Page 1

TC-II

Operating Instructions

Zbrh021e.eps

Read this manual carefully before you use this product and keep it handy for future

reference.

For safety, please follow the instructions in this manual.

Page 2

TC-II Operating Instructions

Printed in Japan

UE USA C593-8602

Page 3

Introduction

This manual contains detailed instructions on the operation and maintenance of this machine. To get

maximum versatility from this machine all operators should carefully read and follow the instructions in

this manual. Please keep this manual in a handy place near the machine.

Please read the Safety Information before using this machine. It contains important information related

to USER SAFETY and PREVENTING EQUIPMENT PROBLEMS.

Notes:

Some illustrations might be slightly different from your machine.

Certain options might not be available in some countries. For details, please contact your local dealer.

Two kinds of size notation are employed in this manual. With this machine refer to the inch version.

Power Source

120V, 60Hz, 5.5 A or more

Please be sure to connect the power cord to a power source as above. For details about power source,

⇒ P.45 “Power Connection”.

Page 4

Note to users in the United States of America

Notice:

This equipment has been tested and found to comply with the limits for a Class B digital device, pursuant to Part 15 of the FCC Rules. These limits are designed to provide reasonable protection against

harmful interference in a residential installation. This equipment generates, uses and can radiate radio

frequency energy and, if not installed and used in accordance with the instructions, may cause harmful

interference to radio communications. However, there is no guarantee that interference will not occur

in a particular installation. If this equipment does cause harmful interference to radio or television reception, which can be determined by turning the equipment off and on, the user is encouraged to try to

correct the interference by one more of the following measures:

Reorient or relocate the receiving antenna.

Increase the separation between the equipment and receiver.

Connect the equipment into an outlet on a circuit different from that to which the receiver is

connected.

Consult the dealer or an experienced radio /TV technician for help.

Warning

Changes or modifications not expressly approved by the party responsible for compliance could void

the user's authority to operate the equipment.

Note to users in Canada

Note:

This Class B digital apparatus complies with Canadian ICES-003.

Remarque concernant les utilisateurs au Canada

Avertissement:

Cet appareil numérique de la classe B est conforme à la norme NMB-003 du Canada.

In accordance with IEC 60417, this machine uses the following symbols for the main switch:

aaaa means POWER ON.

bbbb means POWER OFF.

Page 5

Safety Information

R

R

When using your equipment, the following safety precautions should always be

followed.

Safety During Operation

In this manual, the following important symbols are used:

WARNING:

CAUTION:

Indicates a potentially hazardous situation which, if instructions

are not followed, could result in death or serious injury.

Indicates a potentially hazardous situation which, if instructions are not

followed, may result in minor or moderate injury or damage to property.

R WARNING:

• Connect the power cord directly into a wall outlet and never use an extension cord.

• Disconnect the power plug (by pulling the plug, not the cable) if the

power cable or plug becomes frayed or otherwise damaged.

• To avoid hazardous electric shock, do not remove any covers or

screws other than those specified in this manual.

• To avoid injury, do not touch moving parts or insert your fingers in the

opening during machine operation. To de-energize moving parts,

open the front cover.

• Turn off the power and disconnect the power plug (by pulling the plug,

not the cable) if any of the following conditions exists:

• You spill something into the equipment.

• You suspect that your equipment needs service or repair.

• Your equipment's cover has been damaged.

i

Page 6

R CAUTION:

• Protect the equipment from dampness or wet weather, such as rain, snow,

and so on.

• Unplug the power cord from the wall outlet before you move the equipment.

While moving the equipment, you should take care that the power cord will

not be damaged under the equipment.

• When you disconnect the power plug from the wall outlet, always pull the

plug (not the cable).

• Do not allow paper clips, staples, or other small metallic objects to fall inside

the equipment.

• For environmental reasons, do not dispose of the equipment or expended

supply waste at household waste collection points. Disposal can take place

at an authorized dealer or at appropriate collection sites.

• Be careful not to cut yourself on any sharp edges when you reach inside the

machine to remove misfed sheets of paper or masters.

• Our products are engineered to meet high standards of quality and functionality, and we recommend that you only use the expendable supplies available at an authorized dealer.

ii

Page 7

How to Read This Manual

R

R

Symbols

In this manual, the following symbols are used:

WARNING:

This symbol indicates a potentially hazardous situation that might result in

death or serious injury when you misuse the machine without following the instructions under this symbol. Be sure to read the instructions, all of which are described in the Safety Information section.

CAUTION:

This symbol indicates a potentially hazardous situation that might result in minor or moderate injury or property damage that does not involve personal injury

when you misuse the machine without following the instructions under this

symbol. Be sure to read the instructions, all of which are described in the Safety

Information section.

* The statements above are notes for your safety.

Important

If this instruction is not followed, paper might be misfed, originals might be

damaged, or data might be lost. Be sure to read this.

Preparation

This symbol indicates the prior knowledge or preparations required before operating the machine.

Note

This symbol indicates precautions for operation, or actions to take after misoperation.

Limitation

This symbol indicates numerical limits, functions that cannot be used together,

or conditions in which a particular function cannot be used.

Reference

This symbol indicates a reference.

[]

Keys that appear on the machine's display panel.

{}

Keys built into the machine's operation panel.

iii

Page 8

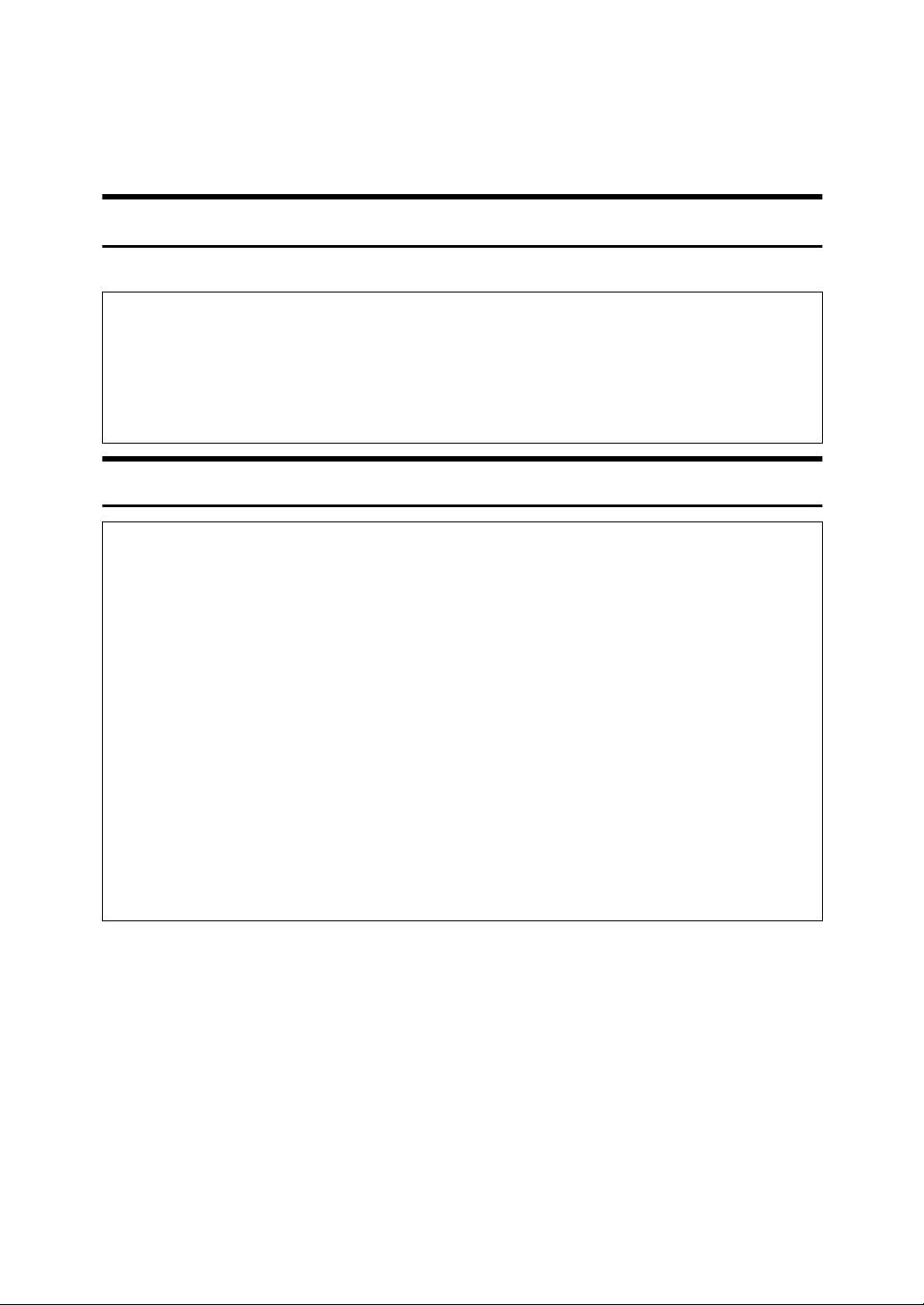

What You Can Do with This Machine

Below is a quick summary of this machine's features and where to look in

this manual for more information.

❖❖❖❖ Standard Printing

⇒ P.15 “Standard Printing”.

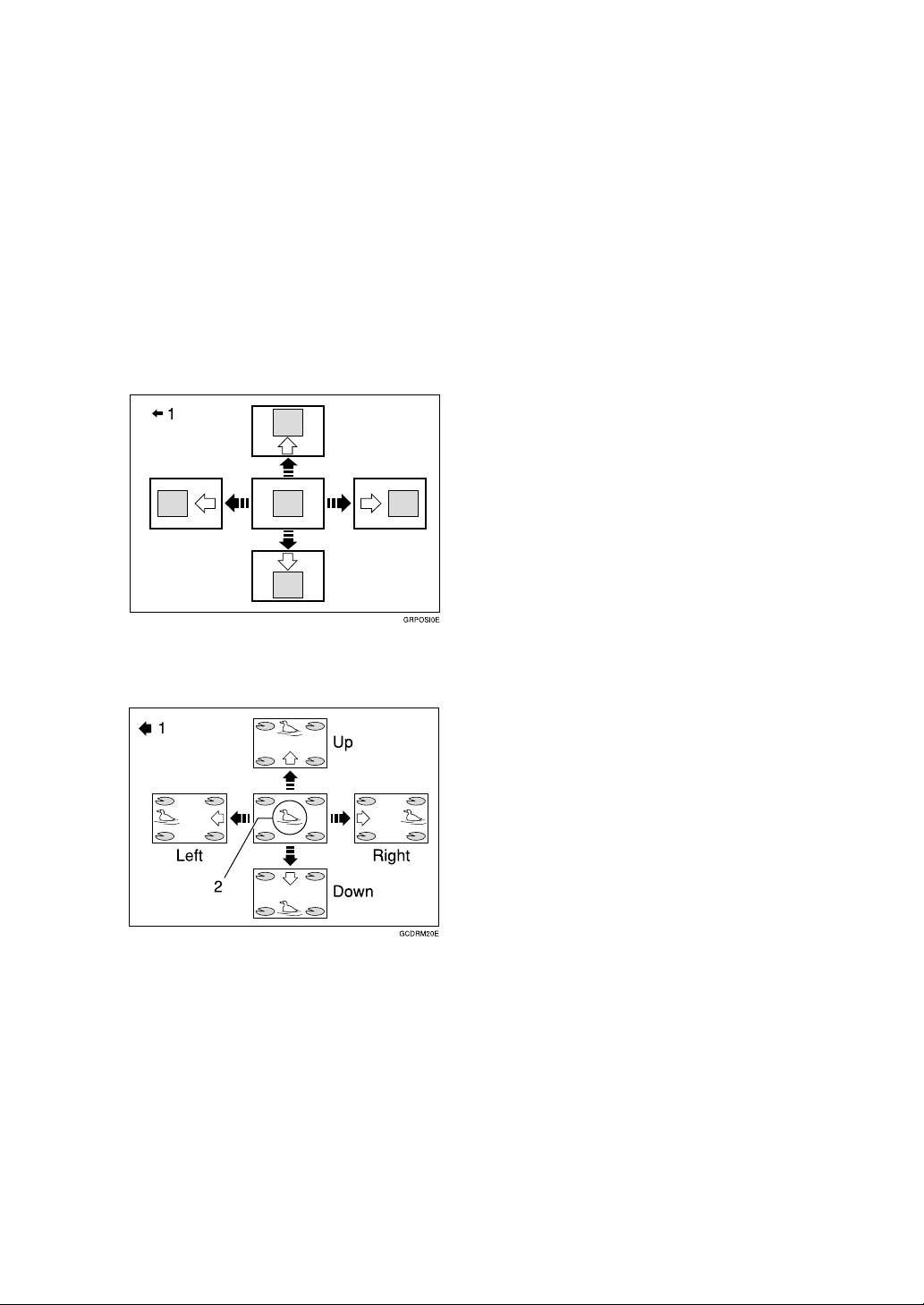

❖❖❖❖ Adjusting the Print Image Position

⇒ P.20 “Adjusting the Position of

Printed Images”.

1: Paper feed direction

1: Paper feed direction

2: Image of Drum 2

❖❖❖❖ Changing the Printing Speed

⇒ P.22 “Changing the Printing

Speed”.

iv

Page 9

TABLE OF CONTENTS

Machine Exterior........................................................................................ 1

Machine Interior......................................................................................... 2

Operation Panel......................................................................................... 4

Keys .............................................................................................................. 4

Indicators....................................................................................................... 5

1.Operation

Setting and Changing the Drum Unit....................................................... 7

Setting the Drum Unit.................................................................................... 7

Changing the Drum Unit................................................................................ 9

Printing Preparations.............................................................................. 10

Loading Paper............................................................................................. 10

Setting Up the Paper Delivery Table........................................................... 11

Turning on the Main Power ......................................................................... 12

Print Paper ............................................................................................... 13

Standard Printing .................................................................................... 15

Removing Prints.......................................................................................... 16

Printing onto Various Kinds of Paper.................................................... 17

Printing onto Thick Paper............................................................................ 17

Printing onto Standard Paper...................................................................... 17

Printing onto Special Kinds of Paper........................................................... 17

Paper Supply Adjustment............................................................................ 18

Adjusting the Position of Printed Images ............................................. 20

Changing the Printing Speed ................................................................. 22

Skip Feed Printing................................................................................... 23

2.User Tools

Accessing the User Tools....................................................................... 25

User Tools................................................................................................ 26

1. System .................................................................................................... 26

v

Page 10

3.Troubleshooting

If Your Machine Does Not Operate as You Want.................................. 29

If You Cannot Make Prints as You Want ............................................... 30

Loading Paper.......................................................................................... 31

When the Add Ink Indicator (j) Lights................................................. 32

x Clearing Misfeeds............................................................................... 34

Paper Misfeed in the Paper Feed Section .................................................. 34

Paper Misfeed in the Paper Feed Section .................................................. 35

Paper Wrapped around the Drum ............................................................... 36

Paper Misfeed in the Paper Exit Section..................................................... 38

Poor Printing............................................................................................ 39

Dirty Background......................................................................................... 39

When the Press Roller is Dirty .................................................................... 41

Faint Prints .................................................................................................. 41

4.Remarks

Do's and Don'ts ....................................................................................... 43

Where to Put Your Machine.................................................................... 44

Environment ................................................................................................ 44

Power Connection....................................................................................... 45

Machine Clearance ..................................................................................... 45

Maintaining Your Machine...................................................................... 46

Cleaning the Main Frame............................................................................ 46

5.Specifications

Main Frame............................................................................................... 47

Consumables........................................................................................... 49

INDEX........................................................................................................ 50

vi

Page 11

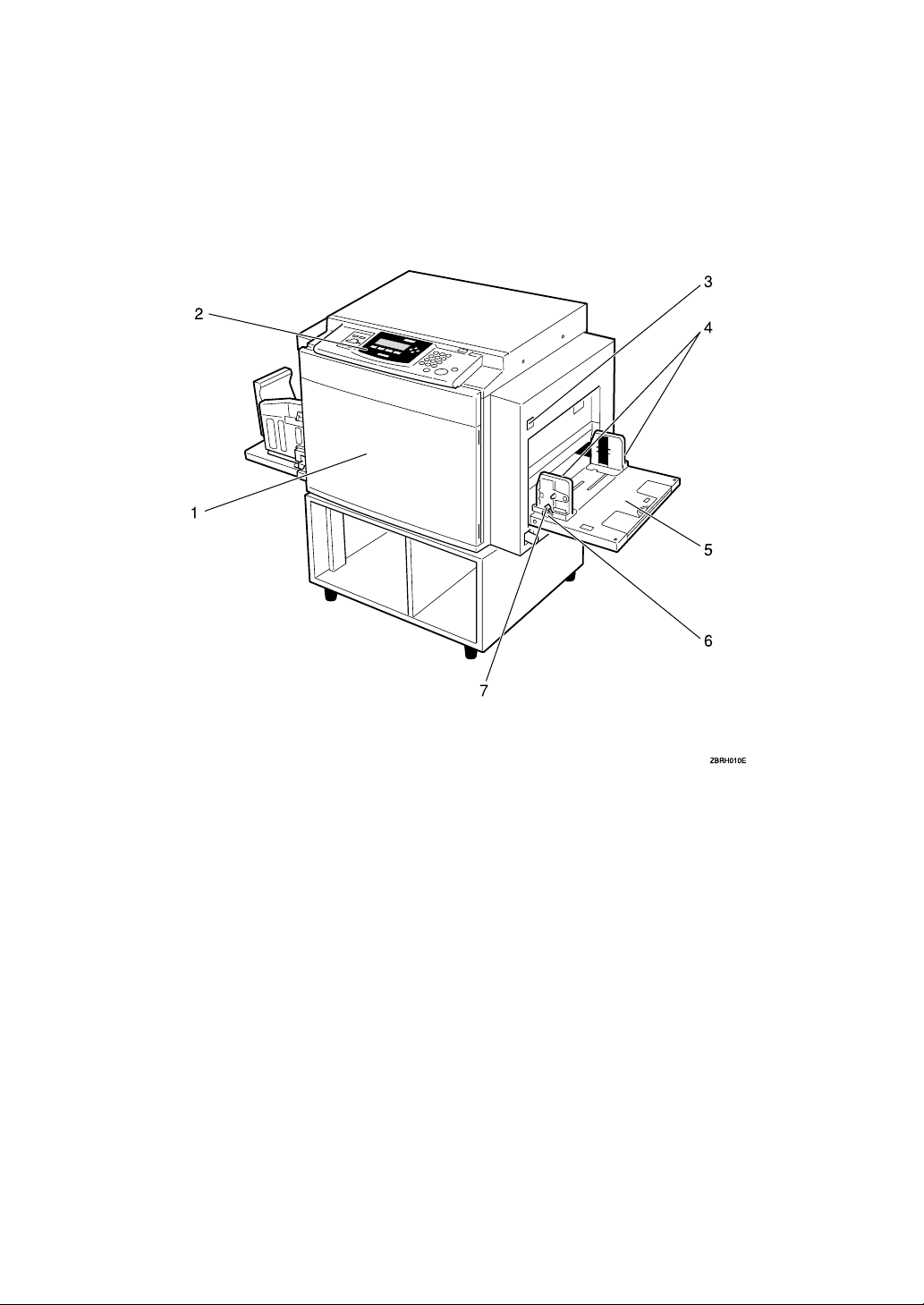

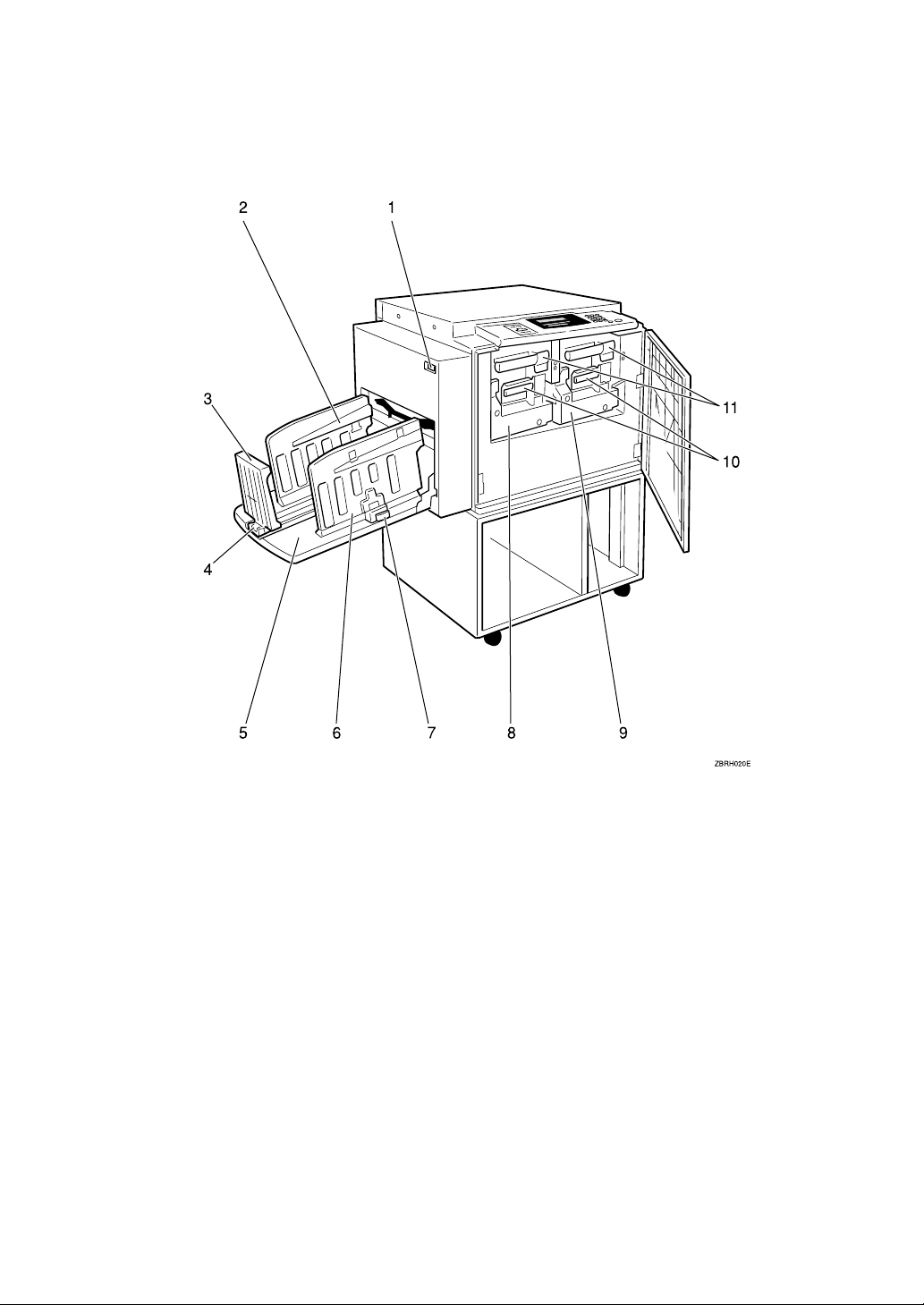

Machine Exterior

1. Front door

Open to access the inside of the machine.

2. Operation panel

⇒ P.4 “Operation Panel”.

3. Paper feed tray down key

Press to lower the Paper feed tray.

4. Paper feed side plates

Prevent paper being fed skewed.

5. Paper feed tray

Set paper here.

6. Paper feed side plates knob

Use to move the side plates.

7. Paper feed side plates knob lock

lever

Fix to the paper feed side plates knob.

1

Page 12

Machine Interior

1. Main switch

Use to turn the power on or off.

2. Paper alignment wings

Lift or lower the wings depending on the

type of paper being used.

3. Paper delivery end plate

This plate aligns the leading edge of

prints.

4. Paper delivery end plate knob

Use to move the end plate.

5. Paper delivery tray

Completed prints are delivered here.

6. Paper delivery side plates

These plates align the prints on the paper

delivery tray.

2

7. Paper delivery side plate knobs

Use to move the side plates.

8. Drum Unit 2

The master is wrapped around this unit.

9. Drum Unit 1

The master is wrapped around this unit.

10. Ink holder

Set the ink cartridge in this holder.

11. Drum unit lock lever B1

Lower to unlock and pull out the drum

unit.

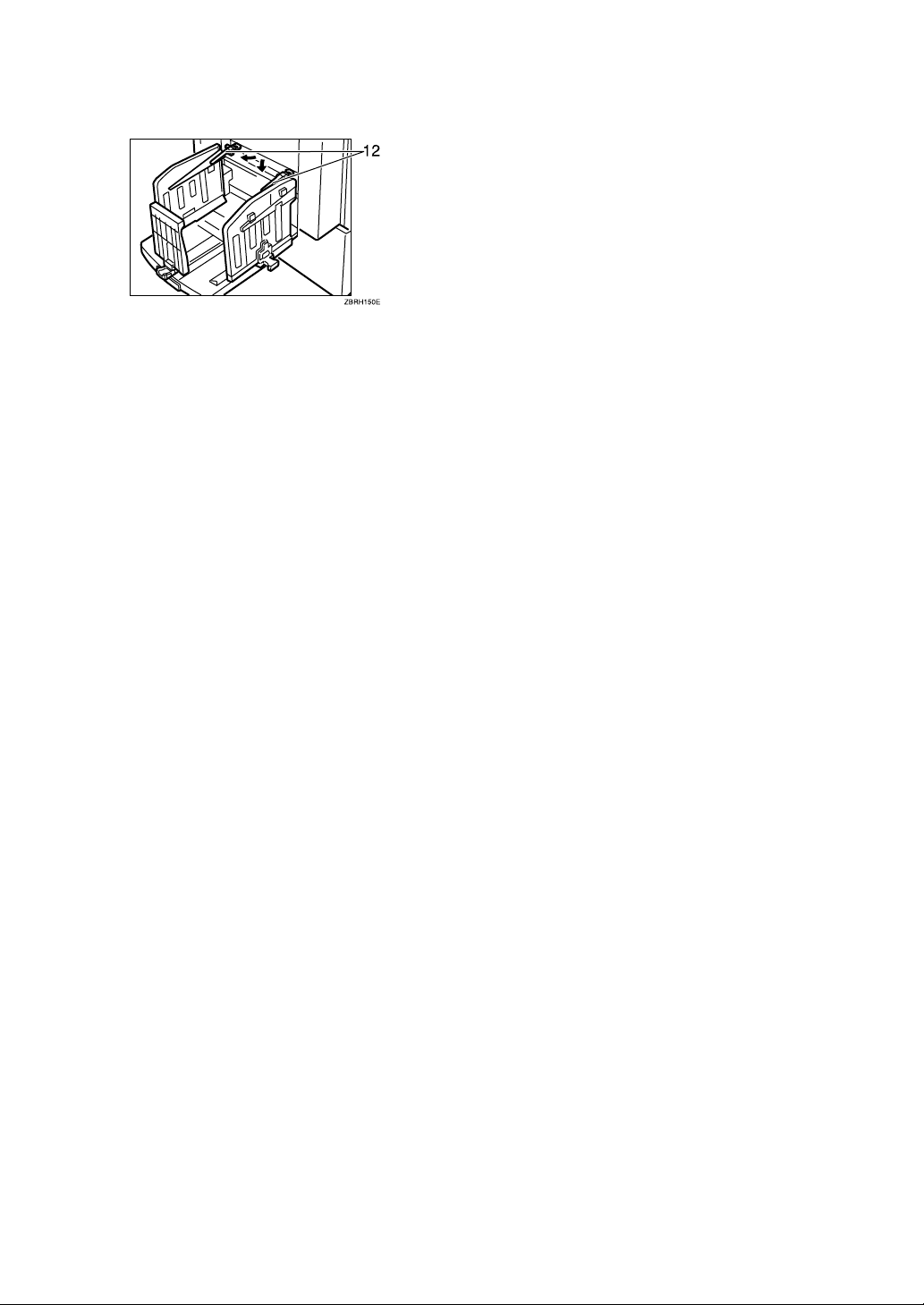

Page 13

12. Trailing edge guides

Swing out these guides when you use

B5L paper.

3

Page 14

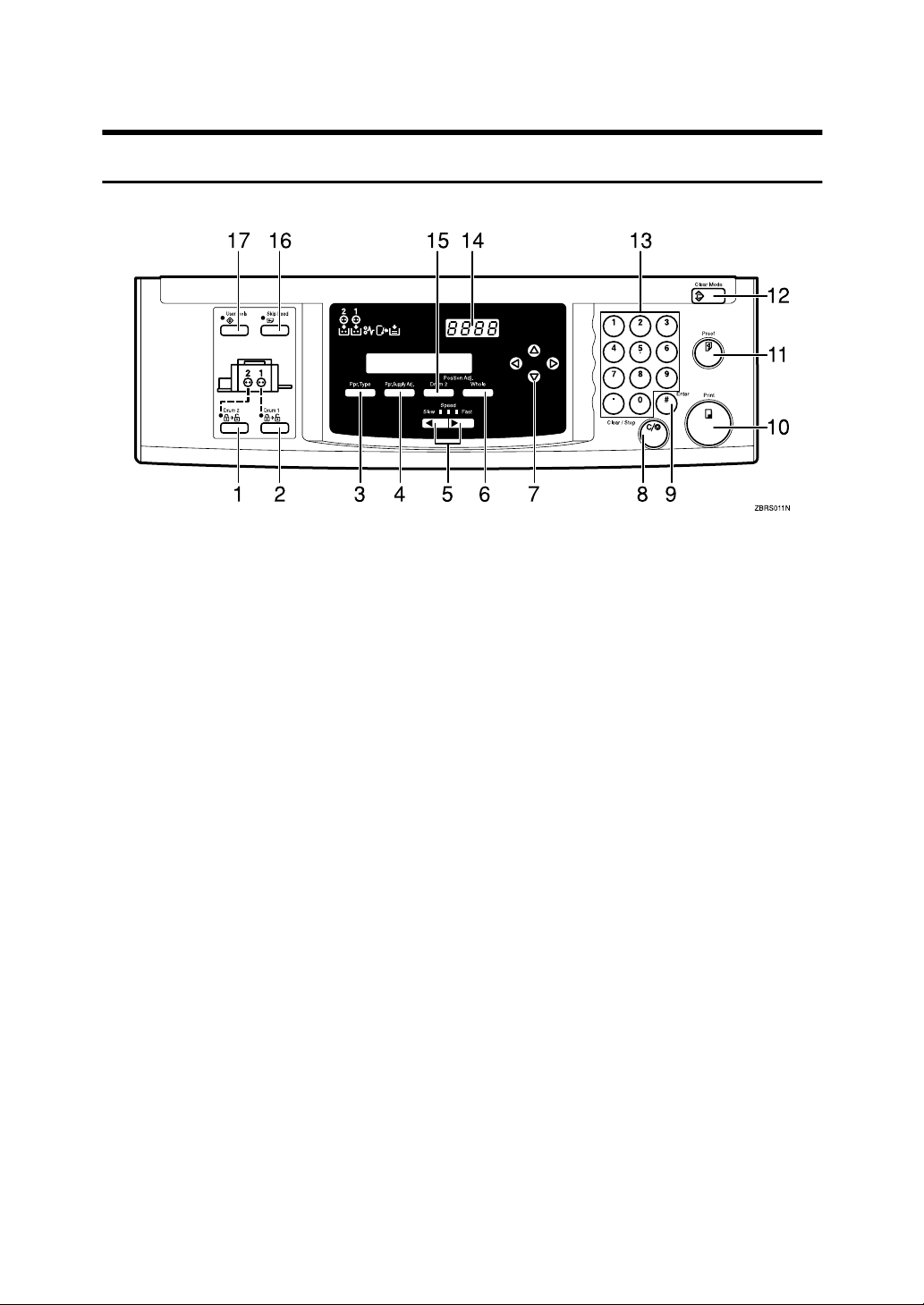

Operation Panel

Keys

1. {

{Drum2}}}} key

{{

Press when you need to set or change the

Drum 2 ⇒ P.7 “Setting the Drum Unit”.

2. {

{Drum1}}}} key

{{

Press when you need to set or change the

Drum 1 ⇒ P.7 “Setting the Drum Unit”.

3. {

{Ppr.Type}}}} key

{{

Press to select the paper type ⇒ P.17

“Printing onto Various Kinds of Paper”.

4. {

{Ppr. Supply Adj}}}} key

{{

Press to change the paper feeding ratio

and paper separation ratio. ⇒ P.18 “Paper

Supply Adjustment”.

5. {

} {{{{VVVV}}}} keys (Speed keys)

{{{WWWW}}}

Press to adjust the printing speed. ⇒ P.4

“Keys”, ⇒ P.22 “Changing the Printing

Speed”.

6. {

{Position Adj/Whole}}}} key

{{

Press to adjust the mixed image positions

of Drum1 and Drum2 ⇒ P.20 “Adjusting

the Position of Printed Images”

7. {

{{{~~~~}}}}{{{{}}}}}}}}{{{{||||}}}}{{{{{{{{}}}

Press to shift the image forward, backward, right, or left. ⇒ P.4 “Keys”, ⇒ P.20

“Adjusting the Position of Printed Images”.

Also use to highlight items you wish to

select on the panel display.

4

} keys

8. {

{Clear/Stop}}}} key

{{

Press to stop printing.

9. {

{#}}}} key

{{

Use to enter data in selected modes.

10. {

{Print}}}} key

{{

Press to start printing.

11. {

{Proof}}}} key

{{

Press to make proof prints.

12. {

{Clear Modes}}}} key

{{

Press to clear any previously entered job

settings.

13. Number keys

Press to enter the desired number of

prints and data for selected modes.

14. Counter

Displays the number of prints entered.

While printing, it shows the number of

prints remaining.

15. {

{Position Adj/Drum2}}}} key

{{

Press to adjust the image position's of Drum2.

16. {

{Skip Feed}}}} key

{{

Press to select skip feed printing. ⇒ P.23

“Skip Feed Printing”

17. {

{User Tools}}}} key

{{

Press to change the default settings to

meet your requirement.

Page 15

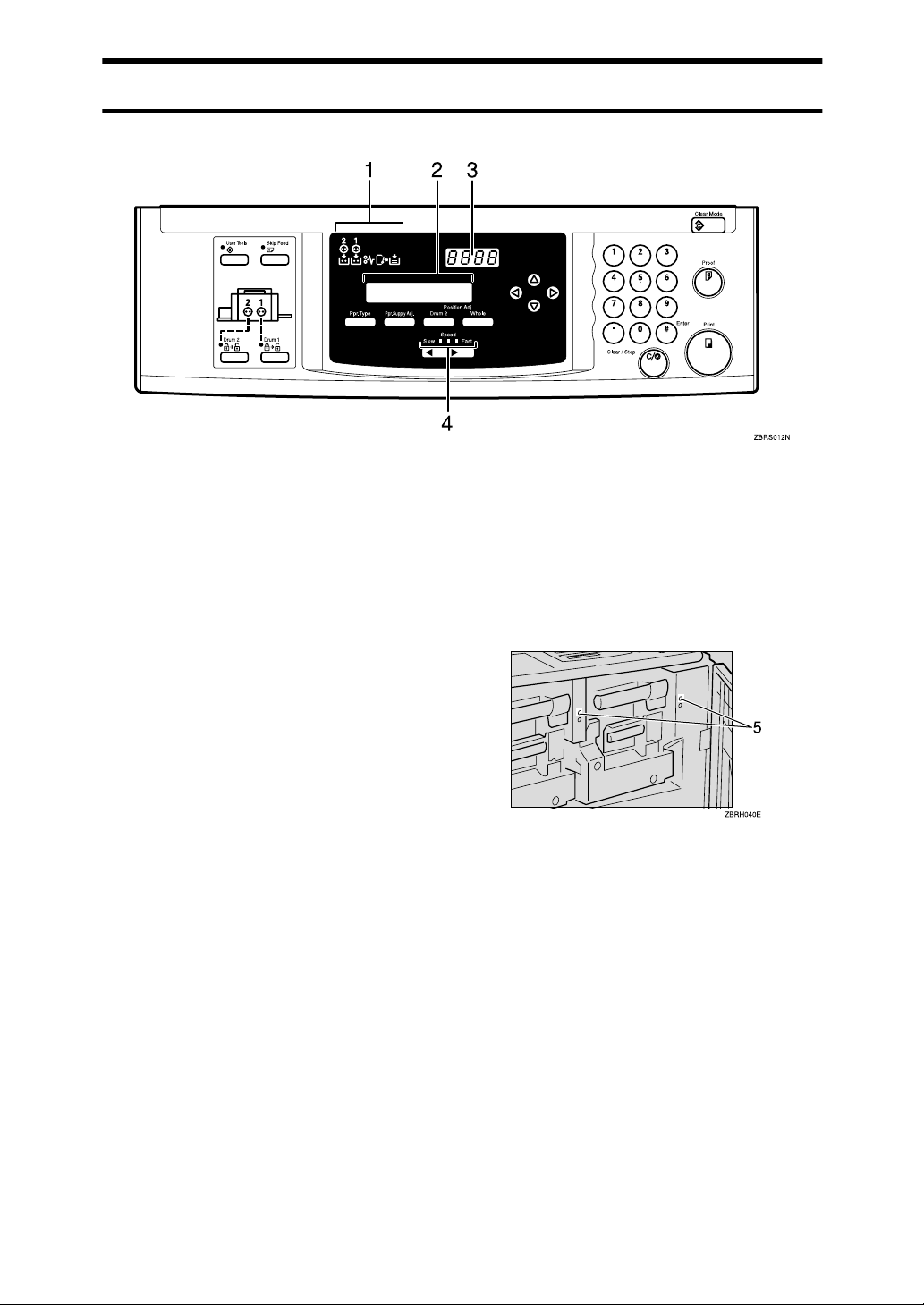

Indicators

1. Error Indicators

These indicators are lit when a non-standard condition occurs within the machine.

2. Guidance Display

Display the machine's condition.

3. Counter

Displays the number of prints entered.

While printing, it shows the number of

prints remaining.

4. Speed Indicators

These indicators show the printing speed

that is selected.

5. Drum set indicator

The green indicator lights when the

drum unit is ready to pull out. If not

ready, the red indicator lights.

5

Page 16

6

Page 17

1. Operation

Setting and Changing the Drum Unit

Before you start printing, you must

make a master print using the master

making unit. The master print is

wrapped around the drum unit.

Note

❒ Color drum units are available as

options in addition to the standard

black unit. For making color prints,

a separate drum unit is necessary

for each color.

❒ Insert the same kinds of drum unit

for both Drum 1 and Drum 2.

❒ Color Drum Type 50S/80S is not

available for this machine.

❒ A4 size master cut drum is not

available for this machine.

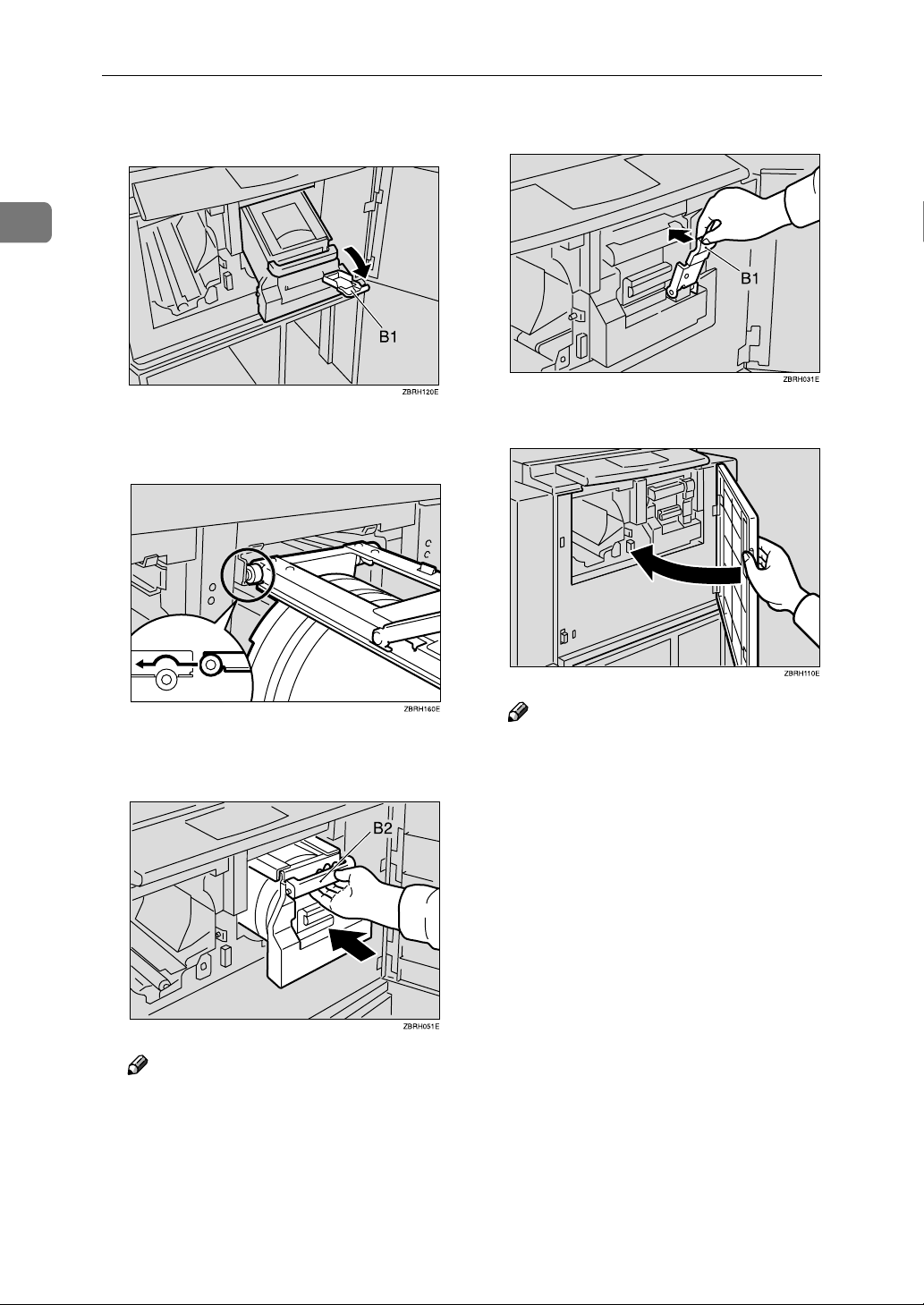

Setting the Drum Unit

Make sure that you select either

A

{{{{Drum1}}}} or {{{{Drum2}}}} before setting

the drum unit.

Open the Front Door.

B

Lift upper drum stay B3 a little to

C

unlock the drum unit, then push

into the drum unit while holding

drum unit handle B2 and upper

drum stay B3.

Note

❒ Make sure that the indicator is

lit.

Note

❒ Make sure the green light be-

side the drum unit lock lever is

on.

❒ If the red light is on, go back to

step 1.

7

Page 18

Operation

1

❒ Make sure that the drum unit

lock lever B1 is released.

Insert the drum unit along the

D

guide rail.

Lift drum unit lock lever B1.

F

Close the front door.

G

Slide in the drum unit until it

E

locks in position.

Note

❒ Insert the same kinds of drum

unit for both Drum1 and

Drum2.

Note

❒ If you want to set another drum

unit, go back to step 1.

❒ Make sure that the Open Cover

Indicator turns off.

8

Page 19

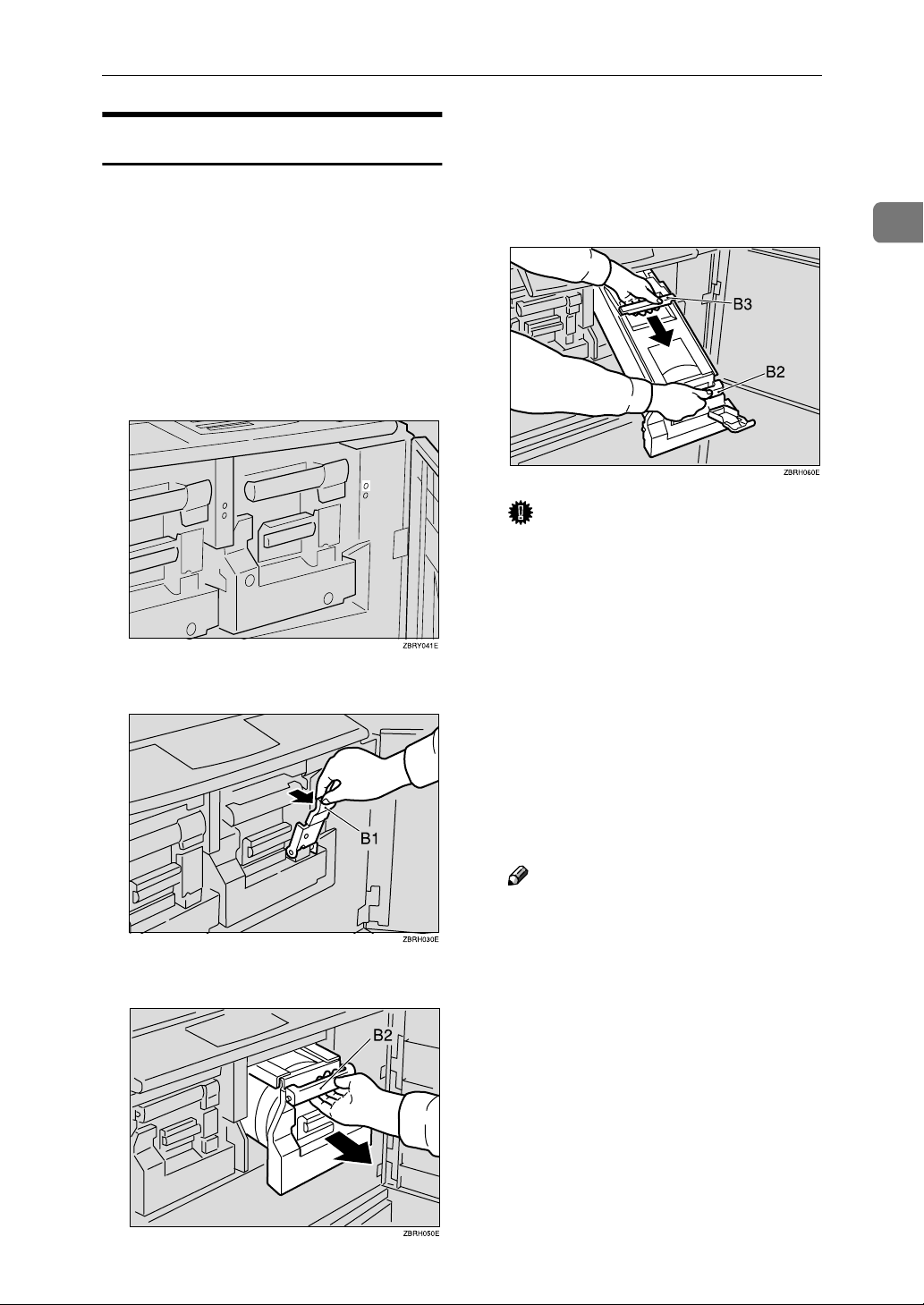

Changing the Drum Unit

Make sure that you select either

A

{{{{Drum1}}}} or {{{{Drum2}}}} before changing the drum unit.

Open the front door.

B

Make sure the green light beside

C

the drum unit lock lever is on before sliding out the drum. If the

red light is on, go back to step

Setting and Changing the Drum Unit

Lift upper drum stay B3 a little to

F

unlock the drum unit, then pull

out the drum unit while holding

drum unit handle B2 and upper

drum stay B3.

.

A

Important

❒ Be careful not to let the drum

unit fall.

1

Lower the drum unit lock lever B1.

D

Pull out drum unit handle B2 slowly.

E

Insert the color drum unit along

G

the guide rail.

Lower drum unit lock lever B1 of

H

the inserted drum.

Slide in the drum unit until it

I

locks in position.

Lift drum unit lock lever B1.

J

Close the front door.

K

Note

❒ Make sure that the Open Cover

indicator turns off.

9

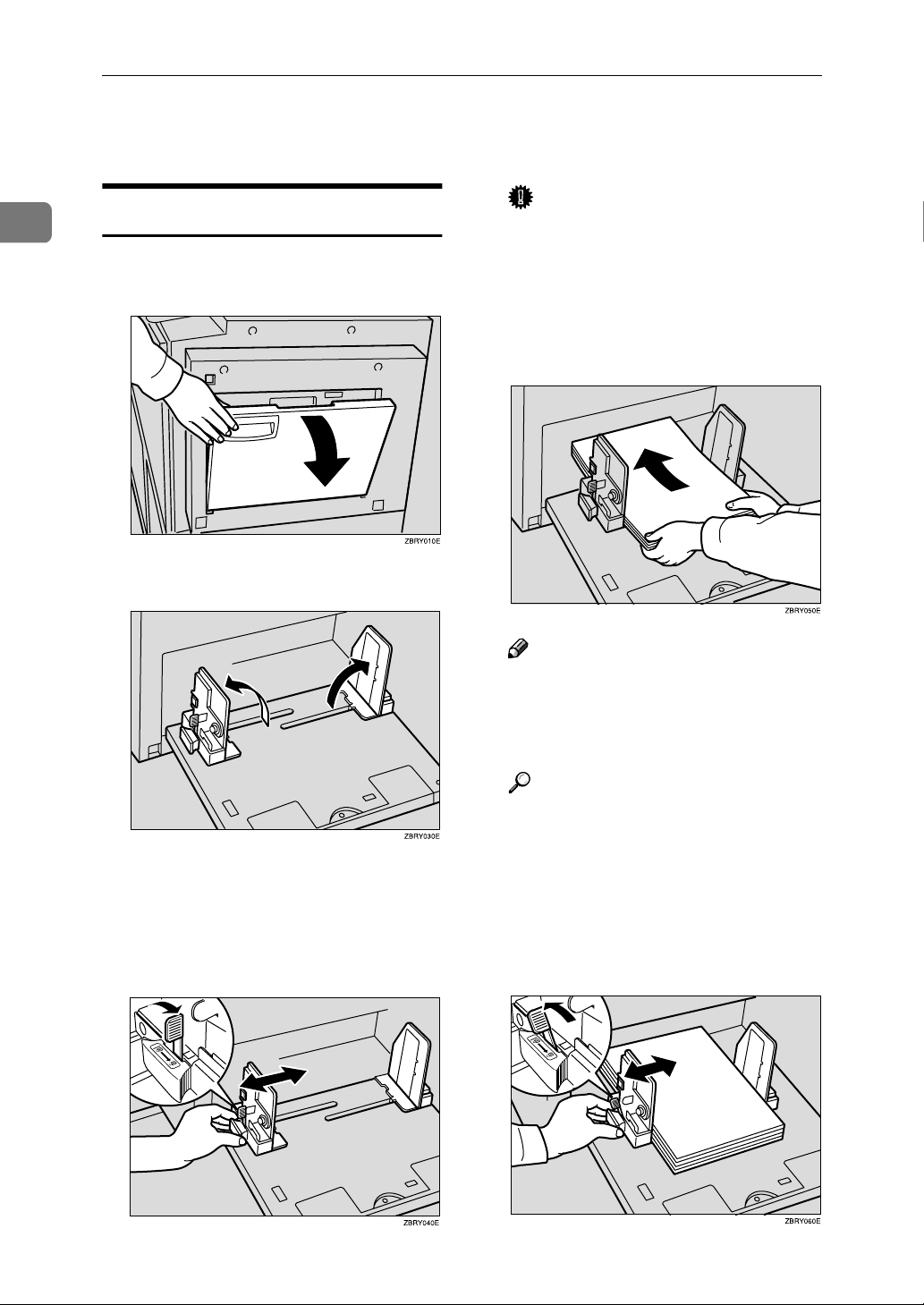

Page 20

Operation

Printing Preparations

1

Loading Paper

Carefully open the paper feed

A

tray.

Lift the feed side/end plates.

B

Important

❒ Always adjust the position with

the lock lever for the paper feed

side plates in the raised position

(lock released).

Place the paper on the paper feed

D

tray.

Note

❒ Correct the paper curl before

loading the paper. If you cannot

do so, stack the paper with the

curl face down.

10

Make sure that the lock lever for

C

the side plate is raised (lock is released), and then grasp the side

plate knob and adjust the side

plate to match the paper size.

Reference

⇒ P.13 “Print Paper”

Make sure that the paper feed

E

side plates are touching both

sides of the paper, and then push

the lock lever for the side plates

down to lock the side plates into

position.

Page 21

Printing Preparations

Important

❒ Always make sure that you push

the lock lever for the side plates

down to lock the side plates in

position.

Note

❒ Make sure that the paper size

and direction in the panel display correspond with the actual

paper size and direction set on

the paper feed tray.

Setting Up the Paper Delivery

Table

Open the Paper Delivery Table.

A

Adjust the paper delivery end

C

plate to match the print paper

size.

Note

❒ The inside of the end plate

should align with the paper size

scale.

When you use thick paper (81.4

g/m2 to 209.3 g/m2, 21.6 lb to

55.6 lb)

1

Lift the paper delivery plates and ad-

B

just the side plates to the paper size.

Note

❒

The inside of the side plates should

align with the paper size scale.

A Adjust the side plates to match

the paper size scale on the

main frame side.

When you use standard paper

(52.3 g/m2 to 81.4 g/m2, 13.9 lb to

21.6 lb)

A Adjust the side plates to match

the paper size scale on the end

plate side.

11

Page 22

1

Operation

Lower or lift the paper alignment

D

wings.

Note

❒ When the guides are up, you

might not be able to load the

unit to full capacity (1,000

sheets) depending on the paper

you are using.

❒ Lift the paper alignment wings

when B5L prints are curled.

Turning on the Main Power

Make sure that the power cord is

A

firmly plugged into the wall outlet.

Turn on the main power switch.

B

When you use 81.4 g/m2, 21.6 lb

or thicker paper

A Lower the paper alignment

wings.

When you use B5L paper

A Swing out the trailing edge

guides.

12

Page 23

Print Paper

The following limitations apply:

Print Paper

Paper Size Paper

Metric Inch

Paper feed tray A3 L, B4 L, A4 L, B5 L,

Others (Vertical: 70 - 297mm,

Horizontal: 250 - 432mm)

11" × 17" L, 8

1

8

/2" × 11" L , Others (Vertical: 2.76" - 11.7", Horizontal: 9.84" - 17")

1

/2" × 14" L,

Weight

52.3 -

209.3g/m

13.9 - 55.6 lb

2

,

Non-recommended paper and envelope:

• Roughly cut paper/envelope

• Paper of different thickness in the same stack

• Envelopes heavier than 85g/m

2

, 22 lb.

• Folded, curled, creased, or damaged paper

•Torn paper

• Slippery paper

• Rough paper/envelope

• Paper with any kind of coating (such as carbon)

• Short grain paper

• Thin paper that has low stiffness

• Paper that is prone to generate a lot of paper dust

• Grained paper loaded with the direction of the grain perpendicular to the

feed direction

• Certain types of long thin envelopes e.g. international mail envelopes

1

• The following types of envelopes:

Note

❒ If you print on rough grained paper, the following problems may occur:

• Black-Spotted image

•Blurred image

•Damaging master

13

Page 24

1

Operation

Important

❒ Correct curls in the paper before placing it in the machine. When you cannot

correct the paper curl, stack the paper with the curl face down or face up as

shown in the illustration. If paper is curled, it might wrap around the drum

or stains might appear.

14

Page 25

Standard Printing

Standard Printing

Set the Drum Unit.

A

Reference

⇒ P.7 “Setting the Drum Unit”

Make sure that the machine is

B

ready for printing.

Make sure that there are no previ-

C

ous settings remaining.

Note

❒ To clear any previous settings,

press the {Clear Modes}.

Set the paper

D

Reference

⇒ P.10 “Loading Paper”

Select the Paper type

E

Reference

⇒ P.17 “Printing onto Various

Kinds of Paper”

❒ If the image density is slightly

dark or light, adjust the image

density, using {WWWW} {VVVV} Speed

keys. ⇒ P.22 “ Changing the

Printing Speed”.

Enter the number of prints re-

H

quired with the number keys.

Note

❒ The counter shows the number

of prints you set.

1

Set your desired settings.

F

Press the {{{{Proof}}}} Key.

G

Note

❒ If the Image position is not cor-

rect, adjust it by using {Whole}

or {Drum 2}. ⇒ P.20 “Adjusting

the Position of Printed Images”.

❒ To change the number entered,

press the {Clear/Stop} key and

enter the new number.

Press the {{{{Print}}}} key.

I

15

Page 26

Operation

1

Note

❒ To stop the machine during a

multi-print run, press the {Clear/

Stop} key.

❒ To return the machine to the ini-

tial condition after printing,

press the {Clear Modes} key.

Removing Prints

Pull the front paper delivery side

A

plate down towards you to open

it.

Remove the prints from the paper

B

delivery tray and close the paper

delivery side plate.

This function is called “Auto Reset”.

Note

❒ You can change the time the ma-

chine can waits before Auto Reset

mode starts.⇒ P.26 “User Tools”.

❒ The machine will not automatical-

ly enter Auto Reset mode in the

following cases:

• If there is no ink

• If paper misfeed occur

• If the machine is printing

• If there is no paper

• If the cover open message is dis-

played

Auto Off

If you do not operate the machine for

a certain period the machine can enter

Quality Standby mode to remove ink

from inside the machine, and then

turn itself off. This function is called

“Auto Off”.

Limitation

Quality Standby mode does not available when you use Color Drum Type

40S/50S.

Auto Reset

The machine returns to its initial condition automatically after your job is

finished.

16

Note

❒ You can change the time the ma-

chine can waits before Auto Off

mode starts.⇒ P.26 “User Tools”.

Page 27

Printing onto Various Kinds of Paper

Printing onto Various Kinds of Paper

Before printing onto thick paper, thin

paper, envelopes or special kinds of

paper loaded in the Paper feed tray,

you must select the paper type.

Printing onto Thick Paper

Printing onto Standard Paper

Press the [Ppr.Type] key.

A

1

If you wish to print onto thick (157 to

209.3g/m

paper, perform the following steps.

Press the [Ppr.Type] key.

A

Select [2:THICK] with {{{{~~~~}}}} {{{{}}}}}}}} key.

B

2

, 42 to 55.6 lb or heavier)

PAPER TYPE 1:STD

2:THICK 3:SPL **

Press the [qqqq] key.

C

Make sure that [1:STD] is selected.

B

PAPER TYPE 1:STD

2:THICK 3:SPL **

Press the [qqqq] key.

C

Printing onto Special Kinds of

Paper

Press the [Ppr.Type] key.

A

Select [3:SPL] with {{{{~~~~}}}} {{{{}}}}}}}} key.

B

PAPER TYPE 1:STD

2:THICK 3:SPL **

17

Page 28

Operation

Press the [qqqq] key.

C

Paper Supply Adjustment

1

Printing onto envelopes

A Place the envelopes in the pa-

per feed tray as shown in the illustration.

GRENVE0E

*: Paper feed direction

Note

❒ When you use envelopes, the

Paper feed tray capacity is

about 150 sheets (85g/m

lb) or enough to load a stack

up to 105mm, 4.1" high.

B If your envelopes do not feed

in well, lift the paper feed tray

a little, and then lower it so that

it slants up slightly.

2

, 22

If paper misfeeds occur frequently,

you can adjust the paper feeding ratio

and paper separation ratio.

Press the {{{{Ppr. Supply Adj}}}} key.

A

FEED PRES. 0123456**

SEPAR PRES 0123456**

Press {{{{~~~~}}}} {{{{}}}}}}}} {{{{||||}}}} {{{{{{{{}}}} or the

B

number keys to adjust the paper

feeding ratios and the paper separation ratios.

Press {{{{#}}}} key.

C

18

ZDZY030E

If the machine does not feed

enough paper

A Change the paper feeding ratio

setting as follows.

Paper type Paper feed pres-

sure ratio

Standard 5∼6(*3)

Thick 6(*5)

Special kinds of

Paper

*: Default

5∼6(*3)

Page 29

If the machine feeds too much

paper

A Change the paper separation

ratio setting as follows.

Paper type Paper feed sepa-

ration ratio

Standard 4∼6(*3)

Thick 3∼4(*2)

Printing onto Various Kinds of Paper

1

Special kinds of

Paper

*: Default

3∼4(*1)

19

Page 30

Operation

Adjusting the Position of Printed Images

1

Use the following procedure to adjust

the position of print images as required.

Note

❒ Unexpected change to the image

position may occur with the following actions:

• Switching Drum1 and 2.

• Remaking a master using the

master making unit.

• Changing the print speed.

There are two kinds of image adjustment as follows:

❖❖❖❖ Overall Image Adjustment

You can adjust the mixed image

position of Drum1 and Drum2.

❖❖❖❖ Drum2 Image Adjustment

You can adjust the image position

of Drum2.

1: Paper Feed Direction

2: Image of Drum2

Note

❒ When the main switch is turned

off, the image returns to the default

position.

Press the [Whole] or [Drum 2] key.

A

20

1: Paper feed direction

OVERALL IMAGE ADJUST

jl0.40in.hi0.40in

Adjust the image position using

B

the {{{{~~~~}}}}, {{{{}}}}}}}}, {{{{||||}}}}, and {{{{{{{{}}}} keys.

Page 31

Adjusting the Position of Printed Images

Note

❒ When you shift the image for-

ward, leave a 10mm, 0.4" margin at the leading edge. If there

is no margin, paper might wrap

around the drum and cause a

misfeed.

❒ If you adjust the image position,

a print shadow might appear.

Overall image adjustment

A You can change the overall im-

age position of both Drum 1

and 2. Use {{{{~~~~}}}} {{{{}}}}}}}} {{{{||||}}}} {{{{{{{{}}}}

keys to shift the image each

way in 0.5mm, 0.02” steps.

Up & Down Right & Left

+10mm, 0.4” or 10mm, 0.4”

+10mm, 0.4” or 10mm, 0 4”

Press the {{{{Proof}}}} key to check the

D

image position.

1

Drum 2 image adjustment

A You can change the image posi-

tion of Drum 2. Use {{{{~~~~}}}} {{{{}}}}}}}}

{|} {{} keys to shift the image

each way in 0.25mm, 0.01”

steps.

Up & Down Right & Left

Moving sums of

both adjustment

functions (Max

10mm, 0.4”)

Press the [Enter] key.

C

+5mm, 0.2” or 5mm, 0 2”

21

Page 32

1

Operation

Changing the Printing Speed

Use the {WWWW} or {VVVV} key to adjust the

printing speed. The relationship between printing speed and print quality depends on the type of paper you

use.

Press the {{{{VVVV}}}} key to increase the

A

speed and press the {{{{WWWW}}}} key to reduce the speed.

Note

❒ The following speeds are avail-

able:

• Setting 1 (default):

90 sheets/minute

• Setting 2:

105 sheets/minute

• Setting 3:

120 sheets/minute

❒ The faster the printing speed be-

comes, the lighter the printing

density is, and vice versa.

❒ If you change the print speed

while printing, a print shadow

might appear.

❒ When the machine is used in

low temperature conditions, the

image density might decrease.

In this case, use setting one.

22

Page 33

Skip Feed Printing

Skip Feed Printing

If the backs of prints are dirty, you

can increase the time between prints

using the {Skip Feed} key. By default,

when one sheet of paper is fed the

drum rotates once. However, you can

select the number of rotations of the

drum. This gives you the chance to remove prints one by one from the paper delivery tray or insert one sheet of

paper between two prints. If you use

this function, you can also use paper

longer than 432mm, 17.0" in spite of

the maximum length limitations of

paper.

Note

❒ Two rotations per sheet of paper is

the default. You can change this

default setting with the user tools.

See “No. of Skip Feed” ⇒ P.23

“Skip Feed Printing”.

❒ The maximum length of paper in

Skip Feed mode is 460mm, 18.1".

❒ When you use paper longer than

432mm, 17.0", completed prints

will not be delivered to the paper

delivery tray properly, so lower

the paper delivery end plate and

receive completed prints by hand.

If necessary, select the number of

B

rotations of the drum per sheet of

paper fed with the {{{{~~~~}}}} {{{{}}}}}}}} keys.

SKIP FEED NO SETTING

INPUT THE NUMBER *

Note

❒ You can also select the number

of rotations with the Number

keys.

❒ You can select from 2 to 9 rota-

tions.

❒ By default, the machine asks

you to confirm the number of

rotations. You can have this step

omitted by adjusting the user

tool settings. See “No. of Skip

Feed” ⇒ P.26 “User Tools”.

Press the [qqqq] key.

C

Press the {{{{Start}}}} key.

D

1

Press the {{{{Skip Feed}}}} key.

A

Check the image position of the

E

trial or proof print.

Note

❒ If the image position is not cor-

rect, adjust it using the [Whole] or

[Drum2] key (⇒ P.20 “Adjusting

the Position of Printed Images”).

Make your prints.

F

23

Page 34

1

Operation

24

Page 35

Accessing the User Tools

2. User Tools

The user tools allow you to customize

various default settings. This section

is intended for the machine administrator.

Press the {{{{User Tools}}}} key.

A

Using the {|}, or {{} key

A Search for the desired user tool

number with the {{{{||||}}}}, {{{{{{{{}}}},

key.

Using the number keys

A Enter the desired user tool

number with the Number

keys.

Change the settings by following

B

the instructions on the panel display. Then press the [qqqq] key.

Press the {{{{User Tools}}}} key to re-

C

turn to the standby display.

Note

❒ The settings are not canceled

even if the main switch is

turned off or the {Clear Modes}

key is pressed.

25

Page 36

User Tools

User Tools

Reference

For how to access the user tools, ⇒ P.25 “Accessing the User Tools”.

2

1. System

No. Mode Description

1 Auto Reset Time The machine returns to its initial condition automatically after

your job is finished. The automatic reset time can be set from 1 to

5 minutes or off (0 minute).

Note

❒ Default: Off

2 Resettable Count The counter shows the number of prints you made.

3 Clr Resettable

Count

4 Max Print The maximum print quantity can be set between 1 and 9999.

5 Total Counter Use to display the total number of prints.

6 Buzzer Off Turns the beeper on or off.

Choose whether the total number of prints is reset.

Note

❒ Default: Not clear

Note

❒ Default: 9999

Note

❒ Default:

❒ Available settings:

• 0: KEY OFF (When you press a key, the beeper does not

sound. When warning messages appear on the panel display, the beeper sounds.)

• 1: ON (The beeper sounds when you press a key or when

warning messages appear on the panel display.)

• 2: OFF (The beeper does not sound when you press keys or

when warning messages appear on the panel display.)

STD.

(standard)

26

7 Auto Off If you do not operate the machine for a certain period the machine

can enter Quality Standby mode to remove ink from inside the

machine, and then turn itself off. This function is called “Auto

Off”. The time can be set from 10 to 90 minutes.

Note

❒ Default: 60 minutes

❒ Quality Standby mode does not available when you use Color

Drum Type 40S/50S.

Page 37

User Tools

No. Mode Description

8 Jump Table You can change the angle of the wing guide depending on the pa-

per type you use.

Note

❒ Default: Auto

❒ Available settings:

• Up (Select this setting when standard thickness or thin paper misfeeds at the paper exit section occur frequently.)

• Down (Select this setting when A4-B5, 8

per is not delivered properly to the paper delivery tray.)

9 Drm Stp Mode You can select the drum which you will be able to pull out imme-

diately after you finish your job without pressing any key.

1

/2" × 11" thick pa-

Note

❒ Default: Drum 1

10 Long Sheet Mode You can select whether you can use paper longer than

432mm,17.0" or not.

Note

❒ Default: Not to use

❒ When you use paper longer than 432mm, 17.0”, lower the pa-

per delivery end plate and receive completed prints by hand.

2

11 Skip Number of

Time

Specifies the number of drum rotations in Skip Feed mode when

the power is turned on.

You can also select whether you can change the number of drum

rotations temporarily when you press the {Skip Feed} key. ⇒ P.23

“Skip Feed Printing”

Note

❒ Default:

• Number of Skip Feed: 2

12 Skip Display On

Mode

When you press {Skip Feed} key, you can select whether optional

print counts display shows up or not.

Note

❒ Default: Off

13 Total Counter

Down

The copy counter can be set to show the number of copies made

(Count Up), or the number of copies remaining to be made

(Count Down).

Note

❒ Default: Yes (Count Down)

14 Print Position You can register the settings of print image position.

15 Feed Setup You can register the settings for frequently use.

27

Page 38

2

User Tools

28

Page 39

3. Troubleshooting

If Your Machine Does Not Operate as You

Want

If a malfunction or a misfeed occurs, the following messages will appear on the

panel display.

Message Meaning

RE-ENTER COPY

NUMBER

DRUM1:

SET COMPLETELY

SC*-**TEL***********

CALL SERVICE

COLD DRUM

NOT TO USE 3RD

SPEED

DRUM1 UNSITABLE

DRUM TYPE

The number of prints exceeds the maximum print quantity.

You can change the maximum number of prints that can be made

in one operation with the user tools. ⇒ P.26

Slide in the drum until it clicks.

Make sure that the drum is completely set in position.

Turn the main switch off and on.

If the message appears again, contact your service representative.

Slow down the printing speed, and then press print key.

Insert the same kinds of drum unit for both Drum1 and Drum2.

If the message appears again, contact your service representative.

“User Tools”

.

----When a service call message is shown on the panel display panel

Turn the main switch off and back on again. If a service code appears again, contact your service representative.

29

Page 40

Troubleshooting

If You Cannot Make Prints as You Want

Problem Cause Action

3

Misfeeds occur frequently. Improper paper type is select-

ed.

Parts of the image are not

printed.

Print shadow appears. The background image densi-

The print image appears too

light.

Scratches appear on the print

image.

The images of drum 1 and 2

do not mix well together.

2nd printing with another

drum is unsatisfactory.

Roller marks appear when

you print onto the reverse side

of paper.

The image is too wide. • Set larger size paper.

ty is too high.

The print speed is too fast. Lower the print speed.

Sharp edges in the machine

may have scratched your

prints.

If the image density is too

high, the background color

might appear strong.

The 1st print image is still wet. Wait until the 1st image be-

1st printed image is still wet

and the press roller becomes

dirty.

Select proper paper type.

⇒Refer to the master making

unit's operating instructions.

• Return the drum unit to

the master making units,

and then reduce the print

image size.

• Switch drum 1 and 2.

• Set thick paper.

• Increase the print speed.

• Set thick paper.

• Switch drum 1 and 2.

• Use the image of drum 1

for background.

comes dry.

• Wait until the 1st printed

image becomes dry.

• Wipe off the ink on the

press roller. ⇒ P.41 “When

the Press Roller is Dirty”

30

An uneven solid image appears.

Large solid image wrinkles

the master.

• Increase the print speed.

• Set thick paper.

• Use Drum2 for a large sol-

id image.

• Use Quality Standby mode

by pressing the

key for more than 3 seconds.

• Return the drum unit to

the master making unit,

and then remake the master with economy mode or

quality start mode.

• When you make master,

make a few trial prints,

and then return the drum

unit to this machine.

⇒Refer to the master making

unit operating instructions.

{

Clear Mode

}

Page 41

Loading Paper

Loading Paper

The Load Paper indicator (B)lights

when the paper feed tray runs out of

paper.

Limitation

❒ Load paper when the paper feed

tray is empty. Do not add paper

when some paper is left in the tray.

Doing so may cause problems,

such as multiple feeds and misfeeds.

❒ If you use a variety of paper while

printing, a print shadow might appear.

Reference

For available paper sizes, ⇒ P.13

“Print Paper”.

Load the paper in the Paper feed

A

tray.

Adjust the paper feed side plate

B

to match the paper size.

3

Note

❒ Correct any paper curl before

loading the paper.

31

Page 42

Troubleshooting

R

R

R

R

When the Add Ink Indicator (j) Lights

The Add Ink indicator (j) lights when it is time to supply ink.

CAUTION:

• If ink comes into contact with your eyes, rinse immediately in running water.

In the case of any abnormal symptoms, consult a doctor.

CAUTION:

• Keep the ink or ink container out of the reach of children.

3

CAUTION:

• If ink is ingested, force vomiting by drinking a strong saline solution and consult a doctor immediately.

CAUTION:

• Our products are engineered to meet high standards of quality and functionality, and we recommend that you only use the expendable supplies available at an authorized dealer.

Note

❒ Be sure to supply ink of the same color as the current drum.

❒ Ink is readily removed from skin by waterless hand cleaners followed by

washing with soap and water.

❒ Be careful not to get any ink on your clothing.

❒ Store ink under low temperature and humidity conditions.

❒ Do not store ink where it will be exposed to heat or direct sunlight.

❒ Store on a flat surface.

Open the front door.

A

Pull out the ink holder.

B

32

Page 43

Remove the used ink cartridge.

C

Remove the cap of the new ink cartridge.

D

Insert the new cartridge into the ink holder.

E

When the Add Ink Indicator (j) Lights

3

Note

❒ Always supply ink of the same color.

Return the ink holder to its original position until it clicks.

F

Close the front door.

G

The machine will start idling to supply ink to the drum.

33

Page 44

Troubleshooting

R

x Clearing Misfeeds

CAUTION:

• Be careful not to cut

yourself on any sharp

yellow edges when

you reach inside the

machine to remove

misfed papers.

----To prevent paper misfeeds:

Check the following before restarting

the printing run.

• Did you select an appropriate pa-

per type with the [Ppr.Type] key?

3

Note

❒ After clearing misfeeds, make sure

that all the doors, covers, and units

are closed and the x indicator is

off.

❒ To prevent misfeeds, do not leave

any torn scraps of paper in the machine.

❒ When clearing misfeeds, do not

turn off the main switch. If you do,

your print settings will be cleared.

❒ If misfeeds occur repeatedly,

please contact your service representative.

Paper Misfeed in the Paper

Feed Section

PAPER FEED JAM

REMOVE PAPER

PAPER TYPE 1:STD

2:THICK 3:SPL **

• Are the side pads in the correct positions?

To print on thin paper (52.3g/m

13.9 lb), slide the levers behind the

paper feed side plates in the direction of the arrow (see illustration).

• When paper is curled, correct the

curl as shown.

2

,

34

MISFED REGISTRATION

REMOVE PAPER

Remove the misfed paper.

A

Z066

Page 45

• When paper edges stick together

or paper is not fed in, shuffle the

paper as shown.

Z067

• When printing onto envelopes or

thick paper, lower the printing

speed. ⇒ P.22 “Changing the Print-

ing Speed”.

x Clearing Misfeeds

Paper Misfeed in the Paper

Feed Section

REGISTRATION JAM

REMOVE PAPER

Open the front door.

A

Lower drum unit lock lever B1.

B

Take out the drum.

C

3

• When a multi-feed occurs or the

paper is skewed, make sure that

the paper feed side plates are properly adjusted. When you load paper on the paper feed tray, make

sure that the paper edge touches

the back fence and paper is placed

on the proper paper size scale.

Only use paper where the leading

edge has two right angle corners.

Pull out the misfed paper gently

D

Note

❒ For how to take out the drum

unit, ⇒ P.9 “Changing the Drum

Unit”.

35

Page 46

3

Troubleshooting

from the inside.

If you cannot remove the misfed

E

paper from the inside, remove

from the Paper feed tray.

Paper Wrapped around the

Drum

When paper is wrapped around the drum

DRUM1:PAPERFED SKEW

REMOVE PAPER

Open the front cover.

A

Lower drum unit lock lever B1.

B

Set the drum unit and close the

F

front door.

----To prevent paper misfeeds:

⇒ P.34 “Paper Misfeed in the Paper Feed

Section”.

Take out the drum.

C

Note

❒ For how to take out the drum

unit, ⇒ P.9 “Changing the Drum

Unit”.

36

Page 47

x Clearing Misfeeds

Remove the misfed paper from

D

the drum.

If you cannot find misfed paper

E

in step DDDD, remove misfed paper

from the press roller.

Set the drum unit and close the

F

front door.

When paper is misfed inside the machine

DRUM1:DELIVERY JAM

REMOVE PAPER

Open the front cover.

A

Take out the drum.

C

Note

❒ For how to take out the drum

unit, ⇒ P.9 “Changing the Drum

Unit”.

Remove the misfed paper from

D

the inside as shown in the illustration.

3

Lower drum unit lock lever B1.

B

If you cannot remove the misfed

E

paper, remove paper from the

press roller.

37

Page 48

3

Troubleshooting

Set the drum unit and close the

F

front door.

----To prevent paper misfeeds:

If the paper is curled or the original's

leading edge margin is too narrow,

the following action is necessary.

• When you use curled paper, correct the curl as shown.

Z066

• If you want to know more details

about leading edge margin, refer

to the master making unit's operating instructions.

Paper Misfeed in the Paper

Exit Section

Slowly but firmly pull out the

A

misfed paper.

----To prevent paper misfeeds:

When a thin paper misfeed in the paper exit section occurs, reduce the

printing speed with the {WWWW}{VVVV}

{Speed} keys (⇒ P.22 “Changing the

Printing Speed”). If you cannot reduce

the printing speed, move the end

plate toward the paper delivery tray

edge.

38

Page 49

Poor Printing

R

R

R

Poor Printing

Dirty Background

If the background of prints is dirty, the drum unit might be dirty.

CAUTION:

• If ink comes into contact with your eyes, rinse immediately in running water.

In the case of any abnormal symptoms, consult a doctor.

CAUTION:

• Keep the ink or ink container out of the reach of children.

CAUTION:

• If ink is ingested, force vomiting by drinking a strong saline solution and consult a doctor immediately.

Note

❒ To avoid getting dirty background prints when printing onto paper smaller

than the original image, select a suitable reduction ratio or use larger print paper.

❒ When printing onto paper that does not absorb ink well, the background of

prints might get dirty. In this case, lower the printing speed or use Skip Feed

mode to dry the ink on the prints.

Open the front cover.

A

Pull out the drum unit.

B

3

Note

❒ For how to take out the drum unit, ⇒ P.9 “Changing the Drum Unit”.

39

Page 50

3

Troubleshooting

While pressing the drum lock, turn the drum until you can see the trailing

C

edge of the master.

With a dry soft cloth, remove any ink that has accumulated on the trailing

D

edge of the drum unit.

40

Important

❒ Do not use benzine, thinner, or other organic liquids—doing so can dam-

age the machine.

Turn the drum unit and lock it until it click after cleaning it.

E

Page 51

Poor Printing

Insert the drum unit until it locks in position, then lower the drum unit

F

lock lever.

Close the front door.

G

When the Press Roller is Dirty

If the background of prints is dirty, the Press Roller might be dirty.

3

Make several prints until clear image appears.

A

Note

❒ If the print is still dirty, contact your service representative.

Faint Prints

If the machine is not used for a long period of time or you change the color drum

unit, the ink on the drum might dry causing print quality to deteriorate. To solve

this problem, set back your drum unit to the Master making unit and use Quality

Start Mode. ⇒Refer to the Master Making Unit's Operating Instructions.

If the print density is still too light even when using Quality Start mode, remake

the master.

41

Page 52

3

Troubleshooting

42

Page 53

4. Remarks

R

Do's and Don'ts

CAUTION:

• Unplug the power cord from the wall outlet before you move the equipment.

While moving the equipment, you should take care that the power cord will

not be damaged under the equipment.

Important

• While printing, do not turn off the main switch.

• While printing, do not unplug the power cord.

• While printing, do not open the door or covers.

• While printing, do not move the machine.

• Open and close the door and covers softly.

• When printing onto paper that contains images on the back, make sure

there is a 10mm (0.4”) margin at the back leading edge. If there is no margin, the machine might incorrectly detect that paper is wrapped around

the drum and stop printing ⇒Refer to the Master Making Unit's Operating

Instructions.

• When you use envelopes or pasted print paper, the leading edge of print

might be damaged.

• Make sure to make a few trial prints to check the image position because the

image position of the trial print might not correspond with that of the original.

• The leading edge of the prints might become stained if the edge touches

the image of prints on the paper delivery tray.

• Print ink on the paper delivery tray might stick to the back side of the next

print.

• Press the {Proof} key to perform a test print as the image density of the first

few prints might be light.

• When the machine is on and the power source is less than 90% of the specified amount, printing quality will decrease. Therefore, make sure the supply from your electrical outlet is at least 90% of the required amount.

• When printing a large solid area on A3, 11" x 17" paper, the sides of the

print tend to curl up after the print is fed out to the paper delivery tray. The

next sheet that feeds out pushes against the curled sheet and a paper misfeed occurs. In this case, slow the printing speed down.

• When you make a lot of prints from a small image, ink might ooze out from

the edges of the master, especially under high temperature and when

printing in two or more colors. In this case, make a new master.

• Large uneven solid image wrinkles the master and you may not print as

you want.

43

Page 54

4

R

R

R

Remarks

Where to Put Your Machine

Environment

Your machine's location should be carefully chosen because environmental conditions greatly affect its performance.

Optimum environmental conditions

CAUTION:

• Keep the equipment away from humidity and dust. Otherwise a fire or an

electric shock might occur.

• Do not place the equipment on an unstable or tilted surface. If it topples

over, it could cause injury.

CAUTION:

• If you use the equipment in a confined space, make sure there is a continuous air turnover.

CAUTION:

• After you move the equipment, use the caster fixture to fix it in place. Otherwise the equipment might move or come down to cause a personal injury.

• Temperature: 10 – 30°C, 50 – 86°F

• Humidity: 20 – 90% RH

• A strong and level floor.

• The machine must be level within 5mm, 0.2" both front to rear and left to

right.

• Be sure to locate this machine in a large well ventilated room that has an air

turnover of more than 30m

3

/hr/person.

Environments to avoid

• Locations exposed to direct sunlight or strong light (more than 1500 lux).

• Locations directly exposed to cool air from an air conditioner or heated air

from a heater (sudden temperature changes might cause condensation within

the machine).

• Places where the machine might be subjected to frequent strong vibration.

• Dusty areas.

• Areas with corrosive gases.

44

Page 55

Where to Put Your Machine

R

R

R

Power Connection

WARNING:

• Only connect the machine to the power source described on the inside

front cover of this manual. Connect the power cord directly into a wall

outlet and do not use an extension cord.

• Do not damage, break or make any modifications to the power cord.

Do not place heavy objects on it. Do not pull it hard nor bend it more

than necessary. These actions could cause an electric shock or fire.

CAUTION:

• Unplug the power cord from the wall outlet before you move the equipment.

While moving the equipment, you should take care that the power cord will

not be damaged under the equipment.

CAUTION:

• When you disconnect the power plug from the wall outlet, always pull the

plug (not the cable).

4

Make sure the plug is firmly inserted in the outlet.

Machine Clearance

Place the machine near the power source, providing clearance as shown.

❖❖❖❖ Main frame

*: Paper delivery tray

1. More than 10cm, 4.0"

2. More than 60cm, 23.7"

3. More than 60cm, 23.7"

4. More than 60cm, 23.7"

45

Page 56

4

Remarks

Maintaining Your Machine

To maintain high print quality, clean

the following parts and units regularly.

❖❖❖❖ Cleaning the machine

Wipe the machine with a soft,

damp cloth. Then wipe it with a

dry cloth to remove the water.

Important

❒ Do not use chemical cleaner or or-

ganic solvent, such as thinner or

benzene. If they get into the machine or melt plastic parts, a failure

might occur.

❒ Do not clean parts other than those

specified in this manual. Such

parts should be cleaned by your

service representative.

Cleaning the Main Frame

Cleaning the paper feed roller (Paper

feed tray)

Wipe off the paper dust on the pa-

A

per feed roller with a damp cloth,

then wipe it with a dry cloth.

Note

❒ If you do not clean the paper

feed roller, paper misfeeds tend

to occur.

46

Page 57

5. Specifications

Main Frame

❖❖❖❖ Configuration:

Floor standing (with custom table or cabinet)

❖❖❖❖ Printing Process:

Twin color press roller printing system

❖❖❖❖ Original Size & Printing Area:

Refer to the Master Making Unit's Operating Instructions

❖❖❖❖ Print Paper Size:

Maximum: 297mm × 432mm, 11.6" × 17.0"

Minimum: 70mm × 250mm, 2.8" × 9.8"

❖❖❖❖ Leading Edge Margin:

Refer to the Master Making Unit's Operating Instructions

❖❖❖❖ Print Paper Weight:

• 52.3 – 209.3g/m2, 13.9 – 55.6 lb

❖❖❖❖ Print Speed:

90.105.120cpm (3 steps)

❖❖❖❖ Color Printing:

Drum unit replacement system

❖❖❖❖ Image Position:

Up&Down Right&Left

Overall Image Adjustment +10mm, 0.4” or —10mm,

0.4”

Drum2 Image Adjustment Moving sums of both adjust-

ment functions (Max 10mm,

0.4”)

❖❖❖❖ Paper Size and Paper Capacity:

1,000 sheets (80g/m2, 20 lb)

❖❖❖❖ Paper Delivery Tray Capacity:

1,000 sheets (80g/m2, 20 lb)

+10mm, 0.4” or —10mm,

0.4”

+5mm, 0.2” or —5mm, 0.2”

47

Page 58

Specifications

❖❖❖❖ Dimensions (W ×××× D ×××× H):

Width Depth Height

Stored 920 mm, 36.2" 630 mm, 24.8" 555 mm, 21.9"

Set up 1,610 mm, 63.4" 630 mm, 24.8" 555 mm, 21.9"

❖❖❖❖ Weight:

• Machine:

Less than 88kg, 194 lb

5

❖❖❖❖ Noise Emission

*1

:

Sound Power Level

Printing Speed Noise Emission

During printing 90cpm 78dB(A)

105cpm 80dB(A)

120cpm 82dB(A)

Stand-by -- 47dB(A)

Sound Pressure Level

During printing 90cpm 65dB(A)

*1

The above measurement made in accordance with ISO 7779 are actual value.

*2

It is measured at the position of the operator.

*2

Printing Speed Noise Emission

105cpm 68dB(A)

120cpm 69dB(A)

❖❖❖❖ Power Consumption:

• Printing:

0.55kW (Max)

❖❖❖❖ Optional Equipment:

• Drum unit: color Drums

A3, 11" × 17"

Note

❒ Specifications are subject to change without notice.

48

Page 59

Consumables

Consumables

Name Size Remarks

Ink-Black 1,000ml/pack Environmental conditions: -5

to 40°C 10 – 95% RH

Ink-Red 1,000ml/pack

Ink-Blue

Ink-Green

Ink-Brown

Ink-Purple

Ink-Yellow

Ink-Navy

Ink-Maroon

Ink-Teal

Ink-Orange

Ink-Gray

Ink-Violet

Ink-Hunter green

Ink-Burgundy

Ink-Gold

Ink-Reflex Blue

Note

❒ Specifications are subject to change without notice.

5

49

Page 60

INDEX

F

,

{~}{}}{|}{{}

4

A

,

26

,

,

25

32

accessing the user tools

Add Ink Indicator (j)

adjusting the position of printed images

20

,

Auto Off

Auto Reset Time

26

B

Buzzer Off

,

26

C

26

,

22

changing the printing speed

,

,

,

49

,

34

4

4

,

clearing misfeeds

{Clear Modes} key

{Clear/Stop} key

Clr Resettable Count

consumables

,

Counter

4

D

,

,

9

,

4

4

,

27

39

,

9

,

2

dirty background

Drm Stp Mode

{Drum1} key

{Drum2} key

Drum unit

drum unit handle B2

drum unit lock lever B1

,

E

environment

,

44

,

,

,

27

1

Feed Setup

front door

I

, 32,

ink

ink holder

49

,

2

J

Jump Table

,

27

K

,

,

4

4

{#} key

keys

L

,

,

31

10

,

27

Loading Paper

loading paper

Load Paper indicator (B)

Long Sheet Mode

M

,

26

,

45

,

1

,

2

2

machine clearance

machine exterior

machine interior

main switch

maintaining your machine

Max Print

,

N

Number keys

,

4

O

48

, 1,

4

operation panel

options

,

,

,

31

46

50

Page 61

P

T

paper alignment wings

paper delivery end plate

paper delivery side plates

paper delivery tray

paper feed side plates

Paper feed side plates knob

Paper feed tray

Paper feed tray down key

paper misfeed in the paper exit section

paper misfeed in the paper feed section

paper or master wrapped around the drum

Paper Type

poor printing

{Position Adj/Drum2} key

{Position Adj/Whole} key

power connection

{Ppr. Supply Adj} key

{Ppr.Type} key

{Print} key

print paper

Print Position

{Proof} key

,

,

17

,

39

,

,

4

, 13, 17,

,

27

,

4

,

2

,

2

,

2

,

2

,

1

,

1

1

,

1

,

4

,

4

,

45

,

4

4

31

R

,

, 34,

,

38

35

36

thick paper

Total Counter

Total Counter Down

trailing edge guides

Troubleshooting

,

17

,

26

,

29

,

,

27

3

U

user tools

{User Tools} key

, 25,

26

,

4

W

what you can do with this machine

when the image density is too light

where to put your machine

{WWWW} {VVVV} keys (Speed keys)

,

,

44

4

,

,

iv

41

Remarks

Resettable Count

,

43

,

26

S

29

,

,

,

47

4

17

,

,

,

15

i

23

,

,

,

27

27

17

Safety Information

,

,

26

service call

Setting and Changing the Drum Unit

Setting Up the Paper Delivery Table

Skip Display On Mode

{Skip Feed} key

Skip Feed printing

Skip Number of Time

Special kinds of Paper

specifications

standard paper

standard printing

System

,

,

7

11

51

Page 62

MEMO

52

Page 63

MEMO

53

Page 64

MEMO

54

UE USA C593

Loading...

Loading...