Ricoh rf780 SPECIFICATIONS

ROLL FEED UNIT

(Machine Code: B435/B436)

11 May, 2001 SPECIFICATIONS

1. OVERALL MACHINE INFORMATION

1.1 SPECIFICATIONS

Roll Paper Size: Width:

210 mm to 914 mm, 8

Length:

150 meters

Diameter:

Less than φ170 mm

Cut Size: –Preset Cut:

1189 mm, 841 mm, 594 mm, 420 mm, 297 mm

48", 36", 24", 18", 12" 46", 34", 22", 17", 11"

Up to 10 extra preset cut lengths can be set using

SP23 ~ 32.

–Selected Length Cut:

297 mm to 3,000 mm (1 mm per step) 11" to 118"

(0.1" per step)

" to 36"

1/2

Paper Transport Velocity: 60 mm/s

Control: Microprocessor

Power Source: +24 volts and +5 volts from the copier

Power Consumption: Maximum 110 W

Dimensions (W x D x H): 1,200 mm x 720 mm x 775 mm

47.24" x 28.35" x 30.51"

Weight: 78 kg, 171.6 lbs (1 roll)

86 kg, 189.2 lbs (2 rolls)

Options

B436-1

ELECTRICAL COMPONENT DESCRIPTIONS 11 May, 2001

1.2 ELECTRICAL COMPONENT DESCRIPTIONS

The index numbers refer to the electrical component layout on the reverse side of

the Point to Point index (Water proof paper).

Name Function Index No.

Motors

Cutter Drives the cutter (DC Reversible Motor). 59

Roll Feed

Magnetic Clutches

Roll Feed 1 Transmits the roll feed motor drive to the 1st

Roll Feed 2 Transmits the roll feed motor drive to the

Switches

Right Cutter Detects whether or not the cutter is at the

Left Cutter

Dehumidity Turns on the RF Dehumidity heaters when

Drives all mechanical components except

the cutter unit (Dc Stepper Motor).

roll feed roller.

2nd roll feed roller.

right home position.

Detects whether or not the cutter is at the

left home position.

not copying.

61

56

60

54

57

62

Sensors

Paper End 1 Detects when the roll runs out of paper. 51

Paper End 2 Detects when the roll runs out of paper. 50

Leading Edge Misfeed detector. Also detects the leading

edge of the paper, triggering the paper

length pulse count.

Door

Printed Circ uit Board

RF Drive

Others

RF Dehumidity Heater 1 Removes humidity from the roll paper. 53

RF Dehumidity Heater 2 Removes humidity from the roll paper. 52

Indicates “Door Open” on the operation

panel and disables the key operation.

Controls all roll feed unit functions

accordance with copier CPU.

55

58

49

B436-2

11 May, 2001 MECHANICAL OPERATION

2. DETAILED SECTION DESCRIPTIONS

2.1 MECHANICAL OPERATION

2.1.1 BASIC OPERATION

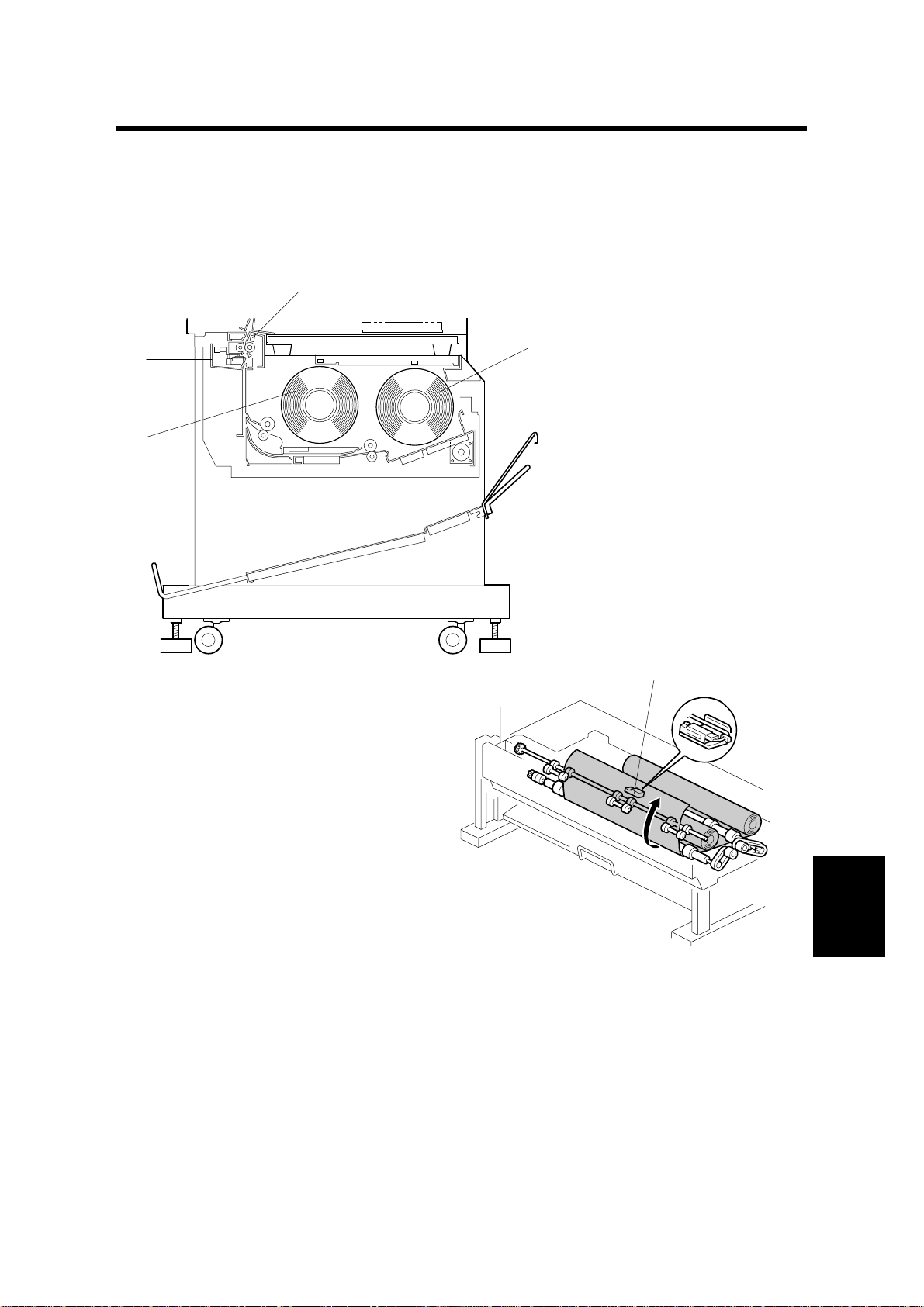

[D]

[C]

[A]

B436D501.WMF

[B]

[D]

B436D103.WMF

There are two types of the roll feed unit. B435 Roll feed unit has one roll feed unit

(1st [A]). B436 Roll feed unit has two roll feed units (1st [A] and 2nd [B]). The cutter

unit [C] uses a sliding rotary cutting blade.

When turning on the main switch or when roll paper is replenished, the roll feed

motor rotates and the leading edge of the roll paper is fed until the roll lead edge

sensor [D] is activated. Then, the leading edge of the roll paper is returned to the

paper feed start position (60 mm before the cutter unit).

B436-3

Options

MECHANICAL OPERATION 11 May, 2001

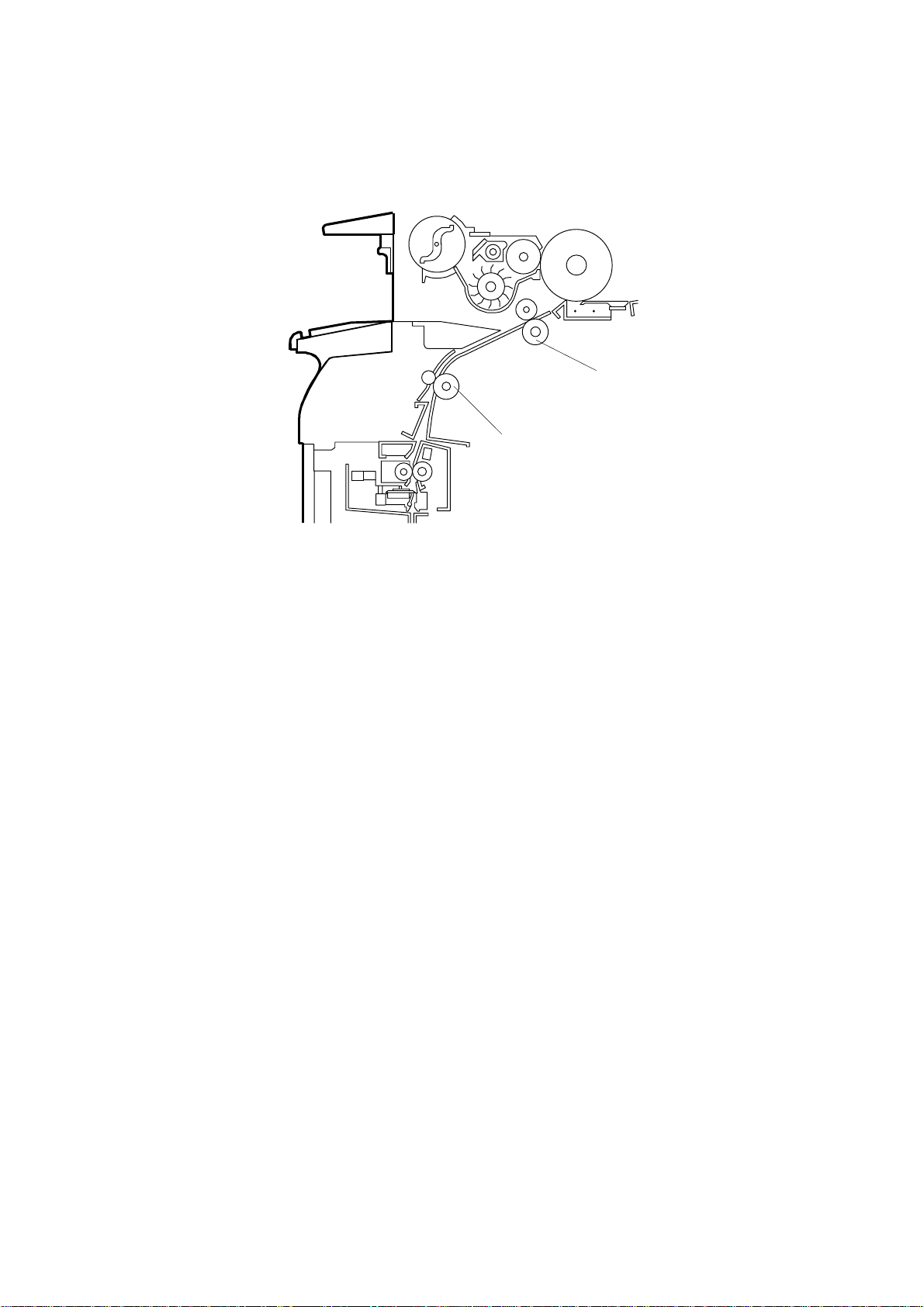

[B]

[A]

B436D502.WMF

After the leading edge of the paper reaches the exit rollers [A], the paper is

directed to the copier registration roller [B]. The registration roller stops rotating

once the registration sensor detects the leading edge of the copy paper. The copy

paper stops and waits for the original. Shortly after the original registration sensor

is activated by the original, the registration roller and roll paper feed motor start to

rotate. The copy paper starts to feed again.

Just before the cut length of copy paper is fed, the speed of the roll paper feed

motor is doubled. A paper buckle forms at the trailing edge of the copy paper.

When the paper reaches the proper length, paper feed motor stops and the cutter

unit cuts the paper. During the time that paper feed motor has stopped, the

registration roller continues to feed the copy paper forward. The paper is cut during

the time it takes for the paper buckle to be pulled taut. This allows for a neat cut.

When the selected cut length is between 245 mm and 340 mm, the paper reache s

the selected length before the registration roller starts to rotate again. In this case,

after the registration roller stops, the roll paper feed motor continues to rotate and a

paper buckle forms at the trailin g edge of the paper. The registration roller brake

ensures that the very stiff types of paper will not rotate the registration rollers as the

excess paper is fed forwards. The paper is then cut.

When the se lected cut lengt h is between 340 mm and 410 mm, the roll cutter unit

cuts the paper after the second rotation of the roll paper feed roller.

The paper buckle forms after the first rotation of the roll paper feed motor, because

the paper feed roller is still rotating after the registration roller has stopped. The

registration roller brake ensures that the very stiff types of paper will not rotate the

registration rollers when the paper buckles while it is stopped at these rollers.

B436-4

Loading...

Loading...