Page 1

PAPER TRAY UNIT

(Machine Code: G520)

Page 2

30 July 1999 SPECIFICATIONS

1. OVERALL MACHINE INFORMATION

1.1 SPECIFICATIONS

Paper Size

Paper Weight: 60 g/m2 ~ 105 g/m2, 16 lb. ~ 28 lb.

Tray Capacity: 500 sheets (80 g/m2, 20 lb.)

Paper Feed System: FRR

Paper Height Detection: 4 steps (100%, 70%, 30%, Near end)

Power Source: 24 Vdc, 5 Vdc (from the copier)

Power Consumption: 50 W

Weight: 25 kg

Size (W x D x H): 540 mm x 600 mm x 270 mm

:

A5 lengthwise to A3

HLT lengthwise to DLT

120 Vac: 115 V version (from the copier)

220 ~ 240 Vac: 224/240 V version (from the copier)

G520-1

Options

Page 3

MECHANICAL COMPONENT LAYOUT 30 July 1999

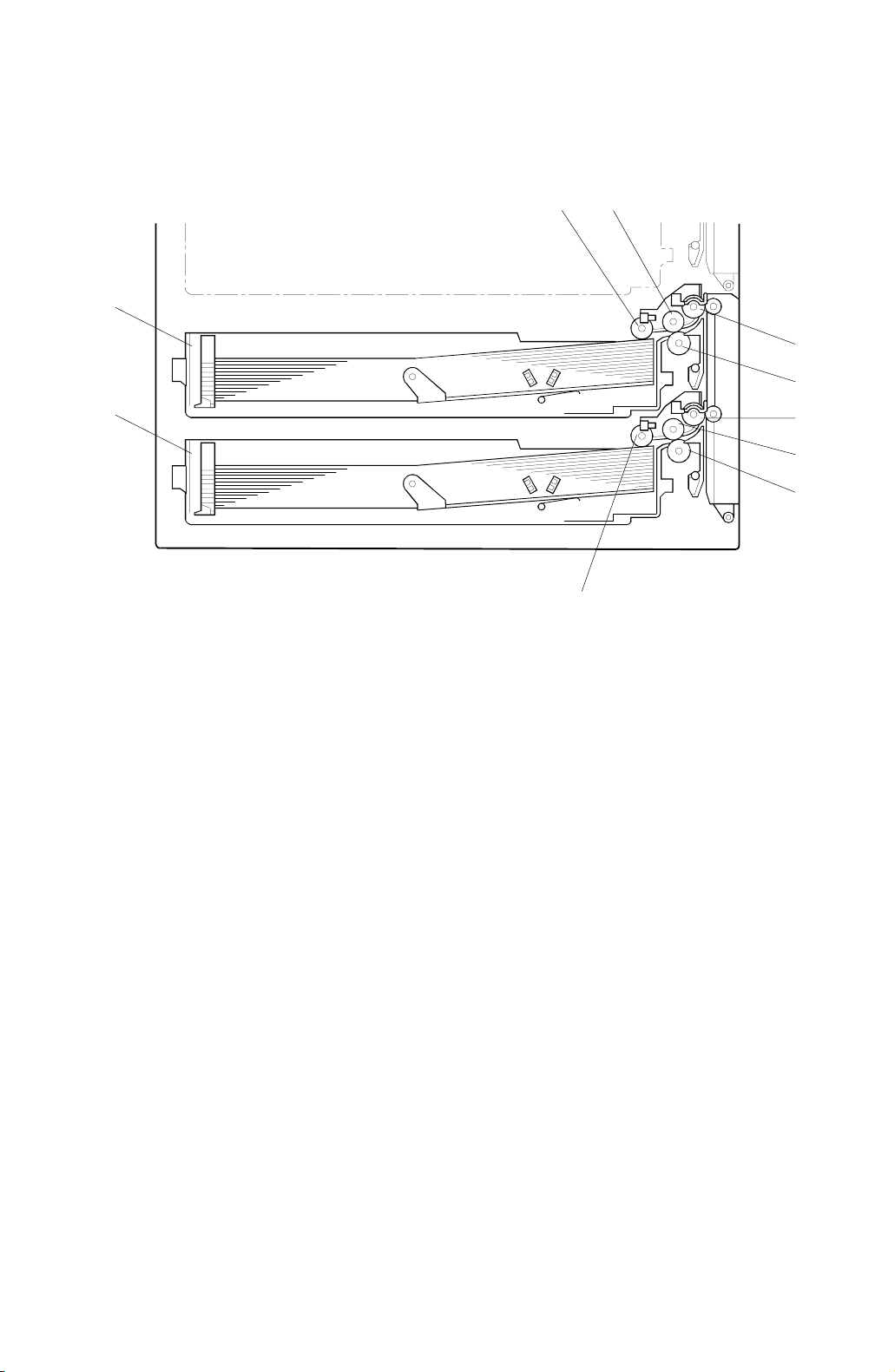

1.2 MECHANICAL COMPONENT LAYOUT

21

10

3

4

9

1. Upper pick-up roller

2. Upper paper feed roller

3. Upper relay roller

4. Upper separation roller

5. Lower relay roller

8

G520V500.WMF

6. Lower paper feed roller

7. Lower separation roller

8. Lower pick-up roller

9. Lower tray

10. Upper tray

5

6

7

G520-2

Page 4

30 July 1999 ELECTRICAL COMPONENT LAYOUT

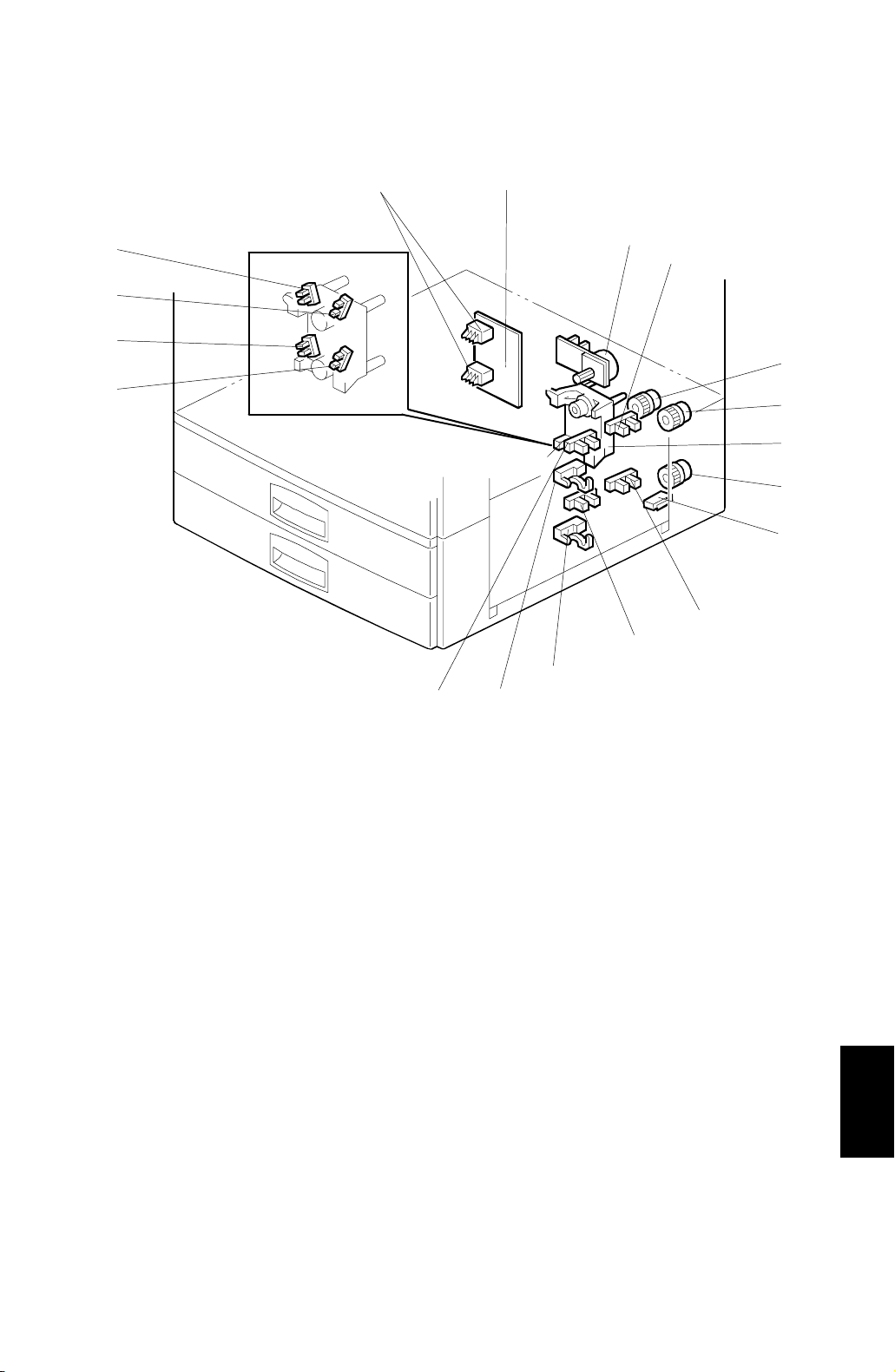

1.3 ELECTRICAL COMPONENT LAYOUT

17

16

15

14

18

13

1

2

3

4

5

6

7

8

9

10

11

12

1. Main board

2. Tray motor

3. Upper paper lift sensor

4. Relay clutch

5. Upper paper feed clutch

6. Tray lift motor

7. Lower paper feed clutch

8. Vertical guide switch

9. Lower paper lift sensor

G520V501.WMF

10. Lower paper end sensor

11. Lower relay sensor

12. Upper relay sensor

13. Upper paper end sensor

14. Lower paper height 2 sensor

15. Lower paper height 1 sensor

16. Upper paper height 2 sensor

17. Upper paper height 1 sensor

18. Tray paper size switch

Options

G520-3

Page 5

ELECTRICAL COMPONENT DESCRIPTION 30 July 1999

1.4 ELECTRICAL COMPONENT DESCRIPTION

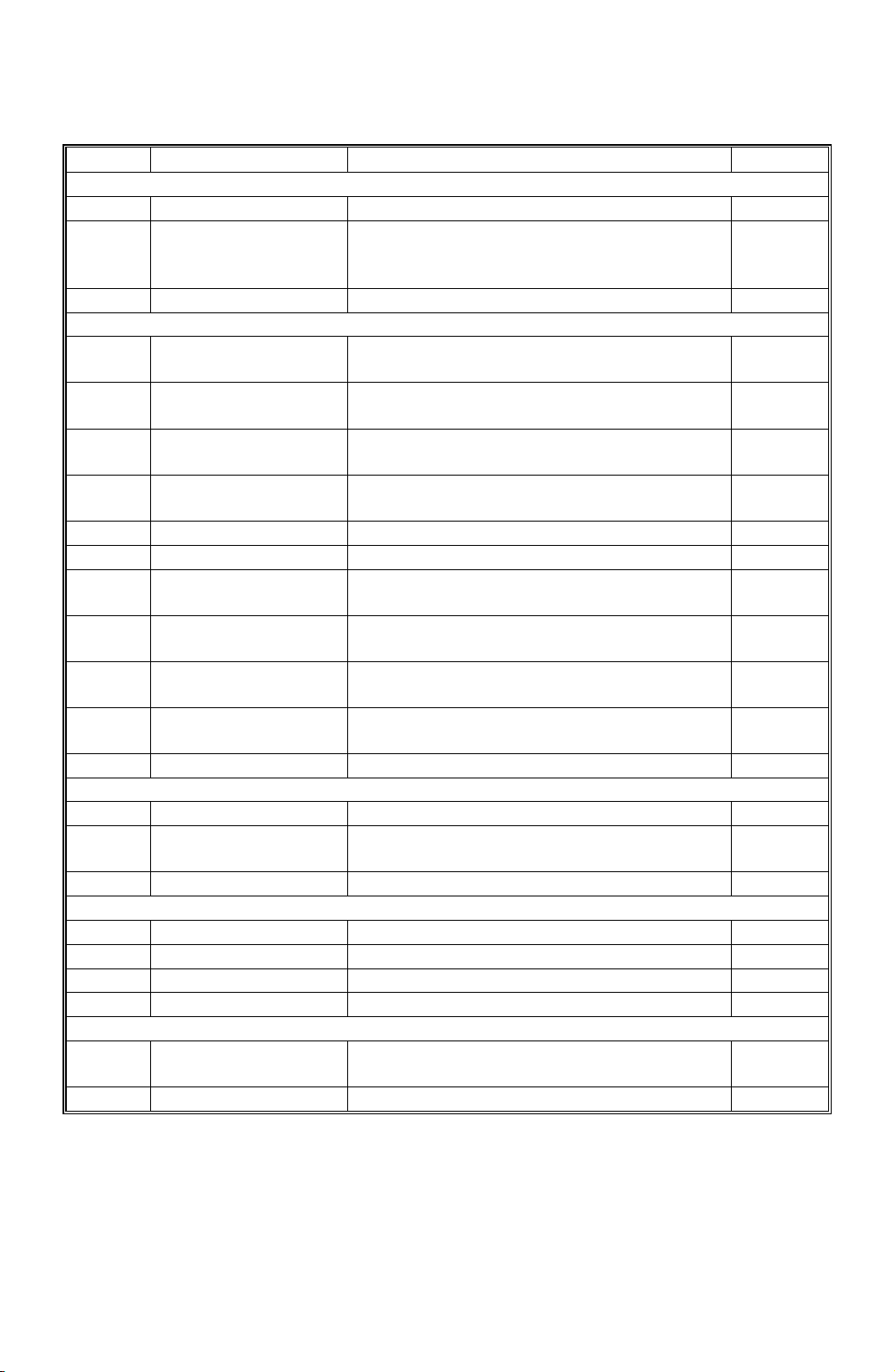

Symbol Name Function Index No.

Motors

M1 Tray Drives all rollers . 2

Tray Lift

M2

Sensors

S1

S2

S3

S4

S5 Upper Relay Detects misfeeds. 12

S6 Lower Relay Detects misfeeds. 11

S7

S8

S9

S10

Upper Paper Lift Detects when the paper in the upper tray is

Lower Paper Lift Detects when the paper in the lower tray is

Upper Paper End Inf orms the copier when the upper tray runs

Lower Paper End

Upper Paper Height 1 Detects the amount of paper in the upper

Upper Paper Height 2

Lower Paper Height 1 Detect s the amount of paper in the lower

Lower Paper Height 2 Detect s the amount of paper in the lower

Lifts the upper and lower tray bottom plates

(there are two motors in this unit, one for

each tray.

at the correct feed height.

at the correct feed height.

out of paper.

Informs the copier when the upper tray runs

out of paper.

tray.

Detects the amount of paper in the upper

tray.

tray.

tray.

6

3

9

13

10

17

16

15

14

Switches

SW1 Vertical Guide Detects whether the vertical guide is open. 8

SW2

Magnetic Clutches

MC1 Upper Paper Feed Starts paper feed from the upper tray. 5

MC2 Lower Paper Feed Starts paper feed from the lower tray. 7

MC3 Relay Drives the transport rollers. 4

PCBs

PCB1

Tray Paper Size Detects the paper size in the paper tray

based on a dial setting.

Main Controls the paper tray unit and

communicates with the copier.

18

1

G520-4

Page 6

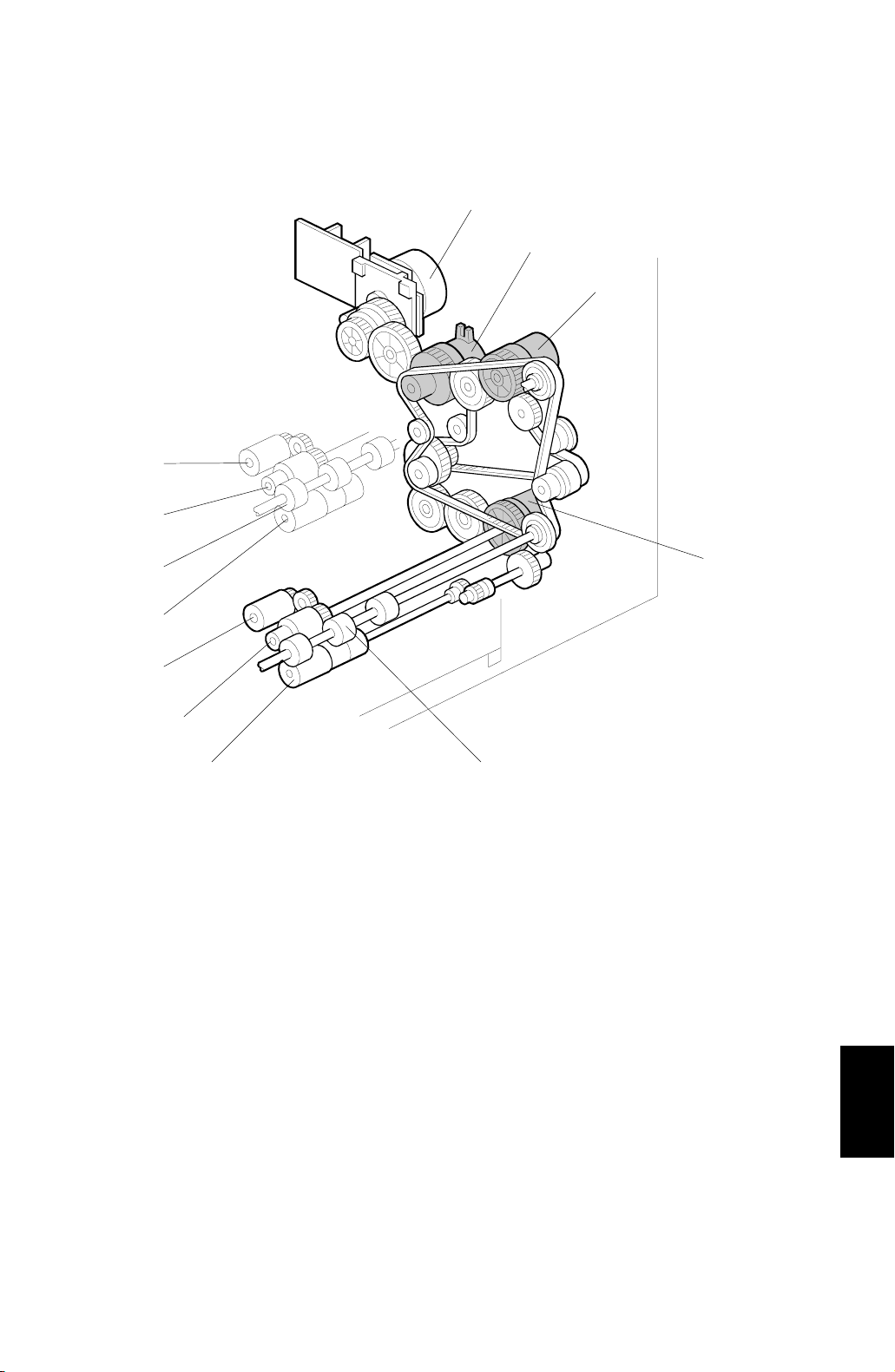

30 July 1999 DRIVE LAYOUT

1.5 DRIVE LAYOUT

1

2

3

12

11

10

9

8

7

1. Tray motor

2. Relay clutch

3. Upper paper feed clutch

4. Lower paper feed clutch

5. Lower relay roller

6. Lower separation roller

4

56

G520V502.WMF

7. Lower paper feed roller

8. Lower pick-up roller

9. Upper separation roller

10. Upper relay roller

11. Upper paper feed roller

12. Upper pick-up roller

G520-5

Options

Page 7

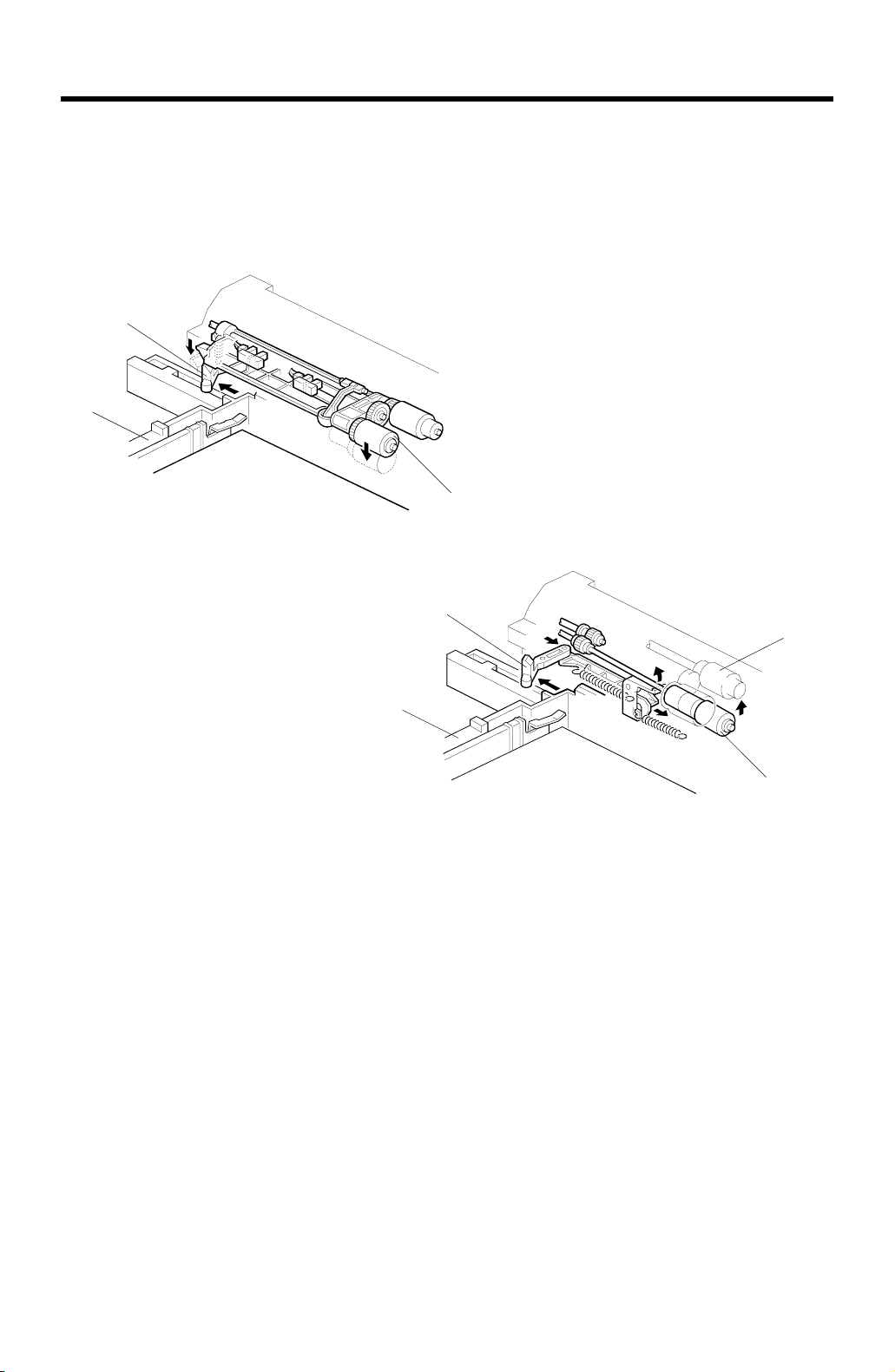

PICK-UP AND SEPARATION ROLLER RELEASE MECHANISM 30 July 1999

2. DETAILED DESCRIPTIONS

2.1 PICK-UP AND SEPARATION ROLLER RELEASE

MECHANISM

[E]

[A]

[D]

G520500.WMF

[E]

[C]

[A]

[B]

G520D501.WMF

When the paper tray [A] is not inside the paper tr ay unit, the separation roller [B] is

shifted away from the paper feed roller [C], and the pick-up roller [D] stays in the

upper position.

When the pa per tray is put into the paper tray unit, it pushes the release lever [E].

This causes the pick-up roller to move down (top diagram) and the separation roller

to move into contact with the paper feed roller (bottom diagram).

G520-6

Page 8

30 July 1999 PAPER LIFT MECHANISM

2.2 PAPER LIFT MECHANISM

[B]

[H]

[F]

[G]

[E]

[D]

[A]

[C]

G520D502.WMF

The paper size switch [A] detects when the paper tray [B] is placed in the machine.

When the machine detects that the paper tray is in the m achine, the tray lift motor

[C] rotates and the coupling gear [D] on the tray lift motor engages the pin [E] on

the lift arm shaft [F]. Then the tray lift arm [G] lifts the tray bottom plate [H].

Options

G520-7

Page 9

PAPER LIFT MECHANISM 30 July 1999

[C]

[B]

[A]

G520D504.WMF

When the paper tray is placed in the machine, the pick-up roller [A] lowers. When

the top sheet of paper reaches the proper height for paper feed, the paper pushes

up the pick-up roller, and the actuator [B] on the pick-up roller supporter activates

the paper lift sensor [C] to stop the tray lift motor.

After several paper feed cycles, the paper level gradually lowers and the paper lift

sensor is deactivated. The tray lift motor turns on again until this sensor is activated

again.

When the tr ay is drawn out of the machine, the tray lift motor coupling gear

disengages the pin on the lift arm shaft, and the tray bottom plate then drops under

its own weight.

G520-8

Page 10

30 July 1999 PAPER END DETECTION

2.3 PAPER END DETECTION

[B]

[A]

[D]

[C]

G520D503.WMF

If there is some paper in the paper tray, the paper stack raises the paper end feeler

[A] and the paper end sensor [B] is deactivated.

When the paper tray runs out of paper, the paper end feeler drops into the cutout

[C] in the tray bottom plate and the paper end sensor is activated.

When the paper tray is drawn out, the pick-up roller supporter [D] lifts up the paper

end feeler.

G520-9

Options

Page 11

PAPER HEIGHT DETECTION 30 July 1999

2.4 PAPER HEIGHT DETECTION

The amount of paper in the tray is

detected by the combination of two

paper height sensors [A] and [B].

When the am ount of paper decreases ,

the bottom plate pressure lever [C]

moves up and the actuator [D], which

is mounted on the same drive shaft as

the pressure lever, rotates.

The following combination of sensor

signals is sent to the copier.

Amount of

Paper

Full OFF ON

Near Full ON ON

Near End 1 ON OFF

Near End 2 OFF OFF

Paper Height

Sensor [A]

Paper Height

Sensor [B]

[D]

[A]

[B]

Full

3511333435

[C]

3511333435

Near Full

Near End 1

3511333435

Near End 2

3511333436

G520D505.WMF

G520-10

Page 12

30 July 1999 PAPER SIZE DETECTION

2.5 PAPER SIZE DETECTION

The paper size switch includes four sensors (microswitches). Actuators behind the

paper size dial actuate the sensors.

Each paper size has its own actuator, with a unique combination of notches. To

determine the paper size, the CPU reads which switches the actuator has turned

off.

The CPU disables paper feed from a tray if the paper size cannot be detected. If

the paper size actuator is broken, or if there is no tray installed, the printer control

board recognizes that the paper tray is not installed.

When the paper size actuator is at the “[” mark, the paper tray can be set up to

accommodate one of a wider range of paper sizes by using one of the user tools

on the machine’s operation pan el .

Models Switch Location

North America Europe 1 2 3 4

8

" x 13" Portrait A3 Portrait ON ON OFF ON

1/2

A4 Landscape A4 Landscape ON ON ON ON

A4 Portrait A4 Portrait ON OFF ON ON

11" x 17" Portrait A5 Portrait OFF OFF ON ON

8

" x 14" Portrait 8" x 13" Portrait ON OFF OFF OFF

1/2

8

" x 11" Portrait 8

1/2

8

" x 11" Landscape 8

1/2

[[

" x 11" Portrait ON ON OFF OFF

1/2

" x 11" Landscape O N OFF ON OFF

1/2

ON ON ON OFF

ON: Pushed OFF: Not Pushed

Options

G520-11

Page 13

DIP SWITCHES 30 July 1999

3. SERVICE TABLES

3.1 DIP SWITCHES

DPS101

12345678

00000000Default

00000001Free run, feed from upper tray

00000011Free run, feed from lower tray

00000101Free run, feed from upper and lower trays alternately

NOTE:

1) Do not use any other settings.

2) To do the free run, proceed as follows:

a) Remove the paper from the tray (this is because the machine has no

jam detection).

b) Set DPS101 for the required free run as shown above.

c) Turn the main power switch off, wait a few seconds, and then switch

it on.

d) Press SW101 to start the free run.

e) To stop the free run, press SW102.

Description

3.2 TEST POINTS

No. Label Monitored Signal

TP100 (24 V) +24 V

TP101 (GND) Ground

TP103 (TXD) TXD to the copier

TP104 (RXD) RXD from the copier

TP105 (5 V) +5 V

TP106 (GND) Ground

3.3 SWITCHES

No. Function

SW101 Starts the free run

SW102 Stops the free run

3.4 FUSES

No. Function

FU101 Protects the 24 V line.

G520-12

Page 14

30 July 1999 COVER REPLACEMENT

4. REPLACEMENT AND ADJUSTMENT

4.1 COVER REPLACEMENT

[B]

[A]

Right Cover

1. Remove the right cover [A] (2 screws).

Rear Cover

1. Remove the rear cover [B] (2 screws).

G520R500.WMF

G520-13

Options

Page 15

ROLLER REPLACEMENT 30 July 1999

4.2 ROLLER REPLACEMENT

4.2.1 PAPER FEED, SEPARATION, AND PICK-UP ROLLERS

[B]

[A]

[C]

G520R501.WMF

1. Remove the paper tray.

Pick-up Roller

2. Replace the pick-up roller [A].

Paper Feed Roller

2. Replace the paper feed roller [B] (1 snap ring).

Separation Roller

2. Replace the separation roller [C].

G520-14

Page 16

30 July 1999 TRAY MOTOR REPLACEMENT

4.3 TRAY MOTOR REPLACEMENT

[A]

1. Remove the rear cover.

2. Remove the tray motor [A] (1 connector, 3 screws).

G520R502.WMF

G520-15

Options

Page 17

PAPER FEED AND RELAY CLUTCH REPLACEMENT 30 July 1999

4.4 PAPER FEED AND RELAY CLUTCH REPLACEMENT

[F]

[F]

[B]

[D]

[C]

[A]

G520R503.WMF

1. Remove the rear cover.

2. Remove the upper paper feed clutch holder [A] (2 screws).

3. Remove the lower paper feed clutch holder [B] (2 screws).

4. Remove the gear holder [C] (3 screws, 1 spring, 1 bearing).

5. Replace the relay clutch [D] (1 connector).

6. Replace the upper feed clutch [E] (1 bushing, 1 connector).

7. Replace the lower feed clutch [F] (1 connector).

G520-16

Page 18

30 July 1999 PAPER FEED UNIT REPLACEMENT

4.5 PAPER FEED UNIT REPLACEMENT

[C]

[A]

G520R504.WMF

[D]

1. Remove the rear cover.

2. Remove the upper and lower paper feed clutch holder.

3. Remove the gear holder.

4. Remove the upper feed clutch [A] or lower feed clutch [B].

[B]

G520R505.WMF

5. Remove the upper or lower gear [C, D].

G520-17

Options

Page 19

PAPER FEED UNIT REPLACEMENT 30 July 1999

[A]

[B]

[C]

G520R506.WMF

[D]

G520R507.WMF

Upper Paper Feed Unit

6. Remove the docking bracket [A] (1 screw).

7. Remove the vertical transport cover [B] of the copier (1 snap ring).

[F]

[E]

8. Remove the upper paper feed unit [C] (2 screws, 1 connector).

Lower Paper Feed Unit

6. Remove the docking bracket [D] (1 screw).

7. Remove the vertical transport guide [E] (2 screws).

8. Remove the lower paper feed unit [F] (2 screws, 1 connector).

G520-18

Page 20

30 July 1999 PAPER END, TRAY LIFT, AND RELAY SENSOR REPLACEMENT

4.6 PAPER END, TRAY LIFT, AND RELAY SENSOR

REPLACEMENT

[C]

[B]

1. Remove the paper feed unit.

[A]

[D]

G520R508.WMF

Paper End Sensor

2. Replace the paper end sensor [A] (1 connector).

Tray Lift Sensor

2. Replace the paper lift sensor [B] (1 connector).

Relay Sensor

2. Remove the sensor bracket [C] (1 screw).

3. Replace the relay sensor [D] (1 connector).

G520-19

Options

Page 21

1

PCB1

1

Main

B6

2

3 4 5 6 7 8 9 10 11

A

POINT TO POINT DIAGRAM (PAPER TRAY UNIT: G520)

-A1

CN101-3

CN101-3

CN101-3

CN101-3

CN101

CN101

CN107

CN107

CN107-B1

CN107-B4

CN107-A7

-A10

-A11

CN107-B7

-B10

-B11

CN103-1

B

Paper End

C

D

E

Sensor

Paper End

Sensor

F

Sensor

G

Upper Paper

Height 1

Sensor

H

Upper Paper

Height 2

Sensor

Lower Paper

I

Height 1

Sensor

Lower Paper

J

Height 2

Sensor

Upper Tray

K

Paper Size

Switch

L

Lower Tray

Paper Size

Switch

M

Upper

Lift

Sensor

Upper

Sensor

Upper

Relay

Sensor

Lower

Lift

Lower

Lower

Relay

S1

S3

S5

S2

S4

S6

S7

S8

S9

S10

SW2

SW3

-2

-1

-2

-1

-2

-1

-2

-1

-3

-2

-1

-3

-2

-1

-3

-2

-1

-3

-2

-1

-3

-2

-1

-3

-2

-1

Vertical

Guide

Switch

N

1 2 3 4 5 6 7 8 9 10 11

SW1

[0] GND2

-A2

[t5] Upper Lift Sensor

-A3

[5] 5V

-A4

[0] GND2

-A5

[t5] Upper Paper End Sensor

-A6

[5] 5V

-A7

[0] GND2

-A8

[s5] Upper Relay Sensor

-A9

[5] 5V

-B1

[0] GND2

-B2

[t5] Lower Lift Sensor

-B3

[5] 5V

-B4

[0] GND2

-B5

[t5] Lower Paper End Sensor

-B6

[5] 5V

-B7

[0] GND2

-B8

[s5] Lower Relay Sensor

-B9

[5] 5V

-A1

[0] GND2

-A2

[s5]

-A3

[5] 5V

-A4

[0] GND2

-A5

[s5]

-A6

[5] 5V

[0] GND2

-B2

[s5]

-B3

[5] 5V

[0] GND2

-B5

-B6

-A8

-A9

-B8

-B9

-2

-4

Lower Paper

[s5]

Height 1 Sensor

[5] 5V

[s5] Size Upper4

[s5] Size Upper3

[0] GND2

[s5] Size Upper2

[s5] Size Upper1

[s5] Size Upper4

[s5] Size Upper3

[0] GND2

[s5] Size Upper2

[s5] Size Upper1

[24] 24V

[t24] Vertical Guide Switch

[s24] 24V

Main Board (PCB1)

Upper Paper

Height 2 Sensor

Upper Paper

Height 1 Sensor

Lower Paper

Height 2 Sensor

GND2 [0]

TXD

GND2 [0]

RXD

GND2 [0]

5V [5]

GND1 [0]

GND1 [0]

GND1 [0]

24V [24]

24V [24]

24V [24]

GND1 [0]

GND1 [0]

GND1 [0]

GND 1[0]

24V [24]

24V [24]

24V [24]

24V [24]

GND2 [0]

5V [5]

FG

CLOCK

CW[t5]/CCW [s5]

ON/OFF [t5]

Lower Tray: -

Lower Tray: +

Upper Tray: -

Upper Tray: +

Lower Paper

Feed Cl.

Upper Paper

Feed Cl.

Relay Clutch [t24]

[t24]

[t24]

[t24]

[t24]

24V [24]

[t24]

24V [24]

[t24]

24V [24]

LD

CN109-A1

-A2

-A3

-A4

-A5

-A6

-B1

-B2

-B3

-B4

-B5

-B6

CN102-1

-10

-11

-12

-13

-14

-15

CN104-1

CN104-5

-6

CN104-7

-8

CN104-9

-10

-15

-2

-3

-4

-5

-6

-7

-8

-9

-2

-3

-4

s

t

[ ]

-14

-13

-12

-11

-10

-9

-8

M1

-7

-6

-5

-4

-3

-2

-1

-4

-3

-2

SYMBOL TABLE

DC Line

Pulse Signal

Signal Direction

Active High

Active Low

Voltage

M2

-1

-2

MC

-1

-2

MC

-1

-2

MC

-1

2

1

3

Printer

Tray

Motor

Tray Lift

Motor

Lower Paper

Feed Clutch

Upper Paper

Feed Clutch

Relay

Clutch

A

B

PAPER TRAY UNIT (G520) ELECTRICAL COMPONENT LAYOUT

18

19

1

2 3

C

17

16

D

15

4

14

5

E

6

7

F

8

9

G

10

11

13

H

Index

Symbol

Motors

I

M1 2 Tray G10

M2 6 Tray Lift J10

Sensors

S1 3 Upper Paper Lift B2

S2 9 Lower Paper Lift E2

J

S3 13 Upper Paper End C2

S4 10 Lower Paper End F2

S5 12 Upper Relay D2

S6 11 Lower Relay F2

K

S7 15 Upper Paper Height 1 G2

S8 14 Upper Paper Height 2 H2

S9 17 Lower Paper Height 1 I2

S10 16 Lower Paper Height 2 J2

Switches

L

SW1 8 Vertical Guide N2

SW2 19 Upper Tray Paper Size K2

SW3 18 Lower Tray Paper Size L2

Magnetic Clutches

M

MC1 5 Upper Paper Feed K10

MC2 7 Lower Paper Feed K10

MC3 4 Relay L10

PCB

N

No. Description P to P

12

Loading...

Loading...