SeeSnake®FlatPack and Color FlatPack

Record Serial Number below and retain product serial number which is located on nameplate.

Serial No.

Kollmann

SeeSnake

®

FlatPack

and Color FlatPack

SeeSnake®Diagnostic Equipment

99 Washington Street

Melrose, MA 02176

Phone 781-665-1400

Toll Free 1-800-517-8431

Visit us at www.TestEquipmentDepot.com

Test Equipment Depot - 800.517.8431 - 99 Washington Street Melrose, MA 02176

FAX 781.665.0780 - TestEquipmentDepot.com

Table of Contents

Recording Form for Machine Model and Serial Number ...........................................................................................1

General Safety Information

Work Area Safety........................................................................................................................................................2

Electrical Safety...........................................................................................................................................................2

Battery Precautions..................................................................................................................................................2

Personal Safety...........................................................................................................................................................2

Tool Use and Care......................................................................................................................................................3

Service ........................................................................................................................................................................3

Specific Safety Information

Equipment Safety........................................................................................................................................................4

Description, Specifications and Standard Equipment

Description ..................................................................................................................................................................4

System Components...................................................................................................................................................4

Camera Head...........................................................................................................................................................4

Drum.........................................................................................................................................................................5

Monitor Pack Camera Control Unit (CCU) ...............................................................................................................5

Specifications..............................................................................................................................................................7

Standard Equipment....................................................................................................................................................7

Set Up and Operation

Equipment Set Up.......................................................................................................................................................7

Connections .............................................................................................................................................................7

Operation..................................................................................................................................................................8

Video Recording.......................................................................................................................................................8

At the Job Site.............................................................................................................................................................9

Transportation & Storage ...........................................................................................................................................10

Centering Guides.........................................................................................................................................................11

Installing the SeeSnake®Star-Type Centering Guides..............................................................................................11

Installing Star-Type Centering Guides ...................................................................................................................11

Removing Star-Type Centering Guides .................................................................................................................12

Installing the SeeSnake®Compact, and FlatPack Ball-Type Centering Guides........................................................12

Maintenance and Cleaning

Preventative Maintenance.........................................................................................................................................13

Camera Head.........................................................................................................................................................13

Spring Assembly ....................................................................................................................................................13

Push Cable and Drum............................................................................................................................................13

Monitor Pack ..........................................................................................................................................................13

Locating Faulty Components.....................................................................................................................................13

Service and Repair ......................................................................................................................................................14

Troubleshooting ..........................................................................................................................................................15

Icon Legend .................................................................................................................................................................15

Lifetime Warranty..........................................................................................................................................Back Cover

Ridge Tool Companyii

SeeSnake®FlatPack and Color FlatPack

Kollmann

SeeSnake®FlatPack and Color FlatPack

Kollmann

Ridge Tool Company2

General Safety Information

CAUTION! Read and understand all instructions. Failure

to follow all instructions listed below may

result in electric shock, fire, and/or serious

personal injury.

SAVE THESE INSTRUCTIONS!

Work Area Safety

• Keep your work area clean and well lit. Cluttered

benches and dark areas may cause accidents.

• Do not operate electrical devices or power tools in

explosive atmospheres, such as in the presence of

flammable liquids, gases, or heavy dust. Electrical

devices or power tools create sparks which may ignite

the dust or fumes.

• Keep bystanders, children, and visitors away

while operating tool. Distractions can cause you

to lose control.

• Do not let visitors contact the tool or extension

cord. Such preventative measures reduce the risk

of injury.

Electrical Safety

• Avoid body contact with grounded surfaces such

as pipes, radiators, ranges and refrigerators. There

is an increased risk of electrical shock if your body is

grounded.

• Tool is only splash resistant when the Monitor

Shield is in place. Water entering a power tool will increase the risk of electrical shock. Keep battery out of

direct contact with water. Protect AC adapter from

damp or wet conditions.

• Do not abuse cord. Never use the cord to carry the

tool or pull the plug from an outlet. Keep cord

away from heat, oil, sharp edges, or moving parts.

Replace damaged cords immediately. Damaged

cords increase the risk of electrical shock.

• When operating a power tool outside, use an out-

door extension cord marked “W-A” or “W

”

. These

cords are rated for outdoor use and reduce the risk of

electrical shock.

• Connect the tool to an AC power supply that

matches the name plate specification (120 or 240

Volts). Incorrect voltage supply can cause electrical

shock or burns.

• Use proper extension cords. (See chart.) Insufficient

conductor size will cause excessive voltage drop and

loss of power.

• Reduce the risk of electrical shock! Keep all elec-

trical connections dry and off the ground. Do not

touch plug with wet hands.

Battery Precautions

• Use only the size and type of battery specified.

• Be sure to install the battery with the correct po-

larity as indicated in the battery compartment.

• Recharge batteries with charging units specified by

the battery manufacturer. Using an improper charger

can overheat and rupture the battery.

• Properly dispose of the battery. Exposure to high

temperatures can cause the battery to explode,

so do not dispose of in a fire. Some countries have

regulations concerning battery disposal. Please follow all applicable regulations.

Personal Safety

• Stay alert, watch what you are doing and use common sense when operating a power tool. Do not

use tool while tired or under the influence of drugs,

alcohol, or medications. A moment of inattention

while operating power tools may result in serious personal injury.

• Dress properly. Do not wear loose clothing or jew-

elry. Contain long hair. Keep your hair, clothing, and

gloves away from moving parts. Loose clothes, jew-

elry, or long hair can be caught in moving parts.

• Gloves should always be worn for health and safety

reasons. Sewer lines are unsanitary and may contain

harmful bacteria and viruses.

• Do not overreach. Keep proper footing and bal-

ance at all times. Proper footing and balance enables

better control of the tool in unexpected situations.

• Use safety equipment. Always wear eye protection.

Dust mask, non-skid safety shoes, hard hat, or hearing

protection must be used for appropriate conditions.

• Use proper accessories. Do not place this product

on any unstable cart or surface. The product may fall

causing serious injury to a child or adult or serious

damage to the product.

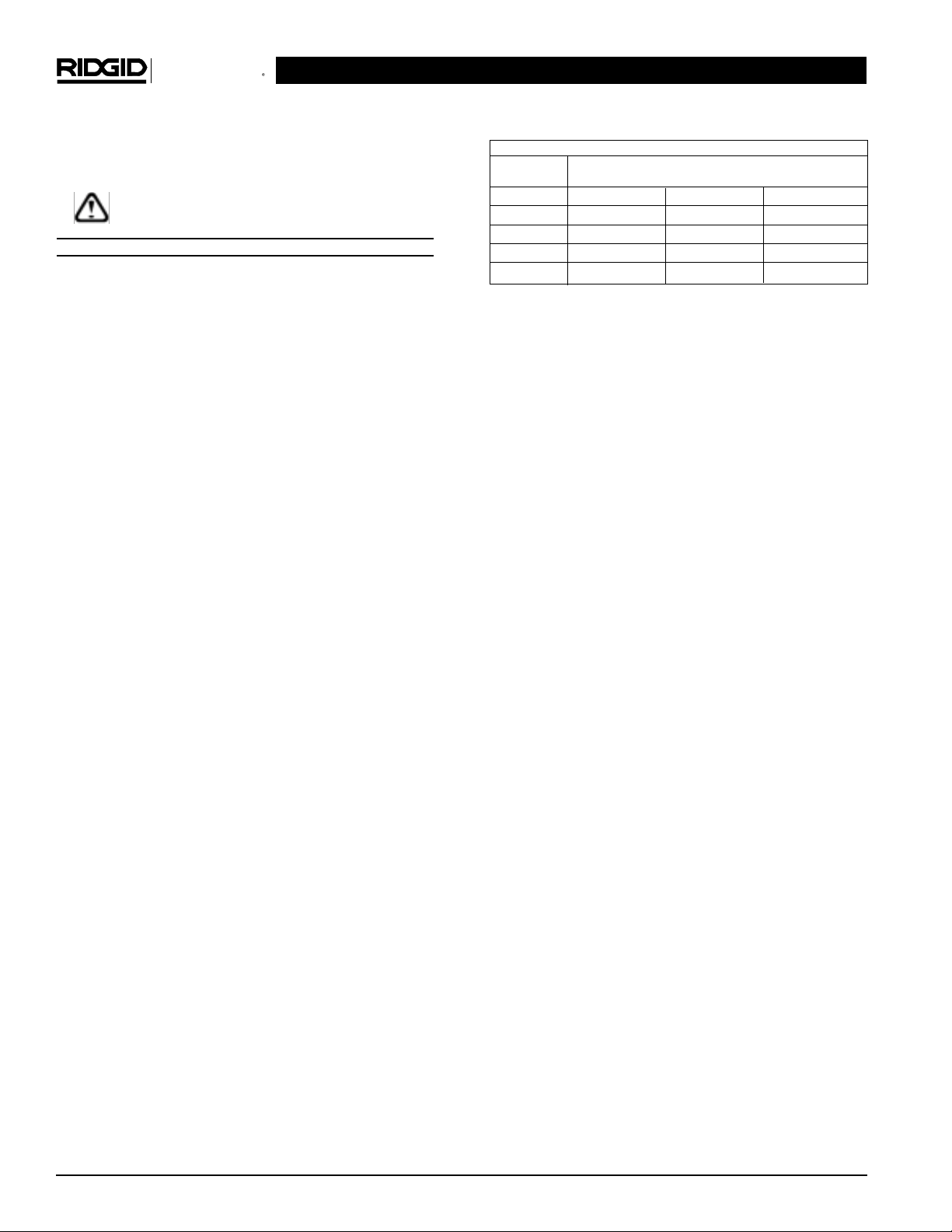

Minimum Wire Gauge for Extension Cord

Nameplate Total Length (in feet/meters),

Amps Gauge (in AWG/mm2)

0 - 25/0 - 8 26 - 50/8 - 15 51 - 100/15 - 30

0 – 6

18 AWG/.75mm216 AWG/1.00mm216 AWG/1.00mm

2

6 – 10

18 AWG/1.00mm216 AWG/1.00mm214 AWG/1.00mm

2

10 – 12

16 AWG/1.50mm216 AWG/1.50mm214 AWG/1.50mm

2

12 – 16

14 AWG/1.50mm212 AWG/1.50mm

2

NOT RECOMMENDED

SeeSnake®FlatPack and Color FlatPack

Kollmann

Ridge Tool Company 3

• Prevent object and liquid entry. Never spill liquid

of any kind on the product. To prevent electrical

shock never push objects of any kind into this product

through openings as they may touch dangerous voltage points or short to parts that could result in a fire or

electrical shock.

• Make sure the pipe you are going to inspect is not

electrically charged, or hot! In some cases ground

circuits may be returned to cast iron pipes causing them to be electrically charged. If you have

any reason to suspect the pipe is hot have it

checked by a qualified electrician before putting

the camera in the line. As sections of pipe joined

with shielded hubless connections or compression

gaskets may be electrically isolated, care should be

taken to check the entire length of any pipe you are

going to inspect.

Tool Use and Care

• Always transport the SeeSnake FlatPack with the

Monitor Shield closed. This prevents product damage.

• Do not use tool if switch does not turn it ON or

OFF. Any tool that cannot be controlled with the switch

is dangerous and must be repaired.

• Store idle tools out of the reach of children and

other untrained persons. Tools are dangerous in

the hands of untrained users.

• Maintain tools with care. Properly maintained tools

are less likely to cause injury.

• Check for breakage of parts, and any other condi-

tions that may affect the tool’s operation. If damaged,

have the tool serviced before using. Many accidents are

caused by poorly maintained tools.

• Use only accessories that are recommended by the

manufacturer for your tool. Accessories that may be

suitable for one tool may become hazardous when

used on another tool.

• Inspect tool and extension cords periodically and

replace if damaged. Damaged cords increase the risk

of electrical shock.

• Keep handles dry and clean; free from oil and

grease. Allows for better control of the tool.

• Store tools in dry, shaded place. Such measures re-

duce the risk of electrical shock.

• Protect against lightning. For added protection for

this product during a lightning storm, or when it is

left unattended and unused for long periods of time,

unplug it from the wall outlet. This will prevent damage

to the product due to lightning and power surges.

• Protect against excessive heat. The product should

be situated away from heat sources such as radiators,

heat registers, stoves or other products (including amplifiers) that produce heat.

Service

• Tool service must be performed only by qualified

repair personnel. Service or maintenance performed

by unqualified repair personnel could result in injury.

• When servicing a tool, use only identical replace-

ment parts. Follow instructions in the Maintenance

Section of this manual. Use of unauthorized parts or

failure to follow maintenance instructions may create a

risk of electrical shock or injury.

• Follow instructions for changing accessories.

Accidents are caused by poorly maintained tools.

• Provide proper cleaning. Unplug this product from the

wall outlet and remove battery before cleaning. Do

not use liquid cleaners or aerosol cleaners. Use a

damp cloth for cleaning.

• Conduct a safety check. Upon completion of any

service or repair of this product, ask the service technician to perform safety checks to determine that the

product is in proper operating condition.

• Damage to the product that requires service.

Unplug this product from the wall outlet, remove the

battery and refer servicing to qualified service personnel under any of the following conditions:

• When the power cord or plug is damaged;

• If liquid has been spilled, or objects have fallen into

product;

• If product does not operate normally by following the

operating instructions;

• If the product has been dropped or damaged in

any way;

• When the product exhibits a distinct change in per-

formance.

In any correspondence, please give all the information

shown on the nameplate of your tool including model

number, voltage and serial number.

SeeSnake®FlatPack and Color FlatPack

Kollmann

4

controllers: Monitor Pack, Color Video Tool Case, Color

Monitor

+

VCR, Monitor+, Monitor+VCR, Power+A, Power+.

System Components

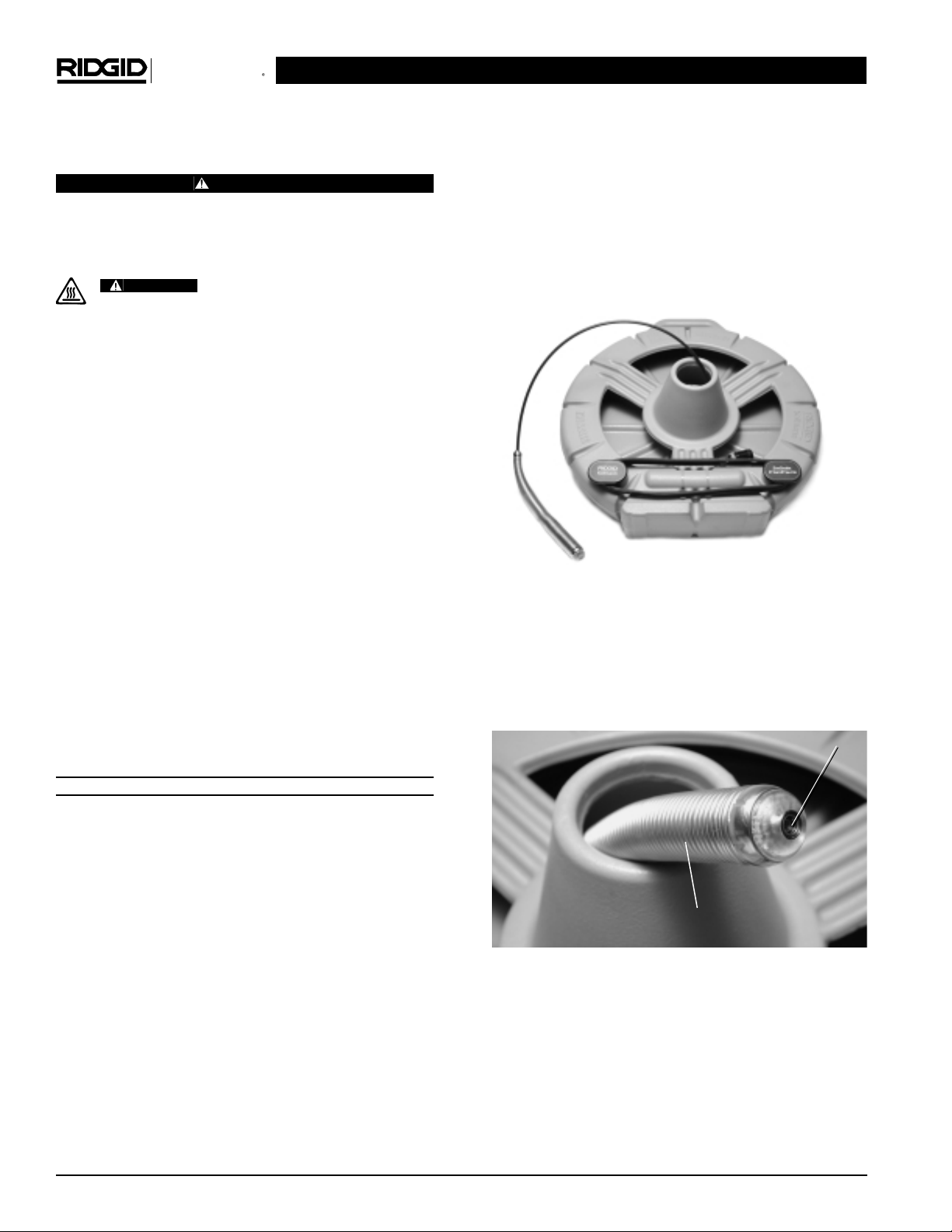

The SeeSnake FlatPack pipe inspection system contains

the following sub assemblies: Camera Head, Drum, and

Monitor Pack camera control unit. Please take a moment

to learn the functions of each of these components.

(Figures 1-3)

Figure 1 – Drum, Push Cable, Camera Head/Spring,

Interconnect Cord

1) Camera Head

The camera head (Figure 2) has adjustable lighting el-

ements and a highly scratch-resistant sapphire window

(Lens Port). The Camera is rated to a water depth of 330′

(100m).

Figure 2 – Camera Head

LED – Light Emitting Diode. The SeeSnake FlatPack

uses infrared LEDs that are invisible to the human

eye but provide the camera’s imaging sensor with plenty

of illumination for a clear picture. The Color FlatPack

uses white LEDs that are clearly visible.

LED Window – The donut shaped window that covers

and protects the LEDs from abrasion.

Specific Safety Information

CAUTION

Read this operator’s manual carefully before using

the product. Failure to understand and follow the

contents of this manual may result in electrical

shock, fire and/or serious personal injury.

Camera head can get HOT! Turn

OFF camera while not in use.

Equipment Safety

• Extension cords are not recommended unless they

are plugged into a Ground Fault Circuit Interrupter

(GFCI) found in circuit boxes or receptacles.

• Do not operate the system with electrical components removed. Exposure to internal parts increases

the risk of injury.

• Do not place the unit in water. Water entering the

housings will increase the risk of electrical shock.

• Do not use the unit as a chair or table. Dropping or

shocking the unit can result in damage to the unit,

which increases the risk of electrical shock.

• If used on a cart, product and cart should be

moved with care. Quick stops, excessive force and uneven surfaces may cause the product and cart

combination to overturn.

• Only the camera head and cable are waterproof.

The monitor is splash-resistant only when the Monitor

Shield is covering the monitor screen and the unit is

operating under battery power. Do not expose AC

adapter to damp conditions.

SAVE THESE INSTRUCTIONS!

Description, Specifications and

Standard Equipment

Description

The SeeSnake FlatPack pipe inspection system consists of the FlatPack drum which contains the camera

and push cable, and the Monitor Pack camera control

unit (CCU). The Monitor Pack has a built-in high-resolution monitor and can be powered from an AC adapter or

rechargeable battery.

The SeeSnake FlatPack pipe inspection system is designed for inspecting 11/2″ to 4″ (38mm to 102mm) drain

lines. Its flexible camera head can negotiate multiple

hard 90° bends and be pushed up to 100′ (30m).

The SeeSnake FlatPack drum is a UL Listed accessory, intended for use only with the following UL Listed SeeSnake

CAUTION

LED Window

Spring Assembly

Test Equipment Depot - 800.517.8431 - 99 Washington Street Melrose, MA 02176

FAX 781.665.0780 - TestEquipmentDepot.com

SeeSnake®FlatPack and Color FlatPack

Kollmann

Ridge Tool Company 5

Spring Assembly – Flexible stainless steel spring and associated components that hold the camera to the push

cable. It provides a flexible transition from camera to push

cable, and protects the terminations within the spring.

In Line Transmitter – Is contained within the spring assembly.

Safety Cable – Stainless steel cable within the spring

assembly that keeps the spring from over-extending

and ensures the camera’s internal connectors are not

stressed when pulling the camera out of a pipe.

2) Drum

Push Cable – (Figure 1) Terminates right behind the

spring. It has a high-strength fiberglass core stiff enough

to allow long distance pushing while flexible enough to

negotiate tight turns. The tough outer jacket is abrasion resistant.

Drum – The push cable is stored in the molded gray

drum. The drum is rust and dent-proof and keeps waste

water off your customers’ carpets.

Interconnect Cord – Stores on the drum and provides

the connection between the camera reel and the CCU.

(Figure 1)

Locking Sleeve – Found at the end of the Interconnect

Cord, it provides a solid connection between the CCU

and the reel.

NOTE! When attaching or removing the Interconnect Cord

from the CCU, ONLY turn the connector’s outer

locking sleeve! Bending or twisting the connector

body inside the locking sleeve will damage the

connector!

3) Monitor Pack Camera Control Unit

(CCU)

The Monitor Pack is a camera control unit (CCU) that

provides power to the camera reel, control of the camera’s light intensity and a built-in monitor for viewing

the image. The Monitor Pack (Figure 3) may be powered

by either a 120 volt or 230 volt AC source. A 14.4V

Makita®rechargeable battery can also power the system.

(See Table below.)

The following Makita®batteries are approved for use with

this system: 1422 (RIDGID P/N 83407), 1433 and 1434.

Monitor Shield – Protects the monitor and internal

electronics (Figure 3 and 4).

Figure 3 – Monitor Pack

Tilt Stand – The front handle attached to the monitor

shield also acts as a tilt stand for positioning the monitor

at different viewing angles (Figure 4).

Figure 4 – Monitor Shield and Tilt Stand/Handle

Monitor Controls – Brightness and contrast may be ad-

justed with the monitor controls. On the B&W version

there is also an image inverter and a Day/Night switch to

further adjust the image viewed on the screen. (Figure 5)

Figure 5 – Adjustment Controls for the B&W (Top) and

Color (Bottom) Monitor Screens

RIDGID Catalog Numbers Description

83407 14.4V Battery

83417 115V Charger

84112 230V Charger

Monitor Shield

and

Release Lever

Monitor Shield

Tilt Stand/Handle

Monitor Power

Contrast

Brightness

Image Invert

Day/Night Switch

Ridge Tool Company6

Red Multifunction Button (Figure 6) – This button serves

the following functions:

• Press and quickly release to turn the system power

ON/OFF.

• Press and hold to cycle through the brightness settings of the camera’s LED lighting.

• Press and hold for ~1 sec. to activate or de-activate

the In-Line Transmitter (See Table 1 for detailed in-

structions.)

NOTE! The B&W FlatPack uses infrared LEDs that are

invisible to the human eye; changes to the

brightness level will only be visible on the monitor screen.

Figure 6 – Monitor Pack Rear Panel

LED Indicators (Figure 7) – The LED indicators above

the monitor screen indicate the following operational

conditions:

RED • Steady Glow – Power ON

RED • Steady Flashing – Indicates low battery status

when running off the optional battery pack

RED • Flash S-O-S (3 short, 3 long, 3 short) pattern in

Morse Code – no video signal from the camera

head

WHITE • Steady Flashing – In-Line transmitter is active

RED • Rapid Flashing slowing from 8 to 4 flashes, 2

flashes, 1 flash, While pushing the red multi-

function button, indicates changes to the

brightness level of the camera’s LED lighting.

(Table 1)

Figure 7 – LED Indicators

SeeSnake®FlatPack and Color FlatPack

Kollmann

Button Press Duration Action LED Indicators*

Quick Press and Release (<1/2sec.) Toggles Power ON/OFF Red - Lit/Unlit

Medium Press and Release (

1

/2– 4 sec.) Toggles SeeSnake In-Line Transmitter ON/OFF White - Flashes slowly

Long Press and Release (>4 sec.) Cycles through LED brightness levels, Release when Red - Rapid flashing slowing

desired level is reached. to 4 flashes, 2 flashes, 1 flash

Table 1 - Multifunction Button

*LED Indicators - See Figure 6.

(Red)

(White)

LED Indicators

Multifunction

Button

Connector for the

Interconnect Cord

External

Power Jack

Video

In/Out Jack

Ground Reference (Future Expansion)

SeeSnake®FlatPack and Color FlatPack

Kollmann

Ridge Tool Company 7

Place the drum so the push cable is easy to manage as

you push the camera through the line. Two to three feet

(about one meter) from the access point is usually the optimal location.

The Monitor Pack can be tilted to several different viewing angles. When a battery is installed, it can be tilted to

rest on its rear supports (Figure 8). The front handle

attached to the monitor shield can also be used as a tilt

stand. Grasp the Monitor Shield Release Lever (Figure

3), pull it toward the handle to release the Monitor Shield,

and rotate the monitor shield down (Figure 4).

TIP: In brightly lit areas, point the monitor screen away

from bright light sources to reduce glare.

Figure 8 – Monitor Pack Tilted Using Rear Supports

Connections

Connect the Monitor Pack to an AC outlet using the

supplied AC adapter. If desired, you can install an optional Makita®14.4V rechargeable battery into the battery

holder on the rear of the unit instead of using the AC

adapter. (Figure 9)

If the AC adapter supplied is a universal type with detachable power cord, use only cord with Class II IEC

60320 connector and mains plug approved for the country where unit is used.

Figure 9 – Battery Holder

Specifications

Line Capacity.................11/2″ to 4″ (38 to 102 mm)

Max. Cable Length........100′ (30 m)

Weight...........................18 lbs (8.2 kg)

Dimensions

CCU Length..................14″ (35.6 cm)

Width...................7.5″ (19 cm)

Height..................10.25″ (26 cm)

Drum Depth...................7.5″ (19 cm)

Width...................24″ (61 cm)

Height..................25.75″ (65.4 cm)

Power Source................120V/60 Hz or 230V/50 Hz,

14.4 VDC Rechargeable

Battery (optional equipment)

Power Ratings

Monitor Pack .............14-16VDC, 15W

FlatPack Drum...........12VDC, 7W

Video Format.................EIA (CCIR Available)

NTSC (PAL Available)

Push Cable Diameter....0.26″ (6.6 mm)

Camera Depth Rating....Waterproof to 330′ (100 m)

Lighting..........................24 Infrared LEDs (B&W)

24 White LEDs (Color)

Oil Filled Tube...............USP Grade Mineral Oil

Operating Environment

Temperature..............32° F to 104° F (0°C to 40°C)

Altitude ......................Up to 6560 ft. (2000 m)

Transient

Over Voltage .............Installation Categories I

(1500V Phase to Earth)

Pollution Degree 2

Storage Temperature....-4°F to 140°F (-20°C to 60°C)

Humidity ........................30-90% RH

Standard Equipment

• Rust Proof Drum with Camera and Cable

• Monitor Pack with B&W or Color Monitor

• In Line Transmitter

• 115V Power Supply or 100-240V Power Supply

• Interconnect Cord

• Instructional Video

• Operator’s Manual

Set Up and Operation

Equipment Set Up

Misuse of the push cable will result in

breakage requiring factory service.

CAUTION

Ridge Tool Company8

NOTE! The Monitor Pack will not recharge the battery;

the battery must be removed from the Monitor

Pack for recharging. Use only the charger specified by the battery manufacturer!

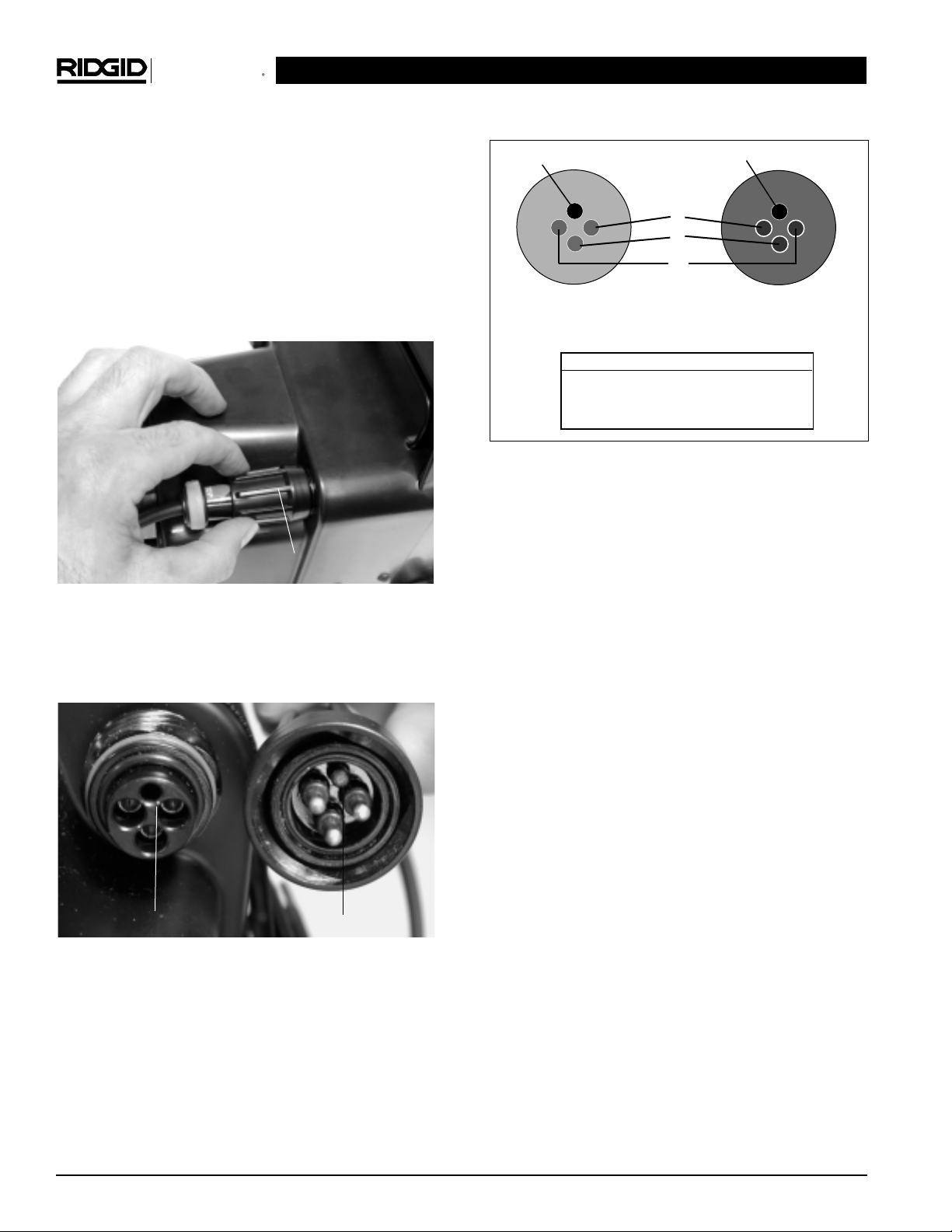

Unwrap the Interconnect Cord from its holder on the

drum and plug its connector into the matching SeeSnake

System connector on the Monitor Pack. To join the connectors, make sure the red arrow on the connector is

facing up, push the connector straight in, and tighten the

locking sleeve. (Figure 10)

Figure 10 – Tightening the Locking Sleeve

If the connector does not push in easily, make sure the

guide pin on the Interconnect Cord’s connector is aligned

with the guide socket on the Monitor Pack’s connector.

(Figure 11)

Figure 11 – Guide Pin on the Interconnect Cord

NOTE! Twist only the outer locking sleeve! Bending or

twisting the connector body inside the locking

sleeve will damage the connector. When unplugging you may wiggle a little, if necessary, but do

not bend or twist.

NOTE! The Interconnect Cord should be disconnected

from the Monitor Pack whenever moving or transporting the system.

Figure 12 – Guide Pin/Socket Diagram

Operation

Press and release the multi-function button on the back

of the Monitor Pack (Figure 6) to turn the power ON. The

red LED indicator will light. You should see an image on

the monitor screen in a few seconds. If you do not,

check to make sure the monitor’s power switch is turned

ON. To turn the system OFF, press and quickly release

the multi-function button.

Put the camera head into the access point and adjust the

camera’s lighting if necessary. To adjust the camera’s

lighting, press and hold the red multi-function button.

After about four seconds, the red LED indicator on the

Monitor Pack will begin flashing rapidly. This indicates

that the camera’s LED lighting elements are cycling

through their brightness levels. When the image inside

the pipe looks good, release the red multifunction button.

TIP: When the Monitor Pack is turned ON, the cam-

era’s lighting will always be at full brightness, and in

most cases will not require adjustment.

If necessary, you may adjust the monitor’s image controls

to further improve the picture. The image controls are located on either the bottom front (B&W) or bottom rear

(color) of the monitor. See Figure 5.

Video Recording

When the Interconnect Cord is plugged into the Monitor

Pack, the Video In/Out jack functions as a Video Out

jack. An RCA cable can be used to connect this jack to

the “Video In” jack of a VCR for recording, or to another monitor. If connecting to another monitor, and it has

a High Z/Low Z switch, place the switch in the High Z position for the best video quality.

SeeSnake®FlatPack and Color FlatPack

Kollmann

Pin/Socket Function

1 ..............................Video Signal

2 ..............................+12 VDC

3 ..............................Neutral

Male Connector Pins

(Interconnect Cord)

Female Connector

Sockets (Connector

for Interconnect Cord)

Guide Pin

Guide Socket

3

2

1

Guide Socket

Guide Pin

Locking Sleeve

9

When the Interconnect cord is NOT plugged into the

Monitor Pack, the Video In/Out jack functions as a Video

In jack. An RCA cable can be used to connect this jack to

the “Video Out” jack of a VCR for reviewing a recording

you have made.

NOTE! The Interconnect Cord must be unplugged to play

back video from a VCR. If you attempt to play

back video while the camera’s Interconnect Cord

is plugged into the Monitor Pack, the monitor’s

image will be distorted.

At the Job Site

The camera pushes better when grip-style rubber

gloves are worn. It is much easier to get a grip on dirty

push cable, and the gloves also keep sludge off the hands.

Proper positioning of the equipment and pushing of

the cable will save time, be more comfortable, and

minimize the potential for equipment damage. (Figure

13.)

Set the monitor in an area where it is unlikely to

fall, and where it can be viewed while you are pushing the camera. A good location is right next to the

cleanout or entry point.

Set the reel about 2′ to 3′ (~1 meter) from the entry.

This will provide ample cable to grasp and will develop

momentum without having slack dragging on the ground.

When pushing, the end of your stroke should be as

close to the entry as possible (Figure 13). Standing too

far back with an excess of cable between your hands and

the entry may cause the cable to fold on itself outside the

entry and damage the cable (Figure 14).

Figure 13 – Equipment Set-Up

Figure 14 – Incorrect Hand Position on Push Cable

DO NOT Fold the push cable onto the sharp edge of

an entry. This can cause it to snap. Extreme caution

must be used to minimize the chance of bending the

push cable on sharp corners. This can cause push cable

failure. If the camera just does not seem to want to go any

farther, DO NOT FORCE THE CAMERA! If another entry

is available, try it, or run water down the line as explained below.

NOTE! Hands should be close to the line opening. DO

NOT catch the cable on the edge of an entry

and continue to push.

Always try to run water down the pipe undergoing inspection. This will keep the system much cleaner, and

allow you to push noticeably farther with less friction. This

will also help you locate the bottom of the pipe. This can

be accomplished by feeding a hose with a small amount

of flow into the entry or occasionally flushing a toilet

that drains to the pipe. If the water is preventing you from

seeing an area of importance, temporarily turn it off.

When inspecting a pipe, it is usually necessary to

give a little extra push in the bends. Back the camera

head approximately 6″ (15 cm) from the bend, if necessary, and give it a quick push, “popping” the camera

through a turn, using the least amount of force required.

Try to be as gentle as possible, and do not hammer or

snap the camera head through corners. In many instances, the best way to inspect a section of pipe is to

push the camera through quickly, then draw the camera

back home slowly and evenly. It is always easier to

control the camera when pulling than when pushing.

Make sure the sapphire window is clean prior to entry. In some cases a slight film of liquid detergent on the

lens port helps minimize the possibility of grease sticking

to the lens port.

SeeSnake®FlatPack and Color FlatPack

Kollmann

Test Equipment Depot - 800.517.8431 - 99 Washington Street Melrose, MA 02176

FAX 781.665.0780 - TestEquipmentDepot.com

SeeSnake®FlatPack and Color FlatPack

Kollmann

Ridge Tool Company10

Do not clear obstructions with the camera head!

This may cause premature failure to your camera

head. The SeeSnake

®

is a diagnostic tool that identifies problems. It should never be used to clear

obstructions. Other tools should be used to make effective repairs. (See Figure 15.)

Figure 15 – Do Not Clear Blockage with Camera Head

If local 120V (or 230V) AC power for the CCU is not

available, you can operate the system using a voltage converter that plugs into your vehicle’s cigarette

lighter. They convert your vehicles 12 volt DC to 120

volts (or 230V) AC.

The system can travel through multiple 45 and 90

degree bends and wyes. Do not, however, try to

force it through a P-trap or Tee if there is a large

amount of resistance.

Be careful in Tee-entries not to fold the camera

back on itself, this could cause the camera to get

caught. (see SeeSnake Tips & Tricks video).

The camera head can get HOT!

When finished with your inspection, or if taking

a prolonged break in the middle of the inspection,

turn off the system. If the camera sits in a pipe, or any

enclosed environment, heat will build-up. This may lead to

the camera head overheating which will cause fuzzy

lines to appear on the monitor. In the event this happens, turn off the system, remove the camera from the

pipe (or enclosed environment) and let the camera head

cool for 10 to 15 minutes. Running water into the line will

also help cool the camera head. Always use the minimum

illumination required to maximize picture quality and to

avoid excessive heat build-up.

Ask customers what is in the line, or what the line is

used for, prior to putting the camera into the line.

Avoid lines containing harsh solvents, chemicals, an

electrical charge and excessive heat.

NOTE! See the Video Tape that came with your system

for valuable Tips and Tricks on how to handle

different situations.

Transportation & Storage

The FlatPack can be laid on its back, set upright, or hung

by its handle during transport and storage. The

Interconnect Cord should always be disconnected from

the CCU and wrapped snugly around the storage hooks

on the drum. For temporary storage at the jobsite the

camera head can be tucked inside the cone (Figure

16) For transportation and storage between jobs the

camera head should be pushed down through the cone

and into the drum to protect the camera and prevent the

spring from taking a set (Figure 17).

The Monitor Pack should always be transported and

stored with the Interconnect Cord disconnected. Care

should be taken to secure the Monitor Pack so it does

not get thrown around during transport, and so that

other equipment does not fall on it. Store the system in

a cool, dry, shaded place.

Figure 16 – Camera Head Stowed Inside Cone

Figure 17

CAUTION

Ridge Tool Company 11

Centering Guides

Installing the SeeSnake

®

Star-Type Centering Guides

Centering guides can improve the picture by bringing the

camera closer to the pipe’s center, allowing the camera

to see an equal amount of the pipe wall in all directions. Centering guides also help by raising the camera

out of sludge that is often found below the water line. This

helps keep the lens cleaner, longer, reduces wear and

tear on the LED Ring. See Figure 18.

We recommend using centering guides whenever possible, but if you are having trouble pushing the camera in

a particular pipe, try it without the guides.

Figure 18 – Centering Guides improve vision by allow-

ing the camera to see an equal amount of

pipe wall in all directions and by raising the

camera out of sludge. They also reduce wear

on the LED ring.

Whether or not you use guides, how many you use,

and where you place them on the spring causes the

camera to behave differently. The best advice is to experiment and decide what’s best for the given job.

One centering guide near the front end of the camera may

bias the camera head upward. This could be beneficial if

you need to see the top of the pipe during your inspection.

Move the guide back a little and the camera head may

bias downward when you push and upward as you pull

back. This could help you see the top and bottom of

larger pipes more easily.

Two centering guides will tend to keep the camera head

aimed toward the center of the pipe, allowing you to

see more of the pipe at once.

Centering guides should be pre-stressed prior to use for

increased flexibility. To do this, slowly bend the spikes

back and forth from the tip (not the base) a few times before use. See Figure 19.

Figure 19 – Pre-stress tabs by placing your finger at the

top of the spike and slowly pushing the spike

90 degrees. Repeat in the other direction.

Star-type centering guide assembly consists of two parts two steel c-ring and the plastic centering guide. See

Figure 20.

Figure 20 – Star-Type Centering Guide Components. You

may use from one to three guides.

Installing Star-Type Centering Guides

1. Position a centering guide and two c-rings over the

spring, with the centering guide between the c-rings.

See Figure 21.

Figure 21 – Guide and C-Rings Positioned On Spring

Assembly.

2. Position the opening in the centering guide 180 degrees opposite the opening in the c-rings. See Figure

22.

3. Press the c-rings into the grooves on each side of the

centering guide until the c-rings snap into place. It’s

SeeSnake®FlatPack and Color FlatPack

Kollmann

C-Rings

Ridge Tool Company12

SeeSnake®FlatPack and Color FlatPack

Kollmann

easiest if you place the closed portion of the c-ring

into the groove and work toward the open end. See

Figure 22.

Figure 22 – Press the c-rings into the grooves on the

centering guide. Make sure the openings in

the c-rings are 180 degrees opposite the

opening in the pipe guide.

Removing Star-Type Centering Guides

1. Pry off each c-ring with the tip of a flat blade screwdriver inserted near the open end of the ring and

the base of the spikes. See Figure 23.

Figure 23 – Place flat tip of screwdriver between c-ring

and base of spike and pry c-ring out of

groove.

2. Slide the c-rings and centering guide over the camera

head.

Installing the SeeSnake®Compact, and

FlatPack Ball-Type Centering Guides

Ball-type centering guides consists of two halves that are

pre-assembled at the factory, and two steel clips that

hold the guide in place on the spring.

Figure 24 – Centering guides improve vision by allow-

ing the camera to see an equal amount of

pipe wall in all directions and by raising the

camera out of sludge. They also reduce

wear on the LED window.

Figure 25 – Retaining Rings in Locked Position

Figure 26 – Unlock Retaining Rings by pulling them up

with a flat-bladed screwdriver.

Open Side of Guide

Retaining Rings

Locked

Retaining Rings

Unlocked

Ridge Tool Company 13

Figure 27 – Slide Ball Guide over spring and push

Retaining Rings down to lock the guides

in place.

Maintenance and Cleaning

CAUTION

Make sure equipment is unplugged from power

source before performing maintenance or making

any adjustment.

Preventative Maintenance

Camera Head

1. The camera head requires little maintenance, other

than keeping the LED window and sapphire window

clean. Use a soft nylon brush, mild detergent, and rags

and sponges from the camera head.

2. When cleaning the camera, do not use scraping tools

as they may permanently scratch these areas.

NEVER USE SOLVENTS to clean any part of the system. Substances like acetone and other harsh

chemicals can cause cracking of the LED window,

which could affect waterproofing.

3. As you use the system more and more, you may be

surprised to find that scratches on the LED window

will have a minimal effect on the performance of the

lighting. DO NOT sand the LED window to remove

scratches, as it is part of the watertight housing.

4. Another good way to extend the life of the camera is

to avoid removing obstructions from pipe with the

camera head. (See Figure 15.)

Spring Assembly

The spring assembly is the area where foreign matter is

most likely to accumulate. Within the spring is the rubber

tube between the push cable and a connector. Should

sharp objects or harsh chemicals, such as solvents or

bleach, be allowed to remain in this area for long periods,

they may wear on these components. Stir in a bucket of

warm water and mild detergent to flush the spring area.

NOTE! Never use a water jetter to clean the spring as-

sembly. If a spring takes a set during storage, dip

it in hot water to straighten.

Push Cable and Drum

The push cable and drum require almost no maintenance. It is important, however, to keep the push cable

clean to spot any excessive cuts or abrasions, while

making it much easier to grasp and push.

NOTE! Whenever you are retrieving push cable into the

drum, an excellent way to cut down on cable

grime is to run it through a rag in the last hand that

touches the cable as it enters the reel.

For a more thorough cleaning, fill the drum with lukewarm

water and a mild detergent. Agitate the drum to help

loosen the grime. Pay out all the cable, drain the water

from the drum (Figure 28), and wipe out the inside of the

drum. Run a rag over the cable as you feed it back into

the drum.

Figure 28 – Open Rubber Plug to Drain Water

Monitor Pack

Wipe the Monitor Pack with a damp cloth. Clean the monitor screen with monitor wipes, which are available at

most computer and office-supply stores. Monitor wipes not

only clean the screen, but also help prevent dust build-up.

Always avoid dropping or shocking the Monitor Pack.

The abrasion resistant acrylic shield can be cleaned with

household glass cleaner and a soft damp cloth.

NOTE! Although the acrylic window resists scratching,

care should be taken to brush off excess abrasive particles prior to cleaning.

Locating Faulty Components

SeeSnake®FlatPack and Color FlatPack

Kollmann

For troubleshooting suggestions

at the end of the manual.

, please refer to Chart 1

Ridge Tool Company14

SeeSnake®FlatPack and Color FlatPack

Kollmann

Service and Repair

CAUTION

Tool should be taken to a RIDGID Independent

Authorized Service Center or returned to the factory. All

repairs made by Ridge service facilities are warranted

against defects in material and workmanship.

Test Equipment Depot - 800.517.8431 - 99 Washington Street Melrose, MA 02176

FAX 781.665.0780 - TestEquipmentDepot.com

Loading...

Loading...