1 -

1

I. INTRODUCTION

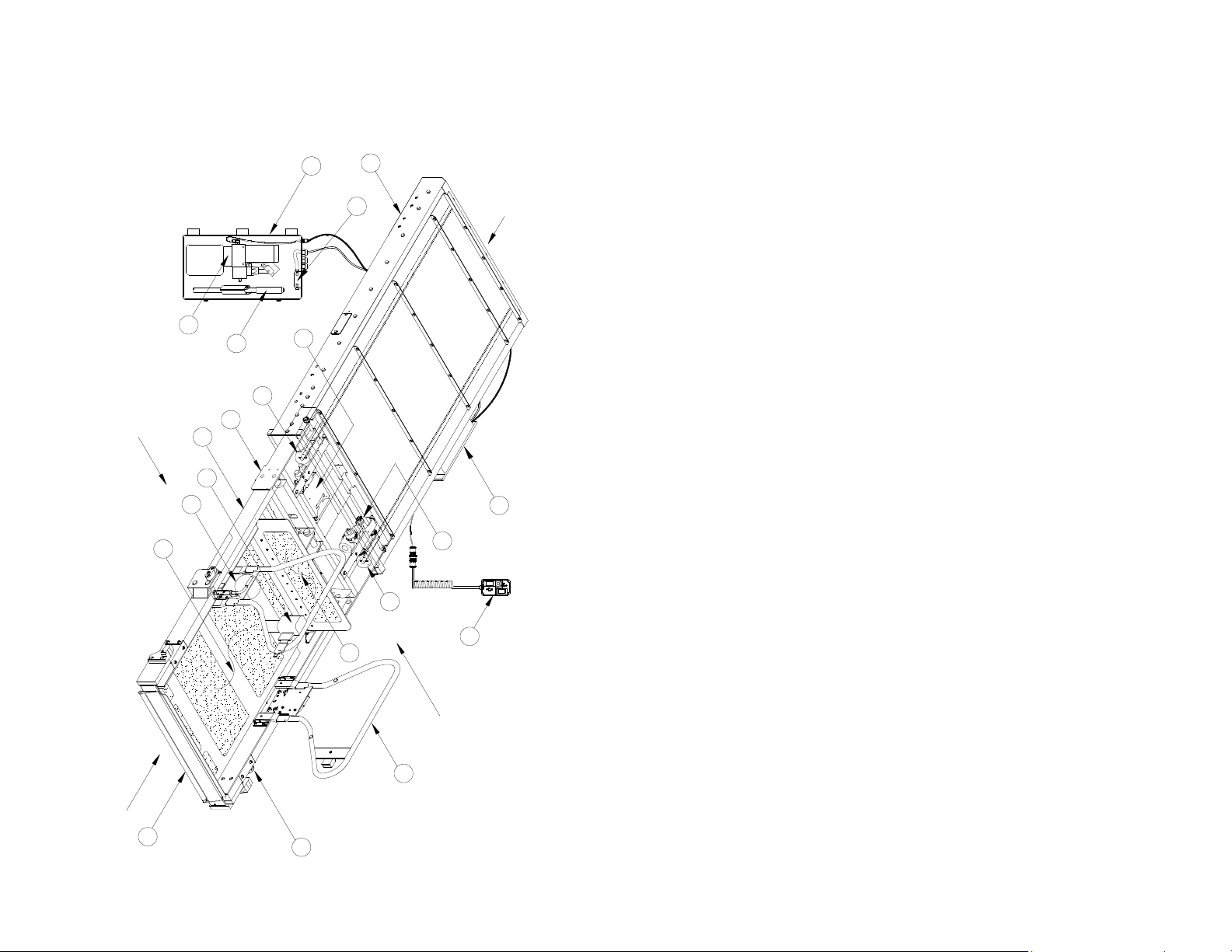

FIGURE 1

-

2: STEPWEL

L MODEL

FIGURE 1

-

1: DEDICAT

ED ENTRY MODEL

Safe and easy access to mass-transit vehicles is provided by the RICON Mirage F9T Transit Use

Wheelchair and Standee Lift. Refer to Figures 1-1 and 1-2. This manual covers both Dedicated

Entry and Stepwell models. The Dedicated Entry model is intended for installation in a vehicle

baggage bay, or similar location. The Stepwell model is installed within a vehicle stepwell.

An electric-motor driven hydraulic pump assures smooth platform movement, with a maximum

capacity of 660 pounds (300 kilograms). It is operated by a trained attendant or the vehicle

operator. The operator uses control switches to withdraw the platform from the vehicle (deploy)

and lower it to ground level. The passenger boards the large non-skid platform and is then is

raised to floor height. The passenger enters the vehicle, the operator lowers the platform and

retracts it back into the vehicle (stow). When the passenger exits, the operator uses control

switches to withdraw the platform from the vehicle (deploy) and raise it to floor height. The

passenger boards the platform and is then lowered to the ground by the operator. The

passenger departs, and the operator returns the platform to the stow position.

One individual can manually operate the

lift when normal power is not present.

A manual release mechanism is provided to ease the task of pulling the

platform out of its enclosure by hand.

The hydraulic pump assembly includes

a manually operated back-up pump to

raise the platform, and a release valve

to lower it. The front platform rollstop,

normally power operated, has a manual

override knob for back-up use.

This manual contains complete operating

instructions for each lift, and a brief maintenance chapter. It is important to passenger safety that the lift operator be familiar

with the Operating Instructions chapter. It

is also important to properly maintain the

lift by following the recommended cleaning,

lubrication, and inspection directions in the

Maintenance chapter.

Please contact Ricon Product Support if you have questions about this manual, or need additional copies:

Ricon Corporation

7900 Nelson Road

Panorama City, CA 91402...................................................................... (818) 267-3000

Outside (818) Area Code......................................................................... (800) 322-2884

World Wide Website......................................................................... www.riconcorp.com

Littlemoss Business Park, Littlemoss Road

Droylsden, Manchester

United Kingdom, M43 7EF............................................................... (+44) 161 301 6000

32DF9T01.A

1 -

2

A. LIMITED WARRANTY

RICON CORPORATION

~ ONE-YEAR LIMITED WARRANTY ~

Ricon Corporation (Ricon) warrants to the original purchaser of this product that Ricon will repair or

replace, at its option, any parts that fail because of defective material or workmanship as follows:

• Repair or replace parts for a period of one year from the date of purchase. A complete list of parts

covered by this warranty can be obtained from an authorized Ricon service technician.

• Labor costs for specified parts replaced under this warranty for a period of one year from date put

into service. A Ricon rate schedule determines parts covered and labor allowed.

If You Need to Return a Product: Return this Ricon product to Ricon Corporation, following the Ricon

RMA procedure. Please give as much advance notice as possible and allow a reasonable amount of

time for repair.

If You are Traveling: All authorized Ricon service technicians will honor this warranty. Consult a tele-

phone directory, or call Ricon Product Support, for the name of the nearest authorized Ricon service

technician. You may also locate a technician at our website, www.riconcorp.com. Click on “Ricon

Corporation” on the home page.

This Warranty Does Not Cover:

• Malfunction or damage to product parts caused by accident, misuse, lack of proper maintenance,

neglect, improper adjustment, modification, alteration, the mechanical condition of the vehicle, road

hazards, overloading, failure to follow operating instructions, or acts of Nature (i.e., weather, lightning, flood, etc.).

NOTE: Ricon recommends this product be inspected by an authorized Ricon service technician at

least once every six months, or sooner if necessary. Any required maintenance or repair

should be performed at that time.

WARNING!

THIS PRODUCT HAS BEEN DESIGNED AND MANUFACTURED TO EXACT SPECIFICATIONS.

- ANY MODIFICATION OF THIS PRODUCT CAN BE DANGEROUS -

This Warranty is Void If:

• The product has been installed or maintained by someone other than an authorized Ricon service

technician.

• The product has been modified or altered in any respect from its original design without written

authorization by Ricon.

Ricon disclaims liability for any personal injury or property damage that results from operation of a

Ricon product that has been modified from the original Ricon design. No person or company is authorized to change the design of this Ricon product without written authorization by Ricon.

Ricon's obligation under this warranty is exclusively limited to the repair or exchange of parts that

fail within the applicable warranty period.

Ricon assumes no responsibility for expenses or damages, including incidental or consequential

damages. Some states do not allow the exclusion or limitation of incidental or consequential damages, so the above limitation or exclusion may not apply.

Important: The warranty registration card must be completed and returned to Ricon within twentydays after installation of this Ricon product for the warranty to be valid. The warranty is not transferable.

The warranty gives specific legal rights. There may be other rights that vary in each state.

32DF9T01.A

1 -

3

B. SHIPMENT INFORMATION

Ricon does not sell directly to the user because of the specialized nature of the product.

The product is distributed through a worldwide network of authorized Ricon service

technicians, who accomplish sales and installation.

Be sure the lift installation kit, if supplied, contains all the items listed on the kit packing

list. Please report any missing items immediately to Ricon Product Support. The

warranty and owner registration cards must be completed and returned to Ricon within

20 days to validate warranty.

NOTE: Sales/Service Personnel must review the Warranty and this Operator Manual with the

user to be certain that they understand safe operation of the product. Instruct the user

to follow the operating instructions without exception.

C. GENERAL SAFETY PRECAUTIONS

The following general safety precautions must be followed during installation, operation,

service, and maintenance:

§ Do not attempt maintenance, repairs, or adjustments without the presence of a

person capable of rendering aid.

§ Attend all injuries, regardless of how slight. Administer first aid or seek medical

attention immediately.

§ Wear protective eye shields and appropriate clothing at all times.

§ Exercise caution when operating lift to avoid injury. Be certain that hands, feet,

legs and clothing are not in path of the platform as it moves.

§ Be cautious when using metallic (conductive) tools near the battery.

§ Check under vehicle before drilling or cutting to avoid damage to the frame, sub-

frame members, wiring, hydraulic lines, etc.

§ Thoroughly understand the operating instructions before attempting to operate lift.

§ Inspect lift before each use. Do not operate lift if an unsafe condition is present,

or if there are unusual noises or movements.

§ Keep others clear during lift operation.

§ Maintain the lift at its highest level of performance by doing the required mainte-

nance. Ricon recommends a thorough inspection every six months.

32DF9T01.A

1 -

4

D. MAJOR LIFT COMPONENTS

FIGURE 1

-

3: LIFT CO

MPONENTS

FOR DEDICATED ENTRY

MODEL

1. DEDICATED ENTRY MODEL

Major components of the Mirage F9T Transit Use Dedicated Entry Wheelchair and

Standee Lift are in Figure 1-3. A description of each component is in Table 1-1.

LEFT

14

3

10

11

15

1

18

REAR

2

4

19

9

7

5

8

9

FRONT

13

12

32DF9T01.A

17

6

RIGHT

16

1 -

5

TABLE 1-1: LIFT COMPONENTS FOR DEDICATED ENTRY MODEL

REF

Left, Right, Front, Rear Reference points from outside vehicle looking inward at lift.

1 Pump Enclosure Contains lift electrical and hydraulic control components.

2

3

4 Pump Handle Used to manually operate hydraulic pump.

5 Pull Box

6 Control Pendant Hand-held device used to control lift operation.

7 Carriage

8

9

10

11 Lifting Frame

12

13 Platform Rollstop

14 Platform Curbed area occupied by passenger during lift operations.

15

16 Standee Handrails Provides platform occupant with a stable handhold.

17 Bridgeplate

18 Enclosure Platform housing is rigidly attached to vehicle chassis.

19 Controller

NAME DESCRIPTION

Electric Circuit

Breakers

Hydraulic Pump

Assy.

Deployment System

Manual Platform

Release Shafts 2ea

Slam-Lock

Handle

Manual Rollstop

Override Knob

Occupant Safety

Belt

Prevents high-current damage to lift electrical components.

Electro-hydraulic unit provides hydraulic pressure used to raise

platform.

Houses electrical termination points to lift, and a hydraulic line

disconnect point.

Part of traveling frame that is mounted on rollers; moves on

rails located inside enclosure. Supports lifting frame.

Part of carriage. Employs an electric gear-motor to propel platform out of enclosure, or pull it back in.

Used when electric power is not available to lift. Releases platform from enclosure to facilitate manual deployment. Actuated

by engaging and rotating either indicated shaft.

Locks handrail in upright position. L-handle unlocks handrail

from upright position before lowering.

Hinged arms that lift or lower platform; driven by single hydraulic cylinder attached to carriage.

Provides manual control of rollstop if electrical power is lost.

Front barrier prevents wheelchair from inadvertently rolling off

the platform during lift use.

Safety belt helps prevent unintentional acceleration of wheelchair from platform. Electrically interlocked so that “UP” and

“DOWN” functions are disabled if the belt is unbuckled.

Plate unfolds when platform is at floor height to bridge gap between platform and vehicle interior.

Translates pendant commands to signals that control lift electrical and hydraulic components.

END OF TABLE

32DF9T01.A

1 -

6

2. STEPWELL MODEL

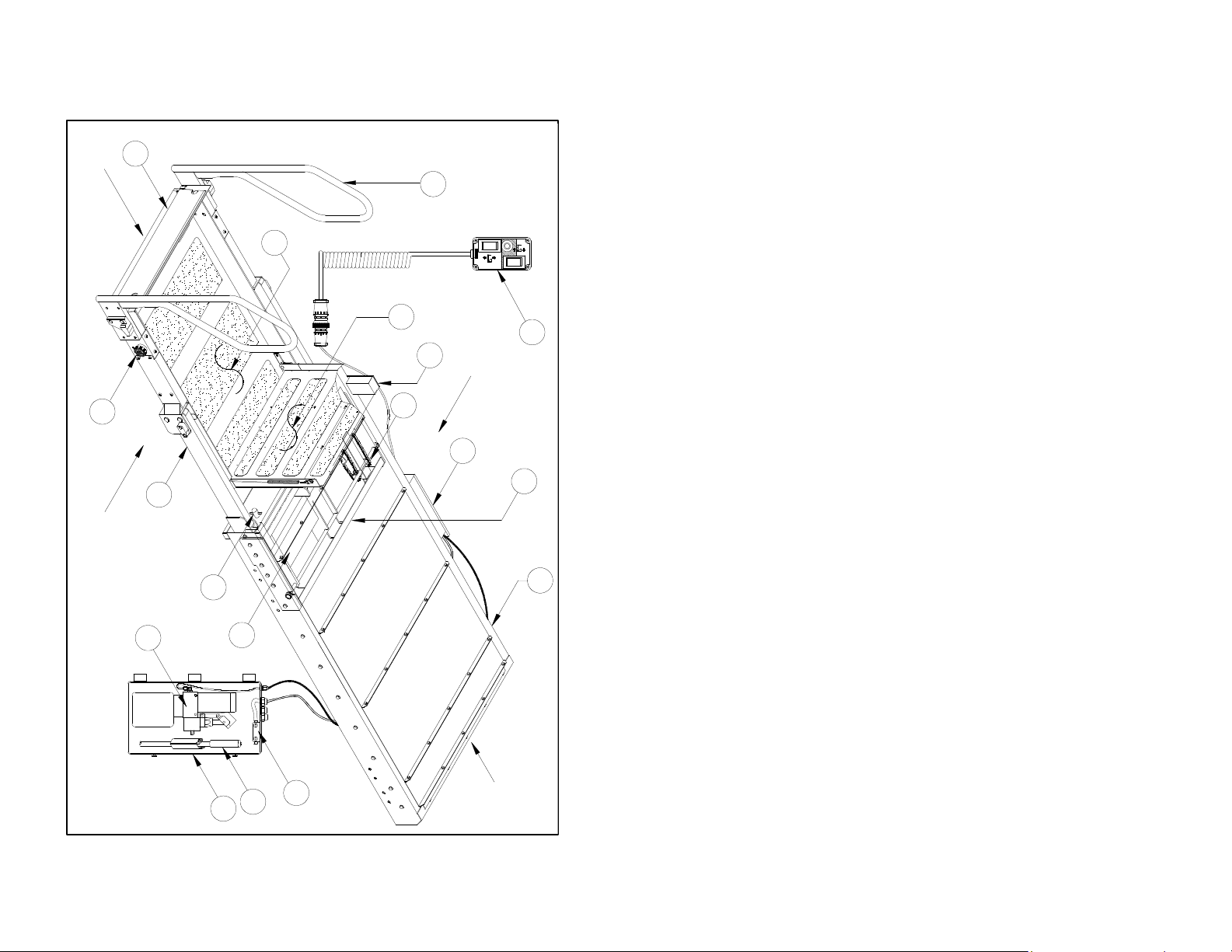

FIGURE 1

-

4: LIFT CO

MPONENTS FOR STEPWEL

L MODEL

Major components of the Mirage F9T Transit Use Stepwell Model Wheelchair and

Standee Lift are in Figure 1-4. A description of each component is in Table 1-2.

FRONT

12

14

13

15

LEFT

16

6

11

RIGHT

8

5

10

9

4

18

7

17

REAR

3

2

1

32DF9T01.A

1 -

7

REF

TABLE OF CONTENTS

NEXT CHAPTER

TABLE 1-2: LIFT COMPONENTS FOR STEPWELL MODEL

NAME DESCRIPTION

Left, Right, Front, Rear

1 Pump enclosure

2 Pump Handle Handle used to manually operate hydraulic pump.

3 Electric Circuit

Breakers

4 Hydraulic Pump

Assy.

5 Pull Box Houses electrical termination points to lift, and a hydraulic line

6 Control Pendant Hand-held device used to control lift operation.

7 Carriage Part of traveling frame that is mounted on rollers; moves on

8 Deployment System Part of carriage. Employs an electric gear-motor to propel plat-

9 Manual Platform Re-

lease Shafts - 2ea

10 Lifting Frame Hinged arms that lift or lower platform; driven by single hydrau-

11 Manual Rollstop

Override Knob

12 Platform Rollstop Front barrier prevents wheelchair from inadvertently rolling off

13 Platform Curbed area occupied by passenger during lift operations.

14 Standee Handrails Provides platform occupant with a stable handhold.

15 Bridgeplate Plate unfolds when platform is at floor height to bridge gap be-

16 Sto-Loc Safety lock retains platform when in stowed position (re-

17 Enclosure Platform housing is rigidly attached to vehicle chassis.

18 Controller Translates pendant commands to signals that control lift elec-

Reference points from outside of vehicle looking inward at installed lift.

Contains lift electrical and hydraulic control components.

Prevents high-current damage to lift electrical components.

Electro-hydraulic unit provides hydraulic pressure needed to

raise platform.

disconnect point.

rails located inside enclosure. Supports lifting frame.

form out of enclosure, or pull it back in.

Used when lift electric power is lost. Releases platform from

enclosure to facilitate manual deployment. Actuated by engaging and rotating either indicated shaft.

lic cylinder attached to carriage.

Provides manual control of rollstop if electrical power is lost.

the platform during lift use.

tween platform and vehicle interior.

tracted); releases automatically when OUT button is pressed.

trical and hydraulic components.

END OF TABLE

32DF9T01.A

Loading...

Loading...