Page 1

RC-210 SERVICE MANUAL

(Machine Code: G549)

Page 2

TABLE OF CONTENTS

1. OVERALL MACHINE INFORMATION........................................ 1-1

1.1 BASIC SPECIFICATIONS..........................................................................1-1

1.2 OTHER SPECIFICATIONS........................................................................1-2

1.3 PAPER SIZE..............................................................................................1-2

2. DETAILED DESCRIPTIONS....................................................... 2-1

2.1 FUNCTIONAL OVERVIEW ........................................................................2-1

2.1.1 SYSTEM LAYOUT ............................................................................2-1

2.1.2 CONTROLLER BOARD LAYOUT.....................................................2-1

2.1.3 DEVICE FUNCTIONS.......................................................................2-2

2.2 PRINT DATA PROCESSING.....................................................................2-3

2.2.1 IMAGE DATA PROCESSING FLOW................................................2-3

2.2.2 UCR (IPD-C)......................................................................................2-4

2.2.3 PURE BLACK FUNCTION (R-PS2) ..................................................2-4

2.2.4 R-PS2 COLOR MANAGEMENT SYSTEM........................................2-4

3. INSTALLATION PROCEDURE................................................... 3-1

3.1 MINIMUM SPACE REQUIREMENTS ........................................................3-1

3.2 CONTROLLER INSTALATION...................................................................3-2

3.2.1 ACCESSORY CHECK ......................................................................3-2

3.2.2 INSTALLATION PROCEDURE.........................................................3-3

1.1.3 INITIAL SETTING..............................................................................3-4

4. SERVICE TABLES...................................................................... 4-1

4.1 SERVICE PROGRAM (SP) MODES..........................................................4-1

4.1.1 HOW TO ENTER SP MODE.............................................................4-1

4.1.2 SP MODE FUNCTIONS....................................................................4-1

4.1.3 SP MODE TABLE..............................................................................4-3

1.2 POWER-UP SELD-DAIGNOSTICS............................................................4-6

1.3 DETAILED SELF-DIAGNOSTICS..............................................................4-7

5. REPLACEMENT AND ADJUSTMENT ....................................... 5-1

5.1 GAMMA CORRECTION.............................................................................5-1

5.2 SOFTWARE UPGRADE PROCEDURE.....................................................5-1

6. TROUBLESHOOTING................................................................ 6-1

6.1 ERROR MESSAGE....................................................................................6-1

6.1.1 OVERVIEW.......................................................................................6-1

6.1.2 DETAILED MESSAGES....................................................................6-2

7. NETWORK INTERFACE BOARD (C4000 FERRET).................. 7-1

7.1 OVERVIEW................................................................................................7-1

7.1.1 SPECIFICATIONS.............................................................................7-1

7.1.2 BLOCK DIAGRAM.............................................................................7-1

i

Page 3

7.2 COMPONENT LAYOUT.............................................................................7-2

7.2.1 NETWORK INTERFACE BOARD DIAGRAM ...................................7-2

7.2.2 DEVICES...........................................................................................7-2

7.3 BASIC OPERATIONS ................................................................................7-3

7.3.1 OVERVIEW.......................................................................................7-3

7.3.2 SWITCH FUNCTION.........................................................................7-4

ii

Page 4

14 September 2000 BASIC SPECIFICATIONS

1. OVERALL MACHINE INFORMATION

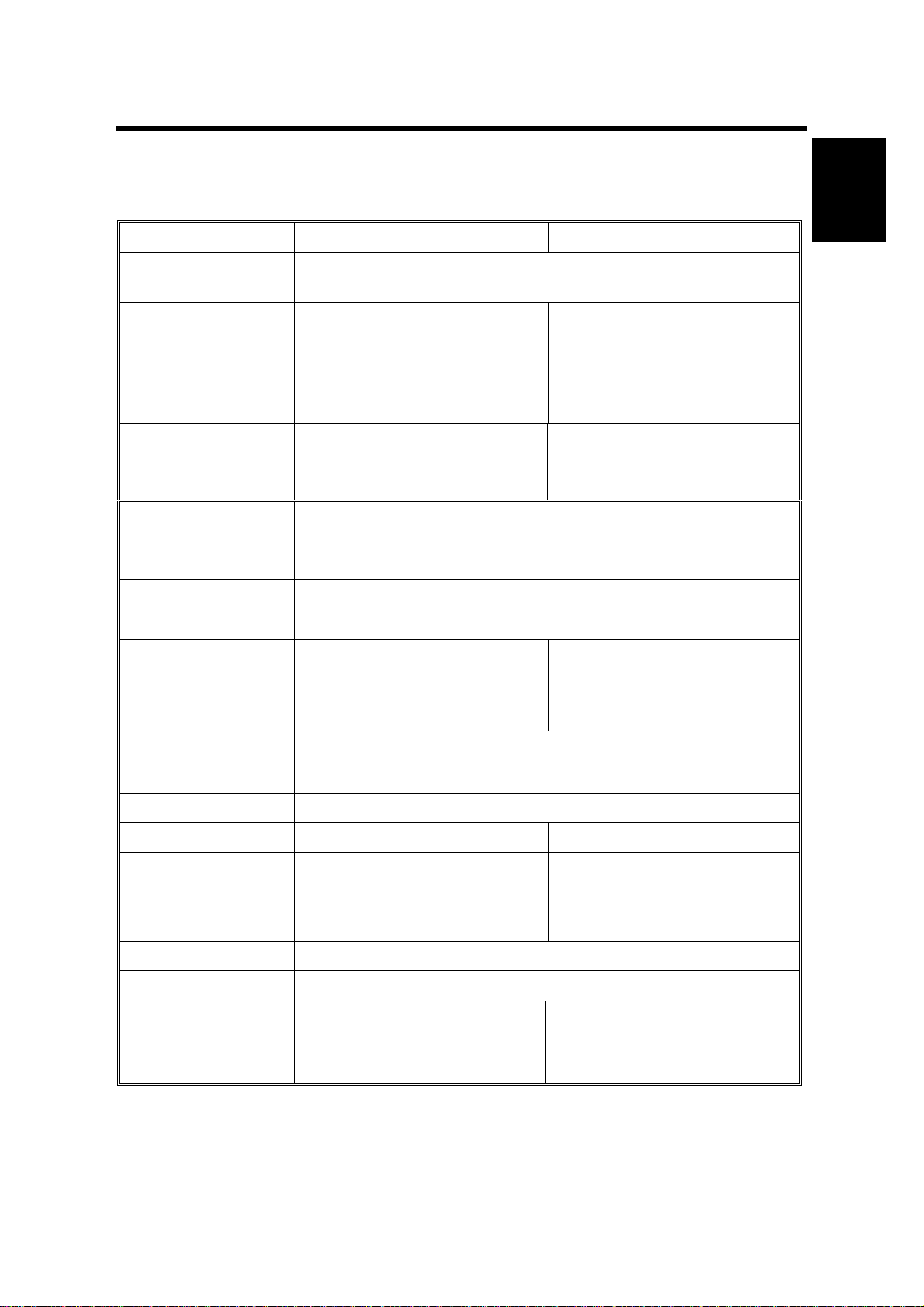

1.1 BASIC SPECIFICATIONS

RC-200 RC-210

Page Description

Language:

Printer Driver:

Resolution: 600 x 600 dpi 600 x 600 dpi

Color Mode: Color (2C or less/3C or more), B&W

Gradation Mode: 2/4/16 gradation levels (1/2/4 bits/pixel) Default setting: 4

Toner Saving: On/Off (printer driver setting) Default Setting : Disabled

Color Correction: On/Off (printer driver setting) Default setting: Enabled

IPDL-C (Intelligent Page Description Language for Color) RPS2

(RICOH-SCRIPT2)

• IPDL-C: Windows 95/98/NT

4.0

• RPS2: Windows 95/98//NT

4.0, Macintosh (PPD for

LaserWriter 8)

gradation levels

• IPDL-C: Windows

95/98/2000 NT 4.0

• RPS2: Windows

95/98/2000/NT 4.0,

Macintosh (PPD for

LaserWriter 8)

Enhanced 4800 x 600 dpi with

smoothing

Overall

Information

Paper Size: See next page

Print Speed:

Interface:

Fonts: Ricoh-Script 2: 39 Roman fonts

CPU: R4310 176MHz R5261 200MHz

RAM: 96MB (Standard and

ROM: 2MB Flash ROM

Scanner Function: Not supported

Option: None

• Color: 4 ppm (A4 sideways)

• B&W: 14 ppm (A258 model)

18 ppm (A259/A260 models)

• Parallel port (IEEE1284B: Compatible / Nibble / ECP

supported)

• 100 BASE-TX, 10 BASE-T

maximum)

• Color: 6 ppm (A4 sideways)

• B&W: 25 ppm (B018 model)

31 ppm (B017 model)

64MB (Standard)

- with optional memory 128MB (additional 64MB)

192MB (additional 128MB)

• Controller Interface Type H

• Memory Unit Type B (64 MB)

• Memory Unit Type B (128

MB)

1-1

Page 5

OTHER SPECIFICATIONS 14 September 2000

1.2 OTHER SPECIFICATIONS

RC-200 RC-210

LAN Interface: 100 BASE-TX, 10 BASE-T

Frame Type: Ethernet II, IEEE802.2, IEEE802.3, SNAP

Network Protocol: TCP/IP, IPX/SPX, NetBEUI, AppleTalk (with RPS2)

SNAP: MIB-II, Printer MIB, Host Resource MIB, Ricoh Private MIB

1.3 PAPER SIZE

The same as the base model (RC-200).

1-2

Page 6

14 September 2000 FUNCTIONAL OVERVIEW

2. DETAILED DESCRIPTIONS

2.1 FUNCTIONAL OVERVIEW

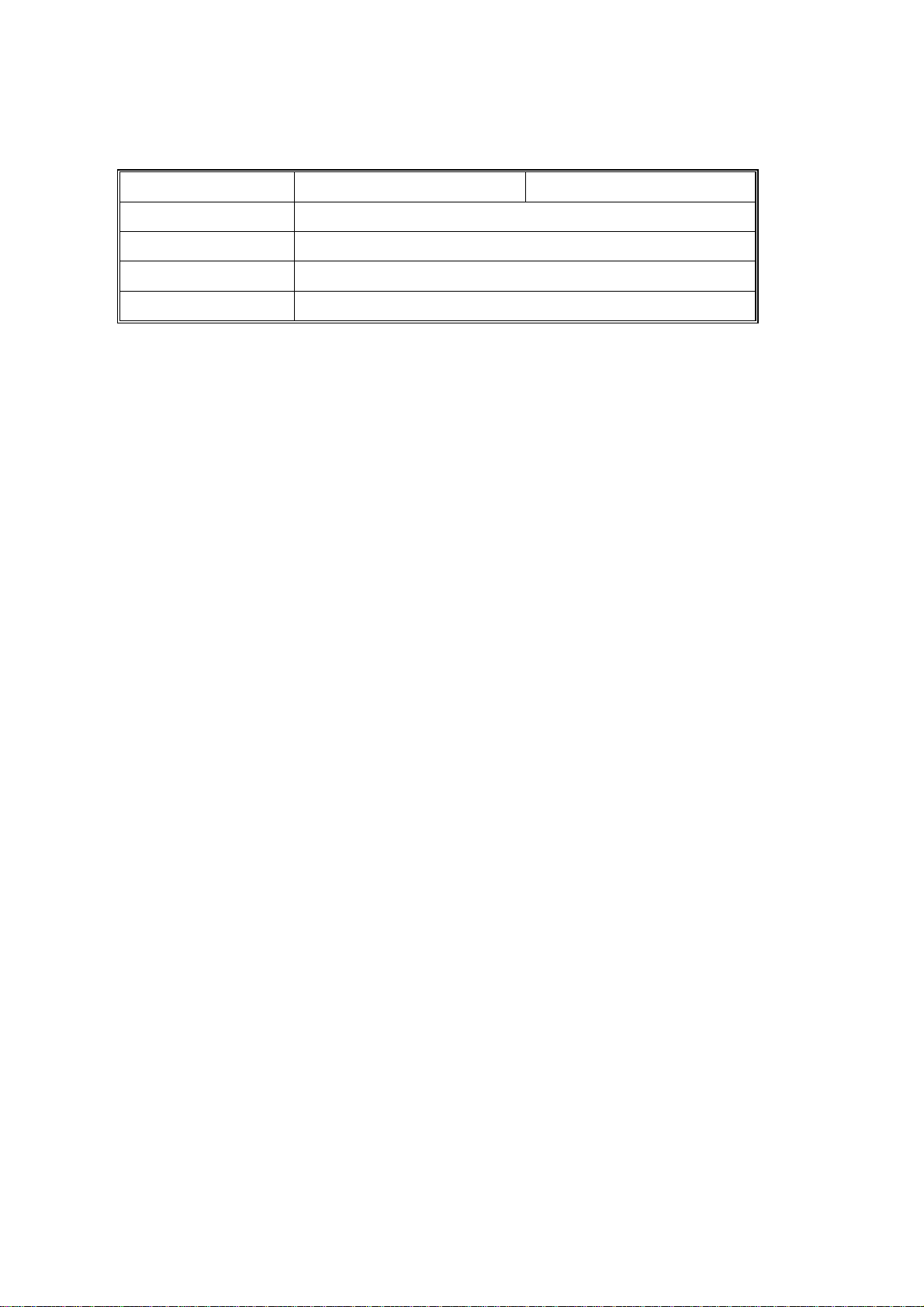

2.1.1 SYSTEM LAYOUT

Controller

Bord

CN4

Option I/F

CN1 & 2

DIMM SLOT (x2)

DIMM

CN3

IC CARD I/F

IC Card

Control Panel

Engine

ENGINE I/F

G549D501.WMF

Host

Host

CN7

IEEE1284 I/F

Network

Board

(Standard)

CN5 CN6

ROM SLOT

RPS

Detailed

Descriptions

2.1.2 CONTROLLER BOARD LAYOUT

DIP Switch

1234

O

N

DIP SW (SW1)

OPTION BUS I/F (CN 4)

ROM SLOT (CN5)

FONT

ROM

5678

IC CARD I/F (CN 6)

FLASH

ROM

O

FF

NVROM

DIMM SLOT (CN2)

DIMM SLOT (CN1)

ASIC

EAGLE2

ENGINE I/F (CN3)

CENTRO I/F (CN 7)

CPU

RM5261

2-1

Copier Engine

G549D502.WMF

Page 7

FUNCTIONAL OVERVIEW 14 September 2000

2.1.3 DEVICE FUNCTIONS

Device Function

CPU VR5261- 200 ( 200MHz)

ASIC EAGLE 2 This ASIC controls the following:

• Memory mapping

• Rest

• DRAM

• Data received from the parallel

• Timer

• Parallel interface

• I/O Port

• Image data compression & decompression

• Engine interface serial communications control

• Interrupt

• Data through function

• Toner saving control

FLASH ROM Stores program (2MB) The flash ROM is programmable via an

IC card.

NVRAM Stores the initial settings and printer parameters.

(8KB EEPROM)

FONT ROM Stores internal printer fonts (Japanese fonts not used).

(One 64-Mbit mask ROMs)

DRAM

DIP SW

64MB DIMM standard memory. (96MB total)

DIP Switch

1234

O

N

G549D512.WMF

SW No. Setting Content

1OFF

2ON

3 - 7 OFF

8ON

Do not touch these switches in the

field.

5678

O

FF

ENGINE I/F (CN 3 )

PARALLEL I/F

(CN7)

• Embedded CIVIC interface

• Provides an interface that connects to a local host

(IEEE1284 compliant).

OPTION I/F (CN4) Network interface

ROM SLOT (CN5)

• A 72-pin slot for accommodating the Ricoh-Script 2

emulation module.

• The emulation module is programmable by flash ROM.

DIMM SLOT (CN1 &2)Slots for accommodating the memory. Standard size is 64MB.

The memory size can be increased to 128MB or 192MB

maximum (with additional 64MB or 128MB memory).

IC CARD SLOT

(CN8)

Accommodates an IC card to upgrade firmware.

2-2

Page 8

14 September 2000 PRINT DATA PROCESSING

2.2 PRINT DATA PROCESSING

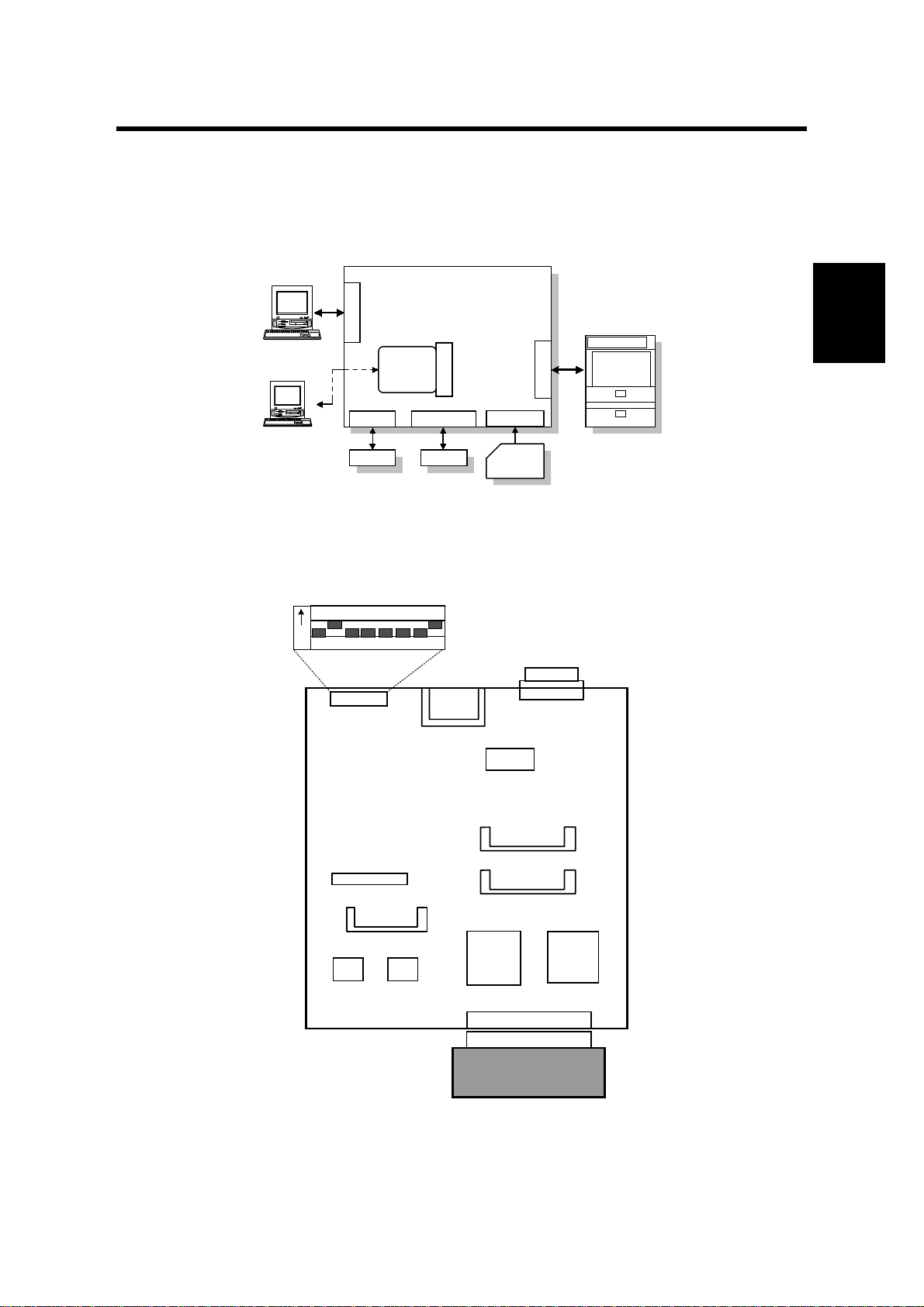

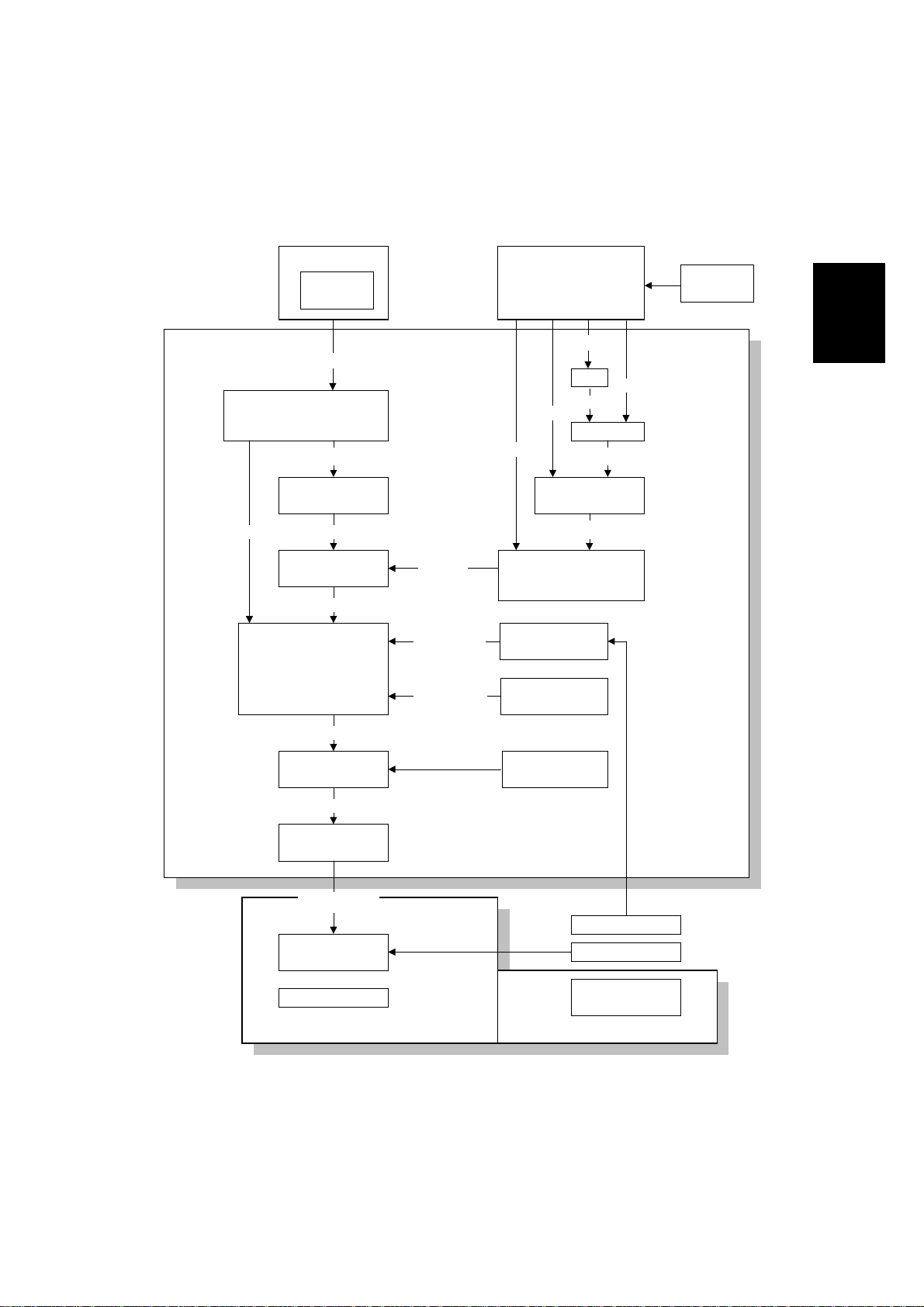

2.2.1 IMAGE DATA PROCESSING FLOW

IPDL-C Driver

CMS

RGB

UCR

R=G=B : Replace with K

(Black Text/Graphic)

RGB 8bit

CMYK Conversion

UCR

K

CMYK 8bit

Maximum Toner

Amount Control

CMYK 8bit

Gamma

Correction

CMYK

8bit

Correction

Correction

R-PS2 Driver

RGB 8bit

CMYK 8bit

CMYK Conversion

Pure Black

K=100% : C=M=Y=0

(Text/Graphic)

Calibration

Manual Gamma

Correction

RGB 8bit

CIE

Lab

UCR

RGB 8bit

Color

CMS

Detailed

Descriptions

Lab

CRD

RGB 8bit

CMYK 8bit

Dithering

CMYK 1/2/4bit

8bit Expansion

CMYK 8bit

Copier Gamma

Correction

LD Control Board

Copier Engine

1/2/4bit

Text/Photo Dither

Controller

Color Calibration

ACC

Scanner IPU

Board

Scanner

G549D506.WMF

2-3

Page 9

PRINT DATA PROCESSING 14 September 2000

2.2.2 UCR (IPD-C)

If the R/G/B data is equal (R=G=B), 100% UCR is applied only in the Black

Text/Graphic mode. Even if gray color is processed with RGB data, gray color will

be duplicated only with black toner if the RGB data is completely equal. This

function gives faster productivity. (This function was adopted on the base model,

RC-200.)

2.2.3 PURE BLACK FUNCTION (R-PS2)

For this new function, if the K value is 100% as a result of UCR (CMYK conversion)

in Text/Graphic mode, all CMY values becomes zero. This avoids colored text.

2.2.4 R-PS2 COLOR MANAGEMENT SYSTEM

Depending on the color setting (Off / Vivid / Supper Vivid / Fine / Super Fine),

image processing of color management differs as shown in diagram on the

previous page. (This CMS is the same as the base mode, RC-200.)

Data Sent From

Driver

CMYK data - CMYK data passes through the CRD.

RGB

Lab -

Driver Color

Setting

Off RGB data passes through the CRD.

Vivid,

Supper Vivid

Fine,

Supper Fine

Image Processing In Controller

• RGB data is converted to CMYK with

almost 100% UCR.

The difference between Vivid and Supper

•

Vivid is the amount of CMY added to K to

give depth to images.

• RGB data is converted to Lab data; t hen,

the Lab color space is converted to a

targeted color space by using an em bedded

CRD or CRD downloaded from an

application.

• The difference between Fine an d Supper

fine is the target color space.

• Lab data is converted to the targeted color

space by using embedded C RD or CRD

downloaded from applicatio n.

2-4

Page 10

14 September 2000 MINIMUM SPACE REQUIREMENTS

3. INSTALLATION PROCEDURE

3.1 MINIMUM SPACE REQUIREMENTS

Provide clearance for the copier, as shown below. If one or more options (such as

the ADF or sorter stapler) are added to the copier, this clearance should be

provided around the entire system. Please refer to the copier service manual for

more details concerning space requirements for this copier.

Installation

G549I123.WMF

NOTE: A space of at least 10 cm (3.9") at the rear of the machine is important for

machine ventilation.

3-1

Page 11

CONTROLLER INSTALATION 14 September 2000

3.2 CONTROLLER INSTALATION

3.2.1 ACCESSORY CHECK

Check the quantity and condition of the accessories in the box with the following

list:

Description Quantity

1. Controller.................................................................................... 1

2. LCD Panel.................................................................................. 1

3. CD ROM..................................................................................... 1

4. Operating Instructions (G549-17)

English ....................................................................................... 1

5. Operating Instructions (G549-27)

English, German, French, Italian, Dutch..................................... 1

6. Installation Procedure (G549-17 only)........................................ 1

7. Screw M3x6................................................................................2

8. Screw M4x8................................................................................4

3-2

Page 12

14 September 2000 CONTROLLER INSTALATION

3.2.2 INSTALLATION PROCEDURE

NOTE: To install this option, the I/F kit (B381) is required.

The maximum output voltage from the controller is DC 5V.

[B]

Installation

[A]

G549I107.WMF

G549I106.WMF

[C]

G549I201.WMF

!

CAUTION

Unplug the copier power cord before starting the following procedure.

1. Remove the I/F cover [A] (4 screws).

2. Cut off and remove the cap [B].

3. Slide the controller unit [C] into the I/F unit and secure the controller (6 screws).

4. Reinstall the I/F cover.

3-3

Page 13

CONTROLLER INSTALATION 14 September 2000

[E]

[A]

[B]

[D]

[C]

G549I101.WMF

5. Remove the LCD cover [A].

6. Pull the LCD harness [B] out (1 clamp [C]).

7. Connect the connector [D] to the LCD panel and install the panel [E] in the

operation panel.

3.2.3 INITIAL SETTING

1. After the controller installation is completed, check if the printer function works

properly by printing out the configuration page.

2. Perform ACC for printer mode on the copier.

3. Perform Color Calibration on the controller.

NOTE: When performing Color Calibration for the controller, first execute ACC for

printer mode on the copier.

3-4

Page 14

14 September 2000 SERVICE PROGRAM (SP) MODES

4. SERVICE TABLES

4.1 SERVICE PROGRAM (SP) MODES

4.1.1 HOW TO ENTER SP MODE

Error Data In

IPDL-C

Ready

On Line

2

1

4

G528D504.WMF

EnterEscapeReset

MenuMedia

35

First press the Reset, On Line, (the screen will display "Offline"), and then press

the Enter key as shown.

When accessing SP mode, the SP mode menu is added to the “Job Timeout”,

“Maintenance” and “Media” menu. To exit the controller from SP mode, follow the

procedure for entering SP mode or turn the main switch off and on. (This returns

the controller to normal mode.)

NOTE: When accessing SP mode, “SP” is dis played on the screen. Do not forget

to exit SP mode after servicing, because users may change the settings or

clear all the settings by accident.

Tables

Service

4.1.2 SP MODE FUNCTIONS

Job Timeout Menu

The following menu is added to the Maintenance section.

Menu Function

3. MinLineWidth

[Minimum Line

Width]

Prints lines with the dot (1 to 4 dots) selected.

When a thin line is not clearly visible on output, this mode can

change the thickness of the line.

NOTE:

• If the application does not support line command, this mode

does not function.

• If this mode is activated, this affects all kinds of line data and

causes a side effect. Therefore, normally this mode should be

off.

4-1

Page 15

SERVICE PROGRAM (SP) MODES 14 September 2000

Maintenance Menu

The following menu is added to the Maintenance section. The part highlighted in

gray is newly added for RC-210.

Menu Function

S1. ColorChart

[Color Chart]

S2. ClearAllMem.

[Clear All Memory]

Prints the color test chart stored in the controller. The dither

mode can be selected by pressing the Media key. These color

test charts are used for checking the image quality.

Dither Modes: 1, 2 and 4 bit Photo and Text.

• The color test chart can be printed on any supported paper

size.

• The pattern layout (size) differs depending on the selected

paper size.

Resets all parameters stored in the NVRAM and network board

to their default values.

The Menu Rest in the User menu only resets all the settings and

data for the User menu.

NOTE:

When clearing the memory, if you do not want to clear the

network settings, execute the Clear All Memory after removing

the network board.

S3. Gamma.Calib.

[Gamma Calibration]

S4. Toner Level Independently adjusts the ID level for CMYK.

S5. Printer ID The printer ID is required to download fonts for RPS2 onto the

S6. Toner Limiter Sets the maximum toner amount for image development.

Adjusts the gamma for highlight, middle, shadow, and ID max of

CMYK independently.

NOTE:

When an image quality problem concerning the color balance or

gradation occurs, check or perform maintenance on the copier

first. Then, adjust the printer gamma when users require fine-

tuning.

HDD. However, this controller does not have an HDD. Therefore,

the printer ID is not used.

Media Menu

The following menu was added to the Media section.

Menu Function

3. Summary Displays the firmware version and memory size on the screen.

4-2

Page 16

14 September 2000 SERVICE PROGRAM (SP) MODES

4.1.3 SP MODE TABLE

When accessing SP mode, the SP mode menus are added to the User menus. The

menus consist of some steps depending on the menu. The following table shows

the steps to access a menu and the selectable mode or data.

NOTE: 1) The bolded value or mode is the default setting.

2) Refer to the Operating Instructions for the detailed function of each User

menu.

3) The bolded and Italic menus in step 2 are only accessible in SP mode.

4) The menus highlighted in gray are new or the menu specifications were

changed from the base model (RC-200).

1. Menu Key

1st step 2nd step 3rd step

IPDL-C

RPS2

System

System

1. Job Timeout

2. I/O Timeout 000 (Off) to 999 seconds

3. MinLineWidth 1 to 4 Dots

4. Toner Usage

1. Color Level 1 / 2 / 4 bit

2. Color Mode

3. Color Set

4. Color Profile

5. Smoothing

6. Toner Saving

7. Dithering

8. Paper Type

9. Auto Tray SW

A. Auto Duplex

B. Duplex Bind

C. Collate / Stack

D. Face UP / Down

E. Job Timeout

F. I/O Timeout 000 (Off) to 999 seconds

G. Feed Timeout 000 (Off) to 999 seconds

H. Printer Error

I Ktalk Mode Not effective

J. Parallel IF1

1. Paper Tray

2. I/O Buffer

3. Transfer

4. PDL Sensing

5. Image Memory

6. Parallel

7. Bi-direction

8. OHP Slip

000 (Off) to 999 seconds

300Sec

Off / On

Color or B&W

Off / Vivid / Super Vivid / Fine / Super Fine

Photograph / Presentation / Solid Color

Off / Auto

Off / On

Auto / Photographic / Text

Plain Paper / OHP / Thick Paper

On / Off

Off / On

Short edge / Long edge

Off / Sort / Stack

Face Down / Face Up

000 (Off) to 999 seconds

300Sec

60Sec

Off / On

System Default / ACK inside / ACK Outside

Tray 1 / Tray 2 / Tray 3 / Tray 4 / Bypass

16KB / 32KB / 64KB / 128KB / 256KB / 512KB

Hi-speed / Normal

Auto / Manual

Off / On

ACK Inside / ACK Outside / STB Down

Original Mode / Standard

On / Off

Tables

Service

4-3

Page 17

SERVICE PROGRAM (SP) MODES 14 September 2000

1st step 2nd step 3rd step

System

System

Maintenance

Print List

9. Printer Lang.

[ Printer Language ]

10. Language

32. IP Address

33. Subnet Mask

34. Gateway Add

[Gateway Address]

35. Access CTL

[Access Control]

36. Access Mask

37. Net Boot

[Network Boot]

38. Frame NW

[Frame Type NW]

39. Active PTL

1. Color Calib.

[Color Calibration]

2. Menu Reset “Press # key”

3. Menu Protect Off / On (See NOTE.)

4. Log Protect Off / On (See NOTE.)

5. Log Clear “Press # key”

6. Ethernet Auto / 10Mbps / 100Mbps (See NOTE.)

S1. ColorChart

[Color Chart]

S2. ClearAllMem.

[Clear All Memory]

S3. Gamma.Calib.

[Gamma Calibration]

S4. Toner Level

S5. Printer ID

S6. Toner Limiter

1. Config. Page “Press # key”

2. Job Log “Press # key”

3. Statistics “Press # key”

IPDL-CSelect PDL

Option#1 RPS2

IPDL-C / RPS

English / French / German / Italian / Dutch /

/ Japanese

011.022.033.044

000.000.000.000

000.000.000.000

000.000.000.000

000.000.000.000

ARP+PING / ARP&RARP / ARP&BOOTP /

ARP&RARP&BOOTP / None / RARP+TF TP /

BOOTP / RARP&BOOTP / DHCP

Auto Select / Ethernet 802.3 / Ethernet 802.2 /

Ethernet 2 / Ethernet SNAP

All Active / None / TCP/IP Only / NetWare Only /

TCP&NetWare / EtherTalk Only / TCP&EtherTalk /

NetW&EtherTalk TCP&NW&EtherTK / NetBEUI Only

/ TCP&NetBEUI / NetW&NetBeui / TCP&NW&NB /

ETalk&NetBeui / TCP&ETK&NB / NW&ETK&NB

See the following table for details.

“Press # key”

“Press # key”

See the following table for details.

Cyan / Magenta / Yellow / Black

Not used

See the following table for details.

Spanish

NOTE: The menus, Menu Protect, Log Protect, and Ethernet are not displayed by

pressing the [Menu] key. To access these menus, press the [Enter],

[Escape], and [Menu] keys in sequence when the printer is on-line.

This procedure was added for system/network administrators in order to

avoid changing the settings by accident.

4-4

Page 18

14 September 2000 SERVICE PROGRAM (SP) MODES

2. Media key

1st step 2nd step

1. Paper Tray

2. By-pass

Size

3. Summary

Tray1 / Tray2 / Tray3 / Tray4 / Byps

A3 (L) / B4(L) / A4(S) / A4(L) / B5 (S) / B5 (L) / A5(S) / A5 (L) / B6 (L) / A6(L) /

11x17(L) / 8.5x14(L) / 8.5x13(L) / 11x8.5(S) / 8.5x11 (L) / 8.5x5.5(S) /

5.5x8.5(L) / 8x13(L) / 8.25x13 (L)

RC-210 / RWC / RPS / EtherNET / Total Memory

3. Gamma Calibration & Toner Limiter & Toner Level

2nd step 3rd step 4th step 5th step 6th step

See

NOTE.

0 to 30

(15)

S3.

Gamma

Calib.

S4.

Toner

Level

NOTE.

S5.

Toner

Limiter

1. 2 bit

2. 4 bit

3. 1 bit

Cyan

Magenta

Yellow

Black

Text

Photo

1. Test Pattern

2. Correction

3. Restore “Press # key”

- <-----+-----> +

Data: 100 to 400 (%)

(260)

Data: 100 to 400 (%)

(260)

“Press # key”.

1 to 32

• Photo / K, C, M, Y / H, M, S,

IDmax

• Letter / K, C, M, Y / H, M, S,

IDmax

Tables

Service

NOTE: For dither processing, 8-bit CMYK data is compressed to 1, 2, or 4 bits.

The controller expands the data into 8 bits again for data processing of the

engine. Changing the toner level setting in SP mode increases or

decreases the data level in the 8-bit expansion process. This SP mode can

adjust the ID level for output.

4. Color Calibration

2nd step 3rd step 4th step 5th step 6th step

1. Color

Calib.

1. 2bit

2. 4 bit

3. 1 bit

1. Test Pattern “Press # key”

“Complete”2. Calibrate “Set Pattern on Glass, Press #”

“Error Press #

to Retry”

3. Restore “Press # key”

4-5

Page 19

POWER-UP SELD-DAIGNOSTICS 14 September 2000

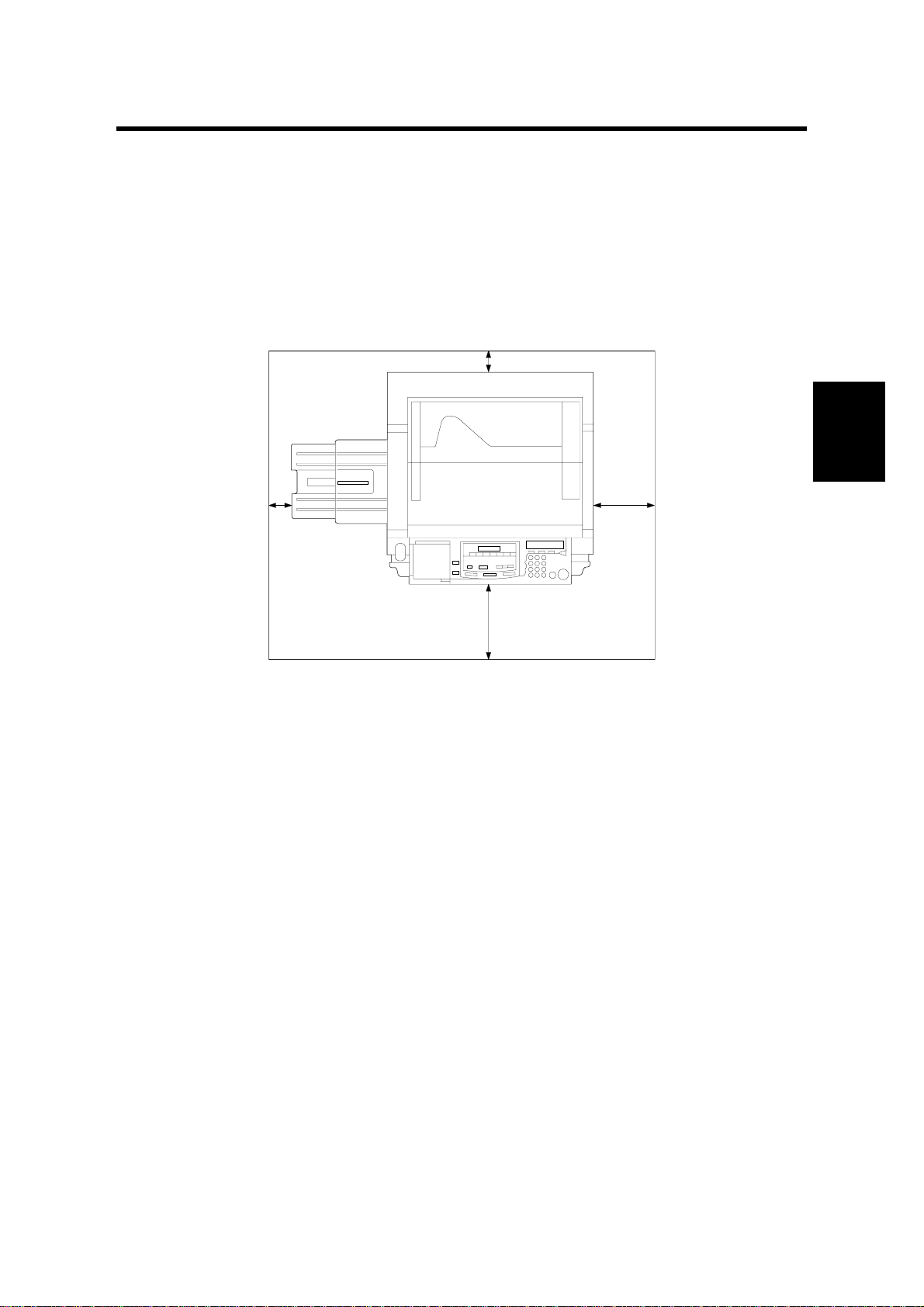

4.2 POWER-UP SELD-DAIGNOSTICS

Code ROM sum check

Check RAM memory size

Read/Write test

Check RAM sum check

Frequency check

Test of timer functions

Operation test

Font ROM sum check

DIMM sum check

Clock generator check

Turn on power

Test Code ROM

Test Standard RAM

Test Standard RAM

Test RAM

Test CPU

Test Timer

Test FPU

Test Font ROM

Test DIMM

Test Clock Generator

Fatal Error Detected

Fatal Error Detected

Fatal Error Detected

Fatal Error Detected

Fatal Error Detected

Fatal Error Detected

Fatal Error Detected

Fatal Error Detected

Fatal Error Detected

Display Error on LCD

Non-fatal Error

Detected

Non-fatal Error

Detected

Start System

Non-fatal Error

NO

Stand-by Condition

Store Error Information

YES

Print List of Settings

(Black/White)

G549D711.WMF

4-6

Page 20

14 September 2000 DETAILED SELF-DIAGNOSTICS

4.3 DETAILED SELF-DIAGNOSTICS

Code ROM sum check

Check RAM memory size

Read/Write test

Check RAM sum check

Frequency check

Test of timer functions

Read/Write test

Operation test

Loop back test

Read/Write test

Turn on power

Test Code ROM

Test Standard RAM

Test Standard RAM

Test RAM

Test CPU

Test Timer

Test Optional RAM

Test FPU

Test Parallel Interface

Test NVRAM

Fatal Error Detected

Fatal Error Detected

Fatal Error Detected

Fatal Error Detected

Fatal Error Detected

Fatal Error Detected

Fatal Error Detected

Fatal Error Detected

Fatal Error Detected

Fatal Error Detected

Fatal Error Detected

Tables

Service

Operation test

DIMM sum check

Clock generator check

Test Font ROM

Test DIMM

Test Clock Generator

Start System

Non-fatal Error

NO

Print List of Settings

(Color)

Stand-by Condition

Fatal Error Detected

Display Error on LCD

Non-fatal Error

Detected

Non-fatal Error

Detected

Store Error Information

YES

Print List of Settings

(Black/White)

G549D712.WMF

4-7

Page 21

14 September 2000 GAMMA CORRECTION

5. REPLACEMENT AND ADJUSTMENT

5.1 GAMMA CORRECTION

Same as the base model (RC-200).

5.2 SOFTWARE UPGRADE PROCEDURE

The controller, Ricoh-Script 2, and network interface boards have a flash ROM for

storing control software. This allows version upgrades using an IC card.

The engine firmware cannot be upgraded in this way. See the engine service

manual for details on how to change this board.

NOTE: Before starting an upgrade procedure, make sure that the software in the

IC card is newer than the software in the controller, Ricoh-Script 2, or

network interface board.

To check, do one of the following:

• Print out a configuration page (user mode).

• Enter controller SP mode and execute “3. Summary” with the [Media]

key. The software version is shown on the operation panel LCD.

Follow the procedure shown below to upgrade the software:

1. Turn off the machine, and then unplug all cables from parallel interface boards

and network interface board, if connected.

2. Remove the handle of the controller (2 screws).

3. Install the IC card in the card slot.

4. Turn on the machine. The machine automatically copies the software from the

IC card to the appropriate IC (controller, Ricoh-Script 2, or network interface

board).

CAUTION: Do NOT turn off the machine while the software is being updated.

Otherwise, the controller, NIB, or Ricoh-Script 2 module may be

damaged.

Adjustment

Replacement

5-1

Page 22

SOFTWARE UPGRADE PROCEDURE 14 September 2000

For the controller or Ricoh-Script 2:

The LCD display on the operation panel changes as shown below as the

rewrite procedure proceeds. (‘MELT’ is displayed during the software upgrade

for Ricoh-Script 2 since it involves a decompression process.)

(MELT ->) ERASE -> WRITE -> VERIFY -> OK!!OK!!

The appearance of the message “OK!!OK!!” indicates that the controller has

received the data from the IC card. However, note that it takes about 30

seconds to rewrite the data in the controller or Ricoh-Script 2 after this message

is displayed.

The message NG!!NG!!” is displayed if an error occurs during the rewrite

process. If this condition occurs, reinstall the IC card and turn the power off and

on again.

For the network interface board:

The appearance of the message “DOWNLOAD OK.” indicates that the

controller has received the data from the IC card. However, note that it takes

about 30 seconds to rewrite the data in the network interface board after this

message is displayed.

DOWNLOAD -> ############ -> DOWNLOAD OK.

The message “DOWNLOAD NG.” is displayed if an error occurs during the

rewrite process. If this condition occurs, reinstall the IC card and turn the power

off and on again.

1. When the rewrite ends, turn off the main switch, and remove the IC card.

2. Reinstall the handle of the controller.

3. Turn the power on again and print the configuration page.

4. Check the new software version and make sure that it matches the version on

the IC card.

5-2

Page 23

14 September 2000 ERROR MESSAGE

6. TROUBLESHOOTING

6.1 ERROR MESSAGE

6.1.1 OVERVIEW

The following types of status and error messages are shown in the table below.

Each message type displays a different priority on the panel screen. When the

controller detects different types of status or errors at the same time, it displays the

message that has the higher priority. Th en the Error indicator will light as shown in

the table.

Type of message Description

Internal Error Controller is out of control. Light

Self-diagnostics

Error

Controller System

Error

SC Code (Copier) Copier cannot be used due to an SC

Warning Error

(Copier)

System Status Displays the status message while

Caution Status

(Copier)

Controller Data

Read Error

Emulation Status Displays the controller status, i.e.

Controller detects error during selfdiagnostics.

Controller cannot work due to a

malfunction.

code.

Copier cannot be used due to status

error. Controller stops ripping and

cancel it depending on the time-out

setting.

the copier is warming up.

Copier can be still used Light

Controller detects that received data

is wrong.

“Initializing”, “Waiting”, “Printing” so

on.

Error

Indicator

Light

Light

Light

Light

Not light

Not light

Not light

Priority

HIGH

LOW

Trouble-

shooting

6-1

Page 24

ERROR MESSAGE 14 September 2000

6.1.2 DETAILED MESSAGES

1. Status Messages

Type Message Descripti on Location / Action

The copier is under the

warm-up or process

control self-check.

diagnostic mode.

Controller is offline status.

The controller cannot

accept or print data.

printing job.

processed.

the next data to print.

System is rebooted or

print job is now being

canceled.

by-pass table.

Toner i ndicated (xxx) is

almost empty (toner near

end condition)

The staples are almost

empty.

There is no paper

indicated (YYY) in the

paper tray.

Toner i ndicated (xxx) is

empty (toner end

condition).

Paper is left in the duplex

tray.

Paper is left in the sorter

bins.

The duplex tray is not

installed correctly.

Paper jam occurs in the

copier.

• Wait until the copier is in

the ready condition.

• Wait until the controller is in

the ready condition.

• Press the Online key to

switch the status.

• Initialization of RPS-2 mode

• The printer is in ready

condition to print.

• Wait for a while. This

message appears only in

the RPS-2 mode.

• Wait for a while.

• Wait for a while.

• Wait for a while.

• Load the indicated paper in

the by-pass table.

• Replenish indicated toner.

• xxx is a color of toner or

CMYK combination.

• Replenish the staples.

• Load the indicated paper in

the paper tray.

• Replenish the indicated

toner.

• Remove paper from the

duplex unit.

• Remove paper from the

sorter bins.

• Reinstall the duplex unit

properly.

• Remove the jammed paper

according to the display on

the copier.

System

Status

Emulation

Status

Caution

Status

Warning

Status

Warming Up

Please Wait The controller under selfOffline

Initializing RPS-2 is initializing.

Ready T he controller is ready for

Printing Doing print job.

Processing Print data is being

Waiting Controller is waiting for

Resetting

Load Paper There is no paper in the

Low on: xxx

Add Staples

Load

YYY

Add Toner

xxx

Remove

Paper From

Duplex Tray

Remove

Paper From

Sorter

Reset Duplex

Tray Correctly

Clear

Misfeed(s)

Trouble-

shooting

6-2

Page 25

14 September 2000 ERROR MESSAGE

Type Message Descripti on Location / Action

Close Door(s)

Doors or covers are open.

• Close doors or covers.

/ Cover(s)

Warning

Status

Power Off /

On

No: XXX

Add Fuser Oil The oil tank is empty.

Waste Toner

Internal error occurs.

The used toner tank is full.

• Turn the main switch off

and on. Fix the problem if it

still occurs.

• Fix the problem.

is Full

Call Service

SC:99

SC code detected on the

copier.

Code number is fixed to

“99” when the copier

detects SC condition.

6-3

Trouble-

shooting

Page 26

ERROR MESSAGE 14 September 2000

2. Controller Error (System or Data Rea d Error)

Error codes highlighted in gray are newly added.

Type Error Code Description Location / Action

System

Error

Data

Read

Error

A3: Error

A6: Error

AB: Error

B0: Error

B1: Error

B3: Error

B4: Error

B5: Error

B7: Error

B9: Error

85: Error

86: Error

91: Error

94: Error

Too much data for

the I/O buffer to

handle

Not enough memory

to print one or more

pages in the job

The controller is

unable to process the

data of job sent

Optional memory

error

Error in the standard

parallel interface

Wrong printer setting

Error in the IC card

slot

Error in RPS2

module

Error in the network

interface board

Error in clock

generator

Error in standard

memory

Wrong p rinter driver

selected / Wrong

interface cable used

Error in the standard

memory

Error in the standard

memory

• Check if the interface cable is

inserted into the controller and your

computer securely.

• Check if the interface cable is

damaged.

• Increase the size of I/O buffer.

• Change the Color Level using the

printer driver to set the image

resolution to [Fast], or change the

Color Level to [1 bit]. Turn on “Image

Memory” using the printer’s “System

Menu”.

• Reduce the amount of data being

sent to the controller.

•

Reinstall/replace optional memory.

• Check the interface cable is inserted

properly or damaged.

• Check controller.

• Reset the controller using “Menu

Reset”

• Check the IC card or controller.

• Reinsert or replace the RPS2

module.

• Reinsert or replace the network

interface board.

•

Check or replace the controller

board.

• Check or replace the controller

board.

• Check if the correct printer drive is

used.

• Check the setting on the driver.

• Check or replace the controller

board.

• Check the total memory size setting

on the driver.

Trouble-

shooting

6-4

Page 27

14 September 2000 ERROR MESSAGE

3. Self-diagnostics error

When a contro ller self-diagnostic error o ccurs, the error code is displayed on the

first line of the screen panel

The second line contains an 8-digit code that gives details of the error for

designers to debug.

• For a memory error, the second line of the panel screen indicates the address in

which the error occurred.

• For errors other than memory errors, the second line always reads “FFFFFFFF”.

Error codes highlighted in gray are newly added.

Error

Code

00XX Exception processing error

01XX Flash ROM sum check error

0201 Standard memory read/write error

0301/

0401

06XX CPU exception self-diagnostics error

0D0X ASIC timer error

0FXX ASIC engine interface error

110X ASIC Centronics interface error

1401 NVRAM error

160X Font ROM error

1B0X Optional Interface Error

200X C l o ck Gen erator Error

250X DIMM (emulation module) error

400X FPU error

Optional memory read/write error

Non-fatal error (printed as B0 in the error log.)

Non-fatal error (printed as B1 in the error log.)

Non-fatal error (printed as B5 in the error log):

2501 & 2507

Description Location

• Controller Board

•

Controller Board

• Controller Board

Controller Board

•

• Controller Board

• Controller Board

•

Controller Board

• Controller Board

• Controller Board

• Controller Board

• Controller Board

•

Controller Board

• RPS2 module (DIMM)

(See NOTE.)

• Controller Board

• Controller Board

Trouble-

shooting

NOTE: If the DIMM is not properly set in the slot or is defective and if the controller

detects it, the controller boots up in IPDL-C mode. In this case, the

controller seems to be OK, however, print-jobs fail if customers use RPS2

for printing. It is necessary to check whether the DIMM is properly installed

in the slot or defective.

6-5

Page 28

ERROR MESSAGE 14 September 2000

4. INTERNAL ERRORS

When an inte rnal error occurs, the message “Power Off / On” is displayed on the

first line of the p anel screen. The internal error code, “No. XXYY-ZZZZZZZZ) is

displayed on the second line of the panel screen. (“XX” denotes a classification

code, “YY” denotes a process number, and “ZZZZZZZZ” denotes the program

address where the error occurred.)

The classification code portions “XX” and their description are as shown below.

“YY” and “ZZZZZZZZ” portions are for designer use only (for debugging).

Code

(Part of “XX”)

00 Error in the TLB user area.

01 CPU TLB update exception

02 CPU mismatch exception (load or fetch)

03 CPU mismatch exception (store)

04 CPU address error exception (load or fetch)

05 CPU address error exception (store)

06 CPU bus error exception (load or fetch)

07 CPU bus error exception (store)

08 CPU system call exception

09 CPU break point exception

10 CPU reserved instruction exception

11 CPU coprocessor disabled exception

12 CPU operation overflow exception

13 CPU trap exception

14 Coherency (instruction) error

15 CPU floating-point operation exception

16 CPU time r int e rrupt

17 ROCKY level 4 interrupt (ART or Tim)

18 ROCKY level 3 inter rupt (C)

19 ROCKY level 2 inter rupt (XINT1 or XINT0)

20 ROCKY level 1 inter rupt (CBE, DBE, Dtc0, EAGLE, EAGLEErr)

21 ROCKY level 0 inter r u pt (Debug)

22 Software interrupt

23 Software interrupt

24 Other CPU exceptions

25 Memory allocation error

26 Overflow error

27 Frame allocation error

28 Card eject error

29 Printer engine error

30 Option board error

31 Session-to-network interface board communication error

Description

Trouble-

shooting

6-6

Page 29

14 September 2000 OVERVIEW

7. NETWORK INTERFACE BOARD (C4000 FERRET)

7.1 OVERVIEW

7.1.1 SPECIFICATIONS

Configuration: Embedded

LAN Interface: 100BASE-TX/10BASE-T

Frame Type: Ethernet II, IEEE802.3, IEEE802.2, SNAP

Protocol: TCP/IP, AppleTalk, NetWare, NetBEUI

SNAP: MIB-II, Printer MIB, Host Resource MIB, Ricoh Private MIB

7.1.2 BLOCK DIAGRAM

Controller

Board

Option Bus I/F

Network

Environment

CPU

ASIC

Ethernet

Controller

Filter Module

LAN I/F

Flash ROM

1MB

SDRAM

8MB (64Mb)

EEPROM

1Kb

Option

7-1

G549O501.WMF

Page 30

COMPONENT LAYOUT 14 September 2000

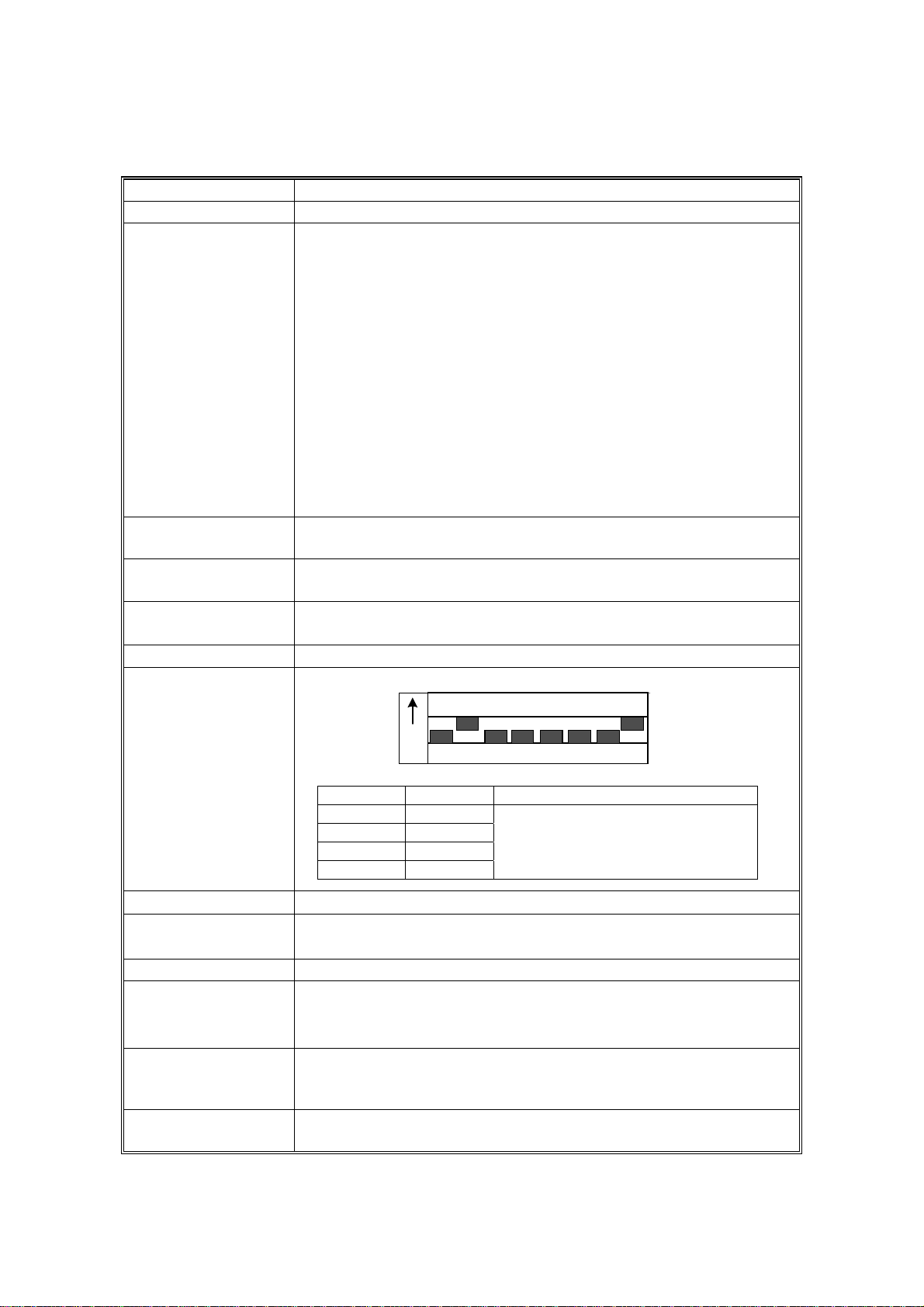

7.2 COMPONENT LAYOUT

7.2.1 NETWORK INTERFACE BOARD DIAGRAM

Flash

ROM

MB87L1231

7.2.2 DEVICES

ASIC

SDRAM

CPU

HD6417612

Ethernet

Controller

AM79C973

RJ-45

LED4(G)

LED3(G)

EEPROM

LED1(Y)

SW2

G549O500.WMF

Device Description

CPU HD6417612RF

ASIC MB87L1231

Flash ROM MBM29LV800BA-70PFTN (8 Mbit)

SDRAM 64Mbit: 100MHz

EEPROM M93C46-WMN6 (1kbit)

Ethernet Controller AM79C973KC/W

7-2

Trouble-

shooting

Page 31

14 September 2000 BASIC OPERATIONS

7.3 BASIC OPERATIONS

7.3.1 OVERVIEW

This network board can manage both 100BASE-TX and 10BASE-T. It has a

maximum data transfer speed of 100Mbps.

The auto-negotiation function automatically switches the communication speed.

The controller board supplies the power source (+5V) and provides the reset

signal. The controller board communicates with the network interface board

through the option I/F connector.

The function of LED and SW is as follows;

Functions

LED1

LED2 Not used

LED3

LED4

SW1

Displays the operating status.

ON: Ready, OFF: Busy

Displays the LAN Type.

ON: 100 BASE-TX, OFF: 10 BASE-T

Displays the link status.

ON: Link safe, OFF: Link failure or Link disable

Resets the NVRAM on the network interface board.

NOTE:This board has the hardware to execute a “Summary Printout”.

However, it does not function on this printer due to the controller

specifications.

7-3

Option

Page 32

BASIC OPERATIONS 14 September 2000

7.3.2 SWITCH FUNCTION

SW1 resets the NVRAM on the network interface board.

NOTE: This board has the hardware to execute a "Summary Printout". However, it

does not function on this printer due to controller specifications.

NVRAM Reset Procedure

This procedure resets all the network settings to the defaults.

• IP address, Subnet Mask, Default Gateway Address, Access Control Mask,

Network Boot, Frame Type (NetWare), Active Protocol, and so on

1. Turn on the main switch while pressing SW1. Keep pressing SW1 for 15

seconds.

2. Release SW1 for 3 seconds, press it again for 3 seconds, and then release it.

NOTE: There is a margin of less than 1 second for error. Use a watch to

measure the time periods as accurately as possible.

3. Turn the main switch off/on to complete the NVRAM reset procedure.

4. Print out the configuration page, and then check the settings. If the procedure

failed, the previous settings remain. Repeat the above procedure until the old

settings have been cleared.

Trouble-

shooting

7-4

Loading...

Loading...