Ricoh ps420 SPECIFICATIONS

LCT

(Machine Code: A862)

20 September 1999 SPECIFICATIONS

1. OVERALL MACHINE INFORMATION

1.1 SPECIFICATIONS

Paper Size

Paper Weight: 60 g/m2 ~ 105 g/m2, 16 lb ~ 28 lb

Tray Capacity: 2,000 sheets (80 g/m2, 20lb)

Remaining Paper Detection: 5 steps (100%, 75%, 50%, 25%, Near end)

Power Source: 24 Vdc, 5 Vdc (from copier)

Power Consumption: 26 W (Max.)/14 W (Ave.)

Weight: 25 kg (55 lbs)

Size (W x D x H): 550 mm x 520 mm x 271 mm

:

A4 sideways/LT sideways

A862-1

Options

MECHANICAL COMPONENT LAYOUT 20 September 1999

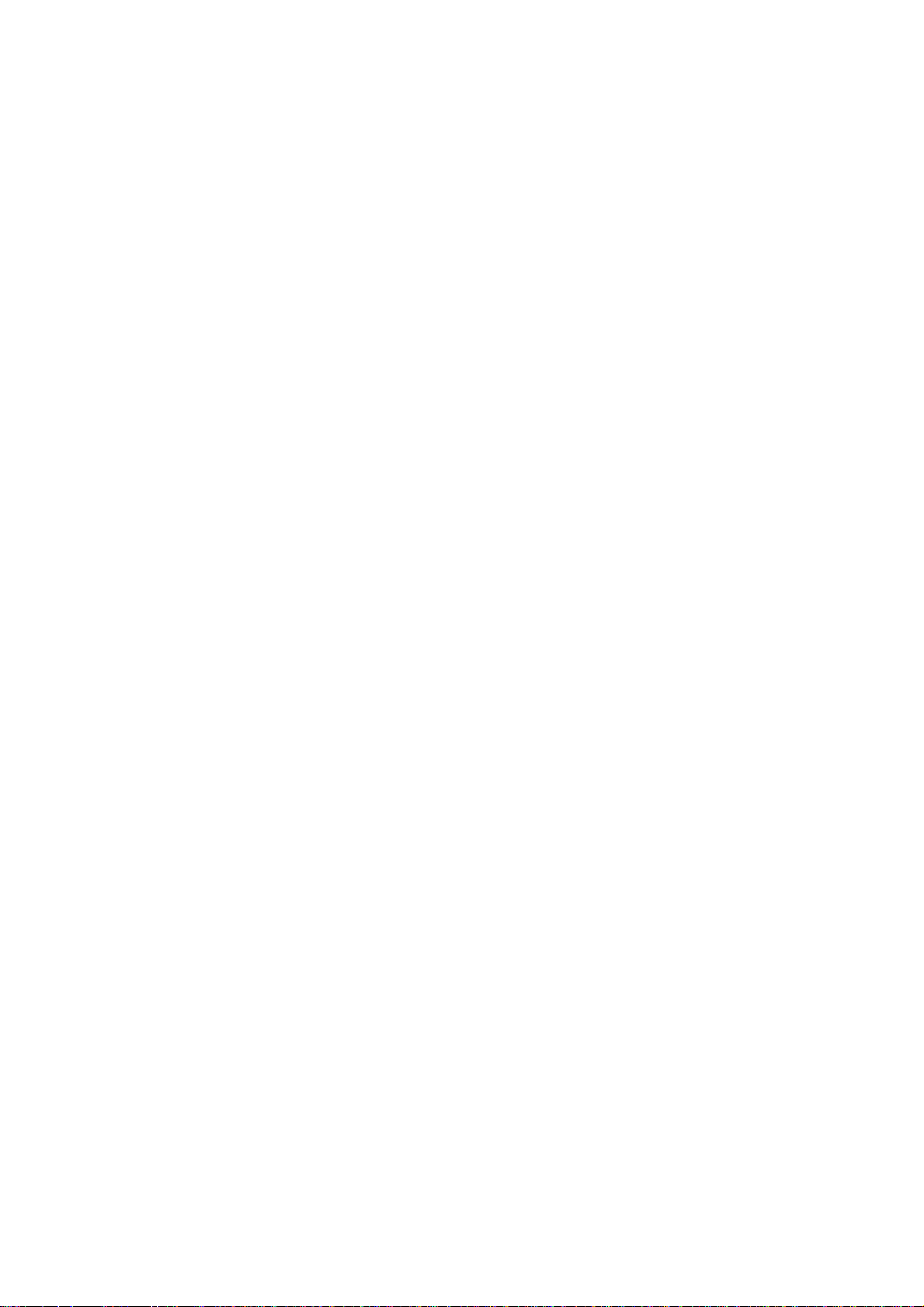

1.2 MECHANICAL COMPONENT LAYOUT

1. Pick-up Roller

10

2143

5

6

7

89

A862D101.WMF

7. Paper Height Sensors 1, 2, 3

2. Upper Limit Sensor

3. Paper Feed Roller

4. Relay Sensor

5. Relay Roller

6. Reverse Roller

8. Lower Limit Sensor

9. Left Paper End Sensor

10. Paper Height Sensors 4,5

A862-2

20 September 1999 ELECTRICAL COMPONENT LAYOUT

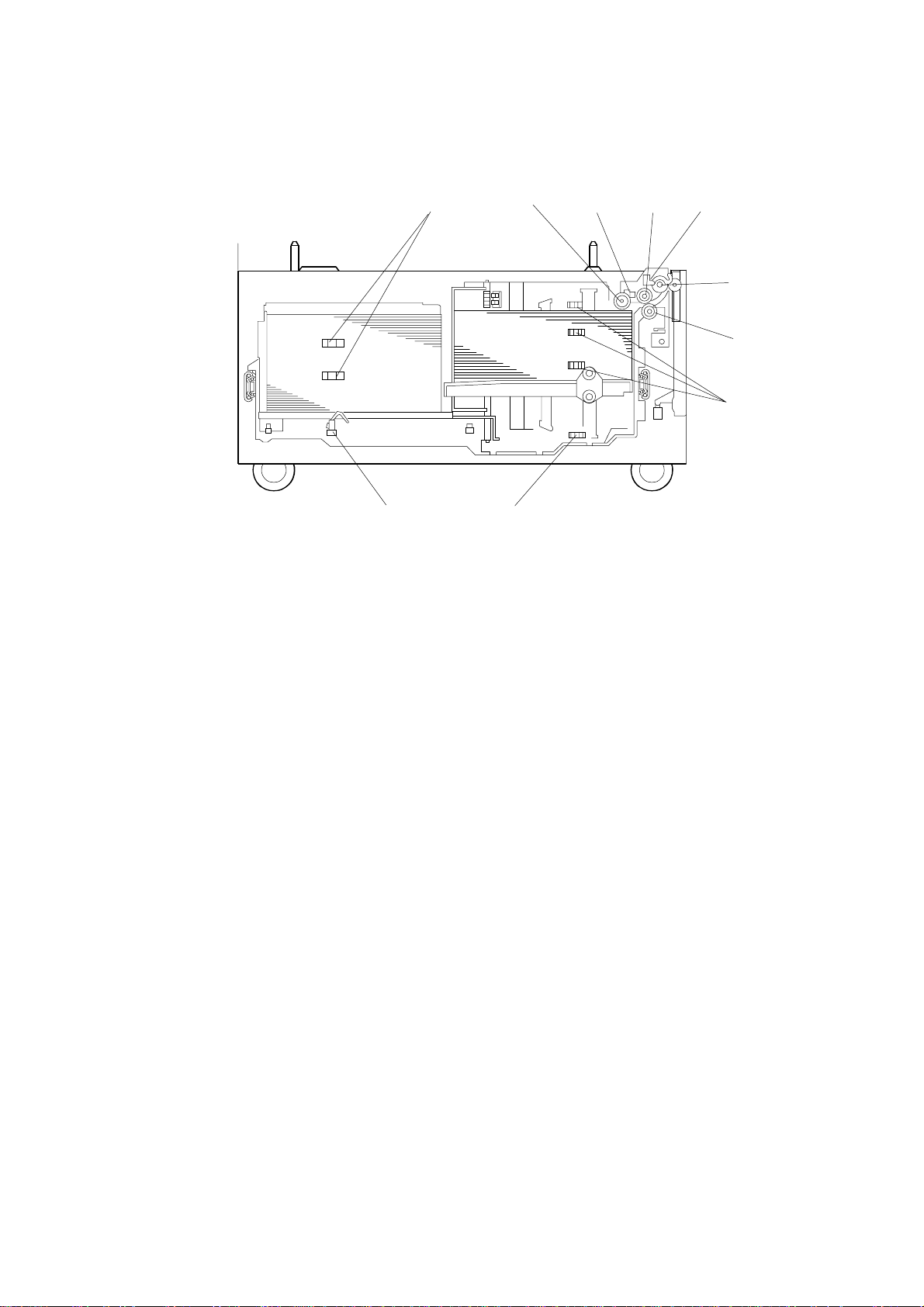

1.3 ELECTRICAL COMPONENT LAYOUT

1

2

3

4

5

7

A862D102.WMF

1. Main Board

2. Tray Sensor

17

16

6

89

20

19

18

14

A862D103.WMF

15

11. Side Fence Open/Closed Sensors

12. Paper Height Sensors 1, 2, 3

10

11

12

13

3. Relay Clutch

4. Paper Feed Clutch

5. Tray Motor

6. Tray Lift Motor

7. Tray Heater (option)

8. Right Tray Paper End Sensor

9. Upper Limit Sensor

10. Relay Sensor

A862-3

13. Lower Limit Sensor

14. Side Fence Solenoid

15. Rear Fence Return Sensor

16. Rear Fence Motor

17. Rear Fence Home Position

Sensor

18. Left Tray Paper End Sensor

19. Paper Height Sensors 4, 5

20. Right Cover Switch

Options

ELECTRICAL COMPONENT DESCRIPTIONS 20 September 1999

1.4 ELECTRICAL COMPONENT DESCRIPTIONS

Symbol Name Function Index No.

Motors

M1 Tray Motor Drives all rollers. 5

M2 Tray Lift Motor Drives the paper tray up or down. 6

Rear Fence

M3

Sensors

S1

S2

S3

S4

S5

S6

S7

S8 Tray Detects whether the tray is correctly set. 2

S9

S10

S11

Solenoids

SOL1

Magnetic Clutches

MC1 Paper Feed Drives the paper feed roller. 4

MC2 Relay Drives the relay roller. 3

PCBs

PCB1

Switches

SW1 Right Cover Detects whether the right cover is open. 20

Motor

Right Tray

Paper End

Relay

Upper Limit Detects when the paper is at the correct

Lower Limit Detects when the tray is completely lowered,

Paper Height

1, 2, 3

Paper Height

4, 5

Rear Fence

Home Position

Side Fence

Open/Closed

Rear Fence

Return

Left Tray

Paper End

Side Fence

Main Controls the LCT and communicates with the

Moves the rear fence to transfer the paper

stack from the paper storage (left) side of the

tray to the paper feed (right) side.

Informs the copier when the paper in the right

side (paper feed side) of the tray has been

used up. If there is a paper stack in the left

side (paper storage side), this is moved into

the right tray. If there is no paper stack in the

left side, paper end is indicated.

Detects the copy paper coming to the relay

roller and checks for misfeeds.

paper feed height.

to stop the LCT motor.

Detects the amount of paper remaining in the

right side of the tray.

Detects the amount of paper remaining in the

left side of the tray.

Detects when the rear fence is at H.P.

Detects whether the side fence is opened on

closed.

Detects when the rear fence has moved the

paper stack from the left side to the right side.

Informs the copier when there is no paper in

the left side (paper storage side) of the tray.

Controls open-close movement of the side

fence.

copier.

16

8

10

9

13

12

19

17

11

15

18

14

1

A862-4

20 September 1999 PAPER FEED

2. DETAILED SECTION DESCRIPTIONS

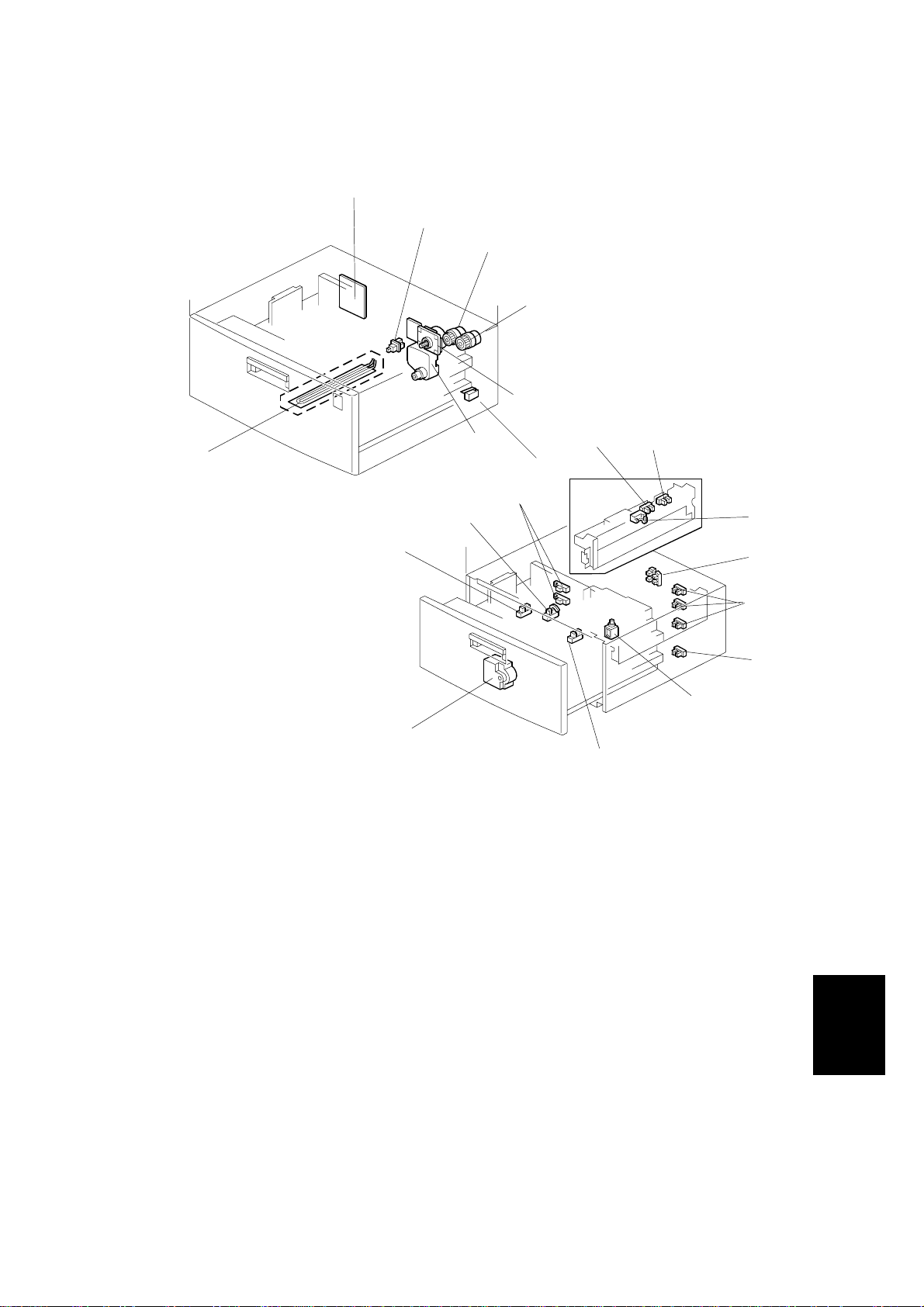

2.1 PAPER FEED

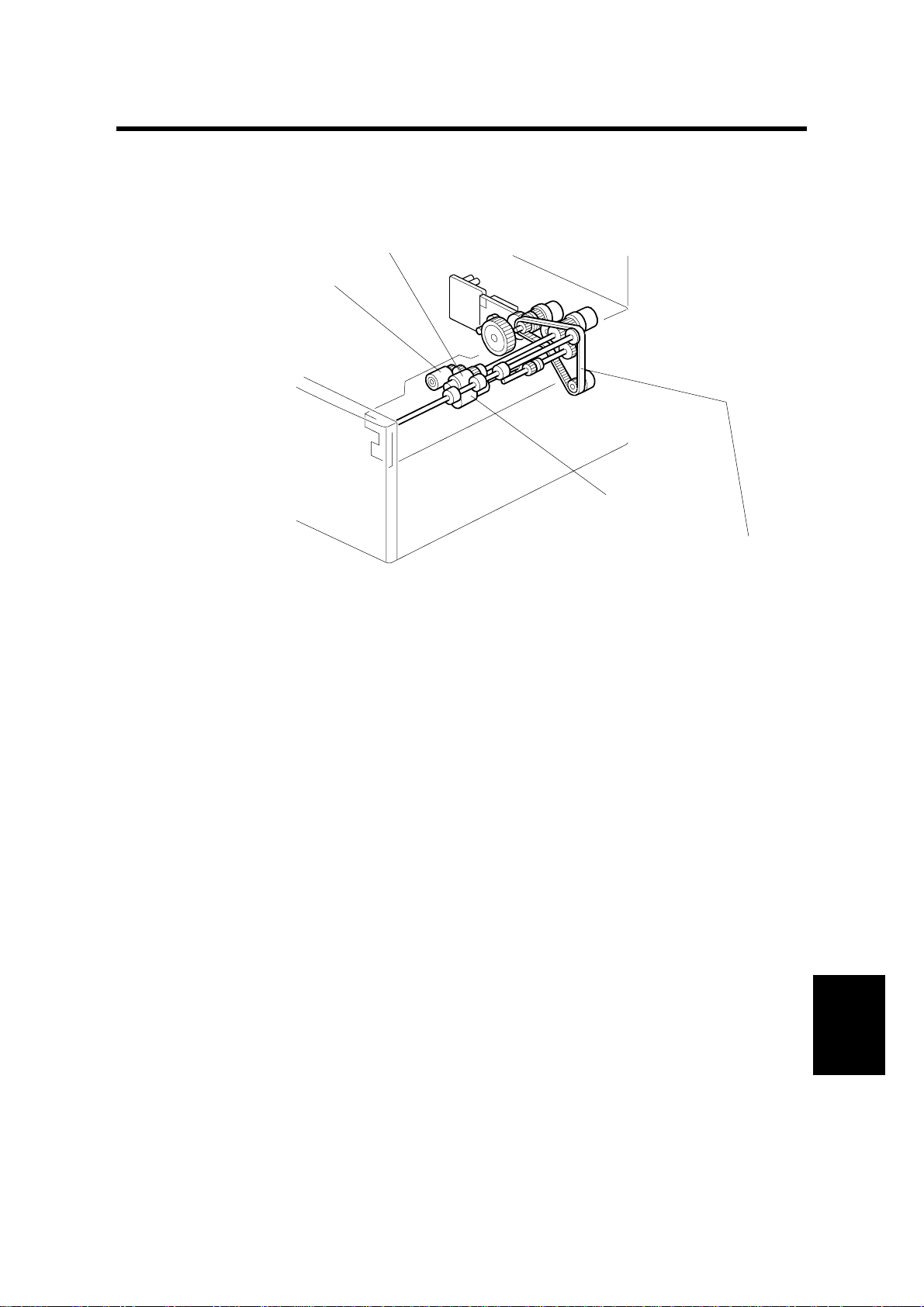

[B]

[A]

[C]

A862D104.WMF

This products uses an FRR type paper feed mechanism.

The paper feed unit consists of the pickup roller [A], paper feed roller [B], reverse

roller [C], and grip and transport rollers.

There is a torque limiter in the back of the reverse roller (ferrite powder type).

A862-5

Options

REVERSE ROLLER AND PICK-UP ROLLER RELEASE 20 September 1999

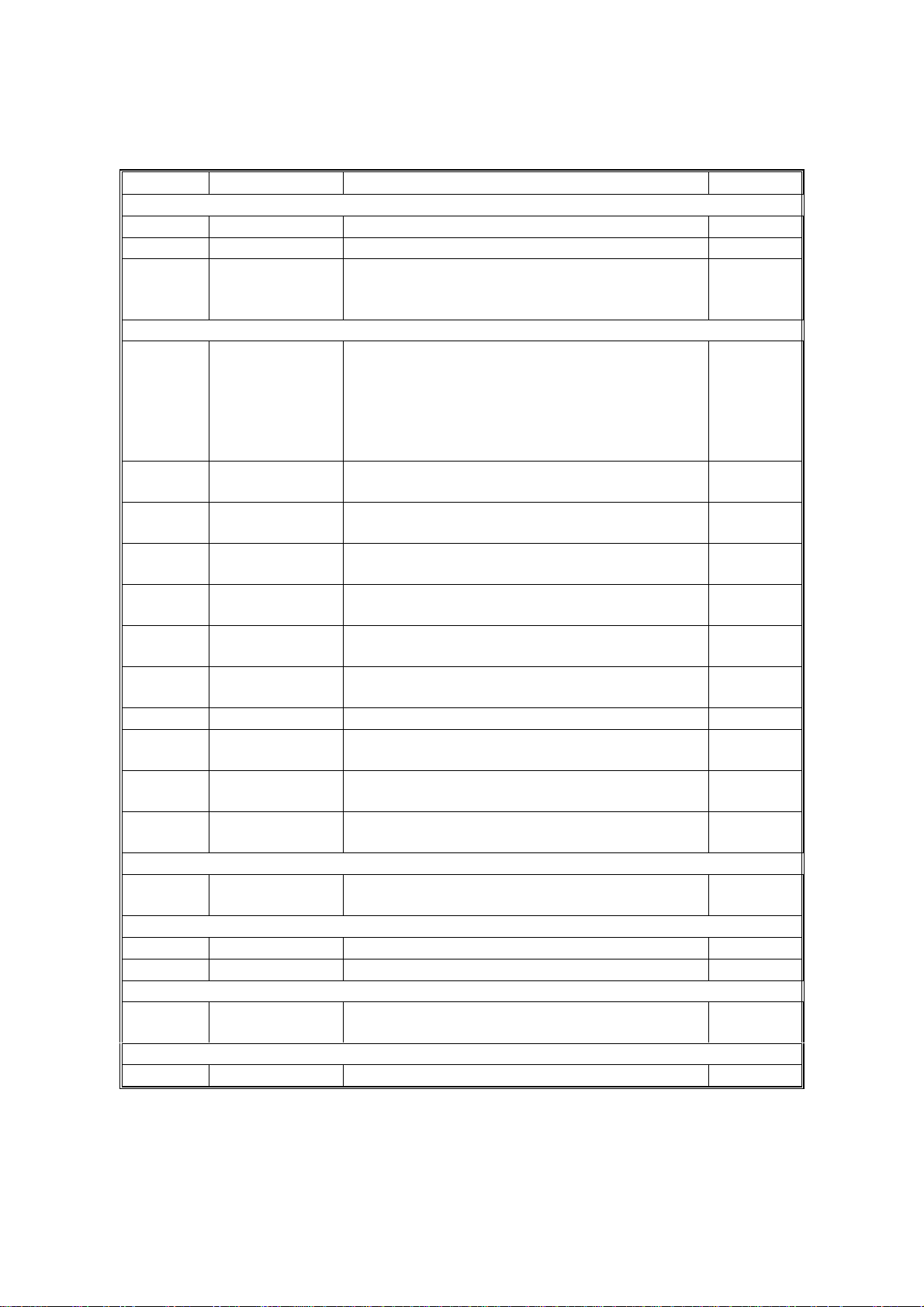

2.2 REVERSE ROLLER AND PICK-UP ROLLER RELEASE

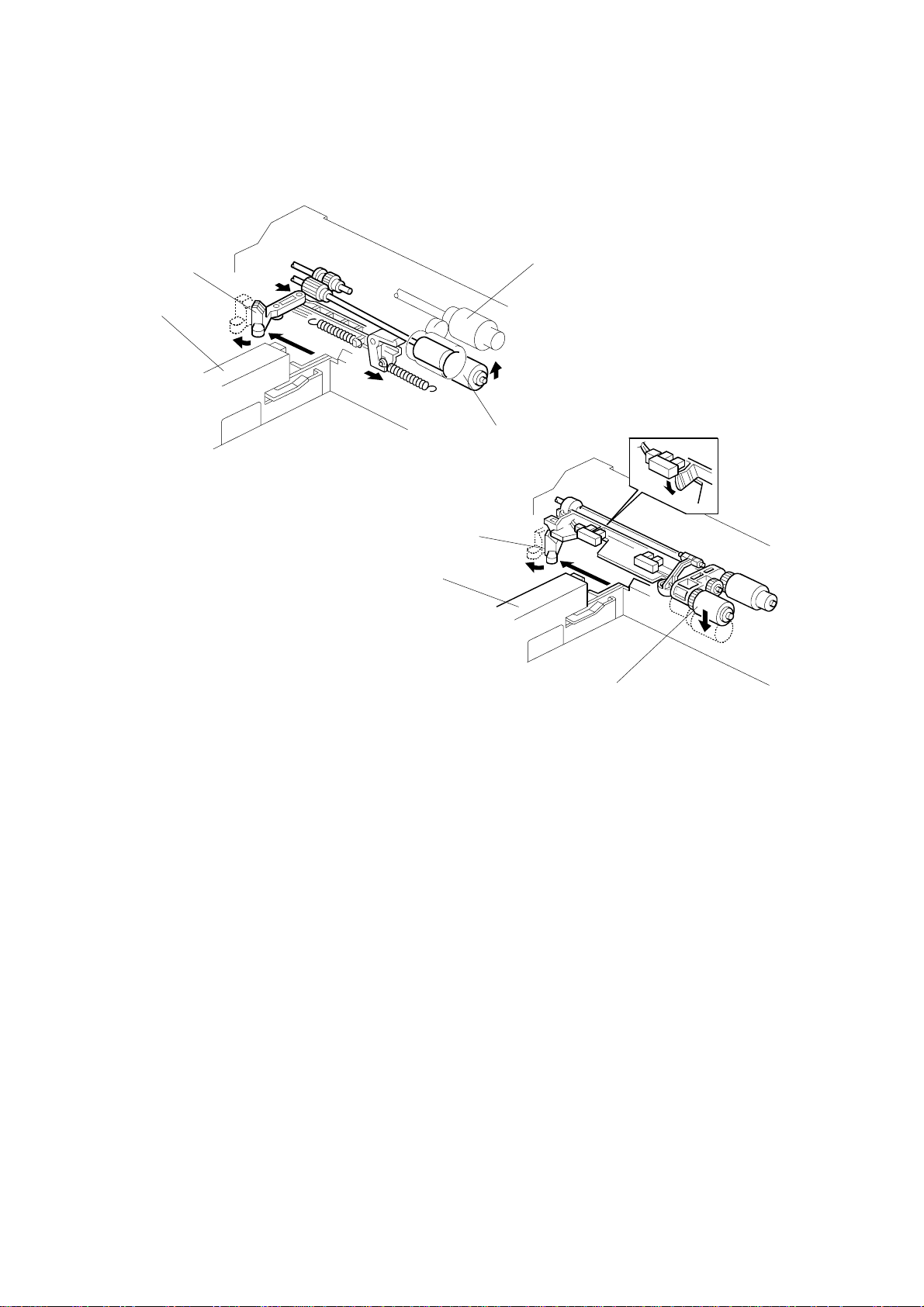

[A]

[E]

[C]

[B]

A862D107.WMF

[E]

[A]

[D]

A862D108.WMF

To prevent the paper from being torn when pulling out the paper feed tray, the

reverse and pickup rollers are set so that they release automatically.

When the paper tray [A] is not inside the machine, the revers e roller [B] is away

from the paper feed roller [C] and the pick-up roller [D] stays in the upper position.

When the pa per tray is set into the m achine, it pushes the release lever [E]. This

causes the pick-up roller [D] to go down into contact with the top sheet of paper

and the reverse roller [B] to move up and contact the paper feed roller.

A862-6

Loading...

Loading...