Page 1

Technical Bulletin No. RTB-010

SUBJECT: Blurred copy problem on editor board DATE: Dec.31,’93

PAGE: 1 of 3

PREPARED BY: T. Okajima

CHECKED BY:

CLASSIFICATION:

Action Required

Trouble shooting

Retrofit Information

Revision of service manual

Information only

Other

FROM: Technical Support Group

MODEL:

PDC-1E (Editor Board)

1. Problem

When making copies with the PDC-1E using the editor board, blurred images might appear

on copies.

2. Cause

This problem occurs due to the deformed pressure pads (mirror surface). The deformed

pad cannot press an original completely and there is a gap between the original and the

exposure glass. The focal depth of the scanner is only 0.25mm. If this gap is 0.25mm or

wider, an image in that part will be blurred.

The present pressure pad is made of polypropylen, which starts to deform from about

79°C (174.2°F) or higher. We suppose that the editor board suffers temperatures of 79°C

or higher during transportation.

The pressure pad of the platen cover for the PDC-1E is the same as that of the editor

board. However, the pressure pad of the platen cover does not have the deformation

problem because during transportation, the pressure pad is on the exposure glass which is

flat. Even under high temperature (higher than 79°C) it will not be deformed by the

exposure glass.

3. Countermeasure

3-1. Material

We have changed the material of the pressure pad from polypropylen to polycarbonate

which does not deform at temperatures under 130°C (266°F).

3-2. Part number for the new pressure pad

Old Part Number New Part Number Description

A0491576 A0921594

This part number will be available as a

service part in February 1994.

Original Pressure Pad

Page 2

Technical Bulletin No. RTB-010

SUBJECT: Blurred Copy Problem on Editor Board DATE: Dec.31,’93

PAGE: 2 of 3

3-3. Modification procedure for the field machine

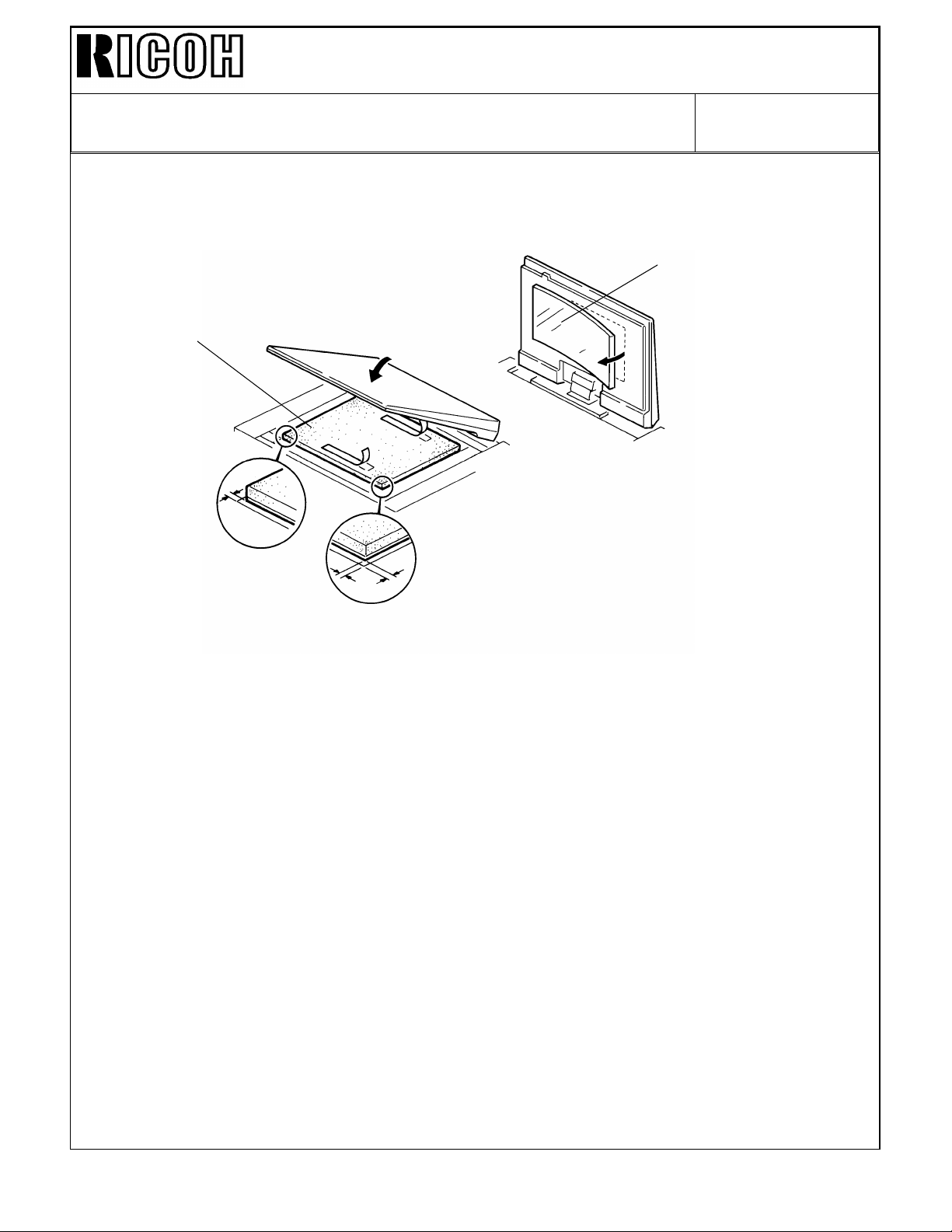

[A]

[B]

W

W

W

W: 1 mm (0.04 inch)

1. Remove the pressure pad [A] from the editor board.

NOTE: As some adhesive tape or sponge might remain on the editor board, make sure

to check and remove everything.

2. Put the new pressure pad [B] as shown in the illustration.

Make a 1mm (0.04 inch) space between the front scale and the front edge of the

pressure pad, and between the right scale and the right side of the pressure pad.

3. Peel off the cover from the two adhesive tapes, close the editor board and press the

editor board by hand. Especially, press the part directly above the tapes.

4. Confirm that there is no blurred image on the copy.

Page 3

Technical Bulletin No. RTB-010

SUBJECT: Blurred Copy Problem on Editor Board DATE: Dec.31,’93

PAGE: 3 of 3

3-4. Cut-in Serial Number

Machine Code Cut-in Serial Number

A988-17 From Oct. 1993 production run (#A3223100001–)

and #A3223080001, 06, 19, 20, #A3223090001, 03

A988-25 From Oct. 19 93 produc tion run (# 429310 0001–)

A988-27 From Oct. 1993 production run (#A3223100001–)

and #A3223070047, 50, 51, 52

4. Others

We do not recommend that you modify the editor board when it is not on the copier, it is

very difficult to adjust the position for setting the pressure pad. You might have matching

problems when the editor board is docked to the copier (e.g.. the pressure pad falls on the

scale or the space between the edge of the pressure pad and the scale is much larger).

Loading...

Loading...