Page 1

M

Model:

3000-sheet Finisher for NAD 30S/30/40

odification

B

Date:

ulletin

30-Jun-98

No:

PAGE: 1/2

1

Modified Article:

From:

Reason for

Modification:

To prevent the positioning fence in the staple tray from coming out of position, the

following parts have been changed.

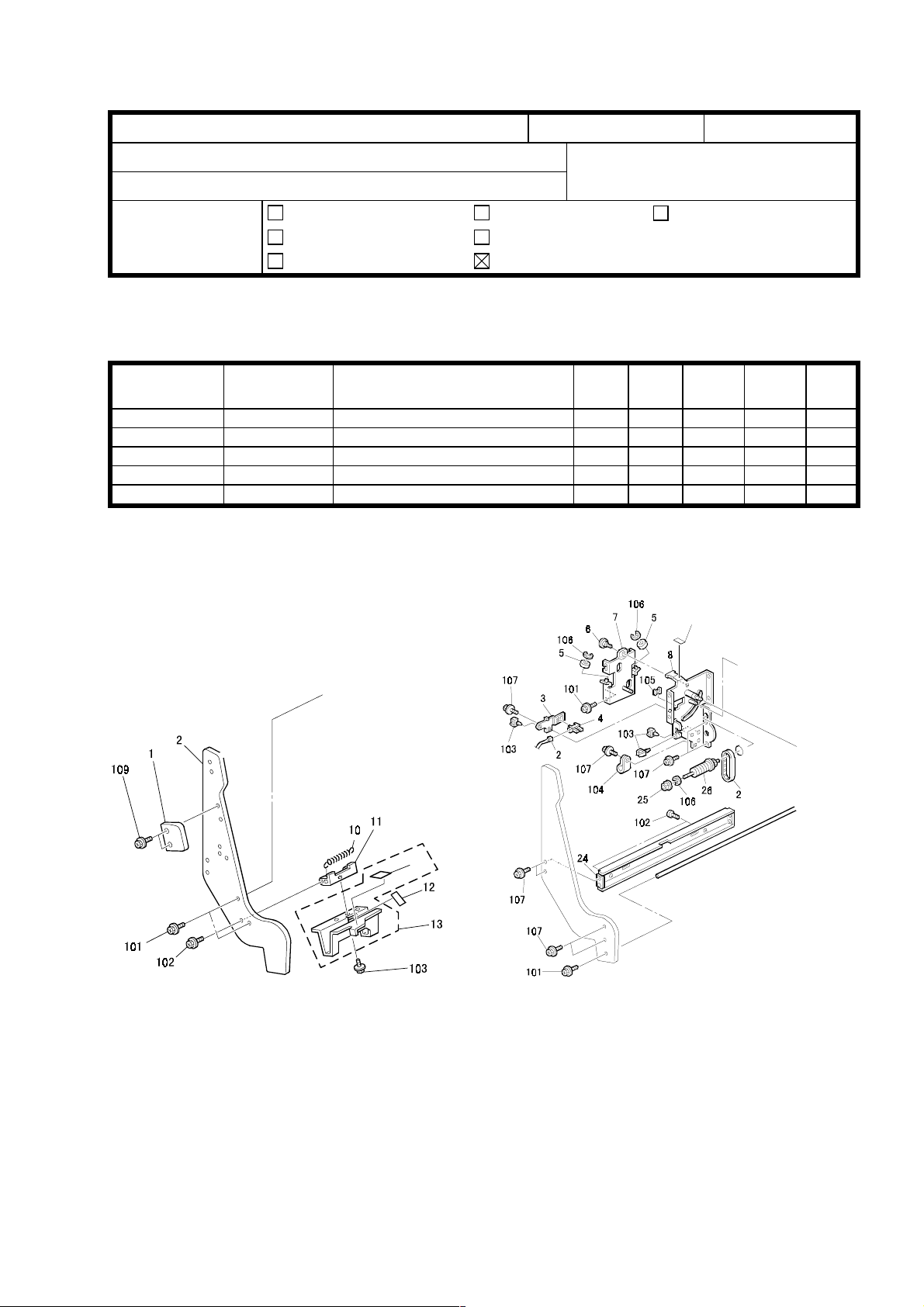

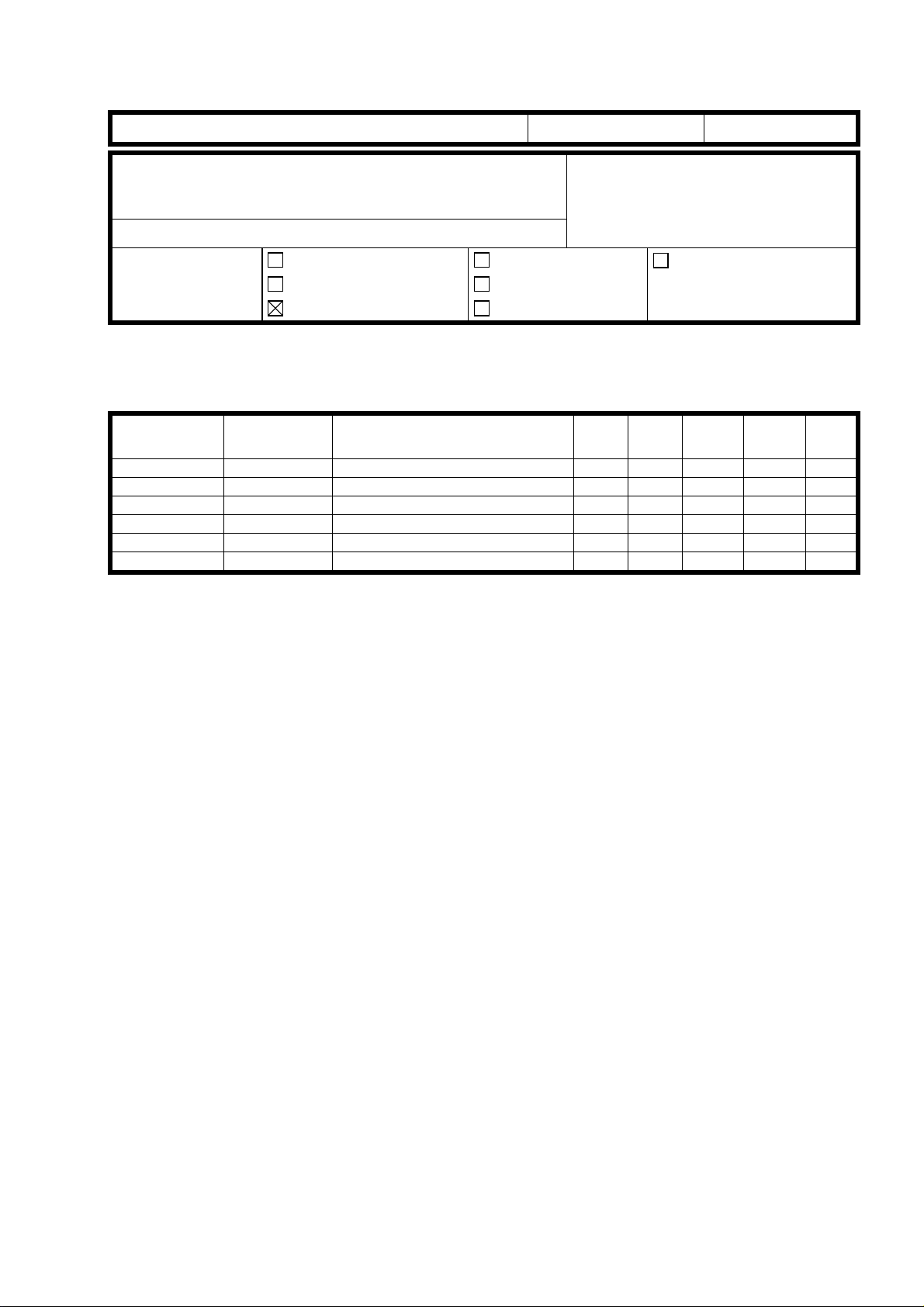

Note 1: Refer to Fig. 1.

Note 2: Refer to Fig. 2.

QAC Field Information Dept.

Old part New part Description Qty Int Page Index Note

number number

A6974210 A6974211 Front Positioning Fence 1 X/O 15 13 1

A6974205 A6974207 Rear Positioning Fence 1 X/O 15 14

Front Positioning Fence, etc.

Parts catalog correction

To facilitate assembly

Part standardization

A6974213 Decal – Front Positioning Fence 1 15 20 1

A6974149 Decal – Staple Unit Holder 1 17 41 2

Vendor change

To improve reliability

Other

Prepared by:

To meet standards

S.Tomoe

( )

41

20

Fig. 1 Fig. 2

Page 2

M

Model:

3000-sheet Finisher for NAD 30S/30/40

Model Name V/Hz Destination Code Serial Number

115V/50 Hz USA, Canada A697-15 1B58050001

230V/60 Hz

115V/50 Hz

SR 730

230V/60 Hz Europe, Asia A697-22 AR38050001

230V/60 Hz Europe, Australia A697-26 3R10580001

230V/60 Hz

115V/50 Hz

odification

USA, Canada, Europe, Asia,

Taiwan, China, etc

USA, Canada, Europe A697-55 L0328050001

B

Date:

ulletin

30-Jun-98

No:

Japan Production

A697-17 A7778050001

PAGE: 2/2

1

Page 3

M

Model: 3000 Finisher for NAD and SP5 Date: 30-Nov-98 No.: 2

odification

B

ulletin

PAGE: 1/1

Modified Article:

From:

Reason for

Modification:

Please correct your finisher parts catalog as follows.

MODEL NAME V/H

Punch Kit Type 450

(3 holes)

GTSS Field Information Dept

Old part

number

A606 8195 A606 1895 Decal – Punch Position (LT) 1 7

Decal - Punch Unit

Parts catalog correction

To facilitate assembly

Part standardization

New part

number

- All A812-17 -

Vendor change

To improve reliability

Other

Description Qty Int Page Index Note

Z

DESTINATION CODE SERIAL NUMBER

Prepared by:

M .Tsuyuki

To meet standards

( )

24

35

1

Page 4

RICOH Modification

Bulletin

PAGE: 1/1

Model:

Modified Article:

From:

Reason for

Modification:

The part number has been changed for part standardization.

3000 Finisher for NAD and SP5

Rear Joint Bracket

GTSS Field Information Dept

Parts catalog correction

To facilitate assembly

Part standardization

Old part

number

A6971136 A6971144 Rear Joint Bracket 1 X/O 7 20

A6971135 A6971143 Front Joint Bracket 1 X/O 7 21

A6971137 A6971148 Grounding Plate 1 X/O 7 22

New part

number

Description Qty Int Page Index Note

Date:

Vendor change

To improve reliability

Other

15-Feb-99

Prepared by:

No.:

E. Fukuyama

To meet standards

( )

3

Page 5

RICOH Modification

Bulletin

PAGE: 1/1

Model:

Modified Article:

Hopper Stopper / Hopper Bracket / Joint

Lever

From:

Reason for

Modification:

NAD 30S/30/40 3000Finisher

Joint Bracket / Grounding Plate / Dust

Technical Service Dept., GTS Division

Parts catalog correction

To facilitate assembly

Part standardization

Date:

15-Apr-99

Prepared by:

Vendor change

To improve reliability

Other

No.:

MA697004

S. Hizen

To meet standards

( )

To standardize with other models, the following parts have been changed as shown below.

Old part

number

A697-1135 A697-1143 Front Joint Bracket 1 O/O 7 21

A697-1136 A697-1144 Rear Joint Bracket 1 O/O 7 20

A697-1137 A697-114 8 Grounding Plate 1 O /O 7 22

A812-7321 A812-7323 Dust Hopper Stopper 1 O/O 23 21

A697-1150 A697-1151 Hopper Bracket 1 O/O 23 20

A697-1127 A6971128 Joint Lever 1 O/O 29 12

New part

number

Description Q’ty Int Page Index Note

Page 6

RICOH Modification

Bulletin

PAGE: 1/2

Model:

Modified Article:

From:

Reason for

Modification:

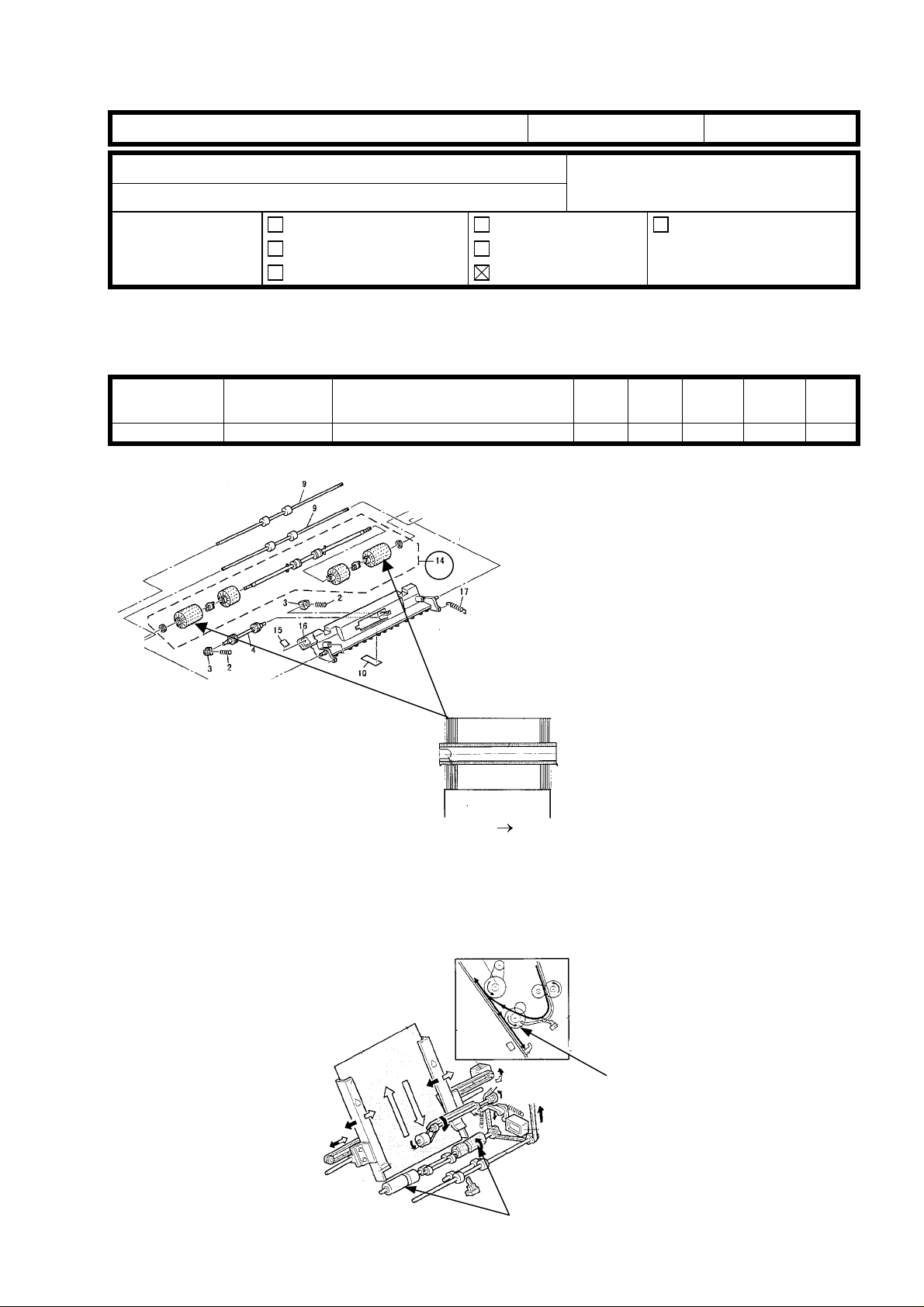

To prevent non-stapling when there are stacking problems with face-curled output, the

width of the outer rollers has been changed from 66 mm to 51 mm.

A697-2135 A697-2146 Exit Roller – Staple Tray 2-2 X/O 11 14

NAD 30S/30/40 3000Finisher

Exit Roller - Staple Tray

Technical Service Dept., GTS Division

Parts catalog correction

To facilitate assembly

Part standardization

Old part

number

New part

number

Description Qty Int Page Index Note

Date:

Vendor change

To improve reliability

Other

15-Apr-99

Prepared by:

No.:

MA697005

S. Hizen

To meet standards

( )

¬

66 mm ® 51 mm

- For your reference Stacking problems occur with curled copies, because the trailing edge of the copy gets

stuck on the brush rollers instead of being stacked properly.

®

Exit Roller – Staple Tray

Exit Roller – Staple Tray

Page 7

RICOH Modification

Bulletin

PAGE: 2/2

Model:

NAD 30S/30/40 3000Finisher

Model Name V/Hz Destination Code Serial Number

115V/50 Hz USA, Canada A697-15 1B59020001

SR 730

230V/60 Hz

115V/50 Hz

230V/60 Hz Europe, Asia A697-22 AR39020001

230V/60 Hz Europe, Australia A697-26 3R10290001

230V/60 Hz

115V/50 Hz

USA, Canada, Europe, Asia,

Taiwan, China, etc

USA, Canada, Europe, A697-55 L0329021637

Date:

15-Apr-99

No.:

MA697005

Japan Production

A697-17 A777901106B

Page 8

M

Reissued: 15-Jun-99

odification

B

ulletin

PAGE: 1/2

Model:

MB Correction

The items in bold italics have been corrected or added.

Modified Article:

From:

Reason for

Modification:

A697-6181 A697-6182 Left Upper Cover 1-1 X/O 7 9 -

The paper curl kit P/N:

for the curl kit have been added to the left upper cover. The part number of the cover has

been changed.

Note: This paper curl kit is only for the SR730 installed on the NAD.

Do not use this kit for the SR730 installed on the SP5.

NAD 30S/30/40

Paper Curl Kit

Technical Service Dept., GTS Division

Parts catalog correction

To facilitate assembly

Part standardization

Old part

number

-

New part

number

A697-9512

A697-9512

Paper Curl Kit 1 - - - -

Description Qty Int Page Index Note

has been registered as a service part. The screw holes

Date:

Vendor change

To improve reliability

Other

30-Apr-99

Prepared by:

No.:

MA230023a

S. Hizen

To meet standards

( )

Side Paper

Guides

Paper Curl Kit: A697-9512

Center Paper

Guide

6 screws

Page 9

M

Reissued: 15-Jun-99

odification

B

ulletin

PAGE: 2/2

Model:

NAD 30S/30/40

Date:

30-Apr-99

No.:

MA230023a

Side Paper Guides

Center Paper Guide

Page 10

M

odification

B

ulletin

PAGE: 1/1

Model:

Modified Article:

From:

Reason for

Modification:

Please correct your finisher parts catalog as follows.

NAD 30S/30/40 3000 Finisher

Finisher Main Board

Technical Service Dept., GTS Division

Parts catalog correction

To facilitate assembly

Part standardization

Old part

number

A6975110 A6975120 Finisher Main Board 1 33 16

New part

number

Description Q’ty Int Page Index Note

Date:

Vendor change

To improve reliability

Other

30-Apr-99

Prepared by:

No.:

E. Fukuyama

To meet standards

( )

MA697006

Page 11

RICOH Modification

Bulletin

PAGE: 1/1

Model:

Modified Article:

From:

Reason for

Modification:

The part number has been changed for part standardization.

NAD 30S/30/40 3000 Finisher

Exit Roller - Staple Tray

Technical Service Dept., GTS Division

Parts catalog correction

To facilitate assembly

Part standardization

Old part

number

A6972146 A6972133 Exit Roller – Staple Tray 1 O/O 11 14

New part

number

Description Q’ty Int Page Index Note

Date:

Vendor change

To improve reliability

Other

30-Oct-99

Prepared by:

No.:

E.Fukuyama

To meet standards

( )

MA697007

Page 12

DELETED

RICOH

MB Correction (Deletion)

The MB (No.MA697008) issued on 30-Nov-99 has been deleted due to an error in the

model name and MB number printer on the top of the bulletin.

odification

M

B

ulletin

PAGE: 1/1

Model:

Modified Article:

From:

Reason for

Modification:

To standardize the part with other models, the scanner unit plate has been changed from

A2326807 to A2841090 with the interchangeability O/O.

A2326807 A2841090 Scanner Unit Plate 1 O/O 9 10

NAD 30S/30/40 3000Finisher

Scanner Unit Plate

Technical Services Dept., GTS Division

Parts catalog correction

To facilitate assembly

Part standardization

Old part

number

New part

number

Description Q’ty Int Page Index Note

Date:

Vendor change

To improve reliability

Other

30-Nov-99

Prepared by:

No.:

MA697008

E.Fukuyama

To meet standards

( )

Page 13

!"#$% M

Reissued: 24-Apr-00

odification Bulletin

PAGE: 1/1

Model:

NAD 30S/30/40 3000 Finisher

Date:

07-Mar-00

No.:

MA697008a

MB Correction

The items in bold italics have been corrected or added.

Modified Article:

From:

Technical Services Dept., GTS Division

Reason for

Modification:

As the fed-out paper is being stacked in the Shift Tray, the trailing edge rubs past the edge of the

Left Upper Cover, causing the stack to become disordered. To prevent this, a small section of the

vertical plate attached to the inside of the cover has been cut out. In addition, a small, rounded

section has been added to the edge of the Lower Exit Guide to improve stacking.

Old part

number

A6976182

A6972180 A6972181 Lower Exit Guide 1-1 X/O 25 17

Left Upper Cover and Lower Exit Guide

Parts catalog correction

To facilitate assembly

Part standardization

New part

Description Q’ty Int Page Index Note

Vendor change

To improve reliability

Other

number

A6976183 Left Upper Cover 1-1 X/O 7 9

Prepared by:

To meet standards

E. Fukuyama

( )

Page 14

!"#$% M

odification Bulletin

PAGE: 1/1

Model:

NAD 30S/30/40 300 Finisher

Modified Article:

From:

Technical Services Dept., GTS Division

Reason for

Modification:

Exit Stay

Parts catalog correction

To facilitate assembly

Part standardization

Date:

14-Apr-00

Prepared by:

Vendor change

To improve reliability

Other

No.:

MA697009

E. Fukuyama

To meet standards

( )

The following part number should be corrected. Please correct your parts catalog.

Old part

number

A6973120A3793121Exit Stay1278

New part

number

Description Q’ty Page Index

Page 15

!"#$% M

odification Bulletin

PAGE: 1/1

Model:

Modified Article:

From:

Reason for

Modification:

To standardize the part with other models, the ball bearing has been changed from A2323562 to

07413506 with the interchangeability O/O.

NAD 30S/30/40 3000 Finisher

Ball Bearing - 6X12X4mm

Technical Services Dept., GTS Division

Parts catalog correction

To facilitate assembly

Part standardization

Old part

number

A2323562 07413506 Ball Bearing – 6X12X4mm 1 O/O 31 21

New part

number

Description Q’ty Int Page Index Note

Date:

25-May-00

Prepared by:

Vendor change

To improve reliability

Other

No.:

MA697010

E. Fukuyama

To meet standards

( )

Page 16

!"#$% M

odification Bulletin

PAGE: 1/1

Model:

NAD 30S/30/40 3000 Finisher

Modified Article:

From:

Technical Services Dept., GTS Division

Reason for

Modification:

Tightener

Parts catalog correction

To facilitate assembly

Part standardization

Date:

22-Feb-01

Prepared by:

Vendor change

To improve reliability

Other

No.:

E. Fukuyama

To meet standards

( )

To standardize parts with a new model, the tighteners have been changed.

Old part

number

A6971625 B3121600 Tightener 1 O/O 31 4

A6971601 B3121610 Tightener 1 O/O 31 7

New part

number

Description Q’ty Int Page Index Note

MA697011

Page 17

!"#$% M

Reissued: 09-Mar-01

odification Bulletin

PAGE: 1/1

Model:

NAD 30S/30/40 3000Finisher

Date:

23-Feb-01

No.:

MA697012a

MB Correction

The items in bold italics have been corrected or added.

Modified Article:

From:

Technical Services Dept., GTS Division

Reason for

Modification:

Finisher Main Board

Parts catalog correction

To facilitate assembly

Part standardization

Vendor change

To improve reliability

Other

Prepared by:

To meet standards

E. Fukuyama

( )

To protect the circuit, diodes have been added to the drive circuits of the shift tray lift

motor.

Old part

number

A6975120 A6975130 Finisher Main Board 1 X/O 33 16

New part

number

Description Q’ty Int Page Index Note

RCL (Japan) Production

Model Name V/Hz Destination Code Serial Number

115V/50 Hz USA, Canada A697-15 1B59090001

SR 730

230V/60 Hz

115V/50 Hz

230V/60 Hz Europe, Asia A697-22 AR39090001

230V/60 Hz Europe, Australia A697-26 3R10990001

230V/60 Hz

115V/50 Hz

USA, Canada, Europe, Asia,

Taiwan, China, etc

USA, Canada, Europe, A697-55 L0329090001

A697-17 A7779080986

Loading...

Loading...