SORTER STAPLER

(Machine Code: A377)

c

23 April 1993 SPECIFICATIONS

1. SPECIFICATIONS

Configuration: Console

Number of Bins: 20 + Proof Tray

Paper for Proof Tray:

Size Maximum: A3, 11" x 17"

Minimum: A6 lengthwise, 51/2" x 81/2"

Weight: 52~157 g/m2,14~42 lb

Capacity: 250 sheets (80 g/m2, 20 lb)

Paper for Bins: See the table below.

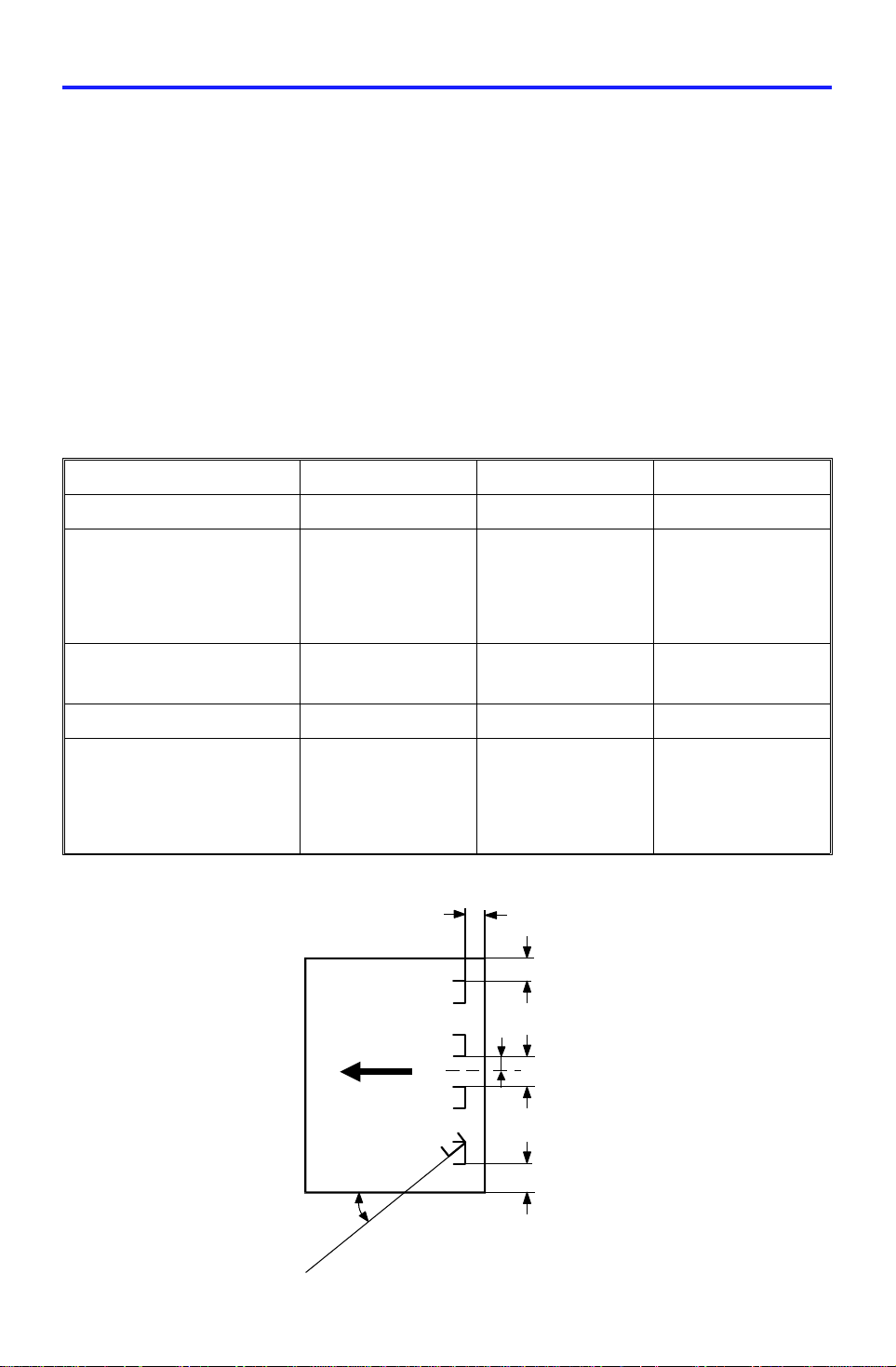

Sort Stack Staple

Maximum paper size A3, 11" x 17" A3, 11" x 17" A3, 11" x 17"

Minimum paper size A5, 51/2" x 81/2"

lengthwise

Maximum paper

weight

Minimum paper weight 52 g/m2, 14 lb 52 g/m2, 14 lb 64 g/m2, 17 lb

Maximum capacity all sizes:

Staple Position:

157 g/m2, 42 lb 157 g/m2, 42 lb 80 g/m2, 20 lb

50 sheets/bin

2 sided copies:

40 sheets/bin

Sideways:

A4, 81/2" x 11"

Lengthwi s e :

A5, 51/2" x 81/2"

all sizes:

40 sheets/bin

2 sided copies:

35 sheets/bin

a

d

e

a = 6 ± 3 mm

b = 6 ± 3 mm

c = 6 ± 3 mm

d = 66 ± 3 mm

e = 132 ± 2 mm

θ = 45 ± 5°

B5, 81/2" x 11"

all sizes:

50 sheets

θ

1

b

SPECIFICATIONS 23 April 1993

Staple Replenishmen t: Cartridge exchange (5,00 0 pie ces/ cartridge)

Power Source: DC24V (from copier)

Power Consumption: Average: less than 80W

Maximum:

in sort/stack mode: less than 100W

in staple mode: less than 300W

Dimensions:

566 x 583 x 978 mm

(W x D x H)

Weight: Approximately 52 kg

2

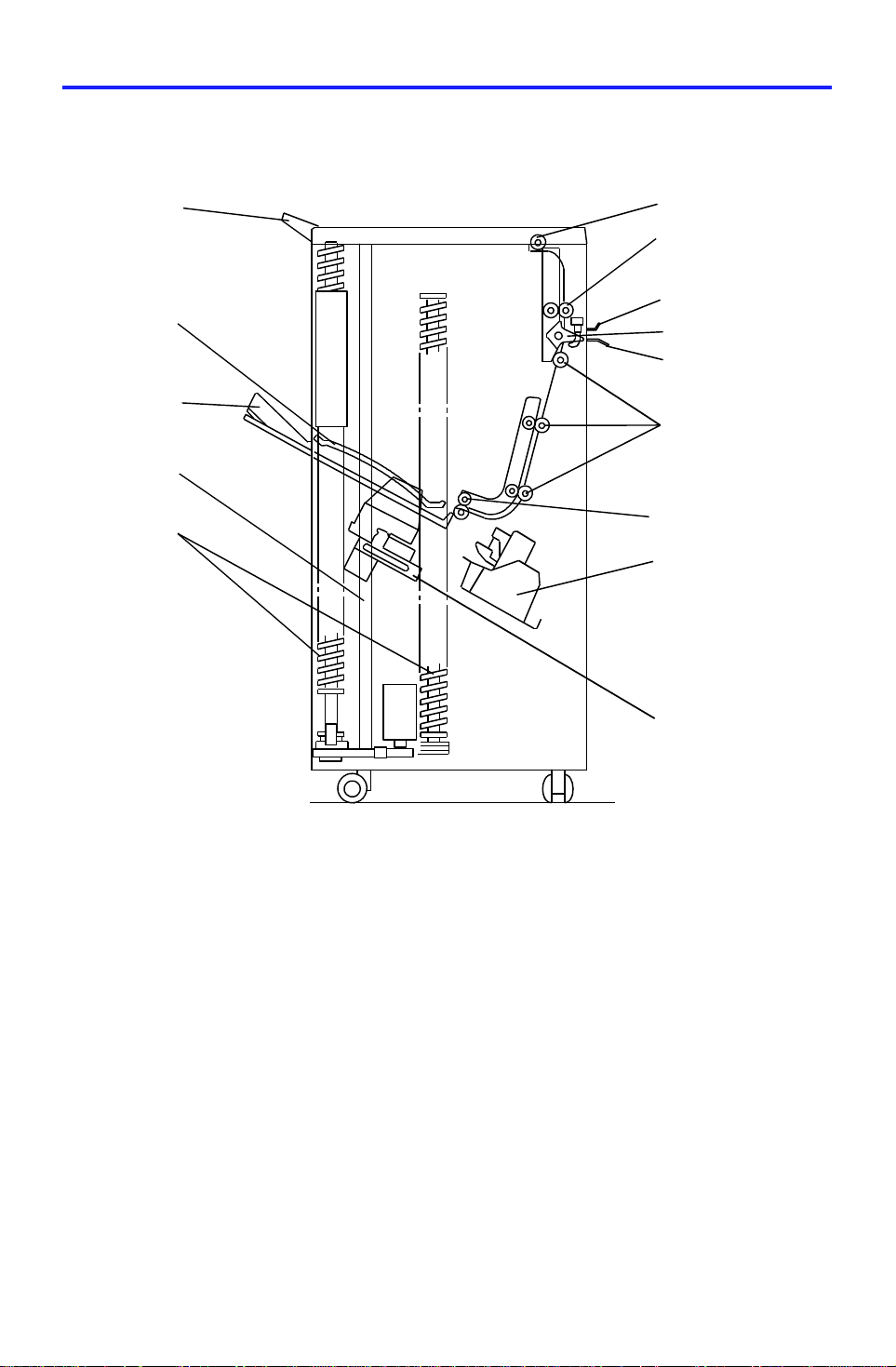

23 April 1993 COMPONENT LAYOUT

2. COMPONENT LAYOUT

2.1 MECHANICAL COMPONENT LAYOUT

14

13

12

11

1

2

3

4

5

6

7

8

9

10

1. Proof Tray

2. Proof Exit Rollers

3. Proof Transport Rollers

4. Upper Entrance Guide

5. Turn Gate

6. Lower Entrance Guide

7. Sorter Transport Rollers

8. Sorter Exit Rollers

9. Staple Unit

10. Grip Assembly

11. Helical Wheels

12. Jogger Plate

13. Bins

14. Upper Guide Plate

3

4

13

13

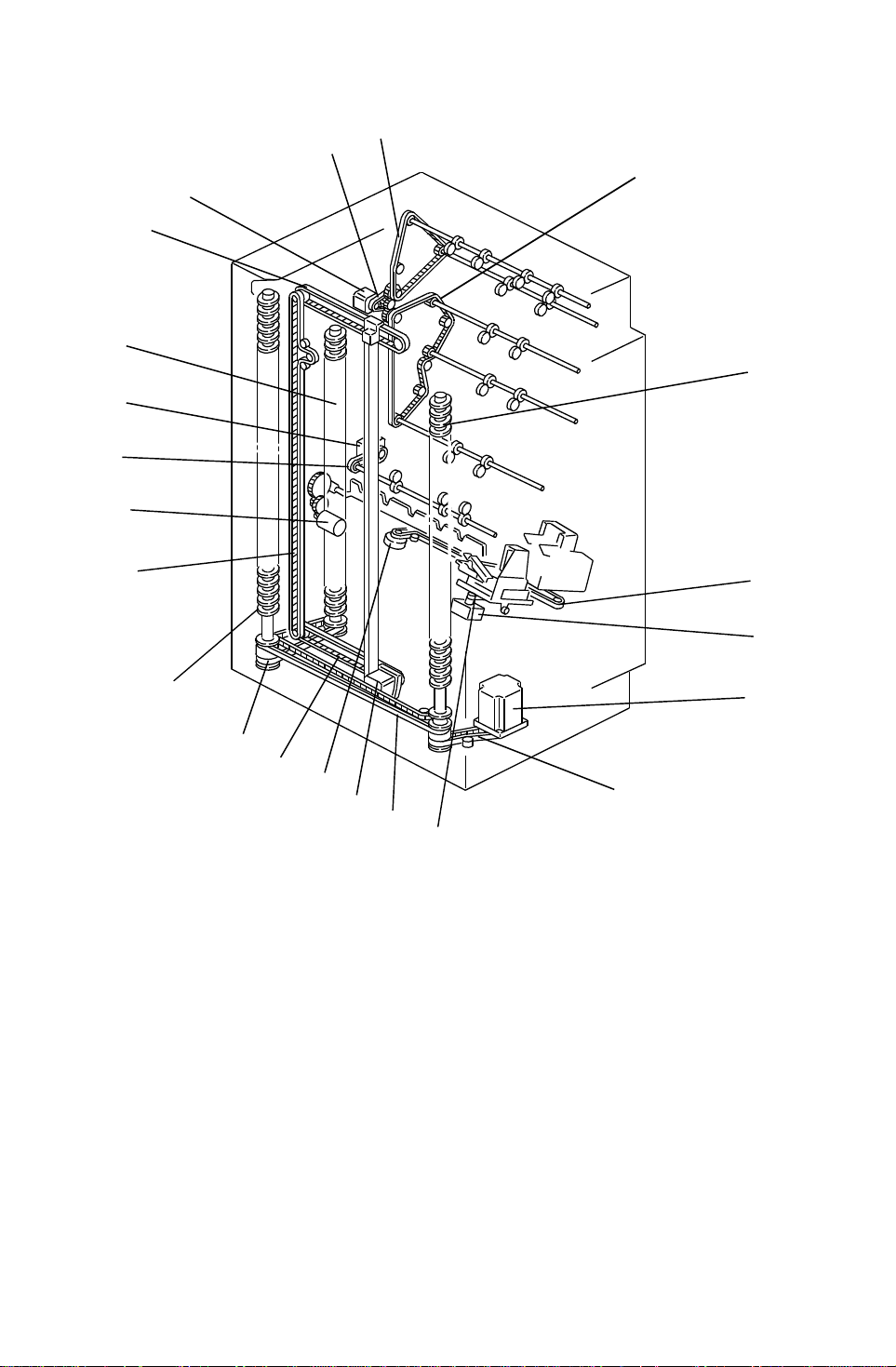

COMPONENT LAYOUT 23 April 1993

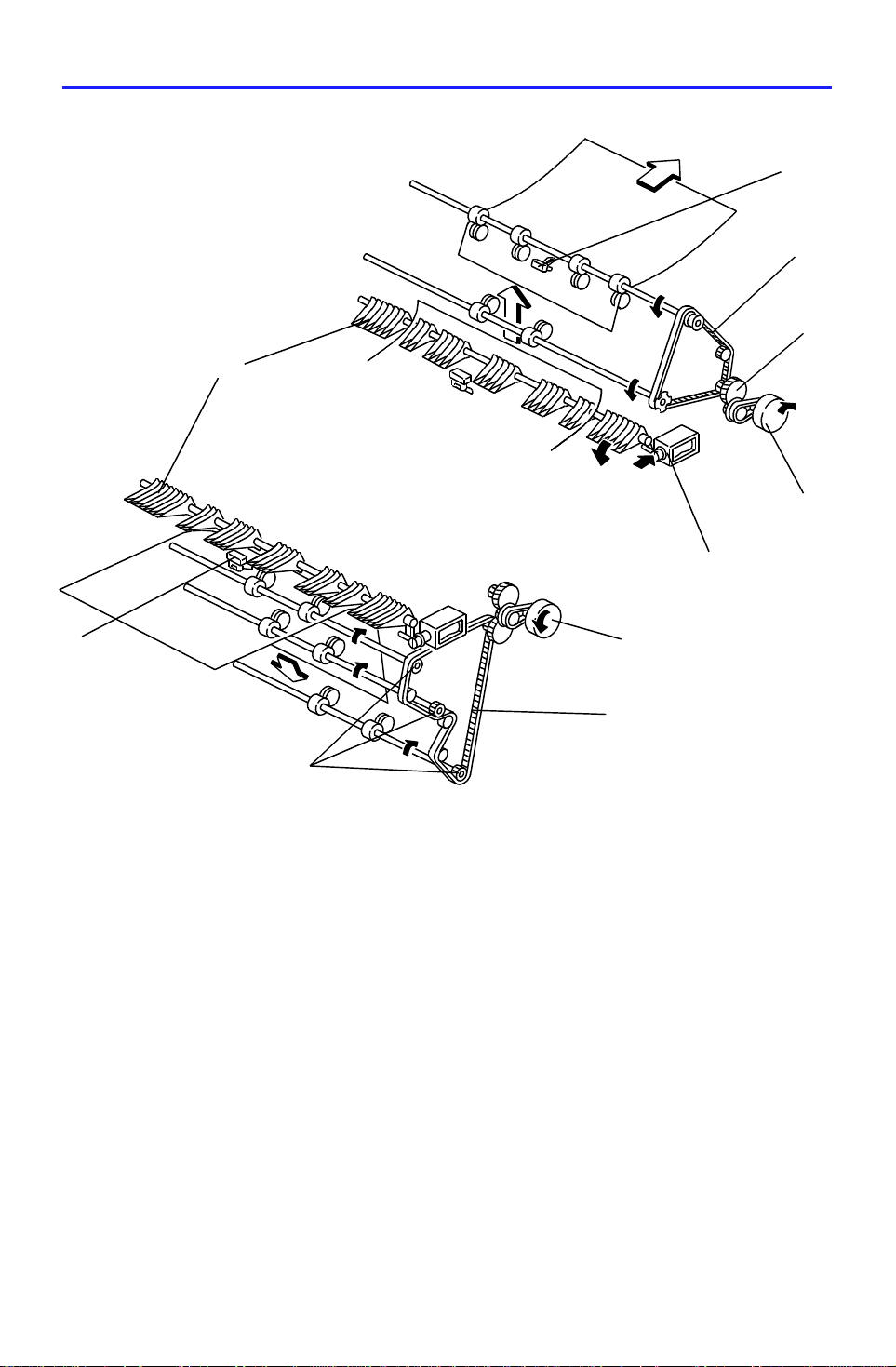

2.2 DRIVE LAYOUT

3

2

1

5

5

16

15

14

5

9

13

1. Main Motor

2. Main Drive Belt

3. Proof Drive Belt

4. Sorter Drive Belt

5. Helical Wheels

6. Staple Unit Drive Belt

12

11

6

7

8

9

9

10

9. Wheel Drive Belts

10. Grip Drive Belt

11. Jogger Motor

12. Staple Unit Drive Motor

13. Jogger Drive Belts

14. Bin Rear Plate Drive Motor

7. Gripper Motor

8. Bin Drive Motor

15. Sorter Exit Drive Belt

16. Sorter Exit Motor

4

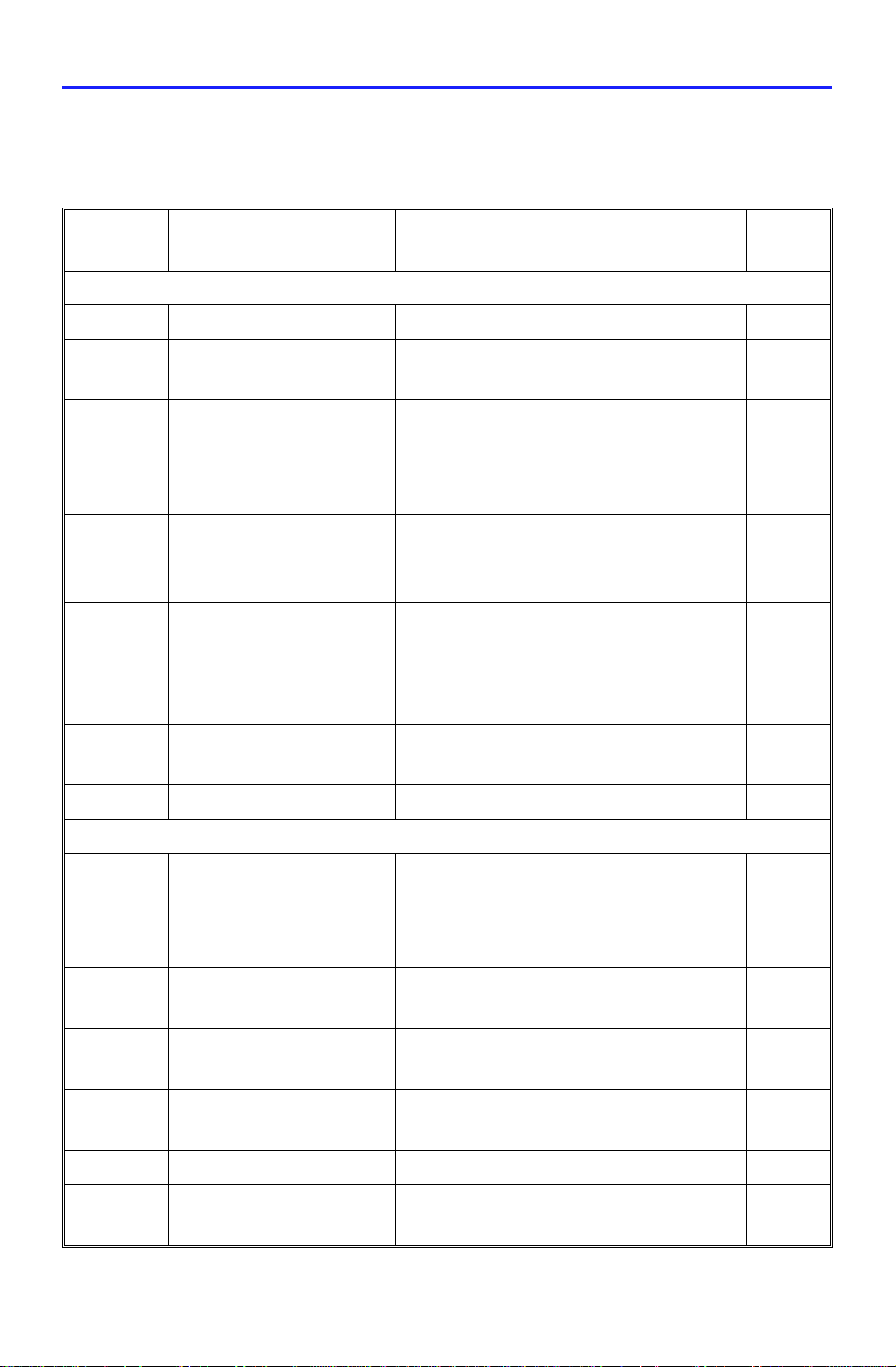

23 April 1993 ELECTRICAL COMPONENT DESCRIPTION

3. ELECTRICAL COMPONENT DESCRIPTION

Please refer to the electrical component layout on th e reverse side of the

Point to Point (Water Pro of Paper) fo r symbol an d ind ex number.

Symbol Name Function

Motors

M1 Ma in Drives the paper transport rollers. 1

M2 S ta ple Feeds the staples and drives the

stapler hammer.

M3 G rip Drives the grip assembly forward

and backward into the bin to grip

the copies and bring th em to the

stapling position.

M4 B in Drive Drives the bins upward and

downward by rotating the thre e

helical wheels.

M5 Jo gg er Drives the jogger plate to jog the

copies against the front side plate.

M6 S taple Unit Drive Drives the staple unit according

to the stapl e position an d angle.

M7 B in Rea r P lat e Drive Drives the bin rear plate down

and up.

Index

No.

10

16

18

20

23

24

M8 S ort er Exit Delivers the paper into the bins. 27

Sensors

S1 Bin Jam (LED) Detects if there is paper jams at

the distribution sect ion and

detects if there is paper in the

bins (light emitting element).

S2 Proof Exit Detects paper jams at the proof

tray exit.

S3 Entrance Detects paper jams at entrance

guides.

S4 Staple HP Detects if the staple hammer is in

the home position.

S5 Staple End Detects staple end. 9

S6 Paper Detects whether copies are under

the hammer.

5

3

4

5

8

11

ELECTRICAL COMPONENT DESCRIPTION 23 April 1993

Symbol Name Function

S7 Staple Unit HP Detects if the staple unit is in the

home position.

S8 Grip HP Detects if the grip assembly is in

the home position.

S9 Bin Jam (Photo Tr.) Detects paper jams at the

distribution section and detects if

there is paper in the bins (light

receiving element).

S10 Wheel Sensor Detects the bin position. 19

S11 Bin HP Detect s if the bins are in the

home position.

S12 Jogger HP Detects if the jogger plate is in

the home position.

S13 Bin Rear Plate Open Detects if the bin rear p lat e is in

the open position .

S14 Bin Rear Plate HP. Detects if the bin rear plate is in

the home (closed) position.

Index

No.

13

15

17

21

22

25

26

Solenoids

SOL1 Turn Gate Opens and closes the turn gate to

direct the copies into eit he r the

proof tray or the bins.

SOL2 Grip Opens and closes the grip arms

to grip copies on the bins.

SOL3 Grip Arm Positioning Moves the grip ass’y to the rear

and front to catch or release the

paper to carry to the stapler.

PCBs

PCB1 DC Supply Provides DC power (In put: 24V

DC, Output:24V/5V DC)

PCB2 Main Control Controls all sorter stapler

functions.

Switches

SW1 Door Safety Cuts the DC power when the

front door is opened.

2

12

14

7

28

6

6

[D]

23 April 1993 BASIC OPERATION

4. BASIC OPERATION

4.1 NORMAL (PROOF MODE) AND SORT/STACK MODE

[C]

[A]

[A]

[B]

Copies exiting the copier pass thro ug h the entrance guide plates [A] to the

turn gate section. The turn gate [B] will send copies eith er to the proof tray or

to the bins, depending on the mod e.

- Normal (proof) mode - (from the turn gate section to the proof tray)-

The turn gate solenoid energize s to tu rn th e turn ga te clo ckwise whe n the

Start key is pressed. The main moto r t urn s coun te rclockwise to rot at es th e

vertical transport rollers [C] and pro of exit roller [ D]. The turn gate directs

copies through the proof transpo rt sect ion to the proof tray.

7

BASIC OPERATION 23 April 1993

- Sort mode - (from the turn gate section to the bins)

[F]

[E]

[D]

[A]

[B]

[H]

[C]

[I]

[G]

In this mode, the tu rn ga te solenoid stays off to keep the turn gate [A ] at the

upper position. The main motor turns clockwise to rotates the sorter transport

rollers [B] and the exit motor rotates the exit rollers [ C].

The turn gate directs copies to the sort er bin s thro ug h the sort er transport

section, then the first copy is delive red between the top bin [D] and the upper

guide plate [E] .

The jogger plate [F] the n jog s to squ are the copies each time.

Before the next copy reache s the sorte r exit roller, the bin drive motor [G]

rotates and advances the bin on e ste p (the he lical whe els [H] ro tate once ).

When the cut out of the actuator reaches below the wheel sensor [I], the bin

drive motor turns off.

Bins advances each time copies are de livere d.

8

23 April 1993 BASIC OPERATION

- Stack mode - (from the turn gate section to the bins)

[F]

[E]

[D]

[A]

[B]

[H]

[C]

[I]

[G]

As with sort mode, the tu rn ga te solenoid stays off and th e turn gate [A] also

stays up when the start key is pressed. The ma in mot or tu rns clockwise to

rotate the sorter transport rolle rs [ B] and the exit mot or rot at es th e exit rollers

[C].

The turn gate directs copies to the sort er bin s thro ug h the sort er transport

section, then th e copies are delivered between the top bin [D] and the upper

guide plate [E] .

The jogger plate [F] the n jog s to squ are the copies each time.

All copies of the copy run are then fed to the first bin . Whe n th e fin al cop y is

delivered, the whe el drive motor [G] turns and advances the bin one step (the

helical wheels [H] rotat e on ce). When the cut ou t of the actuator reache s

below the wheel sensor [I] , the bin drive mot or tu rns of f.

9

BASIC OPERATION 23 April 1993

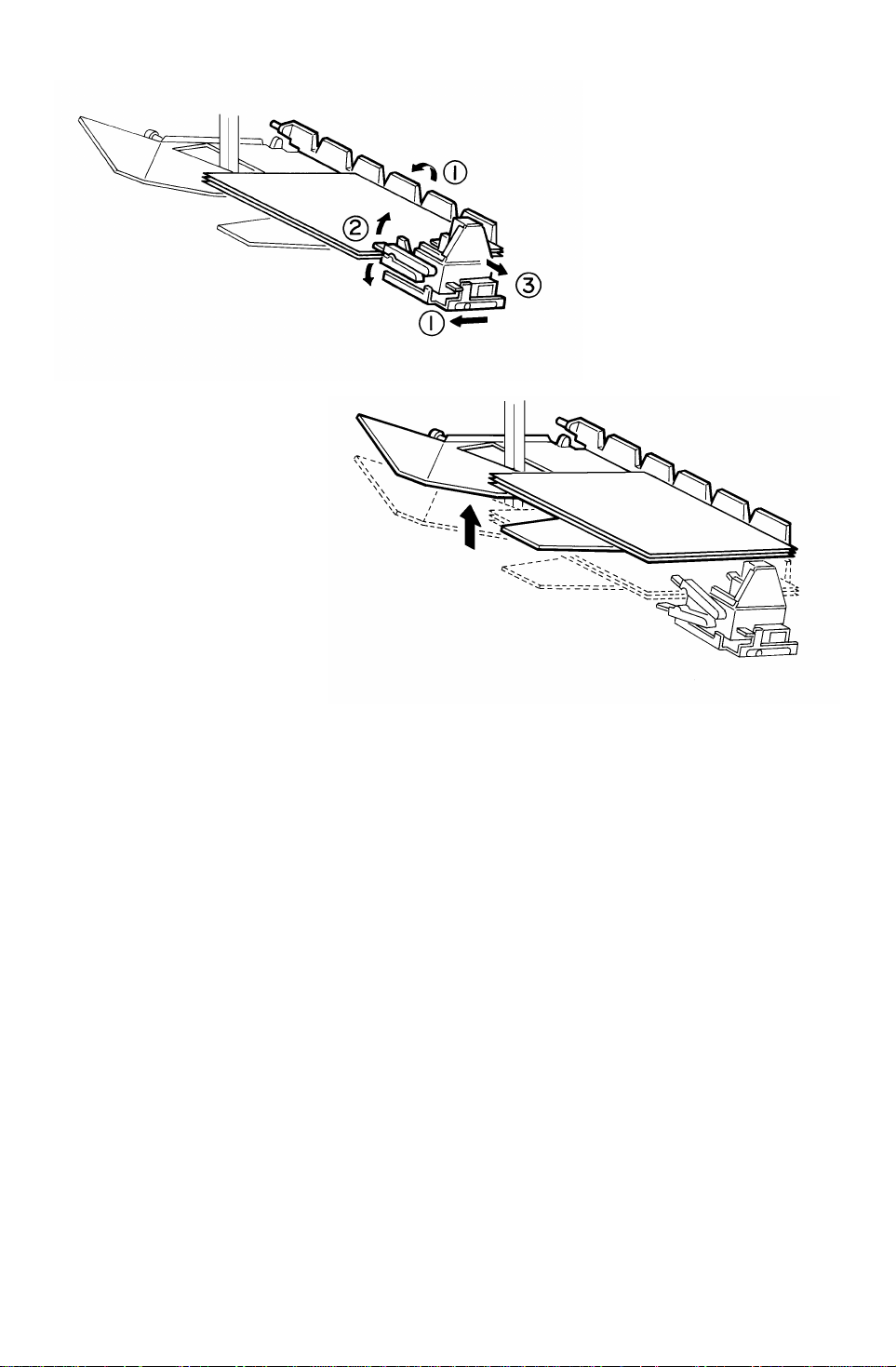

4.2 STAPLE MODE

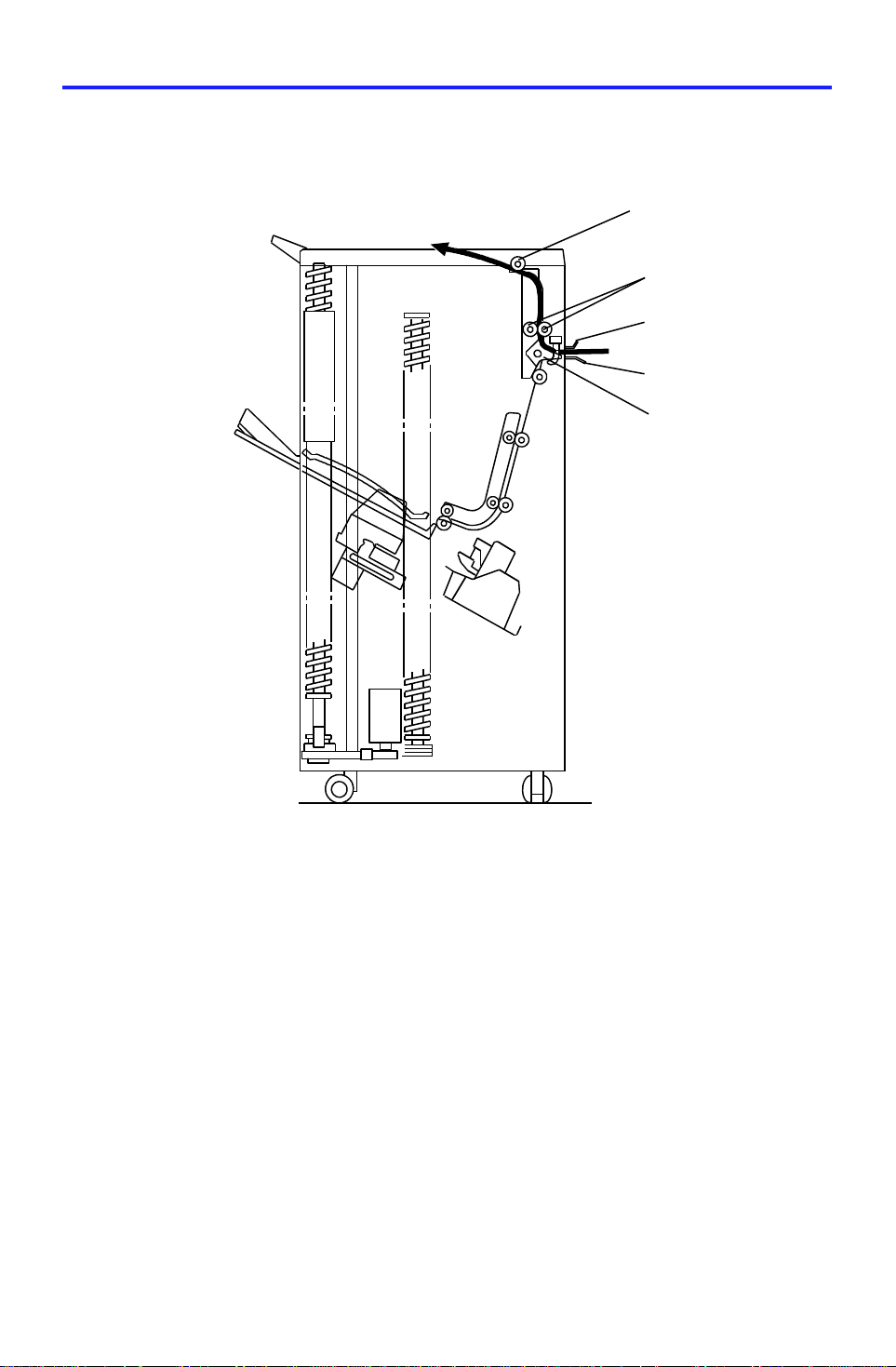

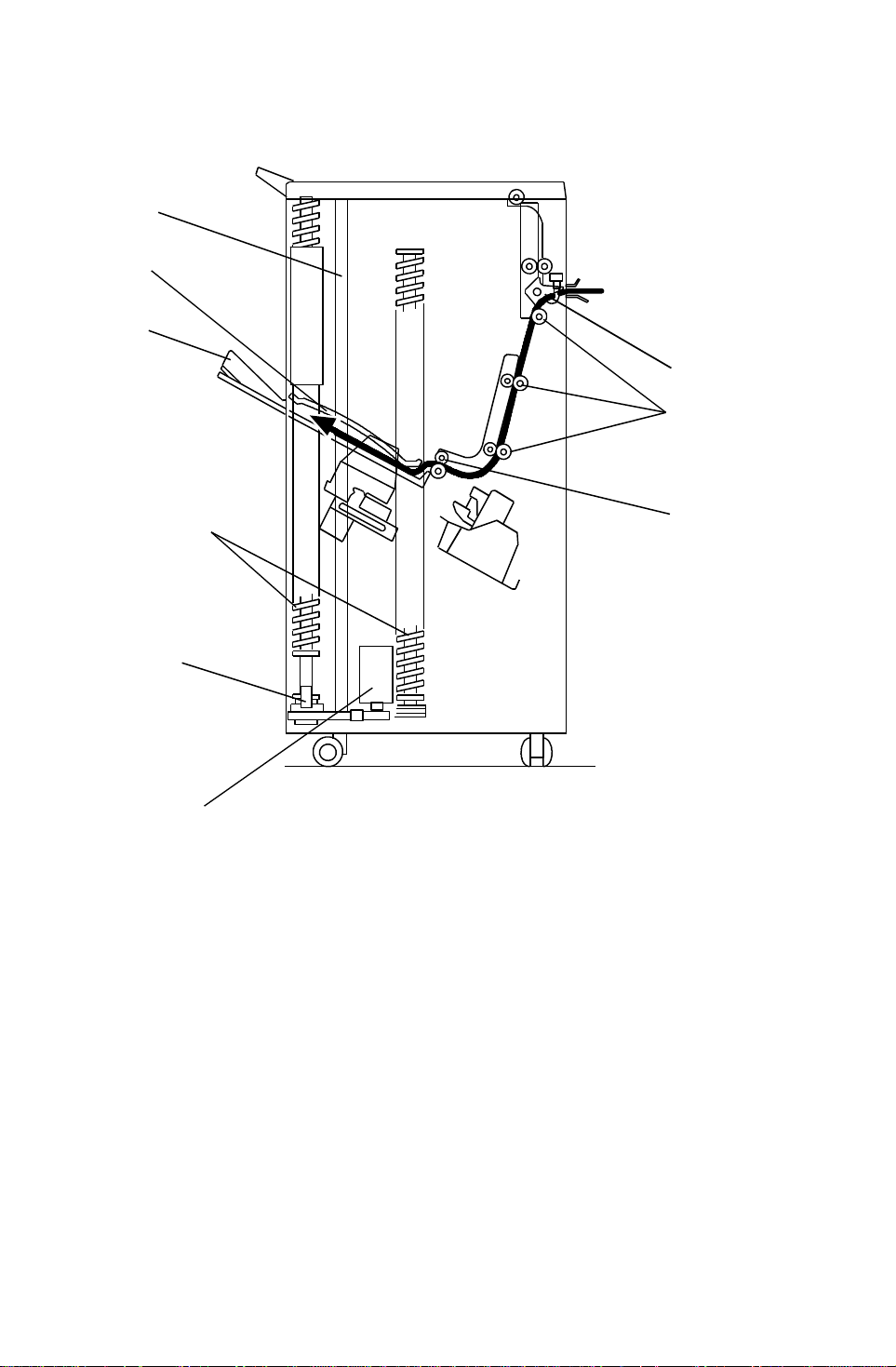

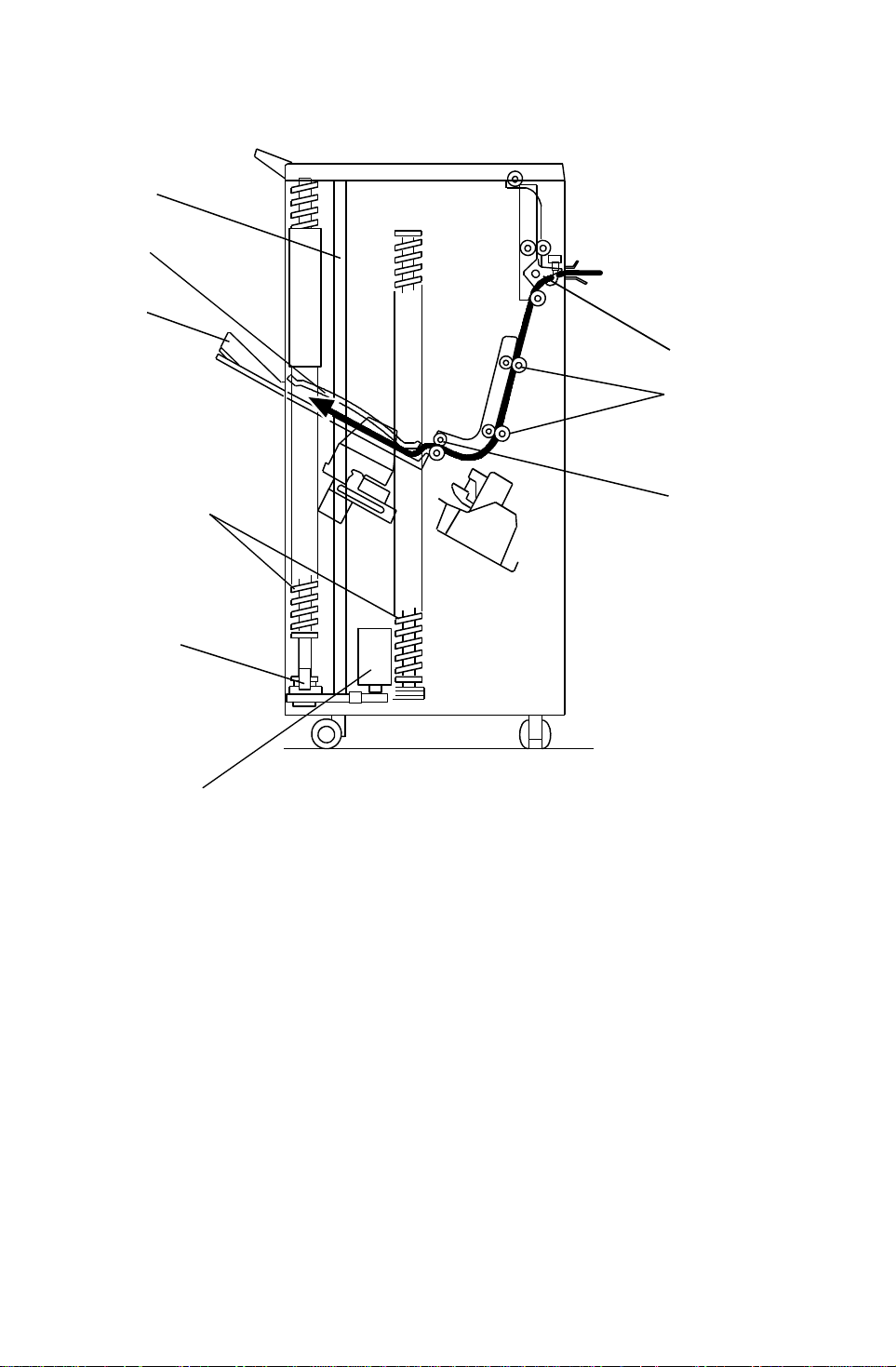

[Fig. 1]

[Fig. 2]

[Fig. 3]

When the final set of copies is jogged [Fig. 1], the staple unit staples the

stacked copies as follows: The grip arms move inside the front sid e pla te and

catches the paper. The bin rear plate is turned so as to be flat wit h th e sorter

bin. The grip assembly brings the copies down underneath the stapler [Fig.

2]. The staple unit changes the position (the position varies depending on the

copy size and staple mode) and the stap ler sta ples the copies [Fig. 3].

10

23 April 1993 BASIC OPERATION

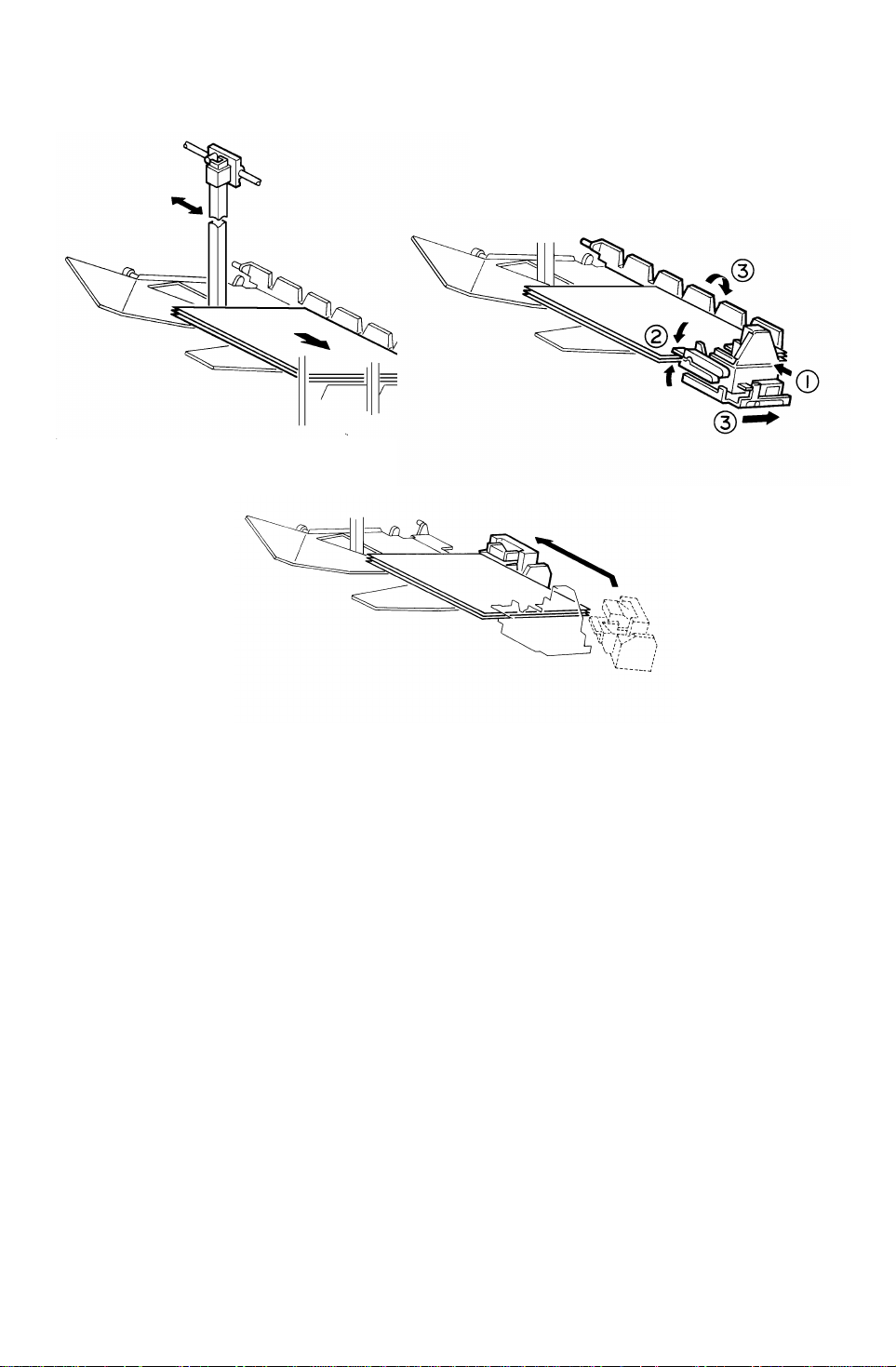

[Fig. 4]

[Fig. 5]

The grip assembly brings the stap led co pie s back to the bin and the bin rear

plate returns to the original position.

The grip assembly releases th e copies and return to outside the front side

plate so as not to disturb th e bin movement [Fig. 4].

The bin advances one step [Fig. 5].

When the final set of copie s is sta ple d, the staple unit is returned to the home

position.

There are two staple modes.

1) Automatic stapling:

In ADF mode, when the staple mode is select ed before pressin g the start

key, copies will be delivered to each bin and sta ple d auto mat ically.

2) Manual stapling:

In sort mode, after copies are sort ed in the bins, the copie s will be stap led

when the manual staple key is pressed then staple position is selected. In

stack mode, manual staplin g is imp ossib le.

11

[B]

TURN GATE SECTION 23 April 1993

5. TURN GATE SECTION

[I]

[D]

[G]

[A]

[C]

[H]

[F]

The turn gate [A] send s copies to the proof tray or the sort er bins depending

on the mode. In the proof mode, the turn gate solenoid [B] turns on and the

main motor [C] turns clockwise whe n th e sta rt key is p resse d.

The turn gate [A], directs copies upward through the proof transport section

to the proof tray. In this mode, the main motor drive is transmitt ed by both the

proof drive belt [D] and sorter drive belt [E] . Howe ver the one way clutch in

each sorter transport rolle r drive gear [F] does not transmit th e drive to the

sorter transport rollers.

In the sort, stack and stap le modes, the turn gate soleno id sta ys o ff to dire ct

copies downward to the sort er transport section. When the start key is

pressed, the main motor [C] turns counte rclockwise .

In this mode, the main motor drive is not transmitted to the pro of drive belt [D]

because of the one way clut ch in the pulley [G].

[C]

[E]

The entrance [H] and the proof exit [I ] sensors monitor the paper jam.

12

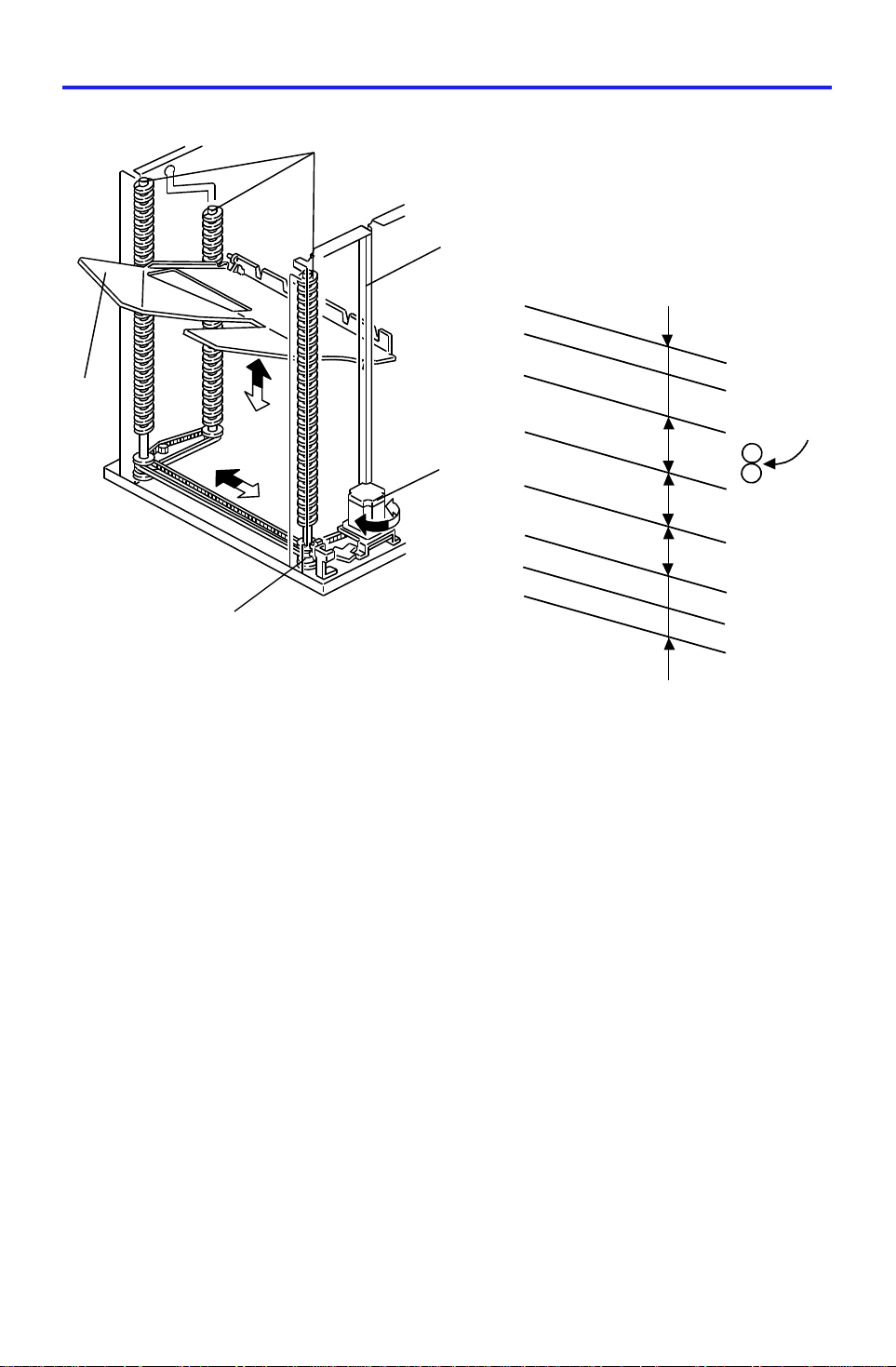

23 April 1993 BIN DRIVE MECHANISM

6. BIN DRIVE MECHANISM

[B]

[E]

[D]

[G]

[A]

[C]

The bin drive mechanism moves th e bin s up an d do wn to receive copies. The

main components in this mecha nism are the bin drive moto r [A] , the three

helical wheels [B], the wheel sensor [C], and the bin s [D] themselves. There

are four pins on each bin. Three of them fit in th e slot on the helical whe els.

Another pin fits into th e slot [E] of the front side fra me.

The pins slide up and down in these slots.

Three timing belts transmit the drive from the bin drive mot or to the three

helical wheels. When it rotates clockwise, the bin s lift (black arrow) and when

it rotates counterclockwise, the bins lower (whit e arro w). The re is a wheel

sensor actuator on the fron t he lical whe el, the actu at or has a slo t which

detects when the helical wheel has rotated 360 degrees.

[F]

15

30

45

40

40

15

15

When the bins are advanced, the helical wheels rotate once (360 degrees )

for each step.

As the pitch of the spiral on the helical wheel is greater when bins are at the

staple and paper exit area than when bins are elsewhere, the amount of bin

shift is greater when bin s are at the staple and paper exit are a. This le ave s

enough space to staple [F] and stack paper [G] and reduces the total

machine height.

13

[E]

BIN HOME POSITION 23 April 1993

7. BIN HOME POSITION

[A]

[B]

[D]

[C]

The bin home position sensor [A] and the wheel sensor [B] ensure that the

sorter exit roller is between the upper gu ide plat e [C] and the 1st bin [D] whe n

all the bins are in the home position.

When the main switch is turned on, the bin lift mot or [E] lowers the bins (turns

counterclockwise) until the bottom bin actua tes the bin home positio n sen sor.

Then, the bin lift motor raises the bins (turns clockwise) until the wheel

sensor activates. Thu s, the bins are in the home positio n.

14

300 msec.

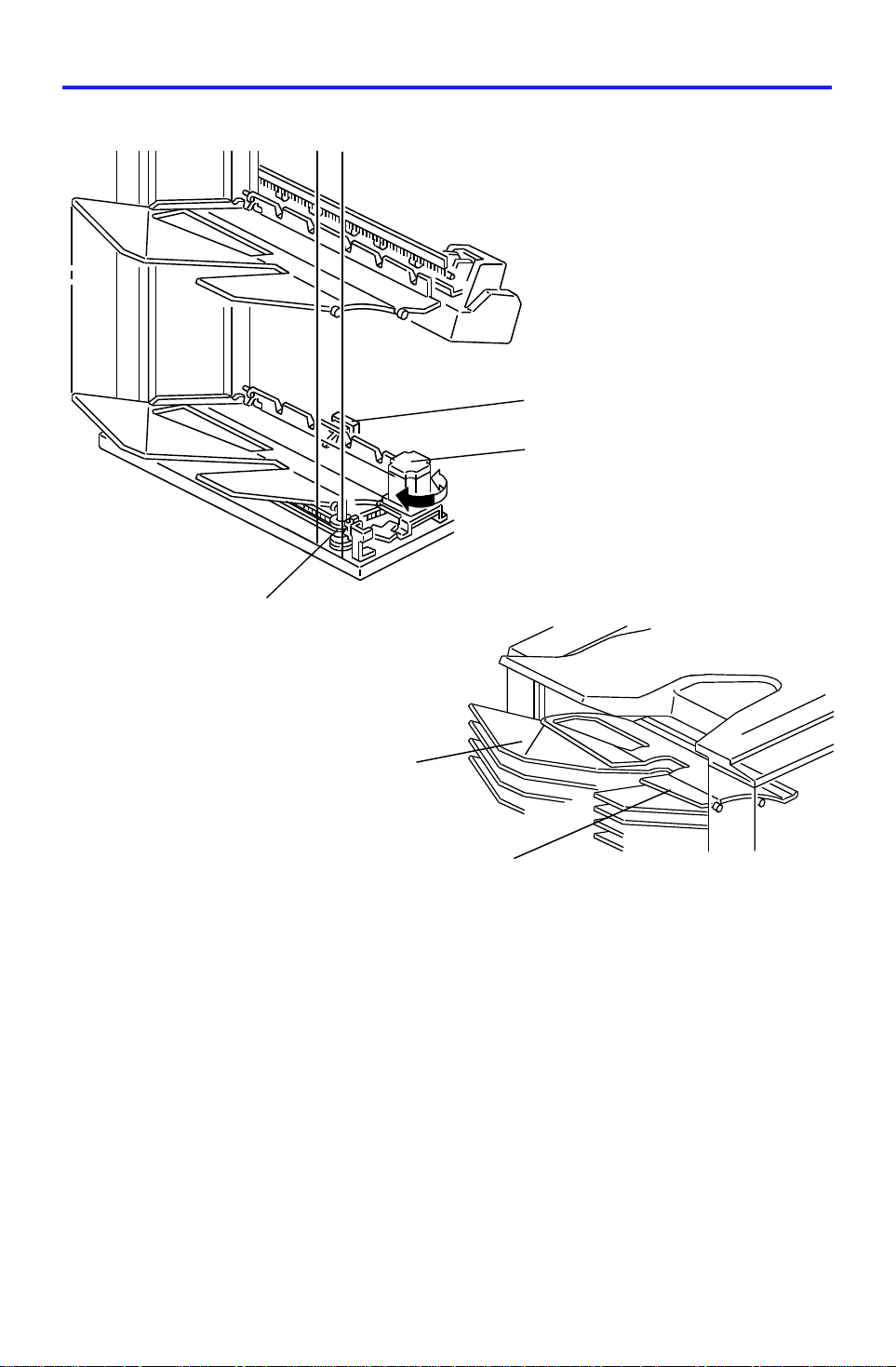

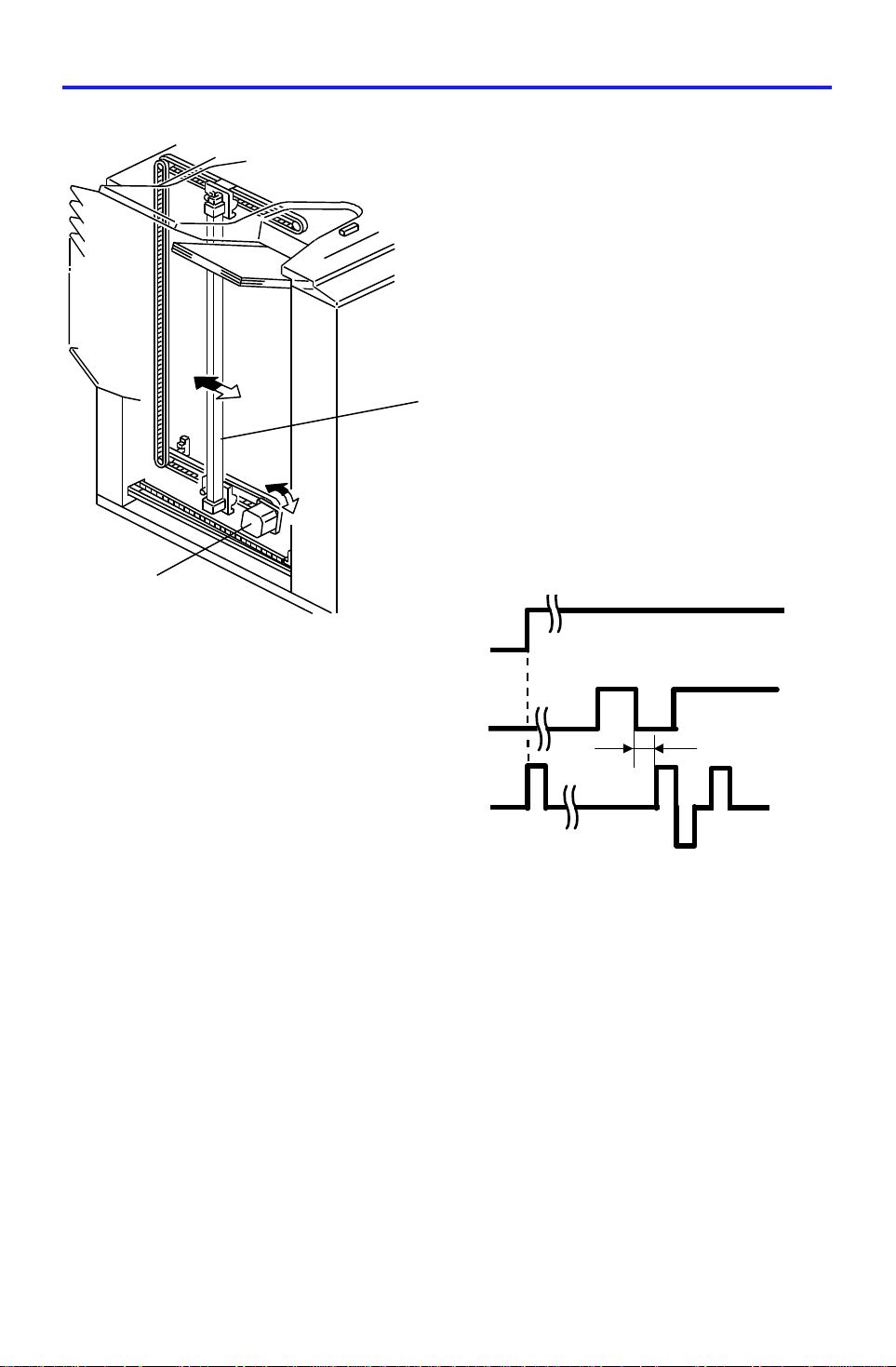

23 April 1993 JOGGER SECTION

8. JOGGER SECTION

[B]

[A]

Copier Main

Motor

Jam Sensor

Jogger Motor

When the Start key is pressed in the sort , sta ple and stack modes, the copier

sends the paper size informatio n to the sorte r stap ler. In acco rdance with this

data, the jogger motor [A] drives the jogger plate [B] from the jogge r home

position to where the widt h is 10 mm wider th an the selected paper.

300 ms after the trailing ed ge of th e copy passes underneath the jam sensor,

the jogger motor rotates forward and in reverse. This makes the jogger plate

push all the copies against the front side plate to square th e she ets. When

the jogger plate pushes the pape r, th e pla te shift s to a positio n 5 mm wider

than the paper size when the bins lift. It shifts to a position 1 mm narrower

than the paper size when the bins lowers.

ON

The jogger plate ret urn s to 10 mm away f rom th e selected paper size for the

next copy.

When the bin sensor detects that all copies are removed from the bins after

jogging is finished, the jogg er pla te returns to its home posit ion.

15

Loading...

Loading...