Issue: 2018-06-12

For baking, roasting and regenerating specially portioned food and for keeping food warm.

For system gastronomy

Observe the operating instructions

Translation of the Original Operating Instructions

DOWNLOAD: USER MANUAL

QR code on type plate

Contents

2

Rieber GmbH & Co. KG

Our solutions guarantee high quality, safety and, above all,

excellent energy efficiency and cost effectiveness.

Contents

1 Revision Index ................................................................................................................................................. 3

2 Important Information ..................................................................................................................................... 3

2.1 Using this guide ..................................................................................................................................................... 3

2.2 Representation conventions in the text ................................................................................................................. 4

2.3 Structure of safety instructions .............................................................................................................................. 4

3 General Safety Instructions ............................................................................................................................ 5

3.1 General behaviour ................................................................................................................................................. 5

3.2 On use of electrical appliances ............................................................................................................................. 5

3.3 Operator's duties ................................................................................................................................................... 6

3.4 Personnel qualification requirements .................................................................................................................... 7

3.5 Provide protective equipment for personnel ......................................................................................................... 7

3.6 Appliance-specific safety instructions ................................................................................................................... 8

3.7 Product identification ........................................................................................................................................... 10

3.8 Information about regulations to be followed ...................................................................................................... 10

3.9 Instructions on behaviour in an emergency ........................................................................................................ 10

4 Purpose .......................................................................................................................................................... 11

5 Description of device .................................................................................................................................... 12

5.1 Designation ......................................................................................................................................................... 12

5.2 Technical data ..................................................................................................................................................... 15

6 Before First Use ............................................................................................................................................. 16

6.1 Transport ............................................................................................................................................................. 16

6.2 Commissioning .................................................................................................................................................... 16

7 Use .................................................................................................................................................................. 19

7.1 Safety information with regard to use ................................................................................................................. 19

7.2 Pour drinking water into the water tank. Top it up regularly. .............................................................................. 20

7.3 Select program .................................................................................................................................................... 21

7.4 Start cooking process .......................................................................................................................................... 21

7.5 Change settings during operation ....................................................................................................................... 22

7.6 Cancel cooking process ...................................................................................................................................... 22

7.7 Keep food warm (HOLD) ..................................................................................................................................... 23

7.8 Set date and time ................................................................................................................................................ 23

7.9 How to switch off the navioven ........................................................................................................................... 24

7.10 Operation of the navioven function keys ............................................................................................................. 24

7.11 The navioven programs ...................................................................................................................................... 27

Revision Index

Rieber GmbH & Co. KG

3

Revision

Change

2011-03-31

First issue

2011-05-06

Review of controls

2011-07-05

Addition to setting time and date, control images

2011-09-19

8.9.5 Note inserted referring to 2 different saving procedures

2012-03-23

Safety note changed on page 30

2012-12-10

Technical data on page 6; images replaced

2017-08-01

Hold function, 2-stage door handle and pump function;

Register, operating manual structure; EU Declaration of

Conformity; Protective cap for core temperature sensor,

maintenance

2018-06-12

Türverschluss auf Seite 8 entfällt

► Read the operating instructions before first using the product.

► Keep this guide in a safe place and pass it onto the next owner should you wish

to part with the product.

8 Cleaning, maintenance and care ................................................................................................................. 34

8.1 Safety information relating to cleaning, maintenance and care .......................................................................... 34

8.2 Cleaning agents for stainless steel ..................................................................................................................... 36

8.3 Choose the correct cleaning method .................................................................................................................. 37

8.4 Overview of cleaning and maintenance intervals ............................................................................................... 39

8.5 Pump residual water out of the appliance, rinse the appliance .......................................................................... 40

8.6 Cleaning .............................................................................................................................................................. 41

8.7 Descale the appliance as required ..................................................................................................................... 45

8.8 Keep ready for next use in dry condition ............................................................................................................ 46

9 Fault - What now? ......................................................................................................................................... 47

10 Warranty and liability .................................................................................................................................... 49

11 Excerpt from the EU Declaration of Conformity ......................................................................................... 50

12 Manufacturer's address ................................................................................................................................ 51

13 Brief instructions .......................................................................................................................................... 52

1 Revision Index

2 Important Information

2.1 Using this guide

This guide contains important information about how you can use the appliance safely and correctly.

If there are any shortcomings in your opinion, please do not hesitate to let us know. With your help, we

will try to become even better.

Important Information

4

Rieber GmbH & Co. KG

CAUTION

indicates potential damage to property without any personal injury.

Failure to follow these instructions may cause damage to property.

User tip

► Useful information or tip

DANGER

indicates imminent danger.

Failure to follow these warning instructions will result in

serious bodily

injury or even death.

WARNING

indicates a

potentially hazardous situation

.

Failure to follow these warning instructions

may

cause

serious bodily

injury or even death

.

CAUTION

indicates a

potentially harmful situation

.

Failure to follow these warnings

may

cause

minor bodily injury

.

2.2 Representation conventions in the text

. . . Highlighting . . . , is a text fragment which needs to be emphasized

Lists are represented in this way.

Instructions on certain actions are represented in this way.

See ‘. . . ’ , cross-reference is represented in this way.

2.3 Structure of safety instructions

The signal words DANGER - WARNING - CAUTION classify the degree of risk of bodily injury in an actual

situation. You can avoid injury by complying with the behavioural rules provided.

The warning triangle symbol indicates a ‘General Danger’.

Rieber GmbH & Co. KG

5

3 General Safety Instructions

This section covers residual risks and hazards associated with the intended use of the appliance. We have

provided a list of all generally valid safety instructions which must be followed.

In the following section, safety information relating to a particular operation or situation is placed before the

appropriate operation step or description of the situation.

3.1 General behaviour

This appliance meets the current state of the art and complies with all acknowledged technical safetyrelated regulations. Nevertheless hazards may still arise.

Only use this appliance when it is in fault-free condition and according to the instructions in this

user guide.

During all phases of the product's life please ensure that the product is safely integrated into its

environment.

Refrain from rearranging or changing the device.

General Safety Instructions

3.2 On use of electrical appliances

Safety instructions according to EN 60745-1:

Work area

Keep your work area clean and tidy. A messy or unlit work area can cause accidents.

Keep children and other people away from the area when work is being carried out.

Electrical safety The plug on the unit must fit in the socket. Do not modify the plug in any way. Never use

an adapter in combination with earthed appliances. Using an unmodified plug and a

suitable socket will reduce the risk of an electric shock.

Avoid bodily contact with earthed surfaces such as pipes, heating units, cookers and

refrigerators. The risk of an electric shock is greater when your body is earthed.

Keep the device away from rain or wet. Allowing water to get into an electric appliance

will increase the risk of electric shock.

Do not use the cable for anything other than the intended purpose to disconnect the plug

from the socket. Always remove whilst holding onto the plug. Keep the cable away from

heat, oil, sharp edges or the moving parts of other appliances. Using damaged or tangled

cables increases the risk of electric shock.

When working with an electrical appliance outdoors, only use extension cables which are

permitted for outdoor use. Using an extension cable suitable for outdoor use reduces the

risk of electric shock.

Risk of fire as a result of heat build-ups possible. Unwind the cable from the cable drum

to prevent a possible heat build-up and/or cable fire. The coupling must have splash

protection, must be made of rubber or be rubber-coated. The cable cross-section must be

at least 1.5mm2.

Safety guidelines for persons Be attentive and pay attention to what you are doing, act rationally when working with an

electrical appliance. Do not use the appliance when tired or under the influence of drugs,

alcohol or medication.

Just one moment of inattention whilst using the appliance can result in serious injury.

Make sure the appliance cannot be switched on unintentionally. Double check that the

main switch is in the "OFF" position before inserting the plug in the socket. Connecting

the appliance to the power supply while it is switched on can cause an accident.

General Safety Instructions

6

Rieber GmbH & Co. KG

Careful handling and use of electrical appliances Never use an electrical appliance with a faulty switch. An electrical appliance which can

no longer be switched on or off is dangerous and must be repaired.

Keep unused electrical devices away from children. Do not allow the appliance to be

used by persons who are not familiar with it or persons who are not familiar with this user

guide. Electrical appliances are dangerous when in the hands of inexperienced persons.

Treat the device with care. Check that moving parts are functioning properly and do not

block; check whether parts are broken or damaged and impairing the functioning of the

device. Have any damaged parts repaired before using the appliance. Many accidents

are caused by poorly-maintained electrical appliances.

Use electrical appliances, accessories etc in accordance with these instructions and in a

manner that is specified for this particular appliance type. When using the appliance,

please take into account the working conditions and the work being carried out. Using

electrical appliances for other uses than that intended can lead to hazardous situations.

Service Only have the device repaired by qualified and authorised staff. Only use original spare

parts. In this way you can ensure that the appliance remains safe.

3.3 Operator's duties

Operator

The operator is the person who operates the appliance for commercial or economic purposes either

himself/herself or lets others use it and bears the legal appliance responsibility for protection of the

user, staff or any third parties during operation.

Operator's duties

The appliance is used in commercial applications. For this reason, the operator of the appliance must

meet all legal duties relating to work safety.

In addition to the safety instructions in this guide, the safety, accident prevention and environmental

protection regulation applying to the application of the appliance must be complied with.

In particular, the following shall apply:

The operator must be familiar with the applicable work safety regulations and identify, by

carrying out a risk analysis, any additional hazards which are due to the place where the

appliance is used. These hazards must be addressed in the form of operating instructions

governing the operation of the appliance.

Throughout the period of use of the device the operator must check that the operating

instructions which he has compiled comply with the current regulations and adapt them if

necessary.

The operator must clearly regulate and define the responsibilities for installation, operation,

troubleshooting, maintenance and cleaning.

The operator must ensure that all employees who use the device have read and

understood these instructions. In addition, the operator must train the personnel and inform

them of the hazards involved at regular intervals.

The operator must provide the personnel with the necessary protective equipment and

issue mandatory instructions on wearing it.

Rieber GmbH & Co. KG

7

In addition, the operator must ensure that the appliance is always in a perfect technical condition. For

this reason, the following shall apply:

The operator must ensure that the maintenance intervals defined in this guide are obeyed.

The operator must regularly check all safety devices for functionality and completeness.

The operator must ensure that the appropriate media connections are present.

The operator must ensure that structural safety measures are performed.

3.4 Personnel qualification requirements

Safe operation requires certain technical skills and personal qualification of each person.

The responsibility for organization lies with the ‘Designated Representative’ (operator).

According to EN 50110-1 a work supervisor is a person who is appointed to take direct

responsibility for the performance of work. If necessary, this responsibility can be assigned

partly to other persons. [...] The designated representative must instruct all persons

involved in the work on all hazards which may not be obvious for them’.

The work may only be performed by ‘instructed persons’ who have been trained

accordingly. Training, instructions must be repeated, proper understanding must be verified

(ideally by way of an appropriate test).

Only ‘Qualified Staff’ are allowed to carry out repair work.

IEC 60204-1 defines qualified personnel as "persons who, on account of their training and

relevant experience are in the position to recognise risks and avoid potentially dangerous

situations."

Electrical work may only be carried out by trained and experienced electricians.

Electro-technically instructed persons may only work under the supervision of a qualified

electrician.

The Circulating air heater unit housing may only be opened/closed for the purpose of

thorough cleaning by appropriately trained and authorised operating personnel. NOTE: This

is only permitted by the manufacturer's service department during the guarantee and

warranty period.

Any repairs and/or overhaul during the warranty period may only be carried out by the

manufacturer´s service department.

General Safety Instructions

‘Warranty and liability’, page 49

3.5 Provide protective equipment for personnel

Ensure that the personnel wear the personal protective equipment appropriate to the relevant

situation.

Wear sturdy shoes to prevent injuries.

Wear safety gloves to avoid burns at hands and arms.

General Safety Instructions

8

Rieber GmbH & Co. KG

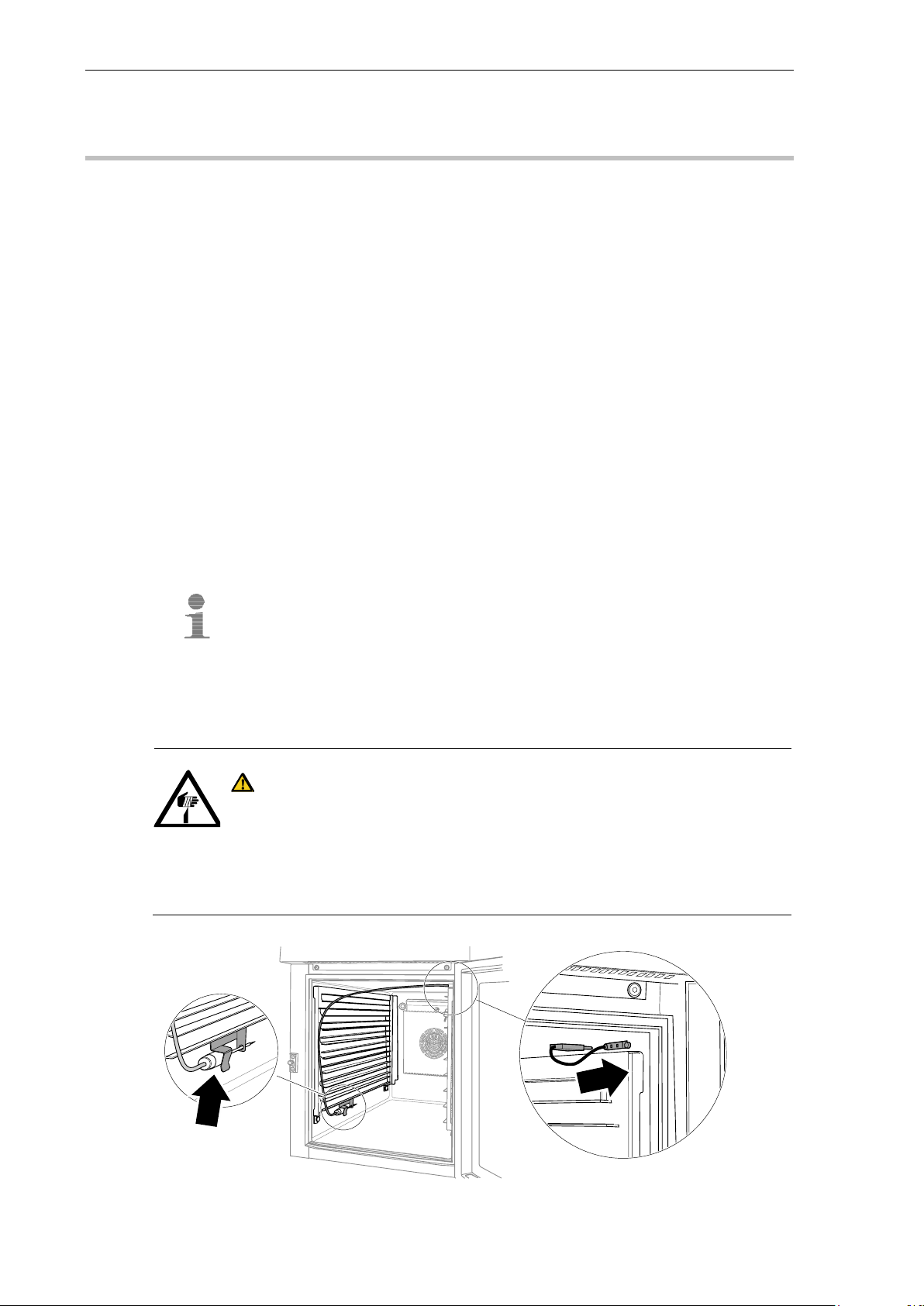

WARNING

Risk of stab wounds when handling the pointed core temperature sensor.

► Be careful.

► Keep the core temperature sensor in a secure location, for example in the holder on

the left register. Do not leave the core temperature sensor lying around loose.

3.6 Appliance-specific safety instructions

This chapter describes general, appliance-specific safety instructions. In the following section, additional safety

information relating to a particular operation or situation is placed before the appropriate operation step or

3.6.1 Safety and monitoring devices

3.6.2 Transport

description of the situation.

The device features a safety cut-out. The product switches itself off automatically in the

event of a fault in the control system..

To increase your safety we recommend that you install a residual current device with a

tripping current of 30 mA upstream of the appliance.

The navioven weighs around 45 kg. Risk of injury when lifting and carrying heavy loads.

Such work may only be carried out by suitable and appropriately trained personnel. If you are not

physically fit, consult your designated representative.

When transporting the appliance hold it at the handle. Transport the appliance with 2 people.

Only transport the appliance when empty, with the mains plug disconnected and the door closed.

User tip: Use the Rieber transport equipment range.

3.6.3 Risks involved in using the sharp core temperature sensor

General Safety Instructions

Rieber GmbH & Co. KG

9

CAUTION

If the plug connector for connecting the core temperature sensor is not fastened, the

sensor may be contaminated; considerable damage is possible.

► Keep the electrical connection for the core temperature sensor closed.

► Use the dummy connector.

CAUTION

If the core temperature sensor is inserted into the ventilation grille of the circulating air

heater, the heater could be damaged; considerable damage is possible.

► Keep the core temperature sensor in a secure location, for example in the holder on

the left register. Do not insert the core temperature sensor into the grille of the

circulating air heater inside the appliance.

3.6.4 Risk of burns and scalds to hands, arms and face

Steam at temperatures of up to 200 °C is released at the back of the appliance. The temperature inside

the appliance can be up to +230 °C. The outside of the housing can reach temperatures of up to 65 °C.

Be careful.

When opening the door using the two-stage door lock allow steam to escape first of all, then open

completely.

Wear protective gloves.

Keep flammable materials away from the product.

3.6.5 Risk of fire and malfunction

Steam at temperatures of up to 200 °C is released at the back of the appliance. The outside of the

housing can reach temperatures of up to 65 °C.

Observe minimum distance for the air circulation at the back panel, ≥ 10 cm.

Keep flammable materials away from the product.

General Safety Instructions

10

Rieber GmbH & Co. KG

The type plate bears the legally required product data.

→ See back of the appliance.

Warning of hot surface

→ See front top left on the appliance, next to the control unit

Warning of electrical voltage

Warning. Unplug mains plug before opening the appliance.’

Languages German, English, French.

→ See back of the appliance.

Note on the distance to be observed at the back of the appliance, otherwise considerable

damage is possible.

→ See pictogram on the back of the appliance.

User tip

► You can find detailed information in the company's internal instructions.

► We recommend that half-yearly emergency training sessions should be carried out.

3.7 Product identification

3.8 Information about regulations to be followed

In addition to this user guide there are a range of health and safety and other regulationsthat are

relevant for the operation of this cooking station; these include HACCP food hygiene regulations for

example.

3.9 Instructions on behaviour in an emergency

In an emergency, always turn the appliance off immediately.

First Aid for burns, scalds, cuts and electric shock

Inform yourself on this before commissioning the appliance.

Store the emergency equipment, including the relevant instructions, at a readily accessible place

near the place of use.

Rieber GmbH & Co. KG

11

4 Purpose

This chapter provides information on the intended use of the product and warns against foreseeable misuse or

abuse, for your safety. Use the appliance for its intended use.

Generally, the following are intended uses for the product:

For system catering, catering, hotels, restaurants and school cafeterias.

Use as a mobile table-top appliance. The appliance is used stationary, without being

moved.

Use as a fitted kitchen appliance for installation in the Rieber ‘aircleansystem’.

Installation only intended and permitted by the Rieber company or a specialist dealer.

Installation by the operator is only permitted in exceptional cases and at the operator's own

responsibility.

For baking, cooking, cooking at core temperature, braising and regenerating meals

comprising specially portioned food and for keeping food warm.

The person responsible for the work, e.g. the chef, programs the navioven parameters.

Wear personal protective equipment such as protective gloves which will prevent you from

burning your arms or hands on hot parts such as heating elements, hot parts of the

appliance, objects and food.

For use by instructed persons only.

Purpose

Prevent any predictable misuse and abuse:

Observe minimum distance for the air circulation at the back panel, ≥ 10 cm. Do not

obstruct the fresh air supply. Steam at temperatures of up to 230 °C is released at the back

of the appliance. The outside of the housing can reach temperatures of up to 65 °C. Ensure

suitable installation conditions.

Remove the protective sheath on the tip of the core temperature sensor before first use,

otherwise there is a risk of significant damage and malfunction.

Do not insert the core temperature sensor into the grille of the circulating air heater inside

the appliance.

Do not operate the appliance unsupervised. To prevent persons from burning themselves

on hot surfaces, use of the product in public, e.g. for self-service, should only be allowed

under supervision.

Installation only intended and permitted by the Rieber company or a specialist dealer, for

example in Rieber's ‘aircleansystem’ installation station. Installation by the operator only

permitted in exceptional cases and at the operator's own responsibility.

Not intended for private use at home.

Do not lean against or sit on the appliance.

Keep any combustible or explosive fluids away from heated appliances. Otherwise a fire or

explosion may occur.

Do not use to heat up a room.

Description of device

12

Rieber GmbH & Co. KG

1 Door lock

2 Carrying handles

3 Water container

4 Control unit

5 Viewing window in the door

6 Core temperature sensor

7 Rubber feet

8 Circulating air heater

9 Left register with holder for

the core temperature sensor

10 Core temperature sensor

11 Dummy connector

12 Right register

5 Description of device

This chapter has interesting facts about the set-up and functionality of this appliance

5.1 Designation

All parts are named here to facilitate further understanding of the manual.

Description of device

Rieber GmbH & Co. KG

13

Detail

Back

Electrical connection

Description of device

14

Rieber GmbH & Co. KG

4 Dial,

protrudes when switched off

6 POWER ON

11 STOP

12 START

Programs

1 Cook

2 Core temperature

3 Fan

5 Menu

Function keys

7 Humidification with steam / emptying,

cleaning

8 Time

9 Core temperature

10 Chamber temperature

Program 1: Cook

Chamber temperature, time and steam can be set.

Program 2: Core temperature

Core temperature, chamber temperature and steam can be set.

Program 3: Fan (passive cooling)

Passive cooling with cooling pellets + circulating air

Program 6: Menu

Stored programs can be selected.

The navioven control unit

Description of device

Rieber GmbH & Co. KG

15

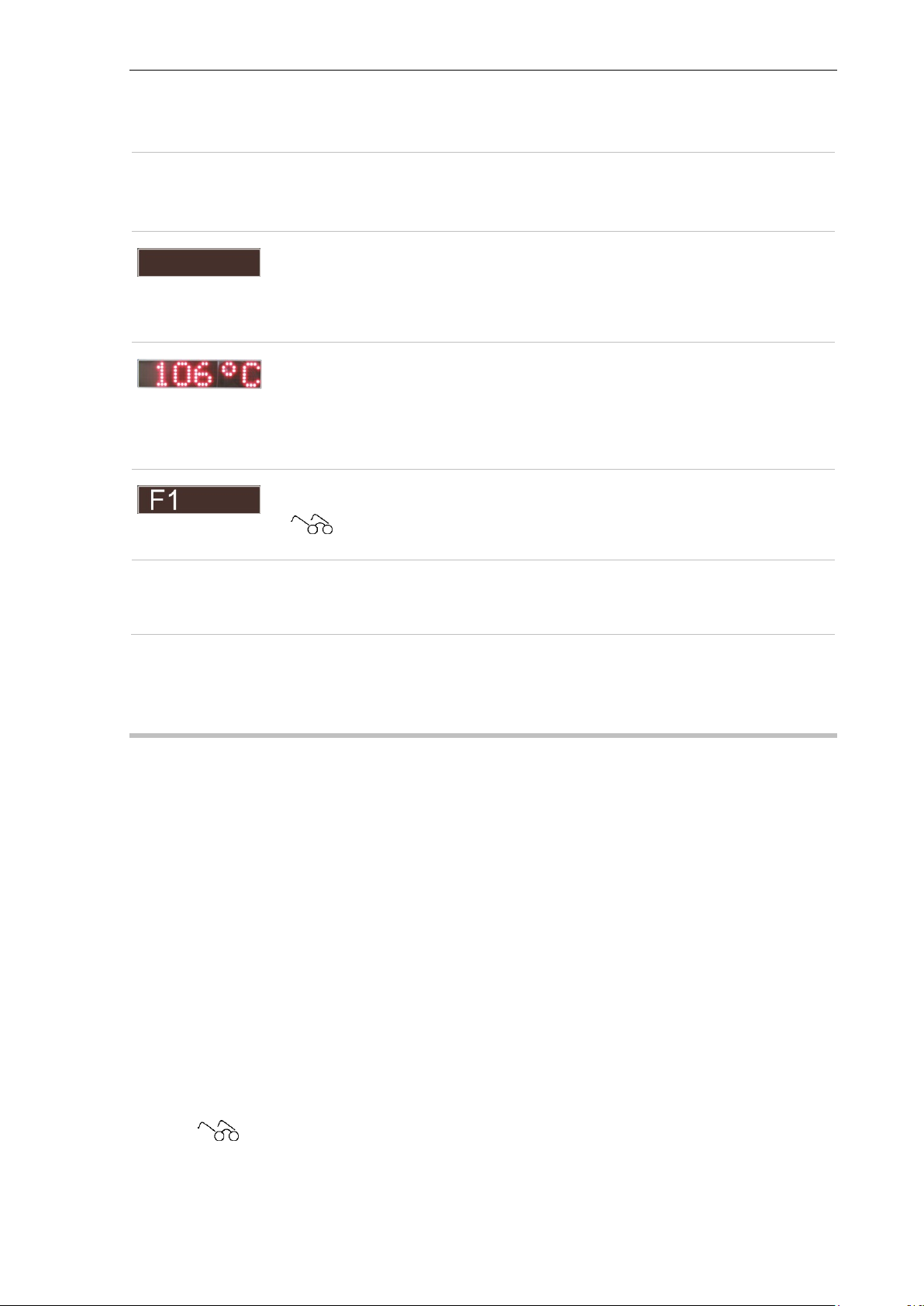

Examples of

displays

Meaning

The navioven is in Standby mode.

The POWER ON LED (6) flashes.

Display is black

Program XX is running.

In the lower menu bar, the Function keys flash indicating the most meaningful

adjustment options.

The current temperature is shown in the display.

F1 in the display indicates: A fault.

See ‘Troubleshooting’ chapter, page 47

Acoustic signal: 10 seconds before a task is run automatically, you will hear an

acoustic signal, e.g. 10 seconds before the cooking time is over.

Rated voltage / mains frequency

1N AC 230V 50/60Hz

Heating capacity

3.2 kW

Ambient conditions

0°C to +80°C

Protection class

IP55 as per DIN EN 60529

(dust-protected, protected against access with a wire, protection

against water jets (nozzle) from any angle)

For installation outdoors a canopy or protection from penetrating

moisture is required.

Mass

approx. 45 kg

Dimensions (W x D x H)

730 x 450 x 560 mm

Temperature range

+20°C to +230°C

Water tank

0.5 litres

Support rails

7 pairs for max. 5 x 1/1 GN 65 mm deep

Display

5.2 Technical data

Detailed specifications for measurements, order number, accessories,

circuit diagrams, spare parts, wear and tear parts:

See catalogue/brochure

If you have any questions, please contact your local Rieber Service.

Before First Use

16

Rieber GmbH & Co. KG

CAUTION

Protective foils or heat-sensitive objects at/in the appliance might damage the appliance

during heating.

► Ensure that there are no protective foils on the inside or outside of the appliance.

► Remove the protective sleeve on the tip of the core temperature sensor before first

use.

6 Before First Use

This chapter describes the measures to be taken before use.

6.1 Transport

# Check/deal with any transport damage

Immediately after delivery, visually check the appliance for any transport damage.

Document any potential transport damage on the consignment note in the presence of the haulage

contractor. Have the damage confirmed by the haulage contractor (with signature).

Decide if you wish to keep the appliance and report the defect using the consignment note, or if

you wish to reject the appliance.

▌ By following this procedure you will ensure proper claim settlement.

# Unpacking

Open the transport packaging at the positions provided for this purpose. Do not tear or cut.

Remove any packaging remnants.

# Scope of delivery

Check the scope of delivery.

6.2 Commissioning

Observe the prerequisites

Observe minimum distance for the air circulation at the back panel, ≥ 10 cm.

Installation only intended and permitted by the Rieber company or a specialist dealer, for

example in Rieber's ‘aircleansystem’ installation station. Installation by the operator is only

permitted in exceptional cases and at the operator's own responsibility.

The appliance has no defects or visible damage.

The appliance is at room temperature and is dry.

Before First Use

Rieber GmbH & Co. KG

17

CAUTION

Protective foils or heat-sensitive objects at/in the appliance might damage the appliance

during heating.

► Ensure that there are no protective foils on the inside or outside of the appliance.

► Remove the protective sleeve on the tip of the core temperature sensor before first

use.

CAUTION

Steam at temperatures of up to 230 °C is released at the back of the appliance. The

outside of the housing can reach temperatures of up to 65 °C.

If the ventilation on the back of the appliance is obstructed, the appliance can be badly

damaged; malfunctions are also possible.

► Observe minimum distance for the air circulation at the back panel, ≥ 10 cm.

► Ensure suitable installation conditions; hot steam is released.

# Dispose of packaging material

Dispose of packaging material in a proper and environmentally compatible manner.

Before First Use

18

Rieber GmbH & Co. KG

Observe the local building inspectorate regulations

Get information from the local authorities.

# Cleaning the navioven

See ‘Cleaning, maintenance and care’ chapter, page 34

# Connecting the navioven Connect the navioven to the power supply.

Rieber GmbH & Co. KG

19

WARNING

The temperature inside the appliance can be up to +230 °C. The outside of the housing

gets hot.

► Be careful.

► When opening the door using the two-stage door lock allow steam to escape first of

all, then open completely.

► Wear protective gloves.

► Keep flammable materials away from the product.

WARNING

Risk of stab wounds when handling the pointed core temperature sensor.

► Be careful.

► Keep the core temperature sensor in a secure location, for example in the holder on

the left register. Do not leave the core temperature sensor lying around loose.

7 Use

7.1 Safety information with regard to use

Use

Comply with the principles for operation

Before each use, check the appliance for any visible damage.

Observe minimum distance for the air circulation at the back panel, ≥ 10 cm.

Comply with the installation conditions.

Make sure there is always drinking water in the water tank. Top up the drinking water regularly.

The appliance is used stationary, without being moved.

Only operate the appliance with adequate lighting.

Risk of burns and scalds to hands, arms and face

Risks involved in using the sharp core temperature sensor

Use

20

Rieber GmbH & Co. KG

CAUTION

If the plug connector for connecting the core temperature sensor is not fastened, the

sensor may be contaminated; considerable damage is possible.

► Keep the electrical connection for the core temperature sensor closed.

► Use the dummy connector.

CAUTION

If the core temperature sensor is inserted into the ventilation grille of the circulating air

heater, the heater could be damaged; considerable damage is possible.

► Keep the core temperature sensor in a secure location, for example in the holder on

the left register. Do not insert the core temperature sensor into the grille of the

circulating air heater inside the appliance.

CAUTION

If the circulating air heater becomes soiled, it may be damaged.

► Prevent liquids from spilling out, use lids. Avoid any soiling.

► Use the navioven stationary, without moving it.

7.2 Pour drinking water into the water tank. Top it up regularly.

Switching on the appliance

Pour drinking water into the water tank,

up to a maximum of 1 cm below the top, ca. 0.5 l.

Make sure there is always drinking water in the tank. Top up the

drinking water regularly.

▌ No error message is given when there is no drinking water in

the container.

Insert plug.

▌ The standby display lights up.

Risks due to soiling of the circulating air heater

Rieber GmbH & Co. KG

21

Choose the program by turning the dial (4).

▌

The display shows the current chamber temperature.

▌

In the lower menu bar, the function keys for the most meaningful

adjustment options flash.

Put the product you want to cook into a GN container.

Press START button (12).

▌

The selected program is executed.

▌

The current chamber temperature is shown in the display.

▌

The respective LED on the dial lights up.

Querying values

Press the respective function key.

▌

The respective setpoint, e.g. the remaining time, is displayed.

Release the function key.

▌

The respective actual value is displayed

▌

After about 10 seconds, the current chamber temperature is shown again

in the display.

After expiry of the cooking time

A signal sounds after expiry of the cooking time.

The program continues.

The current chamber temperature is shown in the display.

7.3 Select program

Use

7.4 Start cooking process

Use

22

Rieber GmbH & Co. KG

▌

The selected program is executed.

▌

The current chamber temperature is shown in the display.

Tap the relevant function key and set the desired value on the dial (6).

▌

The control panel applies the set value for the current cooking process.

Press the STOP button (11) and hold for around 5 seconds: Back to program

selection.

▌

The currently running program is cancelled.

Press the STOP button again and hold for around 5 seconds.

▌

The appliance switches to Standby mode.

▌

The

POWER ON LED

(6) lights up.

Cancel program with real time function

See ‘Unlock the control in real time mode’, page 33

7.5 Change settings during operation

7.6 Cancel cooking process

Rieber GmbH & Co. KG

23

Press and hold down the Chamber temperature button.

With your second finger, press and hold down the STOP button.

Make sure that you do not inadvertently press the

START and STOP buttons at the same time, as in this case the set values

will be lost (RESET).

Set the required keep-warm temperature with the dial.

Then release the STOP button first

followed by the Chamber temperature button.

▌

The keep-warm temperature is saved.

Press and hold down the Time button.

With your second finger, press and hold down the STOP button.

Set the required keep-warm time with the dial.

Then release the STOP button first

followed by the Time button.

▌

The keep-warm time is saved.

In Standby mode press the Time button (8) and hold for around 5 seconds.

Place the flashing bar with the dial (4) in the desired position.

Press the dial.

▌

The value to be changed flashes in the display.

Set the desired value with the dial.

Press the dial again.

▌

The new value is saved.

To close the setting, press the STOP BUTTON (11).

▌

The device is in standby mode.

7.7 Keep food warm (HOLD)

Using the chamber temperature and core temperature settings, you can set a keep-warm phase after

the cooking process.

Use

7.8 Set date and time

Use

24

Rieber GmbH & Co. KG

Press the STOP button (11) and hold for around 5 seconds: Back to program

selection.

▌

The currently running program is cancelled.

Press the STOP button again and hold for around 5 seconds.

▌

The appliance switches to Standby mode.

▌

The current chamber temperature appears in the display.

Turn the dial (4) to the POWER ON setting.

▌

The readings in the display disappear.

Disconnect the electrical connector from the mains if necessary.

Cancel program with real time function

See ‘Unlock the control in real time mode’, page 33

Turn the dial (4) until the display for the desired program lights up.

Press the dial, to open the desired program.

▌

The LEDs on the function keys flash.

Use the function keys to set chamber temperature, core temperature, time and

humidification, depending on the desired program.

▌

The LEDs on the function keys flash.

Chamber temperature function key

Query current chamber temperature

▌

The current temperature is shown in the display, if no other function key

has been pressed.

Query set chamber temperature

Press the Chamber temperature function key (10).

▌

The set temperature is displayed.

▌

After about 10 seconds, the current chamber temperature is shown again

in the display.

Set required chamber temperature

Press and hold down the Chamber temperature function key.

Set the required chamber temperature by turning the dial (4).

Release the Chamber temperature function key.

7.9 How to switch off the navioven

7.10 Operation of the navioven function keys

Use

Rieber GmbH & Co. KG

25

▌

The set value is accepted automatically.

▌

The current chamber temperature is displayed.

Set keep-warm phase (HOLD)

See ‘Keep food warm’, page 23

Core temperature function key

Query set core temperature

Press the Core temperature function key (9).

▌

The set temperature is displayed.

▌

After about 10 seconds, the current core temperature is shown again in

the display.

Query current core temperature

Press and release the Core temperature function key.

▌

The current core temperature is displayed.

Set required core temperature

Press and hold down the Core temperature function key. Set the required core

temperature by turning the dial.

Release the Core temperature function key.

▌

The set value is accepted automatically.

▌

The current chamber temperature is shown in the display again.

Set keep-warm phase (HOLD)

See ‘Keep food warm’, page 23

Time function key

Query set time

Press the Time function key (8).

▌

The set time is displayed.

▌

After about 10 seconds, the current chamber temperature is shown again

in the display.

Query remaining time

Press and release the Time function key.

▌

The remaining time is displayed.

▌

After about 10 seconds, the current chamber temperature is shown again

in the display.

Set required time

Press and hold down the Time function key. Adjust the set time by turning the dial.

Set "--" for endless operation.

Release the Time function key.

▌

The set value is accepted automatically.

▌

The current chamber temperature is shown in the display again.

Use

26

Rieber GmbH & Co. KG

Humidification function key

In order to use this function you must fill the water tank with drinking water beforehand, up

to a maximum of 1 cm below the top, around 0.5 l.

Make sure there is always drinking water in the tank. Top up the drinking water

regularly.

Humidification levels

The air humidification function prevents cooked product from drying out and improves

heat transfer.

4 air humidification levels are available:

0 : Neutral setting, no humidification

Dry: The valve is opened

1 and 2: Controlled humidification

Query humidification level

Press the Humidification function key (7).

▌

The set level is displayed.

Set humidification level

Press and hold down the Humidification function key.

Adjust the humidification level by turning the dial.

Release the Humidification function key.

▌

The set value is accepted automatically.

▌

The current chamber temperature is shown in the display again.

▌

When 50°C is reached, the water pump starts with a pre-pumping time of

6 seconds. Water can enter the interior during this process.

Pump residual water out of the appliance, rinse the appliance

See ‘Pump residual water out of the appliance, rinse the appliance’, page 40

Descale the appliance

See ‘Descale the appliance as required, page 45’

START button

Start program

Press START button (12).

▌

The selected program starts with the saved settings.

STOP button

Reset functions at any time

Press the STOP button (11) and hold for around 5 seconds.

▌

Back to the functions. These can be reset, as described above. The

running program is interrupted.

Press the START button (12) to continue the program.

▌

The current chamber temperature is shown in the display again.

Rieber GmbH & Co. KG

27

End programs

Press the STOP button.

Press the STOP button again and hold for around 5 seconds.

▌

Back to program selection. The running program is terminated.

▌

The current chamber temperature is shown in the display again.

Switch on Standby mode

Press the STOP button again and hold for around 5 seconds.

▌

The appliance switches to

Standby

mode.

▌

The

Power ON LED

(9) lights up.

▌

The displays of the chamber temperature, time and steam function keys

flash (flashing = changeable).

Set chamber temperature, time and humidification.

Press START button (12).

▌

The 'Cook' program starts with the saved settings.

Change settings for the current cooking process

Press the STOP button (11) and hold for around 5 seconds.

▌

Back to the functions. These can be reset. The running program is

interrupted.

Press the START button to continue the program.

▌

The current chamber temperature is shown in the display again.

Cancel program

Press the STOP button and hold for around 5 seconds.

▌

Back to program selection. The running program is terminated.

Press the STOP button again and hold for around 5 seconds.

▌

The appliance switches to Standby mode.

▌

The

POWER ON LED

(6) lights up.

▌

The current chamber temperature is shown in the display again.

7.11 The navioven programs

7.11.1 Program 1: Cook

Use

Use

28

Rieber GmbH & Co. KG

▌

The displays of the core temperature, chamber temperature, time and

humidification function keys flash (flashing = changeable).

Set core temperature, chamber temperature, time and steam.

Press START button (12).

▌

The 'Core temperature' program starts with the saved settings.

Change settings for the current cooking process

Press the STOP button (11) and hold for around 5 seconds.

▌

Back to the functions. These can be reset. The running program is

interrupted.

Press the START button to continue the program.

▌

The current chamber temperature is shown in the display again.

Cancel program

Press the STOP button and hold for around 5 seconds.

▌

Back to program selection. The running program is terminated.

Press the STOP button again and hold for around 5 seconds.

▌

The appliance switches to Standby mode.

▌

The current chamber temperature is shown in the display again.

Passive cooling with circulating air + cooling pellets.

Turn dial (4) to program 3, set fan.

Press the START key.

▌

Circulating air operation begins when the program starts.

▌

The current chamber temperature is shown in the display.

Press the STOP button and hold for around 5 seconds.

▌

Back to program selection. The running program is terminated.

▌

The current chamber temperature is shown in the display again

Press the STOP button again and hold for around 5 seconds.

▌

The appliance switches to Standby mode.

▌

The

POWER ON LED

(6) lights up.

▌

The readings in the display disappear.

7.11.2 Program 2: Core temperature

7.11.3 Program 3: Fan

Cooling is only possible if the navioven contains cooling pellets.

Insert cooling pellets.

Rieber GmbH & Co. KG

29

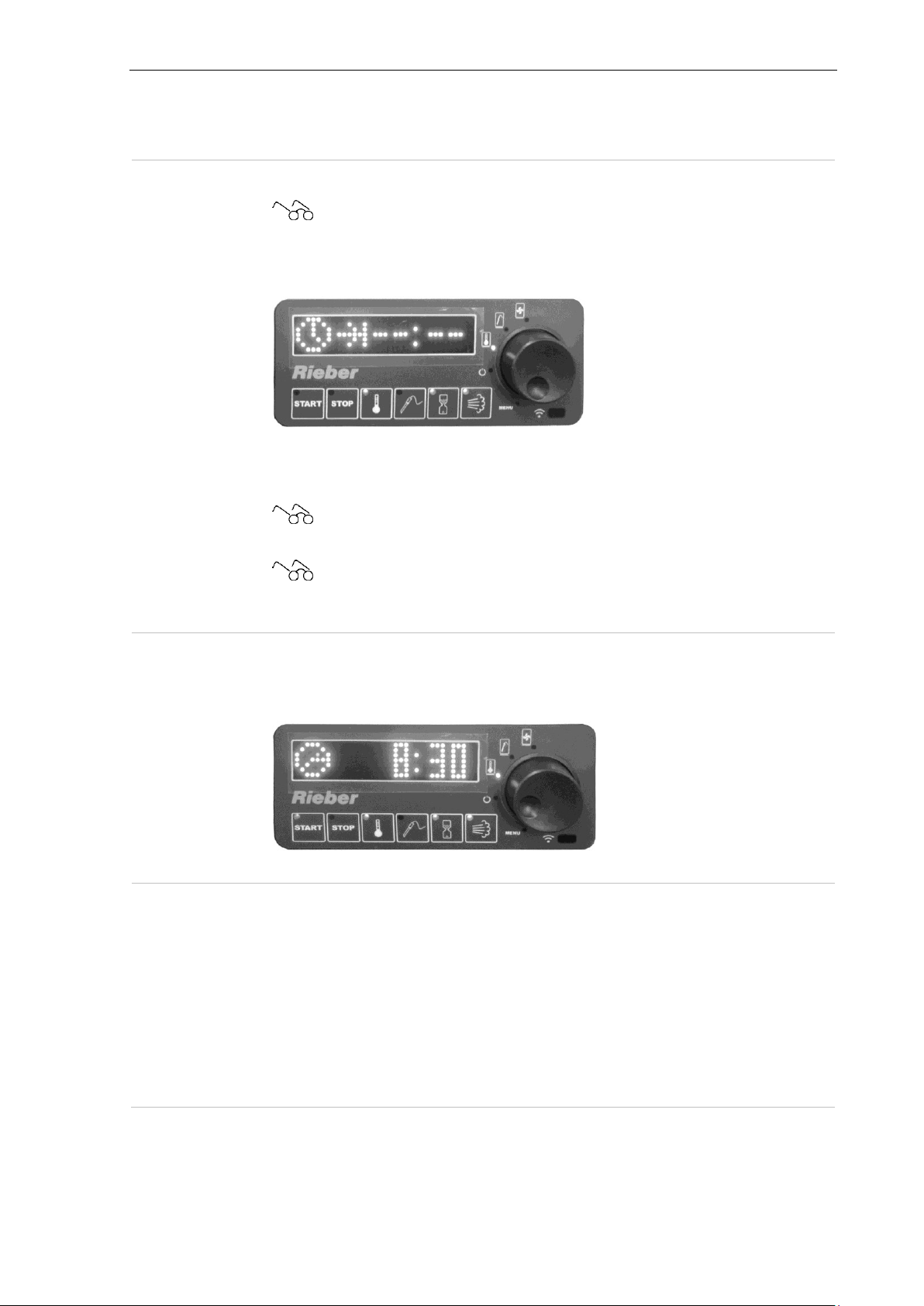

Calling up a menu with real time function

Turn the dial to the Menu position and press.

▌

Menu no. 1 is shown in the display.

Select the desired menu no. YY by turning the dial (6).

▌

The display of the program symbol for menu no. YY lights up. Menus

with real time function are identified by a T in the display.

Press the dial.

▌

First, the following picture is shown in the display:

▌

Then the display shows the start time.

▌

Menu no. YY starts with the settings made.

▌

During automatic execution of the program, the chamber temperature is

shown in the display.

7.11.4 Program 6: Menu (call up saved menus)

This operating mode is an automatic mode. Previously defined programs can be called up.

Once programmed, instructed personnel can prepare the meals easily and precisely.

There are two options for saving and calling up menus:

Timed with real time function. In real time mode no changes can be made to the settings

during execution of the menu.

or

Use

Saving a menu without real time function.

Use

30

Rieber GmbH & Co. KG

Calling up a menu without real time function

Press the dial.

Press the dial again.

▌

The display of the program symbol for menu no. YY flashes, if the

position is free, assigned menu positions are lit.

By turning the dial (6)you can select the menu number YY you want.

▌

The display of the program symbol for menu no. YY lights up.

Press the dial.

Press the START button (15).

▌

Menu no. YY starts with the settings made.

▌

During automatic execution of the program, the current chamber

temperature is shown in the display.

Change settings for the current cooking process

You can only change the settings for the current cooking process in the menu mode

without real time function.

If a value is changed during the program sequence, the change will only affect the

current process. The menu is not automatically overwritten.

Press and hold down the relevant function key.

At the dial (6)set the value you want and then release it to activate the set value.

▌

The changed settings are only adopted for the current cooking process.

The stored menu no. YY is not overwritten.

▌

The current chamber temperature is shown in the display again.

Cancel program without real time function

Press the STOP button again and hold for around 5 seconds.

▌

Back to program selection. The running program is terminated.

Press the STOP button again and hold for around 5 seconds.

▌

The appliance switches to Standby mode.

▌

The POWER ON LED (9) lights up.

▌

The readings in the display disappear.

Cancel program with real time function

See ‘Unlock the control in real time mode’, page 33

Rieber GmbH & Co. KG

31

Set required values for the program.

See chapter ‘Select program’, page 21

Press the dial for about 5 seconds.

▌

The following picture is shown in the display:

There are 2 options for saving a menu.

Variant 1

: Saving a menu

with real time function

See ‘Saving a menu with real time function’, page31

Variant 2

: Saving a menu

without real time function

See ‘Saving a menu without real time function’, page32

Saving a menu with real time function

Select the desired settings with the dial and the function keys.

Press and hold the dial.

▌

The display shows a clock, a flashing arrow and symbolically shows the

time as --:--.

▌

Use the

dial

to set the required start time

Press the dial.

▌

The next free menu number flashes. Assigned menu numbers are lit up.

Press the dial to save the entered program settings under the required menu number

XX or to overwrite. 31 different menus can be saved.

▌

The display shows: "Saving, please wait".

7.11.5 Saving a menu

Use

Use

32

Rieber GmbH & Co. KG

▌

After saving, the set start time of the program is shown in the display.

▌

The program starts automatically at the set time.

▌

During an automatically run program, the current chamber temperature is

shown.

▌

While it is running, the set values cannot be changed.

▌

When the program has finished, "Ready" is shown in the display for about

one hour.

There are 2 subsequent options:

Press the dial.

▌

The menu for the next day is opened again.

Or

The setting can be unlocked.

See ‘Unlock the control in real time mode’, page 27’.

Saving a menu without real time function

Press and hold the dial.

▌

The next free menu number flashes in the display, previously assigned

menu numbers are lit.

▌

Use the

dial

to select the menu number you want.

Press the dial to save the entered program settings under the required menu number

XX or to overwrite. 31 different menus can be saved.

▌

The display shows an OK!

Rieber GmbH & Co. KG

33

Unlock the control in real time mode

Press and hold the START button and the STOP button simultaneously.

▌

The display shows 0000

Use the dial to set the preset start time as a value, e.g. start time 14:30 – value 1430.

Press the dial. The chamber temperature is shown in the display.

If the value is no longer available: Press and hold down the Time function key, until

the start time appears in the display.

Menu

Function

Chamber

temperature

Time

(min)

Humidificati

on

Core

temperature

Comments

1

Regeneration

140 °C

90 2

Cook & Chill

2

Regeneration

140 °C

15 1

Hotel industry

3

Cook

120 °C

20 2

Rice

4

Cook

140 °C

75 0

Pork

5

Core temperature

130 °C

0 58 °C

Roast beef

6

Core temperature

130 °C

0 50 °C

Turkey breast

10

Circulating air

passive

Pellets

7.11.6 Pre-saved menus

Use

Cleaning, maintenance and care

34

Rieber GmbH & Co. KG

WARNING

The temperature inside the appliance can be up to +230 °C.

► When opening the door using the two-stage door lock allow steam to escape first of

all, then open completely.

► Allow the device to cool down.

► Wear protective gloves.

WARNING

Risk of stab wounds when handling the pointed core temperature sensor.

► Be careful.

► Keep the core temperature sensor in a secure location, for example in the holder on

the left register. Do not leave the core temperature sensor lying around loose.

CAUTION

If the plug connector for connecting the core temperature sensor is not fastened, the

sensor may be contaminated; considerable damage is possible.

► Keep the electrical connection for the core temperature sensor closed.

► Use the dummy connector.

8 Cleaning, maintenance and care

This chapter will help you to meet the hygiene requirements.

8.1 Safety information relating to cleaning, maintenance and care

Risk of burns and scalds to hands, arms and face

Risk of stab wounds when handling the pointed core temperature sensor

Cleaning, maintenance and care

Rieber GmbH & Co. KG

35

Danger of electric shock. Risk of death

► Disconnect the appliance from the mains.

► Protect the appliance against moisture. Never direct a jet of water at electrical

components such as heater, controller or ventilation grille.

► Check the heating and connecting cable for any damage.

► Do not use a steam cleaning unit to clean electrical appliances. Doing so may allow

moisture to get into the electrical system and cause a short circuit. Do not expose to

spray water. Wipe electrical parts with a moist cloth only and dry the surface using a

dry cloth.

►

1

Have electrical equipment inspected by a qualified electrician in accordance with

DGUV. Define the inspection cycle according to the conditions of use. Generally this is

every 12 months.

Turn the dial (6) to the POWER setting.

If necessary, press the dial again to switch off the appliance.

▌

The respective display is no longer lit.

Unplug the mains plug and prevent the appliance from accidentally being switched on

again.

1

Prevent risks due to electricity

# Note on switching off the appliance:

Source: DGUV Regulation 3. Electrical Systems and Equipment

Cleaning, maintenance and care

36

Rieber GmbH & Co. KG

Cleaning agent

Suitable

Brush products

Brushes with natural or synthetic bristles

Textiles

Textile material comprising natural and chemical cleaning fibres and textile

fabrics (knitted and woven fabric, cleaning cloths, floor cloth, fringed

material, fleece). Microfibre cleaning textiles are ideal for removing finger

marks from stainless steel surfaces.

Synthetic fleece

Without abrasives.

Mainly produced in the colours white, beige, yellow.

Other

Natural leather (chamois), synthetic leather, synthetic fleece, sponges,

sponge cloths

Cleaning agent

Areas of application

All-purpose cleaners

Particularly for lighter grease stains.

Neutral cleaners

For surfaces soiled with grease and oil (fingerprints); also suitable as a

dishwashing detergent.

Alcohol cleaners

As all-purpose cleaner

Alkaline cleaners

Especially for heavy grease and oil stains (dried-in oils).

Observe the manufacturer's dosage instructions.

Solvent cleaners

Depending on the type, particularly good for the removal of grease, oil, wax,

tar, adhesives, paints and lacquers.

Not suitable for plastics.

Disinfectant cleaners

Effect on pathogenic germs differs depending on active disinfectant

ingredient.

Long-term exposure to sodium hypochlorite can cause damage to the

material. It should not be used if possible. Products should be used, which

are specified in the list of the German Society of Hygiene and Microbiology

(DHGM).

8.2 Cleaning agents for stainless steel

# The following applies for all cleaning agents:

Observe the instructions for use provided by the cleaning agent manufacturer.

# Chemical cleaners for stainless steel

# Mechanical cleaners for stainless steel

Rieber GmbH & Co. KG

37

CAUTION

Incorrect cleaning can damage the surface or even destroy the appliance. Please note:

► Do not scratch the surface with sharp-edged objects. Do not use any abrasive or

aggressive cleaning agents, such as oven spray or a sponge with an abrasive surface.

► Remove dirt with cleaning and care products that are suitable for stainless steel.

► Do not mix standard cleaning agents; do not produce your own cleaning agent.

► Do not use steel wool or steel brushes.

► Avoid extended exposure of stainless steel to liquid containing salt, as this can lead to

surface discolouration and corrosion.

► Avoid direct, extended contact of stainless steel with corroding iron parts, e.g. cast

iron pans or steel kitchen sponges.

CAUTION

Incorrect cleaning can cause damage to the surface.

► A mild washing up detergent diluted in hot water is ideal. Wipe the surfaces

with a damp, non-scratch cloth. After cleaning rub the surfaces dry with a soft

cloth.

User tip

► We recommend Rieber cleaning agent for stainless steel for cleaning stainless

steel.

▌

It is an especially thorough yet gentle cleaner, produces a dazzling shine,

and cleans and protects in one.

Order no.: 72 10 24 08

8.3 Choose the correct cleaning method

Cleaning, maintenance and care

# Clean and service stainless steel parts

Applies to the stainless steel housing of the navioven, outside and inside and the door frame

Cleaning, maintenance and care

38

Rieber GmbH & Co. KG

CAUTION

Incorrect cleaning can cause damage to the surface.

► A mild washing up detergent diluted in hot water is ideal. Wipe the surfaces

with a damp, non-scratch cloth. After cleaning rub the surfaces dry with a soft

cloth.

# Clean and service plastic parts

Applies to operator's controls such as switches and control, door seal, seal of the water tank cover

Remove the door seal for cleaning if necessary.

Cleaning, maintenance and care

Rieber GmbH & Co. KG

39

Interval

Activity to be performed

Page

Daily after use

Pump out residual water, rinse appliance.

Page 40

Switch the appliance off

Page 34

cleaning the navioven

Page37, 41 et

seqq.

Clean core temperature sensor

Page41 et

seqq.

If required

Clean door seal,

at least once a week during use

Page37, 41 et

seqq.

Risk of fire

Remove fluff from the ventilation grille, at

least once a month

Page41 et

seqq.

Descale appliance,

at least every 3 months

Page 45

Every 180 working days or

6 months

Have electrical system /control checked.

Page 34

Ensure preservation of the product

identification

Page 10

8.4 Overview of cleaning and maintenance intervals

Cleaning, maintenance and care

40

Rieber GmbH & Co. KG

Place an empty GN container on the lowest support rail in the

appliance.

Turn the unit off.

Turn the dial to the POWER setting.

The corresponding LED lights up.

Press the Humidification button continuously, until you hear the water pump switch on. The

pumping out process lasts around 5 or 6 seconds. Do not interrupt the process, otherwise the

pumping out process will begin again at the next START of the appliance.

Check that the water has been completely pumped out of the water tank and the interior. Repeat

the process if necessary.

Empty the GN container.

# Rinse the appliance

Place an empty GN container on the lowest support rail in the appliance.

Pour around 0.5 litres of drinking water into the water container.

Note:

The water pump requires three pumping out processes for the 0.5 litres of water.

Press the Humidification button continuously, until you hear the water pump switch on.

When the water pump switches off again, press the Humidification button again continuously,

until you hear the water pump switch on. Repeat the process again, to pump out the water

completely.

Empty the GN container.

8.5 Pump residual water out of the appliance, rinse the appliance

# Pump out residual water

Pump residual water out of the appliance daily after use. If residual water remains in the appliance, this

can impair the taste of the food.

Cleaning, maintenance and care

Rieber GmbH & Co. KG

41

Clean the opening in the rubber plug and clear it with a thin wire if necessary.

User tip. We recommend descaling the appliance regularly,

at least once a month for intensive use,

at least once every 3 months, depending on use.

See ‘Descale the appliance as required’, page 45

Turn the dial (6) to the POWER setting.

If necessary, press the dial again to switch off the appliance.

▌

The respective display is no longer lit.

Open door and allow hot appliance to cool down.

# Clean the water container and lid

8.6 Cleaning

Prerequisite

The residual water has been pumped out of the appliance, the appliance has been rinsed.

See ‘Pump residual water out of the appliance, rinse the appliance’, page 40

WARNING

Before cleaning the device, switch it off and disconnect from the mains.

Cleaning, maintenance and care

42

Rieber GmbH & Co. KG

Risk of fire

Fluff in the ventilation area can cause a build-up of heat which could result in a fire.

► Clean the ventilation grille on the back of the appliance with a cloth or paintbrush, at

least once a month.

CAUTION

An unplugged dummy connector may be damaged or pulled off when removing the

register.

If the opening for connecting the core temperature sensor is not sealed, the sensor may be

contaminated; considerable damage is possible.

► Remove the connector of the core temperature sensor. Insert the dummy

connector into the receptacle.

# Clean door seal

Clean door seal, at least once a week.

User tip. Clean the door seal in the dishwasher.

Alternatively: A mild washing up detergent diluted in hot water is ideal. Wipe the surfaces with a

damp, non-scratch cloth. After cleaning, rub surfaces dry with a soft cloth.

# Remove fluff in the ventilation area

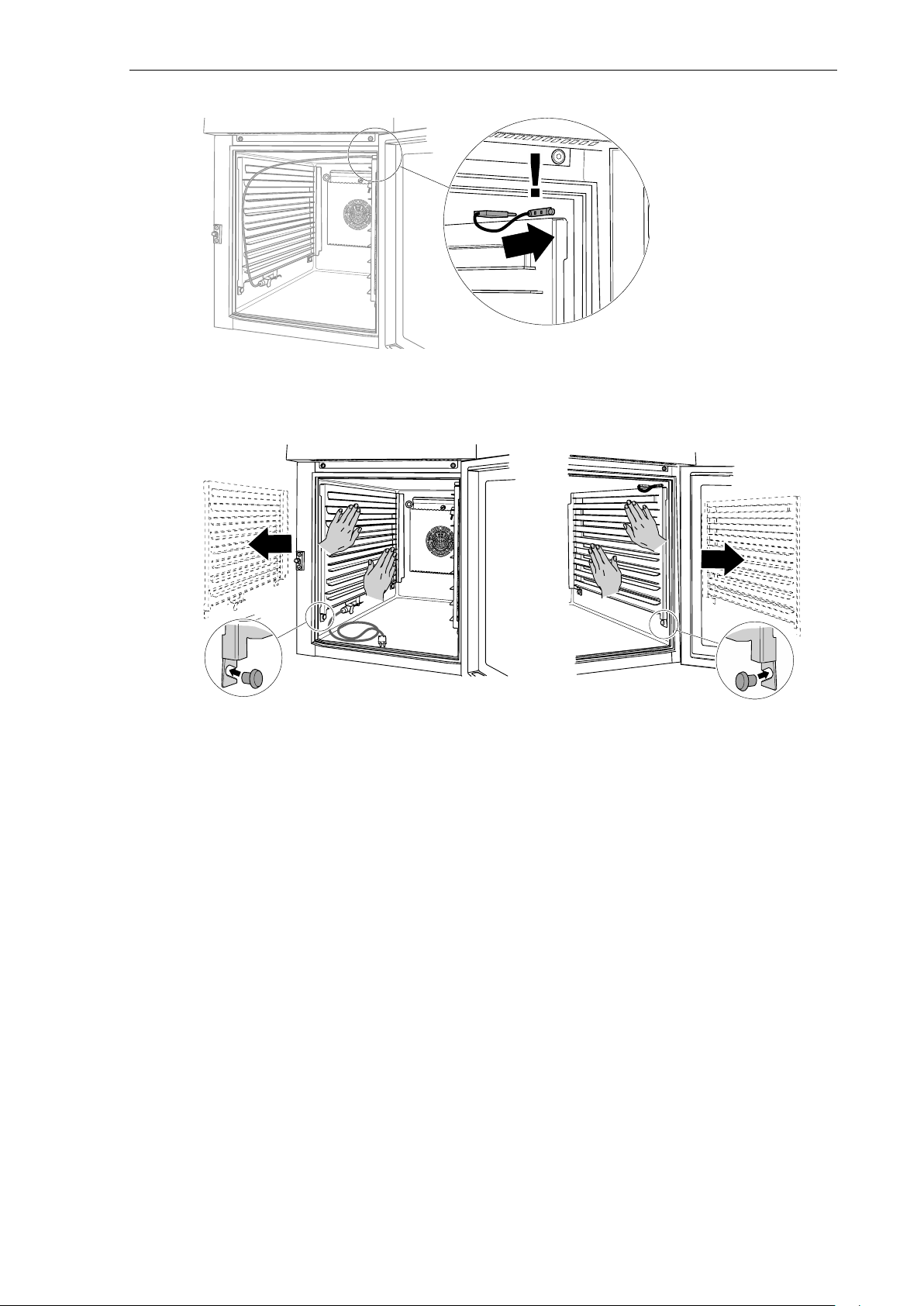

# Removing the registers and the core temperature sensor

WARNING

Take care when handling the pointed core temperature sensor.

Keep the core temperature sensor in a secure location. Do not leave the core temperature sensor

lying around loose.

Cleaning, maintenance and care

Rieber GmbH & Co. KG

43

4x

4x4x

# How to remove the registers: Pull the long side of the register towards you.

Grasp the register with both hands. Pull the long side of the register towards you and remove the

part.

▌ The guide is smooth-running.

Remove the left register. The core temperature sensor can remain in the holder, if it is completely

mounted in the holder and the cable is fixed by hand.

Remove the right register.

Cleaning, maintenance and care

44

Rieber GmbH & Co. KG

4x

4x4x

CAUTION

If installed incorrectly, the plates at the bottom of the register may be bent, so that the

register would have to be replaced.

An unplugged dummy connector may be damaged or pulled off when installing the

register. If the connector is not inserted, liquid or objects such as particles of dirt may enter

the receptacle.

► Insert the dummy connector into the receptacle provided.

► Mount the register evenly on the inside at the top edge with both hands. Pay

attention to the front closure of the inside of the housing and the register.

► Then push the long side of the register into the interior until you feel the end stop.

▌

The guide is smooth-running. The register is guided back at a slight angle.

The 4x guide bolts hold the register.

WARNING

Risk of stab wounds when handling the pointed core temperature sensor.

► Be careful.

# Installing the registers and the core temperature sensor

# Clean core temperature sensor

Mild washing up detergent diluted in hot water is ideal for cleaning. After cleaning, rub surfaces

dry with a soft cloth.

# Finally insert the registers and core temperature sensor into the navioven

See ‘Installing the registers and the core temperature sensor, page 44

Rieber GmbH & Co. KG

45

User tip

Signs of calcification are visible limescale and extended processing time, increased noise

generation, intense steam generation.

► Descale the appliance before a thorough cleaning;

at least once a month for intensive use,

at least once every 3 months depending on use.

WARNING

Use a commercially available descaler for domestic appliances. Observe the

manufacturer's instructions.

Prepare the

descaling solution

with

0.5 litres of

drinking water and the quantity of

descaler specified by the manufacturer. Pour these in.

Place an empty GN container on the lowest support rail in the appliance.

Turn the dial to the POWER setting.

▌

The corresponding LED lights up.

Press the Humidification button continuously, until you hear the water pump switch

on.

Wait until the water pump switches off again and leave the descaling solution to work in

accordance with the manufacturer's instructions, around 10 minutes.

Then press the Humidification button continuously, until you hear the water pump

switch on and the descaling liquid is pumped out.

8.7 Descale the appliance as required

Cleaning, maintenance and care

Cleaning, maintenance and care

46

Rieber GmbH & Co. KG

When the water pump switches off again, press the Humidification button again

continuously, until you hear the water pump switch on and the remaining descaling

solution is pumped out. Wait until the descaling solution is completely pumped out.

Empty the GN container.

# Rinse the appliance 3x.

Place the empty GN container on the lowest support rail in the appliance.

Pour around 0.5 litres of drinking water into the water container.

Note:

The water pump requires three pumping out processes for the 0.5 litres of water.

Press the Humidification button continuously, until you hear the water pump switch

on.

When the water pump switches off again, press the Humidification button again

continuously, until you hear the water pump switch on. Repeat the process again, to

pump out the water completely.

Empty the GN container.

Repeat the complete rinsing process twice more.

Check that the water has been completely pumped out of the water tank and the

interior. Repeat the process if necessary.

See ‘Pump residual water out of the appliance, rinse the appliance’; page 40

8.8 Keep ready for next use in dry condition

Dry the inside of the appliance and leave the door open until the residual moisture has dried off.

Store appliance at room temperature.

Rieber GmbH & Co. KG

47

DANGER

Danger of electric shock. Dangerous electrical voltage.

► Disconnect appliance from mains before any repair work.

► Have all electrical repairs carried out by an authorised electrician only.

Fault

Possible cause

Possible remedy

F1 in the display

Malfunction

Call Rieber Service or

contractual partner

# User

Display is blank

Electrical connector / electrical

cable defective

Disconnect connecting

plug and lock appliance.

# Qualified electrician

Appliance does not heat up/

Temperature too high

Heating defective

Machine parameter P entered

wrongly

Controller defective

Replace

# User

Repair

# Rieber Service or

authorized partner

Control unit

Not functioning

Control unit defective

Repair

# Rieber Service or

authorized partner

Humidification does not

work

No water in the water

container

Scale or dirty

Pour drinking water into

the water container

# User

Descale, clean

# User

Residual water is not

pumped out

Water pump defective

Repair

# Rieber Service or

authorized partner

9 Fault - What now?

Repairs during the warranty period may only be carried out by the manufacturer's service department.

If there is a fault, F1 is shown in the display.

Fault - What now?

Fault - What now?

48

Rieber GmbH & Co. KG

IMPORTANT

Customer service needs information about the type and number of your appliance.

Your appliance is made of high-quality material which can be reused / recycled. For

disposal, disconnect the appliance from mains supply. Unplug the mains plug. Cut off the

cable directly at the casing. Dispose of this appliance properly via your local disposal

facility.

WARNING

Persons with limited sensory and mental ability might get locked in.

► When disposing of the unit, destroy the door lock.

Customer service, spare parts

If you have a fault you cannot remedy yourself, please get in touch with your Rieber partner or

Rieber central customer service.

Disposing of the appliance

Rieber GmbH & Co. KG

49

10 Warranty and liability

Manufacturer liability and warranty shall no longer apply if

you do not follow the information and instructions in this user guide,

do not use the device as it is intended,

See chapter ‘Intended use’

make conversions or functional modifications,

do not use original spare parts.

The "Sales and delivery terms and conditions" of Rieber GmbH & Co. KG shall apply for all warranty

claims made against the manufacturer. For instance, any repairs and/or overhaul during the warranty

period may only be performed by the manufacturer's service department of Rieber, failing which any

claims hereof may be voided. Please contact the manufacturer's service department.

Warranty and liability

not applicable

The following wear parts are not included in the warranty:

Excerpt from the EU Declaration of Conformity

50

Rieber GmbH & Co. KG

11 Excerpt from the EU Declaration of Conformity

EC Declaration of Conformity according to EC Machinery Directive 2006/42/EC

Rieber GmbH & Co. KG hereby declares that the product

navioven

complies with the basic requirements of the EC Machinery Directive 2006/42/EC, Appendix II A,

harmonised standards (DIN EN ISO 12100: Safety of Machinery ― General principles for design ―

Risk assessment and risk minimisation).

EU Declaration of Conformity in accordance with the European Directive on Electromagnetic Compatibility 2014/30/EU.

Rieber GmbH & Co. KG hereby declares that the product

navioven

complies with the basic requirements of the European Directive on Electromagnetic Compatibility

2014/30/EU in respect of its electrical equipment.

A copy of the EU Declaration of Conformity can be obtained from our sales team if required.

Rieber GmbH & Co. KG

51

Rieber GmbH & Co. KG

Hoffmannstraße 44

D 72770 Reutlingen

Tel +49 (0) 7121 518-0

FAX +49 (0) 7121 518-302

E-mail info@rieber.de

www.rieber.de

12 Manufacturer's address

Manufacturer's address

Brief instructions

52

Rieber GmbH & Co. KG

Ausgabe: 2017-04-21

13 Brief instructions

Loading...

Loading...