Page 1

PRINTER CONTROLLER

(Machine Code: B335, B336, B337)

Page 2

TABLE OF CONTENTS

1. OVERALL MACHINE INFORMATION........................................1-1

1.1 INTRODUCTION...................................................................................... 1-1

1.2 SPECIFICATIONS.................................................................................... 1-2

1.3 SOFTWARE ............................................................................................. 1-2

1.3.1 PRINTER DRIVERS........................................................................ 1-2

1.3.2 NETWORK UTILITIES..................................................................... 1-2

1.4 MACHINE CONFIGURATION.................................................................. 1-3

1.5 STRUCTURE............................................................................................ 1-4

1.5.1 BLOCK DIAGRAM........................................................................... 1-4

1.5.2 DESCRIPTIONS.............................................................................. 1-5

2. DETAILED SECTION DESCRIPTIONS.......................................2-1

2.1 HARDWARE OVERVIEW ........................................................................ 2-1

2.2 IMAGE PRINTING.................................................................................... 2-3

2.3 IMAGE DATA PROCESSING................................................................... 2-4

2.3.1 EDGE SMOOTHING........................................................................ 2-4

2.3.2 TONER SAVING MODE.................................................................. 2-4

2.4 FEATURES............................................................................................... 2-5

2.4.1 SORT............................................................................................... 2-5

2.4.2 DUPLEX........................................................................................... 2-5

2.4.3 STAPLE........................................................................................... 2-6

2.4.4 PUNCH............................................................................................ 2-6

2.4.5 JAM RECOVERY............................................................................. 2-7

2.4.6 AUTO TRAY SELECT ..................................................................... 2-7

2.4.7 POWER ON SELF-DIAGNOSTICS................................................. 2-7

Test Items............................................................................................ 2-7

2.5 HARD DISK.............................................................................................. 2-8

2.5.1 PRINTER HDD ................................................................................ 2-8

2.5.2 ENGINE HDD AND CD-R/RW......................................................... 2-8

3. INSTALLATION PROCEDURE...................................................3-1

3.1 PRINTER CONTROLLER (B335/B336).................................................... 3-1

3.1.1 ACCESSORY CHECK..................................................................... 3-1

3.1.2 INSTALLATION PROCEDURE........................................................ 3-1

3.2 PRINTER CONTROLLER (B337)............................................................. 3-4

3.2.1 ACCESSORY CHECK..................................................................... 3-4

3.1.2 INSTALLATION PROCEDURE........................................................ 3-4

3.3 NETWORK INTERFACE BOARD (A855)................................................. 3-8

3.3.1 INSTALLATION PROCEDURE........................................................ 3-8

3.4 POSTSCRIPT KIT (B338)......................................................................... 3-9

3.4.1 INSTALLATION PROCEDURE........................................................ 3-9

3.5 HARD DISK (B349) ................................................................................ 3-10

3.1.1 INSTALLATION PROCEDURE...................................................... 3-10

1

Page 3

3.6 SDRAM DIMM........................................................................................ 3-11

3.6.1 REQUIRED SPECIFICATION CHECK.......................................... 3-11

3.6.2 INSTALLATION PROCEDURE...................................................... 3-11

3.7 CONNECTING THE INTERFACE CABLES........................................... 3-12

3.1.1 PARALLEL INTERFACE ............................................................... 3-12

3.1.2 NETWORK INTERFACE............................................................... 3-12

3.8 CHECKING THE CONNECTION............................................................ 3-12

3.8.1 CONNECTION BETWEEN BASE ENGINE AND PRINTER

CONTROLLER (AND RELATED OPTIONS; POSTSCRIPT ROM,

SDRAM DIMM, HARD DISK DRIVE, NIB)...................................... 3-12

3.8.2 CONNECTION BETWEEN PRINTER CONTROLLER BOARD

AND NETWORK INTERFACE BOARD.......................................... 3-14

How to Print the Network Interface Board Status Sheet..................... 3-14

4. SERVICE TABLES......................................................................4-1

4.1 GENERAL CAUTION................................................................................ 4-1

4.2 SERVICE PROGRAM MODE................................................................... 4-1

4.2.1 SERVICE PROGRAM ACCESS PROCEDURE.............................. 4-1

Entering SP mode................................................................................ 4-1

Exiting SP mode................................................................................... 4-1

4.2.2 SERVICE PROGRAM MODE TABLES........................................... 4-1

4.3 FIRMWARE DOWNLOAD........................................................................ 4-2

4.3.1 FIRMWARE UPDATE USING A FLASH MEMORY CARD

(SP02 AND 04)............................................................................... 4-2

4.3.2 FIRMWARE UPDATE USING PARALLEL PORT............................ 4-3

4.3.3 HARD DISK FORMAT..................................................................... 4-3

4.3.4 COPY FLASH ROM......................................................................... 4-4

Download from ROM DIMM to Printer Controller................................. 4-4

Download from the Controller to ROM DIMM....................................... 4-5

4.3.5 PARALLEL LOOP BACK TEST (SP11)........................................... 4-5

4.4 USER PROGRAM MODE......................................................................... 4-6

4.4.1 UP MODE TABLE (PRINTER FEATURES)..................................... 4-6

4.5 DIP SWITCHES/JUMPER PINS/LEDS..................................................... 4-7

4.5.1 DIP SWITCHES............................................................................... 4-7

4.5.2 JUMPER PINS................................................................................. 4-7

4.5.3 LEDS ............................................................................................... 4-7

5. REPLACEMENT AND ADJUSTMENT ........................................ 5-1

5.1 PRINTER CONTROLLER BOARD........................................................... 5-1

5.2 HARD DISK.............................................................................................. 5-3

5.3 NETWORK INTERFACE BOARD ............................................................ 5-4

5.4 POSTSCRIPT DIMM................................................................................ 5-4

5.5 SDRAM DIMM.......................................................................................... 5-5

2

Page 4

6. TROUBLESHOOTING.................................................................6-1

6.1 ERROR MESSAGES................................................................................ 6-1

Service Call (SC) Codes...................................................................... 6-1

Other Messages................................................................................... 6-2

6.2 LEDS........................................................................................................ 6-3

6.2.1 LOCATION....................................................................................... 6-3

6.2.2 LED CODE TABLE.......................................................................... 6-3

Self-diagnostics.................................................................................... 6-3

Controller Firmware Copy/Download ................................................... 6-4

3

Page 5

1 March, 2000 INTRODUCTION

1. OVERALL MACHINE INFORMATION

1.1 INTRODUCTION

The base engine (Machine Code: A292/A293 and A294/A295) contains an

interface for the multi-function controller. The multi-function controller adds printer

functions. The printer functions can operate independently and simultaneously with

other functions in the background, and their output can be interleaved with the

copy mode output.

The printer supports PCL6 and PostScript 3. The PostScript language is an

optional function.

Print data from the host is transmitted through the standard parallel port or an

optional Network Interface Board (NIB). The parallel port supports bi-directional

Command and Status feed back communication with the base engine.

An optional IDE hard disk drive provides font download and macro download.

An additional SDRAM can be installed to boost the printer performance.

Print data is rasterized at 600 dpi in the controller.

The A294 and A295 engines can print 85 and 105 pages per minute respectively at

600 dpi. The A292 and A293 engines can print 55 and 70 pages per minu te

respectively at 600 dpi.

Overall

Information

1-1

Page 6

SPECIFICATIONS 1 March, 2000

1.2 SPECIFICATIONS

Resolution: 600 x 600 dpi

Gray Scale: 256 levels

Printing Speed: 85 ppm (A294), 105 ppm (A295)

55 ppm (A292), 70 ppm (A293)

Printing Emulation: Main Controller Board: PCL6 (5e + XL)

Optional PS Board: PostScript 3

Printer Fonts: 45 scaleable typefaces in 14 typeface families

(35 Intellifont and 10 TrueType format fonts)

6 bitmapped typefaces in the Line Printer typeface family

Printer Interface: IEEE1284/ECP Bi-directional Parallel x 1 (Standard)

Network Interface x 1 (Option)

Ethernet (100 base-TX/10 base-T for TCP/IP, IPX/SPX,

EtherTalk)

DRAM Capacity: 32 MB (Standard)

An optional SDRAM slot (up to 128 MB)

Total: Up to 160 MB

1.3 SOFTWARE

1.3.1 PRINTER DRIVERS

The following printer drivers are enclosed in the printer manual/driver kit:

•

PCL5e Printer Driver for Windows 95/98/NT4.0

•

PCL6 Printer Driver for Windows 95/98/NT4.0

•

PS3 Printer Driver for Windows 95/98/NT4.0 and Macintosh

1.3.2 NETWORK UTILITI ES

The network utilities are enclosed with the Network Interface Board (NIB) option.

Refer to the NIB manual for details.

1-2

Page 7

1 March, 2000 MACHINE CONFIGURATION

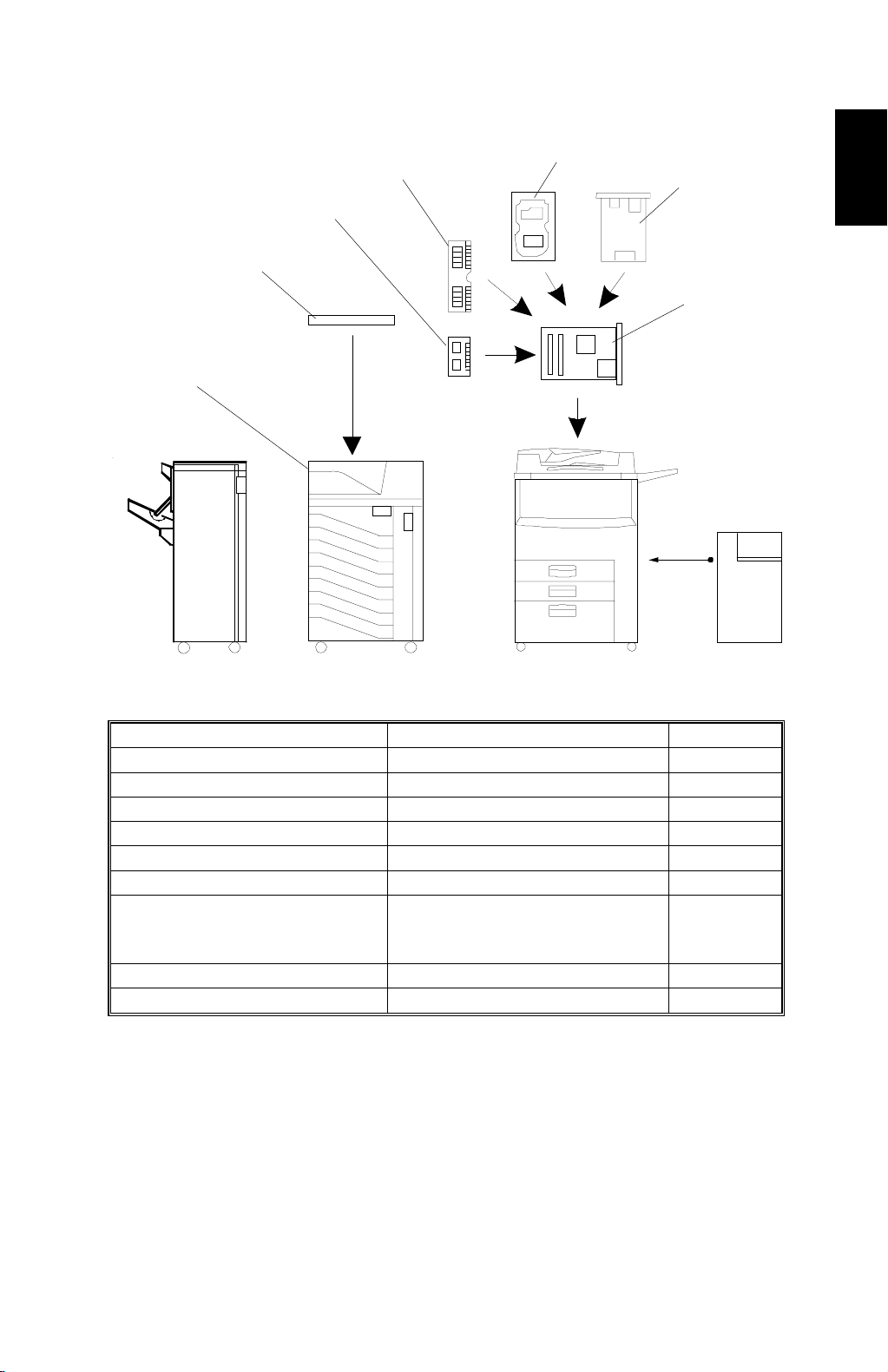

1.4 MACHINE CONFIGURATION

5

4

3

2

1

6

7

Overall

Information

Base Engine

Item Machine Code No.

Mailbox G909 (A292/A293 only) 1

Mailbox Bridge Unit G912 (A292/A293 only) 2

PostScript Kit B338 3

SDRAM --- 4

Hard Disk B349 5

Network Interface Board A855 6

B335 (A295)

Printer Controller

Printer Manual/Driver Kit --- ---

B336 (A294)

B337 (A292/A293)

A852V500.WMF

7

1-3

Page 8

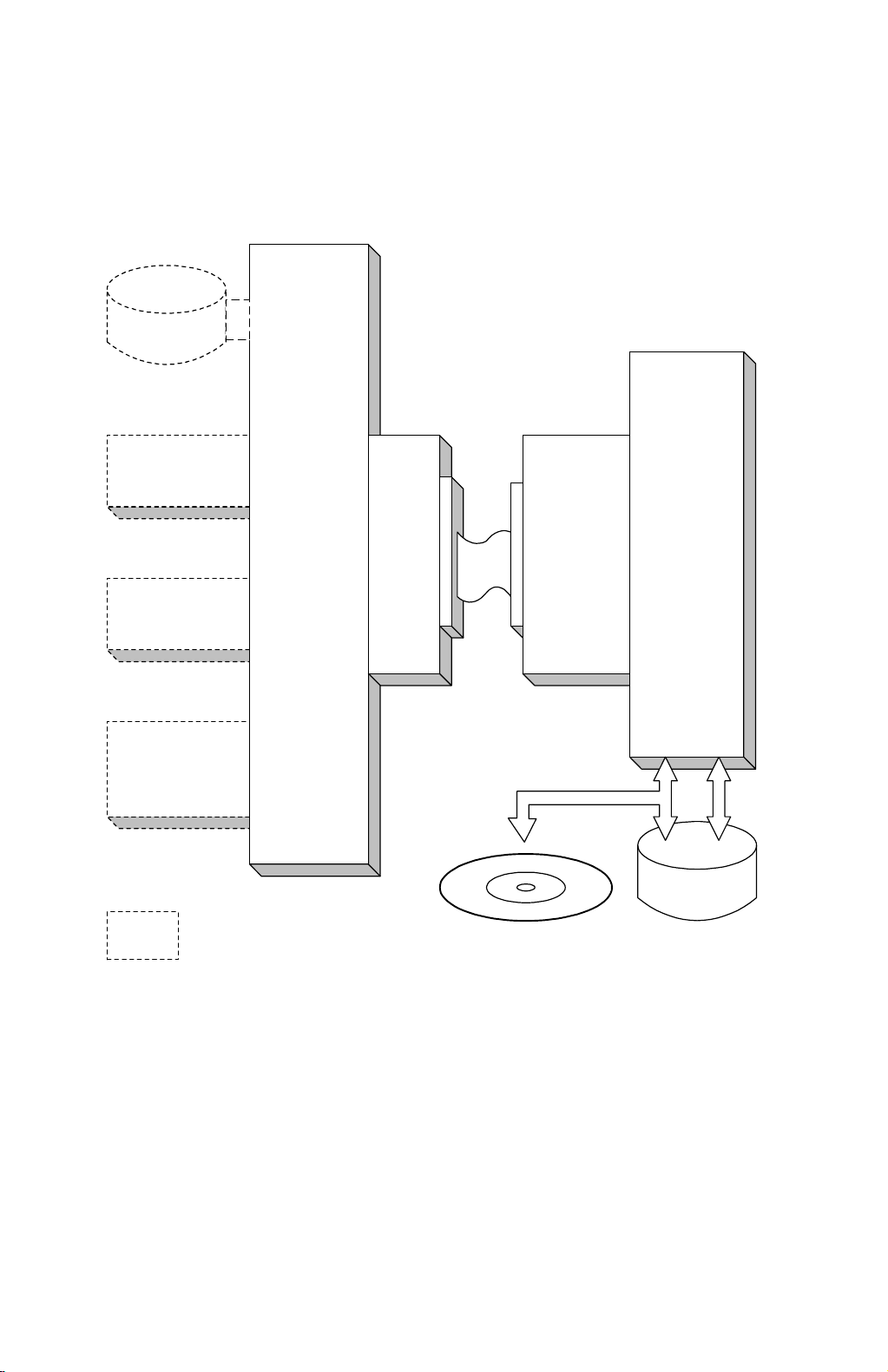

STRUCTURE 1 March, 2000

1.5 STRUCTURE

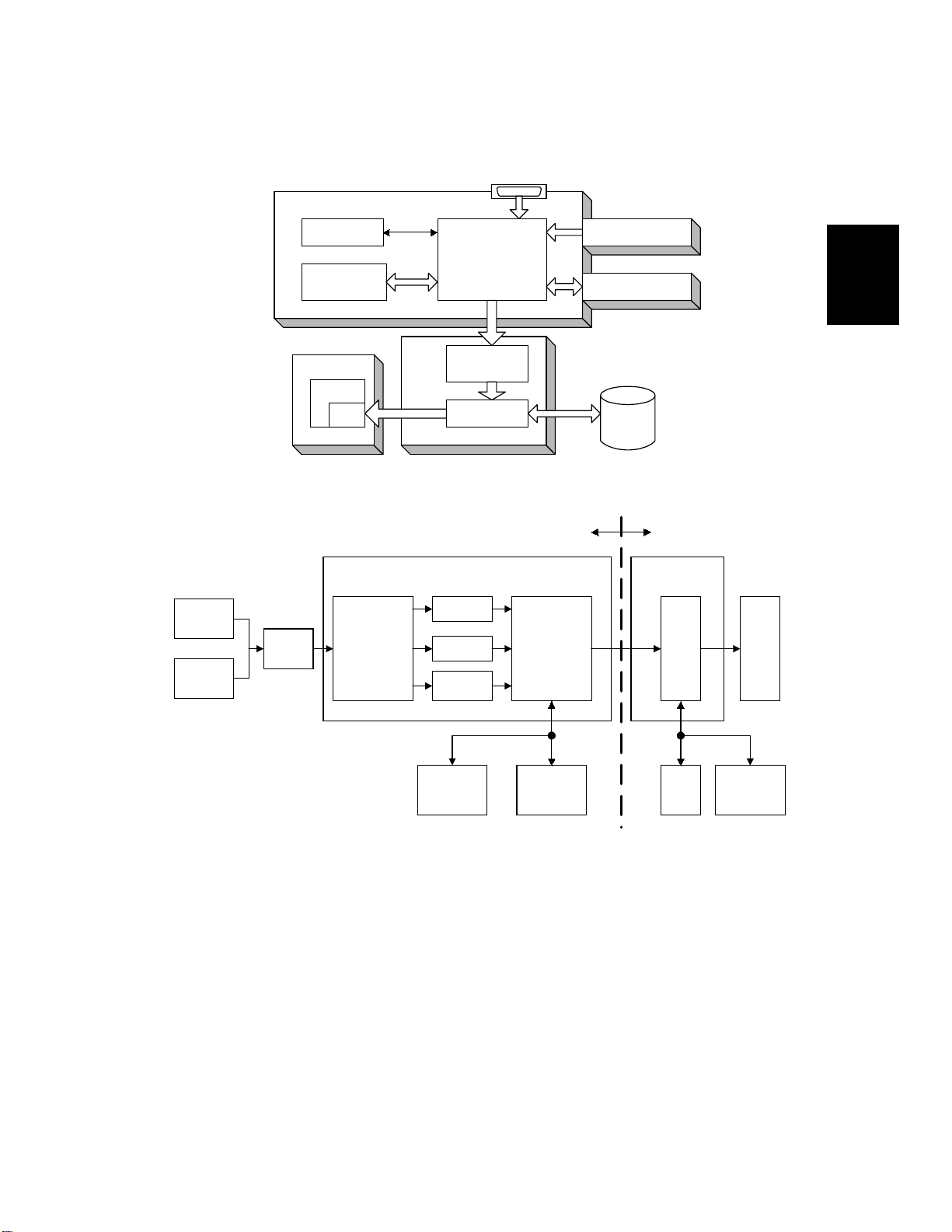

1.5.1 BLOCK DIAGRAM

Hard Disk

(Controller)

PS Kit

SDRAM

Network

Interface

Board

: Printer's Options

Printer

Controller

MB

Interface

Board

CD-R/RW

SICU

(A294/

A295)

BICU

(A292/

A293)

Hard Disk

(Base Engine)

1-4

B335V501.WMF

Page 9

1 March, 2000 STRUCTURE

1.5.2 DESCRIPTIONS

1. Printer Controller

The printer controller handles the following functions:

•

Printer host interface

•

Printing functions

•

Interface and control of controller options (Hard disk, PostScript kit, Network

interface board and SDRAM)

2. Hard Disk (option)

This stores additional soft fonts and macros (both PCL and PostScript fonts).

3. PostScript Kit (option)

This is to add the PostScript 3 feature.

Overall

Information

4. Network Interface Board (option)

The network interface board is an additional printer interface to allow the printer

to be used on a network.

5. SDRAM (option)

There are two SDRAM slots. One slot is for the standard 32 MB SDRAM

module. The other is used for additi onal pr i nter pr ocessi ng me mor y, and a 32,

64, or 128 MB SDRAM module (168 pin PC100) can be installed here. As a

result, up to 160 MB of RAM are installable (32 MB plus 128 MB).

6. Mother Boar d (MB)

This connects the controller to the SICU (A294/A295)/BICU (A292/A293) board

in the printer controller bo x.

1-5

Page 10

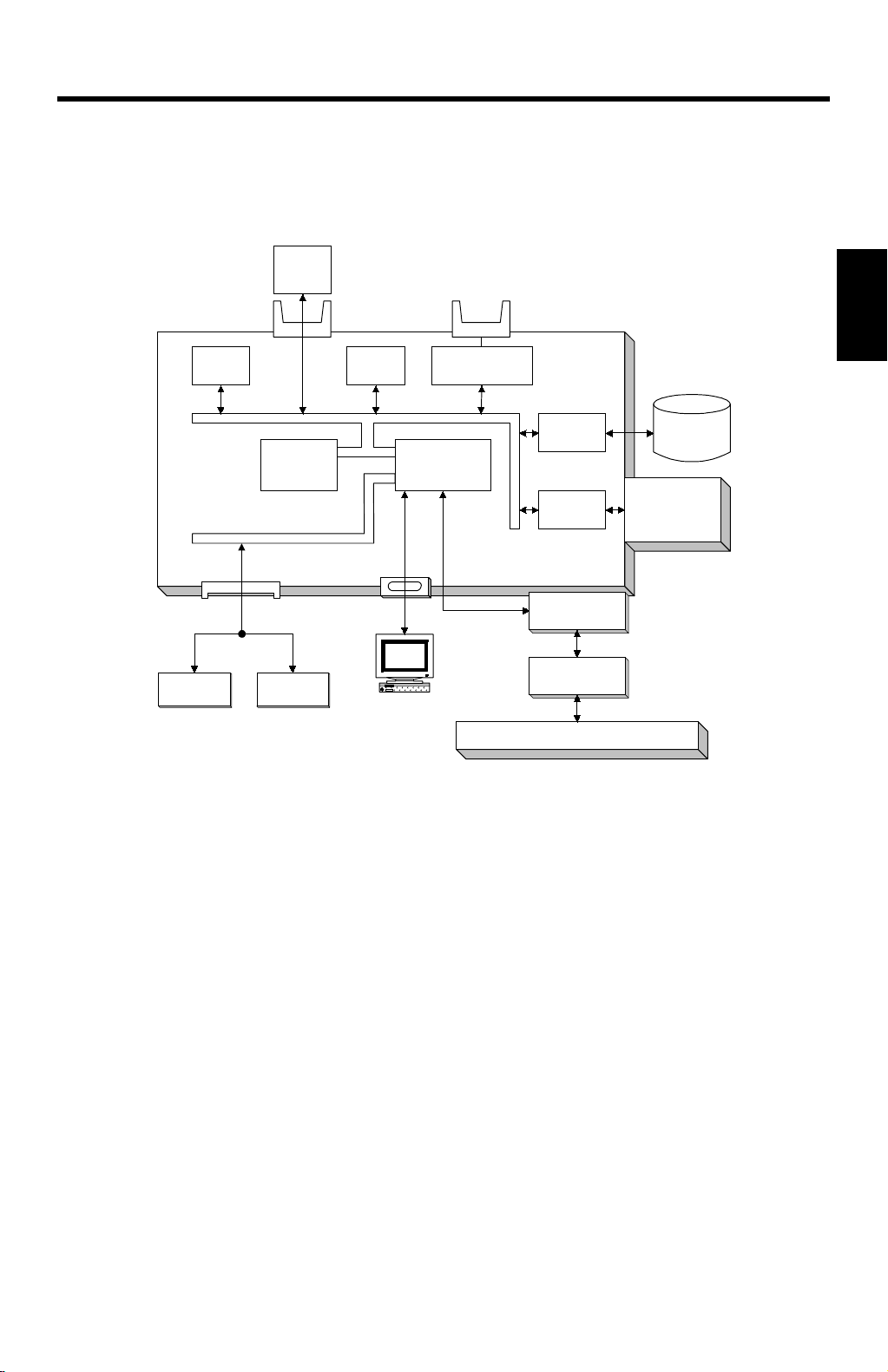

1 March, 2000 HARDWARE OVERVIEW

2. DETAILED SECTION DESCRIPTIONS

2.1 HARDWARE OVERVIEW

Flash

ROM

DIMM

Flash

ROM

CPU

DRAM Bus

NVRAM

CPU Bus

Flash Memory

Card I/F

ROM & I/O Bus

Co-

Processor

EIDE Disk

Interface

NIB

Interface

Printer Controller

HDD

Network

Interface

Board

Detailed

Descriptions

Mother Board

Opt.

SDRAM

Std.

SDRAM

PC/AT Compatible

via Parallel Port

SICU (A294/A295)/BICU (A292/A293)

Interface

Board

B335D500.WMF

The above block diagram shows the major components of the printer controller.

The main features of the controller are as follows.

1. CPU

A Motorola Power PC 740 processor is used. A 66-MHz oscillator is used as the

clock source for both this CPU and the coprocessor.

The processor has a bus clock of 66 MHz and an internal clock of 266 MHz.

2. Co-processor (Peerless QP1910)

This performs the following functions:

•

ROM control

•

I/O control

•

DRAM control

•

Printer video interface

•

Printer communication interface

•

IEEE 1284 compliant bi-directional parallel por t in terface

•

Interrupt control

2-1

Page 11

HARDWARE OVERVIEW 1 March, 2000

3. ROM memory

1) Flash ROM (4 MB)

This flash ROM includes boot code, operation system code, PCL5e codes,

PCL6 code, and font data for PCL languages (resident fonts).

2) Flash ROM DIMM (4 MB for the PostScript option)

This ROM DIMM includes the PostScript code and PostScript font data.

3) SDRAM DIMM (32 MB and an option slot)

This SDRAM DIMM provides page memory and work area.

4. NVRAM (8 KB)

The NVRAM contains the system parameters, printer settings, job record data,

and error record data.

5. Network Interface Board Interface

This controls the optional network interface board provided to support the

network operations.

6. Hard Disk Drive Interface (Enhanced IDE: 6 GB)

The HDD interface is provided to support storage of fonts and macros

downloaded from a PC.

7. Flash Memory Card Interface (PCMCIA Card Slot)

The flash memory card for updating the controller and PostScript firmware is

connected to the flash memory card slot.

8. Power-on Self Diagnostics

When the main power switch is turned on, the controller performs a selfdiagnostic test.

2-2

Page 12

1 March, 2000 IMAGE PRINTING

2.2 IMAGE PRINTING

Parallel Interface, from PC

Printer Controller

NIB

Parallel

Buffer

CPU

Std. SDRAM

DIMM

LD Unit

GAVD

FCI

Co-processor

Intelligent

Personality

Selection

Co-processor

SICU/BICU

PCL-5e

PCL-6

Post

script

IPU

MSU

Image Data

Generation

NIB

Opt. SDRAM

DIMM

HDD

B335D502.WMF

Base EnginePrinter Controller

SICU/BICU

IPU LD

Detailed

Descriptions

Std.

SDRAM

DIMM

Opt.

SDRAM

DIMM

HDD

B335D503.WMF

CD-R/

RW

The printer controller receives print data from a PC through the parallel or network

interface port. The co-processor handles the print data but it only makes raster

image. All image processing, such as edge smoothing and toner saving, are done

in the base engine.

The print data from the PC goes to the buffer in the SDRAM DIMM and then goes

to the co-processor. The co-processor automatically selects the appropriate printer

language and creates the print data to match the selected printer language. Then,

the co-processor sends the print data to the LD unit through the IPU on the SICU

or BICU board. At the same time, the data is also sent to the hard disk for multiple

printing, as well as for backup in case of a paper jam.

2-3

Page 13

IMAGE DATA PROCESSING 1 March, 2000

2.3 IMAGE DATA PROCESSING

The FCI in the LD unit is responsible for edge smoothing and toner saving

functions.

The edge smoothing and toner saving modes can be switched on or off using the

printer user tools or the printer driver.

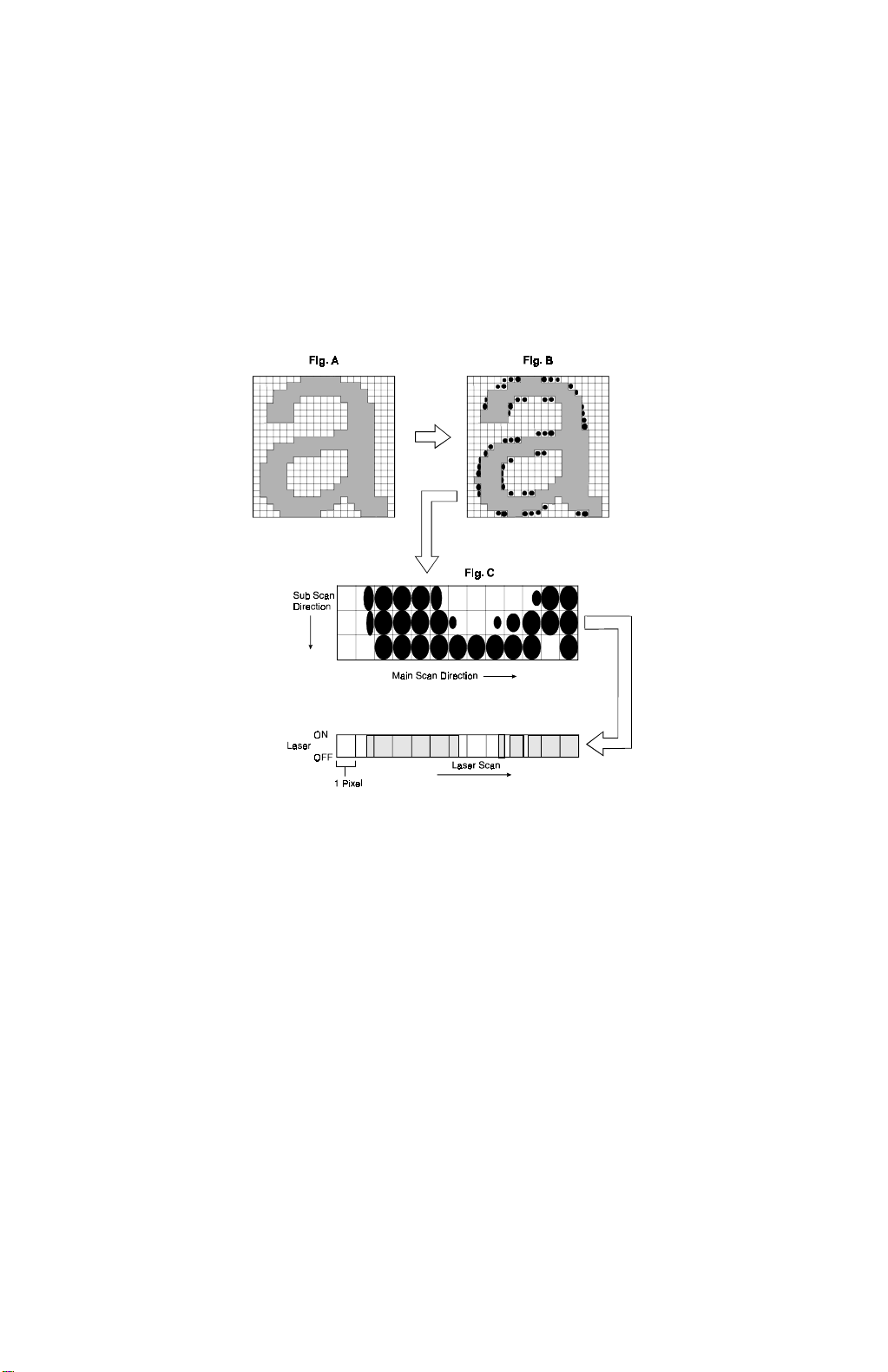

2.3.1 EDGE SMOOTHING

A850D504.WMF

Usually, binary picture processing generates jagged edge on characters (Fig. A).

The FCI reduces the edges of characters using edge smoothing.

Whether a pixel undergoes smoothing depends on the surrounding image data.

Changing the laser pulse position for certain pixels does the smoothing.

2.3.2 TONER SAVING MODE

Toner saving is done by reducing the number of black dots printed, not by varying

the development bias. In toner saving mode, the image data is filtered through a

matrix.

As a result of passing through the filter, less toner is used to create the latent

image on the drum and black areas are printed as gray.

2-4

Page 14

1 March, 2000 FEATURES

2.4 FEATURES

2.4.1 SORT

If “Collate” is turned on when a multi-set job is printed, the first set of the job is

directly printed. At the same time, the print data for the copy job is stored in the

hard disk of the base engine. The remaining sets are printed using the data in the

engine hard disk.

If the finisher is not installed, the rotate sort feature can be used. The SICU or

BICU rotates the image in the same way as the copy mode.

2.4.2 DUPLEX

Duplex printing is available with all output options such as finisher or mailbox but

not with all paper sizes (refer to the specifications section of the base engine

manual). If the selected paper size is not usable in the duplex mode, the job is

printed simplex.

Two types of duplex binding can be selected. Those are short-edge binding and

long-edge binding.

In short-edge binding, the image may be rotated when printing on the second side

of a sheet of paper. The co-processor in the printer controller does the rotation.

The co-processor corrects the page order for duplex printing as follows:

•

Larger than A4 lengthwise/8

1st page – 3rd page – 2nd page – 5th page – 4th page – 7th page – 6th page –

8th page

”x11” (in the case of 8 pages)

1/2

Detailed

Descriptions

•

A4 lengthwise/8

”x11” or smaller (in the case of 14 pages)

1/2

1st page – 3rd page – 5th page – 2nd page – 7th page – 4th page – 9th page –

6th page – 11th page – 8th page – 13th page – 10th page – 12th page – 14th

page

2-5

Page 15

FEATURES 1 March, 2000

2.4.3 STAPLE

The staple function is only available when a finisher is installed.

The finisher has the following stapling positions:

1) Top left slant

2) Top left horizontal

3) Top left vertical

4) Top two staples

5) Left two staples

Depending on the paper orientation, the image may have to be rotated. The coprocessor in the printer controller does this image rotation.

There is a limit for the number of sheets that can be stapled by the finisher. If the

number of sheets for stapling is more than the limit, the set is not stapled.

2.4.4 PUNCH

The punch function is only available when a punch unit is installed on the finisher.

There are several types of punch unit, each having different numbers of holes. The

punching position in relation to the printed image depends on the paper feeding

orientation and imaging. The punching positions are as follows:

1) Left

2) Top

2-6

Page 16

1 March, 2000 FEATURES

2.4.5 JAM RECOVERY

If the jam recovery feature is on and a paper jam occurs, the controller reprints all

the pages that have not been fed out. In usual cases, all image data from the

controller is sent to the hard disk in the base engine. When a jam occurs, the

recovery data is sent from this hard disk.

2.4.6 AUTO TRAY SELECT

When “Auto Select” is selected with the printer driver, the printer searches for a

tray that contains a suitable size and paper type. The search starts from the LCT

as below.

LCT – 1st tray – 2nd tray – 3rd tray

The default setting for the tray priority is LCT. If the LCT is not installed, the default

is the 1st tray.

2.4.7 POWER ON SELF-DIAGNOSTICS

When the main power switch is turned on, the printer controller performs a selfdiagnostic test. If an error is detected, an error message is displayed on the LCD of

the operation panel.

Test Items

Devices always tested

• Co-processor

• Flash ROM

• SDRAM DIMM

• NVRAM

• Engine I/F

Detailed

Descriptions

Devices tested when they are installed

• PS DIMM I/F

• HDD I/F

• Network interface board I/F

The LEDs on the controller board show how the diagnostic is progressing (see

Troubleshooting).

2-7

Page 17

HARD DISK 1 March, 2000

2.5 HARD DISK

Two types of hard disk are used for the printer functions. One type is connected to

the printer controller (Printer HDD). Th e other is in the base engine (Engine HDD).

2.5.1 PRINTER HDD

After installing the printer HDD, it must be formatted. When the main power switch

is turned on and the printer mode key is pressed, the hard disk can be formatted.

When the Con tinue button is pressed, the hard disk is formatted and two partitions

are made. One partition is for PCL and the other is for PostScript (fonts and

macros only).

If the Cancel button is pressed, it is judged that the printer HDD is not installed. If

the Cancel button is pressed by mistake, the printer HDD ca n be formatted by

turning the main power switch off and on or entering the Service Program (SP)

mode.

2.5.2 ENGINE HDD AND CD-R/RW

The hard disk in the base engine is used for the copy, printer, and document server

modes. Therefore, the hard disk has three partitions for each mode. (Refer to HDD

Control in the base engine manual.)

Print data can be saved on the HDD (document server) and on the CD-R/RW via

the document server.

2-8

Page 18

1 March, 2000 PRINTER CONTROLLER (B335/B336)

3. INSTALLATION PROCEDURE

3.1 PRINTER CONTROLLER (B335/B336)

3.1.1 ACCESSORY CHECK

No. Description Q’ty No. Description Q’ty

1 Controller Box 1 6 Screw 8

2 Interface Board 1 7 Cover Bracket 1

3 Bracket – Interface Board 1 8 Ferrite Core 1

4 Interface Cable 1 9 Pr int er Key Top 1

5 Cable Clamp 2

3.1.2 INSTALLATION PROCEDURE

[A]

Installation

[C]

[B]

B316I601.WMF

ø

CAUTION

Unplug the copier power cord before starting the following procedure.

1. Disconnect the ADF connector.

2. Remove the upper rear cover [A] (6 screws).

3. Remove the lower rear cover [B] (6 screws).

4. Remove the printer cover [C].

3-1

Page 19

PRINTER CONTROLLER (B335/B336) 1 March, 2000

[E]

[A]

[C]

[D]

[F]

[G]

[B]

B337I602.WMF

[I]

[H]

B337I605.WMF

5. Pass the interface cable [A] through the cover bracket [B].

6. Attach the ferrite core [C] to the cable.

7. Connect the interface cable to the printer controller [D].

8. Attach the cover bracket (1 clamp [E], 2 screws).

9. Connect the power supply cable [F].

10. Install the controller box [G] (2 screws).

11. Connect the interface cable [H] and attach the metal clamp [I] (1 screw).

12. Reinstall the upper and lower rear covers.

3-2

Page 20

1 March, 2000 PRINTER CONTROLLER (B335/B336)

[A]

[B]

13. Remove the key top cover [A].

14. Attach the printer key top [B].

Installation

B337I606.WMF

3-3

Page 21

PRINTER CONTROLLER (B337) 1 March, 2000

3.2 PRINTER CONTROLLER (B337)

3.2.1 ACCESSORY CHECK

No. Description Q’ty No. Description Q’ty

1 Controller Box 1 7 Ferrite Core 1

2 Interface Board 1 8 Cover Bracket 1

3 Bracket – Interface Board 1 9 Upper Ground Plate 1

4 Interface Cable 1 10 Lower Ground Plate 1

5 Cable Clamp 1 11 Printer Key Top 1

6 Screw 6 12 Printer Key Top Cover 1

3.2.2 INSTALLATION PROCEDURE

[A]

[B]

[C]

B337I101.WMF

ø

CAUTION

Unplug the copier power cord before starting the following procedure.

1. Disconnect the ADF connector [A].

2. Remove the upper rear cover [B] (2 screws).

3. Remove the printer cover [C] (2 screws).

3-4

Page 22

1 March, 2000 PRINTER CONTROLLER (B337)

[A]

[C]

[B]

Installation

B337I102.WMF

4. Remove the duct [A] (1 screw, 1 connector).

[D]

B337I104.WMF

5. Remove the flywheel [B] (3 screws).

6. Remove the bracket [C] (2 screws).

7. Install the interface board [D] (1 screw).

3-5

Page 23

PRINTER CONTROLLER (B337) 1 March, 2000

[A]

[B]

B337I103.WMF

8. Reinstall the duct and flywheel.

[C]

[J]

[H]

[G]

[I]

[D]

B337I105.WMF

[F]

[E]

9. Reinstall the bracket [A] with upper ground plate [B] and lower ground plate [C]

(2 screws).

10. Pass the interface cable [D] through the cover bracket [E].

11. Attach the ferrite core [F].

12. Connect the interface cable to the printer controller [G].

13. Install the cover bracket [E] (1 clamp [H], 2 screws).

14. Connect the power supply cable [I].

15. Install the printer controller box [J] (3 screws).

16. Reinstall the upper rear cover.

3-6

Page 24

1 March, 2000 PRINTER CONTROLLER (B337)

[C]

[B]

[A]

B337I106.WMF

Installation

17. Remove the key top cover [A].

18. Install the printer key top [B].

19. Install the printer key top cover [C].

3-7

Page 25

NETWORK INTERFACE BOARD (A855) 1 March, 2000

3.3 NETWORK INTERFACE BOARD (A855)

3.3.1 INSTALLATION PROCEDURE

[A]

[B]

A855I554.WMF

ø

CAUTION

Unplug the copier power cord before starting the following procedure.

1. Remove the cover bracket [A] (2 screws).

2. Install the network interface board [B] (2 screws that were removed in step 1).

3. Attach the ferrite core [C] to the network cable [D].

[D]

A855I513.WMF

[C]

3-8

Page 26

1 March, 2000 POSTSCRIPT KIT (B338)

3.4 POSTSCRIPT KIT (B338)

3.4.1 INSTALLATION PROCEDURE

[A]

[C]

[B]

Installation

B338I500.WMF

ø

CAUTION

Unplug the copier power cord before starting the following procedure.

1. Remove the printer controller [A] (2 screws).

2. Remove the NIB [B] (2 screws).

3. Install the PostScript Kit [C].

NOTE:

Make sure that the PostScript Kit is properly set.

3-9

Page 27

HARD DISK (B349) 1 March, 2000

3.5 HARD DISK (B349)

3.5.1 INSTALLATION PROCEDURE

[A]

[B]

[D]

ø

CAUTION

Unplug the copier power cord before starting the following procedure.

1. Remove the rear cover of the base engine.

2. Remove the printer controller [A] (2 screws).

3. Remove the memory (SDRAM DIMM) [B].

4. Connect the cable [C] to the printer controller.

5. Attach the hard disk [D] to the printer controller (4 screws).

6. Connect the cable to the hard disk.

7. Reinstall the rear cover of the base engine.

8. After turning on the main switch and pressing the printer mode key, formatting

the hard disk is necessary. (See Service Tables – Service Program Mode –

Hard Disk Format.)

[C]

B349I500.WMF

3-10

Page 28

1 March, 2000 SDRAM DIMM

3.6 SDRAM DIMM

3.6.1 REQUIRED SPECIFICATION CHECK

Before installing the SDRAM DIMM, ensure that it satisfies the following

requirements.

Type PC Compatible

Number of pins 168 pins PC100

Capacity 32, 64, or 128 MB

3.6.2 INSTALLATION PROCEDURE

[A]

[B]

B335I108.WMF

!

CAUTION

Unplug the copier power cord before starting the following procedure.

Installation

1. Remove the printer controller [A] (2 screws).

2. Install the SDRAM DIMM [B].

NOTE: Make sure that SDRAM DIMM is properly installed.

3-11

Page 29

CONNECTING THE INTERFACE CABLES 1 March, 2000

3.7 CONNECTING THE INTERFACE CABLES

3.7.1 PARALLEL INTERFACE

An IEEE1284 compatible printer cable is required to connect the printer controller

to a host PC parallel port.

3.7.2 NETWORK INTERFACE

A Shielded Twisted Pair (STP) cable with RJ45 connectors is required to connect

the Network Interface Board to a computer network. (The cable should be

Category/Type 5 or better.) After all the hardware is installed, the network setup

should be done by the user. The setup procedure is described in the NIB manual.

3.8 CHECKING THE CONNECTION

3.8.1 CONNECTION BETWEEN BASE ENGINE AND PRINTER

CONTROLLER (and related options; PostScript ROM,

SDRAM DIMM, Hard Disk Drive, NIB)

1. Plug in the power cord and turn on the main power switch.

2. Enter the printer user mode.

1) Press the User Tool key.

2) Press the Printer Features button.

3. Print out the printer configuration page.

1) Select the List Print tab.

2) Press the Configuration Page button to print the configuration page. The

machine prints the printer configuration page automatically.

NOTE:

The printer configuration page is similar to that shown on the next page.

For further details about the operation panel settings, refer to the operating

instructions.

3-12

Page 30

1 March, 2000 CHECKING THE CONNECTION

CONFIGURATION MENU

Printer Configuration Page

PCL MENU

ORIENTATION = PORTRAIT

FORM LENGTH = 60 LINES

FONT SOURCE = INTERNAL

FONT NUMBER = 0

POINT SIZE = 12.00

PITCH = 10.00

SYMBOL SET = ROMAN-8

POSTSCRIPT MENU

PRINT ERRORS = OFF

FEEDER MENU

PAGE SIZE = LETTER

PAPER TRAY = AUTO

AUTO TRAY CHANGE = ON

BYPASS PAPER TYPE =

DUPLEX = OFF

BINDING = LONG

SEPARATION = OFF

STAPLE = OFF

PUNCH = OFF

Peerless Print is a trademark of Peerless System Corporation.

Adobe, PostScript, the Adobe logo and the Postscript logo are the trademarks

of Adobe System Incorporated.

PARALLEL MENU

EMULATION = AUTO

BIDIRECTION = ON

I/O TIMOUT = 30

CONFIGURATION MENU

RESOLUTION = 600

AUTO CONTINUE = ON

SMOOTHING = ON

AUTOCONT TIMEOUT = 30

NETWORK MENU

I/O TIMEOUT = 30

TCP/IP SETTING

IP ADDRESS = 131.100.100.111

SUBNET MASK = 255.255.255.0

GATEWAY ADDRESS = 131.100.100.1

PRINTER DETAILS

MODEL:

MANUFACTURER:

MACHINE S/N: 00000010200

SERVICE PHONE: 00-0000-0000

FIRMWARE LEVELS:

Controller 1.15

PeerlessPrint5-E V 1.4.10 98/05/06

PeerlessPrintXL V 1.1.10 98/05/06

PS 1.05

PRINTER OPTIONS

Printer Hard Disk Drive

Adobe Postscript

Network Interface Board

PAPER HANDLING OPTIONS

MSU Installed

Tandem Tray 1

Standard Tray 2

Internal LCT Tray 3

Manual Paper Tray

Large Capacity Tray

Duplex Unit

9 Bin Mailbox Unit

Finisher 3000

Punch Unit, 2 Hole

TOTAL MEMORY = 72 MB

A852I509.WMF

RESOLUTION = 600

AUTO CONTINUE = ON

SMOOTHING = ON

AUTOCONT TIMEOUT = 30

NETWORK MENU

[C]

I/O TIMEOUT = 30

TCP/IP SETTING:

IP ADDRESS = 131.100.100.111

SUBNETMASK = 255.255.255.0

GATEWAY ADDRESS = 131.100.100.1

PRINTER DETAILS

MODEL:

MANUFACTURER:

MACHINE S/N: 00000010200

SERVICE PHONE: 00-0000-0000

[D]

FIRMWARE LEVELS:

Controller 1.15

PeerlessPrint5-E V 1.4.10 98/05/06

PeerlessPrintXL V 1.1.10 98/05/06

PS 1.05

PRINTER OPTIONS:

[A]

Printer Hard Disk Drive

Adobe Postscript

Network Interface Board

PAPER HANDLING OPTIONS:

MSU Installed

Tandem Tray 1

Standard Tray 2

Internal LCT Tray 3

Manual Paper Tray

Large Capacity Tray

Duplex Unit

9 Bin Mailbox Unit

Finisher 3000

Punch Unit, 2 Hole

[B]

TOTAL MEMORY = 72 MB

Installation

A852I510.WMF

Check the following:

•

For the printer controller board, confirm that the machine prints the printer

configuration page.

•

For the hard disk drive and PS kit, confirm that the configuration page includes

them in the “Printer Options” section [A].

•

For DRAM SIMM, confirm that “Total Memory” [B] printed on the configuration

page shows the correct amount of memory in the machine (Std. plus Opt.

SDRAM DIMM).

•

For the NIB, confirm that the configuration page includes the “Network Menu”

section [C] and includes the network interface board in the “Printer Options”

section [A].

•

For the firmware version, check “Firmware Levels” [D].

If any problem occurs with the above checks, reinstall the printer controller and

other options. Then set up the machine again and redo the test.

3-13

Page 31

CHECKING THE CONNECTION 1 March, 2000

3.8.2 CONNECTION BETWEEN PRI NTER CONTROLLER BOARD AND NETWORK INTERFACE BOARD

There are the following two ways to check the connection between the printer

controller board and the network interface board.

1. To see “Network Menu” on the configuration page.

2. To see the Network Interface Board Status Sheet with the network information

that is automatically printed after power on.

How to Print the Network Interface Board Status Sheet

Whenever the main power switch is tu rned on, the network interface board status

sheet is automatically printed.

NOTE:

If any problem is found during the check, try to reinstall the printer controller and

optional equipment. Then, check again.

If the status sheet is not printed, check the Network menu in the printer

user tools.

3-14

Page 32

1 March, 2000 GENERAL CAUTION

4. SERVICE TABLES

4.1 GENERAL CAUTION

Do not turn off the main power switch or change the controller to off-line while the

data LED blinks or is lit. Otherwise, the data that has been stored in the controller

will be lost. If it is necessary to do this, ask the customer for consent.

4.2 SERVICE PROGRAM MODE

4.2.1 SERVICE PROGRAM ACCESS PROCEDURE

The service program (SP mode) access procedure is the same procedure as for

the copy mode.

Entering SP mode

#

→

.

→

-

→

4

→

$

(Hold it for more than 3 seconds.)

Exiting SP mode

Press the Exit key until the standby mode display appears.

4.2.2 SERVICE PROGRAM MODE TABLES

No. Description Function

Flash System From Parallel Downloads the printer controller

firmware from a PC through the

parallel port

firmware using an IC card through

the PCMCIA port

from a PC through the parallel port

using an IC card through the

PCMCIA port

between ROM DIMM and printer

controller

1. Flash

2. Log

3. Reset

Select

01

Flash System From PCMCIA Downloads the printer controller

02

Flash Postscript From Parallel Downloads the PostScript firmware

03

Flash Postscript From PCMCIA Downloads the PostScript firmware

04

Copy Flash ROM Copies the printer controller firmware

05

06 Format Disk Formats the hard disk drive

11 Parallel Loop Back Test Performs the parallel loop back test

01 Print Job Log Data Prints the print/job count log page

02 Print Error Log Data Prints the printer error log page

03 Clear Job Log Counter Clears the print/job counter

04 Print User Code Job Attribute Log Clears the error log counter

05 Print User Code Job Pages Count Prints the gateway address page

System Reset Reset the printer system

01

Tables

Service

4-1

Page 33

FIRMWARE DOWNLOAD 1 March, 2000

4.3 FIRMWARE DOWNLOAD

Firmware for the printer controller and PostScript can be downloaded using a flash

memory card through the PCMCIA port or using a PC through a parallel cable.

4.3.1 FIRMWARE UPDATE USING A FLASH MEMORY CARD (SP02 AND 04)

1. Prepare a flash memory card programmed with the latest firmware.

NOTE: When programming a firmware file in a flash memory card, set the

following parameters:

• Start Address: 000000h

• Length: 3FFFFFh

2. Turn off the main power switch, remove the cover [A] and insert the flash

memory card [B] into the slot. The “A” side of the card must face the front of the

base engine.

[A]

[B]

B335M502.WMF

3. Turn on the main power switch and enter the printer SP mode.

4. Select the Flash tab.

5. Press the “Flash System from PCMCIA” button (to download system firmware)

or the “Flash PostScript from PCMCIA” button (to download PostScript

firmware).

6. Press “Yes” in reply to the confirmation message. The download takes several

minutes. The LEDs on the controller board show how the download is

progressing (see Troubleshooting).

7. When the downloaded is successfully finished, turn off the main power switch,

pull the card out from the slot and turn on the main switch again.

8. Print the “Printer Configuration Page” to check the new firmware version ([User

Tools] – [Printer Features] – [List Print tab] – [Configuration Page]).

The firmware version number is in the “Printer Details” section of this page.

9. System Firmware Downloads: If the controller does not start up after the

download, the download has failed. See “Copy Flash ROM” for how to recover.

4-2

Page 34

1 March, 2000 FIRMWARE DOWNLOAD

4.3.2 FIRMW ARE UPDATE USING PARALLEL PORT

1. Prepare the latest firmware file and Fcopy.exe on a PC.

2. Turn off the main power switch, then connect the PC using a parallel cable.

3. Turn on the main switch and enter the printer SP mode.

4. Select the Flash tab.

5. Press the “Flash System from Parallel” button or the “Flash Postscript from

Parallel” button depending on the firmware type.

6. Press “Yes” in reply to the confirmation message. The LEDs on the controller

board show how the download is progressing (see Troubleshooting).

7. On the PC, access the MS-DOS Prompt and type the following command:

Either

C:\> FCOPY path\filename

or

C:\> COPY /b path\filename port

ø

CAUTION

Do not turn off the main power switch while “Downloading New System

Software” is displayed on the LCD, even if the MS-DOS Prompt mentions

that FCOPY has finished.

Tables

Service

8. When the downloaded is successfully finished, turn off the main power switch,

disconnect the parallel cable if necessary and turn on the main switch again.

9. Print the “Printer Configuration Page” to check the new firmware version ([User

Tools] – [Printer] – [List Print] – [Configuration Page]).

The firmware version number is listed in the “Printer Details” section of the

configuration page.

10. If the printer controller does not start up after downloading system firmware,

this means that the download failed; see “Copy Flash ROM” for how to recover.

4.3.3 H ARD DISK FORM AT

This function is used to format the printer hard disk. If the hard disk is formatted,

the stored data (downloaded fonts and macros) is erased. So, when performing

this function, ask the customer for consent. After this operation, advise the

customer to restore the erased data if necessary.

1. Enter the printer SP mode.

2. Select the Flash tab.

3. Press the “Format Disk” button.

4. Press “Yes” in reply to the confirmation message. The format takes several

minutes.

5. When th e format is successf ully finished, tu rn off the main power switch and

turn it on again.

4-3

Page 35

FIRMWARE DOWNLOAD 1 March, 2000

4.3.4 COPY FLASH ROM

There are two functions. One copies the printer controller firmware from the ROM

DIMM to the printer controller and the other copies the opposite way.

Download from ROM DIMM to printer controller

When downloading the printer controller firmware from either the flash memory

card or a PC is not successfully finished and the printer controller does not start up,

the controller firmware cannot be downloaded again using the flash memory card

or a PC to recover. However, the firmware can be downloaded from a ROM DIMM

by following the procedure below.

CS3

CS2

CS1

CS0

TB1

IC2

IC4

[B]

[A]

PS DIMM SLOT

IC28IC29

TB1

Flash

Printer Controller

DIMM

ROM DIMM

B335M500.WMF

1. Turn off the main power switch and remove the printer controller.

2. Change the position of the TB1 jumper [A] on the controller from CS0 to CS1.

3. Change the position of the TB1 jumper [B] on the ROM DIMM from CS1 to

CS0.

4. Install the ROM DIMM in the PostScript DIMM slot on the controller.

ø

CAUTION

Make sure to install the correct type of ROM DIMM in the PostScript SIMM.

5. Install the printer controller and turn on the main power switch.

6. Enter the printer SP mode, select the Flash tab and Press the “Copy Flash

ROM” button.

7. Press “Yes” in reply to the confirmation message.

8. When the download is successfully finished, turn off the main power switch,

remove the printer controller and remove the ROM DIMM.

9. Reposition the jumpers on the printer controller and ROM DIMM.

10. Reinstall the printer controller and turn on the main power switch.

11. Check that the printer controller starts up.

4-4

Page 36

1 March, 2000 FIRMWARE DOWNLOAD

Download from the controller to ROM DIMM

ø

CAUTION

Never perform this function if the PostScript ROM SIMM is installed on the

controller. Otherwise, the controller firmware will be copied to the

PostScript kit. Take out the PostScript ROM SIMM and install a blank one.

1. Remove the printer contro ller.

2. Make sure that the TB1 jumper on the controller is at CS0.

3. Make sure that the TB1 jumper on the ROM DIMM is at CS1.

4. Install the ROM DIMM on the controller.

5. Install the printer controller and turn on the main power switch.

6. Enter the printer SP mode, select the Flash tab and Press the “Copy Flash

ROM” button.

7. Press “Yes” in reply to the confirmation message.

8. When the download is successfully finished, turn off the main power switch,

remove the printer controller and remove the ROM DIMM.

9. Reinstall the printer controller and turn

on the machine.

4.3.5 PARALLEL LOOP BACK

TEST (SP11)

1. Plug the loop back connector into the

parallel port of the printe r.

2. Enter the printer SP mode, select the

Flash tab and Press the “Parallel

Loop Back Test” button.

3. Press “Yes” in reply to the

confirmation message. The result of

the test will be displayed on the LCD.

Pin No.

1

2

3

4

5

6

7

8

9

10

11

12

13

14

15

16

17

18

19

20

21

22

23

24

25

26

27

28

29

30

31

32

33

34

35

36

Signal Name

/STROBE

DATA_1

DATA_2

DATA_3

DATA_4

DATA_5

DATA_6

DATA_7

DATA_8

/ACK

BUSY

PE

SELECT

/AUTOFD

NC

GND

GND

PLH

GND

GND

GND

GND

GND

GND

GND

GND

GND

GND

GND

GND

/INIT

/FAULT

NC

NC

NC

/SELECTION

Tables

Service

4-5

B335M501.WMF

Page 37

USER PROGRAM MODE 1 March, 2000

4.4 USER PROGRAM MODE

A user program (UP) mode is available for the printer mode as well as for the copy

mode. Press the User Tool button to access it.

4.4.1 UP MODE TABLE (PRINTER FEATURES)

NOTE:

The function of each UP mode is explained in the Printer Reference

section of the operating instructions.

1. PCL

2. Postscript 1. Print Errors

3. Paper Feed

4. Parallel

5. Network

6. Configuration

7. List Print

8. Reset Select

1. Orientation

2. Form Length

3. Font Source

4. Font Number

5. Point Size

6. Font Pitch

7. Symbol Set

1. Page Size

2. Tray Priority

3. Auto Tray Switching

4. Bypass Paper Type (A292/A293 only)

1. Duplex

2. Sort

3. Staple

4. Punch

1. Printer Language

2. Bi-direction

3. I/O Timeout

1. I/O Timeout

2. IP Address

3. Subnet Mask

4. Gateway Address

5. Network Menu Protect

1. Resolution

2. Auto Continue

3. Edge Smoothing

4. Auto Continue Timeout

1. PS Font List

2. PCL Font List

3. PS Demo Page

4. PCL Demo Page

5. Configuration Page

6. Disk Directory List

7. Minor Error Log

1. Job Reset

2. Menu Reset

3. Printer Restart

4. User Code Log Clear

4-6

Page 38

1 March, 2000 DIP SWITCHES/JUMPER PINS/LEDS

4.5 DIP SWITCHES/JUMPER PINS/LEDS

4.5.1 DIP SWITCHES

SW5:

No. Function On OFF

1 Operation mode

2, 3 Not used

4 Cache setting

5 Destination for firmware

downloading

6, 7, 8 Not used

Normal operation

Do not change this setting. Keep at OFF.

Use cache memory

To fla sh ROM

Do not change this setting. Keep at OFF.

Programming firmware

Not use cache memory

To ROM DIMM

NOTE:

The functions of DIP switches no. 4 and 5 are enabled when changing the

setting of no. 1 to the off position. However,

settings

(keep them all on). The firmware download should be done using

the SP mode.

4.5.2 JUMPER PINS

TB1:

Function CS0 CS1

Boot device selection

Boot from resident

flash

4.5.3 LEDS

Symbol Function

PWR This LED turns on when +5 V is supplied to the printer controller.

LED2

LED3

LED4

LED5

Refer to section 6.2 (LEDs) for further details.

do not change the default

Boot from ROM DIMM

Tables

Service

4-7

Page 39

1 March, 2000 PRINTER CONTROLLER BOARD

5. REPLACEMENT AND ADJUSTMENT

ø

CAUTION

Turn off the main power switch and unplug the power cord before

attempting any of the procedures in this section.

5.1 PRINTER CONTROLLER BOARD

- A292/A293 - - A294/A295 -

[B]

[B]

[C]

1. Disconnect the network and Bi-Centronics cables.

[A]

B335R505.WMF

Adjustment

Replacement

2. Remove the cover. (Refer to the installation procedures.)

A294/A295: Lower rear cover (2 screws).

A292/A293: Upper rear cover (2 screws).

3. A294/A295:Remove the controller board [A] (2 screws).

A292/A293:Remove the 3 screws [B] and remove the controller board [C] (2

screws).

5-1

Page 40

PRINTER CONTROLLER BOARD 1 March, 2000

[A]

B335R504.WMF

4. Remove the hard disk, network interface board, PS DIMM, and SDRAM DIMM

if they are installed (see their replacement procedures).

5. Remove the NVRAM [A] from the old printer controller and install it on a new

printer controller.

6. Install the removed options on the new printer controller.

7. Reinstall the rear cover.

5-2

Page 41

1 March, 2000 HARD DISK

5.2 HARD DISK

[A]

[B]

[D]

B335R500.WMF

[C]

1. Remove the printer controller [A] (2 screws).

2. Remove the SDRAM DIMMs [B].

3. Disconnect the IDE cable [C].

4. Remove the hard disk [D] (4 screws).

5. Install a new hard disk and put back the SDRAM DIMMs.

6. Reinstall the controlle r.

7. After turning on the main power switch, format the hard disk.

Adjustment

Replacement

5-3

Page 42

NETWORK INTERFACE BOARD 1 March, 2000

5.3 NETWORK INTERFACE BOARD

[A]

B335R501.WMF

1. Disconnect the network cable.

2. Remove the network interface board [A] (2 screws).

5.4 POSTSCRIPT DIMM

[A]

[B]

B335R502.WMF

[C]

1. Remove the printer controller [A] (2 screws).

2. Remove the network interface board [B] (2 screws).

3. Remove the PS DIMM [C].

5-4

Page 43

1 March, 2000 SDRAM DIMM

5.5 SDRAM DIMM

[A]

[B]

B335R503.WMF

1. Remove the printer controller [A] (2 screws).

2. Remove the SDRAM DIMM [B].

Adjustment

Replacement

5-5

Page 44

1 March, 2000 ERROR MESSAGES

6. TROUBLESHOOTING

6.1 ERROR MESSAGES

If an error occurs, the LED for the printer key turns red and an error message is

displayed on the LCD.

Copy

Document Server

Document Editor

Printer

B335T501.WMF

Service call (SC) codes

SC No. Description / Definition Possible Cause

Functional problems (Self diagnostic error) Printer controller board

SC2000

SC2001

SC2002

A diagnostic error occurred at power on. The

controller has a hardware problem.

Functional problems (Debug trap error)

An error has occurred in the controller. The

controller has a software problem.

Functional problems (Exception error) Pr int er contr oller board

An error has occurred in the controller. The

controller has a software or hardware problem.

defective.

The controller software

has a problem.

defective.

Trouble-

shooting

6-1

Page 45

ERROR MESSAGES 1 March, 2000

Other messages

The following errors might need assistance from service.

Error Message Condition Possible Cause

Printer HDD Error.

Press Reset to cancel

current job.

Parallel Communication

Error.

Please set up

communication

parameters in parallel

menu. Press Reset to

cancel current job.

Print overrun.

Press Reset to cancel

current job, or press

Continue to print.

Memory overflow.

Press Reset to cancel

current job.

A hard disk error was

detected during macro or font

download.

Parallel communication error

occurred during a print job

via the parallel port.

This error occurred when a

file was being printed in

banding mode. A complex

page may not have enough

time to image a band while

the engine is printing the

previous page.

This error occurred during

printing.

The language has sent a file

that is too complex to

interpret in the available

memory.

• Print e r HDD defective

• Print er controller

defective

• An item in t he parallel

menu was set

incorrectly

• Parallel cable defective

• Print er controller

defective

• Insufficient memory

• A complex page is

printed

• The DRAM SIMM board

is defective

• The controller is

defective

• Insufficient memory

• A complex page is

printed

• Th e DRAM SIMM is

board defective

• The controller is

defective

6-2

Page 46

1 March, 2000 LEDS

6.2 LEDS

6.2.1 LOCATION

Five LEDs (LED1 to LED5) are located next to the Bi-Centronics port on the printer

controller. They indicate the progress of the self test, and errors and status

conditions.

LVC61284

54321

Bi-Centronics

T

RS

B335T500.WMF

6.2.2 LED CODE TABLE

Self-diagnostics

The following LED table shows the self-diagnostic function. When an error occurs

during the self-diagnostic test, first all four LEDs blink, then they light as shown in

the following table to indicate the error.

E.g.) RAM error:

All LEDs on (1 s)

→→→→

off (1 s)

→→→→

on (1 s)

→→→→

off (1 s)

1 = LED is on, 0 = LED is off

LEDs

LED2 LED3 LED4 LED5

0 0 0 1 ROM error

0 0 1 0 RAM (resident, SIMM) error:

0 0 1 1 NVRAM error:

0101Fatal error

0 1 1 0 Debug trap error:

NOTE:

1) SC2000 is also displayed.

Description

note 1)

note 2)

2) SC2002 is also displayed.

6-3

→→→→

LED4 on (5 s)

note 1)

Trouble-

shooting

Page 47

LEDS 1 March, 2000

Controller Firmware Copy/Download

While copying or downloading the controller firmware, the following LED status is

indicated.

1 = LED is on, 0 = LED is off, 1/0 = LED is blinking

LEDs

LED2 LED3 LED4 LED5

1 0 0 0 Data downloading

01/00 0Erasing

1/0 1/0 1 0 Programming

0001Verifying

1 0 0 1 Insufficient RAM error

1 0 1 0 Verify fail ure

1 0 1 1 Download failure (check sum error)

1 1 0 0 Erase failure

1 1 0 1 Download failure (other error)

1 1 1 1 Copy/download success

Description

6-4

Loading...

Loading...