R2062 SERIES

3 wire interface Real-Time Clock ICs with Battery Backup switch-over Function

NO.EA-178-080118

OUTLINE

The R2062 is a CMOS real-time clock IC connected to the CPU by three signal lines, CE, SCLK, and SIO, and

configured to perform serial transmission of time and calendar data to the CPU. Further, battery backup

switchover circuit and a voltage detector. The periodic interrupt circuit is configured to generate interrupt signals

with six selectable interrupts ranging from 0.5 seconds to 1 month. The 2 alarm interrupt circuits generate

interrupt signals at preset times. As the oscillation circuit is driven under constant voltage, fluctuation of the

oscillator frequency due to supply voltage is small, and the time ke eping cu rrent is small (TYP. 0.4µA at 3V). The

oscillation halt sensing circuit can be used to judge the validity of internal data in such events as power-on; The

supply voltage monitoring circuit is configured to record a drop in supply voltage below two selectable supply

voltage monitoring threshold settings. The 32.768kHz clock output function (CMOS output) is intended to output

sub-clock pulses for the external microcomputer. The oscillation adjustment circuit is intended to adjust time

counts with high precision by correcting deviations in the oscillation frequency of the quartz crystal unit. Battery

backup switchover function is the automatic switchover circuit between a main power supply and a backup

battery of secondary battery. Since the package for these ICs are FFP12 (2.0x2.0x1.0: R2062Kxx) and

SSOP16 (5.0x6.4x1.25: R2062Sxx (Preliminary)), high density mounting of ICs on boards is possible.

FEATURES

• Minimum Timekeeping supply voltage Typ. 0.75V (Max. 1.00V); VDD pin

• Low power consumption Typ. 0.4µA (Max. 1.0µA)

• Built-in Backup switchover circuit (can be used for a secondary battery , or an ele ctric double layer cap acitor)

• Three signal lines (CE, SCLK, and SIO) required for connection to the CPU. ·····

(Maximum clock frequency of 1MHz (with V

• Time counters (counting hours, minutes, and seconds) and calendar counters (counting years, months,

days, and weeks) (in BCD format)

• Interrupt circuit configured to generate interrupt signals (with interrupts ranging from 0.5 seconds to 1

month) to the CPU and provided with an interrupt flag and an interrupt halt

• 2 alarm interrupt circuits (Alarm_W for week, hour, and minute alarm settings and Alarm_D for hour and

minute alarm settings)

• Built-in voltage detector with delay

• With Power-on flag to prove that the power supply starts from 0V

• 32-kHz clock output pin (CMOS output. “H” level is always equal to VCC.)

• Supply voltage monitoring circuit with two supply voltage monitoring threshold settings

• Automatic identification of leap years up to the year 2099

• Selectable 12-hour and 24-hour mode settings

• Built-in oscillation stabilization capacitors (CG and CD)

• High precision oscillation adjustment circuit

• CMOS process

• Package FFP12 (2.0mm x 2.0mm x 1.0mm : R2062Kxx, SSOP16 (5.0mm x 6.4mm x 1.25mm :

R2062Sxx(Preliminary)),

CC = 3V) )

at VDD=3V

1

R2062 series

K

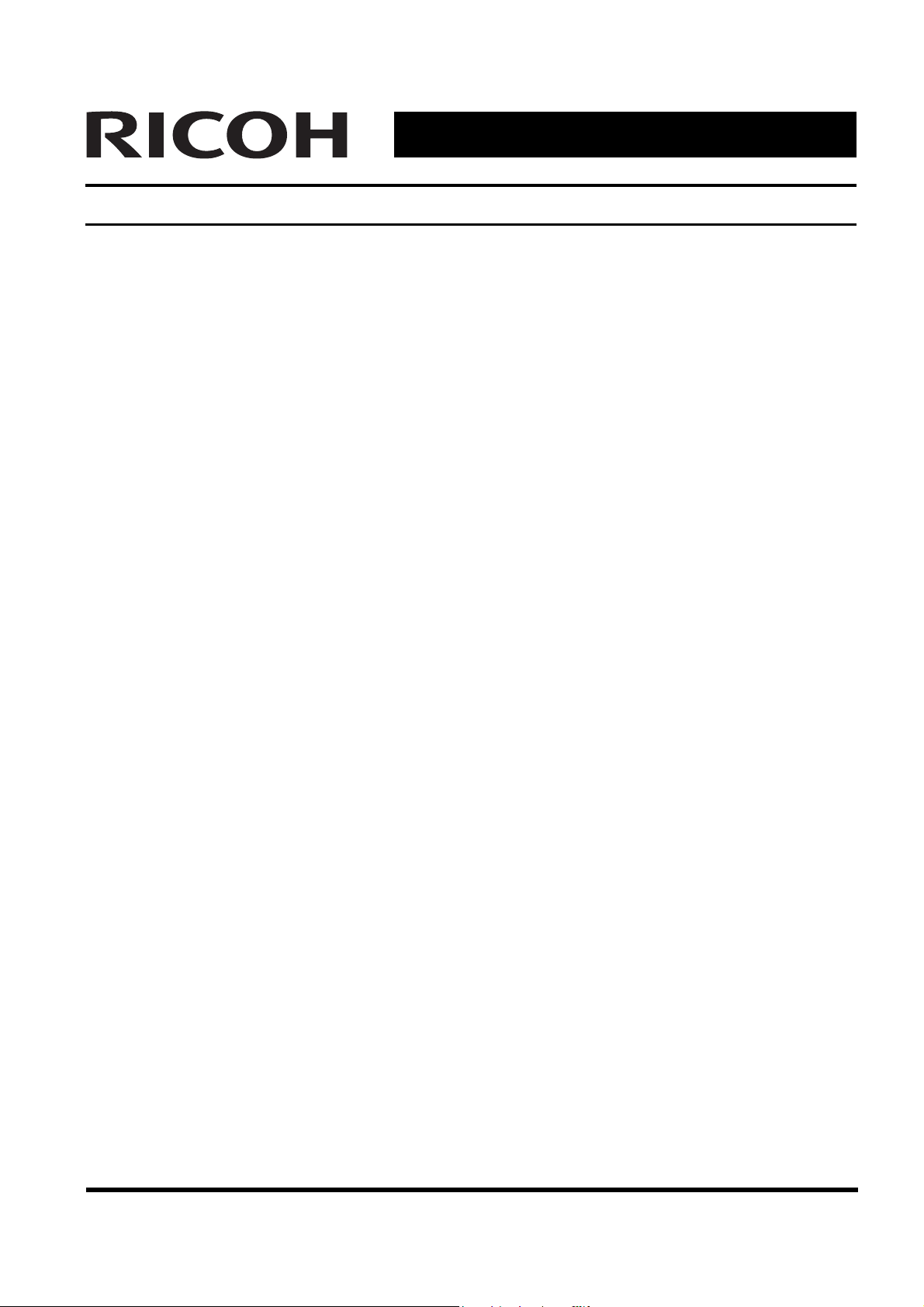

PIN CONFIGURATION

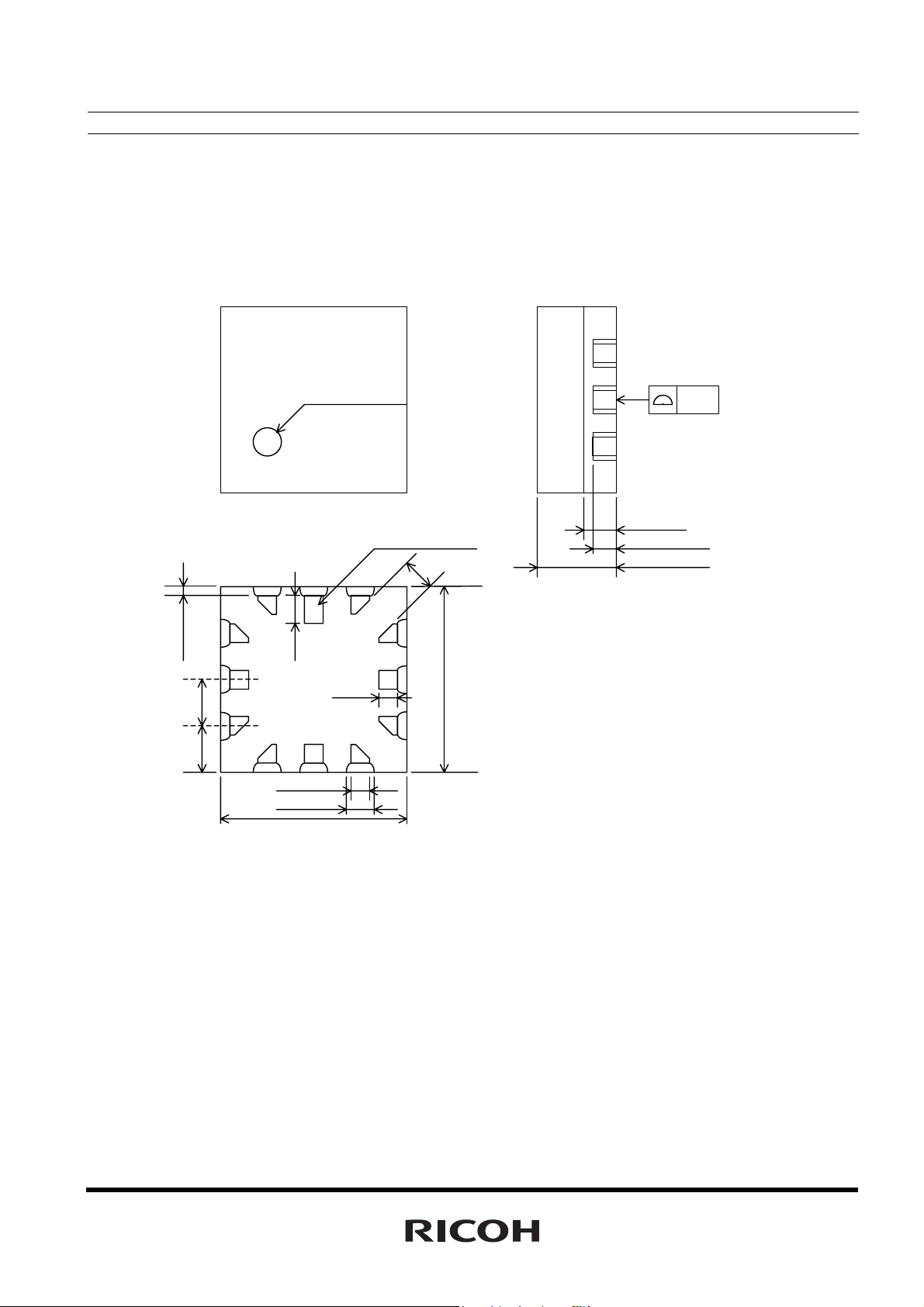

R2062Kxx(FFP12)

CIN

10

VSS

CE

11

12

BLOCK DIAGRAM

R1

Rechargeable

Battery

C2

BATTERY

VOLTAGE

MONITOR

OSCIN

OSCOUT

OSCOUT

INTR

9

OSCIN

8

7

6

5

1

4

2

3

SIO

SCL

CLKOUT

TOP VIEW

REAL

TIME

CLOCK

VDD

VCC

VDCC

VDD

SW1

CLKOUT

DELAY

R2062Sxx(SSOP16)

(Preliminary)

NC

1

VDCC

SCLK

SIO

VSS

NC

CE

2

3

4

5

6

7

8

TOP VIEW

VOLTAGE

DETECTOR

SHIFTER

LEVEL

16

15

14

13

12

11

10

9

VCC

VDCC

CE

SCLK

SIO

CLKOUT

VCC

VDD

NC

OSCIN

OSCOUT

NC

INTR

CIN

MAIN Power

Supply

C3

CPU

CIN

C1

VSS

VOLTAGE

REFERENCE

INTR

2

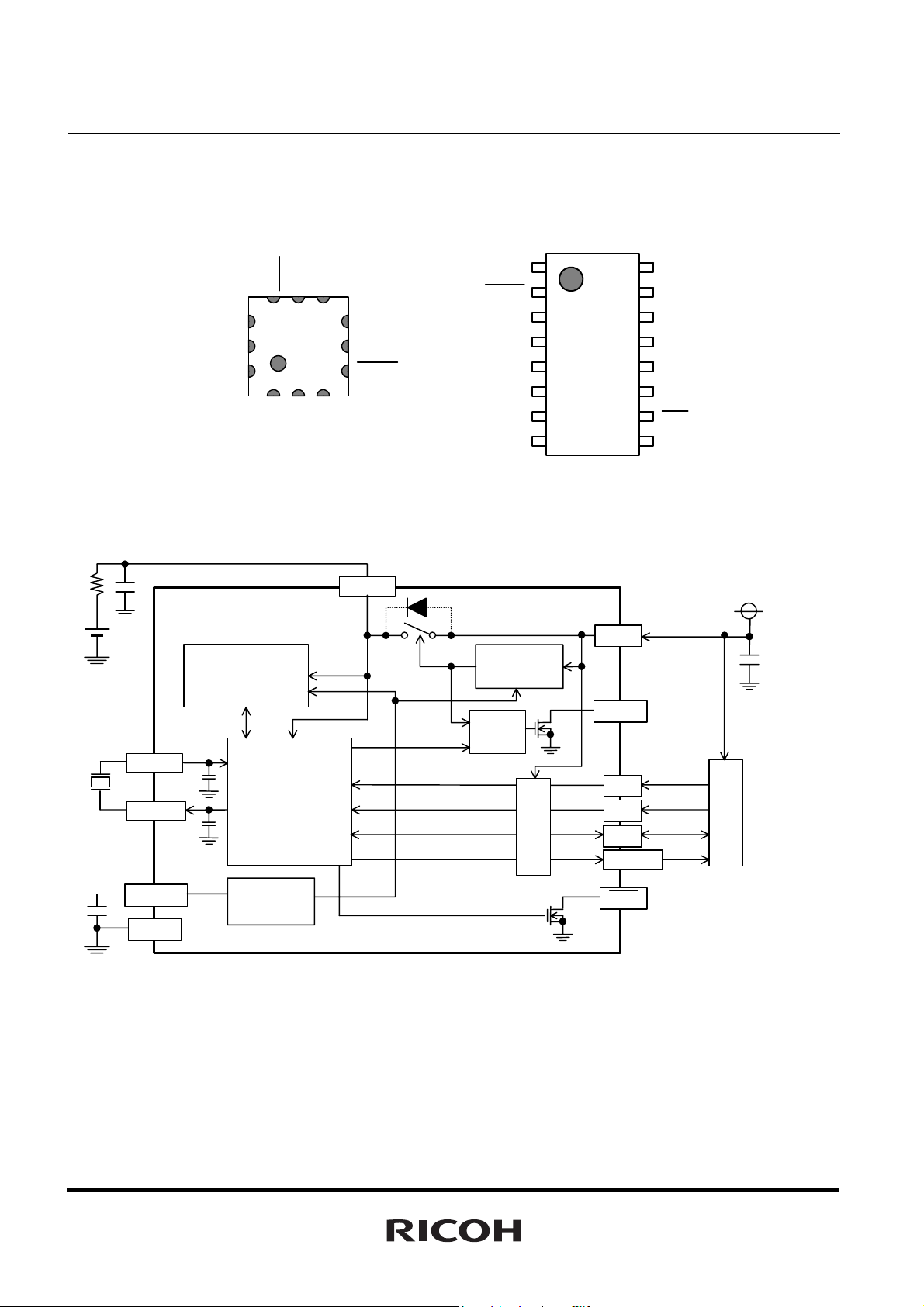

SELECTION GUIDE

In the R2062xxx Series, output voltage and options can be designated.

Part Number is designated as follows:

R2062K01-E2 ←Part Number

↑↑ ↑

R2062abb

Code Description

a

bb Serial number of Voltage detector setting etc.

cc Designation of the taping type. Only E2 is available.

Part Number Package -V

R2062K01-E2 FFP12 2.70(Typ.) P. 6

R2062K02-E2 FFP12 2.90(Typ.) P. 7

-cc

Designation of the package.

K: FFP12

S: SSOP16 (Preliminary)

DET1 (switch-over threshold) DC Electrical

Characteristics

R2062 series

3

R2062 series

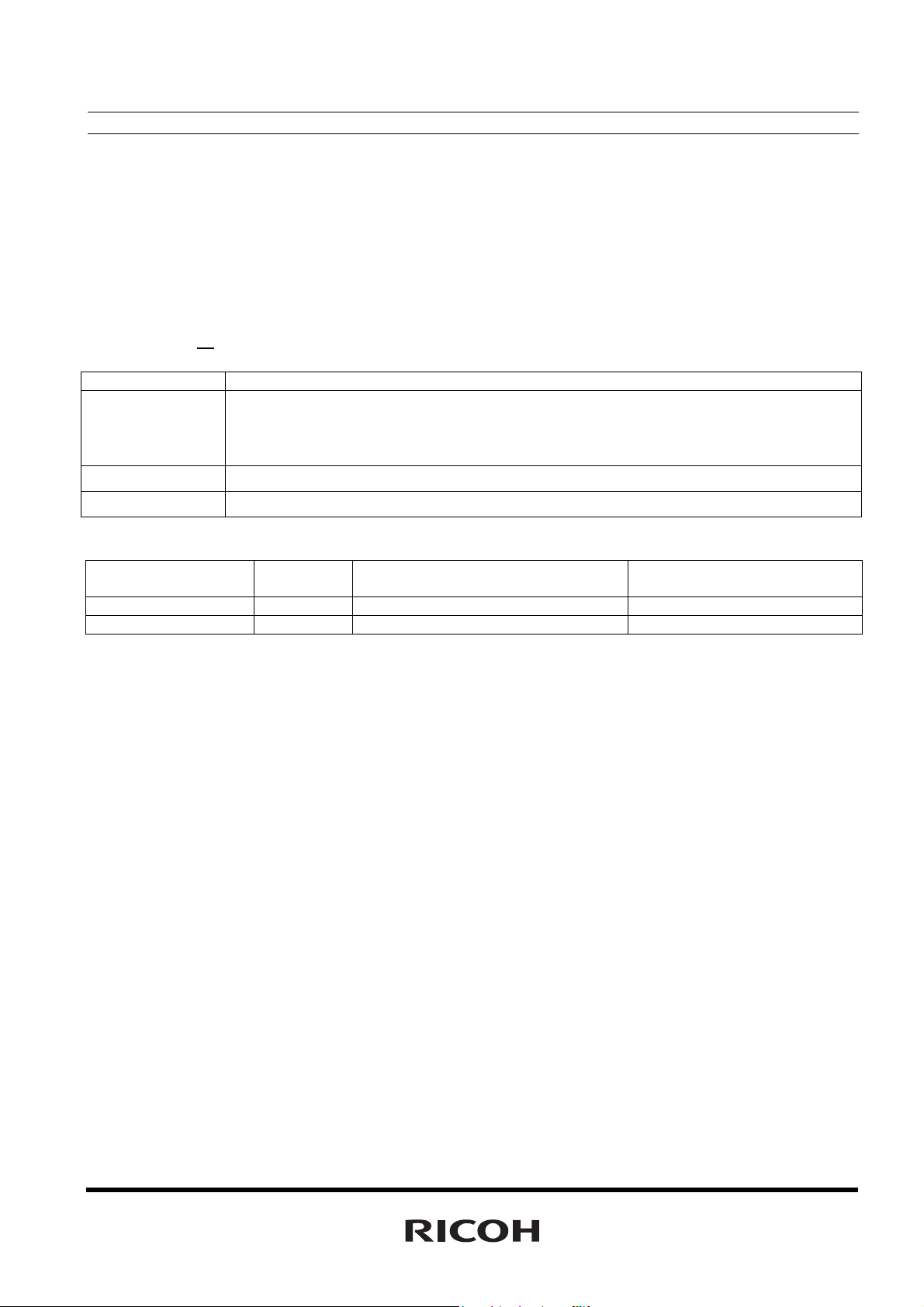

PIN DESCRIPTION

PIN

R2062Kxx

(FFP12)

R2062Sxx

(SSOP16)

12 7 CE Chip enable

Symbol Item Description

The CE pin is used for interfacing with the CPU. Should

Input

be held high to allow access to the CPU. Incorporates a

pull-down resistor. Should be held low or open when the

CPU is powered off. Allows a maximum input voltage of

5.5 volts regardless of supply voltage.

2 4 SCLK Serial

Clock Input

The SCLK pin is used to input clock pulses synchronizing

the input and output of data to and from the SIO pin.

Allows a maximum input voltage of 5.5 volts regardless of

supply voltage.

1 5 SIO Serial

Input /

The SIO pin is used to input or output data intended for

writing or reading in synchronization with the SCLK pin.

Output

9 10

INTR

Interrupt

Output

INTR

The

(Alarm_W) and alarm interrupt (Alarm_D) and output

periodic interrupt signals to the CPU signals. Disabled at

power-on from 0V. Nch. open drain output.

3 3 CLKOUT 32kHz

Clock

The CLKOUT pin is used to output 32.768-kHz clock

pulses. CMOS output. “H” level is always equal to VCC.

Output

5 16 VCC Main

Supply power to the IC.

Battery

input

6 15 VDD Positive

Power

Supply

Input

The VDD pin is connected to the power supply. Connect a

capacitor as much as 0.1µF between VDD and VSS. In

the case of using a secondary battery, connecting the

secondary battery to this pin is possible.

4 2

VDCC

VCC Power

Supply

Monitoring

Result

Output

While monitoring VCC Power supply, if the voltage is

equal or lower than –V

VDCC

to +V

DET1 or more, SW1 turns on. After t DELAY passed,

VDCC

output.

10 9 CIN Noise

Bypass Pin

7 13 OSCIN

Oscillation

Circuit Input

8 12 OSCOUT Oscillation

To stabilize the internal reference, connect a capacitor as

much as 0.1uF between this pin and VSS.

The OSCIN and OSCOUT pins are used to connect the

32.768-kHz quartz crystal unit (with all other oscillation

circuit components built into the R2062 series).

Circuit

Output

11 8 VSS Negative

The VSS pin is grounded.

Power

Sup Supply

Input

- 1,6,11,

14

NC No

Connection

pin is used to output alarm interrupt

DET1, this output level is “L”. When

becomes “L”, SW1 turns off. When VCC is equal

output becomes off, or “H”. Nch Open-drain

4

R2062 series

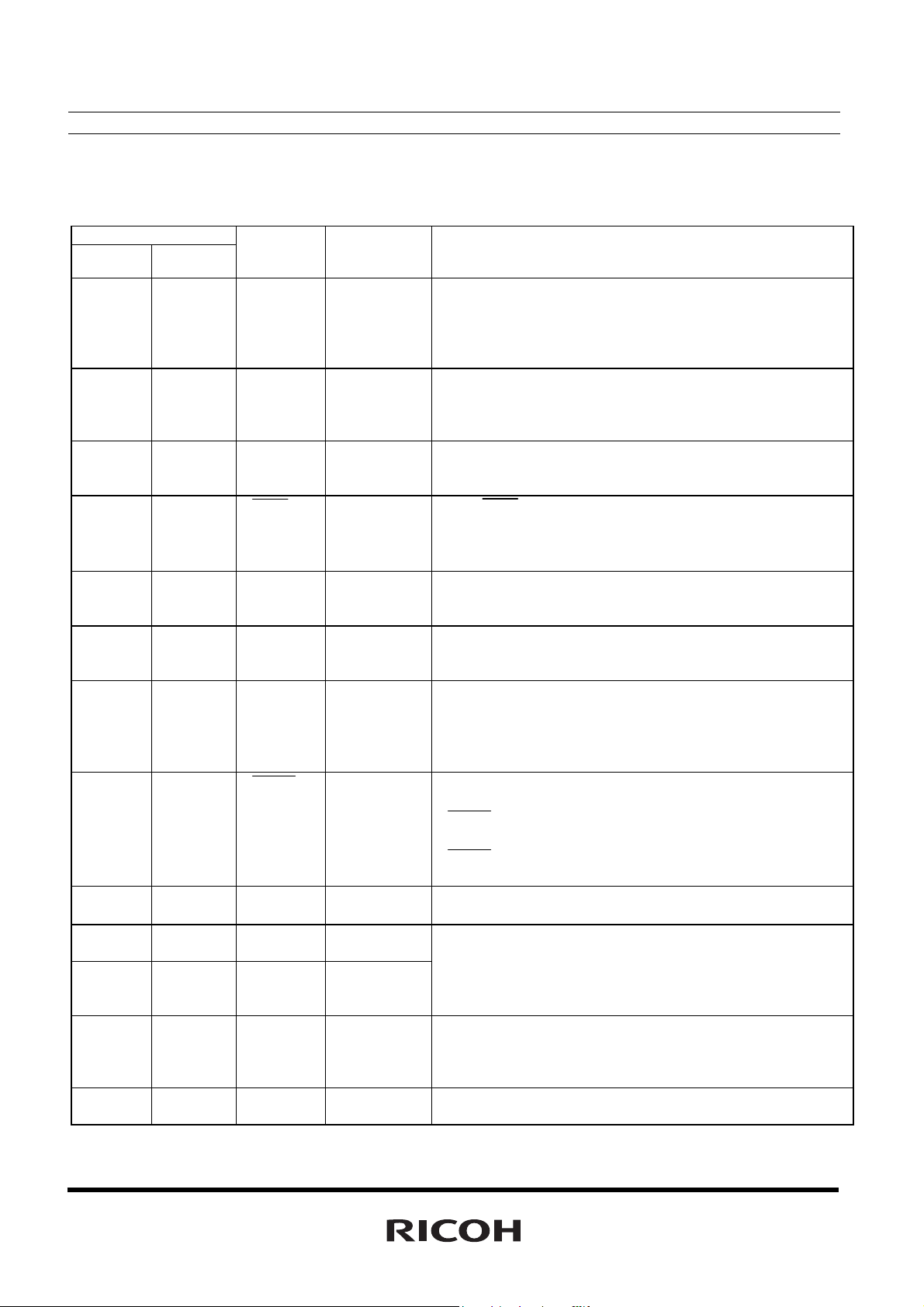

ABSOLUTE MAXIMUM RATINGS

(VSS=0V)

Symbol Item Pin Name Description Unit

VCC Supply Voltage 1 VCC -0.3 to +6.5 V

VDD Supply Voltage 2 VDD -0.3 to +6.5 V

VI

VO

IOUT Maximum Output Current VDD 10 mA

PD Power Dissipation

Topt Operating Temperature -40 to +85

Tstg Storage Temperature -55 to +125

Input Voltage 1 CE, SCLK -0.3 to +6.5 V

Input Voltage 2 SIO -0.3 to VCC+0.3 V

Input Voltage 3 CIN -0.3 to V

Output Voltage 1

Output Voltage 2 SIO, CLKOUT -0.3 to V

INTR

Topt = 25°C

,

VDCC

-0.3 to +6.5 V

300 mW

DD+0.3 V

CC+0.3 V

°C

°C

RECOMMENDED OPERATING CONDITIONS

(VSS=0V, Topt=-40 to +85°C)

Symbol Item Pin Name Min, Typ. Max. Unit

Vaccess Supply Voltage VCC power supply

voltage for interfacing

with CPU

VCLK Minimum Timekeeping

Voltage

CGout,CDout=0pF

*2), *3)

fXT Oscillation Frequency 32.768 kHz

VPUP Pull-up Voltage

*1) -VDET1 in Vaccess specification is guaranteed by design.

*2) CGout is connected between OSCIN and VSS, CDout is connected between OSCOUT and VSS.

R2062 series incorporates the capacitors between OSCIN and VSS, between OSCOUT and VSS.

Then normally, CGout and CDout are not necessary.

*3) Quartz crystal unit: CL=6-8pF, R1=30KΩ

0.75 1.00 V

INTR

,

VDCC

-VDET1

*1)

5.5 V

5.5 V

5

R2062 series

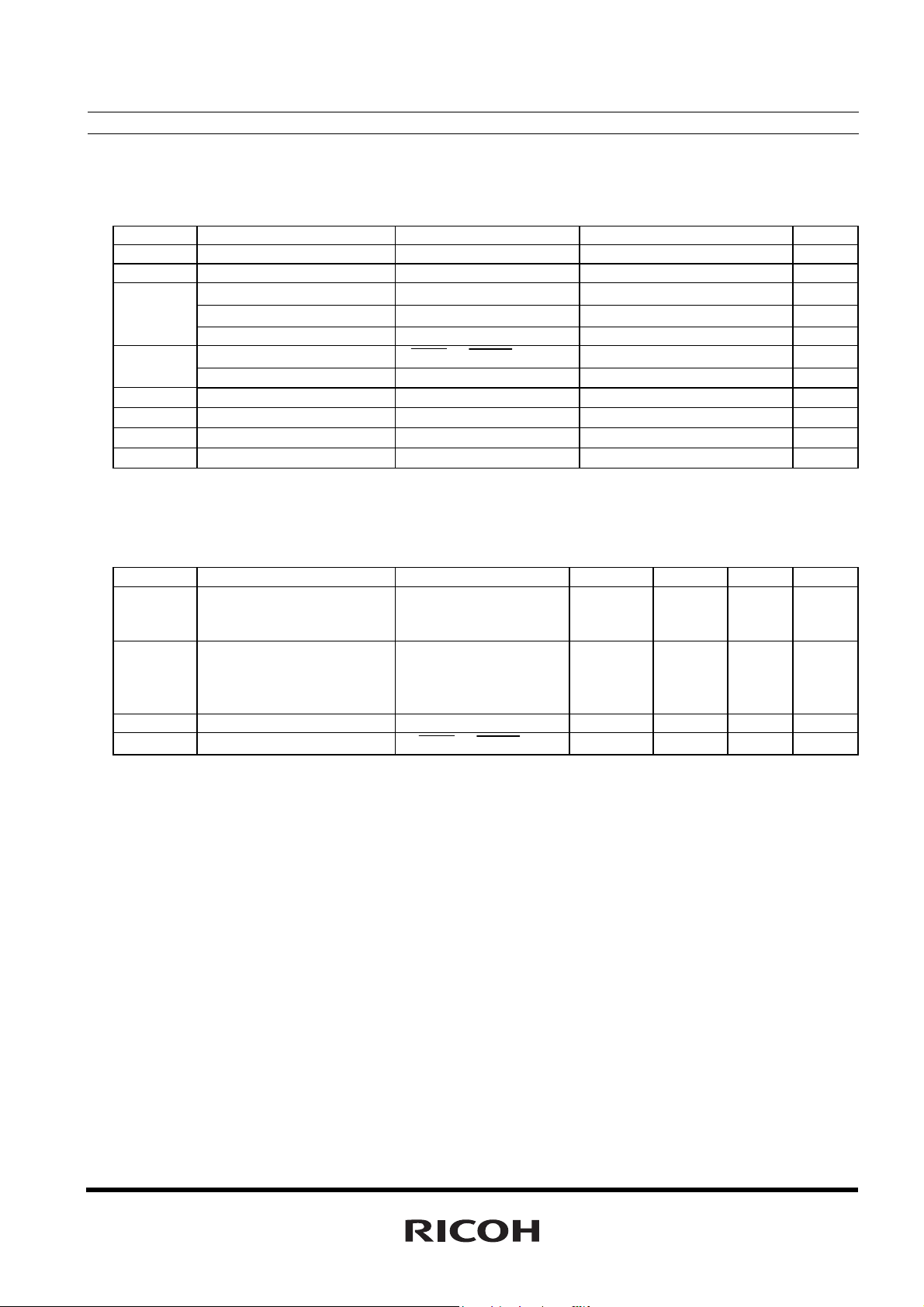

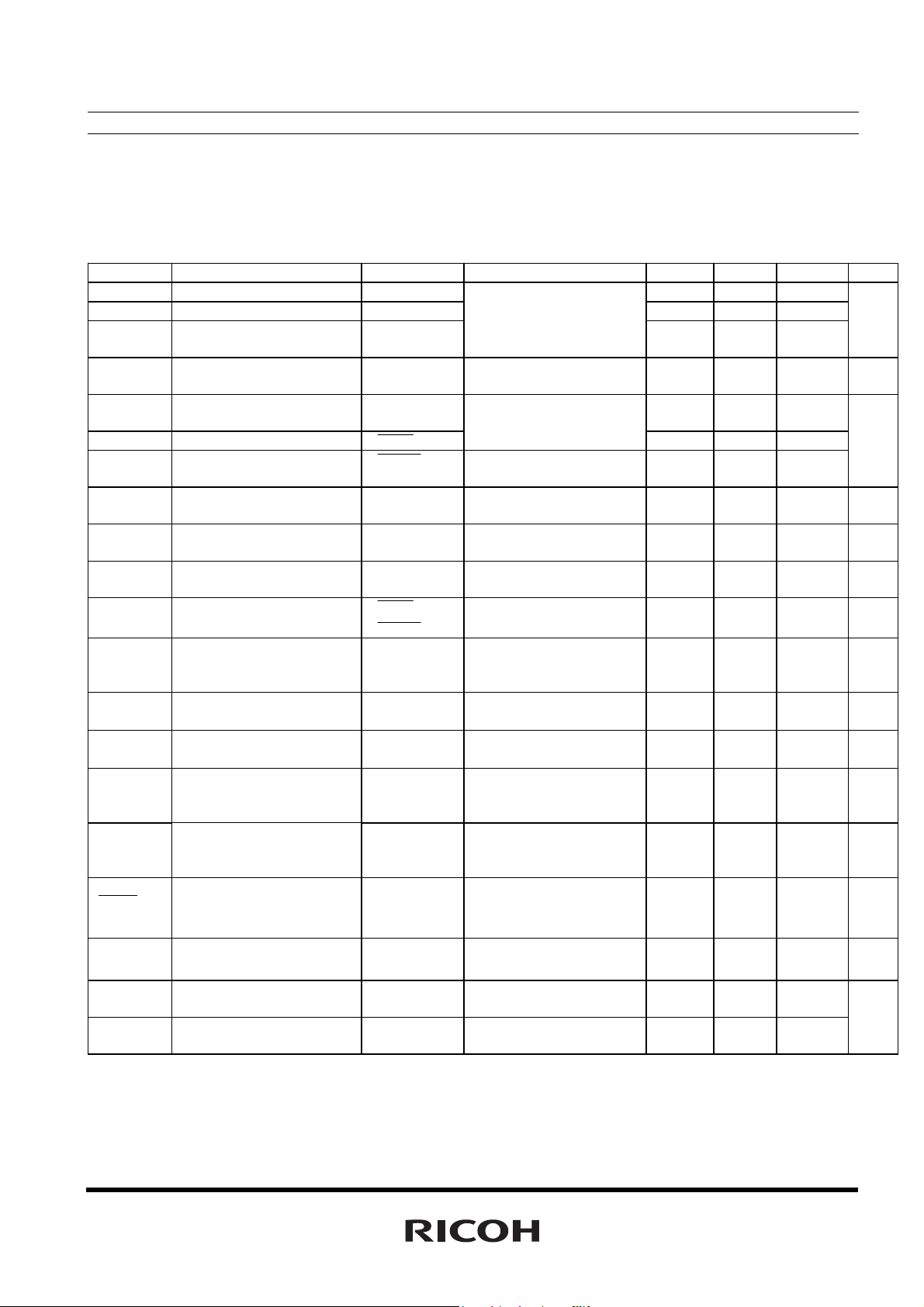

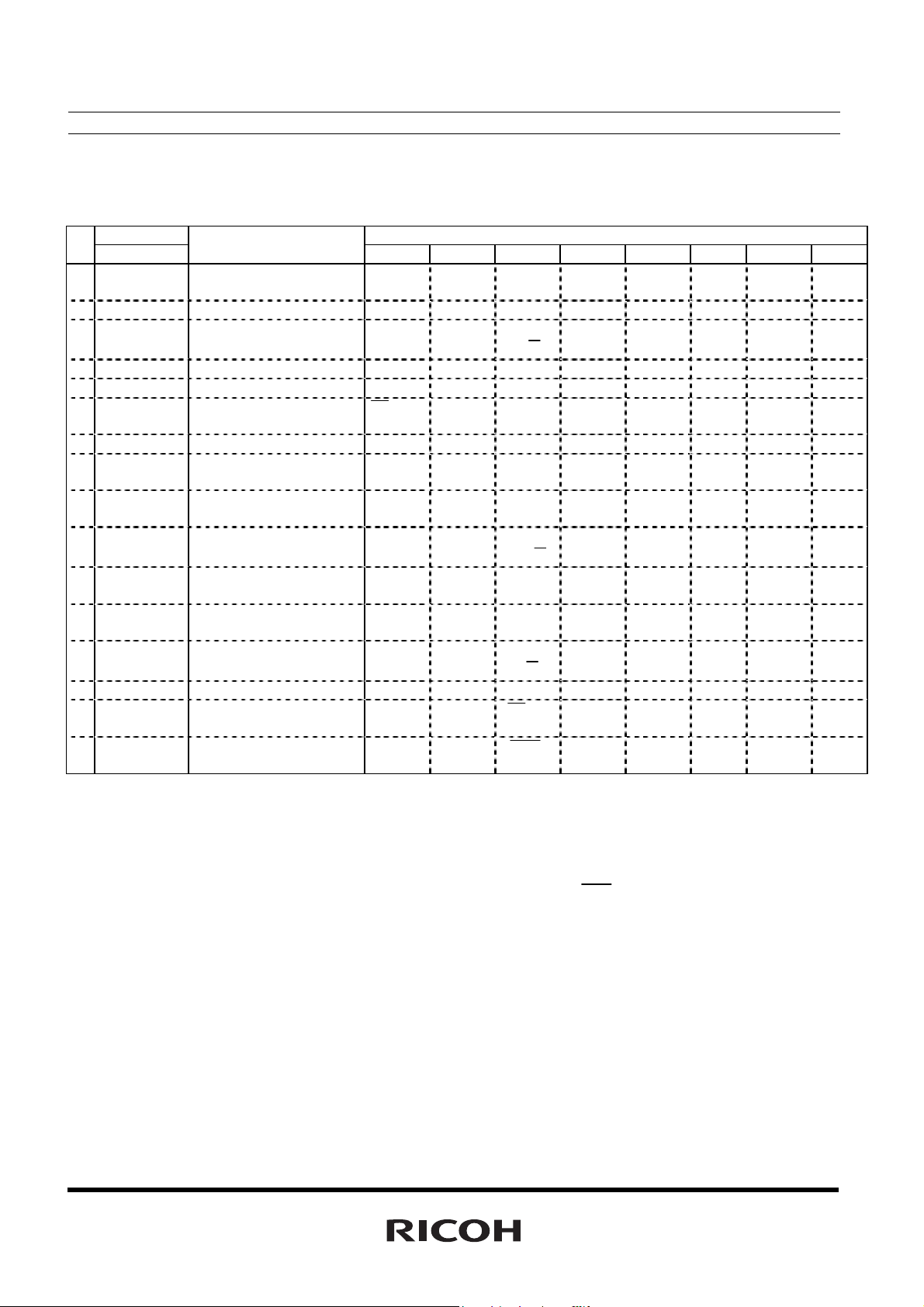

DC ELECTRICAL CHARACTERISTICS

• R2062K01

(Unless otherwise specified: VSS=0V, VCC=3.0V, 0.1uF between VDD and VSS, CIN and VSS,

Topt=-40 to +85°C)

Symbol Item Pin Name Conditions Min. Typ. Max. Unit

VIH1 “H” Input Voltage 1 CE, SCLK 0.8xVCC 5.5

VIH2 “H” Input Voltage 2 SIO 0.8xVCC VCC+0.3

VIL “L” Input Voltage CE, SIO

SCLK

IOH “H” Output

Current

SIO,

CLKOUT

IOL1 “L” Output Current 1 SIO,

CLKOUT

IOL2 “L” Output Current 2

IOL3 “L” Output Current 3

IIL Input Leakage

INTR

VDCC

SCLK VI=5.5V or VSS -1.0 1.0

Current

RDNCE Pull-down Input

CE 40 120 400

register

IOZ1 Output Off-state

SIO VO=5.5V or VSS -1.0 1.0

Current 1

IOZ2 Output Off-state

Current 2

IDD Time Keeping Current

INTR

,

VDCC

VDD VCC=0V, VDD=3.0V,

at Backup mode

VDETH Supply Voltage

Monitoring Voltage “H”

VDETL Supply Voltage

Monitoring Voltage “L”

-VDET1 Detector Threshold

VDD

VDD

VCC

Voltage

(falling edge of VCC)

+VDET1 Detector Released

VCC

Voltage (rising edge of

VCC)

∆VDET

∆Topt

Detector Threshold

and Released Voltage

VCC, VDD

Temperature coefficient

VDDOUT1 VDD Output

VDD

Voltage 1

CG Internal Oscillation

OSCIN 10

Capacitance 1

CD Internal Oscillation

OSCOUT 10

Capacitance 2

*1) Guaranteed by design.

V

-0.3 0.2xVCC

VOH=VCC-0.5V -0.5 mA

OL=0.4V

V

0.5

mA

2.0

V

DD, VCC=2.0V

V

OL=0.4V

0.5

µA

kΩ

µA

V

O=5.5V or VSS

-1.0 1.0

µA

0.4 1.0

µA

Output=OPEN

Time Keeping

VCC=0V,

Topt=+25°C

VCC=0V,

1.90 2.10 2.30 V

1.20 1.35 1.50 V

Topt=25°C

Topt=25°C

Topt=25°C

Topt=-40 to 85°C

*1)

Topt=25°C, V

I

out=1.0mA

CC=3.0V,

2.63 2.70 2.77 V

2.69 2.78 2.87 V

±100

ppm

/°C

V

CC-

0.12

VCC-

0.04

V

pF

6

R2062 series

• R2062K02

(Unless otherwise specified: VSS=0V, VCC=3.3V, 0.1uF between VDD and VSS, CIN and VSS,

Topt=-40 to +85°C)

Symbol Item Pin Name Conditions Min. Typ. Max. Unit

VIH1 “H” Input Voltage 1 CE, SCLK 0.8xVCC 5.5

VIH2 “H” Input Voltage 2 SIO 0.8xVCC VCC+0.3

VIL “L” Input Voltage CE, SIO

SCLK

IOH “H” Output

Current

SIO,

CLKOUT

IOL1 “L” Output Current 1 SIO,

CLKOUT

IOL2 “L” Output Current 2

IOL3 “L” Output Current 3

IIL Input Leakage

INTR

VDCC

SCLK VI=5.5V or VSS -1.0 1.0

Current

RDNCE Pull-down Input

CE 40 120 400

register

IOZ1 Output Off-state

SIO VO=5.5V or VSS -1.0 1.0

Current 1

IOZ2 Output Off-state

Current 2

IDD Time Keeping Current

INTR

,

VDCC

VDD VCC=0V, VDD=3.0V,

at Backup mode

VDETH Supply Voltage

Monitoring Voltage “H”

VDETL Supply Voltage

Monitoring Voltage “L”

-VDET1 Detector Threshold

VDD

VDD

VCC

Voltage

(falling edge of VCC)

+VDET1 Detector Released

VCC

Voltage (rising edge of

VCC)

∆VDET

∆Topt

Detector Threshold

and Released Voltage

VCC, VDD

Temperature coefficient

VDDOUT1 VDD Output

VDD

Voltage 1

CG Internal Oscillation

OSCIN 10

Capacitance 1

CD Internal Oscillation

OSCOUT 10

Capacitance 2

*1) Guaranteed by design.

V

-0.3 0.2xVCC

VOH=VCC-0.5V -0.5 mA

OL=0.4V

V

0.5

mA

2.0

V

DD, VCC=2.0V

0.5

VOL=0.4V

µA

kΩ

µA

V

O=5.5V or VSS

-1.0 1.0

µA

0.4 1.0

µA

Output=OPEN

Time Keeping

VCC=0V,

Topt=+25°C

VCC=0V,

1.90 2.10 2.30 V

1.20 1.35 1.50 V

Topt=25°C

Topt=25°C

Topt=25°C

Topt=-40 to 85°C

*1)

Topt=25°C, V

I

out=1.0mA

CC=3.3V,

2.820 2.900 2.980 V

2.890 2.985 3.080 V

±100

ppm

/°C

V

CC-

0.12

VCC-

0.04

V

pF

7

R2062 series

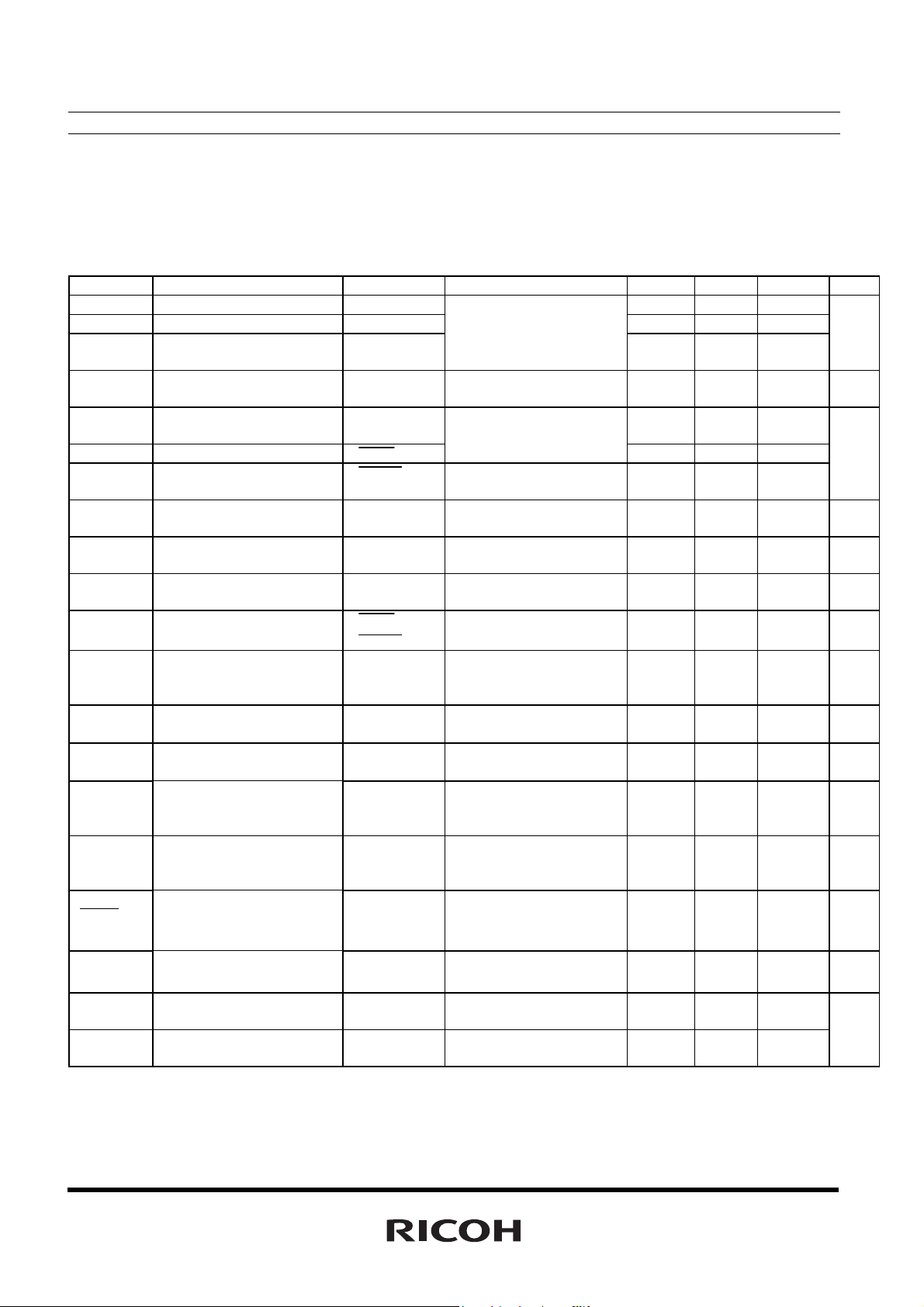

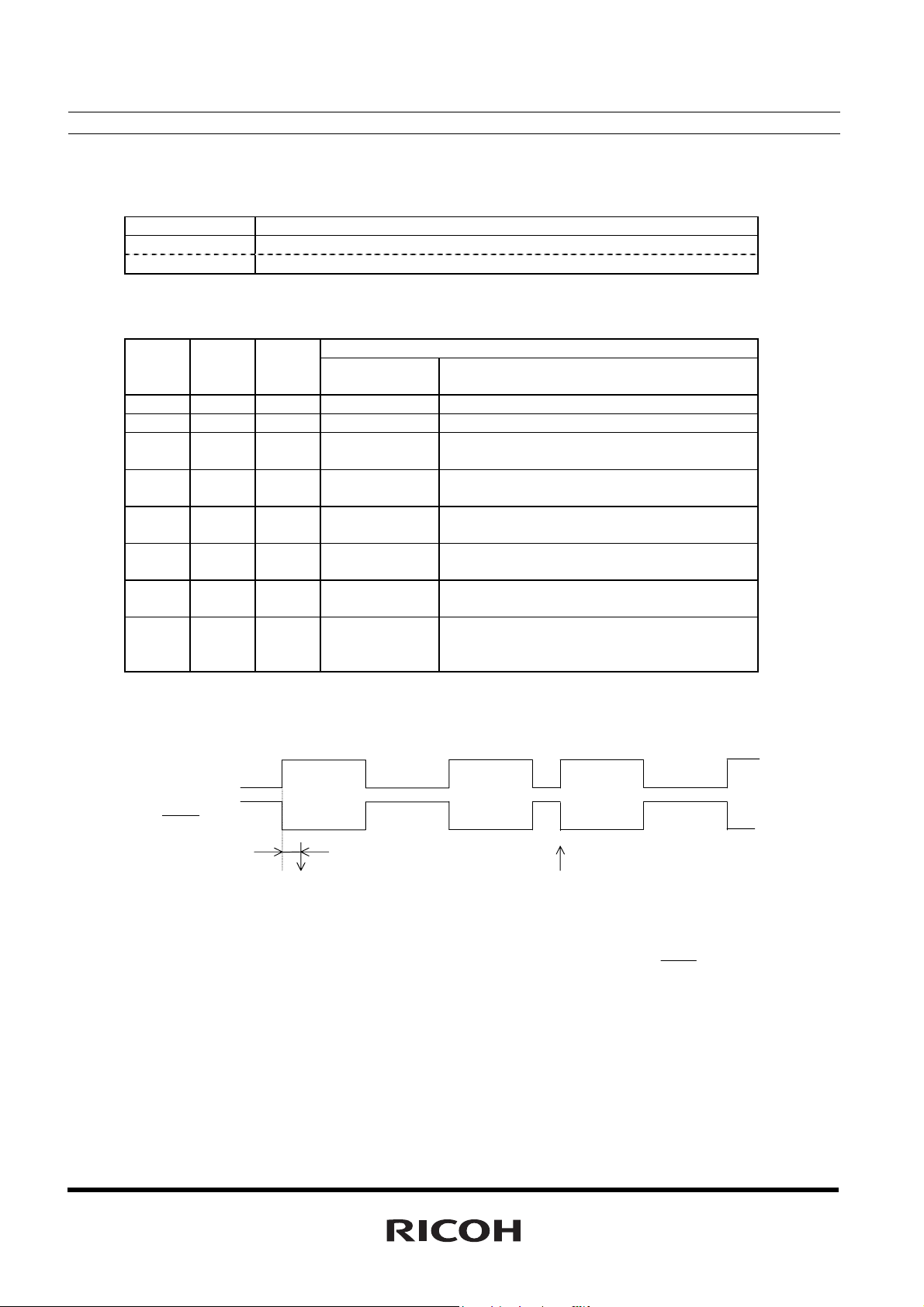

AC ELECTRICAL CHARACTERISTICS

Unless otherwise specified: VSS=0V,Topt=-40 to +85°C

Input and Output Conditions: V

Sym

-bol

t

CE Set-up Time 400 ns

CES

t

CE Hold Time 400 ns

CEH

tCR CE Recovery Time 62

f

SCLK Clock Frequency 1.0 MHz

SCLK

t

SCLK Clock ”H” Time 400 ns

CKH

t

SCLK Clock ”L” Time 400 ns

CKL

t

SCLK Set-up Time 200 ns

CKS

tRD Data Output Delay Time 300 ns

tRZ Data Output Floating Time 300 ns

t

Data Output Delay Time After

CEZ

Falling of CE

tDS Input Data Set-up Time 200 ns

tDH Input Data Hold Time 200 ns

t

Output Delay Time of Voltage

DELAY

Detector

*1) VCC voltage interfacing with CPU is defined by Vaccess (P.5 RECOMMENDED OPERATING

CONDITIONS)

*) For reading/writing timing, see “P.29 Interfacing with the CPU •Considerations in Reading and

Writing Time Data under special condition”.

IH=0.8×VCC,VIL=0.2×VCC,VOH=0.8×VCC,VOL=0.2×VCC,CL=50pF

Item Condi-

Tions

Min. Typ. Max.

DD≥1.7V *1)

V

300 ns

t

CKH

Time

Keeping

t

CKL

100 105 110 ms

Unit

µs

CE

SCLK

SIO(write cycle)

SIO(read cycle)

VCC

VDCC

t

+VDET1

CKS

t

CES

t

CEH

t

CEZ

tCR

t

DS

t

DH

tRD

t

RD

t

RZ

t

DELAY

8

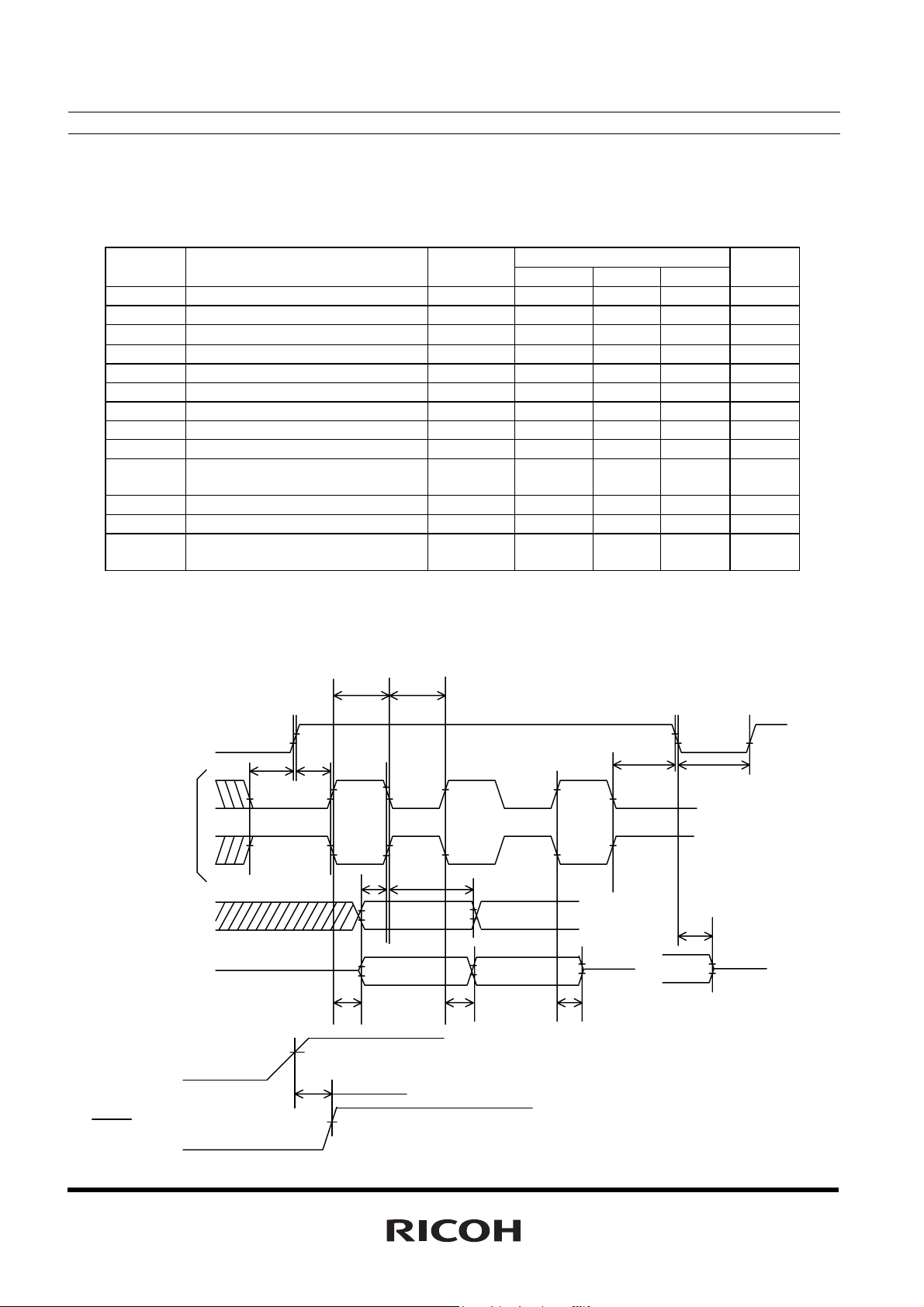

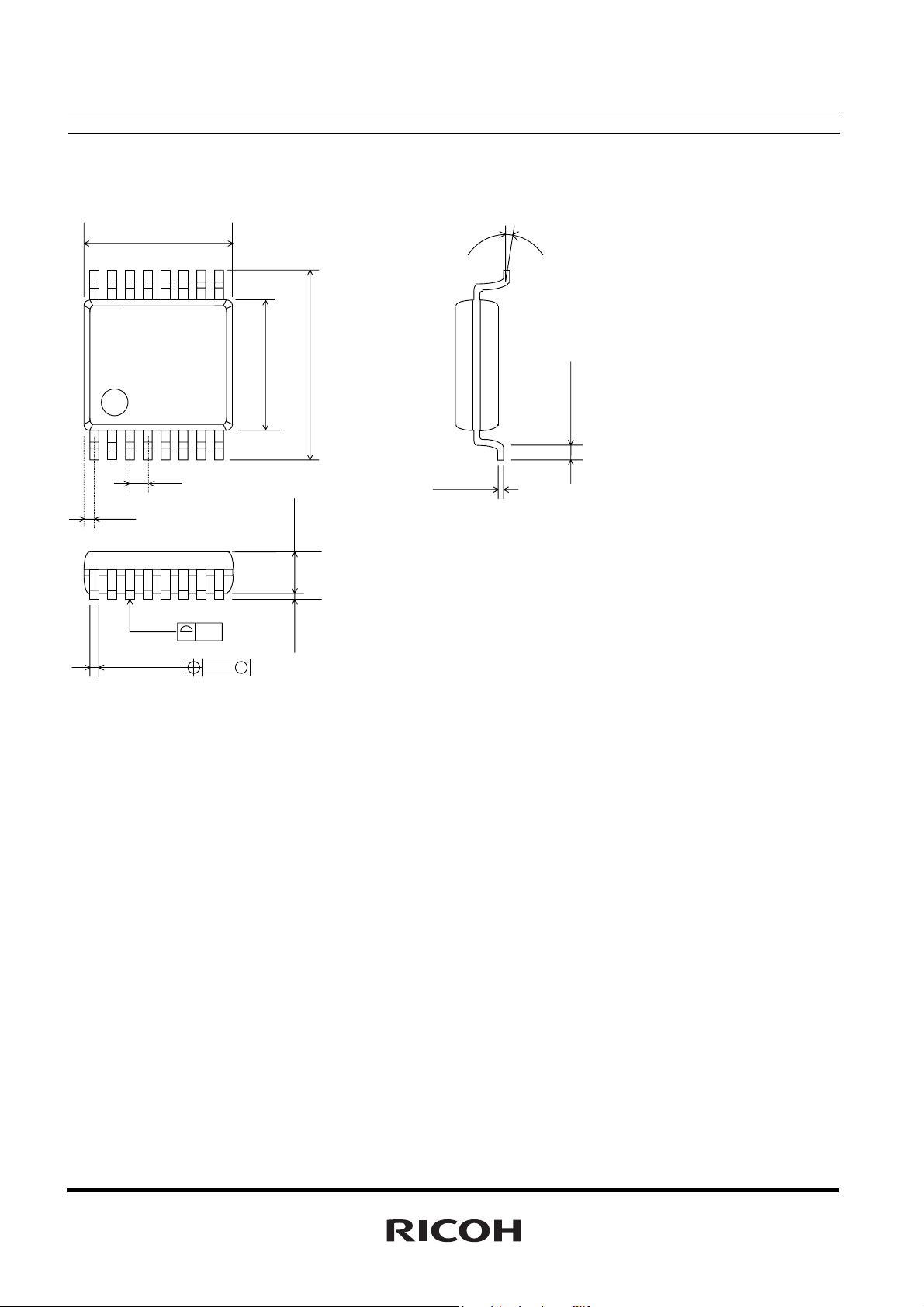

PACKAGE DIMENSIONS

• R2062Kxx

9 7

R2062 series

10

12

0.103

0.5

0.5

1PIN INDEX

0.15

±

0.3

0.2±0.15

(BOTTOM VIEW)

6

4

31

2PIN INDEX

0.35

0.1

±

2.0

0.05

0.35

0.25

1.0Max

0.17±0.1

0.27±0.15

2.0±0.1

unit: mm

9

R2062 series

05

• R2062Sxx (Preliminary)

5.0±0.3

0 to 10°

16

1

0.225typ

0.22

+0.1

-0.05

0.65

0.10

0.15

9

0.3

±

4.4±0.2

6.4

8

1.15±0.1

0.1±0.1

M

TAPING SPECIFICATION

0.15

+0.1

-0.

0.3

±

0.5

unit: mm

The R2062 Series have one designated taping direction. The product designation for the taping components is

"R2062S/Kxx-E2".

10

R2062 series

r

GENERAL DESCRIPTION

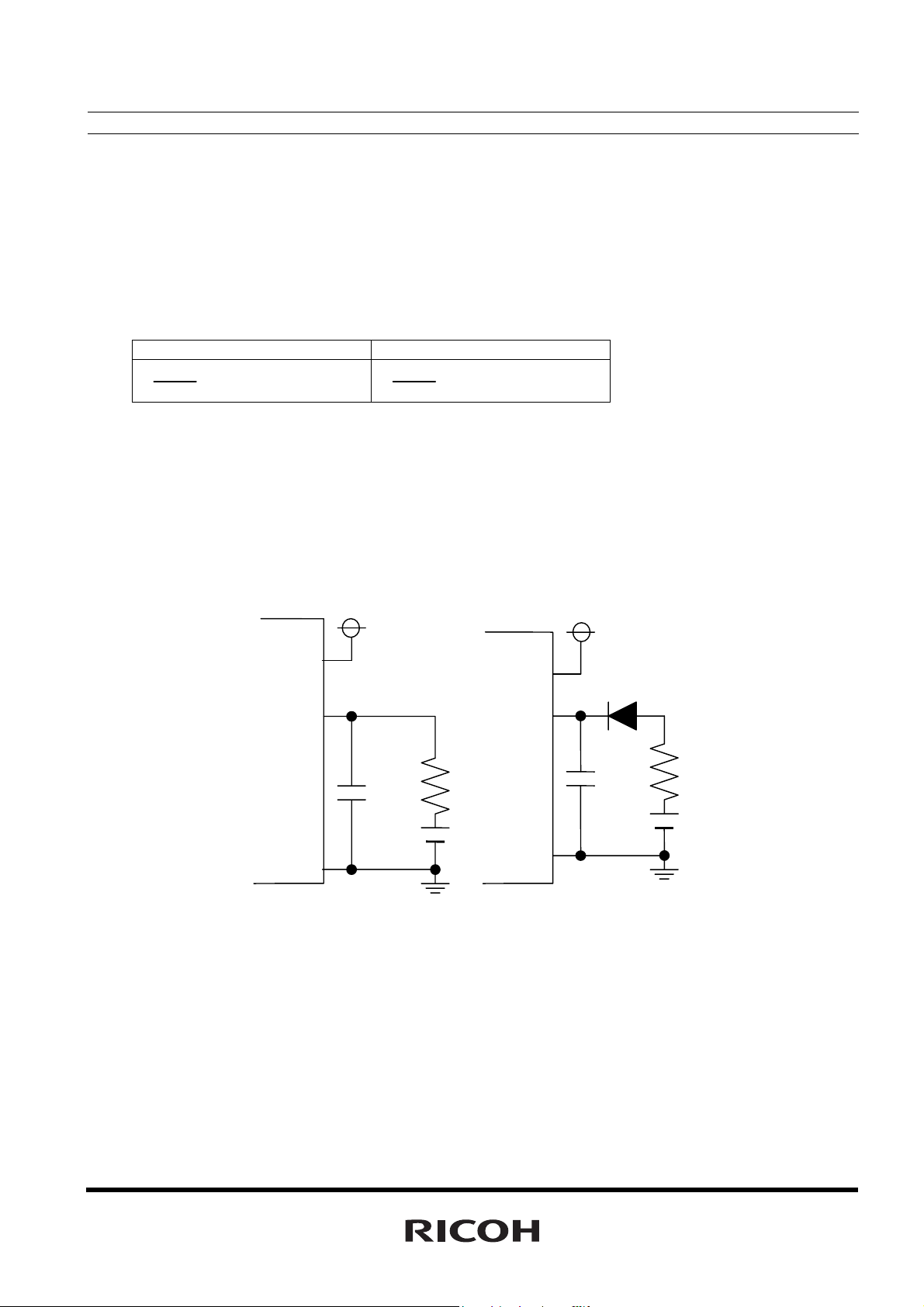

• Battery Backup Switchover Function

The R2062 Series have two power supply input, or VCC and VDD. With mo nitoring VCC pi n input volt age, which

voltage between the two is supplied to the internal power supply is decided.

Refer to the next table to see the state of the backup battery and internal power supply’s state of the IC by each

condition.

V

CC≥VDET1 VCC<VDET1

VCC→RTC, VDD

VDCC

=OFF(H)

As a backup battery, not only a secondary battery such as ML614, TC616, but also an electric double layered

capacitor or an aluminum capacitor can be used. The case of back-up by primary battery, the external diode

must be connected below.

The case of back-up by

capacitor or secondary battery

(Charging voltage is equal to CPU

power supply voltage)

VDD→RTC

VDCC

=L

The case of back-up by

primary battery

VCC

VDD

VSS

CPU powe

supply

0.1µF

ML614

etc.

VCC

VDD

VSS

CPU Power

Supply

0.1µF

CR2025

etc.

• Interface with CPU

The R2062 is connected to the CPU by three signal lines CE (Chip Enable), SCLK (Serial Clock), and SIO

(Serial Input / Output), through which it reads and writes data from and to the CPU. The CPU can be accessed

when the CE pin is held high. Access clock pulses have a maximum fre quency of 1 MHz, allowi ng high -speed

data transfer to the CPU. VCC falls down under -V

DET1, the R2062 stops accessing with CPU.

11

R2062 series

• Clock and Calendar Function

The R2062 reads and writes time data from and to the CPU in units ranging from secon ds to the last two digi ts of

the calendar year. The calendar year will automatically be identified as a leap year when its last two digits are a

multiple of 4. Consequently, leap years up to the year 2099 can automatically be identified as such.

*) The year 2000 is a leap year while the year 2100 is not a leap year.

• Alarm Function

The R2062 incorporates the alarm interrupt circuit configured to generate interrupt signals to the CPU at preset

times. The alarm interrupt circuit allows two types of alarm settings specified by the Alarm_W registers and the

Alarm_D registers. The Alarm_W registers allow week, hour, and minute alarm settings including combinations

of multiple day-of-week settings such as "Monday, Wednesday, and Friday" and "Saturday and Sunday". The

Alarm_D registers allow hour and minute alarm settings. The Alarm_W outputs from

Alarm_D outputs also from

function.

INTR

pin. Each alarm function can be checked from the CPU by using a polling

INTR

pin, and the

• High-precision Oscillation Adjustment Function

The R2062 has built-in oscillation stabilization capacitors (CG and CD), that can be connected to an external

quartz crystal unit to configure an oscillation circuit. Two kinds of accuracy for this function are alternatives. To

correct deviations in the oscillator frequency of the crystal, the oscillation adjustment circuit is configured to allow

correction of a time count gain or loss (up to ±1.5ppm or ±0.5ppm at 25°C) from the CP U. The maximum rang e is

approximately ±189ppm (or ±63ppm) in increments of approximately 3ppm (or 1ppm). Such oscillation

frequency adjustment in each system has the following advantage s :

* Allows timekeeping with much higher precision than conventional RTCs while using a quartz crystal unit with

a wide range of precision variations.

* Corrects seasonal frequency deviations through seasonal oscillation adjustment.

* Allows timekeeping with higher precision particularly with a temperature sensing function out of R TC, through

oscillation adjustment in tune with temperature fluctuations.

• Power-on Reset, Oscillation Halt Sensing Function and Supply Voltage Monitoring Function

The R2062 has 2 power supply pins (VCC, VDD), among them, VCC pin and VDD pin have monitoring function

of supply voltage. VCC power supply monitoring circuit makes

becomes equal or lower than –V

after the delay time, t

The R2062 incorporates an oscillation halt sensing circuit equipped with internal registers configured to record

any past oscillation halt, the oscillation halt sensing circuit, VDD monitoring flag, and power-on reset flag are

useful for judging the validity of time data.

Power on reset function reset the control resisters when the system is powered on from 0V. At the same time, the

fact is memorized to the resister as a flag, thereby identifying whether they are powered on from 0V or battery

backed-up.

The R2062 also incorporates a supply voltage monitoring circuit equipped with internal registers configured to

record any drop in supply voltage below a certain threshol d value. Supply voltage monitoring threshold settings

can be selected between 2.1V and 1.35V through internal register settings. The sampling rate is normally 1s.

DELAY from when the VCC power supply pin become s equal or more than +VDET1.

DET1. At the power-on of VCC, this circuit makes

VDCC

pin “L” when VCC power supply pin

VDCC

pin turn off, or “H”

12

R2062 series

The oscillation halt sensing circuit is configured to confirm the established invalidation of time data in contrast to

the supply voltage monitoring circuit intended to confirm the potential invalidation of time data. Further, the

supply voltage monitoring circuit can be applied to battery supply voltage monitoring.

• Periodic Interrupt Function

The R2062 incorporates the periodic interrupt circuit configured to generate periodic interrupt signals aside from

INTR

interrupt signals generated by the periodic interrupt circuit for output from the

signals have five selectable frequency settings of 2 Hz (once per 0.5 seconds), 1 Hz (once per 1 second), 1/60

Hz (once per 1 minute), 1/3600 Hz (once per 1 hour), and monthly (the first day of every month). Further,

periodic interrupt signals also have two selectable waveforms, a normal pulse form (with a freq uency of 2 Hz or 1

Hz) and special form adapted to interruption from the CPU in the level mode (with second, minute, hour, and

month interrupts). The condition of periodic interrupt signals ca n be monitored with using a polling function.

pin. Periodic interrupt

• 32kHz Clock Output

The R2062 incorporates a 32-kHz clock circuit configured to generate clock pulses with the oscillation frequency

of a 32.768kHz quartz crystal unit for output from the CLKOUT pin (CMOS push-pull output). The 32-kHz clock

output is always enabled and the “H” level of the CLKOUT pin is same as VCC power supply.

13

R2062 series

A

A

A

Address Mapping

Address Register Name D a t a

A3A2A1A0 D7 D6 D5 D4 D3 D2 D1 D0

0 0 0 0 0 Second Counter -

*2)

1 0 0 0 1 Minute Counter - M40 M20 M10 M8 M4 M2 M1

2 0 0 1 0 Hour Counter - - H20

3 0 0 1 1 Day-of-week Counter - - - - - W4 W2 W1

4 0 1 0 0 Day-of-month Counter - - D20 D10 D8 D4 D2 D1

5 0 1 0 1 Month Counter and

Century Bit

6 0 1 1 0 Year Counter Y80 Y40 Y20 Y10 Y8 Y4 Y2 Y1

7 0 1 1 1 Oscillation Adjustment

Register *3)

8 1 0 0 0 Alarm_W

(Minute Register)

9 1 0 0 1 Alarm_W

(Hour Register)

A 1 0 1 0 Alarm_W

(Day-of-week Register)

B 1 0 1 1 Alarm_D

(Minute Register)

C 1 1 0 0 Alarm_D

(Hour Register)

D 1 1 0 1 - - - - - - - -

E 1 1 1 0 Control Register 1 *3) WALE DALE

F 1 1 1 1 Control Register 2 *3) VDSL VDET

Notes:

* 1) All the data listed above accept both reading and writing.

* 2) The data marked with "-" is invalid for writing and reset to 0 for reading.

* 3) When the PON bit is set to 1 in Control Register 2, all the bits are reset to 0 in Oscillation Adjustment

Register, Control Register 1 and Control Register 2 excluding the

* 4) When DEV=0, the oscillation adjustment circuit is configured to allow correction of a time count gain

or loss up to ±1.5ppm.

When DEV=1, the oscillation adjustment circuit is configured to allow correction of a time count gain

or loss up to or ±0.5ppm.

* 5) PON is a power-on-reset flag.

19

/20

DEV

*4)

- WM40 WM20 WM10 WM8 WM4 WM2 WM1

- - WH20

- WW6 WW5 WW4 WW3 WW2 WW1 WW0

- DM40 DM20 DM10 DM8 DM4 DM2 DM1

- - DH20

S40 S20 S10 S8 S4 S2 S1

H10 H8 H4 H2 H1

P/

- - MO10 MO8 MO4 MO2 MO1

F6 F5 F4 F3 F2 F1 F0

WH10 WH8 WH4 WH2 WH1

WP/

DH10 DH8 DH4 DH2 DH1

DP/

12

XST

/24

SCRA

TCH2

PON

*5)

XST

TEST CT2 CT1 CT0

SCRA

TCH1

bit.

CTFG WAFG DAFG

14

R2062 series

Register Settings

• Control Register 1 (ADDRESS Eh)

D7 D6 D5 D4 D3 D2 D1 D0

WALE DALE

WALE DALE

0 0 0 0 0 0 0 0 Default Settings *)

*) Default settings: Default value means read / written values when the PON bit is set to “1” due to VDD

power-on from 0 volts.

12

12

/24

/24

(1) WALE, DALE Alarm_W Enable Bit, Alarm_D Enable Bit

WALE,DALE Description

0 Disabling the alarm interrupt circuit (under the control of the settings

of the Alarm_W registers and the Alarm_D registers).

1 Enabling the alarm interrupt circuit (under the control of the settings

of the Alarm_W registers and the Alarm_D registers)

12

(2)

Setting the

Setting the

/24

12

/24

0 Selecting the 12-hour mode with a.m. and p.m. indications. (Default)

1 Selecting the 24-hour mode

12

/24 bit to 0 and 1 specifies the 12-hour mode and the 24-hour mode, respectively.

24-hour mode 12-hour mode 24-hour mode 12-hour mode

00 12 (AM12) 12 32 (PM12)

01 01 (AM 1) 13 21 (PM 1)

02 02 (AM 2) 14 22 (PM 2)

03 03 (AM 3) 15 23 (PM 3)

04 04 (AM 4) 16 24 (PM 4)

05 05 (AM 5) 17 25 (PM 5)

06 06 (AM 6) 18 26 (PM 6)

07 07 (AM 7) 19 27 (PM 7)

08 08 (AM 8) 20 28 (PM 8)

09 09 (AM 9) 21 29 (PM 9)

10 10 (AM10) 22 30 (PM10)

11 11 (AM11) 23 31 (PM11)

12

/24 bit should precede writing time data

12

/24-hour Mode Selection Bit

(3) SCRATCH2 Scratch Bit 2

SCRATCH2 Description

0 (Default)

1

The SCRATCH2 bit is intended for scratching and accepts the reading and writing of 0 and 1.

The SCRATCH2 bit will be set to 0 when the PON bit is set to 1 in the Control Register 1.

SCRA

TCH2

SCRA

TCH2

TEST CT2 CT1 CT0 (For Writing)

TEST CT2 CT1 CT0 (For Reading)

(Default)

Description

15

R2062 series

A

(4) TEST Test Bit

TEST Description

0 Normal operation mode. (Default)

1 Test mode.

The TEST bit is used only for testing in the factory and should normally be set to 0.

(5) CT2,CT1, and CT0 Periodic Interrupt Selection Bits

Description CT2 CT1 CT0

Wave form

mode

0 0 0 - OFF(H) (Default)

0 0 1 - Fixed at “L”

0 1 0 Pulse Mode

*1)

0 1 1 Pulse Mode

*1)

1 0 0 Level Mode

*2)

1 0 1 Level Mode

*2)

1 1 0 Level Mode

*2)

1 1 1 Level Mode

*2)

* 1) Pulse Mode: 2-Hz and 1-Hz clock pulses are output in synchronization with the increment of the

second counter as illustrated in the timing chart below.

Interrupt Cycle and Falling Timing

2Hz(Duty50%)

1Hz(Duty50%)

Once per 1 second (Synchronized with

second counter increment)

Once per 1 minute (at 00 seconds of

every minute)

Once per hour (at 00 minutes and 00

seconds of every hour)

Once per month (at 00 hours, 00 minutes,

and 00 seconds of first day of every

month)

CTFG Bit

IN T R

Pin

pprox. 92µs

(Increment of second counter)

Rewriting of the second counter

In the pulse mode, the increment of the second counter is delayed by approximately 92 µs from the falling

edge of clock pulses. Consequently, time readings immediately after the falling edge of clock pulses may

appear to lag behind the time counts of the real-time clocks by approximately 1 second. Rewriting the

second counter will reset the other time counters of less than 1 second, driving the

INTR

pin low.

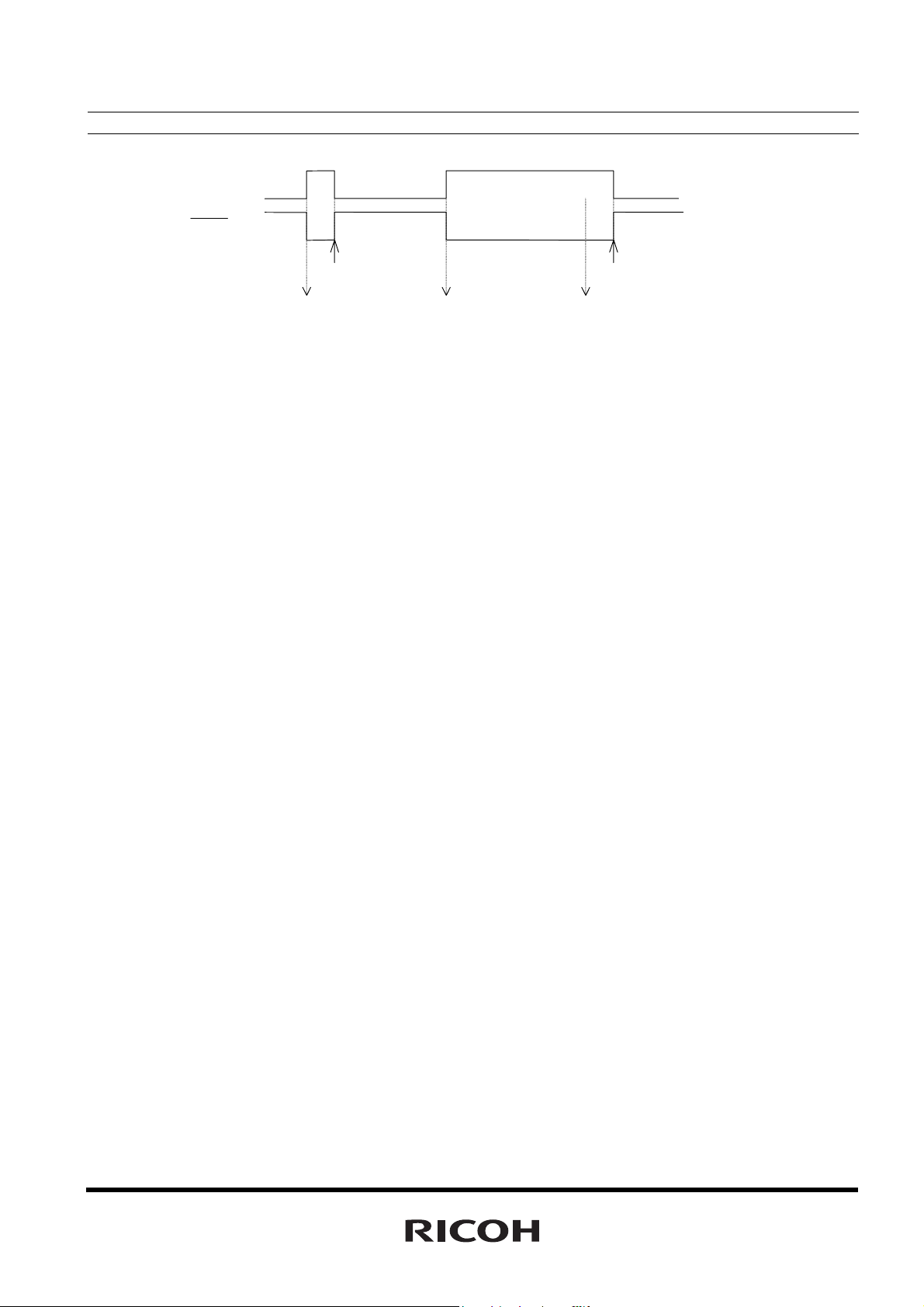

* 2) Level Mode: Periodic interrupt signals are output with selectable interrupt cycle settings of 1 second,

1 minute, 1 hour, and 1 month. The increment of the second counter is synchronized with the falling

edge of periodic interrupt signals. For example, periodic interrupt signals with an interrupt cycle setting

of 1 second are output in synchronization with the increment of the second counter as illustrated in the

timing chart below.

16

R2062 series

CTFG Bit

IN T R

Pin

Setting CTFG bit to 0

(Increment of

second counter)

(Increment of

second counter)

Setting CTFG bit to 0

(Increment of

second counter)

*1), *2) When the oscillation adjustment circuit is used, the interrupt cycle will fluctuate once per 20sec. or

60sec. as follows:

Pulse Mode: The “L” period of output pulses will increment or decrement by a maximum of ±3.784 ms. For

example, 1-Hz clock pulses will have a duty cycle of 50 ±0.3784%.

Level Mode: A periodic interrupt cycle of 1 second will increment or decrement by a maximum of

±3.784 ms.

17

R2062 series

• Control Register 2 (Address Fh)

D7 D6 D5 D4 D3 D2 D1 D0

VDSL VDET

VDSL VDET

0 0

*) Default settings: Default value means read / written values when the PON bit is set to “1” due to VDD

power-on from 0 volts.

XST

XST

Indefinite

(1) VDSL VDD Supply Voltage Monitoring Threshold Selection Bit

VDSL Description

0 Selecting the VDD supply voltage monitoring threshold setting of 2.1v. (Default)

1 Selecting the VDD supply voltage monitoring threshold setting of

1.35v.

The VDSL bit is intended to select the VDD supply voltage monitoring threshold settings.

(2) VDET Supply Voltage Monitoring Result Indication Bit

VDET Description

0 Indicating supply voltage above the supply voltage monitoring

threshold settings.

1 Indicating supply voltage below the supply voltage monitoring

threshold settings.

Once the VDET bit is set to 1, the supply voltage monitoring circuit will be disabled while the VDET bit will

hold the setting of 1. The VDET bit accepts only the writing of 0, which restarts the supply voltage

monitoring circuit. Conversely, setting the VDET bit to 1 causes no event.

XST

(3)

The

halt sensing. The

Oscillation Halt Sensing Monitor Bit

XST

0

1

XST

accepts the reading and writing of 0 and 1. The

Sensing a halt of oscillation

Sensing a normal condition of oscillation

XST

bit will hold 0 even after the restart of oscillation.

(4) PON Power-on-reset Flag Bit

PON Description

0 Normal condition

1 Detecting VDD power-on -reset (Default)

The PON bit is for sensing power-on reset condition.

* The PON bit will be set to 1 when VDD power-on from 0 volts. The PON bit will hold the setting of 1 even

after power-on.

* When the PON bit is set to 1, all bits will be reset to 0, in the Oscillation Adjustment Register, Control

Register 1, and Control Register 2, except

* The PON bit accepts only the writing of 0. Conversely, setting the PON bit to 1 causes no event.

PON SCRA

PON SCRA

1 0 0 0 0 Default Settings *)

TCH1

TCH1

XST

and PON. As a result,

CTFG WAFG DAFG (For Writing)

CTFG WAFG DAFG (For Reading)

(Default)

Description

XST

bit will be set to 0 when the oscillation

INTR

pin stops outputting.

18

R2062 series

A

A

(5) SCRATCH1 Scratch Bit 1

SCRATCH1 Description

0 (Default)

1

The SCRATCH1 bit is intended for scratching and accepts the reading and writing of 0 and 1. The

SCRATCH1 bit will be set to 0 when the PON bit is set to 1 in the Control Register 2.

(6) CTFG Periodic Interrupt Flag Bit

CTFG Description

0 Periodic interrupt output = “H” (Default)

1 Periodic interrupt output = “L”

The CTFG bit is set to 1 when the periodic interrupt signals are output from the

CTFG bit accepts only the writing of 0 in the level mode, which disables (“H”) the

enabled (“L”) again in the next interrupt cycle. Conversely, setting the CTFG bit to 1 causes no event.

(7) WAFG,DAFG Alarm_W Flag Bit and Alarm_D Flag Bit

WAFG,DAFG Description

0 Indicating a mismatch between current time and preset alarm time (Default)

1 Indicating a match between current time and preset alarm time

The WAFG and DAFG bits are valid only when the WALE and DALE have the setting of 1, which is caused

approximately 61µs after any match between current time and preset alarm time specified by the Alarm_W

registers and the Alarm_D registers. The WAFG (DAFG) bit accepts only the writing of 0.

outputs off (“H”) when this bit is set to 0. And

Conversely, setting the WAFG and DAFG bits to 1 causes no event. The WAFG and DAFG bits will have

the reading of 0 when the alarm interrupt circuit is disabled with the WALE and DALE bits set to 0. The

settings of the WAFG and DAFG bits are synchronized with the output of the

timing chart below.

INTR

pin outputs “L” again at the next preset alarm time.

pprox. 61µs

pprox. 61µs

INTR

pin (“L”). The

INTR

INTR

pin as shown in the

pin until it is

INTR

pin

WAFG(DAFG) Bit

INTR

Pin

Writing of 0 to

WAFG(DAFG) bit

(Match between

current time and

preset alarm time)

(Match between

current time and

preset alarm time)

Writing of 0 to

WAFG(DAFG) bit

(Match between

current time and

preset alarm time)

19

R2062 series

A

• Time Counter (Address 0-2h)

Second Counter (Address 0h)

D7 D6 D5 D4 D3 D2 D1 D0

- S40 S20 S10 S8 S4 S2 S1 (For Writing)

0 S40 S20 S10 S8 S4 S2 S1 (For Reading)

0 Indefinite Indefinite Indefinite Indefinite Indefinite Indefinite Indefinite Default Settings *)

Minute Counter (Address 1h)

D7 D6 D5 D4 D3 D2 D1 D0

- M40 M20 M10 M8 M4 M2 M1 (For Writing)

0 M40 M20 M10 M8 M4 M2 M1 (For Reading)

0 Indefinite Indefinite Indefinite Indefinite Indefinite Indefinite Indefinite Default Settings *)

Hour Counter (Address 2h)

D7 D6 D5 D4 D3 D2 D1 D0

- - P/

or H20

0 0 P/A

or H20

0 0 Indefinite Indefinite Indefinite Indefinite Indefinite Indefinite Default Settings *)

*) Default settings: Default value means read / written values when the PON bit is set to “1” due to VDD

power-on from 0 volts.

* Time digit display (BCD format) as follows:

The second digits range from 00 to 59 and are carried to the minute digit in transition from 59 to 00.

The minute digits range from 00 to 59 and are carried to the hour digits in transition from 59 to 00.

The hour digits range as shown in "P15 • Control Register 1 (ADDRESS Eh) (2)

Mode Selection Bit" and are carried to the day-of-month and day-of-week digits in tran sition from PM11 to

AM12 or from 23 to 00.

* Any writing to the second counter resets divider units of less than 1 second.

* Any carry from lower digits with the writing of non-existent time may cause the time counters to

malfunction. Therefore, such incorrect writing should be replaced with the writing of existent time data.

H10 H8 H4 H2 H1 (For Writing)

H10 H8 H4 H2 H1 (For Reading)

12

/24:

12

/24-hour

20

R2062 series

• Day-of-week Counter (Address 3h)

D7 D6 D5 D4 D3 D2 D1 D0

- - - - - W4 W2 W1 (For Writing)

0 0 0 0 0 W4 W2 W1 (For Reading)

0 0 0 0 0 Indefinite Indefinite Indefinite Default Settings *)

*) Default settings: Default value means read / written values when the PON bit is set to “1” due to VDD

power-on from 0 volts.

* The day-of-week counter is incremented by 1 when the day-of-week digits are carried to the day-of-month

digits.

* Day-of-week display (incremented in septimal notation):

(W4, W2, W1) = (0, 0, 0) → (0, 0, 1)→…→(1, 1, 0) → (0, 0, 0)

* Correspondences between days of the week and the day-of-week digits are user-definable

(e.g. Sunday = 0, 0, 0)

* The writing of (1, 1, 1) to (W4, W2, W1) is prohibited except when days of the week are unused.

• Calendar Counter (Address 4-6h)

Day-of-month Counter (Address 4h)

D7 D6 D5 D4 D3 D2 D1 D0

- - D20 D10 D8 D4 D2 D1 (For Writing)

0 0 D20 D10 D8 D4 D2 D1 (For Reading)

0 0 Indefinite Indefinite Indefinite Indefinite Indefinite Indefinite Default Settings *)

Month Counter + Century Bit (Address 5h)

D7 D6 D5 D4 D3 D2 D1 D0

19

/20 - - MO10 MO8 MO4 MO2 MO1 (For Writing)

19

/20 0 0 MO10 MO8 MO4 MO2 MO1 (For Reading)

Indefinite 0 0 Indefinite Indefinite Indefinite Indefinite Indefinite

Year Counter (Address 6h)

D7 D6 D5 D4 D3 D2 D1 D0

Y80 Y40 Y20 Y10 Y8 Y4 Y2 Y1 (For Writing)

Y80 Y40 Y20 Y10 Y8 Y4 Y2 Y1 (For Reading)

Indefinite Indefinite Indefinite Indefinite Indefinite Indefinite Indefinite Indefinite Default Settings *)

*) Default settings: Default value means read / written values when the PON bit is set to “1” due to VDD

power-on from 0 volts.

* The calendar counters are configured to display the calendar digits in BCD format by using the automatic

calendar function as follows:

The day-of-month digits (D20 to D1) range from 1 to 31 for January, March, May, July, August, October,

and December; from 1 to 30 for April, June, September, and November; from 1 to 29 for February in leap

years; from 1 to 28 for February in ordinary years. The day-of-month digits are carried to the month

digits in reversion from the last day of the month to 1. The month digits (MO10 to MO1) range from 1 to

12 and are carried to the year digits in reversion from 12 to 1.

Default Settings *)

21

R2062 series

,F4,F3,F2,F1,

The year digits (Y80 to Y1) range from 00 to 99 (00, 04, 08, …, 92, and 96 in leap years) and are carried to

19

the

The

* Any carry from lower digits with the writing of non-existent calendar data may cause the calendar

counters to malfunction. Therefore, such incorrect writing should be replaced with the writing of existent

calendar data.

/20 digits in reversion from 99 to 00.

19

/20 digits cycle between 0 and 1 in reversion from 99 to 00 in the year digits.

• Oscillation Adjustment Register (Address 7h)

D7 D6 D5 D4 D3 D2 D1 D0

DEV F6 F5 F4 F3 F2 F1 F0 (For Writing)

DEV F6 F5 F4 F3 F2 F1 F0 (For Reading)

0 0 0 0 0 0 0 0 Default Settings *)

*) Default settings: Default value means read / written values when the PON bit is set to “1” due to VDD

power-on from 0 volts.

DEV bit

When DEV is set to 0, the Oscillation Adjustment Circuit operates 00, 20, 40 seconds.

When DEV is set to 1, the Oscillation Adjustment Circuit operates 00 seconds.

F6 to F0 bits

The Oscillation Adjustment Circuit is configured to change time counts of 1 second on the basis of

the settings of the Oscillation Adjustment Register at the timing set by DEV.

* The Oscillation Adjustment Circuit will not operate with the same timing (00, 20, or 40 seconds)

as the timing of writing to the Oscillation Adjustment Register.

* The F6 bit setting of 0 causes an increment of time counts by ((F5, F4, F3, F2, F1, F0) - 1) x 2.

F

The F6 bit setting of 1 causes a decrement of time counts by ((

The settings of "*, 0, 0, 0, 0, 0, *" ("*" representing either "0" or "1") in the F6, F5, F4, F3, F2, F1, and

F0 bits cause neither an increment nor decrement of time counts.

Example:

If (DEV, F6, F5, F4, F3, F2, F1, F0) is set to (0, 0, 0, 0, 0, 1, 1, 1), when the second digits read 0 0, 20, or

40, an increment of the current time counts of 32768 + (7 - 1) x 2 to 32780 (a current time count loss).

If (DEV, F6, F5, F4, F3, F2, F1, F0) is set to (0, 0, 0, 0, 0, 0, 0, 1), when the second digits read 00, 20, 40,

neither an increment nor a decrement of the current time counts of 32768.

If (DEV, F6, F5, F4, F3, F2, F1, F0) is set to (1, 1, 1, 1, 1, 1, 1, 0), when the second digits read 00, a

decrement of the current time counts of 32768 + (- 2) x 2 to 32764 (a current time count gain).

An increase of two clock pulses once per 20 seconds cause s a time count loss of approximately 3 ppm (2 /

(32768 x 20 = 3.051 ppm). Conversely, a decrease of two clock pulses once per 20 seconds causes a

time count gain of 3 ppm. Consequently, when DEV is set to “0”, deviations in time counts can be

corrected with a precision of ±1.5 ppm. In the same way, when DEV is set to “1”, deviations in time

counts can be corrected with a precision of ±0.5 ppm. Note that the oscillation adjustment circuit is

configured to correct deviations in time counts and not the oscillation frequency of the 32.768-kHz clock

pulses. For further details, see "P34 Configuration of Oscillation Circuit and Correction of Time

Count Deviations • Oscillation Adjustment Circuit".

5

F0

) + 1) x 2.

22

R2062 series

A

A

A

• Alarm_W Registers (Address 8-Ah)

Alarm_W Minute Register (Address 8h)

D7 D6 D5 D4 D3 D2 D1 D0

- WM40 WM20 WM10 WM8 WM4 WM2 WM1 (For Writing)

0 WM40 WM20 WM10 WM8 WM4 WM2 WM1 (For Reading)

0

Alarm_W Hour Register (Address 9h)

D7 D6 D5 D4 D3 D2 D1 D0

- - WH20

0 0 WH20

0 0 Indefinite Indefinite Indefinite Indefinite Indefinite Indefinite Default Settings *)

Alarm_W Day-of-week Register (Address Ah)

D7 D6 D5 D4 D3 D2 D1 D0

- WW6 WW5 WW4 WW3 WW2 WW1 WW0 (For Writing)

0 WW6 WW5 WW4 WW3 WW2 WW1 WW0 (For Reading)

0 Indefinite Indefinite Indefinite Indefinite Indefinite Indefinite Indefinite

*) Default settings: Default value means read / written values when the PON bit is set to “1” due to VDD

power-on from 0 volts.

* The D5 bit of the Alarm_W Hour Register represents WP/

a.m. and 1 for p.m.) and WH20 when the 24-hour mode is selected (tens in the hour digits).

* The Alarm_W Registers should not have any non-existent alarm time settings.

(Note that any mismatch between current time and preset alarm time specified by the Alarm_W registers

may disable the alarm interrupt circuit.)

* When the 12-hour mode is selected, the hour digits read 12 and 32 for 0 a.m. and 0 p.m., respectively.

(See "P15 •Control Register 1 (ADDRESS Eh) (2)

* WW0 to WW6 correspond to W4, W2, and W1 of the day-of-week counter with settings ranging from (0, 0,

0) to (1, 1, 0).

* WW0 to WW6 with respective settings of 0 disable the outputs of the Alarm_W Registers.

Indefinite Indefinite Indefinite Indefinite Indefinite Indefinite Indefinite

WH10 WH8 WH4 WH2 WH1 (For Writing)

WP/

WP/

WH10 WH8 WH4 WH2 WH1 (For Reading)

when the 12-hour mode is selected (0 for

12

/24: 12/24-hour Mode Selection Bit")

Default Settings *)

Default Settings *)

23

R2062 series

A

A

A

Example of Alarm Time Setting

Alarm Day-of-week 12-hour mode 24-hour mode

Preset alarm time Sun. Mon. Tue. Wed. Th. Fri. Sat. 10

hr. 1 hr.

WW0 WW1 WW2 WW3 WW4 WW5 WW6

00:00 a.m. on all days 1 1 1 1 1 1 1 1 2 0 0 0 0 0 0

01:30 a.m. on all days 1 1 1 1 1 1 1 0 1 3 0 0 1 3 0

11:59 a.m. on all days 1 1 1 1 1 1 1 1 1 5 9 1 1 5 9

00:00 p.m. on Mon. to

Fri.

01:30 p.m. on Sun. 1 0 0 0 0 0 0 2 1 3 0 1 3 3 0

11:59 p.m.

on Mon. ,Wed., and Fri.

0 1 1 1 1 1 0 3 2 0 0 1 2 0 0

0 1 0 1 0 1 0 3 1 5 9 2 3 5 9

10

min. 1 min.

10

hr. 1 hr.

10

min.1 min.

Note that the correspondence between WW0 to WW6 and the days of the week shown in the above table is

only an example and not mandatory.

• Alarm_D Register (Address B-Ch)

Alarm_D Minute Register (Address Bh)

D7 D6 D5 D4 D3 D2 D1 D0

- DM40 DM20 DM10 DM8 DM4 DM2 DM1 (For Writing)

0 DM40 DM20 DM10 DM8 DM4 DM2 DM1 (For Reading)

0 Indefinite Indefinite Indefinite Indefinite Indefinite Indefinite Indefinite Default Settings *)

Alarm_D Hour Register (Address Ch)

D7 D6 D5 D4 D3 D2 D1 D0

- - DH20

DP/

0 0 DH20

DP/

0 0 Indefinite Indefinite Indefinite Indefinite Indefinite Indefinite Default Settings *)

*) Default settings: Default value means read / written values when the PON bit is set to “1” due to VDD

power-on from 0 volts.

* The D5 bit represents DP/

when the 24-hour mode is selected (tens in the hour digits).

* The Alarm_D registers should not have any non-existent alarm time settings.

(Note that any mismatch between current time and preset alarm time specified by the Alarm_D registers

may disable the alarm interrupt circuit.)

* When the 12-hour mode is selected, the hour digits read 12 and 32 for 0a.m. and 0p.m., respectively.

(See "P15 •Control Register 1 (ADDRESS Eh) (2)

DH10 DH8 DH4 DH2 DH1 (For Writing)

DH10 DH8 DH4 DH2 DH1 (For Reading)

when the 12-hour mode is selected (0 for a.m. and 1 for p.m.) and DH20

12

/24: 12/24-hour Mode Selection Bit")

24

R2062 series

Interfacing with the CPU

• DATA TRANSFER FORMATS

(1) Timing Between CE Pin Transition and Data Input / Output

The R2062 adopts a 3-wire serial interface by which they use the CE (Chip Enable), SCLK (Serial Clock), and

SIO (Serial Input/Output) pins to receive and send data to and from the CPU. The 3-wire serial interface

provides two types of input/output timings with which the SIO pin output and input are synchronized with the

rising or falling edges of the SCLK pin input, respectively, and vice versa. The R2062 is configured to select

either one of two different input/output timings depending on the level of the SCLK pin in the low to high transition

of the CE pin. Namely , wh en the SCLK pin is held lo w in the low t o high transition of the CE pin, the mode ls will

select the timing with which the SIO pin output is synchronized with the rising edge of the SCLK pin input, and

the input is synchronized with the falling edge of the SCLK pin input, as illustrated in the timing chart below.

CE

SCLK

SIO (for writing)

SIO (for reading)

t

CES

t

t

DS

DH

t

RD

Conversely, when the SCLK pin is held high in the low to high transition of the CE pin, the models will select the

timing with which the SIO pin output is synchronized with the falling edge of the SCLK pin input, and the input is

synchronized with the rising edge of the SCLK pin input, as illustrated in the timing chart below.

CE

SCLK

SIO (for writing)

t

CES

t

t

DS

DH

t

RD

SIO (for reading)

25

R2062 series

K

A

A

(2) Data Transfer Formats

Data transfer is commenced in the low to high transition of the CE pin input and completed in its high to low

transition. Data transfer is conducted serially in multiple units of 1 byte (8 bits). The former 4 bits are used to

specify in the Addre s s Pointer a head address with which data transfer is to be commenced from the host. The

latter 4 bits are used to select either reading data transfer or writing dat a transfe r, and to set the Transfer Format

Register to specify an appropriate data transfer format. All data transfer formats are designed to transfer the

most significant bit (MSB) first.

CE

7582312314

6

SCL

SIO

A3

A1 A0 C3 C2 C1 C0

Setting

the Address Pointer

Format Register

D7 D6 D3 D2 D1 D0

Writing or Reading data transferSetting the Transfer

A2

Two types of data transfer formats are available for reading data transfer and writing data transfer each.

• Writing Data Transfer Formats

(1) 1-byte Writing Data Transfer Format

The first type of writing data transfer format is designed to transfer 1-byte data at a time and can be selected by

specifying in the address pointer a head address with which writing data transfer is to be commenced and then

writing the setting of 8h to the transfer format register. This 1-byte writing data transfer can be completed by

driving the CE pin low or continued by specifying a new head address in the address pointer and setting the data

transfer format.

Example of 1-byte Wr i t ing Data Transfer (For Writi ng Dat a t o Addr esses Fh and 7h)

CE

26

SIO

1 1

Specifying Fh

in the

ddress

Pointer

01 0 01 1

Setting 8h in

the Transfer

Format

Register

Data transfer from the host

Data Data

Writing data to

address Fh

0 11 0 0 01 1

Specifying 7h

in the

ddress

Pointer

Setting 8h in

the Transfer

Format

Register

Data transfer from the RTCs

Writing data to

address 7h

R2062 series

A

A

A

(2) Burst Writing Data Transfer Format

The second type of writing data transfer format is designed to transfer a sequence of data serially and can be

selected by specifying in the address pointer a head address with which writing data transfer is to be

commenced and then writing the setting of 0h to the transfer format register. The address pointer is

incremented for each transfer of 1-byte data and cycled from Fh to 0h. This burst writing data transfer can be

completed by driving the CE pin low.

Example of Burst Writing Data Transfer (For W r iting Data to Addresses Eh, Fh, and 0h)

CE

SIO

1 0

Specifying Eh

in the

ddress

Pointer

00 0 01 1

Setting 0h in

the Transfer

Format

Register

Data

Writing data to

address Eh

Data

Writing data to

address Fh

Data transfer from the host Data transfer from the RTCs

Data

Writing data to

address 0h

• Reading Data Transfer Formats

(1) 1-byte Reading Data Transfer Format

The first type of reading data transfer format is designed to transfer 1-byte dat a a t a time and can be sele cted by

specifying in the Address Pointer a head address with which reading data transfer is to be commenced and then

the setting of writing Ch to the Transfer Format Regist er. This 1-byte reading data transfer can be completed by

driving the CE pin low or continued by specifying a new head address in the Address Pointer and selecting this

type of reading data Transfer Format.

Example of 1-byte Reading Data Transfer (For Readi ng Dat a f r om Addr esses Eh and 2h)

CE

SIO

1 0

11 0 01 1 0 10 1 0 00 1

Data Data

Specifying Eh

in the

ddress

Pointer

Setting Ch in

the Transfer

Format

Register

Reading data from

address Eh

Specifying 2h

in the

ddress

Pointer

Setting Ch in

the Transfer

Format

Register

Reading data from

address 2h

Data transfer from the host Data transfer from the RTCs

27

R2062 series

A

A

A

(2) Burst Reading Data Transfer Format

The second type of reading data transfer format is designed to transfer a sequence of data serially and can be

selected by specifying in the address pointer a head address with which reading data transfer is to be

commenced and then writing the setting of 4h to the transfer format register. The address pointer is

incremented for each transfer of 1-byte data and cycled from Fh to 0h. This burst reading data transfer can be

completed by driving the CE pin low.

Example of Burst Reading Data Transfer (For Reading Data from Addresses Fh, 0h, and 1h)

CE

1 1

Specifying Fh

in the

ddress

Pointer

10 0 01 1

Setting 4h in

the Transfer

Format

Register

Data transfer from the host Data transfer from the RTCs

DATASIO

Reading data from

address Fh

DATA DATA

Reading data from

address 0h

Reading data from

address 1h

(3) Combination of 1-byte Reading and writing Data Transfer Formats

The 1-byte reading and writing data transfer formats can be combin ed together and further followed by any other

data transfer format.

Example of Reading Modify Writing Data Transfer

(For Reading and Writing Data from and to Address Fh)

CE

1 1

Specifying Fh

in the

ddress

Pointer

11 0 01 1 1 11 0 0 01 1

Setting Ch in

the Transfer

Format

Register

DATA

Reading data from

address Fh

Specifying Fh

in the

ddress

Pointer

Setting 8h in

the Transfer

Format

Register

DATASIO

Writing data to

address Fh

Data transfer from the host Data transfer from the RTCs

The reading and writing data transfer formats correspond to the settings in the transfer format register as shown

in the table below.

1 Byte Burst

Writing data

transfer

Reading data

transfer

8h

(1,0,0,0)

Ch

(1,1,0,0)

0h

(0,0,0,0)

4h

(0,1,0,0)

28

R2062 series

• Considerations in Reading and Writing Time Data under special condition

Any carry to the second digits in the process of reading or writing time data may cause reading or writing

erroneous time data. For example, suppose a carry out of 13:59:59 into 14:00:00 occurs in the process of

reading time data in the middle of shifting from the minute digits to the hour digits. At this moment, the second

digits, the minute digits, and the hour digits read 59 seconds, 59 minutes, and 14 hours, respectively (indicating

14:59:59) to cause the reading of time data deviating from actual time virtually 1 hour. A similar error also

occurs in writing time data. To prevent such e rrors in reading and writing time data, the R2062 has the function

of temporarily locking any carry to the second digits during the high interval of the CE pin and unlocking such a

carry in its high to low transition. Note that a carry to the second digits can be locked for only 1 second, during

which time the CE pin should be driven low .

Actual time

CE

Time counts

within RTC

The effective use of this function requires the following considerations in reading and writing time data:

(1) Hold the CE pin high in each session of reading or writing time data.

(2) Ensure that the high interval of the CE pin lasts within 1 second. Should there be any possibility of the host

going down in the process of reading or writing time data, make arrangements in the peripheral circuitry as to

drive the CE pin low or open at the moment that the host actually goes down.

(3) Leave a time span of 31µs or more from the low to high transition of the CE pin to the start of access to

addresses 0h to 6h in order that any ongoing carry of the time digits may be completed within this time span.

(4) Leave a time span of 62µs or more from the high to low transition of the CE pin to its low to high transition in

order that any ongoing carry of the time digits during the high interval of the CE pin may be adjusted within this

time span.

The considerations listed in (1), (3), and (4) above are not required when the process of reading or writing time

data is obviously free from any carry of the time digits.

(e.g. reading or writing time data in synchronization with the periodic interrupt function in the level mode or the

alarm interrupt function).

Good and bad examples of reading and writing time data are illustrated on the next page.

13:59:59 14:00:00 14:00:01

Max.62µs

13:59:59

14:00:00

14:00:01

29

R2062 series

A

A

A

A

A

t

A

A

A

A

A

A

A

A

A

A

A

A

A

A

A

Good Example

CE

Time span of 31µs or more

ny address other than addresses 0h to 6h

permits of immediate reading or writing withou

requiring a time span of 31 µs.

SIO

ddress Pointer

= Fh

Transfer Format

Register = 4h

DATA

Reading from

ddress Fh

(control2)

DATA F4h

Reading from

ddress 0h

(sec.)

DATA

Reading from

ddress 1h

(min.)

DATA

Reading from

ddress 2h

(hr.)

Bad Example (1)

(Where the CE pin is once driven low in the process of reading time data)

31µs or more

31µs or more

CE

SIO

0Ch Data Data

ddress Pointer

= 0h

Transfer Format

Register = Ch

Reading from

ddress 0h

(sec.)

14h

ddress Pointer

= 1h

Transfer Format

Register = 4h

Data

Reading from

ddress 1h

(min.)

Reading from

ddress 2h

(hr.)

Bad Example (2)

(Where a time span of less than 31µs is left until the start of the process of writing time data)

Time span of less than 31µs

CE

SIO

= Fh

Transfer Format

Register = 0h

Bad Example (3)

F0h

ddress Pointer

Writing to

ddress Fh

(contorl2)

Data Data Data Data

Writing to

ddress 0h

(sec.)

Writing to

ddress 1h

(min.)

Writing to

ddress 2h

(hr.)

(Where a time span of less than 62µs is left between the adjacent processes of reading time data)

Less than 62µs

CE

SIO

= 0h

Transfer Format

Register = Ch

0Ch

0Ch

ddress Pointer

Data

Reading from

ddress 0h

(sec.)

Data transfer from the host

Data

0Ch

ddress Pointer

= 0h

Transfer Format

Register = Ch

Reading from

ddress 0h

(sec.)

Data transfer from RTCs

Data

30

R2062 series

Configuration of Oscillation Circuit and Correction of Time Count

Deviations

• Configuration of Oscillation Circuit

Typical externally-equipped element

X’tal : 32.768kHz

(R1=30kΩ typ)

(CL=6pF to 8pF)

Standard values of internal elements

CG,CD 10pF typ

Oscillator

Circuit

CG

CD

OSCIN

OSCOUT

32kHz

A

The oscillation circuit is driven at a constant voltage o f approximately 1.2 volt s relative to the level of the VSS pin

input. As such, it is configured to generate an oscillating waveform with a peak-to-peak voltage on the order of

1.1 volts on the positive side of the VSS pin input.

< Considerations in Handling Quartz Crystal Units >

Generally , quartz crystal u nits have ba sic characteristics i ncluding an equivalent series resist ance (R1) indicating

the ease of their oscillation and a load capacitance (CL) indicating the degree of their center frequency.

Particularly, quartz crystal units intended for use in the R2062 are recommended to have a typical R1 value of

30kΩ and a typical CL value of 6 to 8pF. To confirm these recommended values, contact the manufacturers of

quartz crystal units intended for use in these particular models.

< Considerations in Installing Components around the Oscillation Circuit >

1) Install the quartz crystal unit in the closest possible vicinity to the real-time clock ICs.

2) Avoid laying any signal lines or power lines in the vicinity of the oscillation circuit (particularly in the area

marked "A" in the above figure).

3) Apply the highest possible insulation resistance between the OSCIN and OSCOUT pins and the printed

circuit board.

4) Avoid using any long parallel lines to wire the OSCIN and OSCOUT pins.

5) Take extreme care not to cause condensation, which leads to various problems such as oscillation halt.

< Other Relevant Considerations >

1) We cannot recommend connecting the external input of 32.768-kHz clock pulses to the OSCIN pin.

2) To maintain stable characteristics of the quartz crystal unit, avoid driving any other IC through 32.768-kHz

clock pulses output from the OSCOUT pin.

31

R2062 series

A

A

• Measurement of Oscillation Frequency

VCC

OSCIN

OSCOUT

CLKOUT

VDD

VSS

32768Hz

Frequency

Counter

* 1) The R2062 is configured to generate 32.768-kHz clock pulse s for output from the CLKOUT pin.

* 2) A frequency counter with 6 (more preferably 7) or more digits on the order of 1ppm is recommended for

use in the measurement of the oscillation frequency of the oscillation circuit.

• Adjustment of Oscillation frequency

The oscillation frequency of the oscillation circuit can be adjusted by varying procedures depending on the

usage of Model R2062 in the system into which they are to be built and on the allowable degree of time count

errors. The flow chart below serves as a guide to selecting an optimum oscillation frequency adjustment

procedure for the relevant system.

Use 32-kHz

clock output?

Use 32-kHz clock output without regard

llowable time count precision on order of oscillation

frequency variations of crystal oscillator (*1) plus

frequency variations of RTC (*2)? (*3)

Start

llowable time count precision on order of oscillation

NO

YES

to its frequency precision

NO

frequency variations of crystal oscillator (*1) plus

frequency variations of RTC (*2)? (*3)

YES

YES

Course (A)

NO

Course (B)

Course (C)

YES

NO

Course (D)

* 1) Generally, quartz crystal units for commercial use are classified in terms of their center frequency

depending on their load capacitance (CL) and further divided into ranks on the order of ±10, ±20, and ±50ppm

depending on the degree of their oscillation frequency variations.

32

R2062 series

* 2) Basically, Model R2062 is configured to cause frequency variations on the order of ±5 to ±10ppm at 25°C.

* 3) Time count precision as referred to in the above flow chart is applicable to no rmal temperature an d actually

affected by the temperature characteristics and other properties of quartz crystal units.

Course (A)

When the time count precision of each RTC is not to be adjusted, the quartz crystal unit intended for use in that

RTC may have any CL value requiring no presetting. The quartz crystal unit may be subject to frequency

variations which are selectable within the allowable range of time count precision. Several quartz crystal units

and RTCs should be used to find the center frequency of the quartz crystal units by the method described in

"P32 • Measurement of Oscillation Frequency" and then calculate an appropriate oscillation adjustment value

by the method described in "P34 • Oscillation Adjustment Circuit" for writing this value to the R2062.

Course (B)

When the time count precision of each RTC is to be adjusted within the oscillation frequency variations of the

quartz crystal unit plus the frequency variations of the real-time clock ICs, it becomes necessary to correct

deviations in the time count of each RTC by the method described in " P34 • Oscillation Adjustment Circuit".

Such oscillation adjustment provides quartz crystal units with a wider range of allowable settings of their

oscillation frequency variations and their CL values. The real-time clock IC and the quartz crystal unit intended

for use in that real-time clock IC should be used to find the center frequency of the quartz crystal unit by the

method described in " P32 • Measurement of Oscillation Frequency" and then confirm the center frequency

thus found to fall within the range adjustable by the oscillation adjustment circuit before adjusting the oscillation

frequency of the oscillation circuit. At normal temperature, the oscillation frequency of the oscillator circuit can

be adjusted by up to approximately ±0.5ppm.

Course (C)

Course (C) together with Course (D) requires adjusting the time count precision of each RTC as well as the

frequency of 32.768-kHz clock pulses output from the CLKOUT pin. Normally, the oscillation frequency of the

quartz crystal unit intended for use in the RTCs should be adjusted by adjusting the oscillation stabilizing

capacitors CG and CD connected to both ends of the quartz cryst al unit. The R2062, which incorporate the CG

and the CD, require adjusting the oscillation frequency of the quartz crystal unit through its CL value.

Generally , the relation ship between the CL valu e and the CG and CD value s can be represe nted by the following

equation:

CL = (CG × CD)/(CG + CD) + CS where "CS" represents the floating ca pacity of the printed circuit board.

The quartz crystal unit intended for use in the R2062 is recommended to have the CL value on the order of 6 to

8pF. Its oscillation frequency should be measured by the method described in " P32 • Measurement of

Oscillation Frequency". Any quartz crystal unit found to have an excessively high or low oscillation frequency

(causing a time count gain or loss, respectively) should be replaced with another one having a smaller and

greater CL value, respectively until another one having an optimum CL value is selected. In this case, the bit

settings disabling the oscillation adjustment circuit (see " P34 • Oscillation Adjustment Circuit ") should be

written to the oscillation adjustment register.

Incidentally, the high oscillation frequency of the quartz crystal unit can also be adjusted by adding an external

oscillation stabilization capacitor CGout as illustrated in the diagram below.

33

R2062 series

Oscillator

Circuit

CG

RD

CD

OSCIN

32kHz

OSCOUT

*1) The CGout should have a capacitance ranging

from 0 to 15 pF.

CGout

*1)

Course (D)

It is necessary to select the quartz crystal unit in the same manner as in Course (C) as well as correct errors in

the time count of each RTC in the same manner as in Course (B) by the method described in " P34 •

Oscillation Adjustment Circuit ".

• Oscillation Adjustment Circuit

The oscillation adjustment circuit can be used to correct a time count gain or loss with high precision by varying

the number of 1-second clock pulses once per 20 seconds or 60 seconds. When DEV bit in the Oscillation

Adjustment Register is set to 0, R2062 varies number of 1-second clock pulses once per 20 seconds. When

DEV bit is set to 1, R2062 varies number of 1-second clock pulses once per 60 seconds. The oscillation

adjustment circuit can be disabled by writing the settings of "*, 0, 0, 0, 0, 0, *" ("*" representing "0" or "1") to the

F6, F5, F4, F3, F2, F1, and F0 bits in the oscillation adjustment circuit. Conversely, when such oscillation

adjustment is to be made, an appropriate oscillation adjustment value can be calculated by the equation below

for writing to the oscillation adjustment circuit.

(1) When Oscillation Frequency (* 1) Is Higher Than Target Frequency (* 2) (Causing Time Count Gain)

When DEV=0:

Oscillation adjustment value (*3) = (Oscillation frequency - Target Frequency + 0.1)

Oscillation frequency × 3.051 × 10

-6

≈ (Oscillation Frequency – Target Frequency) × 10 + 1

When DEV=1:

Oscillation adjustment value (*3) = (Oscillation frequency - Target Frequency + 0.0333)

Oscillation frequency × 1.017 × 10

-6

≈ (Oscillation Frequency – Target Frequency) × 30 + 1

* 1) Oscillation frequency:

32768 times the frequency of 1Hz clock pulse output from the

INTR

pin at normal temperature in the

manner described in " P32 • Measurement of Oscillation Frequency".

* 2) Target frequency:

Desired frequency to be set. Generally, a 32.768-kHz quartz crystal unit has such temperature

characteristics as to have the highest oscillation frequency at normal temperature. Consequently,

the quartz crystal unit is recommended to have target frequency settings on the order of 32.768 to

32.76810 kHz (+3.05ppm relative to 32.768 kHz). Note that the target frequency differs depending

on the environment or location where the equipment incorporating the RTC is expected to be

operated.

* 3) Oscillation adjustment value:

Value that is to be finally written to the F0 to F6 bits in the Oscillation Adjustment Register and is

represented in 7-bit coded decimal notation.

34

R2062 series

(2) When Oscillation Frequency Is Equal To Target Frequency (Causing Time Count neither Gain nor Loss)

Oscillation adjustment value = 0, +1, -64, or –63

(3) When Oscillation Frequency Is Lower Than Target Frequency (Causing Time Count Loss)

When DEV=0:

Oscillation adjustment value = (Oscillation frequency - Target Frequency)

Oscillation frequency × 3.051 × 10

≈ (Oscillation Frequency – Target Frequency) × 10

When DEV=1:

Oscillation adjustment value = (Oscillation frequency - Target Frequency)

Oscillation frequency × 1.017 × 10

≈ (Oscillation Frequency – Target Frequency) × 30

Oscillation adjustment value calculations are exemplified below

(A) For an oscillation frequency = 32768.85Hz and a target frequency = 32768.05Hz

When setting DEV bit to 0:

Oscillation adjustment value = (32768.85 - 32768.05 + 0.1) / (32768.85 × 3.051 × 10

≈ (32768.85 - 32768.05) × 10 + 1

= 9.001 ≈ 9

In this instance, write the settings (DEV,F6,F5,F4,F3,F2,F1,F0)=(0,0,0,0,1,0,0,1) in the oscillation adjustment

register. Thus, an appropriate oscillation adjustment value in the presence of any time count gain represents a

distance from 01h.

When setting DEV bit to 1:

Oscillation adjustment value = (32768.85 - 32768.05 + 0.0333) / (32768.85 × 1.017 × 10

≈ (32768.85 - 32768.05) × 30 + 1

= 25.00 ≈ 25

In this instance, write the settings (DEV,F6,F5,F4,F3,F2,F1,F0)=(1,0,0,1,1,0,0,1) in the oscillation adjustment

register.

(B) For an oscillation frequency = 32762.22Hz and a target frequency = 32768.05Hz

When setting DEV bit to 0:

Oscillation adjustment value = (32762.22 - 32768.05) / (32762.22 × 3.051 × 10

≈ (32762.22 - 32768.05) × 10

= -58.325 ≈ -58

To represent an oscillation adjustment value of - 58 in 7-bit coded decimal notation, subtract 58 (3Ah) from 128

(80h) to obtain 46h. In this instance, write the settings of (DEV,F6,F5,F4,F3,F2,F1,F0) = (0,1,0,0,0,1,1,0) in the

oscillation adjustment register. Thus, an appropriate oscillation adjustment value in the presence of any time

count loss represents a distance from 8 0h.

When setting DEV bit to 1:

Oscillation adjustment value = (32762.22 - 32768.05) / (32762.22 × 1.017 × 10

≈ (32762.22 - 32768.05) × 30

= -174.97 ≈ -175

-6

-6

-6

)

-6

)

-6

)

-6

)

35

R2062 series

Oscillation adjustment value can be set from -62 to 63. Then, in this case, Oscillation adjustment value is out of

range.

(4) Difference between DEV=0 and DEV=1

Difference between DEV=0 and DEV=1 is following,

DEV=0 DEV=1

Maximum value range -189.2ppm to 189.2ppm -62ppm to 63ppm

Minimum resolution 3ppm 1ppm

Notes:

If following 3 conditions are completed, actual clock adjustment value could be different from target

adjustment value that set by oscillator adjustment function.

1. Using oscillator adjustment function

2. Access to R2062 at random, or synchronized with external clock that has no relation to R2062, or

synchronized with periodic interrupt in pulse mode.

3. Access to R2062 more than 2 times per each second on average.

For more details, please contact to Ricoh.

• How to evaluate the clock gain or loss

The oscillator adjustment circuit is configured to change time counts of 1 second on the basis of the settings of

the oscillation adjustment register once in 20 seconds or 60 seconds. The way to measure the clock error as

follows:

(1) Output a 1Hz clock pulse of Pulse Mode with interrupt pin

Set (0,0,x,x,0,0,1,1) to Control Register 1 at address Eh.

(2) After setting the oscillation adjustment register, 1Hz clock period changes every 20seconds ( or every 60

seconds) like next page figure.

1Hz clock pulse

T0 T0 T0 T1

1 time19 times

Measure the interval of T0 and T1 with frequency counter. A frequency counter with 7 or more digits is

recommended for the measurement.

(3) Calculate the typical period from T0 and T1

T = (19×T0+1×T1)/20

Calculate the time error from T.

36

R2062 series

X

Power-on Reset, Oscillation Halt Sensing, and Supply Voltage

Monitoring

• PON,

The power-on reset circuit is configured to reset control register1, 2, and clock adjustment register when VDD

power up from 0v. The oscillation halt sensing circuit is configured to record a halt on oscillation by 32.768-kHz

clock pulses. The supply voltage monitoring circuit is configured to record a drop in supply voltage below a

threshold voltage of 2.1 or 1.35v.

Each function has a monitor bit. I.e. the PON bit is for the power-on reset circuit, and

oscillation halt sensing circuit, and VDET is for the supply voltage monitoring circuit. PON and VDET bits are

activated to “H”. However,

XST

0, and

The functions of these three monitor bits are shown in the table below.

Function Monitoring for the

Address D4 in Address Fh D5 in Address Fh D6 in Address Fh

Activated High Low High

When VDD power

up from 0v

accept the writing 0 only Both 0 and 1 0 only

The relationship between the PON,

PON

0 0 0 Halt on oscillation, but no drop in

0 0 1 Halt on oscillation and drop in VDD

0 1 0 No drop in VDD supply voltage

0 1 1 Drop in VDD supply voltage below

1 * * Drop in supply voltage to 0v Power-up from 0v,

XST

, and VDET

XST

bit is for the

XST

bit is activated to “L”. The PON and VDET accept only the writing of 0, but

accepts the writing of 0 and 1. The PON bit is set to 1, when VDD power-up from 0V, but VDET is set to

XST

is indefinite.

PON

Monitoring for the

XST

power-on reset function

1 indefinite 0

XST

, and VDET is shown in the table below.

VDET Conditions of supply voltage

VDD supply voltage below

threshold voltage

supply voltage below threshold

voltage, but no drop to 0V

below threshold voltage and no

halt in oscillation

threshold voltage and no halt on

oscillation

and oscillation

oscillation halt sensing

function

ST

Condition of oscillator, and

Halt on oscillation cause of

condensation etc.

Halt on oscillation cause of drop in

back-up battery voltage

Normal condition

No halt on oscillation, but drop in

back-up battery voltage

a drop in supply voltage

below a threshold voltage

of 2.1 or 1.35v

back-up status

VDET

37

R2062 series

g

(

)

VDD

32768Hz Oscillation

Power-on reset flag

(PON)

Oscillation halt

sensin

VDD supply voltage

monitor flag (VDET)

flag

XST

Threshold voltage (2.1V or 1.35V)