Ricoh ST28 SPECIFICATIONS

SORTER STAPLER

(Machine Code: A606)

15 July 1996 SPECIFICATIONS

1. SPECIFICATIONS

Configuration: Console

Number of Bins: 20 + Proof Tray

Paper for Proof Tray:

Size Maximum: A3, 11" x 17"

Minimum: A6 lengthwise, 5

1/2

" x 8

1/2

"

Weight: 52 ~ 157 g/m

2

,14 ~ 42 lb

Capacity: 250 sheets (80 g/m

Paper for Bins: See the table below.

Sort Stack Staple Punch

Maximum paper

size

Minimum paper

size

Maximum paper

weight

Minimum paper

weight

Maximum

capacity

A3, 11" x 17" A3, 11" x 17" A3, 11" x 17" A3, 11" x 17"

Sideways:

1/2

A5, 8

Lengthwise:

A5, 5

157 g/m

52 g/m

all sizes:

50 sheets/bin

2 sided copies:

40 sheets/bin

" x 11"

1/2

" x 8

2

, 42 lb 157 g/m2, 42 lb 80 g/m2, 20 lb 128 g/m2, 34 lb

2

, 14 lb 52 g/m2, 14 lb 64 g/m2, 17 lb 52 g/m2, 14 lb

Sideways:

A4, 8

Lengthwise:

1/2

"

A5, 5

all sizes:

40 sheets/bin

2 sided copies :

35 sheets/bin

1/2

1/2

" x 11"

1/2

" x 8

"

2,

20 lb)

1/2

B5, 8

all sizes:

50 sheets

" x 11" A5 (2 holes)

B5 sideways

1/2

8

" x 11" side

ways (3 holes)

(2 holes)

104 g/m2, 28 lb

(3 holes)

all sizes:

40 sheets

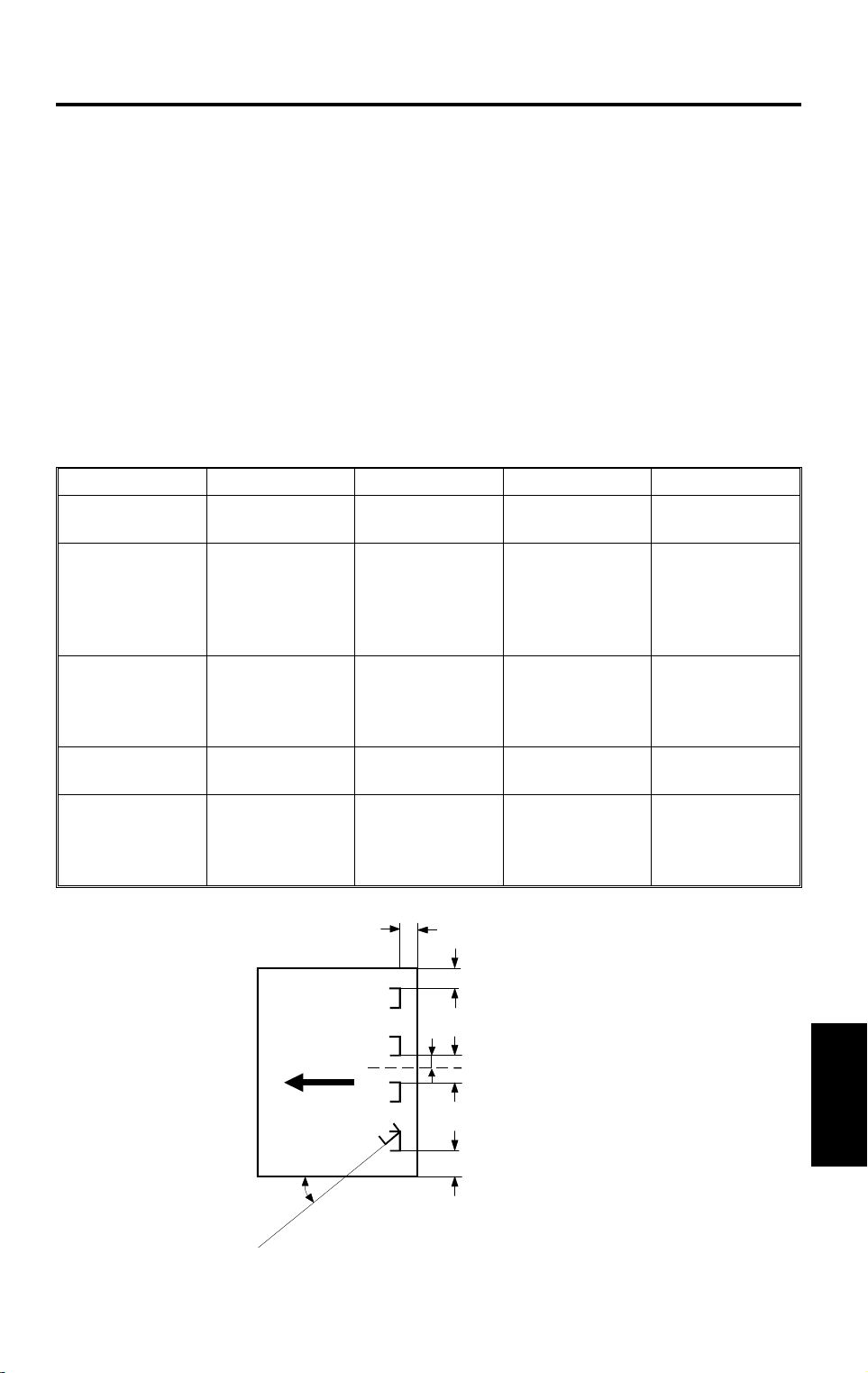

Staple Position:

a

a = 6 ± 3 mm

c

b = 6 ± 3 mm

c = 6 ± 3 mm

d

e

d = 66 ± 3 mm

e = 132 ± 2 mm

θ = 45 ± 5°

Sorter

b

θ

A606V500.wmf

1

SPECIFICATIONS 15 July 1996

Staple Replenishment: Cartridge refile (5,000 pieces/cartridge)

Power Source: DC24 V (from copier)

Power Consumption: Average: less than 60 W (without punch)

less than 70 W (with punch)

Maximum:

i n sort/stack mode: less than 60 W (without

punch)

less than 70 W (with punch)

i n staple mode: less than 45 W

Dimensions:

566 x 583 x 978 mm

(W x D x H)

Weight: Approximately 52 kg

Punch Position: 2 Holes (European version)

a = 12 ± 3 mm

a

b = 40 ± 3 mm

c = 80 ± 1 mm

φ

d

b

c

3 Holes (U.S.A. version)

3/8

a = 9.5 (

c = 216 (8

d = 108 (4

") ± 3 mm

1/2

") ± 1 mm

1/4

") ± 1 mm

d’= ± 3 mm

d’

Punch Hole Size:

2 Holes: φ = 6. 5 ± 0. 5 mm

3 Holes: φ = 8. 0 ± 0. 5 mm

A606V503.wmf

2

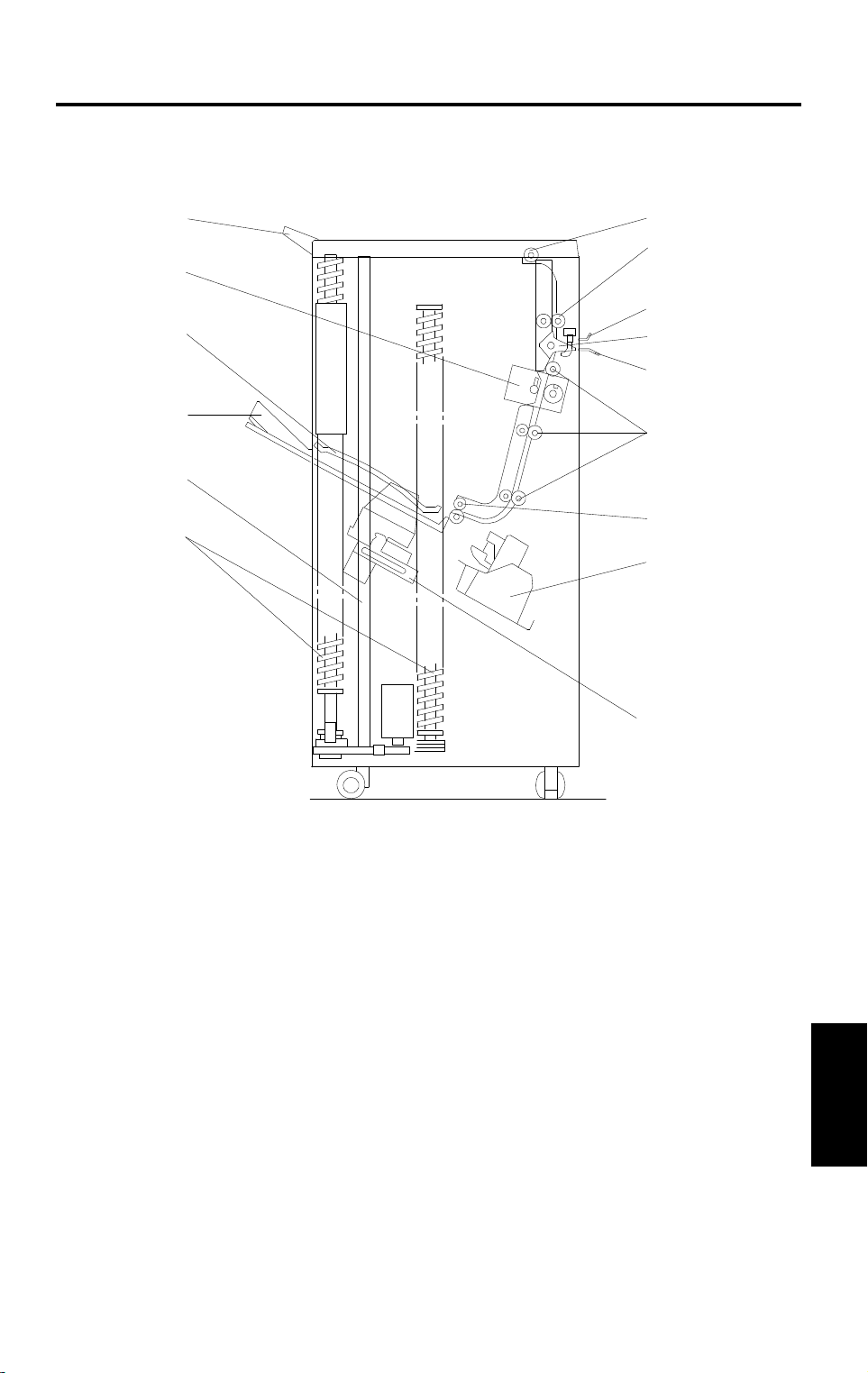

15 July 1996 COMPONENT LAYO UT

2. COMPONENT LAYOUT

2.1 MECHANICAL COMPONENT LAYOUT

1

2

3

15

4

14

5

6

13

7

12

8

11

9

10

1. Proof Tray

2. Proof Exit Rollers

3. Proof Transport Rollers

4. Upper Entrance Guide

5. Turn Gate

6. Lower Entrance Guide

7. Sorter Transport Rollers

8. Sorter Exit Rollers

A606V501.wmf

9. Staple Unit

10. Grip Assembly

11. Helical Wheels

12. Jogger Plate

13. Bins

Sorter

14. Upper Guide Plate

15. Punch Unit (Punch version only)

3

COMPONENT LAYOUT 15 Jul y 1996

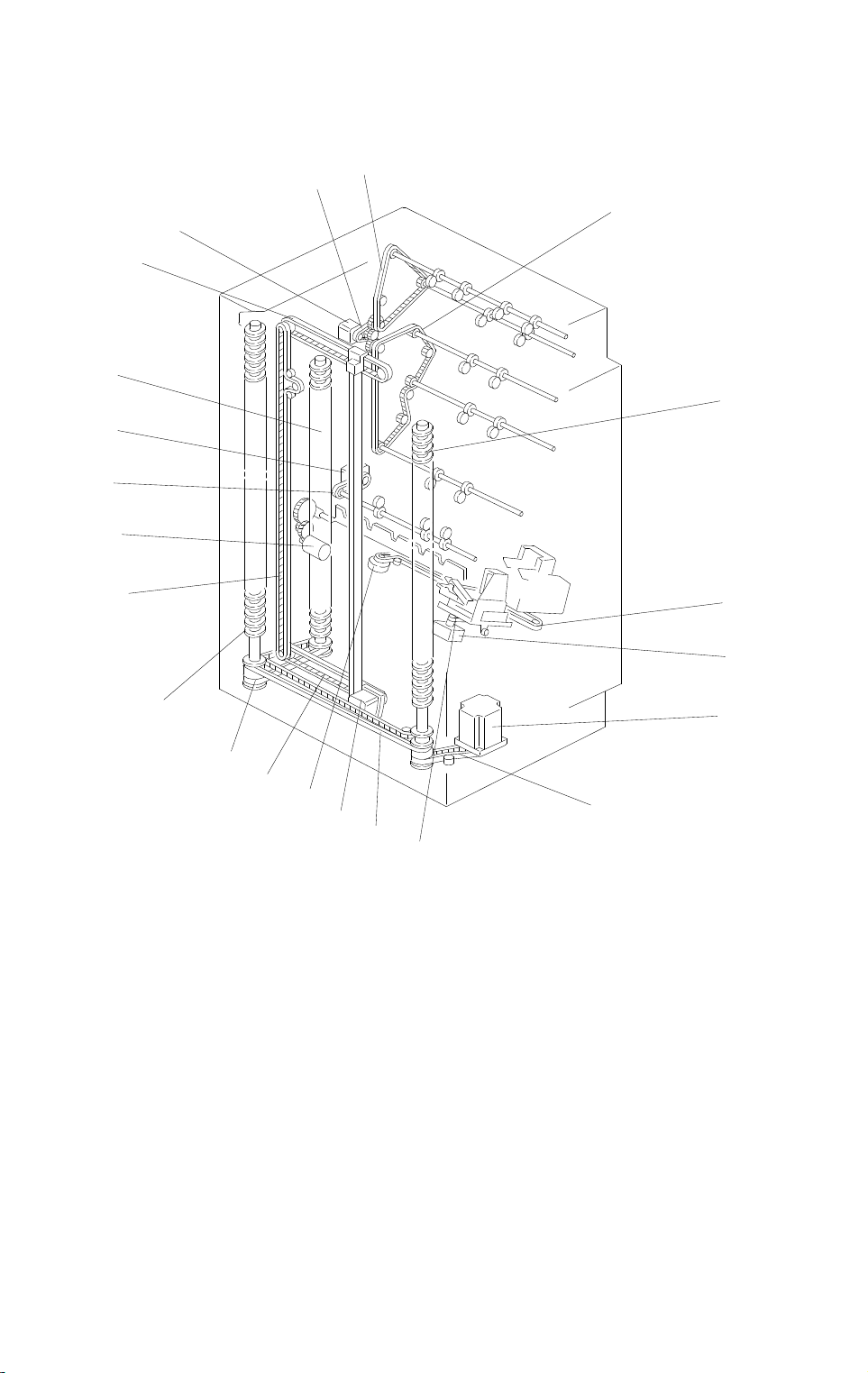

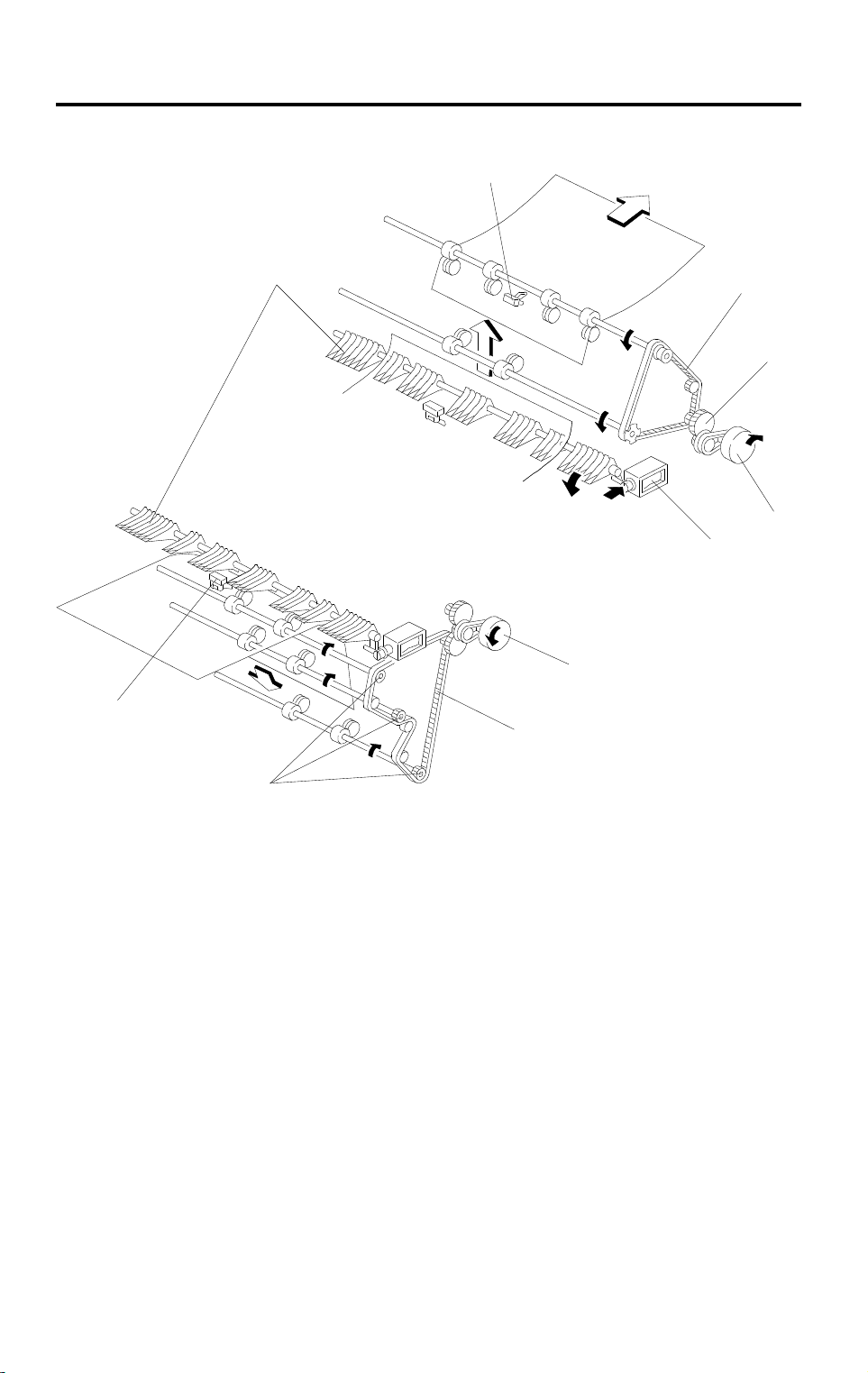

2.2 DRIVE LAYOUT

3

2

4

1

13

5

5

16

15

14

13

6

7

5

9

13

1. Main Motor

2. Main Drive Belt

3. Proof Drive Belt

4. Sorter Drive Belt

5. Helical Wheels

6. Staple Unit Drive Belt

7. Gripper Motor

8. Bin Drive Motor

12

11

8

9

9

10

A606V502.wmf

9. Wheel Drive Belts

10. Grip Drive Belt

11. Jogger Motor

12. Staple Unit Drive Motor

13. Jogger Drive Belts

14. Bin Rear Plate Drive Motor

15. Sorter Exit Drive Belt

16. Sorter Exit Motor

4

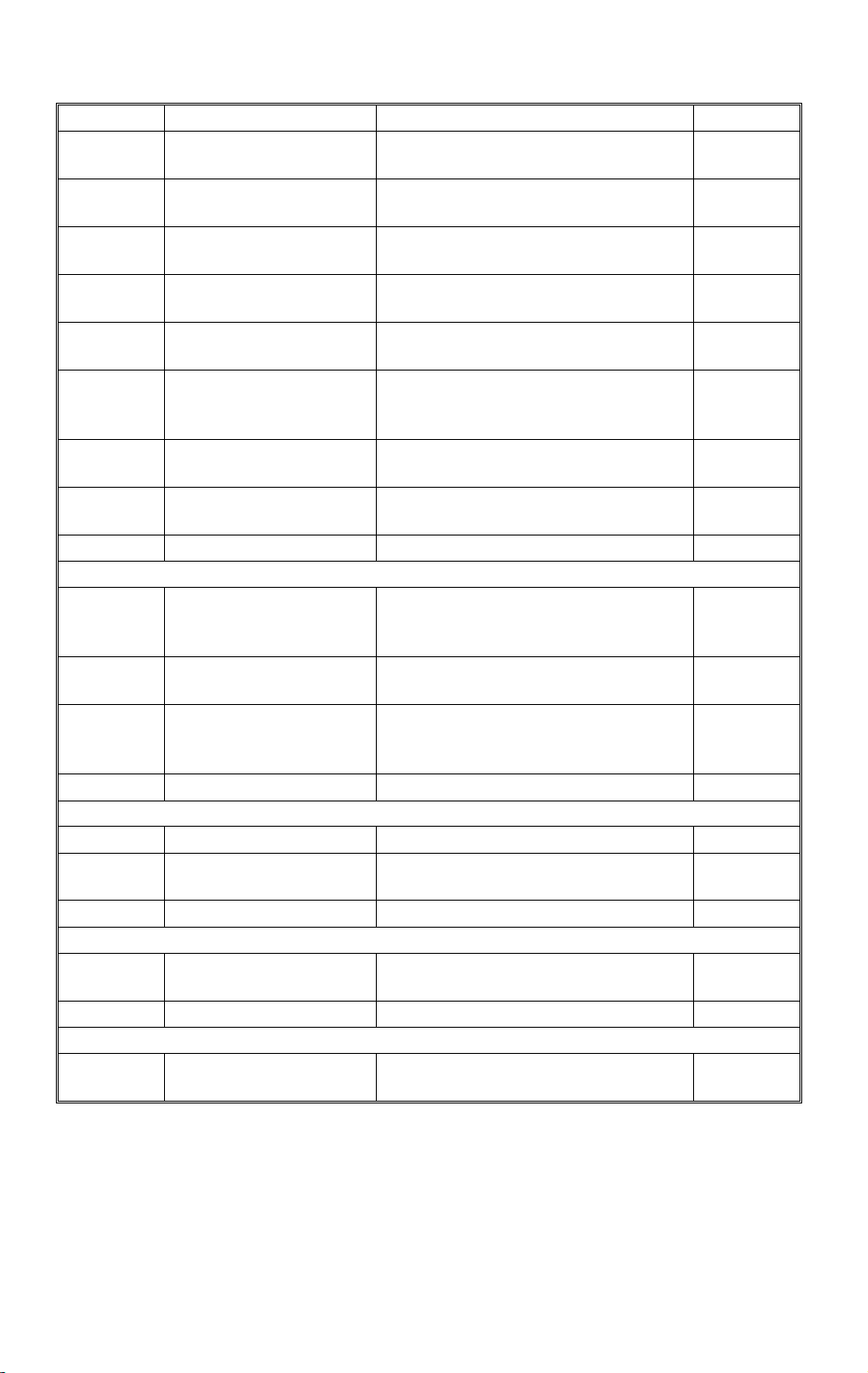

15 July 1996 ELECTRICAL COMPONENT DESCRIPTION

3. ELECTRICAL COMPONENT DESCRIPTION

Please refer to the electrical component layout on the reverse side of the

Point to Point (Water Proof Paper) for symbol and index number.

Symbol Name Function Index No.

Motors

M1 Main Drives the paper tr ansport roller s. 1

M2

M3

M4

M5

M6

M7 Bin Rear Plate Dr i ve Drives the bin rear plate down and up. 24

M8 Sorter Exit Delivers the pape r int o t he bi ns. 27

M9

Staple Feeds the staple s and drives the

stapler hamm er .

Grip Drives the grip assembly forward and

backward into the bi n to grip the

copies and bring t hem to the staplin g

position.

Bin Drive Drives the bins upw ard and downwar d

by rotating the thr ee helical wheel s.

Jogger Drives the jogger pl at e t o jog the

copies agains t the f ront side plate.

Staple Unit Dri ve Drives the stapl e uni t according to the

staple position and angle.

Punch Drive

(Punch versio n onl y)

Drives the hole puncher.

10

16

18

20

23

33

Sensors

Bin Jam (LED) Detects if there is paper jams at the

S1

S2

S3

S4

S5 Staple End Detects staple end . 9

S6

S7

S8

S9

S10 Wheel Sensor Detects the bin position. 19

Proof Exit Detects paper jams at the pr oof tr ay

Entrance Detects paper jams at entranc e

Staple HP Detects if the staple hammer is in the

Paper Detects whether copies are under the

Staple Unit HP Detects if the staple unit is in the

Grip HP Detects if the grip assembly is in the

Bin Jam (Photo Tr. ) Detects paper jams at the distri but i on

distribution sect i on and detects if there

is paper in the bi ns ( l i ght emitting

element).

exit.

guides.

home position.

hammer.

home position.

home position.

section and detects if there is paper in

the bins (light receiving element).

3

4

5

8

11

13

15

17

Sorter

5

ELECTRICAL COMPONENT DESCRIPTION 15 July 1996

Symbol Name Function Index No.

S11

S12

S13

S14

S15

S16

Bin HP Detect s i f the b i ns ar e i n t he home

position.

Jogger HP Detects if the jogger plate is in the

home position.

Bin Rear Plate Open Detects if the bin rear plate is in the

open position.

Bin Rear Plate HP Detects if the bin rear plate is in the

home (closed ) position.

Punch Home position

(Punch versio n onl y)

Punch Rubbish (w aste)

Detects if the hole puncher is in the

home position.

Detects punch rubbish overflow.

Overflow

21

22

25

26

30

31

(Punch versio n onl y)

S17

S18

Cartridge Set Detects if the sta pl e cartridge is

installed or not.

Staple Unit

Pulled-out pos i tion

Detects if the staple unit is in the

pulled-out pos i tion.

7

—

Solenoids

Turn Gate Opens and closes the turn gate to

SOL1

direct the copies i nt o either the proof

tray or the bins.

SOL2

Grip Opens and closes the gri p ar ms to

grip copies on the bins.

Grip Arm Positioni ng Moves the grip ass ’y to the rear and

SOL3

front to catch or rel ease the paper to

carry to the stapler.

PCBs

PCB1 Main Contro l Controls all so rter stapler functio ns. 28

PCB2

Punch Control

(Punch versio n onl y)

Control the punch f unction

Switches

SW1

Door Safety Cuts the DC power when the front

door is opened.

Others

Ohter1

Punch Unit

(Punch versio n onl y)

—32

2

12

14

29

6

6

15 July 1996 BASIC OPERATION

4. BASIC OPERATION

4.1 NORMAL (PROOF MODE) AND SORT/STACK MODE

[D]

[C]

[A]

[A]

[B]

A606D500.wmf

Copies exiting the copier pass through the entrance guide plates [A] to the

turn gate section. The turn gate [B] will send copies either to the proof tray or

to the bins, depending on the mode.

- Normal (proof) mode - (from the turn gate section to the proof tray)-

The turn gate solenoid energizes to turn the turn gate clockwise when the

Start key is pressed. The main motor turns counterclockwise to rotates the

vertical transport rollers [C] and proof exit roller [D]. The turn gate directs

copies through the proof transport section to the proof tray.

7

Sorter

BASIC OPERATION 15 July 1996

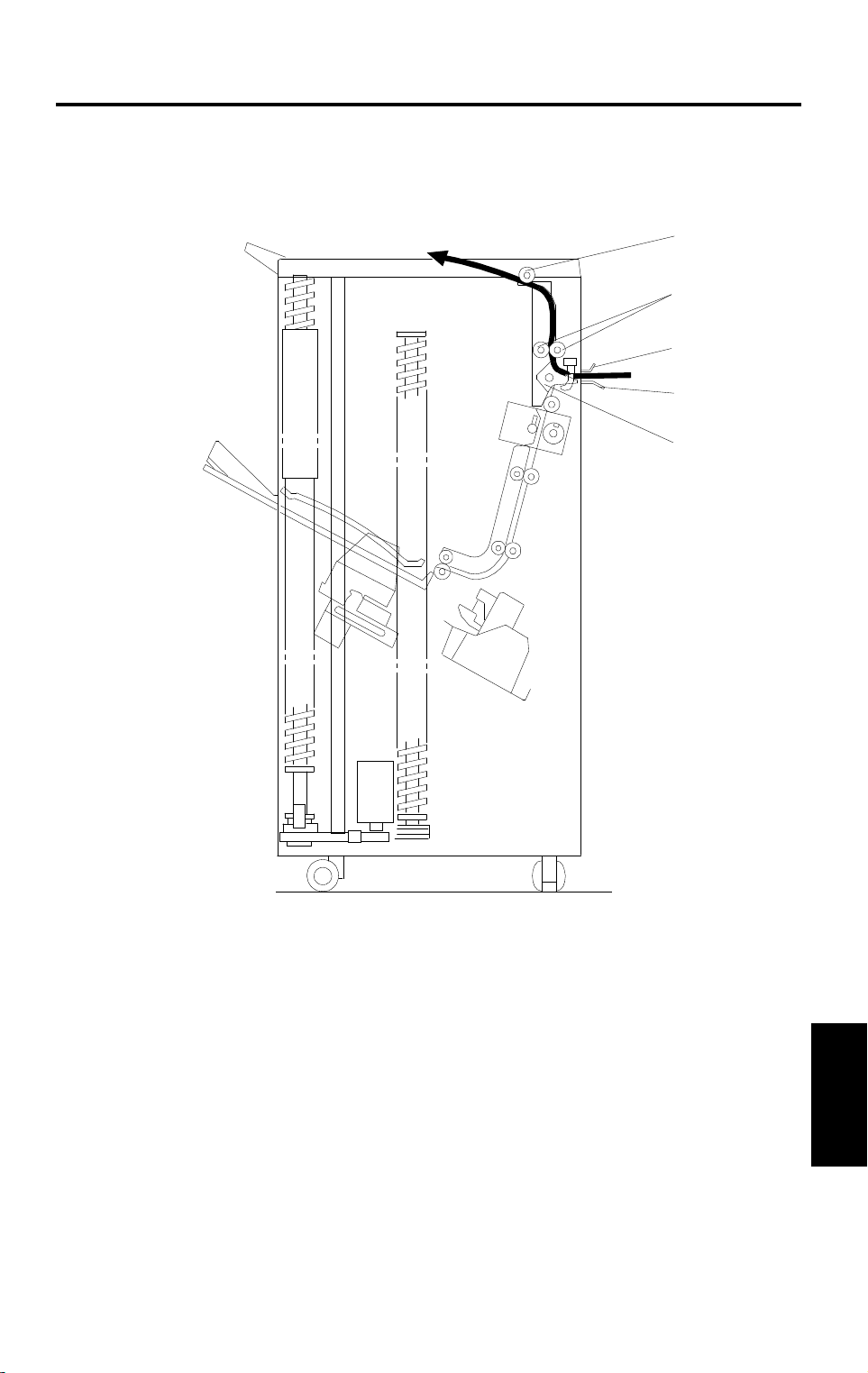

- Sort mode - (from the turn gate section to the bins)

[F]

[A]

[E]

[D]

[B]

[H]

[C]

[I]

[G]

A606D501.wmf

In this mode, the turn gate solenoid stays off to keep the turn gate [A] at the

upper position. The main motor turns clockwise to rotates the sorter transport

rollers [B] and the exit motor rotates the exit rollers [C].

The turn gate directs copies to the sorter bins through the sorter transport

section, then the first copy is delivered between the top bin [D] and the upper

guide plate [E].

The jogger plate [F] then jogs to square the copies each time.

Before the next copy reaches the sorter exit roller, the bin drive motor [G]

rotates and advances the bin one step (the helical wheels [H] rotate once).

When the cut out of the actuator reaches below the wheel sensor [I], the bin

drive motor turns off.

Bins advances each time copies are delivered.

8

15 July 1996 BASIC OPERATION

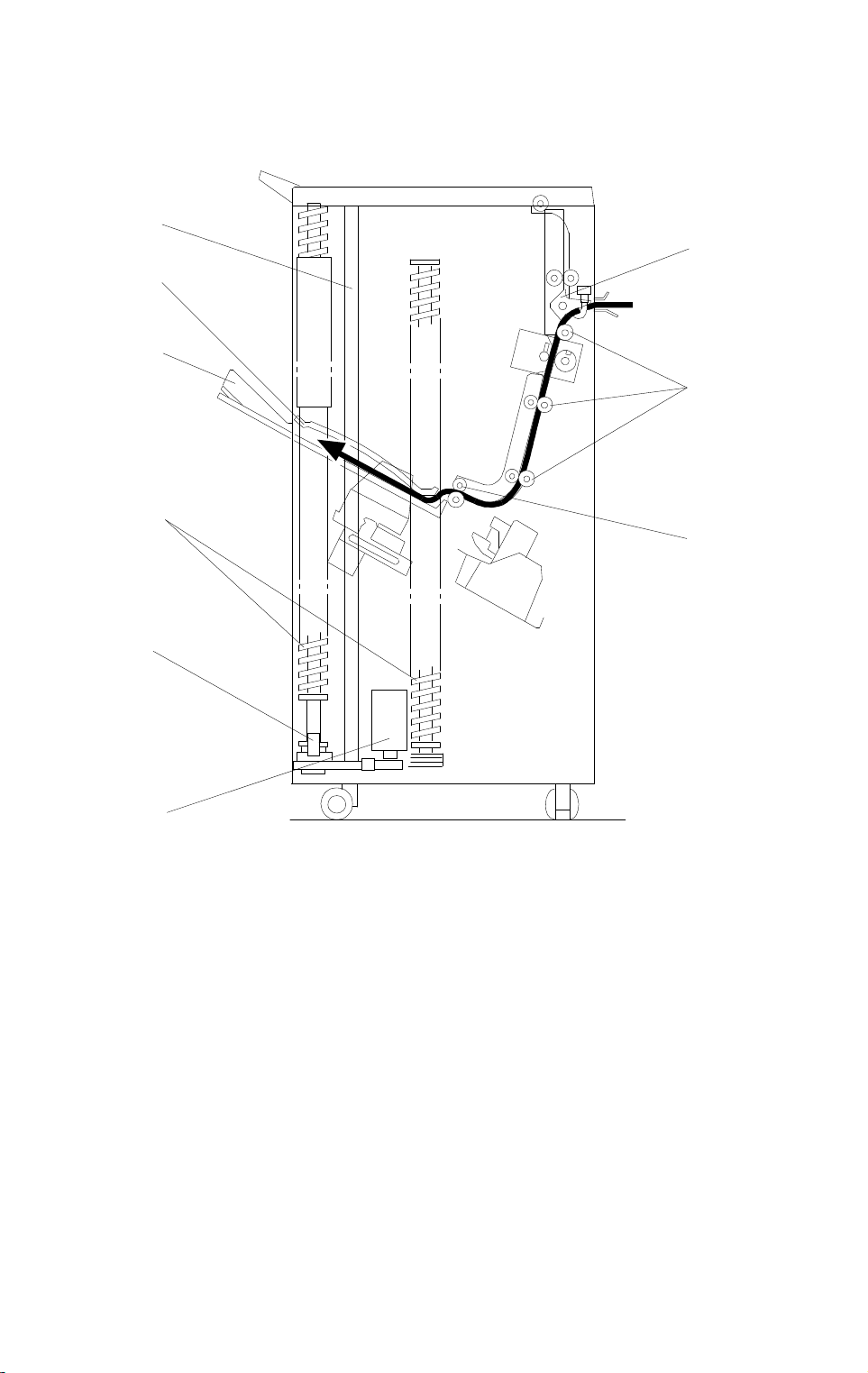

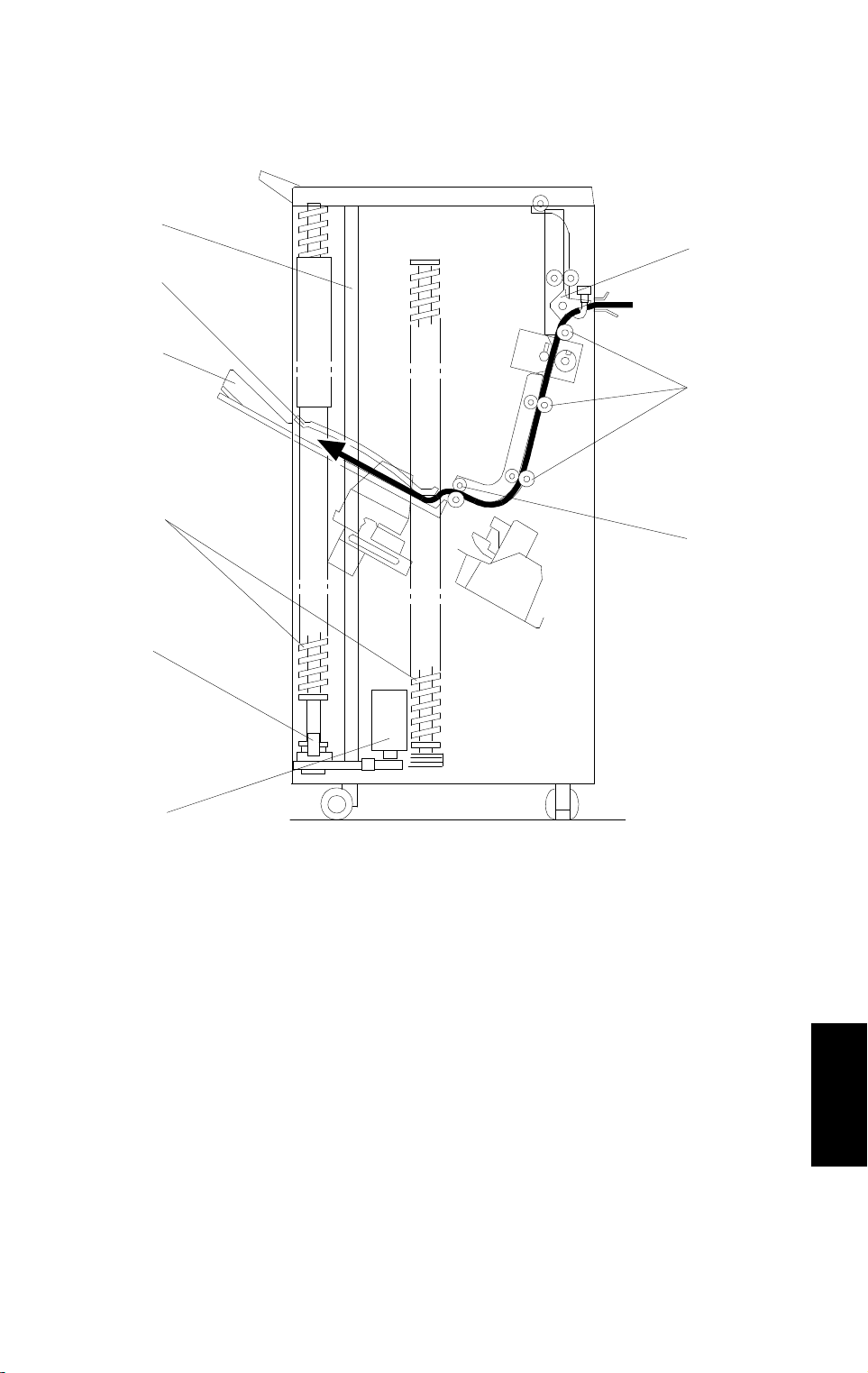

- Stack mode - (from the turn gate section to the bins)

[F]

[A]

[E]

[D]

[B]

[H]

[C]

[I]

[G]

A606D501-2.wmf

As with sort mode, the turn gate solenoid stays off and the turn gate [A] also

stays up when the start key is pressed. The main motor turns clockwise to

rotate the sorter transport rollers [B] and the exit motor rotates the exit rollers

[C].

The turn gate directs copies to the sorter bins through the sorter transport

section, then the copies are delivered between the top bin [D] and the upper

guide plate [E].

The jogger plate [F] then jogs to square the copies each time.

All copies of the copy run are then fed to the first bin. When the final copy is

delivered, the wheel drive motor [G] turns and advances the bin one step (the

helical wheels [H] rotate once). When the cut out of the actuator reaches

below the wheel sensor [I], the bin drive motor turns off.

Sorter

9

BASIC OPERATION 15 July 1996

4.2 STA PLE MODE

[Fig. 1]

A606D502.img

[Fig. 2]

A606D503.img

[Fig. 3]

A606D504.img

When the final set of copies is jogged [Fig. 1], the staple unit staples the

stacked copies as follows: The grip arms move inside the front side plate and

catches the paper. The bin rear plate is turned so as to be flat with the sorter

bin. The grip assembly brings the copies down underneath the stapler [Fig.

2]. The staple unit changes the position (the position varies depending on the

copy size and staple mode) and the stapler staples the copies [Fig. 3].

10

15 July 1996 BASIC OPERATION

[Fig. 4]

A606D505.img

[Fig. 5]

A606D506.img

The grip assembly brings the stapled copies back to the bin and the bin rear

plate returns to the original position.

The grip assembly releases the copies and return to outside the front side

plate so as not to disturb the bin movement [Fig. 4].

The bin advances one step [Fig. 5].

When the final set of copies is stapled, the staple unit is returned to the home

position.

There are two staple modes.

1) Automatic stapling:

In ADF mode, when the staple mode is selected before pressing the start

key, copies will be delivered to each bin and stapled automatically.

2) Manual stapling:

In sort mode, after copies are sorted in the bins, the copies will be stapled

when the manual staple key is pressed then staple position is selected. In

stack mode, manual stapling is impossible.

Sorter

11

TURN GATE SECTION 15 July 1996

5. TURN GATE SECTION

[A]

[I]

[D]

[G]

[C]

[B]

A606D507.wmf

[C]

[H]

[E]

[F]

A606D508.wmf

The turn gate [A] sends copies to the proof tray or the sorter bins depending

on the mode. In the proof mode, the turn gate solenoid [B] turns on and the

main motor [C] turns clockwise when the start key is pressed.

The turn gate [A], directs copies upward through the proof transport section

to the proof tray. In this mode, the main motor drive is transmitted by both the

proof drive belt [D] and sorter drive belt [E]. However the one way clutch in

each sorter transport roller drive gear [F] does not transmit the drive to the

sorter transport rollers.

In the sort, stack and staple modes, the turn gate solenoid stays off to direct

copies downward to the sorter transport section. When the start key is

pressed, the main motor [C] turns counterclockwise.

In this mode, the main motor drive is not transmitted to the proof drive belt [D]

because of the one way clutch in the pulley [G].

The entrance [H] and the proof exit [I] sensors monitor the paper jam.

12

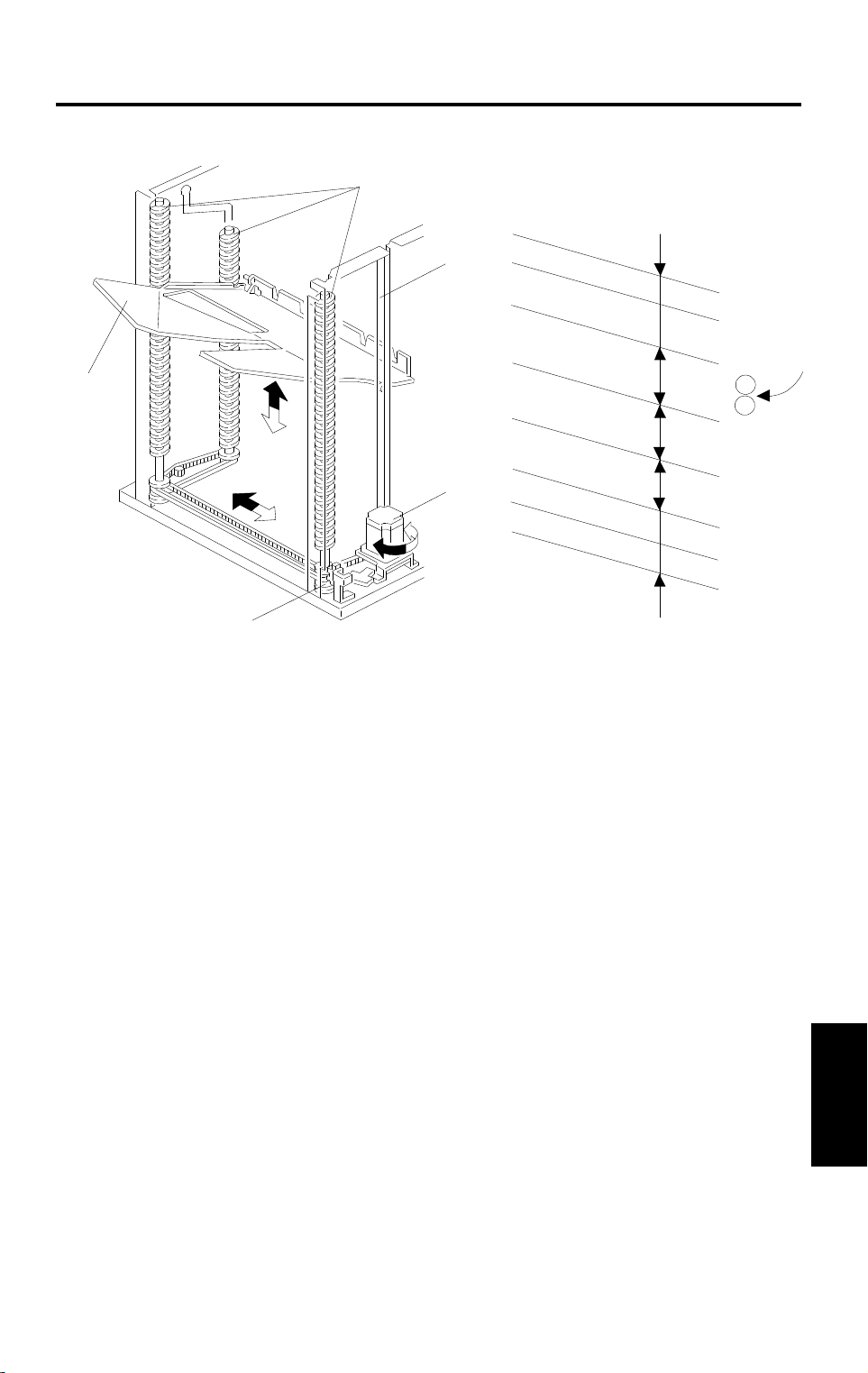

15 July 1996 BIN DRIVE MECHANISM

6. BIN DRIVE MECHANISM

[B]

[E]

15

30

[G]

[D]

45

[F]

40

[A]

40

15

15

[C]

A606D509.wmf

A606D510.wmf

The bin drive mechanism moves the bins up and down to receive copies. The

main components in this mechanism are the bin drive motor [A], the three

helical wheels [B], the wheel sensor [C], and the bins [D] themselves. There

are four pins on each bin. Three of them fit in the slot on the helical wheels.

Another pin fits into the slot [E] of the front side frame.

The pins slide up and down in these slots.

Three timing belts transmit the drive from the bin drive motor to the three

helical wheels. When it rotates clockwise, the bins lift (black arrow) and when

it rotates counterclockwise, the bins lower (white arrow). There is a wheel

sensor actuator on the front helical wheel, the actuator has a slot which

detects when the helical wheel has rotated 360 degrees.

When the bins are advanced, the helical wheels rotate once (360 degrees )

for each step.

As the pitch of the spiral on the helical wheel is greater when bins are at the

staple and paper exit area than when bins are elsewhere, the amount of bin

shift is greater when bins are at the staple and paper exit area. This leaves

enough space to staple [F] and stack paper [G] and reduces the total

machine height.

Sorter

13

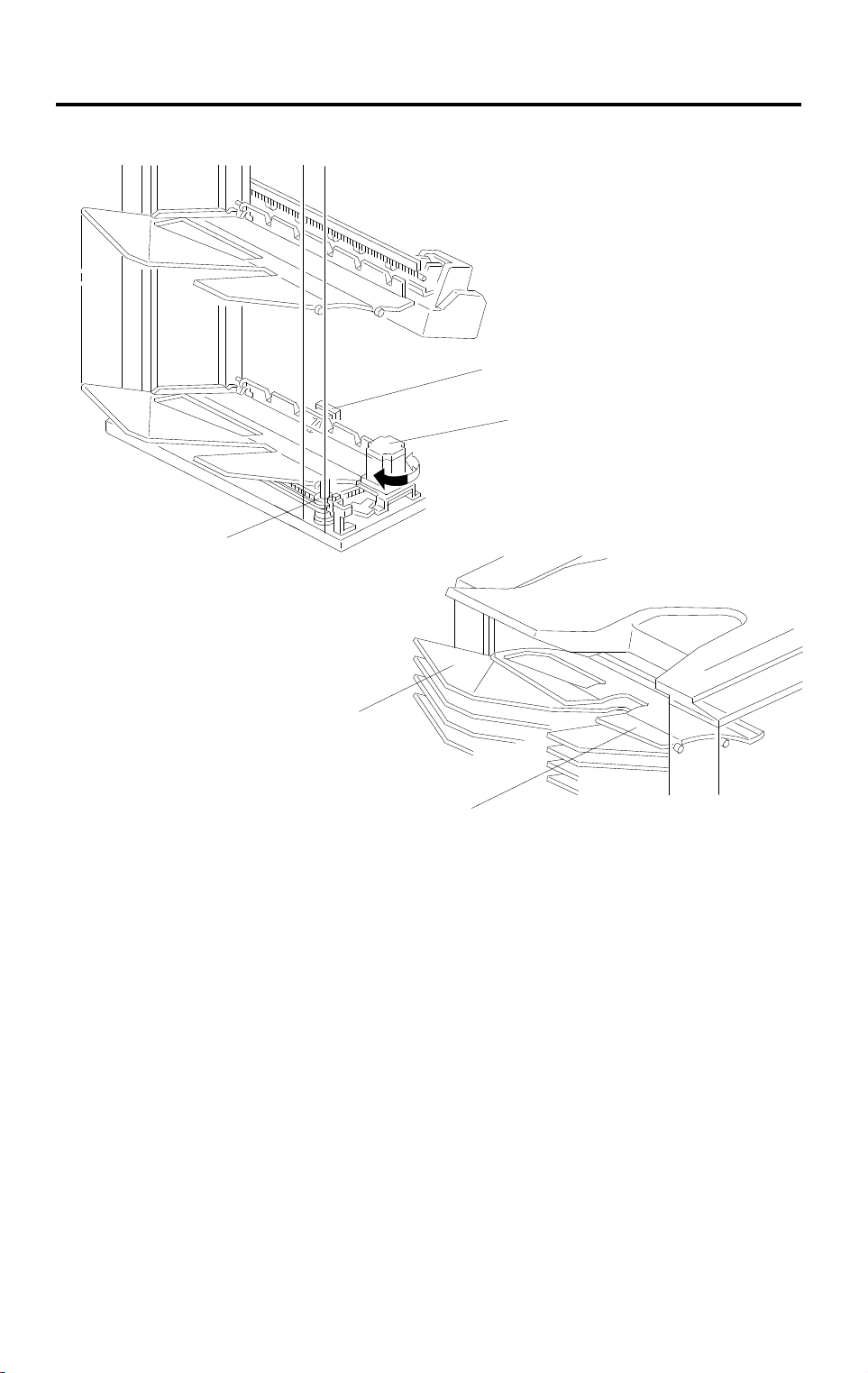

BIN HOME POSITION 15 July 1996

7. BIN HOME POSITION

[A]

[E]

[B]

A606D511.wmf

[D]

[C]

A606D512.wmf

The bin home position sensor [A] and the wheel sensor [B] ensure that the

sorter exit roller is between the upper guide plate [C] and the 1st bin [D] when

all the bins are in the home position.

When the main switch is turned on, the bin lift motor [E] lowers the bins (turns

counterclockwise) until the bottom bin actuates the bin home position sensor.

Then, the bin lift motor raises the bins (turns clockwise) until the wheel

sensor activates. Thus, the bins are in the home position.

14

15 July 1996 JOGGER SECTION

8. JOGGER SECTION

[B]

[A]

A606D513.wmf

Copier Main

Motor

Jam Sensor

Jogger Motor

ON

300 ms

A606D514.wmf

When the Start key is pressed in the sort, staple and stack modes, the copier

sends the paper size information to the sorter stapler. In accordance with this

data, the jogger motor [A] drives the jogger plate [B] from the jogger home

position to where the width is 10 mm wider than the selected paper.

300 ms after the trailing edge of the copy passes underneath the jam sensor,

the jogger motor rotates forward and in reverse. This makes the jogger plate

push all the copies against the front side plate to square the sheets. When

the jogger plate pushes the paper, the plate shifts to a position 5 mm wider

than the paper size when the bins lift. It shifts to a position 1 mm narrower

than the paper size when the bins lowers.

Sorter

The jogger plate returns to 10 mm away from the selected paper size for the

next copy.

When the bin sensor detects that all copies are removed from the bins after

jogging is finished, the jogger plate returns to its home position.

15

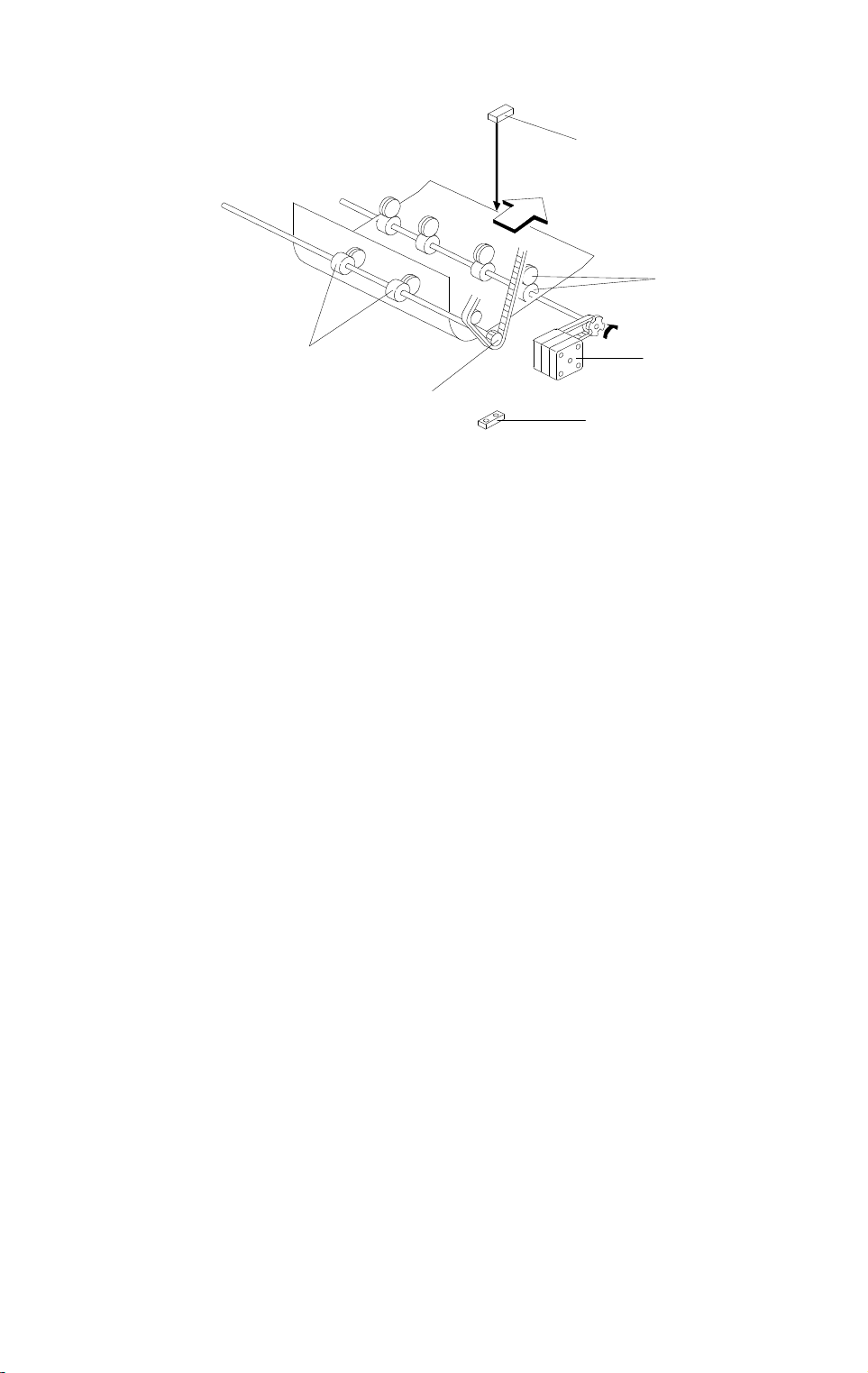

JOGGER SECTION 15 July 1996

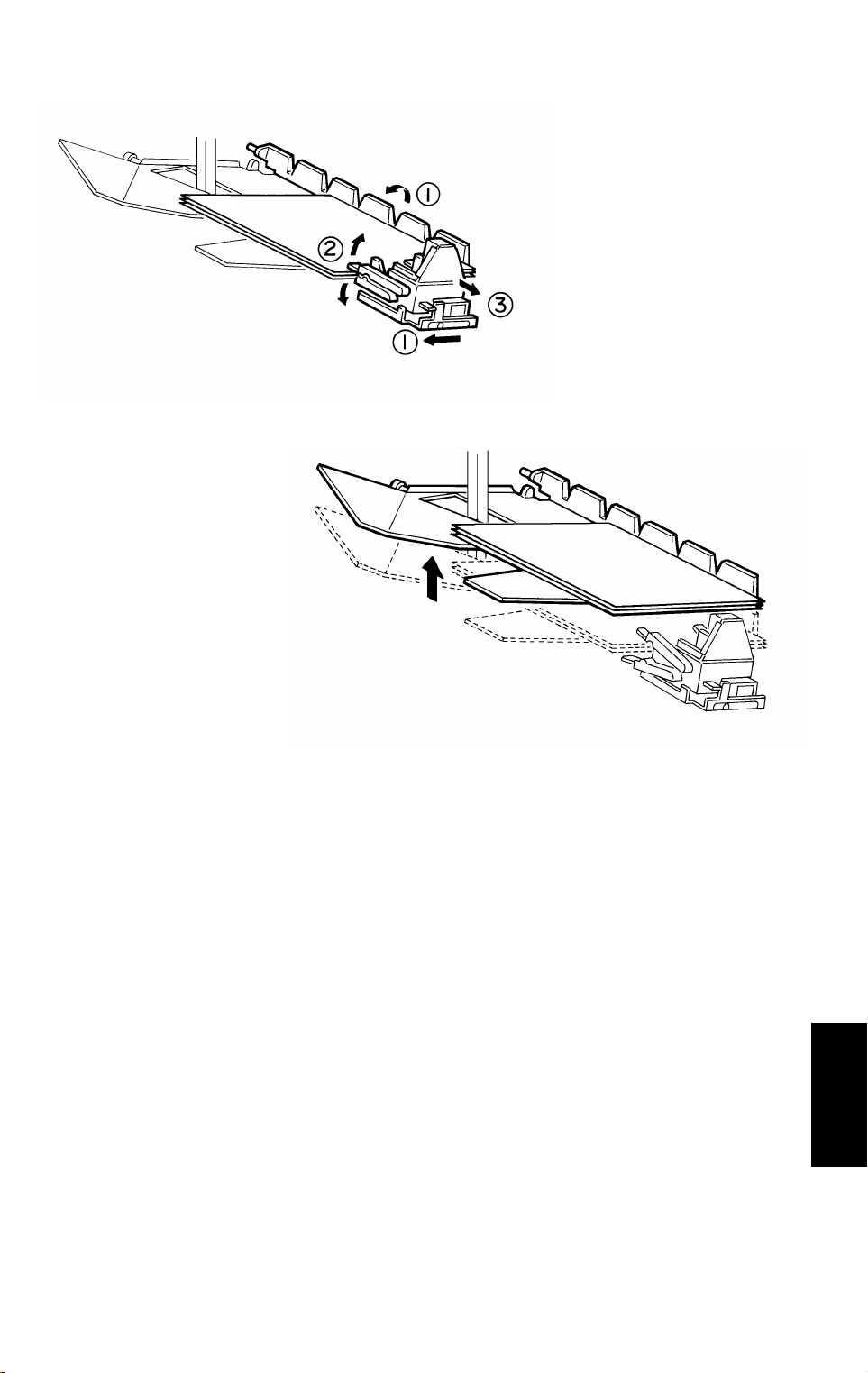

[C]

[B]

Fig. 1

[D]

[A]

[E]

[C]

A606D515.wmf

Normally all rollers in the sorter stapler transport the paper at a speed of 360

mm/s.

To have enough paper jogging time, the sorter exit motor [A] rotation speed

changes to transport the paper quickly and to stack the paper smoothly into

the bins as follows:

360 mm/s: When the sorter exit roller [B] catches the leading edge of the

paper

1,000 mm/s: After the jam sensors [C] detects the leading edge of the paper

600 mm/s: When releasing the trailing edge of the paper

The transport roller [D] is driven at a speed of 360 mm/s constantly, however,

when the sorter exit roller [B] rotates quickly, the transport rollers also rotate

quickly with the pulled paper because of the one way clutch in the drive gear

[E].

- Jogger Off Conditions -

1. Under the following conditions, the jogger plate does not jog after copies

are delivered to the bins.

•

If paper is loaded in a bin by hand while the sort/stack or staple mode

is selected.

•

If the selected paper size does not match stapling specifications.

•

If copy of smaller width is delivered in the bins later in the "Mixed

sizes" mode.

2. If paper is in a bin before the main switch is turned on, the sort/stack

mode is disabled when the sort key is touched.

16

15 July 1996 BIN REAR PLATE DRIVE SECTION

9. BIN REAR PLATE DRIVE SECTION

[A]

[A]

[F]

[J]

[F]

[G]

[E]

[I]

[G]

[C]

[B]

[D]

[H]

[I]

A606D516.wmf

The bin rear plates [A] basically stand up as shown in Fig. 1. They are

lowered only during stapling as shown (Fig. 2).

In the staple mode when all copies have been jogged by the jogger plate, the

bin rear plate drive motor [B] rotates gear [C]. Gear [C] drives the piston rod

[D] to push the lever [E] down.

The holder [F] engaging the pin [G] on the bin rear plate lowers in

accordance with the lever [E] position. Thus, the bin rear plate becomes flat

so as not to interfere with the copies being brought to the staple position by

the grip assembly.

During stapling, the bin rear plate open sensor [H] is interrupted by the

actuator [I] (Fig. 2).

When the bin rear plates are in the home position, the bin rear plate HP

sensor [J] is interrupted by the actuator [I](Fig. 1).

Under this condition, a pin [G] enters the holder [F] or passes through it.

After stapling is completed and stapled paper is returned to the bin, gear [C]

rotates 180 degrees and the bin rear plate returns to its home position.

Sorter

17

Loading...

Loading...