Page 1

1,000-SHEET FINISHER

(Machine Code: B408)

Page 2

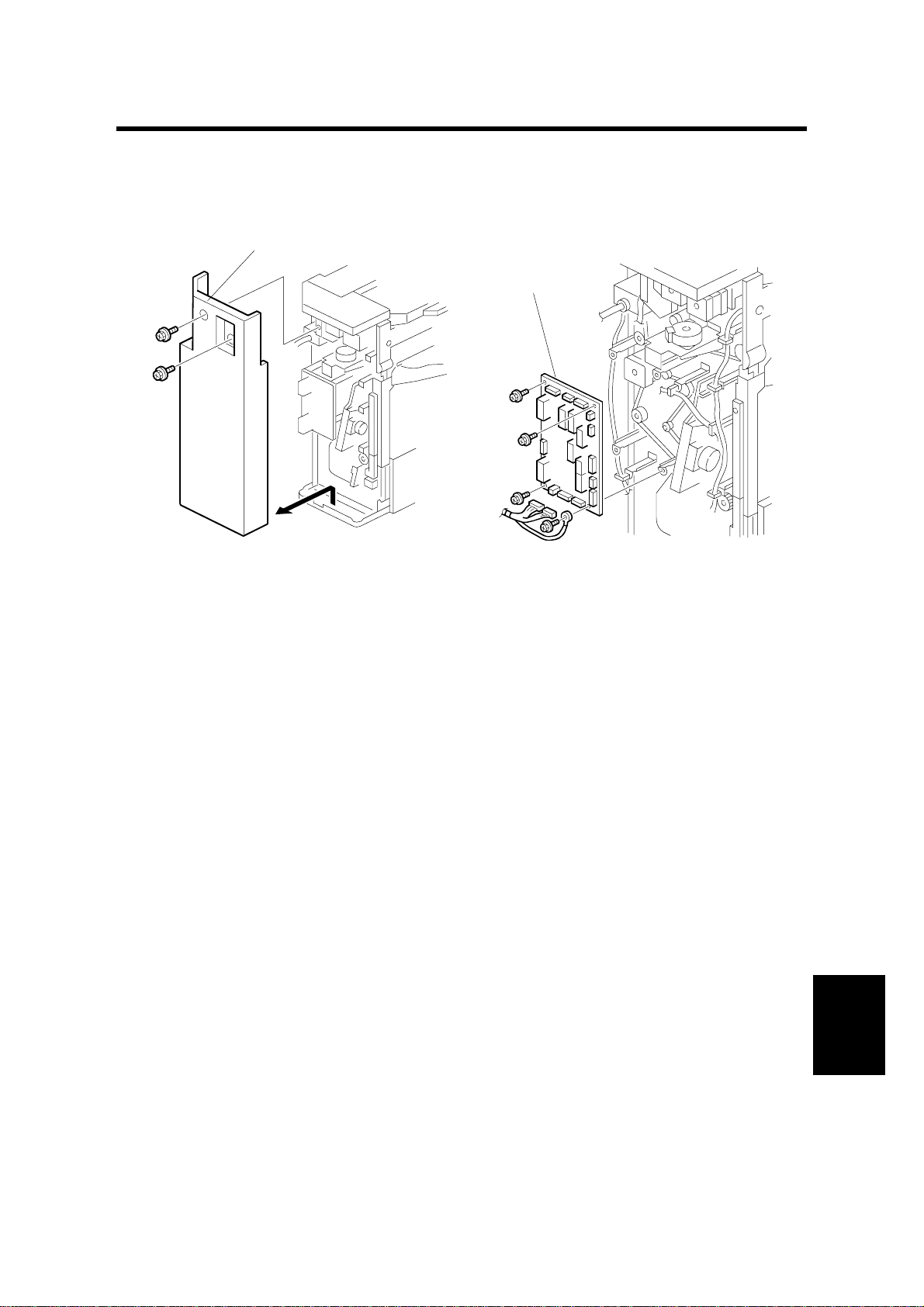

10 August, 2001 MAIN PCB

1. REPLACEMENT AND ADJUSTMENT

1.1 MAIN PCB

[A]

[B]

1. Rear cover [A] (!x 2)

2. Main PCB [B] (!x 4, All ")

B408R109.WMF

B408R110.WMF

B408-1

Options

Page 3

STAPLER UNIT 10 August, 2001

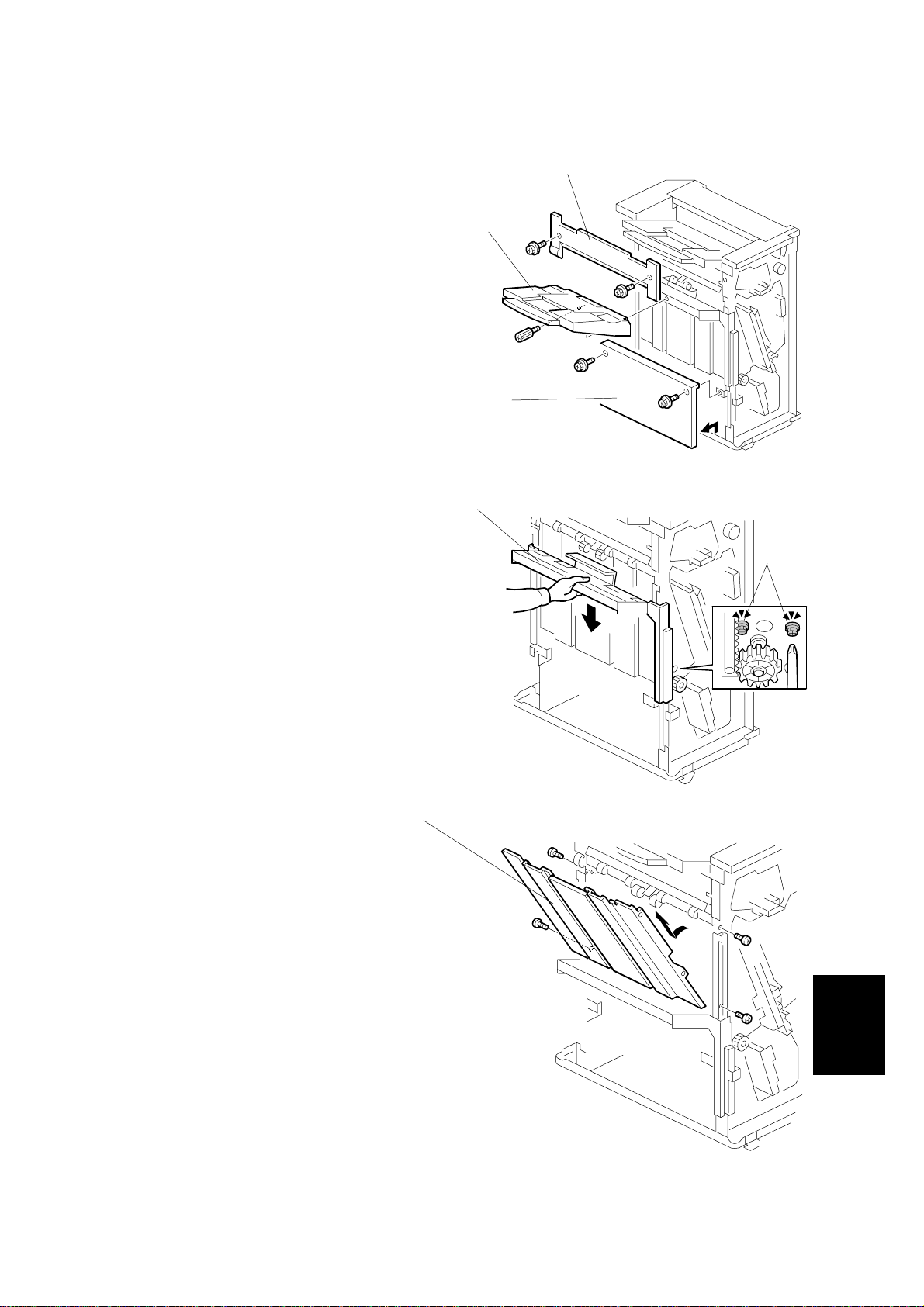

1.2 STAPLER UNIT

1. Side cover [A] (! x 2)

2. Open exit guide plate [B]

3. Upper side cover [C] (! x 2)

4. Front cover support plate [D] (! x 1)

5. Front cover [E]

6. Front inner cover [F] (! x 2)

7. Harness [G]

8. Unhook the spring [H]

9. Turn the stapler unit [I] and take it out.

10. Bracket [J] (! x 2)

[B]

[C]

[A]

B408R102.WMF

[D]

[E]

[F]

[G]

B408-2

B408R113.WMF

[J]

[H]

[I]

B408R114.WMF

Page 4

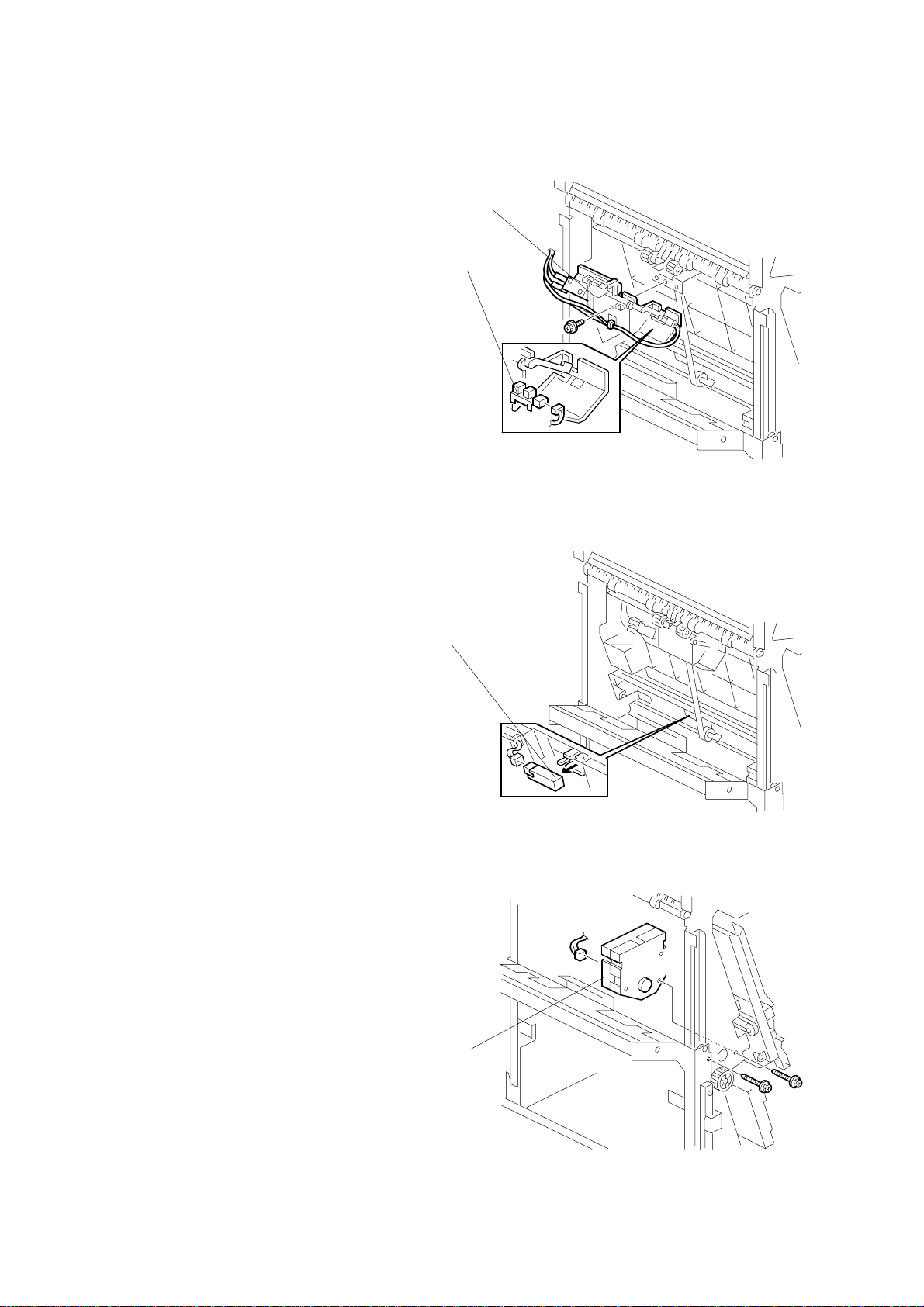

10 August, 2001 MOTORS

1.3 MOTORS

1.3.1 SHIFT MOTOR

1. Rear cover (☛1.1)

2. Shift motor [A] (! x 2, " x 1)

1.3.2 STAPLER MOTOR

1. Rear cover (☛1.1)

2. Stapler motor [B] (! x 2, " x 1)

[A]

B408R123.WMF

[B]

1.3.3 UPPER TRANSPORT MOTOR AND EXIT MOTOR

1. Rear cover (☛1.1)

2. Motor assembly [C] (! x 4, " x 2)

[C]

3. Upper transport motor [D] (! x 4)

4. Exit motor [E] (! x 4)

[D]

[E]

B408R124.WMF

Options

B408R112.WMF

B408-3

Page 5

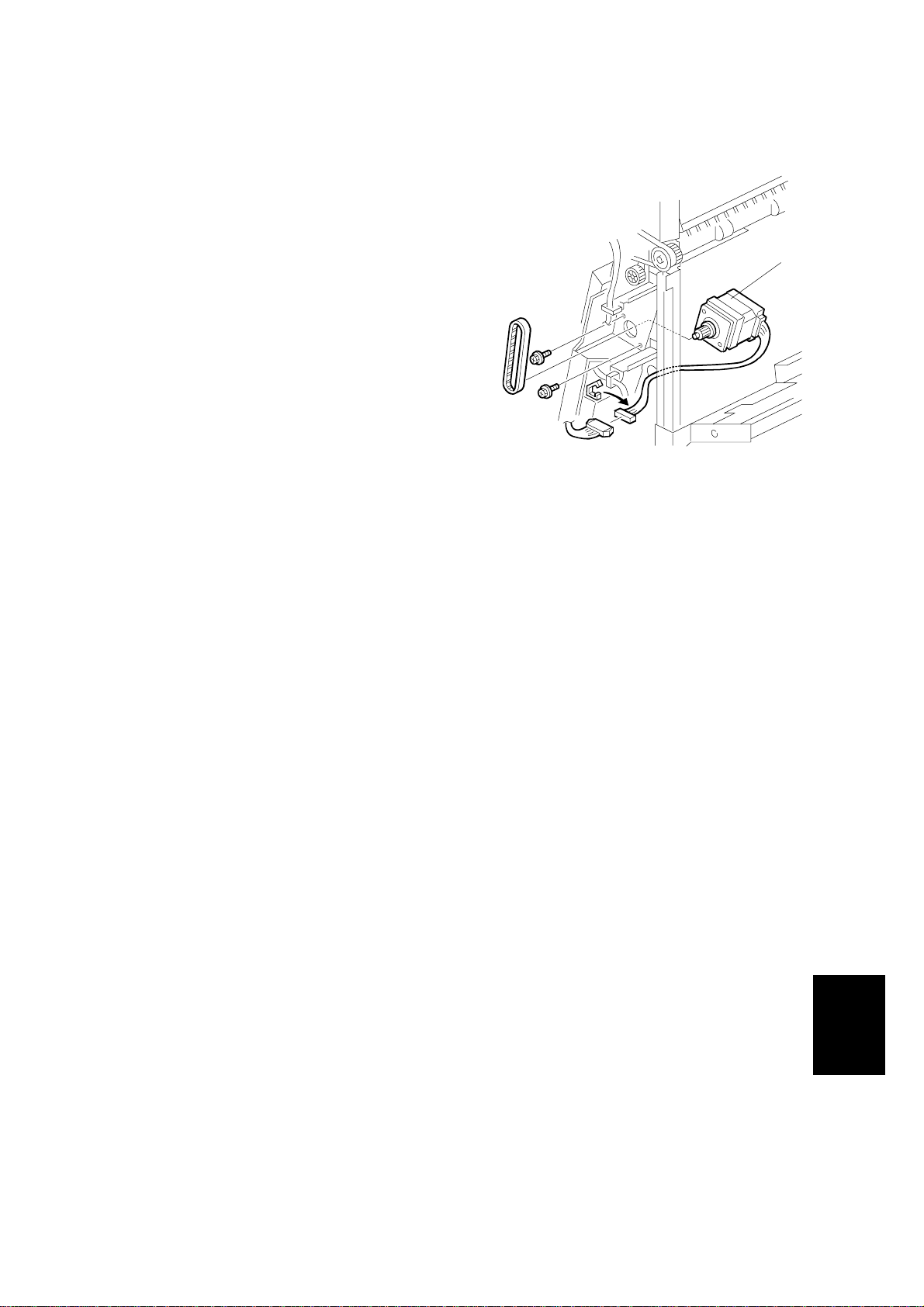

MOTORS 10 August, 2001

1.3.4 LOWER TRANSPORT MOTOR

1. Main PCB (☛1.1)

2. Lower transport motor [A] (! x 2, " x

1)

[A]

B408R111.WMF

B408-4

Page 6

10 August, 2001 MOTORS AND SENSORS

1.4 MOTORS AND SENSORS

1.4.1 PREPARATION

1. Front cover and inner cover (☛1.2)

2. Upper side cover [A] (! x 2)

3. Shift tray [B] (! x 1)

4. Lower side cover [C] (! x 2)

5. Loosen the 2 screws [D].

6. Lower the lower tray guide plate [E].

7. Guide plate [F] (! x 4)

[A]

[B]

[C]

B408R116.WMF

[E]

[D]

[F]

B408R117.WMF

Options

B408R118.WMF

B408-5

Page 7

MOTORS AND SENSORS 10 August, 2001

1.4.2 STACK HEIGHT SENSOR

1. Stack height sensor assembly [A] (! x

1)

[A]

2. Stack height sensor [B] (" x 1)

[B]

B408R121.WMF

1.4.3 STAPLER TRAY PAPER SENSOR

1. Stapler tray paper sensor [C] (" x 1)

[C]

1.4.4 LOWER TRAY LIFT MOTOR

1. Lower tray lift motor [D] (! x 2, " x 1)

B408R120.WMF

[D]

B408-6

B408R119.WMF

Page 8

10 August, 2001 MOTORS AND SENSORS

1.4.5 STACK FEED-OUT MOTOR

1. Stack feed-out motor [A] (! x 2, " x 1)

[A]

B408R122.WMF

B408-7

Options

Page 9

JAM DETECTION 10 August, 2001

2. TROUBLESHOOTING

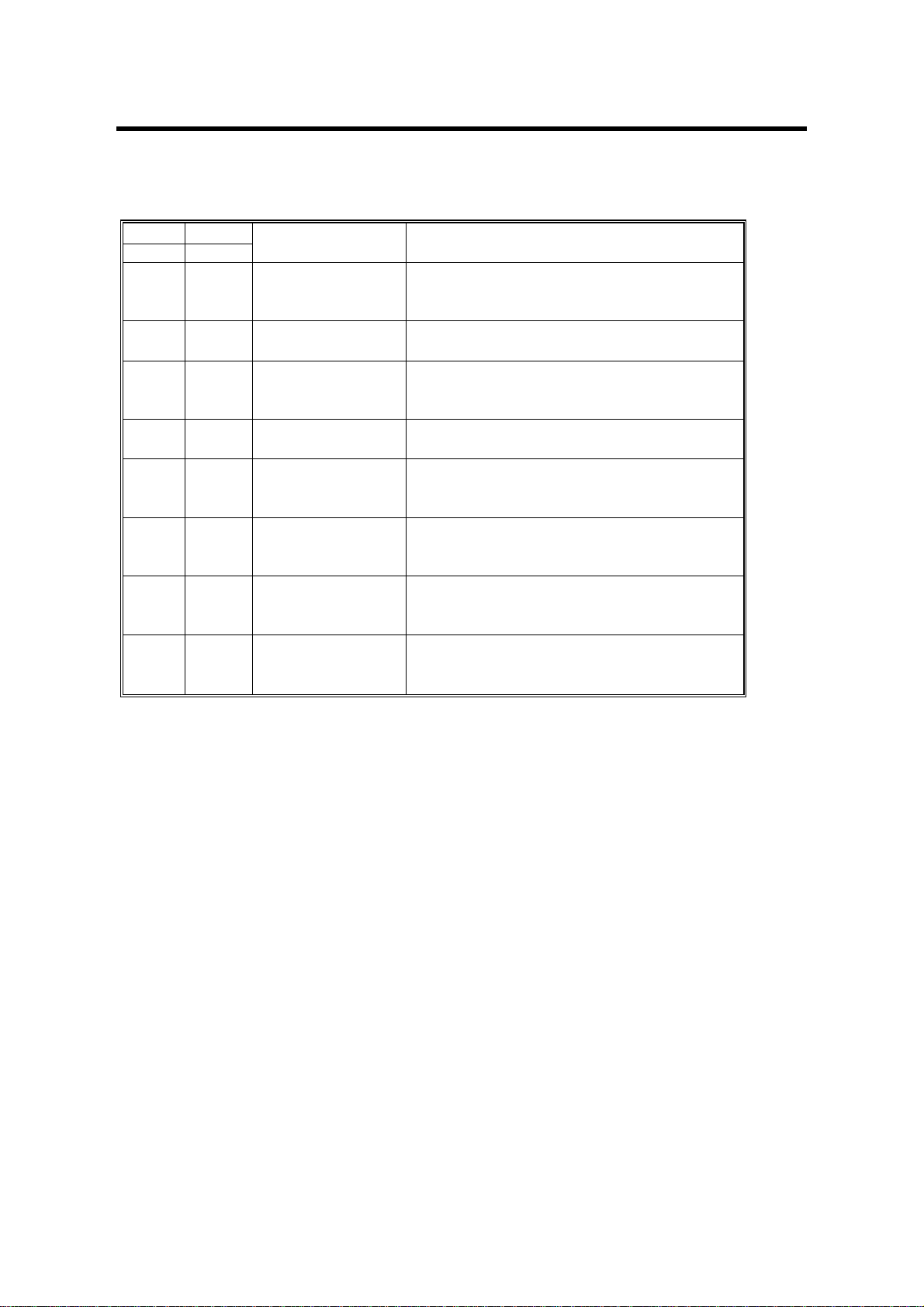

2.1 JAM DETECTION

Mode

Shift Staple

!!

!!

!

!

!

!

!

!

Jam Content

Entrance sensor:

On check

Entrance sensor:

Off check

Lower tray exit

sensor: On check

Tray exit sensor:

Off check

Stapler tray

entrance sensor:

On check

Stapler tray

entrance sensor:

Off check

Lower tray exit

sensor:

On check

Lower tray exit

sensor:

Off check

The entrance sensor does not t urn on w ithin

the normal time after the main machine exit

sensor turns on

The entrance sensor does not t urn of f within

the normal time after it turns on.

The lower tray exit sensor does not turn on

within the normal time after the entrance

sensor turns off.

The tray exit sensor does not turn off within

the normal time after it turns on.

The stapler tray entrance sensor d oes not

switch on within the normal time after the

entrance sensor switched on.

The staple tray entrance sens or does not

turn off within the normal time after it turns

on.

The lower exit sensor does not turn on after

the feed-out pawl feeds out the o ut put s.

The lower exit sensor turns on when the

feed-out pawl returns to its HP after fe edi ng

out the outputs.

B408-8

Page 10

10 August, 2001 DIP SWITCH SETTINGS

3. SERVICE TABLES

3.1 DIP SWITCH SETTINGS

The DIP switch should not be set to any combination other than those described in

the table below.

SW100

12

0 0 Normal operation mode (Default)

1 0 Packing mode.

Description

• Before packing the machine, do the following: Set switch 1 to 1

then back to zero. The lower tray moves to the lowest position.

Then turn off the main switch.

• After unpacking the machine, do the following: After turning the

main switch back on, the lower tray returns to home position

automatically.

B408-9

Options

Page 11

GENERAL LAYOUT 10 August, 2001

4. DETAILED DESCRIPTIONS

4.1 GENERAL LAYOUT

12

2

3

1

13

4

5

6

7

11

10

1. Upper Tray

2. Upp e r Tr ay Exit Roller

3. Entrance Roller

4. Tray Junction Gate

5. Upper Transport Roller

6. Stapler Junction Gate

7. Lower Tran sport R ol lers

8

9

B408D101.WMF

8. Stapler

9. Stack Feed-out Belt

10. Positioning Roller

11. Shift Roller

12. Lower Tray

13. Lower Tray Exit Roller

B408-10

Page 12

10 August, 2001 ELECTRICAL COMPONENT LAYOUT

4.2 ELECTRICAL COMPONENT LAYOUT

10

1

2

11

9

8

1. Upper Cover Switch

2. Paper Limit Sensor

3. Entrance Sensor

4. Exit Guide Plate Motor

5. Exit Guide Plate HP Sensor

6. Front Door Safety Switch

7. Stack Height Sensor

8. Lower Tray Exit Sensor

9. Lower Tray Upper Limit Switch

10. Shift HP Sensor

11. Shift Motor

3

12

4

5

19

18

13

14

20

7

6

B408D102.WMF

21

12. Jogger Fence HP Sensor

13. Positioning Roller Solenoid

14. Stapler HP Sensor

15. Stapler Tray Entrance Sensor

16. Stapler Tray Paper Sensor

17. Stapler Hammer Motor

18. Staple Sheet Sensor

19. Stack Feed-out Belt HP Sensor

20. Stapler Rotation HP Sensor

21. Staple Sensor

17

16

15

B408D103.WMF

B408-11

Options

Page 13

ELECTRICAL COMPONENT LAYOUT 10 August, 2001

22

32

31

30

29

28

27

26

25

22. Tray Junction Gate Solenoid

23. Lower Tray Lift Motor

24. Lower Tray Lower Limit Sensor

25. Stapler Motor

26. Jogger Fence Motor

27. Stack Feed-out Motor

28. Main Board

29. Lower Transport Motor

30. Stapler Junction Gate Solenoid

31. Exit Motor

32. Upper Transport Motor

23

24

B408D104.WMF

B408-12

Page 14

10 August, 2001 ELECTRICAL COMPONENT DESCRIPTION

4.3 ELECTRICAL COMPONENT DESCRIPTION

Symbol Name Function Index No.

Motors

M1

M2

M3 Jogger Fence Drives the jogger fences. 26

M4 Staple Hammer Drives the staple hammer. 17

M5 Stack Feed-out Drives the stack feed-out belt . 27

M6 Exit Guide Plate Opens and close s t he exit guide plate. 4

M7 Exit Drives the exit roller. 31

M8 Lower Tray Lift Moves the lower tray up or down. 23

M9 Shift Moves the shift roller from side to side. 11

M10 Stapler Moves the stapler unit from side to side. 25

Sensors

S1

S2

S3

S4 Shift HP Detects when the shift ro ller is at home position. 10

S5

S6 Stapler HP Detects when the stapler is at home position. 14

S7

S8

S9 Lower Tray Exit Checks for misfeeds. 8

S10 Stack Height Detects the top of the copy paper stack. 7

S11

S12

S13 Staple Sheet Detects the leading edge of the staple sheet . 18

S14

S15

Upper

Transport

Lower

Transport

Entrance

Paper Limit Detects when the paper stack h eight in the

Jogger Fence

HP

Stack Feed-out

Belt HP

Exit Guide PlateHPDetects when the exit guide plate is at home

Stapler Tray

Entrance

Lower Tray

Lower Limit

Stapler Tray

Paper

Stapler RotationHPDetects when the staple hammer is at home

Staple Detects whether there are staples in the staple

Drives the entrance roller and upper t r ansport

rollers.

Drives the lower transport rollers and

positioning roller.

Detects copy paper entering the finisher and

checks for misfeeds.

upper tray is at its limit.

Detects when the jogger fen ce is at home

position.

Detects when the stack feed-out belt is at home

position.

position.

Detects copy paper entering the stapler tray and

checks for misfeeds.

Detects when lower tray is at it s lower limit

position.

Detects when there is copy paper in t he stapler

tray.

position.

cartridge.

32

29

3

2

12

19

5

15

24

16

20

21

Solenoids

SOL1

SOL2

Tray Junction

Gate

Stapler Junction

Gate

Drives the tray junction gate.

Drives the stapler junction g at e.

B408-13

Options

22

30

Page 15

ELECTRICAL COMPONENT DESCRIPTION 10 August, 2001

Symbol Name Function Index No.

SOL3

Switches

SW1

SW2

SW3

PCBs

PCB1

Positioning

Roller

Lower Tray

Upper Limit

Front Door

Safety

Upper Cover Cuts the dc power when the upper cover is

Main Controls the finisher and communicates with the

Moves the positioning roller.

Detects when lower tr ay is at its upper limit

position.

Cuts the dc power when the front door is

opened.

opened.

copier/printer.

13

9

6

1

28

B408-14

Page 16

10 August, 2001 DRIVE LAYOUT

4.4 DRIVE LAYOUT

1

2

4

3

5

6

B408D105.WMF

1. Exit Motor

2. Upper Transport Motor

3. Lower Transport Motor

B408D106.WMF

4. Shift Motor

5. Exit Guide Plate Motor

6. Lower Tray Lift Motor

B408-15

Options

Page 17

DRIVE LAYOUT 10 August, 2001

7

8

9

B408D107.WMF

7. Stack Feed-out Motor

8. Jogger Motor

9. Stapler Motor

B408-16

Page 18

10 August, 2001 JUNCTION GATES

4.5 JUNCTION GATES

[A]

[C]

[B]

[D]

B408D108.WMF

Depending on the finishing mode, the copies are directed up, straight through, or

down by the combination of the tray junction gate [A] and stapler junction gate [B].

These gates are controlled by the tray junction gate solenoid [C] and stapler

junction gate solenoid [D].

Upper tray mode

The tray junction gate solenoid remains off. The copies go up to the upper tray.

Sort/stack mode

The tray junction gate solenoid turns on and the stapler junction gate solenoid

remains off. The copies are sent to the lower tray directly.

Staple mode

The tray junction gate solenoid and the stapler junction gate solenoid both turn on.

The copies go down to the jogger unit.

B408-17

Options

Page 19

UPPER TRAY 10 August, 2001

4.6 UPPER TRAY

[A]

B408D109.WMF

When the paper limit sensor [A] switches on during feed-out for each of three

consecutive sheets of paper, paper overflow is detected.

B408-18

Page 20

10 August, 2001 LOWER TRAY UP/DOWN MECHANISMS

4.7 LOWER TRAY UP/DOWN MECHANISMS

[B]

[A]

[D]

[E]

[C]

B408D112.WMF

The vertical position of the lower tray [A] depends on the height of the copied paper

stack on the lower tray. The stack height sensor feeler [B] contacts the top of the

stack, and the lower tray lift motor [C] controls the tray height.

When the lower tray reaches its lowest poss ible position, the actuator [D] turns on

the lower tray lower limit sensor [E], and copying stops.

Tray Up

When the copy paper on the tray is removed, the stack height sensor turns off and

the tray lifts up. Then, the tray stops when the sensor turns on again (the tray

pushes up the feeler).

Sort/stack Mode (Tray Down)

Every five sheets of paper, the tray goes down until the sensor turns off again.

Then, it goes up until the sensor is on again.

Staple Mode (Tray Down)

After a stapled copy is fed out, the tray goes up for 220 ms and stops for 300 ms.

Then, it goes down for 1 second, waits for 500 ms, then goes up until the sensor

turns on.

Options

B408-19

Page 21

PAPER SHIFT MECHANISM 10 August, 2001

4.8 PAPER SHIFT MECHANISM

[F]

[C]

[B]

[A]

[D]

[E]

B408D110.WMF

In the sort/stack mode, the shift roller [A] moves from side to side to separate the

sets of copies.

The horizontal position of the shift roller is controlled by the shift motor [B] and the

shift gear disk [C]. After the trailing edge of the copy passes the upper transport

roller, the shift motor turns on, driving the shift gear disk and the link [D].

After the paper is delivered to the lower tray [E], the shift roller moves to the HP,

which is detected by the shift HP sensor [F]. Then, when the trailing edge of the

next copy passes the upper transport roller, the shift roller shifts again. This

operation is done every sheet.

When the trailing edge of eac h page in the next set of copies passes the upper

transport roller, the shift roller shifts in the opposite direction.

B408-20

Page 22

10 August, 2001 JOGGER UNIT PAPER POSITIONING MECHANISM

4.9 JOGGER UNIT PAPER POSITIONING MECHANISM

[F]

[E]

B408D114.WMF

[B]

B408D113.WMF

In staple mode, each sheet of copy paper is vertically and horizontally aligned

when it arrives in the jogger unit.

[D]

[A]

[C]

For the vertical paper alignment, the positioning roller solenoid [A] turns on shortly

after the stapler tray entrance sensor [B] turns off, and the positioning roller [C]

pushes the copy against the bottom of the stack stopper [D].

For the horizontal paper alignment, the jogger front fence [E] and the rear fence [F]

move to the waiting position, which is 18 mm away from the side of the paper.

When aligning the paper vertically, the jogger fence moves in 14 mm from the

waiting position. After the vertical position has been aligned, the jogger fence

pushes the paper 4 mm against the rear fence to align the paper horizontally. Then

the jogger fence moves back to the previous position.

B408-21

Options

Page 23

EXIT GUIDE PLATE 10 August, 2001

4.10 EXIT GUIDE PLATE

[B]

[C]

[A]

[D]

B408D111.WMF

When stacking a large size of paper (such as A3, DLT) in the jogger unit, the

leading edge of the paper reaches the exit rollers. To prevent the paper from

running into the exit rollers and not being aligned correctly, the exit guide plate [A]

is moved up to make a gap between the exit rollers. This operation is done for all

paper sizes, but is only needed for the larger sizes.

The exit guide plate motor [B] and exit roller release cam [C] control the exit guide

plate movement. When the exit guide plate motor starts, the cam turns and the exit

guide plate moves up. When stapling is finished, the exit gu ide plate motor turns on

again to close the exit guide plate. When the exit guide plate HP sensor [D] turns

on, the motor stops.

B408-22

Page 24

10 August, 2001 STAPLER MECHANISM

4.11 STAPLER MECHANISM

[E]

[D]

[B]

[C]

[A]

B408D116.WMF

The staple hammer motor [A] drives the staple hammer.

The staple sheet sensor [B] detects the leading edge of the staple sheet at the

stapling position to prevent the hammer from operating if there are no staples at

the stapling position.

If there is no staple cartridge in the stapler unit or no staples in the staple cartridge,

staple end is indicated on the operation panel. The stapler sensor [C] detects this.

The stapler rotation HP sensor [D] checks whether the staple hammer mechanism

returns to home position after each stack has been stapled.

When excessive load is applied to the staple hammer motor, the copier detects a

staple jam. When a staple jam has occurred, the jammed staple is inside the staple

cartridge [E]. Therefore, the jammed staple can be removed easily after pulling out

the staple cartridge.

B408-23

Options

Page 25

STAPLER UNIT MOVEMENT MECHANISM 10 August, 2001

4.12 STAPLER UNIT MOVEMENT MECHANISM

[B]

[A]

B408D117.WMF

The stapler motor moves the stapler [A] from side to side. After the start key is

pressed, the stapler moves from its home position to the stapling position.

If two-staple-position mode is selected, the stapler moves to the front stapling

position first, then moves to the rear stapling position. However, for the next copy

set, it staples in the reverse order (at the rear side first, then at the front side).

After the job is completed, the stapler moves back to its home position. The stapler

HP sensor [B] detects this.

B408-24

Page 26

10 August, 2001 PAPER FEED-OUT MECHANISM

4.13 PAPER FEED-OUT MECHANISM

[A]

[B]

[C]

[D]

B408D118.WMF

After the copies have been stapled, the stack feed-out motor [A] starts. The pawl

[B] on the stack feed-out belt [C] transports the set of stapled copies up and feeds

it to the shift roller. The shift roller takes over stack feed-out after the leading edge

reaches this roller.

Just before the stapled stack passes through the lower tray exit sensor, the stackfeed-out motor turns off until the shift rollers have completely fed the stack out to

the lower tray. Then, the stack-feed-out motor turns on again until the pawl [B]

actuates the stack feed-out belt home positio n sensor [D].

Options

B408-25

Page 27

SPECIFICATIONS 10 August, 2001

5. OVERALL MACHINE INFORMATION

5.1 SPECIFICATIONS

Upper Tray

Paper Size: A3 to A6

DLT to HLT

Power Weight: 60 to 157 g/m2 (16 to 42 lb)

Paper Capacity: 250 sheets (A4 sideways / LT sideways or smaller: 80

g/m2, 20lb)

50 sheets (A3, B4, DLT, LG: 80 g/m2, 20 lb)

Lower Tray

Paper Size: No staple mode:

A3 to B5

DLT to HLT

Staple mode:

A3, B4, A4, B5

DLT to LT

Paper Weight: No staple mode: 60 ~ 157 g/m2 (16 ~ 42 lb)

Staple mode: 64 ~ 90 g/m2 (17 ~ 24 lb)

Stapler Capacity: 30 sheets (A3, B4, DLT, LG)

50 sheets (A4, B5 sideways, LT)

Paper Capacity: No staple mode:

1,000 sheets (A4/LT or smaller: 80 g/m2, 20 lb)

500 sheets (A3, B4, DLT, LG: 80 g/m2, 20 lb)

Staple mode:

(80 g/m2, 20 lb, number of sets)

Set Size 10 to 50

Size

A4/LT sideways

B5 sideways

A4/LT Lengthwise 100 50 to 10 50 to 10

A3, B4, DLT, LG 50 50 to 10 —

2 to 9

100 100 to 20 100 to 20

10 to 30 31 to 50

Staple positions: 1 Staple: 2 positions (Front, Rear)

2 Staples: 2 positions (Upper, Left)

Staple Replenishment: Cartridge (5,000 staples/cartridge)

Power Source: 24 Vdc, 5 Vdc (from the copier/printer)

Power Consumption: 50 W

Weight: 25 kg (55.2 lbs)

Dimensions (W x D x H): 527 x 520 x 790 mm (20.8" x 20.5" x 31.1")

B408-26

Page 28

1

FINISHER (B408) Point to Point Diagram

A

B

Front Door

Safety Switch

Lower Tray Upper

Limit Switch

Upper Cover

C

D

Lower Tray Exit Sn.

E

Stapler Tray Paper

F

Stack Feed-out Belt

Jogger Fence H.P.

G

Bridge

Switch

Entrance Sn.

Paper Limit Sn.

Shift H.P. Sn.

Exit Guide Plate

H.P. Sn.

Stapler H.P. Sn.

Stapler Tray

Entrance Sn.

Lower Tray

Lower Limit Sn.

Stack Height Sn.

Sn.

H.P. Sn.

Sn.

Unit

SW2

SW1

SW3

S1

S2

S4

S9

S7

S6

S8

S11

S10

S12

S5

S3

DC Line

Pulse Signal

Signal Direction

2345678910

CN714-9

-8

-7

-6

-5

-4

-3

-2

-1

CN713-8

-7

-6

-5

-4

-3

-2

-1

CN204-3

-2

-1

CN205-3

-2

-1

CN206-3

-2

-1

CN207-3

-2

-1

CN208-3

-2

-1

CN209-3

-2

-1

CN210-3

-2

-1

CN211-3

-2

-1

CN212-3

-2

-1

CN213-3

-2

-1

CN214-3

-2

-1

CN215-3

-2

-1

SYMBOL TABLE

CN300-1

-2

CN300

CN301-1

-2

-3

CN301

CN302-1

-2

-3

CN303-1

-2

-3

CN304-1

-2

-3

CN305-1

CN306-1

-2

-3

CN306-4

-5

-6

CN302CN303

CN304

-2

-3

CN305CN306

! Active Low

" Active High

[ ] Voltage

T1

CN300-2

-1

CN301-3

-2

-1

CN302-3

-2

-1

CN303-3

-2

-1

CN304-3

-2

-1

CN305-3

-2

-1

CN306-6

-5

-4

CN306-3

-2

-1

CN100-1

CN101-1

CN102-1

CN103-1

CN104-1

CN104-3

CN105-1

CN105-4

CN105-7

-10

CN105-11

-12

-13

CN106-1

CN106-4

CN106-7

CN107-1

CN107-4

CN107-7

CN107-10

-11

-12

N.C.

-2

+24V

-3

+24V

-4

+24V

-5

+24V

-6

GND

-7

GND

-8

GND

-9

GND

GND

-2

GND

-3

+5V

-4

+5V

-5

RXD

-6

ZESM

-7

TXD

-8

+5V

+24V

-2

["24] Front Door Safety Switch

+24V

-2

["24] Lower Tray Upper Limit Switch

+24V

-2

["24] Upper Cover Switch

[!5] Entrance Sensor

-4

GND

-5

+5V

+5V

-2

[!5] Paper Limit Sensor

-3

GND

GND

-5

["5] Shift H.P. Sensor

-6

+5V

N.C.

-8

GND

-9

[!5] Lower Tray Exit Sensor

+5V

GND

["5] Exit Guide Plate H.P. Sensor

+5V

GND

-2

["5] Stapler H.P. Sensor

-3

+5V

[!5] Stapler Tray Entrance Sensor

-5

GND

-6

+5V

GND

-8

["5] Lower Tray Lower Limit Sensor

-9

+5V

GND

-2

["5] Stack Height Sensor

-3

+5V

GND

-5

["5] Stapler Tray Paper Sensor

-6

+5V

GND

-8

["5] Stack Feed-out Belt H.P.Sensor

-9

+5V

GND

["5] Jogger Fence H.P. Sensor

+5V

Main PCB

(PCB 1)

Staple Hammer Motor +[!24]

Staple Hammer Motor +[!24]

+24V

+24V

N.C.

A [24 → 24/0]

A [24 → 24/0]

B [24 → 24/0]

B [24 → 24/0]

N.C.

+24V

+24V

N.C.

A [24 → 24/0]

A [24 → 24/0]

B [24 → 24/0]

B [24 → 24/0]

+24V

+24V

N.C.

A [24 → 24/0]

A [24 → 24/0]

B [24 → 24/0]

B [24 → 24/0]

+24V

A [24 → 24/0]

A [24 → 24/0]

B [24 → 24/0]

B [24 → 24/0]

+24V

+24V

+24V

N.C.

A [24 → 24/0]

A [24 → 24/0]

B [24 → 24/0]

B [24 → 24/0]

+24V

+24V

N.C.

A [24 → 24/0]

A [24 → 24/0]

B [24 → 24/0]

B [24 → 24/0]

N.C.

+24V

+24V

N.C.

A [24 → 24/0]

A [24 → 24/0]

B [24 → 24/0]

B [24 → 24/0]

+24V

+24V

N.C.

A [24 → 24/0]

A [24 → 24/0]

B [24 → 24/0]

B [24 → 24/0]

N.C.

Lower Tray Lift Motor -[!24]

Lower Tray Lift Motor +[!24]

+24V

Tray Junction Gate [!24]

+24V

Stapler Junction Gate [!24]

+24V

Positioning Roller [!24]

+5V

Stapler Rotation Sensor ["5]

Staple Sheet Sensor ["5]

Staple Sensor ["5]

GND

Staple Hammer Motor -[!24]

Staple Hammer Motor -[!24]

CN108-1

-10

-11

-12

-13

-14

-15

CN109-1

CN110-1

CN111-1

CN112-1

-10

-11

-12

-13

-14

-15

CN113-1

-10

CN114-1

CN114-3

CN115-1

CN116-1

CN116-6

-2

-3

-4

-5

-6

-7

-8

-9

-2

-3

-4

-5

-6

-7

-2

-3

-4

-5

-6

-2

-3

-4

-5

-6

-7

-2

-3

-4

-5

-6

-7

-8

-9

-2

-3

-4

-5

-6

-7

-8

-9

-2

-4

-2

-2

-3

-4

-5

-7

-8

-9

CN216-7

-6

-5

-4

-3

-2

-1

CN217-7

-6

-5

-4

-3

-2

-1

CN218-6

-5

-4

-3

-2

-1

CN219-7

-6

-5

-4

-3

-2

-1

CN220-7

-6

-5

-4

-3

-2

-1

CN221-7

-6

-5

-4

-3

-2

-1

CN222-7

-6

-5

-4

-3

-2

-1

CN307-2

-1

CN224-2

-1

CN225-2

-1

CN226-2

-1

CN

CN

CN

CN

CN216CN217

CN218

CN219CN220CN221

CN222

307

224

225

226

CN216-1

CN217-1

CN218-1

CN219-1

CN220-1

CN221-1

CN222-1

CN307-1

CN224-1

CN225-1

CN226-1

T2

-2

-3

-4

-5

-6

-7

-2

-3

-4

-5

-6

-7

-2

-3

-4

-5

-6

-2

-3

-4

-5

-6

-7

-2

-3

-4

-5

-6

-7

-2

-3

-4

-5

-6

-7

-2

-3

-4

-5

-6

-7

-2

-2

-2

-2

CN223-1

CN227-5

CN228-4

A

Upper Transport

M1

Motor

M7

Exit Motor

B

Lower Transport

M2

Motor

Shift Motor

M9

C

Exit Guide Plate

M6

Motor

M5

M3

Stack Feed-out Motor

Jogger Fence Motor

D

E

M10

-2

M8

SOL1

SOL2

SOL3

-4

-3

-2

-1

-3

-2

-1

S14

S13

S15

M4

Stapler Motor

Lower Tray

Lift Motor

Tray Junction Gate

Stapler Junction Gate

Positioning Roller

Stapler Rotation Sn.

Staple Sheet Sn.

Staple Sn.

Staple Hammer

Motor

T3

Staple Unit

F

G

1 2345678910

Page 29

1000-SHEET FINISHER (B408) ELECTRICAL COMPONENT LAYOUT

10

11

32

31

30

1

9

8

7

22

2

3

4

5

12

19

6

B408D102.WMF

18

13

20

14

21

15

Symbol Name Index No. P to P

Motors

M1 Upper Transport 32 A9

M2 Lower Transport 29 B9

M3 Jogger Fence 26 E9

M4 Staple Hammer 17 G4

M5 Stack Feed-out 27 D9

M6 Exit Guide Plate 4 C9

M7 Exit 31 B9

M8 Lower Tray Lift 23 F9

M9 Shift 11 C9

M10 Stapler 25 E9

Sensors

S1 Entrance 3 C2

S2 Paper Limit 2 D2

S3 Jogger Fence HP 12 F2

S4 Shift HP 10 D2

S5 Stack Feed-out Belt HP 19 F2

S6 Stapler HP 14 E2

S7 Exit Guide Plate H P 5 D2

S8 Stapler Tray Entrance 15 E2

S9 Lower Tray Exit 8 D2

S10 Stack Height 7 F2

S11 Lower Tray Lower Limit 24 E2

S12 Stapler Tray Paper 16 F2

S13 Staple Sheet 18 G9

S14 Stapler Rotation HP 20 G9

S15 Staple 21 G9

29

28

27

26

25

24

B408D104.WMF

23

17

16

B408D103.WMF

Solenoids

SOL1 Tray Junction Gate 22 F9

SOL2 Stapler Junction Gate 30 F9

SOL3 Positioning Roller 13 F9

Switches

SW1 Lower Tray Upper Limit 9 C2

SW2 Front Door Safety 6 C2

SW3 Upper Cover 1 C2

PCBs

PCB1 Main 28 A5

Loading...

Loading...