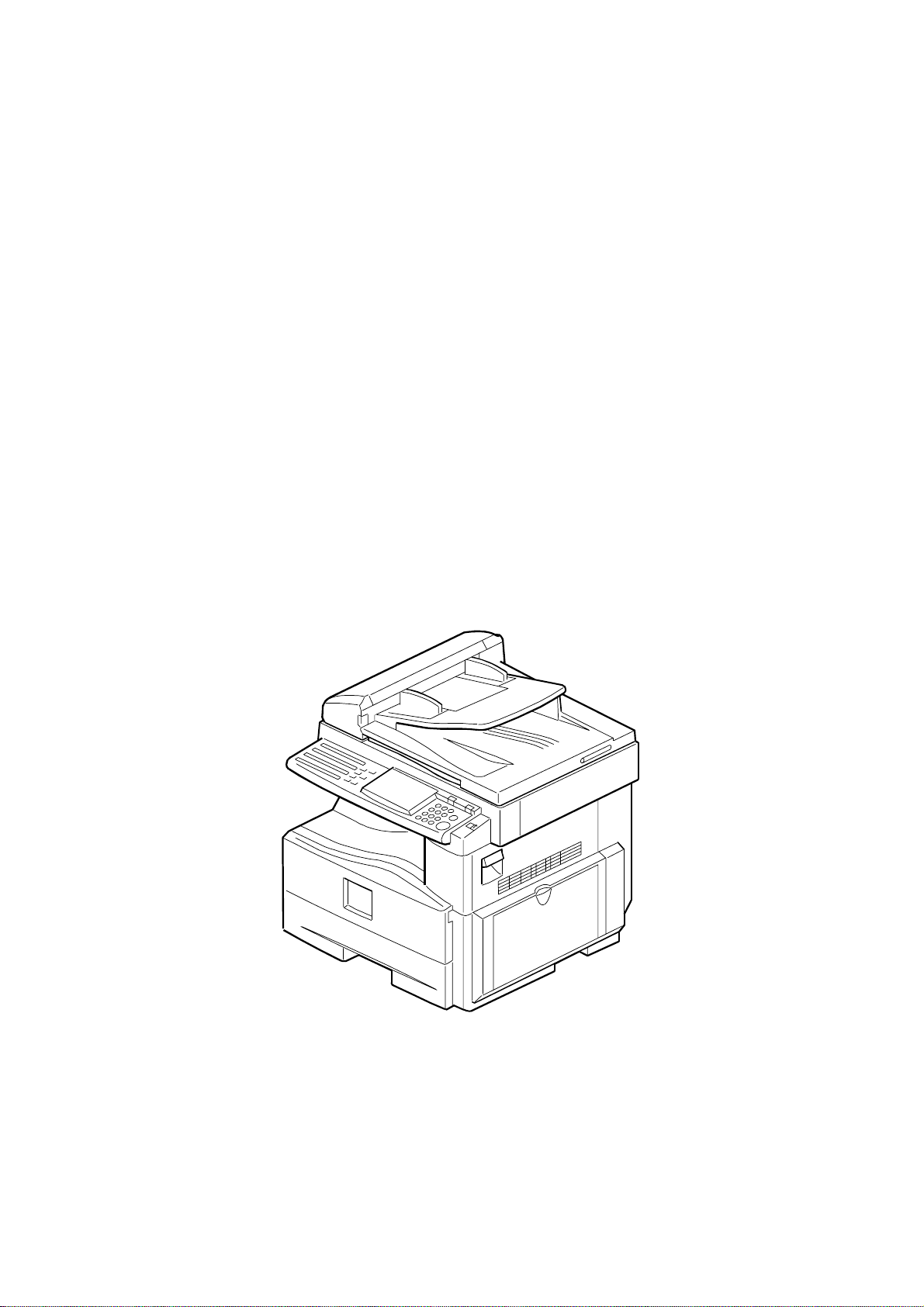

Page 1

Model S-C1

(Machine Code: B045/B049/B044/B046)

SERVICE MANUAL

B046I100.WMF

17 July, 2001

Subject to change

Page 2

!

IMPORTANT SAFETY NOTICES

PREVENTION OF PHYSICAL INJURY

1. Be sure that the power cord is unplugged before disassembling or

assembling parts of the copier or peripherals.

2. The wall outlet should be near the copier and easily accessible.

3. Note that electrical voltage is supplied to some components of the copier

and the paper tray unit even while the main power switch is off.

4. If you start a job before the copier completes the warm-up or initializing

period, keep hands away from the mechanical and electrical components

until job execution has started. The copier will start making copies as soon

as warm-up or initialization is finished.

5. The inside and the metal parts of the fusing unit become extremely hot while

the copier is operating. Be careful to avoid touching those components with

your bare hands.

HEALTH SAFETY CONDITIONS

Toner and developer are nontoxic, but getting either of these into your eyes may

cause temporary eye discomfort. Try to remove with eye drops or flush with

water. If material remains in eye or if discomfort continues, get medical attention.

OBSERVANCE OF ELECTRICAL SAFETY STANDARDS

The copier and its peripherals must be installed and maintained by a customer

service representative who has completed the training course on those relevant

models.

LITHIUM BATTERIES

Incorrect replacement of lithium battery(s) on the FCU may pose risk of

explosion. Replace only with the same type or with an equivalent type

recommended by the manufacturer. Discard used batteries in accordance with

the manufacturer’s instructi ons.

SAFE AND ECOLOGICAL DISPOSAL

1. Do not incinerate toner bottles or used toner. Toner dust may ignite suddenly

if exposed to an open flame.

2. Dispose of used toner, developer, and organic photoconductors in

accordance with local regulations. (These are nontoxic supplies.)

3. Dispose of replaced parts in accordance with local regulations.

1

Page 3

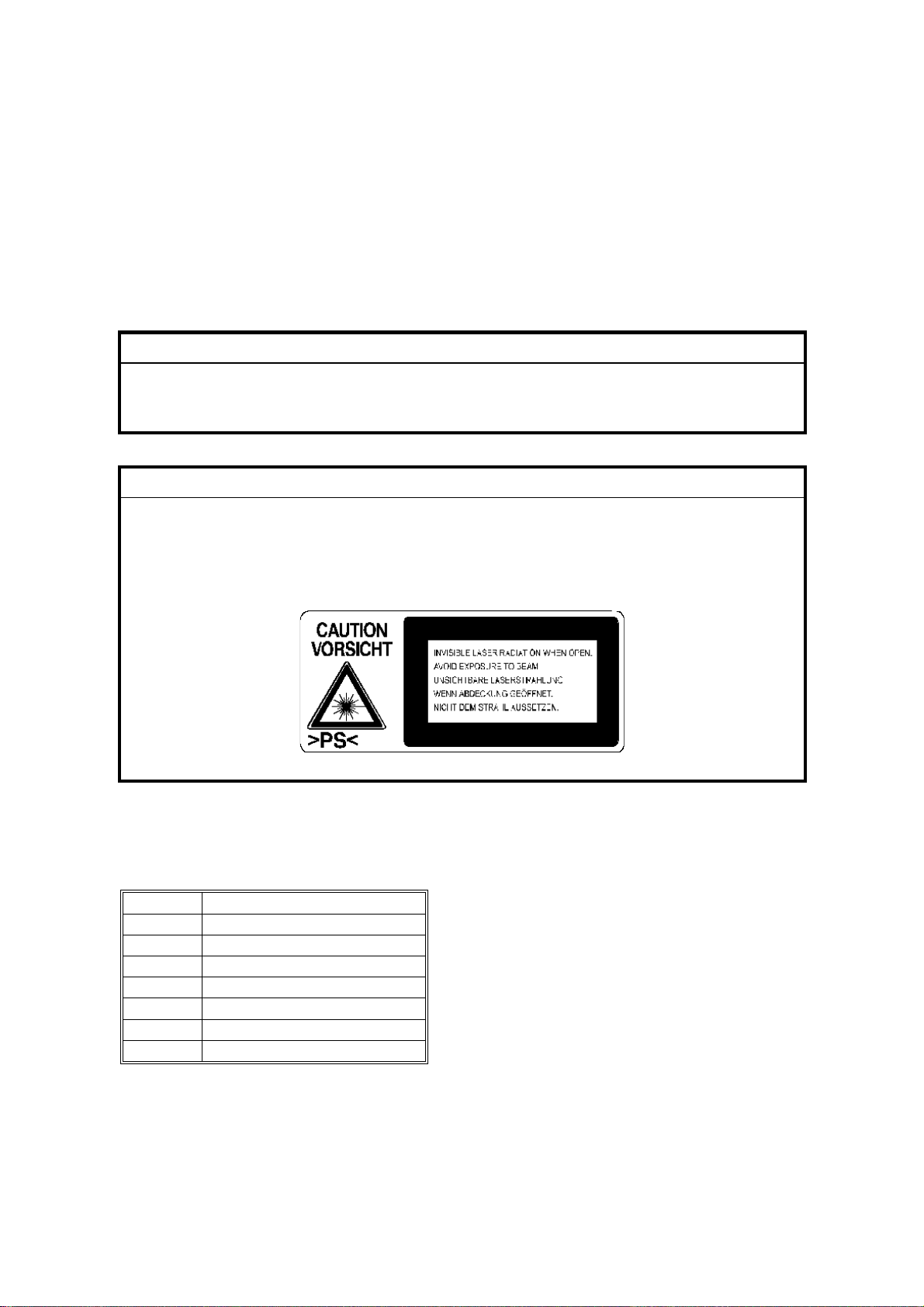

LASER SAFETY

The Center for Devices and Radiological Health (CDRH) prohibits the repair of

laser-based optical units in the field. The optical housing unit can only be repaired

in a factory or at a location with the requisite equipment. The laser subsystem is

replaceable in the field by a qualified Customer Engineer. The laser chassis is not

repairable in the field. Customer engineers are therefore directed to return all

chassis and laser subsystems to the factory or service depot when replacement of

the optical subsystem is required.

!

WARNING

Use of controls not specified in this manual, or performance of

adjustments or procedures not specified in this manual, may result in

hazardous radiation exposure.

!

WARNING FOR LASER UNIT

WARNING: Turn off the main switch before atte mpting any of the

procedures in the Laser Unit section. Laser beams can cause

serious damage to eyes.

CAUTION MARKING:

Symbols and Abbreviations

This manual uses the symbols and abbrev i ati ons show n below.

Symbol Meaning

☛

!

"

#

SEF Short Edge Feed

LEF Long Edge Feed

$

"See," "Refer to"

Clip ring

Screw

Connector

Core Technology manual

2

Page 4

TABLE OF CONTENTS

1 INSTALLATION ........................................................................... 1-1

1.1 INSTALLATION REQUIREMENTS ...........................................................1-1

1.1.1 ENVIRONMENT ...............................................................................1-1

1.1.2 MACHINE LEVEL.............................................................................1-2

1.1.3 MINIMUM OPERATIONAL SPACE REQUIREMENTS ....................1-2

1.1.4 POWER REQUIREMENTS ..............................................................1-3

1.2 COPIER.....................................................................................................1-4

1.2.1 ACCESSORY CHECK......................................................................1-4

1.2.2 INSTALLATION PROCEDURE ........................................................1-4

Initial Programming: Faxless models (B044, B045) .............................1-8

Initial Programming: Fax-equipped models (B046, B049)....................1-8

1.3 PAPER TRAY UNIT ................................................................................1-10

1.3.1 ACCESSORY CHECK....................................................................1-10

1.3.2 INSTALLATION PROCEDURE ......................................................1-10

1.4 PAPER TRAY UNIT HEATER.................................................................1-12

1.4.1 ACCESSORY CHECK....................................................................1-12

1.4.2 INSTALLATION PROCEDURE ......................................................1-12

1.5 DOCUMENT FEEDER ............................................................................1-17

1.5.1 ACCESSORY CHECK....................................................................1-17

1.5.2 INSTALLATION PROCEDURE ......................................................1-17

1.6 DIMM.......................................................................................................1-21

1.6.1 INSTALLATION PROCEDURE ......................................................1-21

2 PREVENTIVE MAINTENANCE SCHEDULES............................. 2-1

2.1 PM TABLES ..............................................................................................2-1

2.2 HOW TO CLEAR THE PM COUNTER......................................................2-2

3 REPLACEMENT AND ADJUSTMENT......................................... 3-1

3.1 PRECAUTIONS.........................................................................................3-1

3.1.1 GENERAL ........................................................................................3-1

3.1.2 LITHIUM BATTERIES ......................................................................3-1

3.1.3 PCU (PHOTOCONDUCTOR UNIT) .................................................3-1

3.1.4 TRANSFER ROLLER.......................................................................3-1

3.1.5 SCANNER UNIT...............................................................................3-2

3.1.6 LASER UNIT ....................................................................................3-2

3.1.7 FUSING UNIT...................................................................................3-2

3.1.8 PAPER FEED...................................................................................3-2

3.1.9 IMPORTANT ....................................................................................3-3

3.2 SPECIAL TOOLS AND LUBRICANTS ......................................................3-3

3.3 EXTERIOR COVER AND OPERATION PANEL .......................................3-4

3.3.1 PLATEN COVER..............................................................................3-4

3.3.2 REAR COVER..................................................................................3-4

3.3.3 COPY TRAY.....................................................................................3-5

3.3.4 SCALE PLATE (B044 AND B045 ONLY) .........................................3-5

3.3.5 LEFT COVER ...................................................................................3-6

i

Page 5

3.3.6 RIGHT COVER.................................................................................3-6

3.3.7 FRONT LEFT COVER AND OPERATION PANEL ..........................3-6

3.3.8 FRONT RIGHT COVER ...................................................................3-6

3.3.9 RIGHT DOOR...................................................................................3-7

3.3.10 BYPASS TRAY (B044 AND B046 ONLY) ......................................3-7

3.3.11 PLATEN COVER SENSOR............................................................3-8

3.4 SCANNER SECTION ................................................................................3-9

3.4.1 EXPOSURE GLASS.........................................................................3-9

Non-DF machines.................................................................................3-9

DF-equipped machines.........................................................................3-9

3.4.2 LENS BLOCK .................................................................................3-10

3.4.3 EXPOSURE LAMP, LAMP STABILIZER BOARD ..........................3-10

3.4.4 SCANNER MOTOR........................................................................3-11

3.4.5 SCANNER HP SENSOR................................................................3-11

3.4.6 SCANNER ALIGNMENT ADJUSTMENT .......................................3-12

3.5 FUSING...................................................................................................3-13

3.5.1 FUSING UNIT.................................................................................3-13

3.5.2 EXIT SENSOR ...............................................................................3-13

3.5.3 HOT ROLLER STRIPPER PAWLS ................................................3-14

3.5.4 HOT ROLLER & FUSING LAMP ....................................................3-15

3.5.5 THERMOFUSE, THERMOSWITCH, AND THERMISTOR.............3-15

3.5.6 PRESSURE ROLLER.....................................................................3-16

3.6 PCU.........................................................................................................3-17

3.7 TONER SUPPLY CLUTCH .....................................................................3-18

3.8 PAPER FEED SECTION.........................................................................3-19

3.8.1 PAPER FEED ROLLER AND FRICTION PAD...............................3-19

3.8.2 PAPER END SENSOR...................................................................3-19

3.8.3 REGISTRATION SENSOR.............................................................3-20

3.8.4 BYPASS PAPER END SENSOR (B044 AND B046 ONLY) ...........3-20

3.8.5 BYPASS FEED ROLLER (B044 AND B046 ONLY) .......................3-21

3.8.6 BYPASS FEED CLUTCH (B044 AND B046 ONLY).......................3-22

3.8.7 BYPASS FRICTION PAD (B044 AND B046 ONLY).......................3-22

3.8.8 REGISTRATION CLUTCH .............................................................3-22

3.8.9 PAPER FEED CLUTCH .................................................................3-23

3.9 IMAGE TRANSFER.................................................................................3-24

3.9.1 IMAGE TRANSFER ROLLER ........................................................3-24

3.9.2 ID (IMAGE DENSITY) SENSOR ....................................................3-24

3.9.3 DISCHARGE PLATE......................................................................3-25

3.10 FUNCTION CONTROL UNIT (FCU) .....................................................3-25

3.11 LASER UNIT .........................................................................................3-27

3.11.1 LOCATION OF “CAUTION” DECAL ............................................3-27

3.11.2 PSU BRACKET ............................................................................3-28

3.11.3 LASER UNIT ................................................................................3-29

3.11.4 LD UNIT........................................................................................3-29

3.11.5 POLYGON MIRROR MOTOR ......................................................3-29

ii

Page 6

3.12 OTHER REPLACEMENTS....................................................................3-30

3.12.1 QUENCHING LAMP.....................................................................3-30

3.12.2 HIGH-VOLTAGE POWER SUPPLY BOARD ...............................3-30

3.12.3 PSU ..............................................................................................3-30

3.12.4 MAIN MOTOR ..............................................................................3-31

3.12.5 EXHAUST FAN ............................................................................3-31

3.13 COPY IMAGE ADJUSTMENTS: PRINTING/SCANNING .....................3-32

3.13.1 PRINTING ....................................................................................3-32

Registration - Leading Edge/Side-to-Side...........................................3-32

Blank Margin.......................................................................................3-33

Main-Scan Magnification.....................................................................3-33

3.13.2 SCANNING...................................................................................3-34

Registration: Platen Mode...................................................................3-34

Magnification.......................................................................................3-34

Standard White Density Adjustment ...................................................3-35

3.13.3 DF IMAGE ADJUSTMENT ...........................................................3-36

Registration and Blank Margin............................................................3-36

Sub-scan Magnification.......................................................................3-36

4 TROUBLESHOOTING ................................................................. 4-1

4.1 SERVICE CALL CONDITIONS .................................................................4-1

4.1.1 SUMMARY .......................................................................................4-1

4.1.2 SC CODE DESCRIPTIONS .............................................................4-2

4.2 ELECTRICAL COMPONENT DEFECTS ..................................................4-7

4.2.1 SENSOR/SWITCH OPEN ERRORS................................................4-7

4.3 BLOWN FUSE CONDITIONS ...................................................................4-7

4.4 DUMPING THE FUSER TEMPERATURE LOG........................................4-8

5 SERVICE TABLES....................................................................... 5-1

5.1 USING SERVICE PROGRAM MODE .......................................................5-1

Accessing SP Mode..............................................................................5-1

Accessing Copy Mode from within SP Mode ........................................5-1

How to Select a Program Number ........................................................5-2

To Input a Value or Setting ...................................................................5-2

5.1.1 SP MODE TABLES ..........................................................................5-3

SP1-XXX (Feed) ...................................................................................5-3

SP2-XXX (Drum)...................................................................................5-4

SP4-XXX (Scanner) ..............................................................................5-9

SP5-XXX (Mode) ................................................................................5-14

SP6-XXX (Peripherals) .......................................................................5-18

SP7-XXX (Data Log)...........................................................................5-19

5.1.2 TEST PATTERN PRINTING (SP5-902) .........................................5-23

5.1.3 INPUT CHECK (SP5-803)..............................................................5-24

Input Check Table...............................................................................5-24

5.1.4 OUTPUT CHECK (SP5-804)..........................................................5-25

Input Check Table...............................................................................5-25

5.1.5 SMC PRINTING (SP5-992) ............................................................5-26

5.1.6 MEMORY ALL CLEAR (SP5-801)..................................................5-27

5.1.7 FREE RUNS...................................................................................5-28

iii

Page 7

5.1.8 PROGRAM UPLOAD/DOWNLOAD ...............................................5-29

Program Download (SP5-827)............................................................5-29

Program Upload (SP5-826) ................................................................5-31

5.1.9 SRAM DATA UPLOAD/DOWNLOAD.............................................5-32

SRAM Data Upload (SP5-824) ...........................................................5-32

SRAM Data Download (SP5-825).......................................................5-33

5.1.10 SERIAL NUMBER INPUT (SP5-811) ...........................................5-33

5.1.11 ID SENSOR ERROR ANALYSIS (SP2-221) ................................5-34

5.1.12 MEMORY READ/WRITE ..............................................................5-35

5.2 USER TOOLS .........................................................................................5-36

5.2.1 HOW TO ENTER AND EXIT USER TOOLS ..................................5-36

5.2.2 USER TOOLS TABLE ....................................................................5-36

System Settings Table........................................................................5-36

Copy Features Table ..........................................................................5-36

6 DETAILED SECTION DESCRIPTIONS ....................................... 6-1

6.1 OVERVIEW ...............................................................................................6-1

6.1.1 COMPONENT LAYOUT...................................................................6-1

6.2 PAPER PATH............................................................................................6-5

6.3 DRIVE LAYOUT ........................................................................................6-6

6.4 BLOCK DIAGRAM: PCBS AND COMPONENTS......................................6-7

6.5 MAIN PCBS...............................................................................................6-8

6.5.1 FCU (FUNCTION/FACSIMILE CONTROL UNIT).............................6-8

SPC2 ....................................................................................................6-9

VPL (Video Processing LSI) .................................................................6-9

CIOP (Communications and I/O Processing)........................................6-9

FROM (Flash ROM) – 2MB ..................................................................6-9

DRAM – 8MB.......................................................................................6-9

SRAM – 128K .......................................................................................6-9

3V/5V Converter ...................................................................................6-9

Energy-Save Switching.........................................................................6-9

Reset/Backup Circuit ..........................................................................6-10

SAF Backup........................................................................................6-10

Analog Processing Circuit...................................................................6-10

Modem................................................................................................6-10

Speaker Driver....................................................................................6-10

Heater Control ....................................................................................6-10

Video Processing Circuit.....................................................................6-10

Power Pack Control ............................................................................6-10

Scanner Driver....................................................................................6-10

Plotter Driver.......................................................................................6-10

6.5.2 SBU (SENSOR BOARD UNIT).......................................................6-11

Buffer ..................................................................................................6-11

CCD ....................................................................................................6-11

Amplifier..............................................................................................6-11

6.5.3 NCU (NETWORK CONTROL UNIT) ..............................................6-12

North America version ........................................................................6-12

Europe/Asia version............................................................................6-12

iv

Page 8

6.6 COPY PROCESS OVERVIEW ...............................................................6-13

6.7 SCANNING..............................................................................................6-15

6.7.1 OVERVIEW ....................................................................................6-15

6.7.2 SCANNER DRIVE ..........................................................................6-16

6.8 IMAGE PROCESSING ............................................................................6-17

6.8.1 OVERVIEW ....................................................................................6-17

6.8.2 IMAGE PROCESSING PATH.........................................................6-18

6.8.3 ORIGINAL MODES ........................................................................6-19

Original Modes: Copying....................................................................6-20

6.8.4 IMAGE PROCESSING STEPS FOR EACH MODE .......................6-21

6.8.5 MODE ADJUSTMENTS .................................................................6-22

To customize... ...................................................................................6-22

Default plotter customization settings for each mode... ......................6-23

6.9 LASER EXPOSURE................................................................................6-24

6.9.1 OVERVIEW ....................................................................................6-24

6.9.2 LD SAFETY SWITCHES ................................................................6-25

6.10 PHOTOCONDUCTOR UNIT (PCU) ......................................................6-26

6.10.1 OVERVIEW ..................................................................................6-26

6.10.2 DRUM DRIVE...............................................................................6-27

6.11 DRUM CHARGE ...................................................................................6-28

6.11.1 OVERVIEW ..................................................................................6-28

6.11.2 CHARGE ROLLER VOLTAGE CORRECTION............................6-29

Correction for Ambient Environment...................................................6-29

6.11.3 CHARGE ROLLER CLEANING....................................................6-30

6.11.4 DETECTION OF A NEW PCU......................................................6-31

At time of copier installation................................................................6-31

When a replacement PCU is installed.................................................6-31

6.12 DEVELOPMENT ...................................................................................6-32

6.12.1 OVERVIEW ..................................................................................6-32

6.12.2 DEVELOPMENT BIAS .................................................................6-33

6.12.3 TONER SUPPLY..........................................................................6-34

Toner-Bottle Models (B044 and B046)................................................6-34

Toner Hopper Magazine (B045 and B049) .........................................6-35

6.12.4 TONER DENSITY CONTROL ......................................................6-36

Overview.............................................................................................6-36

Reference Voltage ..............................................................................6-36

Toner Density Sensor Initial Setting....................................................6-36

Toner Concentration Measurement ....................................................6-37

Vsp/Vsg Detection ..............................................................................6-37

Calculation of Vref ..............................................................................6-37

Toner Supply Determination ...............................................................6-37

Toner Clutch ON Time........................................................................6-37

6.12.5 TONER SUPPLY IF SENSOR READING IS ABNORMAL ...........6-38

ID Sensor............................................................................................6-38

TD Sensor...........................................................................................6-38

v

Page 9

6.12.6 DETECTION OF TONER NEAR END AND TONER END ...........6-38

Toner Near End detected when either of the following occurs............6-38

Toner End detected when any of the following occurs........................6-38

6.13 DRUM CLEANING AND TONER RECYCLING.....................................6-39

6.14 PAPER FEED........................................................................................6-40

6.14.1 OVERVIEW ..................................................................................6-40

6.14.2 PAPER FEED DRIVE MECHANISM ............................................6-41

From Paper Tray.................................................................................6-41

From 100-Sheet Bypass Tray (B044, B046).......................................6-41

From 1-Sheet Bypass Tray (B045, B049)...........................................6-41

6.14.3 PAPER FEED AND SEPARATION ..............................................6-42

6.14.4 PAPER LIFT MECHANISM ..........................................................6-42

PAPER END DETECTION .................................................................6-43

Main Tray............................................................................................6-43

100-Sheet Bypass Tray (B044, B046) ................................................6-43

6.14.5 PAPER REGISTRATION..............................................................6-43

6.15 IMAGE TRANSFER AND PAPER SEPARATION .................................6-44

6.15.1 OVERVIEW ..................................................................................6-44

6.15.2 IMAGE TRANSFER CURRENT TIMING......................................6-45

6.15.3 TRANSFER ROLLER CLEANING................................................6-46

6.16 IMAGE FUSING AND PAPER EXIT......................................................6-47

6.16.1 OVERVIEW ..................................................................................6-47

6.16.2 FUSING DRIVE AND RELEASE MECHANISM ...........................6-47

6.16.3 PRESSURE ROLLER...................................................................6-48

6.16.4 PRESSURE RELEASE ................................................................6-48

Separation ..........................................................................................6-48

6.16.6 FUSING TEMPERATURE CONTROL..........................................6-49

Overview.............................................................................................6-49

Fusing Temperature Control for Thick Paper......................................6-49

6.16.7 OVERHEAT PROTECTION .........................................................6-49

6.17 ENERGY SAVER MODES ....................................................................6-50

6.17.1 MODE TRANSITIONS..................................................................6-50

6.17.2 SYSTEM SETTINGS....................................................................6-51

6.17.3 LOW POWER MODE LEVELS.....................................................6-51

6.17.4 AUTO-OFF LEVEL .......................................................................6-51

6.17.5 TRANSITION OPERATION..........................................................6-51

vi

Page 10

PAPER TRAY UNIT (B421)

1 OVERALL MACHINE INFORMATION...................................B421-1

1.1 MECHANICAL COMPONENT LAYOUT ............................................ B421-1

1.2 ELECTRICAL COMPONENT LAYOUT.............................................. B421-1

1.3 DRIVE LAYOUT ................................................................................. B421-2

1.4 OVERALL ELECTRICAL CIRCUIT .................................................... B421-2

1.5 DETAILED DESCRIPTIONS.............................................................. B421-3

1.5.1 PAPER FEED AND SEPARATION ........................................... B421-3

1.6 PAPER LIFT MECHANISM................................................................ B421-3

1.7 PAPER END DETECTION................................................................. B421-4

1.8 SIDE AND END FENCES .................................................................. B421-5

2 REPLACEMENT AND ADJUSTMENT...................................B421-6

2.1 FEED ROLLER AND FRICTION PAD................................................ B421-6

2.2 REMOVING THE PAPER TRAY UNIT FROM THE COPIER............. B421-6

If Optional Tray Heater Is Not Installed.......................................... B421-6

If Optional Tray Heater Is Installed ................................................ B421-6

2.3 SENSORS.......................................................................................... B421-7

2.4 DRIVE SECTION................................................................................ B421-8

2.4.1 DRIVE BLOCK .......................................................................... B421-8

2.4.2 PAPER FEED MOTOR.............................................................. B421-8

2.4.3 PAPER FEED CLUTCH ............................................................ B421-9

2.4.4 TRAY MAIN BOARD ( 2.4.1) ..................................................... B421-9

DOCUMENT FEEDER (B444)

1 OVERALL INFORMATION ....................................................B444-1

1.1 MECHANICAL COMPONENT LAYOUT ............................................ B444-1

1.2 ELECTRICAL COMPONENT LAYOUT.............................................. B444-2

1.3 DRIVE LAYOUT ................................................................................. B444-3

2 DETAILED SECTION DESCRIPTIONS .................................B444-4

2.1 PICK-UP AND SEPARATION ............................................................ B444-4

2.2 CLUTCH OPERATION....................................................................... B444-4

2.3 TRANSPORT AND EXIT.................................................................... B444-4

2.4 UNIT OPEN SWITCH AND GUIDE OPEN SENSOR......................... B444-5

2.5 OVERALL ELECTRICAL CIRCUIT .................................................... B444-5

3 REPLACEMENT AND ADJUSTMENT...................................B444-6

3.1 DF UPPER COVERS ......................................................................... B444-6

3.2 ORIGINAL TABLE .............................................................................. B444-6

3.3 FEED UNIT......................................................................................... B444-6

3.4 DF PICKUP ROLLER......................................................................... B444-7

3.5 DF FEED ROLLER............................................................................. B444-7

vii

Page 11

3.6 DF SEPARATION ROLLER ............................................................... B444-8

3.7 DF MOTOR ........................................................................................ B444-9

3.8 DF FEED CLUTCH........................................................................... B444-10

3.9 SENSORS........................................................................................ B444-10

3.10 DF EXPOSURE GLASS................................................................. B444-11

3.11 DF CONNECTION BOARD............................................................ B444-11

SPECIFICATIONS

1 GENERAL SPECIFICATIONS..............................................................SPEC-1

2 MACHINE CONFIGURATION.............................................................. SPEC-5

3 OPTIONAL EQUIPMENT..................................................................... SPEC-6

ADF .................................................................................................. SPEC-6

PAPER TRAY UNIT ........................................................................... SPEC-6

viii

Page 12

24 July, 2001 INSTALLATION REQUIREMENTS

1. INSTALLATION

!!!!

CAUTION

Before installing options, please do the following:

1. If there is a fax unit on the machine, print out all messages stored in the

memory, all user-programmed items, and a system parameter list.

2. If there is a printer option on the machine, print out all data in the

printer buffer.

3. Turn off the main switch and disconnect the power cord, the telephone

line, and the network cable.

1.1 INSTALLATION REQUIREMENTS

1.1.1 ENVIRONMENT

–Temperature and Humidity Chart–

Installation

Humidity

80%

54%

Operation range

15%

10°C

(50°F)

27°C

(80.6°F)

(89.6°F)

32°C

Temperature

B046I512.WMF

1. Temperature Range: 10°C to 32°C (50°F to 89.6°F)

2. Humidity Range: 15% to 80% RH

3. Ambient Illumination: Less than 1,500 lux (Do not expose to direct sunlight.)

4. Ventilation: Room air should turn over at least 3 times/hr/person

5. Ambient Dust Less than 0.1 mg/m

3

6. Do not install the machine where it will be exposed to direct sunlight or to direct

airflow (from a fan, air conditioner , air clean er, etc .) .

7. Do not install the machine where it will be exposed to corrosive gas.

8. Place the machine on a firm and level base.

9. Do not install the machine where it may be subjected to strong vibration.

1-1

Page 13

INSTALLATION REQUIREMENTS 24 July, 2001

1.1.2 MACHINE LEVEL

Front to back: Within 5 mm (0.2") of level

Right to left: Within 5 mm (0.2") of level

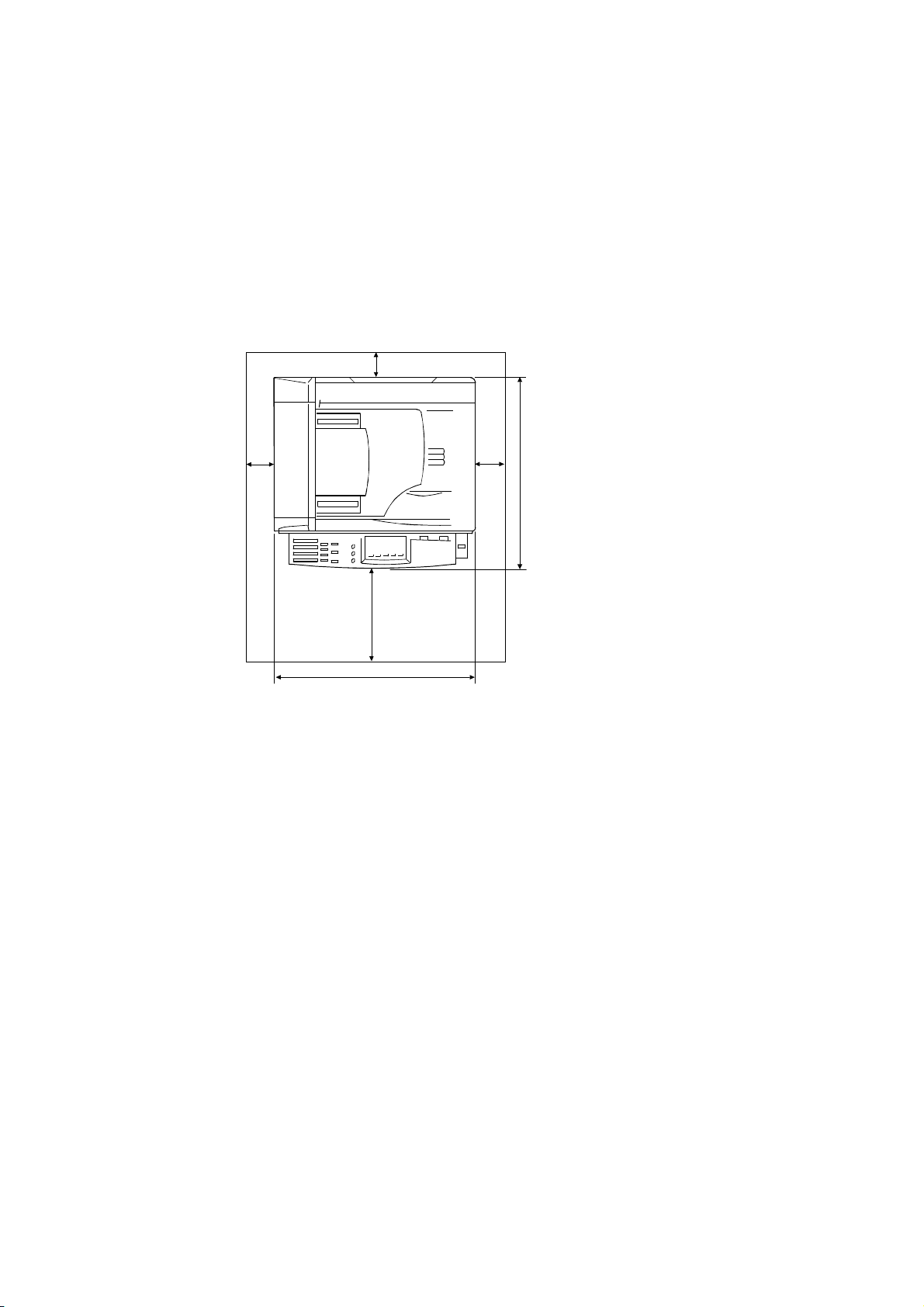

1.1.3 MINIMUM OPERATIONAL SPACE REQUIREMENTS

Place the machine near the power source, providing clearance as shown.

[C]

[D]

[B]

450 mm (17.7")

A: Front > 750 mm (29.6")

[A]

B: Left > 100 mm (3.9 ")

C: Rear > 105 mm (4.1")

D: Right > 230 mm (9.0")

468 mm (18.4")

B046I130.WMF

NOTE: 1) The 750-mm front space indicated above is sufficient to allow the paper

tray to be pulled out. Additional space is required to allow an operator to

stand at the front of the machine.

2) Actual minimum space requirement for left, rear, and right sides is

10mm (0.4") each, but note that this will not allow room for opening of

the bypass tray, right door, platen cover, or ADF unit.

1-2

Page 14

24 July, 2001 INSTALLATION REQUIREMENTS

1.1.4 POWER REQUIREMENTS

!

CAUTION

1. Make sure that the wall outlet is near the machine and easily accessible.

After completing installation, make sure the plug fits firmly into the

outlet.

2. Avoid multi-wiring.

3. Be sure to ground the machine.

Input voltage:

North America: 120 V, 60 Hz, 7 A

Europe: 220 – 240 V, 50/60 Hz, 4 A

Image quality guaranteed at rated voltage ± 10%.

Operation guaranteed at rated voltage ± 15%.

Installation

1-3

Page 15

COPIER 24 July, 2001

1.2 COPIER

1.2.1 ACCESSORY CHECK

Check that you have the accessories indicated below. Note that accessories vary

according to model and location.

No. Description Q’ty

1 Copier Operating Instructio ns (-17, -26, -29) 1

2 EU safety sheet (-22, -24, -26, -27) 1

3 NECR (-17, -27, -29) 1

4 Paper-size decals 1 set

5 Energy Star seal (-26) 1

6 Branding plaques (-22) 1 set

7 Brand decals (-22) 1 set

8 Handset bracket (B046-17) 1

1.2.2 INSTALLATION PROCEDURE

!

CAUTION

Make sure that the copier remains unplugged during installation.

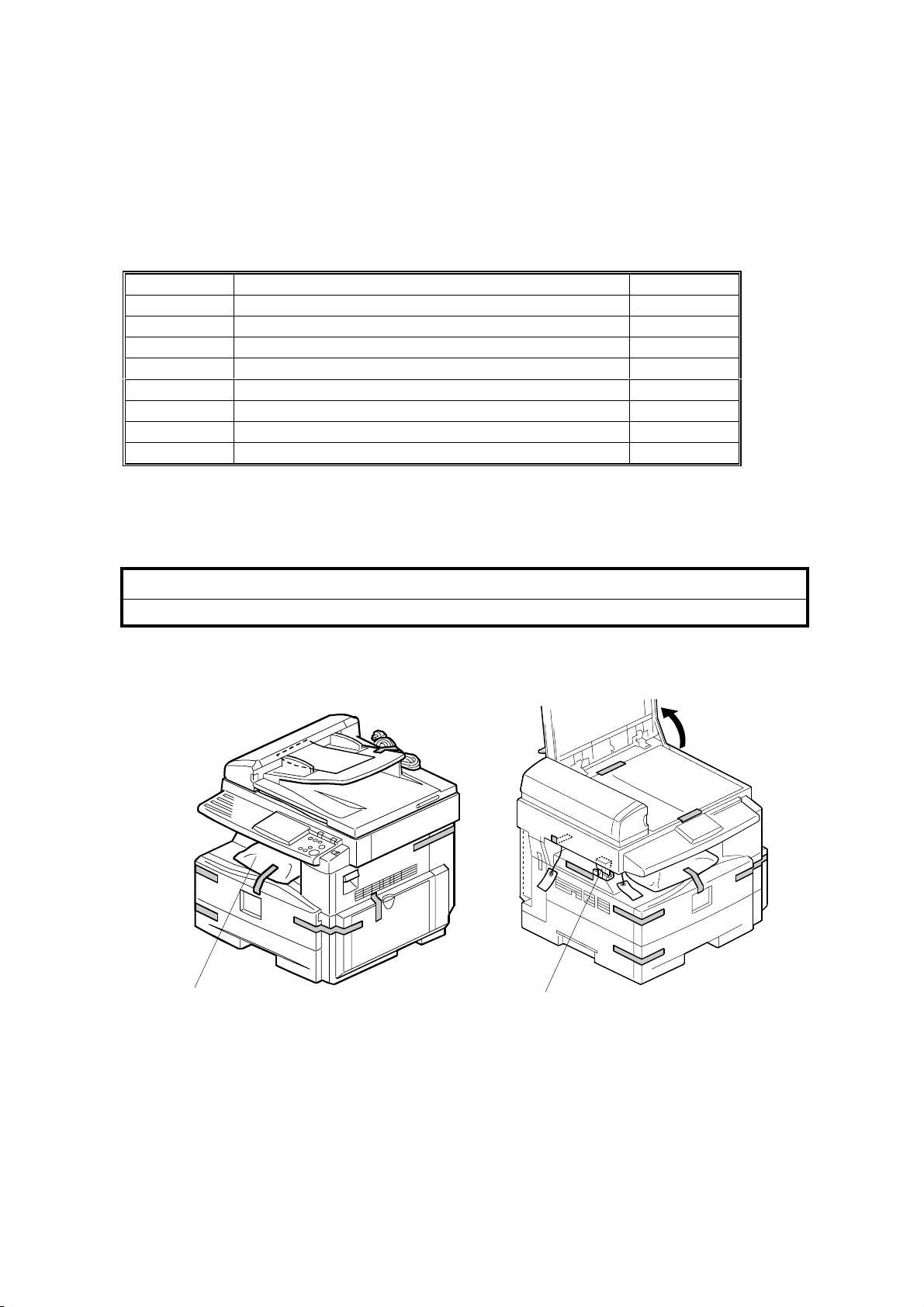

[A]

B046I101.WMF

[B]

B046I124.WMF

1. Remove the strips of tape.

2. Remove the bag [A] holding the included accessories.

3. Remove the spacing wedge [B].

1-4

Page 16

24 July, 2001 COPIER

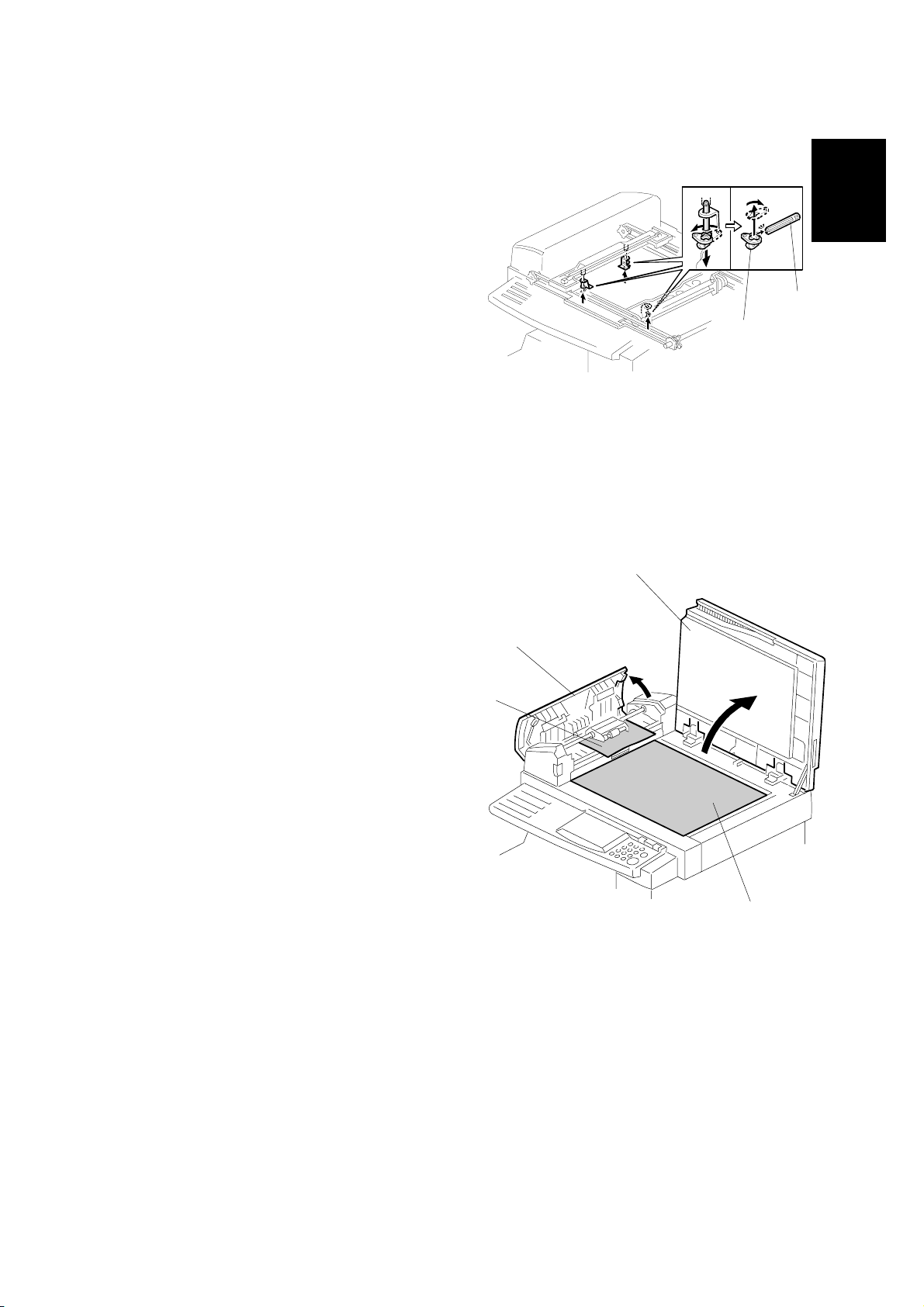

4. Remove the 3 scanner lock pins. (A

tag is hanging from each pin.) To

remove: Grasp the base of the pin [A],

turn 90 degrees, and pull down and

out.

[B]

[A]

Installation

5. Remove the tags from the pins. Then

break each pin off of its base [A],

discard the pin part [B], and set each

base [A] back into its original hole,

turning it 90° to lock it into place. (Be

sure to do this for all three pins.)

6. If installing a DF-equipped model

(B046 or B049): Raise the DF upper

guide [C] and remove the protective

paper [D] at the feed unit. Then lower

the guide.

7. Open the platen cover [E] and remove

the protective paper [F] covering the

exposure glass. Then close the platen

cover.

B046I106.WMF

[E]

[C]

[D]

1-5

B046I107.WMF

[F]

Page 17

COPIER 24 July, 2001

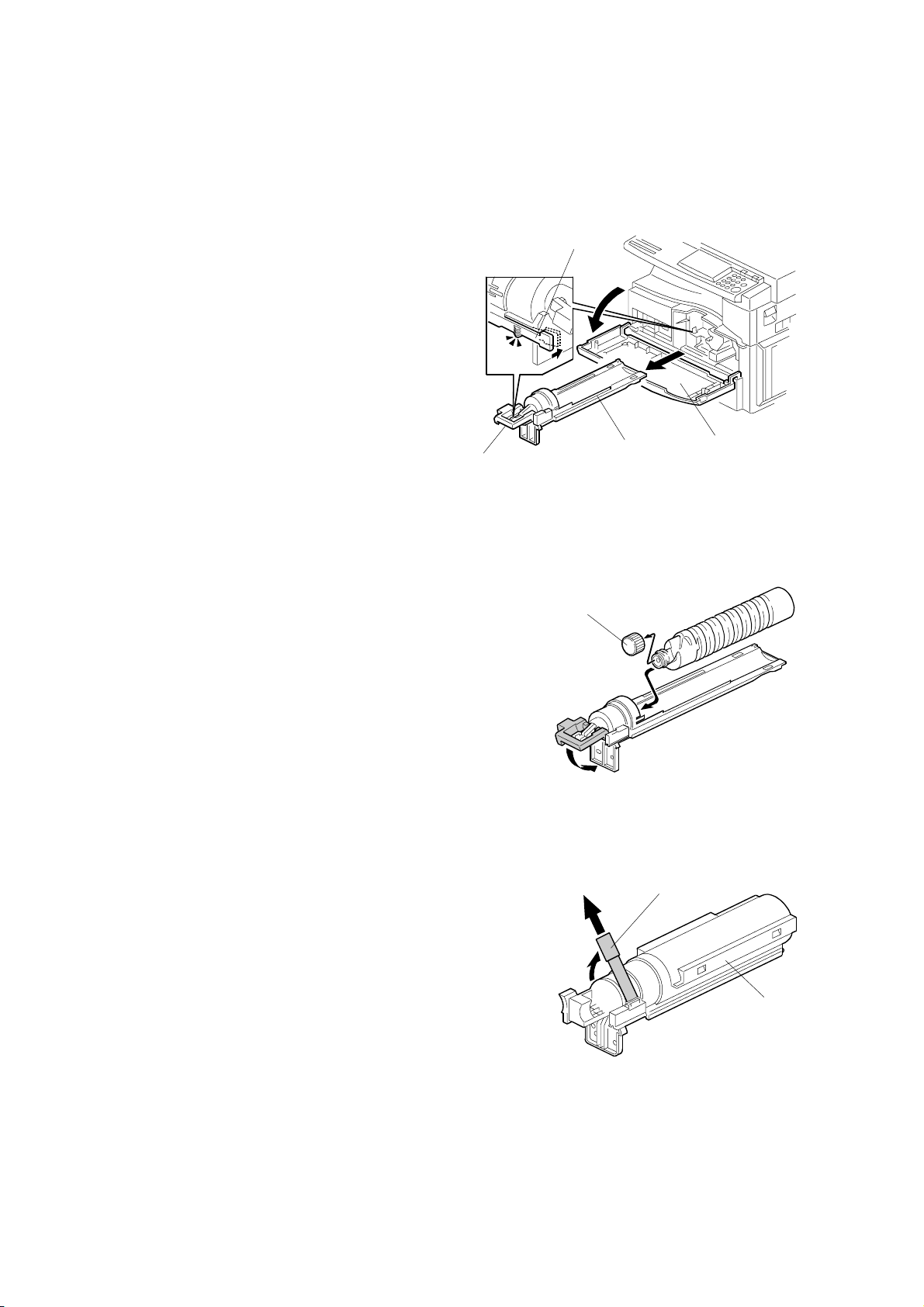

8. Open the front door [A].

9. If installing a toner-bottle model

(B044 or B046):

• Lift lever [B], press in on latch [C]

[C]

and pull the bottle holder [D] out.

(It is not necessary to pull it

completely out of the machine,

however.)

• Take a new bottle of toner, shake

it several times, remove its outer

cap [E], and load as shown. Then

push the bottle holder back into

the machine, and press the latch

[B]

[D]

[A]

down to lock it.

B046I112.WMF

If

installi

ng a toner-hopper magazine model

(B045 or B049):

• Shake the magazine several times, then

peel off the paper [F] from a new THM [G],

and load the THM into the machine.

[E]

B046I301.WMF

[F]

[G]

1-6

B046I114.WMF

Page 18

24 July, 2001 COPIER

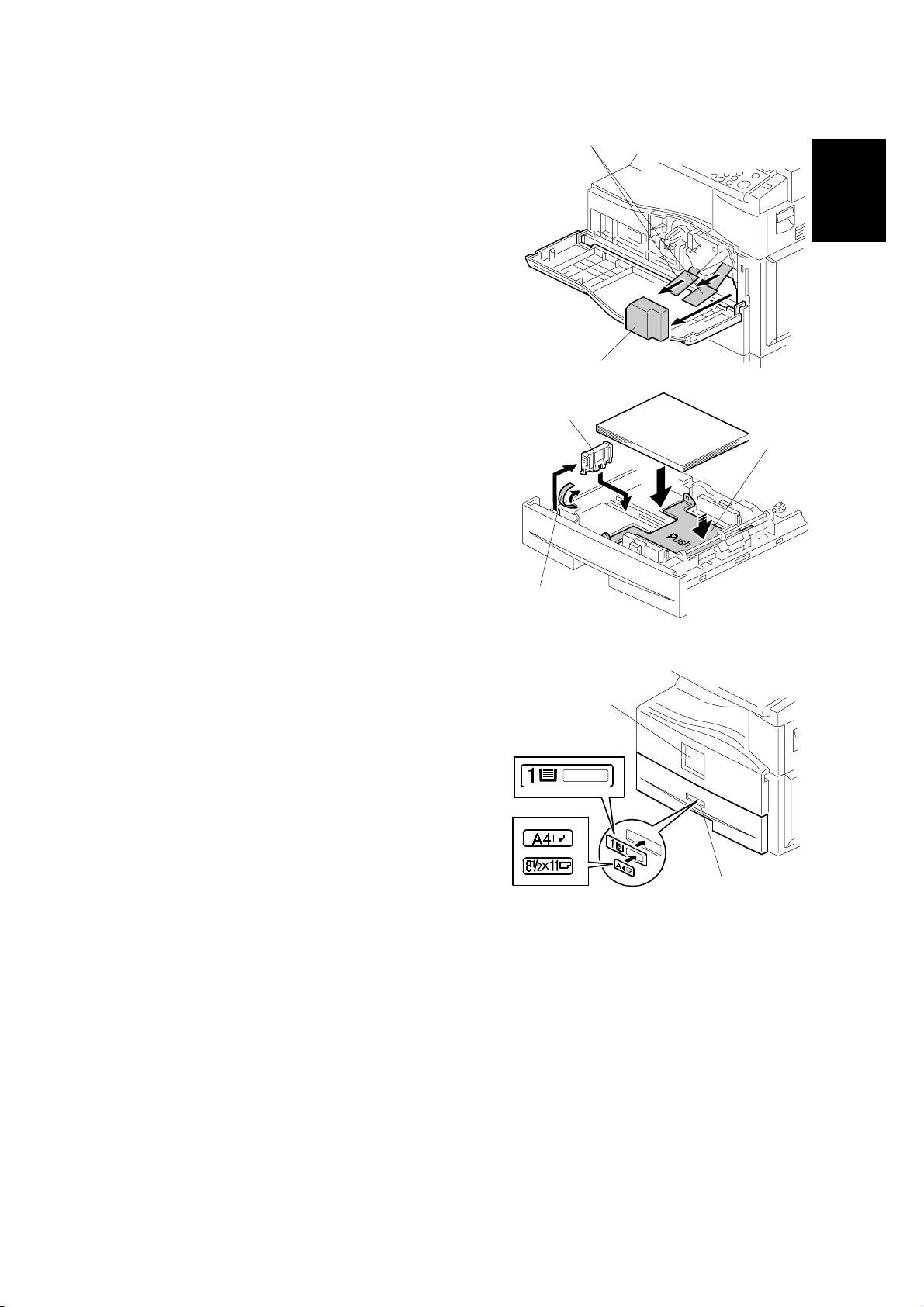

10. Remove the foam cushion [A] and pull the

tabbed strips [B] all the way out of the

PCU. Then close the front door.

11. Pull open the paper tray, and remove the

tape [C] securing the end fence in the

compartment.

12. Push the bottom plate [D] down, load

paper, and adjust the side fences. If

loading paper shorter than A4, remove

the end fence [E] from its compartment,

set it into the tray, and adjust it to the

correct length.

[B]

Installation

[A]

B046I104.WMF

[E]

[D]

[C]

B046I119.WMF

13. Push the tray back in.

14. Adhere the appropriate branding decal

(not shown) to the center of the front

[F]

door [F], and adhere the tray number

decal and appropriate paper- si ze decal

to the front of the paper tray (at [G]) as

shown.

15. Hong Kong only:

If installing model B046 or B049 in

Hong Kong, you must change the

position of the TB1 jumpe r on the NCU.

Turn to the fax service manual and carry

out steps 4 to 8 of the installation

[G]

B046I515.WMF

procedure (fax service manual, section 1.2.2).

16. Plug in the machine and turn on the main switch.

17. Enter SP mode, and run SP7-825 to initialize the electrical total counter to 0.

NOTE:

1) After selecting SP7-825, enter "1" and then hold down the Original

Type key and press the OK key to initialize the counter. If

initialization is successful, the screen displays "Action comp leted."

2) SP7-825 is effective only once, at time of machine installation .

1-7

Page 19

COPIER 24 July, 2001

18. Models B046 and B049 only: Access SP5-992 and select "2" to print out a full

SMC report. Confirm that the report shows a "YES" for SP7-801-3.

19. Models B046 and B049 only: Press the On Hook key on the fax operation

panel, and confirm that you hear a dial tone coming from the monitor speaker.

20. Program the required items, as indicated below.

Initial Programming: Faxless models (B044, B045)

Items to Program (Service Level – SP Mode)

Date and time 5-302

Language replacement (Fir mware download) 5-827

*1

*1: See Section 5 for SP-mode usage instructions.

Items to Program (User Level)

Display contrast

Energy saver level (low power mod e)

Reception mode

Other items, as necessary *2

*2

User Tools

User Tools →

System Settings

*2: Refer to the Operating Instructions for details.

Initial Programming: Fax-equipped models (B046, B049)

Items to Program (Service Level – Serv i ce Functions)

Country code (System switch 0F) 01

Protocol requirements (G3 switch 0 B) - E U only 01

PM call (System switch 01 – bit 0) 01

Country code (NCU parameter 0 0) 07

Service station's fax number 09

*3

Function No.

SP No.

*3: See Section 5.1.1 of the fax service manual for information abou t using

service functions.

1-8

Page 20

24 July, 2001 COPIER

Items to Program (Service Level – SP Mode)

*4

SP No.

Machine's serial number 5-811

Language replacement (Fir mware download) 5-827

PSTN access code (RAM address 4000DB)

PSTN access method (RAM address 4000CD)

7-955

Periodic service call (RAM addresses 40054F to 400553)

*4: See Section 5 for SP-mode usage instructions.

Items to Program (User Administrator Level)

Monitor volume

Display contrast

Date and Time

Reception mode

Fax Header/Own Name/Own No. (TTI/RTI/CSI)

Reports on/off

Country Code (except NA)

Fusing power control during e nergy saver mode System

Language selection Language

Other initial progr amming items *5

*5

User Tools

Fax Features

→ Setup

Key Op. Tools

Settings

Installation

*5: Refer to the Operating Instructions for details.

1-9

Page 21

PAPER TRAY UNIT 24 July, 2001

1.3 PAPER TRAY UNIT

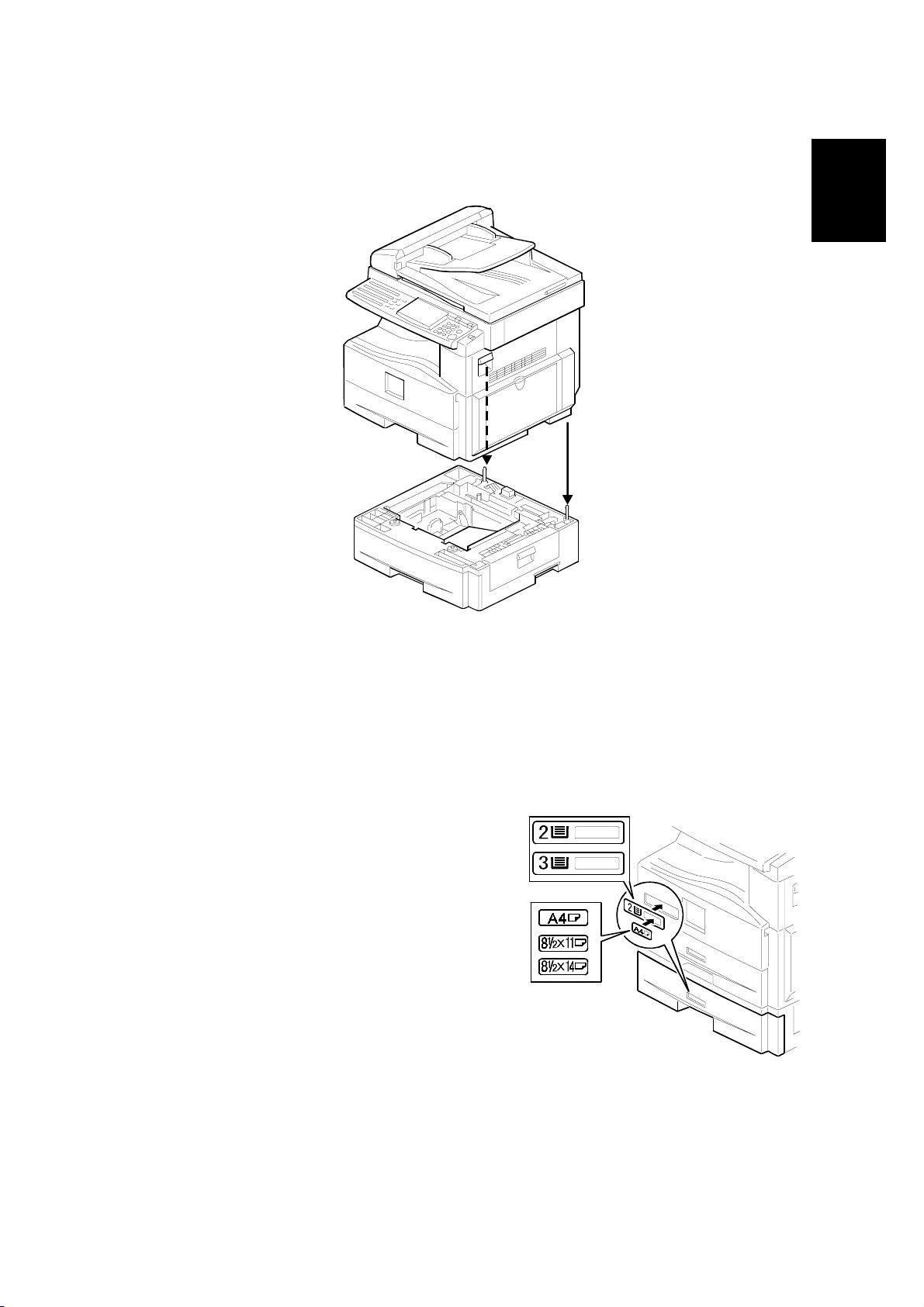

1.3.1 ACCESSORY CHECK

Confirm that you have the accessories indicated below.

No. Description Q’ty

1 Paper-size decals 1 sheet

2 Installation Procedure (for service person) 1

3 Installation Procedur e (for us er) 1

1.3.2 INSTALLATION PROCEDURE

!

CAUTION

Unplug the main machine's power cord before starting the following

procedure.

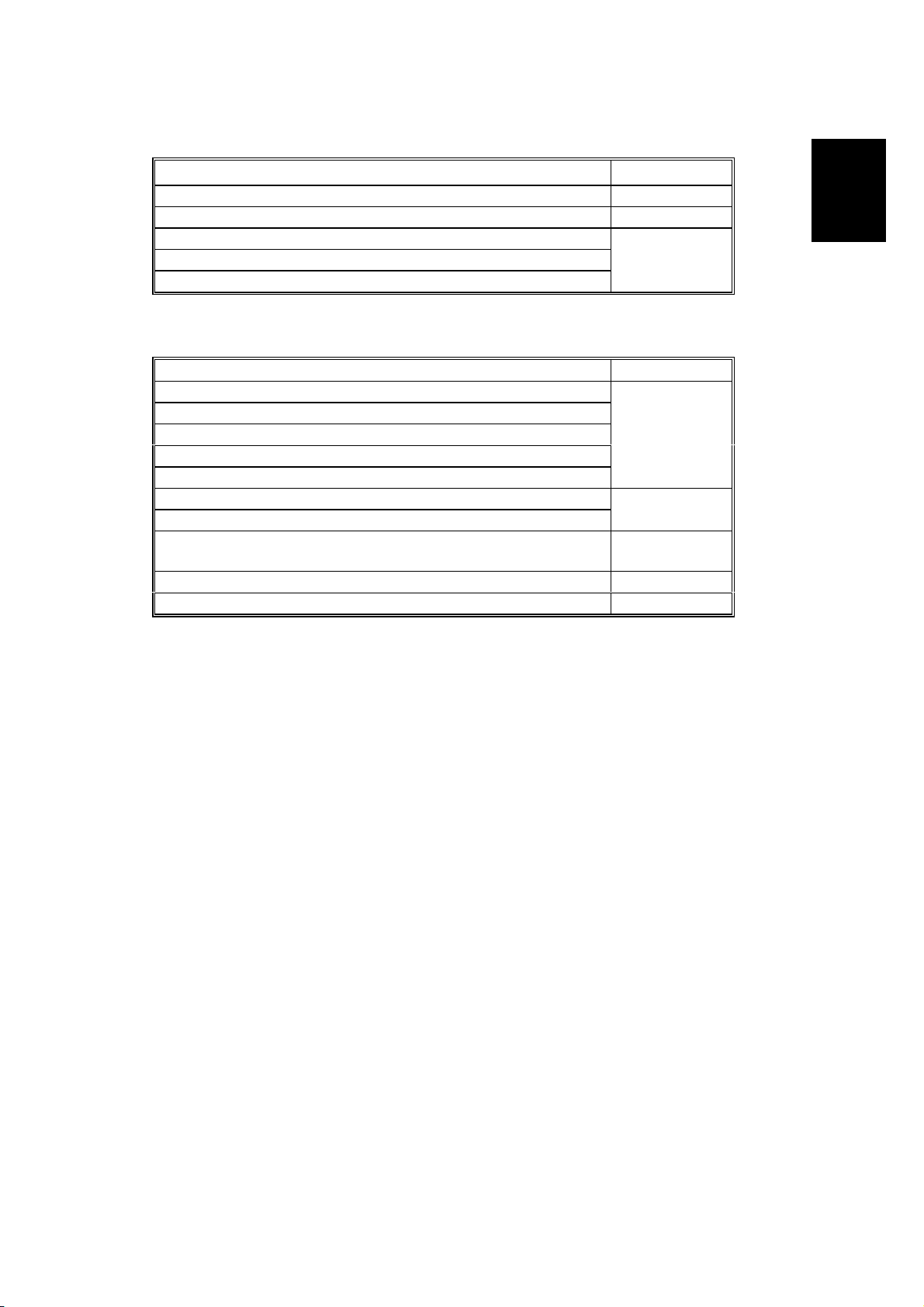

1. Remove the tape at [A], and the tape and cardboard at [B].

2. Pull the paper tray part way out of the unit, remove the tape and cardboard at

[C], and push the tray back in.

[B]

[C]

[A]

B046I516.WMF

1-10

Page 22

24 July, 2001 PAPER TRAY UNIT

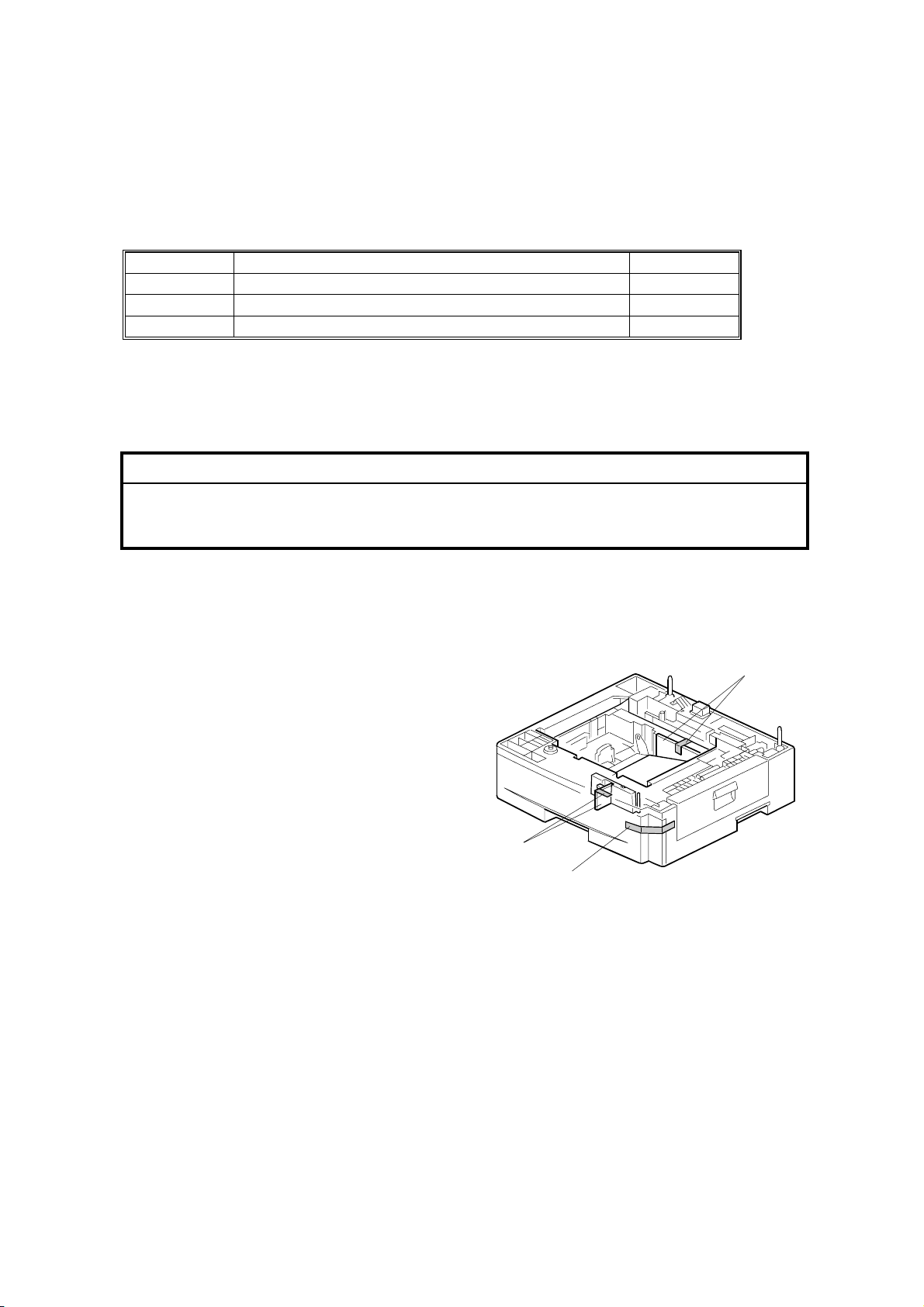

3. Set the machine onto the paper tray unit.

Installation

B046I527.WMF

4. Remove the paper tray from the paper tray unit.

5. Load paper into the paper tray. Adjust the side and end fences as necessary. If

loading 8

"x 14" paper, remove the end fence and set it into the special

1/2

compartment.

6. Set the paper tray back into the paper tray unit.

7. Stick on the appropriate tray-number

decal and paper-size decal, at the

locations indicated in the illustration.

B046I517.WMF

1-11

Page 23

PAPER TRAY UNIT HEATER 24 July, 2001

1.4 PAPER TRAY UNIT HEATER

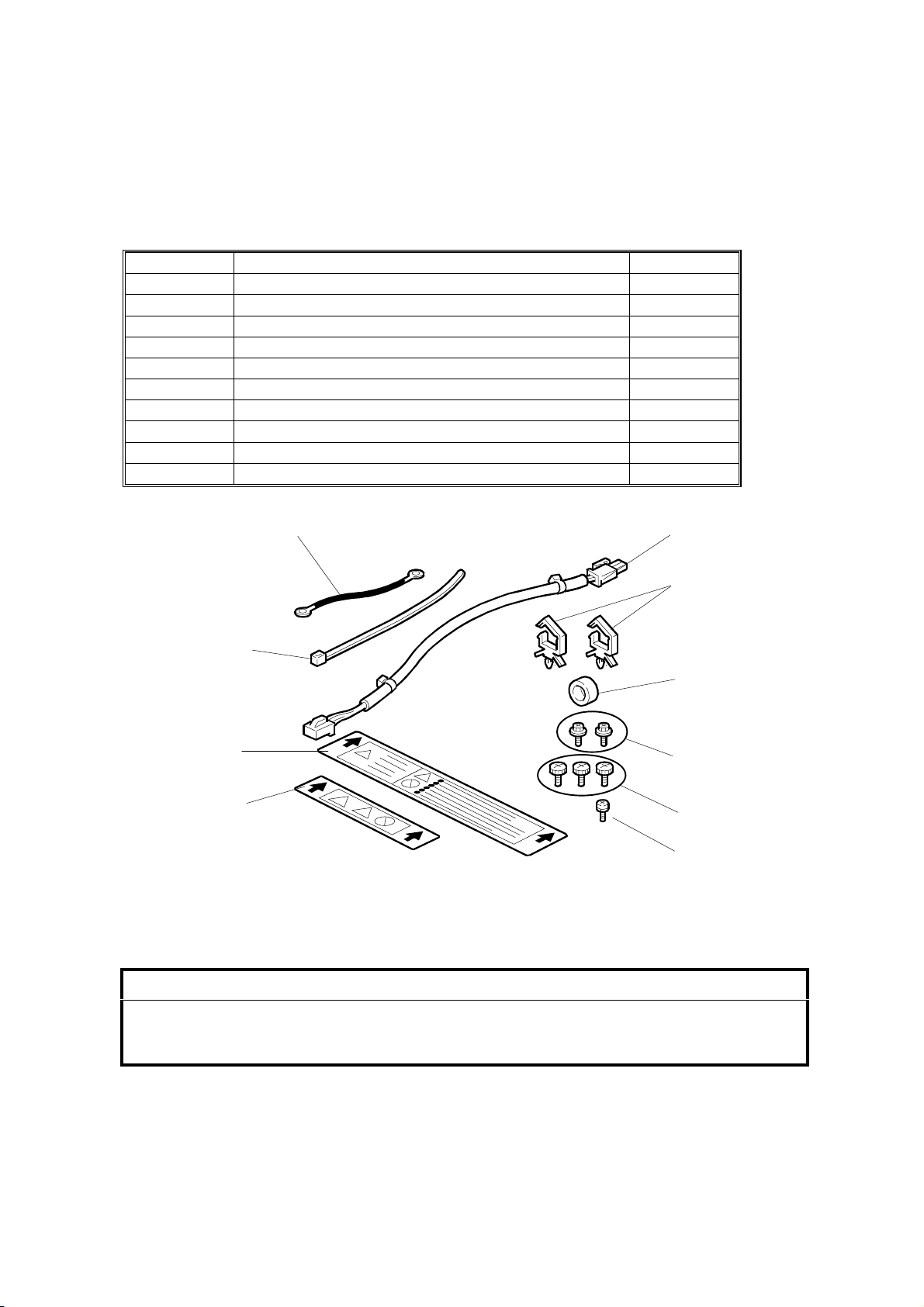

1.4.1 ACCESSORY CHECK

Confirm that you have the accessories indicated below.

No. Description Q’ty

1 Grounding wire 1

2 Relay harness 1

3Clamps 2

4 Ferrite core 1

5 Heater fastening screws 2

6 PTU fastening screws 3

7 Grounding screw 1

8 Decal for copier 1

9 Decal for paper unit 1

10 Tie wrap 1

1

10

9

8

1.4.2 INSTALLATION PROCEDURE

2

3

4

5

6

7

B046I518.WMF

!

CAUTION

Unplug the main machine's power cord before starting the following

procedure.

1. If the paper tray unit is already installed, uninstall it by lifting the copier off of it.

(Refer to illustrations for Procedure 1.3.2, above.)

2. Remove both paper trays—the one from the copier, and the one from the

paper tray unit.

1-12

Page 24

24 July, 2001 PAPER TRAY UNIT HEATER

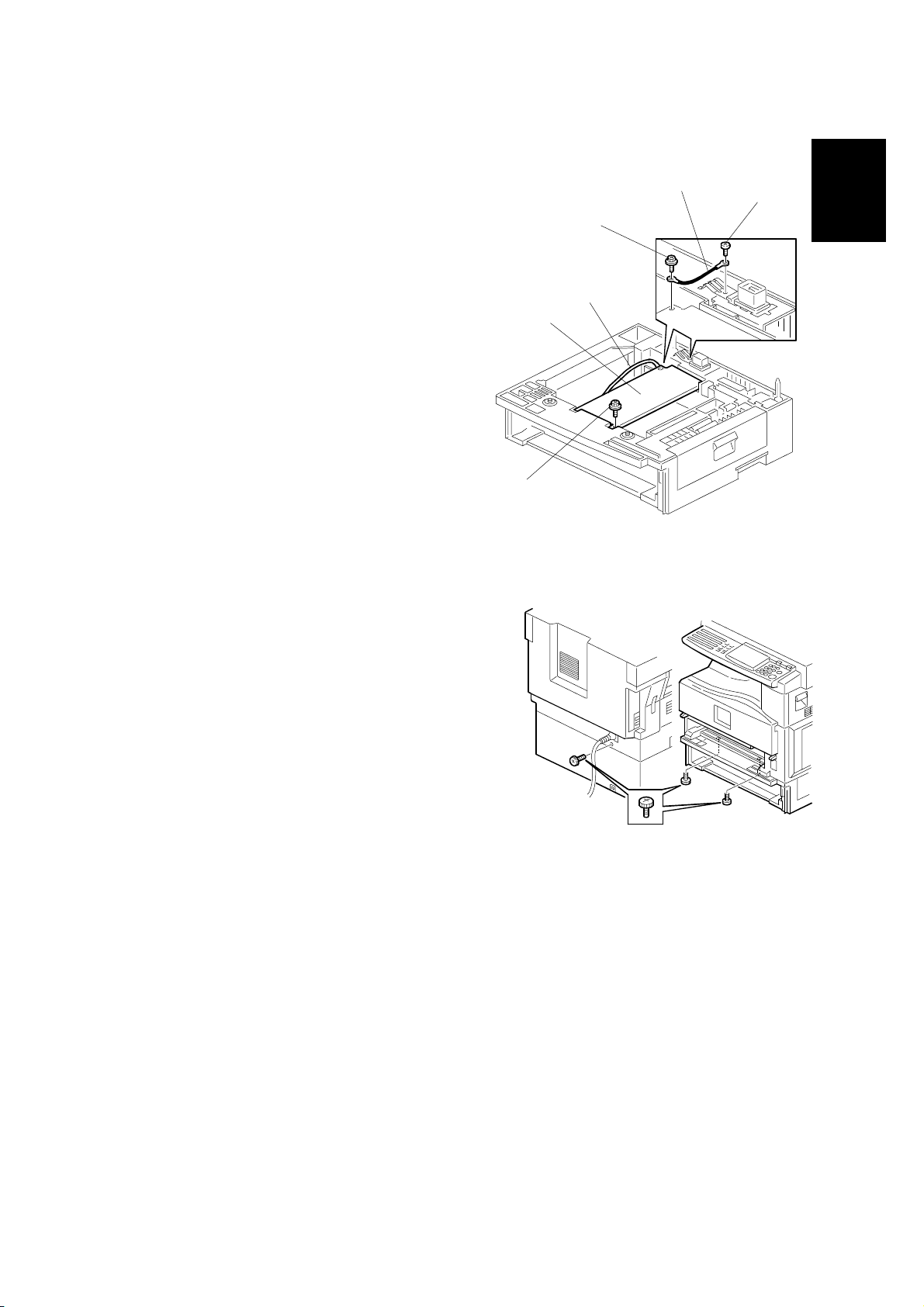

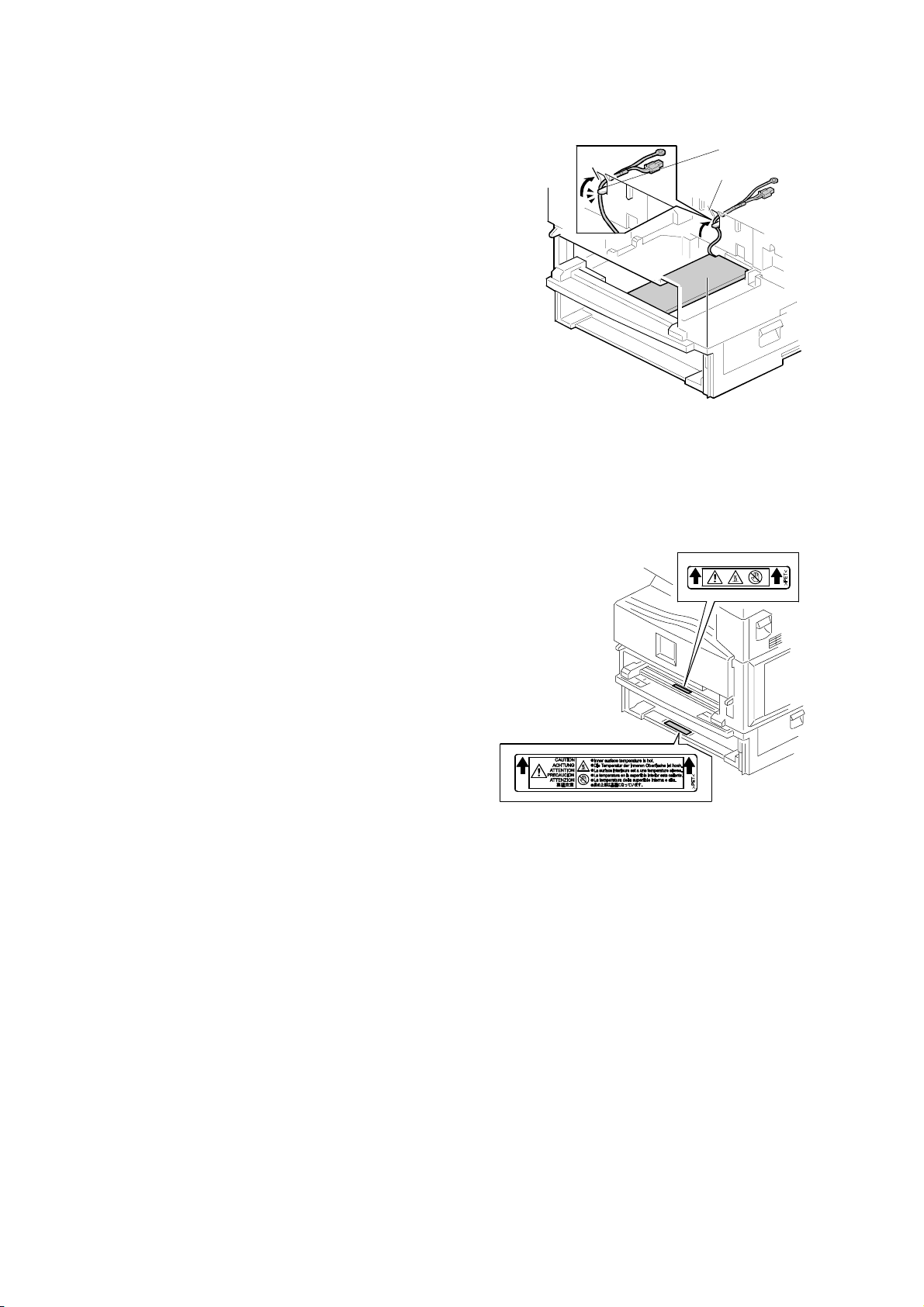

3. Remove the ground screw [A] at the rear of the paper tray unit.

4. Fasten the heater [B] and the supplied

ground wire [C] to the pa per tray unit

with 3 screws as shown. Note that [A]

is the grounding screw you removed at

Step 3 (returned to its original hole),

and [D] and [E] are the two supplied

heater fastening screws.

NOTE: Be sure to position the ground

wire [C] and heater harness [F]

so that they will be out of the

way of the copier when you set

it onto the paper tray unit.

5. Set the copier onto the paper tray unit.

6. Screw the paper tray unit into place using

three supplied PTU fastening screws.

[E]

[B]

[F]

[D]

[C]

[A]

Installation

B046I519.WMF

1-13

B046I500.WMF

Page 25

PAPER TRAY UNIT HEATER 24 July, 2001

7. Open the front door [A] and remove the

copy tray [B] (!×1). Then close the

front door.

8. Remove the rear cover [C] (! x 5).

[B]

[A]

B046I501.WMF

[C]

B046I502.WMF

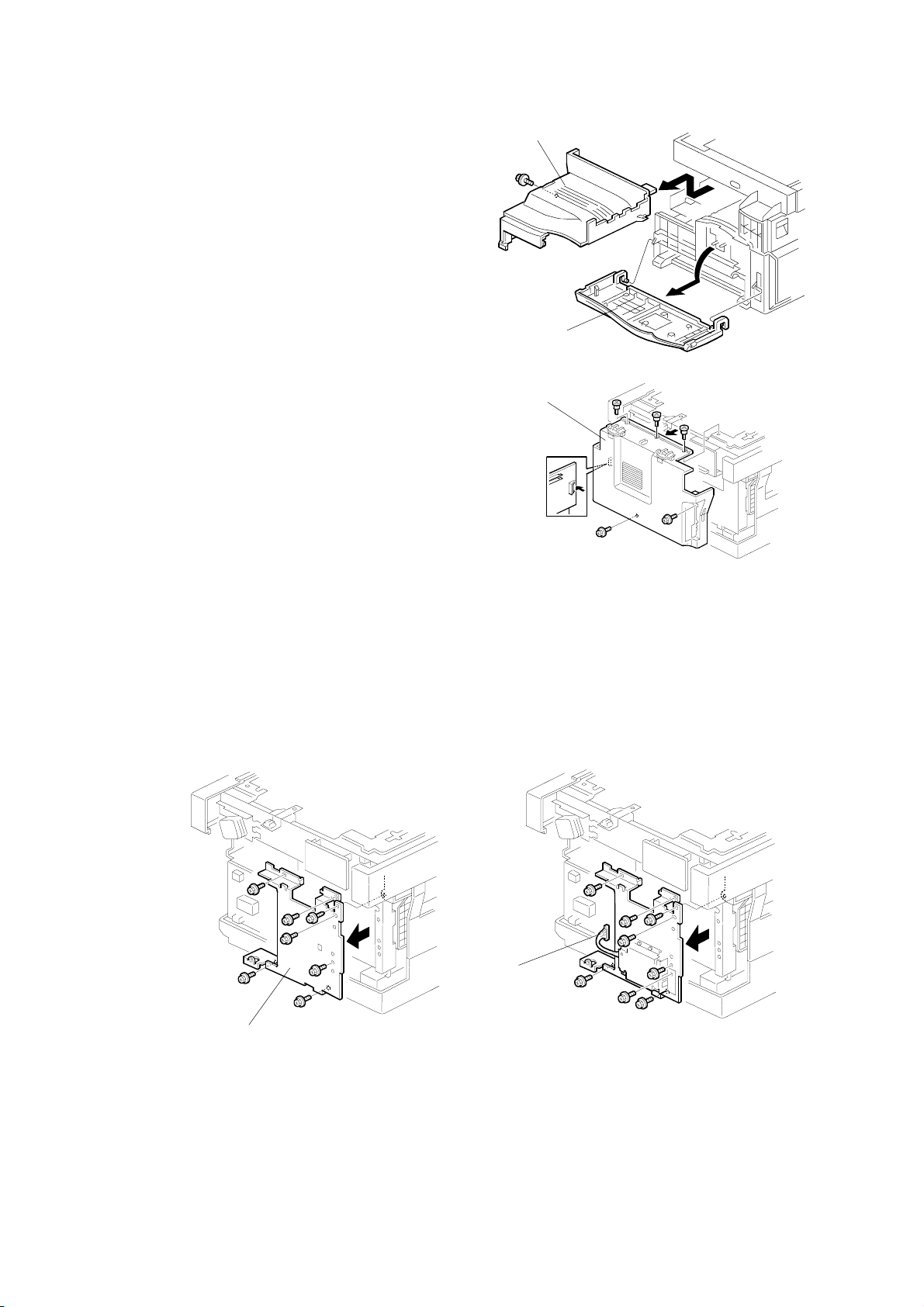

9. Remove the FCU cover plate [D] (7 screws on faxless machines, 8 screws on

fax-equipped machines) .

NOTE: On fax-equipped machines, detach the NCU connector [E] first.

Faxless machines: Fax-equipped machines:

[E]

[D]

B046I503.WMF

B046I504.WMF

1-14

Page 26

24 July, 2001 PAPER TRAY UNIT HEATER

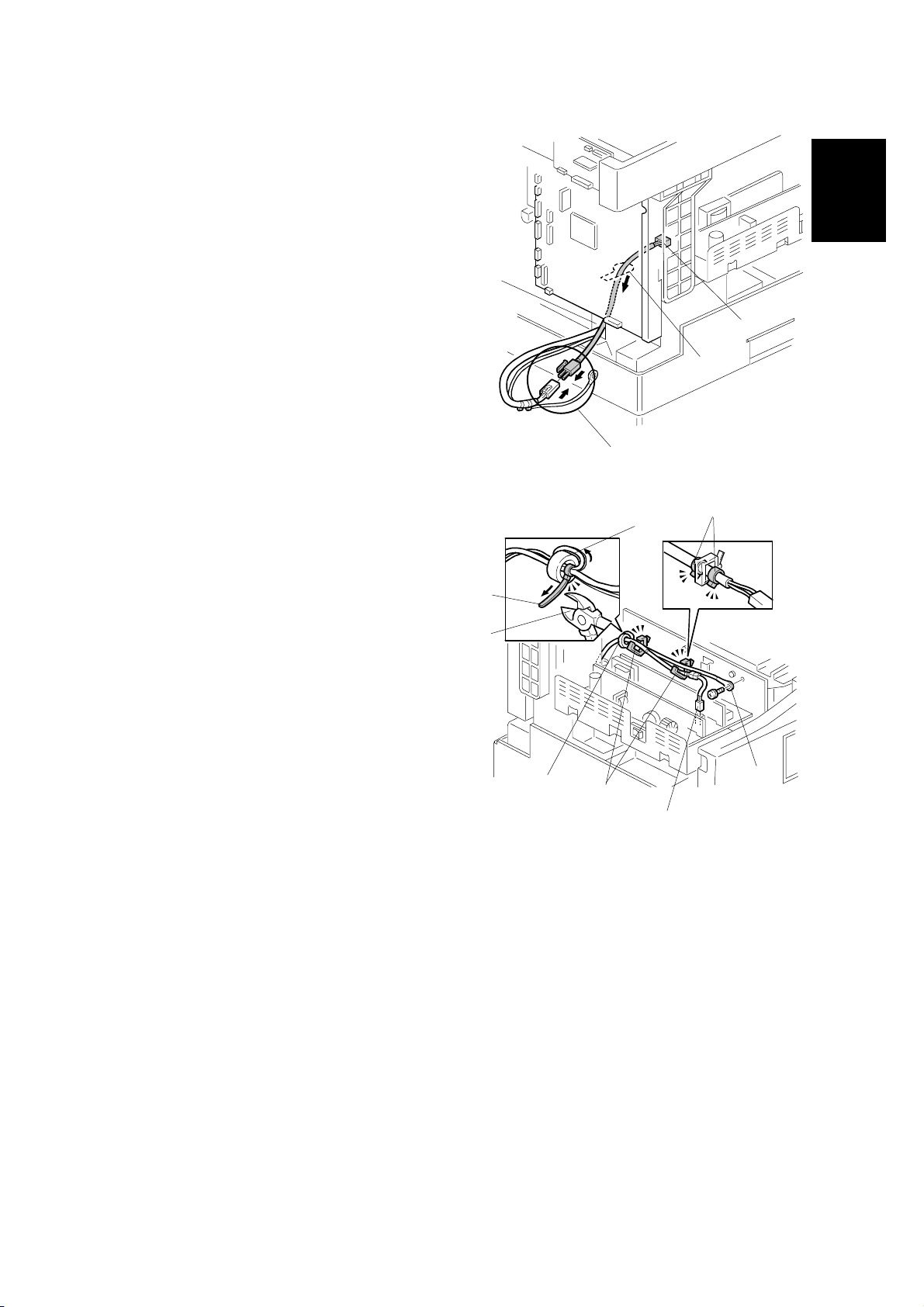

10. Pass the heater's harness through the

hole [A] at the rear of the copier.

11. Pass relay harness [B] through the

circular opening at [C] (at the rear of

[A]

the PSU board bracket), and then

through the hole at [A]. Then connect

[B]

the relay harness to the heater's

harness [D].

[C]

Installation

12. Pull the relay harness back into the

copier. Then set the ferrite core [E]

over the relay harness, and push it

back so that it is over the heater's

harness.

13. Wrap the heater's harness once

around the core (see [F]). Adjust so

that the core is located toward the

rear of the copier (at position [E],

behind the rear clamp). Secure the

core into position using the supplied

tie wrap [G].

14. Clip off the excess length of the tie

wrap [H].

[G]

[H]

[E]

[K]

[D]

B046I520.WMF

[L]

[F]

[J]

B046I521.WMF

[I]

15. Connect the relay harness connector [I] to the large connector at the front

center of the PSU board. Screw the ground wire [J] to the PSU board bracket,

using the included grounding screw.

16. Attach the supplied clamps [K] to corresponding holes on the PSU board

bracket, and set the heater harness though the clamps. Position the harness

so that the front clamp is between the two bindings [L] on the harness. Then

fasten the clamps.

1-15

Page 27

PAPER TRAY UNIT HEATER 24 July, 2001

17. Pull the excess length of the heater's

harness out the hole at the rear [A].

NOTE: Be sure that the harness passes to

the side of the grounding plate [B]

at the bottom of the hole. (The front

of the grounding plate must remain

clear.)

18. Arrange the excess harness length so that it sits beneath the

FCU cover plate.

19. Attach the caution decals

to the locations shown in

the illustration.

[B]

[A]

B046I522.WMF

20. Reinsert the paper trays, and reattach the copy tray and the rear cover.

1-16

B046I523.WMF

Page 28

24 July, 2001 DOCUMENT FEEDER

1.5 DOCUMENT FEEDER

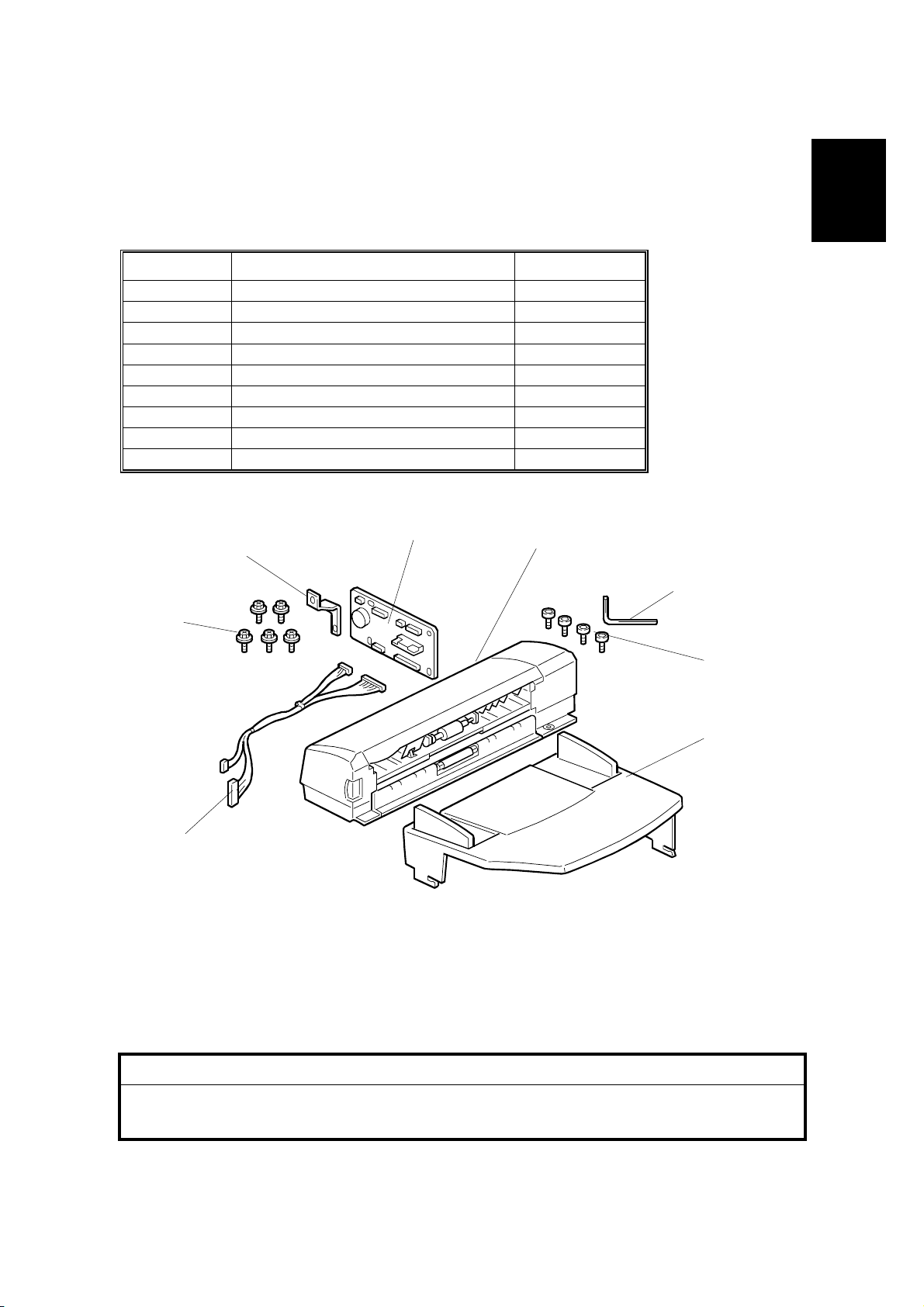

1.5.1 ACCESSORY CHECK

Confirm that you have the components and accessories indicated below.

No. Description Q’ty

1 DF connection board 1

2 DF body 1

3 Hex wrench 1

4Hex screws 4

5 DF original tab le 1

6 Wire harness 1

7 Phillips-head screws 5

8Bracket 1

– Installation Procedure 1

1

8

2

3

7

Installation

4

6

B046I524.WMF

1.5.2 INSTALLATION PROCEDURE

!

CAUTION

Unplug the main machine's power cord before starting the following

procedure.

5

1-17

Page 29

DOCUMENT FEEDER 24 July, 2001

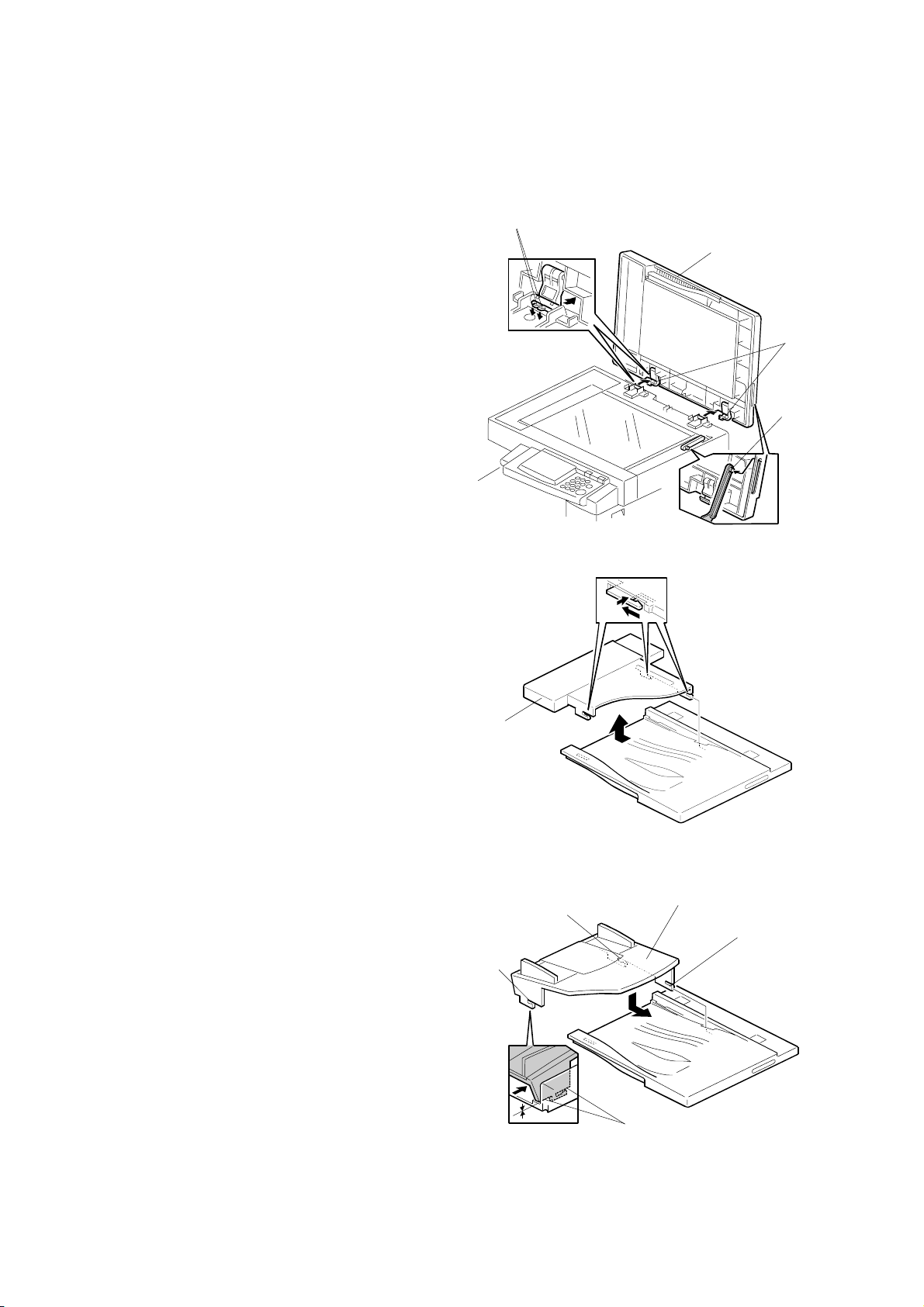

1. Unpack the ADF and remove the packing

tape from the bottom of the ADF body.

[C]

2. Remove the platen cover [A]. To

[A]

remove: Lift the cover, unlatch the

two latches [B] (press down on

the tabs [C] and push the latch

back), and detach the cover from

the hook [D].

[B]

[D]

B046I505.WMF

3. Remove the left piece [E] of the copier's

platen cover by pushing the piece to the

left and then pulling it up and off.

4. Place the DF original table [F] flat onto

the platen cover, so that the 3 latches

go all the way into the openings and so

that the contact area [G] around each

latch is flush against the cover. Then

push so that latch [1] locks into place,

then latch [2], and then latch [3] (at the

rear left).

NOTE: The latches may break if you

try to push the table in at an

angle.

[E]

[1]

[3]

B046I525.WMF

[F]

[2]

[G]

B046I526.WMF

1-18

Page 30

24 July, 2001 DOCUMENT FEEDER

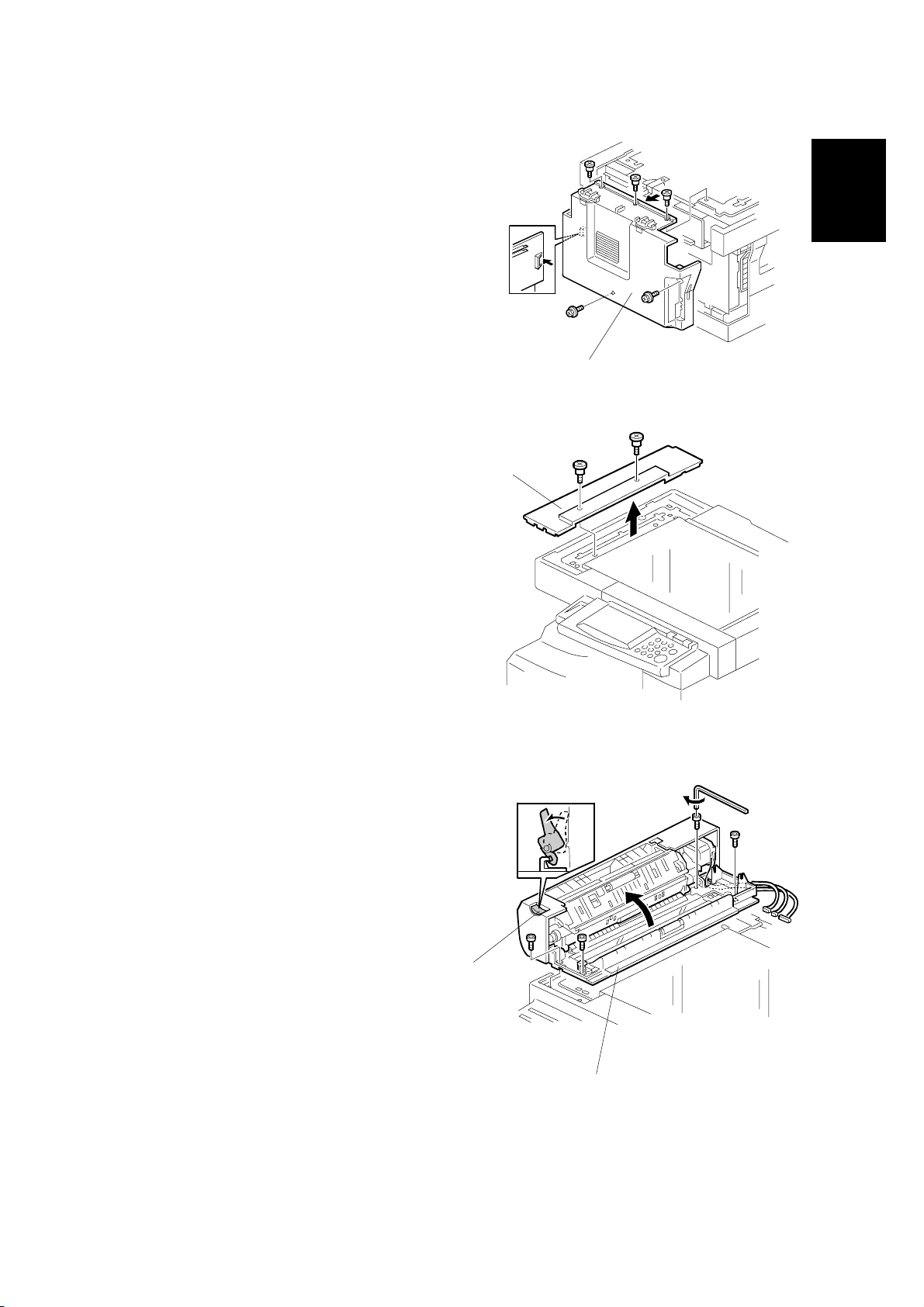

5. Remove the rear cover [A] (! x 5).

[A]

B046I514.WMF

6. Remove the left scale plate [B] (! x 2).

[B]

Installation

7. Set the DF body [C] onto the copier

in its correct position. Press the latch

[D] to raise the top half of the body,

and fasten to the copier with the 4

hex screws (using the included hex

wrench).

B046I506.WMF

[D]

B046I528.WMF

[C]

1-19

Page 31

DOCUMENT FEEDER 24 July, 2001

[B]

8. Install the DF connection board [A] and DF board bracket [B]. (! x 5)

[D]

[C]

[A]

B046I513.WMF

9. Connect the four wire sets from the DF body to CN103, CN105, CN106, and

CN107 on the DF connection board. (Not shown in illustration.)

10. Connect one end of the supplied wire harness [C] to CN101 and CN102 on the

DF connection board, and connect the other end to connectors CN9 and CN10

on the FCU. Secure the wire harness into the clamp [D] located to the side of

the DF board.

11. Reattach the rear cover and the platen cover.

12. Plug in the power cord, and turn on the main switch.

13. Make a full-size copy from the first tray using the ADF, and check the side-toside and leading edge registrations. If the registration is incorrect, adjust as

necessary (☛ 3.13.3).

1-20

Page 32

24 July, 2001 DIMM

1.6 DIMM

1.6.1 INSTALLATION PROCEDURE

!

CAUTION

Unplug the main machine's power cord before starting the following

procedure.

1. Remove the rear cover [A] (! x 5).

Installation

[A]

B046I508.WMF

2. Remove the FCU cover plate [B] (7 screws on faxless machines, 8 screws on

fax-equipped machines) .

NOTE: On fax-equipped machines, detach the NCU connector [C] first.

Faxless machines: Fax-equipped machines:

[C]

[B]

B046I509.WMF

B046I510.WMF

1-21

Page 33

DIMM 24 July, 2001

3. Insert the DIMM [A] at an angle into slot

CN2 on the FCU.

4. Press the free end of the DIMM toward

the FCU, so that the DIMM snaps into

place parallel to the FCU.

5. Reinstall the FCU cover plate and the

rear cover.

[A]

B046I105.WMF

1-22

Page 34

24 July, 2001 PM TABLES

2. PREVENTIVE MAINTENANCE SCHEDULES

2.1 PM TABLES

NOTE: 1) After carrying out PM, clear the PM counter (SP7-804).

2) PM intervals (45k, 90k) indicate the number of prints.

Key: AN: As necessary C: Clean R: Replace I: Inspect

Every

45k

OPTICS

Reflector C C Optics cloth

1st mirror C C Optics cloth

2nd mirror C C Optics cloth

3rd mirror C C Optics cloth

Platen cover C C Dry cloth

Exposure glass C C Dry cloth

Toner shield glass C C Dry cloth

DRUM AREA

PCU R

Transfer roller R

Discharge plate R

PAPER FEED

Paper feed roller R C Water or alcohol.

Friction pad R C Dry cloth

Bottom-plate pad C C Water or alcohol.

Registration roller C C Water or alcohol.

Every

90k

AN NOTE

On B044 and B046: Als o cl ean

toner-bottle holder.

Preventive

Maintenance

FUSING UNIT

Hot roller R

Pressure roller R

Hot roller bearings R

Pressure-roller

bushings

Inlet guide C

Outlet guide C

Hot roller stripper

pawls

Thermistor C

R

I

2-1

Page 35

HOW TO CLEAR THE PM COUNTER 24 July, 2001

Every

90k

DF

Separation roller R C Water or alcohol

Pick-up roller R C Water or alcohol

White plate C Water or alcohol

DF exposure glass C Water

Rollers R0, R1, R2 C Water or alcoho l

Every

120k

PAPER TRAY UNIT

Paper feed roller R

Bottom-plate pad C Dry cloth

Friction pad R

AN NOTE

AN NOTE

2.2 HOW TO CLEAR THE PM COUNTER

After finishing PM, clear the PM counter as follows.

1. Access SP mode 7-804.

2. Hold down the Original Type key and press the OK key (or ! key) to reset the

counter. If the reset is successful, the display shows “Action completed.” If the

reset fails, the display shows “Error!!!”

2-2

Page 36

24 July, 2001 PRECAUTIONS

3. REPLACEMENT AND AD JUSTMENT

3.1 PRECAUTIONS

3.1.1 GENERAL

!

CAUTION

Turn off the main power switch and unplug the machine before starting any

of the replacement procedures described in this section.

But note that you should not turn off the main switch while mechanical parts are

active, as this may cause parts to stop out of home position. Attempting to remove

or install the PCU or other such units while parts are out of home position may

result in damage. Wait for operation to stop before turning off the machine.

3.1.2 LITHIUM BATTERIES

!

CAUTION: Lithium Batteries

Incorrect replacement of lithium battery(s) on the FCU poses risk of

explosion. Replace only with the same type or with an equivalent type

recommended by the manufacturer. Discard used batteries in accordance

with the manufacturer’s instructions.

Adjustment

Replacement

3.1.3 PCU (PHOTOCONDUCTOR UNIT)

The PCU consists of the OPC drum, charge roller, development unit, and cleaning

components. Observe the following precautions when handling the PCU.

1. Never touch the drum surface with bare hands. If the drum surface is dirty or if

you have accidentally touched it, wipe it with a dry cloth, or clean it with wet

cotton and then wipe it dry with a cloth.

2. Never use alcohol to clea n the drum. Alcohol will dissolve the drum surfac e.

3. Store the PCU in a cool dry place.

4. Do not expose the drum to corrosive gases (ammonia, etc.).

5. Do not shake a used PCU, as this may cause toner and developer to spill out.

6. Dispose of used PCU components in accordance with local regulations.

3.1.4 TRANSFER ROLLER

1. Never touch the surface of the transfer roller with bare hands.

2. Be careful not to scratch the transfer roller, as the surface is easily damaged.

3-1

Page 37

PRECAUTIONS 24 July, 2001

3.1.5 SCANNER UNIT

1. Use alcohol or glass cleaner to clean the exposure and scanning glass. This

will reduce the static charge on the glass.

2. Use a blower brush or a water-moistened cotton pad to clean the mirrors and

lenses.

3. Take care not to bend or crease the exposure lamp’s ribbon cable.

4. Do not disassemble the lens unit. Doing so will throw the lens and copy image

out of focus.

5. Do not turn any of the CCD positionin g screws. Doing so will throw the CCD out

of position.

3.1.6 LASER UNIT

1. Do not loosen or adjust the screws securing the LD drive board on the LD unit.

Doing so will throw the LD unit out of ad justment.

2. Do not adjust the variable resistors on the LD unit, as these are permanently

adjusted at the factory. If replacement of the LD drive board is necessary,

replace the entire LD unit.

3. Keep the polygon mirror and toroidal lens free of dust. Laser performance is

very sensitive to dust on these components.

4. Do not touch the shield glass, the lenses, or the surface of the polygon mirror

with bare hands.

3.1.7 FUSING UNIT

1. After installing the fusing thermistor, make sure that it is in contac t with the hot

roller and that the roller can rotate freely.

2. Be careful to avoid damage to the hot roller stripper pawls and their tension

springs.

3. Do not touch the fusing lamp and rollers with bare hands.

4. Make sure that the fusing lamp is positioned correctly and that it does not touch

the inner surface of the hot roller.

Adjustment

Replacement

3.1.8 PAPER FEED

1. Do not touch the surface of paper feed rollers.

2. To avoid misfeeds, the side and end fences in each paper tray must be

positioned correctly so as to align with loaded paper size.

3-2

Page 38

24 July, 2001 SPECIAL TOOLS AND LUBRICANTS

3.1.9 IMPORTANT

1. The machine will automatically start toner agitation when you install a new

PCU. Be sure to wait for initialization to finish before reopening the front cover

or turning off the main switch.

2. If the optional anti-condensation heater (for the optional paper tray unit) is

installed, keep the copier's power cord plugged in even while the main switch is

off, so that the heater remains energized.

3.2 SPECIAL TOOLS AND LUBRICANTS

Part Number Description Q’ty Common with...

A1849501 Optics Adjustment Tools (2 pcs/set ) 1 set Skylark

A2929500 Test Chart – S5S (10 pcs/set) 1 set Mojito

A0299387 Digital Multimeter – F lu k e 87 1 Russian-C, Stinger-C

N8036701 Flash Memory Card (4MB) 1 Russian-C, Stinger-C

N8031000 Case for Flash Memory Card 1 Russian-C, Stinger-C

A2579300 Grease Barrierta – S552R 1 Russian-C, Stinger-C

52039501 Silicone Grease G-501 1 Russian-C, Stinger-C

G0219350 Loop back connector 1 Russian-C, Stinger-C

Adjustment

Replacement

3-3

Page 39

EXTERIOR COVER AND OPERATION PANEL 24 July, 2001

[C]

3.3 EXTERIOR COVER AND OPERATION PANEL

3.3.1 PLATEN COVER

1. Lift the platen cover [A].

2. Unlatch the two latches [B].

NOTE: To unlatch, press down on the tabs [C] and then push the latch back.

3. Detach the cover from the hook [D]

[A]

[B]

[D]

Adjustment

Replacement

3.3.2 REAR COVER

1. Platen cover (☛ 3.3.1)

2. Rear cover [A] (! x 5)

B046R904.WMF

[A]

B046R903.WMF

3-4

Page 40

24 July, 2001 EXTERIOR COVER AND OPERATION PANEL

3.3.3 COPY TRAY

1. Open the front door [A].

2. Copy tray [B] (! x 1)

[B]

[A]

3.3.4 SCALE PLATE (B044 AND B045 ONLY)

1. Scale plate [A] (! × 2)

[A]

B046R912.WMF

Adjustment

Replacement

3-5

B046R551.WMF

Page 41

EXTERIOR COVER AND OPERATION PANEL 24 July, 2001

3.3.5 LEFT COVER

1. Rear cover (☛ 3.3.2)

2. Slide the left cover [A] toward the rear to remove it.

[A]

[B]

[C]

[E]

[D]

Adjustment

Replacement

[F]

[G]

B046R901.WMF

3.3.6 RIGHT COVER

1. Rear cover (☛ 3.3.2)

2. Remove the metal fitting [B], and the platen-cover arm [C].

3. Slide the right cover [D] toward the rear to remove it.

3.3.7 FRONT LEFT COVER AND OPERATION PANEL

1. Front left cover [E] (On B044/5: ! × 2) (On B046/9: ! × 2, " × 2)

NOTE: The illustration shows B046/9.

2. Operation panel [F] (! × 4, " × 1)

3.3.8 FRONT RIGHT COVER

1. Operation panel (☛ 3.3.7)

2. Open the right door.

3. Front right cover [G]

3-6

Page 42

24 July, 2001 EXTERIOR COVER AND OPERATION PANEL

3.3.9 RIGHT DOOR

1. Open the right door [A].

2. Undo the strap [B].

3. Right door (" × 1)

3.3.10 BYPASS TRAY (B044 AND B046 ONLY)

1. Press the stopper rails [A] inward and

remove the bypass tray [B].

[B]

[A]

B046R909.WMF

Adjustment

Replacement

3-7

[B]

[A]

B046R908.WMF

Page 43

EXTERIOR COVER AND OPERATION PANEL 24 July, 2001

3.3.11 PLATEN COVER SENSOR

1. Rear cover (☛ 3.3.2)

2. Platen cover sensor [A] (" × 1)

[A]

B046R931.WMF

Adjustment

Replacement

3-8

Page 44

24 July, 2001 SCANNER SECTION

3.4 SCANNER SECTION

3.4.1 EXPOSURE GLASS

[A]

[B]

Adjustment

Replacement

B046R005.WMF

Non-DF machines

1. Rear cover (☛ 3.3.2)

2. Scale plate (☛ 3.3.4)

3. Exposure glass [A]

DF-equipped machines

1. Rear cover (☛ 3.3.2)

2. Right cover (☛ 3.3.6)

3. Exposure glass [A]

NOTE: When reinstalling: Be sure that the marking on the glass is at the rear left

corner, and be sure the left edge of the glass is aligned flush against the

support ridge [B] on the frame.

3-9

Page 45

SCANNER SECTION 24 July, 2001

3.4.2 LENS BLOCK

1. Exposure glass (☛ 3.4.1)

2. Unclamp four clamps [A], and take

[A]

the wire out of the clamps.

3. Lens block [B] (! × 4, 1 flat cable)

NOTE: 1) Do not loosen the paint-

locked screws holding the

lens unit in place.

2) After installing a new lens

block, carry out copy

adjustments. (☛ 3.13)

3.4.3 EXPOSURE LAMP, LAMP STABILIZER BOARD

1. Exposure glass (☛ 3.4.1)

2. Operation panel (☛ 3.3.7)

[E]

[B]

B046R003.WMF

[B]

Adjustment

Replacement

3. Slide the 1st scanner to a position

where the lamp and scanner are clear

of the metal lids.

4. Disconnect the lamp connector [A].

5. Remove either or both of the following:

• Exposure lamp [B] (1 screw at [C])

• Lamp stabilizer board [D] (2 screws

at [E], 1 flat cable)

[D]

[A]

[C]

B046R001.WMF

3-10

Page 46

24 July, 2001 SCANNER SECTION

3.4.4 SCANNER MOTOR

1. Right cover (☛ 3.3.6)

2. Scanner motor [A] (! × 4, 1 spring,

[A]

" × 1)

NOTE: When reinstalling: Fasten the

screws loosely, then set the

spring in place, then tighten up

the screws.

B046R923.WMF

3.4.5 SCANNER HP SENSOR

Adjustment

Replacement

1. Left cover (☛ 3.3.6)

2. If non-DF machine: Scale plate

(☛ 3.3.4)

If DF-equipped machine: Press on the

DF latch and open the DF.

3. Scanner HP sensor [A] (" × 1)

[A]

B046R020.WMF

3-11

Page 47

SCANNER SECTION 24 July, 2001

3.4.6 SCANNER ALIGNMENT ADJUSTMENT

1. Remove the rear cover (☛ 3.3.2), operation panel (☛ 3.3.7), and exposure

glass (☛ 3.4.1).

2. Loosen the 2 screws holding the 1st and

2nd scanner belts in place.

Adjustment

Replacement

B046D002.WMF

3. Slide the 1st and 2nd scanners so that all four of the following are roughly

aligned on both the front and back sides:

• The hole on the copier's lid

• The hole on the 1st scanner

• The corner right hole on the 2nd scanner

• The hole at the base of the scanner

[A]

4. Insert the two optics adjustment tools

[A], and adjust the scanne rs as

necessary so that the tools go through

all four holes.

5. Tighten the two screws that you

loosened at step 2 above, so that the

belts are firmly clamped into place.

6. Remove the adjustment tools.

3-12

B046D003.WMF

Page 48

24 July, 2001 FUSING

3.5 FUSING

3.5.1 FUSING UNIT

!

CAUTION

The fusing unit can become very hot. Be sure that it has cooled down

sufficiently before handling it.

1. Turn off the main switch, and unplug the machine.

2. Copy tray (☛ 3.3.3)

3. Fusing unit [A] (! × 3, " × 3)

NOTE: When reinstalling the unit:

Replace the spacer [B] in the

correct position, and

remember to set the

grounding wire [C] into place.

3.5.2 EXIT SENSOR

1. Fusing unit (☛ 3.5.1)

2. Exit sensor [A] (" × 1)

[B]

[A]

[C]

B046R501.WMF

Adjustment

Replacement

3-13

[A]

B046R508.WMF

Page 49

FUSING 24 July, 2001

3.5.3 HOT ROLLER STRIPPER PAWLS

[A]

[B]

B046R502.WMF

[E]

Adjustment

Replacement

[D]

B046R507.WMF

[C]

1. Fusing unit (☛ 3.5.1)

2. Separate the fusing unit into two sections: the hot roller section [A], and the

pressure roller section [B]. (! × 2)

NOTE: After removing the screws, lower the pressure roller section about

halfway and then slide it toward the front side to detach it.

3. Hot roller stripper pawls [C] (1 spring for each pawl)

NOTE: 1) To remove the right pawl, first remove the plastic spacer at [D]

(! × 1).

2) When re installing the center p awl, be sure to set roller [E] back

into place.

3-14

Page 50

24 July, 2001 FUSING

3.5.4 HOT ROLLER & FUSING LAMP

[A]

1. Hot roller stripper pawls (☛ 3.5.3)

2. Hot roller assembly [A] (! × 2)

NOTE: 1) Each of the screws has a

washer.

2) After removing the screws,

lift the hot roller assembly

out from the rear side.

3. Fusing lamp [B]

B046R505.WMF

[B]

4. Hot roller [C] (2 C-rings, 1 spacer,

1 gear, 2 bus hings)

[B]

Adjustment

Replacement

[C]

3.5.5 THERMOFUSE, THERMOSWITCH, AND THERMISTOR

1. Remove the hot roller assembly

from the hot roller section.

(☛ 3.5.3)

2. Thermofuse [A] (! × 2).

3. Thermoswitch [B] (! × 2)

NOTE: You must remove the

thermofuse first.

[B]

4. Thermistor [C] (! × 1)

B046R509.WMF

[C]

[A]

B046R506.WMF

3-15

Page 51

FUSING 24 July, 2001

3.5.6 PRESSURE ROLLER

1. Fusing unit (☛ 3.5.1)

2. Separate the fusing unit into two

sections: the hot roller section and the

pressure roller section (☛ 3.5.3, Step 2).

Carry out the remaining steps on the

pressure roller section.

3. Fusing entrance guide [A]

4. 2 springs ([B], [C])

5. 2 pressure arms ([D], [E])

NOTE: Manipulate each arm so

that it comes out through

the slit in the casing.

6. 2 bushings ([F], [G])

[H]

[A]

[B]

[D]

B046R504.WMF

[C]

[E]

[G]

Adjustment

Replacement

7. Pressure roller [H]

[F]

B046R503.WMF

3-16

Page 52

24 July, 2001 PCU

3.6 PCU

[A]

[B]

Adjustment

Replacement

B046I109.WMF

1. Open the right door.

NOTE: Do not forget to open the right door. The PCU may become stuck if

you try to remove it while the front door is closed.

2. Open the front door.

3. Remove the toner bottle holder or THM.

NOTE: If working on a toner-bottle model, clean away all spilled toner from the

toner bottle area and from the inside of the front door.

4. Detach the connector [A] and pull out the PCU [B].

NOTE: 1) After installing the new PCU, be sure to remove the Styrofoam piece

and to pull off the two tags. (☛ 1.1.2, Step 10)

2) The machine will automatically detect the new PCU and begin toner

initialization. (☛ 6.10.4)

3-17

Page 53

TONER SUPPLY CLUTCH 24 July, 2001

3.7 TONER SUPPLY CLUTCH

[C]

[A]

[B]

Adjustment

Replacement

B046R932.WMF

1. Remove the toner bottle or THM.

2. Copy tray (☛ 3.3.3)

3. Rear cover (☛ 3.3.2)

4. Disconnect the connector on C19 on the FCU.

5. Reach into to the machine and push the clutch coupler [A] toward the rear, and

at the same time reach around the back and remove the clip ring [B].

6. Remove the cone and spring, then lift the toner supply clutch mech anism [C]

out of its housing and remove it.

NOTE: When removing, note how the wire goes through a clamp, and also

note where it passes through the rear of the machine.

3-18

Page 54

24 July, 2001 PAPER FEED SECTION

3.8 PAPER FEED SECTION

3.8.1 PAPER FEED ROLLER AND FRICTION PAD

1. Take out the paper tray.

2. Clip ring [A]

3. Pull the shaft back, and lift it out.

4. Remove either or both of the following:

• Paper feed roller [B]

• Friction pad [C]

3.8.2 PAPER END SENSOR

1. Take out the paper tray.

2. Open the right door.

[A]

[B]

[C]

B046R702.WMF

Adjustment

Replacement

3. PCU (☛ 3.5)

4. Paper end sensor [A] (" × 1)

NOTE: When installing the new sensor,

reach your left hand in through the

front and your right hand in

through the right side, and view

from the right side.

B046R929.WMF

[A]

3-19

Page 55

PAPER FEED SECTION 24 July, 2001

3.8.3 REGISTRATION SENSOR

[C]

[A]

B046R926.WMF

1. Take out the paper tray.

2. Open the right door.

[B]

B046R927.WMF

Adjustment

Replacement

3. Black guide piece [A]

4. Registration sensor feeler [B]

5. Registration sensor [C] (" × 1)

3.8.4 BYPASS PAPER END SENSOR (B044 AND B046 ONLY)

1. Right door (☛ 3.3.9)

2. Detach the sensor compartment [A].

3. Bypass paper end sensor [B] (" × 1)

[A]

3-20

B046R924.WMF

[B]

Page 56

24 July, 2001 PAPER FEED SECTION

3.8.5 BYPASS FEED ROLLER (B044 AND B046 ONLY)

[B]

[A]

B046R938.WMF

[D]

[E]

[C]

[A]

[B]

B046R930.WMF

1. Right door (☛ 3.3.9)

2. Unscrew the feed roller frame [A] (! × 2) and rotate it about the feed roller

shaft [B] so that it is upside down.

3. Detach the feed roller shaft [B] from the feed roller frame (unsnap the two snap

pawls [C] and remove the spacer [D]).

4. Bypass feed roller [E]

Adjustment

Replacement

3-21

Page 57

PAPER FEED SECTION 24 July, 2001

3.8.6 BYPASS FEED CLUTCH (B044 AND B046 ONLY)

1. Rear cover (☛ 3.3.2)

2. Right door (☛ 3.3.9)

3. Detach the bypass feed clutch

connector [A] from CN3 on the

high-voltage power supply board.

4. Unscrew the bypass feed roller

housing [B] (! × 2), and pull it out of

the machine.

NOTE: It is not necessary to remove

or disconnect the bypass

paper end sensor.

5. Bypass feed clutch [C] (# × 1)

[B]

B046R925.WMF

[C]

3.8.7 BYPASS FRICTION PAD (B044 AND B046 ONLY)

[A]

Adjustment

Replacement

1. Right door (☛ 3.3.9)

2. Detach the roller housing [B] (! × 2) ,

and move it out of the way.

3. Bypass friction pad [A]

3.8.8 REGISTRATION CLUTCH

1. Rear cover (☛ 3.3.2)

2. High-voltage power supply board

(☛ 3.12.2)

3. Ground plate [A] (!)

[A]

B046R937.WMF

[C]

4. Registration clutch [B] ($× 1, " × 1)

NOTE: To free the clutch, pry clip

[C] gently away from it using

a screwdriver.

3-22

[A]

[B]

B046R950.WMF

Page 58

24 July, 2001 PAPER FEED SECTION

3.8.9 PAPER FEED CLUTCH

[B]

[C]

[A]

Adjustment

Replacement

B046R920.WMF

[D]

[E]

1. Pull the paper tray part way out.

2. High-voltage power supply board

(☛ 3.12.2)

3. Main motor (☛ 3.12.4)

4. Remove 1 screw [A] from the small cover plate.

B046R922.WMF

5. Open 3 clamps [B] on the large cover plate, and remove the wiring.

6. Detach two connectors [C] from the FCU.

7. Large cover plate [D] (! × 7, # × 2, 2 bushings)

8. Paper feed clutch [E]

3-23

Page 59

IMAGE TRANSFER 24 July, 2001

3.9 IMAGE TRANSFER

3.9.1 IMAGE TRANSFER ROLLER

[B]

1. Right door (☛ 3.3.9)

2. Raise the levers ([A], [B]) at the ends

of the image transfer roller, and

remove the roller [C].

NOTE: 1) Note the position of the

2 springs [D] at each end.

When reinstalling the roller,

be sure that the pegs on the

plastic end pieces fit into the

springs.

2) Do not touch the transfer

roller surface with bare

hands.

3.9.2 ID (IMAGE DENSITY) SENSOR

[A]

[A]

[D]

[C]

B046R915.WMF

[B]

Adjustment

Replacement

B046R913.WMF

1. Right door (☛ 3.3.9)

2. Push in the latches as shown, and pry off

the entire section [A].

3. ID sensor [B] (" × 1)

3-24

B046R914.WMF

Page 60

24 July, 2001 FUNCTION CONTROL UNIT (FCU)

3.9.3 DISCHARGE PLATE

1. Right door (☛ 3.3.9)

[A]

2. Use a tweezers to remove the

discharge plate [A].

B046R934.WMF

3.10 FUNCTION CONTROL UNIT (FCU)

NOTE: 1) Before starting replacement, use SP5-824 to save SRAM user data from

the existing FCU into a flash memory card. After finishing the

replacement, use SP5-825 to reload the data from the card into the

SRAM on the new FCU. For instructions, see Section 5.1.8.

2) Replacement FCUs ship with the battery jumper switch set to the OFF

position. Be sure to change the jumper switch to the ON position before

installing the replacem ent FCU.

Adjustment

Replacement

3-25

Page 61

FUNCTION CONTROL UNIT (FCU) 24 July, 2001

[A]

Faxless machine

B046R907.WMF

[B]

Fax-equipped machine:

B046R910.WMF

Adjustment

Replacement

[D]

B046R911.WMF

[C]

1. Rear cover (☛ 3.3.2)

2. FCU cover plate [A] (7 screws on faxless machines, 8 on fax-equipped

machines)

NOTE: On fax-equipped machines, detach the NCU connector [B] first, then

unscrew the cover plate and remove the cover plate together with the

NCU.

3. FCU [C] (all connectors, 2 flat cables, ! x 6)

NOTE: If an optional DIMM is installed on the FCU, remove it and install it on

the new FCU. (☛ 1.6)

4. Before installing the new board, set the new board's TB1 battery jumper switch

[D] to the ON position.

3-26

Page 62

24 July, 2001 LASER UNIT

3.11 LASER UNIT

!

WARNING

The laser beam can cause serious eye damage. Be sure that the main

power switch is off and that the machine is unplugged before accessing