Page 1

BOOKLET FINISHER

(Machine Code: A763)

Page 2

TABLE OF CONTENTS

1. OVERALL MACH INE INFORMATION..................................A763-1

1.1 SPECIFICATIONS..............................................................................A763-1

1.2 ELECTRICAL COMPONENT DESCRIPTION....................................A763-3

1.3 MECHANICAL COMPONENT LAYOUT.............................................A763-6

2. DETAILED DESCRIPTIONS .................................................A763-7

2.1 JUNCTION GATE MECHANISM........................................................A763-7

2.1.1 SHIFT TRAY MODE..................................................................A763-7

A4/LT sideways or shorter.............................................................A763-7

Longer than A4 sideways...............................................................A763-7

2.1.2 PROOF TRAY MODE ................................................................ A763-8

2.1.3 BOOKLET STITCH MODE........................................................A763-8

2.2 PRE-STACK MECHANISM ................................................................A763-9

2.3 PAPER SHIFT MECHANISM ...........................................................A763-10

2.4 PAPER POSITIONING MECHANISM..............................................A763-11

2.5 STAPLER UNIT MOVEMENT MECHANISM....................................A763-12

2.5.1 DRIVE......................................................................................A763-12

2.5.2 MOVEMENT............................................................................A763-12

Front and Rear Stapling...............................................................A763-12

Tow-position Stapling...................................................................A763-12

2.6 STAPLER .........................................................................................A763-13

2.7 SHIFT TRAY MECHANISM..............................................................A763-14

2.8 BOOKLET UNIT GATE MECHANISM..............................................A763-15

2.9 RELAY ROLLER AND POSITIONING PLATE MECHANISM...........A763-17

2.10 POSITIONING ROLLER MECHANISM..........................................A763-18

2.11 BOOKLET UNIT JOGGER MOVEMENT MECHANISM.................A763-19

2.12 BOOKLET STAPLER UNIT............................................................A763-20

2.13 PAPER FOLDER MECHANISM.....................................................A763-21

3. INSTALLA T ION...................................................................A763-23

3.1 ACCESSORY CHECK.....................................................................A763-23

3.2 INSTALLATION PROCEDURE ....................................................... A763-24

4. REPLACEMENT AND ADJUSTMENT................................A763-29

4.1 REMOVAL........................................................................................A763-29

4.1.1 UPPER DOOR.........................................................................A763-29

4.1.2 UPPER REAR COVER............................................................A763-30

4.1.3 LOWER REAR COVER...........................................................A763-30

4.1.4 TOP COVER............................................................................A763-31

4.1.5 UPPER INNER COVER...........................................................A763-31

4.1.6 SHIFT TRAY UNIT...................................................................A763-32

4.1.7 UPPER SHIFT GUIDE.............................................................A763-33

4.1.8 LOWER SHIFT GUIDE............................................................A763-33

4.1.9 EXIT UNIT................................................................................A763-34

i

Page 3

SPECIFICATIONS 31 January 2000

4.1.10 BUFFER ROLLER UNIT........................................................A763-35

4.1.11 STAPLER...............................................................................A763-36

4.1.12 FINISHER BOARD ...............................................................A763-37

4.1.13 BOOKLET UNIT.....................................................................A763-38

4.1.14 FOLDER ROLLERS...............................................................A763-40

4.1.15 FOLDER PLATE....................................................................A763-43

Removal.......................................................................................A763-43

Reinstalling...................................................................................A763-44

4.1.16 BOOKLET STAPLER UNIT...................................................A763-45

Removal.......................................................................................A763-45

Adjustment...................................................................................A763-46

4.1.17 BOOKLET BOARD................................................................A763-48

4.1.18 POSITIONING PLATE UNIT..................................................A763-48

4.1.19 1ST AND 2ND BOOKLET UNIT GATES ...............................A763-49

4.2 ADJUSTMENT..................................................................................A763-50

4.2.1 SHIFT TRAY HEIGHT .............................................................A763-50

4.2.2 JOGGER FENCE POSITION...................................................A763-51

4.2.3 STAPLING POSITOIN.............................................................A763-52

4.2.4 BOOKLET STAPLING POSITION...........................................A763-53

ii

Page 4

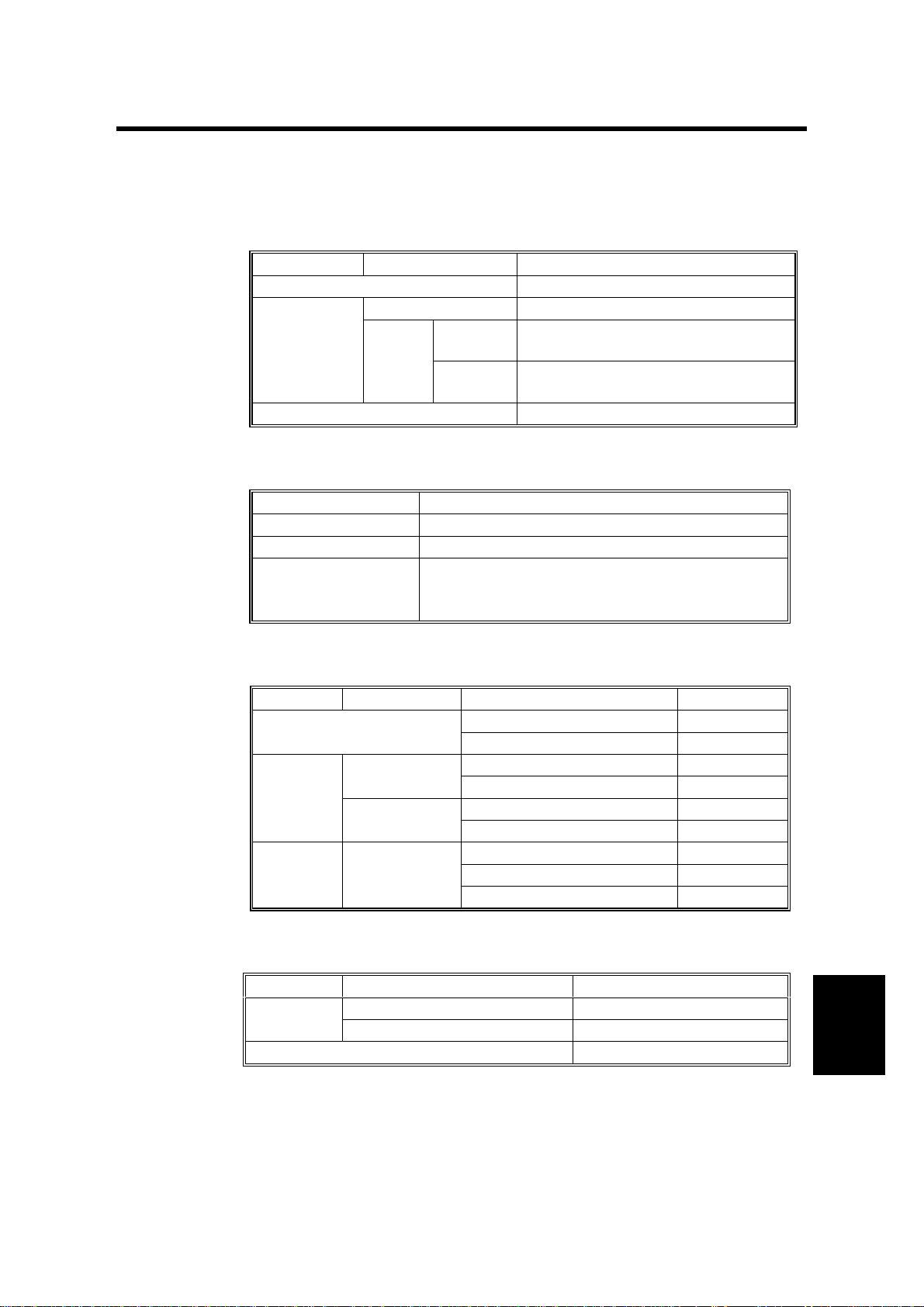

January 31, 2000 SPECIFICATIONS

1. OVERALL MACHINE INFORMATION

1.1 SPECIFICATIONS

Paper Size:

Tray Modes Sizes

Proof tray A3 to A5, DLT to HLT

No staple mode A3 to A5, DLT to HLT

Paper Weight:

Staple

Shift tray

Booklet tray A3 to B5, DLT to LT

Tray Weight

Stack mode 52 g/m2 to 163 g/m2, 14 to 42 lb

Staple mode 64 g/m2 to 80 g/m2, 17 to 21 lb

Saddle stitch mode 64 g/m2 to 80 g/m2, 17 to 21 lb

Mode

Top or

bottom

2 staple

64 g/m

only)

A3 to B5 lengthwise, DLT to HLT

A3, A4 sideways, B5 sideways,

DLT to HLT sideways

2

to 128 g/m2, 17 to 34 lb (Cover sheet

Paper Capacity (80 g/m2, 20 lb):

Tray Modes Paper size Capacity

Proof tray

No staple

Shift tray

Staple

tray

One size

Mixed sizes

Staple Capacity (80 g/m2, 20 lb):

Modes Paper size Total capacity

Staple

Saddle stitch 2-15 sheets

A4-S, LT-S or shorter 2-50 sheets

A4-L, LT-L or longer 2-30 s heets

Staple

A4-S, LT-S or shorter 150 sheets

A4-L, LT-L or longer 75 sheets

A4-S, LT-S or shorter 1000 sheets

A4-L, LT-L or longer 500 sheet

A4-S, LT-S or shorter 750 sheets

A4-L, LT-L or longer 500 sheets

1-5 sheets 25 sets

6-10 sheets 15 sets

11-15 sheets 10 sets

(-L”: Lengthwise ,-S: Sideways)

Options

(-L”: Lengthwise, -S: Sideways)

A763-1

Page 5

SPECIFICATIONS January 31, 2000

Staple Position: Staple mode: 3 positions

1 staple: 2 positions (Front, Rear)

2 staples: 1 position

Saddle stitch mode: 1 position

Staple Replenishment: Cartridge

Staple: 5000 staples

Saddle stitch: 2000 staples

Power Source: 24Vdc (from copier)

Power Consumption: 60 W

Dimensions

800 x 728 x 980 mm, 31.5 x 28.7 x 38.6 inches

(W x D x H) :

Weight: 45 kg

A763-2

Page 6

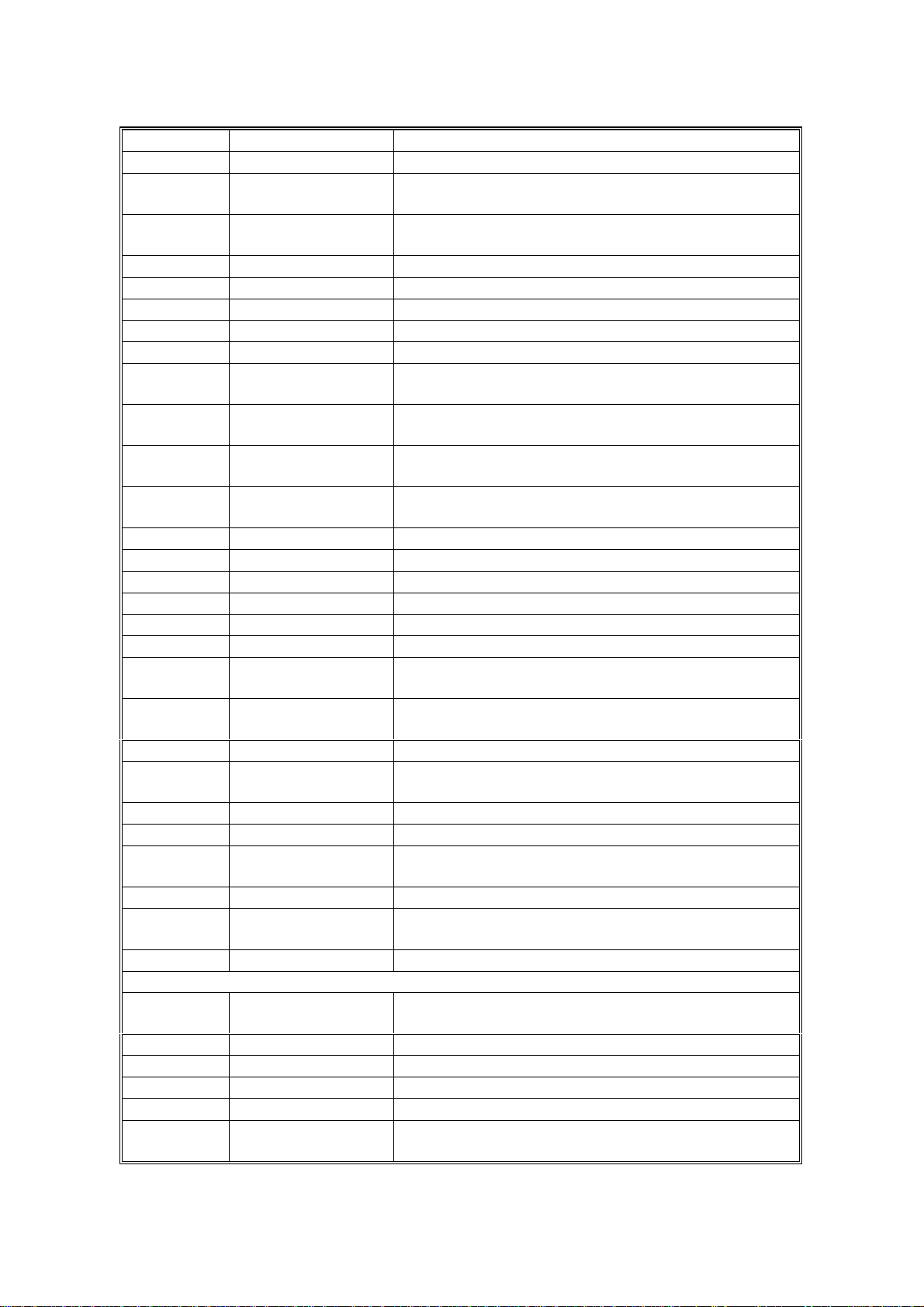

January 31, 2000 ELECTRICAL COMPONENT DESCRIPTION

1.2 ELECTRICAL COMPONENT DESCRIPTION

Symbol Name Function

Motors

M1 Entrance Drives the entrance roller.

M2 Transport Roller Drives the 1st and 2nd transport rollers.

M3 Buffer Roller Drives the buffer roller and the proof tray exit roller.

M4 Jogger Moves the jogger fence.

M5 Stapler Moves the stapler unit.

M6 Staple Hammer Drives the staple hammer in the stapler unit.

M7 Guide Plate Moves the upper exit guide plate up and down.

M8 Exit Motor Drives the exit roller.

M9 Tray Lift Moves the shift tray up and down.

M10 Booklet Transport Drives the relay roller and the positioning roller.

M11 Positioning Plate Moves the positioning plate up and down.

M12 Shutter Guide Moves the shutter guide up and down.

M13 Booklet Jogger Drives the jogger fences.

M14 Front Stapler Drives the staple hammer in the front stapler.

M15 Rear Stapler Drives the staple hammer in the rear stapler.

M16 Folder Roller Drives the folder rollers.

M17 Folder Plate Moves the folder plate.

Sensors

S1

S2

S3

S4 Staple Tray Paper Detects copy paper in the stapler tray.

S5 Jogger HP Detects the home position of the jogger rear fence.

S6 Stapler Unit HP Detects the home position of the stapler unit.

S7 Staple Hammer HP Detects the home position of the staple hammer.

S8 Staple Position Detects when the stapler is in the stapling position.

S9 Upper Exit Guide Detects the upper position of the upper exit guide.

S10 Exit Guide Motor Generates pulses to check the exit guide motor.

S11 Exit Checks for misfeeds at the shift tray.

S12 Exit Motor Generates pulses to check the exit motor.

S13 Shift Tray Paper Detects copy paper on the shift tray.

S14

S15 Shift Tray HP Detects the home position of the shift tray.

S16

S17

Entrance Detects copy paper entering the finisher and

detects misfeeds.

Buffer Roller

Entrance

Straight Path Detects copy paper passig under the buffer roller

Shift Tray height Detects when the top of the copy paper stack in the

Lift Motor 1 Generates pulses to check the lift motor, to control

Lift Motor 2 Generates pulses to check the lift motor, to control

Detects copy paper entering the buffer roller or

proof tray exit guide and detects misfeeds.

and detects misfeeds.

shift tray is at the correct height.

lift motor position, and to detect the motion

direction of shift tray.

lift motor position, and to detect the motion

direction of shift tray.

Options

A763-3

Page 7

ELECTRICAL COMPONENT DESCRIPTION January 31, 2000

Symbol Name Function

S18 Proof Tray Exit Checks for misfeeds at the proof tray.

S19

S20

Proof Tray Limit Detects when the paper stack height in the proof

tray is at its upper limit.

Finisher Set

Detects whether the finisher is installed into the

copier or not.

S21 Shutter Detects whether the shutter is closed or not.

S22 Trailing Edge 1 Detects the relay roller release timing.

S23 Trailing Edge 2 Detects the relay roller release timing.

S24 Trailing Edge 3 Detects the relay roller release timing.

S25 Booklet Entrance Check for paper misfeeds.

S26

S27

S28

S29

Positioning Plate

Paper

Positioning Plate

HP

Positioning Roller

Booklet Jogger HP

Detects copy paper in the positioning plate.

Detects the home position of the positioning plate.

Detects whether the positioning roller is released or

not.

Detects the home position of the jogger fences in

the booklet unit.

S30 Front Staple End Detects staples in the cartridge of the front stapler.

S31 Rear Staple End Detects staples in the cartridge of the rear stapler.

S32 Stapler Unit Set Detects whether the stapler unit is installed or not.

S33 Shutter Guide HP Detects the home position of the shutter guide.

S34 Folder Plate HP Detects the home position of the folder plate.

S35 Folder Plate Return Detects the return position of the folder plate.

S36

S37

Folder Plate Motor Generates pulses to check the folder motor and its

position.

Folder Roller

Detects the position of the folder roller.

Position

S38 Folder Roller HP Detects the home position of the folder roller.

S39

Folder Roller Motor Generates pulses to check the folder roller motor

and its position.

S40 Booklet Exit Checks for misfeeds at the booklet tray.

S41 Booklet Tray Paper Detects copy paper in the booklet tray.

S42

Booklet Entrance

Guide

Detects whether the booklet entrance guide is

opened or not.

S43 Lower Door Detects whether the lower door is opened or not.

S44

Booklet Exit Cover Detects whether the booklet exit cover is opened or

not.

Switches

SW1

Upper Cover

Safety

Cuts the +24V for the motor.

SW2 Shift Tray Safety Cuts the +24V for the motor.

SW3 Shutter Position Cuts the +24V for the motor.

SW4 Upper Exit Guide 1 Cuts the +24V for the motor.

SW5 Upper Exit Guide 2 Cuts the +24V for the motor.

SW6

Shift Tray Upper

Limit

Cuts the +24V for the lift motor.

A763-4

Page 8

January 31, 2000 ELECTRICAL COMPONENT DESCRIPTION

Symbol Name Function

SW7 Cartridge Set Detects the staple cartridge in the stapler.

SW8 Staple End Detects the staples in the cartridge.

SW9 Thermo Detects the lift motor temperature.

SW10 Lower Door Safety Cuts the +24V for the motor.

SW11

Booklet Entrance

Guide Safety

Cuts the +24V for the motor.

SW12 Booklet Exit Safety Cuts the +24V for the motor.

SW13

SW14

Front Staple

Hammer HP

Rear Staple

Hammer HP

Detects the home position of the staple hammer in

the front stapler unit

Detects the home position of the staple hammer in

the rear stapler unit

Solenoids

SOL1 Book let Gate Drives the booklet gate.

SOL2

Buffer Roller

Entrance Gate

Drives the buffer roller entrance gate.

SOL3 Proof Tray Gate Drives the proof tray gate.

SOL4

Buffer Roller Exit

Gate

Drives the buffer roller exit gate.

SOL5 Tr ansport Belt Moves the transport belt to the stopper.

SOL6 Paddle Releases the paddle stopper.

SOL7

SOL8

SOL3

Front Guide

Release

1st Booklet Unit

Gate

2nd Booklet Unit

Gate

Releases the front guide plate.

Drives the 1st booklet unit gate.

Drives the 2nd booklet unit gate.

SOL4 Relay Roller Releases the relay roller.

PCBs

PCB1 Finisher Controls the upper unit.

Lift Motor Sensor Generates pulses to check the lift motor, to control

PCB2

lift motor position, and to detect the motion

direction of the shift tray.

PCB3 Booklet Unit Controls the booklet unit.

PCB4

Trailing Edge

Sensor

Detects the relay roller release timing.

Others

HR1 Stapler Interface Interfaces the stapler and the finisher board.

A763-5

Options

Page 9

January 31, 2000 MECHANICAL COMPONENT LAYOUT

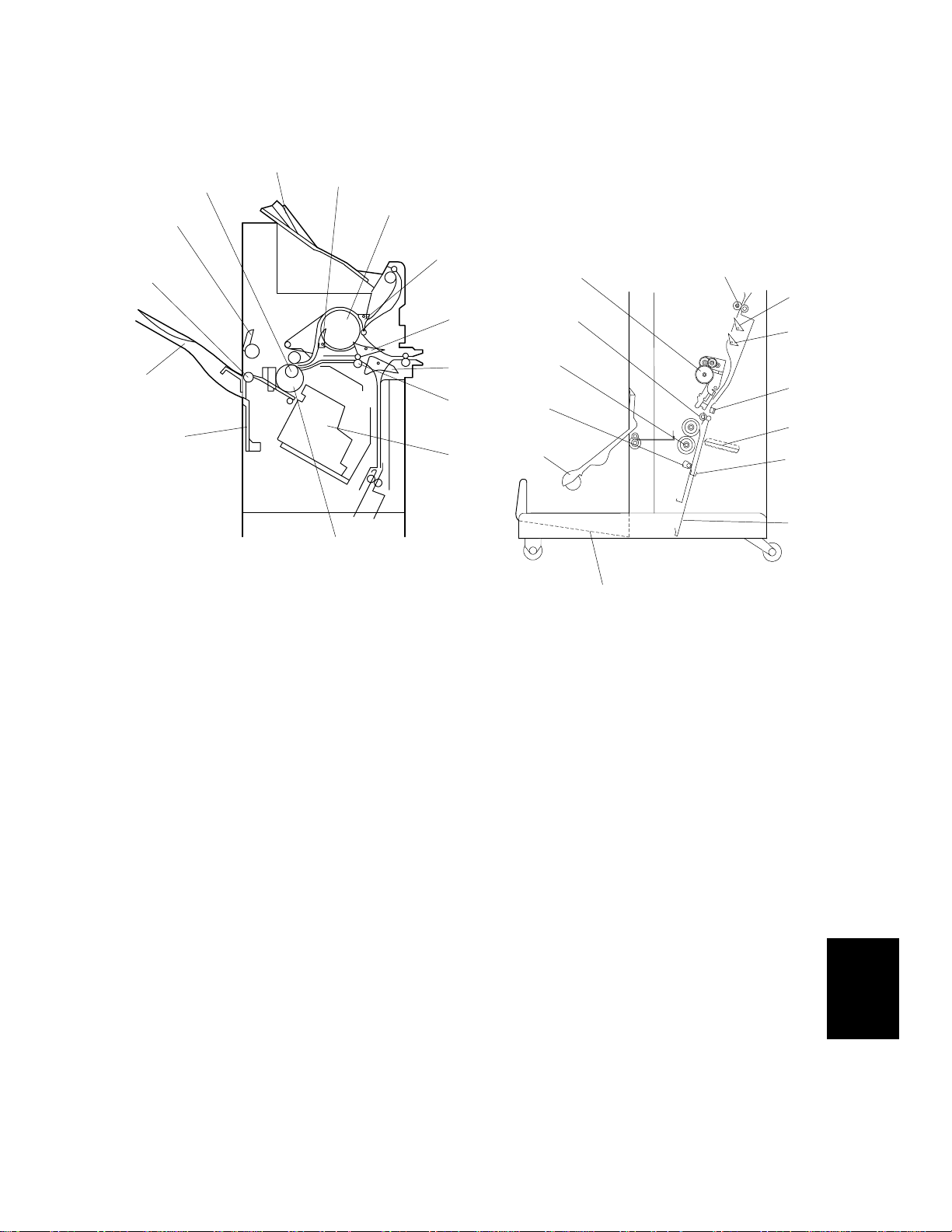

1.3 MECHANICAL COMPONENT LAYOUT

6

5

7

8

4

9

3

27

15

16

10

11

2

12

1

13

24

23

25

26

17

18

19

20

21

14

A763V500.WMF

A763V501.WMF

22

1. Shutter

2. Shift Tray

3. Lower Exit Roller

4. Upper Exit Guide

5. 2nd Transport Roller

6. Proof Tray

7. Buffer Roller Exit Gate

8. Buffer Roller

9. Proof Tray Gate

10. Buffer Roller Entrance Gate

11. Booklet Gate

12. 1st Transport Roller

13. Stapler Unit

14. Transport Belt

15. Booklet Unit Entrance Roller

16. 1st Booklet Unit Gate

17. 2nd Booklet Unit Gate

18. Anvil

19. Folder Plate

20. Positioning Plate

21. Shutter Guide

22. Booklet Tray

23. Exit Guide

24. Positioning Roller

25. Folder Roller

26. Relay Roller

27. Booklet Stapler Unit

Options

A763-7

Page 10

January 31, 2000 JUNCTION GATE MECHANISM

2. DETAILED DESCRIPTIONS

2.1 JUNCTION GATE MECHANISM

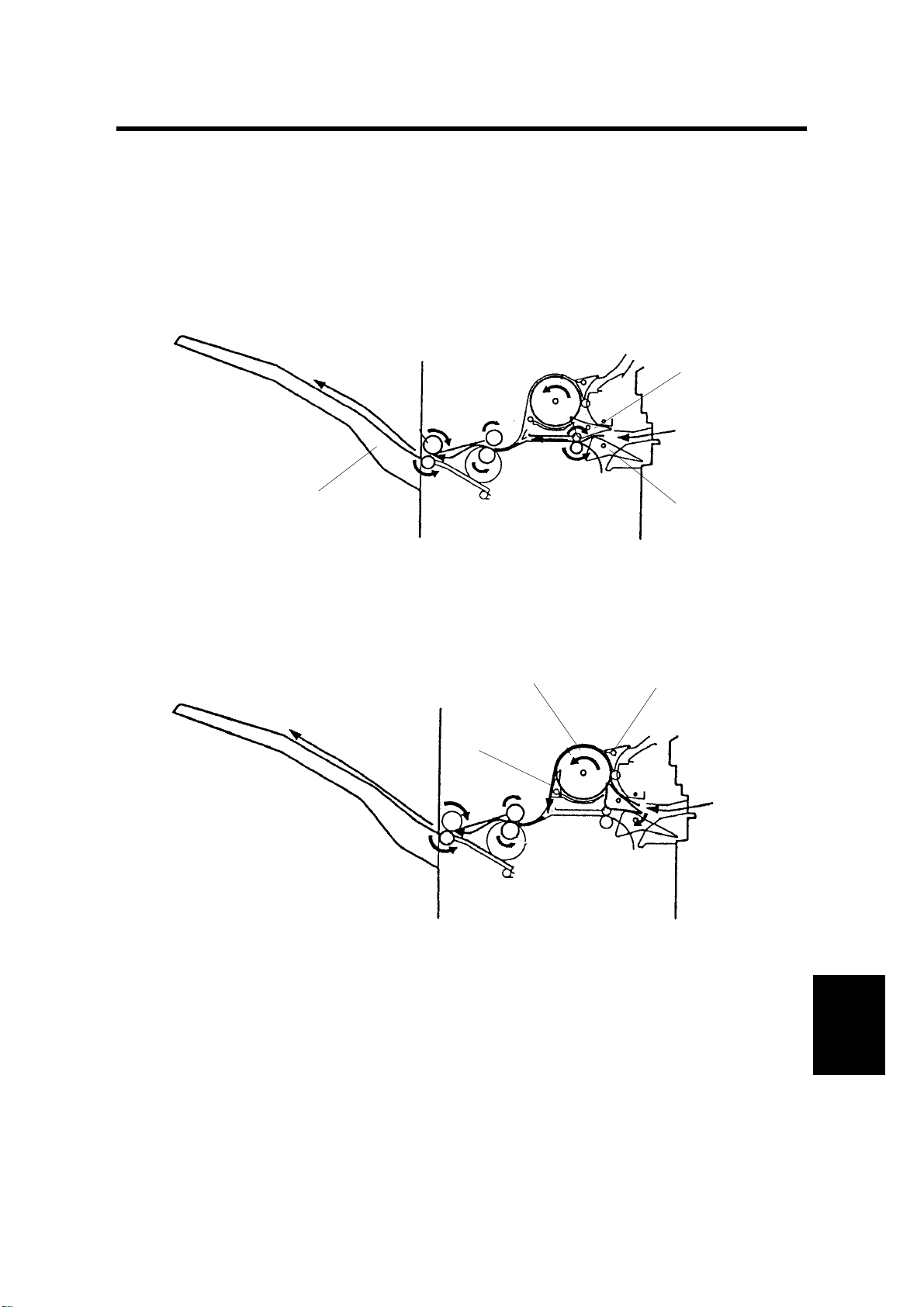

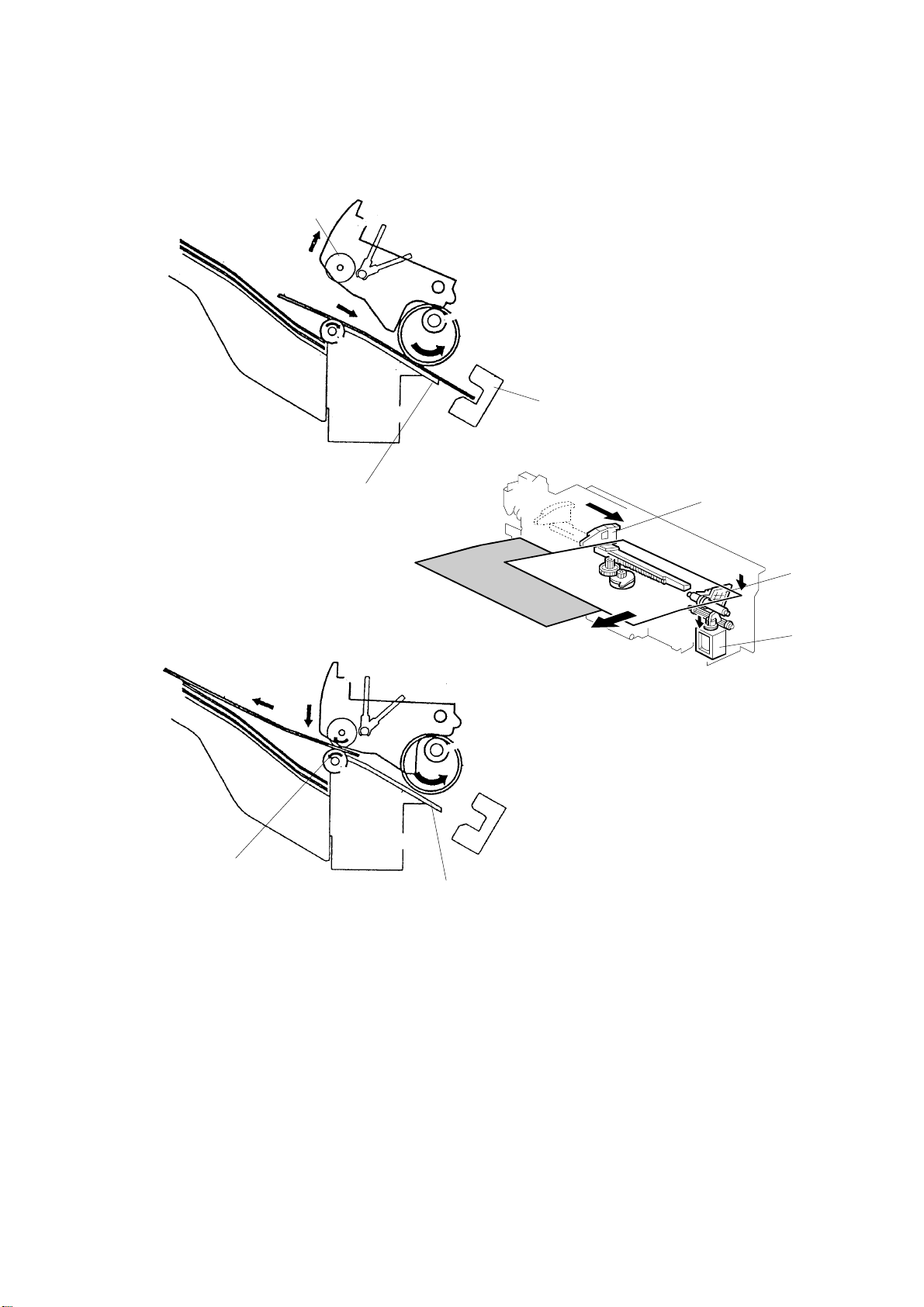

2.1.1 SHIFT TRAY MODE

A4/LT sideways or shorter

[B]

[C]

A763D564.PCX

The booklet gate [A] and buffer roller entrance gate [B] are closed and the copy

paper goes directly to the shift tray [C].

[A]

Longer than A4 sideways

[F]

[E]

[D]

A763D565.PCX

The booklet gate, proof tray gate [D], and buffer roller exit gate [E] are closed, and

the buffer roller entrance gate is opened. The copy paper passes through the

buffer roller [F]. This paper path creates a distance between copies.

A763-7

Options

Page 11

JUNCTION GATE MECHANISM January 31, 2000

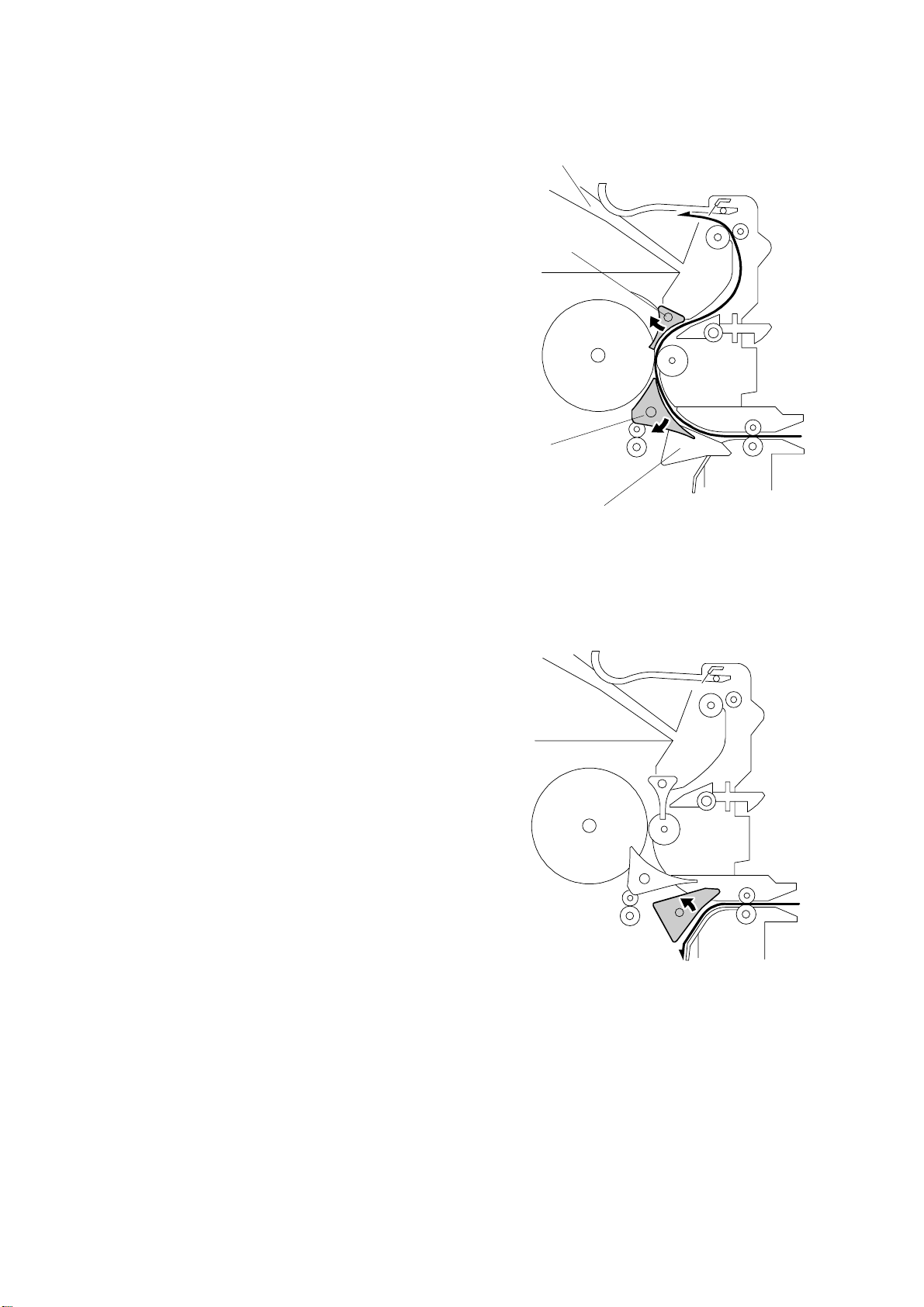

2.1.2 PROOF TRAY MODE

[D]

The booklet gate [A] is closed. The buffer roller

entrance gate [B] and proof tray gate [C] are

closed. The copy paper goes to the proof tray [D].

[C]

[B]

2.1.3 BOOKLET STITCH MODE

The booklet gate is opened and the copy paper

goes to the booklet unit.

[A]

A763D101.WMF

A763-8

A763D102.WMF

Page 12

January 31, 2000 PRE-STACK MECHANISM

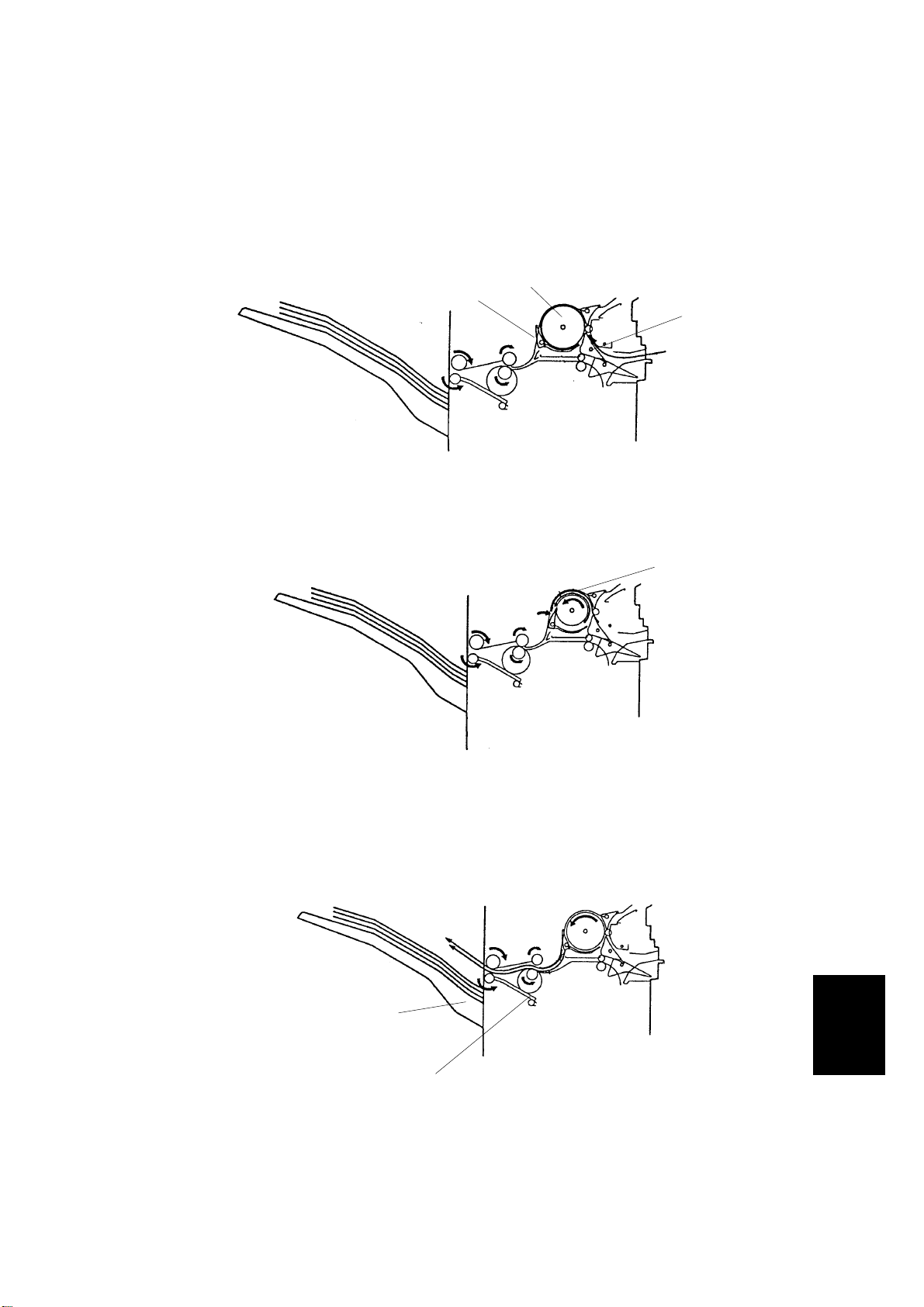

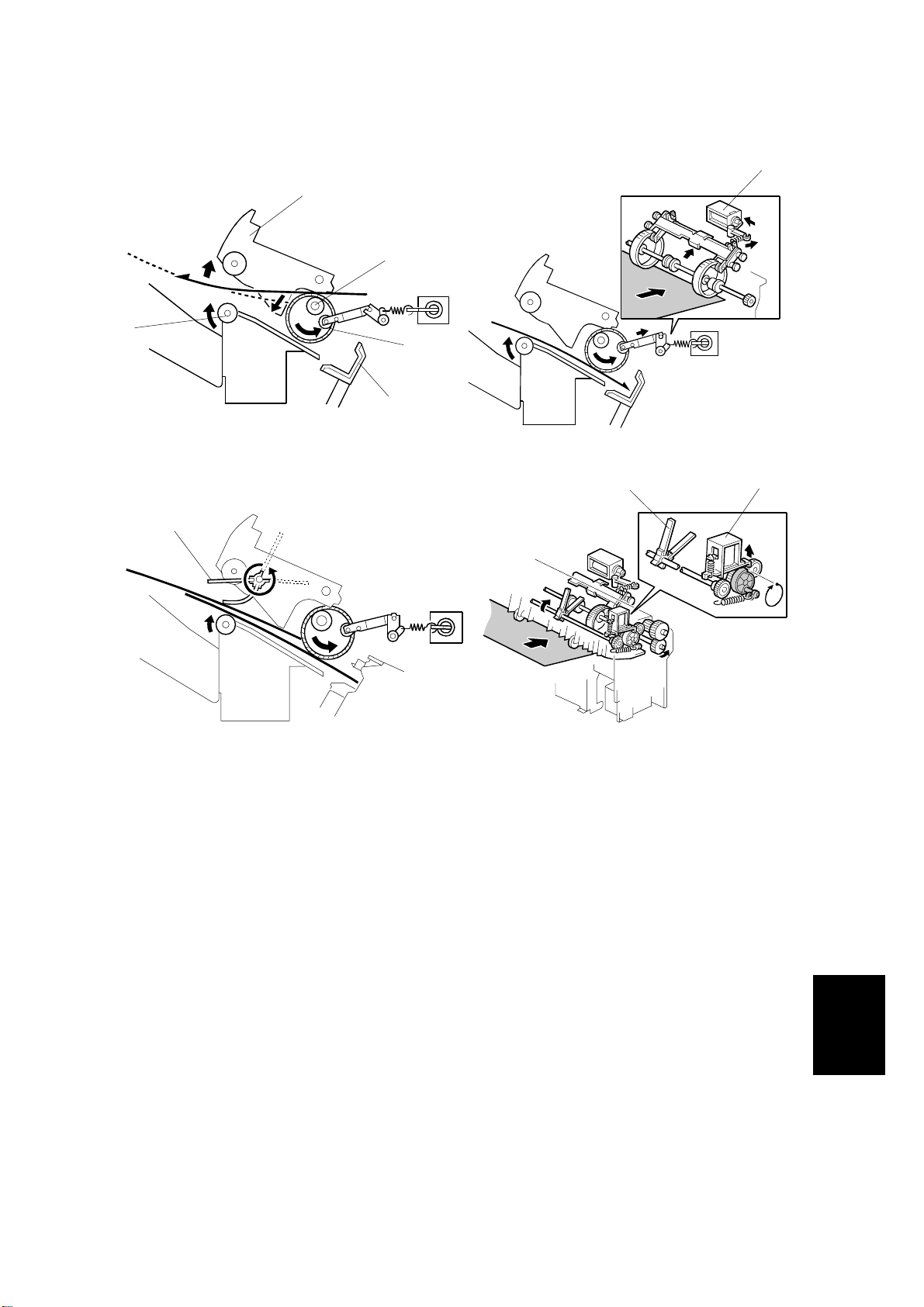

2.2 PRE-STACK MECHANISM

This mechanism improves productivity in staple mode and shift mode.

During stapling, the copier has to wait. This mechanism reduces the wait by

holding the first two sheets of a job while the previous job is still being stapled. It

only works during the second and subsequent sets of a multi-set copy job.

[B]

[C]

[A]

A763D566.PCX

The buffer roller entrance gate [A] and buffer roller exit gate [B] are opened. Then,

the 1st sheet of paper goes around the buffer roller [C].

[D]

A763D567.PCX

When the 2nd copy [D] comes to the buffer roller, the buffer roller exit gate is

closed. The two sheets of paper go to the shift tray [E] or staple tray [F].

[E]

[F]

A763-9

A763D568.PCX

Options

Page 13

PAPER SHIFT MECHANISM January 31, 2000

2.3 PAPER SHIFT MECHANISM

[B]

[C]

A763D569.PCX

[A]

[F]

A763D104.WMF

[G]

[A]

A763D570.PCX

In sort and stack mode, only the 1st sheet of copy paper from the 2nd set is shifted

to the front to separate each set of copies.

When the copy paper comes into the staple tray [A], the upper exit guide [B] (whi ch

contains the upper exit roller) opens. The paper switches back to the stopper [C].

Then the front guide release solenoid [D] turns on and the front guide [E] is

released, the shift motor moves jogger fence [F] to the front, and the copy paper

shifts to the front by 30 mm.

[E]

[D]

After copy paper has been shifted, the upper exit guide closes and the lower exit

roller [G] turns in the opposite direction to feed out the copy paper.

A763-10

Page 14

January 31, 2000 PAPER POSITIONING MECHANISM

2.4 PAPER POSITIONING MECHANISM

[F]

[C]

[A]

[B]

[E]

[D]

A763D105.WMF

A763D106.WMF

[G]

[H]

[G]

A763D108.WMF

A763D111.WMF

When the tr ailing edge of the 1st copy paper passes the 2nd tran sport roller [A],

the lower exit roller [B] stops and turns reverse. At the same time, the upper guide

plate motor turns on and opens the upper exit guide [C]. The copy paper is sent to

the stopper [D] by the lower exit roller and feed belt [E], and it is aligned the by

jogger motor.

The feed belt solenoid [F] turns on to move the feed belt to the stopper. This

function prevents excessive buckling of the paper between belt and stopper.

The paddles [G] send the paper to the stopper starting from the 2nd copy paper.

When the trailing edge of the 2nd copy paper passes the 2nd transport roller, the

paddle solenoid [H] turns on and the drive from the transport roller transmits to the

paddle shaft.

A763-11

Options

Page 15

STAPLER UNIT MOVEMENT MECHANISM January 31, 2000

2.5 STAPLER UNIT MOVEMENT MECHANISM

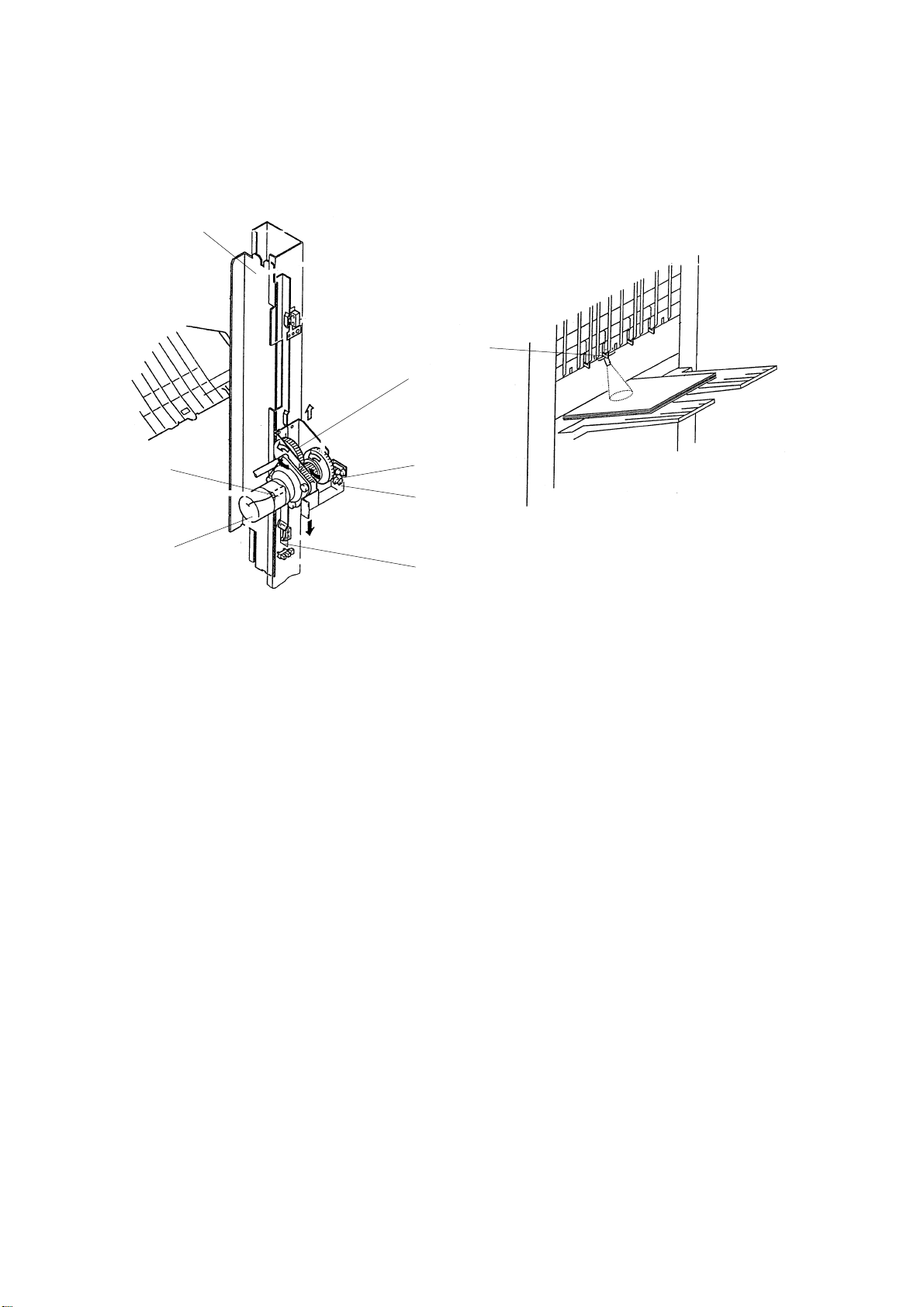

2.5.1 DRIVE

[A]

The stapler motor [A] drives the

stapler unit drive gear [B] via a timing

belt. The stapler unit guide has a rack

gear [C]. The stapler unit moves along

the rack gear via the stapler unit [D]

drive gear.

[D]

A763D107.WMF

2.5.2 MOVEMENT

[B]

[C]

Front and Rear Stapling

When the print key is pressed, the

stapler unit moves to the center. The

stapler unit moves to the front (or rear)

stapling position when the copy paper

comes into the finisher and stays until

the copy job finishes. It returns to home

position when the job is finished.

Tow-position Stapling

When the print key is pressed, the

stapler unit moves to the center. The

stapler unit moves to the rear stapling

position first and moves to the front

stapling position when stapling. Then it

goes back to the center until the copy

job finishes. It returns to home position

when the job is finished.

[A]

A763D114.WMF

A763-12

Page 16

January 31, 2000 STAPLER

2.6 STAPLER

[C]

[D]

[B]

A763D109.WMF

[D]

[A]

[A]

[E]

[G]

A763D571.PCX

[F]

A763D110.WMF

The staple hammer motor [A] drives the cam [B] via 2 gears [C, D] and the guide

roller on the staple hammer moves on the cam [D] . When the guide roller moves to

the highest position on the cam, the copy paper is stapled.

The stapler unit contains the cartridge set switch [E], staple end switch [F] and

staple position sensor [G].

The staple position sensor detects whether the staple sheet has come to the staple

unit or not.

A763-13

Options

Page 17

SHIFT TRAY MECHANISM January 31, 2000

2.7 SHIFT TRAY MECHANISM

[A]

[H]

[C]

[F]

[E]

[D]

A763D576.PCX

[B]

[G]

A763D572.PCX

The guide gear [A] on which the shift tray is mounted is driven by the lift motor [B]

via gear [C].

The finisher board detects the direction of the motor rotation and motor position

using the lift motor sensors 1 [D] and 2 [E].

The lift motor contains a thermoswitch [F]. When it detects 73.5º C, the finisher

board stops the lift motor until its temperature reaches approximately 40º C.

The shutter position switch [G] cuts the lift motor power for safety when the upper

exit guide plate opens.

The shift tray height sensor [H] detects the distance between the sensor and the

top of the copy paper on the shift tray.

A763-14

Page 18

January 31, 2000 BOOKLET UNIT GATE MECHANISM

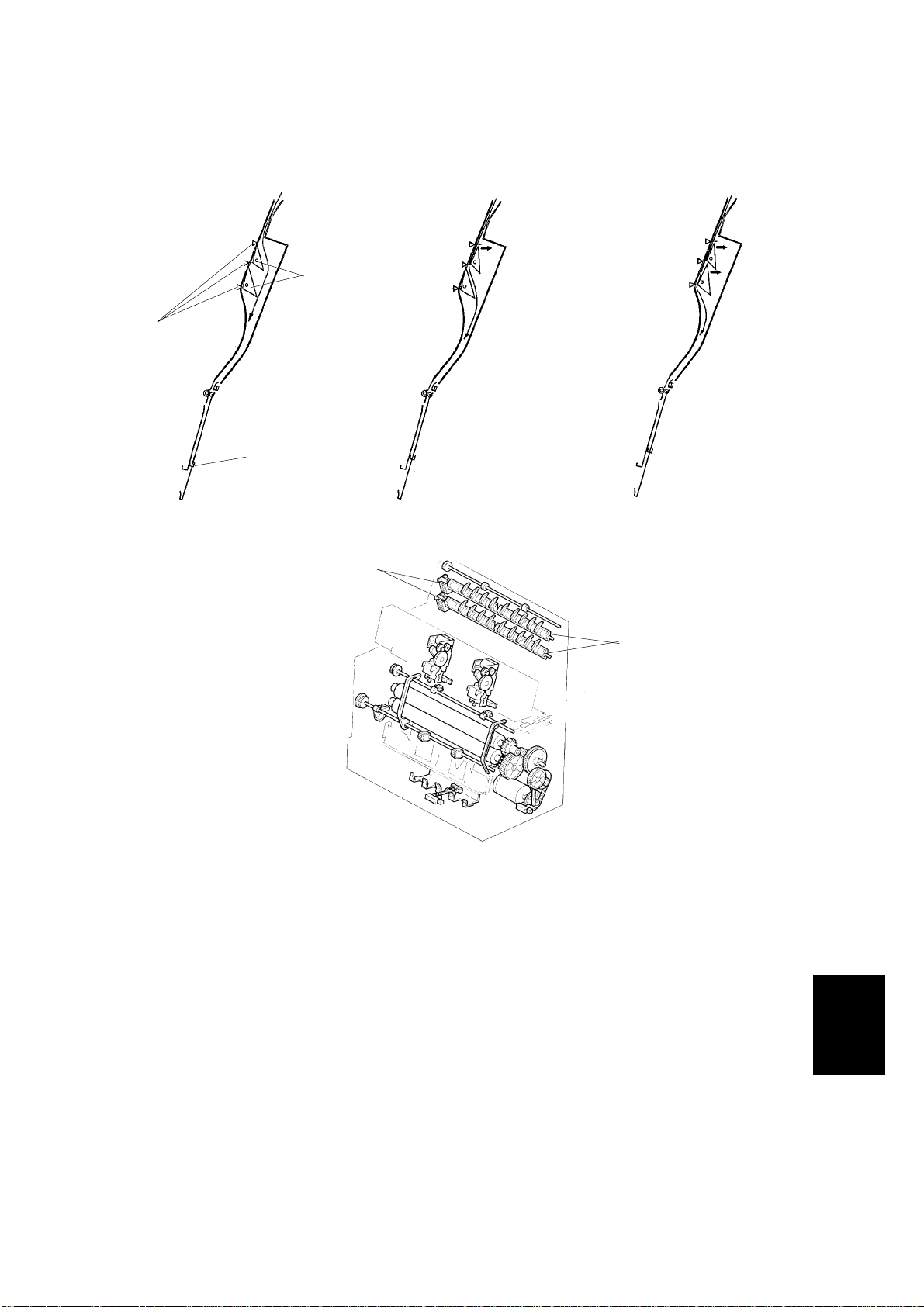

2.8 BOOKLET UNIT GATE MECHANISM

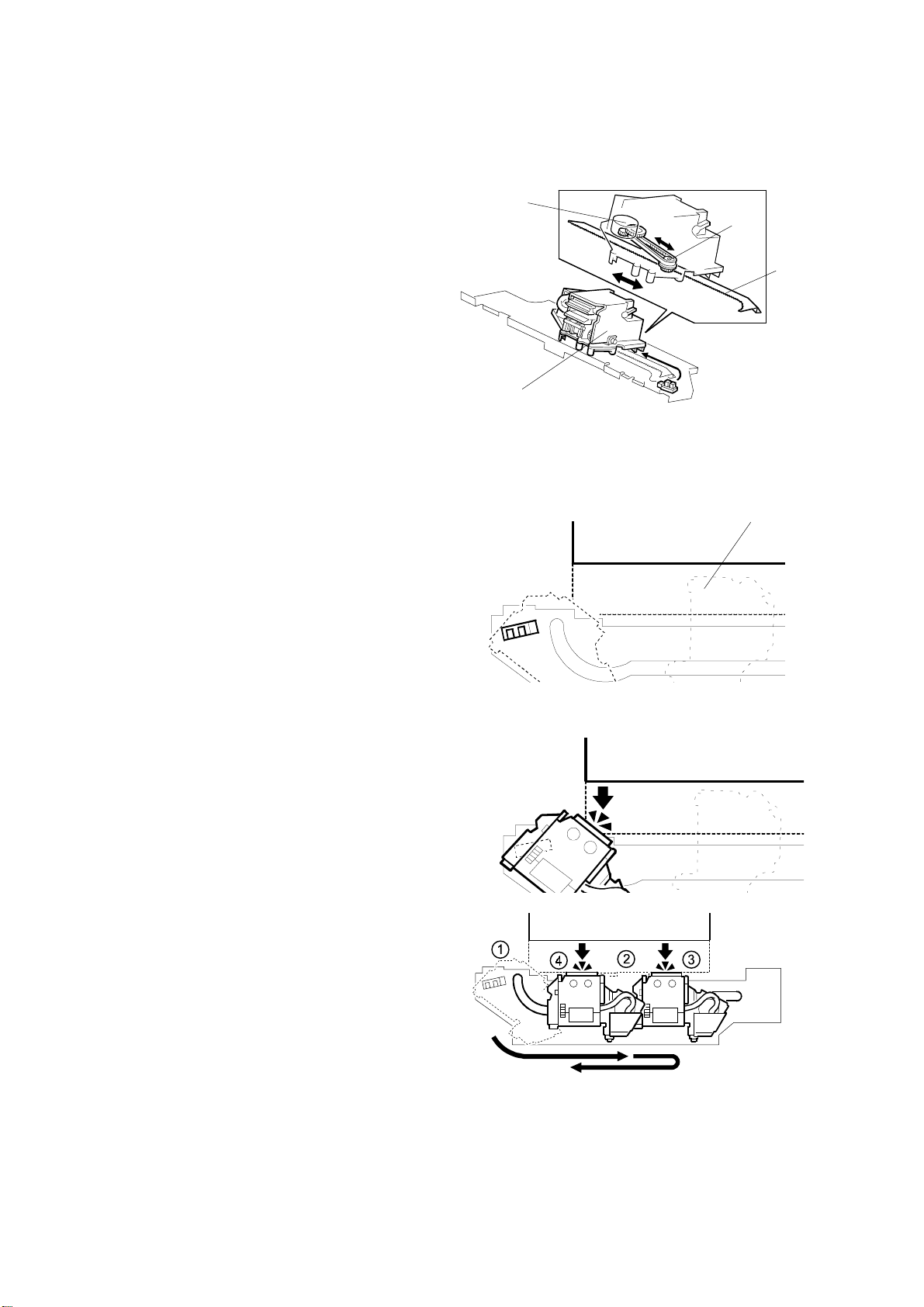

[A]

[B]

[D]

A763D550.PCX

A763D551.PCX A763D552.PCX

[C]

[A]

A763D563.PCX

There are two junction gates [A] and three paper sensors [B] at the entrance area

of the booklet unit.

Depending on paper size, the appropriate gate solenoid(s) [C] are energized to

close the gate(s) in order to transport paper to the positioning plate [D] through a

suitable paper path.

This is done for the following reasons:

• To detect the trailing ed ge of paper with the correct sensor.

• To prevent the leading edge of the next sheet from hitting the trailing edge of the

previous sheets on the positioning plate.

A763-15

Options

Page 19

BOOKLET UNIT GATE MECHANISM January 31, 2000

The following tables show the relation between paper sizes and solenoids/sensors:

A3, 11" x 17" B4, 11" x 14" A4, 8

" x 11"

1/2

1st Solenoid (Gate) OFF (Opened) ON (Closed) ON (Closed)

2nd Solenoid (Gate) OFF (Opened) OFF (Opened) ON (Closed)

A3, 11" x 17" B4, 11" x 14" A4, 8

" x 11"

1/2

Trailing Edge Sensor 1 ON ON ON

Trailing Edge Sensor 2 OFF ON ON

Trailing Edge Sensor 3 OFF OFF ON

A763-16

Page 20

January 31, 2000 RELAY ROLLER AND POSITIONING PLATE MECHANISM

2.9 RELAY ROLLER AND POSITIONING PLATE

MECHANISM

When the f irst sheet of paper comes to the booklet unit, the

booklet transport motor turns on to drive the relay roller [A].

The two relay rollers are out of contact with each other before

the paper comes. When the leading edge of the paper passes

trailing edge sensor 1, the relay roller solenoid is energized to

make the two relay rollers contact each other to transport the

paper to the positioning plate [B]. When the trailing edge of the

paper comes to the trailing ed ge sensor that the paper passes

last, the relay roller solenoid is de-energized. This solenoid

on/off cycle is done for each sheet of paper.

Before paper comes, the positioning plate moves up from the

home position to a position that is suitable for the selected

paper size in order that the middle of the paper just comes to

the stapling position.

[A]

[B]

A763D573.PCX

The positioning plate motor drives the positioning plate using

pulse counts.

Only when the first sheet of paper reaches the positioning

plate, the positioning plate sensor [C] detects the paper.

A763D574.PCX

[A]

[C]

[B]

Options

A763D563.PCX

A763-17

Page 21

POSITIONING ROLLER MECHANISM January 31, 2000

2.10 POSITIONING ROLLER MECHANISM

[C]

[E]

[D]

[A]

[E]

[B]

[D]

A763D554.PCX

[C]

[A]

A763D555.PCX

The booklet transport motor also drives the positioning roller [A] to vertically align

paper against the positioning plate [B].

The positioning roller is not round but elliptical in shape so that it moves away from

the paper while the paper is being horizontally aligned.

The positioning roller sensor [C] detects the actuator [D] on the roller shaft to

determine the rotation of the positioning roller. When the sensor is de-actuated, the

roller is away from the paper and the jogger fences [E] start moving.

A763-18

Page 22

January 31, 2000 BOOKLET UNIT JOGGER MOVEMENT MECHANISM

2.11 BOOKLET UNIT JOGGER MOVEMENT MECHANISM

[A]

[B]

A763D557.PCX

When the start key is pressed, the booklet jogger motor turns on to move the

jogger fences [A] to the waiting positions that a r e 10 mm from each of the paper

side edges .

Each time a sheet of paper reaches the positioning plate [B], the jogger fences

move toward the paper to align the paper once. The fences move back a short

distance and move forward again the paper to align for the second time. Then, the

fences go back to the waiting position.

When the la st sheet is aligned, the fences stay at the aligning positions during

stapling.

A763-19

Options

Page 23

BOOKLET STAPLER UNIT Januar y 31, 2000

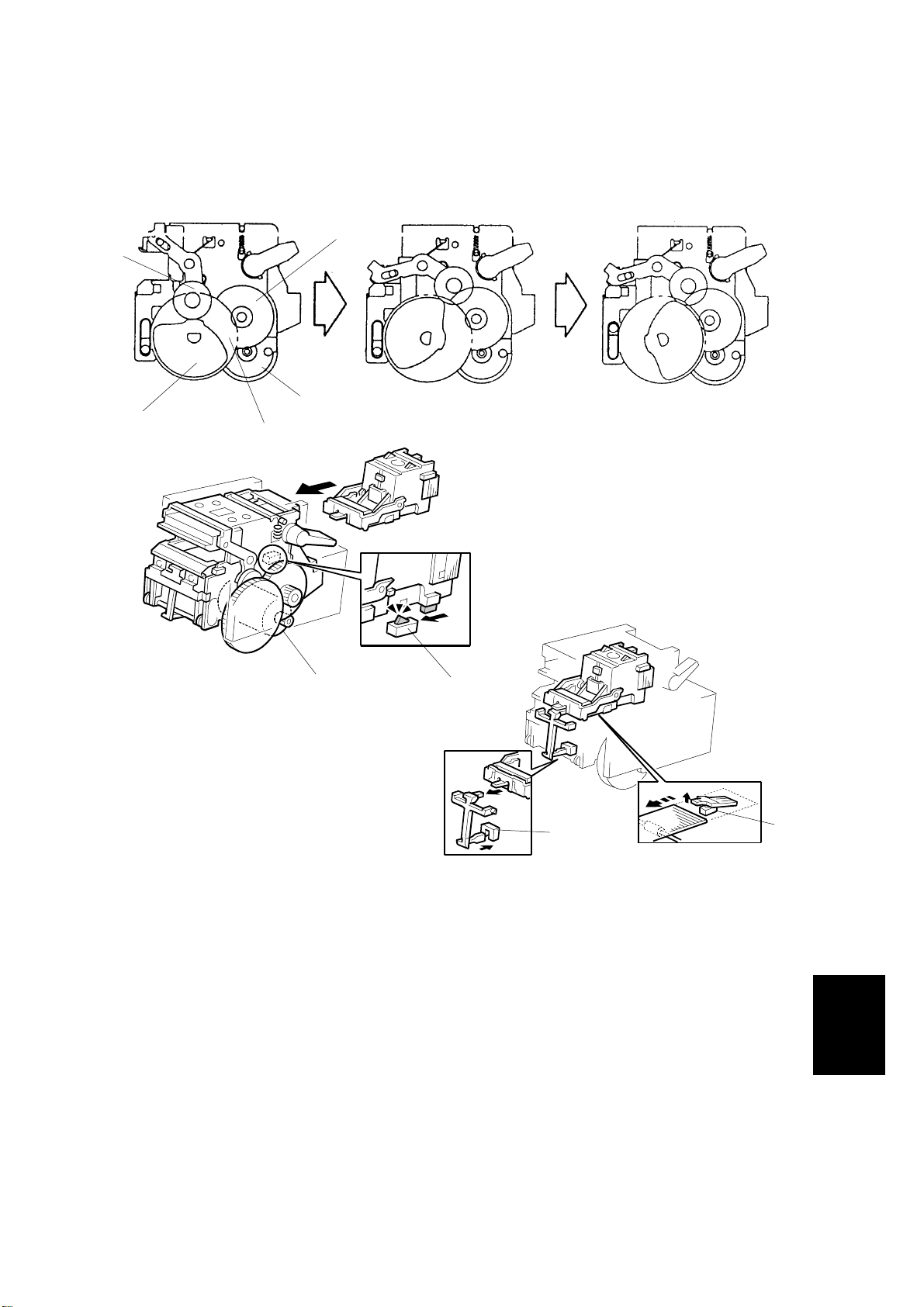

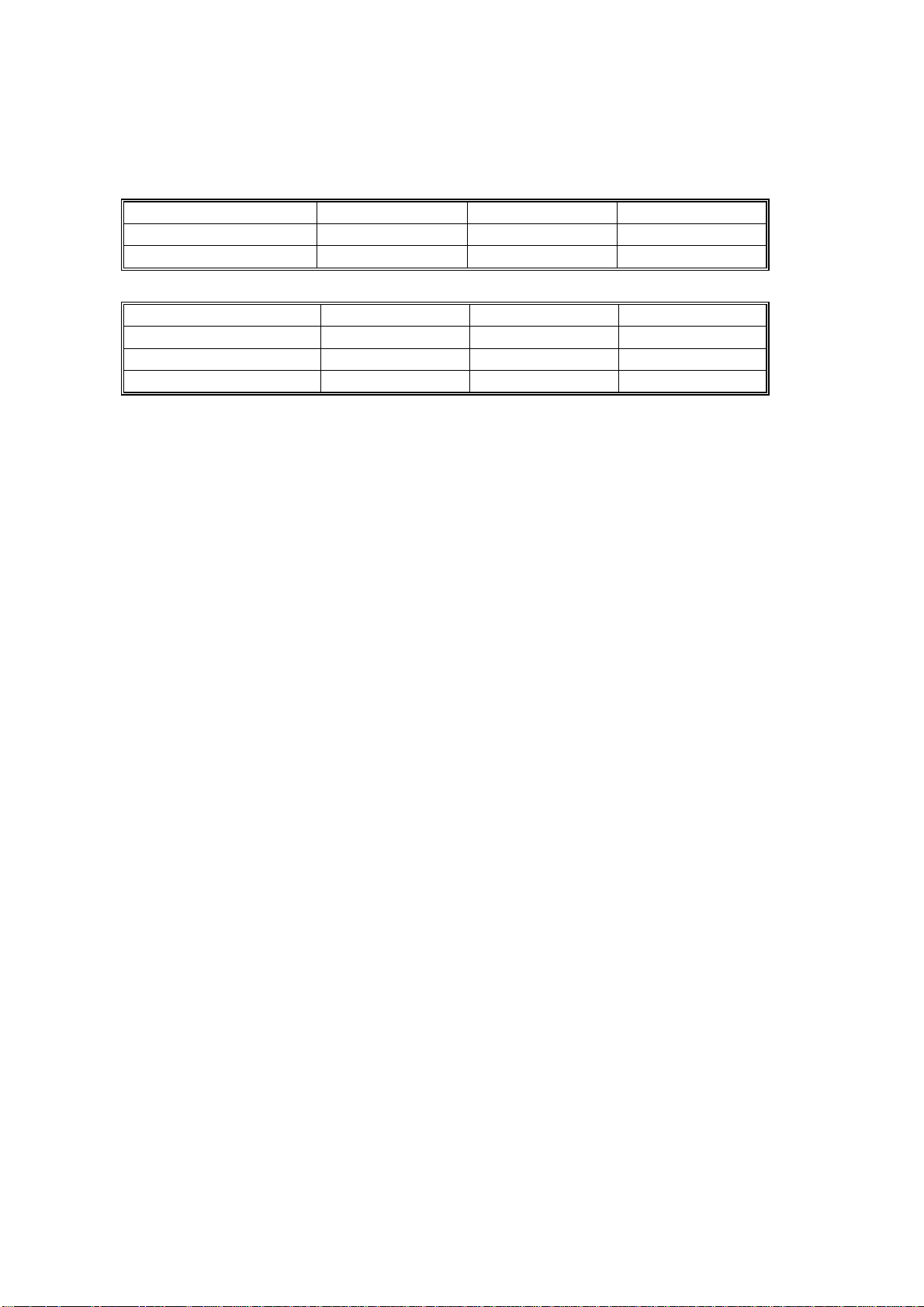

2.12 BOOKLET STAPLER UNIT

A763D575.PCX

There are two staplers whose positions are fixed.

When the jogger fences finish aligning the last sheet, t he jogger fences stay at the

aligning positions and stapling starts. The two staplers do not operate at the same

time, the rear stapler operates first, then the front one. This is for the following

reasons:

• To prevent paper from becoming waved in the area between the two stapled

positions.

• To minimize necessary electric power.

The staple hammer HP switch in each stapler detects a stapling cycle and the

staple end sensor detects the presence of staples in the cartridge.

The stapler unit, including the two staplers, can be pulled out to enable staple

cartridge replacement or jam removal. The stapler unit set sensor detects when the

stapler unit is back in the right position.

A763-20

Page 24

January 31, 2000 PAPER FOLDER MECHANISM

2.13 PAPER FOLDER MECHANISM

[C]

[A]

[B]

[B]

[A]

A763D560.PCX

20 mm

A763D561.PCX

A763D559.PCX

A763D562.PCX

The positioning plate moves down from the stapling position to a position such that

the middle of the paper just comes to the folding position. It depends on the paper

size.

At the same time, the shutter guide motor moves the shutter guide, which is

covering the folder rollers to prevent paper arriving at the positioning plate from

being caught by the rollers, down to the home position.

Shortly after that, the folder plate motor and the folder roller motor start rotating.

The folder plate [A] moves to push the middle of the stapled sheets of paper

toward the folder rollers [B] until the folder plate return sensor [C] is de-actuated.

Then, the folder plate comes back to the home position.

After that, the folder rollers and booklet exit roller feed the paper to the booklet tray.

A763-21

Options

Page 25

PAPER FOLDER MECHANISM January 31, 2000

In the case of 10 sheets or more of A4 or 8

" x 11" paper, folding is done twice for

1/2

20 mm of the leading edge to fold the paper more firmly.

When the leading edge of the folded paper passes 20 mm from the folder rollers,

the folder roller motor reverses to feed the paper back 20 mm. During this action,

the folder plate stays at the return position. (Figure A763D561)

Then, the folder roller motor rotates forward again to feed the set of papers out and

the folder plate goes back to the home position. (Figure A763D562)

A763-22

Page 26

January 31, 2000 ACCESSORY CHECK

3. INSTALLATION

3.1 ACCESSORY CHECK

Check the quantity and condition of the accessories in the box against the following

list.

Description Q’ty

1. Upper Tray.......................................................................... 1

2. Shift Tray.............................................................................1

3. Tapping Screw -M4 x 6....................................................... 1

4. Rail Ass’y............................................................................ 1

5. Joint Bracket....................................................................... 1

6. Tapping Screw - M4 x 16.................................................... 2

7. Rail Bracket......................................................................... 1

8. Tapping Screw - M4 x 6...................................................... 1

9. Harness Cover.................................................................... 1

10. Sensor Feeder.................................................................. 1

7

4

9

10

5

2

1

3

6

8

A763-23

A763I101.WMF

Options

Page 27

INSTALLATION PROCEDURE January 31, 2000

3.2 INSTALLATION PROCEDURE

A763I102.WMF

A763I104.WMF

CAUTION

ø

Keep the power cord unplugged when starting the following procedure.

1. Unpack the finisher and remove the tapes and shipping retainers.

A763-24

Page 28

January 31, 2000 INSTALLATION PROCEDURE

[A]

[B]

A763I105.WMF

[E]

[D]

2. Open the front under door and pull out the staple unit [A].

3. Remove the stapler unit lock plate [B] (1 screw).

4. Push in the stapler unit and shut the front lower door.

5. Remove the right lower cover [C] (4 screws).

6. Remove the front pressure release bracket [D] (1 screw).

7. Remove the rear pressure release bracket [E] (1 screw).

[C]

A763I103.WMF

Options

A763-25

Page 29

INSTALLATION PROCEDURE January 31, 2000

[A]

[B]

[C]

A763I106.WMF

[D]

A763I107.WMF

8. Set the hooks [A] of the shift tray [B] in the notches in the shift tray bracket, and

secure the tray with two M4 x 6 screws.

9. Connect the shift tray sensor harness [C].

10. Install the harness cover [D] (2 hooks).

A763-26

Page 30

January 31, 2000 INSTALLATION PROCEDURE

[A]

[B]

A763I108.WMF

[D]

[E]

[C]

A763I110.WMF

11. Install the upper tray [A] (2 pins).

12. Attach the sensor feeler [B] (2 pins).

13. Attach the rail [C] to the rail bracket [D] as shown.

14. Install the rail bracket [E] on the left lower cover of the copier (2 screws).

A763-27

Options

Page 31

INSTALLATION PROCEDURE January 31, 2000

[A]

[C]

[D]

A763I109.WMF

[B]

A763I111.WMF

15. Install the joint bracket [A] on the left side of the copier (4 screws).

16. Secure the rail [B] to the booklet finisher with 1 M4 screw.

17. Align the finisher on the joint bracket and lock the 2 hooks [C] of the finisher on

the joint bracket.

18. Connect the finisher cable [D] to the copier.

19. Plug in the power cord and turn the main switch on, and perform stapler initial

setting as follows.

1) Enter User Program mode.

2) Press System Settings.

3) Press Basic Page 2.

4) Press Staple Initialization.

5) Press the OK key.

A763-28

Page 32

January 31, 2000 REMOVAL

4. REPLACEMENT AND ADJUSTMENT

4.1 REMOVAL

4.1.1 UPPER DOOR

[A]

A763R579.PCX

1. Open the upper door [A].

2. Remove the lower hinge [B] (1 screw).

3. Push up the upper door and remove it.

[B]

Options

A763-29

Page 33

REMOVAL January 31, 2000

4.1.2 UPPER REAR COVER

[A]

[B]

A763R580.PCX

[C]

1. Hold up the proof tray and open the top cover [A].

2. Unhook the upper rear cover [B] and remove it (3 screws).

4.1.3 LOWER REAR COVER

1. Remove the lower rear cover [C] (4 screws).

A763R104.WMF

A763-30

Page 34

January 31, 2000 REMOVAL

4.1.4 TOP COVER

[A]

[B]

[B]

[C]

A763R580.PCX

1. Hold up the upper tray [A] and open the top cover [B].

2. Push the hooks [C] of the top cover and remove it.

4.1.5 UPPER INNER COVER

A763R581.PCX

[A]

1. Open the upper door.

2. Remove the upper inner cover [A] (1 screw).

A763-31

A763R582.PCX

Options

Page 35

REMOVAL January 31, 2000

4.1.6 SHIFT TRAY UNIT

[D]

[C]

A763R106.WMF

[E]

[B]

[A]

A763R107.WMF

[F]

A763R108.WMF

1. Remove the upper and lower rear covers.

2. Disconnect the connector [A] and remove the grounding wire [B]

(1 screw).

3. Unhook the two stoppers [C] and remove them.

4. Remove the slide guide [D] by pulling it u p.

Remove the shift tray unit [E] by pulling it up.

5.

NOTE:

When reinstalling the shift tray unit, release the clutch gear [F] of the

tray lift motor by carefully inserting a screwdriver.

A763-32

Page 36

January 31, 2000 REMOVAL

4.1.7 UPPER SHIFT GUIDE

[A]

A763R112.WMF

1. Remove the slide guide and shift the shift tray unit down by releasing the clutch

gear of the tray lift motor (see Shift Tray Unit Removal).

Remove the upper

2.

shift guide [A] (6 screws (5 x M4, 1 x M3)).

4.1.8 LOWER SHIFT GUIDE

[A]

A763R109.WMF

1. Remove the shift tray unit.

2. Remove the lower shift guide [A] (2 connectors, 6 screws (3 x M4, 3 x M3)).

Options

A763-33

Page 37

REMOVAL January 31, 2000

4.1.9 EXIT UNIT

[B]

[C]

[A]

A763R113.WMF

[G]

[D]

[E]

A763R114.WMF

1. Remove the shift tray unit, and the upper and lower shift guides.

2. Disconnect the connector [A] and remove the screw [B] that secures the

transport belt unit [C].

3. Disconnect the 4 connectors [D].

4. Hold up the exit unit [E] and remove it with the transport belt unit

(3 screws, 1 clamp).

NOTE:

When installing the exit unit, make su re to position the exit uni t guide

plate (black) [F] over the transport guide plate [G].

[F]

A763-34

Page 38

January 31, 2000 REMOVAL

4.1.10 BUFFER ROLLER UNIT

A763R583.PCX

[D]

[A]

[B]

[C]

A763R112.WMF

[D]

[E]

A763R584.PCX

A763R585.PCX

1. Remove the upper rear cover and the top cover.

2. Disconnect the connector [A].

3. Remove the upper shift guide [B] (6 screws) and the guide holder [C] (2

screws).

4. Unhook the shafts [D], and remove the buffer roller unit [E] (2 clamps).

Options

A763-35

Page 39

REMOVAL January 31, 2000

4.1.11 STAPLER

[A]

[B]

A763R586.PCX

[C]

A763R588.PCX

1. Open the upper front door.

2. Slide the stapler [A] towards the front.

3. Remove the stapler (1 screw, 1 connector [B]).

4. Remove the cover [C] from the stapler (2 screws).

A763R587.PCX

A763-36

Page 40

January 31, 2000 REMOVAL

4.1.12 FINISHER BOARD

[A]

A763R589.PCX

1. Remove the upper rear cover.

2. Remove the finisher board [A] (4 screws, 19 connectors).

NOTE:

Do the following adjustments after replacing the board:

• Shift tray height

• Jogger fence position

• Stapling position

A763-37

Options

Page 41

REMOVAL January 31, 2000

4.1.13 BOOKLET UNIT

[D]

[A]

[B]

[C]

A763R561.WMF

1. Remove the following items.

• Upper and lower rear covers.

• Shift tray unit.

• Lower shift guide.

2. Remove the lower right cover [A] (4 screws).

3. Remove the folder roller knob [B] (1 stepped screw).

4. Remove the lower inner cover [C] and lower door [D] (5 screws).

A763-38

Page 42

January 31, 2000 REMOVAL

[A]

[B]

[C]

[D]

[G]

A763R110.WMF

[E]

A763R101.WMF

A763R111.WMF

[F]

[H]

[I]

[I]

[J]

5. Remove the grounding wire [A] (1 screw) and upper booklet exit guide [B]

(2 screws).

6. Open the lower booklet exit guide [C] and remove it

(1 L-pin [D], 2 connectors [E]).

7. Remove the right front and right rear covers [F , G] (2 screws each).

8. Disconnect the two connectors [H].

9. Remove the two joints [I] and then pull out the booklet unit [J] from the right

side (3 screws).

A763-39

Options

Page 43

REMOVAL January 31, 2000

4.1.14 FOLDER ROLLERS

[A]

A763R590.PCX

[B]

A763R591.PCX

[C]

[D]

A763R592.PCX

1. Remove the booklet unit

2. Remove the drive unit [A] (4 connectors [B], 3 screws [C]).

3. Remove the front and rear tension springs [D].

[D]

A763R593.PCX

A763-40

Page 44

January 31, 2000 REMOVAL

[A]

4-105B.PCX

A763R595.PCX

A763R596.PCX

[B]

[B]

[C]

A763R597.PCX

A763R598.PCX

[C]

Remove

4.

the gears [A] and ball bearings [B] (4 C-rings).

5. Remove the front and rear tighteners [C] (1 stepped screw each).

A763-41

Options

Page 45

REMOVAL January 31, 2000

A763R599.PCX

[A]

6. Remove the jogger plates [A] (1 screw each).

7. Slide the folder rollers [B] to the front and remove them.

[B]

A763R549.PCX

A763-42

Page 46

January 31, 2000 REMOVAL

4.1.15 FOLDER PLATE

[D]

A763R117.WMF

[C]

[B]

[D]

[E]

A763R116.WMF

Removal

1. Remove the following items

• Lower right cover (see “Booklet Unit Removal”)

• Folder rolle r knob (see “Booklet Unit Removal”)

• Lower door and lower inner cover (see “Booklet Unit Removal”)

• Booklet board

2. Release the harness [A] from the clamps.

3. Insert two positioning screws [B] in the holes provided in the folder table [C].

4. Tighten the screws until the ends touch the securing plate [D] for the folder

plate.

5. Remove the folder plate [E] and the securing plate (3 screws).

[A]

A763-43

Options

Page 47

REMOVAL January 31, 2000

Reinstalling

[B]

[C]

[B]

[A]

[A]

A763R575.PCX

A763R578.PCX

[A, B]

[D]

A763R577.PCX

A763R576.PCX

1. Line up the two small holes [A] in the folder plate with the two small protrusions

on the bottom of the securing plate [B]. Then, push the two protrusions through

the holes.

Note: Be sure that the three screw holes are also lined up.

[E]

2. Temporarily fix the two plates together by attaching two strips of electrical tape

[C] along the line where they meet (see the illustration).

NOTE:

1) Be sure to fold the two strips back toward you so that they can

easily be removed.

2) Be careful not to attach the tape too close to the three screw holes.

3. Reattach the two plates [A, B] to the folder table [D] (3 screws).

NOTE:

Tighten these three screws while holding the securing plate against

the two positioning screws [E] that were installed in step 3 of the

"Removal" procedure.

4. Remove the two strips of tape.

A763-44

Page 48

January 31, 2000 REMOVAL

4.1.16 BOOKLET STAPLER UNIT

Removal

[A]

[B]

A763D562.PCX

[C]

A763R563.PCX

1. Remove the lower door and inner cover (see “Booklet Unit Removal”).

2. Remove the guide roller [A] and shaft [B] (1 E-ring).

3. Pull out the booklet stapler unit [C].

Options

A763-45

Page 49

REMOVAL January 31, 2000

[A]

A763R564.PCX

[C]

A763R567.PCX

Adjustment

1. Remove the booklet stapler cover [A] (3 screws).

2. Remove the three paper guides [B] (1 screw each).

3. Loosen the two screws on each of the anvils [C].

[B]

A763R565.PCX

A763-46

Page 50

January 31, 2000 REMOVAL

[A]

[B]

A763R568.PCX

[A]

A763R569.PCX

[C]

[A]

[D]

A763R570.PCX

4. Insert the anvil positioning plate [A] into the staple slot of the stapler [B].

NOTE:

The anvil positioning plate is stored in the booklet stapler cover [C].

5. Rotate the gear to move down the stapler. Then align the anvil positioning plate

and the anvil [D]. Then secure the anvils (2 screws each).

A763-47

Options

Page 51

REMOVAL January 31, 2000

4.1.17 BOOKLET BOARD

[B]

[A]

A763R115.WMF

1. Remove the lower right cover [A] (4 screws).

2. Remove the booklet board [B] (4 screws, 14 connectors).

NOTE:

After replacing the board, adjust the booklet stapling position.

4.1.18 POSITIONING PLATE UNIT

[C]

A763R571.PCX

1. Remove the booklet board (4 screws, 14 connectors).

[D]

2. Slide the paper positioning unit [C] to the right and remove it (2 screws, 2

connectors [D]).

A763-48

Page 52

January 31, 2000 REMOVAL

4.1.19 1ST AND 2ND BOOKLET UNIT GATES

[E]

[A]

[A]

[B]

A763R572.PCX

[D]

[C]

A763R573.PCX

A763R574.PCX

1. Remove the upper and lower rear covers.

2. Release the two tension springs [A] of the booklet entrance guide [B].

3. Remove the booklet unit gate solenoids [C] (1 screw and 1 spring each).

4. Pull out the link of the solenoid [D].

5. Remove the booklet unit gates [E].

A763-49

Options

Page 53

ADJUSTMENT January 31, 2000

4.2 ADJUSTMENT

4.2.1 SHIFT TRAY HEIGHT

SW1

LED 1

SW2

Dip Switch 3

Dip Switch 3

ON

1

LED 2

A763R550.WMF

23 56784

A763R551.WMF

After replacing the finisher board or shift tray height sensor, always do this

adjustment.

1. Remove the upper rear cover.

2. Turn on dip switches 3 -1 and -4 on the finisher board.

3. Put blank paper (A4/8

11") on the shift tray.

1/2" x

4. Press switch 1 (SW1) on the finisher board.

The finisher automatically adjusts the shift tray height when switch 1 is pressed.

• After performing the adjustment, the shift tray will return to home position.

• During the adjustment, LED 1 flashes. After performing the adjustment, LED

1 turns on and remains on.

• If the automatic adjustment fails, the finisher stops and LED 1 turns off.

5. Turn off dip switches 3 -1 and -4, then turn off the copier main switch.

A763-50

Page 54

January 31, 2000 ADJUSTMENT

4.2.2 JOGGER FENCE POSITION

Dip Switch 3

ON

1

23 56784

SW1

SW2

A763R552.WMF

Dip Switch 3

LED 1

LED 2

A763R550.WMF

Jogger Fence

Jogger Fence

Rear

Front

Shutter

A763R553.WMF

After replacing the finisher board or if a paper alignment fault occurs, do this

adjustment.

SW2

SW1

Doing this adjustment once will affect all paper sizes.

1. Remove the upper rear cover.

2. Turn on dip switch 3-1 on the finisher board.

3. Press the following switch on the finisher board.

Using A4: Switch 1 (SW1)

Using 8

" x 11": Switch 2 (SW2)

1/2

• After pressing the switch, the upper exit unit will open and the jogger fences

will move to the A4 or 8

4. Place 10 sheets of A4/8

" x 11" position.

1/2

" x 11" paper between the jogger fences and push

1/2

them until they touch the shutters.

5. Adjust the jogger fence position by pressing switch 1 or 2.

• Switch 1: Move to the front (0.35 mm/press)

• Switch 2: Move to the rear (0.35 mm/press)

6. Press switches 1 and 2 simultaneously to store the adjustment data.

• After pressing the switches, the upper exit unit will close.

7. Turn off dip switch 3-1, then turn off the copier main switch.

Options

A763-51

Page 55

ADJUSTMENT January 31, 2000

4.2.3 STAPLING POSITOIN

290 ± 2 mm (A4Y), 273 ± 2 mm (LTR)

Dip Switch 3

Staple

Rear Front

SW2

SW1

A763R555.WMF

ON

1

23 56784

A763R554.WMF

After replacing the finisher board, do this adjustment. Doing this adjustment once

will affect all paper sizes and all stapling positions.

1. Remove the upper rear cover.

2. Turn on dip switches 3 -1 and -2 on the finisher board.

3. Press the following switch on the finisher board.

Using A4: Switch 1 (SW1)

Using 8

" x 11": Switch 2 (SW2)

1/2

• After pressing the switch, the upper exit unit will open and the transport belt

will rotate.

4. Within five seconds after pressing the switch, place one sheet of A4/8

1/2

paper between the jogger fences and push it until it touches the shutter.

When the staple tray paper senso r detects the paper, the stapler will staple

(rear, 1 point).

5. Take out the stapled paper manually and check the staple position.

Staple position: Good → Tur n o ff dip swi tches 3 -1 and -2 to end the

procedure.

Staple position: No good → Change the staple position by doing the

following steps.

6. Adjust the staple position by pressing switch 1 or 2.

Switch 1: Move the front (0.3 mm/press)

Switch 2: Move to the rear (0.3 mm/press)

7. Press switches 1 and 2 simultaneously to store the adjustment data. After

pressing the switches, check the staple position again.

8. Turn off dip switches 3 -1 and -2, then turn off the copier main switch.

A763-52

" x 11"

Page 56

January 31, 2000 ADJUSTMENT

4.2.4 BOOKLET STAPLING POSITION

Dip Switch 1

LED 1

SW2

A763R557.WMF

Mark

(Trailing edge)

Dip Switch 1

ON

1

23 56784

A763R556.WMF

Slot in direction

(reading edge)

A763R558.WMF

After replacing the booklet board, dip switches 1 -6, -7, -8 on the new board must

be set up the same way as on the old board.

1. Remove the lower right cover (see “Booklet Unit Removal”) and lower rear

cover.

2. Turn on dip switches 1 -1 and -2 on the booklet board.

3. Tape the actuators of the booklet entrance guide sensor (S42) and the booklet

entrance guide safety switch (SW11), so that S42 and SW11 remain actuated.

4. Press switch 2 (SW2) on the booklet board.

• After pressing the switch, the booklet transport motor (M10) will start to

rotate.

5. Put a mark on the trailing edge of some A3/11" x 17" paper (two sheets).

Options

A763-53

Page 57

ADJUSTMENT January 31, 2000

[B]

[A]

A763R548.PCX

6. Open the booklet entrance guide [A], then slide in the two sheets of paper [B]

until their leading edges touch the positioning plate.

7. Press switch 2 on the booklet board.

• The booklet finisher makes a booklet automatically.

A763-54

Page 58

January 31, 2000 ADJUSTMENT

Adjust towards the leading edge

Mark

Folding Position

L

Stapling Position

Example 1: L= 1 mm

Dip switch 1 -6, -7, -8 setting

-6 -7 -8

Adjust away from the leading edge

Stapling Position

L

Folding Position

Example 2: L= 0.75 mm

Adjustment

(0.25 mm/ step)

OFF ON ON +3

OFF ON OFF +2

OFF OFF ON +1

OFF OFF OFF 0

ON OFF ON -1

ON ON OFF -2

ON ON ON -3

ON OFF OFF Do not use

Mark

A763R559.WMF

8. Measure the distance (L) between the stapling position and the folder position.

9. Adjust the stapling position with dip switches 1 -6, -7, -8.

Inputting a lower value than the current setting moves the stapling position

towards the leading edge. Adjusting by 1 step moves the stapling position 0.25

mm.

Example 1:

To move the stapling position 1 mm towards the leading edge.

If dip switch 1 is currently set to +2, set the dip switch to reflect -2 (this moves

the stapling position 4 steps towards the leading edge).

Example 2:

To move the stapling position 0.75 mm away from the leading edge.

If dip switch 1 is currently set to -1, set the dip switch to reflect +2 (this move,s

the stapling position 3 steps away from the leading edge).

10. Turn off dip switched 1-1 and -2, then turn off the copier main switch.

A763-55

Options

Page 59

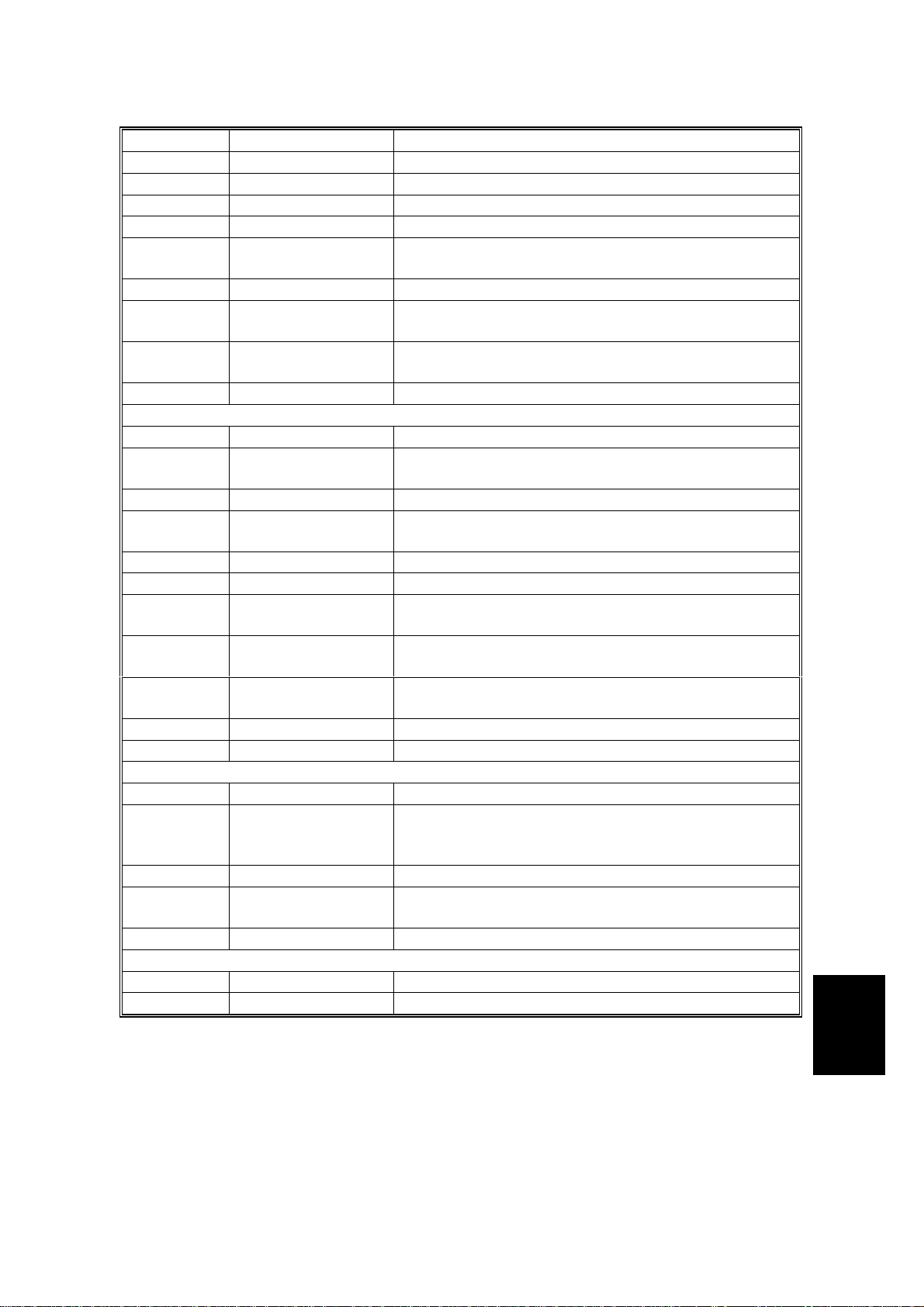

ELECTRICAL COMPONENT LAYOUT (A763) (1/2)

20

19

18

17

16

21

50

46

47

60

48

49

53

54

55

56

66

67

68

69

70

71

72

73

74

75

44

1

2 3

4

52

5

6

7

8

9

10

11

12

51

45

22

43

42

41

40

39

23

24

25

131415

59

61

26

62

63

27

28

29

30

58

57

64

77

76

78

79

80

81

82

84

38

37

31

32

343536

33

65

83

85

86

8788

Page 60

ELECTRICAL COMPONENT LAYOUT (A763) (2/2)

Symbol Name

Motors

M1 Entrance 49 E3

M2 Transport Roller 47 E2

M3 Buffer Roller 48 E3

M4 Jogger 44 E2

M5 Stapler 52 A6

M6 Staple Hammer 51 A7

M7 Guide Plate 46 E4

M8 Exit Motor 45 E3

M9 Tray Lift 50 E2

M10 Booklet Transport 56 I1

M11 Positioning Plate 54 I2

M12 Shutter Guide 55 I2

M13 Booklet Jogger 57 I2

M14 Front Stapler 60 I4

M15 Rear Stapler 53 I5

M16 Folder Roller 59 I1

M17 Folder Plate 58 I1

Symbol Name

Switches

SW1

SW2 Shift Tray Safety 82 E6

SW3 Shutter Position 76 E7

SW4

SW5

SW6

SW7 Cartridge Set 83 A7

SW8 Staple End 83 A7

SW9 Thermo 78 E2

SW10

SW11

SW12

SW13

SW14

Upper Cover

Safety

Upper Exit Guide

1

Upper Exit Guide

2

Shift Tray Upper

Limit

Lower Door

Safety

Booklet Entrance

Guide Safety

Booklet Exit

Safety

Front Staple

Hammer HP

Rear Staple

Hammer HP

Index

No.

Index

No.

77 E6

80 E6

79 E7

81 E6

87 I5

84 I5

88 I6

86 I4

85 I5

P to P

P to P

Symbol Name

Sensors

S1 Entrance 3 A2

S2

S3 Straight Path 21 A5

S4 Staple Tray Paper 8 A2

S5 Jogger HP 19 A3

S6 Stapler Unit HP 16 A4

S7

S8 Staple Position 14 A7

S9 Upper Exit Guide 4 A2

S10 Exit Guide Motor 7 A6

S11 Exit 18 A3

S12 Exit Motor 13 A3

S13 Shift Tray Paper 20 A5

S14 Shift Tray height 1 A2

S15 Shift Tray HP 12 A4

S16 Lift Motor 1 11 A4

S17 Lift Motor 2 10 A4

S18 Proof Tray Exit 5 A6

S19 Proof Tray Limit 6 A6

S20 Finisher Set 20 A6

S21 Shutter 15 A3

S22 Trailing Edge 1 24 F3

S23 Trailing Edge 2 23 F3

S24 Trailing Edge 3 22 F4

S25 Booklet Entrance 32 F5

S26

S27

S28 Positioning Roller 31 F3

S29

S30 Front Staple End 43 I3

S31 Rear Staple End 25 I4

S32 Stapler Unit Set 26 F5

S33 Shutter Guide HP 33 F3

S34 Folder Plate HP 29 F3

S35

S36

S37

Buffer Roller

Entrance

Staple Hammer

HP

Positioning Plate

Paper

Positioning Plate

HP

Booklet Jogger

HP

Folder Plate

Return

Folder Plate

Motor

Folder Roller

Position

Index

No.

2 A5

14 A7

34 F2

35 F2

39 F4

30 F6

36 F5

28 F6

P to P

Symbol Name

Sensors

S39

S40 Booklet Exit 41 F2

S41

S42

S43 Lower Door 42 F5

S44

S45 Upper Door 16 F6

Symbol Name

Solenoids

SOL1 Booklet Gate 72 E4

SOL2

SOL3 Proof Tray Gate 70 E5

SOL4

SOL5 Transport Belt 69 E5

SOL6 Paddle 67 E5

SOL7

SOL8

SOL3

SOL4 Relay Roller 75 I3

PCBs

PCB1 Finisher 61 C7

PCB2 Lift Motor Sensor 63 A4

PCB3 Booklet Unit 65 G6

PCB4

Others

HR1 Stapler Interface 62 -

Folder Roller

Motor

Booklet Tray

Paper

Booklet Entrance

Guide

Booklet Exit

Cover

Buffer Roller

Entrance Gate

Buffer Roller Exit

Gate

Front Guide

Release

1st Booklet Unit

Gate

2nd Booklet Unit

Gate

Trailing Edge

Sensor

Index

No.

37 F4

40 F2

27 F4

38 F5

Index

No.

71 E4

68 E4

66 E5

73 I3

74 I3

64 F3

P to P

P to P

Page 61

1

Shift Tray

Height Sensor

2

3

4

5

6

7

Upper Exit

Guide Sensor

Staple Tray

Paper Sensor

Jogger HP

Shutter Sensor

Exit Sensor

Exit Motor

Finisher Set

Shift Tray HP

Stapler HP

Lift Motor Sensor Board

Lift Motor 1

Lift Motor 2

Shift Tray

Paper Sensor

Upper Door

Buffer Roller

Straight Path

Sensor

Exit Guide

Motor Sensor

Proof Tray Exit

Proof Tray Limit

Staple Motor

Staple Position

Sensor

Staple Hammer HP

Sensor

Cartridge Set Switch

Staple End Switch

Staple Hammer

A B C D E F G H I

CN1-1

Copier

Entrance

Sensor

Sensor

Sensor

Sensor

Sensor

Sensor

Sensor

Sensor

Sensor

Entrance

Sensor

Sensor

Sensor

Motor

S14

S1

S9

S4

S5

S21

S11

S12

S20

S15

S6

S16

PCB2

S17

S13

S22

S2

S3

S10

S18

S19

M5

S8

S7

M6

SW7

SW8

CN114-1

CN106-3

CN127-3

CN122-1

CN121-1

CN118-1

CN134-3

CN112-3

CN117-1

CN130-3

CN129-3

CN400-3

CN400-6

CN101-3

CN113-1

CN105-3

CN110-3

CN501-1

CN502-1

CN503-1

CN306-1

CN207-1

CN212-4

-2

-3

CN202-6

-2

-1

CN204-1

-2

-1

CN207-1

-2

-3

CN207-4

-2

-3

CN205-1

-2

-3

CN207-7

-2

-1

CN207-10

-2

-1

-2

-3

-2

-1

CN210-1

-2

-1

-2

-1

-5

-4

CN1010

-1 -1

-2

-2

-1

-3

-2

-3

CN202-4

-2

-1

CN203-1

-2

-1

-2

-3

-2

-1

-2

-1

CN304-5

-3

-2

-1

-5

-4

-2

-3

-2

-3

-5

-6

-2

-3

-8

-9

-13

-12

-2

-3

CN201

-2

-3

-5

-6

-2

-3

CN18-1

CN17-7

CN20-4

CN20-1

CN9-7

CN9-13

CN12-1

CN12-4

CN12-7

CN12-10

CN12-13

CN14-1

CN12-16

CN24-1

CN15-7

CN11-5

CN26-4

CN26-1

CN8-1

CN6-1

CN9-1

CN9-4

-11

-12

-17

-18

-10

-11

-12

-13CN307-7 CN305-1

-14-2 -2

-15-3 -3

-14

-15

-14

-15

-2-2

-2

-3

-4

-2

-3

-4-4

-8

-9

-5

-6

-2

-3

-5

-6

-2

-3

-8

-9

-2

-3

-5

-6

-8

-9

-2

-3

-2

-3

-8

-9

-6

-7

-5

-6

-2

-3

-2-2 -4

-3-3 -3

-4-4 -2

-5-5 -1

-6

-7

-8

-9

[24]

[0]

TXD

[0]

RXD

[0]

Not used

[0 to 5]

[0]

[5]

[5]

[0]

[s5]

[5]

[0]

[s5]

[5]

[0]

[s5]

[5]

[0]

[s5]

[0]

[s5]

[5]

[0]

[t5]

[5]

[0]

[0 or 5 Þ 0/5]

[5]

[5]

[0]

[s5]

[5]

[0]

[s5]

[5]

[0]

[s5]

[5]

[0]

[0 or 5 Þ 0/5]

[5]

[0]

[0 or 5 Þ 0/5]

[5]

[0]

[t5]

[5]

[0]

[s5]

[5]

[0]

[s5]

[5]

[0]

[s5]

[0]

[0 or 5 Þ 0/5]

[5]

[5]

[0]

[s5]

[5]

[0]

[s5]

[24 Þ 0/24] A

[24 Þ 0/24] B

[24 Þ 0/24] /A

[24 Þ 0/24] /B

[24]

[t5]

[t5] Set

[t5]

[t5]

[t5]

[5]

[0]

[t24] CW

[t24] CCW

[t24] CCW

A

Finisher Board

A

A

(PCB1)

[24]

[24]

RXD

TXD

[s24]

[s24]

[0 to 5]

[24]

[24]

/B [24 Þ 0/24]

/A [24 Þ 0/24]

B [24 Þ 0/24]

A [24 Þ 0/24]

[24]

/B [24 Þ 0/24]

/A [24 Þ 0/24]

B [24 Þ 0/24]

A [24 Þ 0/24]

[s24]

[s24]

[24]

[24]

/B [24 Þ 0/24]

/A [24 Þ 0/24]

B [24 Þ 0/24]

A [24 Þ 0/24]

[24]

[24]

/B [24 Þ 0/24]

/A [24 Þ 0/24]

B [24 Þ 0/24]

A [24 Þ 0/24]

[s24]

[s24]

[24]

[t24]

[24]

[t24]

[24]

[t24]

[24]

[t24]

[24]

[t24]

[24]

[t24]

[24]

[t24]

[24]

[s24]

[s24]

[t24]

[t24]

[s24]

[s24]

CN500-1CN19-1

CN3-1

CN7-4

CN15-1

CN10-1

CN11-10

-11

-12

-13

-14

CN11-1

CN17 -1

CN16 -1

CN11 -8

CN4-1

CN4-5

CN4-7

CN26-7

CN11-3

-14

CN4-3

CN5-1

CN5-4

CN5-7

CN5-9

-10

CN5-11

-12

CN7-1

-2

-2

-3

-4

-5

-6

-5

-2

-2

-3

-4

-5

-6

CN208-1

CN208-6

-2 -7

-2

-3

-4

-5

-6

-2

-3

-4

-5

-6

-9

-2

-6

CN203-4

-8

CN900-1

-8

CN208-8

-4

CN208-10

CN208-11

-4

-3

-5

-6

-8

-2

-3

CN115-2

CN124-5

-2

-3

-4

-5

CN107-2

CN108-2

CN109-2

-5

CN104-3

-2

CN128-2

-9

CN112-1

CN131-1

CN132-1

CN209-2

CN209-3

CN206-3

CN135-1

-3

-1

-1

CN123-3CN9-13

CN504-2

CN504-1

M9

SW9

M2

M4

M8

M1

M3

M7

SOL

SOL

SOL

SOL

SOL

SOL

SOL

SW1

SW2

SW6

SW4

SW5

SW3

1

2

4

3

6

7

5

Tray Lift Motor

Thermo Switch

Transport

Roller Motor

Jogger Motor

Exit Motor

Entrance Motor

Buffer Roller

Motor

Guide Plate

Motor

Booklet Gate

Solenoid

Buffer Roller

Entrance Gate

Solenoid

Buffer Roller

Exit Gate

Solenoid

Proof Tray Gate

Solenoid

Paddle

Solenoid

Front Guide

Release

Solenoid

Transport Belt

Solenoid

Upper Cover

Safety Switch

Shift Tray

Safety Switch

Shift Tray

Upper Limit

Switch

Upper Exit

Guide 1 Switch

Upper Exit

Guide 2 Switch

Shutter Position

Switch

-1

-2

-4

-3

-2

-1

-5

-6

-2

-1

-2

-

-2

-2

-3

-2

-1

-4

-2

-1

[0]

[0]

[0]

[0]

[0]

CN206-6

-2

-5

-4

-3

-2

-1

Positioning

Plate Paper

Sensor

Positioning

Plate HP

Sensor

Booklet Tray

Paper Sensor

Booklet Exit

Sensor

Positioning

Roller Sensor

Shutter Guide

HP Sensor

Folder Plate HP

Sensor

S26

S27

S41

S40

S28

S33

S34

Trailing Edge Sensor Board

Trailing Edge 1

Sensor

Trailing Edge 2

Sensor

Trailing Edge 3

Sensor

Booklet

Entrance Guide

Sensor

Booklet Jogger

HP Sensor

Folder Roller

Motor Sensor

Booklet Exit

Cover Sensor

Lower Door

Sensor

Folder Plate

Motor Sensor

Stapler Unit Set

Sensor

Booklet

Entrance

Sensor

Folder Plate

Return Sensor

Folder Roller

Position

PCB4

S22

S23

S24

S42

S29

S39

S44

S43

S36

S32

S25

S35

S37

CN105-3

CN106-3

CN100-3

CN325-3

CN126-3

CN127-3

CN128-3

CN123-5

CN124-3

CN101-3

CN102-2

CN103-3

CN104-3

CN107-2

CN131-3

CN132-3

CN129-3

CN501-3

CN301-1

-2

-1

CN302-1

-2

-1

CN402

-2

-1

CN425

-2

-1

-2

-1

-2

-1

-2

-1

CN210-1

-4

-3

-2 -4

-2

-1

-2

-1

-3

-1

CN303-3

-1

-2

-2

-1

-3

-1

-2

-1

CN308-1

-2

-1

-2

-1

-2

-1

-3

-2

-1

-3

-2

-1

-2

-3

-2

-3

CN302

-4

-5

-6

CN225

-2

-3

-4

-2

-3

-5-1

-1

-2

-2

-3

CN1-1

CN2-6

CN6-1

CN6-4

CN6-7

CN9-1

CN9-4

CN9-7

CN9-10

-11

-12

CN10-1

CN10-6

CN11-1

CN11-4

CN11-7

CN11-10

-11

-12

CN11-13

-14

-15

CN13-1

CN13-4

CN13-13

-14

-15

CN18-1

-2

-3

-5

-6

-8

-9

-2

-3

-5

-6

-8

-9

-7

-8

-2

-3

-5

-6

-8

-9

-2

-3

-5

-6

-2

-3

-2

-5

-4

-3

-2

-1

-2

-3

-4

-5

[24]

[0]

[0]

[24]

[0]

TXD

[0]

RXD

[5]

[0]

[s5]

[5]

[0]

[s5]

[5]

[0]

[s5]

[5]

[0]

[s5]

[5]

[0]

[s5]

[5]

[0]

[s5]

[5]

[0]

[s5]

[5]

[s5]

[s5]

[s5]

[0]

[5]

[0]

[s5]

[5]

[0]

[s5]

[0]

[0 or 5 Þ 0/5]

[5]

[5]

[0]

[s5]

[5]

[0]

[s5]

[0]

[0 or 5 Þ 0/5]

[5]

[5]

[0]

[s5]

[5]

[0]

[s5]

[5]

[0]

[s5]

Booklet Unit

[s5]

[5]

Board (PCB3)

[0]

B

B

B

[▲24]

[▲24]

[▲24]

[▲24]

[0 Þ 24/0]

[0 Þ 24/0]

[0 Þ 24/0]

[0 Þ 24/0]

[24]

/B [24 Þ 0/24]

/A [24 Þ 0/24]

A [24 Þ 0/24]

B [24 Þ 0/24]

[24]

/B [24 Þ 0/24]

/A [24 Þ 0/24]

A [24 Þ 0/24]

B [24 Þ 0/24]

[24]

/B [24 Þ 0/24]

/A [24 Þ 0/24]

A [24 Þ 0/24]

B [24 Þ 0/24]

[24]

[t24]

[24]

[t24]

[24]

[t24]

[t5]

[s5]

[0 Þ 24/0]

[0 Þ 24/0]

[0 Þ 24/0]

[0 Þ 24/0]

[t5]

[s5]

[0 Þ 24/0]

[0 Þ 24/0]

[0 Þ 24/0]

[0 Þ 24/0]

[s24]

[s24]

[s24]

B

[0]

[0]

[24]

CN4-7

-8

CN4-9

-10

CN5-1

-2

-3

-4

CN7-1

-2

-3

-4

-5

CN7-6

-7

-8

-9

-10

CN12-1

-2

-3

-4

-5

CN15-1

-2

CN15-3

-4

CN15-5

-6

CN8-1

-2

-4

-5

-6

-7

CN8-8-9CN306-7

-11

-12

-13

-14

CN4-1

-2

-3

-4

-5

-6

CN305-7

CN113-2

CN108-1

CN124-4

CN113-5

CN114-5

CN119-5

CN118-2

CN117-2

CN116-2

CN315-3

-6

-5

-4

-3

-2-4-6

-1

CN316-3

-6

-5

-4

-3

-2-4-6

-1

CN205-1

[ ]

-1

-2

-3

-2

-1

-4

-3

-2

-1

-4

-3

-2

-1

-1

-1

-1

16

17

10

-4

-3

-2

13

-1

11

12

SOL

SOL

SOL

10

Front Stapler Unit

S30

-2

-1-3

SW13

-5

M

14

-7

Rear Stapler Unit

S31

-2

-1-10

SW14

-5

-7

M

15

SW11

SW10

SW12

-2

Symbol Table

DC Line

Pulse Signal

Signal Direction

Active High

s

Active Low

t

Voltage

M

M

M

M

M

M

8

9

Folder Roller

Folder Plate

Transport Motor

Booklet Jogger

Positioning

Plate Motor

Shutter Guide

1st Booklet Unit

Gate Solenoid

2nd Booklet

Unit Gate

Relay Roller

Front Staple

End Sensor

Front Staple

Hammer HP

Front Stapler

Rear Staple

End Sensor

Rear Staple

Hammer HP

Rear Stapler

Entrance Gate

Safety Switch

Lower Door

Safety Switch

Booklet Exit

Safety Switch

BOOKLET FINISHER (A763) POINT TO POINT DIAGRAM

Motor

Motor

Booklet

Motor

Motor

Solenoid

Solenoid

Sensor

Motor

Sensor

Motor

Booklet

1

2

3

4

5

6

7

A B C D E F G H I

Loading...

Loading...