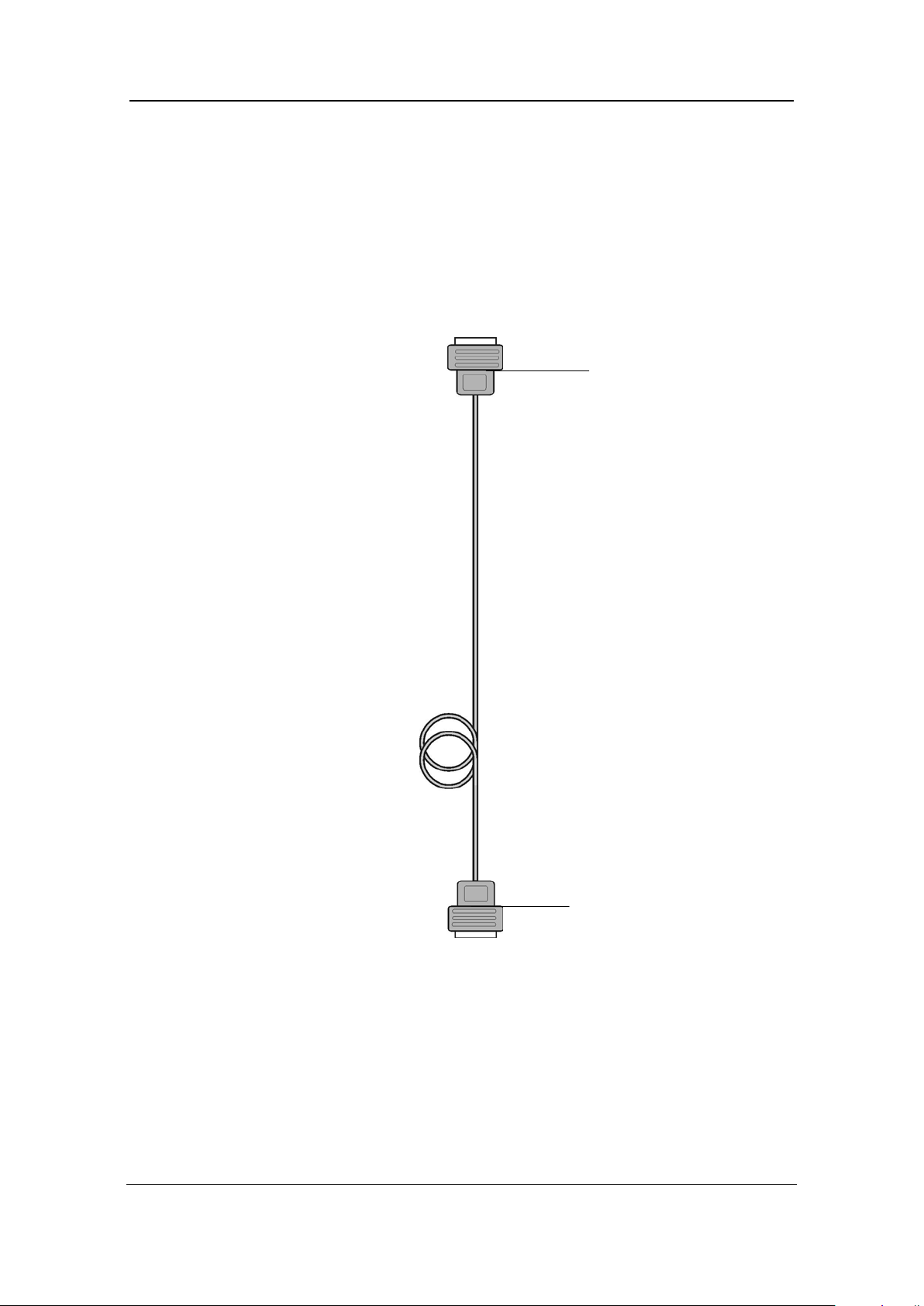

4.3.2 Parallel Data Cable

The parallel data cable uses a standard PC-Printer cable pinning, but needs

improved noise immunity to ensure highest possible data transfer rates. The

cable has to meet the requirements of IEEE Std. 1284-1994. The end of the

parallel cable is equipped with 25-pole Sub-D connectors enabling to connect

the LMS-Q280i directly to the LPT printer port of a personal computer. The

length of the parallel cable is approx. 6 m .

connector, female

Fig. 10 Parallel data cable

connector, male

Technical Documentation and

User Instructions

Laser Mirror Scanner LMS-Q280i

4.3.3 Serial Data Cable

9-pole Sub-D

9-pole Sub-D

Cable configuration:

Page 24 of 79

The cable length is approx. 3m.

connector, female

Fig. 11 Serial data cable

connector, female

Page 25 of 79

Technical Documentation and

User Instructions

Laser Mirror Scanner LMS-Q280i

typically to Ethernet Hub

typically to PC/Laptop

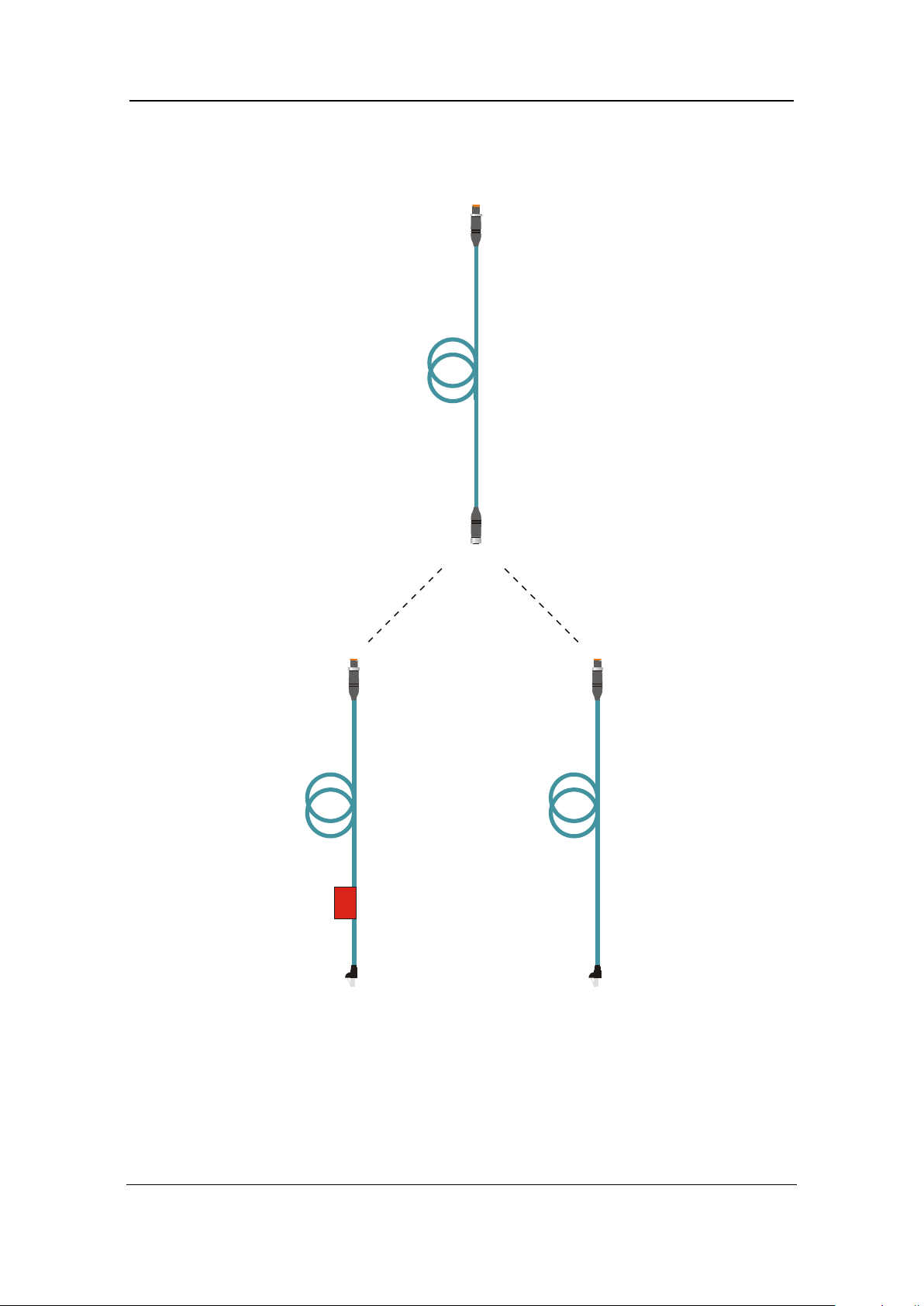

4.3.4 LAN-TCP/IP Data Cable

Using the included Ethernet Interface cables the LMS-Q280i can be connected

to an Ethernet hub or to a PC/Laptop Ethernet connector.

TCP/IP cable

M12-M12, length 3 m

Fig. 12 Ethernet interface cable

cable for direct connection

between LMS-Zxx and PC

Use this cross over

Attention!

M12-RJ45, cross over, length 0.3 m

TCP/IP cable

TCP/IP cable

M12-RJ45, length 0.3 m

Page 26 of 79

Technical Documentation and

User Instructions

Laser Mirror Scanner LMS-Q280i

4.4 Mounting the LMS-Q280i

The base plate of the LMS-Q280i provides 6 pcs. steel inserts with M6 threads,

depth 10mm. This threads are intended to be used for mounting the laser

scanner to a shock proof support plate. For installation of an inertial

measurement unit, the LMS-Q280i provides additionally 6 pcs. steel inserts with

M6 threads in the heat sink profile of the top plate, which are firmly connected to

the internal frame structure. The position of these mounting threads can be

found in the drawing below.

Fig. 13 Position of mounting threads

Page 27 of 79

Technical Documentation and

User Instructions

Laser Mirror Scanner LMS-Q280i

4.5 Inst rument Cooling

To enable appropriate heat dissipation by means of natural air convection, the

heat sink profiles must not be covered by objects which are located very closed

to the laser scanner. Operation at higher ambient temperature and/or reduced

air convection (low atmospheric pressure) could require additional forced

cooling (external fan). The housing surface temperature should not exceed

+40°C.

4.6 Gener a l System Set Up and Cabling

• Provide a suitable power supply for the laser scanner (please refer to

chapter 4.1, Preparing the Power Supply).

• Mount the laser scanner LMS-Q280i by means of the mounting threads.

• Connect the LAN-TCP/IP interface or alternatively the parallel and the

serial interface of the instrument to a personal computer or equivalent

data acquisition unit using the LAN cable or the parallel and serial

connection cables.

• Connect the instrument to the power supply using the power supply

cable.

After switching-on the power supply the scanner starts with

• the “Laser setup and test procedure” (see chapter 4.7 for details),

and then

starts scanning automatically .

Page 28 of 79

Technical Documentation and

User Instructions

Laser Mirror Scanner LMS-Q280i

Fig. 14 Cabling of laser scanner LMS-Q280i

Page 29 of 79

Technical Documentation and

User Instructions

Laser Mirror Scanner LMS-Q280i

4.7 Laser Setup and Test Procedure

At power up a laser setup and test procedure, typically lasting 20 seconds

(the effective time depends on instrument’s and ambient temperature) is

executed. A beep sequence indicates that the setup procedure is in progress.

If the laser setup and test procedure is passed, the laser is ready for

measurement, otherwise an error message is sent.

Technical Documentation and

User Instructions

Laser Mirror Scanner LMS-Q280i

5 Specifications

1)

1500 m

Measurement accuracy

2)

(1σ standard deviation)

First target, last target (up to 4 echoes)

or alternating

Laser pulse repetition rate

PRR

24.000 Hz

:

4)

5.1 Technical data

Technical Data of the Scanning Mechanism

Scanning mechanism: rotating polygon mirror

Number of mirror facets: 4

Scan angle range: 45° (60° at 90% meas. range)

Angular movement: linear

Page 30 of 79

Scan speed : 5 lines/s up to max.80 lines/s

Minimum angle step width : 0.02°

Angle readout resolution: 0.0025°

1) Scanning rates selectable via LAN-TCP/IP or serial interface, max. 30 scans/sec. for 60°

scanning range

Technical Data of the Laser Range Measurement

Measurement principle: Single-shot time-of-flight measurement

Measurement range

for natural targets, ρ ≥ 20%

for natural targets, ρ ≥ 80%

1)

850 m

Maximum range : 2000 m

Minimum range: 30 m

typ.± 20 mm

Measurement resolution:

5 mm

Target detection modes :

3)

Laser wavelength:

Laser beam divergence

Eye safety class according

to IEC60825-1:2001 5)

1) The following conditions are assumed:

• target is larger than the foot print of laser beam

• normal incident angle of laser beam

• visibility 10 km

• average ambient brightness

2) Standard deviation, plus distance depen di ng err or ≤ ± 20ppm

3) Average measurement rate is 1/2 of PRR rate @ scan angle range 45°

4) 0.5 mrad corresponds to 5 cm beam width per 100m distance

5) The classification is based upon the assumption that the laser beam is continuously

scanned.

near infrared

0.5 mrad :

Technical Documentation and

User Instructions

Laser Mirror Scanner LMS-Q280i

560 x 200 x 208,5

(L x W x H)

Temperature range:

Storage:

-10°C up to +50°C

Ethernet, twisted pair LAN,10 /

- Laser safety lock line

- TTL output (optionall y)

Provides the color of target surface as an additional information to each

laser measurement.

co-aligned with transmitter and

receiver channel

blue: 380-470 nm

red: 590–710 nm

Physical and Electrical Data

Main dimensions :

Weight : 20 kg

Protection class: IP54

Page 31 of 79

Operation:

Power consumption: approx. 70 W

Voltage supply range: 18 – 32 V DC

Interfaces

Mechanical interface Steel thread inserts

100 MBit, industrial connector

Serial Interface for configuration,

Data interface

Power supply 10 pin MIL connector

Additional control lines

industrial Sub connector

Parallel ECP interface for data

output , industrial Sub-D

connector

- TTL input for synchronization

0°C up to +40°C

Orientation

Resolution 16 bit each color

Spectral range

Field of view 1.4 mrad

Optional True Color Channel

green: 510-590 nm

Page 32 of 79

Technical Documentation and

User Instructions

Laser Mirror Scanner LMS-Q280i

5.2 Definition of axes

The following drawing shows the definition of the coordinate system of the LMSQ280i.

X-axis

108.8 108.2

Y-axis

Z-axis

Z-axis

Y-axis

156

X-axis

Fig. 15 Definition of axes 1

Page 33 of 79

Technical Documentation and

User Instructions

Laser Mirror Scanner LMS-Q280i

point no. X Y Z

1 -108.2 -252 50

2 -108.2 -252 -50

3 -108.2 -30 50

4 -108.2 -30 -50

5 -108.2 78 50

6 -108.2 78 -50

Coordinates of mounting points for IMU

Z

-X

-Y

Y

X

-Z

ϕ(=0)

ϑ

www.riegl.com

108.8

Y-axis

X-axis

Z-axis

origin of scanner’s

local coordinate system

78

186

408

6xM6

mounting

threads

depth 10 mm

1 2

3 4

5

6

Z-axis

Y-axis

X-axis

100

Fig. 16 Definition of axes 2

Page 34 of 79

Technical Documentation and

User Instructions

Laser Mirror Scanner LMS-Q280i

1 second

L

in

e

S

c

a

n

A

n

g

le

5.3 LMS-Q280i Timing Characteristic

As mentioned in chapter 1.1.2, only a part of the mirror facets can be used for

data acquisition. At the edges of the facets the laser beam is split into two

beams and no measurement is possible. The utilization of 45° out of 90° results

in a duty factor of 50 percent. That is the reason for gap times between two

consecutive scan lines. Fig. 16 shows the timing situation for the LMS-Q280i.

t=1second / Scanning rate

112.5°

90°

s

e

ls

u

P

r

e

s

a

L

scan1

t

scan

Gap

t

gap

scan2 scan N

t

t

t

67.5°

Fig. 17 Timing diagram for the scan mechanism

t laser = 1 / PRR (Pulse repetition rate)

Magnified view

Line Scan angle x t laser [ms]

ts[ms]

Page 35 of 79

Technical Documentation and

User Instructions

Laser Mirror Scanner LMS-Q280i

5.4 External Synchronization and Internal Reference Timer

The LMS-Q280i provides an internal timer with a timing resolution of 10 µs. It is

a 3 byte wide timer and automatically started at power up. With 3 bytes it

overruns every 167.77216 seconds.

The timer value at the start of the scan data line (LineTimeStamp) is

provided for further data processing within the trailer data contained within each

scan line data (see chapter, 6.4.1.4 Structure of trailer). Additionally, a

LaserShotTimeStamp can be added to each measurement, if more detailed

timing information is needed (see chapters 6.4.2 (Fn command) , 6.4.1.3 and

6.4.1.4)

Additionally, the instrument provides an input f or an external SYNC pulse. The

external SYNC pulse synchronizes the internal timer to an external event (e.g.

1pps GPS pulse). The rising edge of the external pulse resets the internal timer

and the number of external SYNC pulses are counted. The counter value is

supplied optionally in the trailer data ( SyncCounter, see chapter 6.4.1.4 )

Specifications of the external SYNC pulse:

Signal level : TTL, positive,

with respect to

GNDout

Pulse duration : min. 15µs

Trigger edge : rising edge

The input is protected against over voltage and negative voltage.

Page 36 of 79

Technical Documentation and

User Instructions

Laser Mirror Scanner LMS-Q280i

6 Data Communication and Interfaces

When using t he LMS -Q280i without Ethernet / TCPIP interface, 2 interfaces are

used:

• a serial RS232 (PC COM-Port) interface for configuration and control

• a parallel ECP (PC LPT-Port) interface for fast scan data outp ut

With the Ethernet / TCPIP interface, these 2 interfaces (2 cable connections)

can be replaced by one interf ace (one cable), using 2 ports: a da ta port (port

number 20001) and a configuration port (port number 20002).

All syntax rules and data format / structure descriptions of the followi ng chapters

are identically used for communication via the TCPIP interface ports, where the

rules relevant for the serial interface are used for the configuration port and the

data structures for ECP parallel interface are used for the data port.

With Ethernet / TCPIP interface some specific commands for TCPIP

configuration ( e.g. IP-address) have to be previously set using the serial RS232

interface.

6.1 Programming Mode / Measurement Mode for Serial Interface

The instrument provides a programming mode to set and display measurement

and control parameters. To enter the programming mode (leaving the

measuring mode) send a ^P (Ctrl P, ASCII 10hex) to the instrument, to leave

the programming mode (re-entering the measuring mode) send a Q<Cr> (like

quit). <Cr> means Carriage return (ASCII 0Dhex).

Measurements and scans are carried out in the measurement mode. After

power up the instrument starts with measurement m ode.

The communication parameters are pre-adjusted in factor y to

19200 baud

1 start bit

8 data bits

no parity

1 stop bit

For achieving electromagnetic compatibility, use original RIEGL data

cable for communications only!

Page 37 of 79

Technical Documentation and

User Instructions

Laser Mirror Scanner LMS-Q280i

6.2 Data Format for Serial Interface

6.2.1 Data Format for Serial Interface in Programming Mode

The programming mode uses ASCII character strings to set parameters or ask

for current parameter settings. After starting programming mode with command

^P, the instrument replies with the message

*<Cr>[<Lf>]

where <Cr> means a Carriage return (0Dhex) and [<Lf>] means an optional

Line Feed (0Ahex) (<Cr> or <Cr><Lf> sequence can be selected by the user

via parameter CS) .

Basically the programming mode works with a command / reply concept: A

command is sent to the instrument, which answers with a reply message.

The first character(s) of the reply message always is(are)

* - when the last command could be interpreted correctly.

- if a ^P has been sent. ^P starts or restarts the programming mode and

additionally clears the receive buffer (so when e.g. sending a ^P

after an incorrect command string part, the incorrect characters already

sent are cleared)

? when the last command could not be interpreted because

• the parameter value is out o f range an d/or

• an array index specified is out of range

?? when the last command could not be interpreted because:

• an unknown command was sent or

• the parameter cannot be accessed in the current access level

= when the value of a parameter was requested.

\ when the line is continued (the reply message consists of more than 1

lines)

Example:

Command Reply Meaning

T1<Cr> *T1<Cr><Lf> Measurement time T1

.T<Cr> =T1<Cr><Lf> Meas. time = T1

ABcd<Cr> ??ABCD<Cr><Lf> ABCD is not a valid command

This example assumes that the separator <Cr><Lf> is selected.

Lower case letters of a command are converted to upper case letters internally.

Line feeds <Lf>, following the <Cr> in the command string, are ignored. Spaces

are ignored and therefore may occur everywhere in the command string.

Page 38 of 79

Technical Documentation and

User Instructions

Laser Mirror Scanner LMS-Q280i

6.2.2 Data Format for Serial Interface in Measurement Mode

Coding mode ASCII or BINARY can be selected by user, see chapter 6.3.4.5,

Coding mode of the serial result data output

Important note: In scanning mode the serial result output must be switched off

by command RO. Set RO8 to output data to ECP port only !

The serial result output is used for scanners for debug and test purposes only.

Data Format in Result Coding Mode ASCII

The ASCII data string has variable length and is delimited by <Cr> or <Cr><Lf>

respectively. The data string is parted into separate blocks. The user can

specify which data blocks are included into the data string.

The first character(s) within the block is(are) named the block identifier. Block

identifiers are always lower case letters, where data (messages and status

information) are always upper case letters The following block identifiers are

used:

r Range

a Signal intensity (Amplitude)

b Line scan angle

q Measurement quality

t SensorTimeStamp (SYNC Timer)

cr True color data, red part

cg True color data, green part

cb True color data, blue part

m Message, status information

The length of the block depends on the data and is not constant. If the character

following the identifier is a "+" , a "-" or a ASCII-digit, the data block represents a

number (e.g. the range in meters). If it is a letter, it represents status

information.

Example: It is assumed that the output of range and amplitude is activated:

r123.4;a138<Cr><Lf>

Error and status information are messages and given in the following format:

(e.g. error: supply voltage too low)

mERROR:LOW_BATT<Cr><Lf>

Note that under environmental conditions providing high elec tromagnetic

irradiance, the amplitude measurement can be disturbed or disorted.

Page 39 of 79

Technical Documentation and

User Instructions

Laser Mirror Scanner LMS-Q280i

Data Format in Result Coding Mode BIN ARY

The binary data string uses the most significant bit 7 (MSB) of data for

synchronization purposes. The MSB is set to 1 for the first byte of the data

string, and is set to 0 for the foll owing bytes.

Data is included in the data string, when the corresponding bit in the Data

format descriptor (see chapter 6.3.4.4, Selecting data blocks for the serial

interface data string) is set. Data is transmitted in order high to low byte.

Data bytes are issued in the following order:

Distance 3 bytes (if corresponding bit is set in F parameter)

Amplitude 1 byte (if corresponding bit is set in F parameter)

Line angle 4 byte (if corresponding bit is set in F parameter)

Quality 1 byte (if corresponding bit is set in F parameter)

SensorTimeStamp 4 byte (if corresponding bit is set in F parameter)

True color data 6 byte (if corresponding bit is set in F parameter)

3 bytes Distance, order D1 – D2 – D3:

Distance [mm] = (D1 and 7Fhex) * 128 * 128 +

(D2 and 7Fhex) * 128 +

(D3 and 7Fhex)

1 byte Amplitude A1:

Amplitude [0..255] = (A1 and 7Fhex) * 2

4 bytes Line angle, order L1 – L2 – L3 – L4:

Line angle[degree/10 000] = (L1 and 7Fhex) * 128 * 128 * 128 +

(L2 and 7Fhex) * 128 * 128 +

(L3 and 7Fhex) * 128 +

(L4 and 7Fhex)

1 byte Quality Q1:

Quality [0..100] = (Q1 and 7Fhex)

4 bytes SensorTimeStamp (SYNC Timer), order T1 – T2 – T3 – T4:

Timer[10-5 s] = (T1 and 7Fhex) * 128 * 128 * 128 +

(T2 and 7Fhex) * 128 * 128 +

(T3 and 7Fhex) * 128 +

(T4 and 7Fhex)

6 byte True color data, order R1-R2-G1-G2-B1-B2:

Red Part= (R2 and 7Fhex) + 128 * (R1 and 7Fhex)

Green Part = (G2 and 7Fhex) + 128 * (G1 and 7Fhex)

Blue Part = (B2 and 7Fhex) + 128 * (B1 and 7Fhex)

Page 40 of 79

Technical Documentation and

User Instructions

Laser Mirror Scanner LMS-Q280i

Example:

Assume that F5 is set; then a data string

82 – 73 – 2F – 1C

means:

Distance = 2*128*128 + 115*128 + 47 = 47.663 mm

Amplitude = 56

Note: The ASCII communication in programming mode is not effected.

Status and error messages are always gi ven in ASCII mode, regardless of

the setting of RM

A correct data reception procedure therefore should read data and wait for a

byte with the MSB set to 1, then read a number of bytes according to the setting

of the F command to read all data of 1 measurement. This method would

automatically ignore all possible ASCII codes (status and error messages and

programming mode).

Page 41 of 79

Technical Documentation and

User Instructions

Laser Mirror Scanner LMS-Q280i

6.3 Parameters and Controlling Commands

6.3.1 Parameter Data Types in Programming Mode

The instrument supports the following data types:

Byte: 8-bit value, signed or unsigned

Integer: 16 bit value, signed or unsigned

Long: 32 bit value, signed or unsigned

String: a sequence of characters

Command: no value specified

These base types can be grouped to

Arrays: of byte, integer, long, string or command

Setting a parameter is done by specifying the parameter name. For arrays the

name is followed by the array range specification given within brackets [ ]. For

Bytes, Integers and Longs an optional “=” may follow. For strings a “=” must

follow. For data types byte, integer, long and string then the value to be set

must follow.

Command Reply Type Meaning

T=3 *T3 Byte Setting measurement ti me

O-1000 *O-1000 Integer Setting range offse t – 1 m

W *W Command Saving parameters

To get (inquire) the value of a parameter, a point “.” is set before the

parameter name.

Command Reply Meaning

.T =T3 Ask for current measurement ti me

.O =O0 Ask for current offset

.ABC ??ABC Don’t know command ABC

.#SN =#SN9991100 Ask for string serial number

If an error is detected (e.g. during execution of a command in programming

mode or previously in measurement mode), all replies in programming mode

get an exclamation mark added. An error is pending until it is acknowledged by

command “ERRACK” (so the exclamation mark is added to all command replies

until the error is acknowledged). See chapter 6.6 for details.

Command Reply Meaning

W *W! Save, an error has occurred

.T =T3! Ask for current measurement time, error pending

Command Reply Meaning

^P *! Start of programming mode, an error is already pending

Page 42 of 79

Technical Documentation and

User Instructions

Laser Mirror Scanner LMS-Q280i

Command

Reply

Meaning

^P * Start the programming mode

Q<Cr>

*Q

Quit the programming mode and return to me as ur e men t

mode

Command

Reply

Meaning

RESET<Cr>

Reset does an internal processor reset and a new start.

t the internal laser hardware is not reset

(it still is power supplied), therefore this is not complete

identical to switching off and on.

Command

Reply

Meaning

DEFAULT<Cr>

*DEFAULT

This command sets several parameters to an

initial default value.

6.3.2 Several Basic Commands

6.3.2.1 Starting and Finishing Programming Mode

Example:

Command Reply Remark

^P * Programming mode start ed

T0 *T0 Set measurement time T0

Q *Q Quit programming mode

6.3.2.2 Reset

Please note tha

6.3.2.3 Setting Parameters to Default Values

The following parameters are set to the listed default status:

Default setting Meaning

T0 Measurement time T0

U0 Range unit meter

A2 Trigger mode free running

F13 Serial interface: data string includes range +

amplitude+ angle

MQ50 Minimum measurement quality 50 percent

O0 Range Offset 0

CS1 Serial interface: Line Separator <Cr> + <Lf>

RM0 Serial interface: Result mode ASCII

RO8 Result output at ECP only

AL0 Amplitude window low value 0

AH255 Amplitude window high value 255

TS1 Last target measurement

Page 43 of 79

Technical Documentation and

User Instructions

Laser Mirror Scanner LMS-Q280i

Command

Reply

Meaning

.HELP

see example

Getting help to the available commands.

HELPFOR=[str]<Cr>

*HELPFOR[STR]

Restrict the list of commands to

are listed.

.HELPGROUPS

see example

Display all available help groups. Each

one group.

.HELP[n]

Getting help for specific helpgroup n. A

HELPFOR=[str] operates additionally.

XB1 ECP output: 1 measurement per block

XM1 ECP output: Hold 1 block in memory

XOS0 ECP output: Range in units of [1 mm]

The tests for electromagnetic compatibility according to the requirements

of the European Union have been performed using default parameter

settings. In case of any disturbances of the instrument's functionalities

due to electromagnetic influences, use default settings.

6.3.2.4 Getting Help

commands including the string [str]. If

[str] is an empty string [], all commands

available command belongs at least to

restriction of the command list by

Example for Help:

Command Reply

HELPFOR=O *HELPFOR=O

.HELP \ O : User offset, Acc=RW, Integer[-32767,32767], Save=W

=HELP

HELPFOR=C *HELPFOR=C

.HELP \ CB : Communication Baudrate, Acc=RW, Byte[0,9], Save=W

\ CP : Communication Parity, Acc=RW, Byte[0,4], Save=W

\ CS : Communication Separator, Acc=RW, Byte[0,1], Save=W

=HELP

HELPFOR *HELPFOR

Each help line to a parameter has the following structure:

\ParName : Short description , Access , Type and Range , Saving

Each lines start with “\” to indicate that another line follows.

ParName shows the parameter name to be entered; e.g. “O” is used to set the

range offset.

ParName[len] indicates an array type with len elements.

Short description describes the meaning of the parameter.

Access describes how the parameter can be used:

Page 44 of 79

Technical Documentation and

User Instructions

Laser Mirror Scanner LMS-Q280i

Command

Reply

Meaning

W<Cr>

*W

Saves parameters permanently. That means that current

needed to save data and to reply.

R = Read, W = Write, RW = Read and Write.

E.g. “HELP” can be used as Read command only (.HELP), “RESET” can be

used as Write command only and “O” can be used as Read and Write

command (writing and reading the offset).

Type and Range describes the parameter type and valid settings..

Byte is a 8 bit value, Integer a 16 bit value, Long a 32 bit value and String a

character string. Command has no additional value to be set.

For Byte, Integer and Long the range of valid settings is indicated in the form

[min,max], where min is the minimum possible setting and max is maximum

possible setting. For strings the value within the brackets describes the

maximum length.

“Save=W” means that the parameter setting can be saved with command “W”,

“Save=#W” means that the parameter setting can be saved with command

“#W” (service level only) and “Save=No” means that nothing is saved.

Example for Help groups:

Command Reply

.helpgroups \ 0: Basic

\ 1: Info

\ 2: Communication

\ 3: Measurement

\ 4: Lase r

\ 5: Scanner Basic

\ 6: Scanner Extended

\ 7: Optic

\ 8: Angular Basic

\ 9: Adjustment

\ 10: Streams

=HELPGROUPS

.help[1] \ TIME : Current time, Acc=RW, String[9], Save=No

\ DATE : Current date, Acc=RW, String[9], Save=No

\ OPTIME[3] : Total operating-/Laser on-/ Motor on time, Acc=R, String[13], Save=No

\ TEMP : Temperature, Acc=R, Byte[-127,127], Save=No

=HELP[1]

6.3.2.5 Saving Parameters Permanently

settings are kept when the instrument is switched off and

on again. Note that some time (typically tenth of seconds,

but under certain circumstances up to 1-2 seconds) is

Page 45 of 79

Technical Documentation and

User Instructions

Laser Mirror Scanner LMS-Q280i

Command

Reply

Meaning

.OPTIME[0]<Cr>

=OPTIME[0]hhhh:mm:ss

Total operating time of scanner, that is

ss seconds

.OPTIME[1]<Cr>

=OPTIME[1]hhhh:mm:ss

Total laser operating time (laser on),

format like OPTIME[0]

.OPTIME[2]<Cr>

=OPTIME[2]hhhh:mm:ss

Total scan operating time (scanner in

motion), format like OPTIME[0]

.OPSECS[0]<Cr>

=OPSECS[0]n

Total operating time of scanner in

seconds, 0 ≤ n ≤ 2147483647

.OPSECS[1]<Cr>

=OPSECS[1]n

Total laser operating time in seconds,

0 ≤ n ≤ 2147483647

.OPSECS[2]<Cr>

=OPSECS[2]n

Total scan operating time (scanner in

2147483647

6.3.2.6 Total Instrument Operating Time

the total time the instrument has been

power supplied.

hhhh hours

mm minutes

motion) in seconds, 0 ≤ n ≤

Page 46 of 79

Technical Documentation and

User Instructions

Laser Mirror Scanner LMS-Q280i

Command

Reply

Range

Meaning

ROn<Cr>

*ROn

Enabling the output of measurement

sets ECP + serial output

Command

Reply

Range

Meaning

ALn<Cr>

*ALn

Setting the minimum value of signal

amplitude values accepted

AHn<Cr>

*AHn

Setting the maximum value of signal

amplitude values accepted

6.3.3 Basic Measurement Parameters

6.3.3.1 Enabling the Desired Data Outputs for Results

0 ≤ n ≤ 255

results for different outputs: The bits of the

value have the following meaning:

bit 0: Serial interface output

bit 3: ECP data output

Example: RO8 sets ECP output only, RO9

In scanning mode enable the ECP data output only, therefore set to RO8 !

Note that the command effects the output of measurement results only.

Therefore e.g. errors are still reported on the serial output, even when the

corresponding data output bit 0 in RO is cleared. Similarly the serial

programming mode is not effected by the setting for the serial data output in

RO.

6.3.3.2 Selective Measurement of Strong Reflector Targets (Setting an Amplitude Window)

0 ≤ n ≤ 255

0 ≤ n ≤ 255

These feature allows to set an signal amplitude window to measure targets with

a reflectivity in a certain range. E.g. to measure only targets equipped with

reflectors and to m ake it insensitive for diffusely reflecting targets, set AL to a

value of approx. 80 and AH to 255.

Page 47 of 79

Technical Documentation and

User Instructions

Laser Mirror Scanner LMS-Q280i

Command

Reply

Range

Meaning

LASERn<Cr>

* LASERn

0 ≤ n ≤ 1

Software laser switch

n=0: laser off (like command ^F in

n=1: laser on (like command ^N in

measurement mode)

Command

Reply

Range

Meaning

TSn<Cr>

*TSn

0: measurement of FIRST TARGET

2: ALTERNATIG first / last targe t

6.3.3.3 Switching the Laser Off and On, Laser Lock

measurement mode)

6.3.3.4 Target Selection

0 ≤ n ≤ 2

1: measurement of LAST TARGET

The LAST TARGET detection is useful for measurement situations where

targets in front (trees, bushes ...) partly block the sight to the desired

measurement target.

For last target detection up to 4 targets with an intermediate distance of at least

5 meters between consecutive targets can be handled.

An ALTERNATING measurement mode enables automatic switching between

first and last target. When scanning, the mode first target / last target is

alternated with ever y laser shot in a scan line. Each line starts with first target

mode.

When using the LMS-Q280i under environmental conditions providing

electrical, electrostatic and/or electromagnetic disturbances, only the

program FIRST TARGET has to be used in the interest of achieving the

highest possible reliability of measurem ent. The programs LAST T ARGET

or ALTERNATING must not be used!

6.3.3.5 Hardware Resolution Mode and Maximum Range

The hardware resolution is fixed 5 mm. Earlier versions of the LMS-Q280i had

user selectable hardware resolution modes (command HWRES) with different

possible maximum range values.

The nominal maximum range is 2000 m; note that the effective maximum

range depends on the target quality (distance to target, reflectivity, visibility, size

of target, angle of incidence of laser beam etc.) and usually is lower.

Page 48 of 79

Technical Documentation and

User Instructions

Laser Mirror Scanner LMS-Q280i

Command

Reply

Range

Meaning

CBn<Cr>

*CBn

n = 8: 38400 n = 9:115200

CPn<Cr>

*CPn

n = 4: 8 Data Bits, Parity = Space

Command

Reply

Range

Meaning

CSn<Cr>

*CSn

Setting the Line Separator for data string sent via

n = 1: Carriage Return + Line Feed <Cr> + <Lf>

Command

Reply

Range

Meaning

6.3.4 Adjusting Parameters for Serial Interface

6.3.4.1 Setting the Baud Rate and Parity

0 ≤ n ≤ 9

0 ≤ n ≤ 4

Setting the Baudrate for communication via serial

interface.

n = 0: 150 n = 1: 300

n = 2: 600 n = 3: 1200

n = 4: 2400 n = 5: 4800

n = 6: 9600 n = 7: 19200

Setting Parity for communication via serial interface.

n = 0: 8 Data Bits, no Parity

n = 1: 8 Data Bits, even Parity

n = 2: 8 Data Bits, odd Parity

n = 3: 8 Data Bits, Parity = Mark (= No Parity, 2

Stop Bits)

Note that it is necessary to save parameters permanently by command “W” and

to reset the instrument to activate new values of CB or CP.

When using the LMS-Q280i under environmental conditions providing

electrical, electrostatic and/or electromagnetic disturbances, data communication with high baud rate s may result in communication errors. In this

case set the baud rate to a lower value.

6.3.4.2 Setting the Line Separator

0 ≤ n ≤ 1

6.3.4.3 Setting the Serial Mode

CMn<Cr> *CMn

0 ≤ n ≤ 1

Note that it is necessary to reset the instrument to activate new values of CM.

serial interface.

n = 0: Carriage Return <Cr>

Setting the serial mode.

n = 0: RS232

n = 1: RS422

Page 49 of 79

Technical Documentation and

User Instructions

Laser Mirror Scanner LMS-Q280i

Command

Reply

Range

Meaning

Fn<Cr>

*Fn

0 ≤ n ≤

Setting the data blocks forming the result output data

Example: F5 sets output of range and am plitu de va lue.

Command

Reply

Range

Meaning

RMn<Cr>

*RMn

Result coding mode. Coding the measurement

ASCII mode, regardless of the setting of RM

6.3.4.4 Selecting Data Blocks for the Serial Interface Data String

65535

string. The bits of the value have the following meaning:

bit 0: Enable range data output

bit 2: Enable amplitude data output

bit 3: Enable angle data output

bit 5: Enable quality data block

bit 6: Enable SYNCTimer data block

bit 7: Enable True color data block

The setting of the F – Parameter also effects the data structure of the ECP

port data, see chapter 6.4.2 .

6.3.4.5 Coding Mode of the Serial Result Data Output

0 ≤ n ≤ 1

result data of the serial data output ASCII

(standard) or binary

Note: The ASCII communication in

programming mode is not effected. Status

and error messages are always given in

Page 50 of 79

Technical Documentation and

User Instructions

Laser Mirror Scanner LMS-Q280i

Command

Range

Meaning

6.3.5 Definition of Scan Pattern

6.3.5.1 Scan Pattern Basics

The scan pattern is mainly defined by the following parameters:

• Start angle

• Angular step width between measurem ents

• Number of measurements forming a scan

RF_START_Ln <Cr>

RF_NUMBER_L n <Cr>

RF_DELTA_L n <Cr>

SC_WRITE <Cr>

0 ≤ n ≤ 3599999

1 ≤ n ≤ XBMAX

1)

see chapter

6.4.2

200 ≤ n ≤ 4000

Activate the scanner settings by

Setting the start angle for the Scan in

units of 0.0001 degree.

1)

Setting the number of measurements

per line.

Note : In scanning mode the setting

of XB for the ECP data output (block

buffer size) is automatically set

equal to RF_NUMBER_L.

Setting the Scan angle increment

between two consecutive laser shots in

units of 0.0001 degree.

Note: Values are truncated

according to the resolution of the

internal angle encoders; e.g. for a

resolution of 2.5 mdeg the value is

truncated to a multiple of 2.5 mdeg

(e.g. a setting of 187 results in an

effective angle increment of 175

according to 7x2.5 mdeg)

internally writing the scanner relevant

parameters to the scanner module (e.g.

scanner speed depending on setting of

RF_DELTA_L).

This command is executed

automatically at startup sequence and

must be sent after changing scanner

parameter RF_DELTA_L.

SC_SCAN <Cr>

SC_SCANCONT <Cr>

SC_NOSCAN <Cr>

Start the scanner motion (movement).

Note: With parameter AUTOSCAN = 1

this is done automatically at startup.

Stop the scanning movement

Page 51 of 79

Technical Documentation and

User Instructions

Laser Mirror Scanner LMS-Q280i

6.3.5.2 Scan Pattern Example

A typical command sequence in order to set a scan pattern with 0.1 degree

angular step width and full (45 degree) scan area would be:

Command meaning

^P enter programming mode

SC_NOSCAN< Cr> stop the scan motion

RF_DELTA_L1000<Cr> angle step width 0.1 degree

RF_NUMBER_L451<Cr> so scan range is 45 degree

(number = (45 / 0.1) + 1)

RF_PRENUM_L2 factory setting for internal timing reasons, there

are two laser shots prior to the begin of scan

line

RF_START_L223000<Cr> start of scan line at angle 22.5000 degree (22.3

+ 2 x 0.1 pre-shots)

note: for calculation of the beam ang l e,

an offset of 45 degree (50 gon) is added,

see chapter 6.4.1.1.3, PolarAngleID

SC_WRITE<Cr> set the parameters (and derived scan speed …)

SC_SCAN<Cr> now start the new scan

W<Cr> save permanently, if desired, otherwise omit

this command

Q>Cr> quit programming mod e

With the nominal laser pulse rate of PRR = 24.000 Hz, the resulting scan rate

(lines per second) is

LPS = RF_DELTA_L * PRR * 4 / 3600000 = 26.7 lines (scans) per second

Automatic Adjustment of Scan Rate:

The line scan rate is adjusted automatically in case the pulse repetition rate

changes in order to keep the angular spacing constant.

Page 52 of 79

Technical Documentation and

User Instructions

Laser Mirror Scanner LMS-Q280i

Command

Meaning

6.3.5.3 Scan Related Commands

.SC_STATUS <Cr>

.SC_STATUS_LIST <Cr>

.SC_ERROR <Cr>

Reading the status from the scanning module. Reading this value

is necessary to get additional error information for the error

“mERROR:SCAN_STATUS”. For correct operation the value is 0.

The bits of returned value (starting with bit index 0) have the

following meaning:

Bit 2: 1=Scanner supply voltage currently out of range

Bit 3: 1= Scan movement not full speed

Bit 4: 1= Scanner movement off

Bit 6: 1= Encoder missing marker pulse

Bit 11: 1= Scan No Motion Error

Bit 12: 1= Line Scanner PLL locked Error

Bit 13: 1= Scanner Supply Voltage out of range Error

Bit 14: 1= Scanner FPGA Boot Error

Bit 15: 1= Scanner FPGA Download Error

Reading and interpreting bits of SC_STATUS, displaying a lis t o f

message lines for eac h bit set in SC_STATUS, each message line

starting with “\”. SC_STATUS = 0 is displayed as

line “\ MOTION_OK”.

Example:

Command Reply:

.SC_STATUS_LIST \ MOTION_OK

=SC_SATUS_LIST

Reading this value is necessary to get additional error information

for the error “mERROR:SCAN_COMMUNICATION”.

The bits of returned value (starting with bit index 0) have the

following meaning:

.SC_ERROR_LIST <Cr>

Bit 0: 1= No PDR Error

Bit 1: 1= Bad Frame Ctrl Byte Error

Bit 2: 1= Bad Checksum at last R/W Error

Bit 3: 1= Bad Echo at last R/W Error

Bit 4: 1= PDR at wrong position Error

Bit 8: 1= Bad command or answer Error

Bit 9: 1= Unknown command Error

Bit 10: 1= PDR2 timeout Error

Bit 12: 1= Error in Scanner, to be found in SC_STATUS

With Error acknowledge command “ERRA CK” the value is set

to 0.

Interpreting bits of SC_ERROR, displaying a list of message lines

for each bit set in SC_ERROR, each message line starting with “\”

Page 53 of 79

Technical Documentation and

User Instructions

Laser Mirror Scanner LMS-Q280i

Command

Meaning

. EALDESC[0]<Cr>

Getting the total angle range of a full circle

. EALDESC[1]<Cr>

Getting the number of encoder lines of a full circle

. EALDESC[2]<Cr>

If 0: angle is scaled in gon; angle resolution of sc an angle = 400 /

360 / EALDESC[1]

.SC_VERSION <Cr>

.EAL <Cr>

Reading the current software version of the scanning module

EALDESC[1]

If 1: angle is scaled in degree; angle resolution of scan angle =

Get the current angle in units of 0.0001 degree

Page 54 of 79

Technical Documentation and

User Instructions

Laser Mirror Scanner LMS-Q280i

Command

Meaning

. #V<Cr>

Getting Software Version

. #VI<Cr>

Getting Instrument Ident

. #VN<Cr>

Getting Instrument Name

. #VM<Cr>

Getting Instrument Modification

. #SN<Cr>

Getting Instruments serial number

Command

Meaning

. V<Cr>

Getting supply voltage in units of 0.1 volt. This voltage is measured internally,

therefore voltage loss from the supply cable can not be taken into account.

. TEMP<Cr>

Getting Temperature within instrument in units of degree Celsius. Note that

ambient temperature.

Command

Meaning

. ERR<Cr>

messages.

ERRACK<Cr>

acknowledged.

6.3.6 Several Additional Commands

6.3.6.1 Getting Version, Type and Serial Number Information

6.3.6.2 Getting Supply Voltage and Instrument Temperature

the temperature within in the instrument usually is some degrees higher than

6.3.6.3 Error Handling

Get a list of errors. Each error detected is listed in a line, where each line

starts with “\” and is followed by an error message. The last line then is

“=ERR” as response to the “.ERR” command.

Note that while in measurement mode errors are automatically sent as

Error acknowledge. This command clears all errors listed with .ERR and no

errors are pending any more. Note that FATAL errors can not be

For detailed description of error handling and error lists see chapter 6.6

Page 55 of 79

Technical Documentation and

User Instructions

Laser Mirror Scanner LMS-Q280i

Command

Meaning

^P

From measurement mode, start programming mode. In programming mode,

the last carriage return (clears the input buffer).

^N

(0Ehex)

Switch on the laser (laser on only when additionally hardware laser lock

is in status “on” and wheel in rotation, see chapter 6.3.3.3)

^F

(06hex)

Switch off the laser

6.3.7 Control Commands in Measurement Mode

(10hex)

^P restarts the program mode, therefore clears all characters already sent since

Page 56 of 79

Technical Documentation and

User Instructions

Laser Mirror Scanner LMS-Q280i

6.3.8 Additional Low Level Commands

The following list of commands is usually not needed for standard usage.

It lists

• Commands needed for debugging and testing

• General range finder commands, not needed for the scanning application

6.3.8.1 Low Level Scanning Commands

ICAN <Cr>

AUTOSCAN n <Cr>

SCAN <Cr>

NOSCAN <Cr>

Super User Password

0 ≤ n ≤ 1

Start the scanning mode in range finder

Stop the scanning mode in range finder

Setting the instrument mode at startup.

For scanning AUTOSCAN must be

set to 1. Value 0 is used only for

factory adjustments.

Needs Super User Password

module. Note that the scanner

(scanning movement) must be started

separately by command SC_SCAN.

With parameter AUTOSCAN = 1,

commands SCAN and SC_SCAN are

executed automatically

Needs Super User Password

module. Note that the scanner

(scanning movement) must be stopped

separately with command

SC_NOSCAN.

For debug purposes only.

Needs Super User Password

SC_RESET <Cr>

.#MID_MAIN <Cr>

.#MID_SUB<Cr>

Resets the scanning unit

Needs Super User Password