Page 1

PAPER TRAY UNIT

(Machine Code: A549/550)

Page 2

10 May 1996 SPECIFICATIONS

1. SPECIFICATIONS

Configuration : Two-tray table or three-tray ta ble

Copy Paper Size: Maximum A3/11" X 17"

Minimum B5/81/2" X 11"

Copy Paper Weight: 52 - 105 g/m2, 14 - 28 lb

Copy Paper Capacity: Approximately 500 sheets

Paper Feed Speed: 20 ~ 40 copies/minute (A4 / 81/2"X11" sideways)

Power Source: DC 24V, 5V and AC 120V, 220~240V from the

main machine

Power Consumption: Maximum 110.5 W

Average 50 W

Dimensions: 620 mm/24.4" (width) X 632 mm /24.9" (depth) X

390 mm/15.4" (height)

Weight: Less than 36 kg/79.4 lb (Two-tray type)

Less than 38 kg/83.8 lb (Three-tray type)

A549/A550-1

Options

Page 3

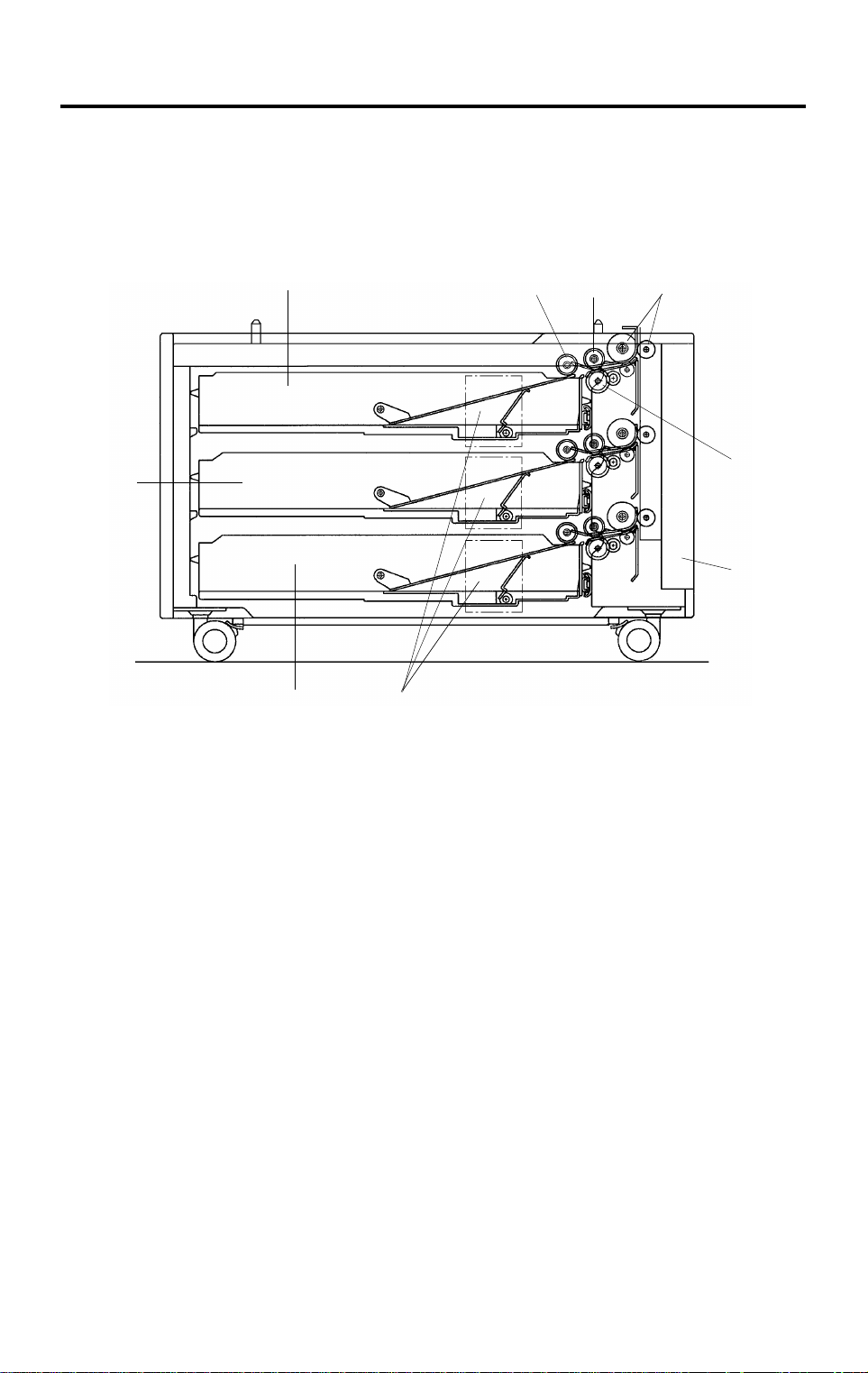

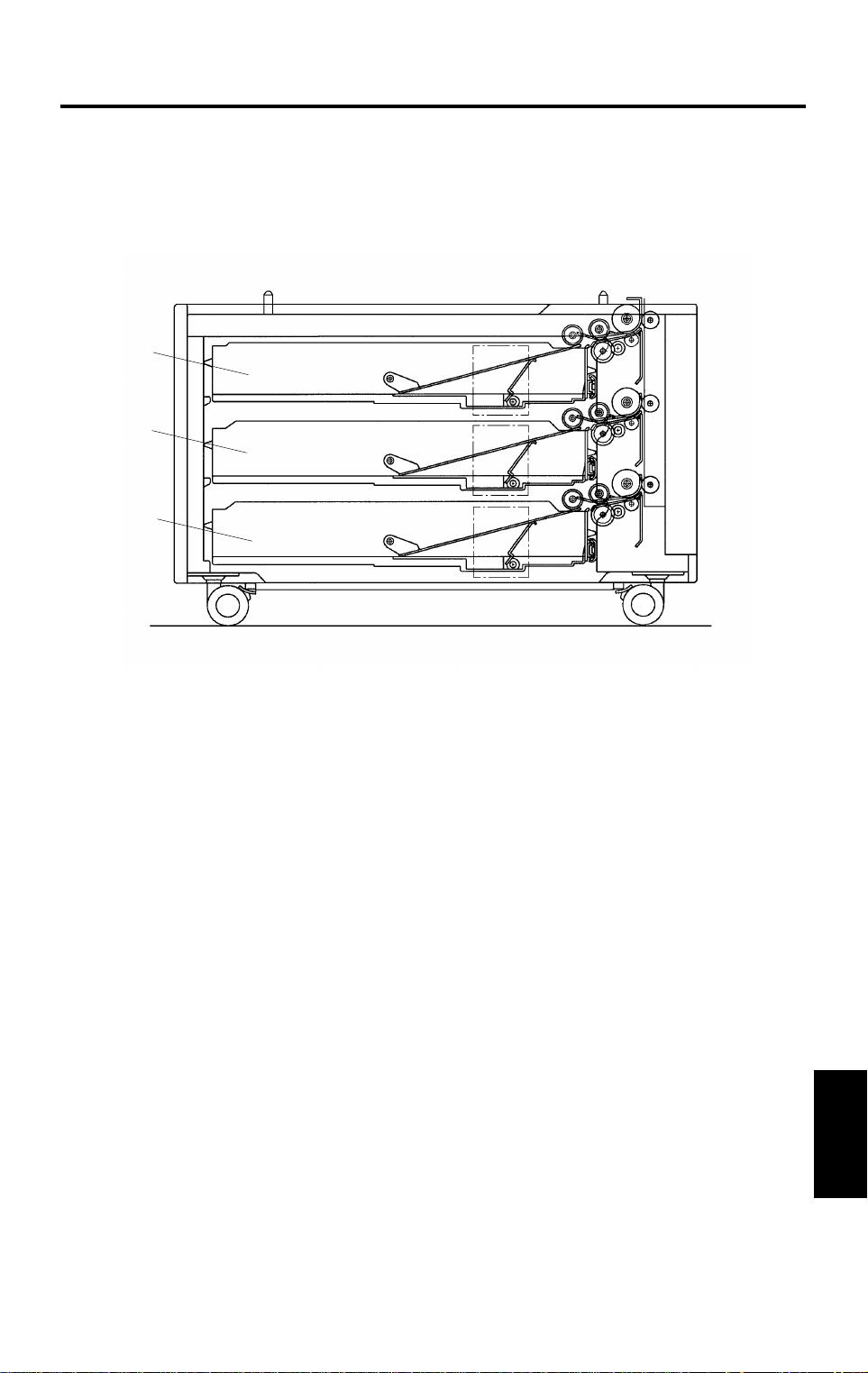

COMPONENT LAYOUT 10 May 1996

2. COMPONENT LAYOUT

2.1 MECHANICAL COMPONENT LAYOUT

1

9

8

7

2

3

4

5

6

1. Paper Tray 1

2. Pick-up Roller

3. Paper Feed Roller

4. Relay Rollers

5. Reverse Roller

A549V502.img

6. Lower Right Door

7. Paper Lift Motors

8. Paper Tray 3 (A549 model only)

9. Paper Tray 2

A549/A550-2

Page 4

213

4

5

6

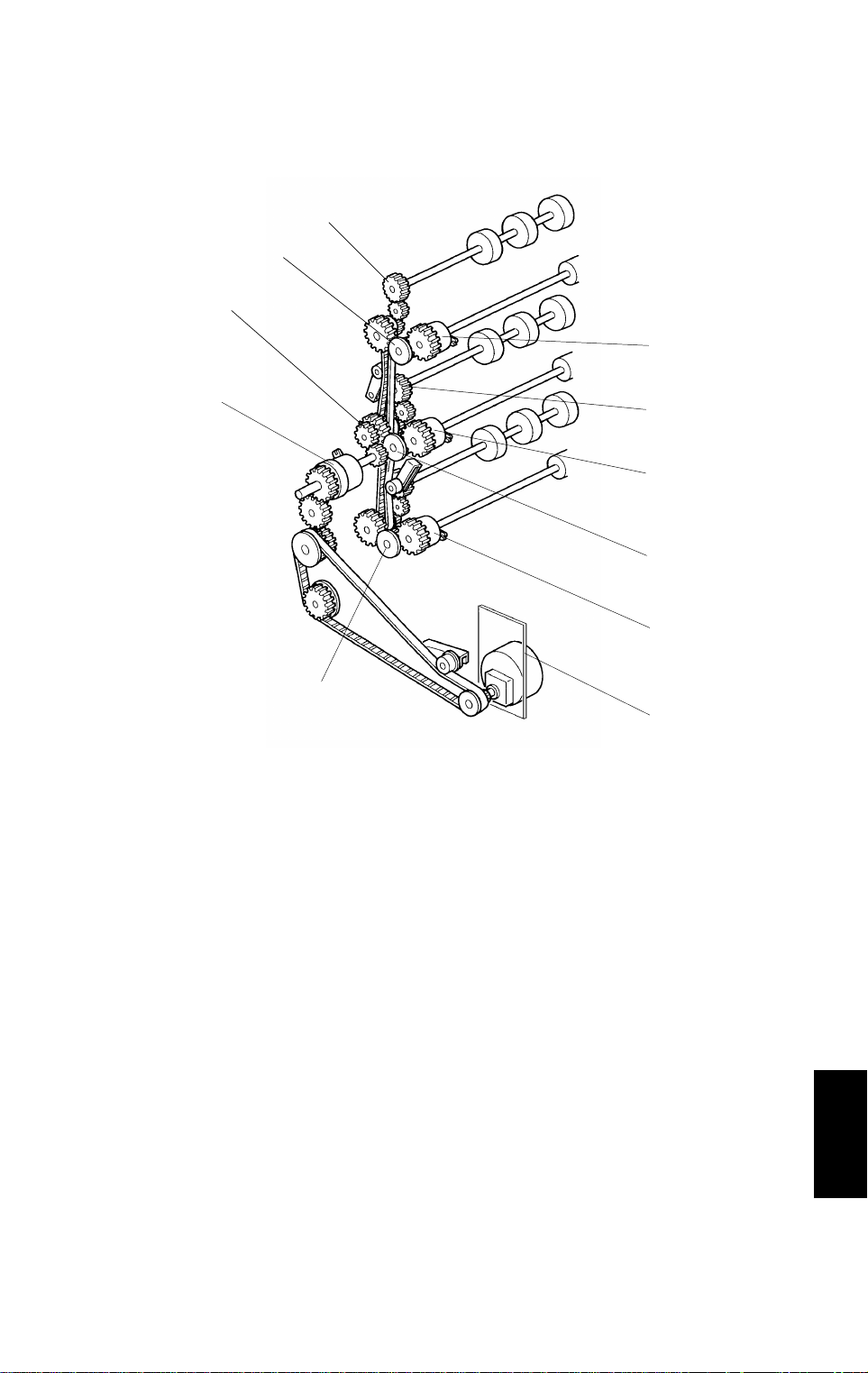

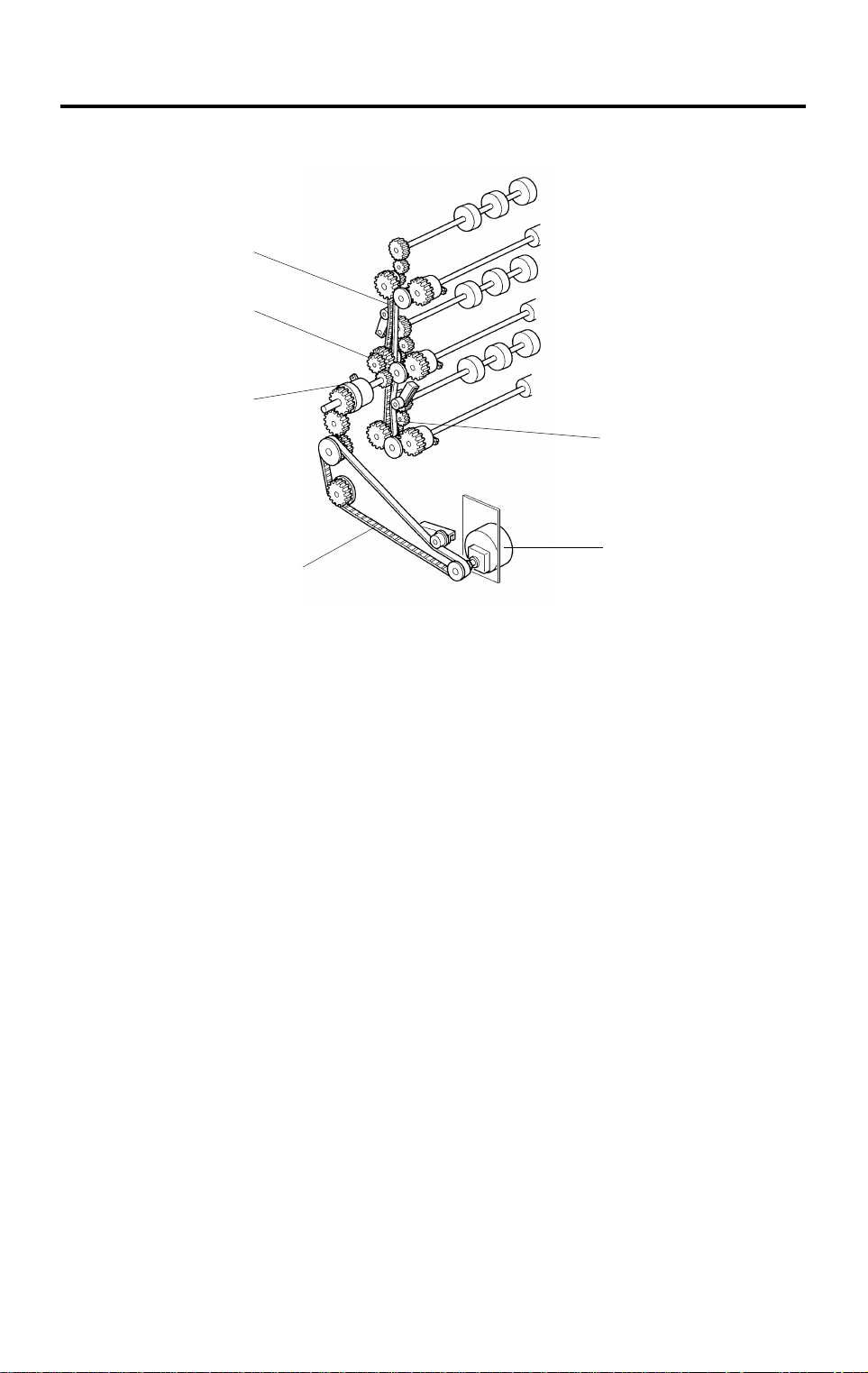

10 May 1996 COMPONENT LAYOUT

2.2 DRIVE LAYOUT

1

4

8

7

4

1. Vertical Transport Roller Gears

2. Paper Feed Clutch 1

3. Paper Feed Clutch 2

4. Separation Roller Gears

5. Paper Feed Clutch 3

A549V503.img

6. Main Motor

7. Relay Clutch

8. Timing Pulley

Options

A549/A550-3

Page 5

COMPONENT LAYOUT 10 May 1996

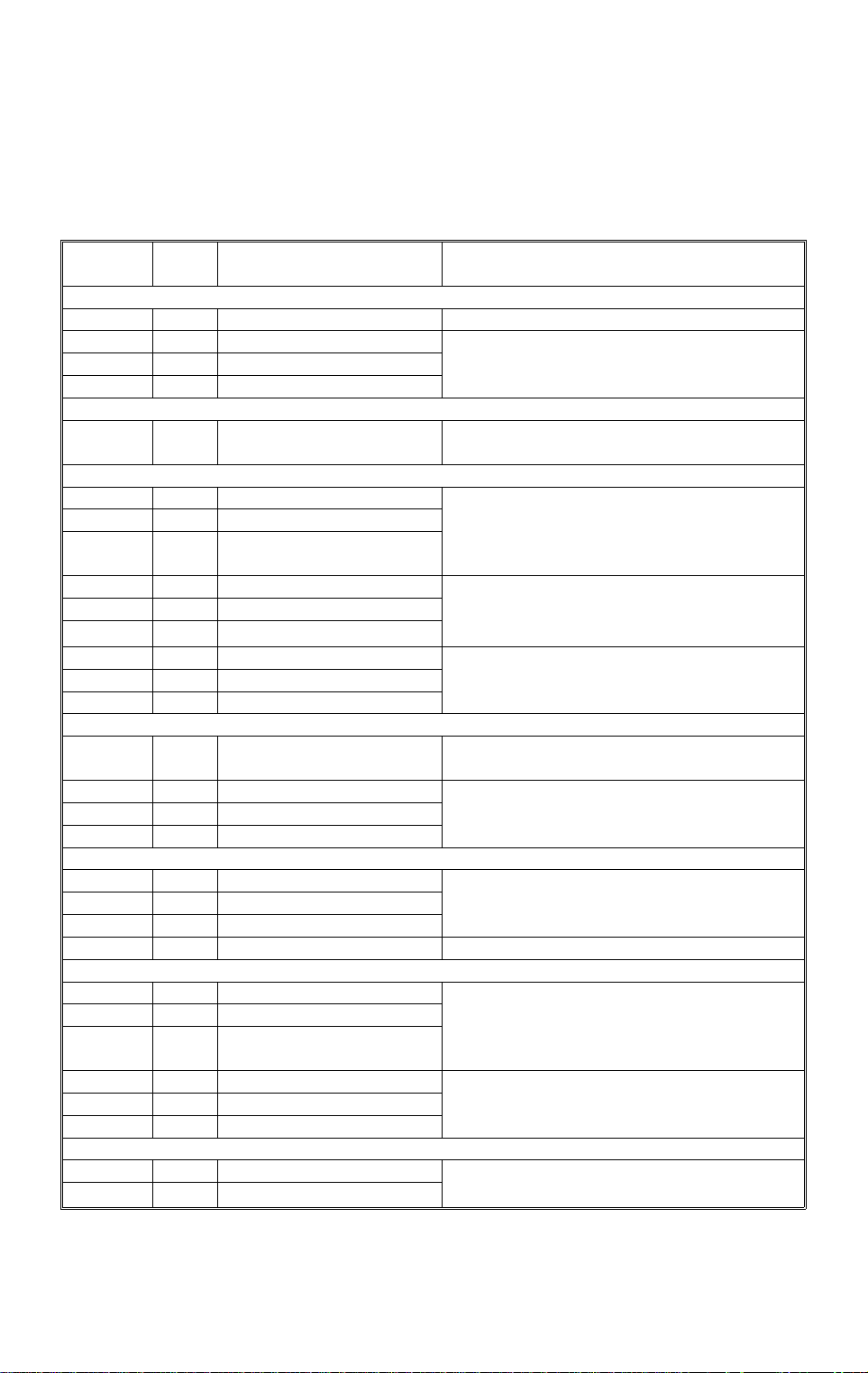

2.3 ELECTRICAL COMPONENT DESCRIPTI ON

Refer to the electrical compo nent layou t on the reverse side of the Point to

Point Diagram (on waterpro of paper).

Symbol

Motors

M1 5 Main Drives all the components of the paper tray

M2 2 Tray lift 1

M3 30 Tray lift 2

M4 29 Tray lift 3 (A549 only)

Circuit board

PCB1 1 Interface board

Sensors

S1 7 Tray upper limit 1

S2 18 Tray upper limit 2

S3 19

S4 25 Relay 1 Detects the leading edge of the paper as it

S5 23 Relay 2

S6 20 Relay 3

S7 28 Paper end 1

S8 24 Paper end 2

S9 21 Paper end 3 (A549 only)

Switches

SW1 22 Tray cover

SW2 3 Tray set 1

SW3 4 Tray set 2

SW4 6 Tray set 3 (A549 only)

Magnetic clutches

CL1 9 Paper feed 1

CL2 12 Paper feed 2

CL3 15 Paper feed 3 (A549 only)

CL4 11 Relay Drives the rollers in the paper trays

Solenoids

SOL1 8 Paper pick-up 1

SOL2 13 Paper pick-up 2

SOL3 16

SOL4 10 Separation 1

SOL5 14 Separation 2

SOL6 17 Separation 3

Heaters

H1 26 Tray (Option) Turns on when the main switch is off to

H2 27 Tray (Option)

Index

No.

Description Note

Tray upper limit 3 (A549

only)

Paper pick-up 3 (A549

only)

Raises the bottom plate in the paper tray

Controls the paper tray in response to

signals from the copier

Detects the top of the stack to stop the tray

lift motor

leaves the tray to control pick-up solenoid

and jam detection timing

Detects when the paper tray is empty

Detects whether the tray unit cover is open

and cuts the 24 Vdc power if it is

Detects whether the paper tray is in place

Starts feeding paper from the tray

Lifts/drops the pick-up roller

Lifts/drops the separation roller

keep the paper in the trays dry

A549/A550-4

Page 6

10 May 1996 OVERVIEW

3. OVERVIEW

[A]

[A]

[A]

A549D502.img

There are two types of paper tray un it: the two-t ray an d three-tray types.

Each paper tray [A] is a drawer type th at can hold up to 500 she et s of pape r.

The paper feed mechan ism uses an FRR feed system. Th e fu nct ion of th e

system is exactly the same as for the main machine except that the re is no

paper size detection. The paper size for each paper tray is input at the

operation panel, eith er by th e user or by a technician.

All the electrical components of the pap er tra y are con tro lled by the copier

main board through the tray interface board .

Options

A549/A550-5

Page 7

DRIVE MECHANISM 10 May 1996

4. DRIVE MECHANISM

[E]

[B]

[D]

[F]

[A]

[C]

A549D503.img

All the tray rollers are driven by the main motor [A] via timing belt s, clut che s

and a train of gears.

Drive is transmitted to the timing pulley [B] thro ugh the timin g belt [C] , rela y

clutch [D] and the gears.

Paper Feed Unit 1:

The drive from the timing pulley is transmitted to the unit throu gh the timing

belt [E].

Paper Feed Unit 2:

The drive from the timing pulley is directly transmitt ed to the unit.

Paper Feed Unit 3:

The drive from the timing pulley is transmitted to the unit throu gh the timing

belt [F].

The main motor and the relay clutch are energized at the same time that the

Start key is pressed.

The paper feed clutch is energize d 300 ms a ft er th e main moto r starts to

rotate. When th e pa pe r fee d clut ch fo r t he select ed paper tray is energized,

paper is fed from the paper tray to the main mach ine through the relay rollers.

A549/A550-6

Page 8

10 May 1996 PAPER FEED AND MISFEED DETECTION TIMING

5. PAPER FEED AND MISFEED DETECTION

TIMING

A4 Sideways, Lower Paper Feed Station, Line spe ed 200 mm/s

A549D504.wmf

J1 and J2: Checks whether the sensor is activated within 500 ms after

the designated time for these sensors.

Options

A549/A550-7

Page 9

SERVICE TABLES 10 May 1996

6. SERVICE TABLES

6.1 DIP SWITCHES

DIP SW 101 (Free Run Mode)

1234567 Function

Off------Speed in the free run mode: 200 mm/s

On------Speed in the free run mode: 150 mm/s

-OnOff----Bank type : 500 sheet type

-OffOn----Bank type : 250 sheet type

---OffOn--

- - - On Off - -

---OnOn--

-----OnOffFree Run Mode 2

-----OnOnFree Run Mode 1

-----OffOffNormal Operation

Normal Operation / Free Run Mode 1*: One-tray type

Free Run Mode 2*: Paper feed tray 1 only

Normal Operation / Free Run Mode 1*: Two-tray type

Free Run Mode 2*: Paper feed tray 2 only

Normal Operation / Free Run Mode 1*: Three-tray type

Free Run Mode 2*: Paper feed tray 3 only

Do not touch dip switches 1 to 5. Switch 8 is not used.

How to do a free run

1. Select either mode 1 or mode 2 with dip switches 6 and 7.

2. Turn off the power, disconnect th e optica l cable, and turn on the power.

3. Press SW101 on the PCB to sta rt th e free run.

4. When you wish to stop the free ru n, press SW1 02 on the PCB and return

the dip switches to their default set tings.

Free Run Mode 1

The paper feed operation performs up to 20 times for each pa per fee d statio n.

(10 s) (10 s) (10 s)

1st feed station 2nd feed station 3rd feed station

Repeat Two paper feed tray type

Repeat Three paper feed tray type

Free Run Mode 2

The paper feed operation run s for all pa per f eed sta tio ns at the same time .

A549/A550-8

Page 10

10 May 1996 SERVICE TABLES

6.2 TEST POINTS

NUMBER FUNCTION

TP101 + 5V

TP102 + 24V

TP103 GND

TP104 TXD (Transmit signal)

TP105 RXD (Receive signal)

TP106 GND

A549/A550-9

Options

Page 11

REPLACEMENT AND ADJUSTMENT 10 May 1996

7. REPLACEMENT AND ADJUSTMENT

7.1 EXTERIOR COVER REMO VAL

[E]

[A]

[D]

[B]

Rear Cover [A]: (2 screws)

Front Lower Cover [B]: [Two-tray type only]

1. Slide out the cassettes.

2. Remove the front lower cover (2 screws).

Right Front Cover [C]:

1. Remove the front lower cove r [ B] .

2. Remove the right front cover (2 screws).

Right Rear Cover [D]:

1. Remove the rear cover [A ].

2. Remove the right rear cover (2 screws).

Left Cover [E]:

1. Remove the rear cover [A ].

2. Remove the front lower cove r [ B] .

3. Remove the left cover (4 screws).

[C]

A549R507.wmf

A549/A550-10

Page 12

[B]

[D]

10 May 1996 REPLACEMENT AND ADJUSTMENT

7.2 PAPER FEED CLUTCH REPLACEMENT

[C]

A549R508.img

1. Remove the rear cover (see Exte rior Cover Removal).

2. Remove the timing belt [A].

3. Remove the drive unit [B] (2 screws, 2 con nectors).

4. Remove the separatio n rolle r gear [ C].

5. Remove the paper feed clutch [D] (1 conn ect or).

NOTE: When rein stalling the clutch, make sure that the clutch stop per

groove engages the sto pp er bracket.

[A]

Options

A549/A550-11

Page 13

REPLACEMENT AND ADJUSTMENT 10 May 1996

7.3 PAPER FEED UNIT REPLACEME NT

[A]

[B]

[C]

[D]

A549R509.wmf

1. Remove the paper feed clutch (see Paper Feed Clutch Replacement).

2. Remove the paper feed roller ge ar [A ].

3. Pull out all the trays.

4. Two-tray type only: Remove the front lower cove r (se e Ext erio r Cover

Removal).

5. Remove the front right cover [B] (2 screws).

6. Remove the paper feed unit [C] (2 screws fo r each unit ).

NOTE: When remo ving the paper feed unit, do the following .

• When removing the paper feed roller ge ar, remove the rubb er

foot [D].

• Remove the joint bracket .

After reinstalling th e pa per t ray, perf orm th e side -to side-re gistration

adjustment (see Removal and Adjustment in the manual for the

copier).

A549/A550-12

Page 14

[B]

10 May 1996 REPLACEMENT AND ADJUSTMENT

7.4 FEED ROLLER, PICK-UP ROLLE R, AND REVERSE

ROLLER REPLACEMENT

[C]

[D]

[A]

A549R510.wmf

1. Remove the paper feed tray [A ] (4 screws).

2. Remove the feed roller [B], pick-up rolle r [C], and reverse roller [D] (1 clip

each).

NOTE: Afte r re inst allin g th e pa per t ray, perf orm th e side -to -side registration

adjustment (see Removal and Adjustment in the manual for the

copier).

Options

A549/A550-13

Page 15

REPLACEMENT AND ADJUSTMENT 10 May 1996

7.5 RELAY SENSOR REPLACEMENT

[A]

[C]

[E]

A549R511.wmf

[B]

A549R513.img

1. Remove the rear cover (see Exterior Cover Removal).

2. Remove the right rear cover (see Exterior Cover Removal).

3. Remove the drive unit [A] (2 screws, 2 connectors).

4. Remove the vertical transpo rt un it [B ] (2 screws).

5. Remove the vertical transpo rt gu ide [C] (4 screws).

[D]

A549R512.wmf

6. Remove the sponge [D].

7. Remove the relay sensors [E ] (1 con ne cto r e ach ).

A549/A550-14

Page 16

PAPER TRAY UNIT (A549/A550) INSTALLATION 10 May 1996

4. PAPER TRAY UNIT (A549/A550)

INSTALLATION

4.1 ACCESSORY CHECK

Check the quantity and cond itio n of the accessories in the box with the

following list:

1. Right Support Bracket .....................................................................1

2. Left Support Bracket........................................................................1

3. Joint Bracket....................................................................................1

4. Shoulder Screw ..............................................................................1

5. Screw - M4 x 8............... .......... .. .. .......... .. .......... .. .. .......... .. .......... .. ..4

6. New Equipment Condition Report...................................................1

7. Installation Procedure .....................................................................1

3-38

Page 17

[A]

10 May 1996 PAPER TRAY UNIT (A549/A550) INSTALLATION

4.2 INSTALLATION PROCEDURE

A549I509.wmf A549I510.wmf

Installation

A549I511.wmf

CAUTION

I

Unplug the copier power cord before starti ng the follow ing proc edur e.

NOTE: Keep the shipping retaine rs aft er inst alling the machine. They will be

reused if the machine is transported to another location. Proper

reinstallation of the shipping retainers is required in order t o avoid

any transport damage.

1. Remove the strips of tape.

2. Remove the bottom plate stopper [A].

3-39

Page 18

PAPER TRAY UNIT (A549/A550) INSTALLATION 10 May 1996

[B]

[F]

[I]

[D]

[H]

[D]

[J]

A549I513.wmf

A549I512.wmf

[C]

For Copiers with an LCT: Do not lift the

copier by holding the LCT unit.

[G]

[E]

[K]

A549I514.wmf

3. Set the copier [B] on th e pa pe r tray un it [C] . Alig n the 2 pins [D] on the

paper tray unit with the holes in the base plate of the copier.

4. Open the lower door [ E] . Also , op en eith er th e LCT [F] or the upp er righ t

door [F], (depending on the type of copier).

5. Secure the copier to the paper tray unit with the joint bra cket [G] .

6. Connect the cable [H] an d op tic fib er [I].

7. Attach the support bracke ts [J] to the bottom of the pap er tra y unit as

shown (4 screws).

CAUTION

I

If you do not attach the support bracket, the machine may fal l

forwards when the paper tray s are pull ed open.

8. Pull out the paper tray an d loa d pa pe r into it . (The pape r size and

direction for each tray sho uld be designated by a customer. )

Position the side and rear fences properly.

9. Turn on the main switch.

10. Enter the prope r pap er size for each paper tray by following the

procedure in the copier’s manual.

11. Attach the appropriate tray decals [K] which are included in the accessory

box with the main copier.

12. Check the machine ’s ope rat ion and copy qu alit y.

3-40

Page 19

10 May 1996 PAPER TRAY UNIT (A549/A550) INSTALLATION

4.3TRAY HEATER (OPTION)

[E]

[F]

[B]

[E]

[F]

[C]

- Two-tray type -

A549I516.wmf

[A]

[H]

- Three-tray type -

[D]

A549I515.wmf

1. Remove the rear cover [A].

[A]

[G]

A549I517.wmf

2. Two-tray type: Remove the second paper tray [B] (4 screws) and the

lower front cover [C] (2 screws).

Installation

Three-tray type: Remove the second and third paper feed trays [D] (4

screws each).

3. Install the tray heaters [E] (2 screws each).

4. Install the clamper [F] and clamp the heater harnesses.

5. Install the heater bracket [G] (2 screws).

6. Connect the heater harnesses.

7. Install the clamper [H] and clamp the heater harnesses.

NOTE:After replacing the paper tray, perform the side-to-side registration

adjustment (see Replacement and Adjustment in the copier manual).

3-41

Page 20

Page 21

PAPER TRAY UNIT (A549/A550) ELECTRICAL COMPO NENT

4

5

17

18

LAYOUT

29

28

27

30

26

12

3

6

7

8

9

10

11

12

13

14

15

16

25

24

23

14

202122

19

A166S502.wmf

Page 22

Index No. Description P to P

Location

1 Interface Board (PCB1) F8

2 Tray Lift Motor 1 (M2) E2

3 Tray Set Switch 1 (SW2) H2

4 Tray Set Switch 2 (SW3) H2

5 Main Motor (M1) F2

6 Tray Set Switch 3 (A549 only) (SW4) I2

7 Tray Upper Limit Sensor 1 (S1) E16

8 Paper Pick-up Solenoid 1 (SOL1) D16

9 Paper Feed Clutch 1 (CL1) K16

10 Separation Solenoid 1 (SOL4) E16

11 Relay Clutch (CL4) J16

12 Paper Feed Clutch 2 (CL2) K16

13 Paper Pick-up Solenoid 2 (SOL2) F16

14 Separation Solenoid 2 (SOL5) G16

15 Paper Feed Clutch 3 (A549 only) (CL3) L16

16 Paper Pick-up Solenoid 3

(A549 only) (SOL3)

17 Separation Solenoid 3 (A549 only) (SOL6) J16

18 Tray upper Limit Sensor 2 (S2) G16

19 Tray upper Limit Sensor 3

(A549 only) (S3)

20 Relay Sensor 3 (A549 only) (S6) C16

21 Paper End Sensor 3 (A549 only) (S9) H16

22 Tray Cover Switch (SW1) A16

23 Relay Sensor 2 (S5) B16

24 Paper End Sensor 2 (S8) F16

25 Relay Sensor 1 (S4) B16

26 Tray Heater (Option) (H1) B6

27 Tray Heater (Option) (H2) C6

28 Paper End Sensor 1 (S7) C16

29 Tray Lift Motor 3 (A549 only) (M4) F2

30 Tray Lift Motor 2 (M3) E2

I16

I16

15

Loading...

Loading...