Page 1

STINGER - P3/P4

SERVICE MANUAL

Subject to change

Ricoh Technical Service

March 12th 1999

Page 2

I

IMPORTANT SAFETY NOTICES

PREVENTION OF PHYSICAL INJURY

1. Before disassembling or assembling parts of the printer and peripherals,

make sure that the printer power cord is unplugged.

2. The wall outlet should be near the printer and easily accessible.

3. If any adjustment or operation check has to be made with exterior covers off

or open while the main switch is turned on, keep hands away from electrified

or mechanically driven components.

4. If a print job has started (the Data In LED has started blinking) before the

printer completes the warm-up or initializing period, keep hands away from

the mechanical and electrical components because the printer starts making

prints as soon as the warm-up period is completed.

5. The inside and the metal parts of the fusing unit become extremely hot while

the printer is operating. Avoid touching those components with your bare

hands.

HEALTH SAFETY CONDITIONS

Toner is non-toxic, but if you get it in your eyes by accident, it may cause

temporary eye discomfort. Try to remove with eye drops or flush with water as

first aid. If unsuccessful, get medical attention.

SAFETY AND ECOLOGICAL NOTES FOR DISPOSAL

1. Do not incinerate the toner cassettes. Toner dust may ignite suddenly when

exposed to an open flame.

2. Dispose of toner cassettes in accordance with local regulations. (This is a

non-toxic unit.)

3. Dispose of replaced parts in accordance with local regulations.

Page 3

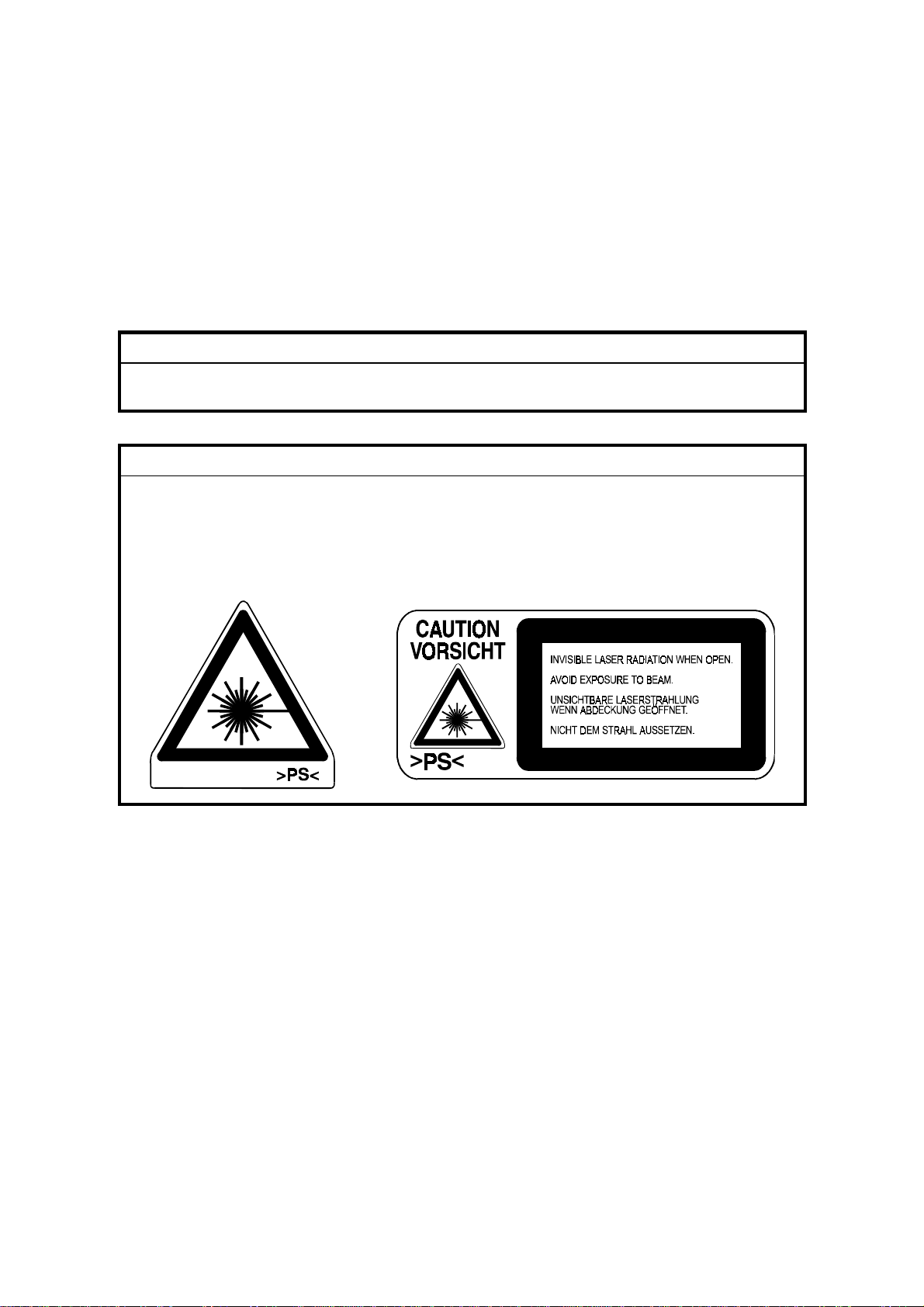

LASER SAFETY

The Center for Devices and Radiological Health (CDRH) prohibits the repair of

laser-based optical units in the field. The optical housing unit can only be repaired

in a factory or at a location with the requisite equipment. The laser subsystem is

replaceable in the field by a qualified Customer Engineer. The laser chassis is not

repairable in the field. Customer engineers are therefore directed to return all

chassis and laser subsystems to the factory or service depot when replacement of

the optical subsystem is required.

WARNING

I

Use of controls, or adjustment, or performance of procedures other than

those specified in this manual may result in hazardous radiation exposure.

WARNING FOR LASER UNIT

I

WARNING: Turn off the main switch before attempting any of the

procedures in the Laser Unit section. Laser beams can

seriously damage your eyes.

CAUTION MARKING:

Page 4

TABLE OF CONTENTS

1. OVERALL MACH INE INFORMATION........................................1-1

1.1 SPECIFICATIONS.................................................................................... 1-1

1.2 MACHINE CONFIGURATION.................................................................. 1-5

1.3 PAPER PATH........................................................................................... 1-6

1.4 MECHANICAL COMPONENT LAYOUT................................................... 1-7

1.5 ELECTRICAL COMPONENT LAYOUT.................................................... 1-8

1.6 ELECTRICAL COMPONENT DESCRIPTIONS...................................... 1-10

1.7 PRINTING PROCESS............................................................................ 1-12

1.8 BOARD STRUCTURE............................................................................ 1-14

1.8.1 OVERVIEW ................................................................................... 1-14

1.8.2 MAJOR COMPONENTS................................................................ 1-15

1.9 COMPARISON....................................................................................... 1-16

2. DETAILED SECTION DESCRIPTIONS.......................................2-1

2.1 PRINTING................................................................................................. 2-1

2.1.1 IMAGE DATA PATH........................................................................ 2-1

2.1.2 PRINTER CONTROL BOARD......................................................... 2-2

2.1.3 IMAGE DATA PROCESSIING......................................................... 2-3

2.1.4 HOST INTERFACE.......................................................................... 2-4

2.2 LASER EXPOSURE................................................................................. 2-5

2.2.1 OVERVIEW ..................................................................................... 2-5

2.2.2 OPTICAL PATH............................................................................... 2-6

2.2.3 AUTO POWER CONTROL (APC)................................................... 2-8

2.2.4 LD SAFETY SWITCH...................................................................... 2-9

2.3 TONER CARTRIDGE............................................................................. 2-10

2.3.1 OVERVIEW ................................................................................... 2-10

2.3.2 DRIVE............................................................................................ 2-11

2.3.3 DRUM CHARGE............................................................................ 2-12

2.3.4 DEVELOPMENT............................................................................ 2-13

2.3.5 DRUM CLEANING......................................................................... 2-15

2.4 IMAGE TRANSFER AND PAPER SEPARATION.................................. 2-16

2.4.1 OVERVIEW ................................................................................... 2-16

2.4.2 TRANSFER ROLLER CLEANING................................................. 2-17

2.5 PAPER FEED......................................................................................... 2-18

2.5.1 OVERVIEW ................................................................................... 2-18

2.5.2 PAPER TRAY................................................................................ 2-20

2.5.3 BY-PASS TRAY............................................................................. 2-25

2.5.4 PAPER REGISTRATION............................................................... 2-27

2.6 IMAGE FUSING...................................................................................... 2-29

2.6.1 OVERVIEW ................................................................................... 2-29

2.6.2 FUSING......................................................................................... 2-30

2.6.3 FUSING UNIT DRIVE.................................................................... 2-30

2.6.4 PRESSURE ROLLER/PAPER EXIT.............................................. 2-31

i

Page 5

2.6.5 FUSING UNIT DRIVE RELEASE................................................... 2-31

2.6.6 NEW FUSING UNIT DETECTION (STINGER - P3 ONLY)............ 2-32

2.6.7 FUSING TEMPERATURE CONTROL........................................... 2-33

2.6.8 OVERHEAT PROTECTION........................................................... 2-35

2.6.9 ENERGY SAVER MODE............................................................... 2-36

2.7 COVER OPEN DETECTION.................................................................. 2-37

2.7.1 FRONT COVER LOCK.................................................................. 2-37

2.7.2 FRONT COVER SAFETY SWITCH............................................... 2-37

2.7.3 REMOVING THE FUSING UNIT................................................... 2-38

2.8 ENGINE CONTROL BOARD.................................................................. 2-39

2.8.1 PCB LAYOUT................................................................................ 2-39

2.8.2 DEVICES....................................................................................... 2-40

2.8.3 STRUCTURE................................................................................. 2-41

2.8.4 CONNECTION TO THE ECB........................................................ 2-42

2.9 SIGNAL TABLE...................................................................................... 2-44

2.10 PRINTER CONTROL BOARD.............................................................. 2-47

2.10.1 PCB LAYOUT.............................................................................. 2-47

2.10.2 DEVICES..................................................................................... 2-48

3. INSTALLA TION...........................................................................3-1

3.1 INSTALLATION REQUIREMENTS .......................................................... 3-1

3.1.1 ENVIRONMENT .............................................................................. 3-1

3.1.2 POWER REQUIREMENTS.............................................................. 3-1

3.2 PRINTER INSTALLATION........................................................................ 3-2

3.3 PAPER FEED UNIT INSTALLATION....................................................... 3-2

3.4 ENVELOPE FEEDER INSTALLATION.....................................................3-2

3.5 HARD DISK INSTALLATION.................................................................... 3-2

3.6 MEMORY UNIT INSTALLATION.............................................................. 3-2

3.7 NETWORK INTERFACE BOARD INSTALLATION.................................. 3-2

3.8 CHECKING THE CONNECTIONS........................................................... 3-3

3.8.1 CONNECTION BETWEEN MAIN PRINTER CONTROL BOARD

(AND RELATED OPTIONS: HDD, RAM SIMM, NIC) AND

OPTIONAL HDD & PERIPHERALS................................................. 3-3

3.8.2 CONNECTION BETWEEN PRINTER CONTROL BOARD AND

NETWORK INTERFACE BOARD.................................................... 3-6

3.8.3 PRINTING THE NETWORK INTERFACE BOARD

CONFIGURATION SHEET.............................................................. 3-6

4. SERVICE PROCEDURES AND TABLES................................... 4-1

4.1 OVERVIEW .............................................................................................. 4-1

4.2 SERVICE PROGRAM MODE................................................................... 4-2

4.2.1 ENABLING AND DISABLING SERVICE PROGRAM MODE.......... 4-2

4.2.2 SERVICE PROGRAM MODE MENU TREE.................................... 4-3

4.2.3 SERVICE MODE MENU TABLE...................................................... 4-5

4.2.4 PRINT LOG...................................................................................... 4-9

4.2.5 PRINTER ID................................................................................... 4-13

4.3 IC CARD BOOT SERVICE MODE ......................................................... 4-15

ii

Page 6

4.3.1 OVERVIEW ................................................................................... 4-15

4.3.2 ENABLING AND DISABLING IC CARD BOOT SERVICE

MODE............................................................................................ 4-15

4.3.3 IC CARD BOOT SERVICE MODE TREE...................................... 4-16

4.3.4 SERVICE MENU TABLE............................................................... 4-17

4.4 EEPROM AND NVRAM RESET PROCEDURES................................... 4-18

4.5 DOWNLOADING NEW CONTROLLER SOFTWARE ............................ 4-19

4.5.1 OVERVIEW ................................................................................... 4-19

4.5.2 DOWNLOADING NEW FIRMWARE FROM AN IC CARD............. 4-20

4.6 USER MENU.......................................................................................... 4-23

4.7 ECB TEST PATTERN............................................................................. 4-24

4.8 DIAGNOSTIC TEST MODES................................................................. 4-25

4.8.1 OVERVIEW ................................................................................... 4-25

4.8.2 POWER-UP DIAGNOSTIC MODE................................................ 4-25

4.8.3 DETAILED DIAGNOSTIC MODE.................................................. 4-26

4.8.4 DIAGNOSTIC TEST DETAILS....................................................... 4-27

5. PREVENTIVE MAINTENANCE...................................................5-1

5.1 PREVENTIVE MAINTENANCE SCHEDULE............................................ 5-1

6. REPLACEMENT A N D ADJUSTMENT........................................ 6-1

6.1 COVERS................................................................................................... 6-1

6.1.1 EXTERIOR COVER REMOVAL...................................................... 6-1

6.1.2 FRONT COVER REMOVAL............................................................ 6-2

6.1.3 CONTROL BOARD COVER REMOVAL ......................................... 6-3

6.2 FUSING UNIT........................................................................................... 6-4

6.2.1 FUSING UNIT REPLACEMENT...................................................... 6-4

6.2.2 HOT ROLLER AND FUSING LAMP REPLACEMENT .................... 6-5

6.2.3 PRESSURE ROLLER REPLACEMENT.......................................... 6-7

6.2.4 FUSING THERMOFUSE REPLACEMENT ..................................... 6-8

6.2.5 FUSING DRAWER CONNECTOR REPLACEMENT....................... 6-9

6.3 TRANSFER ROLLER............................................................................. 6-10

6.3.1 TRANSFER ROLLER REPLACEMENT ........................................ 6-10

6.4 PAPER FEED......................................................................................... 6-11

6.4.1 BY-PASS TRAY REMOVAL.......................................................... 6-11

6.4.2 BY-PASS FEED ROLLER REPLACEMENT.................................. 6-12

6.4.3 PAPER FEED ROLLER REPLACEMENT..................................... 6-15

6.4.4 RELAY ROLLER REPLACEMENT (STINGER - P4 ONLY)........... 6-17

6.4.5 FRICTION PAD REPLACEMENT.................................................. 6-18

6.4.6 TRAY PAPER FEED CLUTCH REPLACEMENT.......................... 6-19

6.5 LASER UNIT........................................................................................... 6-20

6.5.1 CAUTION DECAL LOCATIONS.................................................... 6-20

6.5.2 LASER UNIT/SHIELD GLASS REPLACEMENT........................... 6-21

6.5.3 LD UNIT/LASER SYNCHRONIZATION DETECTOR

REPLACEMENT............................................................................ 6-22

6.5.4 POLYGONAL MIRROR MOTOR REPLACEMENT....................... 6-23

6.5.5 LD UNIT/POLYGONAL MIRROR MOTOR REPLACEMENT........ 6-24

iii

Page 7

6.6 OTHERS................................................................................................. 6-25

6.6.1 TONER NEAR-END SENSOR REPLACEMENT........................... 6-25

6.6.2 MAIN MOTOR/GEAR BOX REMOVAL ......................................... 6-26

6.6.3 ENGINE CONTROL BOARD REPLACEMENT............................. 6-27

6.6.4 PRINTER CONTROL BOARD REPLACEMENT........................... 6-28

6.6.5 HIGH VOLTAGE SUPPLY BOARD............................................... 6-29

6.6.6 POWER SUPPLY UNIT REPLACEMENT..................................... 6-30

6.7 PRINT REGISTRATION ADJUSTMENT................................................ 6-31

7. TROUBLESHOOTING.................................................................7-1

7.1 OPERATOR ERRORS ............................................................................. 7-1

7.2 PRINTER ENGINE SC CODES................................................................ 7-6

7.3 DIAGNOSTIC ERROR CODES................................................................ 7-9

7.3.1 DIAGNOSTIC ERROR CODE TABLE............................................. 7-9

7.4 ELECTRICAL COMPONENT DEFECTS................................................ 7-17

7.4.1 SENSORS..................................................................................... 7-17

7.4.2 SWITCHES.................................................................................... 7-17

7.4.3 FUSES........................................................................................... 7-17

iv

Page 8

OPTION

ENVELOPE FEEDER (Machine Code: G913)

1. OVERALL INFORMATION................................................... G913-1

1.1 SPECIFICATIONS..............................................................................G913-1

1.2 MECHANICAL COMPONENT LAYOUT.............................................G913-1

2. DETAILED SECTION DESCRIPTIONS................................ G913-2

2.1 PAPER LIFT.......................................................................................G913-2

3. INSTALLA TION.................................................................... G913-3

4. REPLACEMENT AND ADJUSTMENT................................. G913-4

4.1 FRICTION PAD REPLACEMENT.......................................................G913-4

PAPER FEED UNIT (Machine Code: G914)

1. OVERALL MACH INE INFORMATION................................. G914-1

1.1 SPECIFICATIONS..............................................................................G914-1

1.1.1 STINGER - P3...........................................................................G914-1

1.1.2 STINGER - P4...........................................................................G914-1

1.2 MECHANICAL COMPONENT LAYOUT.............................................G914-2

1.3 ELECTRICAL COMPONENT LAYOUT..............................................G914-3

1.4 ELECTRICAL COMPONENT DESCRIPTION....................................G914-4

2. DETAILED SECTION DESCRIPTIONS................................ G914-5

2.1 PAPER SIZE DETECTION.................................................................G914-5

2.2 PAPER LIFT.......................................................................................G914-5

2.3 PAPER END DETECTION .................................................................G914-5

2.4 PAPER NEAR END DETECTION ......................................................G914-5

2.5 PAPER FEED.....................................................................................G914-6

3. INSTALLA TION.................................................................... G914-8

4. REPLACEMENT AND ADJUSTMENT................................. G914-9

4.1 PAPER FEED UNIT (OPTION FOR STINGER - P3)..........................G914-9

4.1.1 PAPER FEED ASSEMBLY REMOVAL .....................................G914-9

4.1.2 DRIVE ROLLER REPLACEMENT...........................................G914-10

4.1.3 PAPER FEED MOTOR REPLACEMENT................................G914-11

v

Page 9

4.1.4 PAPER FEED CLUTCH REMOVAL........................................G914-12

4.1.5 PAPER FEED UNIT BOARD/PAPER SIZE SWITCH

REPLACEMENT......................................................................G914-13

4.2 PAPER FEED UNIT (OPTION FOR STINGER - P4)........................ G914-14

4.2.1 PAPER FEED ROLLER/PAPER FEED CLUTCH

REPLACEMENT......................................................................G914-14

4.2.2 PAPER DRIVE ROLLER REPLACEMENT..............................G914-15

4.2.3 DRIVE ROLLER IDLER/FRICTION PAD REPLACEMENT.....G914-16

4.2.4 PAPER FEED MOTOR/PAPER FEED UNIT BOARD

REPLACEMENT......................................................................G914-17

NETWORK INTERFACE BOARD (Machine Code: G919)

1. OVERALL MACH INE INFORMATION................................. G917-1

1.1 SPECIFICATIONS..............................................................................G917-1

2. INSTALLATION PROCEDURE............................................ G917-2

2.1 HARDWARE INSTALLATION ............................................................G917-2

2.1.1 SERIAL NUMBER AND MAC ADDRESS..................................G917-2

2.1.2 STATUS SHEET........................................................................G917-2

2.2 PROGRAMMING NETWORK/PROTOCOL PARAMETERS..............G917-3

2.2.1 IPX NETWORK..........................................................................G917-3

2.2.2 TCP/IP NETWORK....................................................................G917-4

2.2.3 ETHERTALK (APPLETALK) NETWORK...................................G917-5

2.3 SETUP FOR VARIOUS NETWORK TYPES...................................... G917-6

2.3.1 PEER-TO-PEER NETWORK.....................................................G917-6

2.3.2 NOVELL NETWARE NETWORK...............................................G917-7

2.3.3 TCP/IP NETWORK....................................................................G917-7

3. SERVICE TABLES AND PROCEDURES ............................ G917-8

3.1 FACTORY RESET (NVRAM CLEAR).................................................G917-8

3.2 FLASH ROM UPDATE.......................................................................G917-9

3.2.1 INTRODUCTION .......................................................................G917-9

3.2.2 FLASHUP UTILITY (FOR NOVELL IPX NETWORKS)............G917-10

3.2.3 FTPDL UTILITY (FOR TCP/IP NETWORKS)..........................G917-13

4. TROUBLESHOOTIN G........................................................ G917-16

4.1 LED INDICATIONS...........................................................................G917-16

vi

Page 10

APPENDIX

1. DOWNLOADING CONTROLLER FIRMWARE...........APPENDIX-1

1.1 OVERVIEW .............................................................................. APPENDIX-1

1.1.1 IC CARD (FLASH CARD)................................................APPENDIX-1

1.1.2 PC, VIA PARALLEL PORT.............................................. APPENDIX-2

1.1.3 DIMM............................................................................... APPENDIX-2

1.1.4 RELEASING NEW CONTROLLER FIRMWARE............. APPENDIX-3

1.2 SERVICE TOOLS..................................................................... APPENDIX-4

1.2.1 OPERATION PANEL....................................................... APPENDIX-4

1.2.2 SERVICE TOOL MENUS ................................................ APPENDIX-5

1.2.3 STINGER SERVICE UTILITY (SSU)...............................APPENDIX-7

1.3 USING AN IC CARD................................................................. APPENDIX-8

1.3.1 PREPARING THE IC CARD............................................ APPENDIX-8

1.3.2 DOWNLOADING FROM THE IC CARD TO

THE PRINTER............................................................... APPENDIX-13

1.4 USING A DIMM ...................................................................... APPENDIX-14

1.4.1 PREPARING THE DIMM............................................... APPENDIX-14

1.4.2 DOWNLOADING FROM THE DIMM TO

THE PRINTER............................................................... APPENDIX-19

1.5 COPYING FROM A PC DIRECTLY........................................ APPENDIX-20

1.5.1 PREPARATION............................................................. APPENDIX-20

1.5.2 DOWNLOADING TO THE FLASH MEMORY................ APPENDIX-22

1.6 SSU TROUBLESHOOTING ................................................... APPENDIX-26

vii

Page 11

12 March 1999 SPECIFICATIONS

1. OVERALL MACHINE INFORMATION

1.1 SPECIFICATIONS

Configuration: Desktop

Print Process: Laser beam scanning & electrophotographic printing

Monocomponent toner development

Printing Speed

(600 dpi):

First Print Speed: Stinger - P3:

Resolution: True 1,200 x 1,200 dpi (available for PCL6 or PostScript)

Printer Language PCL6/PCL5e

Stinger - P3:

Maximum 20 pages per minute (A4/LT LEF)

Stinger - P4:

Maximum 14 pages per minute (A4/LT SEF)

5.5 s or less (A4/LT - LEF, standard tray)

Stinger - P4:

6.5 s or less (A4/LT - SEF, standard tray)

600 x 600 dpi

300 x 300 dpi (simulated by doubling pixel width and

height at 600 dpi resolution)

Compatible with Laser Jet 5N driver and printer.

Windows 3.1x/95/98, Windows NT4.0 drivers available.

PostScript Level II

Windows 95/98, Windows NT4.0, and Macintosh (OS

7.5 or later) PPDs are available.

Overall

Information

Printer Fonts: PCL6

35 Intellifonts

10 True Type fonts

1 Bitmap font

PS2

35 Adobe type 1 fonts

Printer Interface: Bi-directional IEEE1284 parallel x 1 (Standard)

Ethernet (100 Base-TX/10 Base-T for TCP/IP, IPX/SPX,

EtherTalk)

RS232C interface (Optional)

1-1

Page 12

SPECIFICATIONS 12 March 1999

Printing Paper Size: Stinger - P3:

Maximum A3/11" x 17"

Minimum A5 LEF - Standard Tray

B6 SEF - By-pass Tray

A5 LEF - Optional PFU

Custom paper size (PCL 6/PS): By-pass Tray

11.69" x 17" ~ 3.88" x 5.83"

(297 x 431.8 ~ 98.4 x 148 mm)

Envelope: By-pass & Envelope Feeder

Com#10, C6, DL, Monarch

Stinger - P4:

Maximum A4/LG (only A4/LT for Standard Tray)

Minimum A4/LT – Standard Tray

B6 SEF - By-pass Tray

A5 LEF - Optional PFU

Custom paper size (PCL 6/PS): By-pass Tray

8.5" x 14" ~ 3.88" x 5.83"

(216 x 355.6 ~ 98.4 x 148 mm)

Envelope: By-pass & Envelope Feeder

Com#10, C6, DL, Monarch

Printing Paper Weight: Paper tray: 60 ~ 106 g/m2, 16 ~ 28 lb

By-pass: 60 ~ 162 g/m2, 16 ~ 43 lb

Power Source: Stinger - P3:

120 V, 60 Hz: More than 8.0 A (for North America)

220 V ~ 240 V, 50/60 Hz: More than 8.0 A (for Europe)

Stinger - P4:

120 V, 60 Hz: More than 6.0 A (for North America)

220 V ~ 240 V, 50/60 Hz: More than 5.0 A (for Europe)

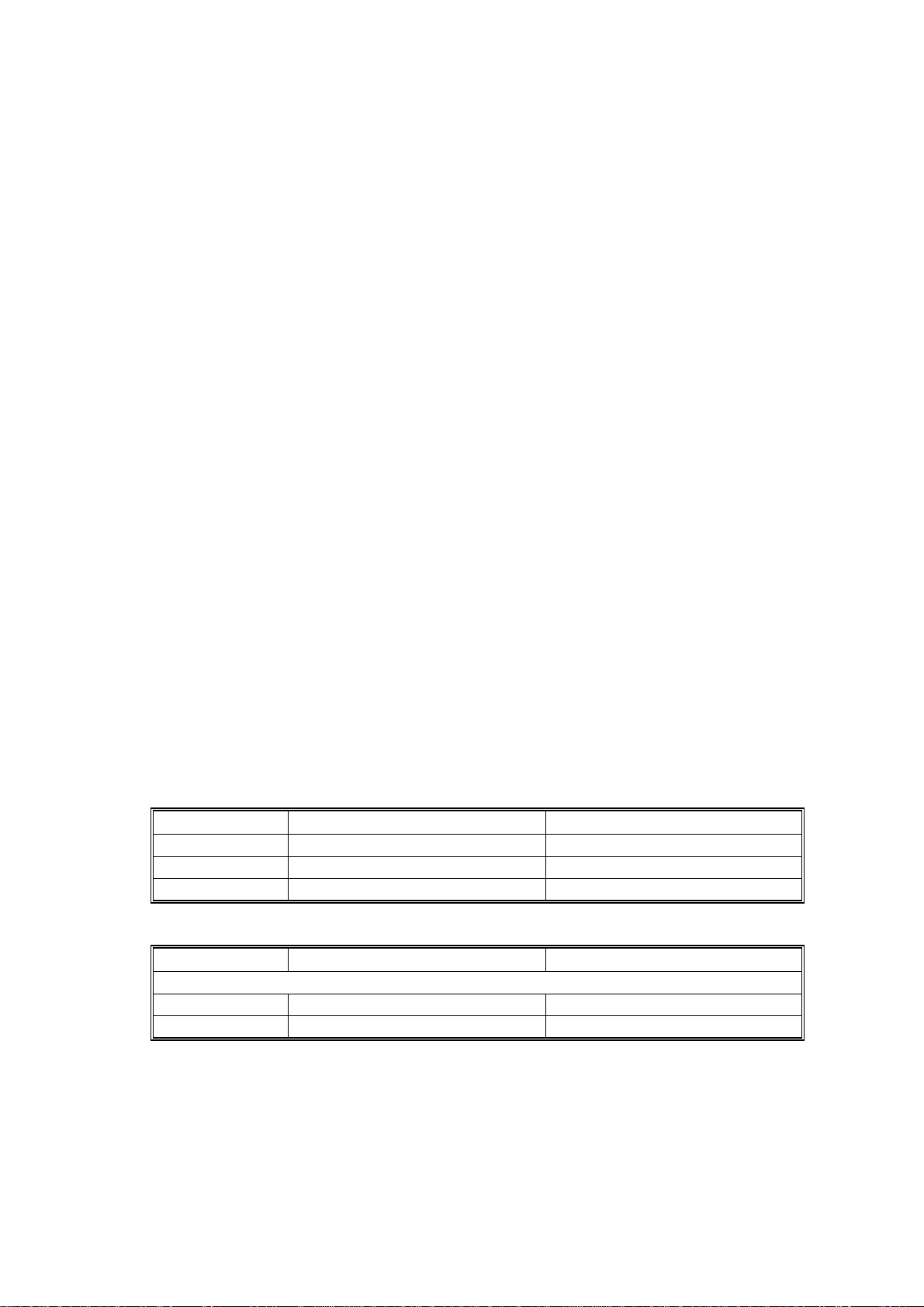

Power Consumption:

Stinger - P3 Stinger - P4

Maximum 795 W or less 600 W or less

Printing 480 W or less 380 W or less

Energy Saver 30 W or less 30 W or less

Noise Emission (All Options Installed):

Stinger - P3 Stinger - P4

Sound Power Level

Printing 64 dB or less 59 dB or less

Stand-by 48 dB or less 48 dB or less

NOTE:

The above measurements were made in accordance with ISO 9296 at

the operator position.

1-2

Page 13

12 March 1999 SPECIFICATIONS

Dimensions (Printer only):

Width Depth Height

Stinger - P3 450 mm (17.7") 420 mm (16.6") 270 mm (10.6")

Stinger - P4 360 mm (14.2") 420 mm (16.6") 270 mm (10.6")

Weight: Stinger - P3: Less than 15 kg (33 Ib.)

Stinger - P4: Less than 12 kg (27 Ib.)

Overall

Information

Warm-up Time

Less than 39 seconds: 23°C

Energy Saver Mode 30 min. is the standard setting; it can be changed with the

Job Control menu

Print Paper Capacity: Standard Tray: 250 sheets

By-pass Tray: 100 sheets

10 envelopes (Stinger - P3)

5 envelopes (Stinger - P4)

Optional Paper Feed Unit: 500 sheets x 2 (Stinger - P3)

500 sheets x 1 (Stinger - P4)

Optional Envelope Feeder: 60 envelopes

Memory:

Standard 8 MB, up to 40 MB with optional SIMM.

Toner Cartridge Information:

Stinger - P3 Stinger - P4

Pre-set

Toner Cartridge

Average

3,000 pages/crtg.;

200g

Measurement Conditions:

Commercial

Toner Cartridge

Average

14,000 pages/crtg.;

750g

1) 5% test pattern

Pre-set

Toner Cartridge

Average

3,000 pages/crtg.;

200g

Commercial

Toner Cartridge

Average

8,000 pages/crtg.;

430g

2) A4 paper

3) LEF for Stinge r - P3, SEF for Stinger - P4

4) Continuous printing

Optional Equipment:

·

A3/DLT paper feed unit (unique for Stinger - P3)

·

A4/LT paper feed unit (unique for Stinger - P3)

·

Paper feed unit (unique for Stinger - P4)

·

Envelope feeder (unique for Stinger - P3)

·

Envelope feeder (unique for Stinger - P4)

·

Network Interface Board

·

1.6 GB HDD unit (hard disk drive unit)

·

RS232 board

Output Paper Capacity: 250 sheets

1-3

Page 14

SPECIFICATIONS 12 March 1999

Utility Software

(Main frame CD-ROM):

Utility Software

(Optional Network Interface

Board):

Maintenance Kit:

·

Printer Drivers

·

PS PPD files

·

Font Manager

·

Aficio Manager

·

Operating Instructions (G031/G032 -22, -27, -29)

·

IP-P2P

·

IPXP2P

·

MAP

·

Bootpl

·

NW setup

·

NIB User’s Manual

·

Acrobat Reader

·

Fusing Unit x 1

·

Transfer Unit x 1

·

Friction Pad x 1

·

Paper Feed Roller x 3 (Stinger - P3)

·

Paper Feed Roller x 1 (Stinger - P4)

1-4

Page 15

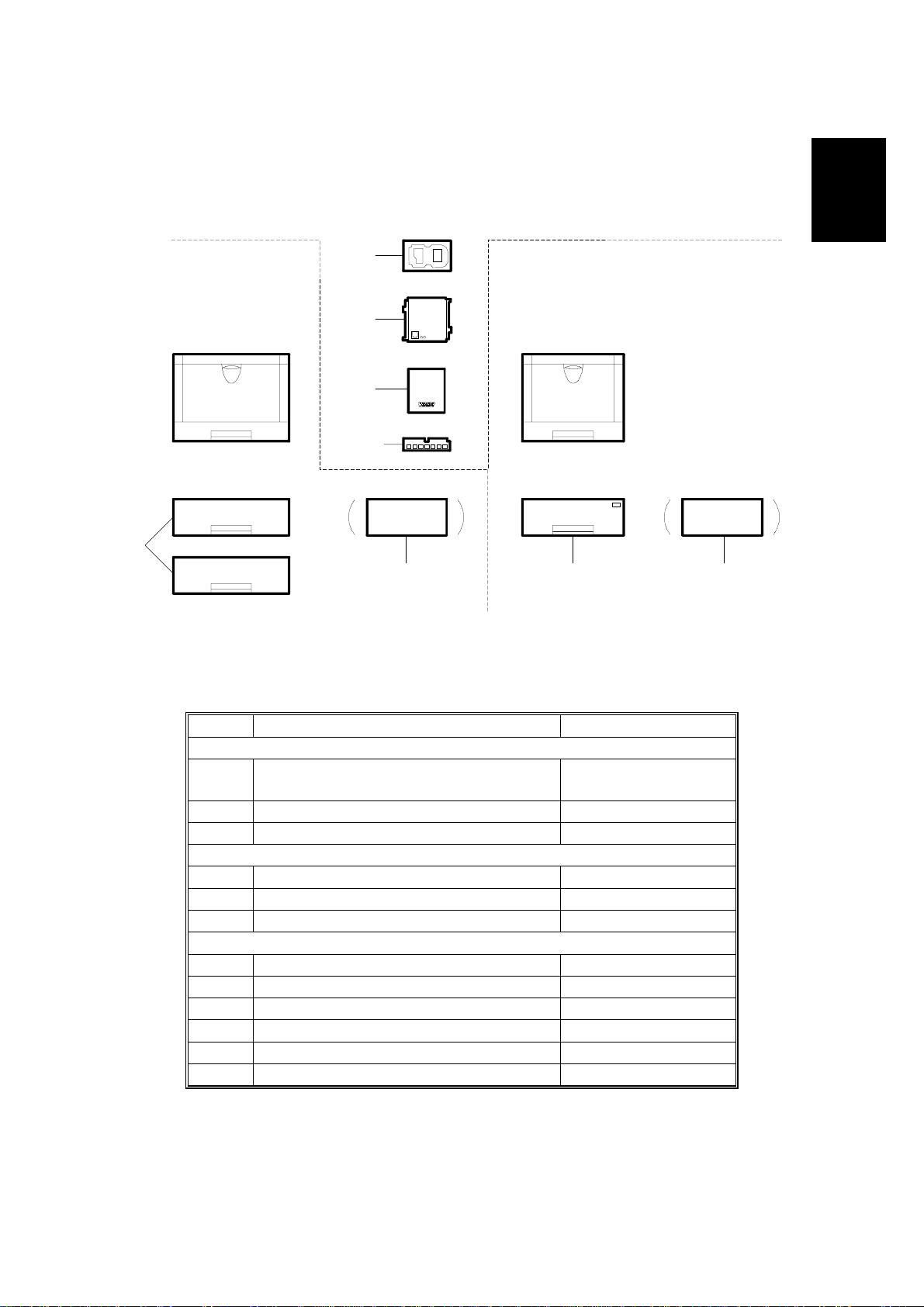

12 March 1999 MACHINE CONFIGURATION

1.2 MACHINE CONFIGURATION

Internal Options

[G]

Stinger - P3

Stinger - P4

G031-17, 22, 27, 29 G032-17, 22, 27, 29

[E]

[F]

[H, I]

[A]

[B]

Overall

Information

[D][C]

G031V500.WMF

*NOTE:

No. Item Machine Code

Stinger - P3

A

B *Envelope Feeder Type 2000 G913-17

Stinger - P4

C Paper Feed Unit Type 1400 G914-57

D Envelope Feeder Type 1400 G913-57

Internal Option s

E Network Int erface Board Type 2000 G919-17

F RS232C Board Type 2000 G527-17

G Hard Disk Drive Type 2000 G690-17

H Memory Unit Type 204 (16 MB) G 688-04

Paper Feed Unit Type 2000 (A4/LT)

Paper Feed Unit Type 2000 (A3/DLT)

I Memory Unit Type 204 (32 MB) G688-05

G915-17, -27

G914-17, -27

The envelope feeder for the Stinger - P3 can only be installed in place of

the optional 2nd paper tray.

1-5

Page 16

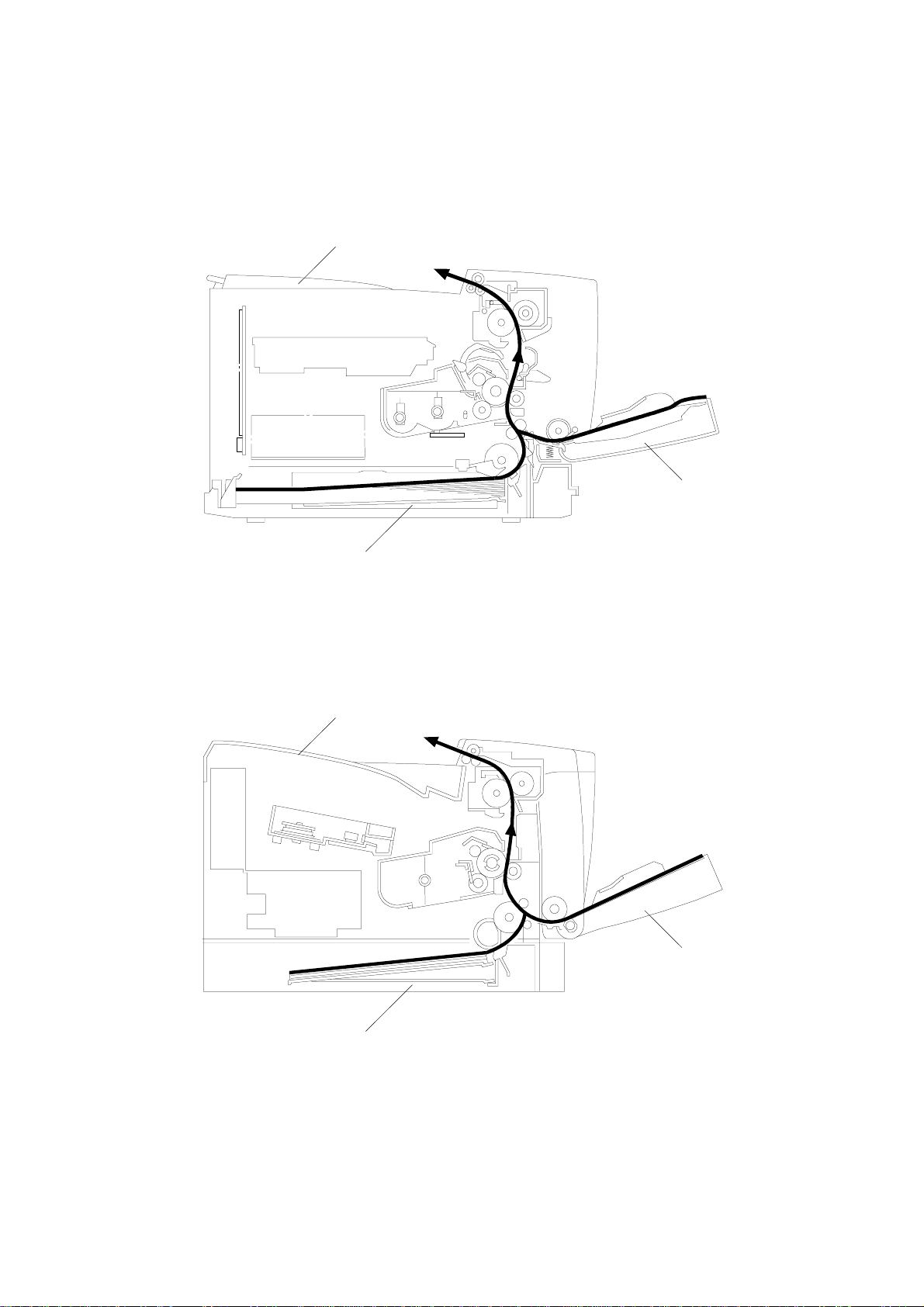

PAPER PATH 12 March 1999

1.3 PAPER PATH

Stinger - P3

Output Tray

By-pass Tray

Stinger - P4

Paper Tray

Output Tray

G031V503.WMF

By-pass Tray

Paper Tray

G031V504.WMF

1-6

Page 17

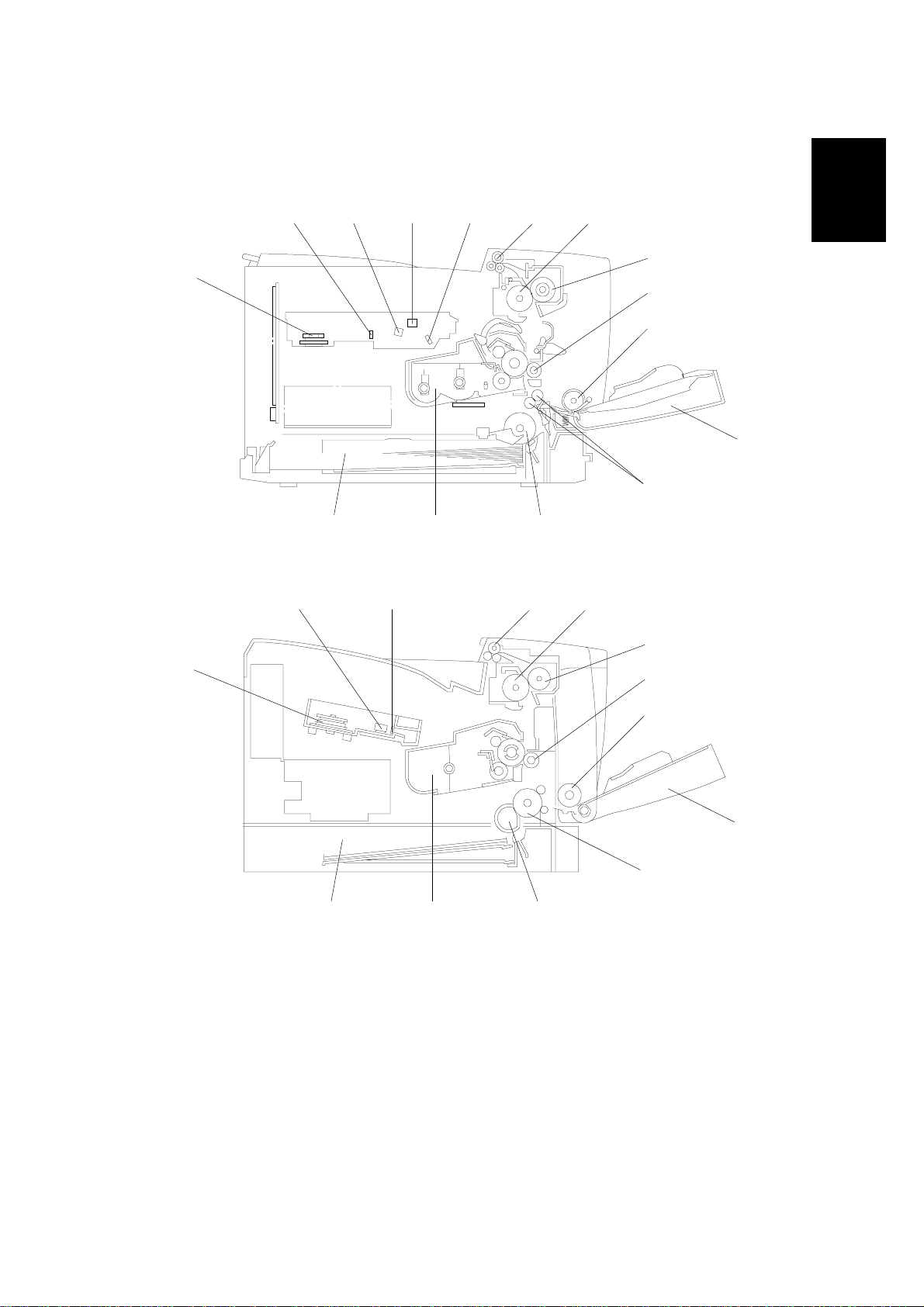

12 March 1999 MECHANICAL COMPONENT LAYOUT

1.4 MECHANICAL COMPONENT LAYOUT

Stinger - P3

11

1312

14

15 1 2

3

4

5

6

7

Overall

Information

Stinger - P4

12

11

1. Exit Roller

2. Hot Roller

3. Pressure Roller

4. Transfer Roller

5. By-pass Feed Roller

6. By-pass Tray

7. Registration Rollers (Stinger - P3)

Relay Roller (Stinger - P4)

8. Paper Feed Roller

15 1 2

910 8

G031V505.WMF

3

4

5

7

910 8

G031V506.WMF

9. Toner Cartridge

10. Paper Tray

11. Polygonal Mirror Motor

12. 1st Mirror (Stinger - P3)

F-theta Lens (Stinger - P4)

13. Barrel Toroidal Lens (Stinger - P3)

14. F-theta Mirror (Stinger - P3)

15. Shield Glass

6

1-7

Page 18

ELECTRICAL COMPONENT LAYOUT 12 March 1999

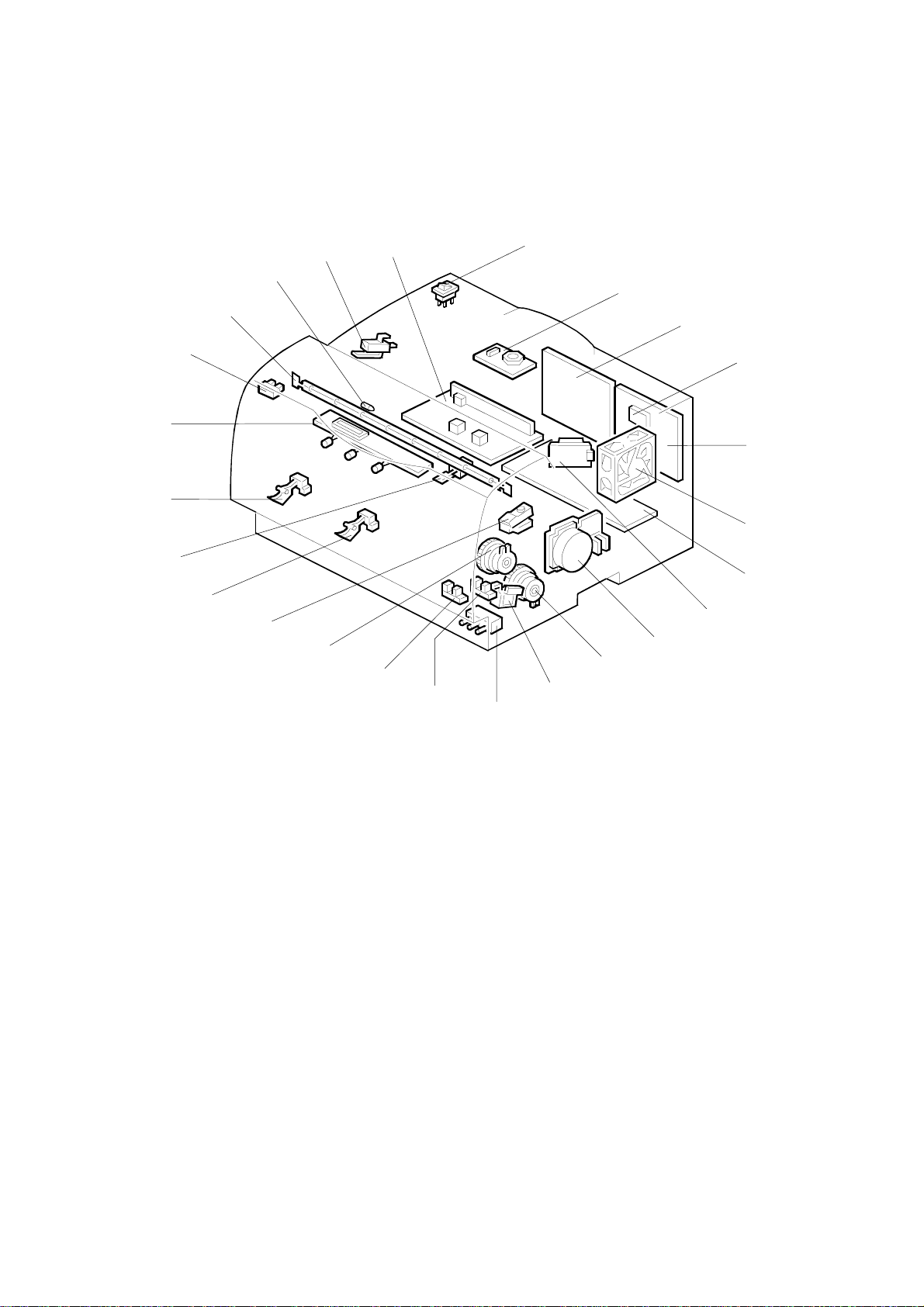

1.5 ELECTRICAL COMPONENT LAYOUT

Stinger - P3

17

16

15

18

14

19

20

13

12

21

11

22

10

23

24

25

1

2

3

4

5

6

7

8

9

G031V501.WMF

1. Laser Synchronization Detector

2. Engine Control Board

3. Exhaust Fan Motor

4. High Voltage Supply Board

5. LD Drive Board

6. Main Motor

7. Tray Paper Feed Clutch

8. By-pass Feed Solenoid

9. Tray Paper Size Switch

10. Registration Sensor

11. By-pass Tray Paper Sensor

12. Registration Clutch

13. Toner Near-end Sensor

14. Tray Paper End Sensor

15. Fusing Thermistor

16. Tray Paper Near-end Sensor

17. Control Panel Board

18. Fusing Exit Sensor

19. Fusing Lamp

20. Thermofuse

21. Front Cover Safety Switch

22. Power Supply Unit

23. Main Switch

24. Polygonal Mirror Motor

25. Printer Control Board

1-8

Page 19

12 March 1999 ELECTRICAL COMPONENT LAYOUT

Stinger - P4

18

19

20

Overall

Information

14

13

12

15

16

11

17

10

21

1

2

3

4

5

9

8

7

6

1. Engine Control Board

2. Exhaust Fan Motor

3. Power Supply Unit

4. High Voltage Supply Board

5. Main Motor

6. Tray Paper Feed Solenoid

7. By-pass Feed Solenoid

8. Toner Near-end Sensor

9. Registration Sensor

10. By-pass Tray Paper Sensor

11. Tray Paper End Sensor

G031V502.WMF

12. Fusing Exit Sensor

13. Fusing Thermistor

14. Control Panel Board

15. Fusing Lamp

16. Thermofuse

17. Front Cover Safety Switch

18. LD Drive Board

(with synchronization detector)

19. Main Switch

20. Polygonal Mirror Motor

21. Printer Control Board

1-9

Page 20

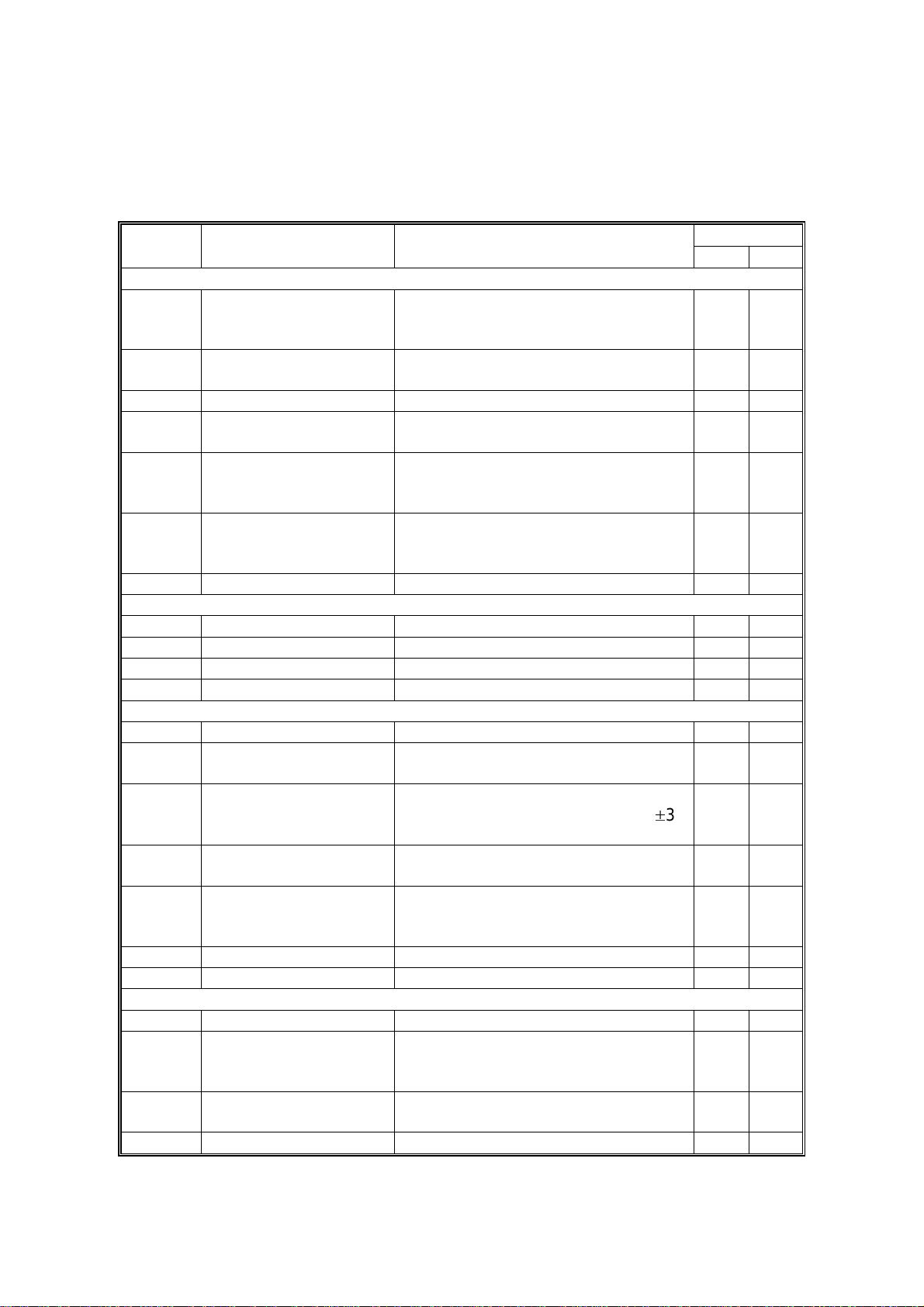

ELECTRICAL COMPONENT DESCRIPTIONS 12 March 1999

1.6 ELECTRICAL COMPONENT DESCRIPTIONS

Refer to the electrical component layout and the point-to-point diagram on the

waterproof paper in the pocket for the locations of these components.

Symbol Description Note

Printed Circuit Boards

High Voltage Supply

PCB1

PCB2

PCB3 LD Drive Board Controls the laser diode. 5 18

PCB4

PCB5

PCB6

Motors

M1 Main Drives the main body components. 6 5

M2 Polygonal Mirror Turns the polygonal mirror. 24 2 0

M3 Exhaust Fan Removes heat from the printer. 3 2

Board

Power Supply Unit

(PSU)

Control Panel Controls the display panel, LED, and

Engine Control Board

(ECB)

Printer Control Board

Supplies high voltage to the drum

charge roller, development roller, and

transfer roller.

Provides dc power to the system and

ac power to the fusing lamp.

the touch key pad.

Controls all base engine functions

either directly or through other control

boards.

Controls the PC interface, print image

processing, operation panel, and

other controller options.

Index No.

P3 P4

44

22 3

17 14

21

25 21

Sensors

S1 Fusing Exit Detects misfeeds. 18 12

S2

S3

S4

S5

S6 Toner Near-end Detects when toner is low. 13 8

Switches

SW1 Main Supplies power to the machine. 23 19

SW2

SW3

Tray Paper End Informs the CPU when the paper tray

runs out of paper.

Tray Paper Near-end

(Stinger - P3)

By-pass Tray Paper

Registration Detects the leading edge of the paper

Front Cover Safety Cuts the +5VLD and +24 V dc power

Tray Paper Size

(Stinger - P3)

Informs the CPU when the amount of

paper in the tray becomes low (50±30

sheets).

Informs the CPU when there is paper

on the by-pass tray.

to determine when to stop the paper

feed clutch, and detects misfeeds.

lines and detects whether the front

cover is open or not.

Determines the size of paper in the

paper tray, based on the dial setting.

14 11

16 —

11 10

10 9

21 17

9—

1-10

Page 21

12 March 1999 ELECTRICAL COMPONENT DESCRIPTIONS

Symbol Description Note

Index No.

P3 P4

Magnetic Clutches

MC1

MC2

Tray Paper Feed

(Stinger - P3)

Registration

(Stinger - P3)

Starts paper feed from the paper tray.

Drives the registration rollers.

7—

12 —

Solenoids

SOL1

SOL2

By-pass Feed Starts paper feed from the by-pass

tray.

Tray Paper Feed

Starts paper feed from the paper tray.

(Stinger - P4)

87

—6

Lamps

L1 Fusing Heats the hot roller. 19 15

Thermistors

TH1

Fusing Monitors the temperature of the hot

roller.

15 13

Thermofuses

TF1

Fusing

Provides back-up overheat protection

in the fusing unit.

20 16

Overall

Information

Others

LSD1

Laser Synchronization

Detector

(Stinger - P3)

Detects the laser beam at the start of

the main scan.

1—

1-11

Page 22

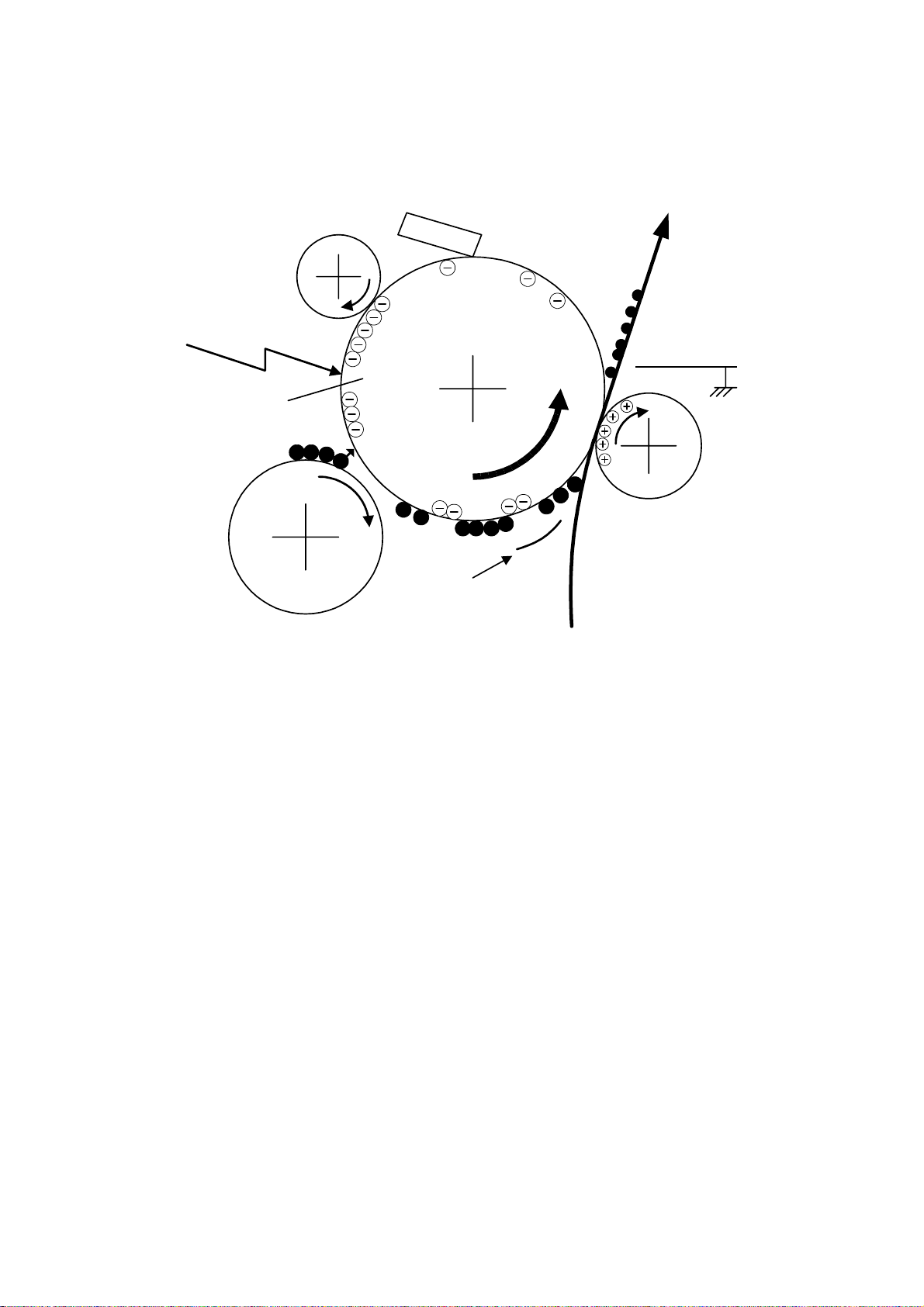

PRINTING PROCESS 12 March 1999

1.7 PRINTING PROCESS

6

1

OPC

–600 V

5

2

–100 V

4

3

–400 V

G031V507.WMF

Stinger - P3/4 use an all-in-one type of toner cartridge that includes the drum,

toner, development roller, charge roller and other components.

1. DRUM CHARGE

In the dark, the charge roller gives a negative charge of –600 volts to the organic

photo-conductive (OPC) drum. The charge remains on the surface of the drum

because the OPC layer has a high electrical resistance in the dark.

2. LASER EXPOSURE

The processed print image data from the engine control board (ECB) is transferred

to the drum by a laser beam, which forms an electrical latent image on the drum

surface. The areas exposed by the laser beam drop to about –100 volts.

3. DEVELOPMENT

The magnetic development brush on the development roller approaches the latent

image on the drum. The development roller gives a negative bias of –400 volts to

the toner. Toner particles jump and electrostatically attach to the areas of the drum

surface where the laser reduced the negative charge on the drum.

1-12

Page 23

12 March 1999 PRINTING PROCESS

4. IMAGE TRANSFER

Paper is fed to the area between the drum surface and the transfer roller at the

proper time for aligning the print paper and the developed image on the drum

surface. Then, the transfer roller applies a positive current to the reverse side of the

paper (the size of the current depends on the resolution and the paper size). This

pulls the toner particles from the drum surface to the paper. At the same time, the

paper is attracted to the transfer roller.

5. PAPER SEPARATION

Paper separates from the drum as a result of the electrostatic attraction between

the paper and the transfer roller. The discharge plate helps separate the paper

from the drum.

6. CLEANING

The cleaning blade removes any toner remaining on the drum surface after the

image is transferred to the paper.

7. QUENCHING

There is no quenching mechanism.

Overall

Information

1-13

Page 24

BOARD STRUCTURE 12 March 1999

g

1.8 BOARD STRUCTURE

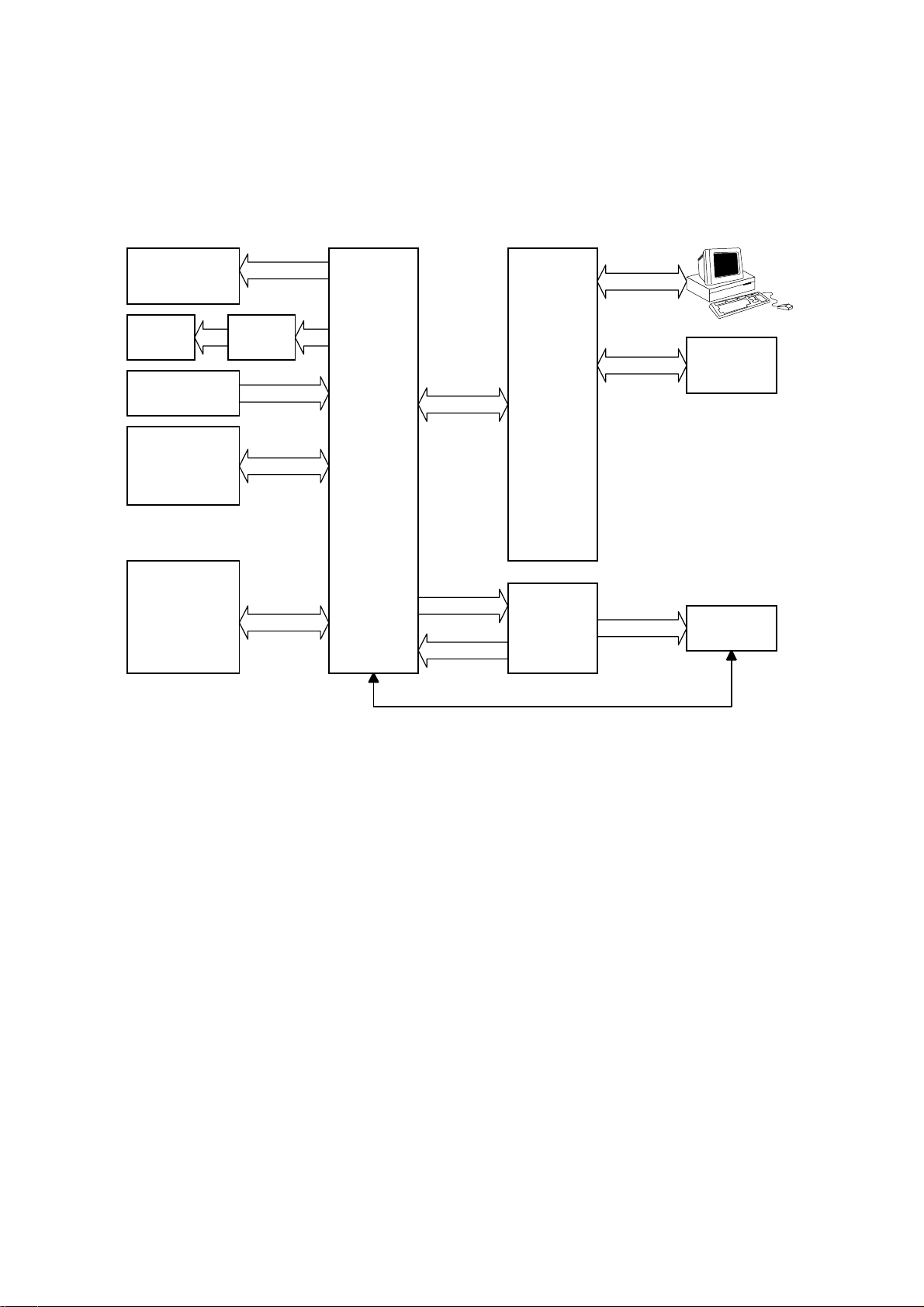

1.8.1 OVERVIEW

Motors &

Clutches

Laser

Diode

Sensors

High Voltage

Supply Board

Paper Feed

Unit

LD Drive

Board

Engine

Control

Board

(ECB)

Video I/F

+5 V/+24 V

Printer

Control

Board

Power

Supply

Unit

(PSU)

Control

Panel

Board

Fusin

Unit

G031V508.WMF

The engine control firmware controls the components connected to the engine

control board (ECB). The printer control board controls the control panel board.

The printer control board is also connected to the personal computer.

1-14

Page 25

12 March 1999 BOARD STRUCTURE

1.8.2 MAJOR COMPONENTS

1. Engine Control Board (ECB)

This is the printer engine control board. It controls the following functions:

·

Engine sequence

·

Machine control, printer engine control

·

Timing control for peripherals

·

Video control

·

Drive control for the sensors, motors, solenoids, and high voltage supply

board

·

PWM control for edge smoothing (PWM is done on the printer control board)

2. Printer Control Board

This is the machine’s main control board. It controls the following functions:

·

IEEE 1284 parallel port

·

Edge smoothing and toner saving

·

Engine control board

·

Control panel board

·

Interfacing with the HDD and NIB

3. LD Drive Board

Overall

Information

This is the laser diode drive circuit board.

4. Power Supply Unit (PSU)

Provides dc power to the system and ac power to the fusing lamp.

5. High Voltage Supply Board

Supplies high voltage to the drum charge roller, development roller, and transfer

roller.

6. Fusing Unit

Fuses toner to the paper. The fusing lamp is controlled by the ECB.

7. Control Panel Board

Controls the display panel, the LED, and the touch keypad.

1-15

Page 26

COMPARISON 12 March 1999

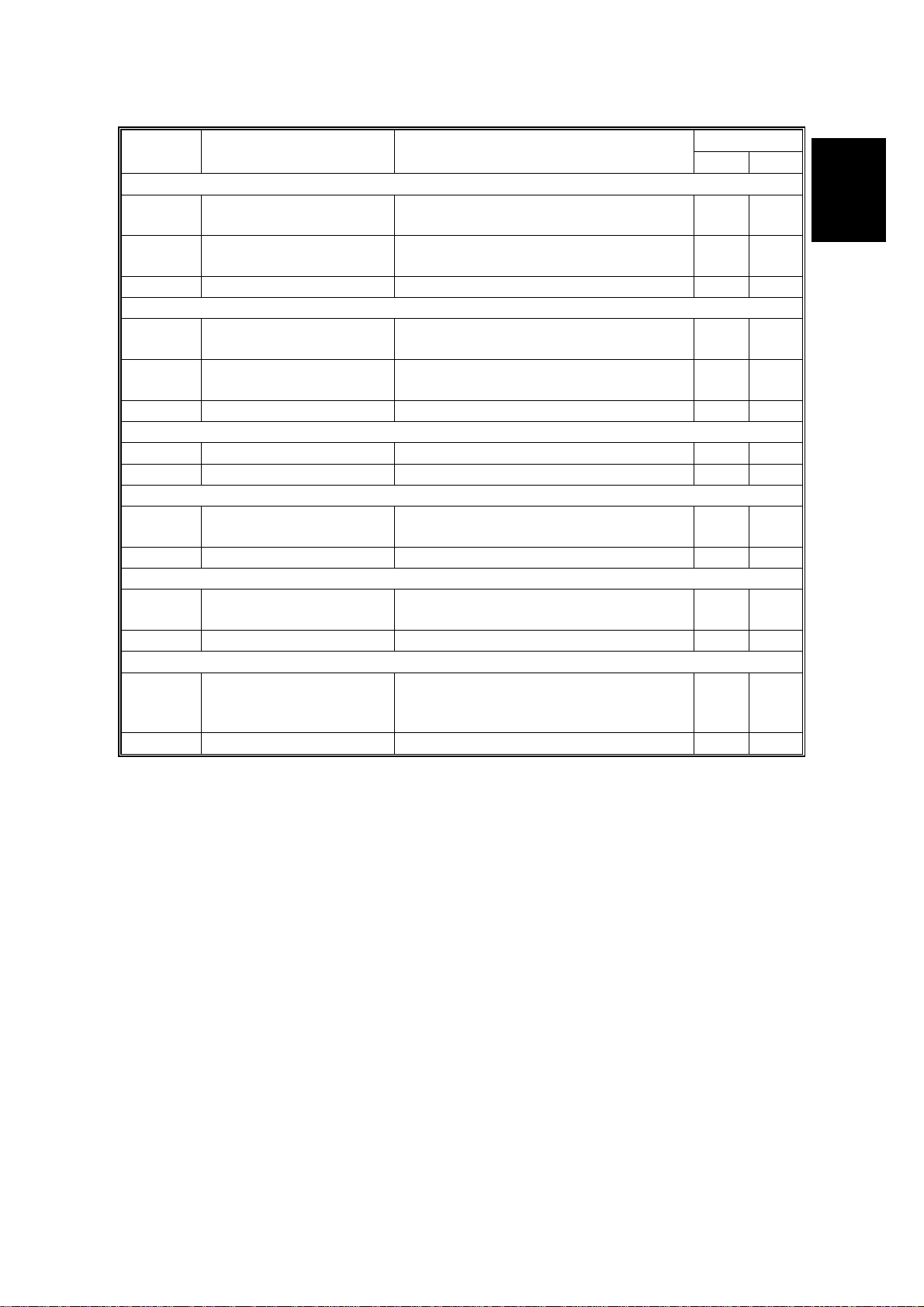

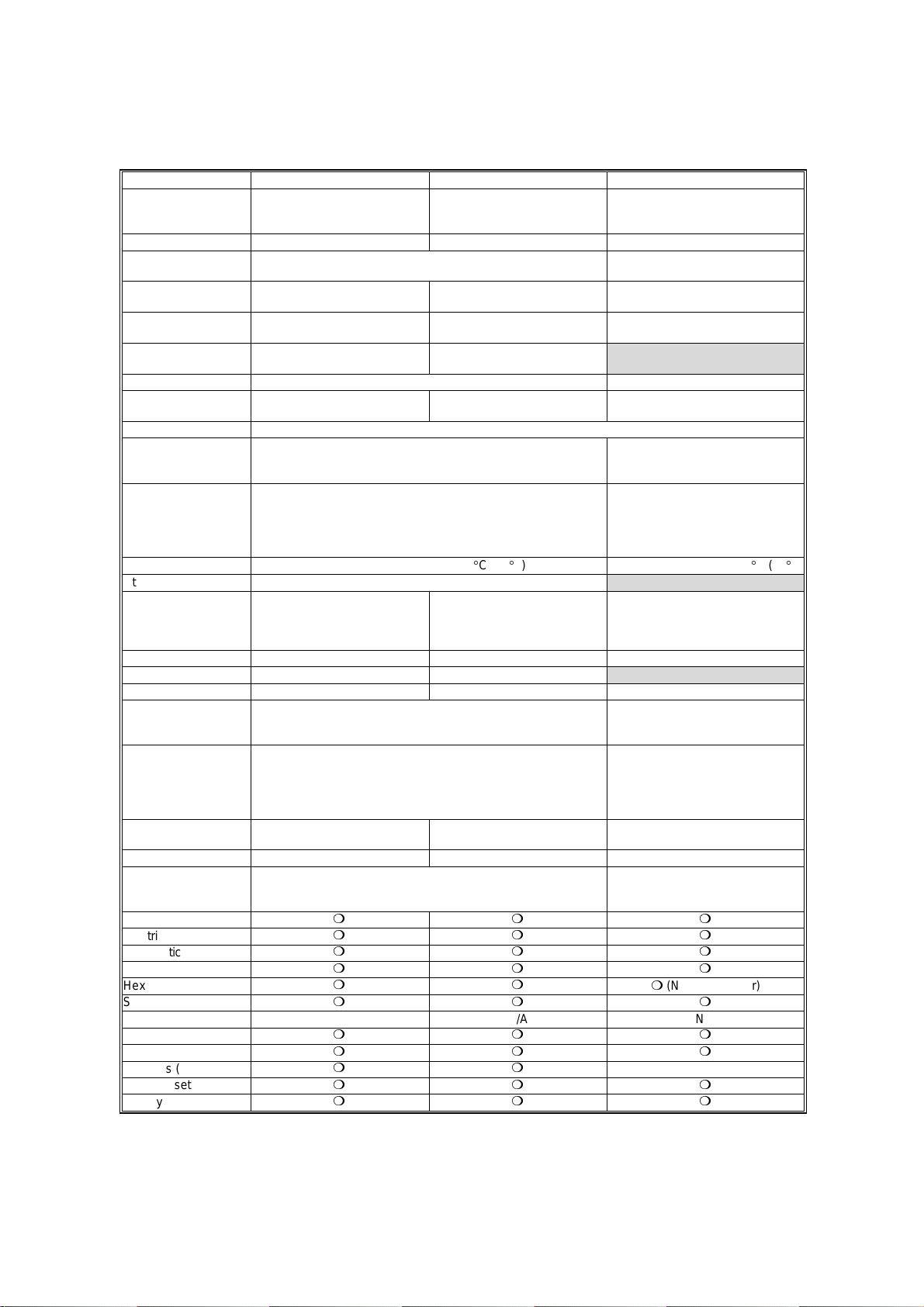

1.9 COMPARISON

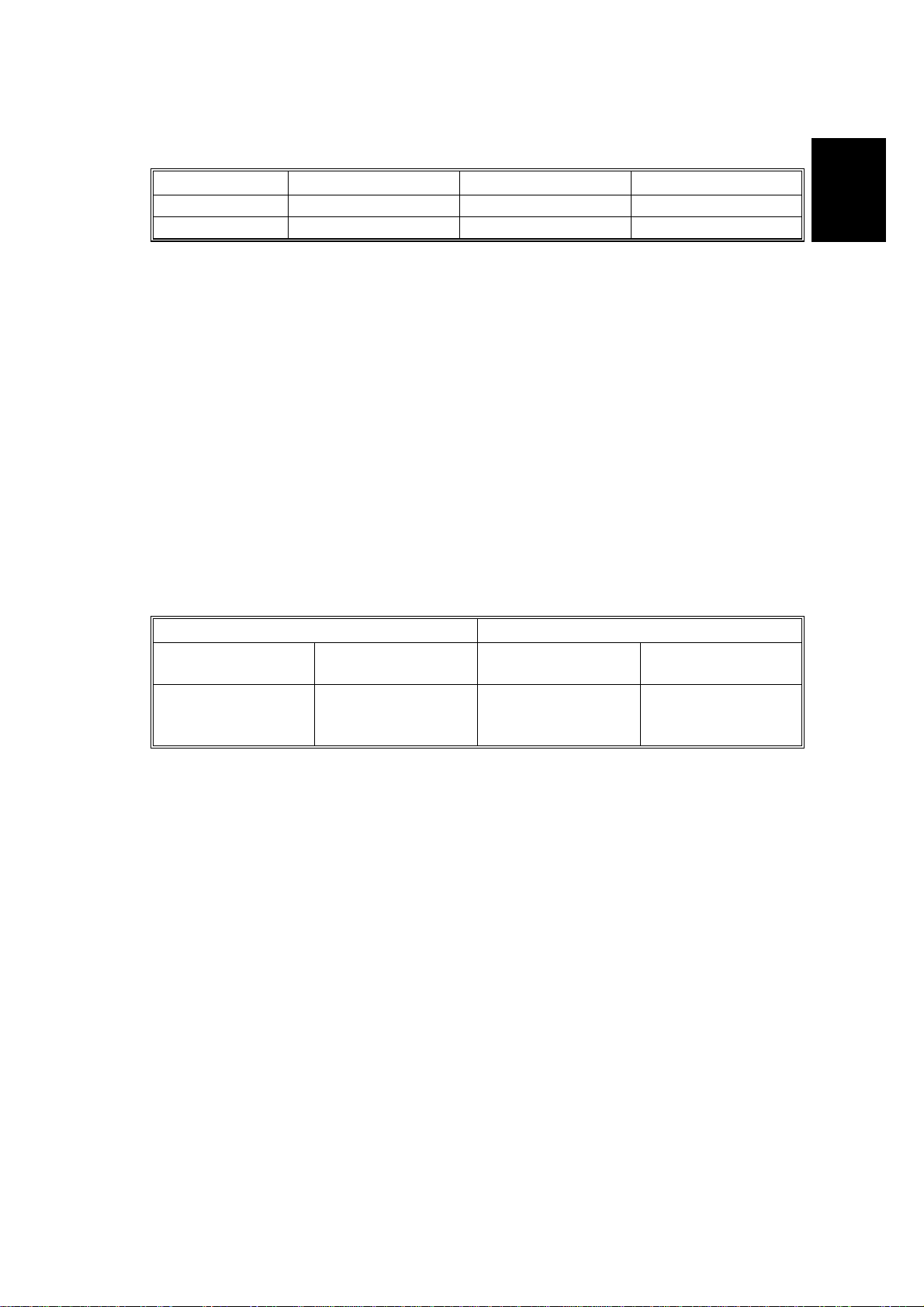

Stinger - P3 Stinger - P4 V20

Standard Paper Tray

Standard Bypass Tray

Optional Paper Tray

Envelope Feeder 10 envelopes 5 envelopes 100 envelopes

Output Paper

Capacity

Input Paper Size

(Std./Opt. Tray)

Input Paper Size

(By-pass Tray)

First Print Speed

Duplex Printing N/A Option

Memory

(Std./Max. with Opt.)

HDD (Option) 1.6 GB

Fonts

Interface Bi-directional parallel x 1

Warm-up Time

Utilities Aficio Manager

Dimensions

(mm: W x D x H)

Weight Less than 15 kg (33 lb.) Less than 12 kg (27 lb.) Less than 44.5 kg (99 lb.)

Consumable Yield Toner Cartridge: 14 K Toner Cartridge: 8 K

PM Kit Maintenance Kit: 80 K Maintenance Kit: 60 K

Technology

Resolution True 1,200 x 1,200 dpi (PCL6/PS)

Continuous Print

Speed

Power Consumption Max. 795 W Max. 600 W Max. 950 W

Drivers PCL6/5e version : Windows 3.1x, 95(98), Windows NT 4.0

Halftoning

Electrical Sorting

Diagnostic Test Mode

Test Print

Hex Dump List

Smoothing

Rotated Sorting N/A N/A N/A

Toner Saving Mode

PDL Auto Change

Overlays (PCL)

Auto Cassette Change

Energy Saver

250 sheets

100 sheets

500 sheets x 2

250 sheets

A3/11" x 17" ~ A5 (LEF) A4 ~ A5 (LEF) A3/11" x 17" ~ A5/5.5" x 8.5" (LEF)

A3/11" x 17" ~ B6 (SEF) free:

11.69" x 17" ~ 3.88" x 5.83"

5.5 s or less

(A4/LT ~ LEF, Standard Tray)

8 MB/40 MB 8 MB/ 40 MB 8 MB/68 MB

PCL6 (35 Intellifonts, 10 True Type fonts and 1 bitmap font)

PS2 (35 Adobe type 1 fonts)

Ethernet (100 Base-Tx/10 Base-T for TCP/IP, IPX/SPX, Ether

Talk)

RS232C (Optional)

Less than 39 seconds: 23°C (73°F) Less than 60 seconds: 23°C (73°F)

450 x 420 x 270 mm

(with Std. Tray adjusted for A4)

450 x 555 x 270 mm

(with Std. Tray adjusted for A3)

Laser beam scanning & electrophotographic printing

Monocomponent development

600 x 600 dpi (PCL6/PCL5e/PS)

300 x 300 dpi (PCL5e/PS)

20 ppm (A4 SEF) 14 ppm (A4 LEF) 25 ppm (A4/LT LEF)

PS PPD: Windows 95 (98), Windows NT 4.0, Macintosh OS 7.5

or later

mm m

mm m

mm m

mm m

mm

mm m

mm m

mm m

mm

mm m

mm m

A4/LG ~ B6 (SEF) free:

8.5" x 14" ~ 3.88" x 5.83"

(A4/LT ~ SEF, Standard Tray)

360 x 420 x 270 mm

(with Std. Tray adjusted for A4)

250 sheets

100 sheets

500 sheets

6.5 s or less

500 sheets x 2 + 1,500 sheets

Standard Output Tray: 400 sheets

A3/11"x17" ~ A5/5.5" x 8.5" (SEF)

PCL5e (35 Intellifont, 10 True Type

font and 1 bitmap font)

PS2 (35 Adobe type 1 fonts)

Bi-directional parallel (Standard)

Ethernet (10 Base 2/T for

IPX/SPX, TCP/IP, Apple Talk)

Token Ring (4 Mbps, 16 Mbps for

IPS/SPX, TCP/IP, Apple Talk)

530 x 625 x 472 mm

(with by-pass tray closed, without

the optional paper tray unit, without

options)

Laser beam scanning &

electrophotographic printing

Dualcomponent development

600 dpi, 400 dpi (available when

the PostScript option is installed),

300 dpi (simulated by doubling

pixel width and height at 600 dpi

resolution)

PCL version : Windows 3.1xx, 95,

Windows NT 3.51/4.0 (PCL & PS

version: Macintosh)

250 sheets

100 sheets

External Tray: 100 sheets

m

(N/A from Driver)

N/A

1-16

Page 27

12 March 1999 PRINTING

2. DETAILED SECTION DESCRIPTIONS

2.1 PRINTING

2.1.1 IMAGE DATA PATH

Drum

LD Unit

LD Drive

Board

ECB

PC AT

Compatible

Parallel

Gate

Array

Printer Control Board

Macintosh

Ethernet

NIB

Optional Bus I/F

CN.

ROCKY W

G031D502.WMF

The printer control board receives the print data from the host computer (AT

compatible Windows PC or Macintosh).

·

For the Stinger - P3, the printer control board has two OBI (Optional Bus

Interface) connectors to connect a network interface board (NIB), RS232C

interface, or HDD unit.

·

For the Stinger - P4, the printer control board has one OBI connector.

Detailed

Descriptions

The printer control board generates the print image data and sends it with

commands to the ECB (Engine Control Board).

The printer control board contains the image processing ASIC (ROCKY W). The

ROCKY W ASIC controls the image processing, IEEE1284 interface, DRAM, edge

smoothing, and toner saving. (ASIC: Application Specific Integrated Circuit)

The ECB contains a gate array. The gate array controls LD print timing control and

the serial interface to the printer control board.

Finally, the ECB sends the video data to the LD drive board.

2-1

Page 28

PRINTING 12 March 1999

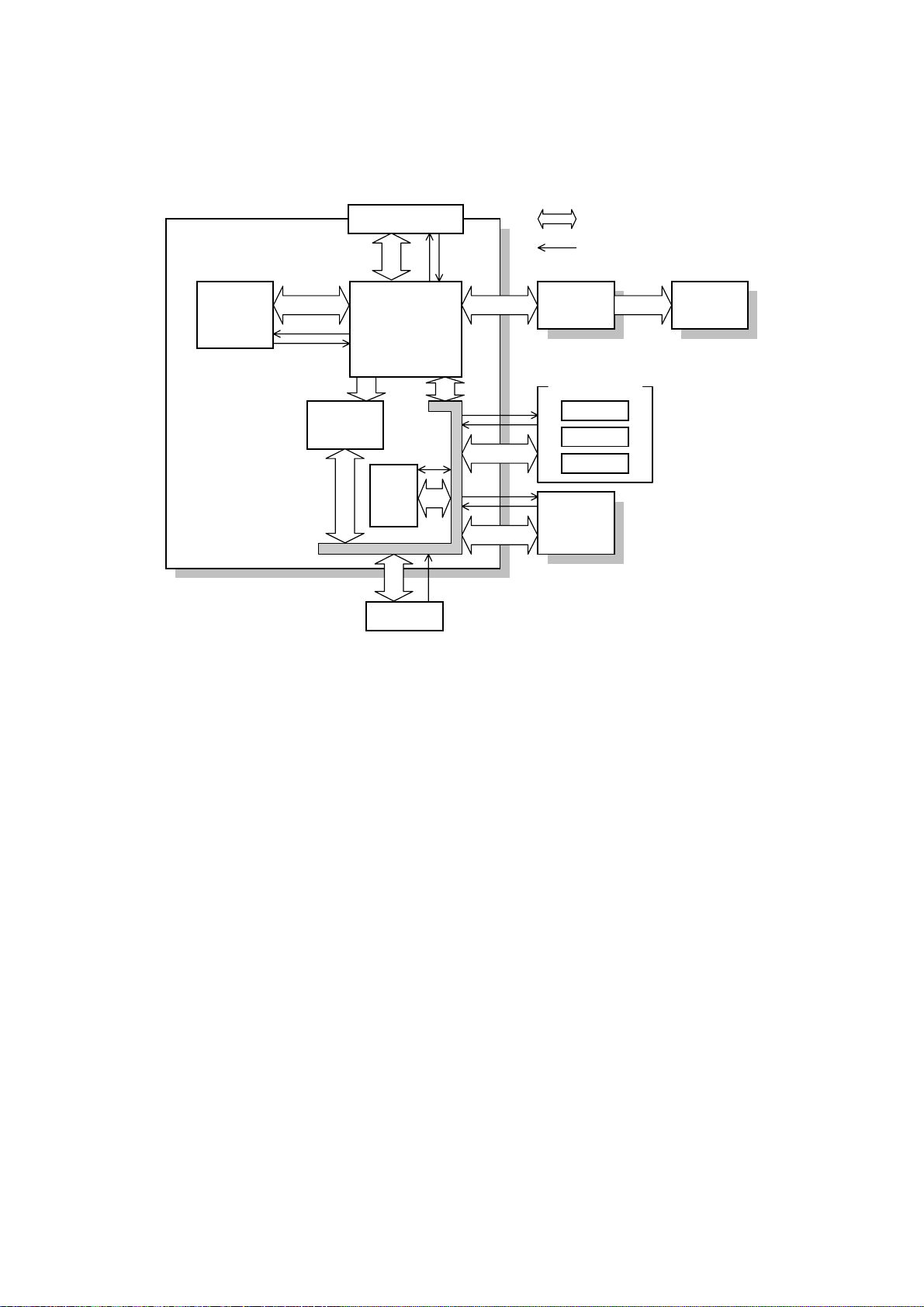

2.1.2 PRINTER CONTROL BOARD

CPU

Printer

Control Board

Parallel I/F

ROCKY W

Resident

DRAM

32-bit Data

Address/Command

ECB LD Unit

(ASIC)

Option Board

NIB

HDD

RS232C

Code

ROM

DIMM

SIMM

G031D503.WMF

The printer control board receives the print data from the computer through the

parallel cable or network interface board.

The printer control board contains the CPU (which is a 64-bit RISC processor), the

ROCKY W ASIC, 8 MB of resident DRAM for main memory, and a 8 MB code

ROM.

A SIMM card can be installed for extra DRAM memory and a DIMM card can be

connected for service purposes (firmware upgrade).

The control board controls the following to produce the print image data.

1) IEEE1284 parallel port interface

2) Control panel

3) Edge smoothing and toner saving

4) Engine control board

5) Interfacing with the HDD, NIB, and RS232C board.

2-2

Page 29

12 March 1999 PRINTING

2.1.3 IMAGE DATA PROCESSIING

Edge smoothing and toner saving are performed by an ASIC (ROCKY W). The

edge smoothing and toner saving modes can be switched on/off with the machine’s

control panel or the printer driver.

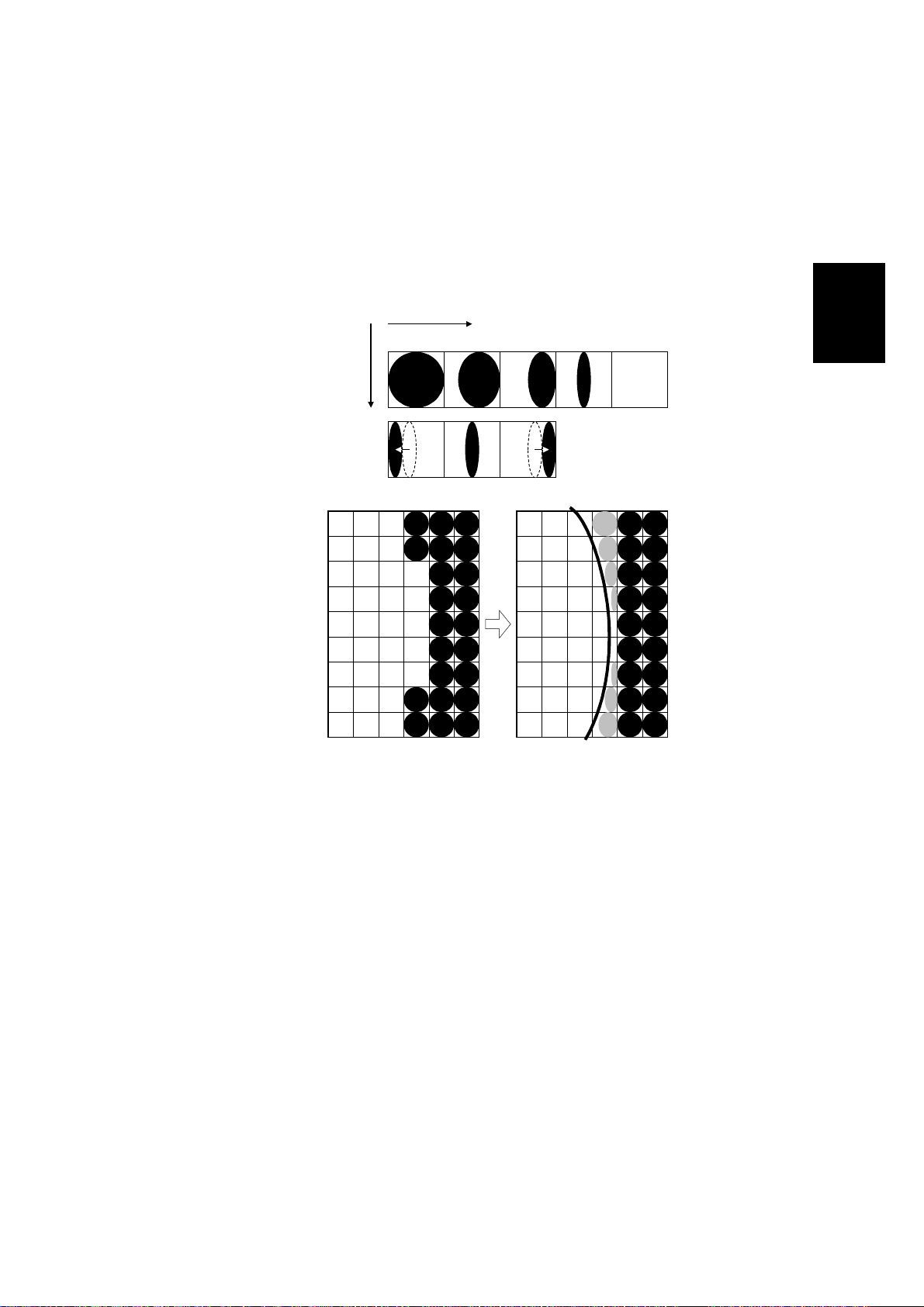

Edge Smoothing

Fig. A

Fig. B

Fig. C

Sub Scan

Direction

Main Scan Direction

4/4 3/4 2/4 1/4 0

G031D504.WMF

Detailed

Descriptions

Jagged edges on characters as shown in the above illustration are reduced using

edge smoothing. Edge smoothing changes the laser pulse duration and position for

certain pixels.

Fig. A shows the four possible pulse durations, and Fig. B shows how the laser

pulse can be in one of three positions within the pixel. Fig. C shows an example of

how edge smoothing is used.

Edge smoothing is not done for 1,200-dpi printing.

Toner Saving Mode

Toner saving is done by reducing the number of black dots in the printed image. An

8 x 8 matrix filter is used.

As a result, less toner is used to create the latent image on the drum and black

areas print as gray.

The printer driver prevents edge smoothing and toner saving mode from being

used at the same time.

2-3

Page 30

PRINTING 12 March 1999

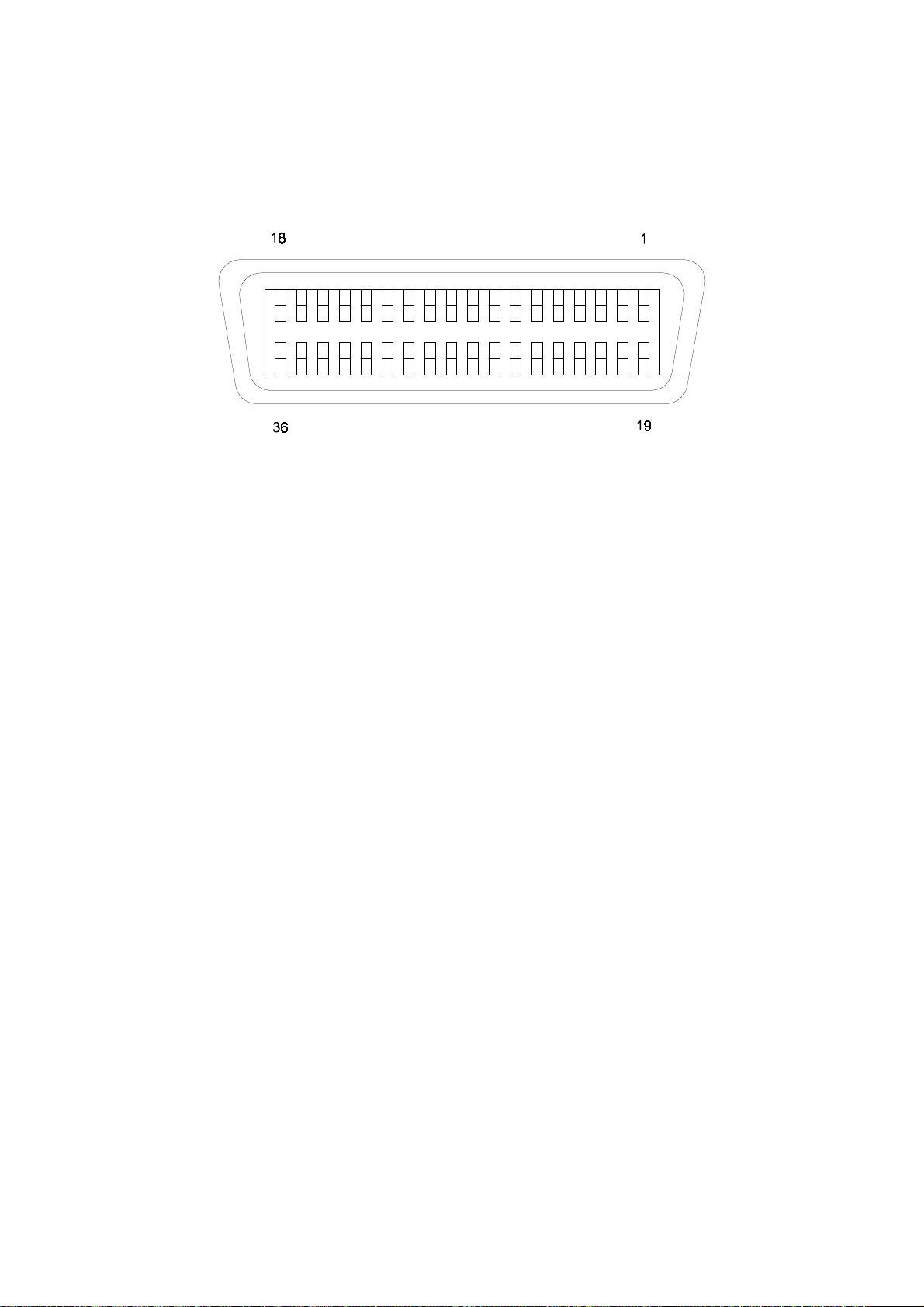

2.1.4 HOST INTERFACE

Bi-directional Parallel Interface

G031D505.WMF

A 36-pin bi-directional parallel interface connector (female) is used.

The bi-directional parallel interface on the controller works in three modes;

Compatible, Nibble and ECP modes. These modes are standardized by IEEE

1284.

2-4

Page 31

12 March 1999 LASER EXPOSURE

2.2 LASER EXPOSURE

2.2.1 OVERVIEW

This machine uses a laser diode to produce electrostatic images on an OPC drum.

The laser diode unit converts image data from the ECB into laser pulses, and the

optical components direct these pulses to the drum.

Exposure of the drum by the laser beam creates the latent image. The laser beam

makes the main scan while drum rotation controls the sub scan.

Stinger - P3 Stinger - P4

Strength of the beam output 5 mW 5 mW

Strength of the beam on the drum 0.636 mW 0.43 mW

Printing Binary (2 bits/pixel) Binary (2 bits/pixel)

There are two polygon motor speeds:

Detailed

Descriptions

-

Stinger - P3

Resolution (dpi) Modes Motor Speed (rpm) Data Frequency (MHz)

600 300/600 dpi printing 22478.22 22.0926

1,200 1,200 dpi printing 22478.22 44.1851

-

- Stinger - P4 -

Resolution (dpi) Modes Motor Speed (rpm) Data Frequency (MHz)

600 300/600 dpi printing 22377.62 15.0528

1,200 1,200 dpi printing 22377.62 30.1056

Differences between 1,200 dpi and 600 dpi printing

To produce 1,200 dpi, the machine uses a di ffere nt data frequency for the main

scan and a different line speed for the sub scan, compared with 600 dpi printing.

For 1,200 dpi printing, the polygon motor works at the same speed as for 600 dpi

printing but the data frequency is twice as fast as in 600 dpi printing.

The paper at 1,200 dpi is fed at half the speed used for 600 dpi, as follows.

600 dpi printing 1,200 dpi printing

Paper feed line speed 92 mm/s 46 mm/s

The beam diameter for 1,200 dpi printing is the same as for 600 dpi printing.

2-5

Page 32

LASER EXPOSURE 12 March 1999

2.2.2 OPTICAL PATH

Stinger - P3

Stinger - P4

[H]

[G]

[A]

[F]

[A]

[J]

[B]

[E]

[C]

[K]

[D]

G031D506.WMF

[C]

[A]: Polygonal Mirror

[B]: Cylindrical Lenses

[C]: LD Drive Board

[D]: Drum

[E]: LD Shutter

[F]: F-Theta Mirror

[I]

[B]

[E]

[D]

G031D507.WMF

[G]: BTL (Barrel Toroidal Lens)

[H]: 1st Mirror

[I]: F-theta Lens

[J]: Laser Synchronization Detector

[K]: Shield Glass

[J]

[K]

2-6

Page 33

12 March 1999 LASER EXPOSURE

The optical path from the laser diode to the drum is shown on the previous page.

The LD drive board [C] outputs the laser beam to the polygonal mirror [A] through

the cylindrical lenses [B], which focus the laser beam.

Stinger - P3

The laser beam goes to the F-theta mirror [F], 1st mirror [H] and BTL [G]. Then, the

beam reaches the drum [D] through the shield glass [K].

The beam reflected by the polygonal mirror writes the pixels of the latent image on

the drum. The F-theta mirror [F] ensures constant intervals between the pixels. The

BTL [G] corrects for irregularities in the polygonal mirror faces.

The laser synchronization detector [J] synchronizes the start of the main scan.

Stinger - P4

The Stinger - P4 has a shorter beam path than the Stinger - P3.

The beam which is reflected by the polygonal mirror goes to the F-theta lens [I].

The beam reaches the drum [D] through the shield glass [K]. The F-theta lens [I]

does the functions of both the F-theta [F] mirror and the BTL [G].

The LD drive board for the Stinger - P4 contains the laser synchronization detector.

Detailed

Descriptions

2-7

Page 34

LASER EXPOSURE 12 March 1999

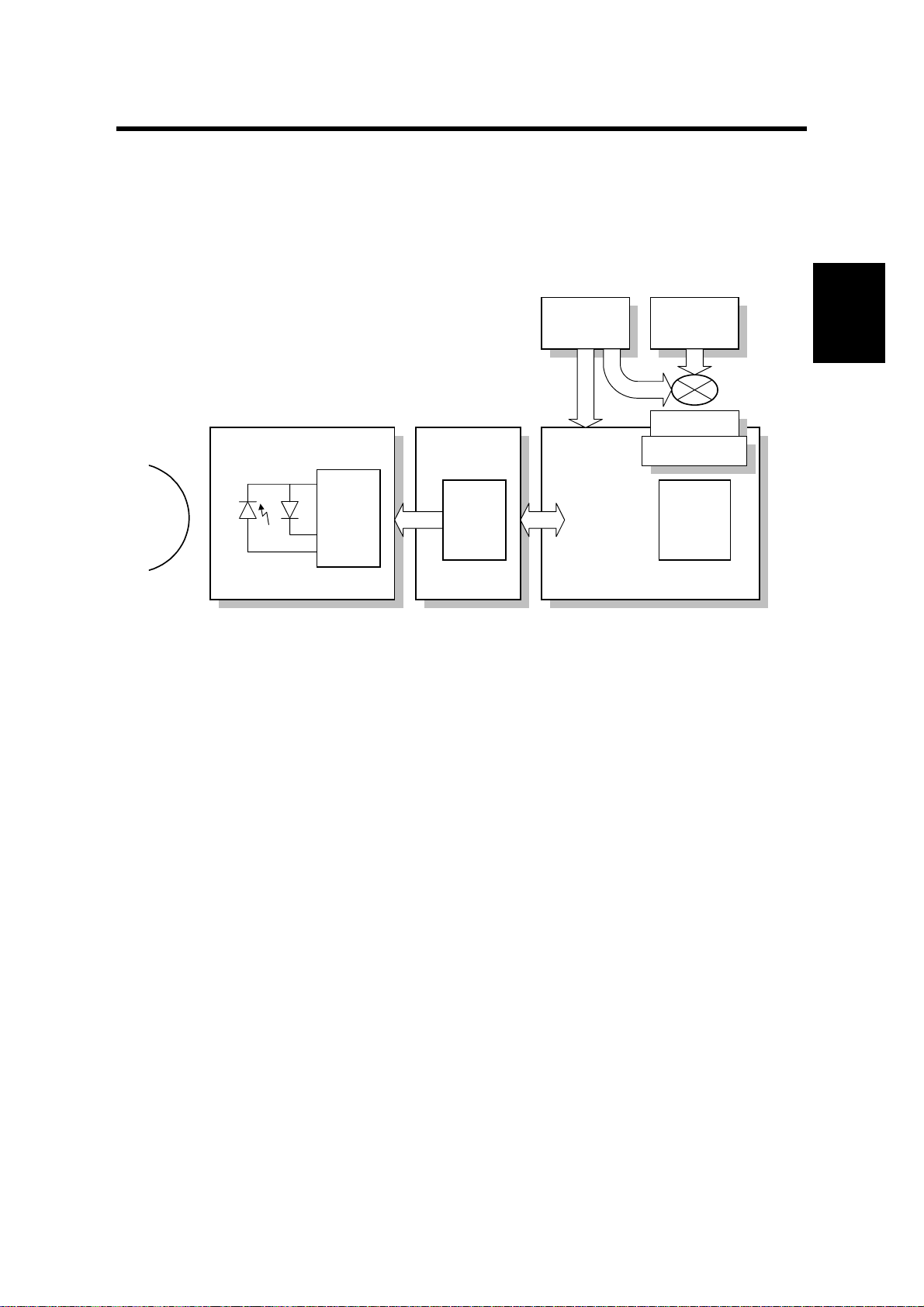

2.2.3 AUTO POWER CONTROL (APC)

LD Drive Board

5V

APC

VIDEO

DPI select

LD OFF

CN1-7

VCC

LD Driver

LD

PD

G031D508.WMF

To prevent the intensity of the laser beam from changing because of temperature,

the machine monitors the laser beam with a photodiode (PD). The PD is enclosed

in the laser diode. The PD passes an electrical current to the LD driver IC and this

IC adjusts its output level to keep the laser diode output constant.

The laser diode power level is adjusted on the production line. Do not touch the

variable resistors on the LD unit in the field.

2-8

Page 35

12 March 1999 LASER EXPOSURE

g

2.2.4 LD SAFETY SWITCH

Power Supply

Unit

CN104-1

+24V

CN103-2CN103-1

Front Cover

Safety Switch

Engine Control

Board

Voltage

ulator

Re

LD Drive Board

CN7-7 CN1-7CN16-1

LD Driver

LD

PD

G031D500.WMF

Front Cover Safety Switch

To ensure that the laser beam does not inadvertently switch on during servicing,

there is a safety switch located at the front cover. The switch is on the LD 24 V line.

Detailed

Descriptions

Mechanical Laser Shutter

When the toner cartridge is removed, the laser shutter is released and this

interrupts the laser beam.

2-9

Page 36

TONER CARTRIDGE 12 March 1999

2.3 TONER CARTRIDGE

2.3.1 OVERVIEW

[A]

[B]

[C]

[D]

[E]

[H][I]

[G] [F]

G031D509.WMF

The toner cartridge consists of the components shown above. The toner cartridge

contains the OPC drum and the toner cassette, and includes the mechanisms for

drum charge, development, and cleaning. The drum is 30 mm in diameter.

[A]: Charge Roller

[B]: Cleaning Blade

[C]: OPC Drum

[D]: Transfer Roller

[E]: Transfer Blade

The main motor drives the rollers in the toner cartridge. The charge roller [A]

charges the drum [C]. Monocomponent toner is used. The cleaning blade [B]

cleans the drum surface.

[F]: Development Roller

[G]: Mixing Blade

[H]: Toner Near-end Sensor

[I]: Agitator

2-10

Page 37

12 March 1999 TONER CARTRIDGE

2.3.2 DRIVE

[A]

[B]

[D]

[C]

G031D510.WMF

The main motor [B] drives the drum [C], the development roller [A], and agitators

[D] through a series of gears. The main motor speed is controlled by the engine

control board (ECB).

Detailed

Descriptions

When a new ca rtridge is installed, the machine clears the near-end condit i on if the

toner near-end sensor detects that there is sufficient toner.

There is no counter for the toner cartridge.

2-11

Page 38

TONER CARTRIDGE 12 March 1999

2.3.3 DRUM CHARGE

[A]

[B]

[E]

[C]

[D]

G031D511.WMF

This machine uses a drum charge roller system instead of a scorotron corona wire

system to charge the drum. The drum charge roller [A] always contacts the surface

of the drum [E] because of the charge roller pressure springs [C], and gives a

negative charge to the drum surface. While the drum is rotating, the drum charge

roller also turns because of friction between the roller and the drum.

The drum charge roller system generates less ozone than a scorotron corona wire

charge system. Due to this, there is no ozone filter in the machine.

The high voltage supply board applies voltage to the drum charge roller through

the charge roller terminal [B], charge roller pressure spring [C], and the charge

roller bushing [D]. Both ac and dc are applied.

Before the laser starts to write to the drum, the charge roller receives –600Vdc and

2 kV peak-to-peak 1 kHz ac from the high voltage supply board. This gives the

drum surface a uniform negative charge of -600 V.

The dc and ac are continually supplied during the printing job. This gives the drum

surface a uniform –600 V charge wherever it passes the charge roller.

At the end of the job, the dc is set to 0 V, but the ac stays on. While the drum

rotates past the charge roller, the ac brings the charge on the drum surface to a

uniform 0 V.

The toner cartridge has no cleaning pad, temperature control, or contact

mechanism for the drum charge roller (the material of the drum charge roller allows

a simple mechanism). The drum charge roller is part of the toner cartridge, so

when the toner runs out, the drum charge roller is changed at the same time. This

happens before the drum charge roller gets dirty.

2-12

Page 39

12 March 1999 TONER CARTRIDGE

2.3.4 DEVELOPMENT

Overview

[F]

[A]

[G]

[B]

[E]

[D] [C]

G031D509.WMF

This machine uses monocompo nent to ner . The Sting er - P3 has two agitators [F] in

the toner cartridge(shown above). The Stinger - P4 has one agitator.

Detailed

Descriptions

The agitator(s) [F] and the mixing blade [D] mix the toner in the toner cartridge and

transport it to the development roller [C]. Friction between the transported toner

and the doctor blade [A] gives the toner a negative charge.

Internal permanent magnets in the development roller attract the toner to the

development roller sleeve. The doctor blade trims the toner to the desired

thickness on the development roller sleeve. The development roller does not

contact the drum [G]. There is a small gap between the toner on the surface of the

development roller sleeve and the drum. Toner jumps across this gap to develop

the latent image.

The development bias consists of ac and dc components. The ac component

improves the transfer of toner.

The transfer blade [B] is charged to the same voltage as the development bias.

This helps to keep the toner on the drum.

The toner near-end sensor [E] is located under the toner cartridge.

2-13

Page 40

TONER CARTRIDGE 12 March 1999

Toner Near-End Sensor

The toner near-end sensor monitors the toner concentration by checking the

magnetic field strength.

When the reading goes down to a threshold value, the machine enters the nearend condition. There is no toner end condition (the user replaces the cartridge

when the print quality has become unacceptable). The threshold value cannot be

changed.

No adjustment is required after the sensor is replaced.

Toner Supply

The toner in the toner cartridge is mixed by the agitator(s) and mixing blade. The

toner near-end sensor is not used to control toner supply. When the machine is

turned on or the front cover is closed, the agitator(s) and the mixing blade rotate to

mix the toner for a brief period.

Development Bias

The high voltage supply unit gives the development roller a charge of –400 V dc

and an ac component of 1.8 kVp-p 1.8 kHz ac is also used. To prevent toner from

transferring to non-image areas on the drum, the development bias is different for

image areas and non-image areas.

2-14

Page 41

12 March 1999 TONER CARTRIDGE

2.3.5 DRUM CLEANING

[D]

[A]

[B]

[C]

Detailed

Descriptions

G031D512.WMF

The cleaning blade [A] removes any toner remaining on the drum after the image is

transferred to the paper. The toner remaining on the drum is scraped off by the

cleaning blade and transferred to the collection area. The mylar sheet [B] prevents

the toner from dropping out of the cleaning unit.

The toner cartridge in the commercial toner cartridge has a toner collection coil [C]

and scraper [D]. These improve the collection of waste toner.

There is no toner recycling mechanism.

2-15

Page 42

IMAGE TRANSFER AND PAPER SEPARATION 12 March 1999

2.4 IMAGE TRANSFER AND PAPER SEPARATION

2.4.1 OVERVIEW

[C]

[A]

[B]

G031D513.WMF

The machine uses a transfer roller [A] which touches the surface of the drum [B].

The high voltage supply unit supplies a positive current to the transfer roller. A

feedback circuit inside the machine automatically keeps the transfer current

constant.

The current depends on the paper size. For A3 paper in the Stinger - P3, 7mA is

supplied, and for A4 paper in the Stinger - P4, 6mA is supplied (for 600 dpi

resolution in both of these cases).

The transfer roller attracts the toner from the drum onto the paper.

Drive from the drum through a gear drives the transfer roller.

The discharge plate [C] and the curvature of the drum helps the paper to separate

from the drum. The discharge plate is connected to ground.

2-16

Page 43

12 March 1999 IMAGE TRANSFER AND PAPER SEPARATION

2.4.2 TRANSFER ROLLER CLEANING

If the paper size is smaller than the printed image, or if a paper jam occurs during

printing, toner may be transfered to the roller surface. To prevent this toner from

transferring to the back side of the printouts, the transfer roller has to be cleaned

before the next printing run.

During transfer roller cleaning, the high voltage supply unit supplies a negative

cleaning bias to the transfer roller. The negatively charged toner on the transfer

roller is then transferred back to the drum. Then a positive cleaning bias is applied

to the transfer roller to push back to the drum any toner which was positively

charged by the transfer roller.

The machine goes through the cleaning mode in the following conditions:

·

After a printer jam has been cleared.

·

Just after the power is switched on.

·

After 10 sheets of paper have been printed and the print job has finished.

Detailed

Descriptions

2-17

Page 44

PAPER FEED 12 March 1999

2.5 PAPER FEED

2.5.1 OVERVIEW

Stinger - P3

[C]

[D]

[B]

[A] [E]

There is a paper tray [A] and a by-pass tray [B].

The paper tray holds 250 sheets. The by-pass tray can hold 100 sheets of paper.

The paper feed roller [C] drives the top sheet of paper from the paper tray to the

registration rollers [D].

The paper tray has a friction pad [E] which allows only one sheet to feed at a time.

When the paper tray is closed af ter the paper is loaded, the paper size actuator

(behind the paper size indicator, which is located at the front right of the tray)

pushes the tray paper size switch. This informs the CPU what paper size is loaded

in the tray and that the tray is in place.

The tray can be extended manually to hold paper longer than A4/Letter size.

G031D514.WMF

2-18

Page 45

12 March 1999 PAPER FEED

Stinger - P4

[B]

Detailed

Descriptions

[D]

[C]

[A] [E]

G031D515.WMF

There is a paper tray [A] and a by-pass tray [B].

The paper tray holds 250 sheets. The by-pass tray can hold 100 sheets of paper.

The paper feed roller [C] drives the top sheet of paper from the paper tray to the

relay roller [D]. Then the relay roller feeds the paper to the registration area.

The paper tray has a friction pad [E] which allows only one sheet to feed at a time.

This machine does not have a paper size switch. So, before printing, the user must

register the paper size in the paper tray at the printer’s operation panel.

The built-in tray can only hold A4 or letter size paper.

2-19

Page 46

PAPER FEED 12 March 1999

2.5.2 PAPER TRAY

Stinger - P3

Tray Extension

The tray can be extended manuall y

to hold paper longer than A4/Letter

size. The default setting of the tray

length is for short paper. To use

longer paper, release the catches

[A] at both sides, then extend the

tray and re-lock the catches.

The paper sizes in the table given

below can be used.

Tray mode Possible Paper Sizes

Short

(default)

Long

A5 Landscape, B5 Landscape, A4 Landscape, 7

8

" x 11" Landscape, 8

1/2

" x 13" Portrait, 8" x 13" Portrait, 8

8

1/2

Portrait, B4 Portrait, A3 Portra it, 11" x 17" Portr ait

[A]

" x 11" Portrait, A4 Portrait

1/2

" x 13" Portrait, 8

1/4

1/4

" x 10

G031D516.WMF

" Landscape,

1/2

" x 14"

1/2

Bottom Plate Lift

The tray bottom plate [B] is connected

to the cassette arms [C] by springs

[D]. When the cassette is put in the

machine, the slopes of the guide

blocks [E] on the machine lift the

cassette arms up and the springs

keep the stack of paper at the correct

height. When the paper is used up,

the springs pull the tray bottom plate

up as shown in the picture.

[E]

[D]

[B]

[C]

G031D517.WMF

2-20

Page 47

12 March 1999 PAPER FEED

Paper Feed Drive

[E]

[F]

[A]

[B]

[C]

[D]

Detailed

Descriptions

G031D518.WMF

The main motor drives the pick-up an d fe ed mec hanism. The tray paper feed clutc h

[A] transfers drive from the main motor to the paper feed roller [B].

This machine uses a feed roller and friction pad mechanism. The friction pad [C]

only allows the top sheet to feed. Therefore, during paper feed, the top sheet of

paper is separated from the stack and fed to the registration rollers [D].

When the paper actuates the registration sensor [E], the tr ay paper feed clutch

turns off. When the paper reaches a certain position, the registration clutch [F]

turns on to transfer drive from the main motor to the registration rollers. Then the

registration rollers feed the paper to the transfer area.

2-21

Page 48

PAPER FEED 12 March 1999

Paper Size Detection

The paper size switch [A] includes

three sensors (microswitches). The

sensors are actuated by actuators on

[C]

[D]

[A]

a dial [B] behind the paper size

indicator plate.

Each paper size has its own actuator,

with a unique combination of notches.

To determine the paper size, the CPU

reads which switches have been

turned off by the actuator.

[B]

The CPU disables paper feed from a

tray if the paper size cannot be

G031D519.WMF

detected. If the paper size actuator is

broken, or if there is no tray installed, the printer control board recognizes that the

paper tray is not installed.

When the paper size actuator is at the "]" mark, the paper tray can be set up to

accommodate one of a wider range of paper sizes by using a user tool at the

machine’s operation panel.

Models Switch Location

North America Europe Left Center Right

8

" x 14" Portrait A5 Landscape On On On

1/2

A4 Landscape A4 Landscape On Off Off

8

" x 11" Portrait A4 Portrait On On Off

1/2

]]

8

" x 13" Portrait 8

1/2

8

" x 11" Landscape 8

1/2

11" x 17" Portrait A3 Portrait Off Off On

" x 13" Portrait Off On Off

1/2

" x 11" Landscape On Off On

1/2

Off On On

On: Pushed Off: Not Pushed

Paper End Detection

When the paper tray runs out of paper, the feeler of the tray paper end sensor

drops into the cutout in the tray bottom plate and this activates the paper end

sensor [C].

Paper Near End Detection

When almost 50 sheets are left on the tray, th e tray bottom pla te pushes up the

feeler of the tray paper near end sensor [D]. However, there is no indication on the

printer’s operation panel; the signal is only for use by the host computer.

2-22

Page 49

12 March 1999 PAPER FEED

Stinger - P4

Bottom Plate Lift

[C]

[A]

[B]

Detailed

Descriptions

G031D520.WMF

The tray bottom plate is connected to the cassette arm [A] by the spring [B]. When

the cassette is put in the machine, the slope of the guide block [C] on the machine

lifts the cassette arm up and the spring lifts up the bottom plate.

2-23

Page 50

PAPER FEED 12 March 1999

Paper Feed Drive

[B]

[D]

[E]

[F]

[C]

[G]

[A]

[I]

[H]

G031D521.WMF

The main motor drives the pick-up and feed mechanism through the paper pick-up

drive gear [D].

To pick up paper, the tray paper feed solenoid [A] turns on and the gear stopper [B]

comes off the paper feed roller gear [C]. This gear does not move immediately,

because the gap in the teeth prevent it from engaging the drive gear [D]. It is first

turned clockwise by a spring until its teeth engage with the drive gear, which now

drives the paper feed roller [E].

At the same time, the cam behind the paper feed roller gear moves the stopper

release lever [G], and this releases the bottom plate stopper [H]. The bottom plate

can then lift the top of the paper stack to the correct height for paper feed.

This machine uses a feed roller and friction pad mechanism. The friction pad [F]

only allows the top sheet to feed to the relay roller [I].

After one turn, the paper feed roller gear stops because the part of the gear without

teeth is now back at the starting position, opposite the pick-up drive gear. The gear

stopper and bottom plate stopper also return to their previous positions

Then the relay rollers feed the paper to the transfer area.

NOTE:

If the gear stopper comes off the paper feed roller gear as a result of shock

or vibration and paper is placed in the tray, the machine starts to feed

paper as soon as it is turned on. To fix this problem, remove all paper from

the paper tray then turn on the machine.

Paper End Detection

This is the same as for the Stinger - P3. There is no near-end detection.

2-24

Page 51

12 March 1999 PAPER FEED

2.5.3 BY-PASS TRAY

Stinger - P3

[A]

[B]

[F]

[G]

[C]

G031D522.WMF

[D]

Detailed

Descriptions

[E]

G031D523.WMF

When paper is placed on the tray, the by-pass tray paper feeler [A] is pushed up

and the actuator leaves the by-pass tray paper sensor [B].

After image processing in the printer control board, the CPU energizes the by-pass

feed solenoid and the by-pass feed roller [C] starts to feed paper to the registration

roller [D]. The by-pass feed roller has two cams [E] and these cams release the bypass tray bottom plate to press the stack of paper against the by-pass feed roller.

This machine uses a feed roller and friction pad mechanism, with drive from the

main motor transmitted when the by-pass feed clutch turns on. The friction pad

only allows the top sheet to feed to the registration rollers.

When the pa per leading edge activates the registration sensor [F], th e registration

clutch [G] turns on.

2-25

Page 52

PAPER FEED 12 March 1999

Stinger - P4

[A]

[B]

G031D524.WMF

[C]

[D]

[E]

G031D525.WMF

When paper is placed on the tray, the by-pass tray paper sensor [A] activates.

After image processing in the printer control board, the CPU energizes the by-pass

feed solenoid [B] and the by-pass feed roller [C] starts to feed paper to the relay

roller [D]. The by-pass feed roller cam [E] releases the by-pass tray bottom plate to

press the stack of paper against the by-pass feed roller.

This machine uses a feed roller and friction pad mechanism, with drive from the

main motor transmitted when the by-pass feed clutch turns on. The friction pad

only allows the top sheet to feed to the relay roller.

2-26

Page 53

12 March 1999 PAPER FEED

2.5.4 PAPER REGISTRATION

Stinger - P3

[B]

[A]

[D]

Detailed

Descriptions

[C]

G031D518.WMF

Main motor rotation is transmitted to the registration clutch gear [A].

The registration sensor [B] is just before the registration rollers [C].

When the pa per leading edge activates the registration sensor, the registration

clutch [D] turns off and the registration rollers stop turning. However, the tray paper

feed roller clutch stays on for a bit longer. This delay allows time for the paper to

press against the registration rollers and buckle slightly to correct skew. The

registration clutch energizes at the proper time to align the paper with the image on

the drum. The registration rollers feed the paper to the image transfer section.

The registration sensor is also used for paper misfeed detection.

2-27

Page 54

PAPER FEED 12 March 1999

Stinger - P4

[A]

[B]

G031D526.WMF

The registration sensor [A] is just after the relay roller [B]. However, this machine

has no registration roller.

A certain time after the paper leading edge activates the registration sensor, the

CPU starts to write the latent image on the drum.

The registration sensor is also used for paper misfeed detection.

2-28

Page 55

12 March 1999 IMAGE FUSING

2.6 IMAGE FUSING

2.6.1 OVERVIEW

8 9

10

7

Detailed

Descriptions

6

1

5

2

34

G031D527.WMF

The fusing unit consists of the following parts.

1. Pressure Roller Release Lever

2. Pressure Spring

3. Fusing Lamp

4. Fusing Thermistor

5. New Fusing Unit Detector (Stinger

6. Hot Roller

7. Exit Roller

8. Fusing Exit Sensor

9. Hot Roller Strippers

10. Pressure Roller

P3 only)

2-29

Page 56

IMAGE FUSING 12 March 1999

2.6.2 FUSING

[D]

[A]

[C]

[B]

G031D528.WMF

After the image has been transferred, the paper enters the fusing unit. The image

is fused to the paper by applying heat and pressure through the combination of hot

roller [A], the fusing lamp [B], and the pressure roller.

The CPU monitors the hot roller temperature through the fusing thermistor [C] that

is in contact with the hot roller surface. The thermofuse [D] protects the fusing unit

from overheating.

2.6.3 FUSING UNIT DRIVE

[B]

[A]

G031D529.WMF

The main motor drives the hot roller [A] through a train of gears.

The hot roller drives the exit roller [B] through a gear.

2-30

Page 57

12 March 1999 IMAGE FUSING

2.6.4 PRESSURE ROLLER/PAPER EXIT

[C]

[A]

[B]

G031D530.WMF

During printing, the pressure roller [A] is pressed against the hot roller [B] by

springs.

Detailed

Descriptions

The hot roller strippers [C] separate the paper from the hot roller and direct it to the

exit roller. Then the exit roller feeds the paper to the paper tray.

2.6.5 FUSING UNIT DRIVE RELEASE

[A]

G031D531.WMF

When the pressure roller release levers [A] are pushed down, the pressure roller

moves away so that jammed paper can be removed.

2-31

Page 58

IMAGE FUSING 12 March 1999

2.6.6 NEW FUSING UNIT DETECTION (STINGER - P3 ONLY)

[D]

[C]

[A]

[B]

G031D532.WMF

The fusing unit in the Stinger - P3 maintenance kit has this detection mechanism

(the fusing unit obtained as a service part does not). When the fusing unit has been

replaced, the CPU detects the new unit and automatically removes the “Replace

Maintenance Kit” from the display and resets the maintenance counter.

NOTE:

The Stinger - P4 doesn’t have this mechanism, so after replacing the fusing

unit, clear the “Replace Maintenance Kit” status using the “User Menu –

Maintenance – PM Clear” procedure.

There are two terminals [A] at the rear left side of the fusing unit. Before

installation, these terminals are in contact [C]. When the machine is turned on after