Page 1

LCT

(Machine Code: A862/B391)

Page 2

10 August, 2001 SPECIFICATIONS

1. OVERALL MACHINE INFORMATION

1.1 SPECIFICATIONS

Paper Size:

Paper Weight: 60 g/m2 ~ 105 g/m2, 16 lb ~ 28 lb

Tray Capacity: 2,000 sheets (80 g/m2, 20lb)

Remaining Paper Detection: 5 steps (100%, 75%, 50%, 25%, Near end)

Power Source: 24 Vdc, 5 Vdc (from copier/printer)

Power Consumption: 26 W (Max.)/14 W (Ave.)

Weight: 25 kg (55 lbs)

Size (W x D x H): 550 mm x 520 mm x 271 mm

A4 sideways/LT sideways

B391-1

Options

Page 3

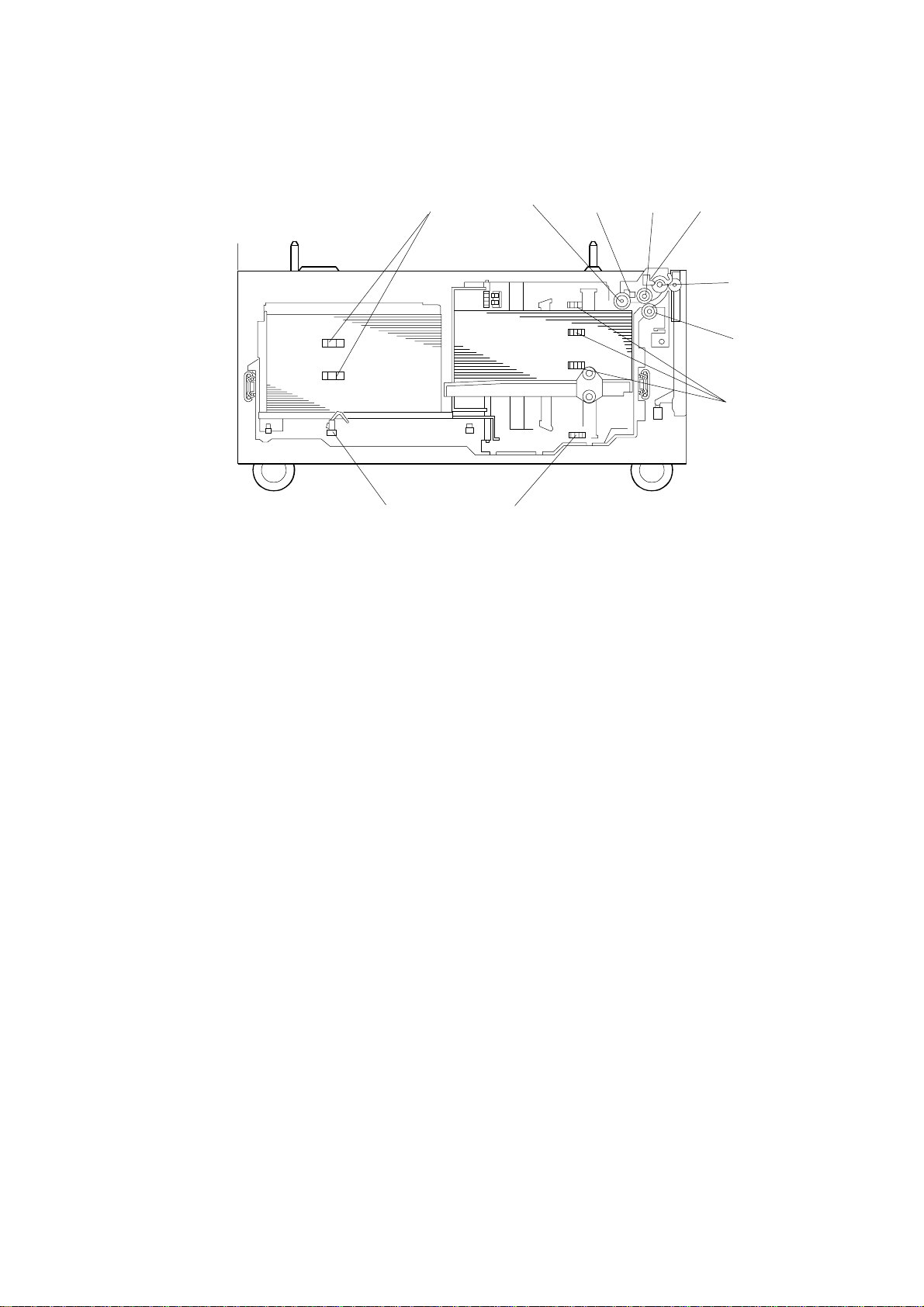

MECHANICAL COMPONENT LAYOUT 10 August, 2001

1.2 MECHANICAL COMPONENT LAYOUT

1. Pick-up Roller

10

2143

5

6

7

89

B391D101.WMF

7. Paper Height Sensors 1, 2, 3

2. Upper Limit Sensor

3. Paper Feed Roller

4. Relay Sensor

5. Relay Roller

6. Reverse Roller

8. Lower Limit Sensor

9. Left Paper End Sensor

10. Paper Height Sensors 4,5

B391-2

Page 4

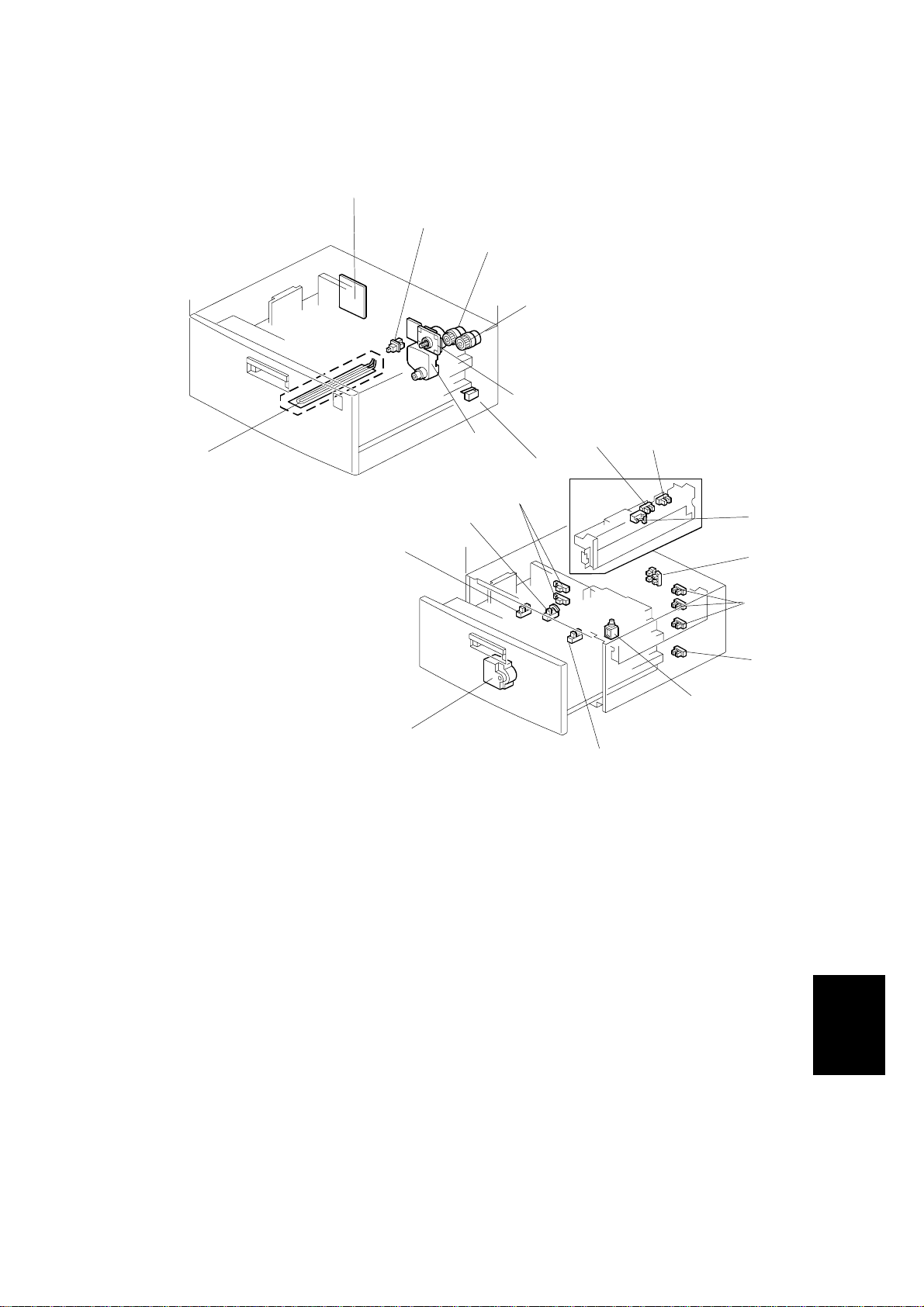

10 August, 2001 ELECTRICAL COMPONENT LAYOUT

1.3 ELECTRICAL COMPONENT LAYOUT

1

2

3

4

5

7

B391D102.WMF

1. Main Board

2. Tray Sensor

17

16

6

89

20

19

18

B391D103.WMF

15

12. Paper Height Sensors 1, 2, 3

13. Lower Limit Sensor

10

11

12

13

14

3. Relay Clutch

4. Paper Feed Clutch

5. Tray Motor

6. Tray Lift Motor

7. Tray Heater (option)

8. Right Tray Paper End Sensor

9. Upper Limit Sensor

10. Relay Sensor

11. Side Fence Open/Closed Sensors

B391-3

14. Side Fence Solenoid

15. Rear Fence Return Sensor

16. Rear Fence Motor

17. Rear Fence Home Position

Sensor

18. Left Tray Paper End Sensor

19. Paper Height Sensors 4, 5

20. Right Cover Switch

Options

Page 5

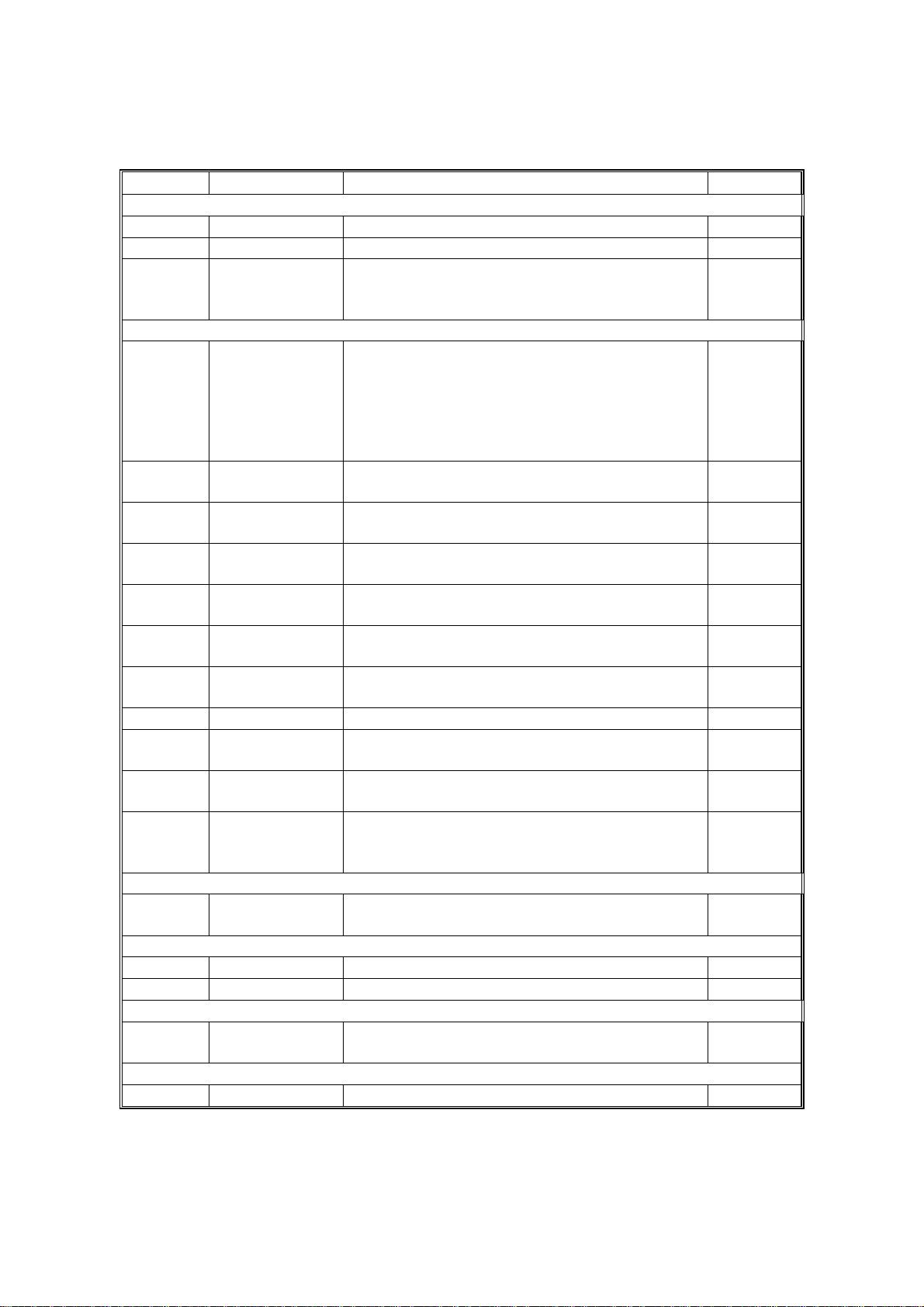

ELECTRICAL COMPONENT DESCRIPTIONS 10 August, 2001

1.4 ELECTRICAL COMPONENT DESCRIPTIONS

Symbol Name Function Index No.

Motors

M1 Tray Motor Drives all rollers. 5

M2 Tray Lift Motor Drives the paper tray up or down. 6

Rear Fence

M3

Sensors

S1

S2

S3

S4

S5

S6

S7

S8 Tray Detects whether the tray is correctly set. 2

S9

S10

S11

Solenoids

SOL1

Magnetic Clutches

MC1 Paper Feed Drives the paper feed roller. 4

MC2 Relay Drives the relay roller. 3

PCBs

PCB1

Switches

SW1 Right Cover Detects whether the right cover is open. 20

Motor

Right Tray

Paper End

Relay

Upper Limit Detects when the paper is at the correct

Lower Limit Detects when the tray is completely lowered,

Paper Height

1, 2, 3

Paper Height

4, 5

Rear Fence

Home Position

Side Fence

Open/Closed

Rear Fence

Return

Left Tray

Paper End

Side Fence Contro ls open-close movement of the side

Main Controls the LCT and communicates with the

Moves the rear fence to transfer the paper

stack from the paper storage (left) side of the

tray to the paper feed (right) side.

Informs the copier/printer when the paper in

the right side (paper feed side) of the tray has

been used up. If there is a paper stack in the

left side (paper storage side), this is moved

into the right tray. If there is no paper stack in

the left side, paper end is indicated.

Detects the copy paper coming to the relay

roller and checks for misfeeds.

paper feed height.

to stop the LCT motor.

Detects the amount of paper remaining in the

right side of the tray.

Detects the amount of paper remaining in the

left side of the tray.

Detects when the rear fence is at H.P.

Detects whether the side fence is opened on

closed.

Detects when the rear fence has moved the

paper stack from the left side to the right side.

Informs the copier/printer when there is no

paper in the left side (paper storage side) of

the tray.

fence.

copier/printer.

16

8

10

9

13

12

19

17

11

15

18

14

1

B391-4

Page 6

10 August, 2001 PAPER FEED

2. DETAILED SECTION DESCRIPTIONS

2.1 PAPER FEED

[B]

[A]

[C]

B391D104.WMF

This products uses an FRR type paper feed mechanism.

The paper feed unit consists of the pickup roller [A], paper feed roller [B], reverse

roller [C], and grip and transport rollers.

There is a torque limiter in the back of the reverse roller (ferrite powder type).

B391-5

Options

Page 7

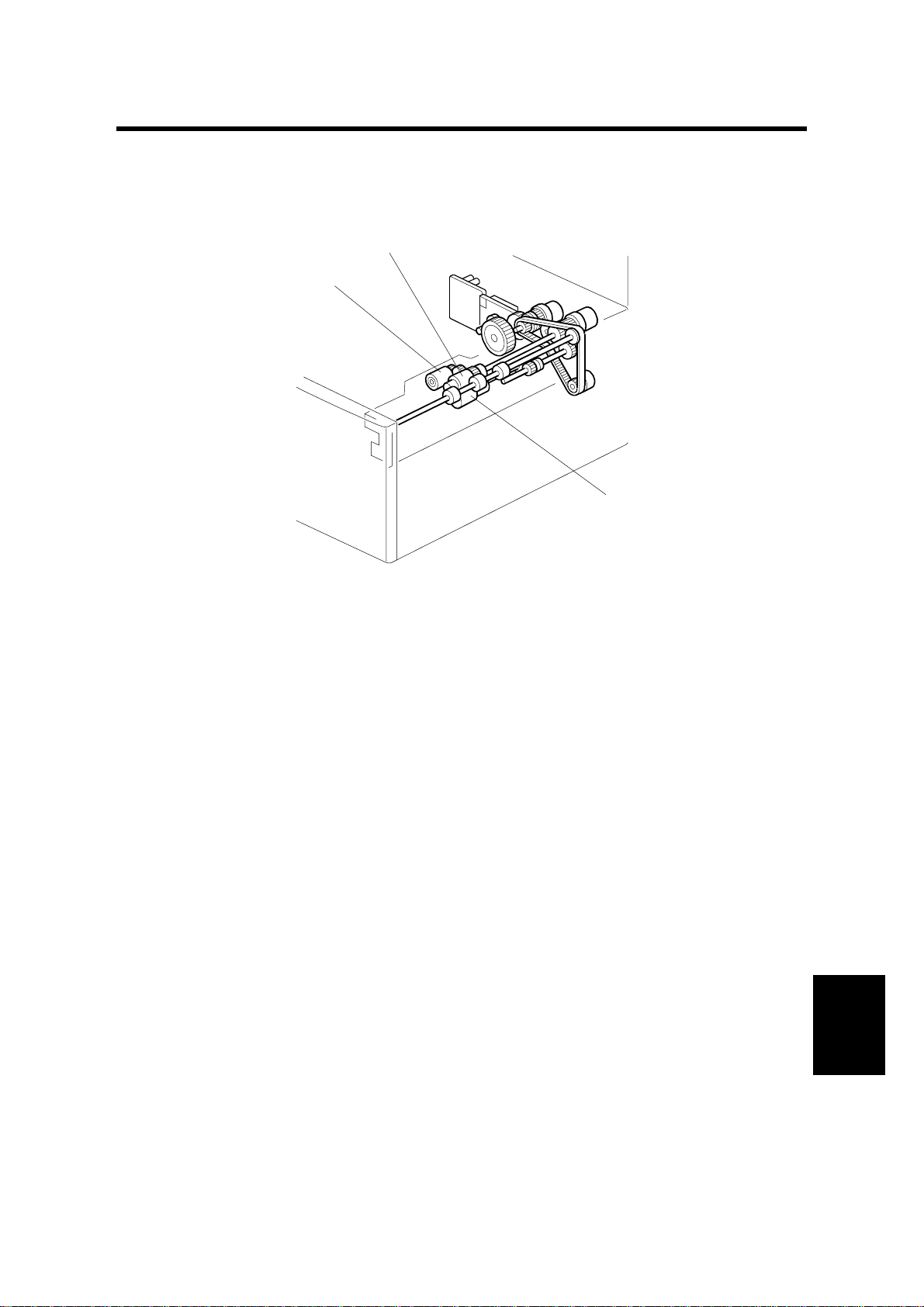

REVERSE ROLLER AND PICK-UP ROLLER RELEASE 10 August, 2001

2.2 REVERSE ROLLER AND PICK-UP ROLLER RELEASE

[A]

[E]

[C]

[B]

B391D107.WMF

[E]

[A]

[D]

B391D108.WMF

To prevent the paper from being torn when pulling out the paper feed tray, the

reverse and pickup rollers are set so that they release automatically.

When the paper tray [A] is not inside the machine, the reverse rolle r [B] is away

from the paper feed roller [C] and the pick-up roller [D] stays in the upper position.

When the paper tray is set into the machine, it pushes the release lever [E]. This

causes the pick-up roller [D] to go down into contact with the top sheet of paper

and the reverse roller [B] to move up and contact the paper feed roller.

B391-6

Page 8

10 August, 2001 TRAY LIFT

2.3 TRAY LIFT

[F]

[G]

[A]

[E]

B391D110.WMF

[B]

[D]

[C]

When the paper feed tray is put in the machine, the tray switc h [A] on the back face

turns on and the tray lift motor [B] starts up. The base plate lift shaft [C] is coupled

to the lift motor at shaft [D], so the base plate of the tray is lifted. After a short while,

the top of the paper stack contacts the pick-up roller and lifts it up.

When this occurs, the actuator enters the upper limit sensor, the sensor turns off

and the lift motor stops. When paper in the tray is used up, the pick-up roller is

gradually lowered, and the actuator leaves the upper limit sensor (turning the

sensor on). When this happens, the lift motor begins turning again. The tray will

then be lifted until the actuator enters the upper limit sensor (turning the sensor off

again).

When the tray is removed from the copier, the coupling between the lift motor [B]

and base plate lift shaft [C] is broken and the base plate goes into a controlled free

fall (using a damper [E] to slow the fall and prevent damage).

B391-7

Options

Page 9

NEAR END/END DETECTION 10 August, 2001

2.4 NEAR END/END DETECTION

This tray can hold two stacks of paper, so the machine needs to monitor the status

of both these stacks. There are seven sensors to do this.

In the right tray (paper feed side), three height sensors measure the height of the

stack, and an end sensor detects when all the paper is used up. As the amount of

paper remaining in the tray decreases, the base plate rises and the actuator

activates the paper height sensors. When paper runs out in the right tray, the stack

in the left tray is moved across to the right tray.

There are also two height sensors ([F] in the diagram on the previous page) and an

end sensor in the left tray (paper storage side) ([G] in the diagram on the previous

page). When there is no paper in both trays, paper end is detected.

The machine determines the amount of remaining paper based on the sensor

outputs, as shown in the following table.

Paper end sensor 1: ❍ = Low (no paper), # = High (paper present)

Other sensors: ❍ = Low (paper present), # = High (no paper)

Amount of paper

100% 75% 50%

Paper Height Sensor 1

Paper Height Sensor 2

Paper Height Sensor 3

Paper End Sensor 1

Paper Height Sensor 4

Paper Height Sensor 5

Paper End Sensor 2

Paper Height Sensor 1

Paper Height Sensor 2 – –

Paper Height Sensor 3 – – –

Paper End Sensor 1

Paper Height Sensor 4

Paper Height Sensor 5

Paper End Sensor 2

❍❍ ❍ ❍❍ ❍ # ❍ ❍

❍❍ ❍ ❍❍ #

❍❍ # ❍ ❍

## # ## # # # #

❍# ❍ ## ❍ ❍ # #

❍❍ ❍ ## ❍ ❍ ❍ ❍

❍❍ ❍ ❍# ❍ ❍ ❍ ❍

Amount of paper

25% Near-end End

#❍ ❍ ❍❍ # #

#❍#

#

## # ## # # ❍

❍# # ## # # #

#❍ # ## # # #

❍❍ ❍ ## ❍ # #

––––

––

–––

–

The following diagram is the sensor layout, as viewed from the front.

Paper Storage Side Paper Feed Side

Paper Height

Sensor 1

Paper Height

Sensor 5

Paper Height

Sensor 2

Paper End

Sensor 1

❍#

#

–

–

Paper Height

Sensor 4

Paper End

Sensor 2

Paper Height

Sensor 3

B391-8

B391D112.WMF

Page 10

10 August, 2001 RIGHT TRAY SIDE FENCE

2.5 RIGHT TRAY SIDE FENCE

[B]

[C]

[D]

[A]

[E]

[F]

[H]

B391D109.WMF

[G]

When the paper in the right tray is used up, the side fence solenoid [F] activates

and stays on until the side fence open/closed sensor [E] detects that the fence is

open. The rear fence [A] then moves the stack of paper from the left tray into the

right tray, as described in the following section. When the stack has been

transferred to the right tray, the rear fence return sensor [G] detects the rear fence

and then the cpu turns off the side fence open solenoid (closing the side fence).

The side fence open/closed sensor [D] detects when the side fence is closed.

When it is not closed, the user is prompted at the operation panel to free the

mechanism.

2.6 LEFT TRAY REAR FENCE

If the right tray paper end sensor detects that there is no paper in the tray (while

the left tray sensor detects that there is still paper in the left tray), the right side

fence [C] opens and the rear fence motor [H] turns on. The rear fence of the left

tray moves and the paper stack is then transferred from the left tray to the right

tray.

When the left tray rear fence activates the rear fence return sens or, the machine

detects that the paper stack has been transferred to the right tray and the rear

fence motor rotates in the opposite direction. When the rear fence HP sensor [B]

comes on, the motor stops.

B391-9

Options

Page 11

RIGHT TRAY PAPER END DETECTION 10 August, 2001

2.7 RIGHT TRAY PAPER END DETECTION

[A]

[B]

[C]

B391D106.WMF

[E]

[D]

B391D111.WMF

The paper end sensor [A] detects when copy paper in the right tray runs out.

When there is paper in the tray, the paper pushes up the paper end f eeler [B] an d

causes the actuator to come between the LED and photo diode of the sensor.

When paper runs out, the feeler drops and the actuator leaves the photointerruptor,

and the machine detects that there is no paper in the tray.

When the tray is being pulled ou t, the lever [E] lifts the pick-up roller and this also

lifts up the feeler.

B391-10

Page 12

10 August, 2001 DETACHING THE TRAY FROM THE MAINFRAME

3. REPLACEMENT AND ADJUSTMENT

3.1 DETACHING THE TRAY FROM THE MAINFRAME

While pressing the stopper attached to the

guide rail, pull out the large capacity tray.

NOTE: When reinstalling the tray, set the

tray on the guide rail and carefully

push the tray in, making sure to keep

the tray level.

[A]

B391R101.WMF

3.2 REAR FENCE HP SENSOR

LT

1. Pull out the large capacity tray.

2. Remove the left tray rear side fence [A] (2 screws).

3. Remove the rear fence bracket [B] (1 screw).

A4

[C]

[B]

B391R102.WMF

[A]

4. Remove the connector of the rear fence HP sensor.

5. Replace the rear fence HP sensor [C] (1 screw).

NOTE: When securing the sensor in place, be sure to fasten the screw in the

proper position.

B391-11

Options

Page 13

CHANGING THE TRAY PAPER SIZE 10 August, 2001

3.3 CHANGING THE TRAY PAPER SIZE

[A]

[B]

B391R103.WMF

1. Remove the screws of all side fences [A], [B].

2. The position of the rear fence HP sensor can then be changed (see Rear

Fence HP Sensor Removal).

3. The paper size display can then be changed with an SP mode.

NOTE: When securing the right tray side fence, fasten the screw after setting the

paper in the right tray and adjusting the fence to the width of the paper.

3.4 LEFT TRAY PAPER END SENSOR

[C]

[A]

[B]

B391R104.WMF

1. Pull out the large capacity tray.

2. Remove the left tray side fence [A] (2 screws).

3. Remove the rear fence bracket [B] (1 screws).

4. Replace the left tray paper end sensor [C] (1 connector).

B391-12

Page 14

10 August, 2001 TRAY LIFT MOTOR

3.5 TRAY LIFT MOTOR

[A]

B391R105.WMF

[B]

1. Remove the brackets (1 screw for each).

2. Remove the rear cover [A] (2 screws).

3. Remove the tray lift motor [B] (3 screws, 1 connector).

B391R106.WMF

Options

B391-13

Page 15

TRAY MOTOR 10 August, 2001

3.6 TRAY MOTOR

[A]

[C]

[B]

1. Remove the rear cover.

2. Remove bracket #1 [A] (2 screws).

3. Remove bracket #2 [B] (2 screws).

4. Remove the tray motor [C] (6 screws, 1 connector).

B391R107.WMF

B391-14

Page 16

10 August, 2001 PAPER FEED CLUTCH AND RELAY CLUTCH

3.7 PAPER FEED CLUTCH AND RELAY CLUTCH

[A]

[D]

[B]

[C]

B391R108.WMF

1. Remove the rear cover.

2. Remove bracket #1 [A] (2 screws).

3. Remove bracket #2 [B] (2 screws).

4. Remove all bushings.

5. Remove the paper feed clutch [C] and relay clutch [D].

6. Replace the required clutch.

NOTE: Make sure to properly secure both clutches before completing installation.

B391-15

Options

Page 17

PAPER FEED UNIT 10 August, 2001

3.8 PAPER FEED UNIT

[A]

[B]

[C]

B391R109.WMF

[E]

B391R110.WMF

[D]

1. Remove the paper feed clutch and relay clutch (see Paper Feed Clutch and

Relay Clutch Replacement).

2. Remove pulleys A [A], B [B], and C [C].

3. Remove the paper feed harness from the main board.

4. Open the vertical transport guide plate [D].

5. Remove the paper feed unit [E] (2 screws).

B391-16

Page 18

10 August, 2001 UPPER LIMIT, RIGHT TRAY PAPER END, AND RELAY SENSORS

3.9 UPPER LIMIT, RIGHT TRAY PAPER END, AND

RELAY SENSORS

[A]

[B]

[D]

[C]

B391R111.WMF

1. Remove the paper feed unit (see Paper Feed Unit Replacement).

2. Replace the required sensor.

• Upper limit [A]

• Relay [B]

• Right tray paper end [C]

NOTE: When replac ing the upper limit [A] and pape r end sensor [C], please be

sure to do so while pushing the release lever [D].

Options

B391-17

Page 19

REAR FENCE MOTOR 10 August, 2001

3.10 REAR FENCE MOTOR

[A]

[B]

[H]

B391R112.WMF

[G]

[F]

[E]

[C]

[D]

B391R113.WMF

B391R114.WMF

1. Pull out the paper feed tray unit.

2. Remove the paper feed tray front cover [A] (2 screws).

3. Remove the left side fence [B].

4. Remove the rear fence drive gear [C] (1 screw). This is in order to free the end

fence [D].

5. Move the end fence to the right (toward the center).

6. Remove the end fence (1 screw).

7. Remove the end fence bracket [E] (2 screws).

8. Remove the bracket [F] (1 screw).

9. Remove the bracket [G] of the rear fence motor assembly (2 screws).

10. Remove the rear fence motor assembly (2 screws).

11. Replace the motor [H] (1 connector).

B391-18

Page 20

10 August, 2001 PICK-UP/ PAPER FEED/REVERSE ROLLERS

3.11 PICK-UP/PAPER FEED/REVERSE ROLLERS

[C]

[A]

[B]

B391R115.WMF

1. Remove the paper tray unit (see Paper Tray Unit Replacement).

2. Remove the sna p ring (1 each for the paper feed and reverse rollers).

3. Remove the pick up roller [A].

4. Replace each roller [B], [C].

NOTE: Install the paper feed rollers the correct way round, as shown in the

illustration. If the rollers are installed incorrectly, this will cause the one-way

clutch to lock.

B391-19

Options

Loading...

Loading...