Page 1

PAPER TRAY UNIT

(Machine Code: A861)

Page 2

17 May, 1999 SPECIFICATIONS

1. OVERALL MACHINE INFORMATION

1.1 SPECIFICATIONS

Paper Size

Paper Weight: 60 ~ 105 g/m2, 16 ~ 28 lbs.

Tray Capacity: 500 sheets (80 g/m2, 20 lbs. ) x 1 tray

Paper Feed System: Feed roller and friction pad

Paper Height Detection: 4 steps (100%, 70%, 30%, Near end)

Power Source: 24 VDC and 5VDC (from the copier):

Power Consumption: Max:20 W (Copying)

Weight: 12 kg (26.4 lbs)

:

A5 to A3

HLT lengthwise to DLT

120 Vac:

120 V version, from the copier when the optional

tray heater is installed

220 ~ 240 Vac:

230 V version, from the copier when the optional

tray heater is installed

23 W (Optional Tray Heater On)

Average:13 W (Copying)

15 W (Optional Tray Heater On)

Size (W x D x H): 550 mm x 520 mm x 134 mm

Options

A861-1

Page 3

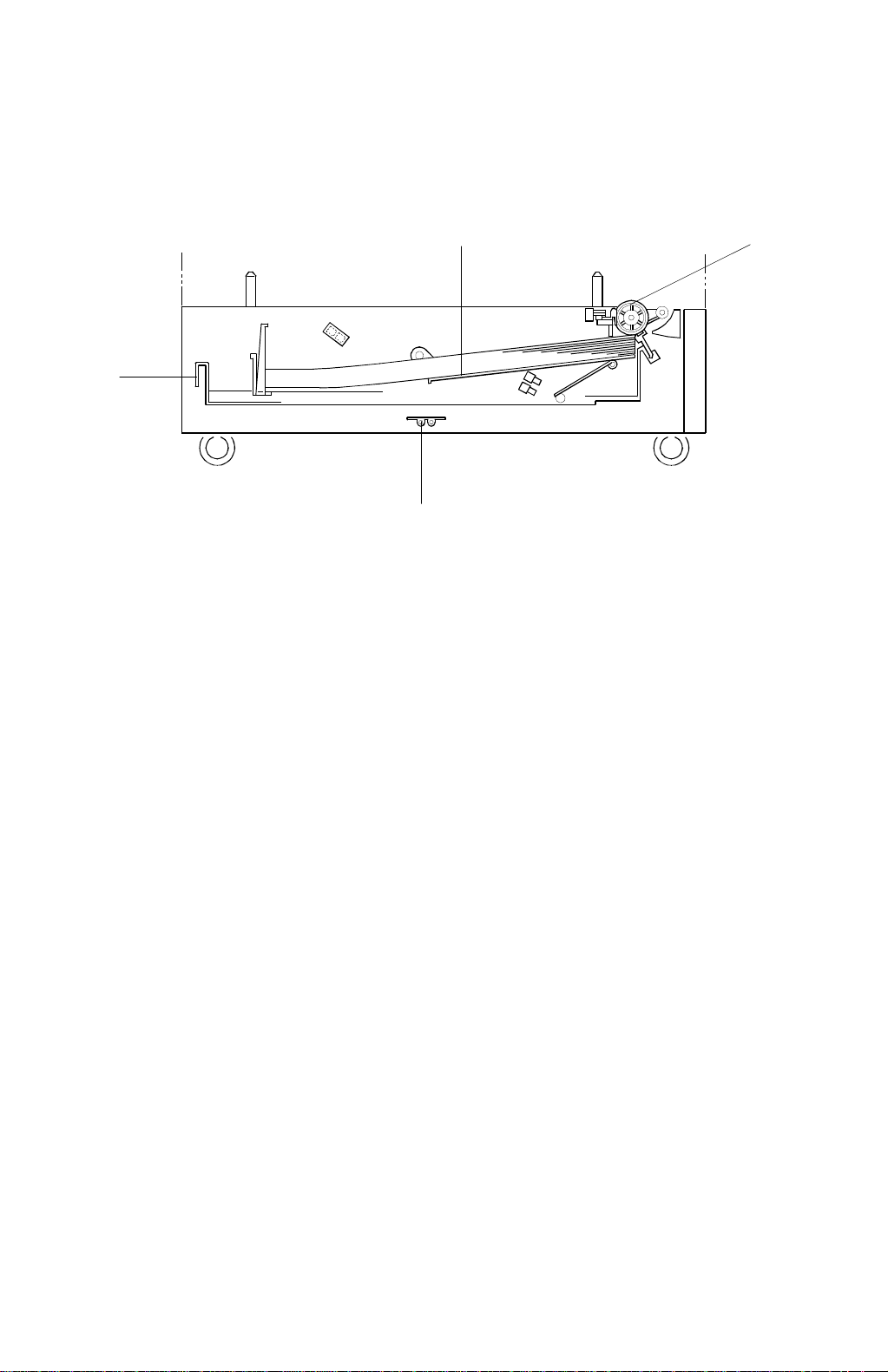

MECHANICAL COMPONENT LAYOUT 17 May, 1999

1.2 MECHANICAL COMPONENT LAYOUT

2

1. Paper Feed Roller

2. Tray

3

4

A861V101.WMF

1

3. Bottom Plate

4. Optional Tray Heater

A861-2

Page 4

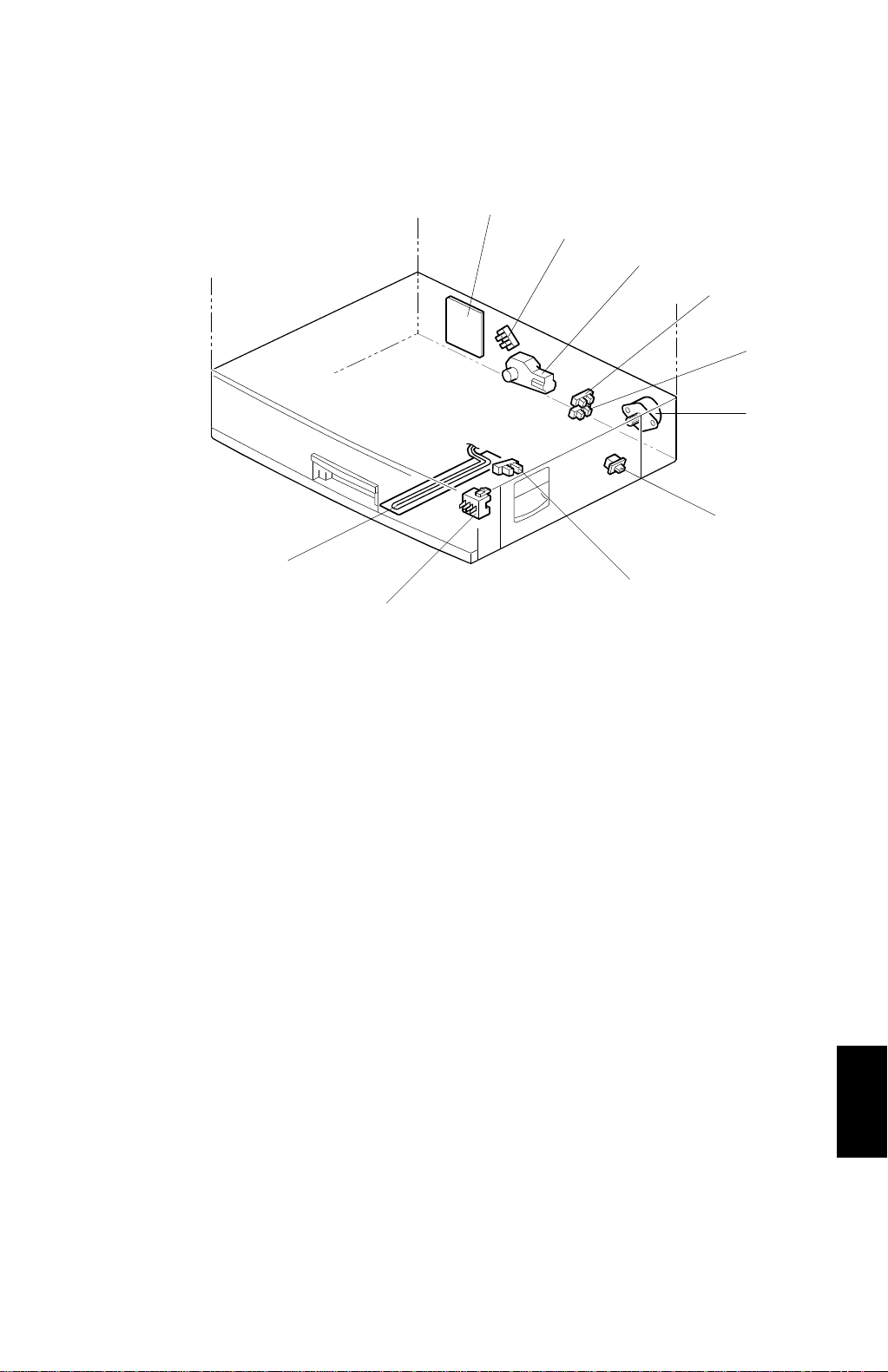

17 May, 1999 ELECTRICAL COMPONENT LAYOUT

1.3 ELECTRICAL COMPONENT LAYOUT

1

2

3

4

5

6

7

10

8

9

A861V102.WMF

1. Tray Main Board

2. Lift Sensor

3. Lift Motor

4. Paper Height 2 Sensor

5. Paper Height 1 Sensor

6. Paper Feed Motor

7. Tray Cover Switch

8. Paper End Sensor

9. Paper Size Switch

10. Optional Tray Heater

Options

A861-3

Page 5

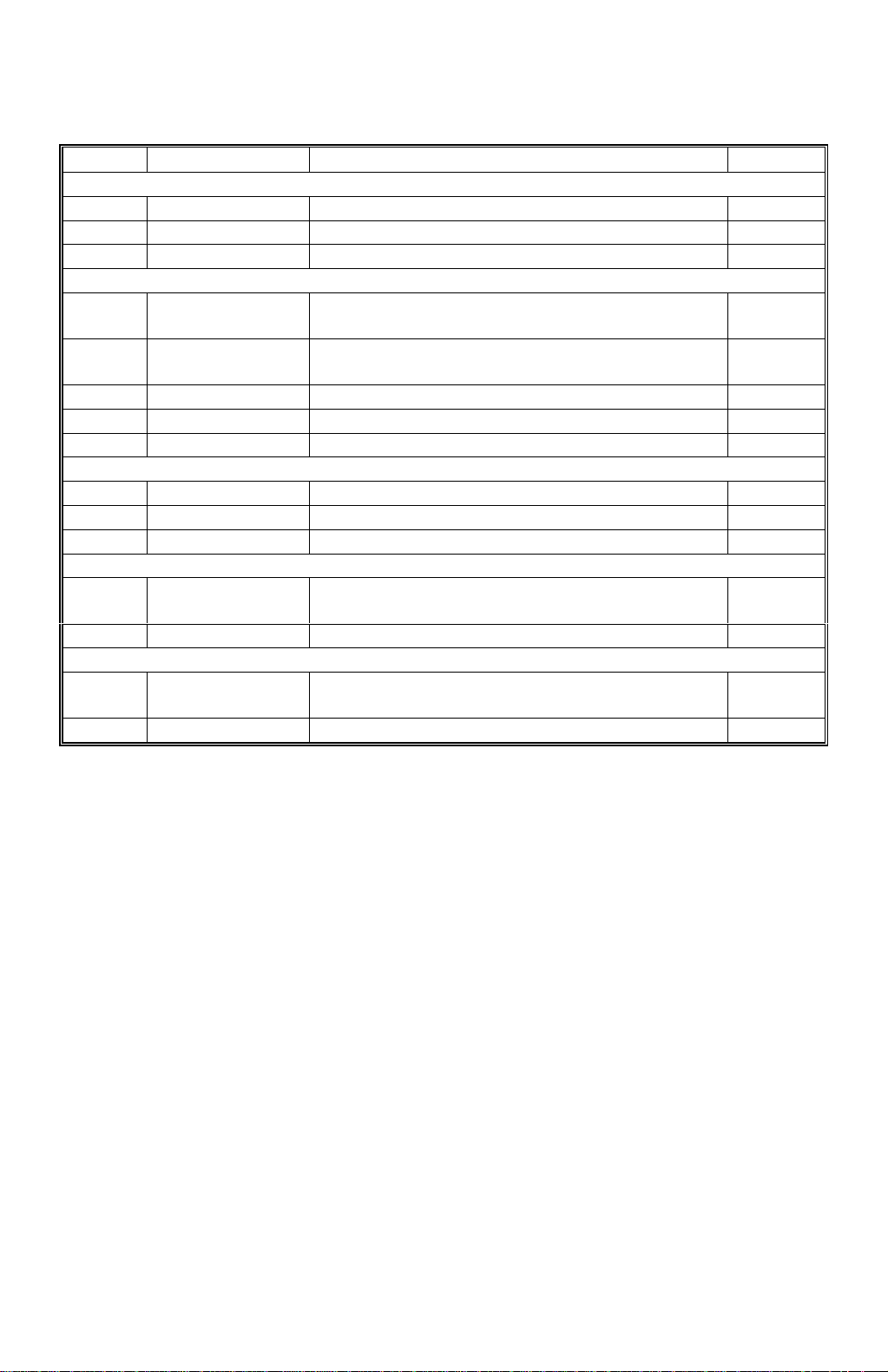

ELECTRICAL COMPONENT DESCRIPTION 17 May, 1999

1.4 ELECTRICAL COMPONENT DESCRIPTION

Symbol Name Function Index No.

Motors

M1 Paper Feed Drives the paper feed roller. 6

M2 Lift Lifts the tray bottom plate. 3

Sensors

S1

S2

S3 Paper Height 1 Detects the amount of paper in the tray. 5

S4 Paper Height 2 Detects the amount of paper in the tray. 4

Switches

SW1 Tray Cover Detects whether the tray cover is opened. 7

SW2 Paper Size Determines what paper size is in the tray. 9

Lift Detects when the paper in the tray is at the

correct feed height.

Paper End Informs the copier when the tray runs out of

paper.

2

8

PCBs

PCB1

Others

H1

Tray Main Controls the paper tray unit and communicates

with the copier.

Optional Tray

Heater

Removes humidity from the paper in the tray.

1

10

A861-4

Page 6

17 May, 1999 DRIVE LAYOUT

1.5 DRIVE LAYOUT

1

2

A861V103.WMF

1. Paper Feed Motor 2. Paper Feed Roller

Options

A861-5

Page 7

PAPER FEED AND SEPARATION 17 May, 1999

2. DETAILED DESCRIPTIONS

2.1 PAPER FEED AND SEPARATION

[A]

[B]

[C]

A861D103.WMF

The paper tray holds 500 sheets. The paper feed roller [A] drives the top sheet of

paper from the paper tray to the copier. The friction pad [B] allows only one sheet

to feed at a time. The friction pad applies pressure to the feed roller with a spring

[C].

A861-6

Page 8

1 October, 1999 PAPER LIFT MECHANISM

2.2 PAPER LIFT MECHANISM

[B]

[A]

[D]

[C]

[K] [G]

[F]

[H]

[A]

A861D106.WMF

[E]

[B]

[I]

[J]

[C]

[D]

[E]

A861D107.WMF

The SP modes mentioned in this section apply to A250 only, and not to G038.

The paper size switch detects when the tray is pushed in.

When the pa per tray is pushed into the mach ine, the pin [A] for the lift moto r

pressure shaft engages the lift motor coupling [B] and the pin [C] for the bottom

plate lift shaft in the tray engages the bottom plate pressure lever coupling [D]. The

pin [E] on the rear of the tray pushes the lock lever so that the lift motor can lift the

bottom plate pressure lev er .

The lift motor turns on, and turns clockwise as viewed on the diagram. The main

pressure spring [K] pulls the bottom plate pressure lever, and this lifts the tray

bottom plate.

When the top of the stack touches the feed roller, the motor cannot pull up the

plate any more, so it pulls the actuator [G] into the lift sensor [F].

The pressure of the feed roller on the paper is now too high, so the lift motor

reverses to reduce this pressure. It reverses for 300 ms or 600 ms, depending on

the paper size. For smaller paper, it reverses the larger amount (600 ms) to reduce

the pressure more.

When the paper tray is pulled out, t he pins [A, C] disenga ge from the couplings [B,

D], and the bottom plate drops. To make it easier to push the tray in, the lift motor

rotates backwards 1.7 seconds to return the bottom plate pressure lever coupling

[D] to the original position.

Options

A861-7

Page 9

PAPER LIFT MECHANISM 17 May, 1999

The paper size thresholds for this feature depend on SP1-908-8 and 9. (Note that

there are two paper size thresholds: small and middle. Some models only use the

small threshold.) The amount of reverse depends on SP 1-908-1, 2, and 3. (See

the table later in this section for details of how these SP modes work.)

For A4-width paper or wider, a projection [H] on the side fence engages the

secondary pressure spring [J] through a lever [I] . Then, the secondary pressure

spring [J] applies paper feed pressure in addition to the main pressure spring [K], to

ensure that extra pressure is applied to wider paper.

As stated earlier, various SP modes control this mechanism. The following table

summarizes them.

No Middle Size Programmed

(Default for A250)

Paper width:

More than 1-908-8

(Default: Wider than HLT)

Amount of reverse:

1-908-1

(Default 300 ms)

Paper width:

1-908-8 or less

(Default: HLT or narrower)

Amount of reverse:

1-908-2

(Default: 600 ms)

With Middle Size Programmed

Paper width:

More than 1-908-9

Amount of reverse:

1-908-1

Paper width:

More than 1-908-8, up to and

including 1-908-9

Amount of reverse:

1-908-3

Paper width:

1-908-8 or less

Amount of reverse:

1-908-2

When the paper tray is pulled ou t, the pins [A, C] disengage from the couplings [B,

D], and the bottom plate drops. To make it easier to push the tray in, the lift motor

rotates backwards 1.7 seconds to return the bottom plate pressure lever coupling

[D] to the original position.

A861-8

Page 10

17 May, 1999 PAPER END DETECTION

2.3 PAPER END DETECTION

[A]

[B]

[C]

A861D105.WMF

If there is some paper in the paper tray, the paper stack raises the paper end feeler

[A] and the paper end sensor [B] is deactivated.

When the paper tray runs out of paper, the paper end feeler drops into the cutout

[C] in the tray bottom plate and the paper end sensor is activated.

When the paper tray is drawn out with no paper in the tray, the shape of the paper

end feeler causes it to lift up.

A861-9

Options

Page 11

PAPER HEIGHT DETECTION 1 October, 1999

2.4 PAPER HEIGHT DETECTION

[B]

[A]

[C]

[C]

A861D107.WMF

The SP modes mentioned in this section apply to A250 only, and not to G038.

The amount of paper in the tray is detected by the combination of on/off signals

from two paper height sensors [A] and [B].

When the amount of paper decreases, the bottom plate pressure lever [C] moves

the actuator up.

The following combination of sensor signals is sent to the copier.

Amount of Paper Paper Height Sensor 1 Paper Height Sensor 2

Near End OFF ON

30% ON ON

70% ON OFF

100% OFF OFF

When the tray contain s paper of a small width, the paper feed pressure may

become too low when the thickness of the stack of remaining paper has

decreased. The lift motor rotates forward 300 ms after the sensor detects a certain

amount of paper remaining in the tray to increase paper feed pressure, simulating

the pressure generated by a full tray.

The amount of remaining paper depends on SP modes 1-908-6 and 7. The amount

of forward rotation depends on SP1-908-4 and 5. Note that there are two paper

size thresholds: small and middle (this is the same as for the paper lift mechanism

described earlier). Some models only use the small threshold. The paper size

thresholds depend on SP1-908-8 and 9.

A861-10

Page 12

17 May, 1999 PAPER HEIGHT DETECTION

The following table summarizes how these SP modes work.

No Middle Size Programmed

(Default for A250)

Paper width:

More than 1-908-8

(Default: Wider than HLT)

Amount of forward rotation:

None

Paper width:

1-908-8 or less

(Default: HLT or narrower)

Amount of remaining paper:

1-908-6

(Default: W hen near-end is

detected)

Amount of forward rotation:

1-908-4

(Default: 300 ms)

With Middle Size Programmed

Paper width:

More than 1-908-9

Amount of forward rotation:

None

Paper width:

More than 1-908-8, up to and

including 1-908-9

Amount of remaining paper:

1-908-7

Amount of forward rotation:

1-908-5

Paper width:

1-908-8 or less

Amount of remaining paper:

1-908-6

Amount of forward rotation:

1-908-4

Options

A861-11

Page 13

PAPER SIZE DETECTION 17 May, 1999

2.5 PAPER SIZE DETECTION

Size

1/2

1/2

1/2

" x 14"

" x 11"

1/2

" x 13")

"

A3, F (8

A4 Lengthwise

A4 Sideways

A5 Sideways,

11" x 17"

B4, 8

B5 Sideways,

8

B5 Lengthwise,

11" x 8

* (Asterisk)

SW

1234

lll

l

m

l

ll

l

m

mmmm

mm

mm

l

: ON (Not pushed)

m

: OFF (Pushed)

m

l

m

mm

mm

mm

l

m

ll

[B]

[A]

A861D108.WMF

There are four paper size microswitches [A] on the front right plate of the paper tray

unit. The switches are actuated by a paper size actuator [B] behind the paper size

indicator plate, which is on the front right of the tray.

Each paper size has its own actuator, with a unique combination of notches. To

determine which size tray has been installed, the CPU reads which microswitches

the actuator has switched off.

The CPU disables paper feed from a tray if the paper size cannot be detected. If

the paper size actuator is broken, or if there is no tray installed, the Add Paper

indicator will light.

When the paper size ac tuator is at the "*" mark, the paper tr ay can be set u p to

accommodate one of a wider range of paper sizes by using user tools. If the paper

size for this position is changed without changing the user tool setting, a paper jam

will result.

A861-12

Page 14

17 May, 1999 SIDE AND END FENCES

2.6 SIDE AND END FENCES

[A]

[D]

[B]

A861D110.WMF

[C]

A861D109.WMF

Side Fences

If the tray is full of paper and it is pushed in strongly, the fences may deform or

bend. This may cause the paper to skew or the side-to-side registration to be

incorrect. To correct this, each side fence has a stopper [A] attached to it. Each

side fence can be secured with a screw [B], for customers who do not want to

change the paper size.

End Fence

As the amount of paper in the tray decreases, the bottom plate [C] lifts up

gradually. The end fence [D] is connected to the bottom plate. When the tray rises,

the end fence moves forward and pushes the back of the paper stack to keep it

squared up

A861-13

Options

Page 15

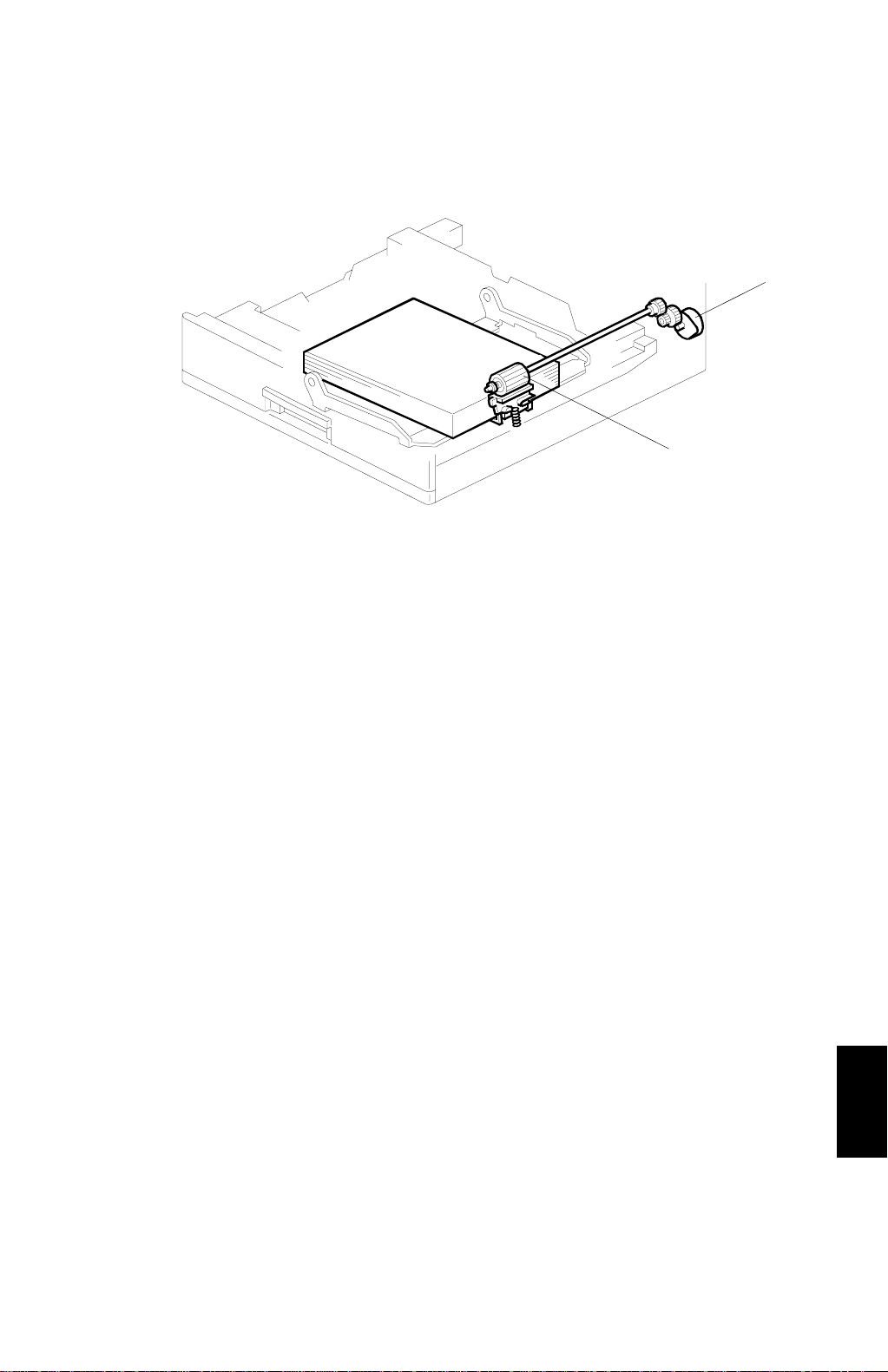

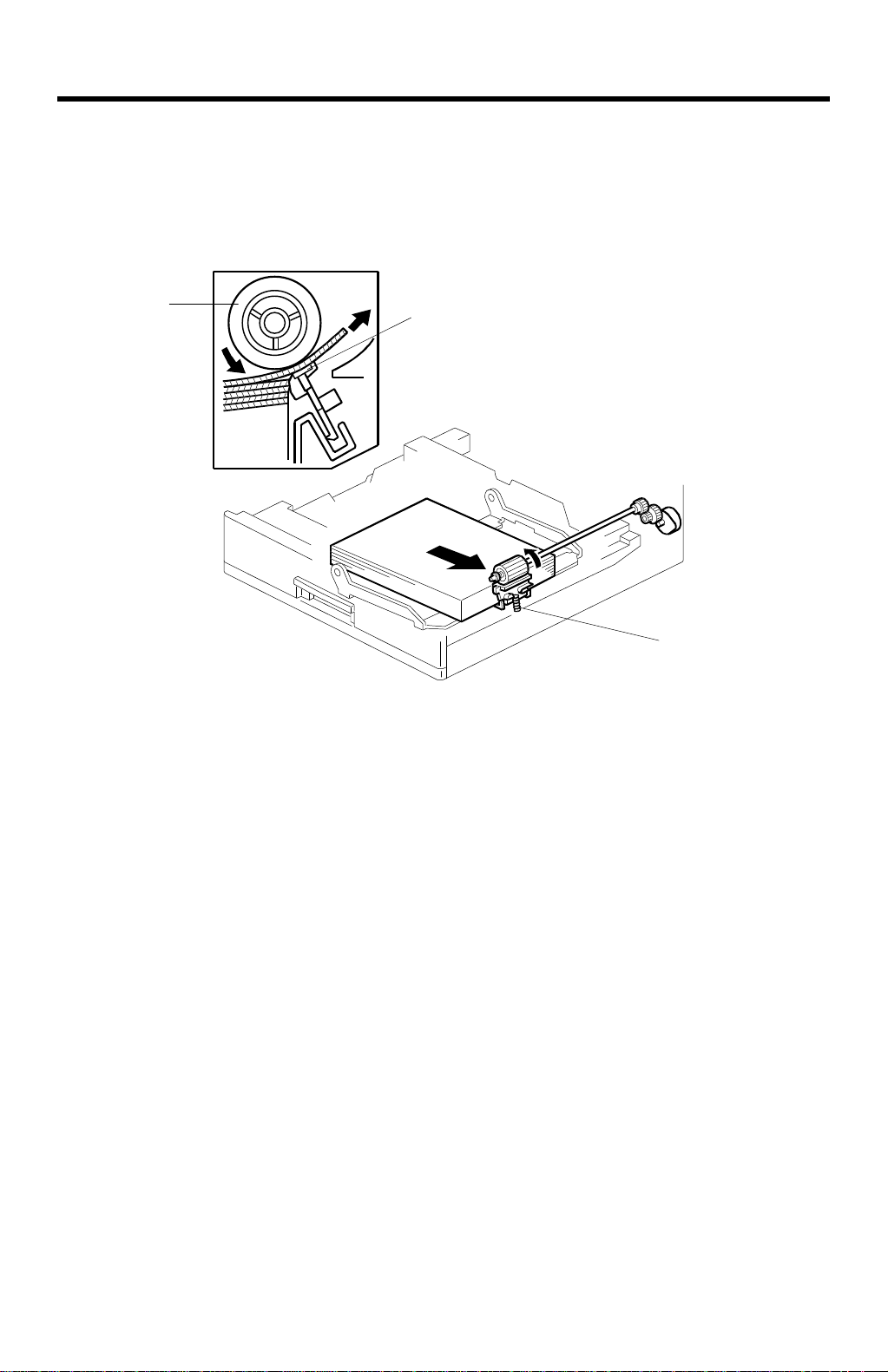

FEED ROLLER REPLACEMENT 17 May, 1999

3. REPLACEMENT AND ADJUSTMENT

3.1 FEED ROLLER REPLACEMENT

[C]

[B]

A861R723.WMF

1. Remove the paper tray [A].

2. Move the release lever [B] to the front.

3. Pull the feed roller [C] to the operation side and remove it.

4. Replace the feed roller.

[A]

A861-14

Page 16

17 May, 1999 TRAY MAIN BOARD REPLACEMENT

[A]

A861R151.WMF

[C]

3.2 TRAY MAIN BOARD REPLACEMENT

1. Remove the rear cover [A] (4 screws).

2. Replace the tray main board [B] (4 screws and 8 connectors).

3.3 TRAY MOTOR REPLACEMENT

1. Remove the rear cover (4 screws).

[B]

A861R103.WMF

2. Disconnect 8 connectors on the tray main board [B].

3. Remove the tray main board with the bracket (2 screws).

4. Remove the tray motor [C] (6 screws and 1 connector).

A861-15

Options

Page 17

TRAY MOTOR REPLACEMENT 17 May, 1999

3.4 TRAY MOTOR REPLACEMENT

[B]

[A]

A861R102.WMF

1. Remove the rear cover [A] (4 screws).

2. Replace the tray motor [B] (2 screws and 1 connector).

A861-16

Page 18

17 May, 1999 LIFT MOTOR REPLACEMENT

3.5 LIFT MOTOR REPLACEMENT

[A]

A861R102.WMF

[C]

1. Pull out the paper tray.

2. Remove the rear cover [A] (4 screws).

3. Disconnect the 2P connector [B].

4. Remove the spring [C].

5. Remove the lift motor unit [D] (3 screws).

6. Remove the lift motor [E] (2 screws).

[D]

[B]

[E]

A861R104.WMF

A861-17

Options

Page 19

PAPER END SENSOR REPLACEMENT 17 May, 1999

3.6 PAPER END SENSOR REPLACEMENT

[C]

[B]

[A]

A861R106.WMF

1. Remove the paper tray.

2. Remove the paper end sensor bracket [A] (1 screw and 1 connector).

3. Replace the paper end sensor [B].

NOTE:

After replacing the sensor, pull the sensor harness to the right side of the

frame [C] so that the harness does not touch the paper in the tray.

3.7 PAPER SIZE SWITCH REPLACEMENT

[D]

[E]

[B]

[A]

A861R101.WMF

[C]

1. Remove the lower tray cover [A] (2 screws).

2. Remove the paper tray [B].

3. Remove the right front cover [C] (1 screw).

4. Remove the paper size switch bracket [D] (1 screw).

5. Replace the paper size switch [E].

A861-18

Page 20

ELECTRICAL COMPONENT LAYOUT (A250/A859/A860/A861/A869)

- A250 -

37

36

35

34

33

32

31

30

29

3

2

1

262728

4

5

2122232425

A250S152.WMF

- A250 -

Symbol Index No. Description P to P

Motors

M1 4 Scanner K2

M2 28 Polygonal Mirror C8

M3 12 Main G2

M4 46 Exhaust Fan B2

Magnetic Clutches

MC1 14 Paper Feed F2

MC2 15 By-pass Feed C2

MC3 18 Vertical Transport F2

MC4 13 Registration B2

Switches

SW1 40 Main B7

SW2 30 Right Door Switch 1 A2

SW3 31 Right Door Switch 2 A2

SW4 25 Vertical Transport Cover Switch B2

SW5 24 Paper Size L2

Sensors

S1 3 Scanner HP K2

S2 37 Original Width J2

S3 6 Original Length 1 I2

S4 6 Original Length 2 I2

S5 21 Toner Near-E nd B2

S6 23 Paper End B2

S7 19 Paper Near-End C2

S8 16 By-pass Tray Paper D2

S9 20 B y-pass Paper Size D2

S10 22 Vertical Transport E2

S11 17 Regis tration D2

S12 35 Fusing Exit A4

S13 27 Exit Tray Paper E2

S14 5 Platen Cover J2

S15 33 AIO Set L2

PCBs

PCB1 44 BICU E9

PCB2 39 PSU C7

PCB3 45 IOB E3

PCB4 8 SBU C9

PCB5 7 Lamp Stabilizer J2

PCB6 26 LD Unit C8

PCB7 36 Operation Panel E10

PCB8 — Memory (option) G9

PCB9 42 Printer Controller (option) G9

PCB10 43 FCU (Option) F10

PCB11 47 NCU (option) —

- A250 -

6

7

8

9

10

11

12

13

14

15

16

17

18

19

20

47

47

46

45

44

42

43

- A250 -

Symbol Index No. Description P to P

Lamps

L1 2 Exposure Lamps J2

L2 10 Fusing Lamp A5

Heaters

H1 1 Anti-Condensation A6

H2 — Drum (option) A6

Others

TF1 9 Fusing Thermofuse A5

TH1 11 Fusing Thermistor A4

PP1 3 8 C/B/T H2

LSD 1 29 Laser Synchronization Detector C9

CO1 48 Total F2

CO2 — Key (option) L1

LED1 32 Exit Tray E 2

LED2 34 1-bin Tray F2

SP1 41 Speaker —

- A869 -

6

A250S153.WMF

1

5

4

- A869 -

Symbol Index No. Description P to P

Motors

M1 1 Tray M1

Sensors

S1 6 Exit N1

S2 5 Paper N1

Switches

SW1 4 B i n Tray N1

PCBs

PCB1 2 1 Bin Tray N2

LEDs

LED1 7 1 Bin Exit Tray F2

Solenoid

SOL1 3 Junction Gate M1

A869S103.WMF

38

39

40

41

2

3

19

18

- A860 -

20

1

17

16

15

14

- A860 -

Symbol Index No. Description P to P

Motors

M1 20 Tray L8

M2 3 Upper Lift N8

M3 18 Lower Lif t M8

Sensors

S1 2 Upper Lift M8

S2 19 Lower Lif t M8

S3 13 Upper Paper End J8

S4 14 Lower Paper End J8

S5 12 Vertical Transport I8

S6 15 Upper P aper Size I8

S7 16 Lower P aper Size I8

S8 5 Upper Paper Height 1 H8

S9 4 Upper Paper Height 2 H8

S10 11 Lower Paper Hei ght 1 G8

S11 10 Lower Paper Hei ght 2 G8

Switches

SW1 8 Tray C over J 8

Magnetic Clutches

MC1 6 Upper Paper Feed J8

MC2 9 Lower Paper Feed K8

MC3 7 Relay K8

PCBs

PCB1 1 Tray Main K7

Others

H1 17 Option Tray Heater N8

1

- A861 -

10

9

2

12

13

A860S102.WMF

2

A861S102.WMF

- A859 -

3

4

5

12

13

6

11

7

8

9

10

10

11

- A859 -

Symbol Index No. Description P to P

Motors

M1

Sensors

S1

S2

S3

S4

S5

S6

S7

S8

Solenoids

SOL1

SOL2

Clutches

MC1

PCBs

PCB1

3

- A861 -

4

Symbol Index No. Description P to P

5

6

7

8

Motors

M1 6 Paper Feed J6

M2 3 Lift H6

Sensors

S1 2 Lift G6

S2 8 Paper End H6

S3 9 Paper Size I6

S4 5 Paper Height 1 H6

S5 4 Paper Height 2 H6

Switches

SW1 7 Tray C over I6

PCBs

PCB1 1 Tray Main H5

Others

H1 10 Option Tray Heater J6

9 DF Transport

6DF Open

13 Registration

2 Feed Cover Open Sensor

3 Original Width

8 Original Length 1

7 Original Length 2

11 Original Set

12 Original Trailing Edge

4DF Pick-up

10 Stamper

1DF Feed

5DF Drive

1

2

3

4

5

6

K6

M6

L6

M6

M6

N6

N6

L6

N6

L6

K6

K6

M5

8

9

A859S102.WMF

7

Page 21

ABC

A250 Point to Point Diagram

1

Paper

Near End

Sensor

-2-3-4

s

t

[5]

[5]

GND [0]

t

[0] GND

[ 5] New Fusing Unit

FU5 FU6

FU2

FU4

PSU (PCB2)

CB

FU1

CN221-1

Registration

Clutch

CN310-1-2CN311-1-2CN309-1

+24V [24]

[24] +24V

[24] +24V.M

-2-3-4

CN305-1

-2-3-4

CN285-1

Polygonal Mirror

-2

-3

SBU

2

3

4

Fusing

Thermister

Fusing Exit

Sensor

Fusing Thermofuse TF1

5

Anti-condensation

6

7

8

9

10

Right

Door

Door

Switch 1

Switch 2

SW2 SW3 SW4

-5-4-3-2-1

CN306-6

t

+5V [5]

LD5VS [ 5]

s

[ 24] SW On

[24] +24V

-2

CN304-1

J K

B7

T

S12

Fusing Lamp L2

J5/N7

Drum Heater

Heater

(230V version only)

Main Switch

Power Supply Cord

*1 *2 *3

230V Machine

115V Machine

Right

t

24V.S [ 24]

H1

Transport

+24V [24]

V

W

Coil

G10

Vertical

Exhaust

Cover

Fan Motor

Switch

CN319-1-2CN322-1

t

+24V [24]

+24V [24]

24V.S2 [ 24]

H2

H1

SW1

X

Y

*1 *2 *3

230V

230

s

115V

115

s

Paper

Toner

Sensor

Sensor

-2

-4

t

[5]

+5V [5]

[0] GND

Fusing Termister

[0] GND

[*2] Fusing Lamp - H

[*2] Fusing Lamp - N

[*3] AC - H

[*3] AC - H

[*3]

[*3]

[*3]

[*3]

[*3]

[*3]

[*2] AC - H

[*2] AC - H

[*2] SW ON - H

[*2] SW ON - N

[*1] AC - H

[*1] AC - N

End

CN325-1

GND [0]

[ 5] Fusing Exit Sensort[5] +5V

FU3

Near End

t

[ 24]

GND [0]

[ 5] Fusing Unit Sett[0] GND

-1-2-3-4-5-6-7-8-9

CN303

CN282-1

-2

CN283-1

-2

-3

-7

-5

-9

-4

-8

CN289-1

-2

CN281-4

-3

-2

-1

J

A4

K

CN287-2

[5] +5V

-1

230V Machine

[0] GND

T280

[*1] AC - H

T281

[*1] AC - N

115V Machine

230

t

115

t

LSD1

Laser

Synchronization

Detector

t

[ 24]

[0] PGND

RA

+12V [12]

-12V [-12]

GND [0]

GND [0]

AGND [0]

+24V [24]

Motor

[5]

t

[5] +5V.D

[0] GND

By-pass

Paper Feed

Clutch

+24V [24]

[5] +5V

[0] GND

-5

-5

+5V [5]

+5V [5]

M2

LD Unit

PCB6

PCB4

Registration

t

[ 24]

CN284-5

CN286-8

Sensor

-2-3-4-5-6

t

[5]

+5V [5]

GND [0]

-2-3-4

CN304-1

-4

-3

-2

-1

-7

-6

-5

-4

-3

-2

-1

CN220

CN200

By-pass

Tray

Paper

Sensor

GND [0]

[ 24] Relay Ont[ 24] Fusing Lamp OntZero Cross

CN104-1

CN112-1

t

[5]

[0] GND

D

+5V [5]

[24] +24V.S1

-5

-2

-3

-4

-5

-6

-7

-8

-2

-3

-4

-5

Paper Size

CN321-1

t

[24] +24V

[0] GND

[ 24] ON

[ 24] Ready

CLOCK

CN111

CN102

By-pass

Sensor

-2-3-4-5-6-7-8

Size 4 [ 5]tSize 3 [ 5]

Vertical

Transport

Sensor

t

t

[5]

GND [0]

GND [0]

Size 2 [ 5]tSize 1 [ 5]

IO Board

PCB3

t

t

[ 5] LED Ont[ 5] Beepert[ 5] Power Keyt[ 5] Pre-heat Key

[-12] -12V

LED

-2

-3-5-4

CN103-1

Operation Panel (PCB7)

EF

Paper

Sensor

GND [0]

Exit Tray LED

1-bin

Copier

Tray

LED1

LED2

-10

-11

-12

-13

-14

-15

t

[5]

+5V [5]

t

[5]t[5]

+5V [5]

+5V [5]

CN301

CN105

Vertical

Paper

Transport

Feed

Clutch

CN307-1-2CN308-1-2CN317-1-2CN309-7

t

[ 24]

+24V [24]

Clutch

+24V.S2 [24]

Total

Counter

t

[ 24]

+24V [24]

Exit Tray

-9

+5V [5]

CN105

1 /IOBCNT2 16 GND 3 1 +5V S 46 GND

2 FUTMP 17 /IOWR 32 GND 4 7 /IORD

3 MCCFB 18 GND 33 BIV FB 4 8 /IOCS

4 TCCFB 1 9 GND 3 4 MCVFB 4 9 GND

5 PCUTEMP 2 0 /IORST 35 TCV FB 5 0 IOCLK

6 GND 21 GND 36 GND 51 GND

7/INTZERO 22SMO8 37GND 52SMO9

8 IOD14 23 SMO6 38 IOD15 53 SMO7

9 IOD12 24 SMO4 39 IOD13 54 SMO5

10 IOD10 2 5 SMO2 40 IOD11 55 SMO3

11 IOD8 26 SMO0 41 IOD9 56 SMO1

12 GND 27 /KCNTO K 42 GND 57 PTRSV I

13 IOA5 28 KEYRXD 43 IOA6 58 KEYTXD

14 IOA2 29 DFRXD 44 IOA3 59 DFTXD

15 IOA0 30 /DFGATE 45 IOA1 60 IOBCNT1

CN111

1 +5V 11 LDDAXD 21 /PCLK 31 GND

2 +5V 12 LDDWXR 22 /PFGATE 32 +5V S

3 GND 13 LDOFF 23 GND

4 GND 14 /L DERR 24 /LDSY NC

5 /BD 15 PSO 25 PSE

6REFCLK 16/PDO0 26/PDE0

7 LDDCLK 17 /PDO1 2 7 /PDE1

8 LDDDI 18 /PDO2 28 /PDE2

9 LDDDO 19 /PLGA TE 29 /VDTHRU

10 /DEVRST2 20 /PLSYNC 30 GND

CN102

1 GND 16 SDO1 31 SDE2 46 GND

2 +5V 17 SDO2 32 SDE3 47 GND

3 +5V 18 SDO3 33 GND 48 -12V

4 +5V 19 GND 34 SDE4 49 - 12V

5 +5V 20 SDO4 35 SDE5 50 GND

6 +5V 21 SDO5 36 SDE6

7 GND 22 SDO6 37 SDE7

8 +12V 23 SDO7 38 GND

9 +12V 24 GND 3 9 /SSCA N

10 +12V 25 GND 40 /SLEAD

11 /R D SYNC 26 /SCLK 41 GND

12 /SHGATE 27 GND 42 SBUDI

13 /OPBSYNC 28 GND 43 SBUD O

14 GND 29 SDE0 4 4 SBUCLK

15 SDO0 30 SDE1 45 SBULATCH

BICU

(PCB1)

t

[0] GND

[0] GND

CLOCK

DATA IN

DATA OUT

[5] +5V

-6-7-8

[5] +5V

-9

-10

-11

-12

-13

CN113

CN

FCU (PCB10)

t

[ 24]

CN114

GH I JK LMN

1-Bin Tray (A869)

Junction

Paper

Gate

Solenoid

SOL

1

-6

CN404-1

t

t

B [24 24/0]

/B [24 24/0]

-2-3-4-5-6-7-8

-2-3-4-5-6-7-8

t

Tray Motor On [ 5]

t

+24V [24]

+24V [24]

+24V [ 24]

t

t

t

t

Connect [ 5]

Door Close [ 5]

Exit Sensor [ 5]

Paper Sensor [ 5]

Sensor

-2-3-4-5-6

CN402-1

t

[5]

GND [0]

1-Bin Tray Board

-9

-9

+5V [5]

GND [0]

PGND [0]

Direction [5:CCW / 0: CW]

Tray Motor

Platen

Cover

Power Pack - B/C/TMain Motor

Original Length

Sensor 2

Original Length

Sensor 1

Original Width

Sensor

M3MC1 MC3 CO1

-8

-9

-10

-11

s

t

GND [0]

GND [0]

On [ 5]

Lock [ 5]

-12

-13

CN302-3

+24V.S1 [24]

+24V.S1 [24]

t

[ 24] 3rd Paper F. MC (A860)t[ 24] Transport MC (A860)

[ 24] 2nd Paper F. MC (A860)t[ 24] Paper Feed Motor (A861)

-A2

-A3

CN312-A1

-A13

-A14

CN100-A15

-4-5-6-7-8

t

t

+24V.S1 [24]

Bias On [ 5]

PWM - Bias [0 0/5]

t

[0/5] Scan B (A860/A861)

[0/5] Scan A (A860/A861)

-A4

-A5

-A11

-A12

+5V [5]

GND [0]

[0/5] Paper Height (A860/A861)

[0/5] Set Bank (A860/A861)

-A6

-A7

-A9

-A10

FB-B.V.

[0/5] 3rd Paper Size (A860)

-A8

-A8

-9

[0/5] 2nd Paper Size (A860)

-A9

-A7

t

PWM-C[0 0/5]

[0/5] Paper Size (A861)

-2-3-4

-5

GND [0]

Length 3 [ 5]tLength 4 [ 5]

[0] GND (A860/A861)

[24] +24V (A860/A861)

-B3

-B4

-B12

-B13

CN320-1

t

Sensor On [ 5]

[24] +24V (A860/A861)

-B5

-B11

-2-3-4-5-6-7-8

t

t

+5V [5]

[0] GND (A860/A861)

[24] +24V (A860/A861)

-B6

-B7

-B9

-B10

GND [0]

Length 1 [ 5]tLength 2 [ 5]

t

[5] +5V (A860/A861)

[ 5] Motor Rotate (A860) / [0] GND (A861)

-B8

-B9

-B7

-B8

+5V [5]

Sensor On [ 5]

[0] GND (A860/A861)

[ 5] Tray Motor (A860)t[ 5] 3rd Lift Motor (-) (A860)

-B10

-B11

-B5

-B6

-10

-11

-12

-13

-14

CN324-1

t

FB-C.V.

Charge On [ 5]

t

[ 24] Relay Clutch (A860)

Not Used

-A10

-A11

-A5

-A6

-A12

-A4

FB-T.C.

s

[ 5] Lower Lift Sensor (A860)

t

PWM - T. C. (-) [0 0/5]

s

[ 5] Upper Lift Sensor (A860)s[ 5] Lift Sensor (A861)

-A13

-A3

t

t

t

+5V [5]

Sensor On [ 5]

PWM - T. C. (+) [0 0/5]

s

[0] GND (A860/A861)

[0] GND (A860/A861)

[ 5] Paper End Sensor (A861)s[ 5] Upper Paper End Sensor (A860)s[ 5] Lower Paper End S. (A860)

-B1

-B2

-A14

-A15

-A2

-A1

-B14

-B15

Tray Main Board (PCB1)

Exposure

Lamp

S2S5

t

Width 2 [ 5]

t

-B12

-B4

-9

t

Width 1 [ 5]

t

[ 5] 3rd Lift Motor (+) (A860)

-B13

-B3

Stabi-

lizer

-10

CN327-1

GND [0]

+24V [24]

t

[ 5] 2nd Lift Motor (-) (A860)t[ 5] Lift Motor (-) (A861)t[ 5] 2nd Lift Motor (+) (A860)t[ 5] Lift Motor (+) (A861)

-B14

-B15

-B1

-B2

L1

-2

GND [0]

Sensor

-3

-4-5-6-7-8

s

t

GND [0]

Close [ 5]

Lamp On[ 24]

[5] +5VE

DFGATE

-A2

CN314-A1

-7-6-5-4-3-2-1

CN120-8

Scanner HP

Sensor

S1S14S3S4PP1S13S10S9S8S11S7S6

+5V [5]

GND [0]

[0] GND

-A3

-A4

[0] GND

s

[5]

[0] GND

-A5

-9

+5V [5]

-A6

CN318-1

+24V [24]

[24] +24V.M

-A7

Scanner Motor

M1

-2-3-4-5-6

t

+24V [24]

A [24 24/0]

[24] +24V.M

[24] +24V.M

-A8

t

/A [24 24/0]

t

B [24 24/0]

t

/B [24 24/0]

Paper Size

Switch

-2-3-4-5-6

CN323-1

t

[5]t[5]

GND [0]

CN314-B1

CN130-9

t

[5]

[5] +5V

AIO Set

CO2

Sensor

S15SW5MC2MC4M4

CN326-4

t

GND [0]

Set [ 5]

[5] +5V

[0] GND

[0] GND

TXD

-B2

-B3

-B4

-B5

-8-7-6-5-4

Key Counter

-2-3-1

t

[ 24]

+24V [24]

[0] GND

RXD

-B6

-B7

-3

t

GND [0]

Set [ 5]

M1

-2-2-3-4-5

CN403-1

t

t

+24V [24]

A [24 24/0]

/A [24 24/0]

CN401-1

CN315-1

t

Junction Gate Solenoid On [ 5]

Document Feeder (A859)

DF Drive Board (PCB1)

[24] +24V

[24 24/0] At[24 24/0] /At[24 24/0] /Bt[24 24/0] B

-2

-4-6-5

M1

DF Transport

Motor

t

-7-8-9

Stamper

Solenoid

[24] +24V

SOL

[5] +5V

Original

Length 1

Sensor

[5]t[0] GND

-6-7-8

t

[5]t[5] +5V

[ 5] LED On

-9

Original

Length 2

Sensor

[ 24]t[24] +24V

-11

[24] +24V

CN260-1

SOL

1

DF Pick-up

Solenoid

t

[ 24]

-2

Registration

[0] GND

CN210-1

Sensor

t

[ 24]

-10

MC1

2

DF Feed

Clutch

t

t

[5]

[0] GND

[0] GND

[5] +5VE

[5] +5V

[5]

-2

-3-5-4

-6-7-8

Original

Set

Open

Sensor

Sensor

s

s

[0] GND

[5] +5V

[5]

[5]

-9

-11

-12

DF

Feed Cover

Open

Sensor

t

[5] +5V

[0] GND

[ 5] Width 1t[ 5] Width 2

-2

-3-5-4

-13

CN230-1

Original

Width

Sensor

t

t

t

t

-5

M2

Lift

s

[0] GND

[0] GND

[5] +5V

[5]

-2-3-4-5-6-7-8

CN102-1

Paper

Paper

Height 1

Height 2

Sensor

Sensor

s

[ 24] (+)t[ 24] (-)

[5] +5V

[0] GND

[5]

-2-3-4

CN105-1

S1 S4 S3 S2 SW2 H1 S2 S7 S1 S3 S4 S5 S6 S8

Lift

Motor

Sensor

s

s

[5] +5V

[5]

[0] GND

Paper

End

Sensor

[5] +5V

[5]

-9

[ 5] Size 1t[ 5] Size 2t[ 5] Size 3t[ 5] Size 4

CN103-1

Paper Tray Unit - 1 Tray (A861)

-A2

-A3

-A4

-A5

-A6

-A7

-A8

-A14

CN100-A15

-A9

-A10

-A11

-A12

-A13

-A1

-B15

[0] GND

-2-3-4

Paper Size

Switch

-B13

-B14

t

t

[5]

[24] +24V

[5] +5V

[24 24/0] A

-5

-B11

-B12

-6

SW1

Tray

Cover

Switch

-B10

-2-3-4

-7

CN101-1

Paper Feed

-B7

-B8

-B9

M1

Motor

-B6

[24 24/0] /B

[24] +24V

[24 24/0] Bt[24 24/0] /A

-5

-6

V W

Optional

Tray

Heater

-B2

-B3

-B4

-B5

[24] +24V

A6

CN270-1

-B1

Tray Main Board (PCB1)

t

[0] GND

CN103-1

s

[0] GND

[5] +5V

[5]

-3-5-4

-2

[0] GND

[5] +5V

[5]s[5]s[5]

-6-7-8

[0] GND

[5] +5V

-9

-10

-11

s

[0] GND

[ 5] Size 2-1t[ 5] Size 2-2t[ 5] Size 2-3t[ 5] Size 2-4t[0] GND

[5] +5V

-2

-3-5-4-6-7-8-9

-12

CN104-1

[ 5] Size 3-1t[ 5] Size 3-2t[ 5] Size 3-3t[ 5] Size 3-4

t

[0] GND

[0] GND

[5] +5V

[5]

-2

-3-5-4

-10

CN102-1

[0] GND

[5] +5V

[5]s[5]

-6-7-8

s

[5] +5V

-9

s

[5] +5V

[24] +24V

[5]

CN110-1-2CN105-1

[ 24]t[ 24]t[ 24]

[24] +24V

-2

-3-5-4

S9 S8 S7 S6 SW2 SW3 S5 S4 S3 S2 S1 H1

Lower

Paper

Height 2

Sensor

Lower

Paper

Height 1

Sensor

Upper

Paper

Height 2

Sensor

Upper

Paper

Height 1

Sensor

Upper Paper

Size Switch

Lower Paper

Size Switch

Vertical

Transpor t

Sensor

Paper Tray Unit - 2 Tray (A860)

Memory

Board

PCB8

CN701

Printer

Controller

PCB9

CN115 CN106

X Y

CN

B8

CN106

1 + 5V 21 MDQ13 41 GND 6 1 GND

2 + 5V 22 MDG12 42 GND 6 2 GND

3 +5V 23 MDQ15 43 MA1 63 /WE2

4 +5V 24 MDQ14 44 MA0 64 /WE1

5 MDQ1 25 MDQ17 45 GND 6 5 GND

6 MDQ0 26 MDQ16 46 GND 6 6 GND

7 GND 27 MDQ19 47 MA3 67 /CAS2

8 GND 28 MDQ18 48 MA2 68 /CAS1

9 MDQ3 29 MDQ21 49 GND 6 9 / RAS1 0

10 MDQ2 30 MDQ20 50 GND 70 /RAS11

11 GND 31 MDQ23 51 MA5 71 /RAS13

12 GND 32 MDQ22 52 MA4 72 /RAS12

13 MDQ5 33 MDQ25 53 GND 73 /RAS15

14 MDQ4 34 MDQ24 54 GND 74 /RAS14

15 MDQ7 35 MDQ27 55 MA7 75 +5V

16 MDQ6 36 MDQ26 56 MA6 76 +5V

17 MDQ9 37 MDQ29 57 MA9 77 +5V

18 MDQ8 38 MDQ28 58 MA8 78 +5V

19 MDQ11 39 MDQ31 59 MA11 7 9 +5V

20 MDQ10 40 MDQ30 60 MA10 8 0 +5V

Lower

Paper

End

Sensor

Upper

SW1

Paper

End

Tray

Sensor

Cover

Switch

Upper

Relay

Paper Feed

Clutch

Clutch

CN113 CN114

1TXDF 21/AWKD1 41GND 1+24V

2 RXDF 22 /AWKD0 42 GND 2 +12V

3 RXRDYF 23 GND 43 /AWFGATE 3 GND

4 /CTSF 24 GND 44 /AWLSYNC 4 -12V

5 /RTS1 25 /ARFGATE 45 /AWLGATE 5 GND

6 /CTS1 26 /ARLSYNC 46 GND 6 +5V

7 TXD1 27 /ARLGATE 47 /AWCLK 7 GND

8 RXD1 28 GND 48 GND 8 +5V

9 /DE1 29 /ARCLK 49 /WRSYNC

10 /WKUP1 30 GND 50 /FSYNC

11 /SLEEP 31 GND

12 /CNFCU 32 GND

13 /CNPRN 33 /ARKD7

14 GND 34 /ARKD6

15 /AWKD7 35 /ARKD5

16 /AWKD6 36 /ARKD4

17 /AWKD5 37 /ARKD3

18 /AWKD4 38 /ARKD2

19 /AWKD3 39 /ARKD1

20 /AWKD2 40 /ARKD0

[24] +24V

-6

MC2MC3MC1

Lower

Paper Feed

Clutch

t

[ 5] Motor Ont[5] Speed

-2

CN101-1

[ 5] Rotatet[0] GND

[5] +5V

-3-5-4

[24] +24V

[24] +24V

-6-7-8

M1

Tray Motor

[24] +24V

[24] +24V

[0] GND

[0] GND

[0] GND

-9

-10

-11

-12

CN115

1 /VDTHRU 21 /ARLG ATE

2 GND 22 GND

3 GND 23 /ARCLK

4 /BD 24 GND

5 GND 25 GND

6 GND 26 /ARKD7

7 RXDF 27 /ARKD 6

8TXDF 28GND

9 /CTSF 29 /ARKD5

10 RXRDYF 30 /ARKD4

11 TXD2 31 GND

12 RXD2 32 /ARKD3

13 /OE2 33 /ARKD 2

14 /WKUP2 34 GND

15 /SLEEP 35 /ARKD1

16 /CNPRN 36 /ARKD0

17 /ARFGATE 37 GND

18 GND 38 GND

19 /ARLSYNC 39 /WRSYNC

20 GND 40 /FSYNC

[0] GND

-13

s

[0] GND

[5]

-2

CN140-1

Lower Lift

Sensor

[5] +5V

-3-5-4

[ 24] (+)t[ 24] (-)

Lower Lift

Motor

t

s

[0] GND

[5]

-6-7-8

Upper Lift

Sensor

[5] +5V

Upper Lift

[ 24] (+)t[ 24] (-)

-9

M2M3

Motor

A6

t

A6

V W

-10

Optional

Tray

Heater

+5V [5]

(PCB1)

-10

-10

PGND [0]

-10

Exit

Sensor

S1S2

GND [0]

-11

-11

+24V [24]

[ 5] LED Ont[0] GND

-11

Bin Tray

Switch

t

[5]

GND [0]

-12

-12

+24V [24]

t

[5] +5V

[5]

-12

-13

-14

Original

Trailing Edge

Sensor

[0] GND

SW1

-7

t

[5]

1

2

3

4

t

[ 5] LED On

5

-15

6

7

8

9

10

ABCDEFGHI JKLMN

Loading...

Loading...