Page 1

LARGE CAPACITY TRAY

(Machine Code: A822)

Page 2

21 September 1998 SPECIFICATIONS

1. OVERALL MACHINE INFORMATION

1.1 SPECIFICATIONS

Copy Paper Size: A4 sideways

B5 Sideways

8

" x 11" sideways

1/2

Copy Paper Weight: 64 ~ 105 g/m2 16~24 lb

Power Source: DC 24 V, 5 V (from the copier)

Power Consumption: 48 W

Dimensions (W x D x H ): 403 x 529 x 608 mm (15.9" x 20.9" x 24.0")

Weight: 22.0 kg (48.5 lb)

Tray Capacity: 3,500 sheets (may vary slightly depending on

paper weight)

A822-1

Options

Page 3

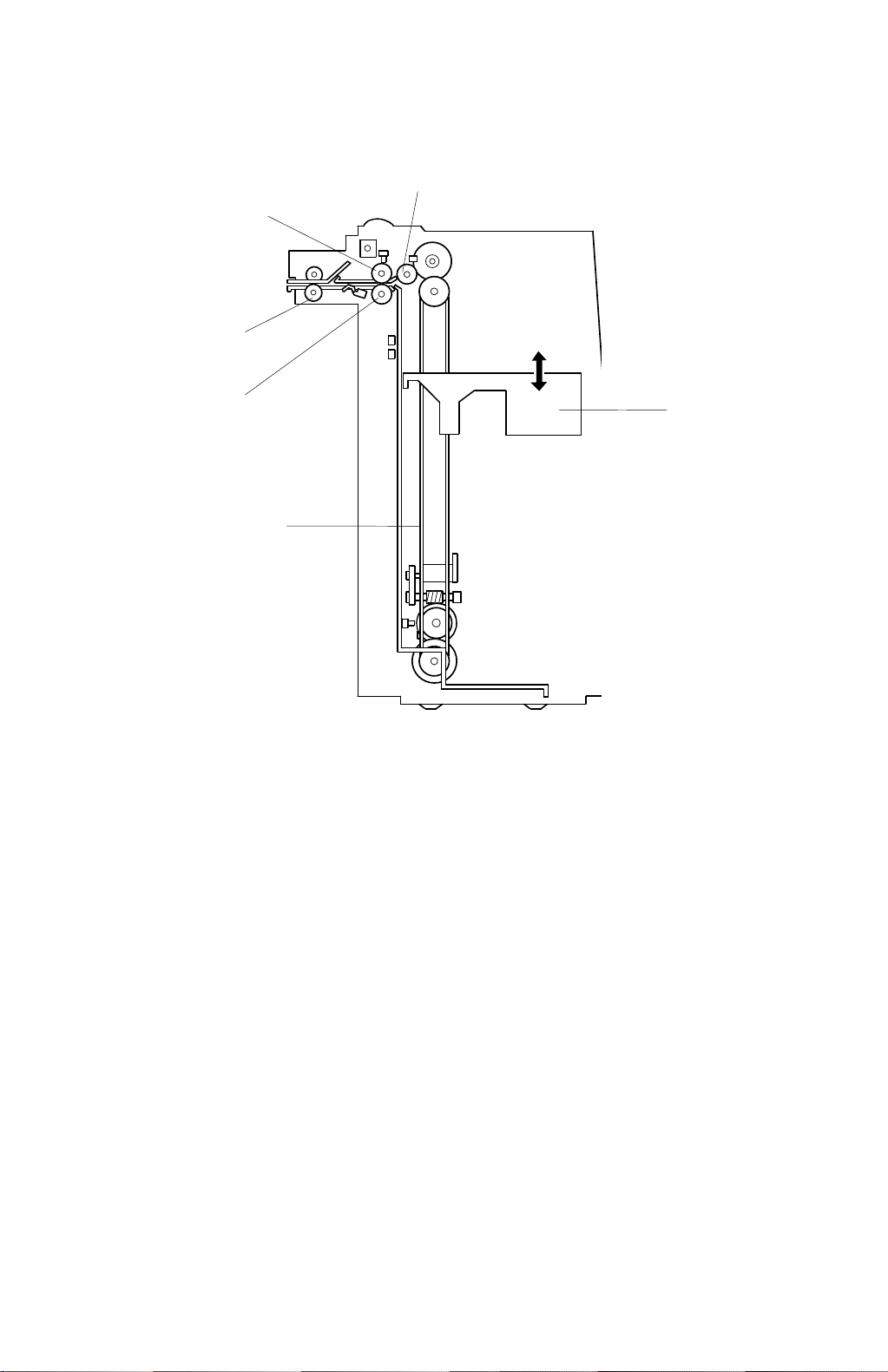

MECHANICAL COMPONENT LAYOUT 21 September 1998

1.2 MECHANICAL COMPONENT LAYOUT

6

5

4

1. Bottom Plate

2. Tray Drive Belt

3

1

2

A822V500.WMF

3. Separation Roller

4. Transport Rollers

5. Feed Roller

6. Pick-up Roller

A822-2

Page 4

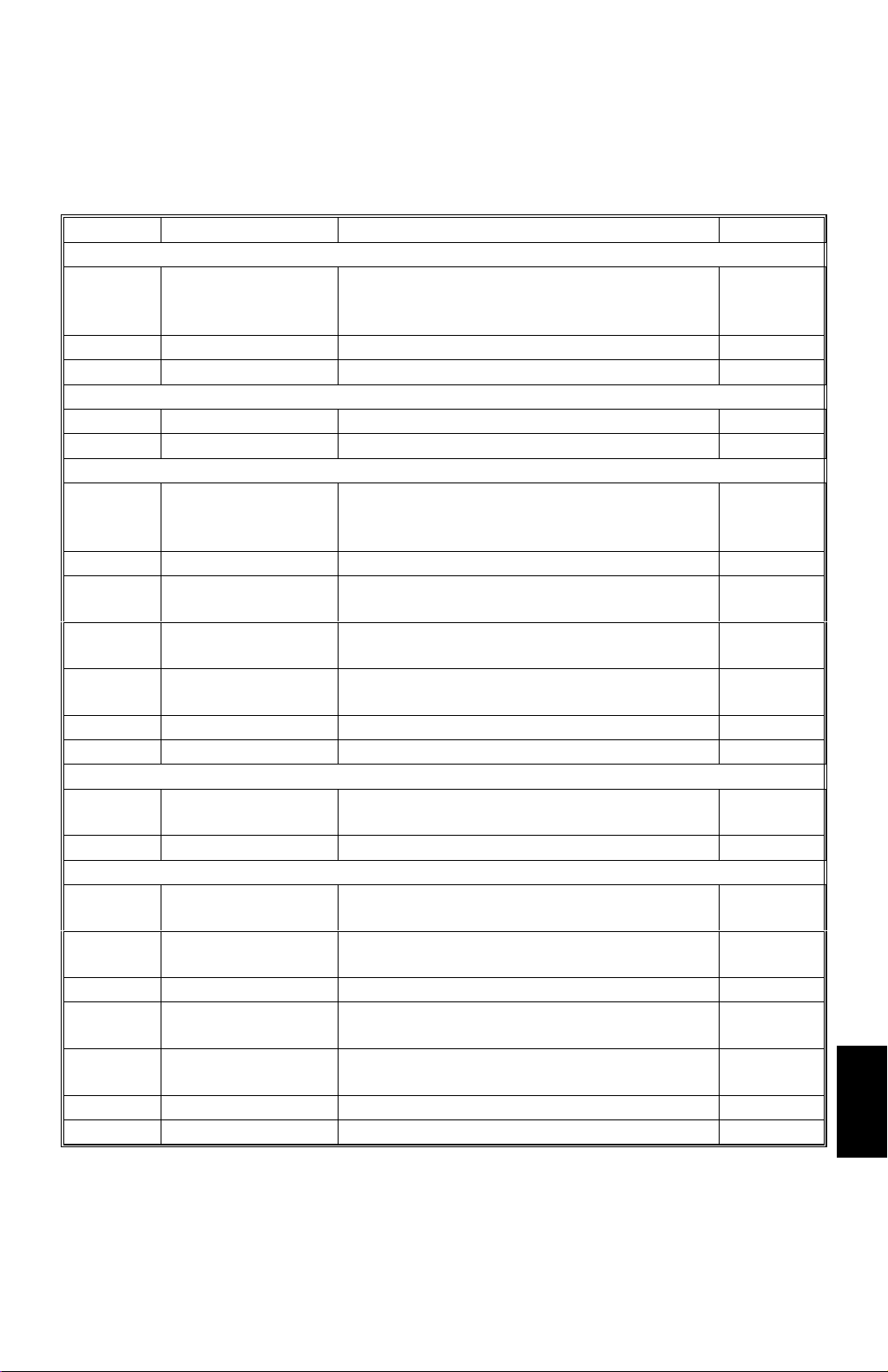

21 September 1998 ELECTRICAL COMPONENT DESCRIPTION

1.3 ELECTRICAL COMPONENT DESCRIPTION

Refer to the electrical component layout on the reverse side of the point-to-point

diagram for the location of the components using the symbols and index numbers.

Symbol Name Functi on I ndex No.

Motors

LCT Lifts and lowers the LCT bottom plate to

M1

M2 Feed Drives all feed and transport rollers. 5

Magnetic Clutches

MC1 Feed Starts the paper feed from the LCT. 4

Switches

LCT Cover 1

SW1

SW2 LCT Cover 2 Detects if the LCT cover is opened or not. 14

SW3

SW4

SW5

SW6 Tray Down Lowers the LCT bottom plate 16

LCT Cover 3 Cuts the power line for LCT when the LCT

Feed Unit Cover 1 Detects if the feed unit cover is opened or

Feed Unit Cover 2

bring the paper to the feed position and

allow loading of the paper.

Ensures that +24V can be passed to the

LCT motor whether the cover is open or

closed.

cover is opened.

not.

Cuts the power line for LCT when the LCT

cover is opened.

11

15

13

6

7

Solenoids

SOL1

Sensors

S1

S2

S3 Paper Position Detects the paper position. 10

S4

S5

S6 Lift Detects the correct paper feed height. 2

Pick-up

Paper End Informs the CPU that there is no paper on

Paper Near End Informs the CPU that about 60 sheets of

Tray Down Informs the CPU that the LCT bottom plate

Feed

Controls the up-down movement of the

pick-up roller.

the LCT bottom plate.

paper remain on the LCT bottom plate.

is in the lowest position.

Control the paper feed clutch off-on timing

and the pick-up solenoid off timing.

3

8

9

12

1

Options

A822-3

Page 5

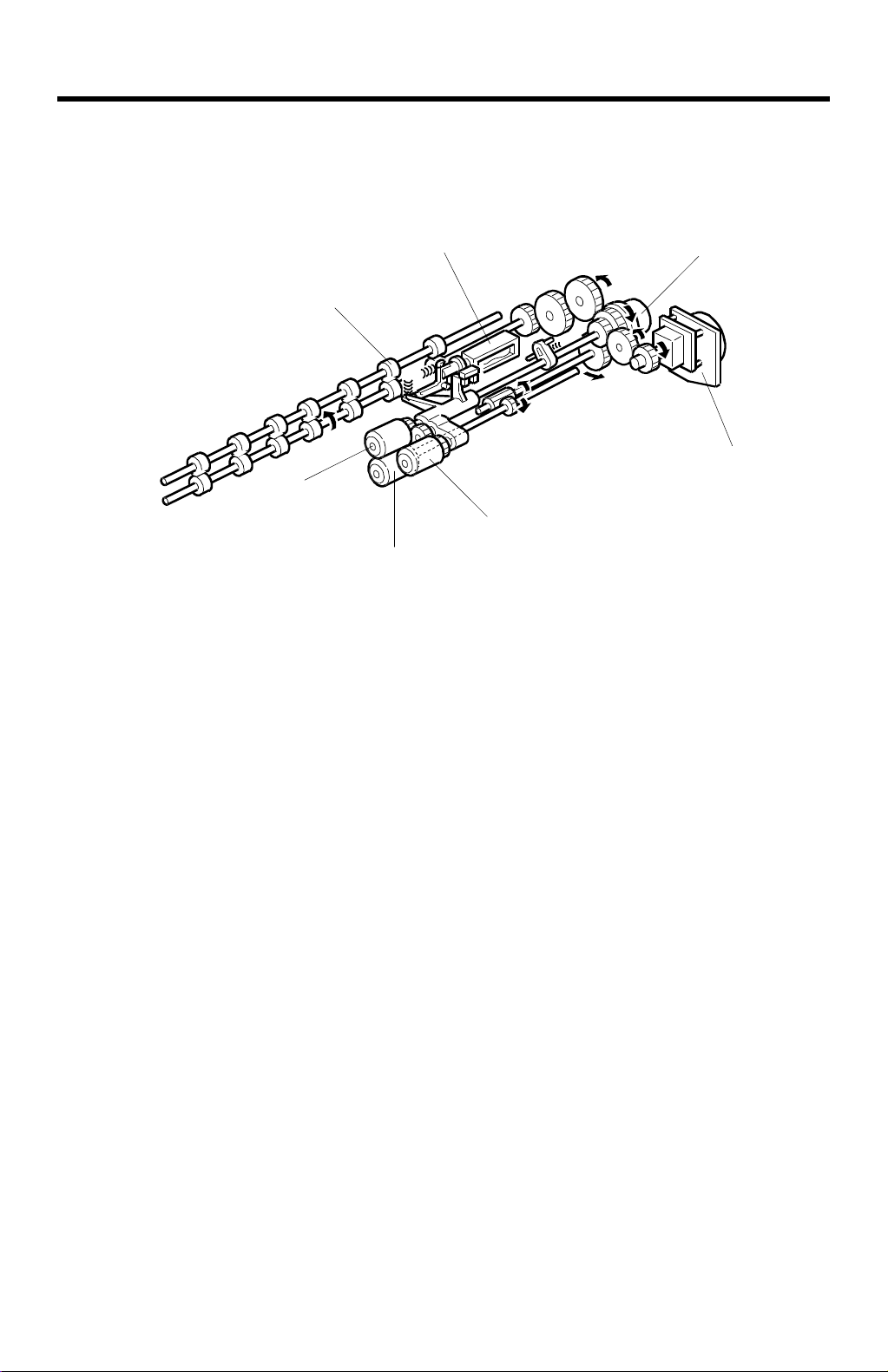

MECHANICAL OPERATION 21 September 1998

2. DETAILED DESCRIPTION

2.1 MECHANICAL OPERATION

[G]

[E]

[C]

[A]

[B]

The LCT uses an FRR feed system which uses three rollers. The pick-up [A],

separation [B] and feed [C] rollers are common with those of the by-pass feed unit

of the mainframe but different from those of the paper feed stations in the paper

tray unit.

A822D500.WMF

[F]

[D]

The LCT feed motor [D] drives the pick-up, separation, feed, and transport [E]

rollers.

The pick-up and feed rollers rotate only when the LCT feed clutch [F] activates.

Paper feeding starts when the LCT pick up solenoid [G] activates.

A822-4

Page 6

21 September 1998 PAPER LIFT MECHANISM

2.2 PAPER LIFT MECHANISM

[C]

[B]

[C]

[D]

[F]

[A]

A822D501.WMF

[E]

A822D505.WMF

The bottom plate [A] of the LCT is raised and lowered by the LCT motor [B] and the

drive belts [C]. When the main switch is on and the LCT cover is closed, the pickup solenoid [D] activates and the LCT motor [B] rotates clockwise to raise the

bottom plate until the top sheet pushes up the pick-up roller [E]. When the lift

sensor [F] is de-actuated, the copier CPU de-activates the LCT motor [B] and the

pick-up solenoid [D].

A822-5

Options

Page 7

PAPER LIFT MECHANISM 21 September 1998

[C]

[A]

[B]

A822D503.WMF

If the tray down switch [A] is pressed, or paper runs out, or a paper jam occurs in

the LCT, the LCT motor [B] rotates counterclockwise to lower the bottom plate.

However, it is not lowered all the way down at this time. When the paper position

sensor [C] activates, the LCT motor stops once. At this point, the bottom plate (or

the top sheet of paper) is positioned about 5 cm below the top. This gives enough

space for the customer to replenish about 500 sheets of paper. If the tray down

switch is then pressed again, the bottom plate moves down and stops once again

when the top sheet of paper just passes the paper position sensor. In this way, the

bottom plate is lowered 5 cm at each press of the tray down switch. This allows the

customer to replenish paper in convenient amounts and at the same position.

A822-6

Page 8

21 September 1998 PAPER END DETECTION

2.3 PAPER END DETECTION

[A]

[B]

A822D504.WMF

The paper end sensor [A] detects paper on the bottom plate. If there is paper on

the table, reflected light from the paper activates the paper end sensor. When the

paper runs out, the paper end sensor de-activates and informs the copier CPU of

the paper end condition.

The paper near end sensor [B] also detects the paper and the tray bottom plate. If

there is enough paper on the table, reflected light from the paper activates the

paper near end sensor. If less than about 60 sheets of paper remain, the paper

near end sensor de-activates because the black colored bottom plate does not

reflect the light from the sensor LED.

A822-7

Options

Page 9

EXTERIOR COVER REMOVAL 21 September 1998

3. REPLACEMENTS AND ADJUSTMENTS

3.1 EXTERIOR COVER REMOVAL

[D]

[B]

[F]

[G]

[E]

[C]

[A]

A822R500.WMF

3.1.1 FRONT COVER REMOVAL

1. Remove the right cover [A] (2 screws).

2. Remove the front cover [B] (3 screws).

3.1.2 REAR LOWER COVER REMOVAL

1. Open the LCT cover [C], then remove it (1 screw).

2. Remove the rear upper cover [D] (1 screw).

3. Remove the rear lower cover [E] (3 screws).

3.1.3 TOP COVER REMOVAL

1. Remove the right cover.

2. Remove the front cover.

3. Remove the hinge bracket [F] (1 screw).

4. Remove the top cover [G].

A822-8

Page 10

21 September 1998 PAPER FEED ROLLERS REPLACEMENT

3.2 PAPER FEED ROLLERS REPLACEMENT

[C]

[D]

[A]

[B]

1. Open the top cover [A].

2. Remove the pick-up roller [B] (1 snap ring).

3. Remove the feed roller [C] (1 snap ring).

4. Remove the separation roller [D] (1 snap ring).

NOTE:

Do not touch the surface of the rollers with oily hands.

The paper feed rollers used in the LCT are different from rollers used in

the 1st ~ 3rd feed units in the paper tray unit. They are not

interchangeable.

A822R501.WMF

A822-9

Options

Page 11

LCT FEED CLUTCH REMOVAL 21 September 1998

3.3 LCT FEED CLUTCH REMOVAL

[A]

[C]

[B]

[D]

[B]

A609R501.WMF

1. Remove the rear upper cover [A] (2 screws).

2. Disconnect the two connectors [B].

3. Remove the harness bracket [C] (2 screws).

4. Remove the bracket [D] with the LCT feed motor (3 screws).

5. Replace the LCT feed clutch [E] (2 Allen screws).

NOTE:

When installing the LCT feed clutch , set the stopper pin on the clutch in

the cut-out [F] on the bracket.

[E]

A822-10

Page 12

21 September 1998 UPPER COVER SWITCHES REMOVAL

3.4 UPPER COVER SWITCHES REMOVAL

[D]

[E]

[C]

[B]

[F]

[A]

[G]

A822R503.WMF

[B]

1. Shade the paper position and paper end sensors with a hand, then push the

tray down switch. (The tray go down to tray down sensor position.)

2. Turn off the main switch.

3. Remove the front cover. (Refer to Front Cover Removal, section 7.1.)

4. Remove the screws [A] securing the side fences [B].

5. Mark the original position of the screws [C] securing the bracket [D].

6. Remove the bracket [D] (2 screws).

7. Remove the paper end sensor [E] (1 connector, 1 screw).

NOTE:

8. Replace the upper cover switches [G] (7 connectors, 2 screws).

NOTE:

When removing the pape r end sensor, do not bend the stay [F].

When re-installing the switches, set the connectors correctly.

A822R504.WMF

Yellow

Blue

Green

Small white

Large white

9. Re-assemble and check copy quality.

A822-11

Options

Page 13

SIDE-TO-SIDE REGISTRATION ADJUSTMENT 21 September 1998

3.5 SIDE-TO-SIDE REGISTRATION ADJUSTMENT

A822R505.WMF

1. Follow the copier’s side-to-side registration adjustment.

Adjustment standard: less than 2 mm difference between the original and the

copy.

A822-12

Page 14

12

11

10

Lens

Verti cal

HP

S3S1

S3 S42

32132

12345

1514131211

-2-3-4-5-6-7-8

CN512-1

[0]

[5]

CC

V[5]

GND [0]

Guide

By-pass

Plate

Tal be

Position

S40M24S41

-B7

-B8

-B9

-B10

[5]

CC

V[5]

GND [0]

AA

CC

CC

[-24] V

[5] V

[5] V

-2-3-4-5-6-7-8

-B10

CN110-1

A

B

Erase Lamp

[12]

[ 0 ]

123

Drum

Potential

G

Position-1

1

6

9875432

10

[5]

CC

V[5]

SW6

321

12345

-B11

-B12

-B13

[5]

GND [0]

[12]

[0 ~ 5] Potential Sensor

E

C

D

(L4)

MM

Optics

Platen

3rd

Cover

[5]

Toner

Near

End

S10

CC

V[5]

[0] CGND

-9

GND [0]

1

-B14

-B15

[5]

[0] CGND

234

F

TH1

1112131415

-10

CC

V[5]

Thermistor [0-5]

[0]

[0/5] Erase Lamp Data

[5] LE

Lens

Scanner

Horizontal

HP

M3

S2

321

6543216543212

123456789

1

1413121110

-2-3-4-5-6-7-8

-11

-12

-13

-14

CN505-1

[5]

CC

AA

V[5]

→→→→→→→

V [24]

GND [0]

GND [0]

[24 0/24]

[24 0/24]

AABBAAB

[0] GND

[0 ~ 5] Fusing Thermistor

[0] GND

[ 5] Fusing Unit Set

[ 5] Power Relay

[ 5] Lead Edge

[ 5] Scan Start

TXD

-9-8-7-6-5-4-3-2-1

CN502-10

-2-3-4-5-6-7-8

CN102-1

[5] OE

[0/5] CLK

[0 ~ 12] TD Sensor VR

[12]

[0 ~ 5] TD Sensor

[0] CGND

[0] CGND

-9

-2-3-4-5-6-7-8

-10

CN114-1

7654321765432

5

1234567

4321321

S8

By-pass

Toner

Paper Size

Density

[24 0/24]

RXD

-9

Transfer Belt P ostioning SOL [ 24]

[0 ~ 5] Paper Size

M

NN

Optics

Lens

Cooling

Fan

M4

M20

1

1011121314

-9

-2

-10

-11

-12

CN517-1

[ 24]

AA

→

V [24]

PGND [0]

[24 0/24]

[24 0/24]

[24 0/24]

B

CC

[0] CGND

[12] +12 V

[5] V

[12] –12 V

→

[24 0/24]

B

V [24]

AAS2

→

[24 0/24]

B

→

[24 0/24]

A

V [24]

AAS2

A

→

[24 0/24]

Duplex Unit Set [t 5]

CGND [0]

CGND [0]

V[5]

V[5]

CGND [0]

CGND [0]

V[5]

V[5]

GND [0]

V [24]

V [24]

V [24]

V [24]

→

[24 0/24]

A

V [24]

→

[24 0/24]

A

→

[24 0/24]

B

V [24]

→

[24 0/24]

B

V [24]

ON [ 24]

Speed [H/24, L/0]

AGND [0]

Speed [H/0, L/24]

V [24]

V [24]

AAS1

AGND [0]

QL, PTL [ 5]

Relay [ 24]

PWM C

PWM G

PWM B

PWMT

T. F / B. C

T. F / B. V

GND [0]

CC

[5] V

[0 ~ 5] Drum Thermistor

[ 5] Drum Unit Set

[0] CGND

-11

-12

-13

-14

1

Pre-Transfer

Quenching

Charge Wire Cleaner

CC

CC

CC

CC

AA

t

[ 24]

AA

t

[ 24]

AA

t

[ 24]

AA

t

[ 24]

AA

AA

AA

t

AA

s

s

t

t

C. F/B

G. F/B

B. F/B

Density

[s 5]

[t 5]

[s 5]

[5]

t

t

Verti cal

987654321

AA

AA

V [24]

V [24]

[24 0/24]

[24 0/24]

AA

Not Used

[0] PGND

[24] V

-2-3-4-5-6

CN501-1

-2-3-4-5-6

-10

CN131-1

Cleaner Motor (+) [ 24]

Cleaner Motor (–) [ 24]

CC

[5] V

[0 ~ 5] ID Sensor

[5] LED

[0] CGND

-9

-10

14151617182223

14151617182223

65431

S9PCB9

Image

Density

N

OO

Origial

Legth

(LTVersion only)

S46

43213215432

123456789

987654321

11

10

-2-3-4-5-6-7-8

CN507-1

CC

CC

V[5]

V[5]

VR [0 ~ 5]

VR [0 ~ 5]

24

24

-9

[t 5]

V[5]CC

GND [0]

GND [0]

GND [0]

OUT [0 ~ 5]

OUT [0 ~ 5]

Optics Control

(PCB4)

CN130-1

-2

-3

-4

-5

-6

CN112-A1

A2

A3

A4

A5

A6

A7

A8

A9

A10

A11

A12

A13

A14

B1

B2

B3

B4

B5

B6

B7

B8

B9

B10

B11

B12

B13

B14

CN111-1

-2

-3

-4

-5

-6

CN105-1

-2

-3

-4

-5

-6

-7

CN116-1

-2

-3

-4

-5

-6

-7

-8

-9

-10

L5

L3

M8

CN606-10

O

131211

123456789

10

11

131211

-10

-11

CN520-1

→→→

Feed-back [0,5 0/5]

A14

A13

A12

A11

A10

A9

A8

A7

A6

A5

A4

A3

A2

A1

B14

B13

B12

B11

B10

B9

B8

B7

B6

B5

B4

B3

B2

B1

CN601-7

-6

-5

-4

-3

-2

-1

-9

-8

-7

-6

-5

-4

-3

-2

-1

13

13

CN661-3

-4

CN663-2

-1

CN662-2

-1

PP

APS

987654321

10

101112

987654321654321

10

-2-3-4-5-6-7-8

A10

A11

A12

A13

A14

B10

B11

B12

B13

B14

B15

CN661

GND [0]

PGND [0]

LED [ 5]

Sensor [ 5]

Motor ON [ 5]

Motor A [5 0/5]

Motor B [5 0/5]

A1

A2

A3

A4

A5

A6

3

A7

2

A8

1

A9

3

2

1

1

2

B2

2

B3

1

B4

2

B5

1

B6

2

B7

1

B8

2

B9

1

6

5

4

3

2

1

3

2

1

3

2

1

T.Belt P.SOL [ 24]

Transfer Feedback Current

Transfer FeedbackVoltage

Developement

Bias (PP2)

[ 24] Cleaner Motor (+)

[ 24] Cleaner Motor (–)

[ 24] QL/PTL

[0] PGND

Charge F/B Current

PWM C

-2-3-4-5-6-7-8

CN602-1

2345678

2345678

-1-2-5

-9-8-7

-11

-10

[ 24] V

AA

[ 24]

Charge

[24]

[ 24]

(PP1)

[ 24](+)

[ 24](–)

-9

-10

-11

-12

CC

CCP

V[5]

GND [0]

V[5]

+12 V [12]

MM

[38] V

[0] MGND

-2

CN516-1

A

B

8F

3

2

1

1

3

2

2

3

1

2

2

3

1

V [24]

AA

PGND [0]

PWMT

GND [0]

GND [0]

AA

Grid G/B Voltage

Grid ON

[0] GND

[24] V

-9

CN603-1

9

10

12

9

10

12

-6

-12

P

Platen

Lens

Cover

Horizontal

Position-2

HP

S43

S4S6 S5

32132165432

12345

-2-3-4-5-6

CN511-1

[5]

[5]

5V[5]

GND [0]

[ 38] Forward

[ 38] Reverse

CN515-2-4CN514-1

M1

Scanner

Registration

M17

Jogger HP

S38

Duplex Exit

S35

Duplex Paper End

S37

Duplex Entrance

S34

Duplex Feed

MC8

DuplexTransport

MC7

SOL

Duplex Positioning

13

SOL

Pressure Arm

14

Jogger

M19

Drum Cooling Fan

M22

Optics Board Cooling Fan

M21

CN605-1

6

CC

V[5]

GND [0]

→

[5] VCC

[0 0/5] A

-2-3-4-5-6

-2

-3

-4

-5

-6

-7

-8

CN681

13

-13

-12V [-12]

Drum Earth

-3

QQ

3rd ScannerAuto Image

M2

1

-2-3-4-5-6

CN506-1

AA

AA

→→→

→

V [24]

V [24]

[24 0/24]

[24 0/24]

[24 0/24]

[24 0/24]

AAB

B

→

[0 0/5] B

[0] GND

[ 5] Connector Set

[0] GND

[0] GND

-7

E

8765432

8765432

8765432

8765432

-8-7-6-5-4-3-2

T r ansfer

(PP3)

CN684

CN683

CN685

CN682-1

SOL

Transfer

Belt

Positioning

1

1

1

1

-1

[0]

[ 24]

CN682-2

1

Q

12

11

10

9

8

7

6

5

4

3

2

1

AABB

CCDD

EE

FF

GG

HH

II

A246/A247/A248/A822 Point to Point Diagram

F1

F2

CN3-1

6A

CN3-2

Fuse

801

802

803

804

805

N.C

RA

Lightening Arrestor

(LA1)

Capacity

Line

10 A

AC

6.3 A

V

AA1

6.3 A

V

AA2

6.3 A

V

AA3

6.3 A

V

AA4

1st Lift

1st Paper End

1st Pick-up

1st Paper Feed

1st Separation

Roller

1st Paper Feed

2nd Paper Feed

2nd Separation

Roller

2nd Paper Feed

N

C.B1

3

2

S14

1

3

2

S17

1

SOL

2

3

2

S11

1

SOL

6

MC

3

S12

SOL

7

MC

4

1

8

CN401-1

CN402-A1

-A10

-A11

-A12

-A13

-A14

[0] CGND

-2

[5]

-3

[5] V

CC

-4

[0] CGND

-5

[0 0/5]

→

-6

[5]

-7

[24] V

AA

-8

[ 24]

[5]

-A2

[0] CGND

-A3

CC

[5] V

-A4

[24] V

AA

-A5

[ 24]

-A6

[24] V

AA

-A7

[ 24]

-A8

[5]

-A9

[0] CGND

[5] V

CC

[24] V

AA

[ 24]

[24] V

AA

[ 24]

2

7

3

6

4

5

5

4

6

3

7

2

1

2

1

2

1

2

1

2

1

2

8

1

7

1

6

2

5

3

4

4

3

5

2

6

1

7

7

1

6

2

5

3

4

4

3

5

2

6

1

7

NF1

L

Paper Feed Control

(PCB5)

9

3

3rd Paper Feed

3rd Separation

Roller

3rd Paper Feed

2

S13

1

SOL

8

MC

5

2

1

2

1

8

2nd Lift

2nd Paper End

2nd Pick-up

3rd Lift

7

3rd Paper End

3rd Pick-up

2nd Paper Size

6

11D

3rd Tray Set

Right Tandem

Lock

Left Tandem

Lock

S15

S18

SOL

3

S16

S19

SOL

4

SW4

J

I

SW5

SOL

9

SOL

10

2

1

2

1

6

5

4

3

2

1

2

1

2

1

5

1st Lift Motor

2nd Lift Motor

3rd Lift Motor

M13

M14

M15

2

1

2

1

2

1

4

3

2nd Paper

Near End

3rd Paper

Near End

Toner Overflow

Toner Collection

3

2

Bottle Set

Toner Recycle

Toner Recycle

Rear Fence

Rear Fence Hp

Rear Fence

Return

Left Tandem

Paper

S22

S23

S45

SW3

M11

M18

S30

S31

S32

2

1

3

2

1

1

1

2

2

3

3

1

2

MC

2

2

1

4

3

2

1

2

1

3

2

1

3

2

1

3

2

1

1

AB

7

1

CN402-B8

-B10

-B11

-B12

-B13

-B14

CN403-A1

CN407-A1

CN411-1

CN412-A7

-A10

-A11

-A12

-B10

-B11

-B12

CN414-1

[5]

-B9

[0] CGND

[5] V

[24] V

[ 24]

[24] V

[ 24]

[0] CGND

-A2

[5]

-A3

[5] VCC

-A4

[0] CGND

-A5

→

[0 0/5]

-A6

[5] VCC

-A7

[24] VAA

-A8

[ 24]

-B1

[0] CGND

-B2

[5]

-B3

[5] VCC

-B4

[0] CGND

-B5

→

[0 0/5]

-B6

[5] VCC

-B7

[24] VAA

-B8

[ 24]

[0] CGND

-A2

[0/5 0] Size 5

-A3

[0/5 0] Size 4

-A4

[0/5 0] Size 3

-A5

[0/5 0] Size 2

-A6

[0/5 0] Size 1

-A7

[ 24]

-A8

[24] VAA

-B3

[0/5 0]

-B4

[0] CGND

-B5

[24]

-B6

[ 24]

-B7

[24]

-B8

[ 24]

[ 24] Up

-2

[ 24] Down

-5

[ 24] Up

-6

[ 24] Down

-7

[ 24] Up

-8

[ 24] Down

[0] CGND

-A8

[0 0/5]

→

-A9

[5] V

[0] CGND

[0 0/5]

→

[5] V

-B2

[0] CGND

-B3

[0 0/5]

→

-B4

[5] V

-B5

[0/5 0]

-B6

[0] CGND

-B7

[24] V

-B8

[ 24]

-B9

[0/5 0] Motor Set

[0] CGND

AA

V

[ 24]

[0/5 0] LeftTray Set

-2

[ 24] Forward

-3

[ 24] Reverse

-5

[0] CGND

-6

[0 0/5]

→

-7

[5] V

-8

[0] CGND

-9

[0] CGND

-10

[0 0/5]

→

-11

[5] V

-12

[0] GND

-13

[0/5 0]

-14

[5] V

CC

AA

AA

→

→

→

→

→

→

CC

CC

CC

→

AA

→

→

CC

CC

→

CC

Motor Speed [H/5, L/0]

Motor ON [t5]

Motor ON [ 5]

Lock [ 5]

RightTray S e t [0 /5 0]

6

2

5

3

4

4

3

5

2

6

1

7

1

8

2

7

3

6

4

5

5

4

6

3

7

2

8

1

1

8

2

7

3

6

4

5

5

4

6

3

7

2

8

1

1

6

2

5

3

4

4

3

5

2

6

1

2

1

1

11

2

10

3

9

4

8

5

7

6

6

7

5

8

4

9

3

10

2

11

1

1

1

2

2

3

3

5

5

6

6

7

7

8

8

9

9

10

10

11

11

12

12

13

13

14

14

15

15

CD

V [24]

AA

V[5]

CC

CGND [0]

AGND [0]

Lock [t5]

CGND [0]

V[5]

CC

AGND [0]

V [24]

AA

VAA [24]

AGND [0]

VCC [5]

CGND [0]

CGND [0]

[0 0/5]

→

CC

V[5]

CGND [0]

[0 0/5]

→

CC

V[5]

CGND [0]

[0 0/5]

→

CC

V[5]

CGND [0]

[0 0/5]

→

CC

V[5]

CGND [0]

CGND [0]

[0 0/5]

→

CC

V[5]

CGND [0]

[0 0/5]

→

CC

V[5]

CGND [0]

[0/5 0]

CC

V[5]

AA

V [24]

[ 24]

AA

V [24]

[ 24]

CN409-1

-2

-3

-4

8

CN408-1

6

-2

5

-3

4

-4

3

-5

2

-6

1

-7

7

1

CN416-1

2

-2

3

-3

4

-4

5

-5

6

-6

CN406-13

-12

-11

-10

-9

-8

-7

-6

-5

-4

-3

-2

-1

CN405-A11

-A10

-A9

-A8

-A7

-A6

-A5

-A4

-A3

-A2

-A1

-B11

-B10

-B9

-B8

-B7

-B6

-B5

-B4

-B3

-B2

-B1

1

-A10

-A11

-A12

-A13

-A14

-B10

-B11

-B12

-B13

-B14

1

2

2

-A2

-A3

-A4

-A5

-A6

-A7

-A8

-A9

-B1

-B2

-B3

-B4

-B5

-B6

-B7

-B8

-B9

3

3

4

4

5

5

6

6

7

7

8

8

9

9

10

10

11

11

12

12

13

13

16

16

17

17

18

18

19

19

20

20

21

21

22

22

23

23

24

24

25

25

26

26

27

27

28

28

29

29

30

30

CN410-A1

→

→

Paper Feed

M12

Toner

M10

Collection

CN104-A1

3

2

1

3

2

1

3

2

1

3

2

1

3

2

1

3

2

1

3

2

1

E

CN1-3

CN1-1

CN1-4

CN1-2

CN4-2

CN2-1

CN2-6

CN2-3

DC Power Supply Unit

(PCB3)

AA2CCMM

CGNDVV

CGND

AGNDVMGND

4

8

11

16

13112

11

12

11

12

A

CN103-1

N.C

-2

[0/5] Scan Input 0

-3

[0/5] Scan Input 1

-4

[0/5] Scan Input 2

-5

[0/5] Scan Input 3

-6

[0/5] Scan Input 4

-7

[0/5] Scan Input 5

-8

[0/5] Scan Input 6

-9

[0/5] Scan Input 7

-10

[0/5] Scan Output 0

-11

[0/5] Scan Output 1

-12

[0/5] Scan Output 2

-13

[0/5] Scan Output 3

[ 5] 3rd Lift Sensor

-A2

[ 5] 2nd Lift Sensor

-A3

Not Used

-A4

[ 5] 1st Lift Sensor

-A5

Not Used

-A6

Not Used

-A7

Not Used

-A8

Not Used

-A9

[0/5] Clock

-A10

[5] LE

-A11

[0] CGND

-B1

[24] VAAS1

-B2

[5] OE

-B3

-B4

[ 5] 3rd Paper Feed Clutch

-B5

[ 5] 2nd Paper Feed Clutch

-B6

Not Used

-B7

[ 5] 1st Paper Feed Clutch

-B8

[ 5] 3rd Paper Feed Sensor

-B9

[ 5] 2nd Paper Feed Sensor

-B10

Not Used

-B11

[ 5] 1st Paper Feed Sensor

Front Side Fence

S26

Open

Front Side Fence

S27

Close

Rear Side Fence

S28

Open

Front Side Fence

S29

Close

Right Tray Down

S24

1st Paper Near

S21

End

Right Tray Paper

S25

SOL

Front Side Fence

11

SOL

Rear Side Fence

12

2

2

1

1

5

5

4

4

9

9

2

33

787

8

22

22CN2-4

11

11

2

2

1

1

CN801-1

HOT

NEUTRAL

Front DoorSafety (SW2)

AA3CACBCCAA1

AGNDVV (+12V)

V (–12V)VVVAGND

510972

9105613246

9105

CA

AA3

CB

V [12]

V [24]

V [–12]

AGND [0]

AA4

6

14

6

13246

-2

-10

CN101-6

CN123-1

CC

V[5]

AA1

AA4

V [24]

V [24]

AGND [0]

AAS1

V [ 24]

CC

V

CGNDYAZB

-2-3-4-5-6

CN124-1

CSS1 CSS2 CSS3

-12

AAS2

V [ 24]

CGND

3

15

23478

23478

-3-4-7-8-9

CN101-2

CGND [0]

Signal Table

< >

s

t

[ ]

F

222

111166CN4-1

Optics Anti-Condensation Heater

2

2

1

1

Transfer Anti-Condensation Heater

Upper Tray Heater

LowerTray Heater

-3

Toner

Development

Supply

5

5

D

823451612345682

CB

9F8P

-5

-2-3-4-5-1-6-8

-11

CN107-7

CC

AA1

V [24]

GNDVCGNDYAZB

AC Line

DC Line

Puls

Signal Direction

Signal Direction

Active High

Active Low

Voltage

V[5]

AA3

V [24]

CC

-3-4-5

CN125-2

Lock [ 5]

CGND

CN126-2

AGND [0]

CGNDYAZB

-3-4-5

ON [ 5]

AGND [0]

CGND

G

4

3

2

1

Main

SW

L

(SW1)

5

6

E

F

9J

CN708-1

Transformer

(220/240V Verstion only)

By-pass

Toner

Bottle

Feed

M7MC1

1

2

1

-9

-10

-11

-12

-13

-14

-15

-16

CC

V[5]

AAS1

AAS2

V [24]

V [24]

Clutch ON [ 24]

AA4

[24] V

[0] AGND

CN120

CN128-1-2CN127-1

3

4

3

4

341

11

12

DF S6 S2 S1 SW6

DF Sorter Stapler Lift

AGND [0]

AA4

[24] V

[0] AGND

-2-3-4

AAS2

ON [ 5]

AGND [0]

Lock [ 5]

V [24]

Speed [H/5, L/0]

[t5] Sorter Detection

[0] CGND

-CN119

CN118-A1

131211

2

45612

[0]

-3

[100]

-5

[230]

M9M16M6

1234587123456872121214321

-2-3-4-5-6-7-8

CN106-1

CC

[ 24]

V[5]

AAS1

ON [ 5]

AGND [0]

AGND [0]

Lock [ 5]

V [24]

CC

CCCCCC

[0] CGND

[5]

[5] V

[0] CGND

[5]

[5] V

[0] CGND

[5]

-A2

-A3

-A7

-A8

-A9

-A4

-A5

76510984321123456789

3

Paper

Paper

Near

End

End

LCT (Option)

H

ACN1

-9

CC

V[5]

[0] CGND

-A12

MainFusing/Duplex

M5

-10

-A13

ACH2

-11

AGND [0]

[5] LED

-B13

131211

CN702-4

ACN2

Fusing Lamp N

[24] VAA

[t 24] Power Relay

-2

CN706-1

H

G

1L

-12

-13

ON [ 5]

Lock [ 5]

Direction [0: ccw, 5: cw]

[0] CGND

[ 5] LCT Connection

[0] CGND

[5]

-B12

-B11

-B10

10

(SW1)

LCT Cover

(SW4)

Feed Unit Cover

-3-2-1

Fusing Lamp H

CC

[5] V

-B9

987654321

3211238

1231098321

Tray

Down

-4-2-5-3-6

CN703-1

ACH

ACN

AAS1

V [24]

[5] V

[5] V

-A6

-A10

-A11

Tray Down

ACH1

AGND [0]

[5] SW

I

JJ

Main

RA1

-2

CN705-1

AA

V [24]

Exposure Lamp N

Exposure Lamp H

Power Relay [ 24]

AC Drive

(PCB2)

Key

Counter

Total Counter

(Option)

CO2

CO1

8G

11H

11H

D

F

H

E

C

G

-A2

-A3

-A4

-A5

-A6

-A7

-A8

CN113-A1

[ 24]

AA

AA

V [24]

V [24]

CGND [0]

CGND [0]

Main SW [ 24]

Front Door Safety [ 5]

Key Counter Comfirm [ 5]

Main Board (PCB1)

CC

CC

[5]

[0] CGND

[5] V

[5]

[0] CGND

[5] V

[5]

[0] CGND

-B8

-B7

-B6

-B5

-B4

-B3

-B2

-B1

101112

13

9

10

32112

3

S4 S5 S3

Paper

Feed

Position

J

L1

Exposure

TS1

314

2

2

1

G

2

1

314

2

-3-2-1

-1

CN701-4

CN704-2

Fusing Lamp 2: N

Fusing Lamp 2: H

Fusing Lamp 1: N

Fusing Lamp 1: H

Exposure Lamp N

Exposure Lamp H

Auto Response

Left

Operation

Panel

PCB7 S44

Operation

PCB6

Panel

Control

-6-5-4-3-2

CN101-7

-A9

-B1

-B2

-B3

-B4

-B5

-B6

-A10

[ 24]

AA

AA

V [24]

V [24]

Auto Response Sensor [ 5]

AAAAAA

[24] V

[ 24]

[24] V

[ 24]

[24] V

[0] AGND

-3-9-2

-11-4-12

CN117-5

511412392

511412392

76455764321

45763124567

21211234568

SOL

MC1

1

Feed

Pick-up

Feed

KK

CN503-1

CN707-8

-7

-6

-5

-4

-3

-2

-1

Verti cal

Transport

Right

Operation

Panel

LCD

PCB8

321

123456789

-1

131211

-A2

-B7

CC

V[5]

CC

[5] V

-1

1

1

M2 M1

-A3

-B8

-B9

-B10

CN108-A1

[5]

TXD

RXD

[5]

VCC

CGND [0]

CGND [0]

[0] AGND

[5] ON

[H/5, L/0] Speed

[ 5] Lock

[ 24] Tray Down

[ 24] Tray Up

[0] AGND

-6

-8

-14

-15-7-10

8

14

15710

16

8

14

15710

16

1

2

LCT

K

LL

Scanner

HP

L2

Fusing 2

Fusing 2

-2

-3

-4

-5

-6

-7

-8

By-pass

Paper

End

S20S39

987654321321213215432

10

-A4

-A5

[5]

CGND [0]

CGND [0]

CC

[5] V

[5]

-A2

CN109-A1

8765432

1234567

3213212

(SW5) Feed Unit Cover

LCT Cover

(SW2) (SW3)

S43

Exit

L2TF1

[ 24] Fusing Lamp 1

[ 24] Fusing Lamp 2

[ 24] Exp.Lamp

[0/5] LampV (–)

[0/5] LampV (+)

[0/5] Zero Cross (–)

[0/5] Zero Cross (+)

[24] V

AASW

By-pass

Pick-up

Registation

SOL

212

101112

-A6

-A7

-A8

-A9

-A10

[5]

CC

CC

V[5]

V[5]

CGND [0]

CC

[0] CGND

[5]

[0] CGND

[5] V

-A3

-A4

-A5

-A6

-A7

SOL

S36

16

Junction

Gate

Duplex

Transport

5

-A11

AA

V [24]

AA

[24] V

-A8

1

8

1

Fusing

Thermistor

By-pass

Feed

MC6

1

13

-A12

-A13

[ 24]

AA

V [24]

AA

[ 24]

[24] V

-A9

-A10

M23

-A14

[ 24]

[ 24]

TH2

8139

4

8139

4

-2-3-4

CN504-1

GND [0]

GND [0]

Fusing Unit Set [ 5]

Fusing Thermistor [0 ~ 5]

Exhaust

Fan

Guide

Plate

SOL

15

-B1

-B2

-B3

-B4

-B5

-B6

-A15

[t24]

[t24]

AA

AA

V [24]

V [24]

Speed H/L [H: 24/L: 0]

CC

CC

[5] V

[5]

[0] CGND

[5] V

[5]

[0] CGND

-B3

-B4

-B5

-B6

-B7

-B8

-B9

65432

1

1234556

32132

1

S33 S42 S7

Paper

Fusing

H

Guide

Exit

Duplex

Cooling

Fan

I9

[t24 ] Power Relay

L

Page 15

ELECTRICAL COMPONENT LAYOUT (A246/A247/A248/A822) 1/2

18

17

16

15

27

28

29

30

31

32

33

19

14

26

20

21

13

22

12

25

132

23

A246S500.WMF

24

4

5

92

93

75

6

74

7

8

38

9

46

39

40

45

91

10

76

77

78

79

80

81

102

103

104

105

82

83

118

90

89

88

87

A246S504.WMF

86

85

84

117

116

115

106

107

108

11

44

41

42

43

59 47

58

57

109

114

56

48

49

113

110

55

54

53

52

51

A246S502.WMF

50

101

94

95

111112

A246S506.WMF

119

120

96

121

60

100

61

122

34

35

36

A246S501.WMF

37

73

72

71

70

A246S503.WMF

68

97

123

62

63

64

65

99

A246S505.WMF

98

134

133

132

124

125

126

131

127

66

130

6769

129

128

A246S507.WMF

Page 16

ELECTRICAL COMPONENT LAYOUT (A246/A247/A248/A822) 2/2

Symbol Name Index No.P to P

Motors

M1 Scanner 5 Q8

M2 3rd Scanner 11 Q12

M3 Lens Horizontal 10 N12

M4 Lens Vertical 19 N12

M5 Main 120 I9

M6 Development 121 G9

M7 Toner Bottle 133 H9

M8 Charge Wire Cleaner 30 O1

M9 Fusing/Duplex 119 19

M10 Toner Collection 126 E7

M11 Toner Recycle 129 A3

M12 Paper Feed 94 E8

M13 1st Lift 95 A5

M14 2nd Lift 97 A4

M15 3rd Lift 98 A4

M16 By-pass Feed 124 H9

M17 Registration 123 Q7

M18 Rear Fence 55 A2

M19 Jogger 43 Q5

M20 Optics Cooling Fan 21 O12

M21 Optics Board Cooling Fan 118 Q5

M22 Drum Cooling Fan 106 Q5

M23 Duplex Cooling Fan 114 L1

M24 Exhaust Fan 104 L9

Magnetic Clutches

MC1 Toner Supply 122 H9

MC2 Toner Recycling 125 A3

MC3 1st Feed 75 A10

MC4 2nd Feed 79 A9

MC5 3rd Feed 82 A8

MC6 By-pass Feed 64 L99

MC7 Duplex Transport 39 Q6

MC8 Duplex Feed 38 Q6

Switches

SW1 Main 117 H11

SW2 Front Door Safety 115 G10

SW3 Toner Collection Bottle 128 A3

SW4 2nd Paper Size 100 A6

SW5 3rd Tray Set 99 A6

SW6 By-pass Table 62 M9

Solenoids

SOL1 Transfer Belt Positioning 34 Q2

SOL2 1st Pick-up 74 A11

SOL3 2nd Pick-up 78 A7

SOL4 3rd Pick-up 83 A7

SOL5 By-pass Pick-up 63 L9

SOL6 1st Separation Roller 76 A10

SOL7 2nd Separation Roller 81 A9

SOL8 3rd Separation Roller 84 A8

SOL9 Right Tandem Lock 96 A5

SOL10Left Tandem Lock 101 A5

SOL11Front Side Fence 54 E1

SOL12Rear Side Fence 49 E1

SOL13Duplex Positioning 40 Q6

SOL14Pressure Arm 44 Q5

SOL15Guide Plate 67 L9

SOL13Junction Gate 60 L1

Symbol Name Index No.P to P

Sensors

S1 Scanner HP 2 M12

S2 3 rd Scanner HP 9 M12

S3 Lens Vertical HP 7 M12

S4 Lens Horizontal HP 12 Q12

S5 APS 20 P12

S6 Auto Image Density 6 O12

S7 Drum Potential 31 M1

S8 Toner Density 37 N1

S9 Image Density 32 N1

S10 Toner Near End 36 M9

S11 1st Paper Feed 91 A10

S12 2nd Paper Feed 89 A10

S13 3rd Paper Feed 87 A9

S14 1st Lift 93 A11

S15 2nd Lift 80 A8

S16 3rd Lift 85 A7

S17 1st Paper End 92 A11

S18 2nd Paper End 90 A8

S19 3rd Paper End 88 A7

S20 By-pass Paper End 65 K9

S21 1st Paper Near End 53 E2

S22 2nd Paper Near End 77 A4

S23 3rd Paper Near End 86 A4

S24 Right Tray Down 52 E2

S25 Right Tray Paper 50 E1

S26 Front Side Fence Open 58 E3

S27 Front Side Fence Close 57 E3

S28 Rear Side Fence Open 48 E2

S29 Rear Side Fence Close 47 E2

S30 Rear Fence HP 59 A2

S31 Rear Fence Return 51 A1

S32 Left Tandem Paper 56 A1

S33 Paper Guide 61 L1

S34 Duplex Entrance 45 Q6

S35 Duplex Exit 42 Q7

S36 Duplex Transport 71 L1

S37 Duplex Paper End 46 Q6

S38 Jogger HP 41 Q7

S39 Vertical Transport 69 K9

S40 Guide Plate Position 68 M9

S41 Registration 70 L9

S42 Fusing Exit 72 L1

S43 Exit 73 K1

S44 Auto Response 17 J9

S45 Toner Overflow 127 A3

S46

S47

S48

Original Length

(LT version only)

Platen Cover Position 1

(Option)

Platen Cover Position 2

(Option)

8O12

3 M12

4Q12

Symbol Name Index No.P to P

PCBs

PCB1 Main 107 J6

PCB2 AC Drive 102 J10

PCB3 DC Power Supply 110 F10

PCB4 Optic Control 105 O10

PCB5 Paper Feed Control 109 C10

PCB6 Operation Panel Control 15 K9

PCB7 Left Operation Panel 18 J9

PCB8 Right Operation Panel 13 K9

PCB9 By-pass Paper Size 66 N1

Lamps

L1 Exposure Lamp 23 J12

L2 Fusing Lamps 24 K12

L3 Quenching 28 O1

L4 Erase 29 M2

L5 Pre-transfer 33 O1

Power Packs

PP1 Charge 27 P1

PP2 Development 108 P4

PP3 Transfer 35 Q2

Heaters

H1 Optic Anti-condensation 16 H12

H2 Transfer Anti-condensation 134 H12

H3 Upper Tray 131 G11

H4 Lower Tray 130 G11

Thermistors

TH1 Optic 1 M12

TH2 Fusing 25 L12

TH3

Others

CB1 Circuit Breaker 113 C12

CO1 Total Counter 132 J9

CO2 Key Counter - J9

LA1 Lightening Arrestor 116 E11

LCD1 LCD 14 K9

NF1 Noise Filter 112 D12

RA1 Main Power Relay 103 J12

TF1 Fusing Thermofuse 26 K12

TR1

TS1 Optics Thermoswitch 22 J2

Drum

(on the image density Sensor)

Transformer

(220 V version only)

(32) N1

111 H10

2

1

3

4

5

6

7

8

9

16

10

11

12

15

13

14

A822S500.WMF

Symbol Name Index No.P to P

Motors

M1 LCT 11 K1

M2 Feed 5 K1

Magnetic Clutch

MC1 Feed 4 K1

Switches

SW1 LCT Cover 1 15 I2

SW2 LCT Cover 2 14 K2

SW3 LCT Cover 3 13 K2

SW4 Feed Unit Cover 1 6 I1

SW5 Feed Unit Cover 2 7 K2

SW6 Tray Down 16 I1

Sensors

S1 Paper End 8 I1

S2 Paper Near End 9 I1

S3 Paper Position 10 J1

S4 Tray Down 12 J1

S5 Feed 1 J1

S6 Lift 2 H1

Solenoids

SOL1 Pick-up 3 J1

Loading...

Loading...