Page 1

Model TH-C1

(Machine Code: B156/B220)

SERVICE MANUAL

10 February 2005

Subject of change

Page 2

Trademarks

Microsoft®, Windows®, and MS-DOS® are registered trademarks of Microsoft

Corporation in the United States and /or other countries.

PostScript® is a registered trademark of Adobe Systems, Incorporated.

PCL® is a registered trademark of Hewlett-Packard Company.

Ethernet® is a registered trademark of Xerox Corporation.

PowerPC® is a registered trademark of International Business Machines

Corporation.

Other product names used herein are for identification purposes only and may be

trademarks of their respective companies. We disclaim any and all rights involved

with those marks.

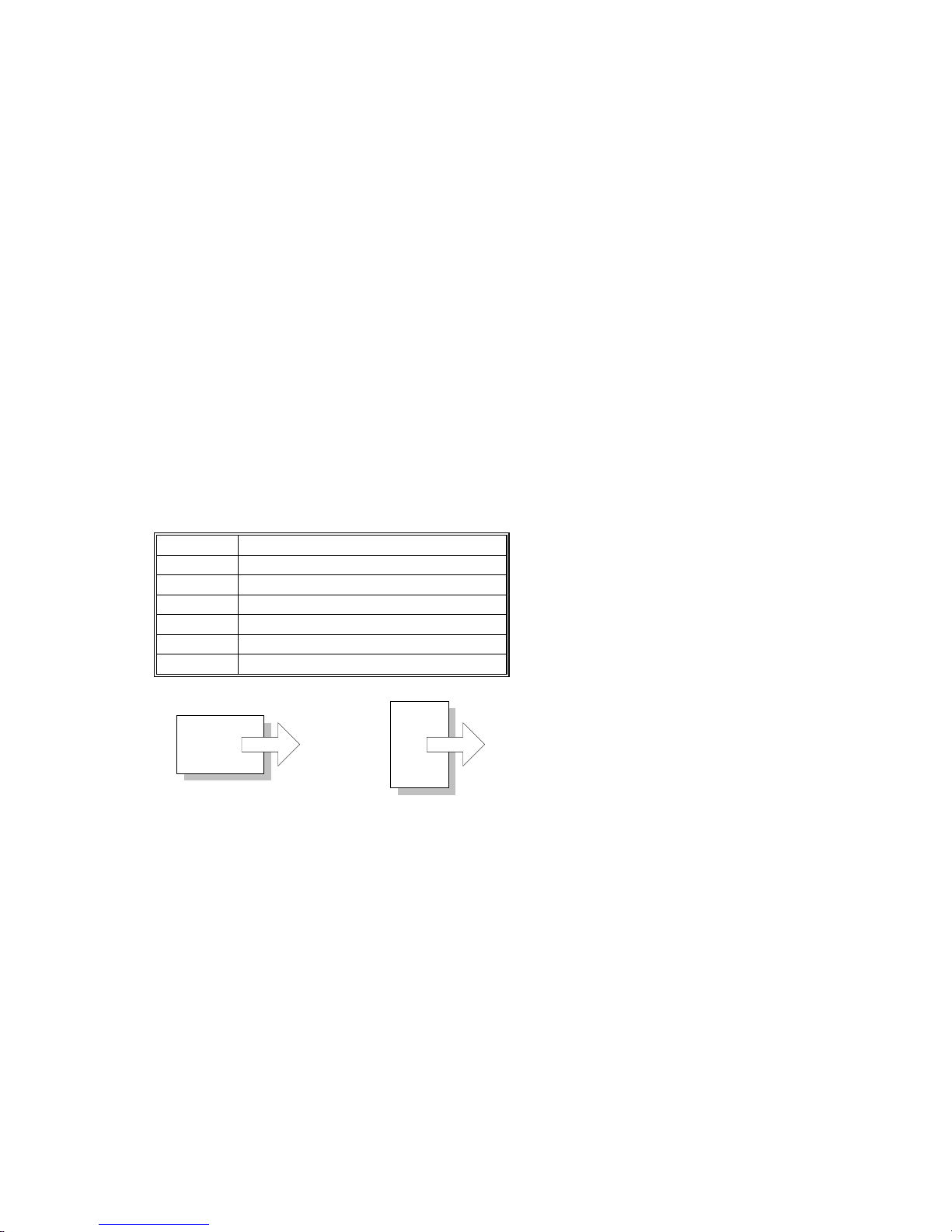

Symbols and Abbreviations

This manual uses several symbols.

Symbol What it means

☛

Refer to section number

!

See Core Tech Manual for details

"

Screw

#

Connector

$

E-ring

%

Clip ring

Long Edge Feed (LEF)Short Edge Feed (SEF)

Page 3

i

TABLE OF CONTENTS

1. INSTALLATION .......................................................................... 1-1

1.1 INSTALLATION REQUIREMENTS ...........................................................1-1

1.1.1 ENVIRONMENT ...............................................................................1-1

1.1.2 MACHINE LEVEL.............................................................................1-1

1.1.3 POWER REQUIREMENTS ..............................................................1-2

1.1.4 SPACE REQUIREMENTS................................................................1-2

1.2 COPIER (B156/B220)................................................................................1-3

1.2.1 POWER SOCKETS FOR PERIPHERALS .......................................1-3

1.2.2 INSTALLATION FLOW CHART........................................................1-4

1.2.3 ACCESSORY CHECK......................................................................1-5

1.2.4 INSTALLATION PROCEDURE ........................................................1-6

1.3 PAPER TRAY UNIT (B456).....................................................................1-13

1.3.1 ACCESSORY CHECK....................................................................1-13

1.3.2 INSTALLATION PROCEDURE ......................................................1-13

1.4 LCT (B457)..............................................................................................1-17

1.4.1 ACCESSORY CHECK....................................................................1-17

1.4.2 INSTALLATION PROCEDURE ......................................................1-17

1.5 AUTO REVERSE DOCUMENT FEEDER (B810)....................................1-21

1.5.1 ACCESSORY CHECK....................................................................1-21

1.5.2 INSTALLATION PROCEDURE ......................................................1-21

1.6 INTERCHANGE UNIT (B481) .................................................................1-24

1.6.1 ACCESSORY CHECK....................................................................1-24

1.6.2 INSTALLATION PROCEDURE ......................................................1-25

1.7 1 BIN TRAY UNIT (B480)........................................................................1-26

1.7.1 ACCESSORY CHECK....................................................................1-26

1.7.2 INSTALLATION PROCEDURE ......................................................1-27

1.8 SHIFT TRAY (B510)................................................................................1-30

1.8.1 ACCESSORY CHECK....................................................................1-30

1.8.2 INSTALLATION PROCEDURE ......................................................1-30

1.9 BY-PASS FEED UNIT (B490) .................................................................1-33

1.9.1 ACCESSORY CHECK....................................................................1-33

1.9.2 INSTALLATION PROCEDURE ......................................................1-33

1.10 DUPLEX UNIT (B509)...........................................................................1-35

1.10.1 ACCESSORY CHECK..................................................................1-35

1.10.2 INSTALLATION PROCEDURE ....................................................1-36

1.11 BRIDGE UNIT (B482)............................................................................1-38

1.11.1 ACCESSORY CHECK..................................................................1-38

1.11.2 INSTALLATION PROCEDURE ....................................................1-38

1.12 1000-SHEET FINISHER (B408)............................................................1-42

1.12.1 ACCESSORY CHECK..................................................................1-42

1.12.2 INSTALLATION PROCEDURE ....................................................1-43

1.13 500-SHEET FINISHER (B458) ..............................................................1-46

1.13.1 ACCESSORY CHECK..................................................................1-46

1.13.2 INSTALLATION PROCEDURE ....................................................1-47

1.14 PLATEN COVER INSTALLATION ........................................................1-49

Page 4

ii

1.15 PRINTER OPTIONS..............................................................................1-50

1.15.1 POSTSCRIPT 3 (B769) ................................................................1-50

1.15.2 FILE FORMAT CONVERTER (B609)...........................................1-51

1.15.3 IEEE1394 INTERFACE (B581) ....................................................1-52

UP Mode Settings for IEEE 1394........................................................1-53

SP Mode Settings for IEEE 1394........................................................1-53

1.15.4 IEEE 1284 (B679).........................................................................1-54

Installation Procedure .........................................................................1-54

1.15.5 IEEE802.11B (G813)....................................................................1-55

UP Mode Settings for Wireless LAN ...................................................1-57

SP Mode Settings for IEEE 802.11b Wireless LAN ............................1-58

1.15.6 BLUETOOTH (B736)....................................................................1-59

1.15.7 CHECKING THE CONNECTIONS ...............................................1-60

1.16 DATA OVERWRITE SECURITY UNIT (B735)......................................1-61

ACCESSORY CHECK........................................................................1-61

Seal Check and Removal ...................................................................1-61

Installation Procedure .........................................................................1-62

1.17 KEY COUNTER INSTALLATION ..........................................................1-64

1.18 ANTI-CONDENSATION HEATER.........................................................1-66

1.19 TRAY HEATER ..................................................................................... 1-68

1.20 TRAY HEATER (OPTIONAL PAPER TRAY UNIT) ...............................1-70

1.21 TRAY HEATER (OPTIONAL LCT) ........................................................1-72

2. PREVENTIVE MAINTENANCE................................................... 2-1

2.1 MAIN UNIT ................................................................................................2-1

2.1.1 OVERVIEW ......................................................................................2-1

2.1.2 WASTE TONER BOTTLES..............................................................2-2

2.1.3 PM TABLE........................................................................................2-3

2.2 OPTIONAL UNIT PM TABLE ....................................................................2-6

3. REPLACEMENT AND ADJUSTMENT........................................ 3-1

3.1 SPECIAL TOOLS ......................................................................................3-1

3.2 FILTERS....................................................................................................3-1

3.3 SCANNER UNIT........................................................................................3-2

3.3.1 EXPOSURE GLASS.........................................................................3-2

3.3.2 APS SENSORS................................................................................3-2

3.3.3 LENS BLOCK ASSEMBLY...............................................................3-3

3.3.4 EXPOSURE LAMP STABILIZER......................................................3-5

3.3.5 SCANNER LAMP .............................................................................3-5

3.3.6 SCANNER I/O BOARD.....................................................................3-8

3.3.7 SCANNER MOTOR..........................................................................3-8

3.3.8 FRONT SCANNER WIRE ................................................................3-8

3.3.9 REAR SCANNER WIRE................................................................. 3-11

3.4 LASER UNIT ........................................................................................... 3-13

3.4.1 CAUTION DECAL LOCATION .......................................................3-13

3.4.2 LASER UNIT ..................................................................................3-14

Adjusting for Image Skew ...................................................................3-16

D-Phase Adjustment...........................................................................3-17

Laser Beam Pitch Adjustment.............................................................3-18

Page 5

iii

3.4.3 POLYGONAL MIRROR MOTOR AND LSD ...................................3-19

3.5 DEVELOPMENT UNIT ............................................................................ 3-20

3.6 PHOTOCONDUCTOR UNIT (PCU) ........................................................3-21

3.6.1 PCU ASSEMBLY............................................................................3-21

3.6.2 WASTE TONER BOTTLES............................................................3-24

3.6.3 CHARGE CORONA UNIT, GRID, WIRE, AND CLEANER.............3-25

3.6.4 CHARGE CORONA WIRE CLEANER MOTOR.............................3-27

3.6.5 OPC BELT CLEANING UNIT .........................................................3-27

3.6.6 IMAGE TRANSFER BELT CLEANING UNIT .................................3-27

3.7 PAPER TRANSFER UNIT.......................................................................3-28

3.7.1 VERTICAL TRANSPORT UNIT......................................................3-28

3.7.2 TRANSFER ROLLER.....................................................................3-28

3.8 FUSING/PAPER EXIT.............................................................................3-29

3.8.1 FUSING UNIT.................................................................................3-29

3.8.2 OIL SUPPLY UNIT .........................................................................3-29

3.8.3 OIL SUPPLY PAD ..........................................................................3-30

3.8.4 CLEANING ROLLER AND FUSING SPONGE ROLLER ...............3-30

3.8.5 OILING ROLLER AND OIL SUPPLY ROLLER ..............................3-31

3.8.6 FUSING LAMPS.............................................................................3-32

When installing the fusing lamps ........................................................3-32

3.8.7 FUSING INNER UNIT.....................................................................3-33

3.8.8 PRESSURE ROLLER THERMOFUSE...........................................3-33

3.8.9 HOT ROLLER STRIPPERS ...........................................................3-34

3.8.10 FUSING BELT UNIT AND PRESSURE ROLLER UNIT...............3-34

3.8.11 PRESSURE ROLLER, PRESSURE ROLLER GEAR,

AND CLEANING ROLLER ..........................................................3-35

3.8.12 PRESSURE ROLLER THERMISTOR..........................................3-36

3.8.13 OIL ABSORBERS.........................................................................3-37

3.8.14 FUSING ENTRANCE AND TRANSFER BELT SENSORS ..........3-38

3.8.15 PAPER EXIT/OVERFLOW SENSORS.........................................3-39

3.9 PAPER FEED AND TRANSPORT ..........................................................3-41

3.9.1 FEED ROLLER AND FRICTION PAD............................................3-41

3.9.2 REGISTRATION SENSOR.............................................................3-42

3.9.3 PAPER FEED SENSOR 1..............................................................3-45

3.9.4 PAPER NEAR-END SENSORS .....................................................3-45

3.9.5 PAPER FEED SENSOR 2..............................................................3-46

3.9.6 PAPER END SENSOR 1................................................................3-47

3.9.7 PAPER END SENSOR 2................................................................3-47

3.10 ELECTRICAL COMPONENTS..............................................................3-48

3.10.1 EXHAUST FAN AND I/O BOARD.................................................3-48

3.10.2 BICU BOARD AND CONTROLLER BOARD................................3-49

3.10.3 HDD..............................................................................................3-50

3.10.4 HIGH VOLTAGE SUPPLY BOARD.............................................. 3-51

3.10.5 POWER SUPPLY UNIT................................................................3-52

3.11 DRIVE UNITS........................................................................................3-53

3.11.1 DEVELOPMENT CLUTCHES ......................................................3-53

K Development Units ..........................................................................3-53

C, Y and M Development Units...........................................................3-53

3.11.2 DEVELOPMENT MOTORS..........................................................3-54

Page 6

i

v

3.11.3 MAIN MOTOR ..............................................................................3-54

3.11.4 PCU GEAR BOX ..........................................................................3-55

3.11.5 FUSING UNIT MOTOR ................................................................3-55

3.11.6 PAPER FEED CLUTCH 1 ............................................................3-56

3.11.7 PAPER FEED MOTOR.................................................................3-56

3.11.8 PAPER FEED CLUTCH 2 ............................................................3-57

3.11.9 REGISTRATION CLUTCH ...........................................................3-57

3.11.10 OIL PUMP ..................................................................................3-58

3.12 COPY ADJUSTMENT ...........................................................................3-59

3.12.1 PRINTING ....................................................................................3-59

Registration - Leading Edge/Side-to-Side...........................................3-59

Blank Margin.......................................................................................3-60

Main Scan Magnification.....................................................................3-60

3.12.2 SCANNING...................................................................................3-61

Scanner Sub-Scan Magnification........................................................3-61

Scanner Leading Edge and Side-to-Side Registration........................3-61

Main Scan Dot Position Correction ..................................................... 3-62

3.12.3 ARDF IMAGE ADJUSTMENT ......................................................3-63

ARDF Side-to-Side and Leading Edge Registration ...........................3-63

ARDF Skew Adjustment .....................................................................3-64

3.13 COLOR ADJUSTMENT.........................................................................3-65

3.13.1 AUTO COLOR CALIBRATION (ACC) ..........................................3-65

3.13.2 PRINTER GAMMA CORRECTION ..............................................3-66

Copy Mode .........................................................................................3-66

Printer Mode .......................................................................................3-70

3.14 SCANNER WHITE LEVEL ADJUSTMENT ...........................................3-72

White Level Check..............................................................................3-72

White Level Adjustment ......................................................................3-72

3.15 TOUCH SCREEN CALIBRATION.........................................................3-75

3.16 CHECKING THE BREAKER SWITCH ..................................................3-76

3.16.1 BREAKER ....................................................................................3-76

4. TROUBLESHOOTING ................................................................ 4-1

4.1 SERVICE CALL.........................................................................................4-1

4.1.1 SERVICE CALL CONDITIONS ........................................................4-1

4.1.2 SC TABLE ........................................................................................4-3

4.2 SELF-DIAGNOSTIC MODE ....................................................................4-22

4.2.1 OVERVIEW ....................................................................................4-22

4.2.2 DETAILED SELF-DIAGNOSTICS ..................................................4-23

4.3 IMAGE TEST MODE ...............................................................................4-24

4.3.1 OVERVIEW ....................................................................................4-24

4.3.2 VPU TEST ......................................................................................4-24

SP4-907-1: VPU Test Pattern: R ........................................................4-24

SP4-907-2: VPU Test Pattern: G ........................................................4-24

SP4-907-3: VPU Test Pattern: B ........................................................4-24

4.3.3 IPU TEST .......................................................................................4-24

4.3.4 GAVD TEST ...................................................................................4-24

4.4 ELECTRICAL COMPONENT DEFECTS ................................................4-25

4.4.1 SENSORS ......................................................................................4-25

Page 7

v

4.4.2 SWITCHES.....................................................................................4-27

4.4.3 BLOWN FUSE CONDITIONS ........................................................4-27

4.5 CHECK POINTS FOR IMAGE PROBLEMS AT REGULAR INTERVALS .. 4-28

4.6 SKEWED IMAGES..................................................................................4-29

4.7 TRAPEZOID IMAGES.............................................................................4-29

4.8 PARALLELOGRAM IMAGES..................................................................4-30

4.9 CHECKING THE IMAGE WITH THE TRIMMING PATTERN..................4-31

4.10 CORRECTING THE IMAGES ............................................................... 4-32

4.10.1 FLOWCHART...............................................................................4-32

4.10.2 ACTION........................................................................................4-33

Adjusting for Image Skew ...................................................................4-36

5. SERVICE TABLES...................................................................... 5-1

5.1 SERVICE PROGRAM MODE....................................................................5-1

5.1.1 SERVICE PROGRAM MODE OPERATION.....................................5-1

Starting the SP mode............................................................................5-1

Quitting the SP mode............................................................................5-1

SP Mode Touch Screen........................................................................5-2

Copy Window for Test Printing .............................................................5-3

Working on SP Mode Menus ................................................................5-3

Service Mode Lock/Unlock ...................................................................5-4

5.1.2 SP MODE TABLE.............................................................................5-5

SP1-XXX: (Feed) ..................................................................................5-5

SP2-XXX: (Drum)..................................................................................5-9

SP3-XXX: (Process) ...........................................................................5-18

SP4-XXX: (Scanner) ...........................................................................5-22

SP5-XXX: (Mode) ...............................................................................5-30

SP6-XXX: (Peripherals) ......................................................................5-54

5. SP MODE .................................................................................. 5-56

5.1 SERVICE PROGRAM MODE..................................................................5-56

5.1.1 DUMMY ..........................................................................................5-56

5.1.2 DUMMY ..........................................................................................5-56

SP7-XXX: (Data Log)..........................................................................5-57

SP8-xxx: Data Log2............................................................................5-66

5. SP MODE .................................................................................. 5-99

5.1 SERVICE PROGRAM MODE..................................................................5-99

5.1.1 DUMMY ..........................................................................................5-99

5.1.2 DUMMY ..........................................................................................5-99

5.1.3 TEST PATTERN PRINTING (SP5-955-1) ....................................5-100

5.1.4 INPUT CHECK .............................................................................5-101

Main Machine Input Check (SP5-803) ..............................................5-101

Table 1: Tray 1 and 2 Paper Size .....................................................5-104

Table 2: By-pass Tray Paper Size ....................................................5-104

Table 3: Optional Paper Tray Unit Paper Size ..................................5-104

Table 4: Optional Paper Tray Unit Paper Near End..........................5-104

ARDF Input Check (SP6-007)...........................................................5-105

Finisher Input Check (SP6-117)........................................................5-106

Page 8

vi

5.1.5 OUTPUT CHECK .........................................................................5-107

Main Machine Output Check (SP5-804) ...........................................5-107

ARDF Output Check (SP6-008)........................................................5-110

Finisher Output Check (SP6-118).....................................................5-110

5.1.6 SMC DATA LISTS (SP5-990).......................................................5-111

5.1.7 ORIGINAL JAM HISTORY DISPLAY ...........................................5-111

Total Count .......................................................................................5-111

Details on the Most Recent Jams .....................................................5-111

5.1.8 COPY JAM HISTORY DISPLAY ..................................................5-112

Total Count .......................................................................................5-112

Details on the Most Recent Jams .....................................................5-112

5.1.9 MEMORY ALL CLEAR (SP5-801)................................................5-113

Using an SD card..............................................................................5-113

Without Using a Flash Memory Card ................................................5-114

5.2 PRINTER SERVICE MODE ..................................................................5-115

5.2.1 SERVICE MODE TABLE..............................................................5-115

Service Table Key.............................................................................5-115

5.2.2 SP MODES RELATED TO THE PRINTER CONTROLLER .........5-117

5.3 SCANNER SERVICE MODE.................................................................5-118

5.3.1 SCANNER PROGRAM MODE TABLE.........................................5-118

SP1-XXX (System and Others).........................................................5-118

SP2-XXX (Scanning-image quality) ..................................................5-118

5.3.2 APS OUTPUT DISPLAY (SP4-301) .............................................5-119

5.4 PROGRAM DOWNLOAD......................................................................5-120

5.4.1 FIRMWARE ..................................................................................5-120

5.4.2 NVRAM DATA UPLOAD/DOWNLOAD ........................................5-121

Uploading NVRAM Data (SP5-824)..................................................5-121

Downloading NVRAM Data (SP5-825) ............................................. 5-122

5.5 SOFTWARE RESET .............................................................................5-123

5.6 SYSTEM SETTINGS AND COPY SETTING RESET............................5-123

5.6.1 SYSTEM SETTING RESET .........................................................5-123

5.6.2 COPIER SETTING RESET ..........................................................5-124

5.7 USER TOOLS .......................................................................................5-125

5.7.1 HOW TO ENTER USER TOOLS..................................................5-125

UP Mode Initial Screen: User Tools/Counter Display .......................5-125

System Settings................................................................................5-125

Copier/Document Server Features ...................................................5-125

Printer, Facsimile, Scanner Settings.................................................5-125

Inquiry...............................................................................................5-125

Counter.............................................................................................5-126

5.8 DIP SWITCHES.....................................................................................5-126

5.9 SD CARD APPLICATION MOVE ..........................................................5-127

Overview...........................................................................................5-127

Move Exec ........................................................................................5-128

Undo Exec ........................................................................................5-128

5.10 USING THE DEBUG LOG...................................................................5-129

5.10.1 SWITCHING ON AND SETTING UP SAVE DEBUG LOG .........5-129

5.10.2 RETRIEVING THE DEBUG LOG FROM THE HDD...................5-132

5.10.3 RECORDING ERRORS MANUALLY .........................................5-133

Page 9

vii

5.10.4 NEW DEBUG LOG CODES .......................................................5-134

SP5857-015 Copy SD Card-to-SD Card: Any Desired Key .............5-134

SP5857-016 Create a File on HDD to Store a Log ..........................5-134

SP5857-017 Create a File on SD Card to Store a Log ....................5-134

6. DETAILED SECTION DESCRIPTIONS ...................................... 6-1

6.1 OVERVIEW ...............................................................................................6-1

6.1.1 MECHANICAL COMPONENTS........................................................6-1

6.1.2 PAPER PATH...................................................................................6-2

6.1.3 DRIVE COMPONENTS....................................................................6-3

Layout...................................................................................................6-3

Drive Power Path..................................................................................6-4

6.1.4 ELECTRICAL COMPONENTS.........................................................6-5

Scanner Unit .........................................................................................6-5

Image Transfer .....................................................................................6-6

Paper Path............................................................................................6-7

Development Units................................................................................6-8

Boards ..................................................................................................6-9

6.2 BOARD STRUCTURE.............................................................................6-10

6.2.1 BLOCK DIAGRAM..........................................................................6-10

6.2.2 CONTROLLER ...............................................................................6-12

6.3 COPY PROCESS....................................................................................6-14

6.4 PROCESS CONTROL ............................................................................6-16

6.4.1 OVERVIEW ....................................................................................6-16

6.4.2 PROCESS CONTROL STEPS.......................................................6-16

Six Steps.............................................................................................6-16

When is Process Control Done? ......................................................... 6-16

Supplementary Information on Process Control .................................6-17

6.5 SCANNING..............................................................................................6-19

6.5.1 OVERVIEW ....................................................................................6-19

6.5.2 SCANNER DRIVE ..........................................................................6-20

Book Mode..........................................................................................6-20

ARDF Mode ........................................................................................6-20

6.5.3 ORIGINAL SIZE DETECTION........................................................6-21

6.6 IMAGE PROCESSING ............................................................................6-23

6.6.1 OVERVIEW ....................................................................................6-23

6.6.2 SBU BLOCK DIAGRAM .................................................................6-24

Signal Processing ...............................................................................6-24

A/D Conversion...................................................................................6-24

White Level Correction........................................................................6-24

Others.................................................................................................6-24

Black Level Correction........................................................................6-25

VPU Test Mode ..................................................................................6-25

6.6.3 IMAGE PROCESSING ...................................................................6-26

Shading Correction .............................................................................6-26

Picture Element (Dot Position) Correction ..........................................6-26

Scan Line Correction ..........................................................................6-26

Scanner Gamma Correction (RGB Gamma Correction).....................6-27

Filtering ...............................................................................................6-27

Page 10

viii

ADS (Auto Image Density Selection) ..................................................6-27

Image Separation................................................................................6-28

ACS (Auto Color Selection) ................................................................6-28

Color Conversion ................................................................................6-29

Main Scan Magnification.....................................................................6-29

Printer Gamma Correction..................................................................6-30

Error Diffusion.....................................................................................6-32

6.7 PHOTOCONDUCTOR UNIT (PCU) ........................................................6-33

6.7.1 OVERVIEW ....................................................................................6-33

6.7.2 CHARGE CORONA UNIT ..............................................................6-34

Power Supply......................................................................................6-34

Grid and Wire Cleaning.......................................................................6-34

Quenching ..........................................................................................6-36

6.7.3 OPC BELT DRIVE..........................................................................6-36

6.7.4 OPC BELT CLEANING UNIT .........................................................6-37

Bottle Detection ..................................................................................6-37

Waste Toner Collection.......................................................................6-37

Drive ...................................................................................................6-38

6.7.5 IMAGE TRANSFER BELT UNIT.....................................................6-38

Drive ...................................................................................................6-38

Belt Mark Detection.............................................................................6-39

Transfer Roller ....................................................................................6-39

6.7.6 IMAGE TRANSFER BELT CLEANING UNIT .................................6-40

Image Transfer Belt Cleaning .............................................................6-40

Waste Toner Collection.......................................................................6-40

Set Switch and Full Sensor.................................................................6-40

Contact Mechanism ............................................................................6-41

Power Supply......................................................................................6-42

Drive ...................................................................................................6-42

6.8 LASER EXPOSURE................................................................................6-43

6.8.1 OVERVIEW ....................................................................................6-43

6.8.2 POLYGON MIRROR MOTOR UNIT...............................................6-44

Speed .................................................................................................6-44

6.8.3 SYNCHRONIZATION DETECTOR ................................................6-44

6.8.4 LD UNIT..........................................................................................6-44

6.8.5 LD SAFETY SWITCH.....................................................................6-45

Front Door...........................................................................................6-45

Circuit..................................................................................................6-45

Operation Panel Display and Switch Mechanism ...............................6-46

6.9 DEVELOPMENT .....................................................................................6-47

6.9.1 OVERVIEW ....................................................................................6-47

6.9.2 DEVELOPMENT UNIT ...................................................................6-48

Replacing Units...................................................................................6-48

Distinguishing the development unit with the one for the B051 series ....6-48

Memory chip .......................................................................................6-48

6.9.3 TONER SUPPLY MECHANISM.....................................................6-49

Drive ...................................................................................................6-49

Rollers and Agitators...........................................................................6-50

Shutter ................................................................................................6-50

Page 11

ix

6.9.4 TONER END DETECTION.............................................................6-51

Mechanism .........................................................................................6-51

Toner Near-End Detection..................................................................6-51

Toner End Detection...........................................................................6-52

Toner End Recovery...........................................................................6-52

6.9.5 DEVELOPMENT UNIT CONTACT MECHANISM..........................6-53

Mechanism .........................................................................................6-53

Reverse Rotation ................................................................................6-54

6.9.6 POWER SOURCE..........................................................................6-55

Development, Toner Supply, and Doctor Rollers................................6-55

Doctor Roller.......................................................................................6-55

6.10 PAPER FEED........................................................................................6-56

6.10.1 OVERVIEW ..................................................................................6-56

Transport Speed .................................................................................6-57

Friction Pad.........................................................................................6-57

6.10.2 DRIVE MECHANISM....................................................................6-57

Feed and Vertical Transport ............................................................... 6-57

Registration.........................................................................................6-57

6.10.3 PAPER LIFT.................................................................................6-58

Lift Mechanism....................................................................................6-58

Paper End/Near-End Detection ..........................................................6-58

6.10.4 PAPER SIZE DETECTION...........................................................6-59

Mechanism .........................................................................................6-59

Switch Pattern.....................................................................................6-59

6.11 PAPER TRANSFER AND SEPARATION..............................................6-60

6.11.1 OVERVIEW ..................................................................................6-60

Jammed Paper Release .....................................................................6-60

Image Transfer and Paper Separation................................................6-60

6.11.2 CONTACT/SEPARATION MECHANISM .....................................6-61

Timing.................................................................................................6-61

Mechanism .........................................................................................6-61

6.11.3 POWER SUPPLY.........................................................................6-62

Circuit..................................................................................................6-62

Paper Transfer Roller Bias..................................................................6-62

Discharge Plate ..................................................................................6-62

Temperature/Humidity Control............................................................6-62

Roller Cleaning ...................................................................................6-63

6.12 IMAGE FUSING AND PAPER EXIT......................................................6-64

6.12.1 OVERVIEW ..................................................................................6-64

6.12.2 DRIVE...........................................................................................6-65

6.12.3 FUSING UNIT COMPONENTS ....................................................6-66

Fusing Belt..........................................................................................6-66

Heating Roller Lamp and Pressure Roller Lamp.................................6-66

Fusing Bias .........................................................................................6-67

Fusing Unit SCs..................................................................................6-67

6.12.4 OIL SUPPLY.................................................................................6-68

Oil Supply ...........................................................................................6-68

Oil Supply ...........................................................................................6-69

Oil End Detection and Recovery.........................................................6-70

Page 12

x

6.12.5 TEMPERATURE CONTROL ........................................................6-71

6.12.6 ENERGY SAVER MODES ...........................................................6-72

Overview............................................................................................. 6-72

Panel Off Mode...................................................................................6-73

Low Power Mode ................................................................................6-74

Auto Off Mode.....................................................................................6-75

6.12.7 PAPER EXIT ................................................................................6-76

Drive ...................................................................................................6-76

Paper Jam Detection ..........................................................................6-76

6.12.8 PAPER OVERFLOW DETECTION ..............................................6-76

6.13 PRINT DATA PROCESSING ................................................................6-77

6.13.1 RPCS DRIVER .............................................................................6-77

6.13.2 PCL5C DRIVER............................................................................6-77

6.13.3 PS3 DRIVER ................................................................................6-78

CMS (Color Management System) .....................................................6-78

Gray Correction ..................................................................................6-78

BG/UCR (Black Generation/Under Color Removal)............................6-78

Gamma Correction..............................................................................6-78

Toner Limitation..................................................................................6-79

Dither Processing and ROP/RIP.........................................................6-79

6.14 FILE FORMAT CONVERTER (MLB).....................................................6-80

6.15 DATA OVERWRITE SECURITY UNIT (B735)......................................6-81

6.15.1 AUTO ERASE MEMORY .............................................................6-81

Types of Data Overwritten and Not Overwritten .................................6-81

Overwrite timing..................................................................................6-81

SPECIFICATIONS

1. GENERAL SPECIFICATIONS (MAIN UNIT)....................................... SPEC-1

2.1 SYSTEM COMPONENTS ........................................................... SPEC-3

2.2 OPTIONAL EQUIPMENT ............................................................ SPEC-6

ARDF ..............................................................................................Spec-6

Bridge Unit ......................................................................................Spec-6

By-pass Tray Unit ...........................................................................Spec-7

Duplex Unit .....................................................................................Spec-7

Interchange Unit .............................................................................Spec-7

LCT.................................................................................................Spec-8

Paper Tray Unit...............................................................................Spec-8

Shift Tray Unit .................................................................................Spec-8

1-Bin Tray Unit................................................................................Spec-9

500-Sheet Finisher..........................................................................Spec-9

1000-sheet Finisher ......................................................................Spec-10

Upper Tray....................................................................................Spec-10

Lower Tray....................................................................................Spec-10

Page 13

10 February 2005 INSTALLATION REQUIREMENTS

1-1

Installation

1. INSTALLATION

1.1 INSTALLATION REQUIREMENTS

1.1.1 ENVIRONMENT

1. Temperature Range:

10°C to 32°C (50°F to 89.6°F) (humidity to be 54% at

32°C, 89.6°F)

2. Humidity Range:

15% to 80% Rh (temperature to be 27°C, 80.6°F at

80%)

3. Ambient Illumination: 2000 lux or less (keep the machine out of direct

sunlight.)

4. Ventilation: Air turnover of more than 30 m3/hr/person or more

5. Ambient Dust: Less than 0.10 mg/m3 (2.7 x 10

– 6

oz/yd3)

6. Avoid exposing the machine to sudden temperature changes, which include:

1) Direct cool air from an air conditioner

2) Direct heat from a heater

7. Avoid installing the machine in areas that may be exposed to corrosive gas.

8. Install the machine at a location lower than 2,000 m (6,500 ft.) above sea level.

9. Install the machine on a strong, level base.

10. Avoid installing the machine in areas that may be subjected to strong vibration.

1.1.2 MACHINE LEVEL

Front to back: Within 5 mm (0.2") of level

Right to left: Within 5 mm (0.2") of level

Page 14

INSTALLATION REQUIREMENTS 10 February 2005

1-2

1.1.3 POWER REQUIREMENTS

!CAUTION

1. Insert the plug firmly in the outlet.

2. Avoid using an outlet extension plug or cord.

3. Ground the machine.

1. Input voltage level: 120 V, 60 Hz, More than 12 A

220 ∼ 240 V, 50/60 Hz, More than 8 A

110 V, 50/60 Hz, More than 13A

2. Permissible voltage fluctuation: ±10%

3. Do not put or place anything on the power cord.

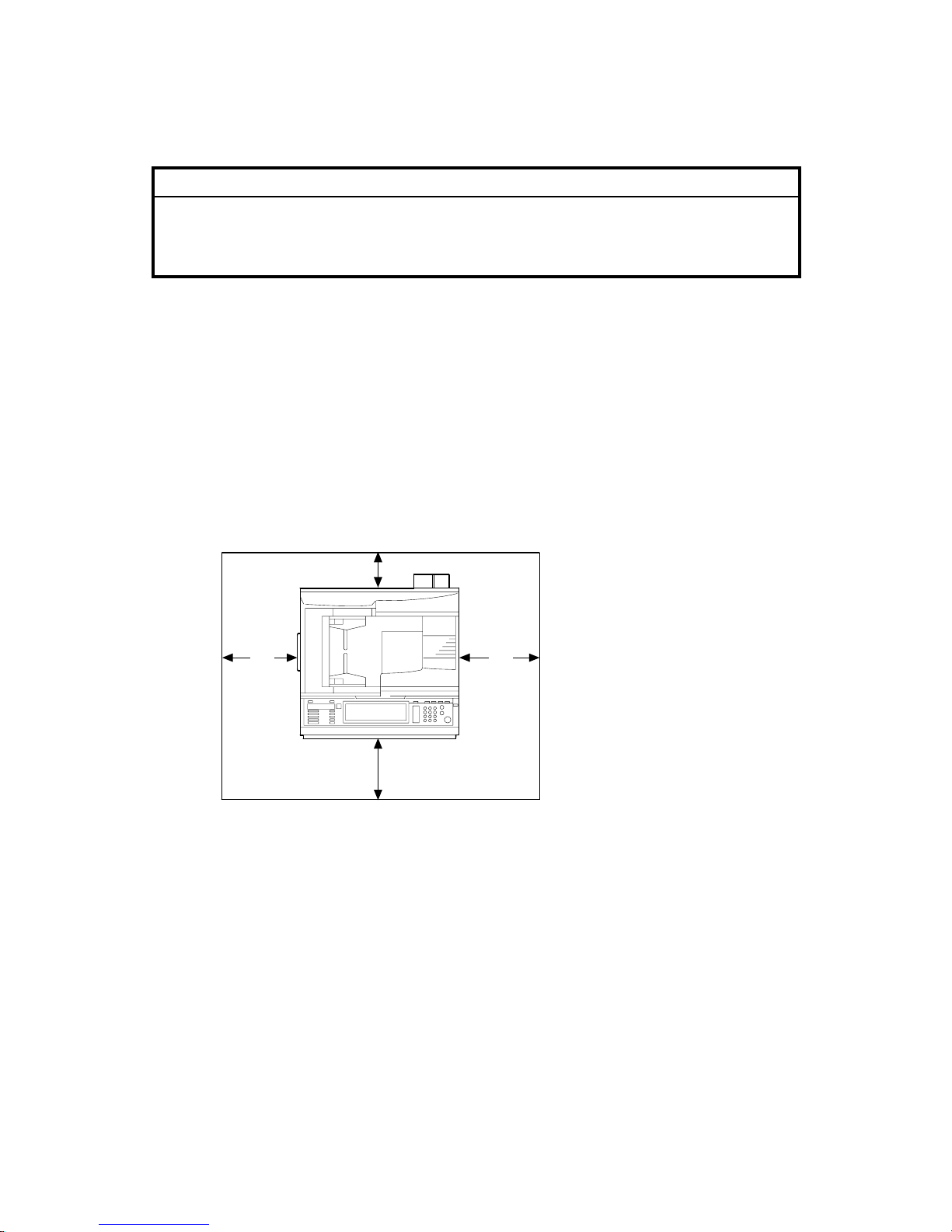

1.1.4 SPACE REQUIREMENTS

B156I501.WMF

A

: Over 100 mm (4")

B: Over 100 mm (4")

C: Over 550 mm (22")

D: Over 750 mm (29.6")

A C

B

D

Page 15

10 February 2005 COPIER (B156/B220)

1-3

Installation

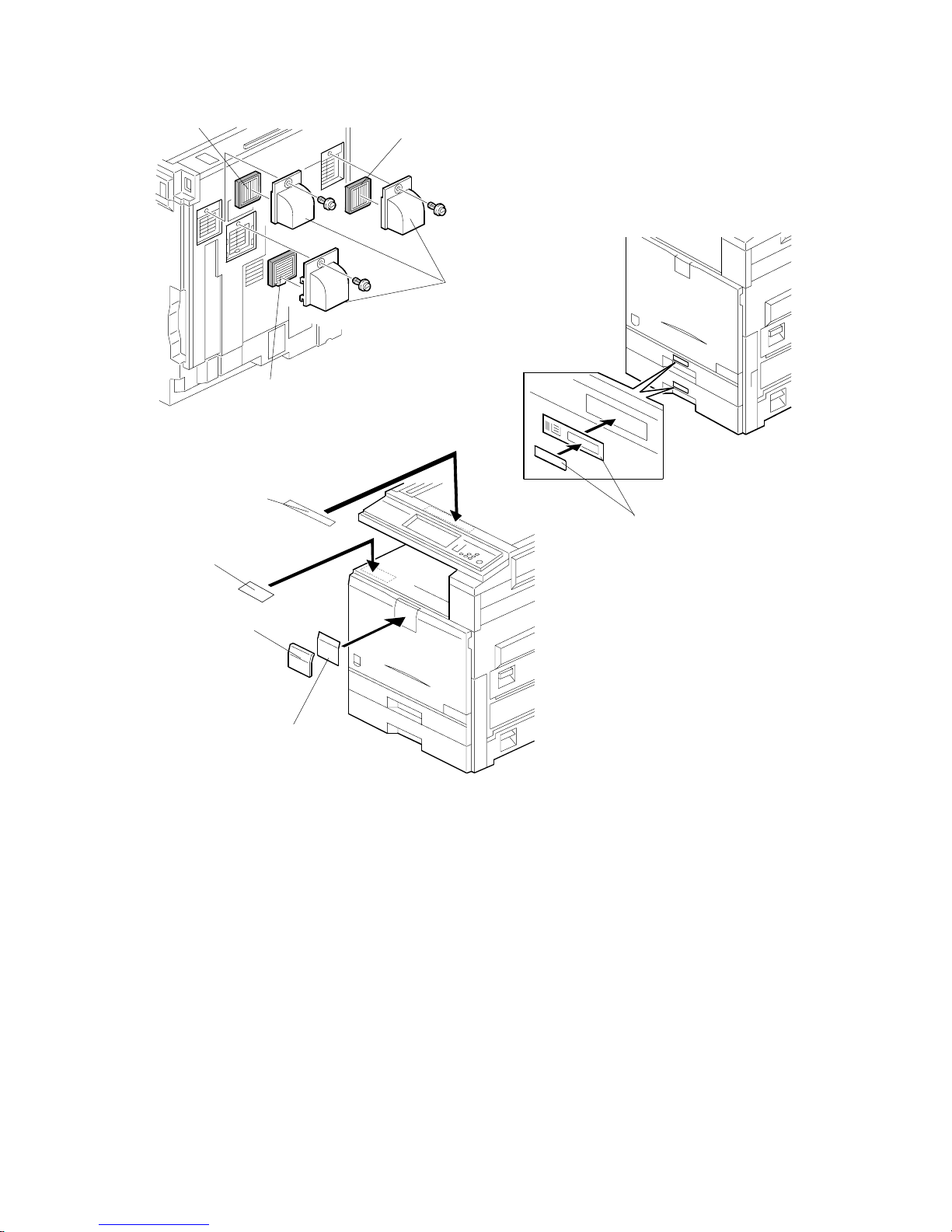

1.2 COPIER (B156/B220)

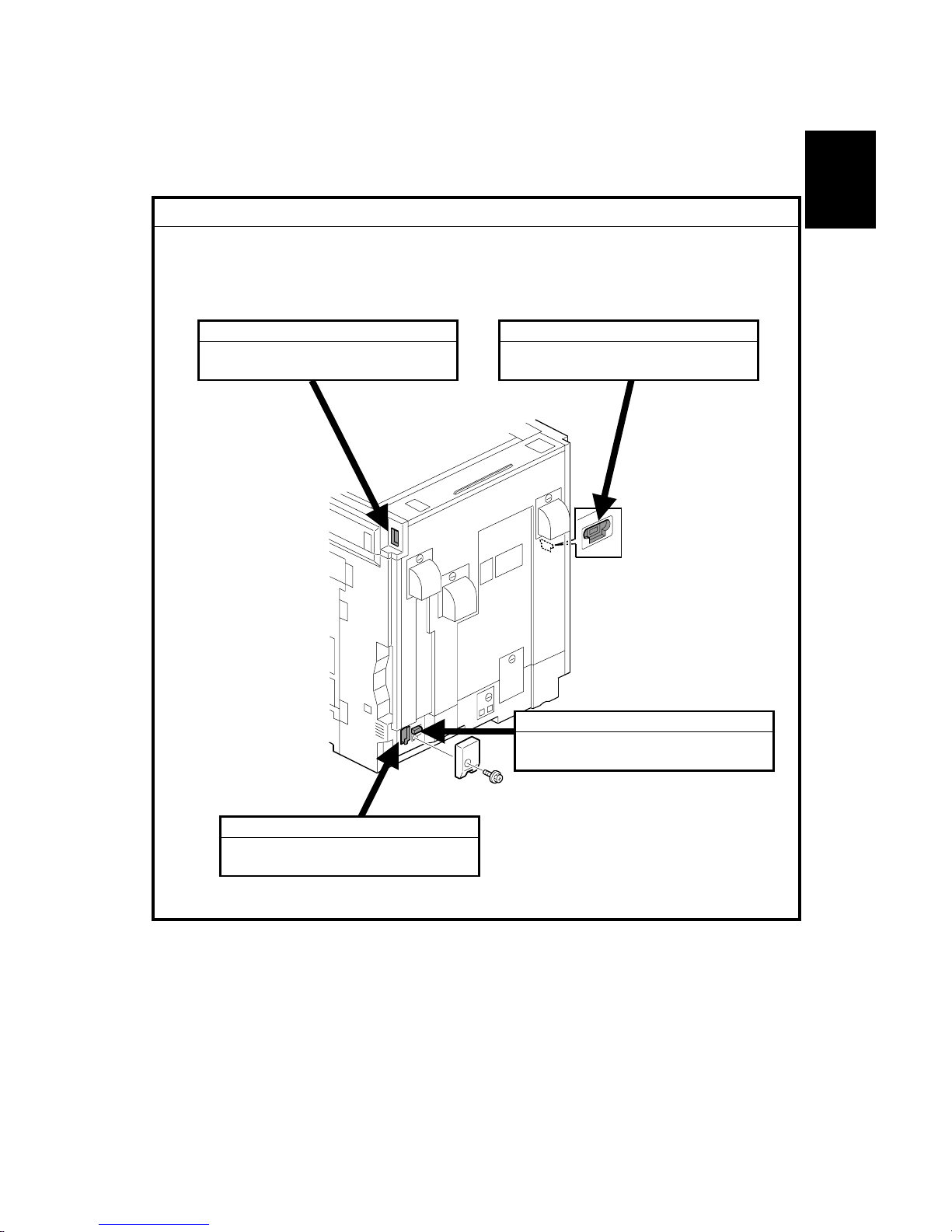

1.2.1 POWER SOCKETS FOR PERIPHERALS

!CAUTION

Rating voltage for peripherals.

Make sure to plug the cables into the correct sockets.

B156I502.WMF

1. ADF

1. Rating voltage output connector

for accessory Max. DC24 V

2. Finisher

1. Rating voltage output connector

for accessory Max. DC24 V

3. By-pass Tray

1. Rating voltage output connector

for accessory Max. DC24 V

4. Duplex Unit

1. Rating voltage output connector

for accessory Max. DC24 V

Page 16

COPIER (B156/B220) 10 February 2005

1-4

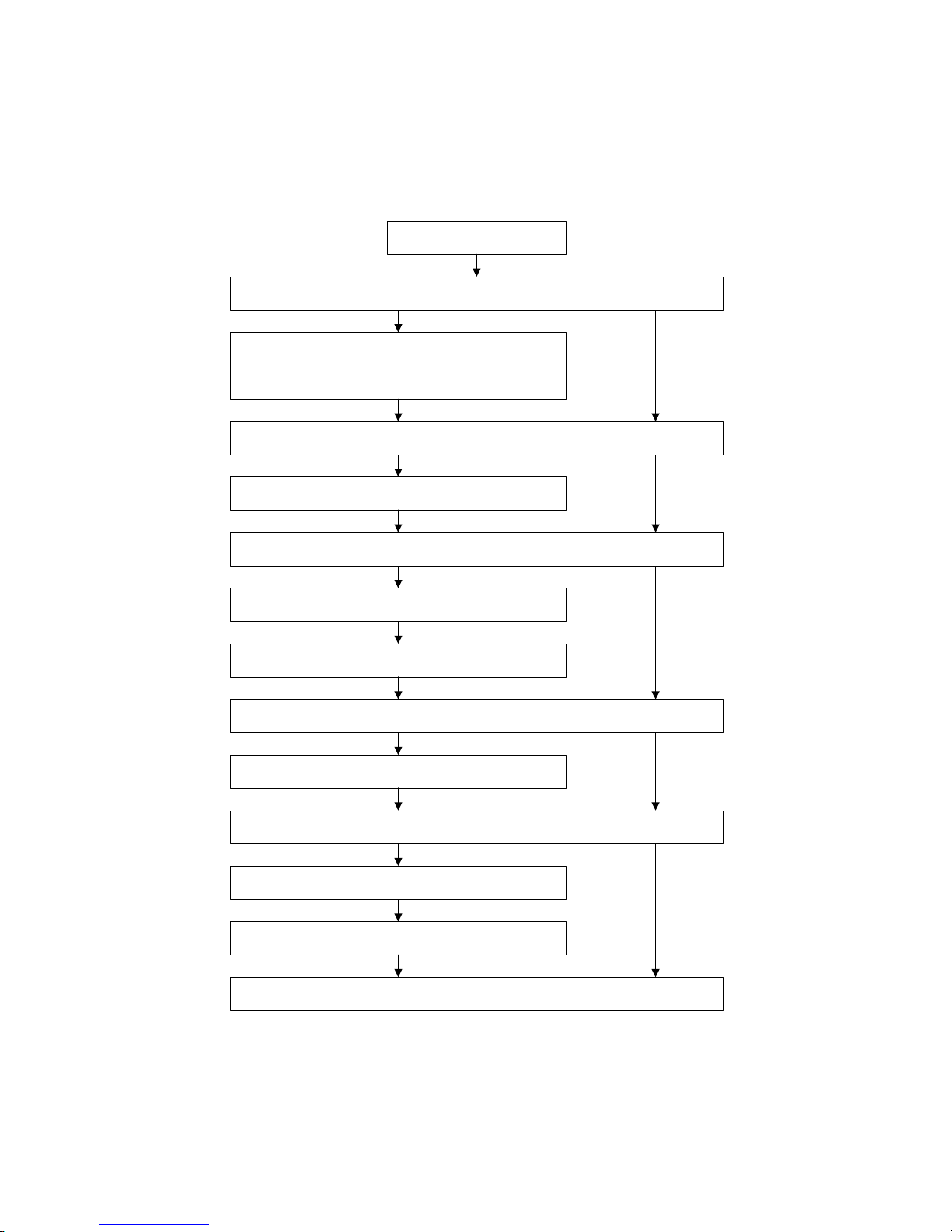

1.2.2 INSTALLATION FLOW CHART

The following flow chart shows how to install the optional units more efficiently.

Unpack the copier

Place the copier on the Paper Tray Unit or LCT

Install the Paper Tray Unit or LCT

Install the copier

Install the By-pass Tray

Yes No

Yes No

Install the Interchange Unit

Install the Duplex Unit and/or 1-bin Tray Unit

Yes No

Install the Shift Tray

Yes No

Install the Bridge Unit

Install the Finisher

Yes No

Does the user require the Paper Tray Unit, LCT, or Finisher?

Does the user require the By-pass Tray?

Install the ARDF or Platen Cover (if required)

Does the user require the Duplex Unit and/or 1-bin Tray Unit ?

Does the user require the Shift Tray?

Does the user require the Finisher?

Yes

B156I503.WMF

Page 17

10 February 2005 COPIER (B156/B220)

1-5

Installation

1.2.3 ACCESSORY CHECK

Check the quantity and condition of the accessories in the box against the following

list:

No. Description Q’ty

1 Paper Tray Decal 1

2 Model Name Decal 1

3 NECR 1

4 Factory Data Sheet 1

5 Filter Duct 3

6 Filter 3

7 Caution Decal – Power/Paper 1

8 Decal – Copy prohibition 1

9 Manual Holder 1

10 Operating Instructions – System Setting 1

11 Operating Instructions – Copy Reference 1

12 Operating Instructions – Printer 2

13 Operating Instructions – Security 1

14 Instruction Procedure Sheet 1

15 Sheet – Notes for User 1

16 Screw for Manual Holder 2

17 Stamp 1

18 Cloth (ADF Standard version only) 1

19 Cloth Holder (ADF Standard version only) 1

Page 18

COPIER (B156/B220) 10 February 2005

1-6

1.2.4 INSTALLATION PROCEDURE

!CAUTION

Unplug the machine power cord before starting the following procedure.

If the optional paper tray or the optional LCT will be installed at the same time,

place the copier on the paper tray unit or the LCT first, then install the copier and

the other options.

NOTE: Keep the shipping retainers after installing the machine. They will be

reused when the machine is moved to another location in the future.

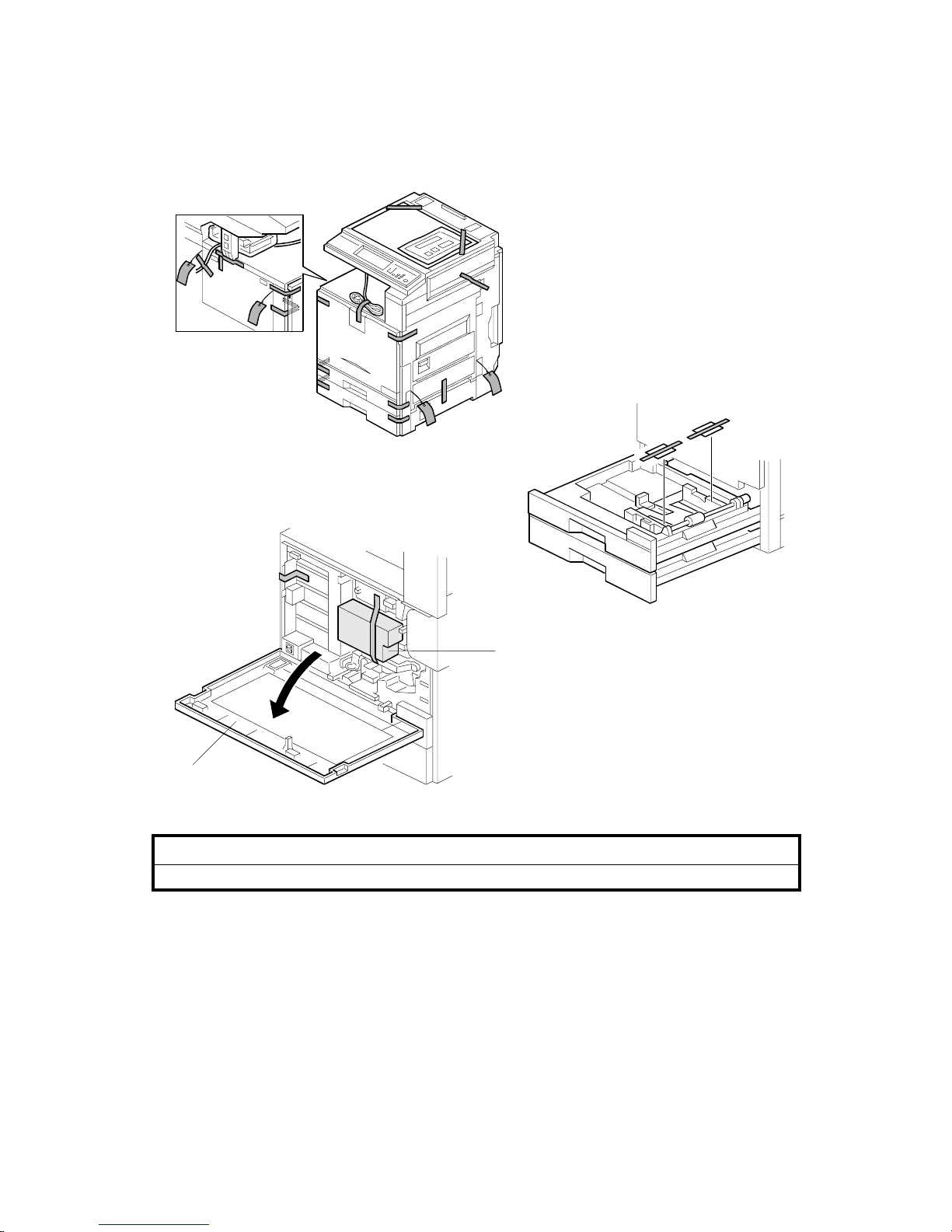

1. Remove the tapes.

2. Open the front cover [A] and remove the shipping retainer [B].

B156I504.WMF

B156I505.WMF

B156I506.WMF

[A]

[B]

Page 19

10 February 2005 COPIER (B156/B220)

1-7

Installation

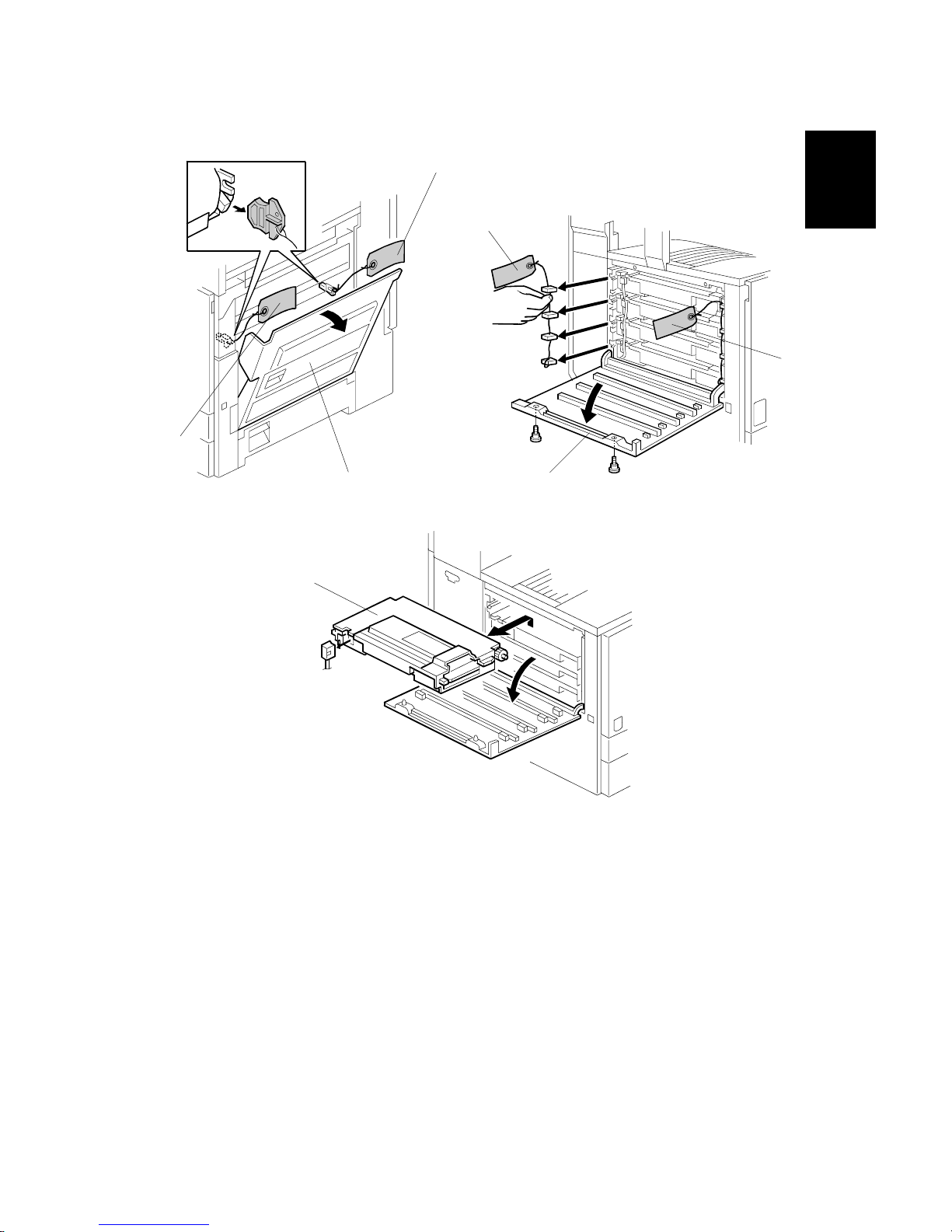

3. Open the right cover [A], and remove the red tags [B].

4. Open the left cover [C] (! x 2), and remove the red tags [D].

5. Pull out all development units [E] (" x 1 each).

B156I509.WMF

B156I507.WMF

B156I508.WMF

[C]

[D]

[D]

[A]

[B]

[B]

[E]

Page 20

COPIER (B156/B220) 10 February 2005

1-8

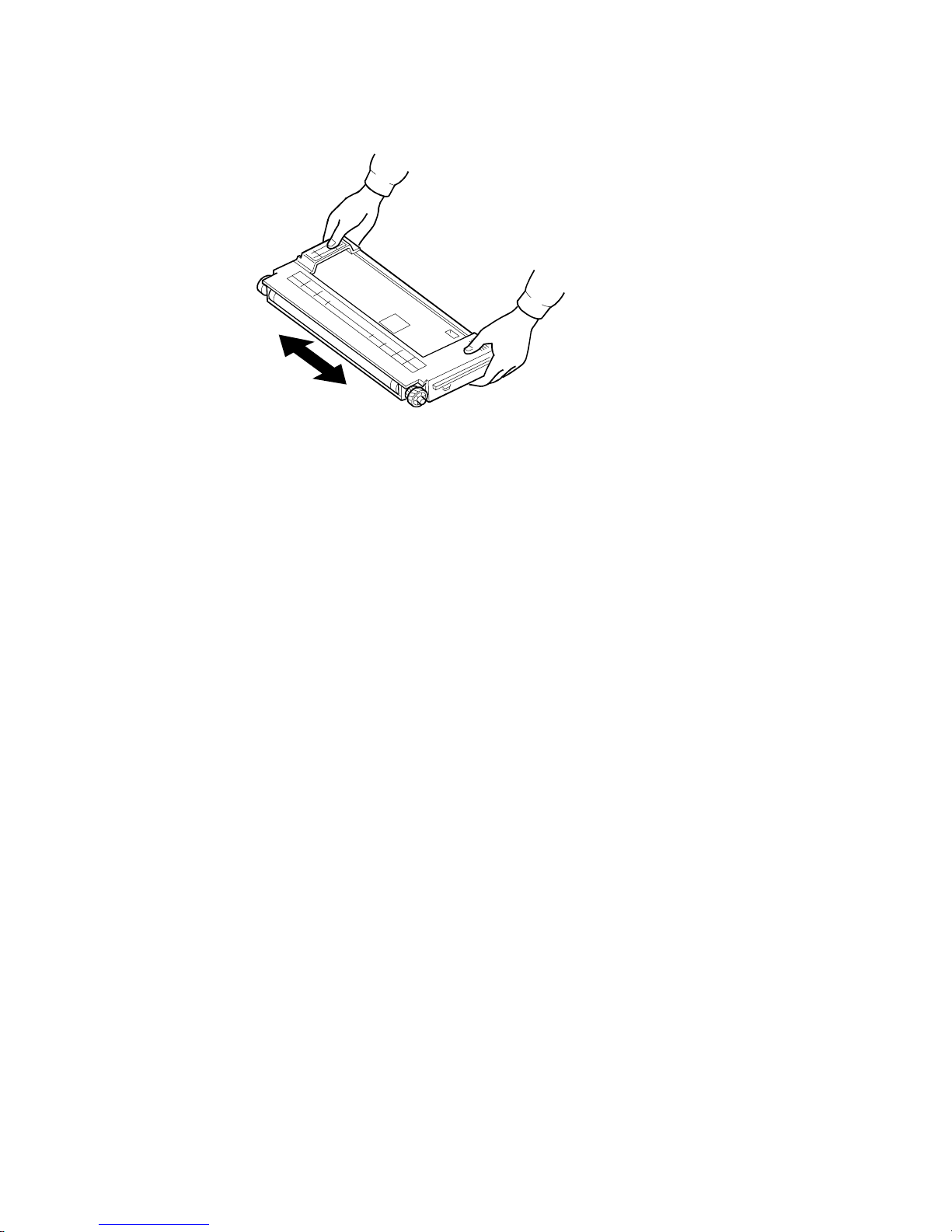

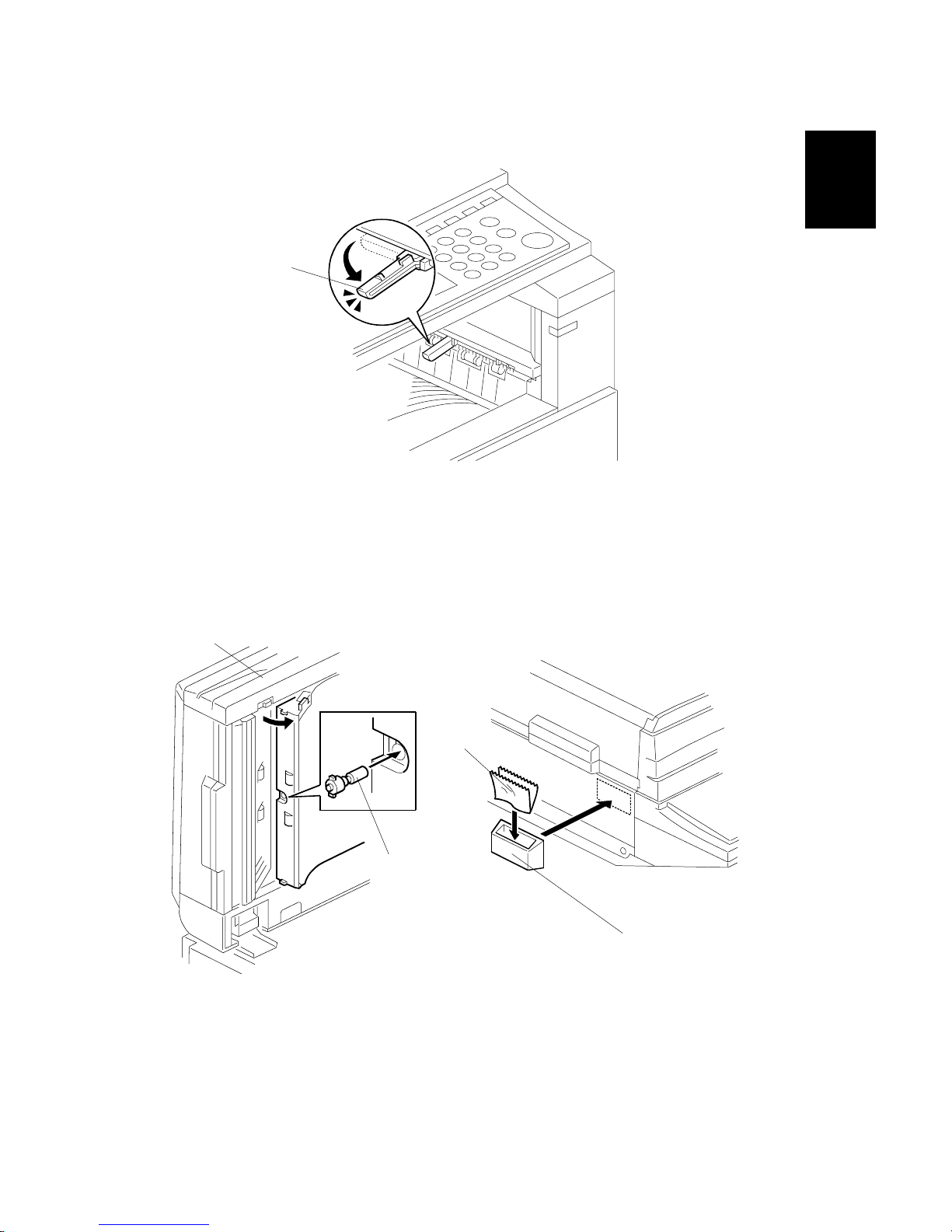

6. Keep the development unit level and shake the development unit about 10

times from side to side.

NOTE: 1) Do not touch the development roller or the development roller gear.

2) Use caution not to drop the cartridge or to damage it.

3) If the cartridge has not been shaken well, the machine takes a

longer time to initialize the development unit, or an error message or

SC350 is displayed. When either of them is displayed, turn the main

switch off and on.

B156I511.WMF

Page 21

10 February 2005 COPIER (B156/B220)

1-9

Installation

7. Reinstall the development units, and close the left cover.

NOTE: A white line or band may appear on one end of the paper if a

development unit is incorrectly installed. To correct this, pull out the

development unit partially (about 30 mm) and slowly reinstall it.

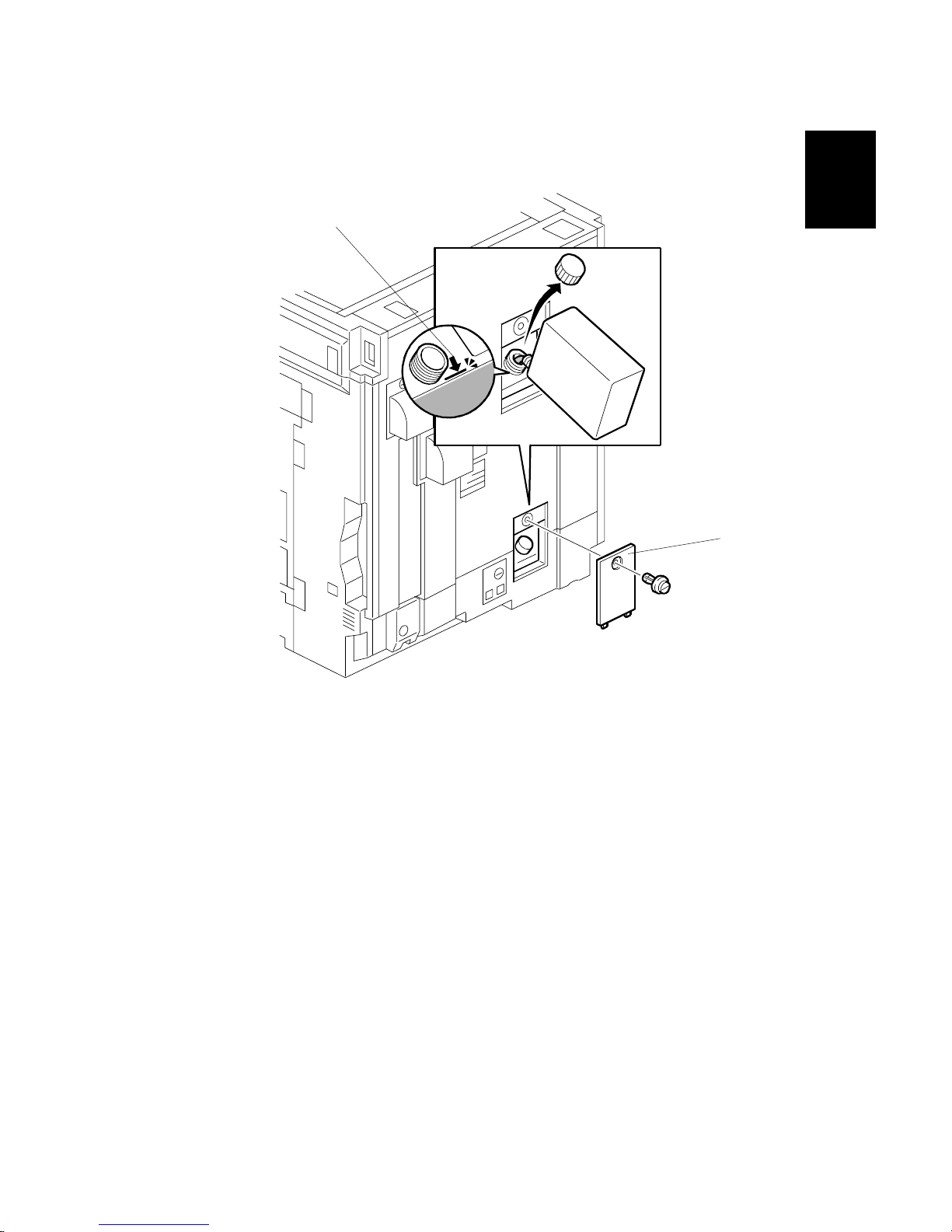

8. Remove the oil tank cover [A] (1 clip), and fill the oil tank to the maximum line.

NOTE: Do not fill the oil tank past the arrow [B].

B156I513.WMF

[A]

[B]

Page 22

COPIER (B156/B220) 10 February 2005

1-10

9. Install the filters [A] and ducts [B] as shown.

10. Attach the appropriate model name decal [C] with cover [D] to the front cover.

11. Attach the caution decal [E] to the tray. Attach the copy prohibition decal [F] to

the top.

12. Pull the paper tray out, and adjust the side guides and end guide to match the

paper size.

NOTE: To move the side guides, first pull out the tray fully, then push down the

green lock at the rear inside the tray.

13. Attach the appropriate paper tray number decals [J] to the paper trays.

NOTE: Paper tray number decals are also used for the optional paper tray or

the optional LCT. Keep any remaining decals for use with these

optional units.

B156I514.WMF

B156I516.WMF

B156I515.WMF

[A]

[B]

[A]

[A]

[J]

[C]

[D]

[E]

[F]

Page 23

10 February 2005 COPIER (B156/B220)

1-11

Installation

14. If the optional bridge unit will not be installed: Swing the sensor feeler [A]

out.

15. Install the optional ARDF (EU model only) or the optional platen cover (see

ARDF Installation or Platen Cover Installation).

16. Install the stamp cartridge [B] if the ARDF [C] was installed.

17. Attach the cloth holder [D] to the left side of the scanner as shown. Then put

the cloth [E] in the cloth holder if the ARDF was installed.

B156I517.WMF

B502I006.WMF

B810I504.WMF

[A]

[B]

[C]

[D]

[E]

Page 24

COPIER (B156/B220) 10 February 2005

1-12

18. Plug in the machine and turn the main power switch on. The machine

automatically performs the initialization procedure. After this has finished, the

Start button LED turns green.

19. Make copies of image samples (text, photo, and text/photo modes).

20. Perform Automatic Color Calibration (ACC).

NOTE: Since this machine has been subject to color adjustment using

Automatic Color Calibration (ACC) at the factory, there is no need to

make automatic color calibration again if the customer is satisfied with

the image sample. If the customer is not satisfied, do the following.

1) Print the ACC test pattern (UP mode – Maintenance – ACC – Start).

2) Place the printout on the exposure glass.

3) Place 10 sheets of white paper on top of the test chart. Then, close

the ADF or platen cover.

4) Press “Start Scanning” on the LCD panel. The machine performs the

ACC.

21. If you want to enable the Ethernet NIB function, set SP5-985-001 to “1: enable”.

If you want to enable the USB function, set SP5-985-002 to “1: enable”.

NOTE: The defaults are “0: disabled”.

22. Make sure that the sample image has been copied normally.

23. Remove the double-sided tape from

the manual holder. Then attach it [A] to

the left side of the copier (! x 2).

NOTE: When you install the 1,000-Sheet

Finisher (B408), attach the manual

holder a different location.

B156I532.WMF

[A]

Page 25

10 February 2005 PAPER TRAY UNIT (B456)

1-13

Installation

1.3 PAPER TRAY UNIT (B456)

1.3.1 ACCESSORY CHECK

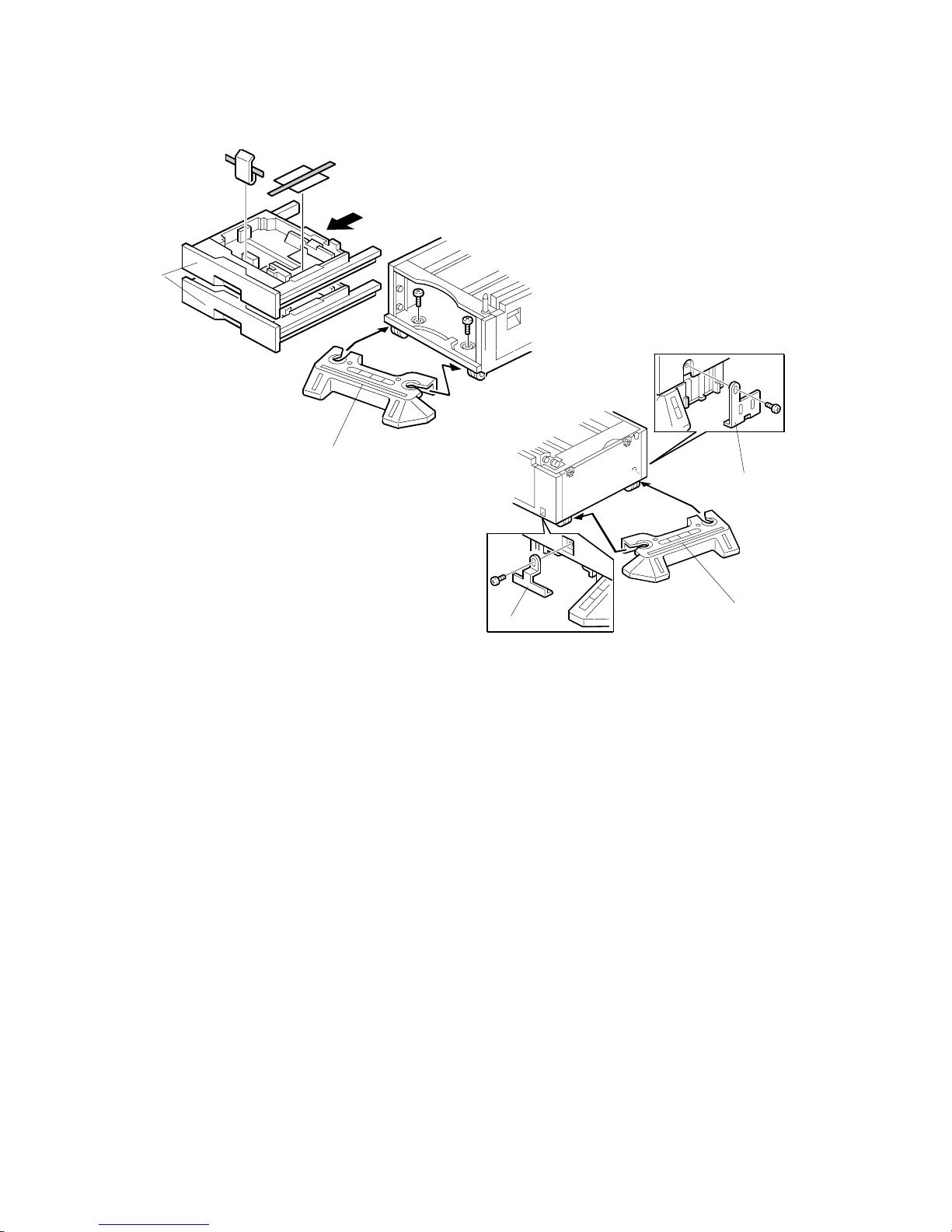

Check the quantity and condition of the accessories against the following list.

No. Description Q’ty

1 Right Stand Bracket 1

2 Left Stand Bracket 1

3 Securing Bracket 2

4 Front Stand 1

5 Rear Stand 1

6 Screw – M4x10 4

7 Knob Screw 2

8 Stepped Screw 2

1.3.2 INSTALLATION PROCEDURE

!CAUTION

Unplug the machine power cord before starting the following procedure.

1. Remove the strips of tape.

B456I001.WMF

B456I002.WMF

1 2 3

4 5

6 7 8

Page 26

PAPER TRAY UNIT (B456) 10 February 2005

1-14

2. Remove the paper trays [A] from the paper tray unit and remove the shipping

retainers.

3. Install the front stand [B] (! x2).

4. Install the rear stand [C].

5. Attach the two stand brackets [D] (! x1 each).

B456I103.WMF

B456I104.WMF

[A]

[B]

[D]

[C]

[D]

Page 27

10 February 2005 PAPER TRAY UNIT (B456)

1-15

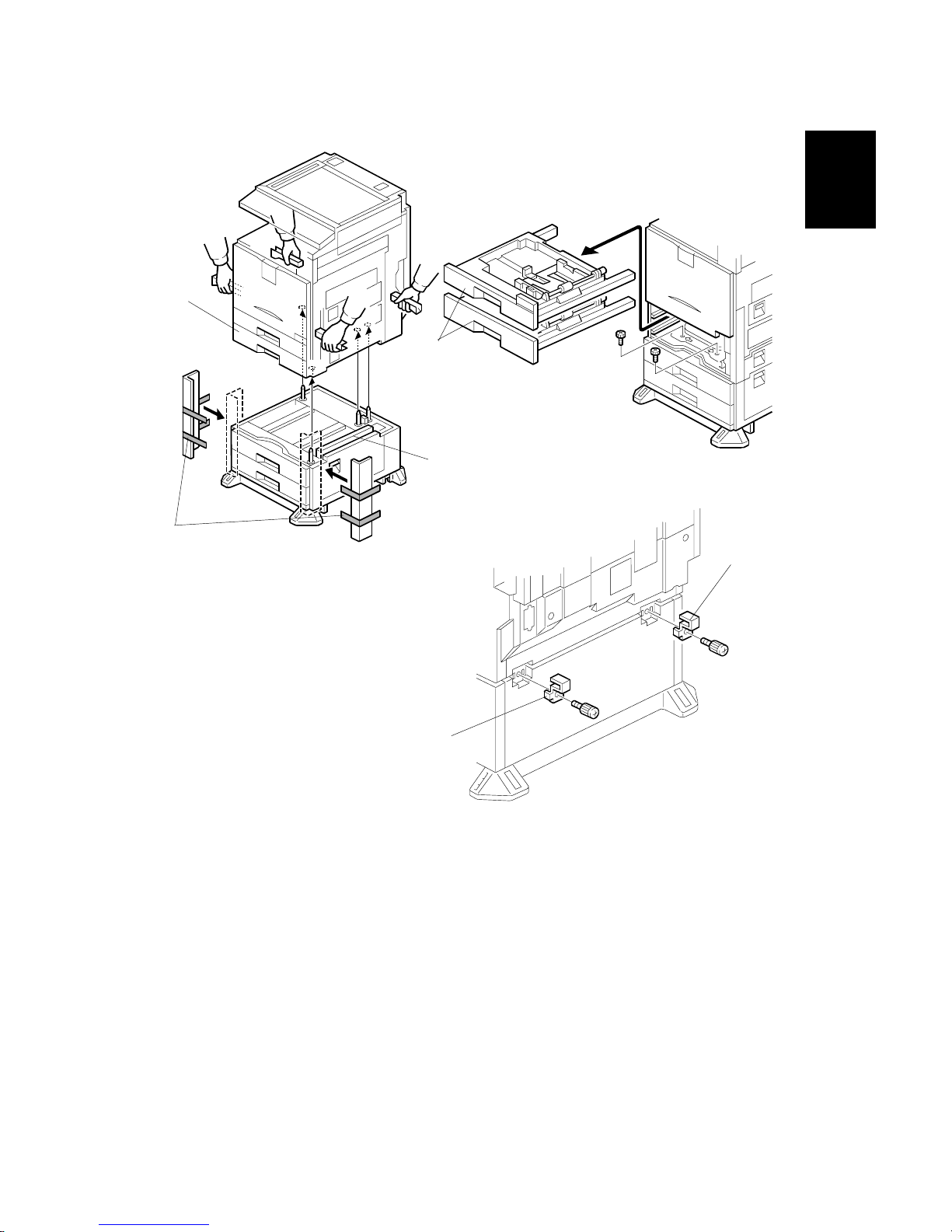

Installation

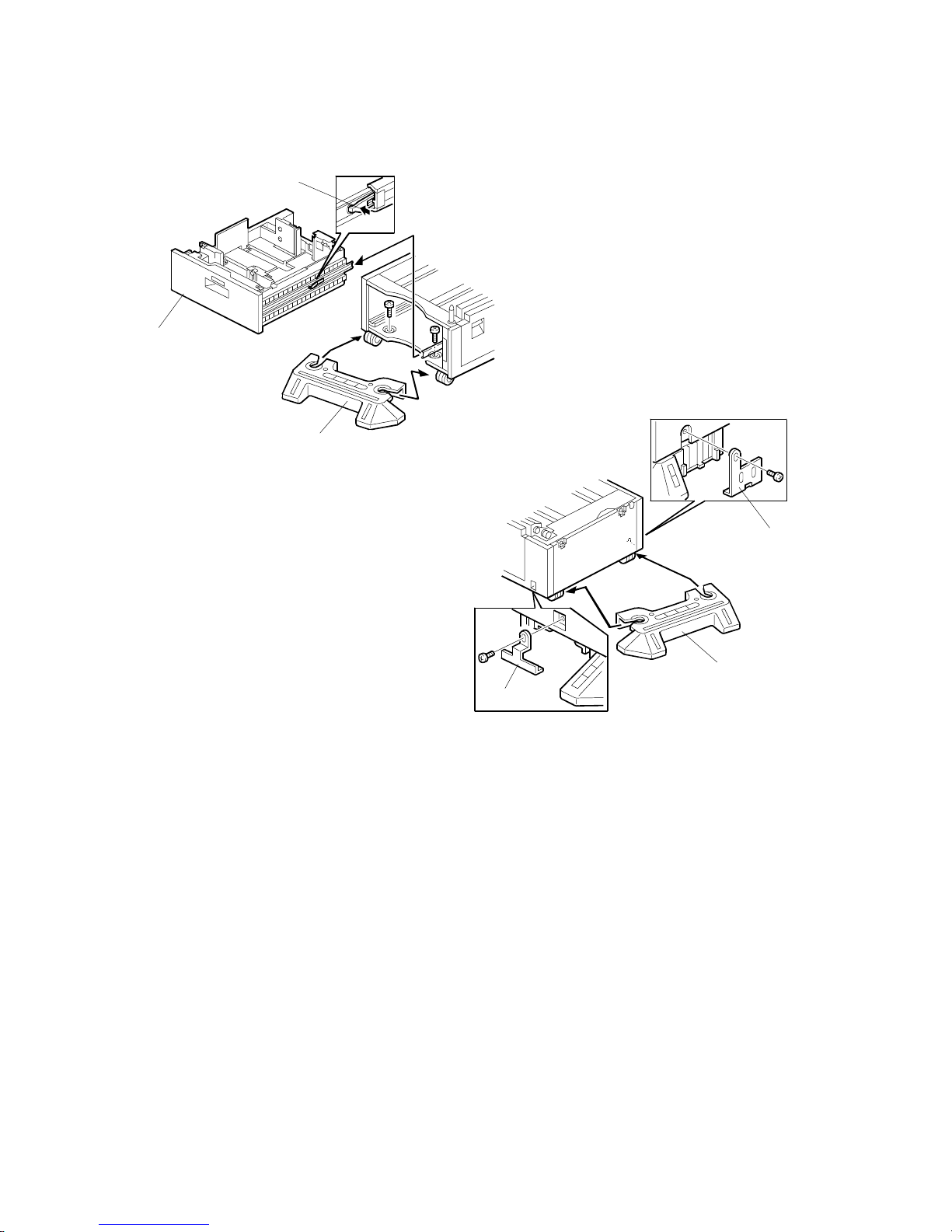

6. Attach the cardboard guides [A] to each side of the paper tray unit [B].

7. Set the copier [C] on the paper tray unit [B]. Use the cardboard guides.

8. Remove the cardboard guides from the paper tray unit.

9. Remove the paper trays [D] from the copier and secure the paper tray unit

(! x2).

10. Attach a securing bracket [E] to each side of the paper tray unit, as shown

(! x1 each).

B456I215.WMF

B456I106.WMF

B456I212.WMF

[A]

[B]

[D]

[E]

[E]

[C]

Page 28

10 February 2005

1-16

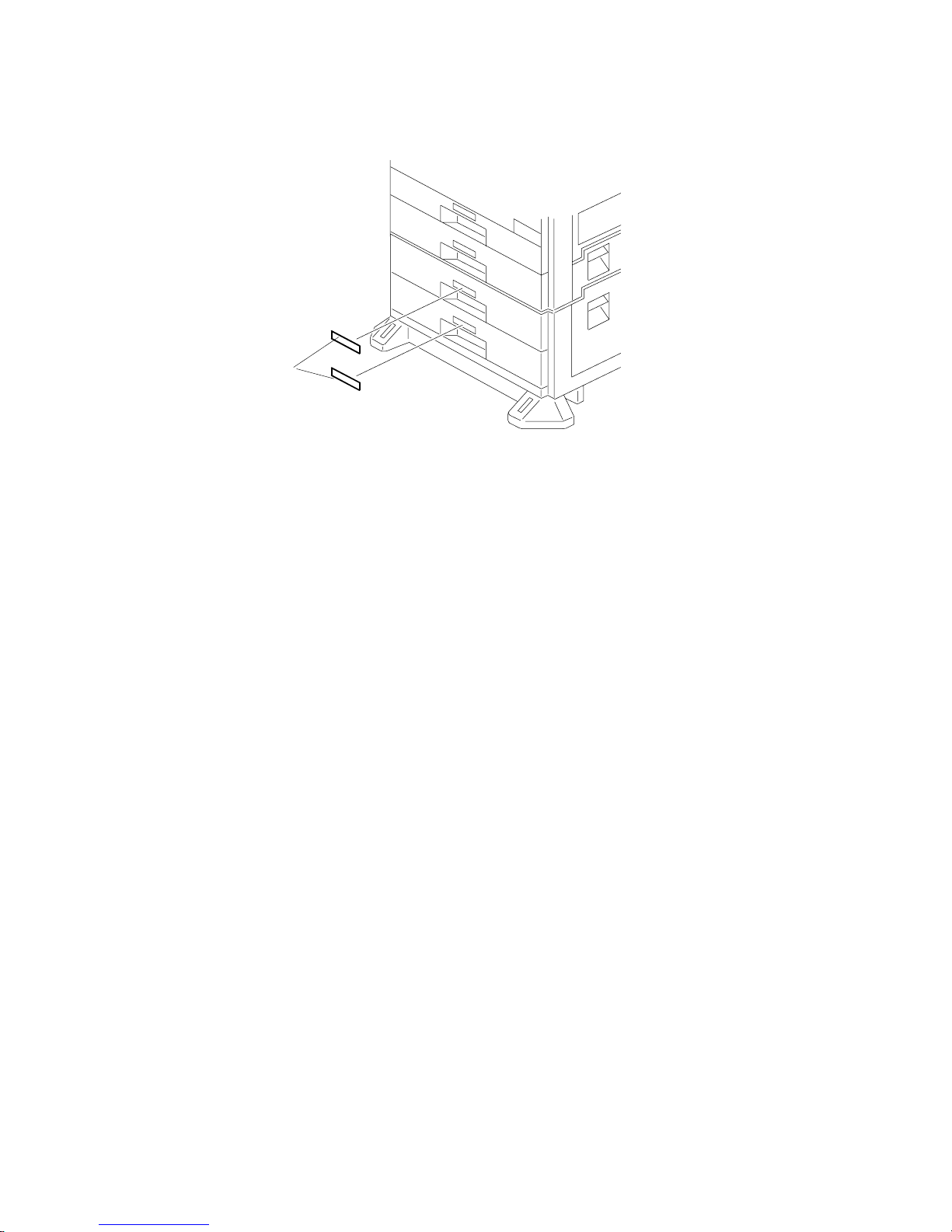

11. Reinstall the paper trays and attach the appropriate paper tray number decal

[A] to the paper tray.

NOTE: The paper tray number decal is in the accessory box for the main

copier.

12. Load paper into the paper trays.

13. Turn on the main switch.

14. Check the machine’s operation and copy quality.

B456I004.WMF

[A]

Page 29

10 February 2005 LCT (B457)

1-17

Installation

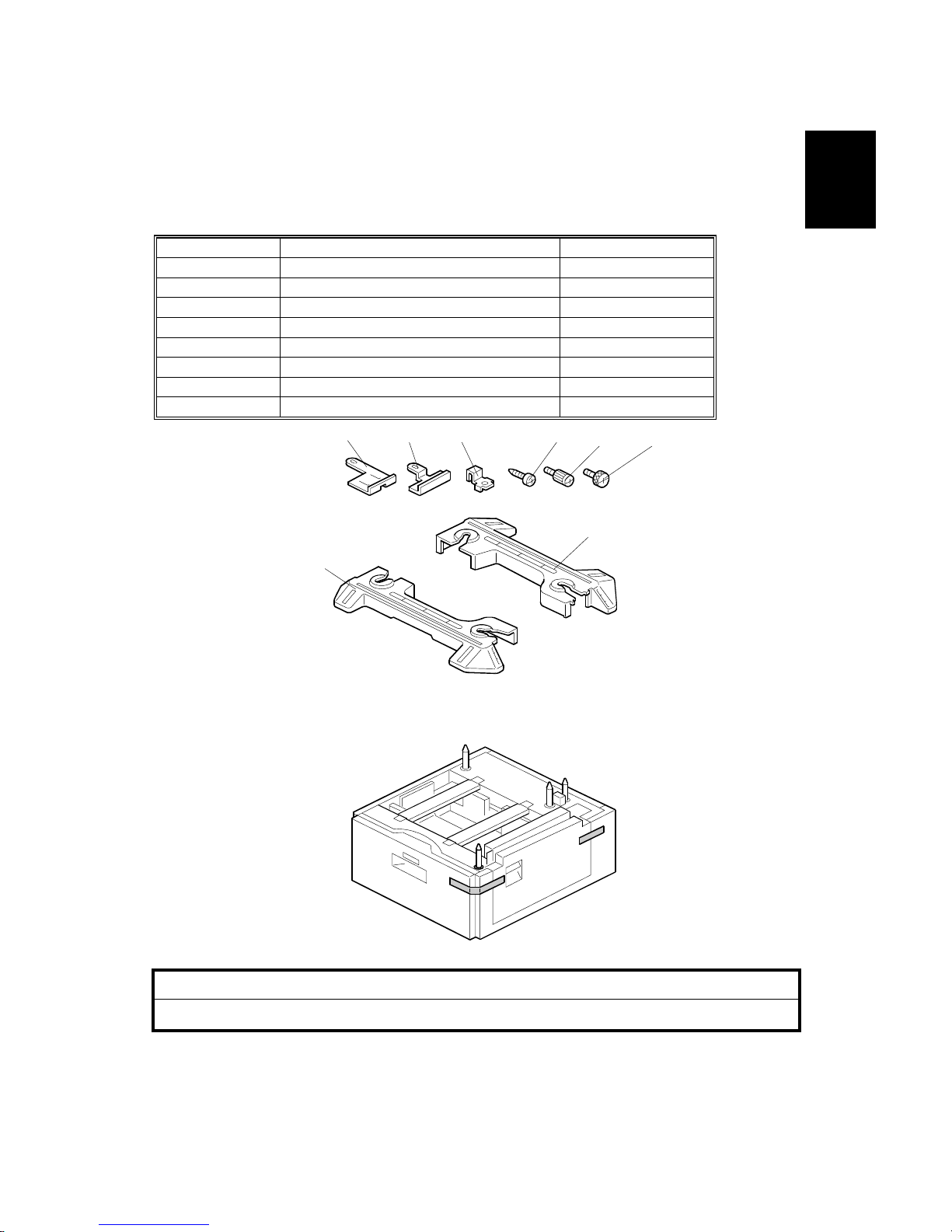

1.4 LCT (B457)

1.4.1 ACCESSORY CHECK

Check the quantity and condition of the accessories against the following list.

No. Description Q’ty

1 Right Stand Bracket 1

2 Left Stand Bracket 1

3 Securing Bracket 2

4 Front Stand 1

5 Rear Stand 1

6 Screw – M4x10 4

7 Knob Screw 2

8 Stepped Screw 2

1.4.2 INSTALLATION PROCEDURE

!CAUTION

Unplug the machine power cord before starting the following procedure.

1. Remove the strips of tape.

B457I007.WMF

B457I001.WMF

1

2 3

4

5

6

7 8

Page 30

LCT (B457) 10 February 2005

1-18

2. While pressing the stopper [A] attached to the guide rail, pull out the large

capacity tray [B].

3. Install the front stand [C] (! x2).

4. Install the rear stand [D].

5. Attach the two stand brackets [E] (! x1 each).

B457I003.WMF

B457I104.WMF

[A]

[B]

[E]

[D]

[E]

[C]

Page 31

10 February 2005 LCT (B457)

1-19

Installation

6. Attach the cardboard guides [A] to each side of the LCT [B].

7. Set the copier [C] on the LCT [B]. Use the cardboard guides.

8. Remove the cardboard guides from the LCT.

9. Remove the paper trays [D] from the copier and secure the LCT (! x2).

10. Attach a securing bracket [E] to each side of the LCT, as shown (! x1 each).

B456I215.WMF

B457I152.WMF

B457I156.WMF

[A]

[B]

[D]

[E]

[E]

[C]

Page 32

LCT (B457) 10 February 2005

1-20

11. Reinstall the paper trays and attach the appropriate paper tray number decal

[A] to the LCT.

NOTE: The paper tray number decal is in the accessory box for the main

copier.

12. Load paper into the LCT.

13. Turn on the main switch.

14. Check the machine’s operation and copy quality.

B457I005.WMF

[A]

Page 33

10 February 2005 AUTO REVERSE DOCUMENT FEEDER (B810)

1-21

Installation

1.5 AUTO REVERSE DOCUMENT FEEDER (B810)

1.5.1 ACCESSORY CHECK

Check the quantity and condition of the accessories against the following list.

No. Description Q’ty

1 Scale Guide 1

2 DF Exposure Glass 1

3 Stud Screw 2

4 Knob Screw 2

5 Original Size Decal 2

6 Screwdriver Tool 1

7 Cloth 1

8 Holder 1

1.5.2 INSTALLATION PROCEDURE

!CAUTION

Unplug the copier power cord before starting the following procedure.

1. Remove the strips of tape.

B386I500.WMF

B386I101.WMF

1

2

4

5

3

6

7

8

Page 34

AUTO REVERSE DOCUMENT FEEDER (B810) 10 February 2005

1-22

2. Remove the left scale [A] (! x 2).

3. Peel off the backing [B] of the double-sided tape attached to the glass holder.

4. Place the DF exposure glass [C] on the glass holder.

NOTE: When installing the DF exposure glass, make sure that the white point

[D] is on the lower front side of the glass, as shown.

5. Peel off the backing [E] of the double-sided tape attached to the rear side of the

scale guide [F], then install the scale guide [F] (! x 2 removed in step 2).

6. Install two stud screws [G].

7. Mount the DF on the copier, then slide the DF to the front as shown.

8. Secure the DF unit with two screws [H].

9. Connect the cable [I] to the copier.

B386I107.WMF

B386I108.WMF

[H]

[I]

[H]

[A]

[B]

[C]

[D]

[E]

[F]

[G]

[G]

Page 35

10 February 2005 AUTO REVERSE DOCUMENT FEEDER (B810)

1-23

Installation

10. Peel off the platen sheet [A] and place it on the exposure glass.

11. Line up the rear left corner of the platen sheet flush against corner [B] on the

exposure glass.

12. Close the ARDF.

13. Attach the appropriate scale decal [C] as shown.

14. Turn the main power switch on. Then check if the document feeder works

properly.

15. Make a full size copy. Check that the registrations (side-to-side and leading

edge) and image skew are correct. If they are not, adjust the registrations and

image skew (refer to Replacements and Adjustments – Copy Adjustments).

B386I110.WMF

B386I111.WMF

B386I501.WMF

[A]

[B]

[C]

Page 36

INTERCHANGE UNIT (B481) 10 February 2005

1-24

1.6 INTERCHANGE UNIT (B481)

1.6.1 ACCESSORY CHECK

Check the quantity and condition of the components against the following list.

No. Description Q’ty

1 Interchange Unit 1

B481I101.WMF

Page 37

10 February 2005

1-25

Installation

1.6.2 INSTALLATION PROCEDURE

!CAUTION

Unplug the copier power cord before starting the following procedure.

1. Remove all tapes.

2. Open the right cover [A] of the copier.

3. Open cover [B] and remove it.

4. Remove the connector cover [C] (! x1).

5. Open the cover [D] of the interchange unit.

6. Install the interchange unit [E] (" x1).

NOTE: Take care not to pinch the harness at the front side.

7. Secure the interchange unit with the knob screws [F].

8. Reinstall the connector cover [G] which was removed in step 4 (! x 1).

B481I103.WMF

B481I102.WMF

[A]

[B]

[C]

[D][E]

[F]

[F]

[G]

Page 38

1 BIN TRAY UNIT (B480) 10 February 2005

1-26

1.7 1 BIN TRAY UNIT (B480)

1.7.1 ACCESSORY CHECK

Check the quantity and condition of the components against the following list.

No. Description Q’ty

1 1-Bin Tray Unit 1

2 Tray 1

3 Sub-Tray 1

4 Tray Guide 1

5 Shield Mylar 1

6 Sub Paper Guide 1

7 Paper Guide 1

8 Tapping Screw M3x8 2

B480I101.WMF

1

2

3

4

5

6

7

8

Page 39

10 February 2005 1 BIN TRAY UNIT (B480)

1-27

Installation

1.7.2 INSTALLATION PROCEDURE

!CAUTION

Unplug the copier power cord before starting the following procedure.

NOTE: Before installing this 1-bin tray unit, the optional interchange unit

(B481) must be installed.

1. Remove all tapes.

2. If the optional bridge unit has been installed, open the right jam removal cover

[A] of the bridge unit.

If the optional bridge unit is not installed, skip this step.

B480I107.WMF

[A]

Page 40

1 BIN TRAY UNIT (B480) 10 February 2005

1-28

3. Peel off the backing of the double-sided tape attached to the shield mylar [A].

Then attach the shield mylar to the 1-bin unit, as shown.

4. If the front right cover [B] is installed, remove it (! x1).

5. Remove the cover [C].

6. Install the 1-bin tray unit [D] (! x1).

7. Disconnect the connector [E] and remove the LED board [F].

B480I108.WMF

B480I102.WMF

B480I103.WMF

[A]

[B]

[C]

[D]

[E]

[F]

Page 41

10 February 2005 1 BIN TRAY UNIT (B480)

1-29

Installation

8. Install the LED board [A] on the front right cover (! x1).

9. Reinstall the front right cover [B] (" x2, ! x1).

10. Peel off the backing of the double-sided tape attached to the paper guide [C].

Then attach the paper guide to the underside of the scanner unit as shown.

11. Peel off the backing of the double-sided tape attached to the sub paper guide

[D]. Then attach the sub paper guide to the underside of the scanner unit as

shown.

12. Install the tray guide [E].

13. Install the tray [F].

14. Install the sub-tray [G].

15. Turn on the main power switch and check the 1-bin tray unit operation.

B480I109.WMF

B480I104.WMF

B480I106.WMF

[A]

[B]

[C]

[D]

[E]

[F]

[G]

Page 42

SHIFT TRAY (B510) 10 February 2005

1-30

1.8 SHIFT TRAY (B510)

1.8.1 ACCESSORY CHECK

Check the quantity and condition of the components against the following list.

No. Description Q’ty

1 Shift Tray Unit 1

2 Paper Guide - Large 1

3 Paper Guide - Small 2

4 Stepped Screw 1

5 Core 1

1.8.2 INSTALLATION PROCEDURE

!CAUTION

Unplug the copier power cord before starting the following procedure.

1. Remove all tapes (see the diagram at the top of the page).

2. Remove the covers [A] (! x1).

3. Replace screw [B] with a stepped screw [C].

4. Install the large paper guide [D] and two small paper guides [E], as shown.

B510I111.WMF

B510I102.WMF

[A]

[D]

[E]

[E]

1

2

3

4

[B]

[C]

5

Page 43

10 February 2005 SHIFT TRAY (B510)

1-31

Installation

5. Remove the connector cover [A] (! x 1).

6. Remove the rear cover [B] (! x2).

7. Pass the harnesses [C] through the opening [D], and install the shift tray unit

[E], as shown.

NOTE: 1) Set the shift tray on the stepped screw.

2) The shift tray must be installed under the paper guides [F] installed

in step 4.

B510I103.WMF

B510I211.WMF

[D]

[C]

[B]

[E]

[F]

[A]

Page 44

SHIFT TRAY (B510) 10 February 2005

1-32

8. Remove the screws [A]. (! x 6)

9. Remove the SD-card slot cover [B]. (! x 1)

10. Open the controller box [C].

11. Connect the harness [D], as shown.

12. Attach the harnesses with clamps [E]. Then attach the core [F].

NOTE: Make sure that the core [F] does not cause damage to the harnesses.

13. Assemble the machine.

14. Turn on the main power switch.

15. Check the shift tray operation.

B510I201.WMF

B510I202.WMF

B510I203.WMF

[A]

[A] [B]

[C]

[D]

[E]

[F]

Page 45

10 February 2005 BY-PASS FEED UNIT (B490)

1-33

Installation

1.9 BY-PASS FEED UNIT (B490)

1.9.1 ACCESSORY CHECK

Check the quantity and condition of the components against the following list.

No. Description Q’ty

1 By-pass Tray Unit 1

2 Tapping Screw 3

3 Decal 1

1.9.2 INSTALLATION PROCEDURE

!CAUTION

Unplug the copier power cord before starting the following procedure.

1. Remove all tapes (see the diagram at the top of the page).

2. Remove the entrance cover [A] (!x 2).

B490I001.WMF

B490I113.WMF

1

2

3

[A]

Page 46

BY-PASS FEED UNIT (B490) 10 February 2005

1-34

3. Install the by-pass tray unit [A] (! x3, " x1).

4. Attach the decal [B] as shown.

5. Turn the main power switch on and check the by-pass tray function.

6. Go into the SP mode. Change these SP settings.

SP1003

Default

(No By-pass tray)

By-pass tray

installed

001 0 2

002 –2 0

003 –2 0

004 0 2

Make a copy from the by-pass tray. Then check the registration.

B490I114.WMF

B490I002.WMF

[A]

[B]

Page 47

10 February 2005 DUPLEX UNIT (B509)

1-35

Installation

1.10 DUPLEX UNIT (B509)

1.10.1 ACCESSORY CHECK

Check the quantity and condition of the accessories against the following list.

No. Description Q’ty

1 Duplex Unit 1

2 Upper Bracket 1

3 Rear Holder Bracket 1

4 Front Holder Bracket 1

5 Clip 2

6 Tapping Screw – M4x6 3

7 Tapping Screw – M3x6 1

B509I101.WMF

1

2

3

4

5

6

7

Page 48

DUPLEX UNIT (B509) 10 February 2005

1-36

1.10.2 INSTALLATION PROCEDURE

!CAUTION

Unplug the copier power cord before starting the following procedure.

NOTE: Before installing the duplex unit, the optional interchange unit (B481)

must be installed.

1. Remove all tapes (see the previous page).

2. Remove five covers [A] (! x1).

3. Install three brackets [B] (! x1 each – M4x6).

B509I102.WMF

B509I103.WMF

[A]

[A]

[A]

[B]

[B]

Page 49

10 February 2005 DUPLEX UNIT (B509)

1-37

Installation

4. Set the duplex unit [A] on the brackets [B] (1 clip).

5. Attach the link [C] to the shaft [D] and secure it with the clip.

6. Remove the connector cover [E] (! x1).

7. Connect the cable [F] and secure the grounding wire [G] (! x1).

8. Install the connector cover.

9. Turn on the main power switch and check the duplex unit function.

B509I104.WMF

B509I105.WMF

[A]

[B]

[C]

[D]

[B]

[F]

[E]

[G]

Page 50

BRIDGE UNIT (B482) 10 February 2005

1-38

1.11 BRIDGE UNIT (B482)

1.11.1 ACCESSORY CHECK

Check the quantity and condition of the accessories against the following list.

No. Description Q’ty

1 Bridge Unit 1

2 Rear Joint Bracket 1

3 Front Joint Bracket 1

4 Knob Screw 1

5 Screw – M3x6 1

6 Screw – M4x14 4

7 Core 1

1.11.2 INSTALLATION PROCEDURE

!CAUTION

Unplug the copier power cord before starting the following procedure.

1. Remove all tapes.

2. If the sensor feeler [A] is out, fold it away into the machine.

B482I151.WMF

B482I500.WMF

[A]

1

2

3

4

5 6

7

Page 51

10 February 2005 BRIDGE UNIT (B482)

1-39

Installation

3. Remove the front right cover [A] (! x1).

4. Remove two covers [B] (! x1 each).

5. Remove the connector cover [C] (! x 1).

6. Remove the rear cover [D] (! x2).

7. Pass the harnesses [E] through the opening [F], and install the bridge unit [G]

(! x2).

8. Reinstall the front right cover.

B482I102.WMF

B482I103.WMF

B482I209.WMF

[A]

[B]

[B]

[E]

[F]

[G]

[D]

[C]

Page 52

BRIDGE UNIT (B482) 10 February 2005

1-40

9. Remove the screws [A] (! x 6).

10. Remove the SD-card slot cover [B] (! x 1).

11. Open the controller box [C].

B482I207.WMF

B482I208.WMF

[A]

[A]

[B]

[C]

Page 53

10 February 2005 BRIDGE UNIT (B482)

1-41

Installation

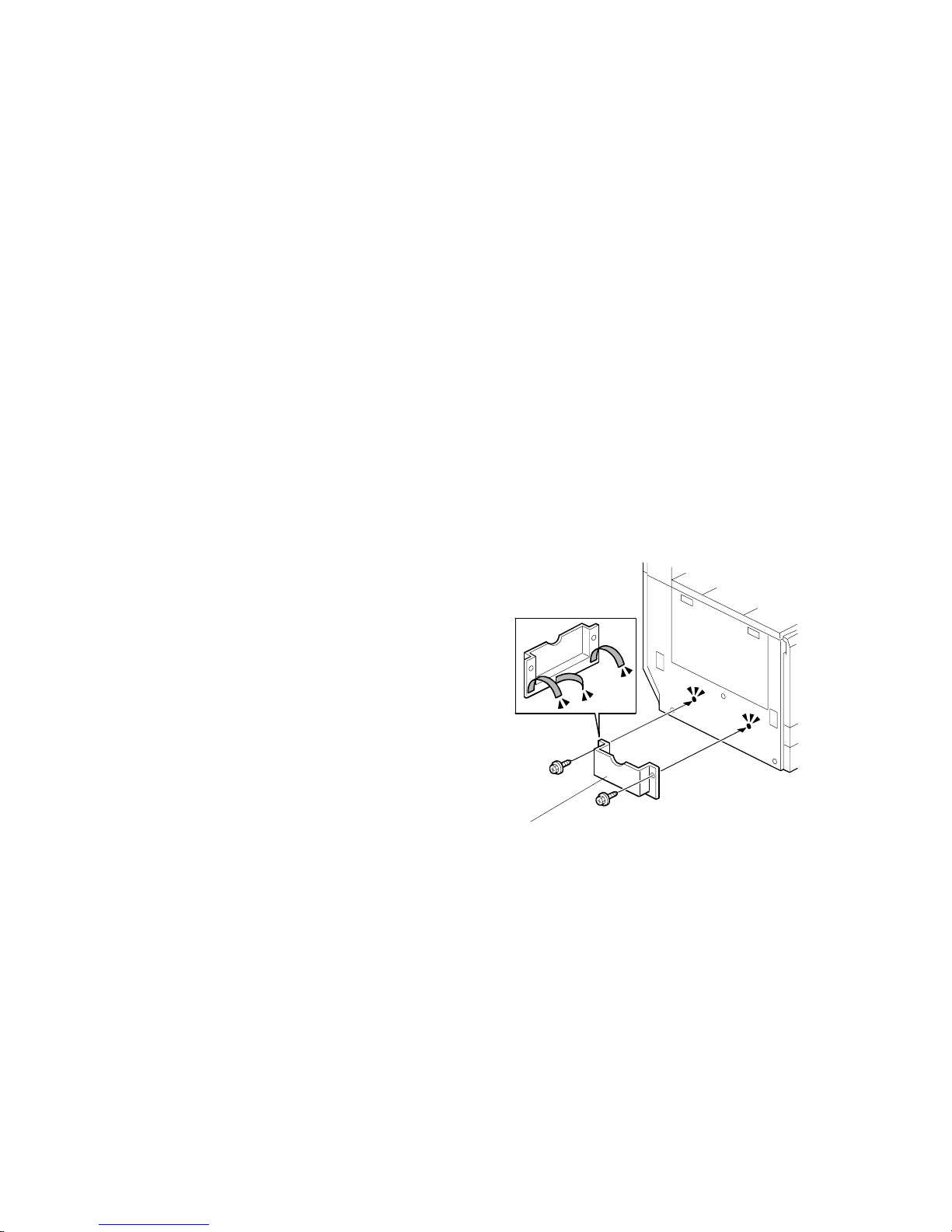

12. Connect the harnesses [A], as shown.

13. Attach the harnesses with clamps [B].

14. Attach the core [C].

NOTE: Make sure that the core does not cause damage to the harnesses.

15. Reinstall the rear cover.

16. When the finisher (Machine code:

B408) will be installed, attach the

front joint bracket [D] and rear joint

bracket [E] (! x2 each).

17. Install the optional finisher (refer to the

finisher installation procedure).

B482I206.WMF

B482I105.WMF

[A]

[C]

[B]

[E]

[D]

Page 54

1000-SHEET FINISHER (B408) 10 February 2005

1-42

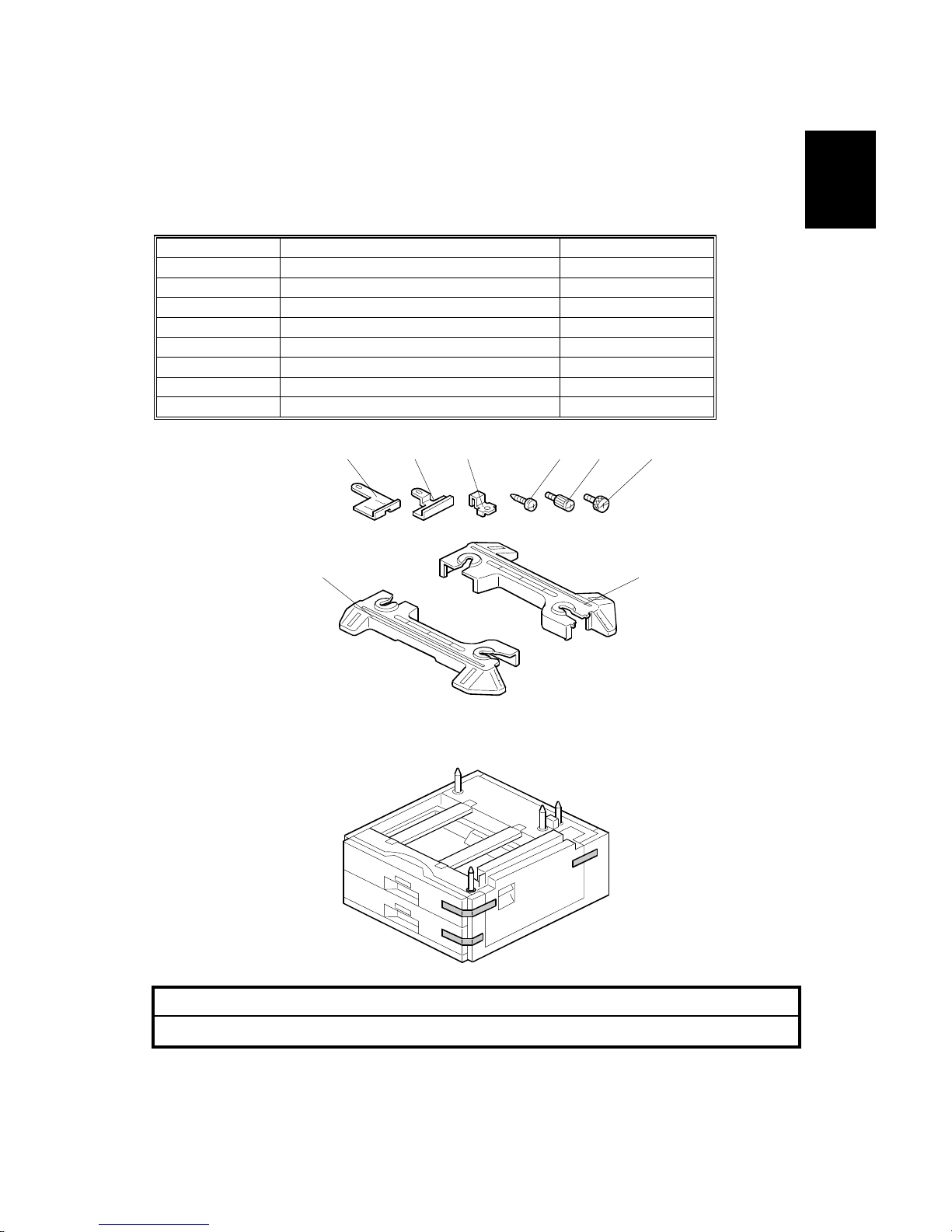

1.12 1000-SHEET FINISHER (B408)

1.12.1 ACCESSORY CHECK

Check the quantity and condition of the accessories against the following list.

No. Description Q’ty

For

B022/B027/B031/

B089/B093/B097

For

B051/B052/

B156/B220

For

B079/B082/

B135/B138

1 Front Joint Bracket 1

!

---

!

2 Rear Joint Bracket 1

!

--- ---

3 Rear Joint Bracket 1 --- ---

!

4 Grounding Plate 1

!

---

!

5 Copy Tray 1

! ! !

6 Staple Position Decal 1

! ! !

7 Screw - M4 x 14 4 ! (Use 3) --- ! (Use 4)

8 Knob Screw - M4 x 10 1

! ! !

9 Screw - M3 x 8 1

!

---

!

10 Knob Screw - M3 x 8 1

! ! !

! = Necessary, --- = Not necessary

B408I502.WMF

1

2

3

4

5

8

9

6

7

10

Page 55

10 February 2005 1000-SHEET FINISHER (B408)

1-43

Installation

1.12.2 INSTALLATION PROCEDURE

!CAUTION

Unplug the main machine power cord before starting the following

procedure.

NOTE: The following options must be installed before installing this finisher.

- Bridge Unit (B482)

- Paper Tray Unit (B456) or LCT (B457)

Also, the optional adjustment table (B488) is required.

1. Unpack the finisher and remove the tapes.

B408I102.WMF

B408I103.WMF

[A]

Page 56

1000-SHEET FINISHER (B408) 10 February 2005

1-44

2. Unpack the adjustment table (B488).

3. Set the finisher [A] on the adjustment table [B] and secure the finisher

(! x 1).

4. Install the grounding plate [C] which is in the accessory box for the adjustment

table (! x 2).

5. Open the front door [D], then pull the locking lever [E].

6. Align the finisher on the joint brackets, and lock it in place by pushing the

locking lever.

7. Secure the locking lever (1 knob screw - M3 x 8) and close the front door.

8. Install the copy tray [F] (1 knob screw - M4 x 10).

9. Connect the finisher cable [G] to the main machine.

B408I114.WMF

B408I152.WMF

[D]

[E]

[F]

[G]

[A]

[B]

[C]

Page 57

10 February 2005 1000-SHEET FINISHER (B408)

1-45

Installation

10. Attach the staple position decal [A] to the ARDF as shown.

11. Turn on the main power switch and check the finisher operation.

B408I501.WMF

[A]

Page 58

500-SHEET FINISHER (B458) 10 February 2005

1-46

1.13 500-SHEET FINISHER (B458)

1.13.1 ACCESSORY CHECK

Check the quantity and condition of the accessories against the following list.

No. Description Q’ty

1 Unit Holder 1

2 Entrance Guide 1

3 Shift Tray 1

4 Snap Ring 2

5 Knob Screw 2

B458I102.WMF

1

2

3

4

5

Page 59

10 February 2005 500-SHEET FINISHER (B458)

1-47

Installation