Page 1

3,000-SHEET FINISHER

(Machine Code: A697)

Page 2

June 30, 1998 SPECIFICATIONS

1. OVERALL MACHINE INFORMATION

1.1 SPECIFICATIONS

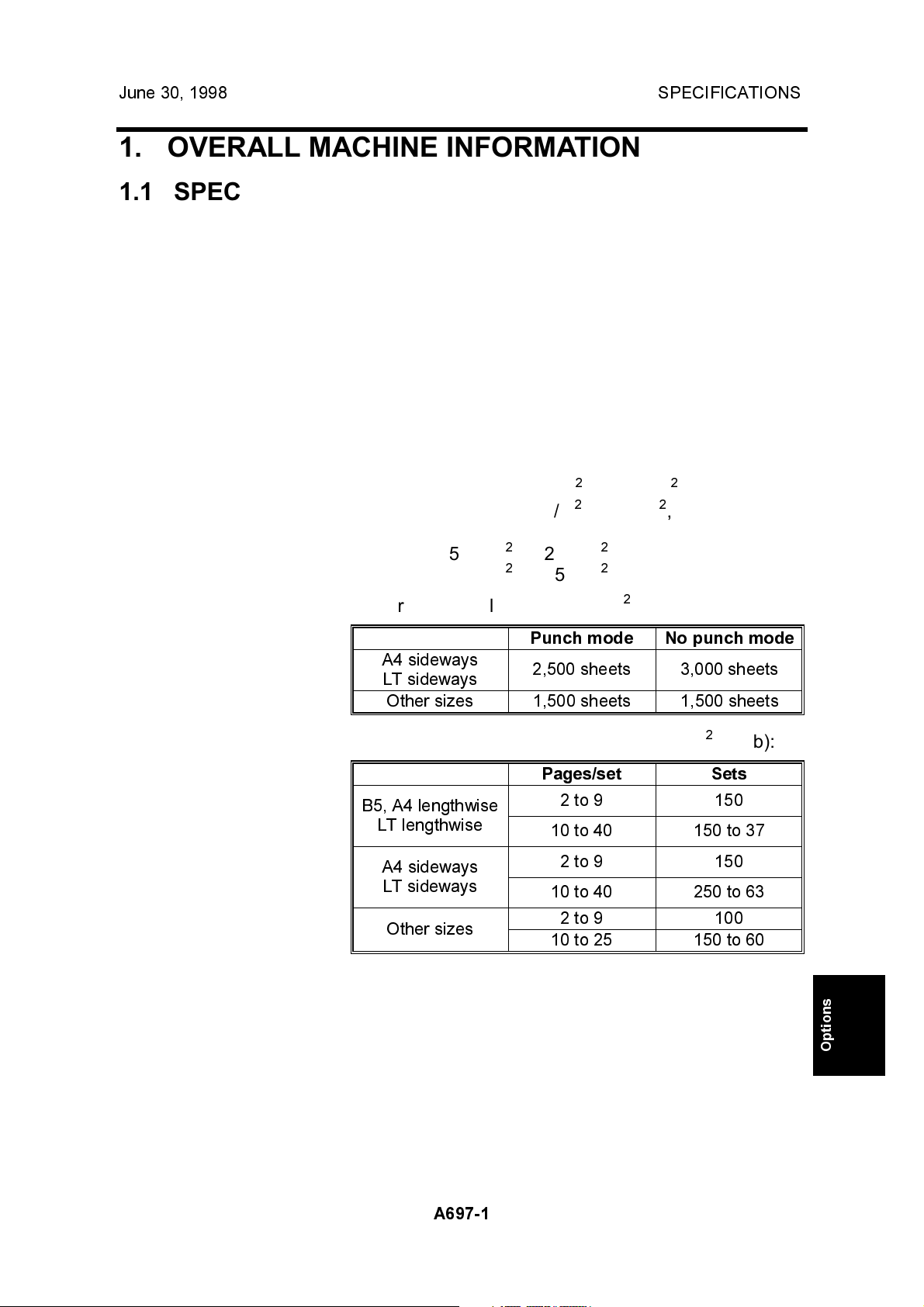

The punch unit is an option for this machine.

Paper Size: No punch mode

Shift Tray: A3 to B5/DLT to LT

(B6 lengthwise in no shift mode and no

staple mode)

Upper Tray: A3 to A6 lengthwise/DLT to HLT

Punch mode

2 holes: A3 to A5/DLT to LT

3 holes: A3, B4, A4 sideways, B5 sideways

DLT, LT sideways

Paper Weight: No punch mode

No staple mode: 52 g/m2 ~ 157 g/m2, 14 ~ 42 lb

Staple mode: 64 g/m2 ~ 80 g/m2, 17 ~ 21 lb

Punch mode

2 holes: 52 g/m2 ~ 128 g/m2, 14 ~ 34 lb

3 holes: 52 g/m2 ~ 105 g/m2, 14 ~ 28 lb

Paper Capacity: Shift tray/no staple mode (80 g/m2, 20 lb):

Punch mode No punch mode

A4 sideways

LT sideways

Other sizes 1,500 sheets 1,500 sheets

2,500 sheets 3,000 sheets

Shift tray/staple mode/punch mode (80 g/m2, 20 lb):

Pages/set Sets

B5, A4 lengthwise

LT lengthwise

A4 sideways

LT sideways

Other sizes

2 to 9 150

10 to 40 150 to 37

2 to 9 150

10 to 40 250 to 63

2 to 9 100

10 to 25 150 to 60

Options

A697-1

Page 3

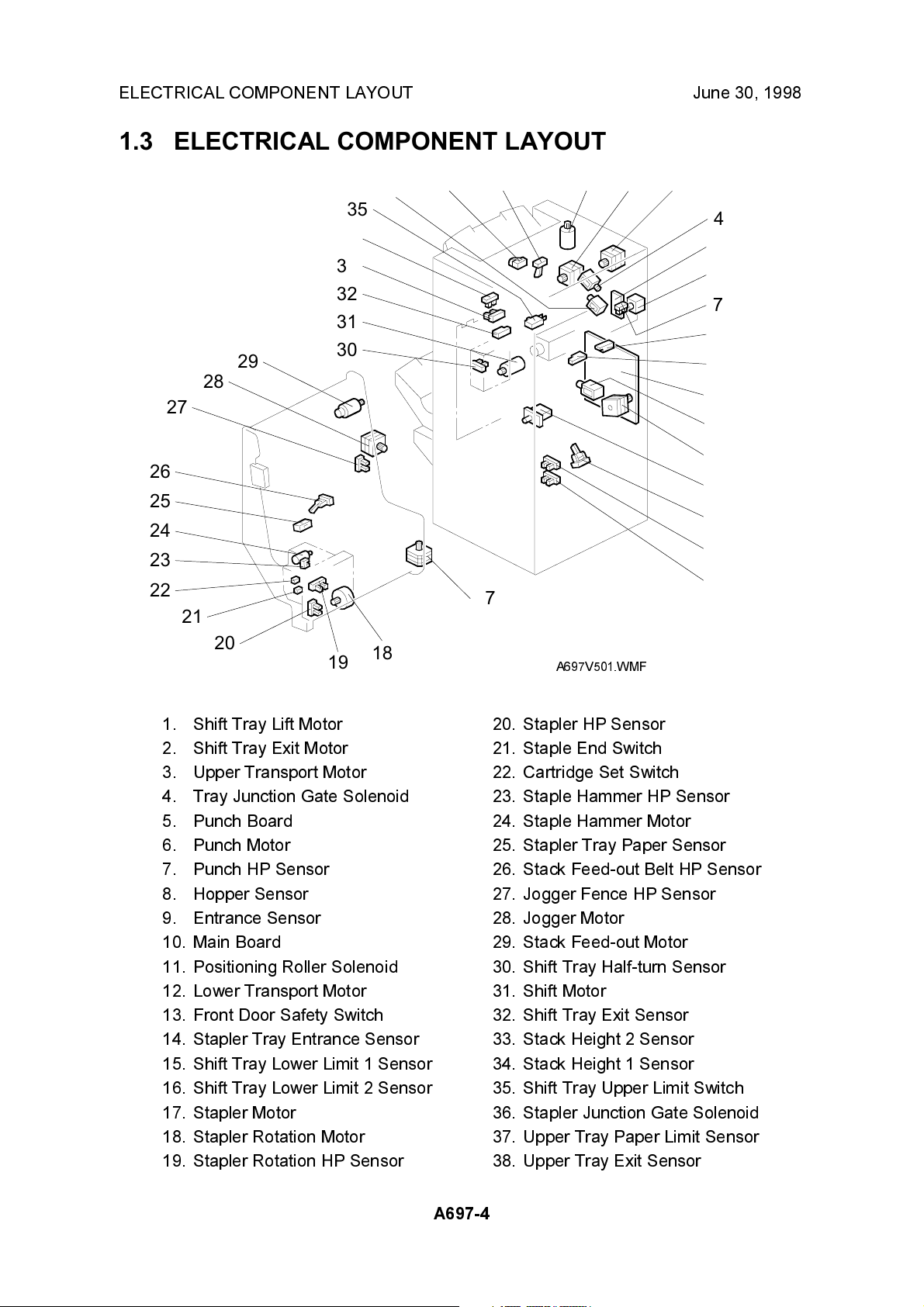

SPECIFICATIONS June 30, 1998

Shift tray/staple mode/no punch mode (80 g/m2, 20 lb):

Pages/set Sets

B5, A4 lengthwise

LT lengthwise

2 to 9 150

10 to 50 150 to 30

A4 sideways

LT sideways

Other sizes

Upper tray (80 g/m2, 20 lb):

Punch mode No punch mode

A4/LT or smaller 200 sheets 250 sheets

Larger than A4/LT 50 sheets 50 sheets

Stapler Capacity (pages/set, 80 g/m2, 20 lb paper):

Punch mode No punch mode

A4/LT or smaller 40 sheets 50 sheets

Larger than A4/LT 25 sheets 30 sheets

Staple Position: 4 positions

1 staple: 3 positions

(Front, Rear, Rear-Oblique)

2 staple: 1 position

Staple Replenishment: Cartridge (5,000 staples)

2 to 9 150

10 to 50 300 to 60

2 to 9 100

10 to 30 150 to 50

Power Source: 24 Vdc (from copier)

Power Consumption: 48 W

Weight: 45 kg

Size (W x D x H): 625 mm x 545 mm x 960 mm

A697-2

Page 4

June 30, 1998 MECHANICAL COMPONENT LAYOUT

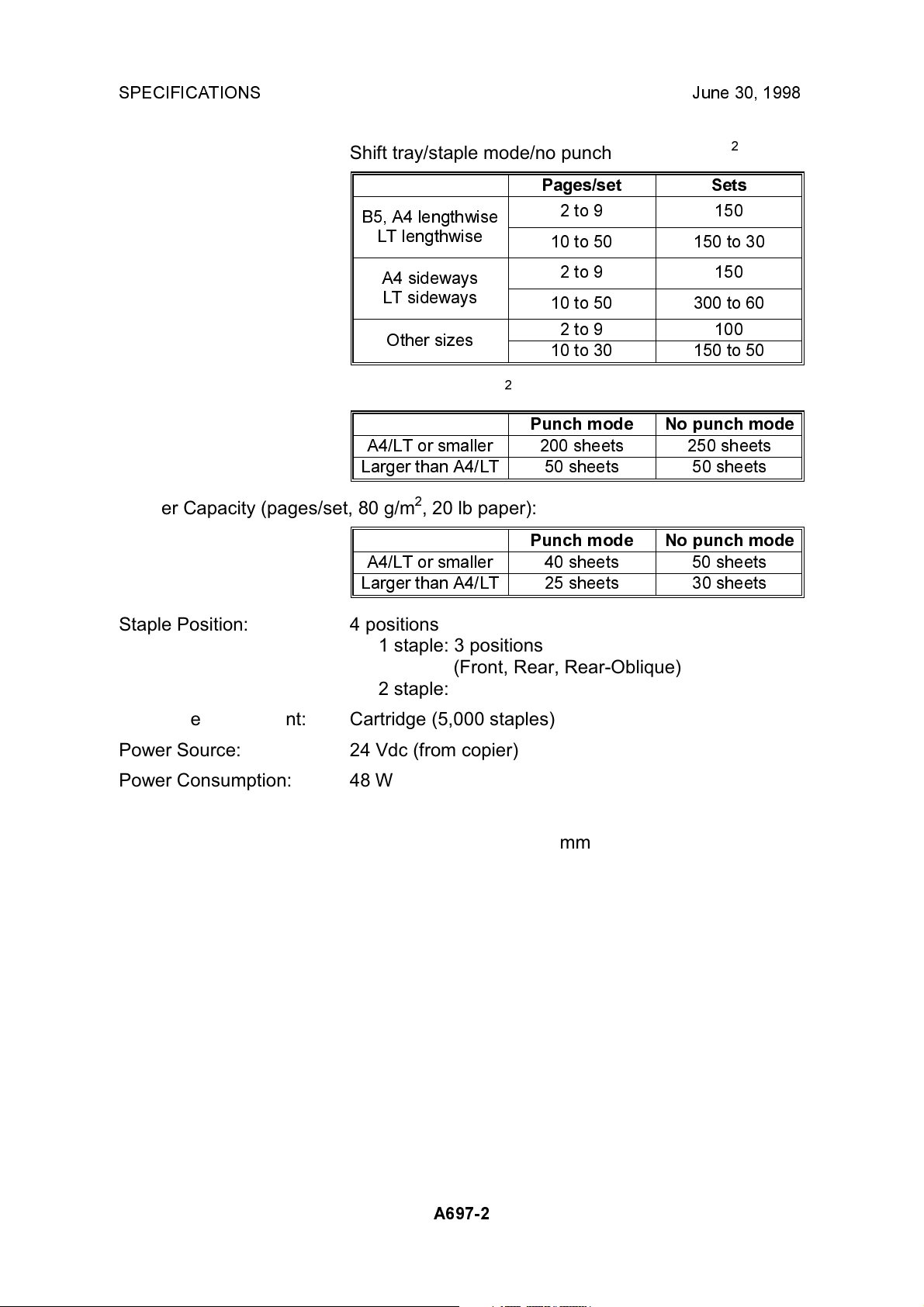

1.2 MECHANICAL COMPONENT LAYOUT

17

16

15

14

13

1

2 3 4

5

6

7

8

9

10

12

1. Upper Tray

2. Upper Tray Exit Roller

3. Upper Transport Roller

4. Tray Junction Gate

5. 1st Entrance Roller

6. Punch Unit

7. 2nd Entrance Roller

8. Punch Waste Hopper

9. Stapler Junction Gate

11

A697V500.WMF

10. Lower Transport Rollers

11. Alignment Brush Roller

12. Stapler

13. Positioning Roller

14. Stack Feed-out Belt

15. Middle Transport Roller

16. Shift Tray Exit Roller

17. Shift Tray

Options

A697-3

Page 5

ELECTRICAL COMPONENT LAYOUT June 30, 1998

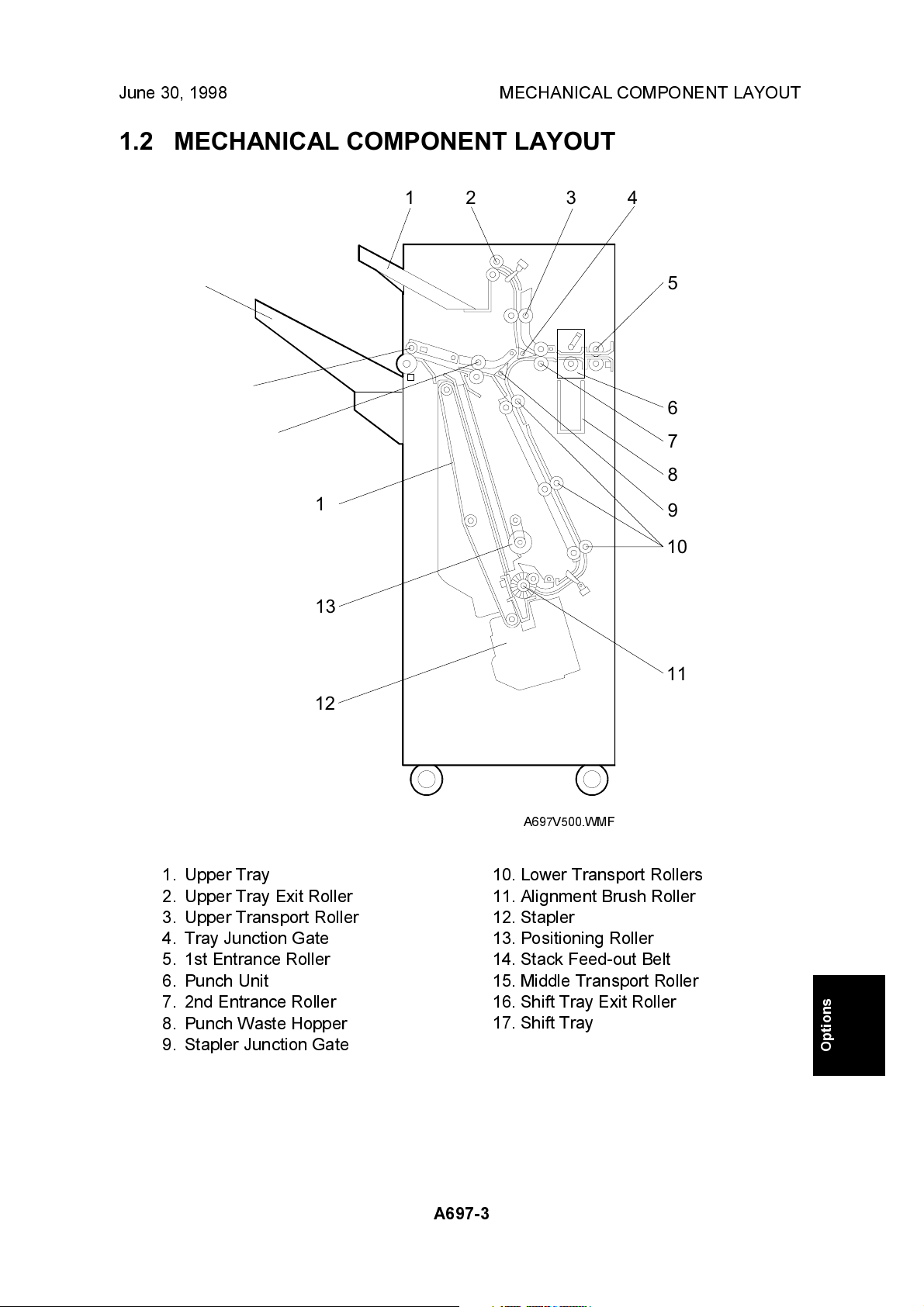

1.3 ELECTRICAL COMPONENT LAYOUT

26

25

24

23

22

27

21

28

29

34

33

32

31

30

35

36

37 38 1 2 3

4

5

6

7

8

9

10

11

12

13

14

15

16

17

20

1. Shift Tray Lift Motor

2. Shift Tray Exit Motor

3. Upper Transport Motor

4. Tray Junction Gate Solenoid

5. Punch Board

6. Punch Motor

7. Punch HP Sensor

8. Hopper Sensor

9. Entrance Sensor

10. Main Board

11. Positioning Roller Solenoid

12. Lower Transport Motor

13. Front Door Safety Switch

14. Stapler Tray Entrance Sensor

15. Shift Tray Lower Limit 1 Sensor

16. Shift Tray Lower Limit 2 Sensor

17. Stapler Motor

18. Stapler Rotation Motor

19. Stapler Rotation HP Sensor

19

18

A697V501.WMF

20. Stapler HP Sensor

21. Staple End Switch

22. Cartridge Set Switch

23. Staple Hammer HP Sensor

24. Staple Hammer Motor

25. Stapler Tray Paper Sensor

26. Stack Feed-out Belt HP Sensor

27. Jogger Fence HP Sensor

28. Jogger Motor

29. Stack Feed-out Motor

30. Shift Tray Half-turn Sensor

31. Shift Motor

32. Shift Tray Exit Sensor

33. Stack Height 2 Sensor

34. Stack Height 1 Sensor

35. Shift Tray Upper Limit Switch

36. Stapler Junction Gate Solenoid

37. Upper Tray Paper Limit Sensor

38. Upper Tray Exit Sensor

A697-4

Page 6

June 30, 1998 ELECTRICAL COMPONENT DESCRIPTION

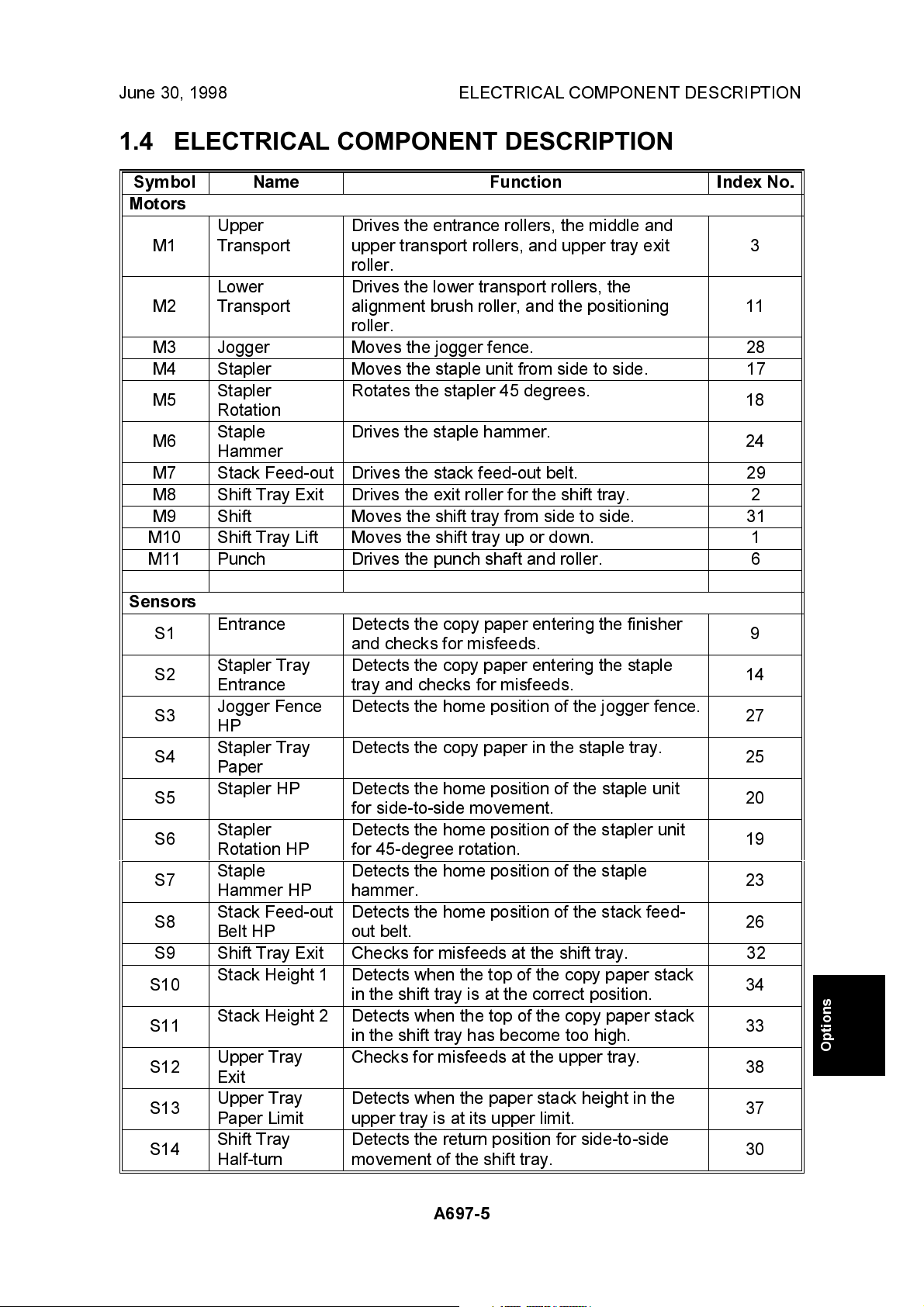

1.4 ELECTRICAL COMPONENT DESCRIPTION

Symbol Name Function Index No.

Motors

Upper

M1

M2

M3 Jogger Mo ves the jogger fence. 28

M4 Stapler Moves the staple unit from side to side. 17

M5

M6

M7 Stack Feed-out Drives the stack feed-out belt. 29

M8 Shift Tray Exit Drives the exit roller for the shift tray. 2

M9 Shift Mo ves the shift tray from side to side. 31

M10 Shift Tray Lift Moves the shift tray up or down. 1

M11 Punch Drives the punch shaft and roller. 6

Transport

Lower

Transport

Stapler

Rotation

Staple

Hammer

Drives the entrance rollers, the middle and

upper transport rollers, and upper tray exit

roller.

Drives the lower transport rollers, the

alignment brush roller, and the positioning

roller.

Rotates the stapler 45 degrees.

Drives the staple hammer.

3

11

18

24

Sensors

S1

S2

S3

S4

S5

S6

S7

S8

S9 Shift Tray Exit Checks for misfeeds at the shift tray. 32

S10

S11

S12

S13

S14

Entrance Detects the copy paper entering the finisher

and checks for misfeeds.

Stapler Tray

Entrance

Jogger FenceHPDetects the home position of the jogger fence.

Stapler Tray

Paper

Stapler HP Detects the home position of the staple unit

Stapler

Rotation HP

Staple

Hammer HP

Stack Feed-out

Belt HP

Stack Height 1

Stack Height 2 Detects when the top of the copy paper stack

Upper Tray

Exit

Upper Tray

Paper Limit

Shift Tray

Half-turn

Detects the copy paper entering the staple

tray and checks for misfeeds.

Detects the copy paper in the staple tray.

for side-to-side movement.

Detects the home position of the stapler unit

for 45-degree rotation.

Detects the home position of the staple

hammer.

Detects the home position of the stack feed-

out belt.

Detects when the top of the copy paper stack

in the shift tray is at the correct position.

in the shift tray has become too high.

Checks for misfeeds at the upper tray.

Detects when the paper stack height in the

upper tray is at its upper limit.

Detects the return position for side-to-side

movement of the shift tray.

9

14

27

25

20

19

23

26

34

33

Options

38

37

30

A697-5

Page 7

ELECTRICAL COMPONENT DESCRIPTION June 30, 1998

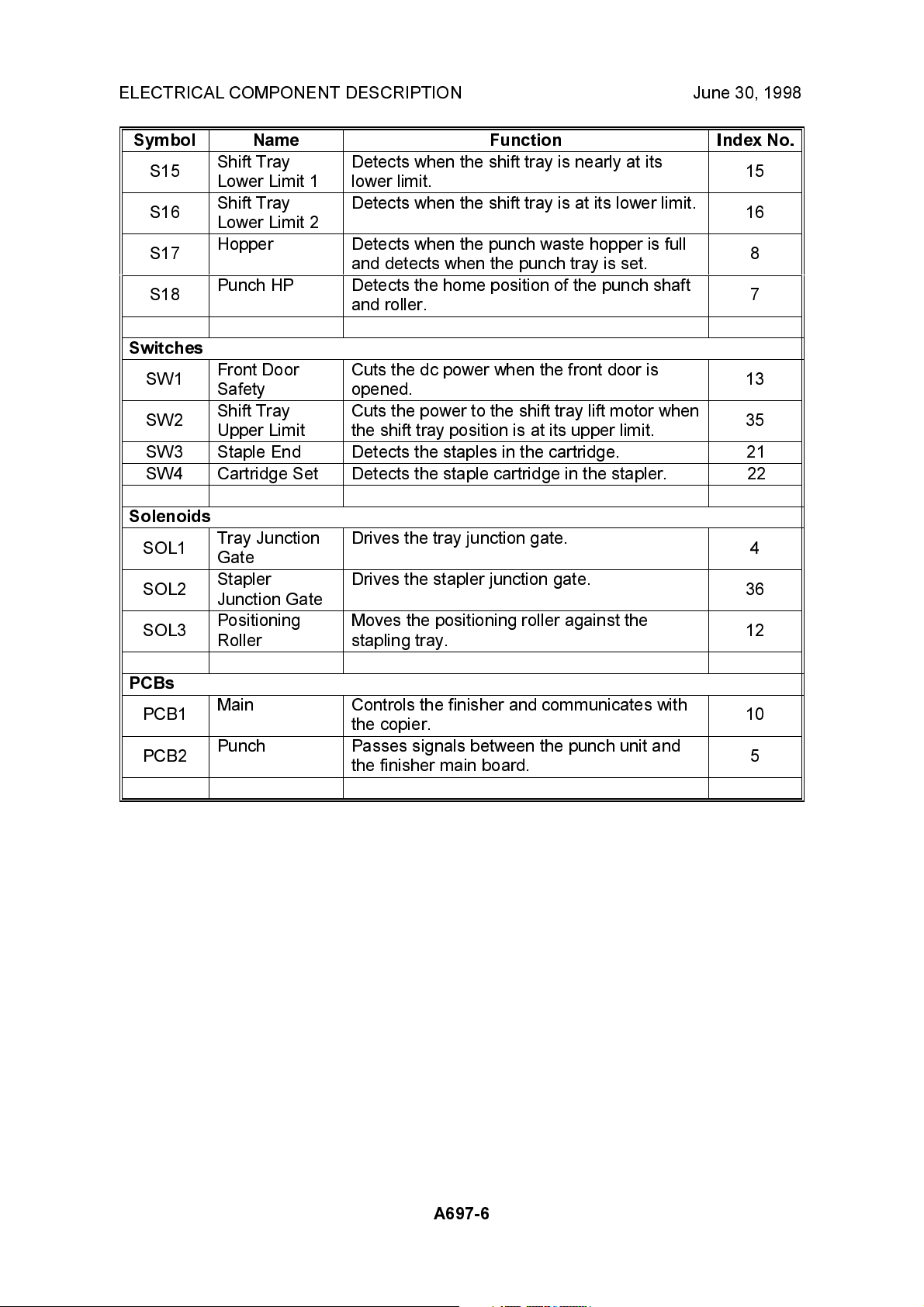

Symbol Name Function Index No.

S15

S16

S17

S18

Shift Tray

Lower Limit 1

Shift Tray

Lower Limit 2

Hopper Detects when the punch waste hopper is full

Punch HP Detects the home position of the punch shaft

Detects when the shift tray is nearly at its

lower limit.

Detects when the shift tray is at its lower limit.

and detects when the punch tray is set.

and roller.

15

16

8

7

Switches

SW1

SW2

Front Door

Safety

Shift Tray

Upper Limit

Cuts the dc power when the front door is

opened.

Cuts the power to the shift tray lift motor when

the shift tray position is at its upper limit.

13

35

SW3 Staple End Detects the staples in the cartridge. 21

SW4 Cartridge Set Detects the staple cartridge in the stapler. 22

Solenoids

SOL1

SOL2

SOL3

Tray Junction

Gate

Stapler

Junction Gate

Positioning

Roller

Drives the tray junction gate.

Drives the stapler junction gate.

Moves the positioning roller against the

stapling tray.

4

36

12

PCBs

PCB1

PCB2

Main Controls the finisher and communicates with

the copier.

Punch

Passes signals between the punch unit and

the finisher main board.

10

5

A697-6

Page 8

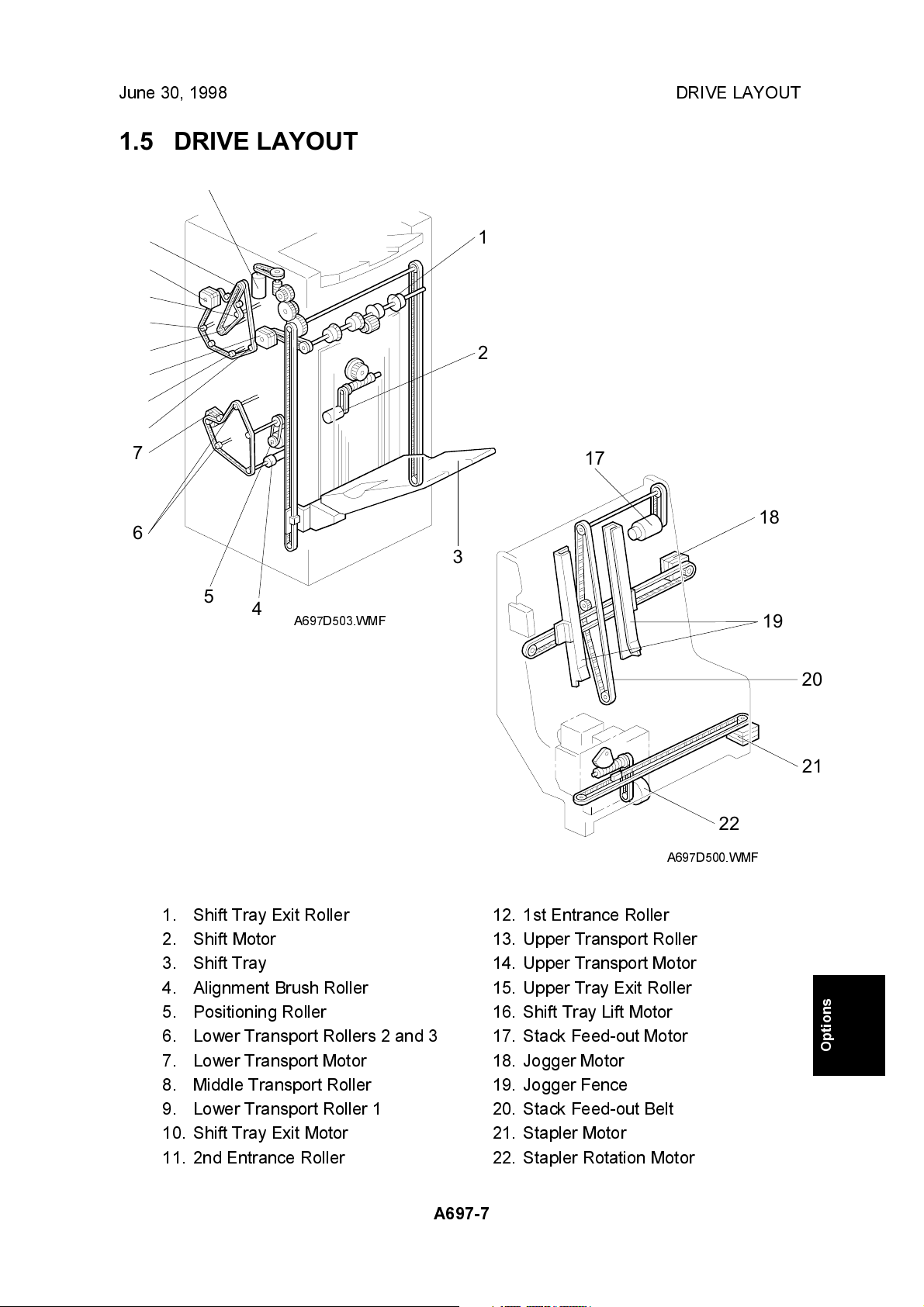

June 30, 1998 DRIVE LAYOUT

1.5 DRIVE LAYOUT

16

15

14

13

12

11

10

9

8

7

6

1

2

17

18

3

5

4

A697D503.WMF

19

20

1. Shift Tray Exit Roller

2. Shift Motor

3. Shift Tray

4. Alignment Brush Roller

5. Positioning Roller

6. Lower Transport Rollers 2 and 3

7. Lower Transport Motor

8. Middle Transport Roller

9. Lower Transport Roller 1

10. Shift Tray Exit Motor

11. 2nd Entrance Roller

A697-7

A697D500.WMF

12. 1st Entrance Roller

13. Upper Transport Roller

14. Upper Transport Motor

15. Upper Tray Exit Roller

16. Shift Tray Lift Motor

17. Stack Feed-out Motor

18. Jogger Motor

19. Jogger Fence

20. Stack Feed-out Belt

21. Stapler Motor

22. Stapler Rotation Motor

21

22

Options

Page 9

TRAY AND STAPLER JUNCTION GATE MECHANISM June 30, 1998

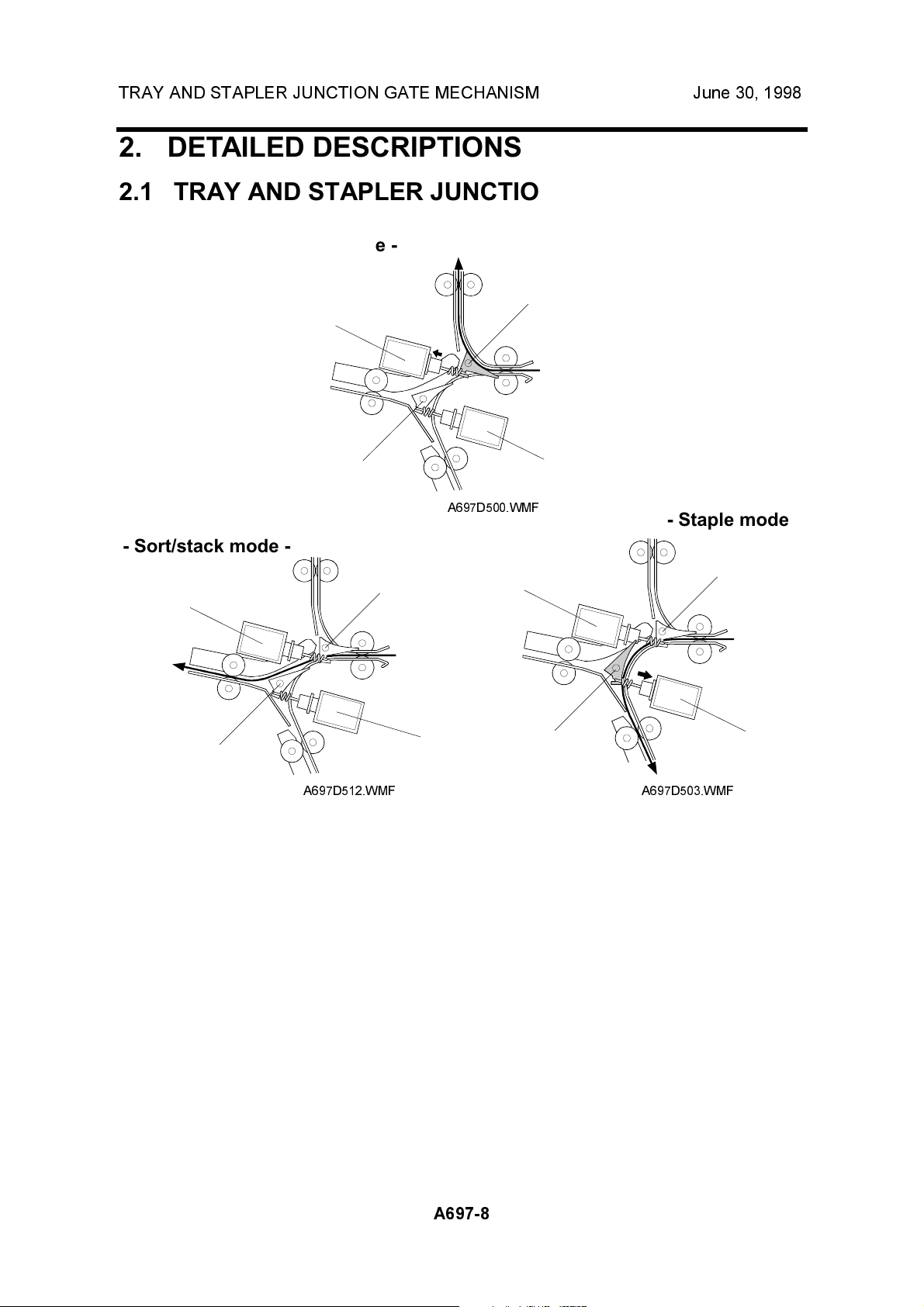

2. DETAILED DESCRIPTIONS

2.1 TRAY AND STAPLER JUNCTION GATE MECHANISM

- Upper tray mode -

[A]

[C]

[B]

A697D500.WMF

[D]

- Staple mode -

- Sort/stack mode -

[A]

[A]

[C]

[C]

[B]

A697D512.WMF

[D]

[B]

A697D503.WMF

[D]

Depending on the finishing mode, the copies are directed up, straight through, or

down by the combination of the tray junction gate [A] and stapler junction gate [B].

These gates are controlled by the tray junction gate solenoid [C] and stapler

junction gate solenoid [D].

Upper tray mode

The tray junction gate solenoid turns on. The copies go up to the upper tray.

Sort/stack mode

The tray junction gate solenoid and the stapler junction gate solenoid remain off.

The copies are sent to the shift tray directly.

Staple mode

The tray junction gate solenoid remains off and the stapler junction gate solenoid

turns on. The copies go downwards to the jogger unit.

A697-8

Page 10

June 30, 1998 JOGGER UNIT PAPER POSITIONING MECHANISM

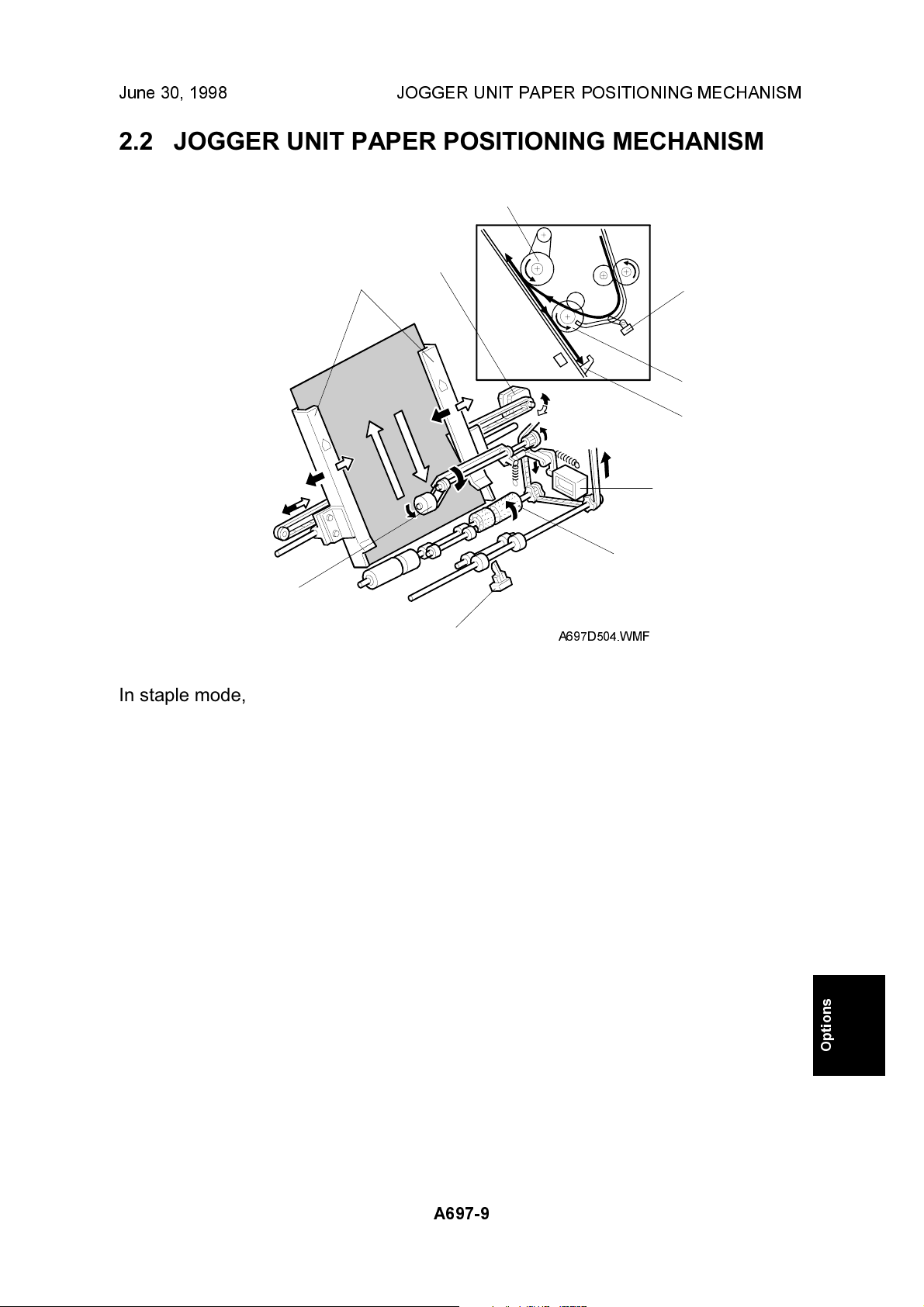

2.2 JOGGER UNIT PAPER POSITIONING MECHANISM

[C]

[F]

[G]

[A]

[D]

[E]

[B]

[D]

[C]

[A]

A697D504.WMF

In staple mode, each sheet of copy paper is vertically and horizontally aligned

when it arrives in the jogger unit.

Vertical Paper Alignment

After the trailing edge of the copy passes the stapler tray entrance sensor [A], the

positioning roller solenoid [B] is energized for 280 ms to push the positioning roller

[C] into contact with the paper. The positioning roller and alignment brush roller [D]

rotate to push the paper back and align the trailing edge of the paper against the

stack stopper [E].

Horizontal Paper Alignment

When the print key is pressed, the jogger motor [F] turns on and the jogger fences

[G] move to the waiting position, which is 7 mm wider on both sides than the

selected paper.

When the trailing edge of the paper passes the staple unit entrance sensor, the

jogger motor turns on for approximately 70 ms to move the jogger fences 5 mm

towards the paper. After a short time, the jogger motor turns on again

approximately for 60 ms for the horizontal paper alignment then goes back to the

waiting position.

A697-9

Options

Page 11

STAPLER UNIT MOVEMENT MECHANISM June 30, 1998

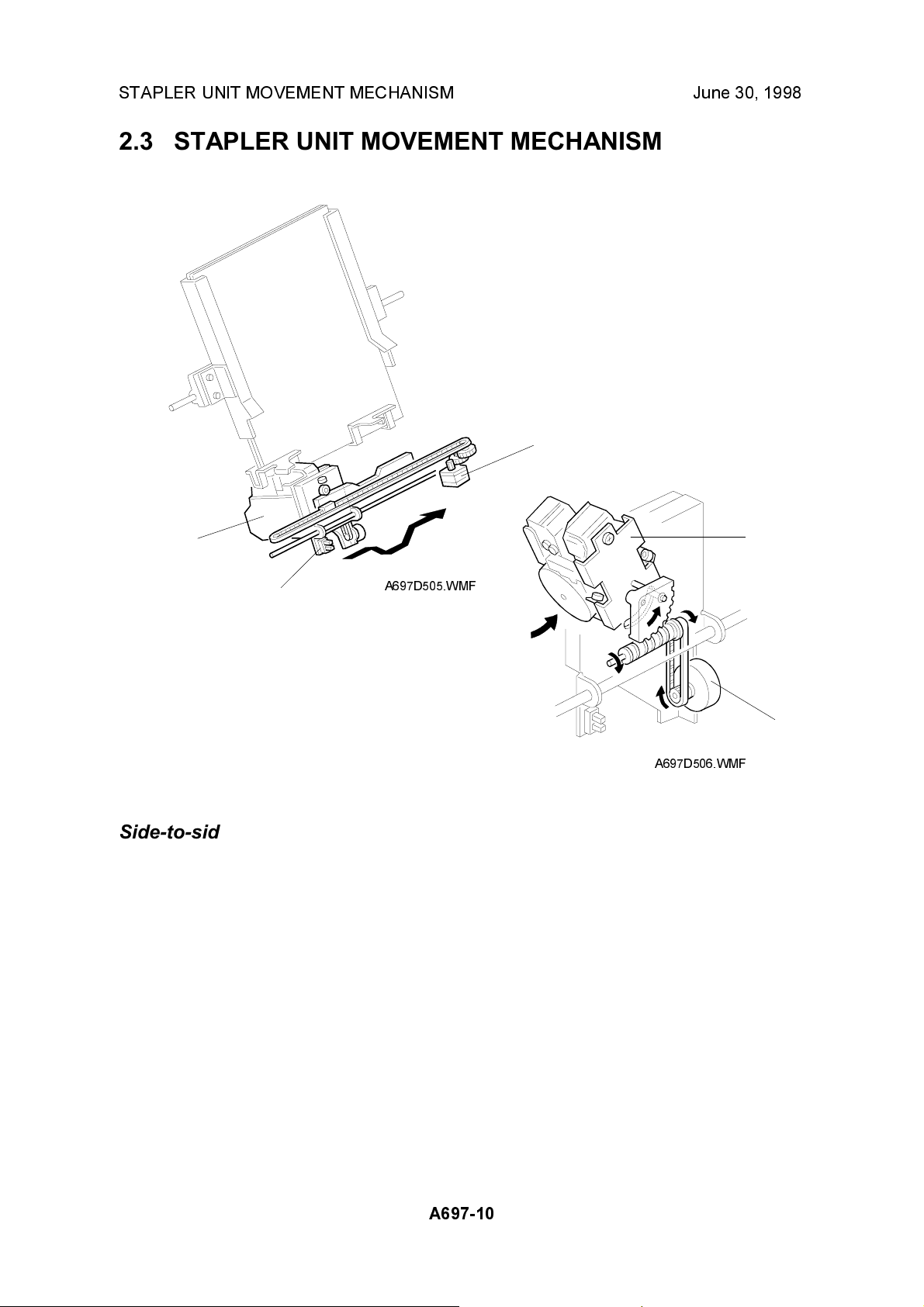

2.3 STAPLER UNIT MOVEMENT MECHANISM

[A]

[B]

[C]

A697D505.WMF

A697D506.WMF

[B]

Side-to-side:

The stapler motor [A] moves the stapler [B] from side to side. After the start key is

pressed, the stapler moves from its home position to the stapling position.

If two-staple-position mode is selected, the stapler moves to the front stapling

position first, then moves to the rear stapling position. However, for the next copy

set, it staples in the reverse order (at the rear side first then at the front side).

After the job is completed, the stapler moves back to its home position. This is

detected by the stapler HP sensor [C].

[D]

Rotation:

In the oblique staple position mode, the stapler rotation motor [D] rotates the

stapler 45° after it moves to the stapling position.

A697-10

Page 12

June 30, 1998 STAPLER

2.4 STAPLER

[A]

[E]

[B]

[C]

[F]

A697507.WMF

[D]

[G]

[H]

[I]

A697D508.WMF

The staple hammer [A] is driven by the staple hammer motor [B] via gears [C], two

cams [D], and two links [E].

When the aligned copies are brought to the stapling position by the positioning

roller, alignment brush roller and jogger fences, the staple hammer motor starts.

When the cams complete one rotation, the staple hammer home position sensor

[F] turns on, detecting the end of the stapling operation. The staple hammer motor

then stops.

There are two sensors in the stapler. One is the staple end switch [G] for detecting

staple end conditions (it detects when there is only one sheet of staples left in the

cartridge). The other is the cartridge set switch [H] for detecting whether a staple

cartridge is installed.

When a staple end or no cartridge condition is detected, a message is displayed

advising the operator to install a staple cartridge. If this condition is detected during

a copy job, the indication will appear, but the copy job will not stop.

The staple cartridge has a clinch area [I], in which jammed staples are left.

Operators can remove the jammed staples from this area.

Options

A697-11

Page 13

FEED-OUT MECHANISM June 30, 1998

2.5 FEED-OUT MECHANISM

[E]

[D]

[A]

[B]

[F]

[B]

[C]

A697D509.WMF

After the copies have been stapled, the stack feed-out motor [A] starts. The pawl

[B] on the stack feed-out belt [C] transports the set of stapled copies up and feeds

it to the exit roller [D]. The shift tray exit roller [D] takes over the stack feed-out after

the leading edge reaches this roller.

Just before the stapled copies pass through the shift tray exit sensor, the stackfeed-out motor turns off 600 ms to wait until the exit rollers have completely fed the

stapled stack out to the shift tray [E]. Then, the stack-feed-out motor turns on again

until the pawl actuates the stack feed-out belt home position sensor [F].

A697-12

Page 14

June 30, 1998 SHIFT TRAY UP/DOWN MECHANISM

2.6 SHIFT TRAY UP/DOWN MECHANISM

[D]

[F]

[E]

[A]

[K]

[J]

[I]

[G]

[H]

A697D510.WMF

[B]

[C]

The shift tray lift motor [A] controls the vertical position of the shift tray [B] through

gears and timing belts [C]. When the main switch is turned on, the tray is initialized

at the upper position. The tray is moved up until stack height sensor 1 [D] is deactuated.

During copying, the actuator feeler [E] gradually rises as the copy stack grows, and

the actuator gradually moves towards stack height sensor 2 [F].

In sort/stack mode, if stack height sensor 2 is actuated for 3 seconds, the shift tray

lift motor lowers the shift tray for 15 ms.

In staple mode, when the stack feed-out motor starts, the tray is moved down until

stack height sensor 1 is actuated and then moved up until stack height sensor 1 is

de-actuated. This corrects the current tray position. Then, the tray is moved down

again until stack height sensor 1 is actuated to make space for the coming set of

copies and then moved up until stack height sensor 1 is de-actuated. This means

the tray lowers earlier in staple mode, to prevent the next copy suddenly exceeding

the space currently available on the tray.

For both modes, the shift tray will rise until stack height sensor 1 is de-actuated

when the user takes the stack of paper from the shift tray.

This machine has two shift tray lower limit sensors 1 [G], 2 [H]. Shift tray lower limit

sensor 1 detects the near lower limit and sensor 2 detects the lower limit. When the

actuator [I] enters sensor 1, a message will be displayed and copying will continue.

When the actuator enters sensor 2, a message will be displayed and copying will

stop.

Options

The shift tray upper limit switch [J] prevents the drive gear from being damaged if

stack height sensor 1 fails. When the shift tray pushes up the shift tray positioning

roller [K], the switch will cut the power to the shift tray lift motor.

A697-13

Page 15

SHIFT TRAY SIDE-TO-SIDE MECHANISM June 30, 1998

2.7 SHIFT TRAY SIDE-TO-SIDE MECHANISM

[A]

[D]

[C]

[F]

[E]

[B]

A697D511.WMF

In sort/stack mode, the shift tray [A] moves from side to side to separate the sets of

copies.

The horizontal position of the shift tray is controlled by the shift motor [B] and shift

gear disk [C]. After one set of copies is made and delivered to the shift tray, the

shift motor turns on, driving the shift gear disk and the shaft [D]. The end fence [E]

is positioned by the shaft, creating the side-to-side movement.

When the shift gear disk has rotated 180 degrees (when the shift tray is fully shifted

across), the cut-out in the shift gear disk turns on the shift tray half-turn sensor [F]

and the shift motor stops. The next set of copies is then delivered. The motor turns

on, repeating the same process and moving the tray back to the previous position.

A697-14

Page 16

June 30, 1998 PUNCH UNIT DRIVE MECHANISM

2.8 PUNCH UNIT DRIVE MECHANISM

[C]

[D]

[B]

[A]

A697D501.WMF

The punch unit makes 2 or 3 holes (depending on the type of punch unit) at the

trailing edge of the paper.

The punch unit is driven by the punch motor [A]. The punch motor turns on 78 ms

after the trailing edge of the paper passes through the entrance sensor [B], and

makes the punch holes.

The home position is detected by the punch HP sensor [C]. When the cut-out on

the punch shaft gear disk [D] enters the punch HP sensor, the punch motor stops.

The punch position is adjusted as follows:

Right to left: SP mode

Front to rear: Spacers

A697-15

Options

Page 17

PUNCH WASTE COLLECTION MECHNISM June 30, 1998

2.9 PUNCH WASTE COLLECTION MECHNISM

[B]

[D]

[C]

[A]

A697D502.WMF

The punch waste is collected in the punch waste hopper [A], which is under the

punch unit.

When the punch waste covers the hole [B] in the hopper, the hopper sensor [C]

turns on and a message will be displayed after the copy job finishes.

The hopper sensor also works as the hopper set sensor. If the punch waste hopper

is not set, the hopper sensor moves away from the hole in the hopper holder [D]

and a message is displayed. This message is the same as for the hopper full

condition.

A697-16

Page 18

June 30, 1998 JAM CONDITIONS

2.10 JAM CONDITIONS

1. The entrance sensor does not turn on within 450 ms after the copier exit sensor

turns off.

2. The entrance sensor does not turn off within 1,325 ms after it turns on.

3. The upper tray exit sensor does not turn on within 1,630 ms after the entrance

sensor turns on.

4. The upper tray exit sensor does not turn off within 1,325 ms after it turns on.

5. In sort/stack mode, the shift tray exit sensor does not turn on within 2,090 ms

after the entrance sensor turns on.

6. In sort/stack mode, the shift tray exit sensor does not turn off within 1,325 ms

after it turns on.

7. In staple mode, the stapler tray entrance sensor does not turn on within 3,700

ms after the entrance sensor turns on.

8. In staple mode, the stapler tray entrance sensor does not turn off within 1,325

ms after it turns on.

9. In staple mode, the stapler tray paper sensor does not turn off within 250

pulses of the stack feed-out motor after it starts.

10. In staple mode, the shift tray exit sensor does not turn off within 1,260 ms after

the stack feed-out motor starts.

A697-17

Options

Page 19

TIMING CHARTS June 30, 1998

2.11 TIMING CHARTS

2.11.1 A4 SIDEWAYS (2 SHEETS): NORMAL AND PUNCH MODE

Copier > Finisher

Motor On

(Exit Sensor On)

Motor On

Motor Off

Finisher > Copier

Exit

Finisher

Entrance Sensor

Punch HP Sensor

Shift Tray Exit Sensor

Punch Motor

Upper Transport Motor

Punch Motor

Tray Junction Gate

Solenoid

(Exit Sensor On)

78ms

A697D513.WMF

A697-18

Page 20

June 30, 1998 TIMING CHARTS

2.11.2 A4 SIDEWAYS (2 SHEETS): SORT/STACK AND PUNCH

MODE

Copier > Finisher

Motor On

(Exit Sensor On)

Motor On

Motor Off

Finisher > Copier

Exit

Finisher

Entrance Sensor

Punch HP Sensor

Shift Tray Exit Sensor

Shift Tray Half Turn

Upper Transport Motor

Shift Tray Exit Motor

Punch Motor

Shift Motor

(Exit Sensor On)

78ms

A697D514.WMF

A697-19

Options

Page 21

TIMING CHARTS June 30, 1998

2.11.3 A4 SIDEWAYS (2 SHEETS): STAPLE AND PUNCH MODE

Copier > Finisher

(Exit Sensor On)

Motor On

Stapler On

Motor Off

Finisher > Copier

Exit

Staple Count

Finisher

Entrance Sensor

Punch HP Sensor

Stapler Entrance Sensor

Stapler Tray Paper Sensor

Shift Tray Exit Sensor

Upper Transport Motor

Lower Transport Motor

Punch Motor

Jogger Motor

Stapler Motor

Jogger Fence HP Sensor

Stapler HP Sensor

Stapler Junction Gate

Solenoid

Positioning Roller Solenoid

Staple Hammer Motor

Staple Hammer HP Sensor

Stack Feed-out Motor

Stack Feed-out Belt HP

Sensor

Shift Tray Exit Motor

70ms

40ms

100ms

A697D515.WMF

A697-20

Page 22

June 30, 1998 DIP SWITCHES

3. SERVICE TABLES

3.1 DIP SWITCHES

DPS100 DPS101

12341234

00000000Default

11011000Stack feed-out motor on

11100100Free run: sort/stack mode

11100010Free run: one staple (front side)

11100001Free run: two staples

NOTE:

Do not use any other settings.

Description

3.2 TEST POINTS

No. Label Monitored Signal

TP101 (GND) Ground

3.3 LED

No. Function

LED100 Monitors the stack feed-out motor speed.

3.4 VARIABLE RESISTORS

No. Function

VR100 Adjust the stack feed-out motor speed.

3.5 FUSES

No. Function

FU100 Protects 24 V.

Options

A697-21

Page 23

COVER REPLACEMENT June 30, 1998

4. REPLACEMENT AND ADJUSTMENT

4.1 COVER REPLACEMENT

[B]

[D]

[E]

[F]

Rear Cover

1. Remove the rear cover [A] (3 screws).

Upper Left Cover

[C]

A697R500.WMF

[A]

1. Remove the upper left cover [B] (2 screws).

Upper Cover

1. Remove the upper left cover.

2. Remove the upper cover [C] (2 screws).

Front Door

1. Remove the upper left cover.

2. Remove the upper cover.

3. Remove the upper bracket [D] (1 screw).

4. Remove the front door [E].

Left Front Cover

1. Remove the rear cover.

2. Remove the upper cover.

3. Remove the front door.

4. Remove the left front cover [F] (2 screws).

A697-22

Page 24

June 30, 1998 COVER REPLACEMENT

[G]

[I]

[B]

[E]

[J]

[F]

[C]

[D]

A697R500.WMF

[A]

[H]

Shift Tray

1. Remove the rear cover [A].

2. Rotate the shift tray lift motor and lower the shift tray [B].

3. Remove the shift tray (4 screws).

Lower Left Cover

1. Remove the shift tray.

2. Remove the upper left cover [C].

3. Remove the upper cover [D].

4. Remove the front door [E].

5. Remove the left front cover [F].

6. Remove the lower left cover [G] (4 screws).

Right Cover

1. Remove the right cover [H] (2 screws).

Front Shift Tray Cover

1. Remove the front shift tray cover [I] (1 screw).

Options

Rear Shift Tray Cover

1. Remove the rear shift tray cover [J] (1 screw).

A697-23

Page 25

POSITIONING ROLLER REPLACEMENT June 30, 1998

4.2 POSITIONING ROLLER REPLACEMENT

[B]

[C]

1. Open the front door.

2. Remove the snap ring [A].

3. Release the rubber belt [B].

4. Replace the positioning roller [C].

[A]

A697R501.WMF

A697-24

Page 26

June 30, 1998 ALIGNMENT BRUSH ROLLER REPLACEMENT

4.3 ALIGNMENT BRUSH ROLLER REPLACEMENT

[D]

[B]

[E]

[C]

[F]

[A]

[H]

[G]

A697R502.WMF

1. Open the front door and pull out the jogger unit.

2. Remove the rear cover.

3. Remove the main board [A] (6 screws, all connectors).

4. Remove a screw [B] and a tension spring [C] for the tension bracket [D], and

release the tension of the timing belt.

5. Remove the front side E-ring [E] and bushing [F].

6. Remove the alignment brush roller assembly.

7. Remove the timing pulley [G] (1 E-ring).

8. Replace the alignment brush roller [H] (1 spacer, 1 bushing).

A697-25

Options

Page 27

SENSOR REPLACEMNT June 30, 1998

4.4 SENSOR REPLACEMNT

4.4.1 STACK HEIGHT SENSOR 1 AND 2

[A]

[B]

[D]

[C]

1. Remove the upper left cover.

2. Remove the upper cover.

3. Remove the sensor feeler [A] (1 screw, 1 connector).

4. Remove the sensor bracket [B] (1 screw).

5. Replace the stack height sensor 1 [C] or 2 [D].

A697R503.WMF

A697-26

Page 28

June 30, 1998 SENSOR REPLACEMNT

4.4.2 UPPER TRAY PAPER LIMIT AND EXIT SENSOR

[C]

[D]

[B]

[A]

A697R504.WMF

1. Remove the upper left cover.

2. Remove the upper cover.

Upper Tray Paper Limit Sensor

3. Remove the sensor bracket [A] (1 screw).

4. Replace the upper tray paper limit sensor [B] (1 connector).

Upper Tray Exit Sensor

3. Remove the sensor bracket [C] (1 screw).

4. Replace the upper tray exit sensor [D] (1 connector).

A697-27

Options

Page 29

SENSOR REPLACEMNT June 30, 1998

A

4.4.3 SHIFT TRAY EXIT SENSOR

[A]

[D]

[B]

697R505.WMF

[C]

A697R506.WMF

1. Remove the rear cover.

2. Remove the upper left cover.

3. Remove the upper cover.

4. Open the front door and remove the upper exit guide [A] (1 plastic clip).

5. Remove the guide stay [B] (2 screws).

6. Remove the discharge brush [C] (2 screws).

7. Replace the shift tray exit sensor [D] (1 screw, 1 connector).

A697-28

Page 30

June 30, 1998 SENSOR REPLACEMNT

4.4.4 ENTRANCE AND STAPLER TRAY ENTRANCE SENSOR

[B]

[A]

[D]

[C]

A697R507.WMF

1. Remove the finisher from the copier.

Entrance Sensor

2. Remove the sensor bracket [A] (1 screw).

3. Replace the entrance sensor [B] (1 screw, 1 connector).

Stapler Tray Entrance Sensor

2. Remove the sensor bracket [C] (1 screw).

3. Replace the stapler tray entrance sensor [D] (1 screw, 1 connector).

Options

A697-29

Page 31

SENSOR REPLACEMNT June 30, 1998

4.4.5 STAPLER ROTATION HP SENSOR

[B]

[A]

[D]

[C]

A697R510.WMF

1. Remove the stapler unit.

2. Remove the screw [A] and rotate the stapler bracket [B].

3. Remove the sensor bracket [C] (1 screw).

4. Replace the stapler rotation HP sensor [D] (1 connector).

A697-30

Page 32

June 30, 1998 STAPLER REMOVAL

4.5 STAPLER REMOVAL

[A]

1. Open the front door and pull out the jogger unit.

2. Move the stapler to the front.

3. Remove the stapler [A] (1 screw, 1 connector).

A697R509.WMF

A697-31

Options

Page 33

PUNCH POSITION ADJUSTMENT June 30, 1998

4.6 PUNCH POSITION ADJUSTMENT

A697R508.WMF

Right to left

This position is adjusted by SP modes.

Front to rear

The optional punch units have the following 3 spacers as accessories.

1 mm thickness: 2 pcs

2 mm thickness: 1 pc

The punch position can be adjusted by up to 4 mm by combinations of the 3

spacers.

A697-32

Page 34

June 30, 1998 STACK FEED-OUT MOTOR SPEED ADJUSTMENT

4.7 STACK FEED-OUT MOTOR SPEED ADJUSTMENT

NOTE:

This adjustment is required after replacing the main board.

1. Set the DIP switches on the finisher main board as follows.

DIP SW 1 2 3 4

DIP100 On On Off On

DIP101 On Off Off Off

2. If LED100 remains lit, turn VR100 counterclockwise until LED100 starts

blinking.

3. Turn VR100 clockwise until the LED stops blinking and remains lit.

A697-33

Options

Page 35

3,000-SHEET FINISHER (A697) ELECTRICAL COMPONENT LAYOUT

26

25

24

23

22

27

21

28

29

34

33

32

31

30

35

36

37 38 1 2 3

4

5

6

7

8

9

10

11

12

13

14

15

16

17

20

Index

Symbol

Motors

M1 3 Upper Transport B13

M2 11 Lower Transport C13

M3 28 Jogger L13

M4 17 Stapler N13

M5 18 Stapler Rotation O13

M6 24 Staple Hammer Q13

M7 29 Stack Feed-out H13

M8 2 Shift Tray Exit G13

M9 31 Shift I13

M10 1 Shift Tray Lift E13

M11 6 Punch S2

Sensors

S1 9 Entrance E2

S2 14 Stapler Tray Entrance F2

S3 27 Jogger Fence HP N2

S4 25 Stapler Tray Paper N2

S5 20 Stapler HP O2

S6 19 Stapler Rotation HP P2

S7 23 Staple Hammer HP R13

S8 26 Stack Feed-out Belt HP M2

S9 32 Shift Tray Exit H2

S10 34 Stack Height 1 I2

S11 33 Stack Height 2 J2

S12 38 Upper Tray Exit F2

S13 37 Upper Tray Ppaer Limit G2

S14 30 Shift Tray Half-turn L2

S15 15 Shift Tray Lower Limit 1 J2

S16 16 Shift Tray Lower Limit 2 K2

S17 8 Hopper R2

S18 7 Punch HP Q2

No.

Description P to P

19

18

Index

Symbol

Switches

SW1 13 Front Door Safety D2

SW2 35 Shift Tray Upper Limit J13

SW3 21 Staple End R13

SW4 22 Cartridge Set Q13

Solenoids

SOL1 4 Tray Junction Gate E13

SOL2 36 Stapler Junction Gate J13

SOL3 12 Positioning Roller K13

PCBs

PCB1 10 Main T6

PCB2 5 Punch Q4

No.

Description P to P

Page 36

1234567891011121314

POINT TO POINT DIAGRAM (FINISHER 3,000: A697)

A

Copier

B

C

Front Door

D

Safety Switch

Entrance

E

Sensor

Stapler Tray

Entrance

Sensor

F

Upper Tray

Exit Sensor

Upper Tray

G

Paper Limit

Sensor

H

Shift Tray

Exit Sensor

Paper Height 1

I

Sensor

Paper Height 2

Sensor

J

Shift Tray

Lower Limit 1

Sensor

K

Shift Tray

Lower Limit 2

Sensor

Shift Tray

L

Half-turn

Sensor

Stack Feed-

out Belt HP

M

Sensor

Jogger Fence

HP Sensor

N

Stapler Tray

Paper Sensor

O

Stapler HP

Sensor

Stapler Rotation

P

HP Sensor

Punch HP

Sensor

Q

Hopper

Sensor

R

Punch

Motor

S

S1

S2

S12

S13

S9

S11

S10

S15

S16

S14

S8

S3

S4

S5

S6

S18

S17

M11

SW1

CN650

CN254-1

CN204-1

CN205-1

-1

-2

-3

-1

-2

-3

-1

-2

-3

-1

-2

-3

CN267-1

CN257-1

-1

-2

-3

CN268-1

CN258-1

CN208-1

CN259-1

-1

-2

-3

CN620

-6

-1

-5

-2

-4

-3

CN620CN630

-1 -3

-2

-2

-1

-3

CN610-1

-2

-3

-2

-3

-2

-3

-2

-3

-2

-3

-2

-3

-2

-3

-2

-3

-2

-3

-2

-4

-5

-6

-7

CN266

CN256

CN206

CN206

CN207

CN209

Punch

Board

(PCB2)

CN101-1

CN102-2

CN103-1

CN104-6

CN104-3

CN105-3

-1

-2

-3

-1

-2

-3

-1

-2

-3

-4

-5

-6

-1

-2

-3

-1

-2

-3

CN106CN366

CN106CN356

CN106CN316

CN106CN306

CN107-9

CN107-6

CN107CN307

CN108-9

CN108-6

CN108-3

CN109-6

CN109CN309

-1

-2

-3

-4

-5

-6

-7

-8

-9

-10

-11

[24] 24V

-2

[24] 24V

-3

[24] 24V

-4

[0] GND1

-5

[0] GND1

-6

[0] GND1

[0] GND2

-3

RXD

-4

[0] GND2

-5

TXD

[24] 24V

-2

[s24] Front Door Safety Switch

A

[0] GND2

-5

[t5] Entrance Sensor

-4

[5] 5V

[5] 5V

-2

[t5] Stapler Tray Entrance Sensor

-1

[0] GND2

[5] 5V

-2

[0] GND2

-1

[t5] Upper Tray Exit Sensor

-13

[0] GND2

-12

[t5] Upper Tray Paper Limit Sensor

-11

[5] 5V

-10

[0] GND2

-9

[t5] Shift Tray Exit Sensor

-8

[5] 5V

-6

[5] 5V

-5

[0] GND2

-4

[s5] Paper Height 1 Sensor

-3

[5] 5V

-2

[0] GND2

-1

[s5] Paper Height 2 Sensor

[5] 5V

-8

[s5] Shift Tray Lower Limit 1 Sensor

-7

[0] GND2

[5] 5V

-5

[s5] Shift Tray Lower Limit 2 Sensor

-4

[0] GND2

-3

[5] 5V

-2

[s5] Shift Tray Half-turn Sensor

-1

[0] GND2

[5] 5V

-8

[0] GND2

-7

[s5] Stack Feed-out Belt HP Sensor

[5] 5V

-5

[s5] Jogger Fence HP Sensor

-4

[0] GND2

[0] GND2

-2

[s5] Stapler Tray HP Sensor

-1

[5] 5V

[5] 5V

-5

[s5] Stapler HP Sensor

-4

[0] GND2

-3

[5] 5V

-2

[s5] Stapler Rotation HP Sensor

-1

[0] GND2

CN121CN600

-11

[s5] Hopper Sensor

-10

[t5] Punch Unit Installed

-9

[s5] Punch HP Sensor

-8

[t24 0/24 ] Punch Motor B

-7

[t24 0/24 ] Punch Motor A

-6

[t24 0/24 ] Punch Motor B

-5

[t24 0/24 ] Punch Motor A

-4

[0] GND2

-3

[5] 5V

-2

[0] GND1

-1

[24] 24V

A

Main Board

(PCB1)

T

A

Upper Transport Motor:A[t24 0/24 ]

Upper Transport Motor:A[t24 0/24 ]

Upper Transport Motor:B[t24 0/24 ]

Upper Transport Motor:B[t24 0/24 ]

A

Lower Transport Motor:A[t24 0/24 ]

Lower Transport Motor:A[t24 0/24 ]

Lower Transport Motor:B[t24 0/24 ]

Lower Transport Motor:B[t24 0/24 ]

A

Shift Tray Lift Motor:+[t24]

Shift Tray Lift Motor:-[t24]

Tray Junction Gate Sol. [t24]

A

Shift Tray Exit Motor:A[t24 0/24 ]

Shift Tray Exit Motor:A[t24 0/24 ]

Exit Motor:B[t24 0/24 ]

Exit Motor:B[t24 0/24 ]

A

Stapler Rotation Motor:A[t24 0/24 ]

Stapler Rotation Motor:A[t24 0/24 ]

Stapler Rotation Motor:B[t24 0/24 ]

Stapler Rotation Motor:B[t24 0/24 ]

A

Stack Feed-out Motor:+[t24]

Stack Feed-out Motor:-[t24]

Stack Feed-out Motor F.S. [0/12]

Stack Feed-out Motor F.S. [0/12]

Shift Tray Upper Limit Switch [s24]

Stapler Junction Gate Sol. [t24]

Positioning Roller Sol. [t24]

A

Jogger Motor:A[t24 0/24 ]

Jogger Motor:A[t24 0/24 ]

Jogger Motor:B[t24 0/24 ]

Jogger Motor:B[t24 0/24 ]

A

Stapler Motor:A[t24 0/24 ]

Stapler Motor:A[t24 0/24 ]

Stapler Motor:B[t24 0/24 ]

Stapler Motor:B[t24 0/24 ]

A

Staple Hummer Motor:+[t24]

Staple Hummer Motor:+[t24]

Staple Hummer Motor:-[t24]

Staple Hummer Motor:-[t24]

Cartridge Set Switch [s5]

Staple End Switch [t5]

Staple Hammer Sensor [s5]

Stapler Installed [t5]

24V(A) [24]

24V(B) [24]

24V(A) [24]

24V(B) [24]

A

Shift Motor [t24]

A

A

A

24V [24]

24V(A) [24]

24V(B) [24]

24V [24]

24V [24]

24V [24]

24V [24]

24V(A) [24]

24V(B) [24]

24V(A) [24]

24V(B) [24]

24V(A) [24]

24V(B) [24]

GND2 [0]

CN110-1

CN111-1

CN112-1-2CN212-2

CN112-4-5CN222-2

CN113-1 CN213-7

CN114-1

CN115 CN315

-1

-2

CN115-3-4CN215-2

CN116-1

CN117-1

CN118-1 CN218-7

CN118-8 CN228-7

CN119-1 CN219-7

CN120-12 CN220-1

5V [5]

CN210-7

-2

-4

-5

-6

-7

CN211-7

-2

-4

-5

-6

-7

-2

-4

-5

-6

-7

CN214-5

-2

-4

-5

CN215

-4

-3

-2

-2

-2

-4

-5

-6

-7

-9

-11

-12

-13

-14

-2

-4

-5

-6

-7

-11

-9

-8

-6

-5

-4

3

-2 -11

-1

-10

-12

A

-6

-4

-3

-2

-1

-6

-4

-3

-2

-1

-1

-1

-6

-4

-3

-2

-1

-4

-2

-1

-2

-1

M1

M2

M10

SOL

1

M8

M7

M9

SW2

-1

SOL

2

SOL

3

-6

-4

-3

-2

-1

-6

-4

-3

-2

-1

-6

-4

-3

-2

-1

-2

-4

-5

-7

-8

-9

M3

M4

M5

M6

SW4

SW3

S7

Upper

Transport

Motor

Lower

Transport

Motor

Shift Tray

Lift Motor

Tray Junction

Gate Solenoid

Shift Tray

Exit Motor

Stack

Feed-out

Motor

Shift

Motor

Shift Tray

Upper Limit

Switch

Stapler

Junction Gate

Solenoid

Positioning

Roller

Solenoid

Jogger

Motor

Stapler

Motor

Stapler

Rotation

Motor

Stapler

B

C

D

E

F

G

H

I

J

K

L

M

N

O

P

Q

R

SYMBOL TABLE

DC Line

Pulse Signal

S

Signal Direction

Active High

s

Active Low

t

Voltage

[]

T

1234567891011121314

Loading...

Loading...