Page 1

TWO-TRAY FINISHER

(Machine Code: G565)

Page 2

23 February, 2001 COVERS

1. REPLACEMENT AND ADJUSTMENT

1.1 COVERS

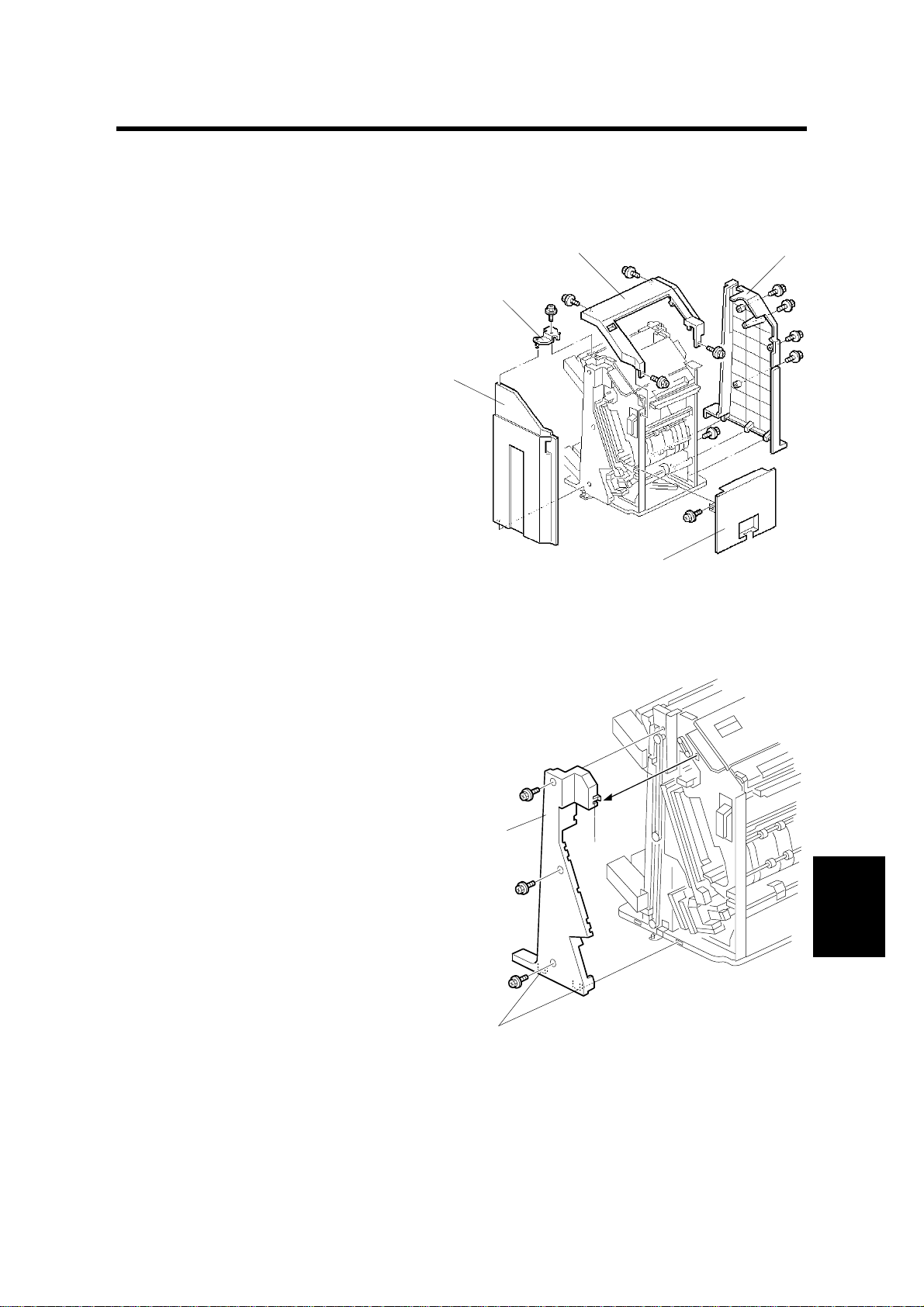

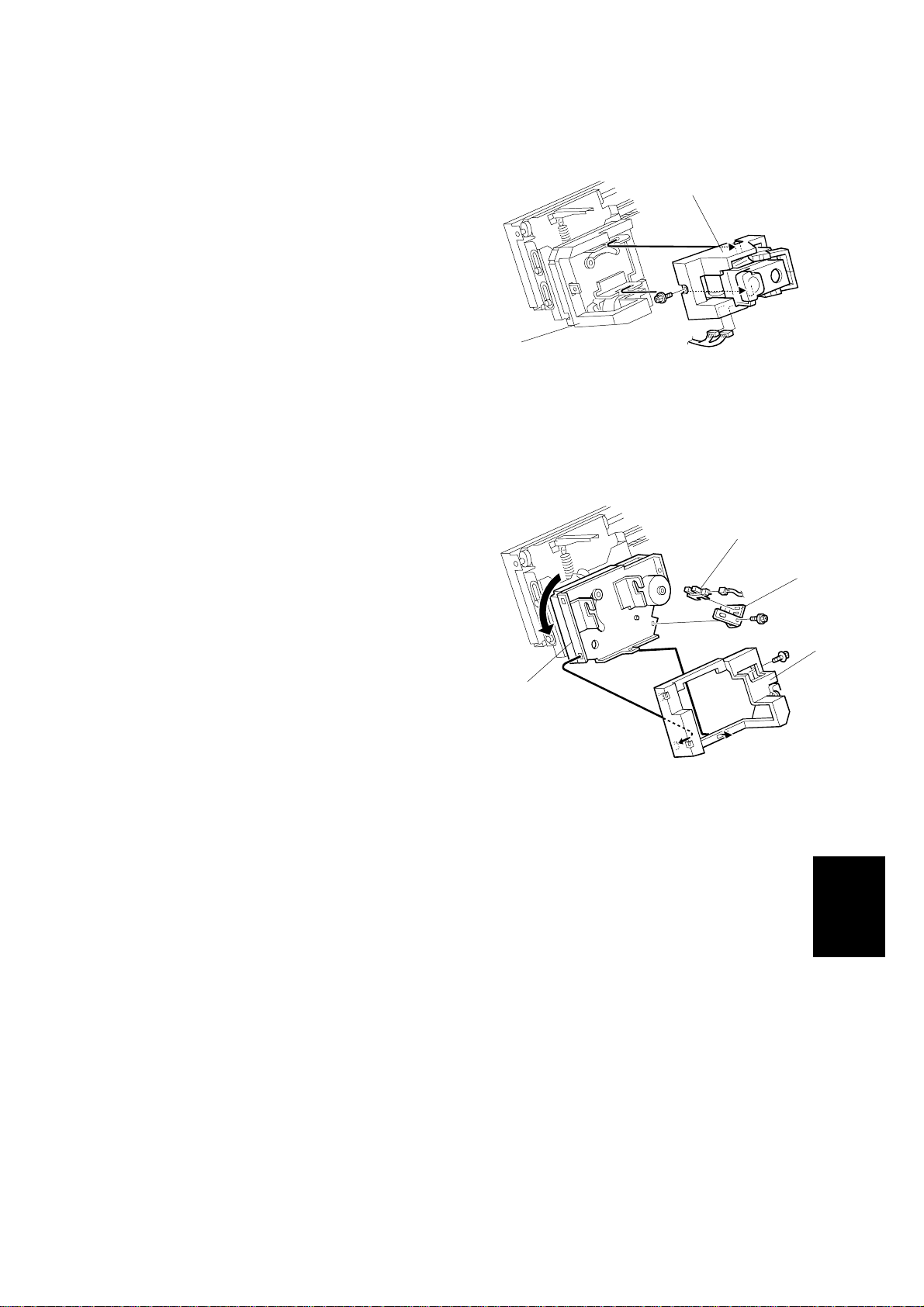

1.1.1 EXTERNAL COVERS

1. Top cover [A] (! x 4)

NOTE: If the shift tray below is

blocking the screw hole,

remove the shift tray.

[A]

[B]

[D]

2. Bracket [B] (! x 1)

3. Front door [C]

4. Rear cover [D] (! x 4)

5. Right cover [E] (! x 2)

1.1.2 INNER COVER

1. Front cover (☛ 1.1.1 EXTERNAL

COVERS)

2. Inner cover [A] (! x 3, tabs [B] x 3)

[C]

[E]

G565R151.WMF

[B]

G565-1

[A]

[B]

Peripherals

G565R102.WMF

Page 3

POSITIONING ROLLER 23 February, 2001

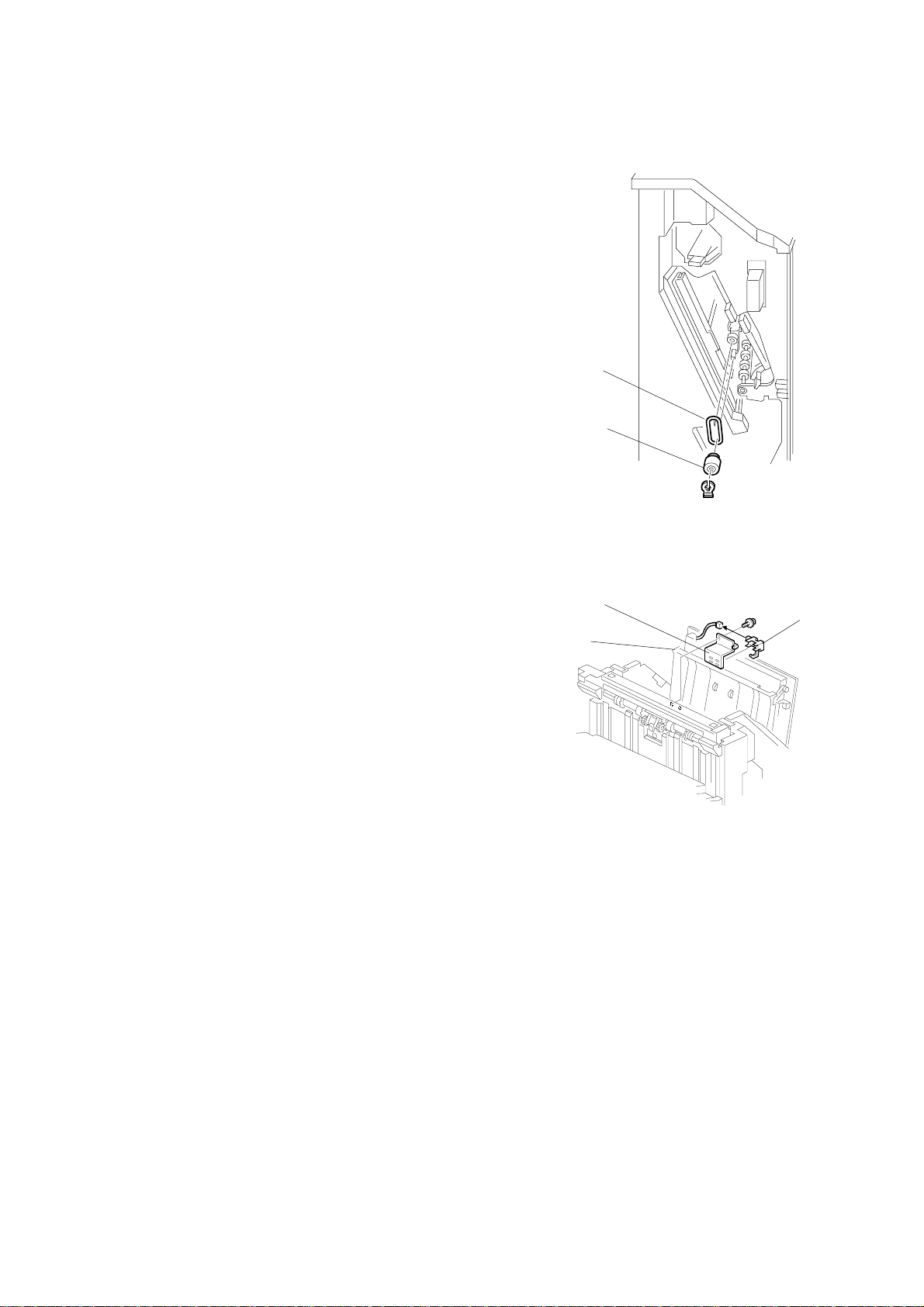

1.2 POSITIONING ROLLER

1. Open the front door.

2. Positioning roller [A] (" x 1)

3. Belt [B]

[B]

[A]

G565R103.WMF

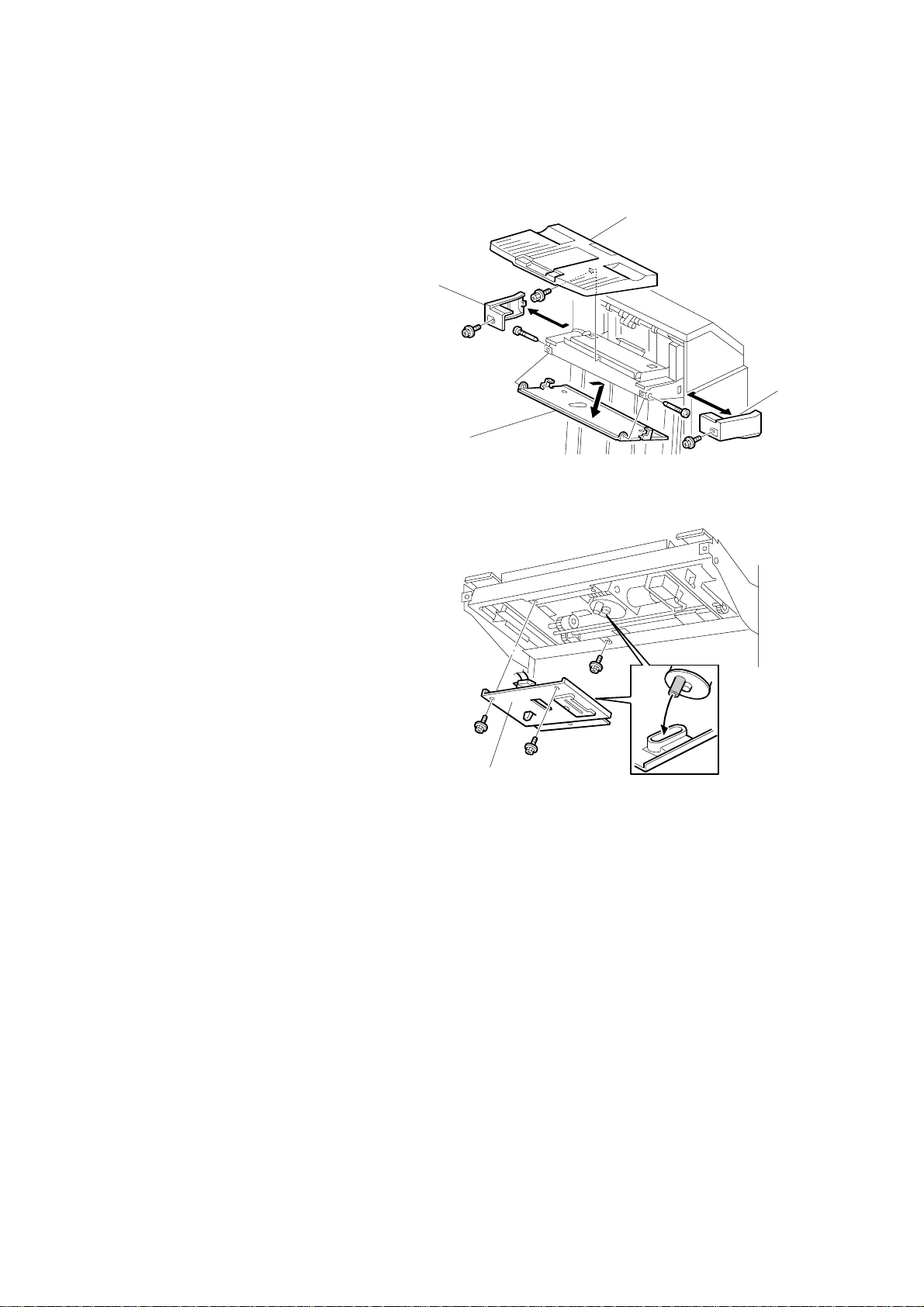

1.3 TRAY 1 EXIT SENSOR

1. Top cover (☛ 1.1.1 EXTERNAL COVERS)

2. Open transport door [A]

3. Bracket [B] (! x 1, (# x 1)

4. Tray 1 exit sensor [C]

[B]

[C]

[A]

G565R104.WMF

G565-2

Page 4

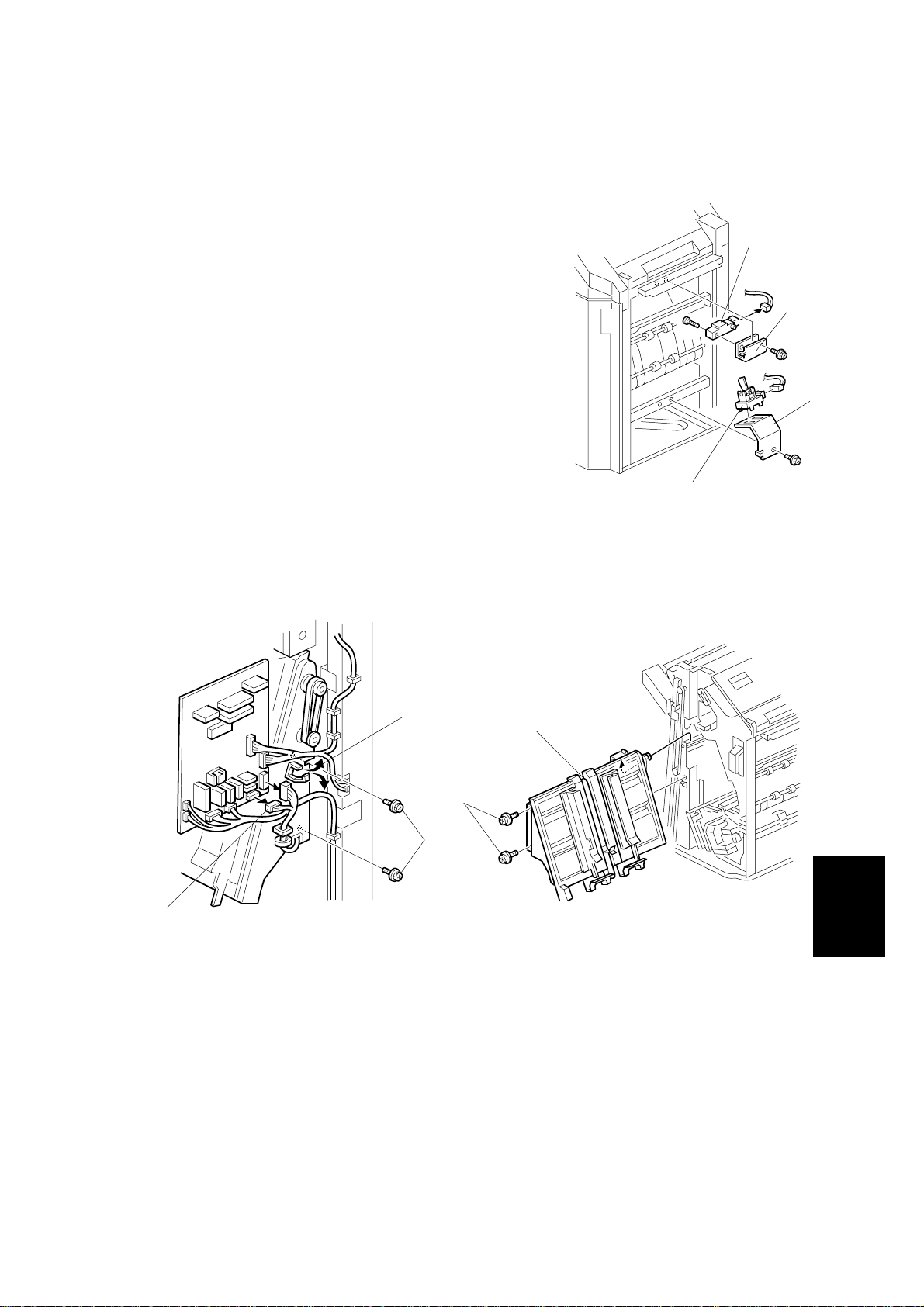

23 February, 2001 ENTRANCE SENSOR/STAPLER TRAY ENTRANCE SENSOR

1.4 ENTRANCE SENSOR/STAPLER TRAY ENTRANCE

SENSOR

1. Entrance sensor bracket [A] (! x 1, # x 1)

2. Entrance sensor [B] (! x 1)

3. Stapler tray entrance sensor bracket [C] (! x

1, # x 1)

4. Stapler tray entrance sensor [D]

1.5 STAPLER TRAY

[D]

[B]

[A]

[C]

G565R105.WMF

[A]

[C]

[E]

[D]

[B]

G565R106.WMF

G565R107.WMF

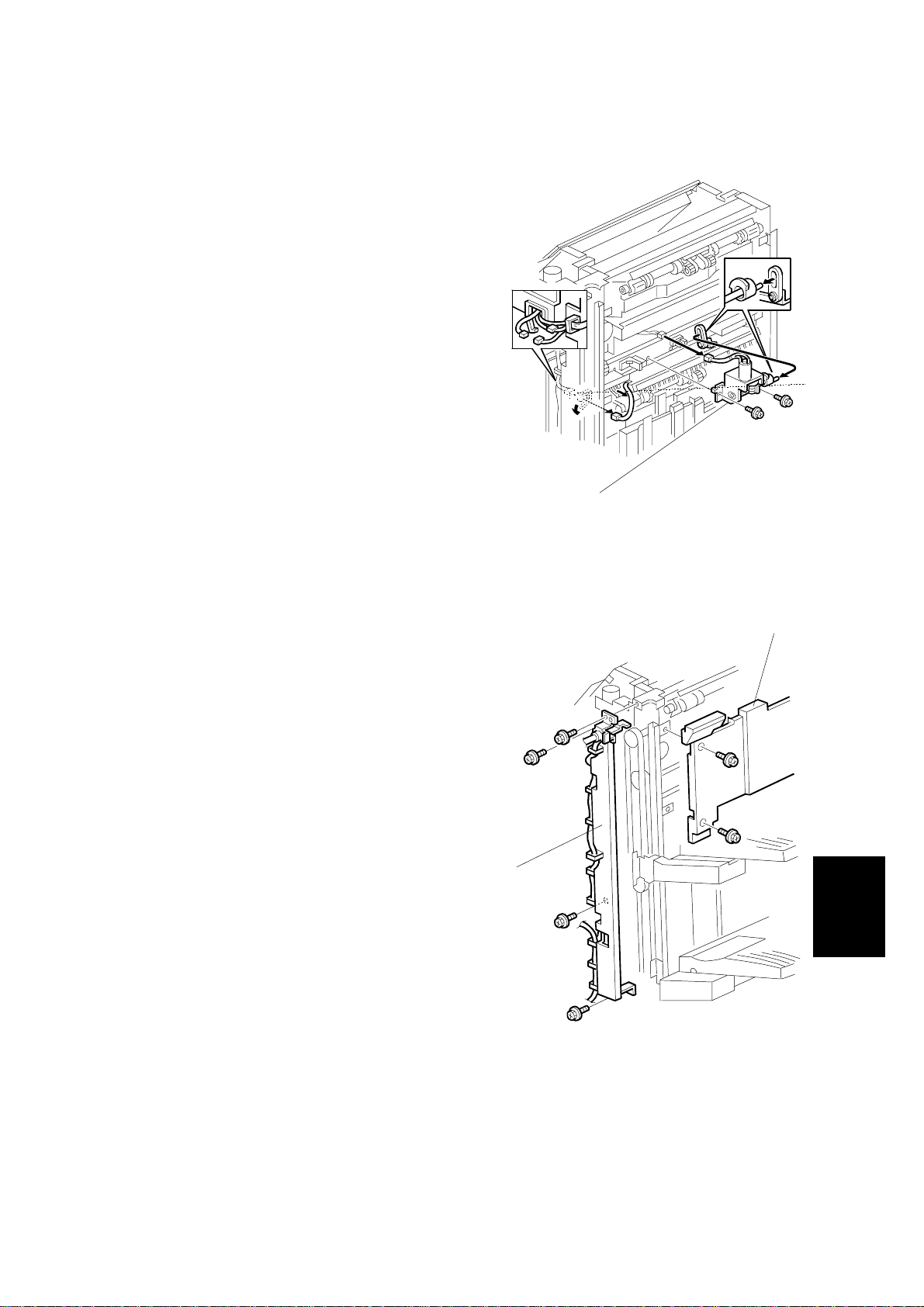

1. External covers, front door, inner cover (☛ 1.1.1 EXTERNAL COVERS, 1.1.2

INNER COVER)

2. Two clamps [A]

3. Harnesses [B] (# x 8)

4. Stapler tray [C] (! x 2 [D], ! x 2 [E])

NOTE: At the front of the finisher, pull the stapler tray toward you and lift it out.

Peripherals

G565-3

Page 5

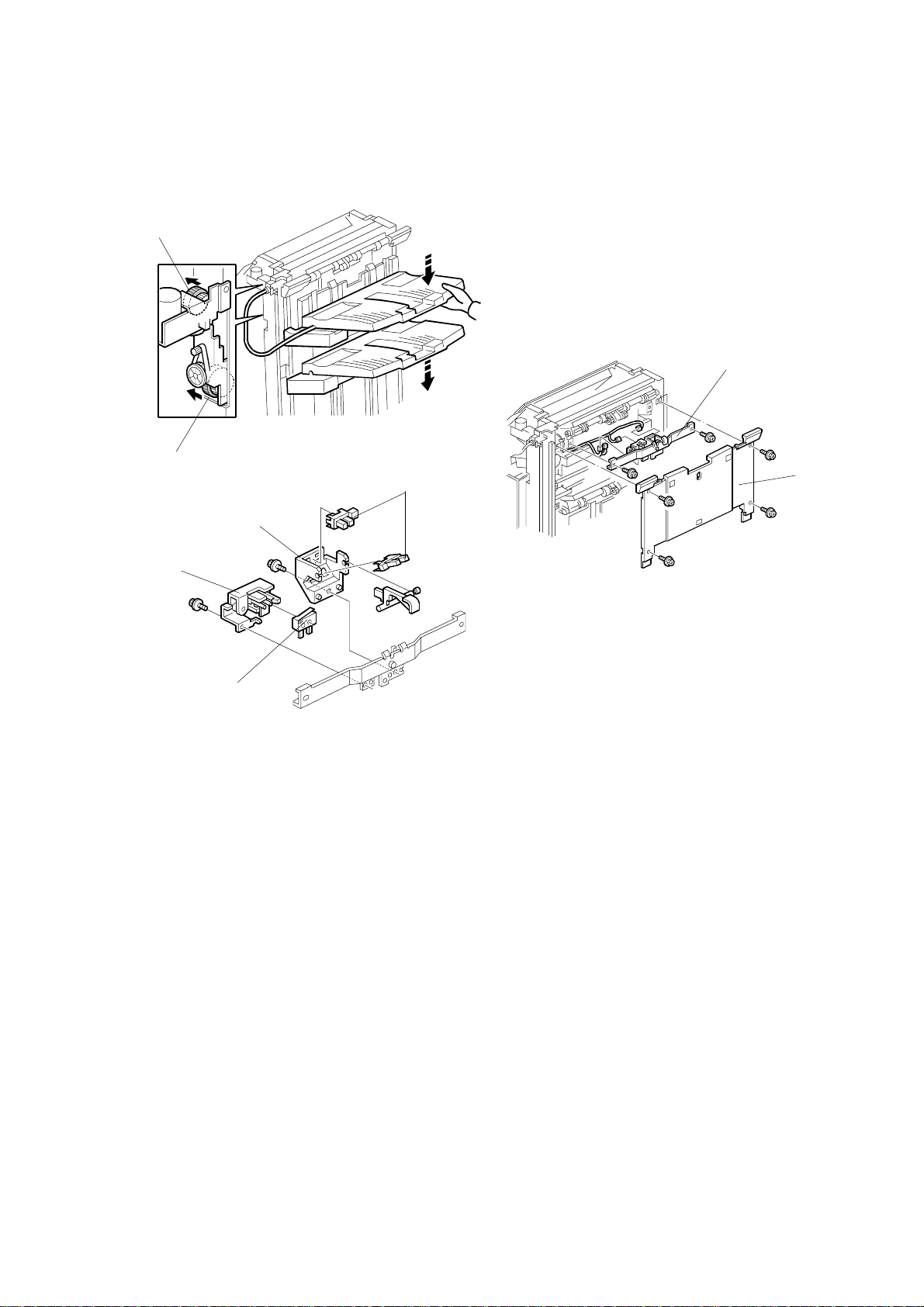

UPPER STACK HEIGHT SENSORS/TRAY 1 UPPER LIMIT SWITCH 23 February, 2001

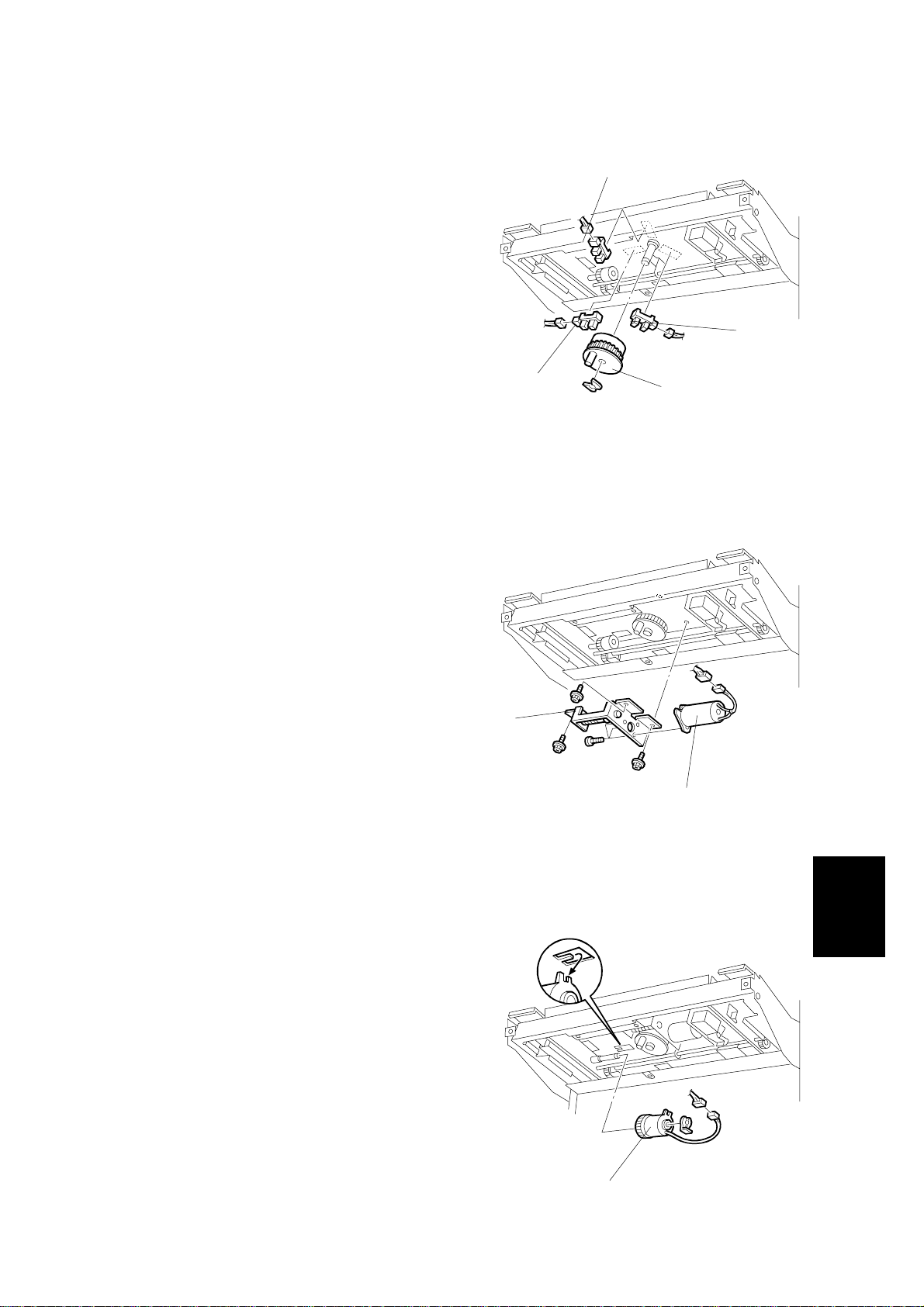

1.6 UPPER STACK HEIGHT SENSORS/TRAY 1 UPPER

LIMIT SWITCH

[B]

[D]

G565R201.WMF

[A]

[F]

[E]

[C]

[G]

G565R109.WMF

[H]

G565R110.WMF

1. External covers (☛ 1.1.1 EXTERNAL COVERS)

2. Place one hand under tray 2 (the lower tray), press in on the gear [A] to release

the tray, and then support it with your hand as it descends.

3. Place one hand under tray 1 (the upper tray), press in on the gear [B] to

release the tray, and then support it with your hand as it descends.

4. Tray 1 back fence [C] (! x 4)

5. Sensor stay [D] (! x 2, (# x 4)

6. Plastic bracket [E] (! x 1)

7. Stack height sensors [F]

8. Metal bracket [G] (! x 1)

9. Upper limit switch [H]

G565-4

Page 6

23 February, 2001 EXIT GUIDE PLATE MOTOR

1.7 EXIT GUIDE PLATE MOTOR

1. Tray 1 back fence (☛ 1.6 UPPER

STACK HEIGHT SENSORS/TRAY 1

UPPER LIMIT SWITCH)

2. Exit guide plate motor [A] (! x2, #

x1)

NOTE: Disengage the shaft of the exit

guide plate motor from the

ring.

G565R111.WMF

[A]

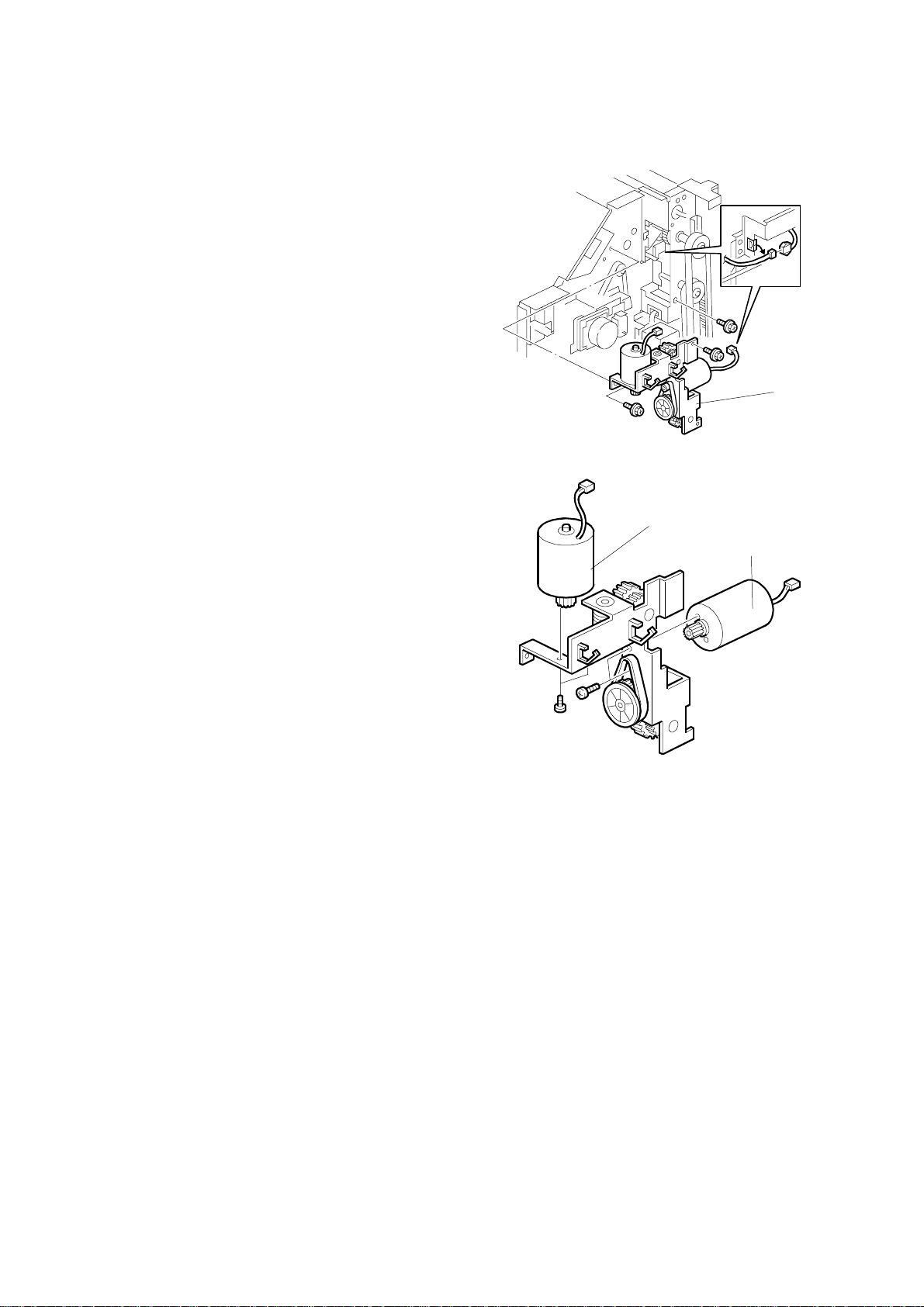

1.8 LIFT MOTORS

1. Top cover and rear cover (☛ 1.1.1

EXTERNAL COVERS)

2. Tray 1 back fence [A] (☛ 1.6 UPPER

STACK HEIGHT SENSORS/TRAY 1

UPPER LIMIT SWITCH)

3. Sensor stay [B] (! x 4)

[A]

[B]

Peripherals

G565R203.WMF

G565-5

Page 7

LIFT MOTORS 23 February, 2001

4. Motor bracket [C] (! x 3, # x 2)

[C]

G565R204.WMF

5. Tray 1 lift motor [D] (! x 2, drive belt)

6. Tray 2 lift motor [E] (! x 2, drive belt)

[D]

[E]

G565R205.WMF

G565-6

Page 8

23 February, 2001 LOWER EXIT SENSOR

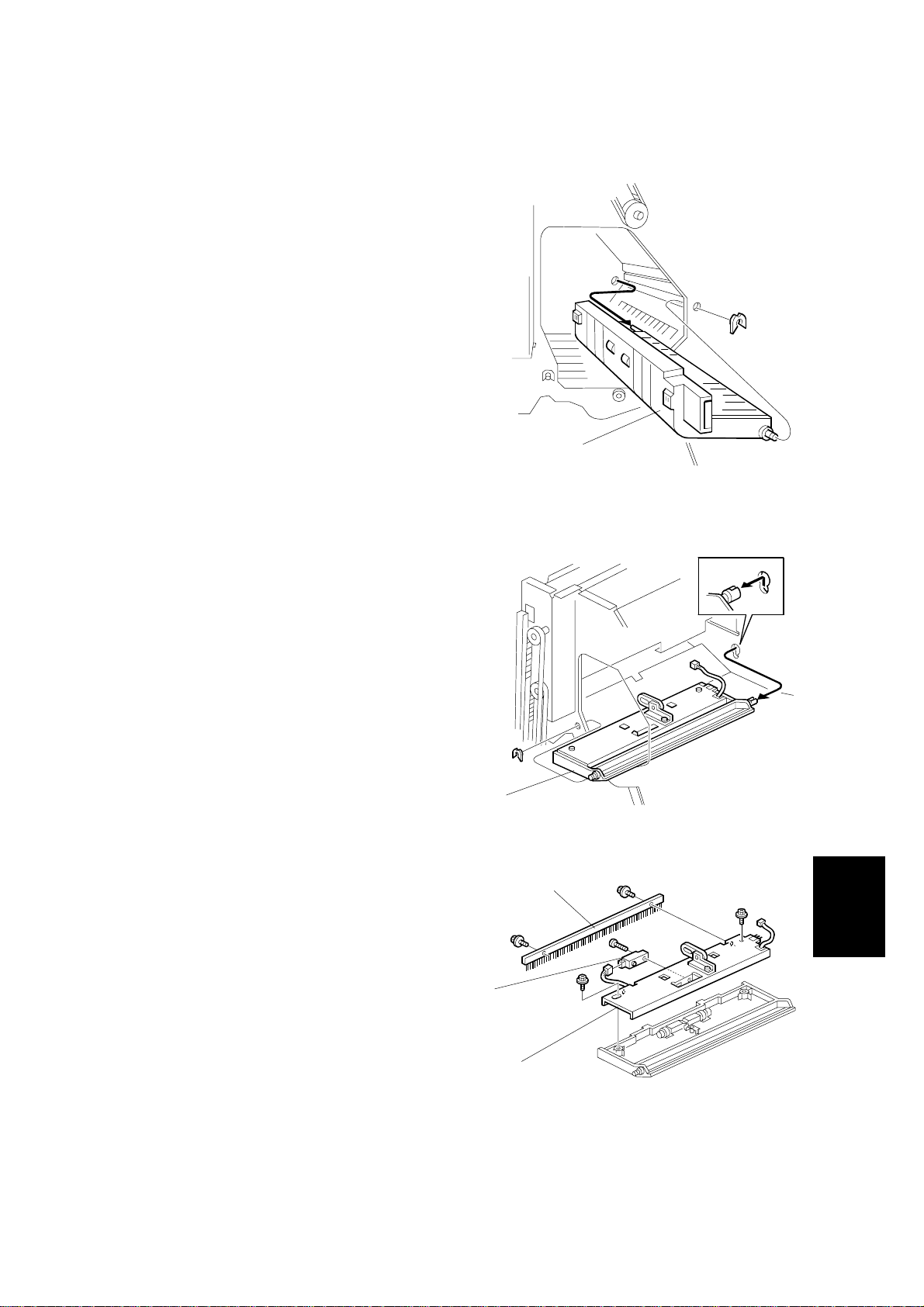

1.9 LOWER EXIT SENSOR

1. Front door, external and internal

covers. (☛ 1.1 COVERS)

2. Exit guide plate motor (☛ 1.7 EXIT

GUIDE PLATE MOTOR)

3. Guide plate [A] (" x 1)

NOTE: Pull the shaft toward you

through the round hole.

[A]

G565R112.WMF

4. Guide plate exit assembly [B] (# x 1,

" x 1)

5. Anti-static brush [C] (! x 2)

6. Bracket guide exit [D] (! x 2)

7. Lower exit sensor [E] (! x 1, # x 1)

[B]

G565R113.WMF

[C]

Peripherals

[E]

G565-7

[D]

G565R114.WMF

Page 9

LOWER STACK HEIGHT SENSORS 23 February, 2001

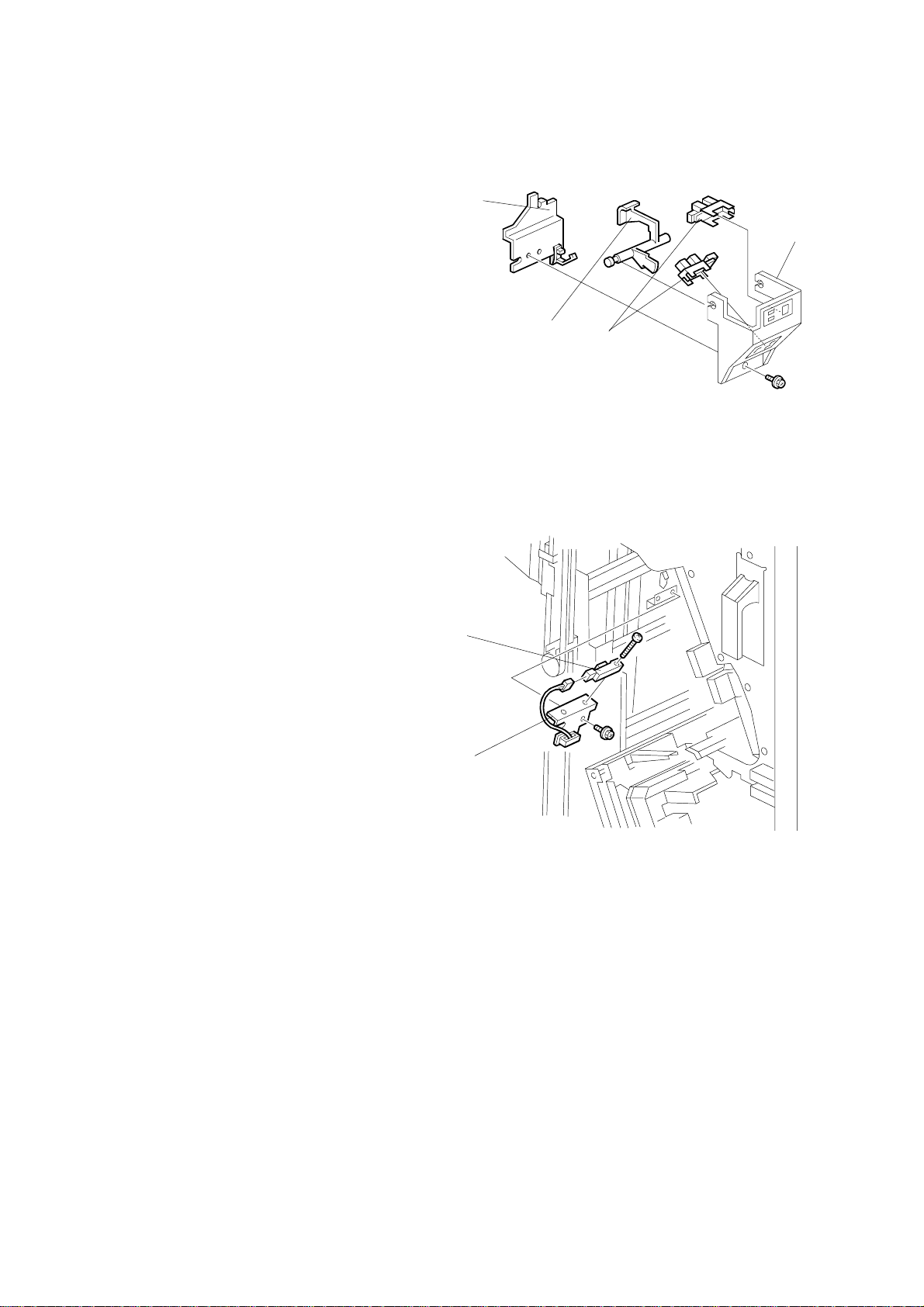

1.10 LOWER STACK HEIGHT SENSORS

1. Stapler tray (☛ 1.5 STAPLER TRAY)

[B]

2. Sensor bracket [A] (! x 1, # x 2)

3. Bracket [B] (! x 1)

4. Feeler [C]

5. Lower stack height sensors [D]

[C]

1.11 TRAY 2 SHUNT POSITION SENSOR

1. Stapler tray (☛ 1.5 STAPLER TRAY)

2. Sensor bracket [A] (! x 1, # x 1)

3. Tray 2 shunt position sensor [B] (! x 1)

[B]

[A]

[D]

G565R116.WMF

[A]

G565R202.WMF

G565-8

Page 10

23 February, 2001 STAPLER UNIT

1.12 STAPLER UNIT

1. Open the front door

2. Stapler unit [A] (! x 1, # x 2)

NOTE: Hold the stapler holder [B] with

one hand as you remove the

stapler. Do not twist or rotate

the stapler bracket as you

remove it.

[B]

1.13 STAPLER ROTATION HP SENSOR

1. Stapler unit (☛ 1.12 STAPLER UNIT)

2. Carefully rotate the stapler holder [A].

3. Stapler cover [B] (! x 1)

4. Sensor bracket [C] (! x 1, # x 1)

[A]

G565R117.WMF

[D]

[C]

5. Stapler rotation HP sensor [D]

[B]

[A]

G565R118.WMF

Peripherals

G565-9

Page 11

TRAY 1 INTERIOR 23 February, 2001

1.14 TRAY 1 INTERIOR

1.14.1 TRAY 1 COVERS

1. Tray 1 [A] (! x 1)

2. Rear tray cover [B] (! x 1)

3. Front tray cover [C] (! x 1)

4. Bottom tray cover [D] (! x 2)

5. Bottom bracket [E] (! x 3)

[A]

[B]

[C]

[D]

G565R207.WMF

[E]

G565-10

G565R208.WMF

Page 12

23 February, 2001 TRAY 1 INTERIOR

1.14.2 TRAY SHIFT SENSORS AND TRAY RELEASE SENSOR

1. Tray 1 covers (☛ 1.14.1 TRAY 1

COVERS)

2. Gear disk [A] (" x 1)

3. Tray shift sensors [B] (# x 1 each).

4. Tray release sensor [C] (# x 1)

1.14.3 TRAY 1 SHIFT MOTOR

1. Tray 1 covers (☛ 1.14.1 TRAY 1

COVERS)

2. Motor bracket [A] (! x 3, # x 1)

[B]

[B]

[C]

[A]

G565R210.WMF

3. Tray 1 shift motor [B] (! x 3, belt x 1)

1.14.4 BACK FENCE LOCK CLUTCH

1. Tray 1 covers (☛ 1.14.1 TRAY 1

COVERS)

2. Back fence lock clutch [A] (" x 1, # x

1)

[A]

[B]

G565R209.WMF

Peripherals

G565-11

B352R211.WMF

[A]

Page 13

FINISHER MAIN BOARD 23 February, 2001

1.15 FINISHER MAIN BOARD

1. Rear cover (☛ 1.1.1 EXTERNAL

COVERS)

2. Main PCB [A] (! x 6, All #)

[A]

G565R206.WMF

1.16 PUNCH HOLE POSITION ADJUSTMENT

To adjust the position of the punch holes in the paper feed direction, use the

appropriate SP mode.

To adjust the horizontal position of the holes, use the spacers provided with the

punch unit.

1. Rear cover (☛ 1.1.1

EXTERNAL COVERS)

2. Punch unit [A] (! x 3, # x 5)

3. Spacers [B]

The punch position can be adjusted

by up to 4 mm using combinations

of the 3 spacers provided with the

finisher.

G565-12

[A][B]

G565R119.WMF

Page 14

23 February, 2001 JAM DETECTION

2. TROUBLESHOOTING

2.1 JAM DETECTION

Mode

Shift 1 Shift 2 Staple

!!!

!!!

!

!

!

!

!

!

!

Jam Content

Entrance sensor:

no detection

Entrance sensor:

no detection

Upper exit sensor:

no detection

Upper exit sensor:

jam

Lower exit sensor:

no detection

Lower exit sensor:

jam

Stapler tray

entrance sensor:

no detection

Stapler tray

entrance sensor:

jam

Lower tray exit

sensor: no

detection

After the exit sensor in the main machine

went off, the entrance sensor did n ot switch

on for at least 2 s.

After the entrance sensor swit ched on, it did

not remain on for at least 150 ms.

1

After the entrance sensor swit ched on, the

upper exit sensor did not remain on for at

least 59 pulses.

After the upper exit sensor swit ched on, it

did not switch off within 150 ms.

2

1

After the entrance sensor swit ched on, the

lower exit sensor did not sw it ch on within 59

pulses.

After the lower exit sensor swit ched on, it

did not switch off within 150 ms.

2

1

After the entrance sensor swit ched off, the

stapler tray entrance sensor did not switch

on within 102 pulses.*

2

After the stapler tray entrance sensor

switched on, it did not switch off within 5 9

pulses.*

1

After the transport motor switched on, t he

lower tray exit sensor did not switch on

within 1260 ms.

*1

: Timing for A4 L (differs according to paper size).

*2

: Counted by entrance motor pulses because timing differs for feed out.

Peripherals

G565-13

Page 15

DIP SWITCH SETTINGS 23 February, 2001

3. SERVICE TABLES

3.1 DIP SWITCH SETTINGS

The DIP switches should not be set to any combination other than those described

in the table below.

DPS101

1234

0000Default.

1 1 1 0 Free run. No paper.

0 0 0 1 Transportation See the note below.

NOTE: To position the shift trays for shipping, on the finisher main board set DIP

SW4 ON, cycle the main machine power off and on, then set DIP SW4

OFF. The shift trays move automatically to the shipping position. After

unpacking the machine again and switching on, turn all DIP switches off to

put the machine into factory default mode.

Mode Description

3.2 TEST POINTS

No. Label Monitored Signal

TP101 GND Ground

TP102 5 V 5 V

TP103 RX D Received command data

TP104 TXD Transmitted command data

3.3 FUSES

No. Function

FU101 Protects 24 V.

G565-14

Page 16

23 February, 2001 GENERAL LAYOUT

4. DETAILED DESCRIPTIONS

4.1 GENERAL LAYOUT

1

8

2

3

7

4

6

5

G565D118.WMF

1. Upper junction gate

2. Punch unit (option)

3. Stapler junction gate

4. Pre-stack tray

5. Stapler

6. Stapler tray

7. Tray 2

8. Tray 1

Tray junction gate: Directs paper either to the upper or lower exit. In staple mode,

the stack always goes out to the lower exit.

Stapler junction gate: Directs paper either to the lower exit or to the stapler tray.

Pre-stack tray: When staplin g multiple prints (A4 LEF, LT LEF, B5 LEF only) in the

staple mode, the first sheet of the second print waits here for the next sheet to feed

while the previous stack is stapled. After the second print is fed, the first and

second sheets are fed together to the pre-stack tray. This delay allows enough time

for the previous stack to be stapled without interrupting paper feed.

Peripherals

Shift trays: Tray 1 (upper) and tray 2 (lower) shift side to side in the sort mode,

and raise and lower to receive ejected prints.

Stapler tray jogger: Employs positioning rollers and jogger fences to align stacks

for stapling.

Punch unit. Punches holes in stacked prints.

G565-15

Page 17

DRIVE LAYOUT 23 February, 2001

4.2 DRIVE LAYOUT

4

3

2

14

13

12

11

10

1

5

6

15

7

16

9

8

G565D104.WMF

1. Tray 1 lift motor

2. Entrance roller

3. Tray 2 lift motor

4. Upper exit roller

5. Tray 1 shift motor

6. Exit guide plate motor

7. Lower exit roller

8. Tray 2 shift motor

9. Exit motor

18

10. Lower transport motor

11. Pre-stack motor

12. Upper transport motor

13. Punch motor

14. Entrance motor

15. Stack feed-out motor

16. Jogger motor

17. Stapler motor

18. Stapler rotation motor

17

G565D103.WMF

G565-16

Page 18

23 February, 2001 JUNCTION GATES

4.3 JUNCTION GATES

The two junction gates can direct paper to three destinations.

In sort/stack mode for tray 1, the tray junction

solenoid [A] is on, and the prints go to the upper

exit (tray 1 is at the upper exit for sort/stack mode).

In sort/stack mode for tray 2, both the tray junction

gate solenoid [A] and stapler junction gate solenoid

[B] are off, and prints go to the lower exit.

[A]

G565D205.WMF

[A]

In staple mode, the tray junction solenoid [A] is off and

the stapler junction gate solenoid [B] is on, and prints

go to the stapler tray.

[B]

[B]

G565D206.WMF

[A]

Peripherals

G565D207.WMF

G565-17

Page 19

TRAY SHIFTING 23 February, 2001

4.4 TRAY SHIFTING

4.4.1 TRAY SHIFT MECHANISMS

[F]

[A] [B]

[C]

[D]

[E]

G565D106.WMF

Tray 1 (Upper Tray)

In sort/stack mode, tray 1 [A] moves from side to side to separate the printed sets.

The tray 1 shift motor [B], inside the shift tray, controls the horizontal position of

tray 1 through the timing belt [C] and gear disk [D].

After one print set is delivered to tray 1, the shift motor turns on, driving the gear

disk and the arm [E], and the tray drive unit moves to one side.

Two shift sensors [F] detect when to stop this side-to-side movement. There is a

cut-out in the gear disk. The shift tray moves in one direction until one of the shift

sensors detects the cut-out. Then the shift tray stops.

The next set of prints is then delivered, and the gear disk is turned in the opposite

direction until the other shift sensor is activated.

G565-18

Page 20

23 February, 2001 TRAY SHIFTING

Tray 2 (Lower Tray)

[C]

[A]

[E]

[D]

[B]

G565D105.WMF

In sort/stack mode, tray 2 [A] moves from side to side to separate the sets of prints.

The shift mechanism for tray 2 is similar to that used for tray 1. However, when the

tray 2 shift motor [B] turns on, the arm [D] moves the entire end fence [C] from side

to side (not just the tray).

After the gear disk has turned 180 degrees, the cut-out in the gear disk enters the

tray half- turn sensor [E], and the motor stops . When the next set of prints is

delivered, the motor turns on again, and moves the tray back to its previous

position.

Peripherals

G565-19

Page 21

TRAY UP/DOWN MECHANISMS 23 February, 2001

4.5 TRAY UP/DOWN MECHANISMS

4.5.1 TRAY 1

[A]

[C]

[F]

[G]

[H]

[I]

[E]

[D]

[C]

[B]

G565D204.WMF

Introduction

The tray 1 lift motor [A] controls the vertical position of tray 1 [B] through gears and

timing belts [C].

Normal and sort/stack modes

When the ma in s witch is turned on, the tr ay is initialized at the upper position. To

do this, the tray is moved up until upper stack height sensor 1 [D] is de-actuated.

During printing, if upper stack height sensor 2 [E] is actuated, the tray 1 lift motor

lowers the tray for a specified time.

When the tray lowers during printing, th e actuator [F] will pass through the tray 1

overflow 1 sensor [G]. When the actuator drops below the sensor (to deactivate the

sensor), the machine detects that the paper stack height has exceeded the

overflow limit.

The upper limit switch for tray 1 [H] prevents the drive gear from being damaged if

the upper stack height sensor 1 should fail. If the tray is raised to the tray

positioning roller [I], the switch will automatically cut the power to the tray 1 lift

motor.

G565-20

Page 22

23 February, 2001 TRAY UP/DOWN MECHANISMS

Staple Mode

[A]

[B]

[D] [E]

[G]

[C]

[F]

G565D204.WMF

In staple mode, stapled stacks can be delivered to either tray, but they can only go

to the lower exit. So, if tray 1 is selected, tray 1 [A] moves down to the lower paper

exit.

Tray 1 lowers until the actuator [B] enters the tray 1 lower limit sensor [C]. Tray 1

then lifts up until lower stack height sensor 1 [D] is activated.

When tray 1 is moved down to the lower exit, tray 2 must be moved down out of

the way. So, tray 2 [E] is also lowered until the tray 2 shunt position sensor [F]

detects tray 2 (or the top of the paper stack in tray 2).

The method of paper height detection is the same as for the upper exit area.

When the tray lowers during printing, t he actuator will enter the tray 1 overflow 2

sensor [G]. When this happens, the machine detects that the paper stack height

has exceeded the overflow limit.

Peripherals

G565-21

Page 23

TRAY UP/DOWN MECHANISMS 23 February, 2001

Tray 1 release mechanism

When tray 1 is selected for staple mode, tray

1 must be moved down to the lower paper

exit. However, to move past the sensors at

the lower exit, the tray must be moved away

from the finisher.

To do this, the tray 1 shift motor turns until

the cut-out in the gear disk enters the tray

release sensor [A]. At this time, the arm [B]

has reached position [C], and is pushing

against the plate [D], in towards the finisher.

However, the plate is fixed, so the tray

moves out away from the finisher.

Then, the tray 1 shift motor stops, then the

tray 1 lift motor lowers tray 1.

When the tray 1 lower limit sensor is

activated (as described on the previous

page), the tray has moved past the sensors

at the lower exit. The tray 1 shift motor turns

on again until the gear disk activates the

tray shift sensor [E]. This moves the tray

back against the finisher.

[D]

[B]

[C]

[A]

G565D201.WMF

[E]

Next, tray 1 lifts until the finisher detects that

the tray is at the correct height.

When tray 1 is at the lower exit, the tray lock

solenoid [F] is on, and the lever [G] locks

the tray. This prevents the user from mov ing

the tray out of position (the first tray has

some play when it is at the lower position).

Before tray 1 goes back to the upper exit

area, the tray lock solenoid [F] turns off to

unlock the tray. In addition, the back fence

lock clutch [H] turns on to hold the back

fence [I]. This prevents the springs inside

the back fence from suddenly contracting

(these springs normally keep the tray steady

during side-to-side shift).

Then, tray 1 is released and it moves up to

the upper exit area.

[I]

G565D202.WMF

[F]

[G]

[H]

B352D203.WMF

G565-22

Page 24

23 February, 2001 TRAY UP/DOWN MECHANISMS

4.5.2 TRAY 2

[H]

[A]

[C]

[E]

[D]

[F]

[E]

[B]

[D]

[F]

[C]

Overflow condition

Normal ModeMulti Tray Staple Mode

G565D500.WMF

[G]

G565D109.WMF

The tray 2 lift motor [A] controls the vertical position of tray 2 [B] through gears and

timing belts [C].

The paper height detection is the same as for tray 1.

When the tray lowers during printing, the tray is judged to be overflowing when the

tray 2 overflow sensor 1 [D] is off and the tray 2 overflow sensor-2 [F] is on (see

‘Normal Mode’ in the above diagram).

In the multi-tray staple mode (selected by the service technician), the machine

detects that the paper stack height has exceeded the overflow limit when the

actuator [E] enters the tray 2 overflow 1 sensor [D].

The lower limit sensor [G] for tray 2 detects when tray 2 is at its lowest limit and

stops the tray 2 lift motor.

The function of the tray 2 upper limit switch [H] is the same as for tray 1.

Peripherals

G565-23

Page 25

TRAY UP/DOWN MECHANISMS 23 February, 2001

4.5.3 PRE-STACK MECHANISM

[B]

[A]

[C]

[D]

G565D200.WMF

NOTE: This feature is available only when using A4 L, LT L, and B5 L.

During stapling, the main machine must wait. This mechanism reduces the wait by

holding the first two sheets of a job while the previous job is still being stapled. It

only works during the second and subsequent sets of a multi-set print job.

The pre-stack junction gate solenoid [A] switches on after the first sheet activates

the entrance sensor. This directs the sheet to the pre-stack tray [B].

The pre-stack feed roller [C] stops for a specifie d time after the trailing edge of the

paper has passed through the entrance sensor and stops the paper from leaving

the pre-stack tray.

At the same time, the pre-stack junction gate solenoid switches off, and the second

sheet is sent to the paper guide [D]. The pre-stack feed roller (controlled by the

pre-stack motor) starts to rotate again for a specified time after the trailing edge of

the second page has been passed through the entrance sensor, and then both

sheets are sent to the stapler tray together.

G565-24

Page 26

23 February, 2001 JOGGER UNIT PAPER POSITIONING MECHANISM

4.6 JOGGER UNIT PAPER POSITIONING MECHANISM

[C]

[E]

[A]

[B]

[F]

[D]

G565D110.WMF

In staple mode, each sheet of print paper is vertically and horizontally aligned when

it arrives in the stapler tray.

Vertical Paper Alignment

After the trailing edge of the paper passes the stapler tray entrance sensor [A], the

positioning roller solenoid [B] is energized for a specified time to push the

positioning roller [C] into contact with the paper.

The positioning roller rotates to push the paper back and align the trailing edge of

the paper against the stack stopper [D].

Horizontal Paper Alignment

When the start key is pressed , the jogger motor [E] turns on and the jogger fences

[F] move to the waiting position, which is 8 mm wider on both sides than the

selected paper.

When the trailing edge of the paper passes the stapler tra y e ntrance sensor, the

jogger motor turns on to move the jogger fences 5 mm towards the paper. After a

short time, the jogger motor turns on again for the horizontal paper alignment then

returns to the waiting position.

G565-25

Peripherals

Page 27

STAPLER MECHANISM 23 February, 2001

4.7 STAPLER MECHANISM

4.7.1 STAPLER MOVEMENT

[D]

[B]

[A]

[B][E]

G565D112.WMF

[C]

G565D113.WMF

The stapler can be moved from side to side or rotated according to the

requirements of the selected stapling mode.

Stapler Rotation

After the start key is pressed, the stapler rotation motor [A] rotates the staple unit

[B] until the stapler rotation HP sensor [C] is activated. Then, the stapler moves

from front to rear of the finisher.

When oblique stapling at one pos ition has been selected, after the stapler moves

to the stapling position, the stapler rotation motor rotates the stapler 45 degrees

(clockwise) at the stapling positio n before the stapler fires.

Side-to-Side Movement

The stapler motor [D] moves the stapler from side to side. After the start key is

pressed, the stapler moves from its home position to the stapling position.

The amount of movement required to reach the stapling position is determined by

the size of the selected paper. If the two-staple mode is selected, the stapler

moves to the front stapling position first, and then moves to the rear stapling

position. However, for the next print set, it staples in the reverse order.

After the stapling job is finished, the stapler returns to its home position,

determined by the stapler HP sensor [E].

G565-26

Page 28

23 February, 2001 STAPLER MECHANISM

4.7.2 STAPLER

[D]

[B]

[C]

G565D208.WMF

[A]

The staple hammer is driven by the stapler hammer motor [A] inside the stapler.

As soon as the paper stack is aligned, the staple hammer motor starts. When

stapling is finished, the staple hammer HP sensor [B] is turned on, and the staple

hammer motor then stops.

The staple end sensor [C] detects the staple end condition and whether the staple

cartridge is installed or not. If a stapler cassette is not installed, or after the stapler

cassette runs out of staples, a message is displayed in the operation panel. If this

condition is detected during a print job, the indicator will appear, but the print job

will not stop.

The staple position sensor [D] detects if there is a staple sheet at the stapling

position. After a new staple cartridge is installed, the staple hammer motor turns on

to transfer the staple sheet until the staple position sensor is activated by the staple

sheet.

If a staple jam occurs and overloads the motor, this causes a staple jam message

to appear on the operation panel.

Peripherals

G565-27

Page 29

STAPLER MECHANISM 23 February, 2001

4.7.3 FEED OUT AND TRANSPORT

[A]

[C]

[I]

[B]

G565D115.WMF

[D]

[G]

[F]

[H]

G565D114.WMF

When stapling starts, the exit guid e plate motor [A] switches on and opens the exit

guide plate [B], so that the stapled stack can exit to the tray. The exit guide plate

sensor [C] detects when to switch off the exit guide plate motor.

After the prints have been stapled, the stack feed-out motor [D] starts. The pawl [E]

on the stack feed out belt [F] lifts the stapled set and feeds it to the tray [G].

The exit guide plate closes at a specified interval after the stapled prints have

started to feed out. Then the exit roller takes over the stack feed-out. The stack

feed-out motor turns off when the pawl actuates the stack feed-out belt home

position sensor [H].

[E]

When tray 1 is passing this area on its way back up to the upper exit, the exit guide

safety switch [I] cuts power to the tray lift motor if the guide is opened too far. This

prevents damage to the user’s fingers if they are inside the lower exit when the tray

is moving up.

G565-28

Page 30

23 February, 2001 PUNCH UNIT (OPTIONAL)

4.8 PUNCH UNIT (OPTIONAL)

The punch unit punches holes in printed sheets, one by one. The punch unit is

provided with a new punch mechanism to improve the accuracy of punching.

[A]

[E]

[D]

[C]

G565D102.WMF

[B]

[I]

G565D101.WMF

[F]

4.8.1 PUNCH DRIVE MECHANISM

The punch drive mechanism is driven by the punch motor [A]. Each sheet is

positioned and punched by pressure f rom above. A certain time after the trailing

edge of the paper passes through the finisher entrance sensor [B], the punch

motor turns on and the paper stops. Then the punch clutch [C] turns on to make

the punch holes.

[H]

[G]

Peripherals

The home position is detected by the punch HP sensor [D]. When the cut-out in the

punch shaft disk [E] enters the punch HP sensor, the punch clutch turns off.

When the finisher has received the command that changes the number of punch

holes, the punch hole motor [F] turns on until the disk changes the status of the

punch hole switch [G] (until it switches on or off). This indicates that the cover [H]

and the punch cam [I] have moved to one side or the other to change the number

of holes.

G565-29

Page 31

PUNCH UNIT (OPTIONAL) 23 February, 2001

4.8.2 PUNCH WASTE COLLECTION

[A]

[B]

[C]

G565D153.WMF

Waste punchouts are collected in the punch waste hopper [A] below the punch unit

inside the finisher.

When the top of the punchout waste in the hopper reaches and actuates the

hopper sensor [B], a message will be displayed on the operation panel after the

current job is completed.

This sensor also detects whether the punch waste hopper is installed. When the

waste hopper is taken out, the arm [C] moves down and this will actuate the sensor

and display a message in the operation panel. This message is the same as for the

hopper full condition.

G565-30

Page 32

ABC

D

EF

GH

POINT TO POINT WIRING DIAGRAM (Two-tray Finisher: G565)

24V

24V

24V

1

Main Unit

GND

GND

GND

GND

TXD

GND

RXD

N.C

N.C

N.C

N.C

N.C

N.C

N.C

Front Door Safety Sw

Entrance Cover Sn.

Entrance Sensor

Staple Tray Entrance Sn.

2

Upper Stack Height 1 Sn.

Upper Stack Height 2 Sn.

CN1-8

CN2-9

-7

-6

-5

-4

-3

-2

-1

-8

-7

-6

-5

-4

-3

-2

-1

(SW6)

S1

S2

S19

S14

S15

CN203-1

CN200-1

CN202-1

CN706-1

CN705-1

-2

-3

CN203-3

-2

-3

-2

-3

-2

-3

-2

-3

CN203-1

-2

-1

-2

-3

(SW3)

Tray 1 Upper Limit Sw

CN205-1

Upper Exit Sn.

Upper Cover Sn.

Lower Exit Sn.

CN702-1

3

Lower Stack Height 2 Sn.

Lower Stack Height 1 Sn.

S18

S17

CN701-1

S23

S13

-2

-3

-2

-3

Tray 2 Overflow 2 Sn.

CN404-1

Tray 1 Overflow 2 Sn.

S29

-2

-3

Shift Mode Sn.

CN402-1

Tray 1 Overflow 1 Sn.

S31

-2

-3

Tray 1 Lower Limt Sn.

Tray 2 Overflow 1 Sn.

4

Tray 2 Shunt Position Sn.

S10

CN608-3

-2

-1

Tray 2 Lower Limit Sn.

Stack Feed-out H.P Sn.

Staple Tray Paper Sn.

Stapler H.P Sn.

Jogger H.P Sn.

CN303-1

S20

CN100-1

S35

-2

-3

-2

-3

S5

Stapler Rotation H.P Sn.

5

Front Set Sw (SW7)

Rear Set Sw (SW8)

CN204-1

CN100-1

CN304-1

S24

-2

-3

-2

-3

S6

S28

S25

S7

S8

S22

-2

-3

S21

Punch Motor

Punch CL

Punch H.P Sn.

Punch Hopper Sn.

6

Punch Hole Sw

Punch Hole Motor

CL

2

CN605-1

S12

S11

M17

-2

-3

CN512-3

CN510-6

CN508-1

-2

-3

CN403-1

-2

-3

CN405-1

-2

-3

CN507-1

-2

-3

CN506-3

CN509-1

-2

-3

CN305-1

-2

-3

CN308-3

CN309-1

-2

-3

CN704-2

CN704-1

CN703-2

CN703-1

M9

-2

-3

-4

-5

-6

-7

-8

SW5

-2

-1

-5

-4

-3

-2

-1

-2

-1

-2

-1

CN603-2

CN602-1

CN605-1

CN604-1

CN601-1

CN606-1

CN512-1

-2

-3

CN510-1

-2

-3

-4

-5

-6

CN506-1

-2

-3

CN308-1

-2

-3

CN704-1

CN704-2

CN703-1

CN703-2

-3

-4

-5

-2

-2

-3

-4

-5

-6

-7

-8

-2

-3

-2

-3

-2

-3

-4

CN101-1

CN102-1

CN103-1

CN104-10

CN104-3

CN132-10

CN132-7

CN132-2

CN105-6

CN105-3

CN106-9

CN106-6

CN129-15

CN129-11

CN129-7

CN129-3

CN117-13

CN117-10

CN117-3

CN108-9

CN108-6

CN108-3

CN109-6

CN109-3

CN134-4

CN130-8

CN130-2

CN131-15

CN131-3

CN107-4

+24V

-2

+24V

-3

+24V

-4

GND

-5

GND

-6

GND

-7

N.C

-8

N.C

N.C

-2

GND

-3

TXD

-4

GND

-5

RXD

-6

N.C

-7

N.C

-8

N.C

-9

N.C

24V

-2

[!24] Front Door Safety Sw

+5V

-9

["5] Entrance Cover Sn.

-8

GND

-7

N.C

-6

+5V

-5

["5] Entrance Sensor

-4

GND

+5V

-2

GND

-1

[!5] Staple Tray Entrance Sn.

+5V

-9

[!5] Upper Stack Height 1 Sn.

-8

GND

+5V

-6

[!5] Upper Stack Height 2 Sn.

-5

GND

-4

N.C

-3

N.C

-1

[!5] Tray 1 Upper Limit Sw

+5V

-5

["5] Upper Exit Sn.

-4

GND

+5V

-2

["5] Upper Cover Sn.

-1

GND

GND

-8

[!5] Lower Exit Sn.

-7

+5V

+5V

-5

[!5] Lower Stack Height 2 Sn.

-4

GND

-3

+5V

-2

[!5] Lower Stack Height 1 Sn.

-1

GND

+5V

-14

[!5] Tray 1 Overflow 2 Sn.

-13

GND

-12

N.C

+5V

-10

[!5] Tray 1 Overflow 2 Sn.

-9

GND

-8

N.C

+5V

-6

[!5] Shift Mode Sn.

-5

GND

-4

N.C

+5V

-2

[!5] Tray 1 Overflow 1 Sn.

-1

GND

+5V

-12

[!5] Tray 1 Lower Limt sn.

-11

GND

+5V

-9

[!5] Tray 2 Overflow 1 Sn.

-8

GND

-7

N.C

-6

+5V

-5

[!5] Tray 2 Shunt Position Sn.

-4

GND

+5V

-2

[!5] Tray 2 Lower Limit Sn.

-1

GND

+5V

-8

["5] Stack Feed-out H.P Sn.

-7

GND

+5V

-5

[!5] Jogger H.P Sn.

-4

GND

+5V

-2

["5] Staple Tray Paper Sn.

-1

GND

+5V

-5

[!5] Stapler H.P Sn.

-4

GND

+5V

-2

[!5] Stapler Rotation H.P Sn.

-1

GND

Set Deteciton

-3

Set Deteciton

-2

Set Deteciton

-1

GND

N.C

-7

GND

-5

+24V

-4

["5] Punch Motor ON/OFF

-3

["5] Punch LD

["24] Punch CL

-1

+24V

GND

-14

GND

-13

Punch Unit Detection

-12

Punch Unit Detection

-11

Punch Unit Detection

-10

Punch Unit Detection

-9

GND

-8

GND

-7

N.C

-6

+5V

-5

["5] Punch H.P Sn.

-4

GND

GND

-2

["5] Punch Hopper Sn.

-1

+5V

GND

-3

["5] Punch Hole SW

-2

+24V

-1

["24] Punch Hole Motor ON/OFF

Main (PCB 1)

Entrance Motor: A [0-24]

Entrance Motor: A [0-24]

Entrance Motor: B [0-24]

Entrance Motor: B [0-24]

Upper Transport Motor: A [0-24]

Upper Transport Motor: A [0-24]

Upper Transport Motor: B [0-24]

Upper Transport Motor: B [0-24]

Lower Transport Motor: A [0-24]

Lower Transport Motor: A [0-24]

Lower Transport Motor: B [0-24]

Lower Transport Motor: B [0-24]

Exit Motor: A [0-24]

Exit Motor: A [0-24]

Exit Motor: B [0-24]

Exit Motor: B [0-24]

Tray2 Lift Motor: + ["24V]

Tray2 Lift Motor: - ["24V]

Tray1 Lift Motor: + ["24V]

Tray1 Lift Motor: - ["24V]

Exit Guide Plate Motor: + ["24V]

Exit Guide Plate Motor: - ["24V]

Stack Feed-out Motor: A [0-24]

Stack Feed-out Motor: A [0-24]

Stack Feed-out Motor: B [0-24]

Stack Feed-out Motor: B [0-24]

Jogger Motor: A [0-24]

Jogger Motor: A [0-24]

Jogger Motor: B [0-24]

Jogger Motor: B [0-24]

Tray2 Shift Motor: - ["24V]

Tray2 Shift Motor: + ["24V]

Tray2 Upper Limit SW [!24V]

Tray2 Upper Limit SW [!24V]

Tray2 Half-turn Sn. ["5]

Staple Rotation Motor: A [0-24]

Staple Rotation Motor: A [0-24]

Staple Rotation Motor: B [0-24]

Staple Rotation Motor: B [0-24]

Stapler Motor: A [0-24]

Stapler Motor: A [0-24]

Stapler Motor: B [0-24]

Stapler Motor: B [0-24]

Pre-stack Motor: A [0-24]

Pre-stack Motor: A [0-24]

Pre-stack Motor: B [0-24]

Pre-stack Motor: B [0-24]

Tray Shift 2 Sn. ["5]

Staple Mode Sn. [!5]

Tray Shift 1 Sn. [!5]

Tray Release Sn. [!5]

Tray Lock Sol. ["24]

Back Fence Lock CL ["24]

Tray 1 Shift Motor- ["24]

Tray 1 Shift Motor+ ["24]

Tray 1 Safety SW [!24]

Tray 1 Safety SW [!24]

Tray Junction Gate Sol. ["24]

Positioning Roller Sol. ["24]

Pre-stack Juction Gate Sol. ["24]

Stapler Junction Gate Sol. ["24]

Exit Guide Plate Open Sn. [!5]

Exit Guide Safety SW [!24]

Staple Hammer Motor-B [0-24]

Staple Hammer Motor-B [0-24]

Staple Hammer Motor+B [0-24]

Staple Hammer Motor+B [0-24]

Staple Hummer H.P Sn. [!5]

Staple Position Sn. [!5]

Staple End Sn. [!5]

Punch Unit

+24V

+24V

+24V

+24V

+24V

+24V

+24V

+24V

+24V

+24V

+24V

+24V

+24V

+24V

GND

+24V

+24V

+24V

+24V

+24V

+24V

GND

GND

GND

GND

+24V

+24V

+24V

+24V

+24V

GND

+24V

GND

CN121-1

-2

-3

-4

-5

-6

CN110-1

-2

CN111-1

CN113-1

CN112-1

CN114-1

CN115-1

CN116-1

CN109-8

CN118-1

CN128-1

CN119-1

CN133-1

CN127-1

CN120-1

CN124-1

CN125-1

CN126-1

CN123-4

CN122-5

-3

-4

-5

-6

-7

-2

-3

-4

-5

-6

-7

-2

-3

-4

-5

-6

-7

CN501-1

-2

-3

CN401-2

-4

-5

-6

CN510-2

-7

-8

CN301-8

-2

-3

CN301-1

-4

-5

-6

-7

-8

CN217-7

-9

-10

-11

-12

-13

-14

-15

CN504-5

-2

-3

-4

-5

-6

-7

CN504-3

-8

-9

CN216-7

-2

-3

-4

-5

-6

-7

CN227-7

-9

-10

-11

-12

-13

-14

-2

-3

-4

-5

-6

CN207-13

-2

-3

-4

-5

-6

-7

-8

-9

-10

-11

-12

-13

CN208-8

-2

-3

-4

-5

-6

-7

-8

CN206-11

-2

-3

-4

-5

-6

-7

-8

CN206-3

-9

-10

-11

-2

-2

-2

-2

-2

-3

-4

-5

-6

-7

-8

-3

-2

-1

-4

-3

-2

-1

CN501-2

-2

-1

-1

-9

-5

-7

-11

-6

-5

-4

-3

-2

-1

-4

-2

-1

-6

-5

-4

-3

-2

-1

-6

-5

-4

-3

-2

-1

-12

-11

-10

-9

-8

-6

-5

-4

-3

-2

-1

-7

-5

-4

-2

-1

-9

-7

-5

-2

-1

-1

CN401-1

-2

CN510-1

-2

CN301-4

-3

CN301-11

-7

-5

-1

CN217-1

-2

-3

-4

-5

-6

-7

CN606-2-1CN606-1

CN504-1

-2

CN504-3

-4

-5

CN216-1

-2

-3

-4

-5

-6

-7

CN227-1

-2

-3

-4

-5

-6

-7

CN207-1

-2

-3

-4

-5

-6

-8

-9

-10

-11

-12

-13

CN208-1

-2

-4

-5

-7

-8

CN206-1

-3

-5

-7

CN310-4

CN311-5

-3

-2

-1

-4

-3

-2

-1

N.C

N.C

N.C

N.C

N.C

N.C

N.C

N.C

5V

N.C

N.C

+5V

+5V

N.C

+5V

+5V

24V

N.C

24V

N.C

N.C

N.C

N.C

N.C

N.C

N.C

N.C

24V

5V

N.C

N.C

N.C

+5V

M1

Entrance Motor

M13

Upper Transport Motor

M5

Lower Transport Motor

M2

Exit Motor

M6

Tray 1 Lift Motor

M15

M3

M12

Stack Feed-out Motor

Jogger Motor

M4

-2

M10

Stapler Rotation Motor

M11

Stapler Motor

Pre-Stack Motor

M8

SOL

1

CL1

M14

SOL

5

SOL

SOL

2

SOL

M16

Tray 2 Lift Motor

Exit Guid Plate Motor

Tray 2 Shift Motor

M7

CN607-3

-2

-1

CN412-3

-2

-1

CN413-3

-2

-1

CN414-3

-2

-1

CN414-3

-2

-1

Tray Lock Sol.

Back Fence Lock CL

Tray 1 Shift Motor

Tray Junction Gate Sol.

Positioning Roller Sol.

3

Pre-stack Junction Gate Sol.

Stapler Junction Gate Sol.

4

CN503-3

-2

-1

(SW1)

Exit Guide Safety Sw

Staple Hammer Motor

[ ]

(SW4)

(SW4)

S9

Tray 2 Half-turn Sn.

S27

Tray Shift 2 Sn.

S30

Staple Mode Sn.

S26

Tray Shift 1 Sn.

S16

Tray Release Sn.

(SW2)

(SW2)

S3

Exit Gide Plate Open Sn.

Symbol Table

DC Line

Pulse Signal

Signal Direction

Active High

"

Active Low

!

Signal Level

Tray 2 Uppre Limit SW

Tray 1 Safety Sw

1

2

3

4

5

6

Staple Unit

ABC

D

EF

GH

Page 33

ELECTRICAL COMPONENT LAYOUT (G565)

15

14

13

12

16

11

17

1

2

3

4

5

6

7

8

9

10

G565D901.WMF

28

27

26

18

19

30

29

20

21

22

23

24

25

G565D902.WMF

Page 34

44

41

40

39

38

37

36

42

43

35

34

31

32

33

G565D903.WMF

60

59

58

61

62

57

56

55

54

45

46

47

48

49

50

51

52

53

G565D251.WMF

Page 35

G565D904.WMF

68

63

64

65

66

67

Page 36

ELECTRICAL COMPONENT DESCRIPTION (G565)

Symbol Description Index No. P-to-P

Motors

M1 Entrance 40 F1

M2 Exit 31 F2

M3 Exit guide plate 30 G2

M4 Jogger 33 F3

M5 Lower transport 37 F1

M6 Tray 2 lift 44 G2

M7 Tray 2 shift 24 G3

M8 Pre-stack 38 G4

M9 Punch 64 B5

M10 Stapler rotation 54 F3

M11 Stapler 34 F3

M12 Stack feed-out 32 F2

M13 Upper transport 39 F1

M14 Tray 1 shift 8 F5

M15 Tray 1 lift 43 F2

M16 Staple hammer 57 G6

M17 Punch hole 68 B6

Sensors

S1 Entrance cover 46 B2

S2 Entrance 47 B2

S3 Exit guide plate open 18 G6

S4 Staple position 61 E6

S5 Jogger HP 48 B4

S6 Tray 2 overflow-2 26 B3

S7 Tray 2 overflow-1 27 B4

S8 Tray 2 lower limit 25 B4

S9 Tray 2 half-turn 22 G3

S10 Tray 2 shunt position 23 B4

S11 Punch hopper 63 B6

S12 Punch HP 65 B6

S13 Lower exit 19 B3

S14 Upper stack height 1 2 B2

S15 Upper stack height 2 3 B2

S16 Tray release 16 G4

S17 Lower stack height 1 20 B3

S18 Lower stack height 2 21 B3

S19 Staple tray entrance 52 B2

S20 Staple tray paper 51 B5

S21 Stapler rotation HP 55 B5

S22 Stack feed-out HP 62 B4

S23 Upper cover 45 B3

S24 Upper exit 1 B3

S25 Tray 1 lower limit 11 B4

S26 Tray shift 1 4 G4

Page 37

Symbol Description Index No. P-to-P

S27 Tray shift 2 5 G4

S28 Shift mode 14 B3

S29 Tray 1 overflow-2 12 B3

S30 Staple mode 6 G4

S31 Tray 1 overflow-1 15 B4

S32 Staple hammer HP 60 E6

S34 Staple end 58 E6

S35 Stapler HP 56 B5

Selenoids

SOL1 Tray lock 7 F4

SOL2 Pre-stac k junctio n gate 35 F5

SOL3 Positioning roller 36 G5

SOL4 Stap ler junction gate 41 G5

SOL5 Tray junct ion gate 42 F5

Switches

SW1 Exit guide safety 29 G6

SW2 Tray 1 safety 9 G5

SW3 Tray 1 upper limit 17 B2

SW4 Tray 2 upper limit 28 G3

SW5 Punch hole 67 C6

SW6 Front door safety 53 B2

SW7 Front set 50 B5

SW8 Rear set 49 B5

Electrical Clutches

CL1 Back fence lock 10 G4

CL2 Punch 66 B5

PCBs

PCB1 Main 13 D4

PCB2 Stapler Sensor 59 NA

Loading...

Loading...