Page 1

Technical Bulletin No. RTB-001

SUBJECT: Sorter Stapler Installation Procedure DATE: 15 May, ’92

PAGE: 1 of 1

PREPARED BY: M. Furusawa

CHECKED BY: T. Morita

CLASSIFICATION:

Action Required

Troubleshooting

Retrofit Information

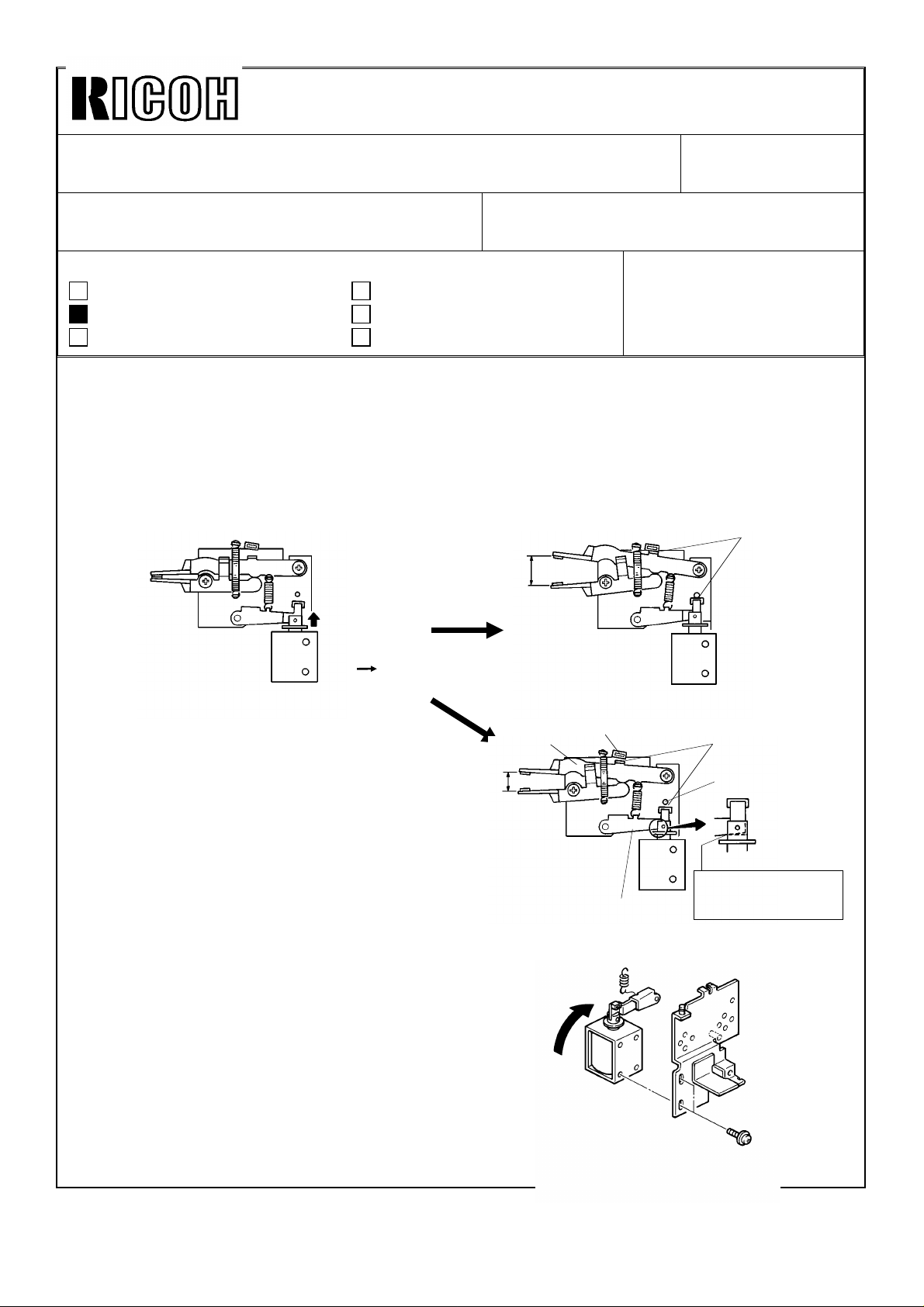

When installing the sorter stapler, the procedure described below should be added to the

original installation procedure:

Service manual:

Sorter Stapler - 13. Installation Procedure (page 26)

Steps added between 5. and 6.

[Y]

[X]

Revision of service manual

Information only

Other

FROM: Copier Technical Support Section

MODEL: A7 Series

• Remove the cover plate [X] from the sorter adapter (2 screws).

• Install the upper exit guide mylar [Y] on the sorter adapter and fix it

with the cover plate as shown.

NOTE: This mylar is required to prevent some brands of paper, which curl too much after

fusing, from jamming at the sorter stapler entrance area.

The upper exit guide mylar (P/N A3666060) has been enclosed as an accessory in

the machine box from the first mass production.

We will issue an M/B for the upper exit guide mylar later.

Page 2

Technica l Bulletin No . RTB-01 0

[B]

SUBJECT: Sorter Stapler ( A366) Gripper Operation DATE: Feb . 15, ’ 9 3

PAGE: 1 o f 2

PREPARED BY: M . Fu ru saw a

FROM: Copier Technical Support Section

CHECKED BY: T. Ito

CLASSIFICATION:

Action Required

Troubleshooting

Retrofit Information

Revision of service manual

Information only

Other

MODEL:

A7 Series

(A069/A073/A074)

[PHENOMENON]

During stapling operation, the gripper pushes the bottom cop y out of position.

[CAUSE]

The grippers are not opening wide enough.

24 - 25 mm

SOL.

ON OFF

[OK]

No Gap

When t he g rip s o leno id tu rn s o ff, th e

grippers should open wide enough.

If th e so leno id p lu ng er is c aug h t b y t he

solenoid arm [ A], the arm and the upper

gripper [B] cannot reach the stoppers

[C,D]. Refer to the figure [NG].

[ACTION]

1. Loosen the screws securing the grip

so len o id .

Then tighten the screws while turning the

grip solenoid, as shown by the arrow at the

right.

NOTE: Make sure that the solenoid stroke is

maintained for 2.5 ± 0.5 mm.

20 mm

[NG]

[D]

[A]

Gap

[C]

Plunger is caught at

this point and stops.

Page 3

Technica l Bulletin No . RTB-01 0

SUBJECT: Sorter Stapler ( A366) Gripper Operation DATE: Feb . 15, ’ 9 3

PAGE: 2 o f 2

2. If there still be a gap "A" after performing step 1,

lengthen the solenoid arm spring [E] as shown.

NOTE: Be careful not to lengthen the spring too much,

or the spring will not hook the gripper properly.

Leng then by "A" as sho wn.

With the above two actions the width

of the gripper opening can be

adjusted by about 5 mm.

x

A= Gap

[E]

x+ A

Loading...

Loading...