Page 1

3,000-SHEET FINISHER

(Machine Code: B302)

Page 2

22 October 1999 SPECIFICATIONS

1. OVERALL MACHINE INFORMATION

1.1 SPECIFICATIONS

The punch unit is an option for this machine.

Paper Size: No punch mode

Shift Tray: A3 to A5/DLT to HLT

Upper Tray: A3 to A5, A6 lengthwise, B6 lengthwise/

DLT to HLT

Punch mode

2 holes: A3 to A5/DLT to HLT

3 holes: A3, B4, A4 sideways, B5 sideways

DLT, LT sideways

4 holes (Europe):A3 to A5

DLT to LT, HLT sideways

4 holes (North Europe): A3 to B5, A5 sideways

DLT to LT, HLT sideways

Staple Mode

A3 to B5/DLT to LT

Paper Weight: No punch mode

2

No staple mode: 52 g/m

~ 216 g/m2, 14 ~ 42 lb

Staple mode: 64 g/m2 ~ 80 g/m2, 17 ~ 21 lb

Punch mode

2 holes: 52 g/m2 ~ 163 g/m2, 14 ~ 42 lb

3 holes: 52 g/m2 ~ 163 g/m2, 14 ~ 42 lb

4 holes: 52 g/m2 ~ 128 g/m2, 14 ~ 34 lb

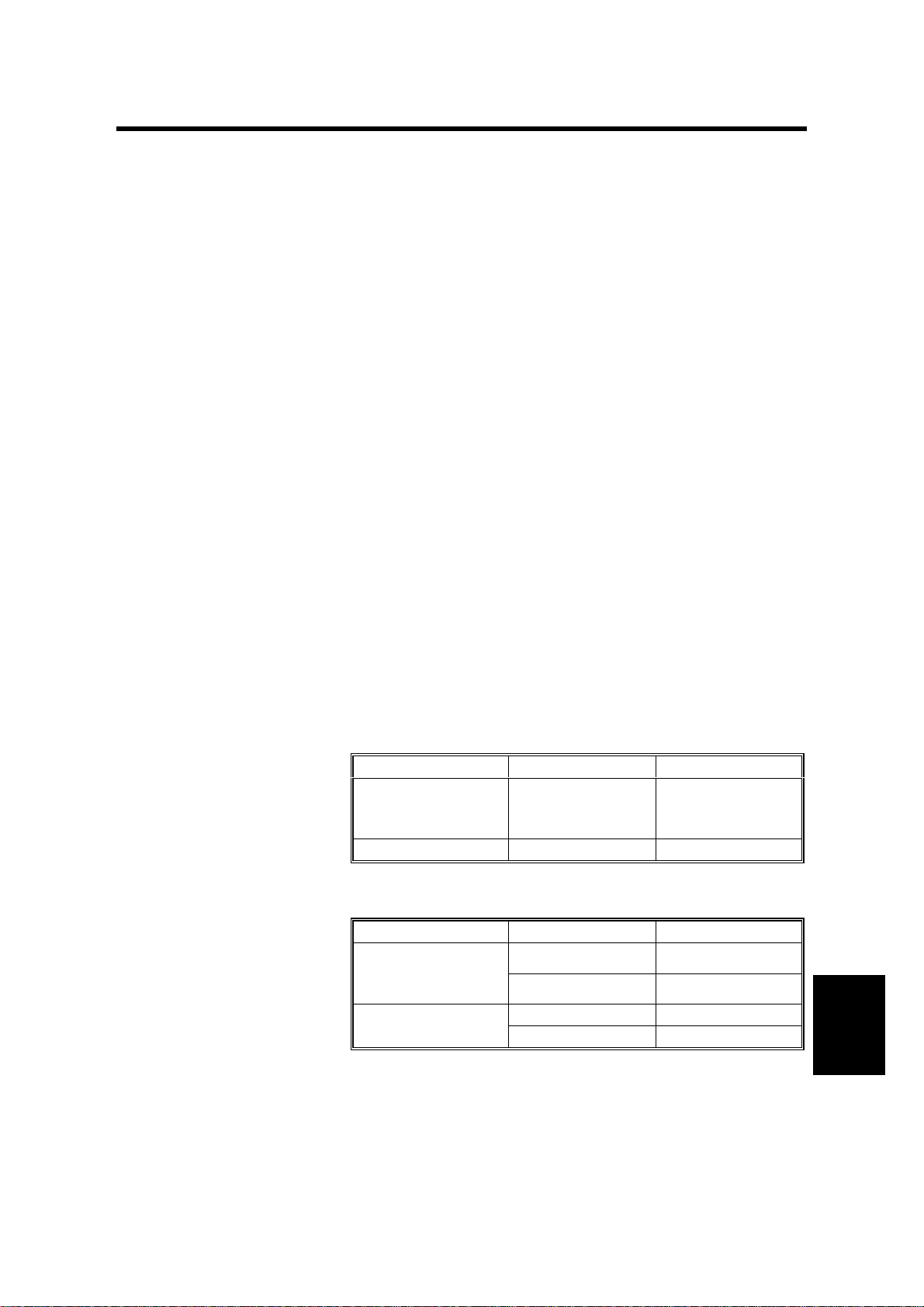

Paper Capacity: Shift tray/no staple mode (80 g/m2, 20 lb):

Punch mode No punch mode

B5 sideways

A4 sideways

LT sideways

Other sizes 1,500 sheets 1,500 sheets

2,500 sheets 3,000 sheets

Shift tray/staple mode/punch mode (80 g/m2, 20 lb):

Pages/set Sets

B5 sideways

A4 sideways

LT sideways

Other sizes

2 to 9 150

10 to 80 200 to 30

2 to 9 100

10 to 40 150 to 30

Options

B302-1

Page 3

SPECIFICATIONS 22 October 1999

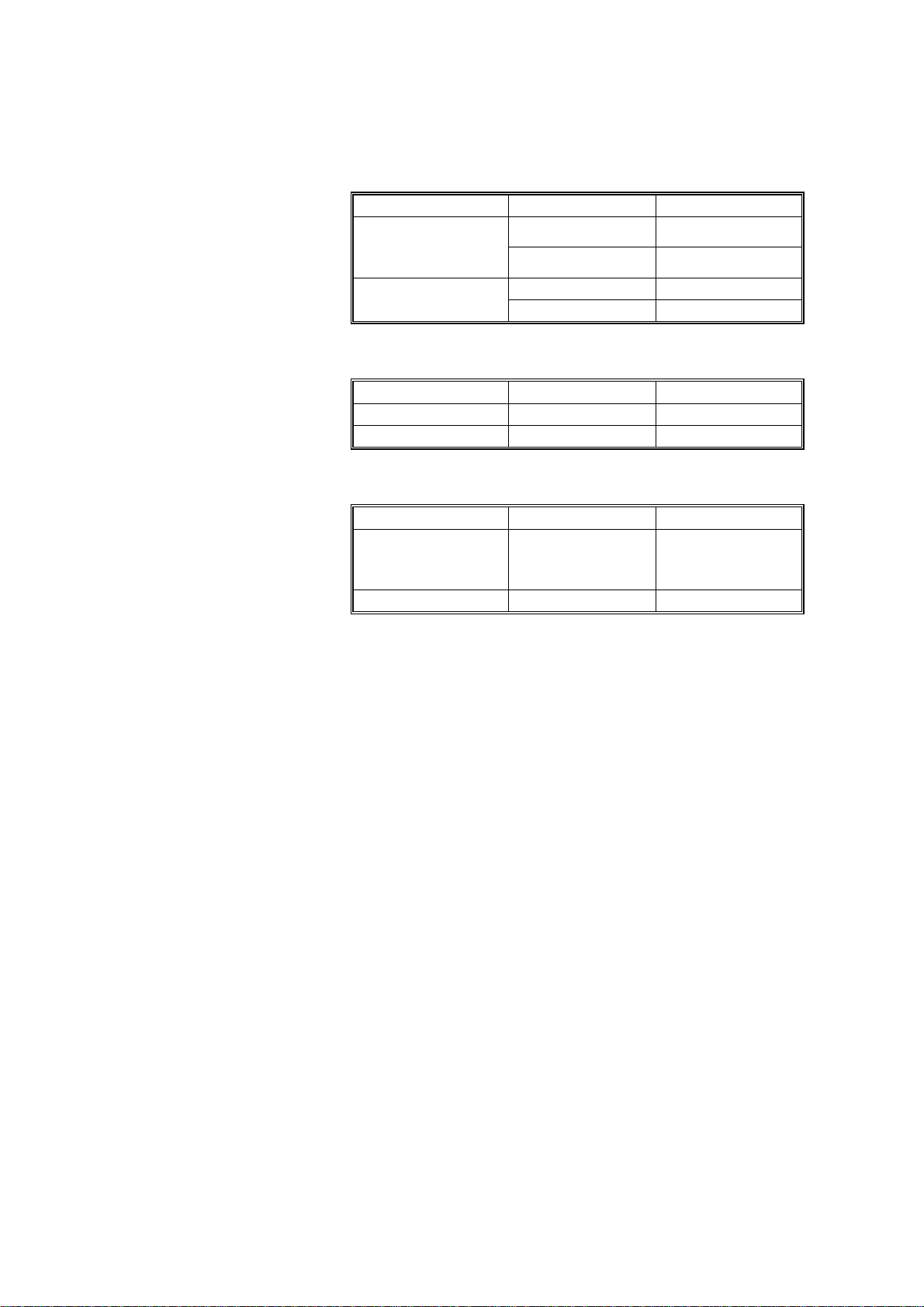

Shift tray/staple mode/no punch mode (80 g/m2, 20 lb):

Pages/set Sets

B5 sideways

A4 sideways

LT sideways

Other sizes

2 to 9 150

10 to 100 200 to 30

2 to 9 150

10 to 50 150 to 30

Upper tray (80 g/m2, 20 lb):

Punch mode No punch mode

A4/LT or smaller 400 sheets 500 sheets

Larger than A4/LT 200 sheets 250 sheets

Stapler Capacity (pages/set, 80 g/m2, 20 lb paper):

Punch mode No punch mode

B5 sideways

A4 sideways

LT sideways

Other sizes 40 sheets 50 sheets

80 sheets 100 sheets

Staple Position: 4 positions

1-staple: 3 positions (Front, Rear, Rear-Oblique)

2-staple: 1 position

Staple Replenishment: Cartridge (5,000 staples)

Power Source: 24 Vdc (from copier)

Power Consumption: 120 W

Weight: 60 kg

Size (W x D x H): 800 mm x 730 mm x 980 mm

B302-2

Page 4

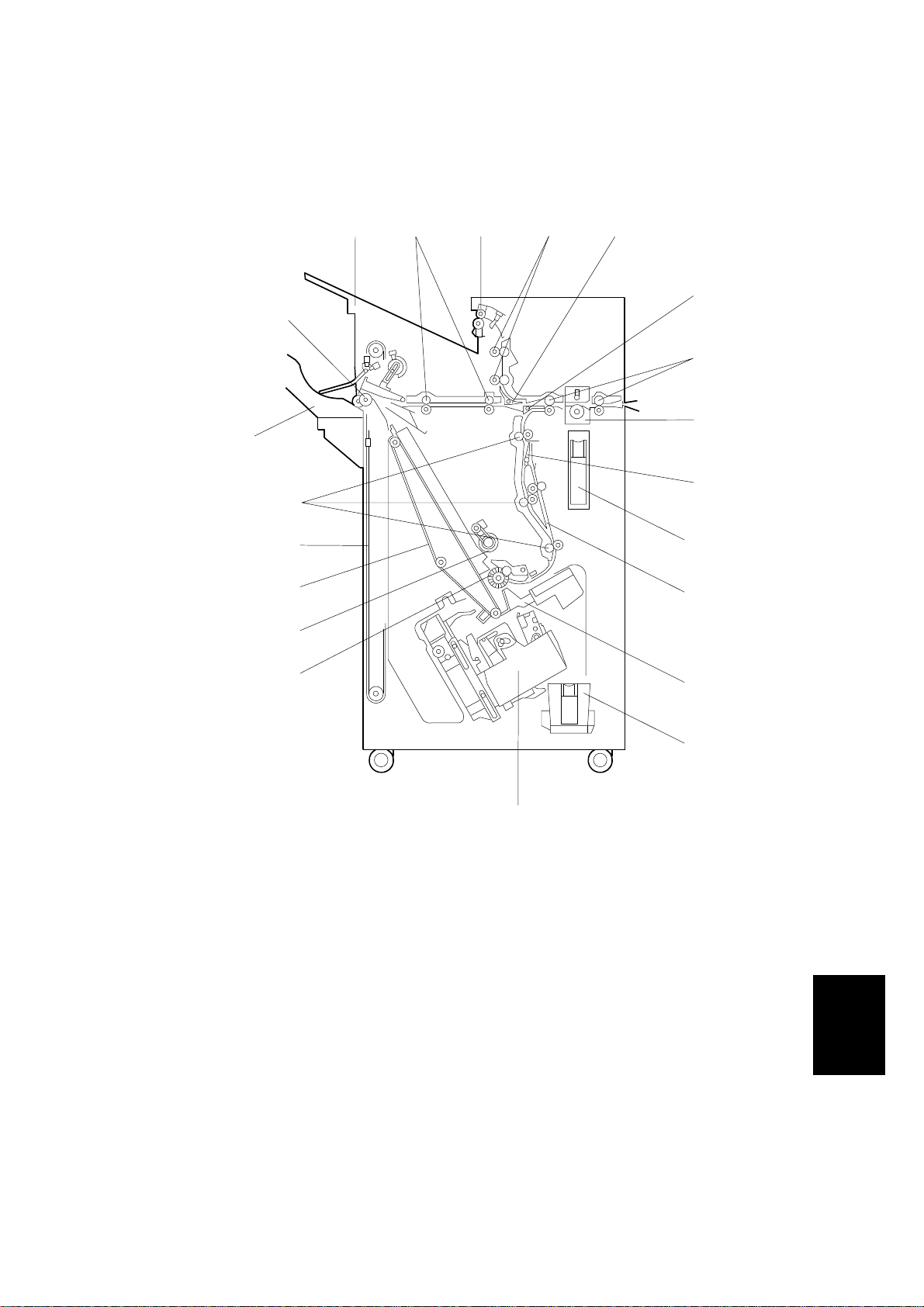

22 October 1999 MECHANICAL COMPONENT LAYOUT

1.2 MECHANICAL COMPONENT LAYOUT

20

21

19

18

17

16

15

1 2 5

3

4

6

7

8

9

10

11

12

1. Upper Tray

2. Middle Transport Rollers

3. Upper Tray Exit Roller

4. Upper Transport Rollers

5. Tray Junction Gate

6. Stapler Junction Gate

7. Entrance Rollers

8. Punch Unit

9. Pre-stack Junction Gate

10. Punch W aste Hopper

11. Pre-stack Tray

13

14

B302V500.WMF

12. Stack Plate

13. Staple W aste Hopper

14. Stapler

15. Alignment Brush Roller

16. Positioning Roller

17. Stack Feed-out Belt

18. Shift Tray Drive Belt

19. Lower Transport Rollers

20. Shift Tray

21. Shift Tray Exit Roller

Options

B302-3

Page 5

ELECTRICAL COMPONENT DESCRIPTION 22 October 1999

1.3 ELECTRICAL COMPONENT DESCRIPTION

Symbol Name Function

Motors

M1

M2

M3 Jogger Moves the jogger fence.

M4 Stack Plate Drives the stack plate.

M5 Stapler Moves the staple unit from side to side.

M6 Stapler Rotation Rotates the stapler 45 degrees.

M7 Staple Hammer Drives the staple hammer.

M8 Stack Feed-out Drives the stack feed-out belt.

M9 Exit Guide Opens and closes the upper exit guide.

M10 Shift Tray Exit Drives the exit roller for the shift tray.

M11 Shift Moves the shift tray from side to side.

M12 Shift Tray Lift Moves the shift tray up or down.

M13 Punch Drives the punch shaft and roller.

Upper Transport Drives the entrance rollers, the middle and upper

transport rollers, and upper tray exit roller.

Lower Transport

Drives the lower transport rollers, the alignment brush

roller, and the positioning roller.

Sensors

S1

S2

S3

S4 Jogger Fence HP Detects the home position of the jogger fence.

S5 Stapler Tray Paper Detects the copy paper in the stapler tray.

S6 Stack Plate HP Detects the home position of the stack plate.

S7

S8

S9 Staple Hammer HP Detects the home position of the staple hammer.

S10 Cartridge Set Detects the staple cartridge in the stapler.

S11 Staple End Detects the staples in the cartridge.

S12

S13

S14 Exit Guide Open Detects whether the guide plate is opened or not.

S15 Shift Tray Exit Checks for misfeeds at the shift tray.

S16

S17

S18 Upper Tray Exit Checks for misfeeds at the upper tray.

Entrance Detects the copy paper entering the finisher and

checks for misfeeds.

Pre-stack Tray

Paper

Stapler Tray

Entrance

Stapler HP Detects the home position of the staple unit for sideStapler Rotation HP Detects the home position of the stapler unit for 45-

Staple Waste

Hopper

Stack Feed-out BeltHPDetects the home position of the stack feed-out belt.

Stack Height 1 Detects when the top of the copy paper stack in the

Stack Height 2 Detects when the top of the copy paper stack in the

Determines when to turn off the pre-stack paper

stopper solenoid.

Detects the copy paper entering the stapler tray and

checks for misfeeds.

to-side movement.

degree rotation.

Detects when the staple waste hopper is full.

shift tray is at the correct position.

shift tray has become too high.

B302-4

Page 6

22 October 1999 ELECTRICAL COMPONENT DESCRIPTION

Symbol Name Function

S19

S20

S21

S22

S23

S24

Upper Tray Paper

Limit

Shift Tray Half-turn Detects the return position for side-to-side movement

Shift Tray Lower

Limit 1

Shift Tray Lower

Limit 2

Punch Waste

Hopper

Punch HP Detects the home position of the punch shaft and

Detects when the paper stack height in the upper tray

is at its upper limit.

of the shift tray.

Detects when the shift tray is nearly at its lower limit.

Detects when the shift tray is at its lower limit.

Detects when the punch waste hopper is full and

detects when the punch tray is set.

roller.

S25 Stapler Return Detects the on timing of the stapler return solenoid.

Switches

SW1 Front Door Safety Cuts the dc power when the front door is opened.

SW2

Shift Tray Upper

Limit

Cuts the power to the shift tray lift motor when the

shift tray position is at its upper limit.

Solenoids

SOL1

Stapler Junction

Gate

Drives the stapler junction gate.

SOL2 Tray Junction Gate Drives the tray junction gate.

SOL3

SOL4

Pre-stack Junction

Gate

Pre-stack Paper

Stopper

Drives the pre-stack junction gate.

Drives the pre-stack paper stopper.

SOL5 Positioning Roller Moves the positioning roller against the stapling tray.

SOL6

Stapler Return

Returns the stapler to its guide from the user

operation position.

PCBs

PCB1

PCB2

Main

Punch Passes signals between the punch unit and the

Controls the finisher and communicates with the

copier.

finisher main board.

B302-5

Options

Page 7

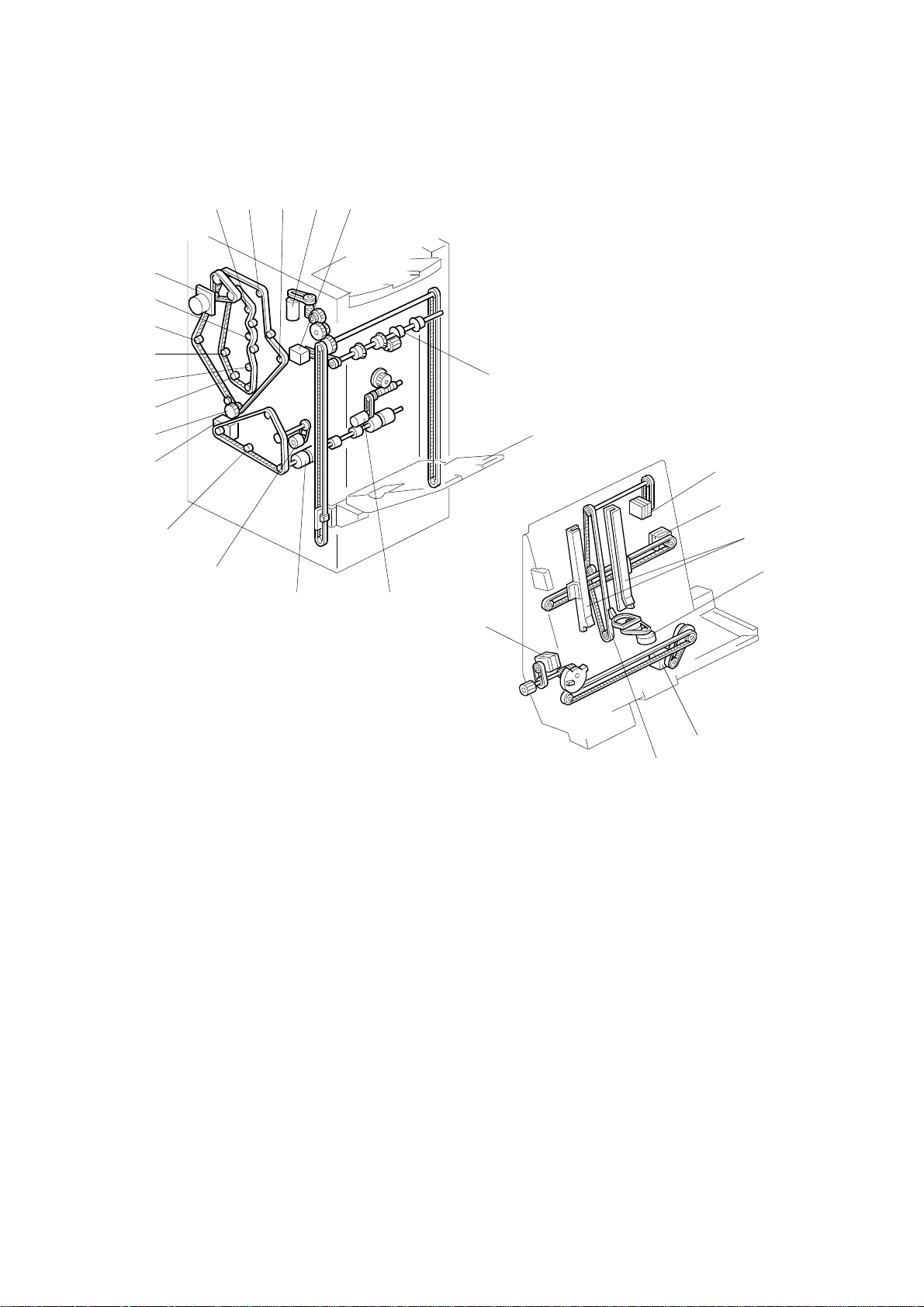

DRIVE LAYOUT22 October 1999

1.4 DRIVE LAYOUT

1 2 3 4 5

19

18

17

16

15

14

6

13

12

11

10

B302V503.WMF

1. Upper Transport Roller 2

2. Upper Tray Exit Roller

3. Lower Transport Roller 2

4. Shift Tray Lift Motor

5. Shift Tray Exit Motor

6. Shift Tray Exit Roller

7. Shift Tray

8. Shift Motor

9. Staple Tray Exit Roller

10. Positioning Roller

11. Lower Transport Roller 3

12. Lower Transport Motor

13. Lower Transport Rollers 2

9 8

7

20

21

22

23

26

24

25

B302V504.WMF

14. Lower Transport Roller 1

15. Transport Roller 1

16. Entrance Roller 2

17. Entrance Roller 1

18. Upper Transport Roller 1

19. Upper Transport Motor

20. Stack Feed-out Motor

21. Jogger Motor

22. Jogger Fence

23. Stack Plate Motor

24. Stapler Motor

25. Stack Feed-out Belt

26. Stapler Rotation Motor

B302-6

Page 8

22 October 1999 TRAY AND STAPLER JUNCTION GATE

2. DETAILED DESCRIPTIONS

2.1 TRAY AND STAPLER JUNCTION GATE

- Upper Tray Mode -

[D]

[A]

[C]

[B]

- Sort/Stack Mode - - Staple Mode -

[A]

[C]

B302D505.WMF

[B]

[D]

B302D506.WMF

[A]

[C]

B302D507.WMF

[D]

[B]

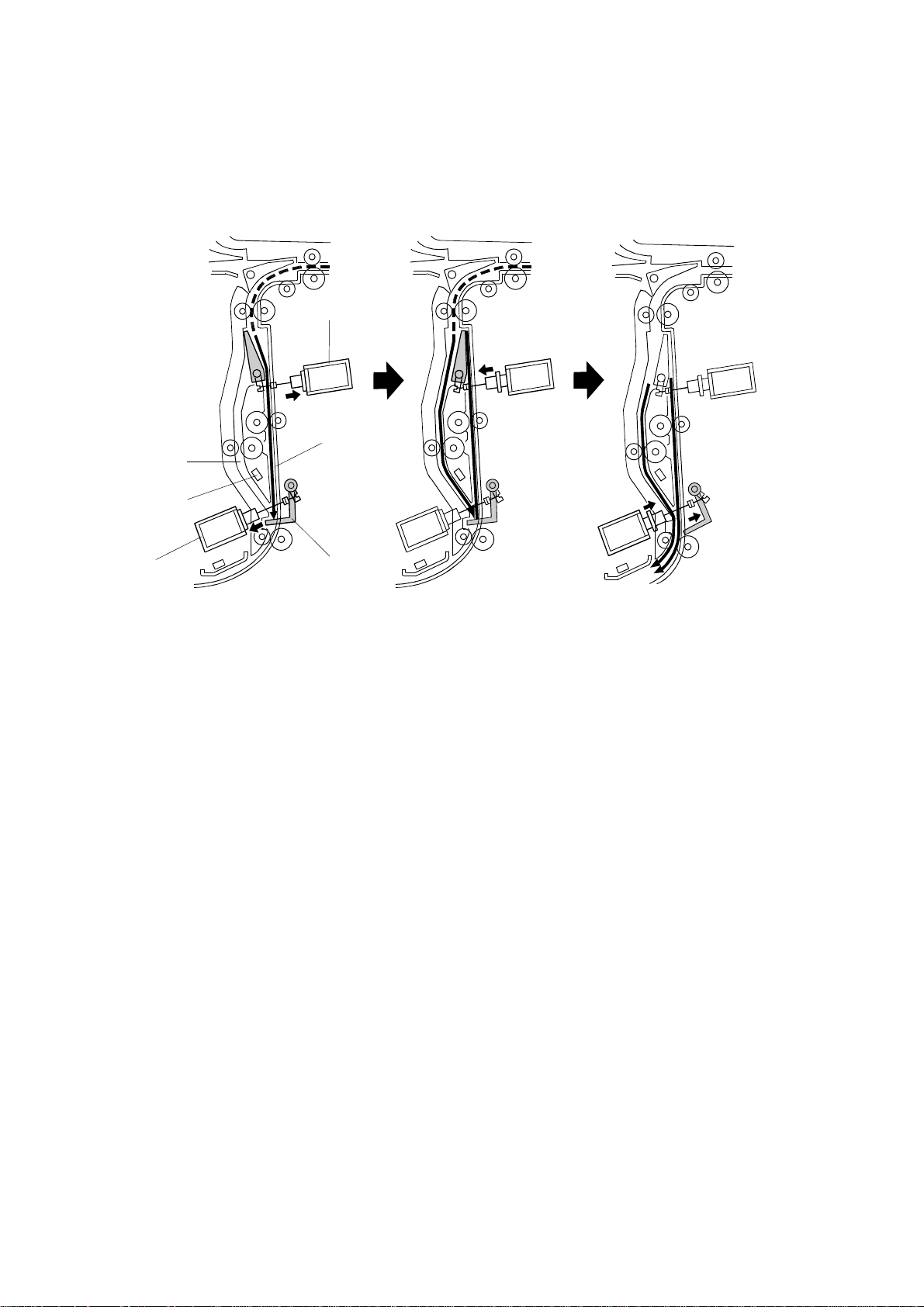

Depending on the finishing mode, the copies are directed up, straight through, or

down by the combination of the tray junction gate [A] and stapler junction gate [B].

These gates are controlled by the tray junction gate solenoid [C] and stapler

junction gate solenoid [D].

Upper Tray Mode

The stapler tray junction gate solenoid remains off and the tray junction gate

solenoid turns on. The copies go up to the upper tray.

Sort/Stack Mode

The tray junction gate solenoid and the stapler junction gate solenoid remain off.

The copies are sent to the shift tray directly.

Staple Mode

The stapler junction gate solenoid turns on. The copies go downwards to the

jogger unit.

B302-7

Options

Page 9

PAPER PRE-STACKING 22 October 1999

2.2 PAPER PRE-STACKING

[A]

[B]

[E]

[F]

[C]

[D]

B302D000.WMF

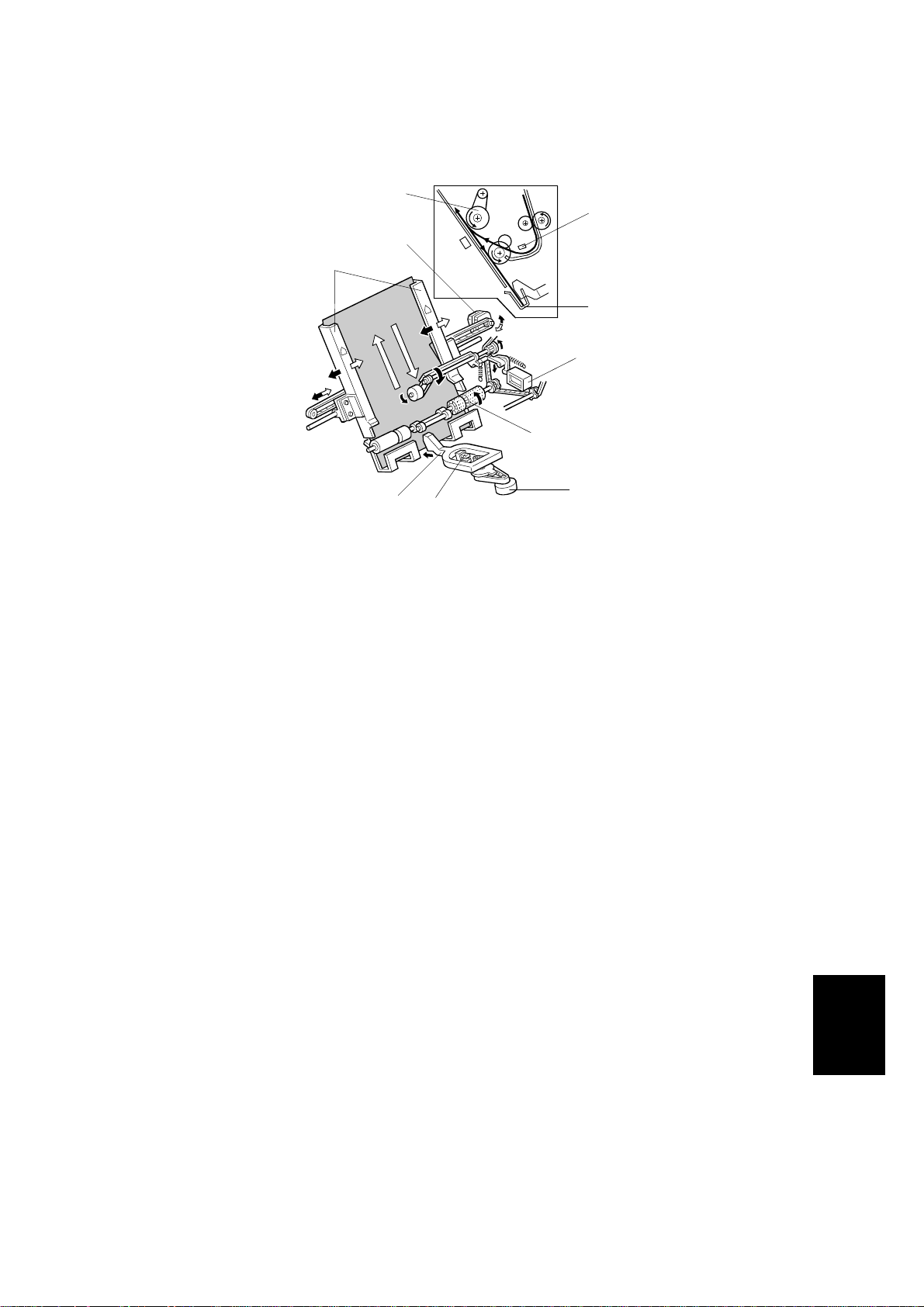

This mechanism improves productivity in staple mode. It is only used when copying

on A4, LT, or B5 (all sideways).

During stapling, the copier has to wait. This mechanism reduces the wait by

holding the first two sheets of a job while the previous job is still being stapled. It

only works during the second and subsequent sets of a multi-set copy job.

The pre-stack junction gate solenoid [A] turns on about 230 ms after the 1st sheet

of paper turns on the entrance sensor, and this directs the sheet to the pre-stack

tray [B]. (This sheet cannot be fed to the stapler yet, because the first set is still

being stapled.) The pre-stack paper stopper solenoid [C] turns on about 680 ms

after the 1st sheet turns on the entrance sensor. The pre-stack paper stopper [D]

then stops the paper.

The pre-stack junction gate solenoid turns off 450 ms after the trailing edge of the

1st sheet passes through the entrance sensor, and the 2nd sheet is sent to the

paper guide [E]. The pre-stack paper stopper is released about 50 ms after the 2nd

sheet turns on the pre-stack stopper sensor [F], and the two sheets of copy paper

are sent to the stapler tray. All sheets after the 2nd sheet go to the stapler tray via

the paper guide [E].

B302-8

Page 10

22 October 1999 JOGGER UNIT PAPER POSITIONING

2.3 JOGGER UNIT PAPER POSITIONING

[C]

[A]

[G]

[F]

[E]

[B]

[D]

[I]

[H]

[J]

B302D508.WMF

In staple mode, each sheet of copy paper is vertically and horizontally aligned

when it arrives in the jogger unit.

Vertical Paper Alignment

Approximately 60 ms after the trailing ed ge of the copy passes the staple tray

entrance sensor [A], the positioning roller solenoid [B] is energized to push the

positioning roller [C] into contact with the paper. The positioning roller and

alignment brush roller [D] rotate to push the paper back and align the trailing edge

of the paper against the stack stopper [E].

Horizontal Paper Alignment

When the prin t key is pressed, the jogger motor [F] turns on and the jogger fences

[G] move to the waiting position, which is approximately 7 mm wider on both sides

than the selected paper.

When the tr ailing edge of the paper passes the staple unit entra nce sensor, the

jogger motor turns on for approximately 32 ms (4.7 mm) to move the jogger fences

approximately 5 mm towards the paper. After a short time, the jogger motor turns

on again approximately 18 ms (3.0 mm) for the horizontal paper alignment then

goes back to the waiting position.

Paper Stack Correction

After the paper is aligned in the stapler tray, the stack plate motor turns [H] on for

short time to correct the paper stack and the stack plate [I] push the paper against

the staple tray.

When the next copy pape r turns on the s tapler tray entrance sensor, the stack

plate motor turns on gain to return to its home position. The home position is

detected by stack plate HP sensor [J].

B302-9

Options

Page 11

STAPLER UNIT MOVEMENT 22 October 1999

2.4 STAPLER UNIT MOVEMENT

[A]

[B]

[C]

B302D513.WMF

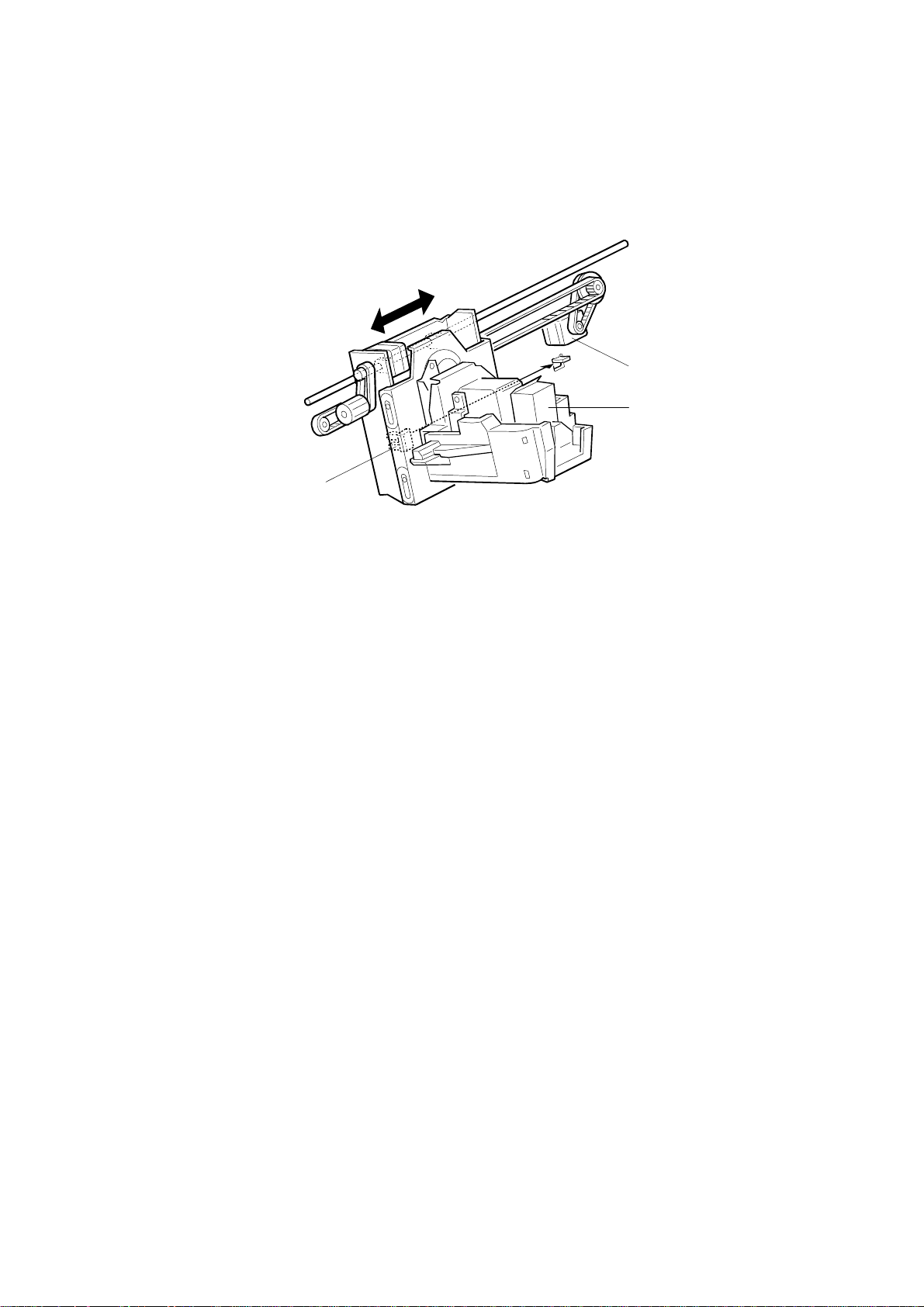

Side-to-Side

The stapler motor [A] moves the stapler [B] from side to side. After the start key is

pressed, the stapler moves from its home position to the stapling position.

If two-staple-position mode is selected, the stapler moves to the front stapling

position first, then moves to the rear stapling position. However, for the next copy

set, it staples in the reverse order (at the rear side first then at the front side).

After the job is completed, the stapler moves back to its home position. This is

detected by the stapler HP sensor [C].

B302-10

Page 12

22 October 1999 STAPLER UNIT MOVEMENT

[A]

[B]

[F]

B302D514.WMF

[D]

[E]

B302D523.WMF

[C]

B302D515.WMF

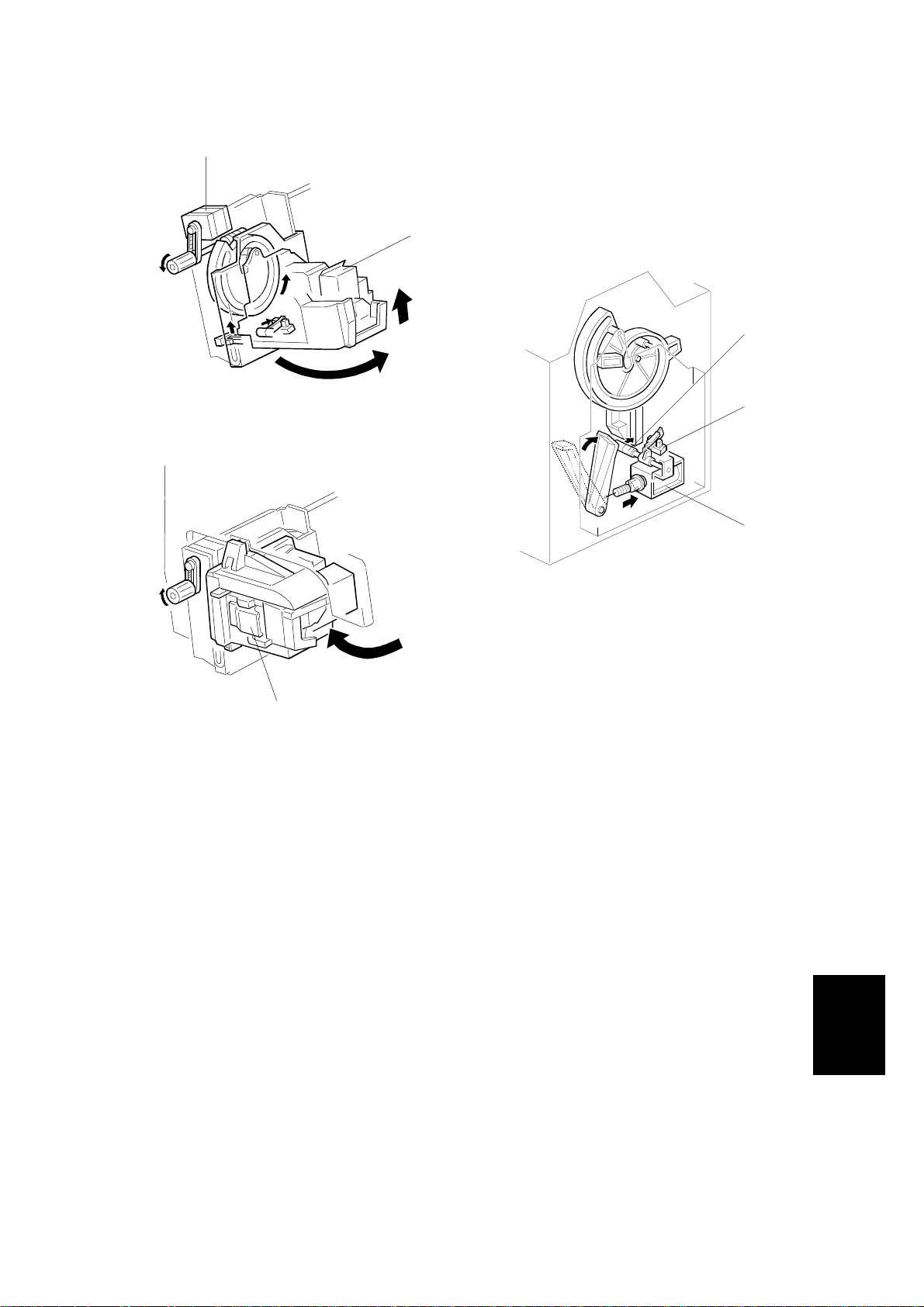

Rotation (1)

In the oblique staple position mode, the stapler rotation motor [A] rotates the

stapler units [B] 45° to counterclockwise after it moves to the stapling position.

Rotation (2)

When the s taple end cond ition arises, the stapler motor moves the stapler to the

front and the stapler rotation motor rotates the stapler unit to clockwise to remove

the staple cartridge [C]. This allows the user to add new staples.

Once the staples have been installed, and the front door closed, the stapler unit

returns to its home position. As the stapler unit is returning to the home position,

the stapler return sensor [D] is activated, the return solenoid [E] turns on and it

assists the guide roller [F] to return to its guide (this guide directs the stapler during

rotation).

B302-11

Options

Page 13

STAPLER 22 October 1999

2.5 STAPLER

[C]

[E]

[B]

[D]

[A]

B302D516.WMF

B302D521.WMF

[E]

[F]

B302D522.WMF

[G]

When the aligned copies are brought to the stapling position by the positioning

roller and jogger fences, the staple hammer motor [A] starts stapling.

During stapling, the stapler trims off the excess length [B] of the staples by lowering

the cutter [C]. This excess length depends on the number of copies in the set;

there will be very little for a stack containing 100 sheets. The staple waste drops

into the tray [D] in the stapler. When the stapler unit returns to its home position,

the tray hits the shaft [E] and the tray opens. The staple waste drops into the staple

waste hopper [F]. When the staple waste hopper is full, the actuator on its base

activates the staple waste hopper sensor [G]. An SC is displayed.

B302-12

Page 14

22 October 1999 STAPLER

[C]

[B]

B302D517.WMF

[A]

[D]

[E]

[G]

[F]

B302D518.WMF

The stapler has a staple end sensor [A], cartridge set sensor [B] and staple

hammer HP sensor [C].

When a staple end or no cartridge condition is det ected, a message is displayed

advising the operator to install a staple cartridge. If this condition is detected during

a copy job, the indication will appear, and the copy job will stop.

The staple cartridge has a clinch area [D], in which jammed staples are left.

Operators can remove the jammed staples from this area.

When the operator lifts the release lever [E], the clinch area is released from the

cartridge by pushing the holders [F]. The jammed staples can be removed.

The staple sheet can be feed manually by sliding the knob [G].

Options

B302-13

Page 15

FEED-OUT 22 October 1999

2.6 FEED-OUT

[D][G]

[A]

[B]

[E]

[C]

[H]

[F]

B302D519.WMF

B302D512.WMF

After the copies have been stapled, the stack feed-out motor [A] starts. The pawl

[B] on the stack feed-out belt [C] transports the set of stapled copies up and feeds

it to the shift tray exit roller [D]. When stapling starts, the exit guide motor [E] opens

the upper exit guide [F], which includes the upper shift tray exit roller [G], in order to

feed out the leading edge of the copy set smoothly. The exit guide motor turns on

again a certain time after stapling is complete, and the upper exit guide plate is

lowered. Then the shift tray exit roller takes over the stack feed-out.

The on-off timing of the exit guide motor is detected by the exit guide open sensor

[H].

The stack-feed-out motor turns off when the pawl actuates the stack feed-out belt

home position sensor [I].

[I]

B302-14

Page 16

22 October 1999 SHIFT TRAY UP/DOWN MOVEMENT

2.7 SHIFT TRAY UP/DOWN MOVEMENT

[A]

[K]

[D]

[E]

[J]

[G]

[H]

[F]

[B]

[I]

[C]

B302D010.WMF

The shift tray lift motor [A] controls the vertical position of the shift tray [B] through

gears and timing belts [C]. When the main switch is turned on, the tray is initialized

at the upper position. The tray is moved up until stack height sensor 1 [D] is deactuated.

In sort/stack mode, if stack height sensor 2 [E] is actuated for 2 seconds, the shift

tray lift motor lowers the shift tray for 20 ms.

In staple mode, when the pawl on the stack feed-out belt reaches the upper

position of the staple unit, the shift tray lift motor lowers the shift tray for 400 ms

and stops for 200 ms. Then, it lifts the shift tray until stack height sensor 1 is deactuated by the feeler [F]. This means the tray lowers earlier in staple mode, to

prevent the next copy suddenly exceeding the space currently available on the

tray.

For both modes, the shift tray will rise until stack height sensor 1 is de-actuated

when the user takes the stack of paper from the shift tray.

This machine has two shift tray lower limit sensors 1 [G], 2 [H]. Shift tray lower limit

sensor 1 detects the near lower limit and sensor 2 detects the lower limit. When the

actuator [I] enters sensor 1, a message will be displayed and copying will continue.

When the actuator enters sensor 2, a message will be displayed and copying will

stop.

Options

The shift tray upper limit switch [J] prevents the drive gear from being damaged if

stack height sensor 1 fails. When the shift tray pushes up the shift tray positioning

roller [K], the switch will cut the power to the shift tray lift motor.

B302-15

Page 17

SHIFT TRAY SIDE-TO-SIDE MOVEMENT 22 October 1999

2.8 SHIFT TRAY SIDE-TO-SIDE MOVEMENT

[D]

[A]

[F]

[C]

[E]

[B]

B302D520.WMF

In sort/stack mode, the shift tray [A] moves from side to side to separate the sets of

copies.

The horizontal position of the shift tray is controlled by the shift motor [B] and shift

gear disk [C]. After one set of copies is made and delivered to the shift tray, the

shift motor turns on, driving the shift gear disk and the shaft [D]. The end fence [E]

is positioned by the shaft, creating the side-to-side movement.

When the shift gear disk has rotated 180 degrees (when the shift tray is fully shifted

across), the cut-out in the shift gear disk turns on the shift tray half-turn sensor [F]

and the shift motor stops. The next set of copies is then delivered. The motor turns

on, repeating the same process and moving the tray back to the previous position.

B302-16

Page 18

22 October 1999 PUNCH UNIT DRIVE

2.9 PUNCH UNIT DRIVE

[D]

[C]

[A]

[B]

B302D001.WMF

The punch unit makes 2 or 3 holes (depending on the type of punch unit) at the

trailing edge of the paper.

The punch unit is driven by the punch motor [A]. The punch motor turns on 78 ms

after the trailing edge of the pape r passes through the entrance sensor [B], and

makes the punch holes.

The home position is detected by the punch HP sensor [C]. When the cut-out in the

punch shaft gear disk [D] enters the punch HP sensor, the punch motor stops.

The punch position is adjusted as follows:

·

Right to left: SP mode

·

Front to rear: Spacers

B302-17

Options

Page 19

PUNCH WASTE COLLECTION 22 October 1999

2.10 PUNCH WASTE COLLECTION

[D]

[B]

[C]

[A]

B302D002.WMF

The punch waste is collected in the punch waste hopper [A], which is under the

punch unit.

When the punch waste covers the hole [B] in the hopper, the punch waste hopper

sensor [C] turns on and a message will be displayed after the copy job f inishes.

The punch waste hopper sensor also works as the hopper set sensor. If the punch

waste hopper is not set, the sensor stays away from the hole in the hopper holder

[D] and a message is displayed. This messag e is the same as for the hopper ful l

condition.

B302-18

Page 20

22 October 1999 JAM CONDITIONS

2.11 JAM CONDITIONS

1. The entrance sensor does not turn on when the copier has fed paper 426 mm

after the copier exit sensor turned off.

2. The entrance sensor does not turn off when the upper transport motor has fed

paper 1.5 times the paper’s length after it turned on.

3. The upper tray exit sensor does not turn on when the upper transport motor

has fed paper 574 mm after the entrance sensor turned on.

4. The upper tray exit sensor does not turn off when the upper transport motor

has fed paper 1.5 times the paper’s length after it turned on.

5. In sort/stack mode, the shift tray exit sensor does not turn on when the upper

transport motor has fed paper 783 mm after the entrance sensor turned on.

6. In sort/stack mode, the shift tray exit sensor does not turn off when the upper

transport motor has fed paper 1.5 times the paper’s length after it turned on.

7. In staple mode, the stapler tray entrance sensor does not turn on when the

upper and lower transport motor have fed paper 835 mm after the entrance

sensor turned on.

8. In staple mode, the stapler tray entrance sensor does not turn off when the

upper transport motor has fed paper 1.5 times the paper’s length after it turned

on.

9. In staple mode, the stapler tray paper sensor does not turn off within 250

pulses of the stack feed-out motor after it started.

10. In staple mode, the shift tray exit sensor does not turn off within 1,260 ms after

the stack feed-out motor started.

B302-19

Options

Page 21

DIP SWITCHES 22 October 1999

3. SERVICE TABLES

3.1 DIP SWITCHES

DPS100

1234

0000Default

1 0 0 0 Free run: A4 sideways, staple mode

0 1 0 0 Free run: staple and tray shift

NOTE:

Do not use any other settings.

Description

3.2 TEST POINTS

No. Label Monitored Signal

TP100 (5V) +5 V

TP101 (GND) Ground

TP102 (RXD) RXD

TP103 (TXD) TXD

3.3 FUSES

No. Function

FU100 Protects 24 V.

B302-20

Page 22

22 October 1999 COVER REPLACEMENT

4. REPLACEMENT AND ADJUSTMENT

4.1 COVER REPLACEMENT

[A]

[D]

[B]

B302R502.WMF

[C]

B302R505.WMF

Front Door

1. Remove one screw and loosen the other screw of the upper hinge for the front

door [A].

2. Remove the front door [B].

Left Inner Cover

1. Remove the front door.

2. Remove the left inner cover [C] (1 screw).

Inner Cover

1. Remove the three screws and unhook the pawls.

2. Remove the inner cover [D].

B302-21

Options

Page 23

COVER REPLACEMENT 22 October 1999

[C]

[F]

[B]

[G]

[G]

B302R503.WMF

[A]

[H]

[H]

Table

1. Slide the table [A] to the right and remove it (2 screws).

Upper Tray

1. Click the release lever [B].

2. Remove the upper tray [C].

[D]

[D]

[E]

[E]

B302R504.WMFB302R504.WMF

Left Upper Cover

1. Remove the left upper cover [D].

Left Lower Cover

1. Remove the left lower cover [E].

Upper Cover

1. Remove the table.

2. Remove two stepped screws [F].

3. Remove the left upper cover.

4. Slide across the right cover [G] and remove it (2 screws).

Rear Cover

1. Remove the rear cover [H] (2 screws).

B302-22

Page 24

22 October 1999 COVER REPLACEMENT

[A]

[B]

B302R501.WMF

[C]

[D]

B302R504.WMF

Shift Tray

1. Remove the left upper cover.

2. Rotate the shift tray lift gear [A] manually to lower the shift tray [B]

3. Remove the shift tray (4 screws).

Front Shift Tray Cover

1. Remove the front shift tray cover [C] (1 screw).

Rear Shift Tray Cover

[B]

1. Remove the rear shift tray cover [D] (1 screw).

B302-23

Options

Page 25

POSITIONING ROLLER REPLACEMENT 22 October 1999

4.2 POSITIONING ROLLER REPLACEMENT

[A]

1. Open the front door.

2. Remove the snap ring [A].

3. Release the rubber belt [B].

4. Replace the positioning roller [C].

[C]

[B]

B302R506.WMF

B302-24

Page 26

22 October 1999 ALIGNMENT BRUSH ROLLER REPLACEMENT

4.3 ALIGNMENT BRUSH ROLLER REPLACEMENT

[B]

[D]

B302R507.WMF

[C]

[A]

[E]

[H]

[I]

[F]

[G]

B302R508.WMF

1. Open the front door and pull out the staple unit.

2. Remove the rear cover.

3. Remove the screw [A] and a tension spring [B] for the tension bracket [C], and

release the tension of the timing belt.

4. Remove the pulley [D] and ball bearing [E] (1 E-ring each).

5. Remove screw [F] of the inner cover [G].

6. Open the guide [H] and a part of the inner cover, and remove the alignment

brush roller assembly [I] (1 E-ring).

7. Replace the alignment brush roller (1 E-ring, 1 ball bearing).

Options

B302-25

Page 27

SENSOR REPLACEMENT 22 October 1999

4.4 SENSOR REPLACEMENT

4.4.1 STACK HEIGHT 1, 2 AND EXIT GUIDE OPEN SENSOR

[A]

[B]

[C]

[D]

[E]

[F]

B302R509.WMF

1. Remove the upper cover.

Stack Height Sensors 1 and 2

2. Remove the sensor feeler [A] (1 screw).

3. Remove the sensor bracket [B] (1 screw).

4. Replace the stack height sensor 1 [C] or 2 [D] (1 connector each).

Exit Guide Open Sensor

2. Remove the sensor bracket [E] (1 screw).

3. Replace the exit guide open sensor [F] (1 connector).

B302-26

Page 28

22 October 1999 SENSOR REPLACEMENT

4.4.2 UPPER TRAY PAPER LIMIT AND EXIT SENSOR

[D]

[B]

[C]

[A]

[E]

B302R510.WMF

1. Remove the upper cover.

Upper Tray Paper Limit Sensor

2. Remove the sensor cover [A] (2 screws).

3. Remove the sensor bracket [B] (1 screw).

4. Replace the upper tray paper limit sensor [C] (1 connector).

Upper Tray Exit Sensor

2. Remove the sensor bracket [D] (1 screw).

3. Replace the upper tray exit sensor [E] (1 connector).

Options

B302-27

Page 29

SENSOR REPLACEMENT 22 October 1999

4.4.3 SHIFT TRAY EXIT SENSOR

[C]

[B]

[A]

B302R511.WMF

1. Remove the upper cover.

2. Open the front door.

3. Remove the inner cover.

[A]

[D]

[E]

B302R512.WMF

4. Release two springs [A] of the upper exit guide [B].

5. Release the link [C] from the cam and remove the upper exit guide (1 plastic

clip, 1 connector).

6. Remove the guide stay [D] (2 screws).

7. Replace the shift tray exit sensor [E] (1 screw, 1 connector).

B302-28

Page 30

22 October 1999 SENSOR REPLACEMENT

4.4.4 ENTRANCE AND STAPLER TRAY ENTRANCE SENSORS

[B]

[A]

B302R513.WMF

Entrance Sensor

1. Remove the finisher from the copier.

2. Remove the sensor bracket [A] (1 screw).

3. Replace the entrance sensor [B] (1 screw, 1 connector).

Stapler Tray Entrance Sensor

1. Open the front door.

2. Remove the sensor bracket [C] (1 screw).

[D]

[C]

B302R514.WMF

3. Replace the stapler tray entrance sensor [D] (1 screw, 1 connector).

B302-29

Options

Page 31

SENSOR REPLACEMENT 22 October 1999

4.4.5 PRE-STACK STOPPER SENSOR

[A]

B302R515.WMF

[D]

[B]

[C]

B302R516.WMF

1. Remove the rear cover.

2. Remove two plastic clips from the guide [A].

3. Open the front door.

4. Remove the left vertical transport guide [B].

5. Remove the middle vertical transport guide [C] (1 connector).

6. Replace the pre-stack paper sensor [D] (1 connector).

B302-30

Page 32

22 October 1999 SENSOR REPLACEMENT

4.4.6 STAPLE WASTE HOPPER SENSOR

[A]

[B]

[C]

B302R517.WMF

1. Open the front door and pull out the stapler unit.

2. Remove the staple waste hopper [A] (1 plastic clip).

3. Remove the hopper holder [B] (2 E-rings).

4. Replace the staple waste hopper sensor [C] (1 connector).

B302-31

Options

Page 33

SENSOR REPLACEMENT 22 October 1999

4.4.7 STAPLER ROTATION HP AND STAPLER RETURN

SENSORS

[C]

[A]

[B]

B302R519.WMF

1. Remove the stapler unit.

2. Remove the stapler bracket [A] (4 screws, 2 springs).

Stapler Rotation HP Sensor

3. Replace the stapler rotation HP sensor [B] (1 connector).

Stapler Return Sensor

3. Replace the stapler return sensor [C] (1 connector).

B302-32

Page 34

22 October 1999 STAPLER REMOVAL

4.5 STAPLER REMOVAL

[B]

[A]

B302R518.WMF

1. Open the front door and pull out the staple tray.

2. Remove the stapler unit harness cover [A].

3. Remove the stapler [B] (1 screw, 2 connectors).

Options

B302-33

Page 35

PUNCH POSITION ADJUSTMENT 22 October 1999

4.6 PUNCH POSITION ADJUSTMENT

B302R520.WMF

Right to Left

This position is adjusted by SP modes.

Front to Rear

The optional punch units have the following 3 spacers as accessories.

1 mm thickness: 2 pcs

2 mm thickness: 1 pc

The punch position can be adjusted by up to 4 mm by combinations of the 3

spacers.

B302-34

Page 36

ELECTRICAL COMPONENT LAYOUT (FINISHER: B302)

46

45

44

43

42

41

40

39

47

B302S501.WMF

48

2

1

3

4

5

6

38

37

36

35

34

33

32

31

30

29

22

23

24

25

26

27

28

19

7

8

9

10

11

12

13

14

15

16

17

18

2021

B302S502.WMF

Symbol Index No. Description P to P

Motors

M1 7 Upper Transport A6

M2 14 Lower Transport C6

M3 37 Jogger F6

M4 23 Stack Plate G6

M5 22 Stapler G6

M6 33 Stapler Rotation I6

M7 28 Staple Hammer I6

M8 38 Stack Feed-out F6

M9 47 Exit Guide C6

M10 3 Shift Tray Exit B6

M11 40 Shift D6

M12 2 Shift Tray Lift C6

M13 9 Punch J2

Sensors

S1 10 Entrance B2

S2 39 Pre-stack E2

S3 21 Stapler Tray Entrance F2

S4 36 Jogger Fence HP F2

S5 35 Stapler Tray Paper F2

S6 24 Stack Plate HP G2

S7 32 Stapler HP G2

S8 31 Stapler Rotation HP G2

S9 30 Staple Hammer HP J2

S10 29 Cartrid ge Set J2

S11 27 Staple End J2

S12 18 Staple Waste Hopper I2

S13 34 Stack Feed-out Belt HP F2

S14 46 Exit Guide Open C2

Symbol Index No. Description P to P

S15 43 Shift Tray Exit C2

S16 45 Stack Height 1 D2

S17 44 Stack Height 2 D2

S18 1 Upper Tray Exit C2

S19 48 Upper Tray Paper Limit C2

S20 41 Shift Tray Half-turn D2

S21 19 Shift Tray Lower Limit 1 E2

S22 20 Shift Tray Lower Limit 2 E2

S23 13 Punch Waste Hopper J2

S24 8 Punch HP I2

S25 25 Stapler Return I2

Switches

SW1 17 Front Door Safety B2

SW2 42 Shift Tray Upper Limit C6

Solenoids

SOL1 4 Stapler Junction Gate D6

SOL2 5 Tray Junction Gate D6

SOL3 11 Pre-stack Junction Gate E6

SOL4 16

SOL5 15 Positioning Roller E6

SOL6 26 Stapler Return I6

PCBs

PCB1 12 Main K4

PCB2 6 Punch J3

Pre-stack Paper

Stopper

E6

Page 37

1234567

POINT TO POINT DIAGRAM (Finisher: B302)

A

Copier

B

Front Door Safety

CN500-8

-7

-6

-5

-4

-3

-2

-1

CN505-8

-7

-6

-5

SW1

Switch

CN305-3

Entrance Sensor

Upper Tray Exit

Sensor

Upper Tray Paper

C

Limit Sensor

Shift Tray Exit

Sensor

Exit Guide Open

Sensor

Stack Height 2

Sensor

D

Stack Height 1

Sensor

Shift Tray Half Turn

Sensor

Shift Tray Lower

Limit 2 Sensor

E

Shift Tray Lower

Limit 1 Sensor

Pre-stack Tray Paper

Sensor

Stapler Tray

Entrance Sensor

Stack Feed-out Belt

F

HP Sensor

Stapler Tray Paper

Sensor

Jogger Fence HP

Sensor

Stack Plate HP

Sensor

G

Stapler HP Sensor

Stapler Rotation HP

S1

CN310-3

S18

CN315-3

S19

CN320-3

S15

CN325-3

S14

CN330-3

S17

CN335-3

S16

CN340-3

S20

CN345-3

S22

CN350-3

S21

CN355-3

S2

CN360-3

S3

CN365-3

S13

CN370-3

S5

CN375-3

S4

CN380-3

S6

CN385-3

S7

CN390-3

S8

Sensor

CN395-3

Stapler Return Sensor

I

Staple Waste Hopper

S25

CN400-3

S12

Sensor

Punch HP Sensor

Punch Waste Hopper

Sensor

J

Punch Motor

S24

S23

M

13

CN510-3

-2

-1

CN515-3

-2

-1

CN520-3

-2

-1

CN525-3

-2

-1

CN530-9

-2

-1

CN530-6

-2

-1

CN530-3

-2

-1

CN535-3

-2

-1

-2

-1

-2

-1

CN540-1

-2

-1

CN545-3

-2

-1

CN550-6

-2

-1

CN550-3

-2

-1

-2

-1

-2

-1

-2

-1

-2

-1

-2

-1

CN555-3

-2

-1

Punch

(PCB2)

PCB

-2

-1

-2

-1

-2

-1

-2

-1

-8

-7

-5

-4

-2

-1

-2

-1

-2

-3

-2

-1

-5

-4

-2

-1

-2

-1

CN100-1

CN105-1

CN110-1

CN115-1

CN115-4

CN115-7

CN120-1

CN120-4

CN120-7

CN120-10

-11

-12

CN125-1

CN125-4

CN125-7

CN130-1

CN130-4

CN135-1

CN135-4

CN135-7

CN135-10

-11

-12

CN140-1

CN140-4

CN140-8

-10

CN140-11

-12

-13

CN215

-12

-1

-11

-2

-10

-3

-4

-8

-9

-10

-11

-12

[24] +24V

-2

[24] +24V

-3

[24] +24V

-4

[0] GND

-5

[0] GND

-6

[0] GND

-7

[0] GND

-8

[24] +24V

[0] GND

-2

TXD

-3

[0] GND

-4

RXD

[24] +24V

-2

[s24] +24V SW

[0] GND

-2

[t5]

-3

[5] +5V

[t5]

-5

[0] GND

-6

[5] +5V

[5] +5V

-8

[t5]

-9

[0] GND

[0] GND

-2

[t5]

-3

[5] +5V

[0] GND

-5

[t5]

-6

[5] +5V

[0] GND

-8

[s5]

-9

[5] +5V

[0] GND

[s5]

[5] +5V

[0] GND

-2

[s5]

-3

[5] +5V

[0] GND

-5

[s5]

-6

[5] +5V

[0] GND

-8

[s5]

-9

[5] +5V

[0] GND

-2

[t5]

-3

[5] +5V

[0] GND

-5

[t5]

-6

[5] +5V

[s5]

-2

[0] GND

-3

[5] +5V

[0] GND

-5

[t5]

-6

[5] +5V

[0] GND

-8

[s5]

-9

[5] +5V

[0] GND

[s5]

[5] +5V

[0] GND

-2

[s5]

-3

[5] +5V

[0] GND

-5

[s5]

-6

[5] +5V

[0] GND

-9

[s5]

[5] +5V

[0] GND

[s5]

[5] +5V

[t5] Hopper Sensor

[t5] Installed

[s5] HP Sensor

-9

Type 1

-8-5

Type 2

-7-6

[t5] ON

-6-7

[0] Direction

-5

[0/5] Clock

-4

[0] GND

-3

[5] +5V

-2

[0] GND

-1

[24] +24V SW

Main Board

(PCB1)

+24V SW [24]

+24V SW [24]

GND [0]

GND [0]

Speed [0/5]

Rotate [t5]

Clock [0/5]

Direction [5]

ON [t5]

GND [0]

+5V [5]

+24V SW [24]

+24V SW [24]

A [24 0/24]

/A [24 0/24]

B [24 0/24]

/B [24 0/24]

+[s24]

[t24]

+[s24]

-[s24]

+24V SW [24]

[t24]

+24V SW [24]

+24V SW [24]

A [24 0/24]

/A [24 0/24]

B [24 0/24]

/B [24 0/24]

[t24]

+24V SW [24]

+24V [24]

[t24]

+24V [24]

[t24]

+24V [24]

[t24]

+24V [24]

[t24]

+24V SW [24]

[t24]

+24V SW [24]

+24V SW [24]

A [24 0/24]

/A [24 0/24]

B [24 0/24]

/B [24 0/24]

+24V SW [24]

+24V SW [24]

A [24 0/24]

/A [24 0/24]

B [24 0/24]

/B [24 0/24]

+24V SW [24]

+24V SW [24]

A [24 0/24]

/A [24 0/24]

B [24 0/24]

/B [24 0/24]

+24V SW [24]

+24V SW [24]

A [24 0/24]

/A [24 0/24]

B [24 0/24]

/B [24 0/24]

+24V SW [24]

+24V SW [24]

A [24 0/24]

/A [24 0/24]

B [24 0/24]

/B [24 0/24]

+24V SW [24]

[t24]

+[s24]

-[s24]

GND [0]

Ready [t5]

Cartridge Set [t5]

Staple End [t5]

GND [0]

Hammer HP [t5]

+5V [5]

CN145-1

-10

-11

-12

CN150-1

CN160-3

CN150-9

-10

CN150-12

-13

CN155-1

CN160-1

CN165-1

CN165-3

CN170-1

CN175-1

CN180-1

CN190-1

CN190-9

-10

-12

-13

-14

-15

CN195-1

CN195-9

-10

-12

-13

-14

-15

CN200-1

CN200-9

-10

CN205-1

CN210-1

-2

-3

-4

-5

-6

-8

-9

-2

-4

-5

-6

-7

-5

-2

-4

-5

-6

-7

-2

-2

-4

-2

-2

-2

-2

-4

-5

-6

-7

-2

-4

-5

-6

-7

-2

-4

-5

-6

-7

-2

-2

-3

-4

-5

-6

-7

CN560-3

CN560-5

-1

-4

CN405-12

-11

-10

CN410-7

CN415-2

CN420-2

CN425-2

CN430-2

CN435-2

CN440-7

CN445-7

CN450-7

CN455-7

CN460-7

CN465-2

-9

-8

-7

-5

-4

-3

-2

-1

-6

-4

-3

-2

-1

-1

-1

-7

-6

-4

-3

-2

-1

-1

-1

-1

M1

M

10

M

12

M9

M2

M

11

SOL

2

SOL

1

SOL

3

SOL

4

SOL

5

-6

-4

-3

-2

-1

-6

-4

-3

-2

-1

-6

-4

-3

-2

-1

-6

-4

-3

-2

-1

-6

-4

-3

-2

-1

-1

M3

M8

M4

M5

M6

SOL

6

M7

S10

S11

S9

SYMBOL TABLE

DC Line

Upper Transport

Shift Tray Exit Motor

SW2

Shift Tray Upper

Limit Switch

Shift Tray Lift Motor

Exit Guide Motor

Lower Transport

Shift Motor

Tray Junction Gate

Stapler Junction

Gate Solenoid

Pre-stack Junction

Gate Solenoid

Pre-stack Paper

Stopper Soleniod

Positioning Roller

Jogger Motor

Stack Feed-out

Stack Plate Motor

Stapler Motor

Stapler Rotation

Stapler Return

Motor

Motor

Solenoid

Solenoid

Motor

Motor

Solenoid

Stapler

A

B

C

D

E

F

G

I

J

Pulse Signal

Signal Direction

s

Active High

t

[]

Active Low

Voltage

KK

1234567

Loading...

Loading...