Page 1

LCT

(Machine Code: A683)

Page 2

30 March, 1999 SPECIFICATIONS

1. OVERALL MACHINE INFORMATION

1.1 SPECIFICATIONS

Paper Size:

Paper Weight: 60 g/m2 ~ 105 g/m2, 16 lb ~ 28 lb

Tray Capacity: 1500 sheets (80 g/m2, 20lb)

Remaining Paper Detection: 5 steps (100%, 75%, 50%, 25%, Near end)

Power Source: 24 Vdc, 5 Vdc (from copier)

Power Consumption: 40 W

Weight: 17 kg

Size (W x D x H): 390 mm x 500 mm x 390 mm

A4 sideways/LT sideways

A683-1

Peripherals

Page 3

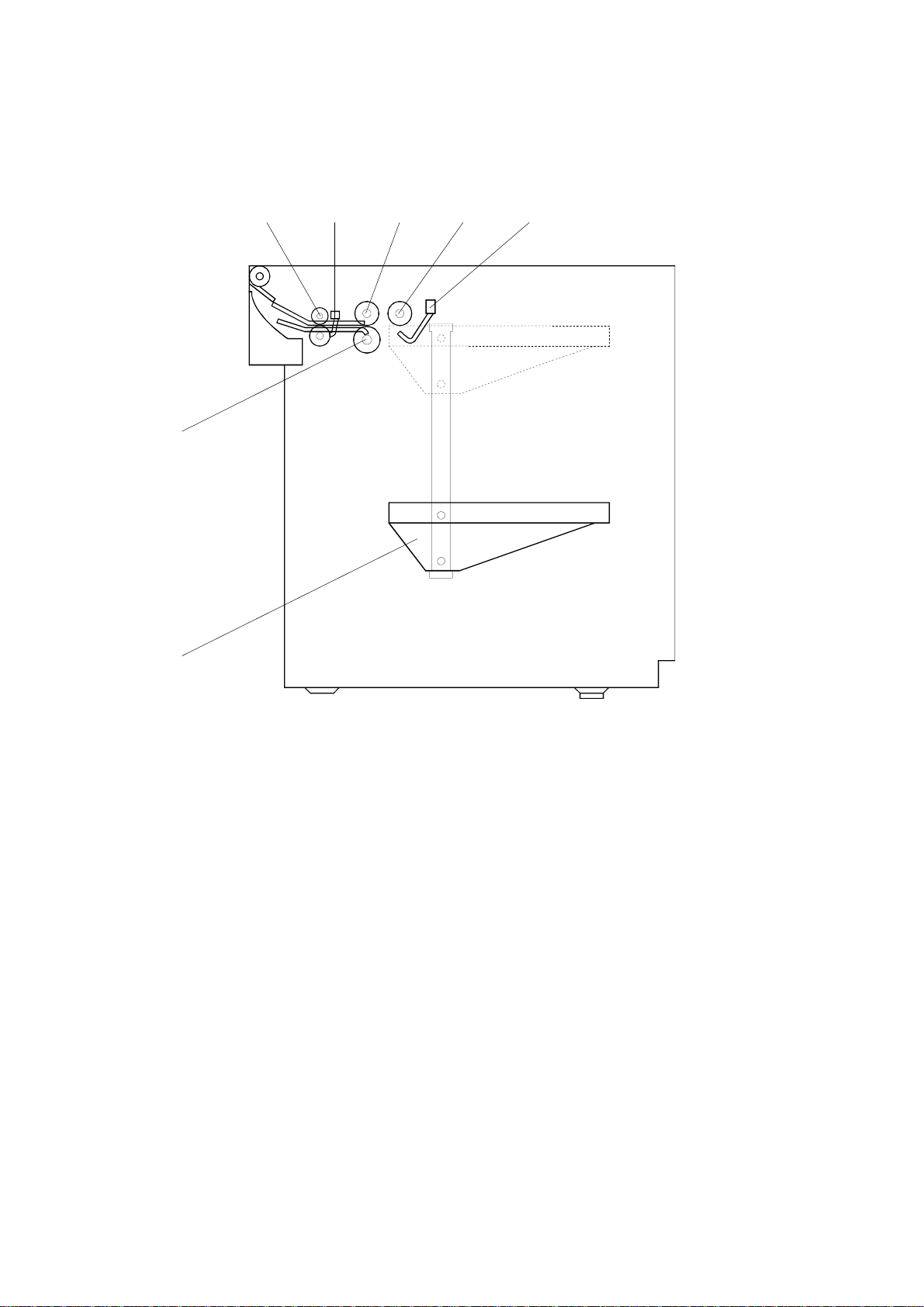

MECHANICAL COMPONENT LAYOUT 30 March, 1999

1.2 MECHANICAL COMPONENT LAYOUT

2

3 4 51

7

6

1. Relay Roller

2. Relay Sensor

3. Paper Feed Roller

4. Pick-up Roller

A683V500.WMF

5. Paper End Sensor

6. Paper Tray

7. Separation Roller

A683-2

Page 4

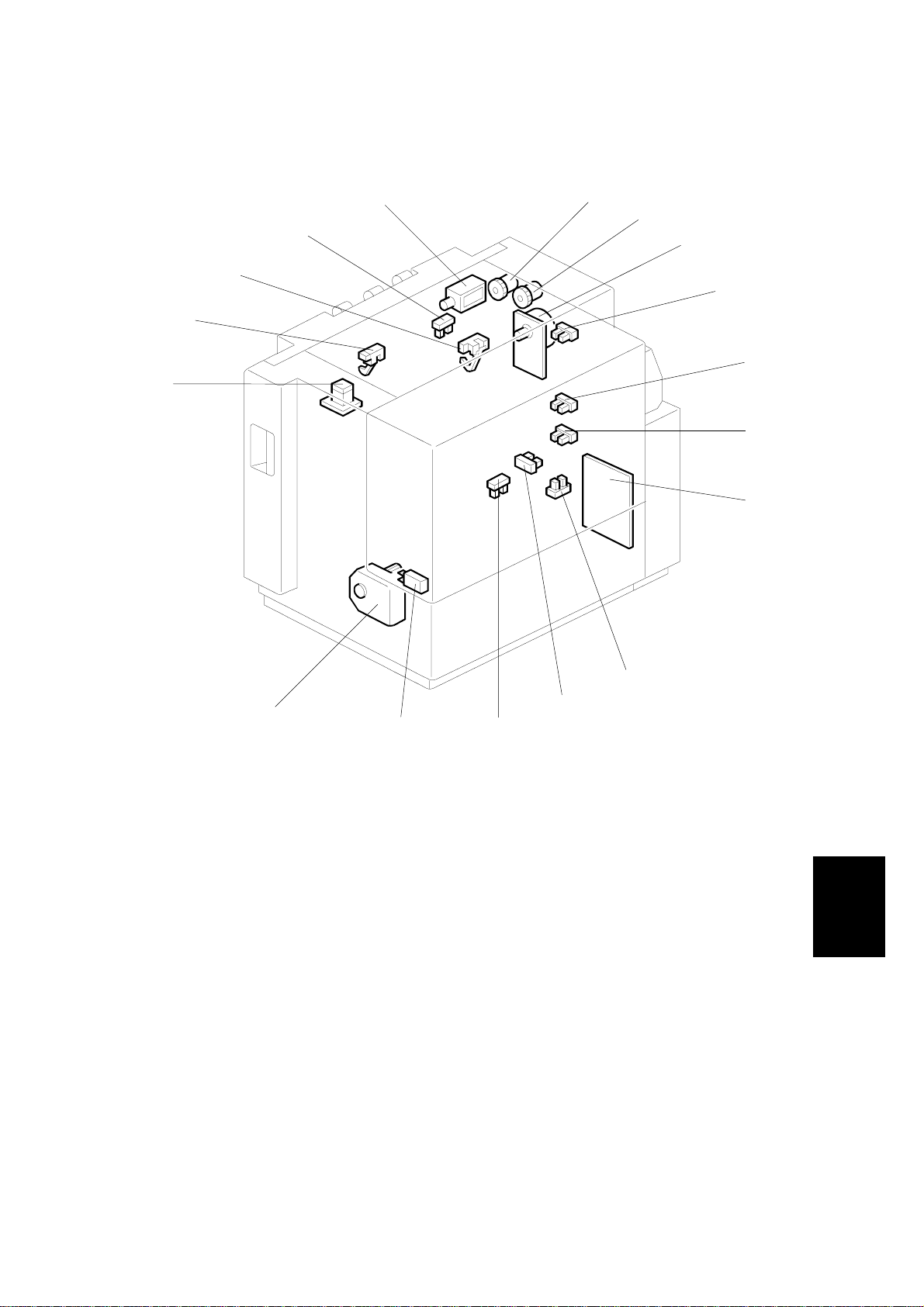

30 March, 1999 ELECTRICAL COMPONENT LAYOUT

1.3 ELECTRICAL COMPONENT LAYOUT

13

14

15

16

17

1

2

3

4

5

6

7

12

11

1. Relay Clutch

2. Paper Feed Clutch

3. LCT Motor

4. Paper Height 1 Sensor

5. Paper Height 2 Sensor

6. Paper Height 3 Sensor

7. Main Board

8. Side Fence Position Sensor

9. Lower Limit Sensor

8

9

10

A683V501.WMF

10. LCT Set Sensor

11. Tray Cover Switch

12. Lift Motor

13. Down Switch

14. Relay Sensor

15. Paper End Sensor

16. Lift Sensor

17. Pick-up Solenoid

Peripherals

A683-3

Page 5

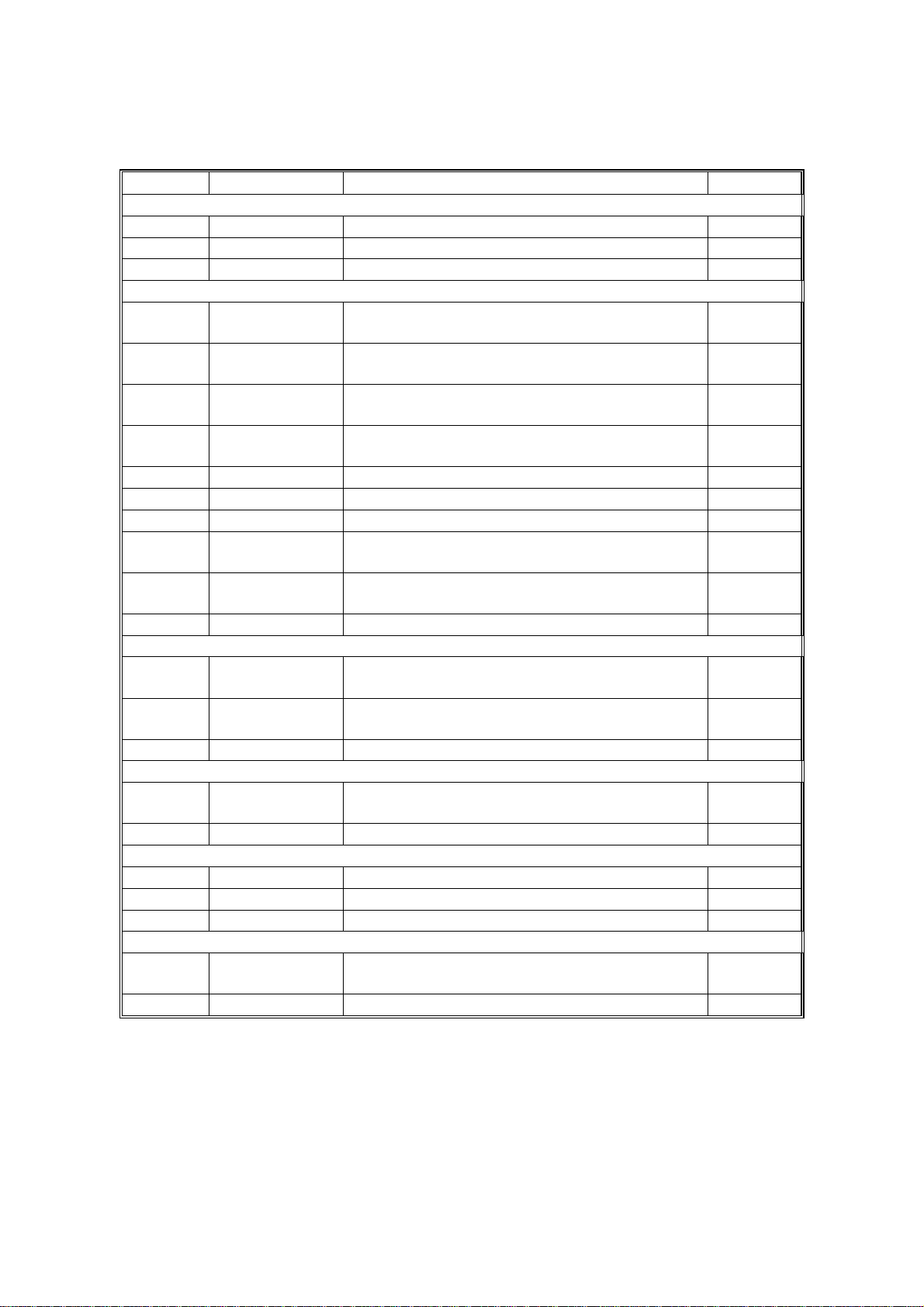

ELECTRICAL COMPONENT DESCRIPTION 30 March, 1999

1.4 ELECTRICAL COMPONENT DESCRIPTION

Symbol Name Function Index No.

Motors

M1 LCT Drives all rollers. 3

M2 Lift Drives the paper tray up or down. 12

Sensors

S1

S2

S3

S4

S5 Paper Height 1 Detects the paper height. 4

S6 Paper Height 2 Detects the paper height. 5

S7 Paper Height 3 Detects the paper height. 6

S8

S9

Paper End Informs the copier when the paper has run

out.

Relay Detects the copy paper coming to the relay

roller and checks for misfeeds.

Lift

Lower Limit

LCT Set Detects whether the LCT is correctly set or

Side Fence

Position

Detects when the paper is at the correct

paper feed height.

Detects when the tray is completely lowered,

to stop the LCT motor.

not.

Detects when the side fence is set at the A4

size position.

15

14

16

9

10

8

Switches

SW1

SW2

Solenoids

SOL1

Magnetic Clutches

MC1 Paper Feed Drives the paper feed roller. 2

MC2 Relay Drives the relay roller. 1

PCBs

PCB1

Tray Cover

Down Lowers the LCT bottom plate if pressed by

Pick-up

Main Controls the LCT and communicates with the

Stops the LCT lift motor when the tray cover

is opened.

the user.

Controls up-down movement of the pick-up

roller.

copier.

11

13

17

7

A683-4

Page 6

30 March, 1999 DRIVE LAYOUT

1.5 DRIVE LAYOUT

321

10

4

9

8

5

7

1. Relay Clutch

2. Paper Feed Clutch

3. LCT Motor

4. Tray Bottom Plate

5. Pick-up Roller

6

A683V502.WMF

6. Tray Drive Belts

7. Lift Motor

8. Separation Roller

9. Paper Feed Roller

10. Relay Roller

Peripherals

A683-5

Page 7

PAPER FEED MECHANISM 30 March, 1999

2. DETAILED DESCRIPTIONS

2.1 PAPER FEED MECHANISM

[D]

[A]

[B]

[C]

A683D500.WMF

This machine uses the FRR paper feed system (paper feed roll er [A], separ ati o n

roller [B], pick-up roller [C]).

When the start key is pressed, the pick-up solenoid [D] energizes and the pick-up

roller touches the paper.

A683-6

Page 8

30 March, 1999 TRAY LIFT AND PAPER HEIGHT DETECTION MECHANISM

2.2 TRAY LIFT AND PAPER HEIGHT DETECTION MECHANISM

[D]

[F]

[B]

[G]

[A]

[H]

[C] [E]

A683D501.WMF

The lift motor [A] controls the vertical position of the tray bottom plate [B] through

gears and timing belts [C].

Tray lifting conditions

When the tray lift sensor [D] turns off in the following conditions, the tray lift motor

raises the tray bottom plate until the tray lift sensor [D] turns on again.

• Just after the main switch is turned on

• During copying

• Just after the tray cover is closed

• Just after leaving the energy saving mode

Tray lowering conditions

In the following conditions, the lift motor lowers the tray bottom plate until the lower

limit [E] sensor turns on.

• Just after the paper end sensor turns on

• Just after the down switch is pressed by the user

The amount of the paper in the tray is detected by combination of high/low outputs

from three sensors (paper height sensor 1 [F], 2 [G], and 3 [H].)

Amount of paper

Near end On (High) Off (Low) Off (Low)

25% Off (Low) On (High) Off (Low)

50% Off (Low) On (High) On (High)

75% Off (Low) Off (Low) On (High)

100% Off (Low) Off (Low) Off (Low)

Paper Height

Sensor 1

A683-7

Paper Height

Sensor 2

Paper Height

Sensor 3

Peripherals

Page 9

TRAY UNIT SLIDE MECHANISM 30 March, 1999

2.3 TRAY UNIT SLIDE MECHANISM

[B]

[A]

A683D502.WMF

When there is a paper jam between the copier and the LCT, the user releases the

lock lever [A] and can slide the LCT away from the copier to remove the jammed

paper.

When sliding the LCT back into position, the LCT is secure d against the co pier in

the correct position by the docking pins [B] on the LCT.

A683-8

Page 10

30 March, 1999 DIP SWITCHES

3. SERVICE TABLES

3.1 DIP SWITCHES

DPS101

12345678

10000000Default

10000001Free run

NOTE: 1) Do not use any other settings.

2) To do the free run, proceed as follows:

1. Remove the paper from the LCT (this is because the machine has no

jam detection).

2. Set DPS101 for the free run as shown above.

3. Turn the main switch off, wait a few seconds, then switch back on.

4. Press SW101 to start the free run.

5. To stop the free run, press SW102.

3.2 TEST POINTS

No. Label Monitored Signal

TP100 (24 V) +24 V

TP101 (GND) Ground

TP103 (TXD) TXD to the copier

TP104 (RXD) RXD from the copier

TP105 (5 V) +5 V

TP106 (GND) Ground

Description

3.3 SWITCHES

No. Function

SW101 Starts the free run

SW102 Stops the free run

3.4 FUSES

No. Function

FU101 Protects the 24 V line.

Peripherals

A683-9

Page 11

COVER REPLACEMENT 30 March, 1999

4. REPLACEMENT AND ADJUSTMENT

4.1 COVER REPLACEMENT

[D]

[F]

[B]

[A]

Tray Cover

1. Remove the tray cover [A] (1 snap ring).

Front Cover

1. Remove the front cover [B] (2 screws).

Rear Cover

1. Remove the tray cover.

2. Remove the cover hinge [C] (2 screws).

3. Remove the rear cover [D] (3 screws).

Right Lower Cover

[E]

[C]

A683R500.WMF

1. Remove the right lower cover [E] (2 screws).

Upper Cover

1. Remove the front cover.

2. Remove the rear cover.

3. Remove the upper cover [F].

A683-10

Page 12

30 March, 1999 ROLLER REPLACEMENT

4.2 ROLLER REPLACEMENT

4.2.1 PAPER FEED, SEPARATION, AND PICK-UP ROLLERS

[B]

[A]

[C]

[D]

A683R501.WMF

1. Push the down switch to lower the tray bottom plate until it reaches its lowest

position.

2. Open the tray cover.

Pick-up Roller

3. Replace the pick-up roller [A] (1 snap ring).

Paper Feed Roller

3. Replace the paper feed roller [B] (1 snap ring).

Separation Roller

3. Remove the guide plate [C] (2 screws).

Peripherals

4. Replace the separation roller [D] (1 snap ring).

A683-11

Page 13

TRAY LIFT AND PAPER END SENSOR REPLACEMENT 30 March, 1999

4.3 TRAY LIFT AND PAPER END SENSOR REPLACEMENT

[A]

[C]

[B]

1. Remove the front and rear cover.

2. Remove the upper cover.

3. Remove the sensor bracket [A] (1 screw).

Tray Lift Sensor

3. Replace the tray lift sensor [B] (1 connector).

Paper End Sensor

3. Replace the paper end sensor [C] (1 connector).

A683R502.WMF

A683-12

Page 14

30 March, 1999 RELAY SENSOR REPLACEMENT

4.4 RELAY SENSOR REPLACEMENT

[B]

[A]

[C]

A683R503.WMF

1. Pull out the LCT.

2. Remove the joint guide [A] (4 screws).

3. Remove the sensor bracket [B] (1 screw).

4. Replace the relay sensor [C] (1 connector).

Peripherals

A683-13

Page 15

SIDE FENCE POSITION CHANGE 30 March, 1999

4.5 SIDE FENCE POSITION CHANGE

[A]

A4

LT

[B]

A4 →→→→ LT

A683R504.WMF

1. Push the down switch to lower the tray bottom plate until it reaches its lowest

position.

2. Remove the tray cover.

3. Remove the front and rear side fences [A, B] (1 screw each).

4. Install the side fences in the correct position.

A683-14

Loading...

Loading...