Page 1

20-BIN SORTER STAPLER

(Machine Code: A834)

Page 2

24 February, 1999 SPECIFICATIONS

1. OVERALL MACHINE INFORMATION

1.1 SPECIFICATIONS

Paper Size for Bins Sort/Stack Modes:

Lengthwise: A6 to A3

5

" x 8

1/2

Sideways: A5 to A4

5

" x 8

1/2

Paper Weight for Bins: Sorting: 52 ~ 160 g/m2 (14 ~ 43 lb)

Stacking: 52 ~ 160 g/m2 (14 ~ 43 lb)

Stapling: 52 ~ 160 g/m2 (14 ~ 43 lb)

Bin capacity: Sorting:

A4, 8

x 11" or smaller:

1/2

30 copies (80g/m2, 20 lb)

B4, 8

x 14" or larger:

1/2

25 copies (80g/m2, 20 lb)

Stacking:

A4, 8

x 11" or smaller:

1/2

25 copies (80g/m2, 20 lb)

B4, 8

x 14" or larger:

1/2

20 copies (80g/m2, 20 lb)

" (HLT) to 12" 18"

1/2

" (HLT) to 8

1/2

" x 11" (LT)

1/2

Stapler Capacity: 2 ~ 30 copies (80 g/m2, 20 lb)

Proof Tray Capacity: 100 sheets (80g/m2, 20 lb)

Number of Bins: 20 bins + proof tray

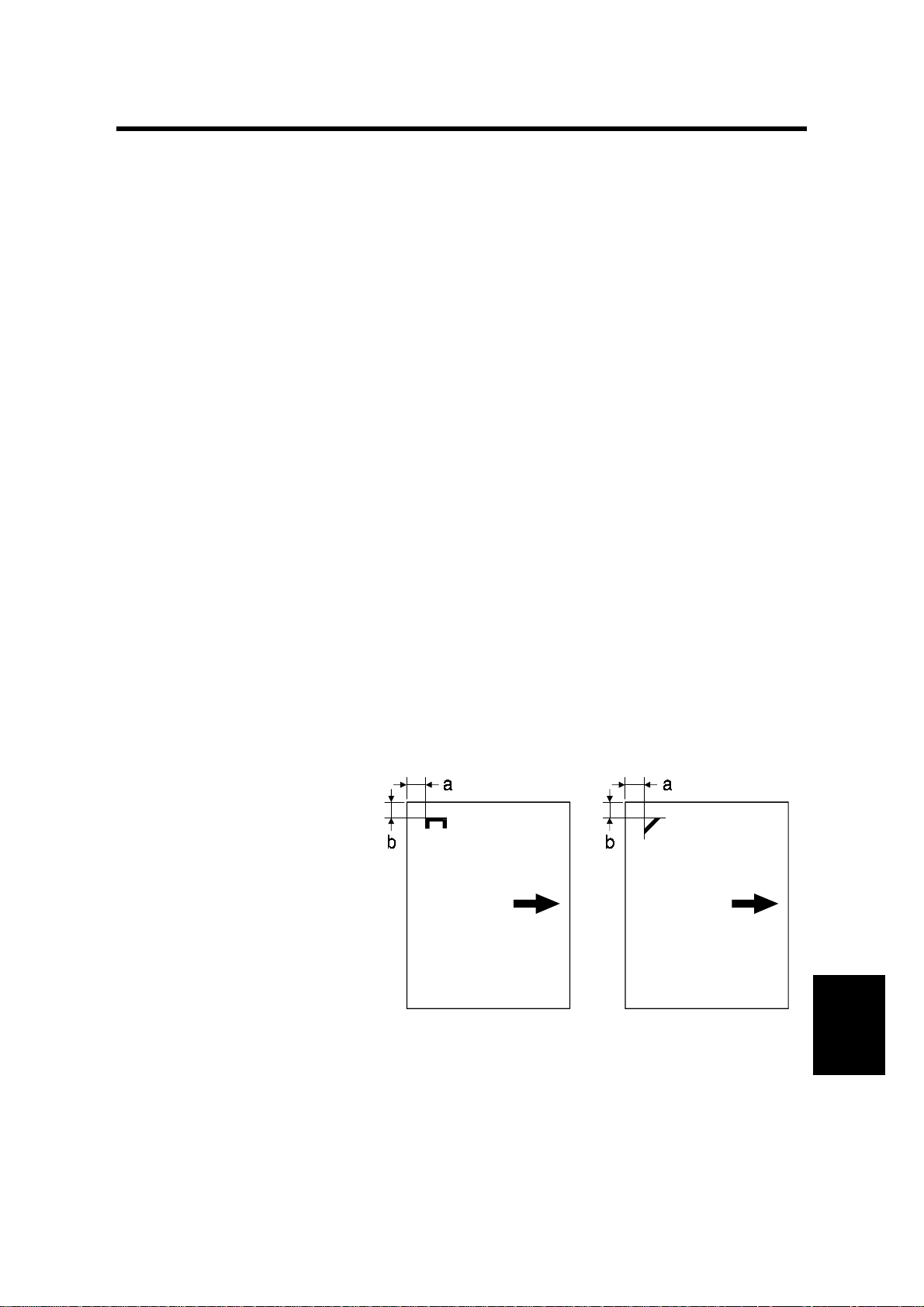

Stapling Position:

a = 6 ± 3 mm b = 6 ± 3 mm

A834V500.WMF

Options

A834-1

Page 3

SPECIFICATIONS 24 February, 1999

Staple Replenishment: Cartridge exchange (2,000 staples/cartridge)

Power Source: DC 24 V (from the copier)

Power Consumption: Average: less than 35 W

Average for Sorting: less than 30 W

Average for Stapling: less than 33 W

Weight: 20.5 kg (45.2 lb)

Dimensions (W x D x H): 430 x 570 x 680 mm (17.0" x 22.5" x 26.8")

•

Specifications are subject to change without notice.

A834-2

Page 4

24 February, 1999 COMPONENT LAYOUT

1.2 COMPONENT LAYOUT

1.2.1 MECHANICAL COMPONENT LAYOUT

1

2

7

3

4

6

5

1. Helical Wheels

2. Jogger Plate

3. Grip Assembly

4. Transport Rollers

5. Staple Unit

6. Bins

7. Proof Tray

A834V501.WMF

Options

A834-3

Page 5

COMPONENT LAYOUT 24 February, 1999

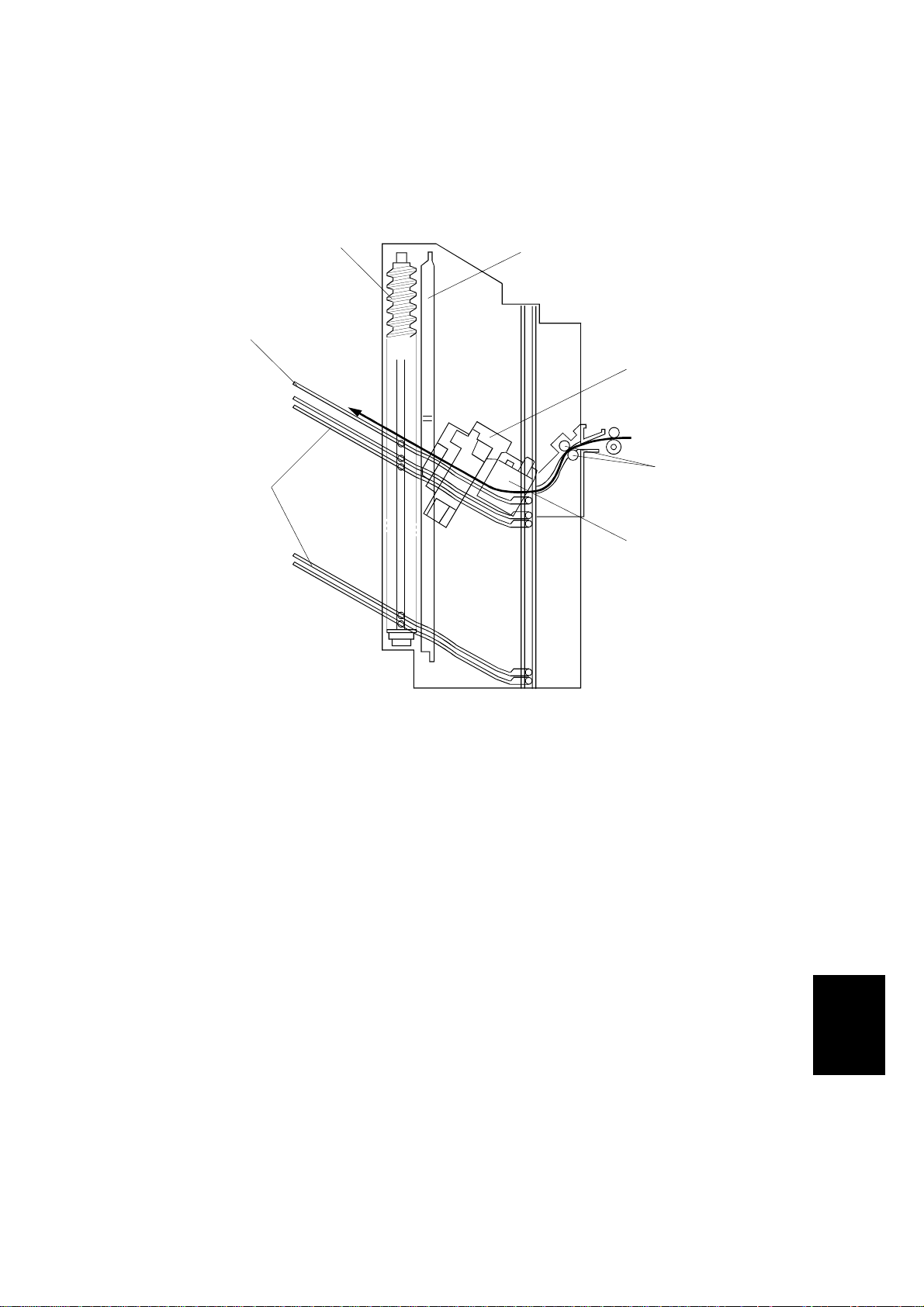

1.2.2 DRIVE LAYOUT

1 2

4

1. Jogger Drive Belt

2. Transport Roller

3. Wheel Drive Belts

4. Helical Wheels

3

A834V502.WMF

A834-4

Page 6

24 February, 1999 COMPONENT LAYOUT

1.2.3 ELECTRICAL COMPONENT DESCRIPTION

Refer to the electrical component layout on the reverse side of the point to point

diagram (on waterproof paper).

Symbol Name Function Index No.

Motors

M1 Main Drive Drives the transport roller 16

M2 Jogger Drives the jogger plate to square the copies 9

M3 Bin Drive Drives the bins 14

M4 Stapler Drives the stapler hammer 7

Grip Drives the grippers forwards and back into

M5

Sensors

S1

S2

S3

S4 Sorter Entrance Detects paper jams 2

S5

S6 Wheel Detects the bin position. 12

S7

S8

S9 Staple End Detects when the staples have run out 18

S10

Bin

(Phototransistor)

Grip Home

Position

Bin Home

Position

Jogger Home

Position

Bin (LED) Detects whether there is paper in the bins

Stapler Paper Detects whether any copies are under the

Staple Hammer

Home Position

the bin to grip the copies and bring them to

the stapling position

Detects whether there is any paper in the

bins (light receiving element)

Detects when the grip assembly cam gear

has rotated once

Detects whether the bins are at home

position

Detects whether the jogger plate is in its

home position

(light emitting element)

staple hammer.

Detects whether the staple hammer is at

home position

3

1

6

11

13

10

4

17

Switches

SW1

SW2 Stapler Cuts the signals to the stapler. 8

Circuit Board

PCB1 Main Controls all sort er/ stapler functions 15

Door Safety Cuts the dc +24 V supply when either the

unit or the stapler cover is opened.

A834-5

5

Options

Page 7

BASIC OPERATION 24 February, 1999

2. DETAILED DESCRIPTIONS

2.1 BASIC OPERATION

2.1.1 NORMAL MODE AND SORT/STACK MODE

[F]

[E]

[A]

[C]

[B]

[D]

A834D500.WMF

Copies exiting the copier pass through the entrance guide plate [A]. The transport

roller will send copies either to the proof tray or to each bin, depending on the

selected mode.

During copying, all rollers in the sorter stapler transport the paper at a speed which

depends on the copier. When the trailing edge of the copy passes the fusing exit

sensor, the speed of the rollers changes to 600 mm/s. This makes enough time for

the jogger plate to square the stack of paper and to stack the paper smoothly into

the bins.

Normal (Proof) Mode

When the “Start” key is pressed, the transport motor [B] energizes to rota te the

transport rollers [C]. The transport rollers send copies to the proof tray directly.

Sort Mode

When sort mode is selected, the bin drive motor [D] energizes to rotate the helical

wheels. The helical wheels [E] rotate twice to move the top bin to the transport

roller position, then the first copy is delivered to the top bin.

After the first copy of the first original has been fed to the top bin, the bin drive

motor moves the bins up one step (the helical wheels rotate once) so that the

second copy of the first original will be delivered to the next bin.

The jogger plate [F] squares the copies after each copy has been fed to a bin. After

all the copies of the first original have been delivered to each bin, the sorter stapler

maintains its status (the bin drive motor does not rotate).

A834-6

Page 8

24 February, 1999 BASIC OPERATION

The first copy of the second original is delivered to the final bin that was used for

the first original, then the final bin descends one step. The bins descend each time

a copy of the second original is delivered.

The direction of motion of the bins alternates for each page of the original until the

copy run is finished.

Stack Mode

[A]

A834D501.WMF

When stack mode is selected, the top bin advances to the transport rolle r position

in the same way as in sort mode.

After the first copy is delivered to the top bin, the jogger plate [A] moves across to

square the copy. The jogger plate squares the copies after each copy has been fed

to a bin.

After one set of copies for the first original has been delivered to the top bin, the bin

drive motor moves the bins up one step. Then, one set of copies of the second

original will be delivered to the next bin.

Options

A834-7

Page 9

BASIC OPERATION 24 February, 1999

2.1.2 STAPLE MODE

[B]

A834D502.WMF

[A]

[C]

[D]

A834D503.WMF

Mechanism

The stapler is only available in sort mode.

When the jogger plate has squared the final set of copies, the grip arms [A] move

inside the front side frame and catch the paper. The grip assembly brings the

copies into the stapler [B], and the stapler staples the copies.

After stapling, the grip assembly [C] brings the stapled copies back to the bin and

releases the copies. Then the grip assembly goes back to the normal position. The

bin either advances or descends one step [D] (depending on whether the page is

an odd or even numbered page of the original).

When the final set of copies has been stapled, the bins go back to the standby

position.

There are two staple modes.

Automatic Stapling

In ADF mode, when staple mode is selected before pressing the “Start” key, copies

will be delivered to each bin and stapled automatically.

Manual Stapling

In platen cover mode, after the copies have been sorted into the bins, the staple

mode LED starts to blink. If the sort key is pressed while this LED is blinking, the

copies will be stapled.

A834-8

Page 10

24 February, 1999 BASIC OPERATION

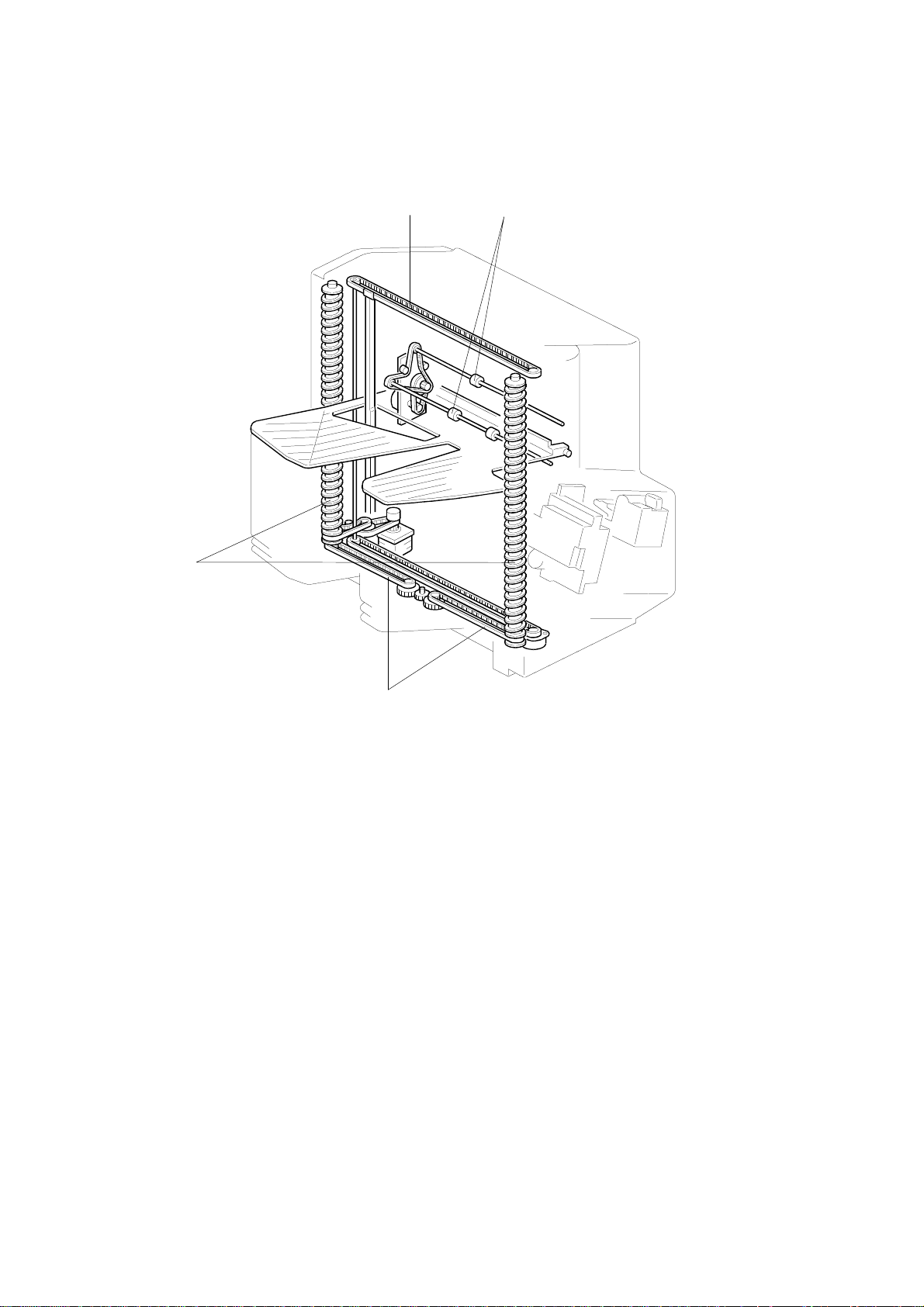

2.1.3 BIN DRIVE MECHANISM

[E]

[D]

[C]

[A]

[B]

A834D504.WMF

The bin drive mechanism moves the bins up and down to receive copies.

There are four pins on each bin. Two pins fit into the slots [A] in both the front and

rear side frames; the pins slide up and down in these slots. The other two pins fit

into the slot in the helical wheels; as the helical wheels turn, these pins move up

and down, and the other pins move up and down in the slots at the other end of the

bin.

The bin drive motor [B] drives the helical wheels [C] through timing belts as shown.

When the motor rotates clockwise, the bins lift; when it rotates counterclockwise,

the bins lower. There is a wheel sensor [D] located under the actuator [E] on the

rear helical wheel; the actuator has a slot which detects when the helical wheel has

rotated once.

When the bins are advanced, the helical wheels rotate once for each step. As the

pitch of the spiral on the helical wheel is greater when the bins are at the stapling

and paper exit area than when the bins are elsewhere, the amount of bin shift is

greater when the bins are at the stapling and paper exit area. This leaves enough

space to staple and stack the copies. Also, this reduces the total machine height.

Options

A834-9

Page 11

BASIC OPERATION 24 February, 1999

2.1.4 BIN HOME POSITION

[A]

A834D505.WMF

The bin home position sensor [A] ensures that the proof tray is lower than the

transport roller when the bins are in the home position.

When the main switch is turned on, the sorter stapler initializes itself to check

whether the component parts work or not. At this time, the bin drive motor raises

the bins for a few moments, then it lowers the bins until the bottom bin actuates the

bin home position sensor.

A834-10

Page 12

24 February, 1999 BASIC OPERATION

2.1.5 JOGGER MECHANISM

[B]

[C]

[E]

[D]

A834D506.WMF

[A]

The jogger motor [A] drives the jogger plate [B] through the timing belts [C].

The jogger is at home position when the actuator on the jogger plate goes into the

jogger home position sensor [D].

In standby mode, the jogger plate is at the home position. When the “Start” key is

pressed, the copier sends the paper size information to the sorter stapler.

In sort, staple, and stack modes, the jogger moves three times to square the stack

of paper. First, when the paper has been fed completely into the bin (at the proper

time after the copy has passed through the entrance sensor [E], depending on the

paper length), the jogger motor moves the jogger plate out of the jogger home

position. Then, the jogger motor drives the jogger plate to the width of the copy.

Finally, the jogger plate moves inward to push all the copies against the front side

frame, which squares the sheets of paper. Then the jogger plate returns to the

home position.

A834-11

Options

Page 13

BASIC OPERATION 24 February, 1999

2.1.6 GRIP ASSEMBLY

[G]

[H]

[J]

[D]

[I]

A834D507.WMF

[B]

[E]

[C]

[F]

[A]

A834D509.WMF

A834D508.WMF

The grip assembly consists of the grip motor [A], the timing belt [B], the drive gear

[C], the grip home position sensor [D], and the cam gear [E].

The grip motor drives the cam gear through the timing belt and drive gear. Cam

gear rotation drives the mechanism that catches the copies and moves the grip

arm unit [F]. When the cam gear rotates clockwise one full turn, the grip arm moves

to catch the copies and returns to the home position to prepare for stapling. After

stapling, the cam gear rotates counterclockwise once so that the stapled copies go

back to the bin, and the cam gear returns to its home position.

When the cam pushes the roller [G] on the lever [H] and the lever pushes the grip

arm, the grip arm can catch the copies.

A pin [I] on the cam gear fits into the slot in the grip arm unit. So, when the cam

gear rotates, the slot moves the grip arm unit inward and outward.

The actuator [J] on the cam gear activates the grip home position sensor once

every rotation of the cam gear. This allows the sorter stapler to determine that the

cam gear has rotated once.

A834-12

Page 14

24 February, 1999 BASIC OPERATION

2.1.7 STAPLER UNIT

[C]

[D]

[A]

[G]

[F]

[H]

[B]

[E]

A834D510.WMF

The stapler motor [A] drives the staple hammer [B] using the gears [C] and the cam

[D].

The roller [E] feeds the staple sheets under the hammer.

When the grip unit brings the aligned copies to the staple position, the stapler

motor starts rotating and the copies are stapled. When the cam completes one

rotation, the staple hammer home position sensor [F] is deactuated and the stapler

motor stops.

When the stapler paper se nsor [G] in the grip assembly does not detect an y copies

under the hammer, the stapler motor does not rotate.

When the trailing edge of the last staple sheet passes through the staple end

sensor [H], the sorter stapler enters the staple near end condition. After the current

job is completed, the Add Staples indicator lights on the operation panel. Then the

copier cannot be used whenever the staple mode is selected.

A834-13

Options

Page 15

BASIC OPERATION 24 February, 1999

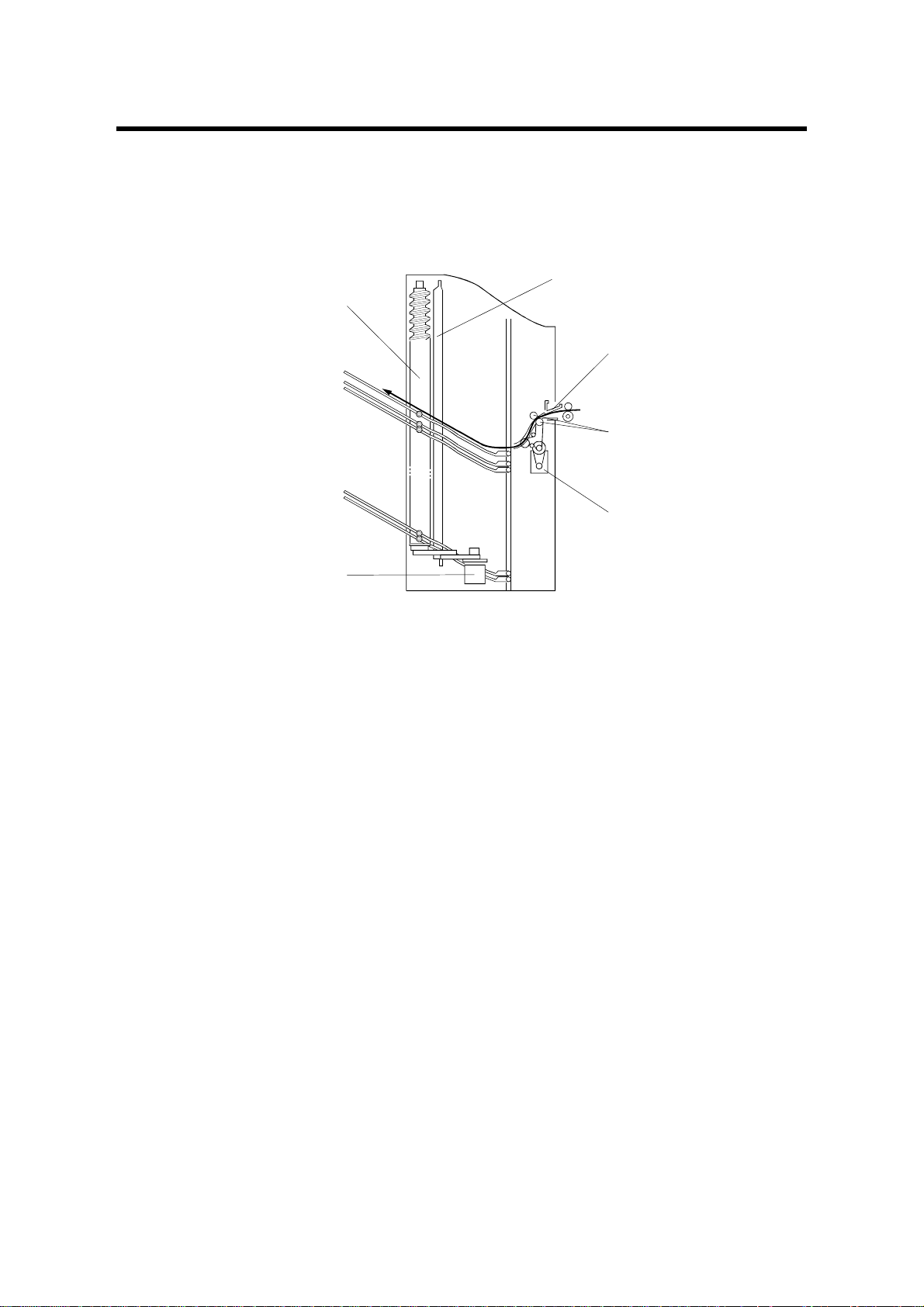

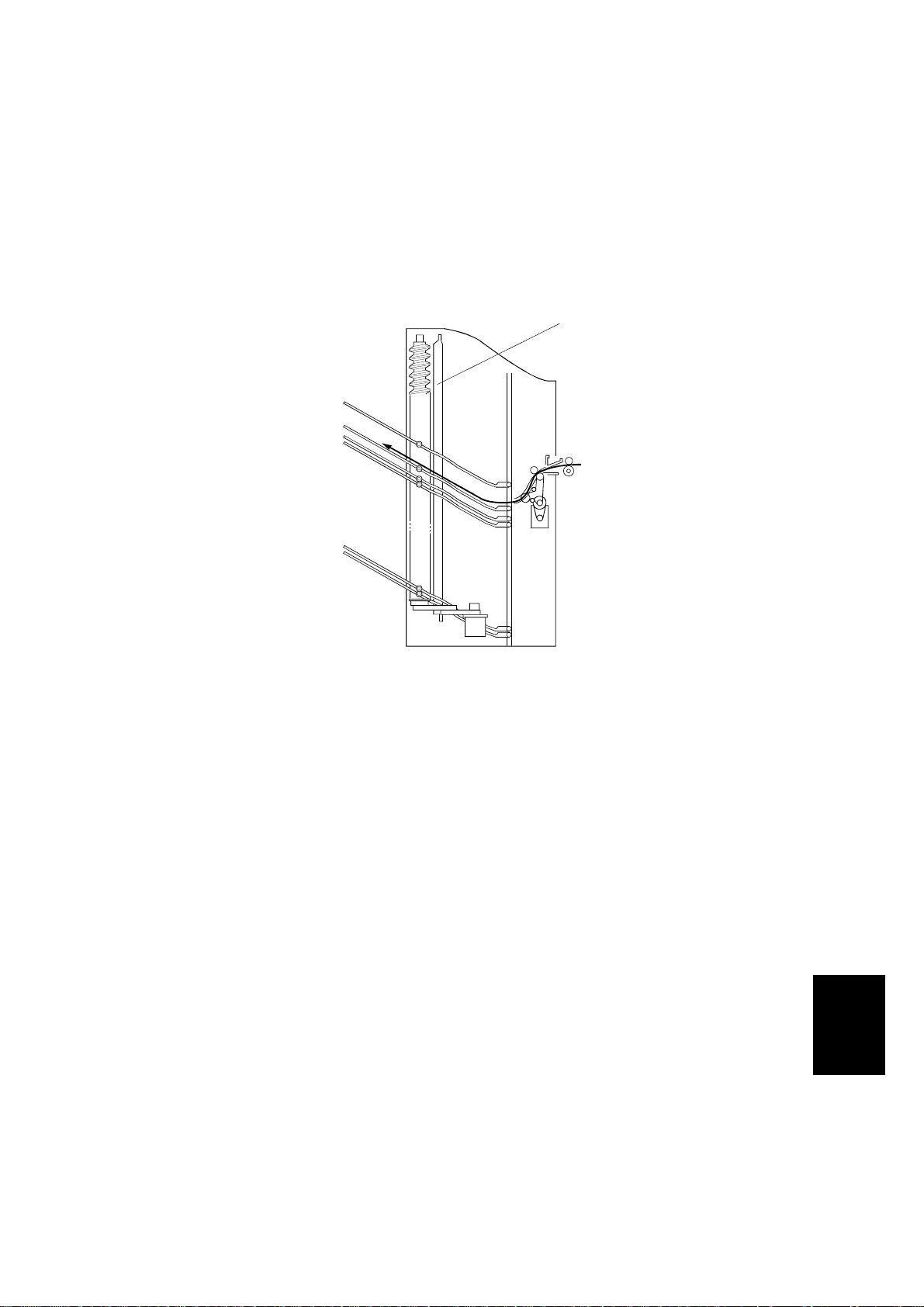

2.1.8 STAPLER SWITCH

[A]

[B]

A834D511.WMF

The stapler switch [A] below the grip assembly cuts the dc +24 V supply to the

stapler. In proof mode, all bins lower and push the lever [B]. This opens the stapler

switch so that the signal to the stapler is cut. In sort and staple modes, all bins are

advanced and the switch is closed so that the signal can be supplied to the stapler.

Staple Mode Disabling Conditions

1. Under the following conditions, staple mode is disabled.

•

If there is paper in a bin before the main switch is turned on.

•

If the selected paper size does not match the stapling specifications.

•

If the paper is fed from the by-pass feed table.

•

If the stack or interrupt modes are selected.

2. Under the following conditions, staple mode is canceled if it had been selected.

•

If paper is inserted into a bin by hand while the staple mode is selected.

•

If only one sheet is delivered to the bin.

•

If the number of sheets to be stapled exceeds the stapler capacity.

A834-14

Page 16

24 February, 1999 BASIC OPERATION

2.1.9 PAPER FEED AND MISFEED DETECTION TIMING

Proof Mode

A4 sideways, five copi es, 150 mm/s

*1: The value of the low speed depends on the copier.

A834D512.WMF

Sorter Mode

A4 sideways, two copies a of two-page original, 150 mm/s

A834D513.WMF

*1: The start times of the bin drive and the jogger motors depend on the paper size

as shown in the following table.

*2: Bin No.

Options

A834-15

Page 17

BASIC OPERATION 24 February, 1999

Paper Size

Bin drive

motor timing

Jogger

motor timing

A3/11" x 17" 80 ms 270 ms

B4 160 ms 190 ms B5 sideways 160 ms 190 ms

A4 sideways/

11" x 8

1/2

"

Staple Mode

80 ms 270 ms

A4 sideways, two copies of a two-page original, after sorting, 150 mm/s

Paper Size

A4

lengthwise/

" x 11"

8

1/2

B5

lengthwise

Bin drive

motor timing

motor timing

24 ms 96 ms

310 ms 40 ms

Jogger

A834-16

A834D514.WMF

Page 18

24 February, 1999 BASIC OPERATION

2.1.10 JAM DETECTION

Paper Jam

A4 sideways

A834D515.WMF

J1: The sorter entrance sensor does not turn on within 2 s after the fusing exit

sensor has turned on.

J2: The fusing exit sensor does not turn off within 11.4 s after the sorter entrance

sensor has turned on.

J3: The sorter entrance sensor does not turn off within 1 s after the fusing exit

sensor has turned off.

Staple Jam

In the following conditions, a staple jam will occur and the sorter jam indicator on

the operation panel will light.

1. If the stapler paper sensor is on just after the main switch is turned on or just as

the stapler cover is closed.

2. If the stapler paper sensor stays on after the stapling job has been finished.

Options

A834-17

Page 19

EXTERIOR COVER REMOVAL 24 February, 1999

3. REPLACEMENT AND ADJUSTEMENT

3.1 EXTERIOR COVER REMOVAL

[D]

[C]

[B]

[E]

3.1.1 FRONT COVER

1. Remove the front cover [A] (2 screws).

3.1.2 REAR COVER

1. Remove the rear cover [B] (3 screws).

3.1.3 TOP COVER

1. Remove the rear cover [B].

2. Remove the top cover support bracket [C] (1 screw).

3. Remove the top cover [D] (1 screw).

3.1.4 LOWER COVER

[A]

A834R506.WMF

1. Remove the front cover [A] and the rear cover [B].

2. Remove the lower cover [E].

A834-18

Page 20

24 February, 1999 STAPLER UNIT REMOVAL

3.2 STAPLER UNIT REMOVAL

[A]

[B]

[A]

A834R500.WMF

1. Remove the front cover. (See Exterior Cover Removal.)

2. Loosen the screws [A].

3. Remove the stapler unit [B], as shown (1 screw and 1 connector).

Options

A834-19

Page 21

GRIP ARM REPLACEMENT 24 February, 1999

3.3 GRIP ARM REPLACEMENT

[A]

[B]

[D]

[C]

A834R501.WMF

[F]

[E]

A834R502.WMF

1. Remove the front cover. (See Exterior Cover Removal.)

2. Remove the grip assembly [A] (4 screws, 2 connectors, and 1 grounding wire).

3. Remove the spring [B] and remove the slider [C].

4. Remove the grip arm unit [D] (1 screw and 1 clip).

5. Remove the grip arm plate [E] (2 screws).

6. Replace the grip arms [F].

A834-20

Page 22

24 February, 1999 BIN REMOVAL

3.4 BIN REMOVAL

[C]

[A]

[D]

[B]

[D]

A834R503.WMF

[E]

[F]

A834R504.WMF

1. Remove the front, rear, and top covers. (See Exterior Cover Removal.)

2. Remove the upper stay bracket [A] (4 screws and 1 connector).

3. Loosen the two screws [B], then remove the timing belt [C].

4. Remove the brackets [D] (3 springs each).

[E]

5. While moving the helical wheels [E] outward, remove the bins [F].

A834-21

Options

Page 23

TRANSPORT MOTOR REMOVAL 24 February, 1999

3.5 TRANSPORT MOTOR REMOVAL

[A]

A834R505.WMF

1. Remove the sorter stapler (1 screw and 1 chain).

2. Remove the rear cover. (See Exterior Cover Removal.)

3. Remove the transport motor [A] (2 screws).

A834-22

Page 24

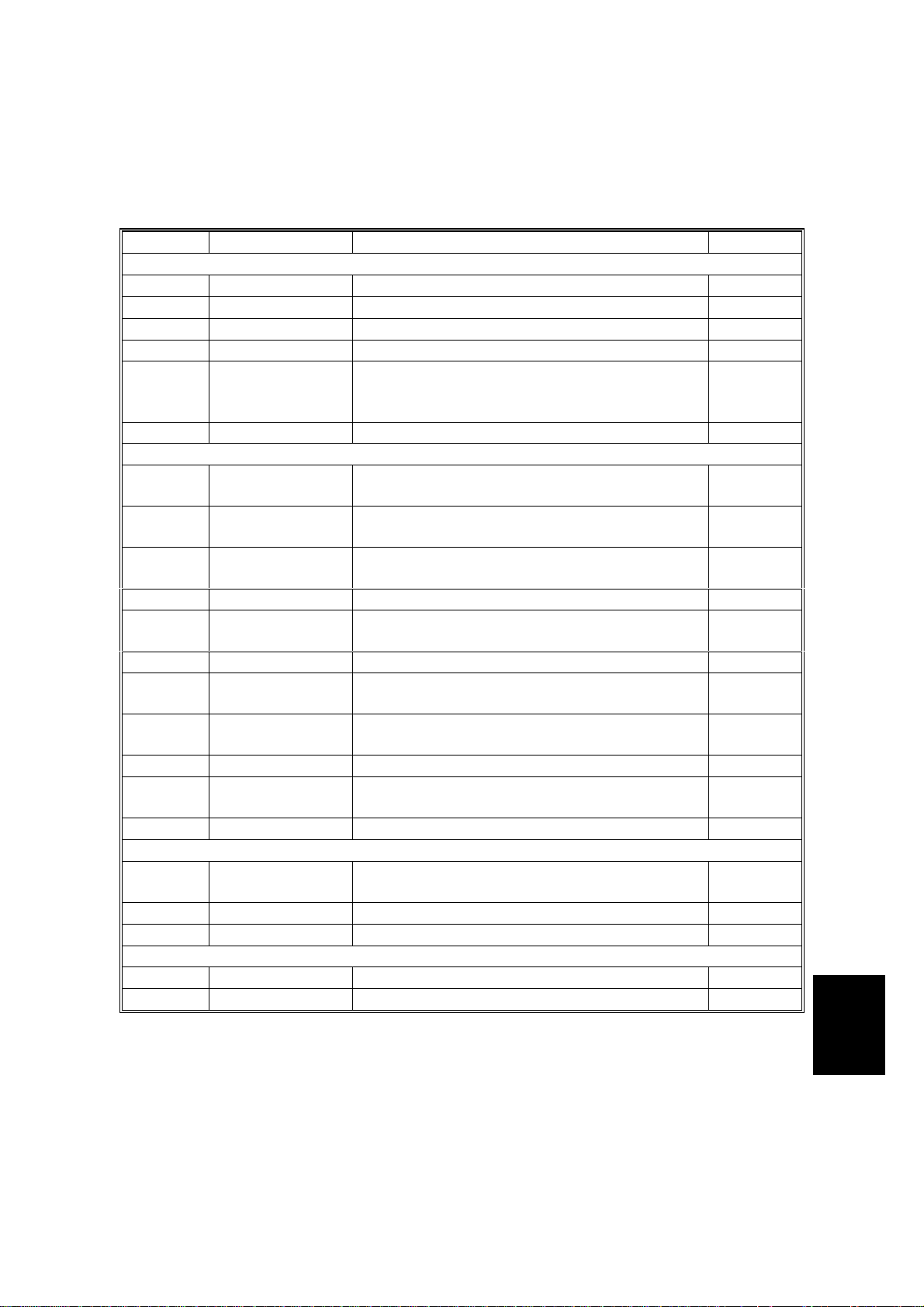

20-BIN SORTER STAPLER (A834) ELECTRICAL COMPONENTS

15

14

13

12

11

10

16

9

1

2

A834S500.WMF

3

4

5

6

7

17

8

18

A834S501.WMF

Index No. Description Symbol P-to-P

1 Bin Sensor (Photo tr.) S1 I16

2 Sorter Entrance Sensor S4 H16

3Grip Motor M5 H2

4 Stapler Paper Sensor S8 C16

5 Door Safety Switch SW1 A5

6 Grip Home Position Sensor S2 D16

7 Stapler Motor M4 D1

8 Stapler Switch SW2 F5

9 Jogger Motor M2 G2

10 Bin Sensor (LED) S7 L16

11 Bin Home Position Sensor S3 K16

12 Wheel Sensor S6 B16

13 Jogger Home Position Sensor S5 A16

14 Bin Drive Motor M3 J2

15 Main Board PCB1 F8

16 Main Drive Motor M1 F17

17 Staple Home Position Sensor S10 E1

18 Staple End Sensor S9 E1

Loading...

Loading...