Page 1

FINISHER

Click here for information on differences

between the SR700 and the SR710

(Machine Code: A612)

Page 2

22 March 1996 OVERALL MACHINE INFORMATION

1. OVERALL MACHINE INFORMATION

1.1 SPECIFICATIONS

Paper Size: Standard copyin g/ St ack mode

Maximum: 11" x 17" /A3

Minimum: 51/2" x 81/2"/A5

Staple mode

Maximum: 11" x 17" /A3

Minimum: 8" x 11"/B5

Paper Weight: Standard copyin g/ St ack mode

14 ~ 42 lb/52 ~ 157 g/m

Staple mode

17 ~ 21 lb/64 ~ 80 g/ m

Paper Capacity: 1,500 sheets:

81/2" x 11"/A4 or smaller size (20 lb/80 g/m2)

1,000 sheets:

81/2" x 14"/B4 or larger size (20 lb/80 g/m2)

2

2

Stapler Capacity: 81/2" x 11"/A4 or smaller size (20 lb/80 g/m2):

from 2 to 50 sheets

81/2" x 14"/B4 or large size (20 lb/80 g/m2):

from 2 to 30 sheets

Staple Replenishmen t: Cartridge exchange (5, 000 staples/cartridge)

Power Source: DC 24 V (from copier)

Power Consumption: 48 W (average)

Weight: 35 kg (77.2 lb)

Finisher

1

Page 3

a

OVERALL MACHINE INFORMATION 22 March 1996

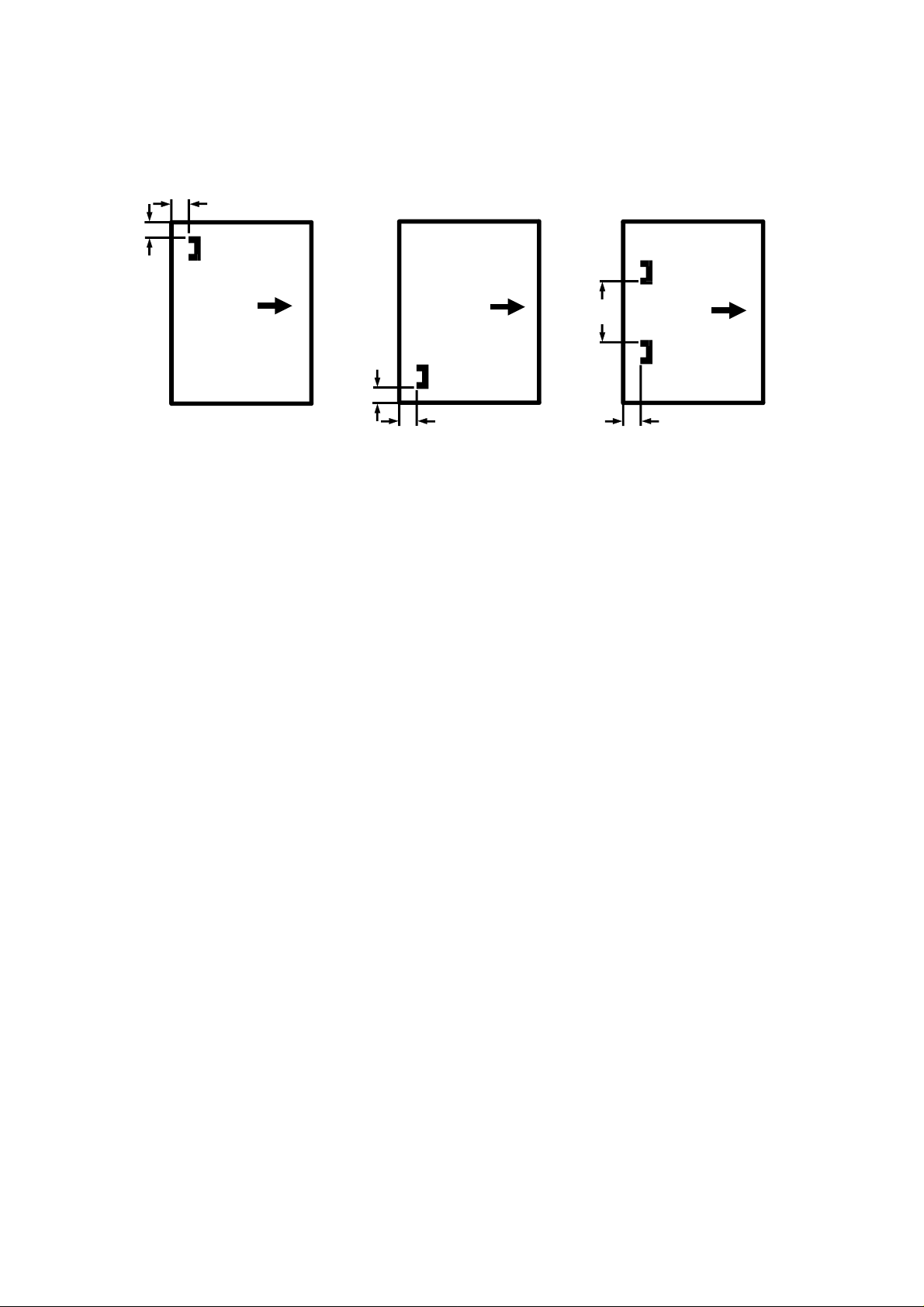

Stapling Position:

- 1 staple - - 2 staples -

b

b

b

aa

A612V500.wmf

a = 0.24" ± 0.12" (6 ± 3 mm)

b = 0.24" ± 0.12" (6 ± 3 mm)

a = 0.24" ± 0.12" (6 ± 3 mm)

b = 0.24" ± 0.12" (6 ± 3 mm)

Dimensions: 26.5" x 20.5" x 37.5"

(671 mm x 514 mm x 950 mm)

a = 0.24" ± 0.12" (6 ± 3 mm)

b = 5.20" ± 0.12" (132 ± 3 mm)

2

Page 4

12

11910

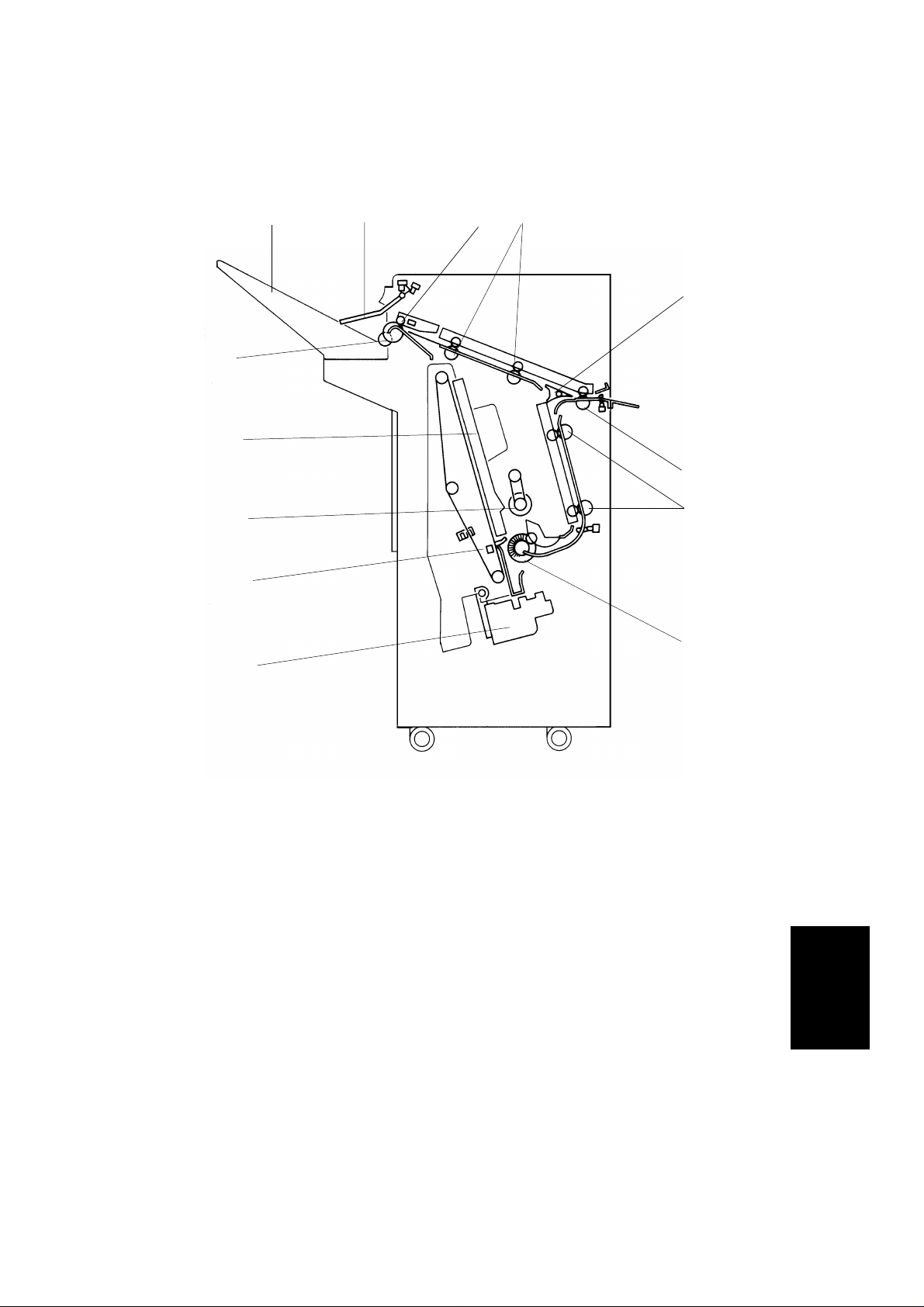

22 March 1996 OVERALL MACHINE INFORMATION

1.2 MECHANICAL COMPONENT LAYOUT

2

1

13

3

4

5

6

8

7

1. Stack Height Sensor Feeler

2. Shift Tray

3. Shift Tray Positioning Roller

4. Jogger Unit

5. Positioning Roller

6. Stack Feed-out Belt

7. Stapler Unit

A612V501.img

8. Alignment Brush Roller

9. Lower Transport Rollers

10. Entrance Rollers

11. Junction Gate

12. Upper Transport Rollers

13. Exit Rollers

Finisher

3

Page 5

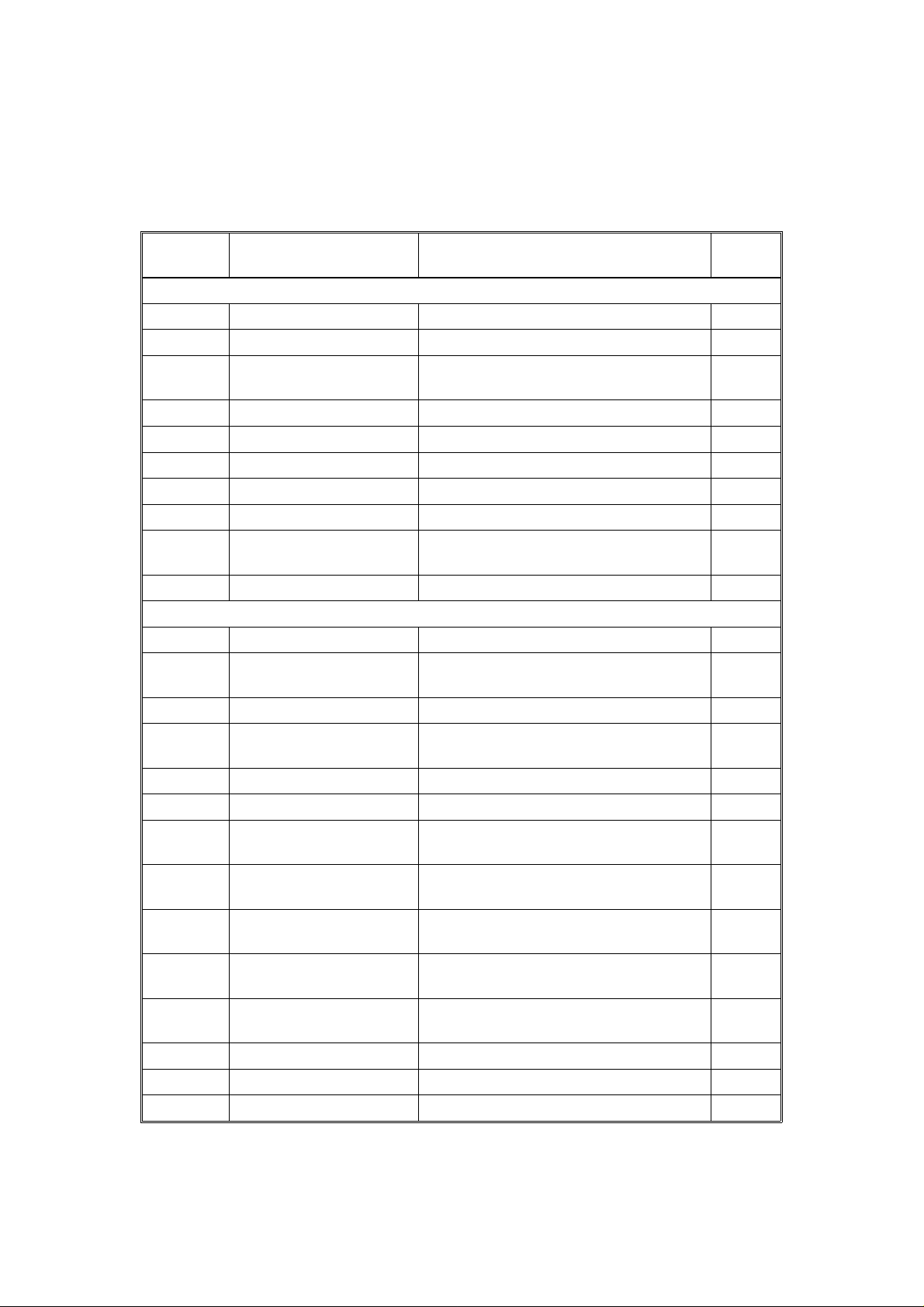

OVERALL MACHINE INFORMATION 22 March 1996

1.3 ELECTRICAL COMPONENT DES CRIPTI O N

Refer to the electrical compo nent layou t on the reverse side of the

point-to-poin t dia gram (on waterproof paper) for the index numbe rs.

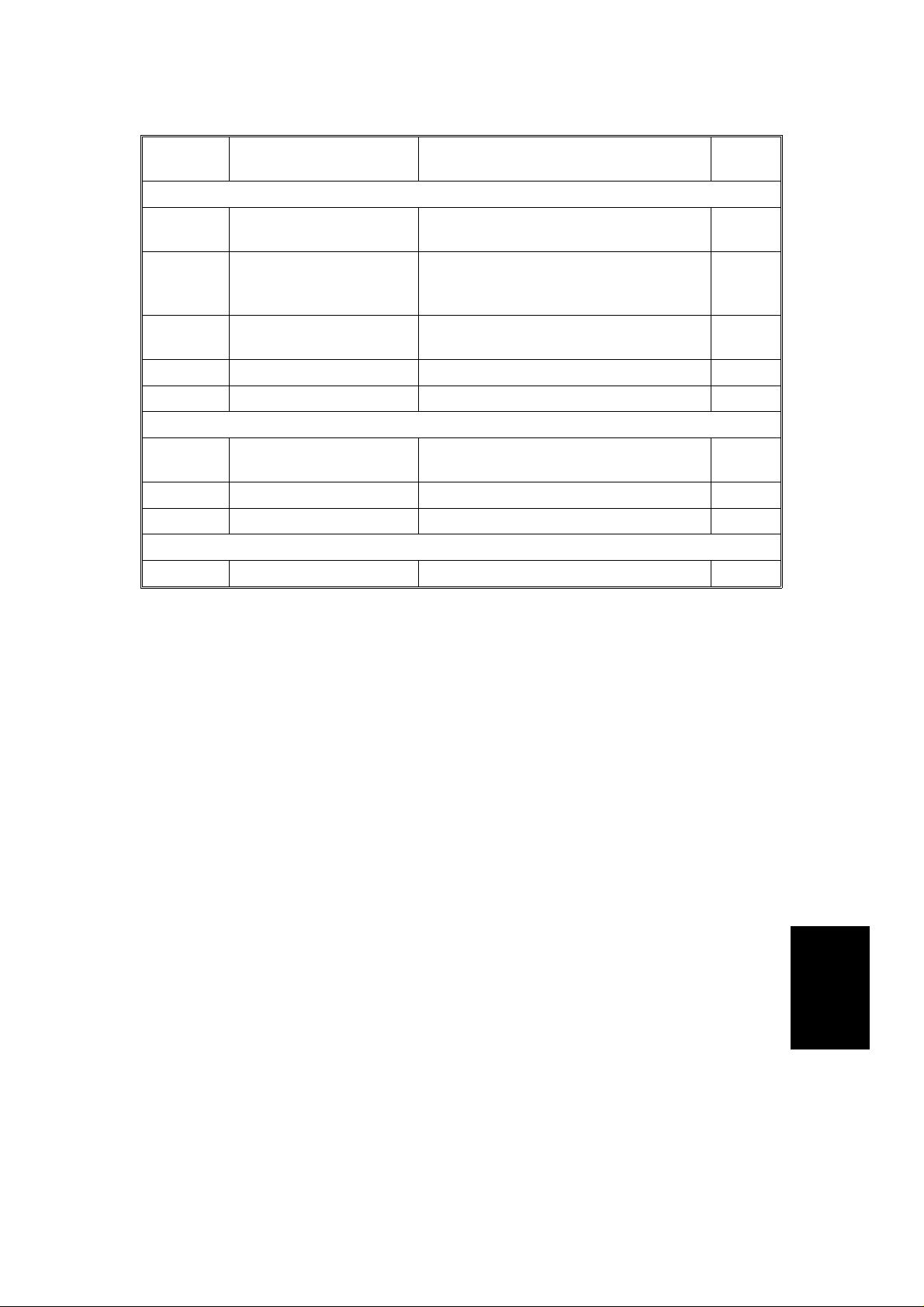

Symbol Name Function

Motors

M1 Transport Drive Drives the transport rollers. 21

M2 Shift Tray Lift Moves the shift tray up or down. 25

M3 Exit Drive Drives the exit roller and the shift tray

positioning roller.

M4 Stack Feed-out Drives the stack feed-out belt. 5

M5 Jogger Moves the jogger fences. 19

M6 Stapler Drive Moves the stapler unit. 17

M7 Shift Moves the shift tray from side to side. 7

M8 Staple Drives the staple hammer. 13

M9 Lower Transport Drive Drives the transport rollers of the stapler

section.

Sensors

S1 Entrance Detects copy paper entering the finisher. 26

S2 Jogger Unit Entrance Detects copy paper entering the jogger

unit.

S3 Jogger Unit Paper Detects copy paper in the jogger unit. 8

S4 Stack Feed-out Belt HP Detects the home position of the stack

feed-out belt.

S5 Jogger HP Detects the jogger home position. 18

S6 Exit Detects misfeeds in the exit area. 3

S7 Stack Height 1 Detects copy paper stack height in

staple mode.

S8 Stack Height 2 Detects copy paper stack height in

sort/stack mode.

S9 Shift Tray Lower Limit Detects the lower limit of the shift tray

position.

S10 Staple Hammer HP Detects the staple hammer home

position.

S11 Shift Tray Half-Turn Detects the side-to-side position of the

shift tray.

S12 Stapler Unit HP Detects the stapler unit home position. 10

Index

No.

27

22

24

9

2

1

15

14

6

4

Page 6

22 March 1996 OVERALL MACHINE INFORMATION

Symbol Name Function

Switches

SW1 Front Door Safety Cuts the dc power when the front door is

opened.

SW2 Shift Tray Upper Limit Cuts the power to the shift tray lift motor

when the shift tray position is at its upper

limit.

SW3 Cartridge Set Detects whether a staple cartridge is

installed.

SW4 Staple End Detects staples in the cartridge. 11

Solenoids

SOL1 Positioning Roller Lowers the positioning roller in the

jogger unit.

SOL2 Junction Gate Drives the junction gate. 23

PCBs

PCB1 Main Control Controls overall finisher operation. 16

Index

No.

28

4

12

20

Finisher

5

Page 7

5

1

OVERALL MACHINE INFORMATION 22 March 1996

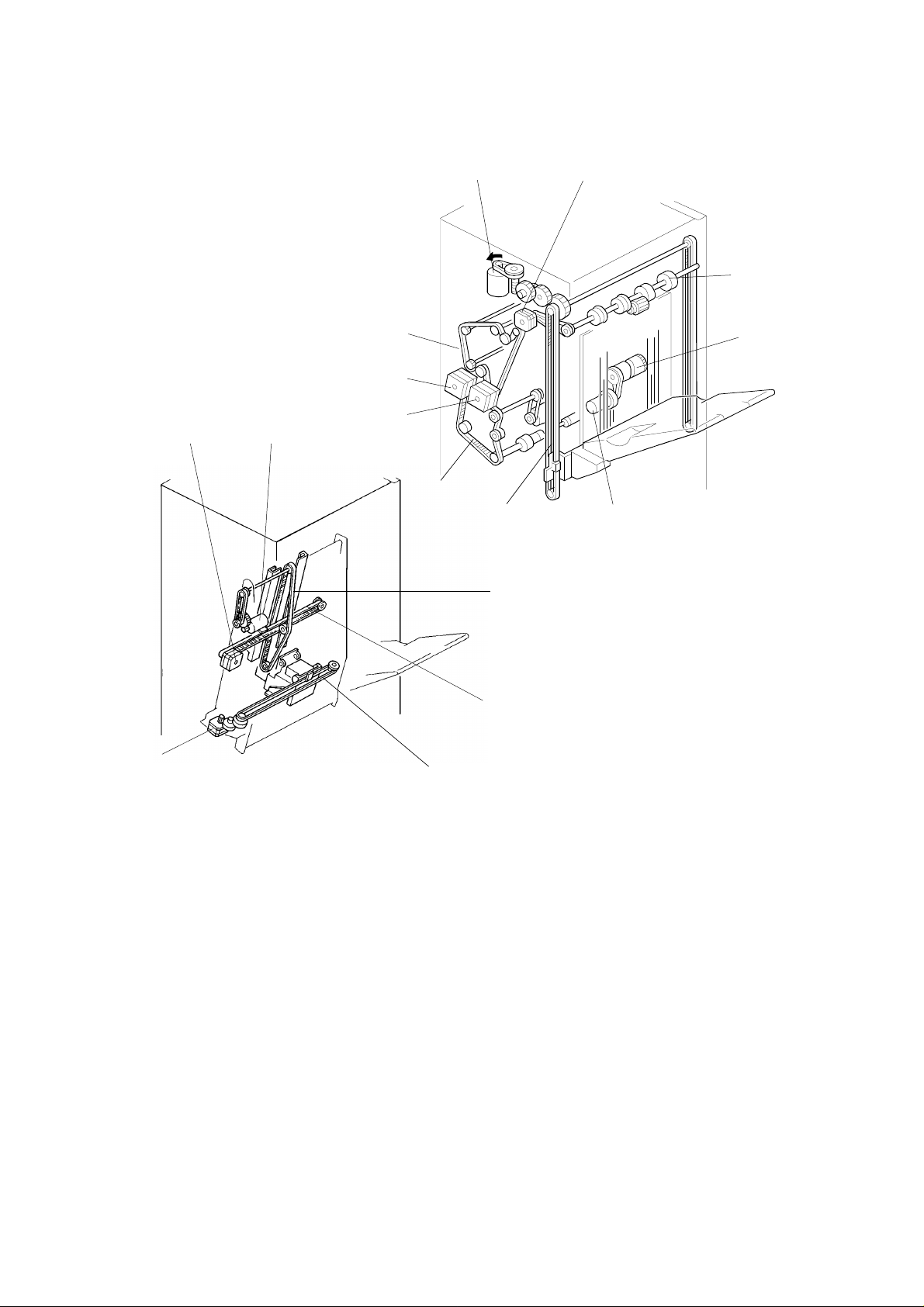

1.4 DRIVE LAYOUT

10

2

13

12

11

9

8

7

6

14

A612V502.img

16

15

3

4

A612V503.wmf

1. Exit Drive Motor (M3)

2. Exit Roller

3. Shift Cam

4. Shift Motor (M7)

5. Shift Tray Lift Belt

6. Lower Transport Drive Belt

7. Transport Drive Motor (M1)

8. Lower Transport Drive Motor

9. Upper Transport Drive Belt

10. Shift Tray Lift Motor (M2)

11. Stack Feed-out Moto r (M4 )

12. Jogger Motor (M5)

13. Stapler Drive Motor (M6)

14. Stapler Drive Belt

15. Jogger Drive Belt

16. Stack Feed-out Belt

(M9)

6

Page 8

[A]

[E]

22 March 1996 OVERALL MACHINE INFORMATION

1.5 BASIC OPERATI ON

[B]

[F]

[D]

[C]

A612V501-2.img

The finisher recognizes the base copier type by receivin g the copier’s paper

exit speed data when the main switch is turn ed on. The pa per transport

speed depends on the base copier.

After the copy is completed, the paper is directed to the finisher. If the

sort/stack mode is selecte d, the junction gate [A] dire cts the paper upwards

to send it to the shift tray [B]. In these modes, th e shif t tra y is shifte d fro m

side to side to stagge r and sepa rat e set s of cop ies. The amount of shift is

approximately 30 mm.

When the staple mode is selected, th e jun ctio n gate direct s the paper

downwards to send it to the jogger un it [C] . Ea ch time a copy is delive red to

the jogger unit, the position ing roller [D], the alignment brush ro ller [E ], and

the jogger fences [F ] squ are the stack of copies. After the final copy of the set

is squared, the set is stap led , an d th en delive red to th e shif t tray.

7

Finisher

Page 9

SECTIONAL DESCRIPTIONS 22 March 1996

2. SECTIONAL DESCRIPTIONS

2.1 PAPER DELIVERY S WITCHI NG

[B]

[A]

[C]

A612D500.img

Depending on the sele cte d finishing mode, the copie s are directed up or

down by the junction gate [A ], which is controlled by a solenoid. This

happens after the ent ran ce sen sor [C] has been activated.

(1) When the exit sensor of the copie r is activat ed while in sta ple mode , th e

solenoid [B] is energ ized . The n, the junction gate directs the copies down

to send them to the jogger unit.

(2) When the exit sensor of the copie r is activat ed while in th e sort /st ack

mode, the solenoid stays off. The junction gat e dire cts th e copies up to

send them to the shif t tra y.

8

Page 10

22 March 1996 SECTIONAL DESCRIPTIONS

2.2 SHIFT TRAY UP/DOWN MECHANI S M

[F]

[B]

[J]

[E]

[D]

[A]

[J]

[H]

[I]

[G]

[C]

A612D502.wmf

The shift tray lift motor (a dc mot or) [B ] con tro ls the vertica l posit ion of the

shift tray [A] through gears and timing belts [C]. When the main switch is

turned on, the tray is initialized at the upper position. The tray’s upper

position is detecte d whe n th e shift tray pushes up actuat or [D] unt il the

actuator has just left the stack height sensor 1 [E], and is now between the

two sensors [E] and [F] .

During copying, the actuator feeler gradually rises as the copy stack grows,

and the actuator gradu ally move s towa rds sta ck heig ht sensor 2. In sort/stack

mode, if the actuator remains inside stack height sensor 2 [F] for 4 s, the shift

tray lift motor lowers the tray unit for 50 ms. In staple mode, if th e act uato r

leaves stack height sen sor 1 fo r 4 s during a copy run , th e mot or lowe rs t he

tray until stack height senso r 1 is actua ted. This mean s the tray lowe rs earlie r

in staple mode, to preven t pro ble ms cause d by sud de n arrivals o f sta ple d

stacks of paper on the tray (sta plin g is don e insid e the machine, and the

stapled copy is fed out to th e tra y; the second copy may suddenly exceed the

space currently availab le on the tray).

For both modes, the shift tray will rise when the user takes th e sta ck of pape r

from the tray during cop ying.

When the tray reaches its lower limit, actuat or [H] enters th e lower limit

sensor [G], and cop ying stop s. After copying ends and th e mach ine stop s,

the tray is raised to its uppermost position 4 s after the copies are removed.

The shift tray upper limit switch [I] prevent s the drive gears fro m bein g

damaged if stack heig ht senso r 1 fa ils. When the shift tray pu she s up th e shif t

tray positioning roller [J], the switch cuts the power to the shift tray lift motor.

9

Finisher

Page 11

[E]

SECTIONAL DESCRIPTIONS 22 March 1996

2.3 SHIFT TRAY SIDE-TO-S IDE S HIFT MECHANI S M

[B][C]

[A]

[D]

[F]

[G]

[H]

A162D503.img

In the sort/stack mode, the shift tray [A ] move s from side to side to stagg er

and separate the set s of cop ies.

The horizontal position of the shift tray is controlled by the shift moto r (dc

motor) [B] and the shift cam (helical cam) [C]. After one set of origina ls is

copied and delivered to the shift tray, the shift motor [ B] start s rota tin g, driving

the shift cam through the timin g belt. The pin [D] fixe d to the shift tray base

plate [E] is position ed in the groo ve on the shift cam, creating the side-to-side

movement required to sta gg er th e cop ies.

When the shift cam has rotated 180 degrees (when the tray is fully shifted

across), the plate [F] on the shift cam pushes the actuator [G] of the shift tray

half-turn sensor [H] and the shift motor stops. The next set of copies is then

delivered. The moto r ro ta te s, rep ea ting the same process and moving the

tray back to the previous posit ion .

10

Page 12

[F]

[D]

22 March 1996 SECTIONAL DESCRIPTIONS

2.4 STAPLE UNIT PAPE R PO SITI O NING

[C]

[B]

[D]

[F]

[E]

[A]

[H]

[G]

[C]

A612D504.img

In staple mode, each sheet of cop y paper is vertically and horizontally

aligned when it arrives in the jogger unit.

For horizontal pape r align men t, the jogger motor [A] moves bot h th e front and

the rear jogger fences [B ] to align the copies.

For vertical paper alignment, th e positio nin g roller [C] an d the alignment

brush roller [D] push the copy again st th e stack stopper [E].

After the trailing edge of the copy passes th e jog ger unit entrance sensor [F],

the positioning roller sole no id [G ] is energized for 280 ms to push the

positioning roller int o conta ct with the paper. The positioning roller rotates to

push the paper back and align the trailin g edge of the pape r aga inst the stack

stopper. Both the positioning roller and the alignme nt brush roller are driven

by the lower transport drive motor throu gh the timing belt [H].

11

Finisher

Page 13

[B]

SECTIONAL DESCRIPTIONS 22 March 1996

2.5 JOGGER MOVEMENT

(2)(1) (3)

7 mm 2 mm

[A]

A612D505.wmf

When the Start key is pressed, the copie r sends the paper size inf ormation to

the finisher. In accorda nce with th at dat a, the jogg er mot or (ste pp er mot or)

starts rotating to position the front and rea r jogg er fe nce s [A] 7 mm away from

the selected paper’s edges. (1)

After the trailing edge of the copy passes th e jog ger unit entrance sensor,

each jogger fence moves inward 5 mm. They stop 2 mm away from the paper

edges. (2)

Just after the position ing roller pushes the copy back, each jogger fence

moves inward 2 mm more so that the leaf spring [B] on the rear jogg er fe nce

pushes the copy side ed ge slight ly. (3)

After a copy is stacked in the jogg er tra y, the jogger fences move back 7 mm

from the copy edge for the next copy.

12

Page 14

22 March 1996 SECTIONAL DESCRIPTIONS

2.6 STAPLER

[G]

[H]

[E]

[B]

[A]

[D]

[C]

[F]

A612D507.wmf

[J]

A612D506.wmf

The staple hammer [A] is drive n by th e sta ple r motor [B] via gears [C], two

eccentric cams [D], and two links [E] .

When the aligned copie s are bro ug ht to th e sta pling position by the

positioning roller, alignment brush roller and jogger fences, th e sta ple r moto r

starts. When the cams comp lete one rotation, th e sta ple hamme r h ome

position sensor [F] tu rns on , de te cting the end of the stapling ope rat ion. The

stapler motor then stops.

There are two sensors in the stapler un it. One is the staple end switch [G ] fo r

detecting staple en d con ditions (it detects when there is o nly one sheet of

staples left in the cartridg e). The othe r is the cartridge set switch [H] for

detecting whether a staple cartridge is installed.

When a staple end or no staple cart ridge condition is detecte d, a message is

displayed advising the opera to r to inst all a staple cartridge. If this condition is

detected during a copy job, the indication will appear, but will not stop the

copy job in any way.

Finisher

The staple cartridge has a clinch area [J], in which th e jamme d staples are

left. Operators can remo ve th e jamme d staples from the cartridge.

13

Page 15

SECTIONAL DESCRIPTIONS 22 March 1996

2.7 STAPLER UNIT SIDE-TO- SIDE MOV EME NT

[C]

[B]

[A]

A612D508.wmf

Customers can select one of the following three different staple mod es:

Staple 1: Top left

Staple 2: Bottom left

Staple 3: Top/Bottom left

The stapler drive motor [A ] (a ste pp er mot or) move s the stapler un it [B ] fro m

side to side. After the Start key is pressed, the stapler moves from its home

position to the sta ple posit ion .

If staple mode 3 is selected, the stap ler un it move s to th e fro nt staple po sitio n

first, then moves to the rear staple po sitio n. Howeve r, fo r t he next copy set , it

staples in the reverse ord er; tha t is, at the rear side first an d th en at th e fro nt.

After the job is complet ed , the stapler unit moves back to its ho me position.

(The stapler unit home position sensor [C] is actuated.)

14

Page 16

22 March 1996 SECTIONAL DESCRIPTIONS

2.8 FEED-OUT TO THE SHIFT TRAY

[E]

[A]

[B]

[D]

A612D509.img

[C]

[B]

After the copies ha ve be en stap led, the stack feed-out motor [A] starts. The

pawl [B] on the stack feed -ou t be lt [C] tran sports the set of stapled cop ies up ,

and feeds it to the shift tray. Approximately 0.6 second after the stack

feed-out motor starts, the motor stops for 400 ms. At this moment, the exit

rollers catch the stapled cop ies to feed th em out to the shift tray. Then the

motor rotates again until th e pawl actu at es th e sta ck feed-o ut belt home

position sensor [D].

The exit drive motor starts to drive the exit rollers [E ] whe n the first copy

activates the entrance sen sor. The exit drive mot or spe ed is reduce d just

before each sheet of copy pa pe r is complet ely fed out. This is to ensure an

even copy stack.

Finisher

15

Page 17

INSTALLATION PROCEDURE 22 March 1996

3. INSTALLATION PROCEDURE

[A]

[B]

A612I500.wmf

[C]

[D]

CAUTION

I

Unplug the power cord before begining the follow ing proc edur e.

In European countries only (step 1 ~ 4)

1. Peel off the backin g [A] of the double sided tap e af fixed to the copier

grounding plate [B].

2. Attach the copier grounding plate to the copier as shown.

3. Peel off the backin g [C] of the double sided ta pe aff ixed to the PFU

grounding plate [D].

4. Attach the PFU grounding plate to the paper feed unit as shown.

A612I501.wmf

16

Page 18

22 March 1996 INSTALLATION PROCEDURE

[B]

[A]

[B]

A612I502.wmf

[C]

[D]

[D]

[G]

[F]

[C]

A612I503.wmf

5. Remove the strips of tape [A ] an d the cushoins [B].

6. Open the front door and remove the strips of tap e [C] and cushions [D].

7. Extend the staple unit [F].

8. Remove the strip of tape [G].

Finisher

17

Page 19

INSTALLATION PROCEDURE 22 March 1996

[A]

[A]

[C]

[B]

[E]

A612I508.wmf

[F]

[D]

A612I504.wmf

9. Remove the screws [A] from th e lef t cove r.

10. Install the fro nt conn ect ing bracke t [B] (2 screws– M4 x 12) and the rear

connecting bracket [C] (2 screws– M4 x 12).

11. Affix the mylar strip [D] to the copy exit area, as shown .

NOTE: Carefully align the edge of the cover [E ] with the myla r gude.

12. Affix the cushion [F] to th e lower exit plate, as shown.

18

Page 20

[A]

[J]

22 March 1996 INSTALLATION PROCEDURE

[G]

[E]

[C]

[F]

[D]

[B]

A612I505.wmf

[K]

[L]

[K]

[H]

[I]

A612I506.wmf

13. Open the front door of the finisher and remove the screw [A], which

secures the locking lever [B]. Then pull the locking lever (This causes the

lever to move out and down).

14. Affix the cushion [C] on th e met al stay (not on the cover) as shown.

15. Install the entrance guid e pla te [D] (2 screws -M4 x 6).

16. Open the two clamps; remove the cable [E] and the fiber optic cable [F].

17. Remove the rear cover [G] (6 screws).

18. Align and install the finisher to the connecting brackets. Lock them in

place by raising the locking lever [H].

Finisher

NOTE: Ensure the mylar strip [I] is located betwee n the guides [J].

19. Secure the locking leve r [H] (1 screw) an d th e fin ishe r (2 screws [K] ).

20. Install the shift tra y [L] (4 screws – M4 x 8).

19

Page 21

INSTALLATION PROCEDURE 22 March 1996

[B]

[A]

A612I507.wmf

19. Reinstall the rear cover.

20. Connect the cable [A] and the fiber optic connector [B].

21. Plug in the copier.

22. Turn on the main switch and test the newly inst alle d finisher’s operation.

NOTE: The copier automatically re cog nize s tha t th e fin ishe r has be en

installed. The stapler will begin stap ling after ab ou t 10 copie s

(This allows the first staple to come to the pro pe r posit ion in the

cartridge).

20

Page 22

22 March 1996 SERVICE TABLES

4. SERVICE TABLES

4.1 TEST POINT TABLE (MAIN BOARD)

Number Function

TP100 GND

TP101 5 V

TP102 24 V

4.2 FUSE TABLE

Number Rated Current Location

Fuse 100 5A Main PCB

4.3 LED TABLE

LED No. ON Status During Adjustment

LED100 Stack feed-out motor speed is normal.

*NOTE:Adjust the speed of the stack fe ed -ou t mot or by setting DIP SW

100/101 to Moto r Test Mod e (see belo w). The n ad just VR10 0. If

the motor speed is either too high or too low, LED 100 will blink.

4.4 DIP SW TABLE

4.4.1 Factory Setting

DIP SW100 DIP SW101

12341234

00000000

4.4.2 Motor Test Mode

DIP SW100 DIP SW101

12341234

11011000

Stack Feed-out Motor

After setting DIP SW10 0, turn on switch 1 of DIP SW10 1 to start

the stack feed-out motor. Turn off DIP SW101-1 to sto p th e motor.

Motor

Finisher

21

Page 23

SERVICE TABLES 22 March 1996

4.4.3 Free Run Test Mode Without Paper

DIP SW100 DIP SW101

12341234

11101000

11100100

11100010

11100001

Shift tray mode

Staple mode - Top left

Staple mode - Bottom left

Staple mode -

Test Type

Top/Bott om lef t

Start the free run test mode by chan gin g DIP SW10 0 then DIP SW101

to select the require d te st as shown in the table.

In shift tray mode, the fin ishe r wo rks as if 10 sets of 5 LT pa ges

are being sorted. The mach ine the n initializes itself and repeats the

operation.

In staple mode, th e fin ishe r wo rks as if 5 sets of 5 LT pages are being

stapled and delivered. The machine then initializes itself and rep ea ts th e

operation.

22

Page 24

[E]

[F]

[B]

22 March 1996 REPLACEMENT AND ADJUSTMENT

5. REPLACEMENT AND ADJUSTMENT

5.1 EXTERIOR REMOVAL

[G]

[A]

[C]

[D]

[H]

[I]

[J]

A612R500.img

[I]

1. Remove the left upper cover [A] (2 screws).

2. Remove the upper cover [B] (3 screws).

3. Remove the upper door bra cket [C] (1 screw) and remove the front door

[D].

4. Remove the lower front cover [E ] (2 screws).

5. Remove the front shif t cove r [F] (2 screws).

6. Remove the rear cover [G] (6 screws).

7. Remove the shift tray [H] (4 screws).

NOTE: The shift tray cannot be remove d if it is at its uppe rmost posit ion .

Bring the shift tray down by ma nually turning the shift tray lift

motor timing belt.

8. Remove the fron t and rear tray cover [I] (1 screw at the fro nt, 2 screws at

the rear).

9. Remove the left cover [J] (4 screws).

Finisher

23

Page 25

[I]

REPLACEMENT AND ADJUSTMENT 22 March 1996

5.2 ALIGNMENT BRUSH ROLLER REPLACEMENT

[B]

[D]

[A]

[C]

[H]

[J]

A612R501.wmf

[I]

[H]

[E]

[F]

[G]

[E]

[F]

A612R502.img

1. Open the front door and slid e out the jogger unit .

2. Remove the rear cover.

3. Loosen the screw [A] and flip the tension bracket [B] to release the

tension of the lower t ran spo rt drive belt.

4. Remove the E-ring [C], slide out the pulley [D], remove 2 E-rings [E], then

remove 2 bushings [F].

NOTE: When reinstalling, th e metal bushing goes at the fron t side.

5. Remove the alignmen t bru sh rolle r assemb ly [G] .

6. Remove the 2 E-rings [H] and th e bru sh rolle rs [ I] .

NOTE: Do not lose the link keys [J].

24

Page 26

22 March 1996 REPLACEMENT AND ADJUSTMENT

5.3 STACK HEIGHT SENSOR REPLACE MENT

[E]

[B]

[C]

[D][A]

A612R503.img

1. Remove the upper cover.

2. Remove the stack heigh t sen sor act ua to r [A] (1 screw).

3. Remove the bracket [B ] (1 screw, 2 connect ors).

4. Replace stack height sensor 1 [C] and stack height sensor 2 [D].

NOTE: When reinstalling the bracket [B], align the edge of the bracket

with the stay [E].

Finisher

25

Page 27

REPLACEMENT AND ADJUSTMENT 22 March 1996

5.4 POSITIONING ROLLER REPLACEMENT

[A]

1. Open the front door and slid e out the jogger unit .

2. Remove the position ing roller [A ] (1 sna p ring).

A612R504.img

26

Page 28

[B]

22 March 1996 REPLACEMENT AND ADJUSTMENT

5.5 BELT TENSION ADJUSTMENT

[C]

[A, B]

[a, b]

[C]

[A]

A612R507.wmf

A612R510.wmf

[D]

A612R511.img

1. Remove the rear cover an d adjust the

tension of belt [A] with tightener [a ].

Remove the left upper co ver, the upper

cover, the front door , th e fro nt shift cover and

the lower front cover (2 screws). Ad just the

belt [B] with tighte ne r [b] .

Standard: 6 mm deflection at 50 ± 20 g

pressure.

2. Open the front do or and slide out the jogger

unit. Adjust the te nsio n of belt [C] with

tightener [c].

Finisher

A612R508.wmf

[c]

Standard: 8 mm deflection at 100 ± 30 g

pressure.

27

Page 29

REPLACEMENT AND ADJUSTMENT 22 March 1996

[D]

[d]

150 ± 40 g

A612R509.img

3. Open the front door and slide out the jogge r unit . Ad just the tension of

belt [D] with tightener [d].

Standard: 8 mm deflection at 150 ± 40 g pressure.

28

Page 30

FINISHER (A612) ELECTRICAL COMPONENTS

23

22

21

20

19

18

24

25

26

27

28

1

2

3

4

5

6

7

8

9

10

11

12

17

16

13

14

15

Page 31

Index. No. Index No. Description P to P

1 S8 Stack Height 2 Sensor F2

2 S7 Stack Height 1 Sensor G2

3 S6 Exit Sensor G2

4 SW2 Shift Tray Upper Limit Switch F18

5 M4 Stack Feed-out Motor J16

6 S11 Shift Tray Half Turn Sensor F2

7 M7 Shift Motor E18

8 S3 Jogger Unit Paper Sensor H4

9 S4 Stack Feed-out Belt HP Sensor J4

10 S12 Stapler Unit HP Sensor I4

11 SW4 Staple End Switch L3

12 SW3 Cartridge Set Switch L3

13 M8 Staple Motor K2

14 S10 Staple Hammer HP Sensor L3

15 S9 Shift Tray Lower Limit Sensor E4

16 PCB1 Main Control Board C10

17 M6 Staple Drive Motor H17

18 S5 Jogger HP Sensor I4

19 M5 Jogger Motor I17

20 SOL1 Positioning Roller Solenoid F17

21 M1 Transport Drive Motor C17

22 M9 Lower Transport Drive Motor K17

23 SOL2 Junction Gate Solenoid D17

24 S2 Jogger Unit Entrance Sensor E4

25 M2 Shift Tray Lift Motor D2

26 S1 Entrance Sensor D4

27 M3 Exit Drive Motor G17

28 SW1 Front Door Safety Switch L17

Loading...

Loading...