Page 1

20-BIN SORTER STAPLER

(Machine Code: A554)

Page 2

13th January 1995 SPECIFICATIONS

1. SPECIFICATIONS

Paper Size for Bins: Sort or stack mode:

Maximum: A3, 11" x 17"

Minimum: A5, 51/2" x 81/2" lengthwise

Staple mode:

Maximum: A3, 11" x 17"

Minimum: B5, 81/2" x 11"

Paper Weight for Bins: Sort mode:

52 - 93 g/m2, 14 - 24 lb

Stack mode:

64 - 93 g/m2, 17 - 24 lb

Staple mode:

52 - 80 g/m2, 14 - 21 lb

Number of Bins: 20 bins + proof tray

Stapler

20-bin Sorter

Bin Capacity: Sort mode: 30 sheets (A4, 81/2" x 11")

15 sheets (A3, 11" x 17")

Stack mode: 15 sheets

Proof tray - 100 sheets

(52 – 80 g/m2, 14 – 21 lb)

- 50 sheets

(81 – 128 g/m2, 22 – 34 lb)

- 30 sheets

(129 – 157 g/m2, 35 – 42 lb)

Stapler Capacity: A4, 81/2" x 11" or smaller: 2 – 20 copies

B4, 81/2" x 14" or larger: 2 – 10 copies

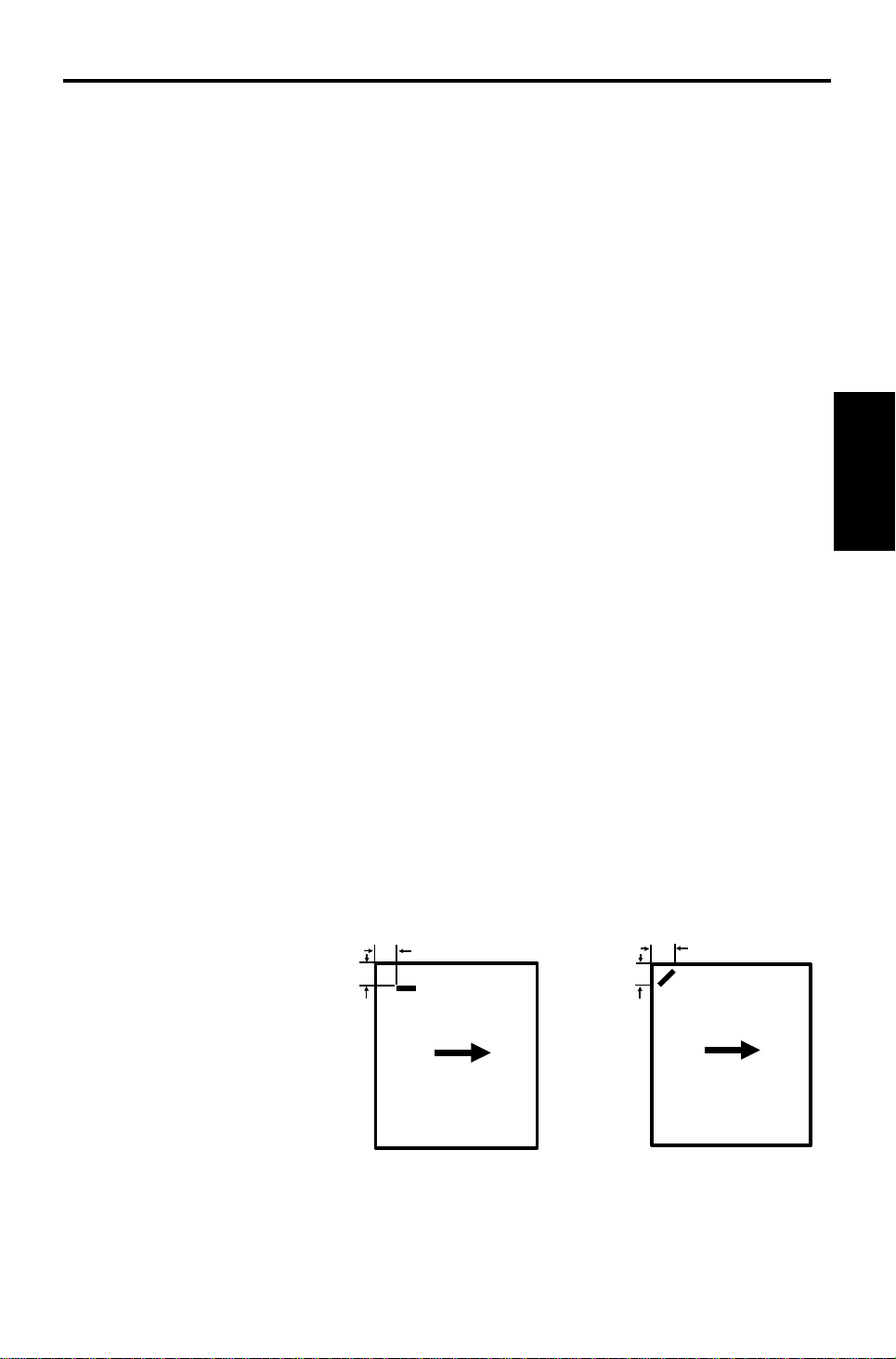

Stapling Position:

(Horizontal)

a

b

(Diagonal)

a

b

a = b

= 6 ± 3 mm

= 0.24" ± 0.12"

1

a = 16 ± 3 mm

= 0.63" ± 0.12"

b = 10 ± 3 mm

= 0.39" ± 0.12"

Page 3

SPECIFICATIONS 13th January 1995

Staple Replenishment: Cartridge exchange

(3,000 staples/cartridge)

Power Source: DC 24V, 5V (form the copier)

Power Consumption: 34 W

Dimensions:

(W x D x H)

412 x 600 x 690 mm

(16.2" x 23.6" x 27.1")

Weight: About 25 kg, 55.1 lb

(Main Frame: 22 kg, 48.5 lb

Mounting Frame: 3 kg, 6.6 lb)

2

Page 4

13th January 1995 COMPONENT LAYOUT

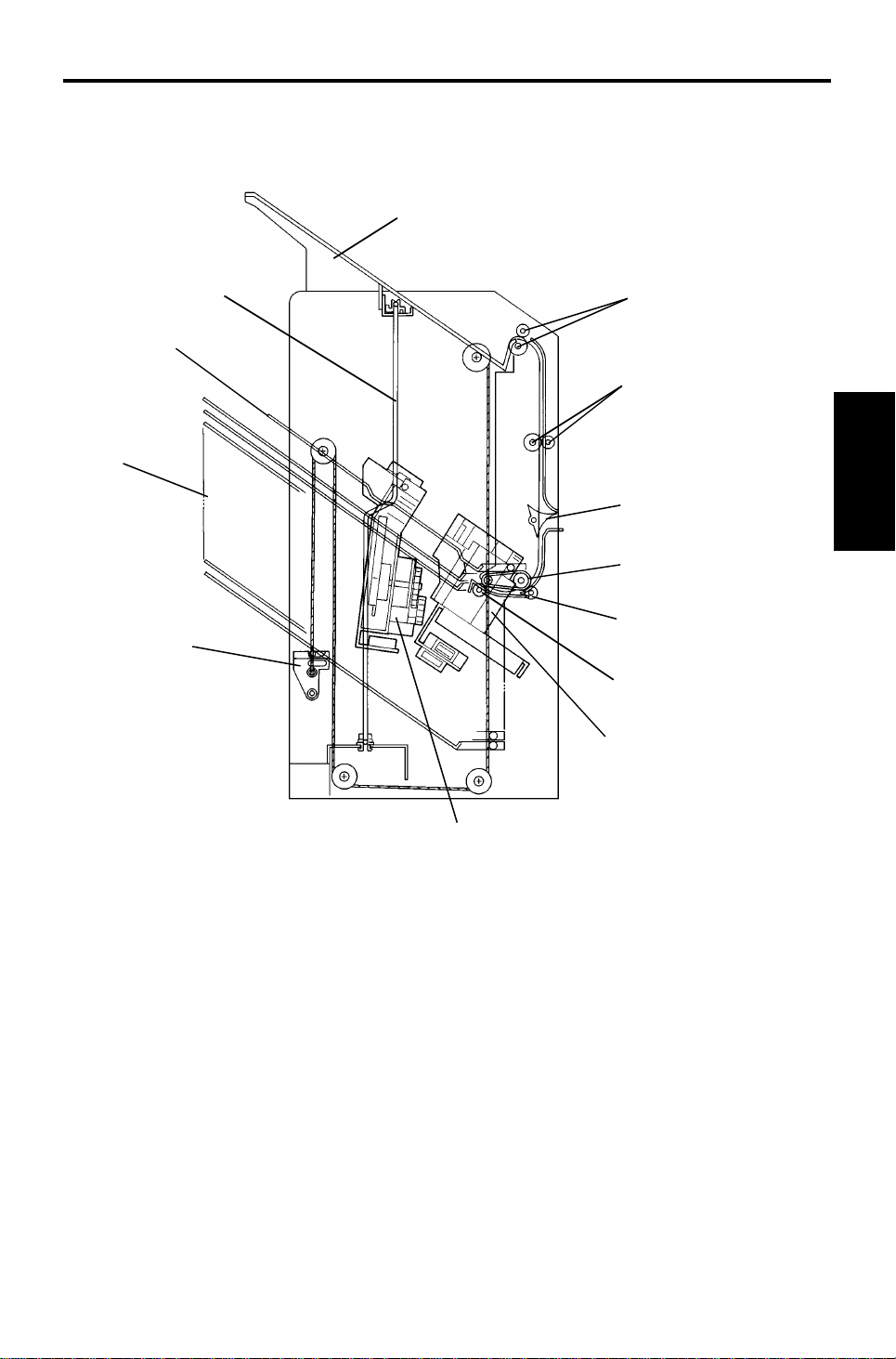

2. COMPONENT LAYOUT

2.1 MECHANICAL COMPONENT LAYOUT

1

11

12

10

13

2

3

4

5

6

7

8

Stapler

20-bin Sorter

1. Proof Tray

2. Proof Tray Exit Rollers

3. Vertical Transport Rollers

4. Turn Gate

5. Bin Transport Belt

6. Bin Transport Roller

7. Bin Exit Roller

9

8. Stapler

9. Grip Assembly

10. Bin Support Block

11. Bins

12. Suppor t Bin

13. Jogger Bar

3

Page 5

10

COMPONENT LAYOUT 13th January 1995

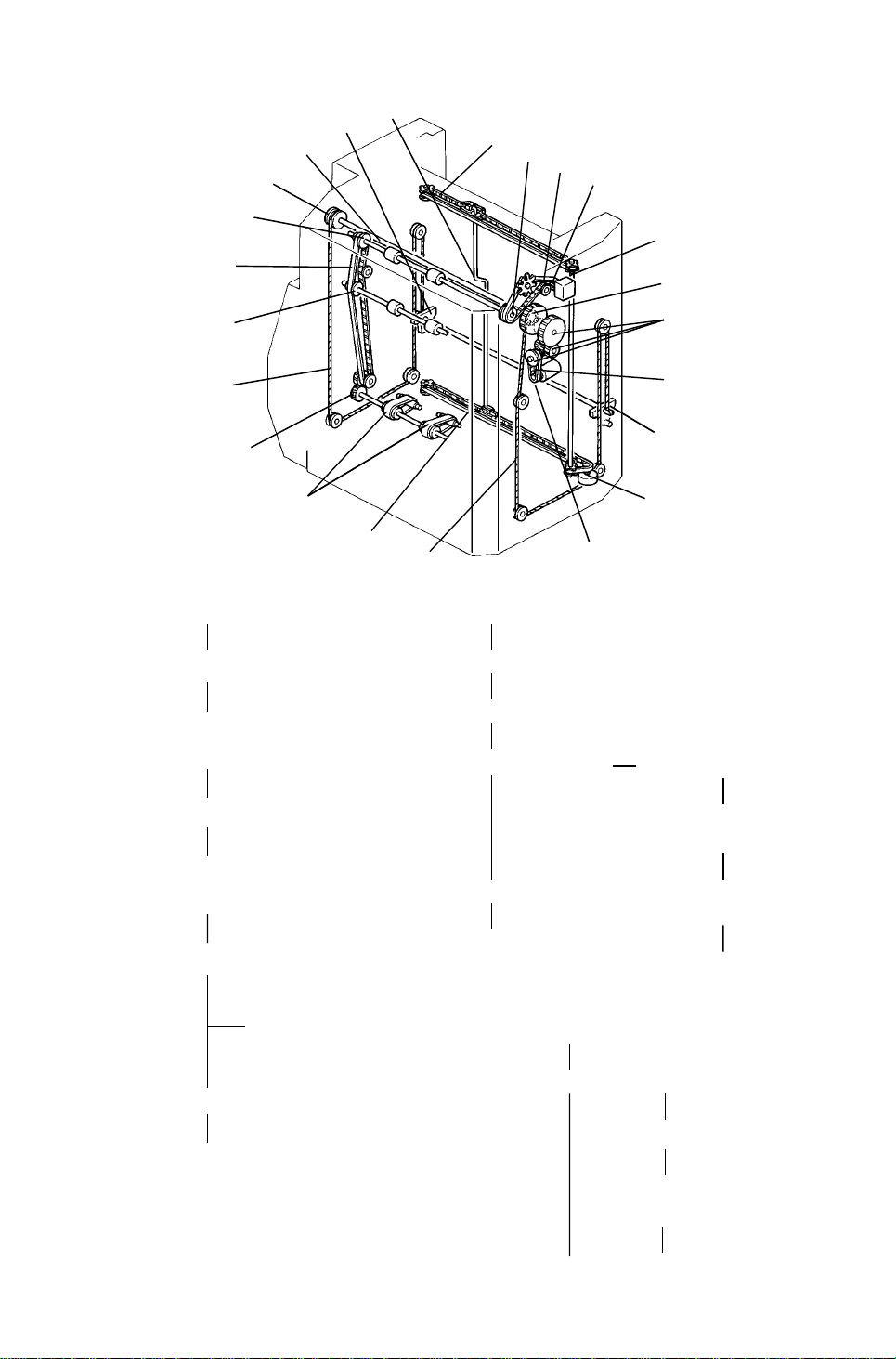

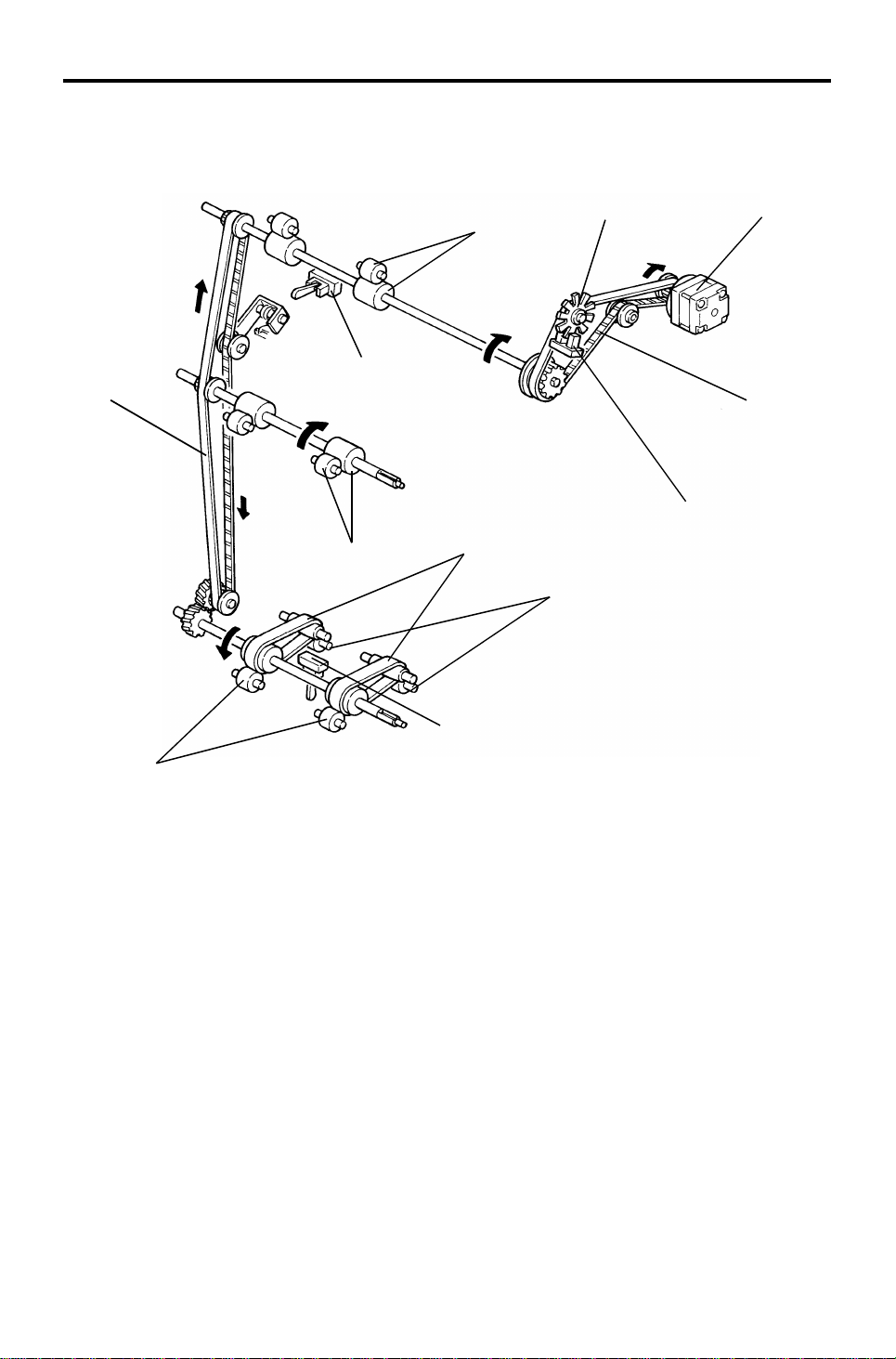

2.2 DRIVE LAYOUT

22

21

20

19

18

17

16

15

14

4. Roller Drive Motor Pulley

23

1

2

13

12

11. Bin Lift Motor Pulley

3

4

5

6

7

8

9

11

3. Rear Roller Drive Belt

2. Proof Tray Exit Roller

Pulley (Rear)

(Proof Tray Exit Roller)

19. Proof Tray Exit Roller

Pulley (Front)

18. Front Roller Drive Belt

17. Vertical Transport

Drive Pulley

15. Bin Transport Drive Gear

14. Bin Transport Belts

8. Bin Lift Drive Belt

7. Bin Lift Gears

6. Bin Lift Gear/Pulley

12. Rear Bin Lift Wire

9. Rear Bin Support

Block

10. Jogger Motor Pulley

13. Lower Jogger Drive Belt

21. Bin Drive Shaft

20. Front Bin Lift

Pulley

16. Front Bin Lift

Wire

22. Front Bin

Support Block

5. Jogger Drive Shaft

1. Upper Jogger

Drive Belt

23. Jogger Bar

4

Page 6

13th January 1995 COMPONENT LAYOUT

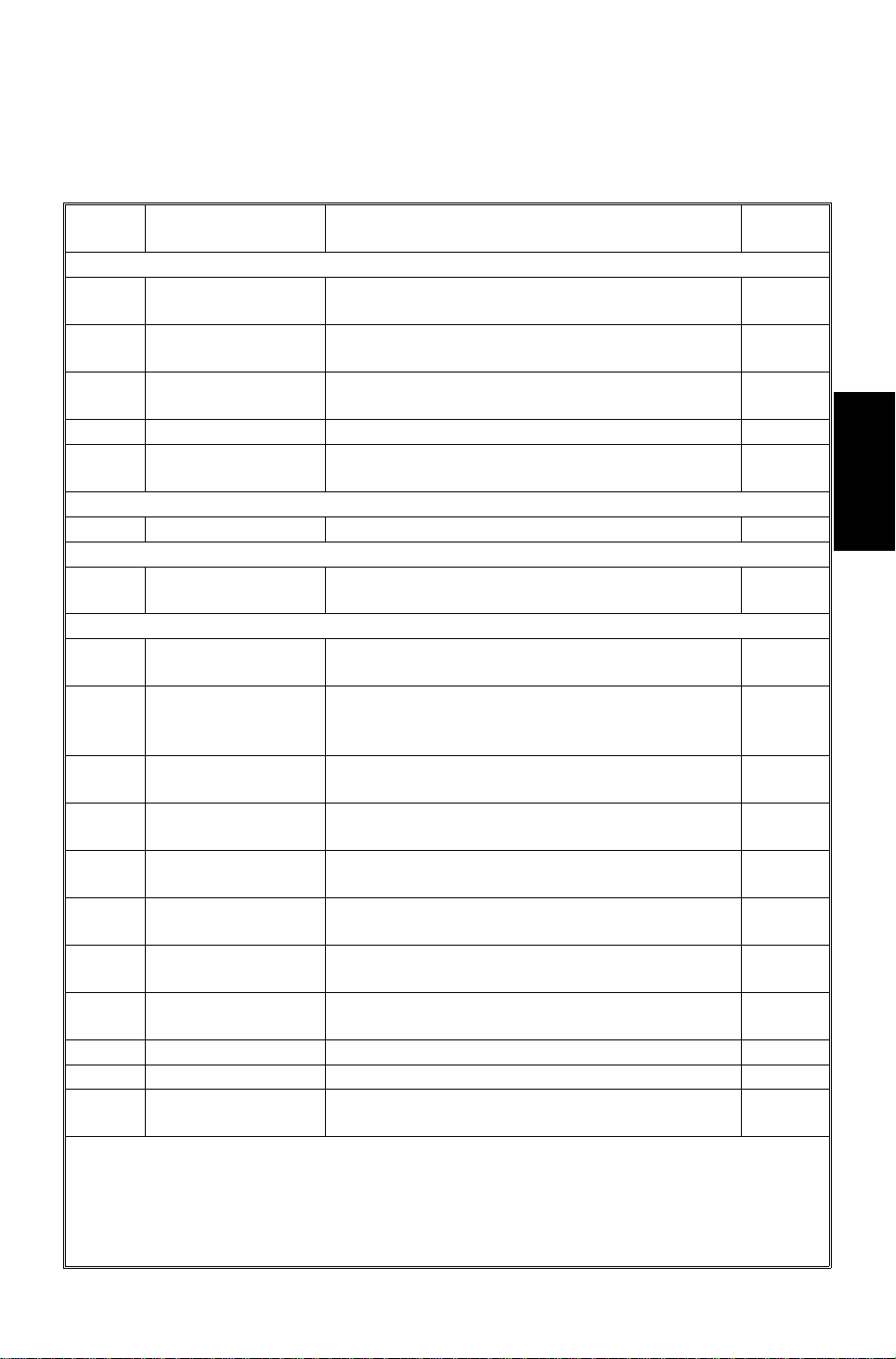

2.3 ELECTRICAL COMPONENT DESCRI P TI ON

Refer to the electrical compone nt layou t on the reverse side of the Poin t to

Point diagram (on waterproof paper).

Symbol Name Function

Motors

M1 Bin Lift

M2 Jogger

M3 Grip

M4 Stapler Feeds the staples and drives the stapler hammer. 12

M5 Roller Drive

Circuit Board

PCB1 Main Control Controls all sorter stapler functions. 18

Solenoid

SOL 1 Turn Gate

Sensors

S1 Bin Lift Timing -1

S2 Bin Lift Timing -2

S3 Jogger H.P.

S4 Paper

S5 Bin (LED)

S6 Bin (Photo transistor)

S7 Grip H.P.

S8 Bin H.P.

S9 Bin Exit Detects paper jams at the bin exit area. 5

S10 Proof Tray Exit Detects paper jams at the proof tray exit area. 4

S11 Roller Drive Timing

Lifts and lowers the bins via a belt, gears, and

wires.

Drives the jogger bar to jog the copies against

the front side plate.

Drives the grip assembly into the bin to grip the

copies and bring them to the stapling position.

Drives the proof tray exit, vertical transport

rollers, and bin transport belts.

Opens and closes the turn gate to direct the

copies into either the proof tray or the bins.

Monitors the rotation of the bin lift motor by

detecting the timing disk.

Controls the stop timing of the bin lift motor so

that the bin lift timing sensor no. 1 can detect the

timing disk properly.

Detects whether the jogger bar is at the home

position.

Detects whether there are any copies under the

hammer.

Detects whether there is any paper in the bins

(light emitting element).

Detects whether there is any paper in the bins

(light receiving element).

Detects whether the grip assembly is at the

home position.

Detects whether all the bins are in the down

(home) position.

Monitors the roller drive motor speed by

detecting the timing disk.

Index

No.

23

20

13

1

Stapler

20-bin Sorter

6

24

25

19

8

3

17

16

15

2

5

Page 7

COMPONENT LAYOUT 13th January 1995

Symbol Name Function

Switches

SW1 Upper Lift Limit

SW2 Wire Tension

SW3 Front Door Cuts the 24 Vdc line when the front door is open. 14

SW4 Sorter Stapler Set

SW5 Staple End Detects the staple end condition. 10

SW6 Staple Guide Detects whether the staple guide plate is closed. 9

SW7 Staple H.P.

The bin lift motor stops when this switch detects

the upper limit position of the bins.

The bin lift motor stops when this switch detects

the lower limit position of the bins through the bin

lift wire tension.

Cuts the 24 Vdc line when the sorter stapler unit

is open.

Detects whether the staple hammer is at the

home position.

Index

No.

22

21

7

11

6

Page 8

13th January 1995 BASIC OPERATION

3. BASIC OPERATION

3.1 NORMAL MODE AND SORT/STACK MODE

[E]

[C]

[G]

[F]

[B]

Stapler

20-bin Sorter

[A]

[D]

Copies [A] exiting the copier pass t hro ug h the entra nce guide plates to the

turn gate area. The turn gate [B] will sen d copies either to the proof tray or to

the bins, depending on the mode.

- Normal mode -

In this mode, copies pass from the turn gate sectio n to the proo f tray.

When the copier signals the S/S CPU to start the motor, the roller drive motor

[C] rotates all the rollers in the S/S pap er path . At the same time , th e tu rn

gate solenoid [D] is energized and the turn gat e tu rns clockwise . The turn

gate directs copies to the proof tra y [E] through the vertical transport and

proof tray exit rollers [F and G].

7

Page 9

BASIC OPERATION 13th January 1995

- Sort/Stack mode -

[C]

[G]

[H]

[A]

[I]

[B]

[D]

[E]

[F]

In this mode, copies pass from the turn gate section to the bins.

The turn gate solen oid [A] stays off and th e turn gate [B] stays up when t he

S/S roller drive motor [C] starts rot at ing. The turn gate directs copies

downward and the bin transport belt [D] exits copies t o th e bin through the bin

transport and bin exit rollers [E and F].

The jogger bar [G] th en moves th e copy towards the front and jo gs it against

the front side plate to square the copies.

The bin lift motor [H] turn s on whe n th is jogg ing operation is almost finished

and advances the bin one ste p up along the bin cam track [I]. The bin lif t

motor stops at the proper time to posit ion the next bin at the bin exit area.

This bin movement is done fo r each co py in sort mode and for the final copy

of each original in stack mode.

The up and down movement of th e bins in both sort and stack modes is the

same as for other moving bin type sorters.

8

Page 10

Figure 4

13th January 1995 BASIC OPERATION

3.2 STAPLE MODE

[A]

Figure 1 Figure 2

[B]

Figure 3

When the final set of copies has been jogged in sort mode, the staple unit

staples the stacked co pie s as f ollo ws:

Figure 1:

If the final copy is fed out to a bin other than the first one, all the bins lower to

the home position (the first bin is positioned at the bin exit area ). The jogger

bar [A] moves towards th e fro nt to jog the copies stacked in th e first bin. Then

it stops 15 mm away from the side edge of the pa pe r.

Figure 2:

The bins move one step up to place the first bin at the stap ling posit ion.

Stapler

20-bin Sorter

Figure 3:

The grippers [B] move forward, an d grip the copies.

Figure 4:

The grippers bring the copies up unde rne at h the sta pler. At the same time,

the jogger bar jogs the cop ies stacked in the second bin to pre pa re for the

next stapling operation . The n th e jog ger bar returns to the position 15 mm

away from the side edge of th e pa pe r.

9

Page 11

BASIC OPERATION 13th January 1995

Figure 5

Figure 6

Figure 5:

The stapler staples th e cop ies.

Figure 6:

The copies are pushed back int o the bin. Then the grippe rs ope n an d ret urn

to the home position.

The bins move one step up for the next stapling opera tio n.

When the final set of copies is stapled, the bins lower and stop when the final

bin that was used just before the entire stapling operation is positione d at the

bin exit.

There are two staple modes.

1) Automatic stapling:

In ADF/ARDF mode, when the user selects sta ple mode before pressing

the Start key, the copies will be delivered to each bin and stapled

automatically.

2) Manual stapling:

In sort mode, after copies are sort ed in the bins, the copie s will be stap led

when the user presses the sta ple key after copying. In stack mode,

manual stapling is impossible.

10

Page 12

[B]

13th January 1995 TURN GATE SECTION

4. TURN GATE SECTION

[B]

[E]

[E]

[C]

[A]

[A]

[D]

The turn gate directs copies to the pro of tray or to the bins depe nding on the

mode selected.

Stapler

20-bin Sorter

In the normal mode, the turn gat e sole no id [A] turns on together with the

roller drive motor when the copier signals the S/S CPU to sta rt th e motor. The

turn gate [B] rotates clockwise to dire ct cop ies up ward [C] th rou gh the vertical

transport section to th e proof tray. The turn gate solen oid stays on during the

copy cycles, and turns off when the proo f tra y exit sensor detects the trailing

edge of the last copy and the S/S CPU receives the signal from the copier to

stop the motor.

In the sort, stack, or staple mode, the turn gate solenoid stays off to keep the

turn gate up so that copies are direct ed down ward [D] to the bin transport

section.

The solenoid lever [E] is bent at a righ t an gle to en sure tha t the lever moves

only if the solenoid switches fro m on to off, or from off to on.

11

Page 13

[F]

ROLLER DRIVE AND CONTROL 13th January 1995

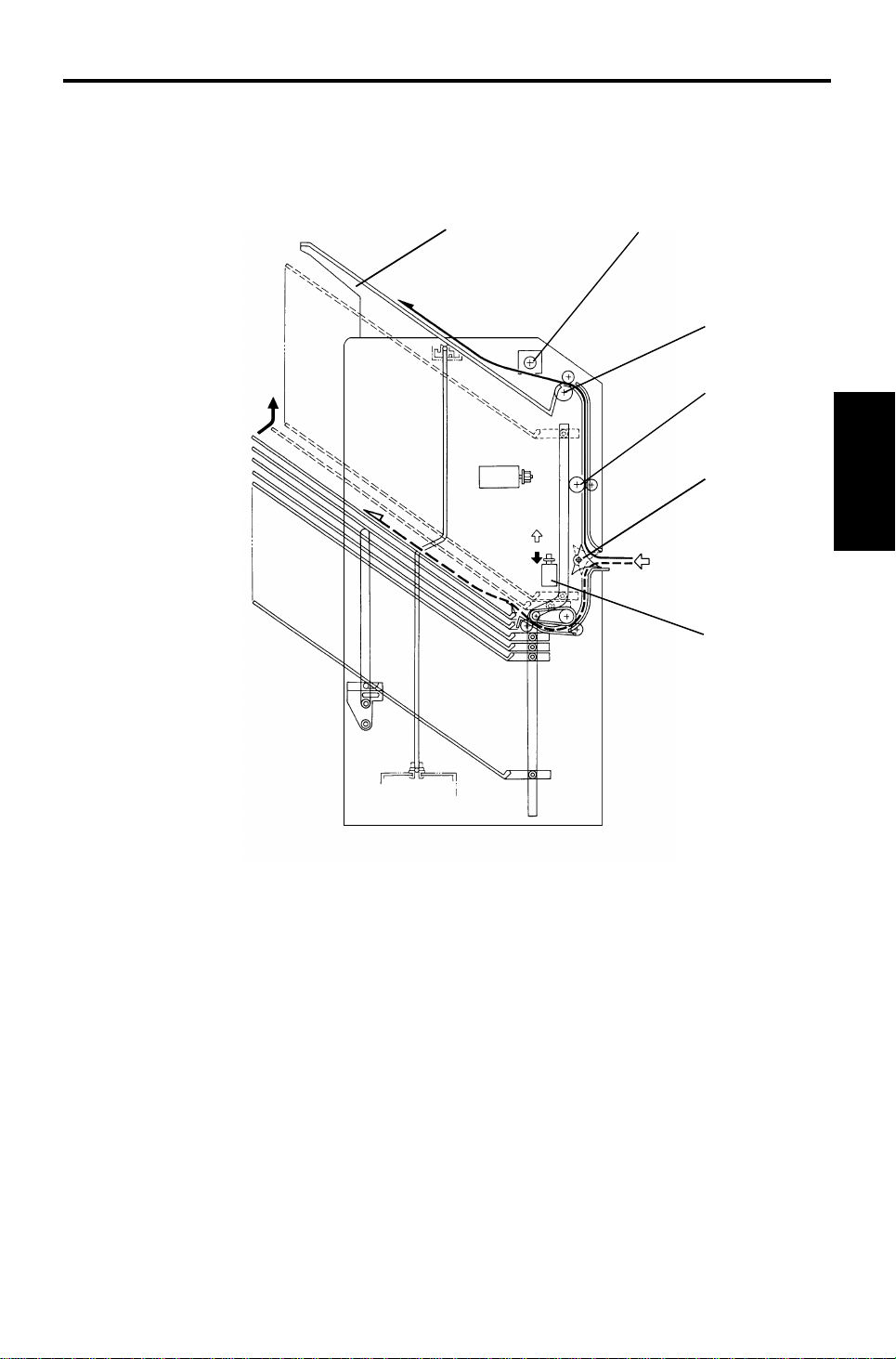

5. ROLLER DRIVE AND CONTROL

[G]

[E]

[I]

[C]

[J]

[B]

[D]

[K]

[A]

[H]

[L]

The roller drive motor (a stepper motor) [A ] drive s the proo f tra y exit rolle rs

[B], vertical transport rollers [C] , bin transport belts [D], bin tran sport rollers

[E], and bin exit rollers [F] via the front and rear roller drive be lts [G and H],

pulleys, and gears, as shown above.

The roller drive motor turns on when the copier signals the S/S CPU to switch

the motor on. When the proof tra y exit sen sor [I] (in the normal mode) or the

bin exit sensor [J] (in the sort/stack/staple mode) detects the trailing edge of

the final copy, the S/S CPU info rms the copie r t hro ugh th e fib er cab le an d the

interface PCB. The n the copier signals the S/S to stop the roller drive motor.

The S/S CPU monitors the roller drive motor speed by counting pulse s from

the timing disc [K] through the roller drive timing sensor [L ].

12

Page 14

13th January 1995 ROLLER DRIVE AND CONTROL

To feed copies out as fast as possible, th e S/ S CPU con tro ls t wo mot or

rotation speeds.

The normal speed depends on the copier’s p ape r tra nsp ort speed. The S/S’s

paper transport speed is almost the same as bu t sligh tly fa ster than the

copier’s.

In the normal mode, the roller drive motor changes the paper tra nsp ort speed

from normal to high (500 mm/s, fixed) when the S/S CPU receives the pape r

exit signal from the copier. The roller drive motor changes the paper transp ort

speed from high to normal 100 milliseconds aft er th e pro of tray exit senso r

detects the trailing edge of the copy.

In the sort/stack/sta ple mo de, the roller drive motor also changes the paper

transport speed from normal to high and the n from high to normal. The timin g

is the same as in the normal mode, bu t the bin exit sensor is used to dete ct

the trailing edge instead of the pro of tray exit sensor. The high speed is

almost double the normal speed, and it changes depending on the paper size

(900, 960, or 1 ,0 00 mm/ seco nd).

Stapler

20-bin Sorter

13

Page 15

[M]

BIN DRIVE AND CONTROL 13th January 1995

6. BIN DRIVE AND CONTROL

[G]

[J]

[F]

[I]

[H]

[L]

[E]

[K]

[B]

[A]

[C]

[D]

[C]

[E]

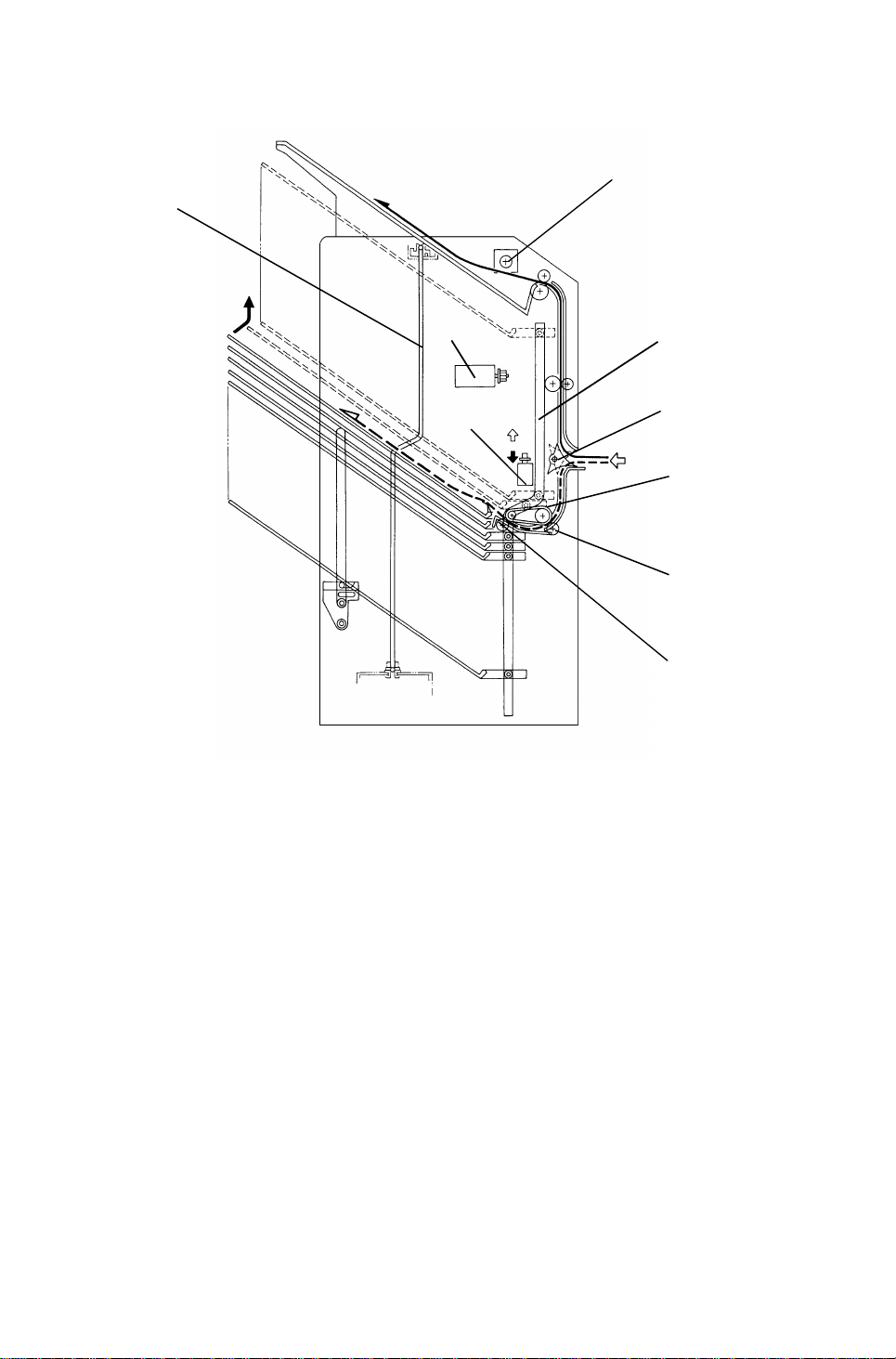

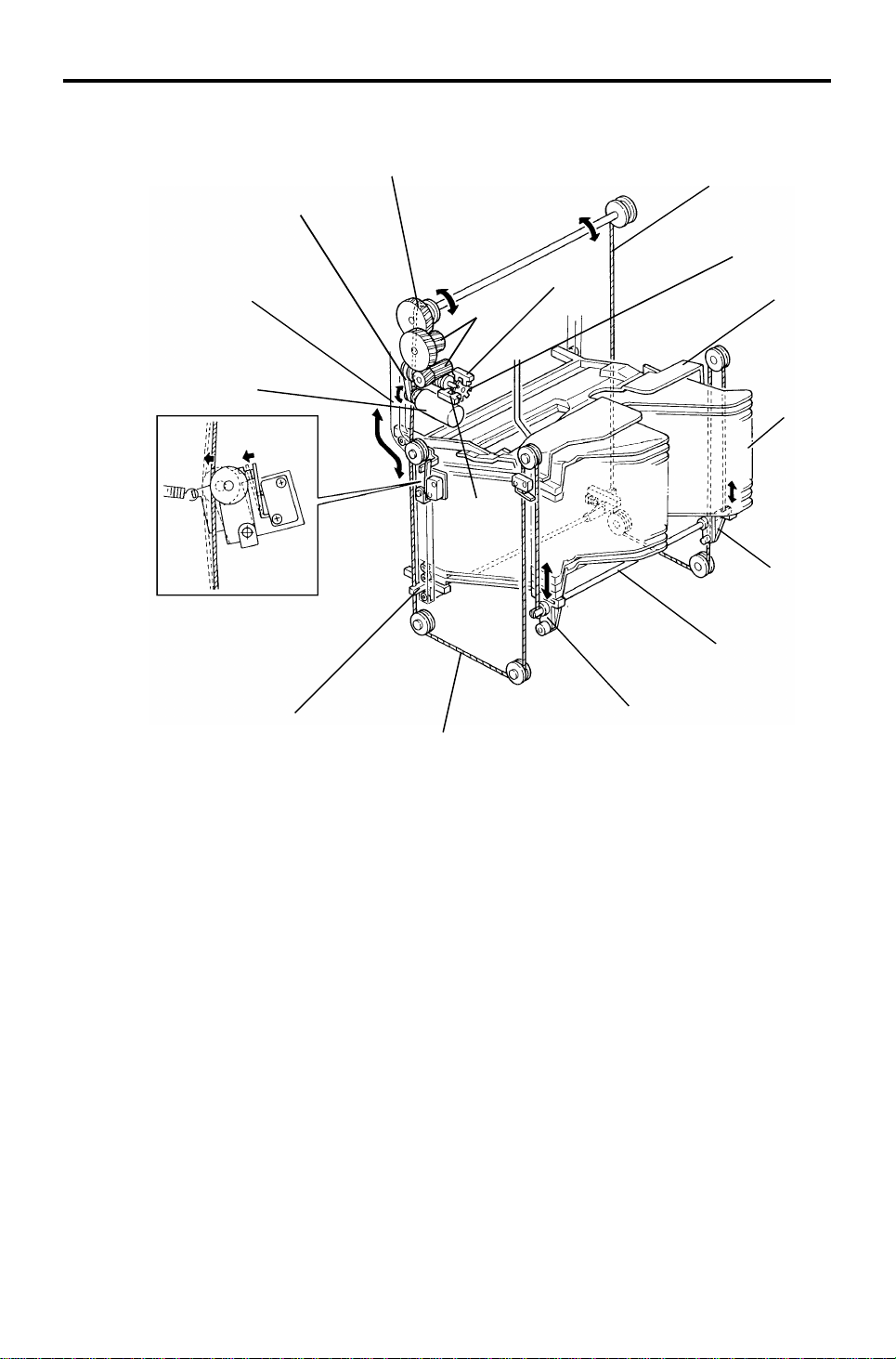

All the 20 bins [A] and the support bin [B] are piled up on the bin support

blocks [C]. The front and rea r bin support blocks are connecte d by th e bin lift

shafts [D], the ends of which are fixed to the bin lif t wires [E ] as shown. The

bin lift motor [F] (dc motor) drives the bin lift wires thro ug h the bin lif t drive

belt [G], bin lift gears [H], an d th e bin lift gear/pulley [I]. Then the bins are

driven up and down along the front an d rea r bin cam tracks [J].

The S/S CPU controls the amount of bin lift motor rotation by monitorin g the

pulses from the timing disc [K] th rough the bin lift timing sensors 1 and 2 [L

and M]. Bin lift timing sensor 1 (blue con ne cto r) is use d for coun tin g th e

timing pulses. Bin lift timing sensor 2 (white connector) is used to determin e

the motor stop timing so that the edge of the timing disc slots is not

positioned at timing sensor 1.

[C]

14

Page 16

13th January 1995 BIN DRIVE AND CONTROL

[A]

[G]

[D]

[E]

Stapler

20-bin Sorter

[F]

[B]

[C]

If the bin lift motor [A] fails t o sto p the bin s at the hig he st po sitio n, the re ar

end of the left bin lift shaft [B] activate s the upper lift limit switch [C] (which is

a normally-closed type) to open the 24 Vdc line to th e bin lift mot or.

The front right bin suppo rt blo ck [D] ha s an act uator on its underside. When

all the bins are lowered and the first bin is positioned at the bin exit are a, the

actuator activates the bin home position sensor [E] and the bin lift motor turns

off.

If the bin lift motor fails to stop lowering the bins at the bin home positio n, the

rear bin lift wire [F] slackens. The n th e wire tension switch [G] (which is a

normally-open type) is deactivat ed , which ope ns th e 24 Vdc line to the bin lift

motor.

15

Page 17

BIN DRIVE AND CONTROL 13th January 1995

[A]

[B]

[E]

[C]

[D]

Fig. 1

Fig. 2

[F]

Fig. 3 Fig. 4

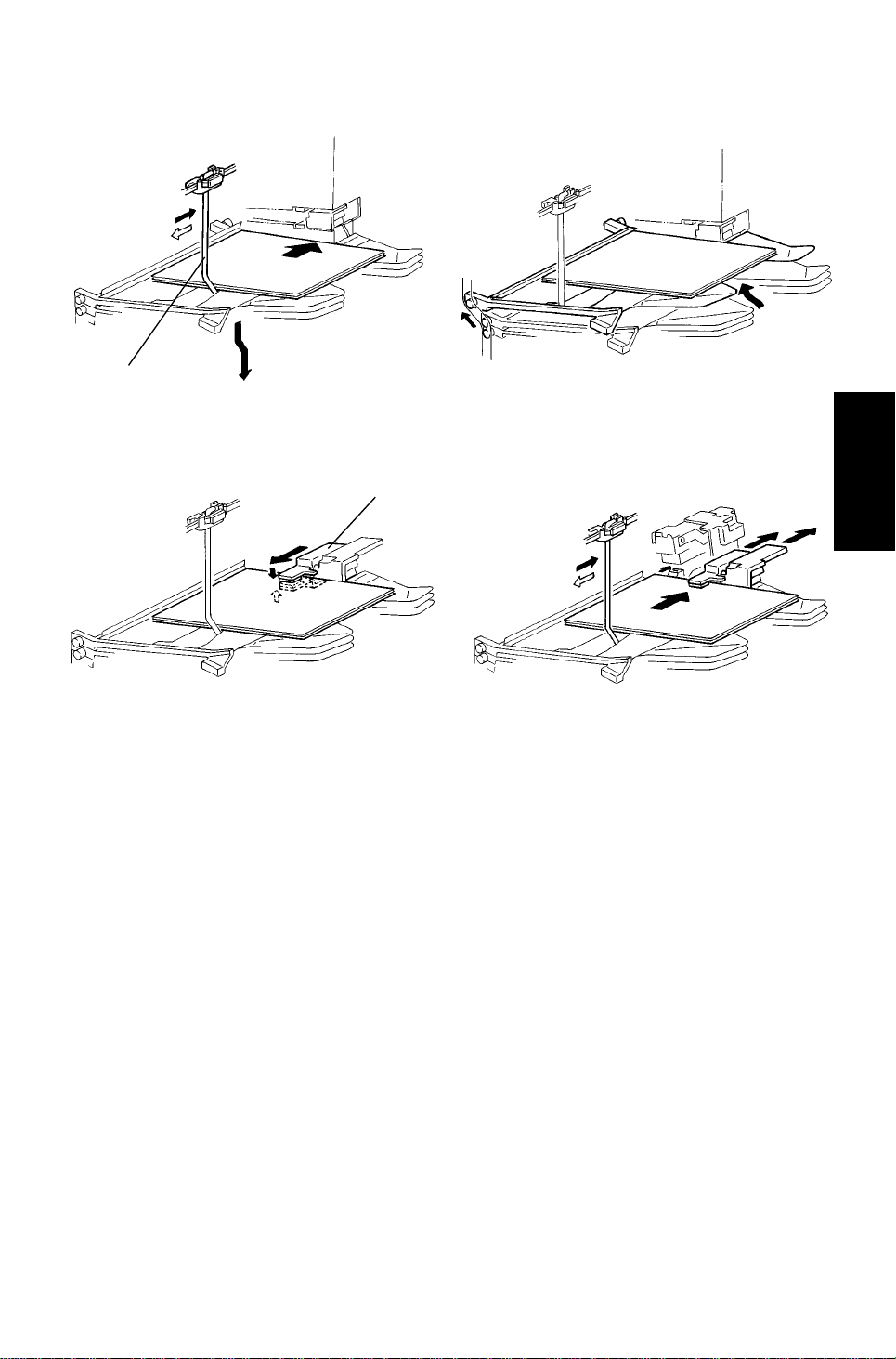

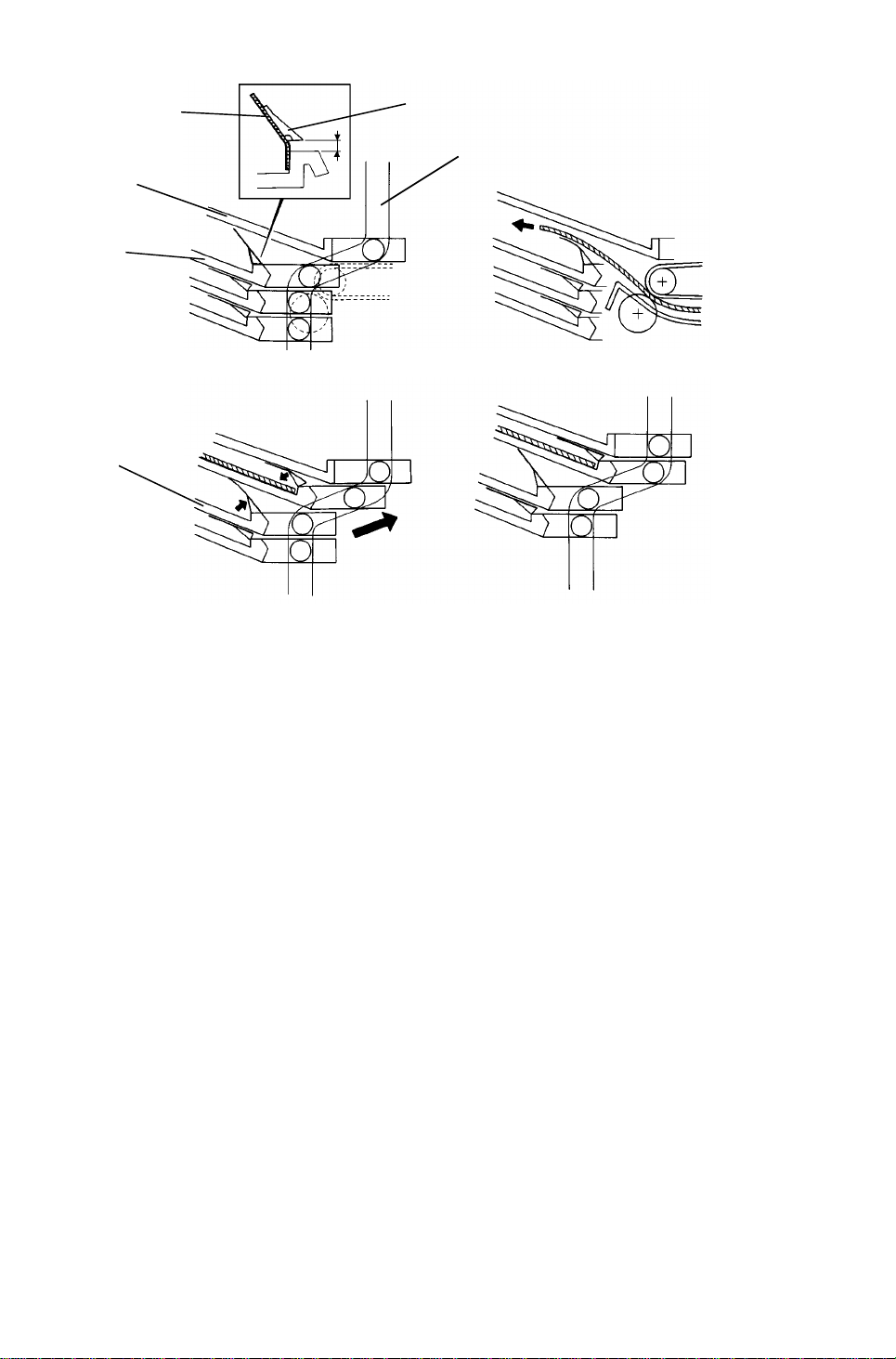

An end fence mylar [A] is attached to each bin entra nce and an end fence

block [B] is stuck on the mylar. These are att ached with two-sided tape, as

shown in figure 1. There is a twisted spring at the rear end of the bin entrance

to raise the end fence block and mylar. Whe n the bin s are at the bin ho me

position, the support bin [C] and th e first bin [D] are positio ne d at the bend in

the bin cam track [E] as shown. The supp ort and first bins have a space

between them so that the end fence mylar can fully rise until the end fence

block stops it.

The space between the support and first bin s is at the bin entra nce section

as shown in figure 2. Since the end fence mylar is t hin , the copy exits to the

first bin over the mylar. The steep angle of the bin helps th e exit ed copy slide

back due to its own weight und er the mylar against the bin entrance.

When the bins move up along the bend of the bin cam track, the end fence

mylar and block of the first bin are pushed down by th e sup port bin, and

those of the second bin [F] rise as shown in figure 3.

When the bin lift motor stops, the first and second bins are positioned as

shown in figure 4. The lowe red end fence mylar helps to prevent the copy in

the first bin from moving out of the jogged posit ion . The end fence mylar an d

block of the second bin are ready to receive the next copy.

16

Page 18

13th January 1995 JOGGER SECTION

7. JOGGER SECTION

[D]

[F]

[A]

[E]

[C]

[B]

When the Start key is pressed in the sort , sta ck, or staple mode, the copier

sends the paper size information to the sorter st apler. When a copy enters

the sorter stapler entrance , th e jog ge r bar [A ] stays at the home position

which is detected by the jogger home position sensor [B].

At the appropriate time (depending on the selected paper size) after the

trailing edge of the copy is detected by the bin exit sen sor, the jogg er mot or

[C] (a stepper motor) rotates forward and in reverse to move the jogger bar

via the upper and lower jogger drive belt s [D and E]. As the copy is f ed out

into the bin at the cent er, the jogger bar moves the cop y all the way t o th e

front, and pushes th e pa pe r sid e edge by 5 mm (0. 2") aga inst the front side

plate [F]. Then the jogger bar moves back to the posit ion wh ich mat ches the

paper width. Shortly after that, the jogger bar retu rns to its home position.

This jogger bar movement is perfo rmed for ea ch cop y to squ are the copy

stack.

Stapler

20-bin Sorter

In the automatic or manu al sta ple modes, the jogger bar also moves to

ensure that the stacked copies are squared bef ore stap ling. For how the

jogger moves, see "Basic Operat ion - St aple Mode".

17

Page 19

JOGGER SECTION 13th January 1995

- Jogger off conditions -

1. Under the following conditions, the jogger bar does not jog after a copy is

delivered to the bin.

• If paper is loaded in a bin by hand while the sort/sta ck or stap le

mode is selected.

• If the selected paper size does not match the stapling specification s.

• If copies of different width are delivered to the bins.

2. If there is paper in a bin before the main switch is turned on, the

sort/stack mode is disabled when the sorter key is pressed.

18

Page 20

Fig. 2

13th January 1995 GRIP ASSEMBLY

8. GRIP ASSEMBLY

[K]

[A]

[E]

[B]

[D]

Fig. 1

Figure 1:

The grip assembly consists of th e gripper guide bracket [A] , th e gripper

assembly [B], and the bin sid e pla te [C]. The major component s o f th e grip pe r

assembly are the grip motor [D] (a stepper mot or), dual cam plat e [E ], grip

home position sensor [F], grippers [G], and grip cam follower [H].

[I]

[C]

[G]

[J]

[H]

[F]

[L]

Fig. 3

Stapler

20-bin Sorter

When the copier main switch is turned on, the grip motor ro tate s forwa rd

and/or reverses to position the whole gripper assembly at the home position.

The home position is detected by the grip home position sensor and the

sensor actuator on the dual cam plate.

Figure 2:

When the bin lift motor stops during the automatic or ma nual sta pling cycle,

the grip motor starts rotating . As th e dual cam plate turns counter-clockwise,

the cam groove [I] and the pin [J] on the gripper guide bracke t move the

whole gripper assembly alo ng the gripp er gu ide ro d [K ] into the bin.

Figure 3:

When the high lobe of the grip cam [L] (t he small ca m on th e du al cam pla te )

pushes up the grip cam follower, the grippers close to grip the cop ies that are

stacked in the bin.

19

Page 21

[B]

Fig. 6

GRIP ASSEMBLY 13th January 1995

Fig. 4

[A]

[C]

[C]

Fig. 5

Figure 4:

As the dual cam plate rotates further, the cam groove and the pin move the

whole gripper assembly with the gripp ed copies back to the stapling position.

Then the grip motor stops.

Figure 5 and 6:

The upper gripper has a proje ctio n [A] for hooking the bin side plat e [B ].

When the gripper moves into the bin, the proje ctio n moves over the bin side

plate. When the gripp ers close , the projection hooks the bin side plat e.

Therefore, the gripp ers bring the stacked copies in to the stap ler together with

the bin side plate.

When the grippers move to the sta plin g po sitio n, the S/S CPU checks th e

paper sensor [C] to see if there is any pape r the re or not. If the paper sensor

is activated, the stapler motor starts rotating and the copies are stap led .

When the stapler motor stops, the grip mot or starts rotating in reverse. The n

the gripper assembly brings back the stapled copies into the bin, the grippers

open, and the gripper assembly returns to the home position.

20

Page 22

[I]

13th January 1995 STAPLER

9. STAPLER

[B]

[D]

[C]

[A]

[G]

[E]

[F]

[B]

[H]

Stapler

20-bin Sorter

[H]

[J]

In automatic or manual staplin g mod e, the stapler motor [A] rotates when the

grip motor stops rotat ing aft er the grippers bring the stacke d copies to the

stapling position.

The staple gear [B] rotate s coun te rclockwise , an d the pin on the gear rot at es

the staple arm [C] counterclockwise, then clockwise. The rat che t [D] lowers

and rises to rotate the ratchet whe el [E] counterclockwise. Then the st aple

feed rollers [F] turn via gears to feed a staple shee t to the hamme r.

While both the front and rear staple arms rotate cou nt erclo ckwise, the

hammer [G] lowers. At the same time, the stap le cam pla te [H] lifts the

clincher [I]. The hammer and the clin che r stap le th e cop ies. Then , while the

staple arms rotate clockwise, the hammer rises and the clincher lowers.

When the staple home position switch (a normally-closed typ e) [J] is

deactivated, the stapler mot or sto ps.

21

Page 23

STAPLER 13th January 1995

[B]

[E]

[A]

[C]

[D]

When all the staple sheet s are fed out of the staple cartridge, a notch cut out

of the staple pressure plate [A] deactivate s the stap le end switch (a norma llyclosed type) [B]. The S/S CP U send s the stap le en d signal to the copier. Afte r

the stapling job is completed for all the bins, the Add Staples indicator lights

on the copier operatio n pa ne l and the Read y indicator turns off whenever the

staple mode is selected.

Staple jams are easily cleared by opening the staple guide plate [C]. The

staple guide switch (a normally-closed type) [D] detects whether the staple

guide plate is closed or open . When the S/S front door and S/S unit it self are

closed with the staple guide plate open, the Add Sta ple s in dica tor lights on

the copier operation panel.

The stapler can be swung on the stapler support bracket [E ] an d it ha s tw o

lock positions. One is for horizon tal stapling and the other is for diagona l

stapling (at 25 degrees).

22

Page 24

13th January 1995 STAPLER

- Stapler inoperative conditions -

1. Under the following conditions, the staple mode is inoperative when the

staple key on the operation panel is pressed.

• If there is paper in a bin before the main switch is turned on.

• If the selected paper size does not match the stap ling specif ications.

2. Under the following conditions, the staple mode is canceled.

• If paper is loaded into a bin by hand while stap le mod e is se lect ed .

• If only one copy is delivered to th e bin.

• If the jogger operat ion has not been performed.

• If some already-stapled copies are present in the bin s.

• If the number of sheets delivered to th e bin exceeds the stapler

capacity.

Stapler capacity: 2 to 20 sheets for A4, B5, and 81/2 " x 11"

2 to 10 sheets for B4, A3, 81/2" x 14", and

11" x 17"

The stapler capacity can be increa sed by 5 for both pap er size typ es

by changing the SP mode setting fo r the Stapling Limit. (If this is

done, the staplin g fu nction is not guaranteed.)

Stapler

20-bin Sorter

3. Under the following conditions, manual stapling mod e in sort mode is

inoperative.

• If paper is loaded into a bin by hand while sort mode is selected.

• If the paper size in the bin does not match the sta plin g spe cifications.

• If only one copy is delivered to th e bin.

• If copies of different width are delivered to the bin.

• If some already-stapled copies are present in the bin.

23

Page 25

JAM DETECTION AND STAPLER ERROR 13th January 1995

10. JAM DETECTION AND STAPLER ERROR

10.1 SORTER JAMS

- Normal Mode -

Copier Paper

Exit Sensor

Proof Tray

Exit Sensor

- Sort/Stack/Staple

Mode -

Copier Paper

Exit Sensor

Bin Exit

Sensor

[A]

[B]

The sorter stapler main contro l board dete cts pape r jams in the sorte r stapler,

or between the sorter staple r and the copie r. To de te ct jams, the S/S CPU

uses the paper exit on/off signal f rom th e cop ier, and the proof tray exit

sensor [A] (in normal mode) or the bin exit sensor [B] (in sort/stack/staple

mode).

Jam check timing in normal and in sort/st ack/ sta ple modes is shown above.

There are two time scales: one in seco nds and milliseconds, and one in

pulses. The pulses are the timin g pu lses fro m t he roller drive timing sensor.

Since the paper transport speed of the sorter stapler (this is the normal spe ed

mode) depends on that of the copier, the sorter stapler ca nnot operate on a

fixed time scale. Therefore , to match the sorter stapler speed to th e cop ier’s,

the copier sends a signal to the S/S CPU; this controls the normal speed of

the roller drive motor (the speed in high spe ed mode neve r change s) and this

generates the pulse rate.

24

Page 26

13th January 1995 JAM DETECTION AND STAPLER ERROR

If the proof tray exit sensor or the bin exit sensor is actua te d when the sorter

stapler unit or the front door is opened and closed, or when the main switch is

turned on, a sorter jam signal is sent to the copier.

Sorter jam conditions are rese t by op en ing and clo sing the sorter stapler unit

or the front door after clearing the jammed paper.

When an abnormal condition of the main motor, bin lift mot or, or jogger motor

is detected for the first time, the copier’s operation panel will indicate a sorter

jam. When the abnormal condition is detected for the second time, the S/ S

CPU sends an error signal to the copier. The copier’s opera tio n panel will

indicate a service call code.

10.2 STAPLER ERROR

The sorter stapler main control board detects a stapler error when th e

following conditions are detected. The copier’s operation pan el will indica te a

sorter jam, and stapling will stop in the se case s.

Stapler

20-bin Sorter

• If the paper sensor is actua ted when the sorter stapler or the front

door is opened or closed, or when the main switch is turned on.

• If the paper sensor is actua te d when the grip assembly retu rns to the

home position after the stapling operation .

• The first time an abnormal condition of the stapler motor or grip

motor is detected.

The second time an abnormal condition is detected, the copier’s

operation panel will indicate a service call code.

25

Page 27

Turn Gate

Solenoid

Interface

Motor

OFF signal

TIMING CHARTS 13th January 1995

11. TIMING CHARTS

Timing Chart 1: Normal Mode (A4 sideways, 5 copi es)

Paper exit signal

from copier

Roller Drive

Motor

Proof Tray

Exit Sensor

Normal

mode

signal

Motor ON

signal

Normal speed

High speed

SS paper

exit signal

Timing Chart 2: Sort Mode (A4 sideways, 2 copies for 5 bins)

Interface

Motor ON

signal

Paper exit signal from copier

Motor OFF

signal

Roller

Drive

Motor

Bin Lift

Motor

Jogger

Motor

Bin Exit

Sensor

Bin Number

Paper Size

A3 350 ms 190 ms 900

B4 350 ms 160 ms 900

A4 sideways 205 ms 375 ms 960

A4 lengthwise 610 ms 0 ms 900

B5 sideways 150 ms 370 ms 900

B5 lengthwise 230 ms 0 ms 900

11" x 17" 295 ms 130 ms 900

1/2" x 14" 675 ms 90 ms 900

8

1/2" x 11" sideways 130 ms 265 ms 960

8

1/2" x 11" lengthwise 625 ms 0 ms 900

8

Bin Lift Motor

ON Timing

Jogger Motor

ON Timing

High Speed

(mm/s)

26

Page 28

Interface

Bin Lift Motor

Jogger Motor

Stapler Motor

13th January 1995 TIMING CHARTS

Timing Chart 3: Stapling (A4 side wa ys , 2 copi es for 5 bins)

Grip Motor

Staple ON

signal

1 staple cycle

Staple count

signal

Job completion

signal

Returns to

H.P.

Stapler

20-bin Sorter

27

Page 29

ACCESSORY CHECK 13th January 1995

12. ACCESSORY CHECK

Check the quantity and cond itio n of the accessories in the box as listed

below:

1. Proof Tray............................................................................1

2. Staple Cartridge ..................................................................1

3. Staple Position Decal..........................................................1

4. Stepped Screw ...................................................................1

5. Philips Truss Head Screw - M4 x 6.....................................1

6. Philips Pan Head Screw - M4 x 14......................................4

7. New Equipment Condition Report

(–17 machines only) ...........................................................1

8. Installation Procedure .........................................................1

28

Page 30

13th January 1995 INSTALLATION PROCEDURE

13. INSTALLATION PROCEDURE

[A]

Stapler

20-bin Sorter

[B]

Make sure to follow the instructions below when unpacking and

installing the sorter stapler.

• Grasp the stay [A] when unpacking the sorter stapler.

• Never hold the guide plate [B] when unpackin g the sorter stapler.

If you hold the guide plate, it migh t be dama ge d and this will

cause paper jams.

• Avoid catching the guide plate [B] on anything when installing

the sorter stapler.

29

Page 31

INSTALLATION PROCEDURE 13th January 1995

[A]

[B]

NOTE: (1) Keep the shipping retainers after installing the machine. They will

be reused if the machine will be tran sported to an another

location in the future.

(2) Proper reinstallat ion of th e ship pin g retainers is required in order

to avoid any transport damage.

(3) A sorter adapter (A568) is req uire d to install this sorter stapler in

the A157/A159/A160/A 16 1/A1 62 copie rs. Be fo re inst alling this

sorter stapler, please in sta ll the sorte r a dapt er in th e cop ier.

CAUTION

!

Unplug the copier power cord before starting the fol low ing proc edur e.

1. Remove the strips of tape and the shipping ret ain ers [A].

2. Open the front door [B] and remove the strips of tape from the staple unit

and close the front door.

30

Page 32

13th January 1995 INSTALLATION PROCEDURE

[A]

[B]

[C]

[E]

[D]

3. Remove the two plastic caps [A] from the copier left cover with nippers.

4. Remove the rear cover [B] of the sorter staple r.

5. Release the lock lever [C] of the sorter stapler and un ho ok the sorter

stapler mounting frame [D] while releasing the stopper [E] as shown.

Stapler

20-bin Sorter

31

Page 33

[M]

INSTALLATION PROCEDURE 13th January 1995

[D]

[C]

[A]

[F]

[E]

[B]

[G]

[J][I]

[L]

[H]

[K]

[N]

6. Remove the M4 x 8 round head screws from the left cover of the copier

(A153/A155/A156 copiers: 2 screws [A], A157/A159/A160/A161 /A1 62

copiers: 3 screws [A] and [B]).

7. Mount the sorter stapler mounting frame [C] on the copier as shown

(4 – M4 x 14 screws).

NOTE: When hooking the sorter stapler mounting frame on the left side

of the copier, make sure th at the posit ioning hooks [D] on the

frame are properly inserted in th e po sitio nin g ho les [E ] in the

copier.

8. Remove the junction gate [F] (1 snap ring) before installin g th e sorter

stapler. This prevent s the junction gate from damaging the guide plate of

the sorter stapler mounting frame.

9. Install the sorter stapler [G] on the sort er sta pler mounting frame (2 hinge

pins at the rear).

NOTE: First, lift the sorter stapler ont o the sup po rt pla te [H], ope nin g the

sorter stapler about 30 degrees. Then, insert the upper stud [I]

into the upper hinge ho le [J] . Finally, insert the lower stud [K] into

the lower hinge hole [L].

10. Remount the junction gate [F] (1 snap ring).

11. Connect the link lever [M] to th e sort er sta pler using the stepped screw

[N], then close the sorter stapler.

32

Page 34

13th January 1995 INSTALLATION PROCEDURE

[B]

[A]

[C]

12. Connect the connectors [A] to the sockets on th e rea r o f th e copier.

13. Remount the rear cover [B] (4 screws).

Stapler

20-bin Sorter

14. Mount the proof tray [C] (1 screw) a s shown .

33

Page 35

INSTALLATION PROCEDURE 13th January 1995

[C]

[B]

[A]

[D]

[E]

[C]

15. Open the front door o f th e sorter stapler and swing the sta ple unit [A] up.

16. Remove the green plastic clip [B ] fro m t he st aple cartridge [C] and correct

the position of the sta ple sheet [D] to make it flush with the other sheets

in the cartridge.

17. Install the cartridge in the stapler while holding the staple unit.

18. Put the staple unit back in its original position, close th e sorter stapler

front door, and plug in the copier.

19. Attach the staple positio n decal [E ] to the ARDF as shown .

20. Turn on the copier main switch and test the operat ion of the sorter stapler.

NOTE: The stapler will not be stapling for the first 10 or so copies until

the first staple comes to th e pro pe r position from the cartridge.

34

Page 36

13th January 1995 SERVICE TABLES (MAIN BOARD)

14. SERVICE TABLES (MAIN BOARD)

14.1 DIP SWITCHES

DIP SW 100 - Combination s oth er than those below are used only at the

factory.

1 2 3 4 5 Function Remarks

0 0 0 0 0 Normal Machine Operation

1 0 0 0 Sorter Free Run #1

1

0 1 0 0 Stapler Free Run #2

1 1 0 0 Sorter & Stapler Free Run #3

0 0 0 0 1 Bin Sensor Adjustment (see section 15.6.2)

To make a free run

1. Select the required free run mo de wit h switches 2 an d 3.

2. Set switch 1 to 1. The free run starts.

3. To end the free run, set switch 1 to 0, then set switches 2 and 3 back to 0.

Remarks

#1 The roller drive motor turns on (alternately at low and high speed).

The sorting operation is repeat ed from th e 1st bin to the 20th bin .

Stapler

20-bin Sorter

Operated componen ts: • Turn gate solenoid

• Bin lift motor

• Jogger motor (for A4 sideways)

#2 Stapling is repeated from the 1st bin to th e 20 th bin. (I f th ere are

staples in the staple unit, the stap ling ope rat ion is skipped. If

there is paper in the bins, the jogger mot or do es not turn on.)

Operated componen ts: • Bin lift motor

• Grip motor

• Stapler motor

• Jogger motor (for A4 sideways)

#3 #1 and #2 are repeated together alternately.

14.2 LED AND VARIABLE RESISTOR

LED No. VR No. Function

100 100 Adjusts bin sensor sensitivity

14.3 TEST POINTS

Number Function

TP100 GND

TP101 +24V

TP102 +5V

35

Page 37

REPLACEMENT AND ADJUSTMENT 13th January 1995

15. REPLACEMENT AND ADJUSTMENT

15.1 STAPLER REMOVAL

[A]

[B]

[D]

1. Open the front door [A] of the sorter stapler and swing the staple unit [B]

up.

2. Remove the staple unit cover [C] (1 screw).

[C]

3. Remove the stapler [D] (1 screw and 1 connector).

36

Page 38

13th January 1995 REPLACEMENT AND ADJUSTMENT

15.2 GRIP ASSEMBLY REMOVAL

[A]

Stapler

20-bin Sorter

[C]

[B]

[D]

1. Remove the proof tray [A] (1 screw).

2. Swing out the sorter stapler an d disco nnect the link lever [B] (1 stepped

screw).

3. Remove the front cover [C] (remove 2 screws and loosen 2 screws).

4. Remove the grip assembly [D] (2 screws and 1 connector).

37

Page 39

REPLACEMENT AND ADJUSTMENT 13th January 1995

15.3 BIN REPLACEMENT

[B]

[A]

[C]

1. Remove the proof tray [A] (1 screw).

2. Remove the sorter stapler from the copier.

3. Remove the jogger bar [B] as shown.

4. Remove the upper securing screw of each bin link [C] (1 screw each).

38

Page 40

13th January 1995 REPLACEMENT AND ADJUSTMENT

[C]

[D]

[A]

Stapler

20-bin Sorter

[B]

5. Remove the support bin [A] and the bins [B] one by one .

(1) Hold the bin [A or B] with both hands.

(2) Push the bin forward until the wh eels [C] reach the bend in the track.

(3) Push the left side of the bin forward and pull that side up.

(4) As you pull the left side up, the right whe el will le ave its t rack.

(5) When the left wheel re ach es the slot [D], pull the bin out .

39

Page 41

REPLACEMENT AND ADJUSTMENT 13th January 1995

[C]

[E]

[D]

[A]

[B]

6. Install the support bin [A] and the bins [B] on e by one.

(1) Hold the bin top side up with both hands.

(2) Tilt the bin so the left side is higher t hen th e right side.

(3) Pass the left wheel [C] through the slot [D]. At th e same time, pass

the right wheel [E] just be low th e stapler opening.

(4) Set the left wheel in to the left track, then push the right wheel into the

right track.

40

Page 42

13th January 1995 REPLACEMENT AND ADJUSTMENT

15.4 BIN LIFT WIRE REPLACEMENT

15.4.1 Wire Removal

[A]

[C]

Stapler

20-bin Sorter

[B]

1. Remove the sorter stapler from the copier.

2. Remove the following parts:

• Proof Tray [A] (1 screw).

• Front Cover [B] (loosen 2 screws and remove 2 screws)

• Rear Cover [C] (4 screws)

3. Turn the bin lift drive belt so that the bin lift ge ar/ pu lley comp on en t rotates

counterclockwise. Contin ue this un til th e rear b in lift wire beco mes loose

enough to remove the wire.

41

Page 43

[A]

REPLACEMENT AND ADJUSTMENT 13th January 1995

[D]

[E]

[B]

[F]

[C]

- Front side -

4. Remove the stapler unit [A] (3 screws and 1 connector [9P]).

5. Swing the bin shaft cover [B ] as sho wn (2 screws an d 1 conne cto r ).

6. Remove the bin support block stopper [C] as shown.

7. Remove the wire pulley [D] (1 E-ring).

NOTE: Be careful not to lose the pin [E].

8. Remove the bin lift wire [F].

42

Page 44

13th January 1995 REPLACEMENT AND ADJUSTMENT

[B]

[A]

[E]

Stapler

20-bin Sorter

[D]

[C]

- Rear side -

9. Remove the sorter power cord bracket (1 screw; see section 15.6.1).

10. Remove the main control boa rd [A ] (1 screw, 13 connectors, and 5

locking supports).

11. Remove the bin lift shaft cove r [B] (2 screws).

12. Remove the timing sensor bracket [C] (1 screw).

13. Remove the bin drive bracket [D] (2 screws with spring washer, 1

connector, and 3 wire saddles).

14. Remove the bushing [E].

43

Page 45

REPLACEMENT AND ADJUSTMENT 13th January 1995

[C]

[B]

[A]

[D]

15. Remove the bin lift block stopper [A ] as shown.

16. Remove the wire pulley/gear [B] (2 E-rings).

NOTE: Be careful not to lose the pin [C].

17. Remove the bin lift wire [D].

44

Page 46

- Rear -

[G]

[C]

[H]

13th January 1995 REPLACEMENT AND ADJUSTMENT

15.4.2 Wire Instal lation

[A]

[P]

[K]

[Q]

[B]

[E]

[D]

[I]

[F]

[G]

Rear

[E] [D]

[A]

Front

[L]

[O]

[J]

- Front -

[H]

[Q]

Stapler

20-bin Sorter

[F]

[P]

[N]

[P]

[A]

599mm (23.58")

[M]

[F]

877.6 mm (34.55")

1. Put the bead [A] at the end of the wire in the slot in the wire pulle ys [B, C],

2. Insert the pin [D] into the bin drive shaft [E] and then push in the wire

pulleys.

3. Wind the wire one and a half turns as shown and put the bead [F] in the

slot in the bin support block [G ].

4. Put the bin support block stopper [H] on the bin support block.

5. Run the wires over the pulleys [Front wire: I/J/K, Rear wire: L/M/N/O] and

put the bead [P] in the slot in the bin lift shaf t [Q].

6. Reassemble the sorter stapler.

NOTE: When installing the bin drive bra cket, make sure that the bin lift

wires are wound from the inner side to the oute r side of th e

pulleys as shown.

45

Page 47

REPLACEMENT AND ADJUSTMENT 13th January 1995

15.5 VERTICAL TRANSPORT UNIT REMOVAL

[C]

[B]

[A]

[G]

1. Remove the sorter stapler from the copier.

[D]

[F]

[E]

2. Remove the proof tray, the front cover, the rear cover, and the upper

cover.

3. Remove the upper hinge [A] (2 screws) and the sorter stapler set switch

bracket [B] (1 screw).

4. Remove the grounding screw [C] and disconnect the main harne ss [D] (5

connectors and 3 harness clamps).

5. Remove the timing belt [E] from the pulley [F].

6. Remove the vertical transport unit [G] (8 screws).

46

Page 48

13th January 1995 REPLACEMENT AND ADJUSTMENT

15.6 MAIN CONTROL BOARD REPLACEMENT AND

ADJUSTMENT

15.6.1 Main Control Board Replacement

[A]

Stapler

20-bin Sorter

[B]

1. Remove the proof tray, the rear cover, and the powe r co rd bra cket [A].

2. Disconnect the main control board connectors and fiber cable.

3. Replace the main control board [B] and connect the connectors.

4. Turn on the copier main switch.

5. Adjust the bin sensor (see the next page).

6. Turn off the main switch.

47

Page 49

[B]

REPLACEMENT AND ADJUSTMENT 13th January 1995

15.6.2 Bin Sensor Adjustment

[C]

[A]

1. Turn on DIP SW100-5 [A]

2. If LED100 [B] is lit, turn VR100 [C] counterclockwise until LED100 tu rns

off.

3. Turn VR100 clockwise until LED100 just turns on.

4. Turn off DIP SW100-5.

48

Page 50

13th January 1995 REPLACEMENT AND ADJUSTMENT

15.7 BELT TENSION ADJUSTMENT

[A]

Bending = a

Stapler

20-bin Sorter

[B]

1. Remove the required covers for the following belt tension adjustments as

listed below:

Timing Belt [A]

(Roller Drive Motor)..................................... Proof Tray

Rear Cover

Timing Belt [B]

(Grip Motor) ....... .. .. .. .... .. .. .. .. .. .. .... .. .. .. .. .. .. ... Proof Tray

Front Cover

2. Adjust the timing belt tension as follows:

Timing Belt Bending Tension

A 4 mm (0.16")

B 4 mm (0.16")

150±50 g

200±50 g

49

Page 51

ELECTRICAL COMPONENT DEFECTS 13th January 1995

16. ELECTRICAL COMPO NENT DEFECTS

16.1 SENSORS

Component

(Symbol)

Bin Lift

Timing -1

(S1)

Bin Lift

Timing -2

(S2)

Jogger H.P.

(S3)

Paper (S4)

≥ 4.0 V

≤1.0 V

≥ 4.0 V

≤1.0 V

≤4.0 V

≥ 1.0 V

≥ 4.0 V

≤ 1.0 V

CN Condition

Open

(stays

High)

Shorted

170-8

170-5

170-2

140-5

(stays

Low)

Open

(stays

High)

Shorted

(stays

Low)

Open

(stays

High)

Shorted

(stays

Low)

Open

(stays

High)

Shorted

(stays

Low)

Symptom

At main sw power-up Ready condition

The Sorter Jam

indicator starts blinking.

––

The Sorter Jam

indicator starts blinking.

The jogger motor keeps rotating until the Sorter

Jam indicator starts blinking.

–

The Sorter Jam

indicator starts blinking.

The Sorter Jam

indicator starts blinking

when copies are made

in sort/stack or staple

mode.

After the sorter stapler

or front door is

opened/closed, "SC

code (721)" will be

displayed.

The Sorter Jam

indicator starts blinking

when copies are made

in sort/stack or staple

mode.

After the sorter stapler

or front door is

opened/closed, "SC

code (722)" will be

displayed.

Stapling does not occur

even though there is a

set of copies at the

stapling position.

The Sorter Jam

indicator starts blinking

when copies are made

in sort/stack or staple

mode.

50

Page 52

13th January 1995 ELECTRICAL COMPONENT DEFECTS

Component

(Symbol)

Bin-LED

(S5)

Bin-Photo.

Tr (S6)

Grip H.P.

(S7)

Bin H.P.

(S8)

≥ 4.0 V

≤ 1.0 V

≥ 4.0 V

≤ 1.0 V

≥ 4.0 V

≤ 1.0 V

CN Condition

Open

(stays

140-4

155-3

115-2

130-11

Low)

Shorted

(stays

High)

Open

(stays

High)

Shorted

(stays

Low)

Open

(stays

High)

Shorted

(stays

Low)

Open

(stays

High)

Shorted

(stays

Low)

Symptom

At main sw power-up Ready condition

The Sorter Jam indicator starts blinking when

sort/stack or staple mode is selected.

––

Stapling does not occur

–

The Sorter Misfeed Location indicator starts

blinking when sort/stack or staple mode is

selected.

The Sorter Jam

indicator starts blinking.

The grip motor keeps

rotating until the Sorter

Jam indicator starts

blinking.

––

The Sorter Jam

indicator starts blinking.

even though copying

has been completed in

staple mode.

The Sorter Jam

indicator starts blinking

when copies are made

in sort/stack or staple

mode.

After the sorter stapler

or front door is

opened/closed, "SC

code (723)" will be

displayed.

The Sorter Jam

indicator starts blinking

when copies are made

in sort/stack or staple

mode.

After the sorter stapler

or front door is

opened/closed, "SC

code (723)" will be

displayed.

–

Stapler

20-bin Sorter

Bin Exit (S9)

≥ 4.0 V

≤ 1.0 V

150-4

Open

(stays

High)

Shorted

(stays

Low)

–

The Sorter Jam

indicator starts blinking.

51

The Sorter Jam

indicator starts blinking

when copies are made

in sort/stack or staple

mode.

Page 53

ELECTRICAL COMPONENT DEFECTS 13th January 1995

Component

(Symbol)

Proof Tray

Exit (S10)

Roller Drive

Timing

(S11)

≥ 4.0 V

≤ 1.0 V

≥ 4.0 V

≤ 1.0 V

CN Condition

Open

(stays

High)

150-7

150-11

Shorted

(stays

Low)

Open

(stays

High)

Shorted

(stays

Low)

Symptom

At main sw power-up Ready condition

The Sorter Jam

–

The Sorter Jam

indicator starts blinking.

The Sorter Jam

indicator starts blinking.

indicator starts blinking

when copies are made

in normal mode.

The Sorter Jam

indicator starts blinking

or " SC code (720) " is

displayed when copies

are made.

52

Page 54

13th January 1995 ELECTRICAL COMPONENT DEFECTS

16.2 SWITCHES

Component

(Symbol)

Upper Limit

(SW1)

Wire Tension

(SW2)

Front Door

(SW3)

Sorter Stapler

Set (SW4)

Staple End

(SW5)

Staple Guide

(SW6)

Staple H.P.

(SW7)

CN No. Condition

Open The Sorter Jam indicator

165-1

Shorted – –

Open The Sorter Jam indicator

165-4

Shorted – –

100-3 Open "C-5" is displayed even if the front door is closed.

Shorted "C-5" is not displayed even if the front door is opened.

100-3 Open "C-5" is displayed even if the sorter stapler is closed.

Shorted "C-5" is not displayed even if the sorter stapler is

130-9

130-8

130-6 Open The Sorter Jam indicator starts blinking or "SC code

Open The Add Staples indicator does not light even though

Shorted The Add Staples indicator lights even though the

Open The Add Staples indicator does not light even though

Shorted The Add Staples indicator lights even though the

Shorted

At main sw power-up Ready condition

starts blinking.

starts blinking.

opened.

the staple cartridge is empty.

staple cartridge is not empty.

the staple guide is opened.

staple guide is closed.

(724)" is displayed when copies are made in staple

mode.

Symptom

The Sorter Jam indicator

starts blinking when

copies are made in

sort/stack or staple mode.

After the sorter stapler or

front door is

opened/closed, "SC code

(721)" will be displayed.

The Sorter Jam indicator

starts blinking when

copies are made in

sort/stack or staple mode.

After the sorter stapler or

front door is

opened/closed, "SC code

(721)" will be displayed.

Stapler

20-bin Sorter

16.3 FUSES

Component

(Symbol)

FU100

(Main Control

Board)

Condition Symptom

Open The Sorter Jam indicator starts blinking when copies

are made in staple mode.

After the sorter stapler or front door is

opened/closed, "SC code (724)" will be displayed.

53

Page 55

Loading...

Loading...