Ricoh S-P2 Service Manual

Model S-P2

Machine Code: M001

SERVICE MANUAL

September, 2008

Subject to change

Safety, Conventions, Trademarks

Safety

Prevention of Physical Injury

1. Before disassembling or assembling parts of the printer and peripherals, make sure that the printer

power cord is unplugged.

2. The wall outlet should be near the printer and easily accessible.

3. Note that some components of the printer and the paper tray unit are supplied with electrical voltage

even if the main power switch is turned off.

4. If any adjustment or operation check has to be made with exterior covers off or open while the main

switch is turned on, keep hands away from electrified or mechanically driven components.

5. The inside and the metal parts of the fusing unit become extremely hot while the printer is operating.

Be careful to avoid touching those components with your bare hands.

6. To prevent a fire or explosion, keep the machine away from flammable liquids, gases, and aerosols.

Health Safety Conditions

Toner and developer are non-toxic, but if you get either of them in your eyes by accident, it may cause

temporary eye discomfort. Try to remove with eye drops or flush with water as first aid. If unsuccessful, get

medical attention.

Observance of Electrical Safety Standards

The printer and its peripherals must be installed and maintained by a customer service representative who

has completed the training course on those models.

Safety and Ecological Notes For Disposal

1. Do not incinerate toner bottles or used toner. Toner dust may ignite suddenly when exposed to an

open flame.

2. Dispose of used toner, developer, and organic photoconductors in accordance with local regulations.

(These are non-toxic supplies.)

3. Dispose of replaced parts in accordance with local regulations.

4. When keeping used lithium batteries in order to dispose of them later, do not put more than 100

batteries per sealed box. Storing larger numbers or not sealing them apart may lead to chemical

reactions and heat build-up.

1

• The controller board in this machine contains a lithium battery.

• The danger of explosion exists if a battery of this type is incorrectly replaced. Replace only with the

same or an equivalent type of battery recommended by the manufacturer.

• Dispose of batteries in accordance with the manufacturer's instructions and local laws and regulations.

LASER SAFETY

The Center for Devices and Radiological Health (CDRH) prohibits the repair of laser-based optical units

in the field. The optical housing unit can only be repaired in a factory or at a location with the requisite

equipment. The laser subsystem is replaceable in the field by a qualified Customer Engineer. The laser

chassis is not repairable in the field. Customer engineers are therefore directed to return all chassis and

laser subsystems to the factory or service depot when replacement of the optical subsystem is required.

• Use of controls, or adjustment, or performance of procedures other than those specified in this manual

may result in hazardous radiation exposure.

• Turn off the main switch before attempting any of the procedures in the Laser Unit section. Laser beams

can seriously damage your eyes.

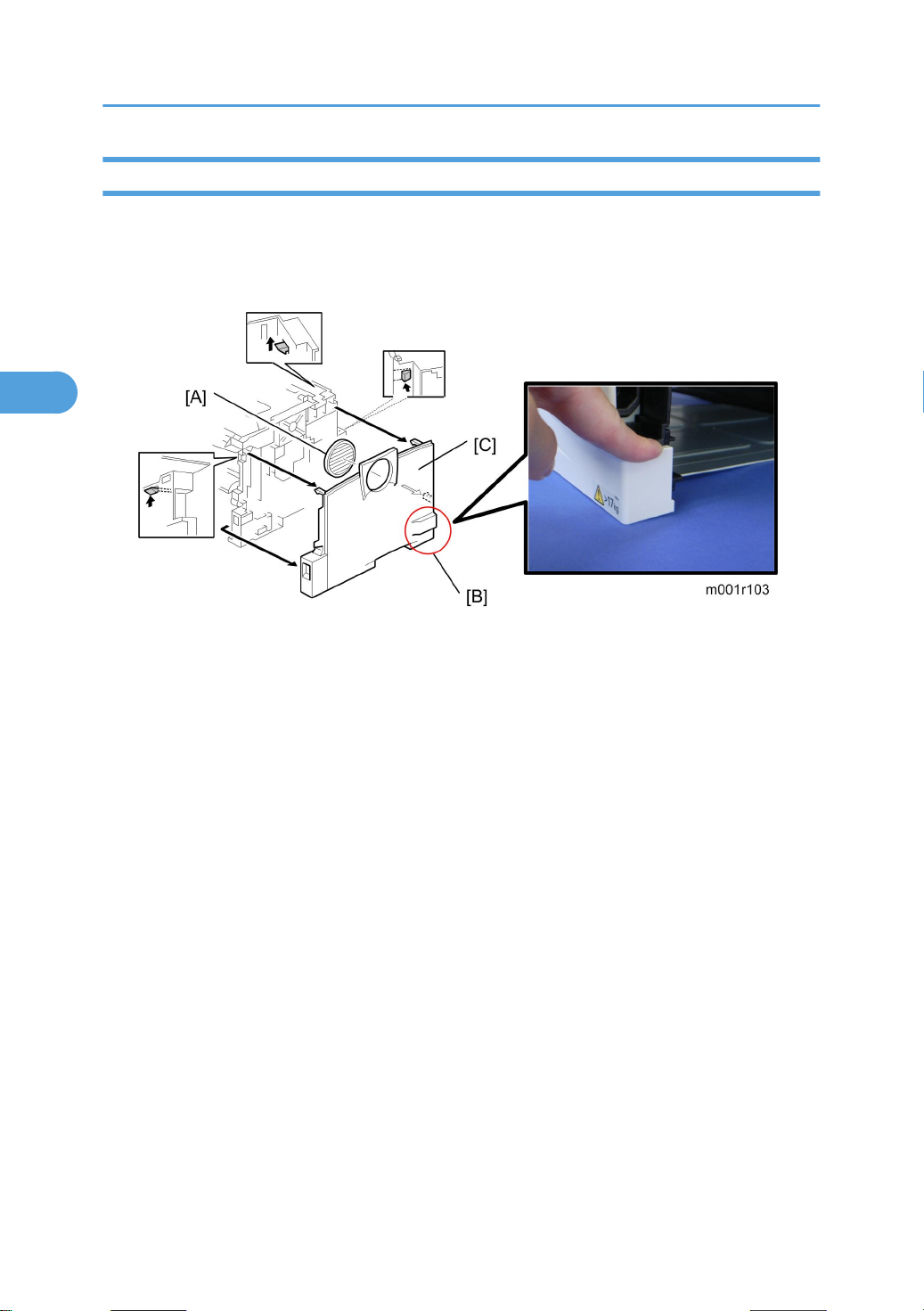

Caution Labels

2

Conventions and Trademarks

Conventions

Symbol What it means

* Refer to section number

See Core Tech Manual for details

Screw

Connector

E-ring

C-ring

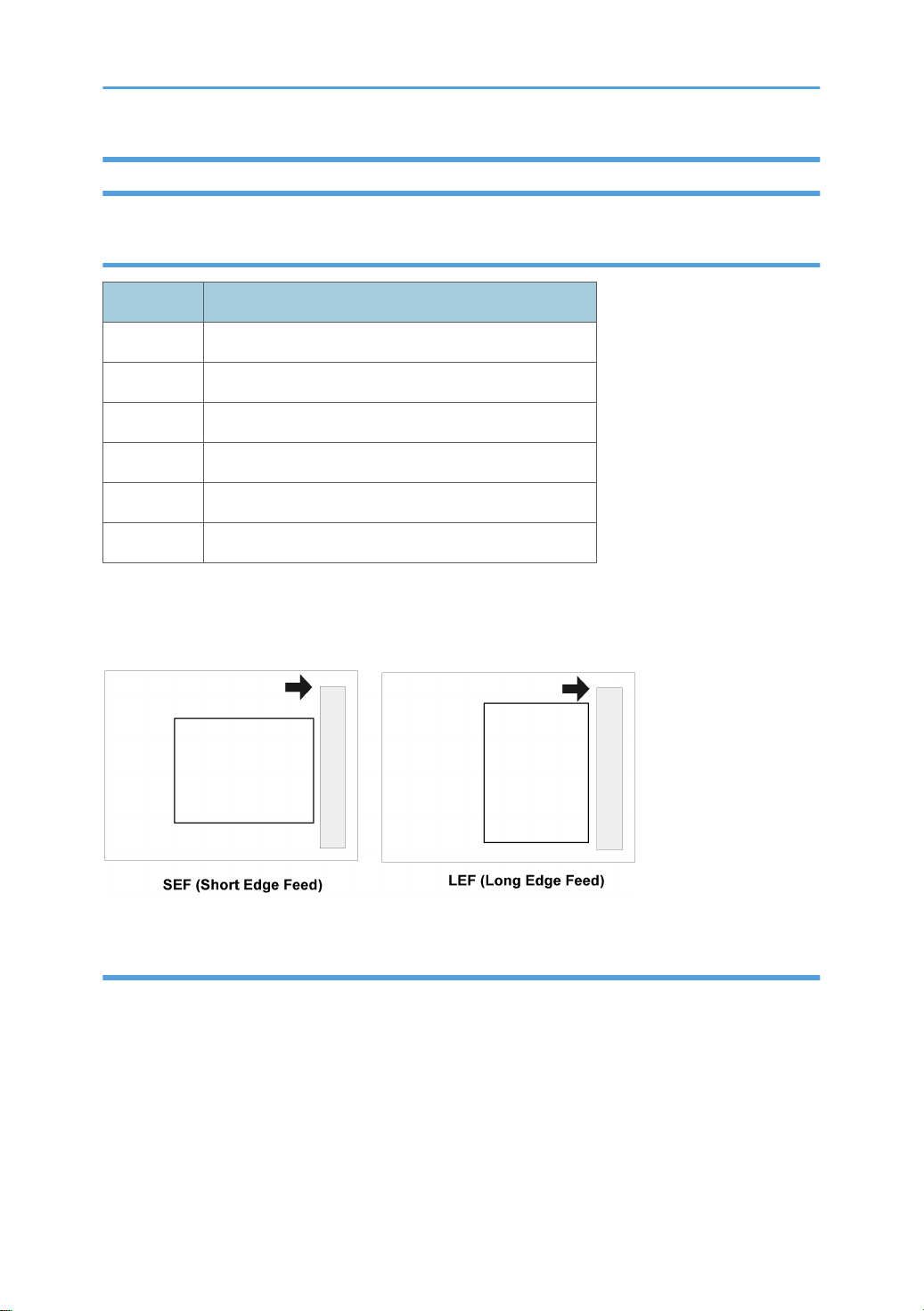

The following notations are used in text to describe the direction of paper feed: lengthwise and sideways.

The annotations “SEF” and “LEF” denote “Short Edge Feed” and “Long Edge Feed". (The arrows indicate

the direction of paper feed.)

Trademarks

Microsoft®, Windows®, and MS-DOS® are registered trademarks of Microsoft Corporation in the United

States and /or other countries.

PostScript® is a registered trademark of Adobe Systems, Incorporated.

PCL® is a registered trademark of Hewlett-Packard Company.

Ethernet® is a registered trademark of Xerox Corporation.

PowerPC® is a registered trademark of International Business Machines Corporation.

3

Other product names used herein are for identification purposes only and may be trademarks of their

respective companies. We disclaim any and all rights involved with those marks.

This manual uses several symbols and some simple abbreviations.

4

TABLE OF CONTENTS

Safety, Conventions, Trademarks......................................................................................................................1

Safety..............................................................................................................................................................1

Conventions and Trademarks........................................................................................................................3

1. Installation

Installation Requirements.................................................................................................................................11

Environment..................................................................................................................................................11

Machine Level .............................................................................................................................................12

Required Space ..........................................................................................................................................12

Power Supply ..............................................................................................................................................12

Machine Installation ........................................................................................................................................14

Data Overwrite Security Unit Installation.......................................................................................................15

Installation....................................................................................................................................................15

Checking and Completing the Installation.................................................................................................16

2. Preventive Maintenance

User Maintenance............................................................................................................................................17

Service Maintenance.......................................................................................................................................18

3. Replacement and Adjustment

General.............................................................................................................................................................21

Precautions on Disassembly .......................................................................................................................21

Releasing Plastic Latches.............................................................................................................................22

After servicing the machine.........................................................................................................................22

Special Tools ...................................................................................................................................................24

Covers...............................................................................................................................................................25

Upper Cover................................................................................................................................................25

Left Cover......................................................................................................................................................26

By-Pass Tray Unit.........................................................................................................................................26

Front Cover...................................................................................................................................................27

Right Cover...................................................................................................................................................28

Laser Unit..........................................................................................................................................................29

Caution Decal Locations ............................................................................................................................29

Polygon Mirror Motor ................................................................................................................................29

Laser Synchronization Detector..................................................................................................................30

Laser Unit......................................................................................................................................................31

5

Laser Diode Unit...........................................................................................................................................32

Laser Beam Pitch Adjustment ......................................................................................................................33

Transfer Roller ..................................................................................................................................................35

Toner End Sensor ............................................................................................................................................36

Fusing................................................................................................................................................................37

Fusing Unit....................................................................................................................................................37

Hot Roller and Fusing Lamp .......................................................................................................................37

Pressure Roller..............................................................................................................................................40

Thermistor and Thermostat .........................................................................................................................40

Hot Roller Strippers .....................................................................................................................................41

Paper Feed........................................................................................................................................................42

Paper Feed Roller .......................................................................................................................................42

Friction Pad ..................................................................................................................................................43

By-pass Tray.....................................................................................................................................................44

Printer Controller Board ..................................................................................................................................45

Engine Board ...................................................................................................................................................46

Main Motor......................................................................................................................................................47

Clutches.............................................................................................................................................................48

By-pass Feed Clutch and Relay Clutch......................................................................................................48

Paper Feed Clutch and Registration Clutch...............................................................................................49

PSU, HVPS........................................................................................................................................................51

Fans...................................................................................................................................................................53

Cooling Fan..................................................................................................................................................53

PSU Fan........................................................................................................................................................53

4. Troubleshooting

Service Call Conditions...................................................................................................................................55

Summary.......................................................................................................................................................55

SC Code Descriptions.................................................................................................................................55

Error Messages................................................................................................................................................69

General Troubleshooting.................................................................................................................................75

Image Adjustment........................................................................................................................................75

Electrical Defects..........................................................................................................................................75

Skew Adjustment..........................................................................................................................................78

6

Streaks in the Sub Scan Direction...............................................................................................................78

Miscellaneous Problems..............................................................................................................................79

5. Service Tables

Service Program Mode ..................................................................................................................................81

Service Program Mode: Overview.............................................................................................................81

Printer Controller Service Mode ....................................................................................................................83

Bit Switch Programming...............................................................................................................................83

Service Mode Menu ("1. Service Menu").................................................................................................83

Printer Engine Service Mode...........................................................................................................................87

Service Mode Table....................................................................................................................................87

Firmware Update...........................................................................................................................................145

Type Of Firmware.....................................................................................................................................145

Precautions.................................................................................................................................................145

Machine Firmware Update......................................................................................................................146

NVRAM Data Upload/Download..............................................................................................................148

Uploading NVRAM Data.........................................................................................................................148

Downloading NVRAM Data....................................................................................................................149

SD Card Application Move..........................................................................................................................151

Overview....................................................................................................................................................151

Move Exec.................................................................................................................................................151

Undo Exec..................................................................................................................................................152

Controller Self Test at Power-On..................................................................................................................154

Menu Mode ..................................................................................................................................................155

Controller Board DIP Switches ....................................................................................................................160

Card Save Function.......................................................................................................................................161

Overview....................................................................................................................................................161

Procedure...................................................................................................................................................161

Error Messages..........................................................................................................................................163

6. Details

Overview........................................................................................................................................................165

Mechanical Component Layout ..............................................................................................................165

Paper Path .................................................................................................................................................166

Board Structure..............................................................................................................................................167

7

Block Diagram ..........................................................................................................................................167

Controller Board .......................................................................................................................................167

Printing Process..............................................................................................................................................169

Overview ...................................................................................................................................................169

Laser Exposure ..........................................................................................................................................170

Cartridge Overview .................................................................................................................................173

Drum Charge ............................................................................................................................................174

Development..............................................................................................................................................174

Toner End Detection .................................................................................................................................176

Paper Feed.....................................................................................................................................................181

Overview ...................................................................................................................................................181

Paper Tray .................................................................................................................................................182

By-pass tray ..............................................................................................................................................187

Image Fusing and Paper Exit........................................................................................................................188

Overview ...................................................................................................................................................188

Fusing Drive ..............................................................................................................................................189

Fusing Entrance and Guide Shaft ............................................................................................................189

Pressure Roller ..........................................................................................................................................190

New Fusing Unit Detection ......................................................................................................................191

Fusing Temperature Control ....................................................................................................................192

Paper Exit ..................................................................................................................................................194

Energy Saver Mode .................................................................................................................................194

Controller Functions.......................................................................................................................................196

7. Specifications

Basic Specifications.......................................................................................................................................197

General Specifications..............................................................................................................................197

External Options........................................................................................................................................199

Paper Sizes................................................................................................................................................200

Operating Environment.............................................................................................................................203

Operation Panel LED Specifications........................................................................................................203

Controller Specifications...............................................................................................................................205

Controller Board........................................................................................................................................206

Printing Functions.......................................................................................................................................207

8

Printer Drivers.............................................................................................................................................207

Supported Environments...........................................................................................................................209

Controller Interface Specifications...........................................................................................................212

Supported Utilities.....................................................................................................................................213

Machine Configuration ................................................................................................................................215

System Components..................................................................................................................................215

9

10

1. Installation

1

Installation Requirements

Environment

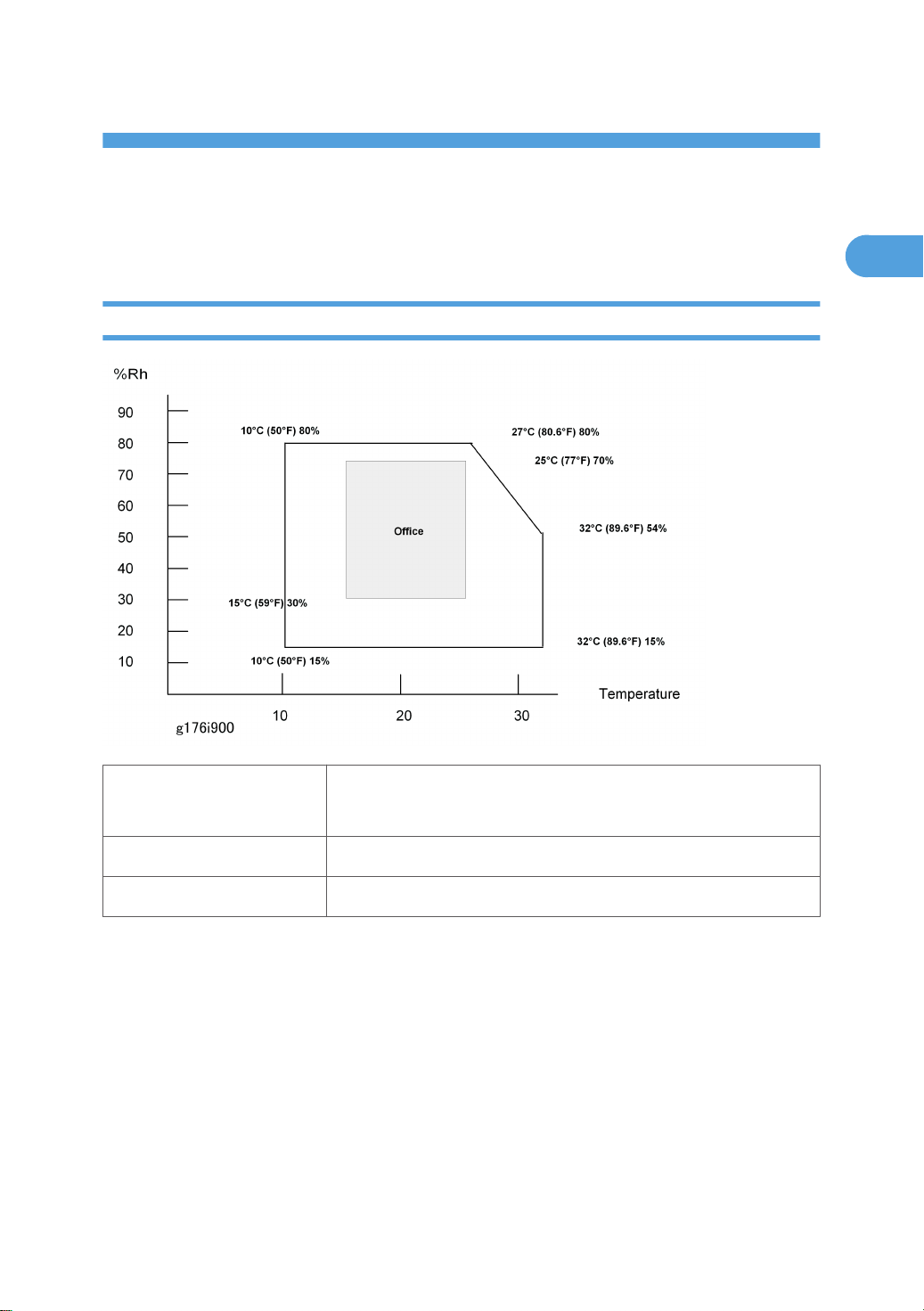

Temperature/Humidity

Ranges:

Ambient Illumination: Less than 2000 lux (do not expose to direct sunlight).

Ventilation: 3 times/hr/person

1. Avoid areas that are exposed to sudden temperature changes. This includes:

• Areas directly exposed to cool air from an air conditioner.

• Areas directly exposed to heat from a heater.

2. Do not install this machine in an area where it will be exposed to corrosive gases.

3. Do not install the machine at locations over 2,500 m (8,125 ft.) above sea level.

4. Put the machine on a strong and level base. Inclination on any side should not exceed 5 mm.

5. Do not put the machine where it may be subjected to strong vibrations.

Acceptable: 10C (50F) 15% to 27C (80.6F) 80%

Recommended (Office): 15C (59F) 30% to 25C (77F) 70%

11

1. Installation

1

Machine Level

Front to back: Within 5 mm. (0.2 inches) of level.

Right to left: Within 5 mm. (0.2 inches) of level.

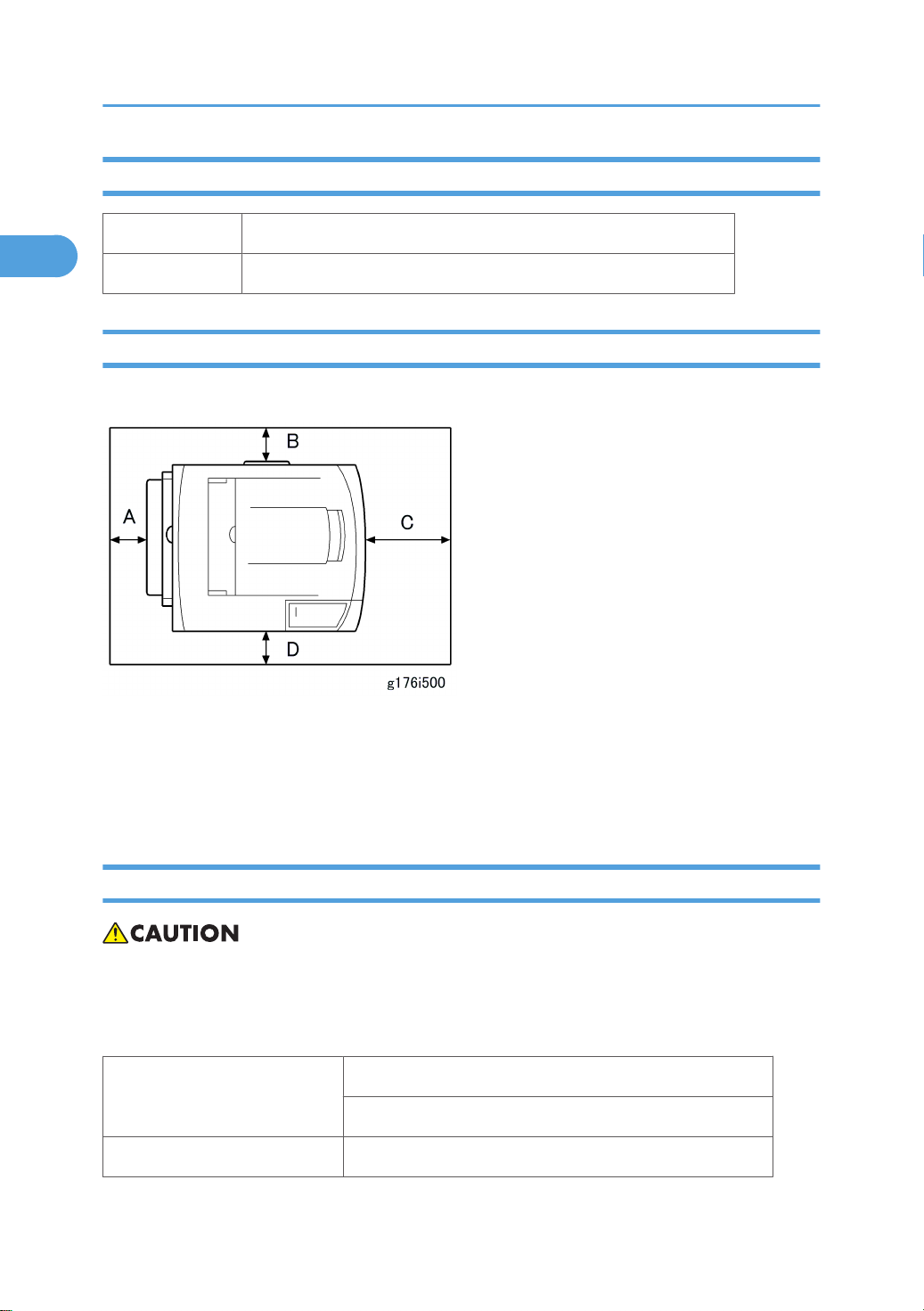

Required Space

Place the machine near the power source, providing the clearance as shown below:

A: Over 10 cm (4 inches)

B: Over 10 cm (4 inches)

C: Over 40 cm (15.8 inches)

D: Over 10 cm (4 inches)

Power Supply

• Make sure the plug is firmly inserted in the outlet.

• Avoid multi-wiring.

• Be sure to ground the machine.

NA: 120 volts, 60 Hz

Input voltage level

EU: 220-240 volts, 50 Hz/60 Hz

Permitted voltage Fluctuation: ±10 %

12

• Never place anything on the power cord.

1

Installation Requirements

13

1. Installation

1

Machine Installation

Refer to the following sections of the “Operating Instructions” for installation details for all models.

Main unit - Quick Installation Guide

Paper Feed Unit G894 Paper Feed Unit TK1030

Envelope Feeder G362 Envelope Feeder Type400

Duplex Unit G893 AD1000 (Duplex Unit)

Memory Unit Type G 128 MB M354

Memory Unit Type G 256 MB D362

Hard Disk Drive Type 2670 M352

IEEE 802.11a/g interface Unit Type L

Options

Drivers - Section 1 of the Software Guide

*1: These units cannot be installed at the same time.

M344 (NA) *1

IEEE 802.11a/g interface Unit Type M M344 (EU)

*1

IEEE 1284 Interface Board Type A B679

Gigabit Ethernet Board Type A G874 *1

VM Card Type K M354

Data Storage Card Type A G874

Data Overwrite Security Unit Type L M352

SD Card for Netware Printing Type B M352 Software Guide, Section 6

Hardware Guide, Section 2

14

Data Overwrite Security Unit Installation

1

Data Overwrite Security Unit Installation

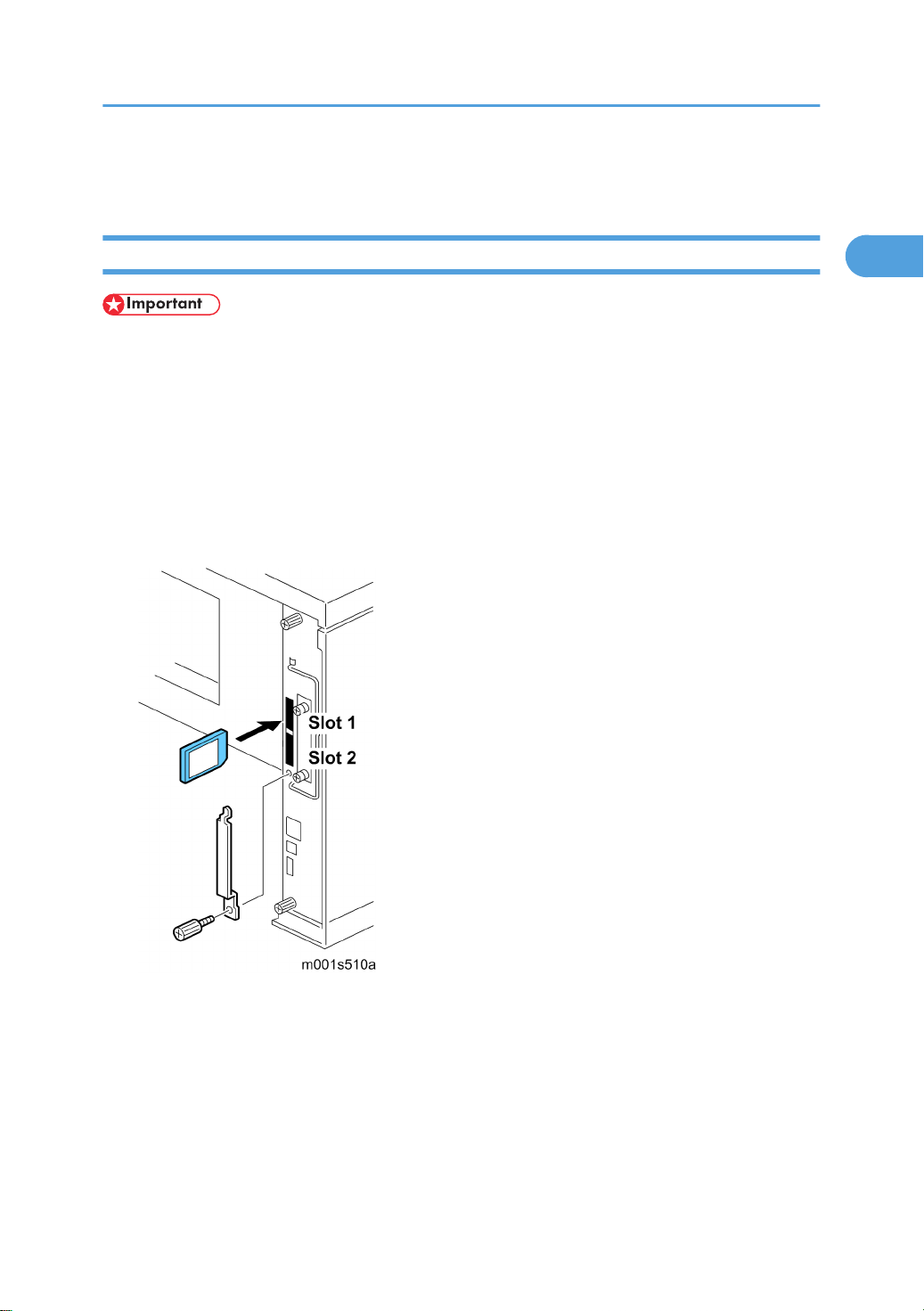

Installation

• The correct number and type for this installation is Type L. Do not attempt to install any other type

(Type C, Type D, for example).

• The SD card that holds the DOS application must always reside in SD card slot 1. (This can be the

original SD or another SD card where the DOS application has been moved with SP5873.)

1. If the machine is on, turn off the main power switch.

2. Disconnect the network cable.

3. Turn the main power switch on.

4. Turn the operation switch and main power switch off.

5. Remove the SD card slot cover (x1).

6. Insert the DOS SD card into Slot 1.

7. Reconnect the network cable, if the network is connected to the copier.

8. Turn the main power switch on.

9. Enter the SP mode and do SP5878 and push [#Enter] to enable the DOS application.

10. Go out of the SP mode, turn the operation switch off, then turn the main power switch off.

15

1. Installation

1

Checking and Completing the Installation

Do this procedure to confirm that the data overwrite security feature is enabled and operating.

1. Turn the machine power on.

2. .Do SP5990 005 (Diagnostic Report) to print the diagnostic report

3. Check the diagnostic report.

• Under [ROM No./Firmware Version] you should see "M3525814" displayed for "HDD Format

Option".

• Under [Loading Program] you should see "GW1a_zoffy: M3525814"

Important

• The numbers in the diagnostic report must match. (The ROM number and firmware version

number change after the firmware has been upgraded.)

• If the ROM numbers or version numbers do not match, this means that the DOS unit type was

incorrect (not "Type L"),

• If this occurs:

(1) Obtain the Type L DOS unit card or confirm that the DOS unit is Type L.

(2) Replace the NVRAM on the controller board.

(3) Insert the Type L DOS unit SD card in Slot 2.

(4) Do the DOS unit installation procedure again.

4. Push and release in this order: [#Enter]> [Escape]> [Menu].

5. Push [] or [] to display "Maintenance" then push [#Enter].

6. Push [] or [] to display "Memory Erase" and "Erase All Mem."

7. If you see "Memory Erase" and "Erase All Mem." in the selections, then the DOS application has been

enabled and is operating.

16

2. Preventive Maintenance

2

User Maintenance

The customer can replace all PM items with the Maintenance Kit.

The user can maintain this machine. For more see "Printer Engine Service Mode".

The operation panel shows “Replace Maintenance Kit” when the PM counter reaches 90K. After the user

replaces the fusing unit in the maintenance kit, the machine automatically resets the PM counter.

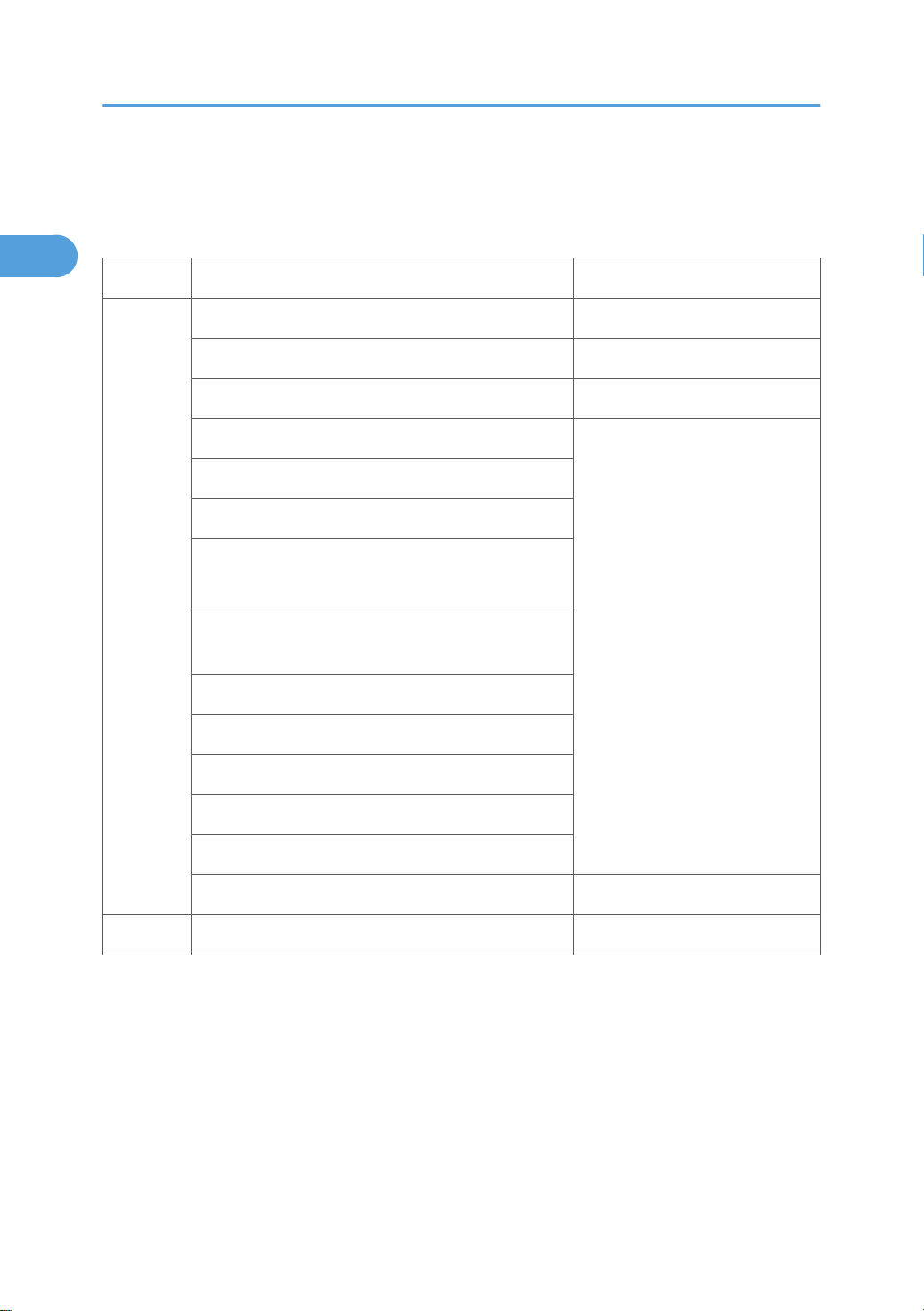

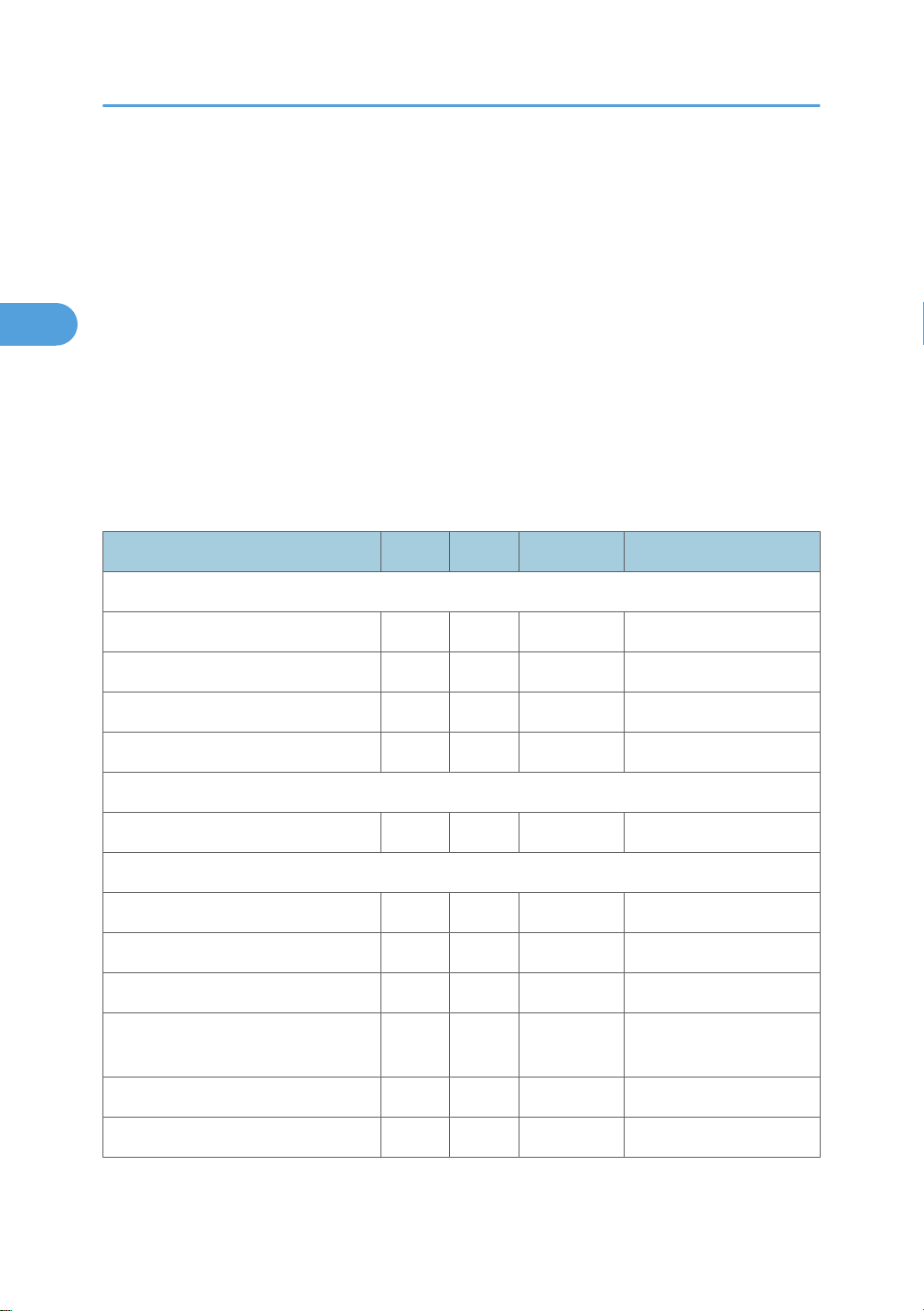

Item Quantity Remarks

Fusing unit 1 -

Transfer roller 1 -

Paper feed roller 3 For standard and optional tray(s)

Friction pad 3 For standard and optional tray(s)

17

2. Preventive Maintenance

2

Service Maintenance

To enable the machine for maintenance by the service technician, the meter-charge mode must be set to

“enabled” with SP5930.

The table below shows the PM items serviced by the service technician.

After completing a PM procedure, reset the PM counter for the replaced part with SP7-804.

Symbol key:

• C: Clean

• R: Replace

• L: Lubricate

• I: Inspect

Main unit

Item 90K EM Quantity Remarks

Paper Feed

Paper Feed Roller R C 1 Clean with water

Friction Pad R C 1 Clean with water

Registration Roller C C 1 Clean with water

Bottom Plate Pad C C 1 Clean with water

Around the Drum

Transfer Roller R 1

Fusing Unit and Paper Exit

Hot Roller R 1

Pressure Roller R 1

Hot Roller Strippers R 3

Fusing Thermistor R C 1

Bushings - Hot Roller R 2

Bushings - Pressure Roller R 2

Clean with alcohol if

necessary.

18

Service Maintenance

2

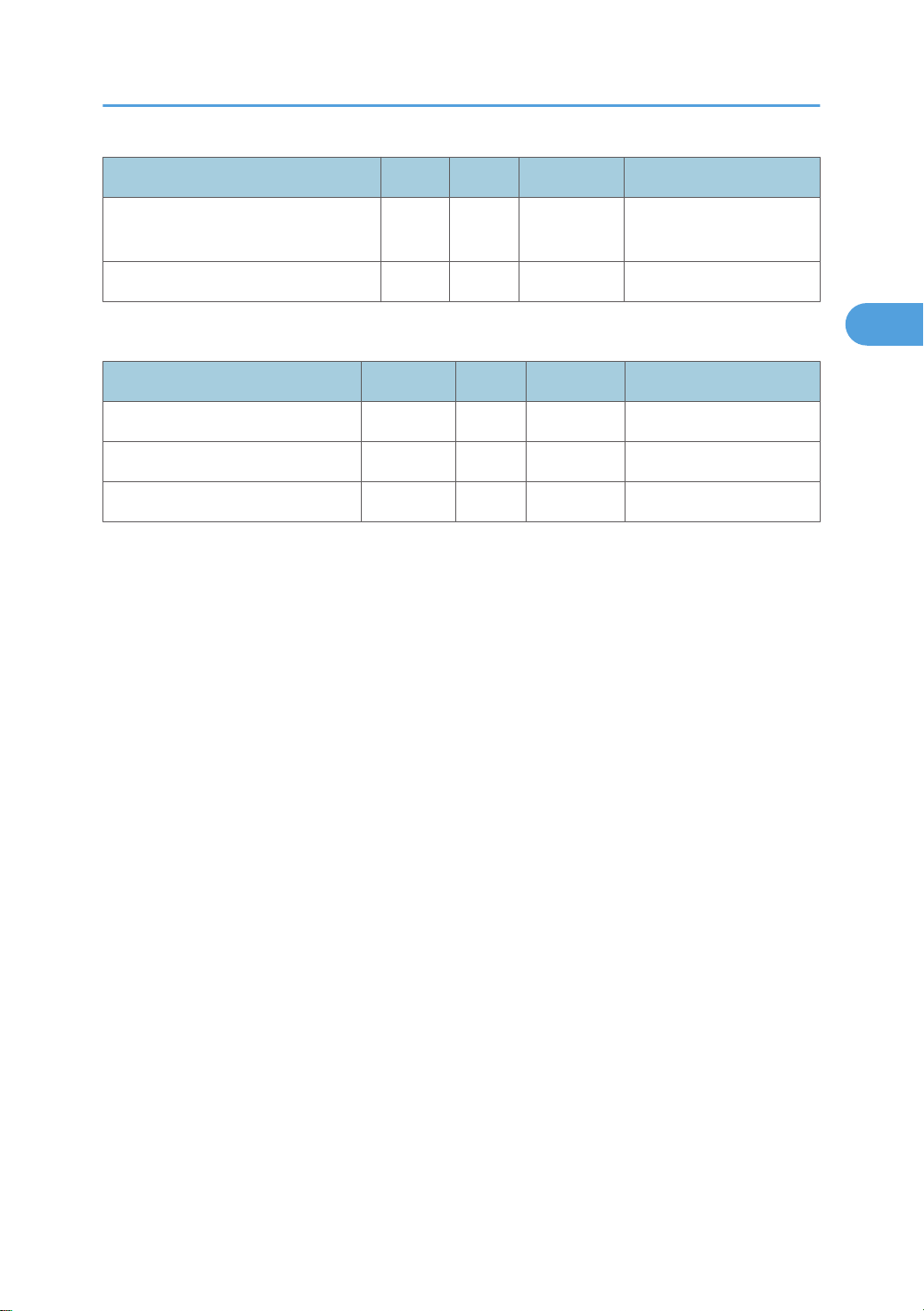

Item 90K EM Quantity Remarks

Fusing Entrance and Exit Guide Plates C 1 each

Fusing Unit Ass'y 110V/220 V R 1

Paper Tray Unit

90K EM Quantity NOTE

Paper Feed Roller R C 1 Clean with water

Friction Pad R C 1 Clean with water

Bottom Plate Pad C C 1 Clean with water

Clean with water or

alcohol

19

2. Preventive Maintenance

2

20

3. Replacement and Adjustment

3

General

Precautions on Disassembly

• Always turn off the main power switch and unplug the machine before attempting any of the

procedures in this section.

Use extreme caution when removing and replacing components. The cables in the machine are located

very close to moving parts; proper routing is a must.

After components have been removed, any cables that have been displaced during the procedure must

be restored as close as possible to their original positions. Before removing any component from the

machine, note any cable routings that may be affected.

Before servicing the machine:

1. Verify that documents are not stored in memory.

2. Remove the print cartridge before you remove parts.

3. Unplug the power cord.

4. Work on a flat and clean surface.

5. Replace with authorized components only.

6. Do not force plastic material components.

Make sure all components are returned to their original positions.

Laser Unit

1. Do not loosen or adjust the screws securing the LD drive board on the LD unit. Doing so will throw the

LD unit out of adjustment.

2. Do not adjust the variable resistors on the LD unit, as these are permanently adjusted at the factory.

If replacement of the LD drive board is necessary, replace the entire LD unit.

3. Keep the polygon mirror and toroidal lens free of dust. Laser performance is very sensitive to dust on

these components.

4. Do not touch the shield glass or the surface of the polygon mirror with bare hands.

5. Do not adjust the Laser Synchronization detector on the LD unit, as these are permanently adjusted

at the factory. If the position of the Laser Synchronization detector has changed from the factory set

position, SC 322 will be shown.

Transfer Roller

1. Never touch the surface of the transfer roller with bare hands.

21

3. Replacement and Adjustment

3

2. Be careful not to scratch the transfer roller, as the surface is easily damaged.

Fusing

1. After installing the fusing thermistor, make sure that it is in contact with the hot roller and that the roller

can rotate freely.

2. Be careful to avoid damage to the hot roller stripper pawls and their tension springs.

3. Do not touch the fusing lamp and rollers with bare hands.

4. Make sure that the fusing lamp is positioned correctly and that it does not touch the inner surface of

the hot roller.

Paper Feed

1. Do not touch the surface of paper feed rollers.

2. To avoid misfeeds, the side and end fences in each paper tray must be positioned correctly so as to

align with loaded paper size.

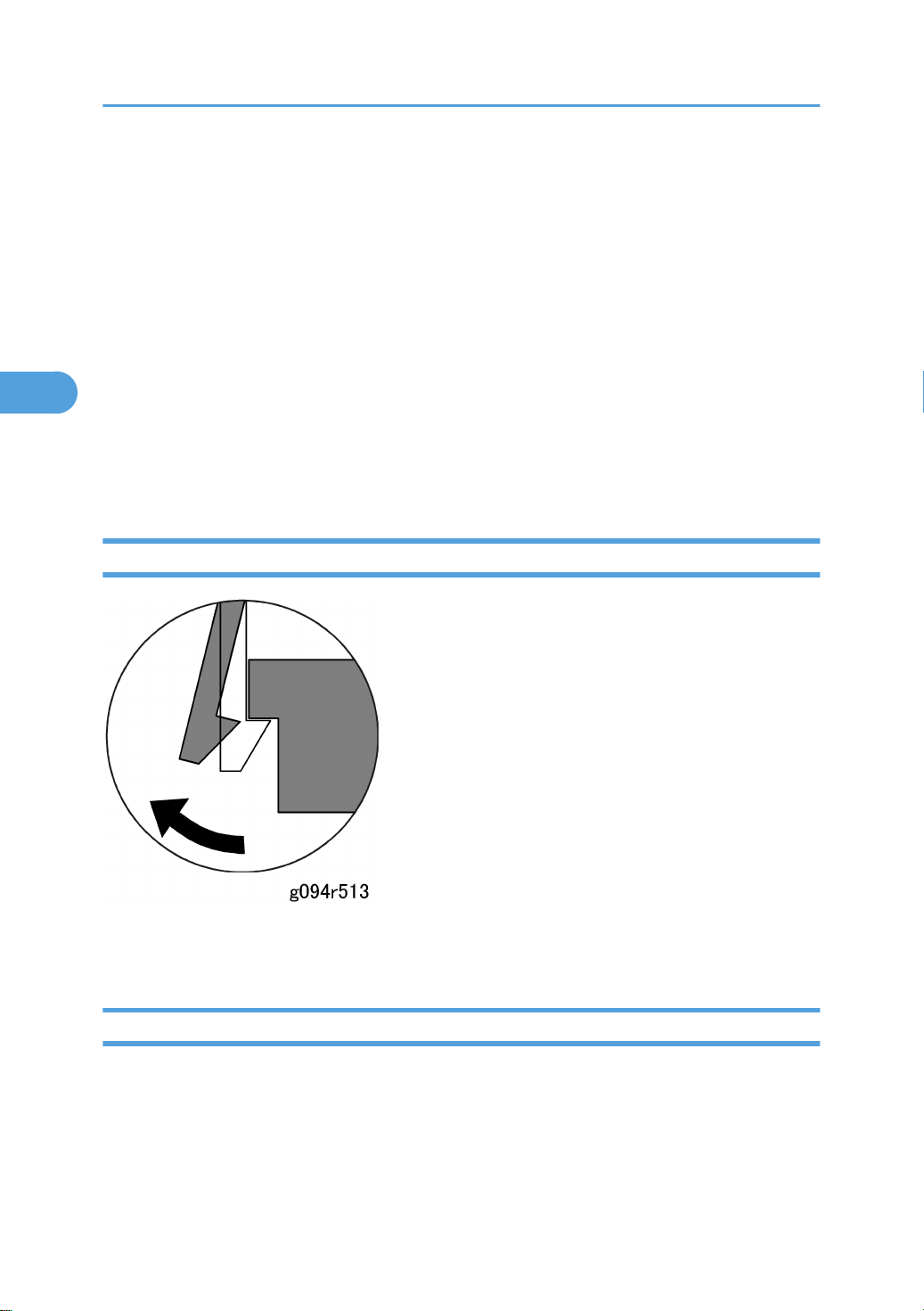

Releasing Plastic Latches

Many of the parts are held in place with plastic latches. The latches break easily, so release them carefully.

To release a latch, press the hook end of the latch away from the part to which it is latched.

After servicing the machine

1. Make sure all parts that require grounding are properly grounded.

2. Make sure the interlock switch is functioning.

3. Do not leave unused solder or parts inside the machine.

4. Do not leave any tools inside the machine.

22

5. Make sure all wires are properly connected and routed.

3

6. Make sure wires are not jammed between parts of the machine.

General

23

3. Replacement and Adjustment

3

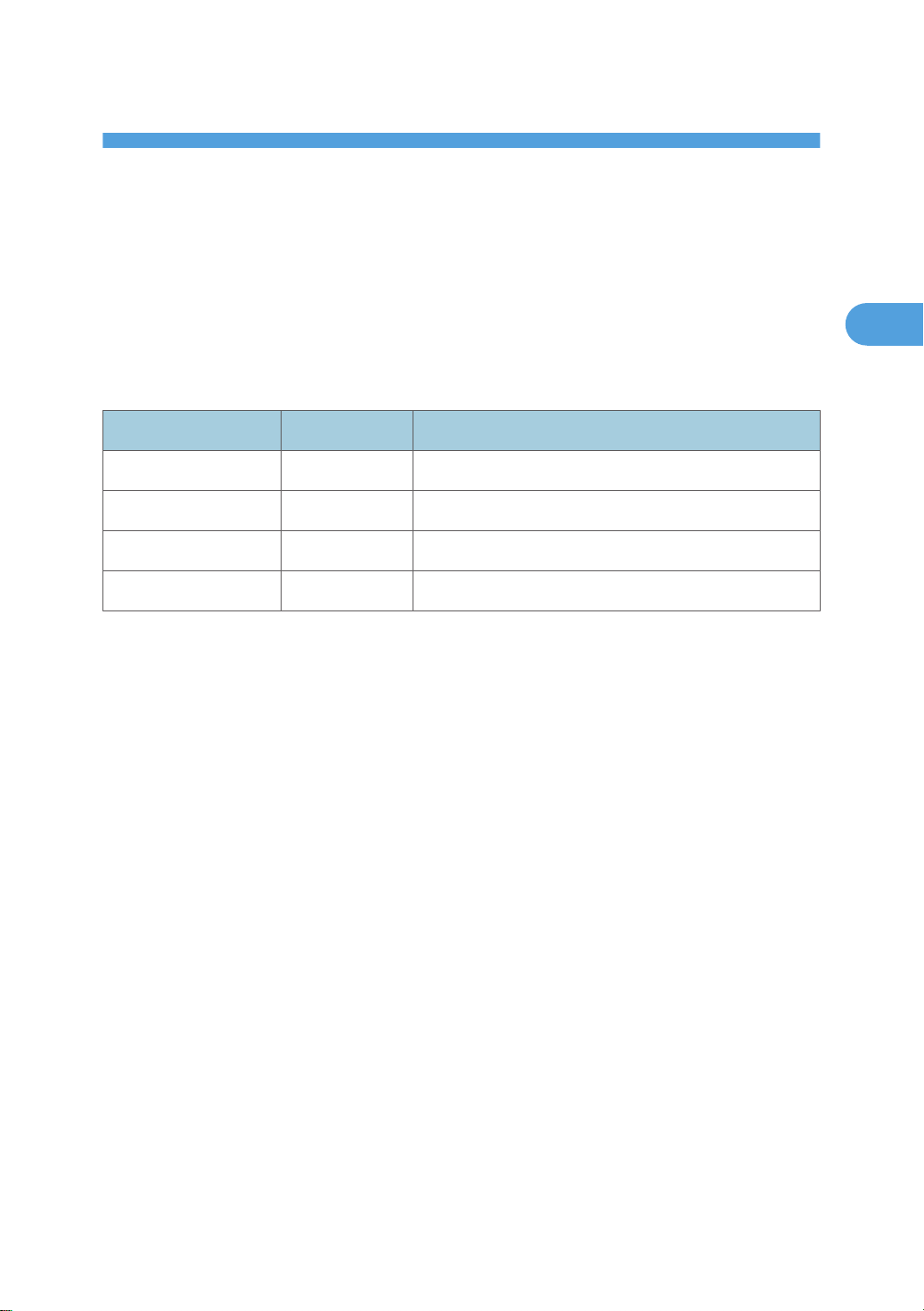

Special Tools

Part No. Description Q’ty Remarks

1 B6455010 SD Card 1 Common

2 B6456700 PCMCIA Card Adapter 1 Common

3 B6456800 USB Reader/Writer 1 Common

4 VSSM9000 Digital Multimeter – FLUKE 187 1 Common

5 A0069104 Scanner Positioning Pin 1 Common

Ricoh System Information Tool (Support

Tool Ver. 2)

6 ---

• Basic version 1

• Mail version 1

24

Covers

3

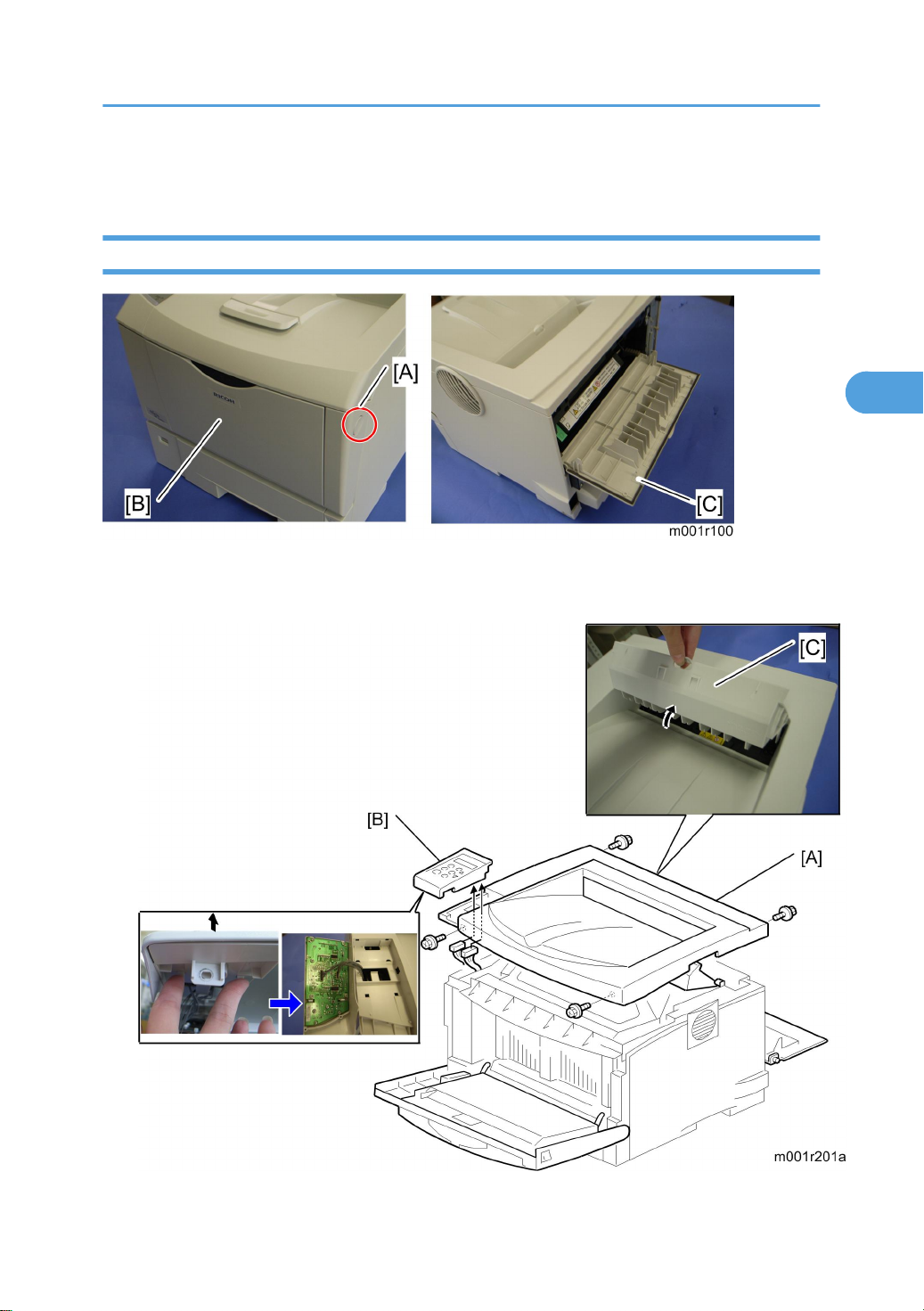

Upper Cover

1. Gentry push the front cover release button [A], and open the front cover [B].

2. Open the rear cover [C].

Covers

25

3. Replacement and Adjustment

3

3. Remove four screws of the upper cover [A].

4. Operation panel [B] (2 hooks, x 2)

5. Open the exit guide plate [C], and then remove the upper cover [A].

• Remove the exit guide plate after you have removed the upper cover.

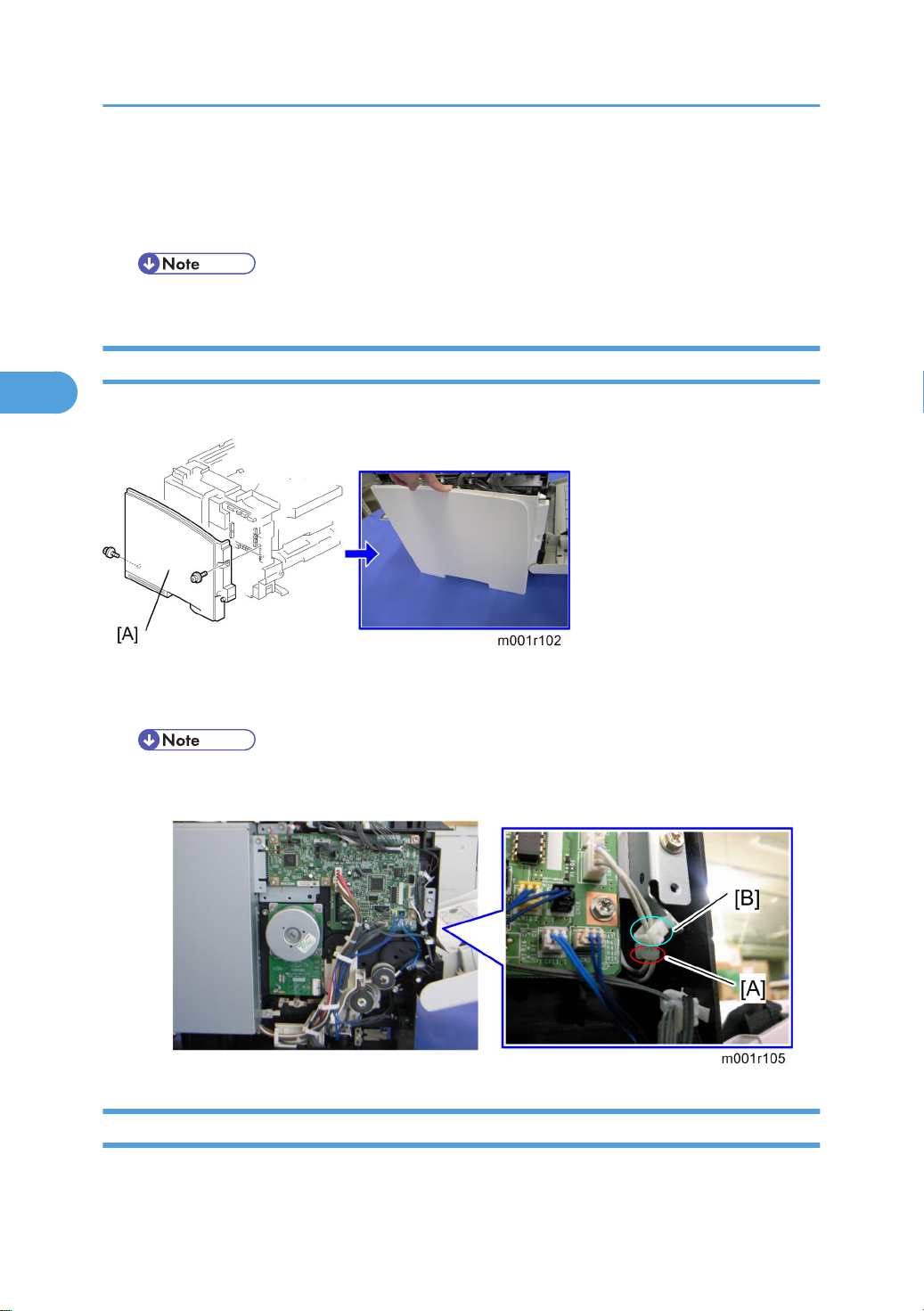

Left Cover

1. Upper cover (* Upper Cover)

1. Left cover [A] ( x 2)

2. Push down the left cover as shown above.

• Make sure that the harness band [A] is placed at clamp [B] the under, when reinstalling the left

cover.

By-Pass Tray Unit

1. Standard paper tray

26

2. By-pass tray unit [A] (hooks x 2)

3

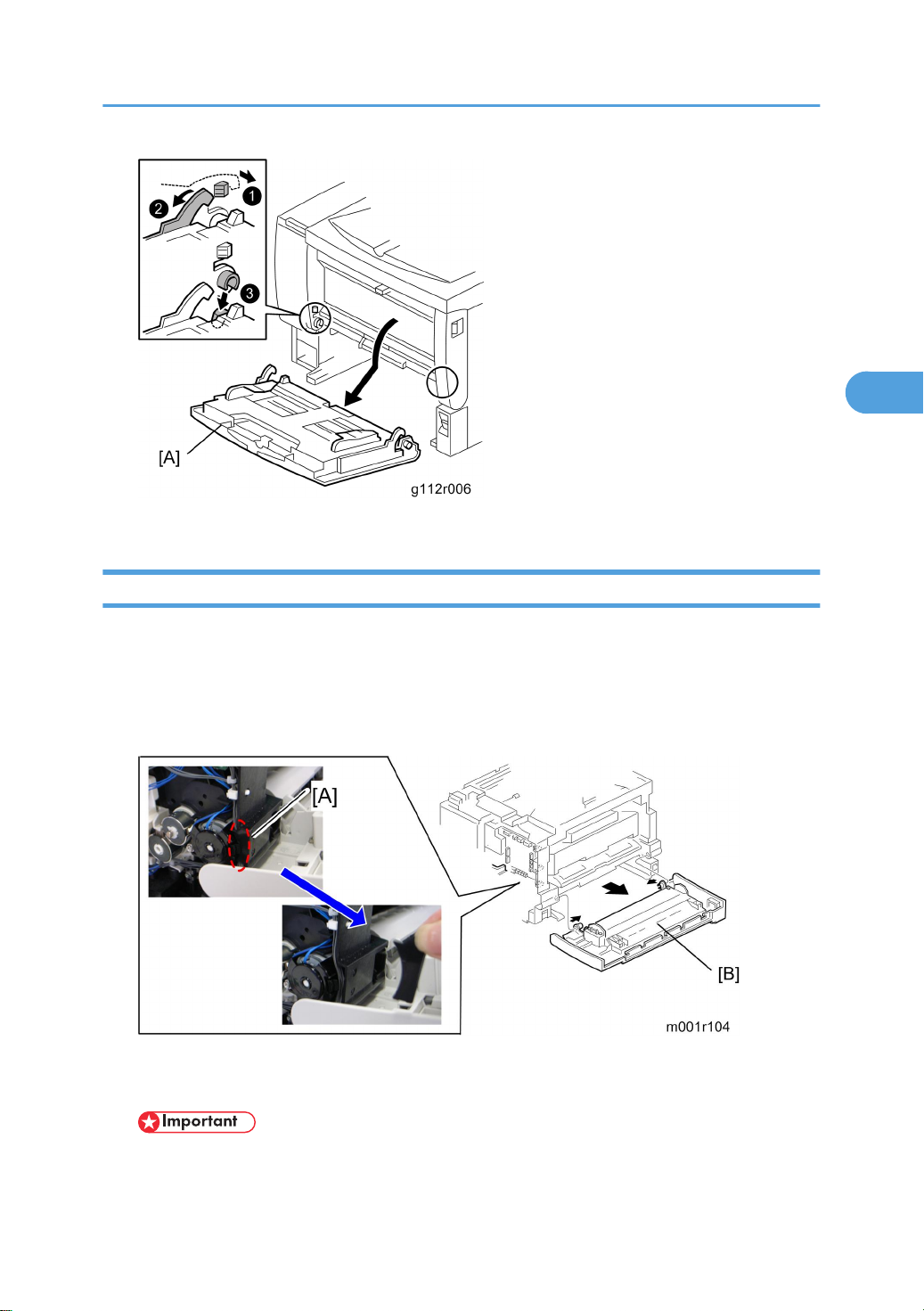

Front Cover

Covers

1. Standard paper tray

2. By-pass tray unit (* By-pass Tray Unit)

3. Upper cover (* Upper Cover)

4. Left cover (* Left Cover)

5. Holder [A] (hook)

6. Front cover [B] ( x 3, x 2)

• Remove the by-pass tray unit before removing the front cover.

27

3. Replacement and Adjustment

3

Right Cover

1. Upper cover (* Upper Cover)

2. Left cover (* Left Cover)

3. Front cover (* Front Cover)

4. Fan cover [A]

5. Release the three hooks, and push down the place [B] as shown above.

6. Right cover [C]

28

Loading...

Loading...