Page 1

500-SHEET FINISHER

(Machine Code: G302/B442)

Page 2

10 August, 2001 EXTERIOR

1. REPLACEMENT AND ADJUSTMENT

1.1 EXTERIOR

NOTE: This manual uses several symbols. The meanings for these symbols are

as follows:

☛: See or refer to !: screw ": connector #: clip

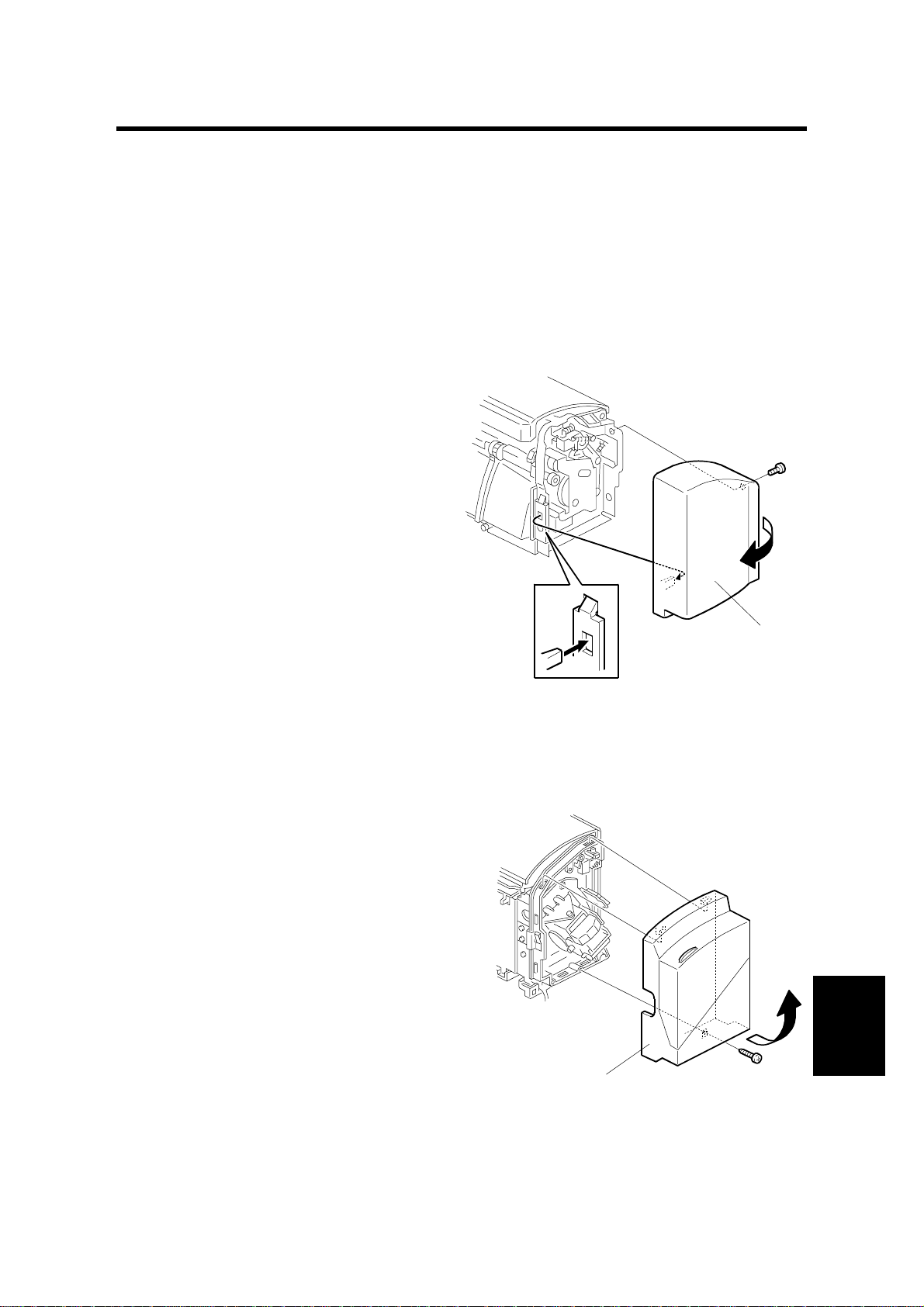

Front cover

[A]: : Front cover (!1)

Rear cover

[A]: Rear cover (!1)

[A]

B442R101.WMF

Options

[A]

B442R102.WMF

B442-1

Page 3

EXTERIOR 10 August, 2001

Top cover

[A]: Top cover (2 links)

[A]

Front lower guide

B442R105.WMF

[A]

B442R116.WMF

[B]

B442R104.WMF

[A]: Output tray (#2)

[B]: Front lower guide (!2)

NOTE: 1) When re-attaching th e lower guide, be sure that it is not in contact with

the exit lower guide and that the exit lower guide moves smoothly.

2) Make sure that the blue and black cables are in the correct position, as

engraved on the inside of the front lower guide.

B442-2

Page 4

10 August, 2001 EXTERIOR

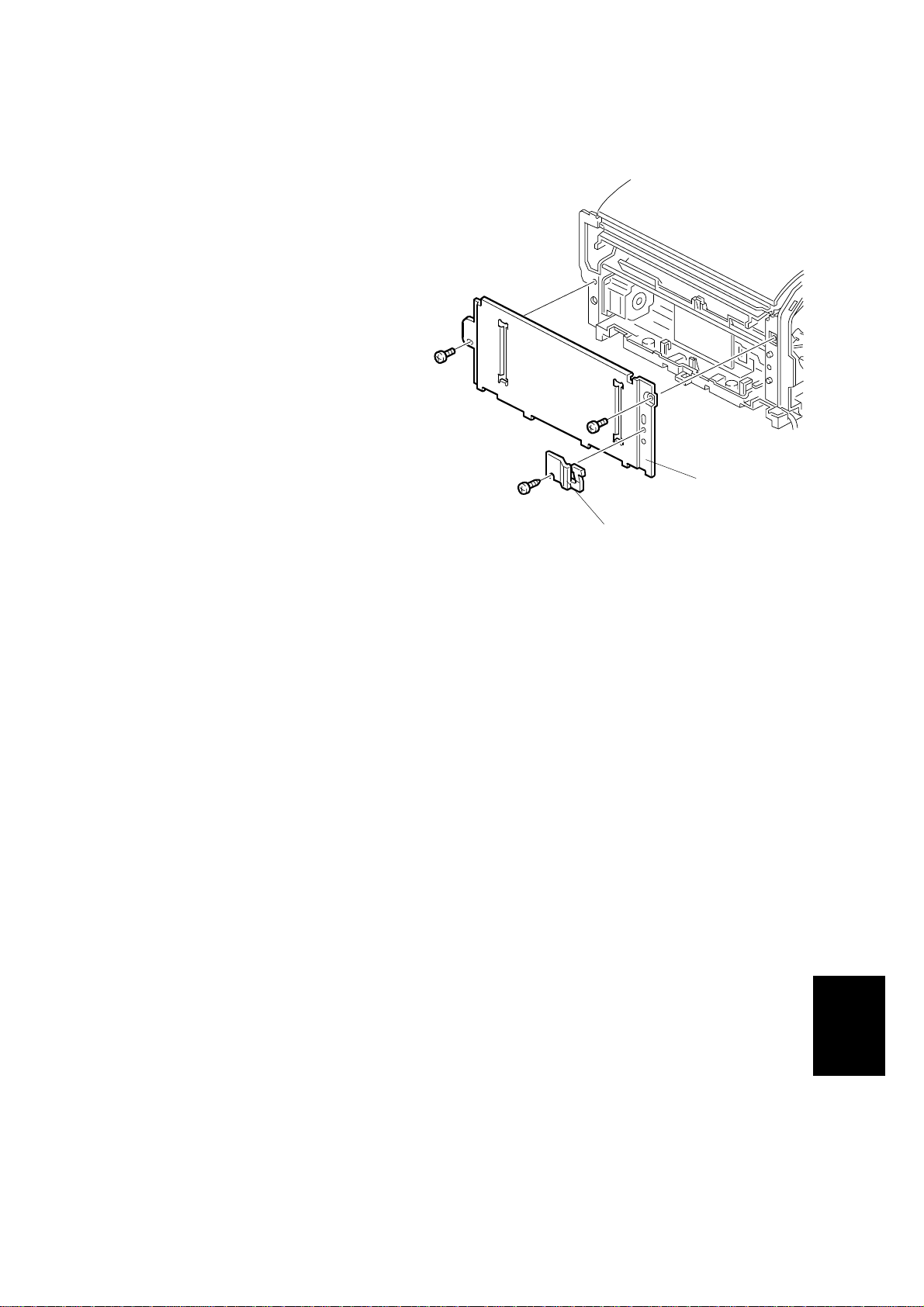

Right cover

[A]: Grounding plate (!1)

[B]: Right cover (!2)

[B]

[A]

B442R103.WMF

B442-3

Options

Page 5

ENTRANCE UPPER GUIDE / PAPER EXIT UNIT 10 August, 2001

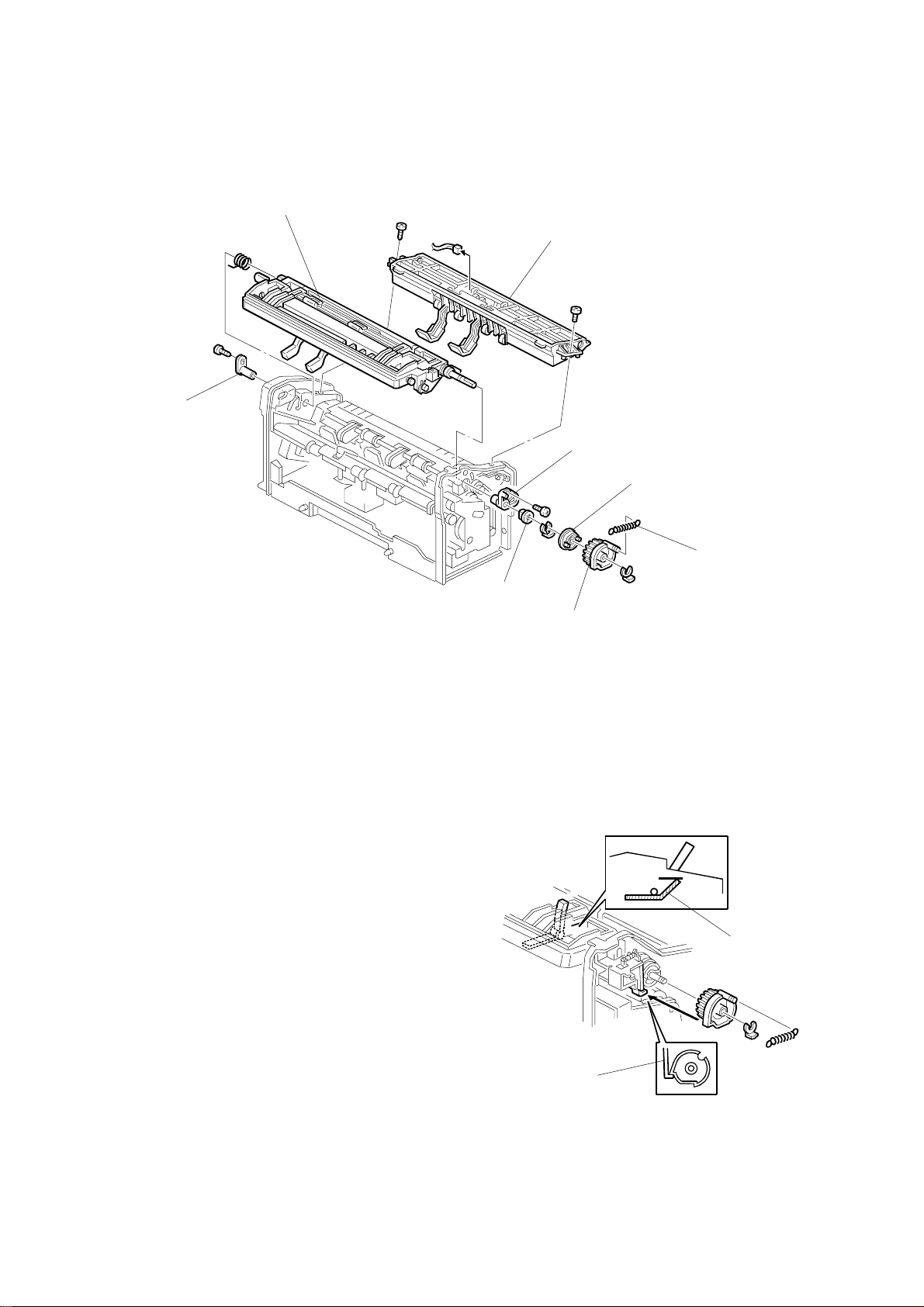

1.2 ENTRANCE UPPER GUIDE / PAPER EXIT UNIT

[H]

[A]

[G]

[F]

[D]

[E]

[C]

B442R106.WMF

• Front, rear, and top covers and front lower guide (☛ 1.1 Exterior)

[A]: Entrance upper guide (!2, "1)

[B]: Paddle gear spring

[C]: Paddle gear (#1)

[D]: Paddle gear holder

[E]: Bushing (#1)

[F]: Paper exit unit holder (!1)

[G]: Rear paper exit unit holder (!1)

[H]: Exit unit

NOTE: Keep the paper exit unit stays in

the upper position. Rotate the

paddle roller into the position

shown in the illustration [a]. Then,

insert the paddle gear, making

sure that the pawl on the gear’s

[b]

outer frame is resting on the clutch

link [b].

[B]

[a]

B442R107.WMF

B442-4

Page 6

10 August, 2001 ENTRANCE LOWER GUIDE

1.3 ENTRANCE LOWER GUIDE

• Entrance upper guide (☛ 1.2 Entrance

upper guide / Exit unit)

• Exit unit (☛1.2 Entrance upper guide /

Exit unit)

[A]: Release tension bracket (!1)

[B]: Reverse roller gear bracket (!2)

[C]: Timing belt

[D]: Entrance lower guide

NOTE: When re-assembling the tension

bracket, rotate the main motor

[B]

counter clockwise to tighten the

timing belt.

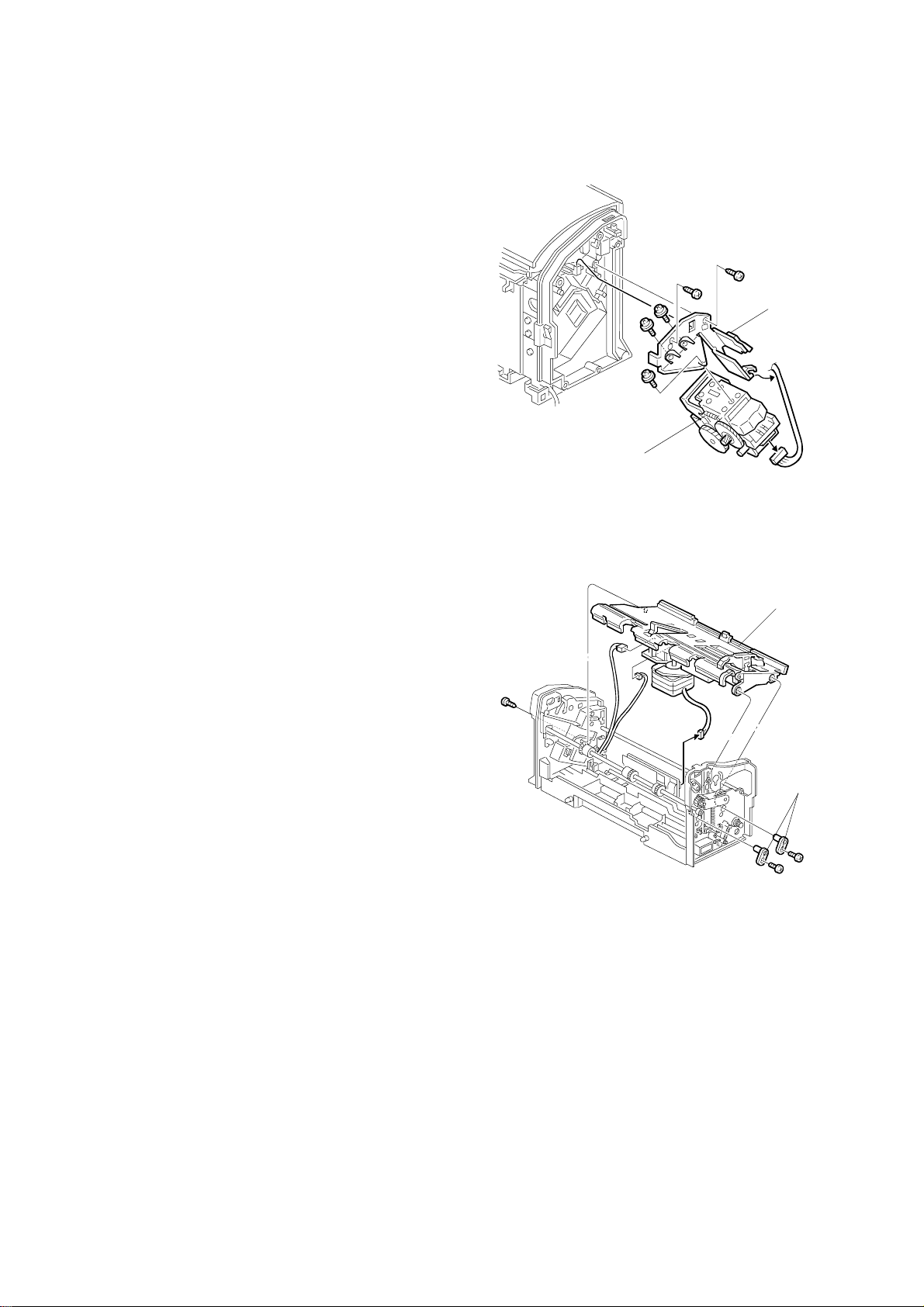

1.4 PAPER EXIT UNIT GEAR / PADDLE ROLLER

SOLENOID

[D]

[A]

[C]

B442R108.WMF

• Front cover (☛ 1.1 Exterior)

[A]: Gear bracket (!3)

[B]: Paper exit unit gear

[C]: Paddle roller solenoid (!1)

B442R109.WMF

[C]

[B]

[A]

Options

B442-5

Page 7

STAPLER UNIT 10 August, 2001

1.5 STAPLER UNIT

• Rear cover (☛1.1 Exterior)

[A]: Stapler unit bracket (!2, "1)

[B]: Stapler unit (!3)

[A]

[B]

B442R115.WMF

1.6 JOGGER TRAY UNIT

• Entrance upper guide and paper exit unit

(☛1.2 Entrance upper guide / paper exit

unit)

• Entrance lower guide (☛1.2 Entrance

lower guide)

• Paper exit unit gear and Paddle roller

solenoid (☛1.4 Paper exit unit gear /

Paddle roller solenoid)

• Stapler unit (☛ 1.5 Stapler unit)

[A]: Jogger tray unit holders (!2)

[B]: Jogger tray unit (!1, "3)

NOTE: Be sure to connect the black cable

to the paper exit sensor and the

blue one to the jogger home

position sensor.

[B]

[A]

B442R110.WMF

B442-6

Page 8

10 August, 2001 PAPER EXIT SENSOR FEELER

1.7 PAPER EXIT SENSOR FEELER

• Jogger tray unit (☛1.6 Jogger tray unit)

• Jogger motor (☛1.9 Jogger motor)

[A]: Paper exit sensor feeler

[A]

B442R121.WMF

1.8 MAIN MOTOR

• Right cover (☛1.1 Exterior)

[A]: Release tension bracket (!1)

[B]: Main motor (!2, "1)

[A]

[B]

B442R113.WMF

B442-7

Options

Page 9

JOGGER MOTOR 10 August, 2001

1.9 JOGGER MOTOR

• Front lower guide (☛1.1 Exterior)

[A]: Jogger motor (!2, "3)

[A]

B442R114.WMF

1.10 CONTROL BOARD

• Front lower guide (☛1.1 Exterior)

[A]: Control board (!1, "12)

B442R112.WMF

[A]

B442-8

Page 10

10 August, 2001 OUTPUT TRAY UNIT

1.11 OUTPUT TRAY UNIT

[D]

[A]

[E]

[B]

[F]

[A]: Output tray cover (!2)

[B]: Tray holder (!1)

[C]

B442R117.WMF

[G]

B442R118.WMF

B442R119.WMF

[C]: Links

[D]: Connector cover

[E]: Output tray motor link unit (!1)

[F]: Rear cover (!1)

[G]: Output tray motor ("1)

NOTE: When re-attaching the moto r link

unit, the arrows on each of the

gears need to face each other as

shown in the illustration.

B442-9

Options

B442R120.WMF

Page 11

OVERALL MACHINE INFORMATION 10 August, 2001

2. DETAILED DESCRIPTIONS

2.1 OVERALL MACHINE INFORMATION

2.1.1 COMPONENT LAYOUT

Mechanical component layout

89

10

1

2

1. Output tray

2. Stack height detection lever

B442D101.WMF

3

6. Lower entrance guide

7. Upper entrance guide

7

6

5

4

3. Paper exit roller

4. Jogger tray

5. Reverse roller

8. Paper exit unit

9. Paddle roller

10. Lower exit guide

B442-10

Page 12

10 August, 2001 OVERALL MACHINE INFORMATION

Drive layout

7

2

8

3

4

1. Main motor

2. Exit roller timing belt

3. Main motor timing belt

4. Output tray motor

1

B442D103.WMF

65

5. Output tray link gears

6. Paper exit unit drive gear

7. Reverse roller

8. Paper exit roller

B442-11

Options

Page 13

OVERALL MACHINE INFORMATION 10 August, 2001

2.1.2 ELECTRICAL COMPONENT DESCRIPTIONS

14

13

16

15

17

18

12

1

11

10

2

3

4

5

6

7

B442D102.WMF

9

8

See the next page for the component description table.

B442-12

Page 14

10 August, 2001 OVERALL MACHINE INFORMATION

Symbols Name Function Index No.

Motors

M1 Main Drives all the rollers 6

M2 Jogger Drives the jogger fence 9

M3 Output Tray Drives the tray up and down 12

Stapler Drives the stapler 16

Sensors

S1 Entrance Detects paper at the entrance 3

S2 Exit Detects paper at the exit 15

S3 Stack height Detects the top of the paper stack 13

S4 Lever Detects the position of stack height lever 14

S5

Jogger home

position

Detects the position of the jogg er fe nce

2

S6 Top cover Detects if the top cover is ope n 1

S7

S8

Tray upper limit Detects when the tray is lifted to the upper

limit

Stack near-limit Detects w hen the tray is at its lowest limit

(almost full)

11

10

Solenoids

SOL1 Exit unit gear Moves the paper exit unit up and down 7

SOL2 Paddle roller Switches paddle roller rotatio n on and off. 5

SOL3

Stack height

lever

Moves the stack height lever int o cont act

with the top of the stack.

PCBs

PCB1 Main control Controls all finisher functions 4

Switches

SW1 Paper exit unit Switches DC for the stapler unit on and off. 18

SW2 Staple unit cover Cuts DC when staple unit cover is open.

8

17

B442-13

Options

Page 15

DETAILED SECTION DESCRIPTIONS 10 August, 2001

2.2 DETAILED SECTION DESCRIPTIONS

2.2.1 OUTPUT TRAY MECHANISM

Stack height detection

[D]

[C]

[B]

[A]

B442D104.WMF

Stack height detection lever [A]: Driven by stack height lever solenoid [B].

Two sensors detect the height of the stack in the output tray: the stack height [C]

and lever [D] sensors.

Stack height

sensor

Off Off

Off On Target position

On On

On Off The stac k height detection lever is at home position.

Off: Actuator not in sensor

Lever sensor Status

The stack height is below t he target. The output tray is

lifted to the target positi on.

The stack height is more the target . The output tray is

lowered to the target position.

At the start of a print job, the solenoid turns off. The stack height detection lever

comes down, to detect the current stack level.

When a sheet of paper is being fed out, the solenoid turns on and the lever goes

back up to home position (inside the unit).

After paper has been fed out, the solenoid turns on again, and the lever detects the

level of the stack.

B442-14

Page 16

10 August, 2001 DETAILED SECTION DESCRIPTIONS

Output tray up/down mechanism

[D]

[E]

[B]

[A]

[C]

B442D105.WMF

Overview

The output tray motor [A] lifts/lowers the tray if the stack height is not at the target

position.

Gears [B] and [C] keep the angle of the tray constant at any tray position.

Output Tray Downward Movement

The top of the paper stack is checked after every page (or set of pages) has been

fed out. If the top of the stack is higher than the target level, the output tray motor

moves the tray down.

When the stack near-limit sensor [D] detects the actuator on gear [C], a stack nearlimit signal is transferred to the main frame. The tray cannot move any lower. The

next time the top of the stack height is above the target level, printing stops.

Output Tray Upward Movement

If paper is removed from the stack, the top of the stack will be lower than the target

level, and the output tray motor moves the tray up.

When the tray upper limit sensor [E] detects the actuator on gear [B], the tra y

cannot be moved up any more, so the motor stops.

B442-15

Options

Page 17

DETAILED SECTION DESCRIPTIONS 10 August, 2001

2.2.2 PAPER FEED

Overview

The following paper feed out modes can be selected at the printer driver.

Mode Description

Straight feed out mode Paper is fed directly to the output tray without shifting or sta pl ing.

Shift sorting mode Alternate sets are shifted before being fed to the output tray.

Stapling mode All sets are shifted and stapled, then fed to the output t r ay.

Straight feed out mode

Before the job, the exit unit [A] is up, and the exit unit gear solenoid [B] is on,

pulling lever [C] away from the exit unit gear [D].

At the start of the job, the stack height detection lever detects the top of the stack.

The tray moves up or down if the top of the stack is not at the correct level.

[A]

[F]

[J]

[E]

[H]

[I]

[G]

[D]

[B]

[C]

[G]

[C]

B442D106.WMF

B442D109.WMF

When the paper exit sensor in the main frame turns on, the finisher ma in m otor

starts. It drives the exit unit gear [D] through idle gear [E]. The gear pulls paper exit

unit [A] down, using the paper exit link [F]. The link also moves the paper exit roller

[H] up through the exit roller drive gear [G].

When the motor starts, the solenoid switch es off and a spring pushes lever [C] into

contact with the exit unit gear [D].

When a part of the exit unit gear without threads [I] faces the idle gear, the gear

stops turning (see the left-hand diagram). The lever [C] catches a peg on the exit

unit gear, to make sure that it stops at the correct position. The paper exit rollers

[H] now contact each other and the main motor feeds out the paper.

When the last page has been fed out, the solenoid turns on to pull the lever away

from the gear. The gear starts turning, to lift the exit unit to the standby position.

When the other part of the exit unit gear without threads [J] faces the idle gear, the

exit unit gear stops. Then, the main motor stops and the solenoid turns off.

B442-16

Page 18

10 August, 2001 DETAILED SECTION DESCRIPTIONS

Shift sorting mode

[D]

[C]

[B]

B442D111.WMF

[A]

[E]

B442D113.WMF

[F]

At the start of the job, and for odd numbered sets of copies, the mechanism is the

same as the straight feed out mode. However, even numbered sets are fed back to

the jogger tray, which shifts the sets to one side before feeding them out.

This section describes what happens for even-numbered sets (sets 2, 4, 6 etc) of

the job.

A short time after the entrance sensor [A] detects the first page of the set, the

paper exit unit solenoid turns on to restart the rotation of the paper exit unit gear,

raising the paper exit unit to the standby position. It stays there until after the last

page of the set.

The paper cannot feed out, so it drops into the jogger tray [B]. The paddle roller

solenoid [C] turns on and the paddle roller [D] feeds the paper to the reverse roller

[E]. The reverse roller feeds the paper to the end fence [F] of the jogger tray.

Options

B442-17

Page 19

DETAILED SECTION DESCRIPTIONS 10 August, 2001

[B]

[A]

[C]

[D]

B442D107.WMF

After the paper reaches the end fence [A], the jogger fence [B] shifts the paper

across. The jogger motor [C] drives the jogger fence. The home position sensor [D]

detects when the jogger fence has returned to home position.

When the ne xt set begins, the paper exit unit moves down, and the machine

operates the same way as straight feed out mode. At this time, the entire set in the

jogger tray is fed out at the same time as the first page of the next set. However,

the set coming from the jogger tray has been shifted to one side.

If the last set is an even-numbered set, the paper exit unit must be pulled down to

feed the final set out of the jogger tray. Then the exit unit moves back up to the

standby position.

The capacity of the jogger tray is 30 sheets. If the set contains more than 30

sheets, the machine feeds out the first 30 from the jogger tray, then continues with

the rest of the set, using the jogger tray.

B442-18

Page 20

10 August, 2001 DETAILED SECTION DESCRIPTIONS

Stapling mode

[B]

[D]

[F]

[E]

[C]

B442D112.WMF

[B]

B442D114.WMF

[A]

[G]

B442D106.WMF

The stapler is attached to the jogger tray, so all sets go to the jogger tray.

After all pages of a set have entered the jogger tray and been shifted across, the

paper exit link [A] pulls the paper exit unit [B] down until knob [C] on the exit unit

pushes the link lever [D] for the exit unit switch [E]. This turns on the exit unit

switch. When this switch is on, dc is supplied to the stapler unit [F] and the main

motor is turned off.

The exit unit switch is activated when the exit unit is pulled part-way down. After

stapling the set of prints, the paper exit unit is pulled down again until the unit

comes in contact with the paper exit roller [G], and the stapled set is fed out.

B442-19

Options

Page 21

DETAILED SECTION DESCRIPTIONS 10 August, 2001

2.2.3 JAM CONDITIONS

Sensors Conditions

Remaining paper detection Entrance

Exit

Non-feed at the entrance

Entrance

Jamming at the entrance

Entrance

Non-feed inside the unit

(Straight feed out mode only) Exit

Jamming at the exit

Jogger tray

Exit

Exit

Either the entrance or exit sensor detects

paper just after the unit is in it ialized.

The entrance sensor is not activ at ed within a

certain period after the paper exit sensor

detects paper.

The entrance sensor is not de-activated after

paper is fed 1.3 times the length of the

paper.

The exit sensor is not activ at ed within a

certain period after the entrance sensor

detects paper.

The exit sensor is not de-activated after

paper is fed for a certain period.

The exit sensor is de-activated during paper

shifting or stapling.

2.2.4 ERROR DETECTION

Conditions

Jogger motor error Jogger home position sensor does n ot shut of f a fter jog ger

motor starts.

Jogger motor home position

detection error

Stapler error

Output tray upper limit error Tray upper limit sensor i s act iv at ed.

Output tray motor error The output tray is away from the target position for more

Stack height detection error The stack height detection lever does not return to its home

Jogger home position sensor does n ot t urn on after paper

shifting.

Stapler home position sensor (inside stapler unit) does not

turn on after stapling.

than 10 seconds.

position before going to detect the stack height.

NOTE: The above errors are indicated as “Finisher jam” at the first occurrence.

If the same error happens again in the next job, “finisher error” is indicated.

B442-20

Page 22

10 August, 2001 SPECIFICATIONS

3. OVERALL MACHINE INFORMATION

3.1 SPECIFICATIONS

Paper Size: A3, B4, A4, B5 sideways (Metric)

DLT, LG, LT (Inch)

Paper Weight 52 ~ 128 g/m2, 14 ~ 34 lb.

Staple Capacity: 20 sheets (A3, B4, DLT, LG : 80 g/m2, 20 lb)

30 sheets (A4, B5 sideways, LT : 80 g/m2, 20 lb)

Stack Capacity (Maximum): 500 sheets (A4/LT or smaller: 80 g/m2, 20 lb.)

250 sheets (A3, B4, DLT and LG: 80 g/m2, 20 lb.)

Stapling Positions: 1

Staple Replenishment: Cartridge (3,000 staples/cartridge)

Power Source: 24 V DC, 5 V DC (from the copier/printer)

Power Consumption: 48 W

Weight: 8.3 kg (18.4 lbs.)

Dimensions (W x D x H): 350 x 490 x 230 mm

B442-21

Options

Loading...

Loading...