Page 1

!"#$% T

echnical Bulletin

PAGE: 1/3

Model:

Subject:

From:

Bellini

Decal - Paper Set Direction

Technical Services Dept., GTS Division

Classification:

Troubleshooting

Mechanical

Paper path

Other ( )

Part information

Electrical

Transmit/receive

Date:

26-May-00

Prepared by:

No.:

RA294013

H.K.

Action required

Service manual revision

Retrofit information

The following decal has been added to the accessories for the mainframe copier and LCT

from May production.

New part

Description Q’ty Int Page Index Note

number

A2941307 Decal - Paper Set Direction 3 181 *43

A2941307 Decal - Paper Set Direction 3 37 *18

A294

copier

B303

LCT

*:New index

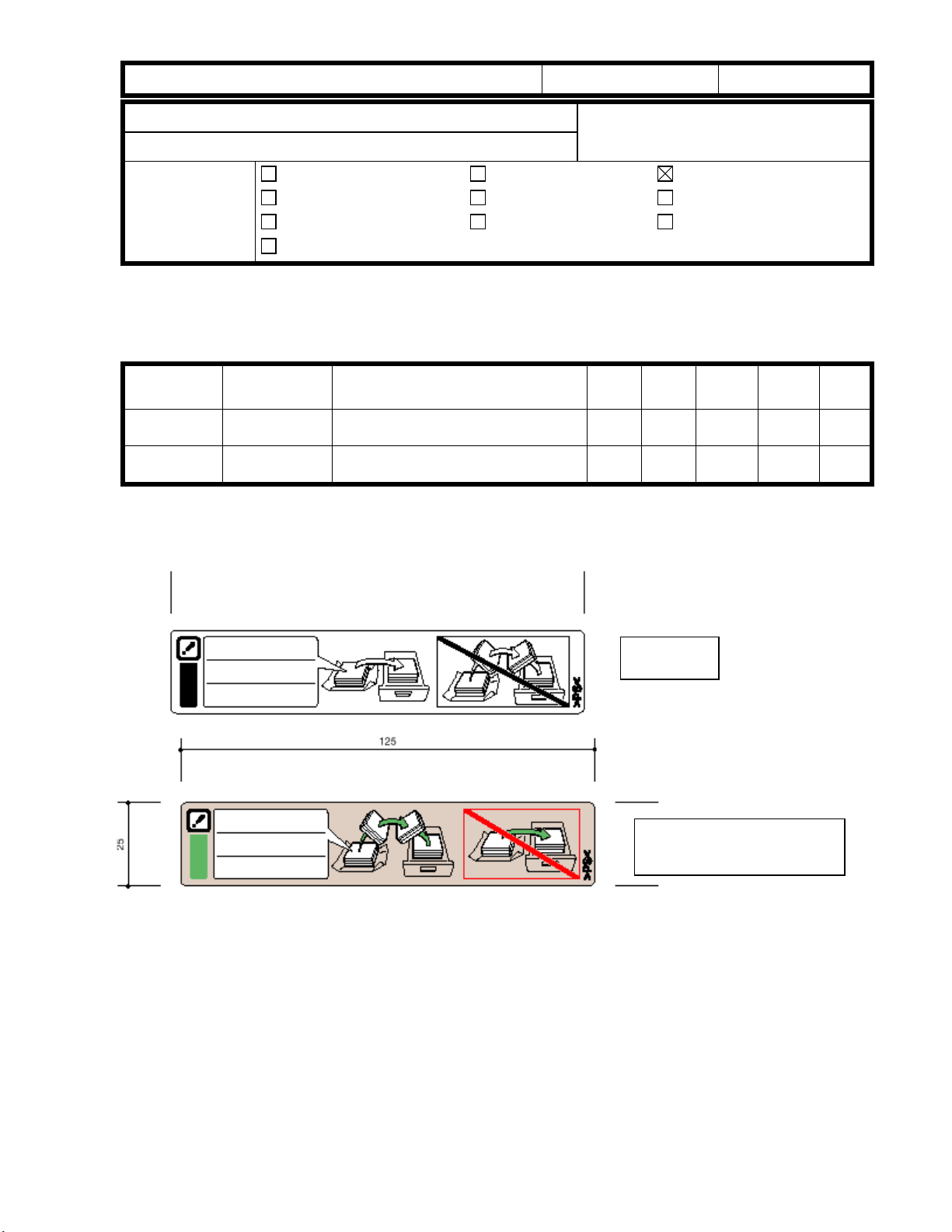

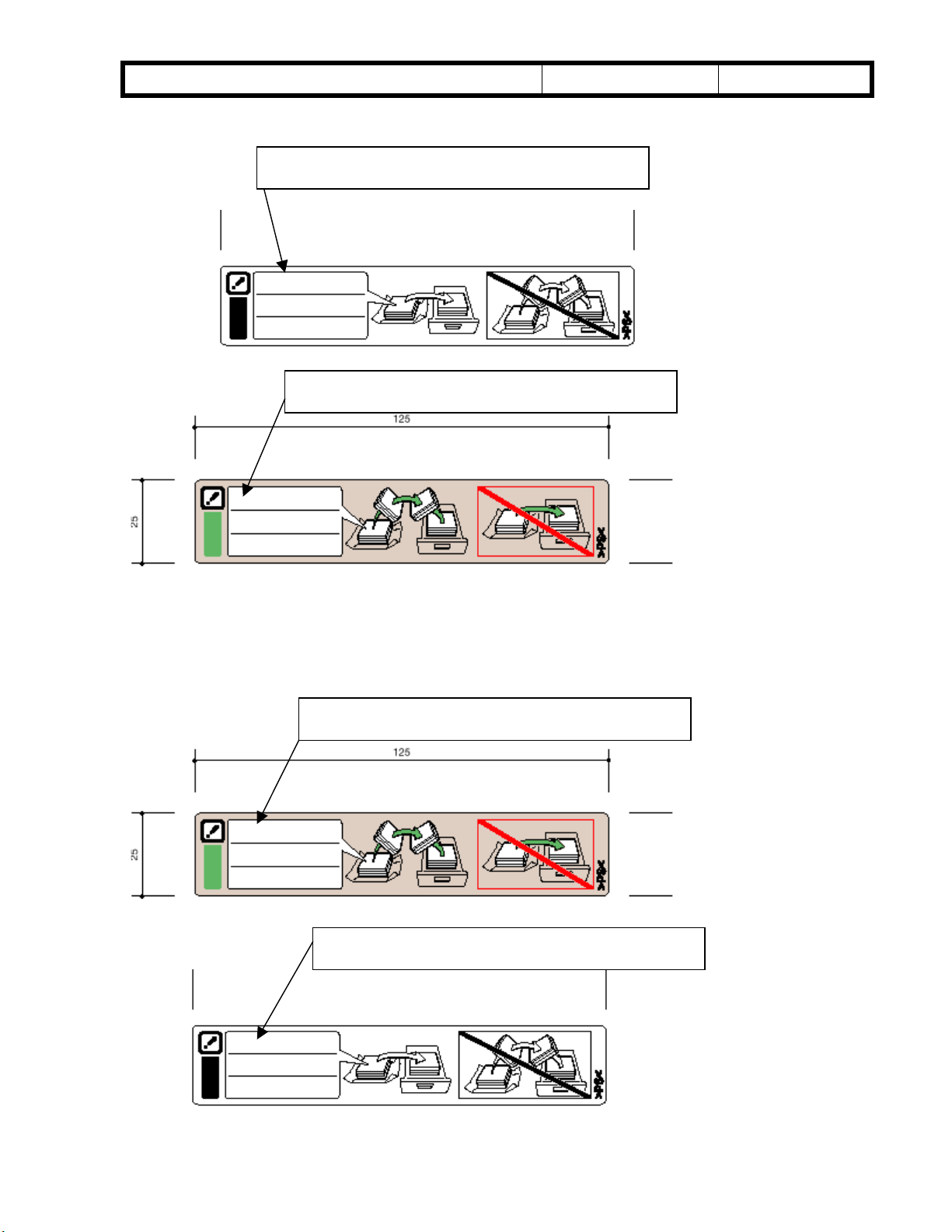

Face-up

Face-down

Decal - Paper Set Direction

The finisher stacking ability depends on the paper load orientation (face-up or face-down).

For some paper brands, face-up produces better stacking and for other brands, face down

is better. The above decal instructs customers on loading paper in order to prevent

unnecessary service calls. Therefore, please use this decal for operator training.

Page 2

echnical Bulletin

T

PAGE: 1/2

Model:

Subject:

From:

Bellini

Paper Guide Fence

Technical Services Dept., GTS Division

Classification:

Troubleshooting

Mechanical

Paper path

Other ( )

Part information

Electrical

Transmit/receive

Date:

03-Aug-00

Prepared by:

No.:

RA294028

H.K.

Action required

Service manual revision

Retrofit information

SYMPTOM

The end fence may detach due to vibration during transport.

CAUSE

The diameter of the holes in the paper guide fence for inserting the end fence was slightly

too large (i.e. Knob Screw with Rubber Tube). This is a side effect from the previous

modification (MB No.004).

SOLUTION

Final countermeasure on the production line

The diameter of the holes in the paper guide fence for inserting the end fence has been

decreased from 5.5 mm to 4.5 mm. Please refer to MB No. 006.

Temporary countermeasure on the production line

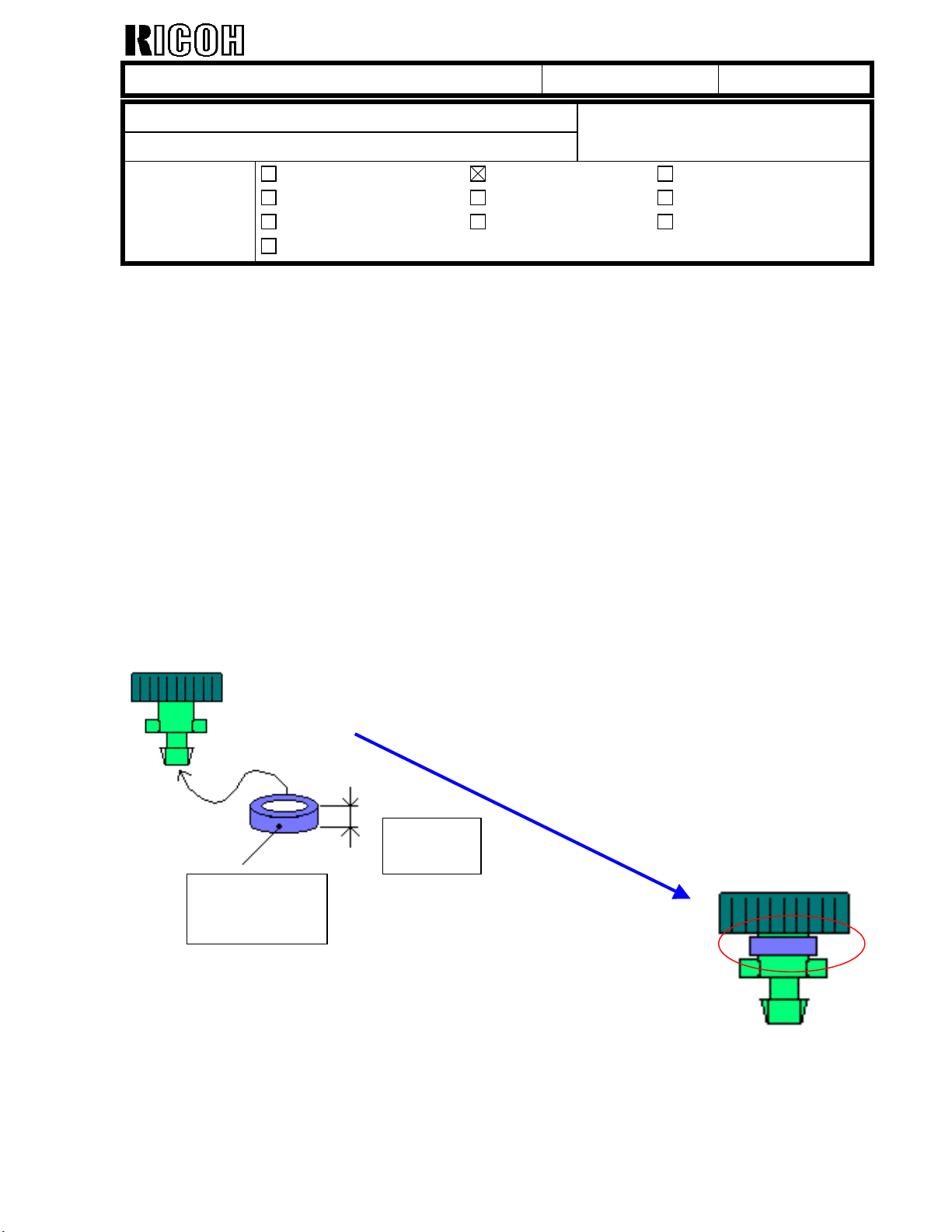

1.5 mm

Rubber ring

An extra rubber ring (1.5 mm) has been attached to the end fence to prevent it from

dropping. This rubber ring is made by cutting the Rubber Tube (B3032788) in the

production line to a thickness of 1.5 mm.

Page 3

echnical Bulletin

T

PAGE: 2/2

Model:

Note: When the new paper guide fence (B3032789: MB No.006) is installed in machines

with the extra rubber ring, it is not necessary to remove the rubber ring from the end fence.

Note:

We have applied the temporary solution at the factory from the same cut-in serial numbers

listed in MB No.004, except for the machines listed below. These units have already been

shipped and do not contain the countermeasures. However we estimate the occurrence

rate to be very low. Please reattach the end fence if it has come off during transport.

B30317 33 units:

Bellini

Rubber Tube - 2x4x33

B3032788

Date:

03-Aug-00

No.:

RA294028

H3900400592 to H3900400624

Page 4

!"#$% T

echnical Bulletin

PAGE: 2/3

Model:

1. Using the mainframe paper trays, make more than 10 copies of a given paper brand

2. Compare the curl of the two bunches of paper by placing them on a flat surface.

3. If the face-down bunch shows less curling, write in the brand name on the face-down

4. Repeat steps 1 to 3 for all the brands of paper normally used by the customer.

5. Repeat steps 1 to 4 for LCT paper feed.

6. Attach the two decals [A] to the copier paper feed tray and LCT as shown.

Note: Two decals can be attached to each copier feed tray. However, there is only room

for one decal on the LCT. Therefore, attach the LCT decal with more brand names onto

the LCT itself. Attach the other to one of the areas labeled [B] below, whichever the

customer prefers.

Bellini

face-up and face-down. Try to use paper which is normally used by the customers.

label (and vice-versa).

Note: With the LCT, the paper is not inverted as it is when fed from the copier trays.

Therefore, the same brand of paper should yield opposite results. Please confirm this

when testing with the LCT and write in the brand name on the appropriate label.

B

Date:

26-May-00

No.:

RA294013

Example:

Copier feed:

Brand A curls less when facing up.

Brand B curls less when facing down.

LCT feed:

Brand A curls less when facing down.

Brand B curls less when facing up.

A

Page 5

!"#$% T

echnical Bulletin

PAGE: 3/3

Model:

Copier feed:

Bellini

Date:

[A] Write down brand names.

[B] Write down brand names.

26-May-00

No.:

RA294013

-------------------------------------------------------------------------------------------------------------------

LCT feed:

[A] Write down brand names.

[B] Write down brand names.

Page 6

echnical Bulletin

T

PAGE: 1/4

Model:

Subject:

From:

Bellini

LCT Tray Heater Kit

Technical Services Dept., GTS Division

Classification:

Troubleshooting

Mechanical

Paper path

Other ( )

Part information

Electrical

Transmit/receive

Date:

19-Jul-00

Prepared by:

No.:

RA294024

H.K.

Action required

Service manual revision

Retrofit information

Part Number of the Tray Heater Kit

The part number for the LCT Tray Heater Kit is not listed in the parts catalogue or service

manual. This kit can be ordered as a spare part.

The part number is as follows:

Old part

number

New part

Description Q’ty

number

A2949500 Tray Heater Kit - 230V 18W

1

This kit includes the following components:

Old part

number

New part

number

AX400053

Description Q’ty

Anti-Condensation Heater - 240V

18W

B3033841 Heater Cover

B3035324 Interface Harness

04514008B Philips Tapping Screw - M4x8

11050310 Harness Clamp - LWS-1S

11050292 Wire Saddle

2

1

1

6

2

1

Page 7

echnical Bulletin

T

PAGE: 2/4

Model:

Installation procedure for the Tray Heater Kit

1. Remove the LCT unit from the main copier and remove the LCT right cover.

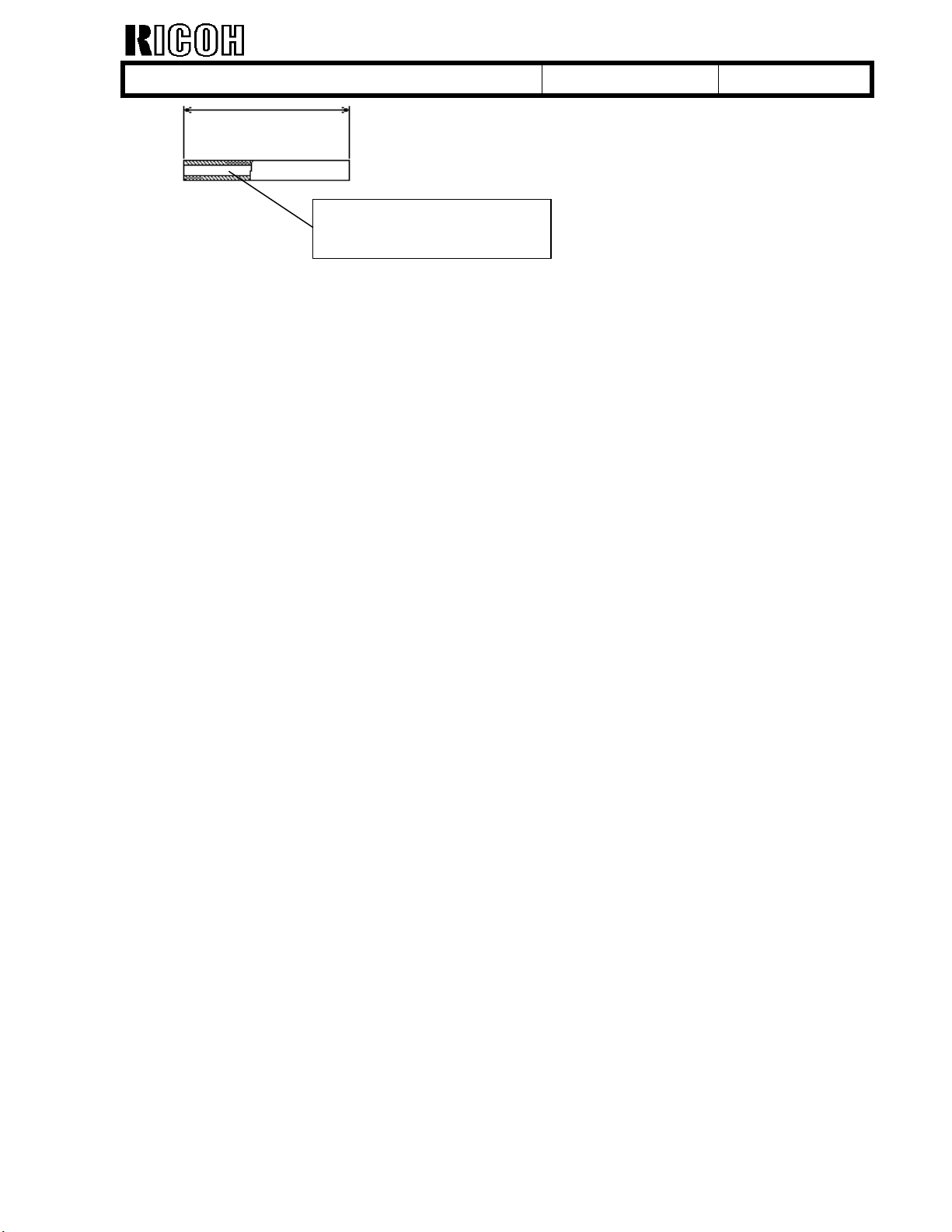

2. Attach the two anti-condensation heaters [A and B] (2 screws each) to the LCT bottom

3. Attach the heater cover [C] (2 screws).

4. Attach the two cable clamps [D] to the LCT bottom plate as shown.

5. Lead the heater cables [E and F] through the cable clamps. Insert the connectors into

6. Connect the connectors [G and H] (interface cables) to the connectors that were just

Bellini

plate.

the connector bracket holes shown below.

inserted into the connector bracket holes (step 5).

G and H

D

Date:

19-Jul-00

E and F

No.:

RA294024

C

A and B

Page 8

echnical Bulletin

T

PAGE: 3/4

Model:

For steps 7-10, refer to the second illustration below.

Note: In accordance with safety standards, the connecting cable [A] must not be touching

the interface cable [B] when the optional LCT tray heaters are installed. Therefore, be sure

to perform steps 7-10 so that the cables remain separated.

7. Replace the wire saddle with the new one ([C] P/N: 11050292), which is included in the

8. Lead the connecting cable [A] as shown.

9. Connect the connector [D] of the interface cable to the mainframe interface.

10. Re-install all parts.

Bellini

optional tray heater kit.

[A]

Date:

[C]

19-Jul-00

No.:

RA294024

[D]

[B]

Page 9

echnical Bulletin

T

PAGE: 4/4

Model:

As mentioned on pg. 2-124 of the Service Manual, all anti-condensation heaters are

disconnected from the AC drive board before being shipped.

When the heater AC cable connector [A] is connected to the AC drive board, the transfer

anti-condensation (drum) heater will be turned on along with the other optional heaters

when the main switch is off.

main switch and unplug the copier power cord.

Bellini

Caution: Before plugging in the heater AC harness connector, be sure to turn off the

Date:

19-Jul-00

AC Drive Board

No.:

RA294024

Heater AC cable connector

Note: The heater AC cable connector is hung on the clamp under the AC drive board.

Page 10

echnical Bulletin

T

PAGE: 1/2

Model:

Subject:

From:

Bellini

Multi-feeding fom LCT

Technical Services Dept., GTS Division

Classification:

Troubleshooting

Mechanical

Paper path

Other ( )

Part information

Electrical

Transmit/receive

Date:

Prepared by:

SYMPTOM

Multi-feeding from the LCT.

CAUSE

The paper stack height is too high.

SOLUTION

Lower the paper stack height by shifting the tray lift sensor.

The procedure is as follows:

13-Oct-00

No.:

RA294035

S. Hizen

Action required

Service manual revision

Retrofit information

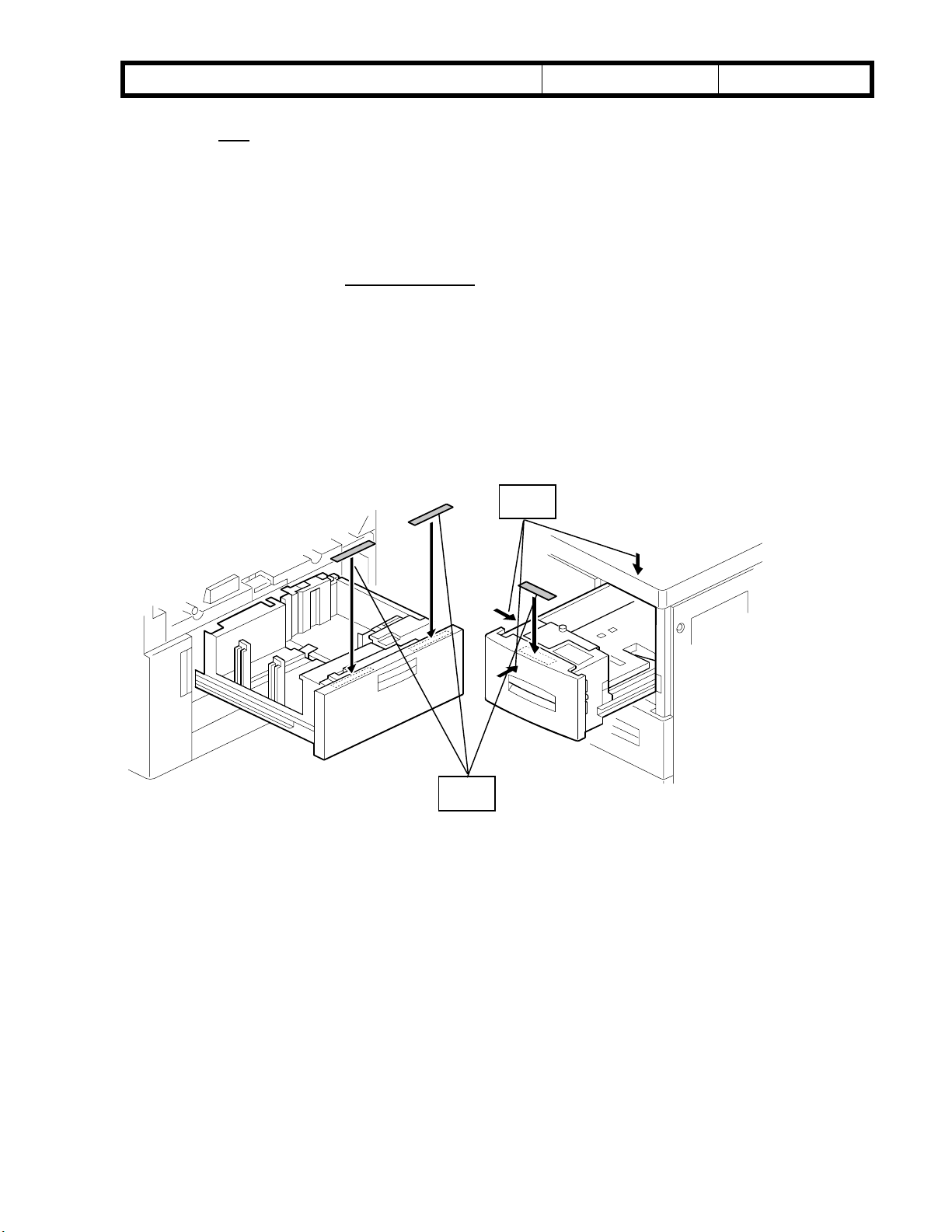

1. Remove the LCT right cover and inner cover and pull out the tray.

2. Remove the paper feed unit (see the service manual, page 6-62).

Paper Feed Unit

Paper Feed Unit

3. Remove the sensor bracket.

4. Remove the paper lift sensor.

Page 11

echnical Bulletin

T

PAGE: 2/2

Model:

5. Remove the cut-out from the bracket with a pair of wire cutters as shown in the

6. Install the paper lift sensor on the bracket.

7. Install the bracket as shown in the illustration. The gap between the bracket and the

Bellini

illustration.

unit is 2.5 mm (0.1 inch): If the customer uses thicker paper and non-feeding

occurs, shift the sensor bracket to reduce the gap.

Paper Feed Unit

2.5 mm (0.1 inch)

Date:

13-Oct-00

Lift Sensor Bracket

No.:

RA294035

Paper Lift Sensor

Page 12

echnical Bulletin

T

PAGE: 1/8

Model:

Subject:

From:

Bellini

LCT Guide Plate Kit

Technical Services Dept., GTS Division

Classification:

Troubleshooting

Mechanical

Paper path

Other ( )

Part information

Electrical

Transmit/receive

Date:

09-Nov-00

Prepared by:

No.:

RA294038

J. Mochizuki

Action required

Service manual revision

Retrofit information

To improve durability, the guide plate B3033645 and related parts have been modified. For

details please refer to MB303007. A2949902 (LCT Guide Plate Kit) has been registered as

a service part to supply the modified parts as a set.

This kit includes the following parts:

[A] B3033646 Guide Plate (1 pc)

[B] B3033680 Linkage Bracket (1 pc)

[C] B3033685 Collar (1 pc)

[D] AA060830 Tighten Spring (1 pc)

[E] 68032273 Stepped Screw (1 pc)

[F] B3031330 Decal - Misfeed

[A] to [E] of the above list have been used for mass production machines from the

following cut-in serial numbers. Please refer to MB303007.

B30314 L0680080001

B30317 H3900700001

B30324 L0680080029

B30326 4B30800001

B30327 H3900800146

B3031330 [F] includes three decals which will be stuck on the LCT inner cover from

November production.

[B]

[E]

[A]

[C]

[D]

Page 13

echnical Bulletin

T

PAGE: 2/8

Model:

Bellini

Guide plate installation procedure

1. Removal of Relay Transport Unit from LCT.

(1) Remove the stay from the LCT (4 screws).

4 screws

Date:

Stay

09-Nov-00

No.:

RA294038

Note: When removing the stay, be careful not to

deform the part shown in the illustration to

the left.

Page 14

echnical Bulletin

T

PAGE: 3/8

Model:

(2) Remove the harness around the relay transport unit from the harness clamps and board.

Bellini

[Front view of Relay Transport Unit] [Rear view of Relay Transport Unit]

Date:

09-Nov-00

No.:

RA294038

Remove harness from clamps.

Remove the connector on

the right.

Page 15

echnical Bulletin

T

PAGE: 4/8

Model:

(3) Remove the relay transport unit from the LCT (4 screws).

Note: As there are hooks, please lift and remove the relay transport unit.

Bellini

[Front view of Relay transport unit] [Rear view of Relay transport unit]

Date:

09-Nov-00

No.:

RA294038

Caution: Please be careful when handling the relay transport unit because there are sharp

edges on the unit.

Page 16

echnical Bulletin

T

PAGE: 5/8

Model:

Bellini

Date:

2. Removal of Old Parts on the Relay Transport Unit

(1) Remove the spring.

AA060817

Tighten Spring

09-Nov-00

No.:

RA294038

P. 4/7

(2) Remove the linkage bracket.

B3033681

Linkage Bracket

(3) Remove the Stepped Screw.

AA143444

Stepped Screw

Page 17

echnical Bulletin

T

PAGE: 6/8

Model:

(4) Remove the guide plate (2 stepped screws).

Bellini

[Front view of Relay Transport Unit] [Rear view of Relay Transport Unit]

Date:

09-Nov-00

No.:

RA294038

B3033645

Guide Plate

Page 18

echnical Bulletin

T

PAGE: 7/8

Model:

Bellini

Date:

09-Nov-00

No.:

RA294038

3. Installation of Countermeasure Parts on Relay Transport Unit

(1) Install the guide plate (B3033646) (2 stepped screws)

[Front view of Relay Transport Unit] [Rear view of Relay Transport Unit]

(2) Install the collar (B3033685) with the stepped screw (68032273)

Page 19

echnical Bulletin

T

PAGE: 8/8

Model:

(3) Install the linkage bracket by hooking it on the stepped screw.

(4) Lubricate with Silicone Grease G501 (52039502) at the parts in the photo.

Bellini

Sliding part with

stepped screw

Date:

09-Nov-00

B3033680

Linkage Bracket

Hook from Round part

No.:

RA294038

(5) Install the tighten spring (AA060380)

Sliding part

with frame

(6) Re-install the relay transport unit.

(7) Re-assemble the LCT.

Loading...

Loading...