Page 1

T

echnical

B

ulletin

RTB Correction

Reissue date :

15-Jun-98

The items in bold italics have been corrected or added.

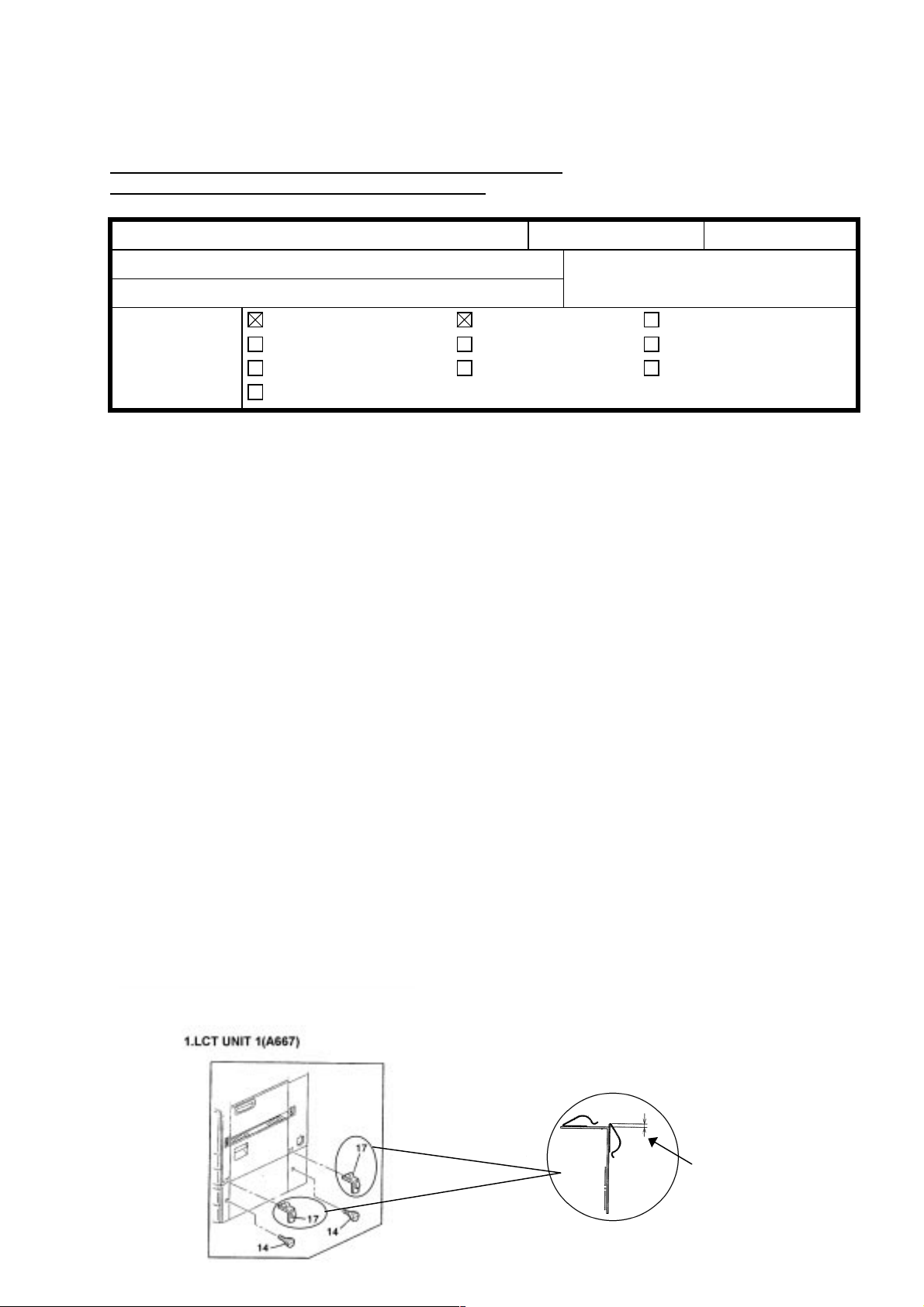

The illustration has changed as shown below.

Model:

AD1(LCT Option)

Date:

31-Jan-98

No:

PAGE: 1/3

48A

Subject:

From:

Classification:

During an internal test, the following problems were found and some parts have been improved

from December production ’97.

SYMPTOM

1. The grounding plate (A6676151) was broken at installation.

2. Paper jam

3. Noise

CAUSE

1. W hen the LCT is installed on the main frame, the spring plate might be cracked.

2. W hen the dust rubbed off the timing belt gets between the timing pulley and the drive shaft, the

rotation of the pulley is affected and paper jams might occur.

Paper jam and Noise

QAC Field Information Dept.

Troubleshooting

Mechanical

Paper path

Other ( )

Part information

Electrical

Transmit/receive

Prepared by:

Action required

Service manual revision

Retrofit information

K.Ugaeri

3. Rotation noise from the relay roller (but t he noise level is still within specif ication)

COUNTERMEASURE

1. W hen installing the LCT, take care not to press the grounding plate too hard.

Permanent countermeasure

The shape of the grounding plate has been modified (A6676151->A6676151A) and

RCL will supply the countermeasure parts to each subsidiary.

RC : 50 sets

RE : 80 sets

RH : 20 sets

1

±

2

→

2

+1 –0.5

Page 2

T

Model:

AD1(LCT Option)

echnical

B

ulletin

Date:

31-Jan-98

No:

PAGE: 2/3

48A

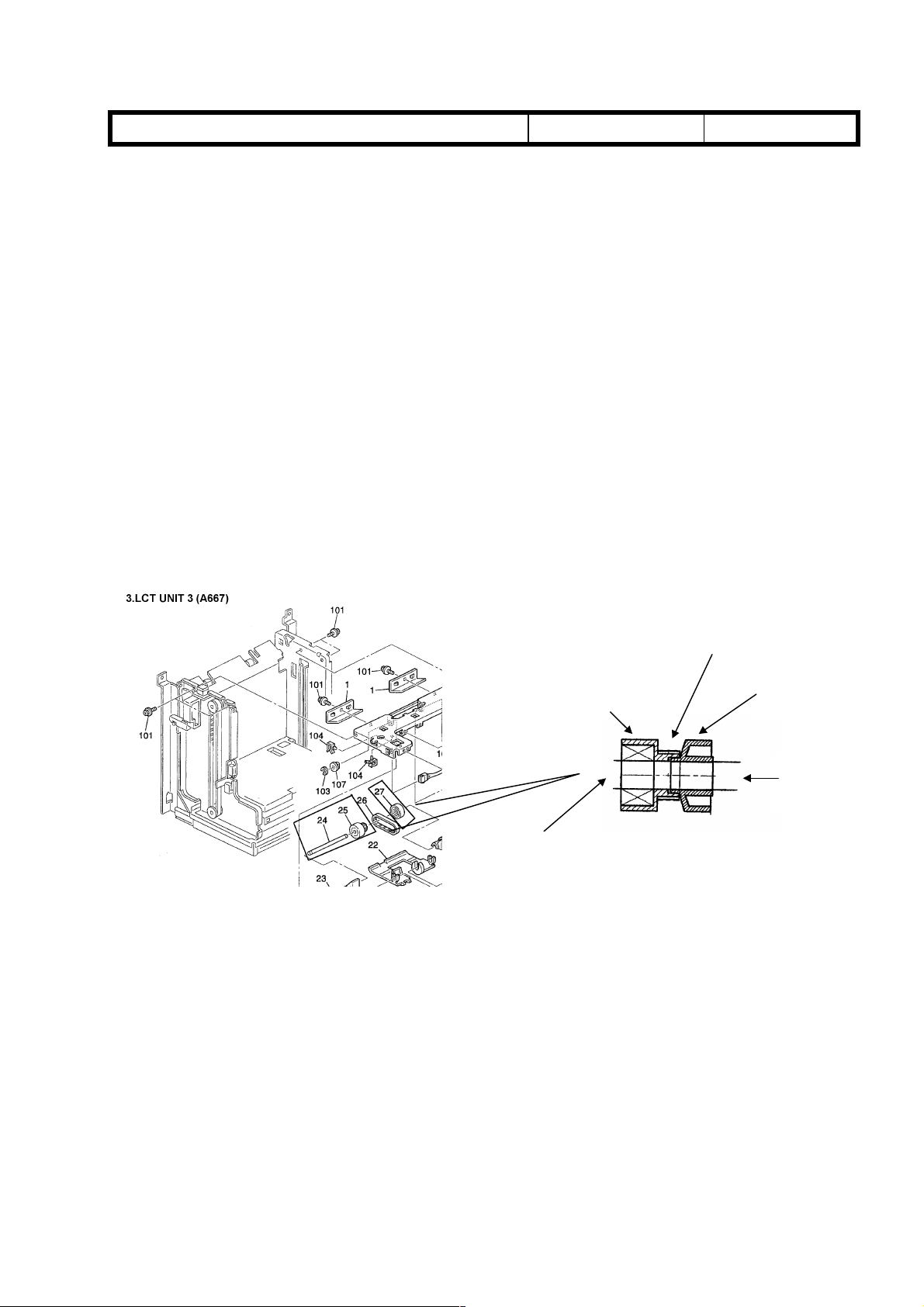

2. Clean the drive shaft of the timing pulleys (P7 – Index 24,

Permanent Countermeasure

To prevent this problem in the LCT , the material of the shaft and the shape of the

pulley and collar have been modified to reduce the dust from the timing belt and to

prevent the dust from getting into the pulley . RCL will supply the countermeasure

parts to each subsidiary.

RC : 100 sets

RE : 160 sets

RH : 40 sets

1. AA140627 → AA140693

2. H5154713 → A6672615

3. H5154714 → A6672616

The interchangeability for these parts is available as a combination.

Drive Shaft – Feed Roller

Timing Pulley Collar – 6x8

Timing Pulley – 22Z

25,27

}

).

X/O as a combination

A taper is added to

the collar.

Pulley

(A6672616)

The collar has been made so that a

portion of it is inserted into the pulley.

Collar

(A6672615)

Drive Shaft

(AA140693)

Page 3

T

Model:

3. Lubricate the shaft of the feed rollers.

AD1(LCT Option)

Permanent Countermeasure

To reduce the rotation noise from the relay roller, a fly wheel is added to stabilize the

rotation. The material of the shaft and the shape of the timing pulley have been

modified.

5.LCT UNIT 5 (A667)

echnical

B

ulletin

Date:

31-Jan-98

No:

PAGE: 3/3

48A

Loading...

Loading...